Patents

Literature

44results about How to "Help burn" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pyrolysis gasification furnace

ActiveCN109780548AAvoid lostUtilize concentration and fullIncinerator apparatusCombustion chamberFlue gas

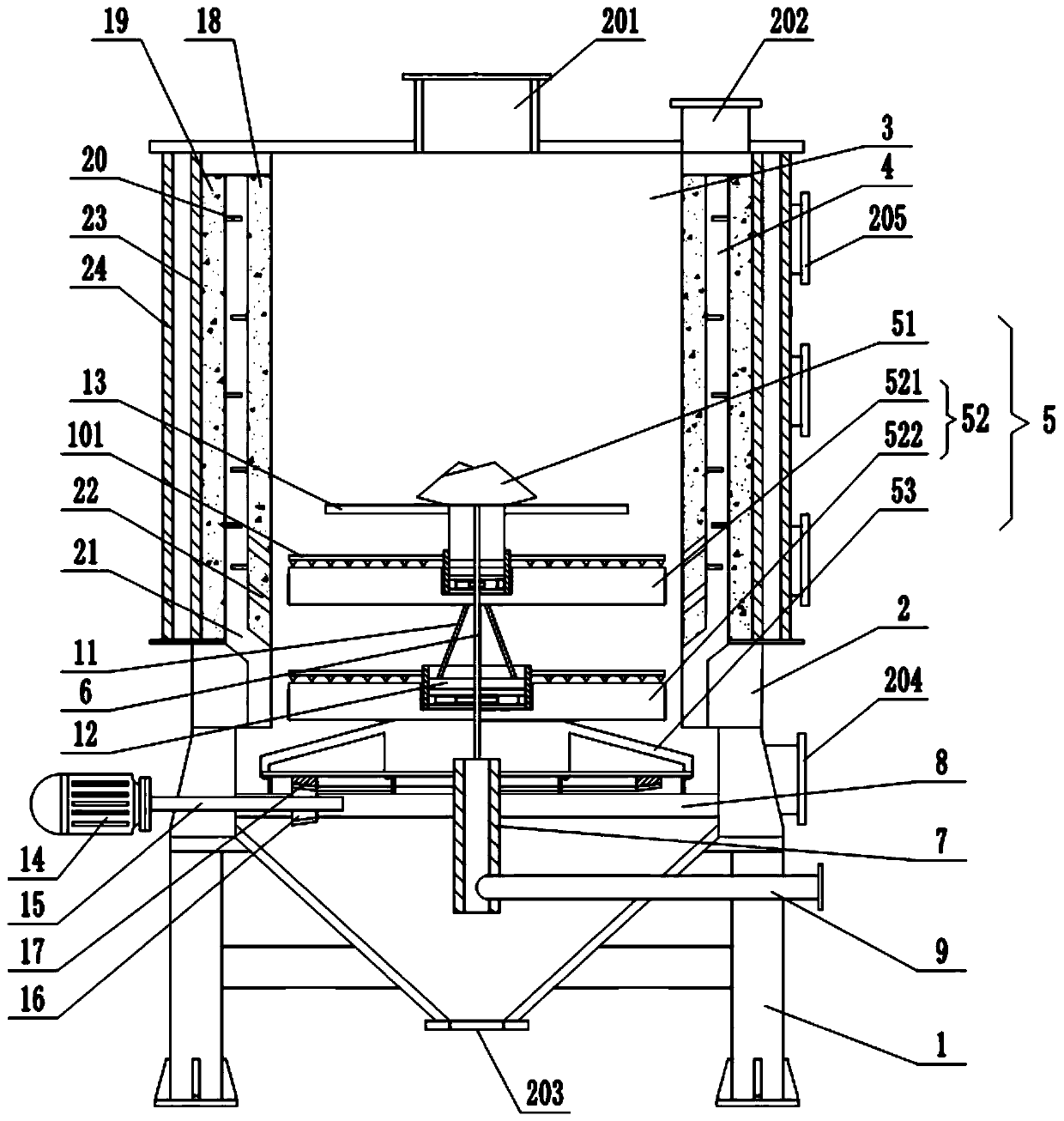

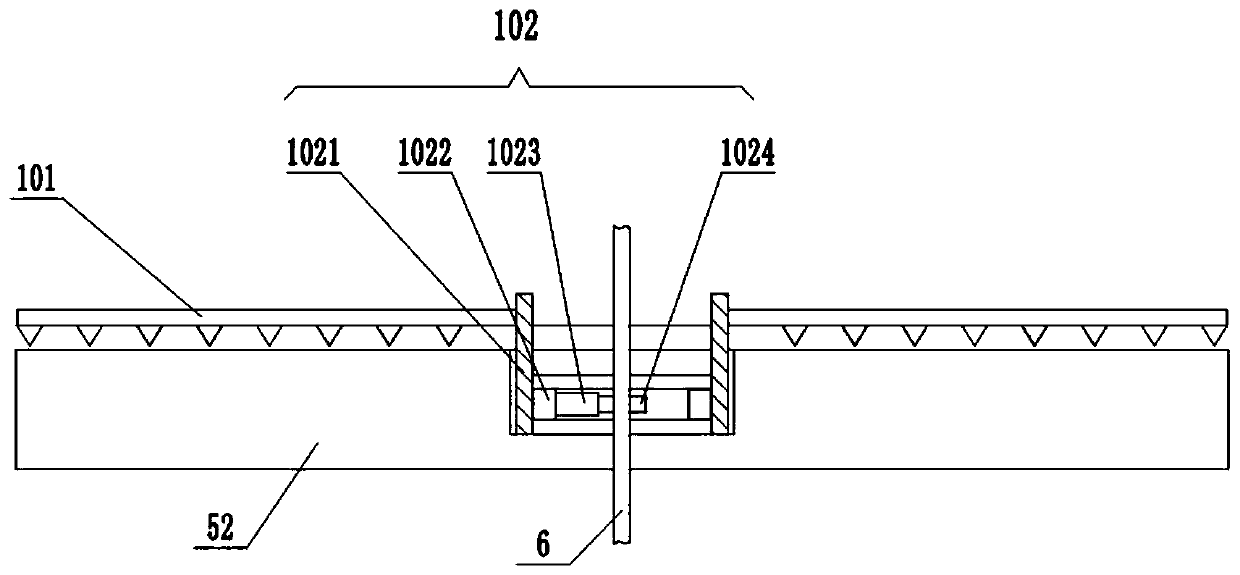

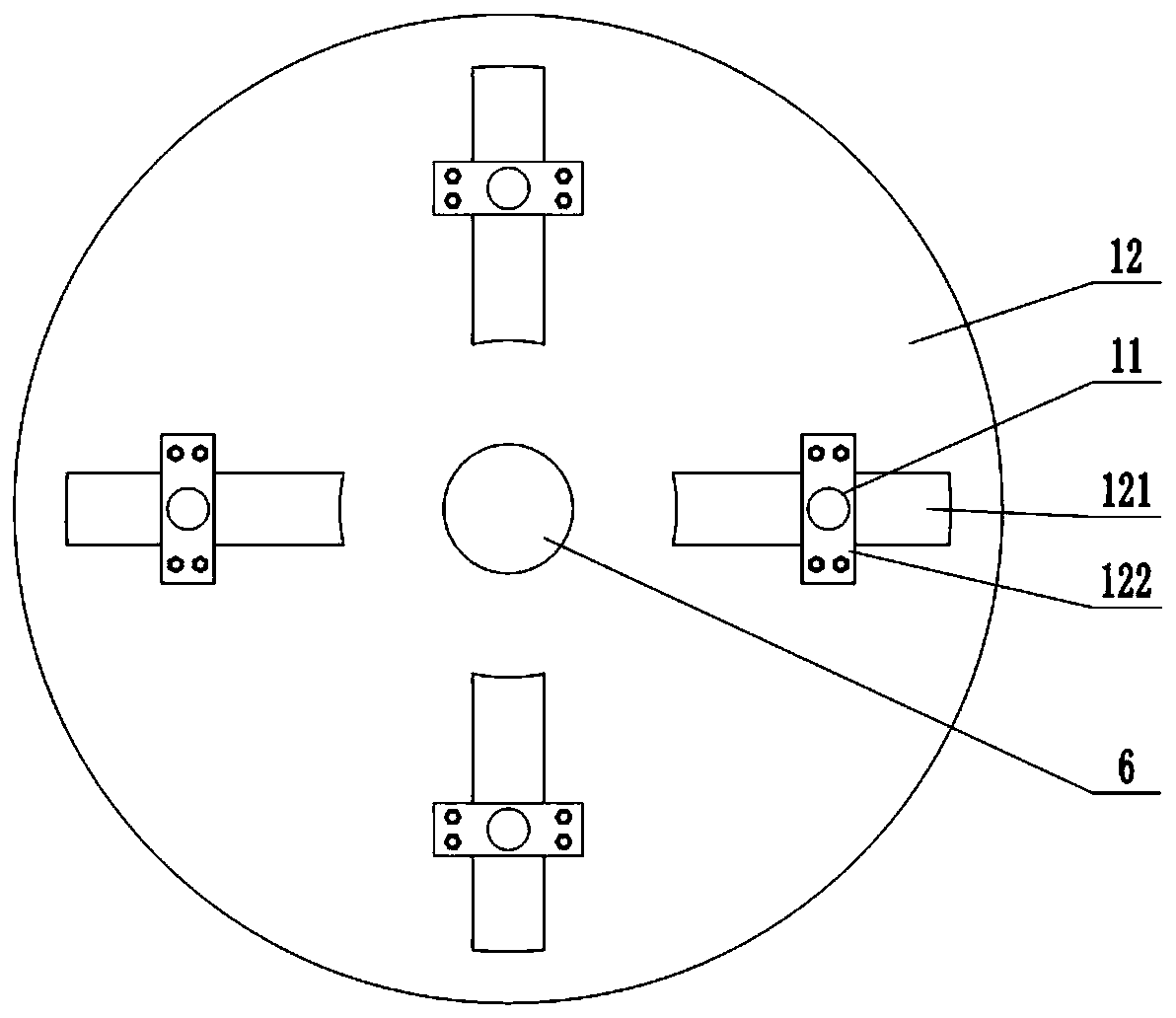

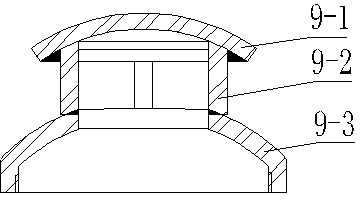

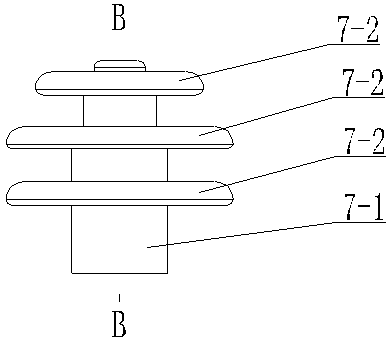

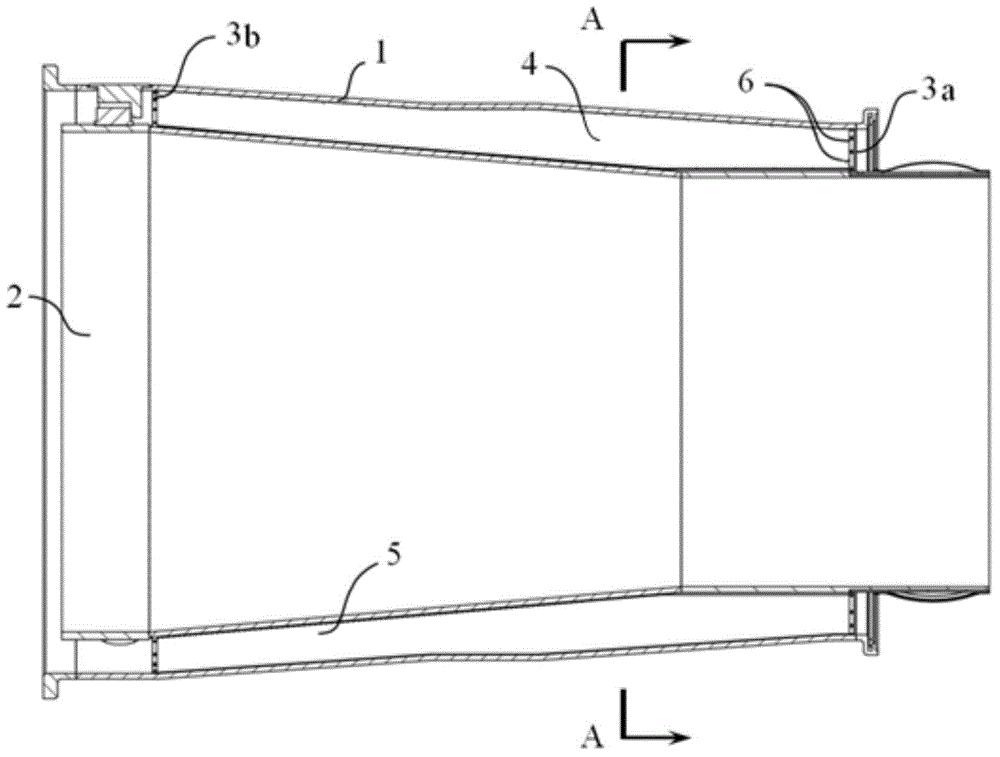

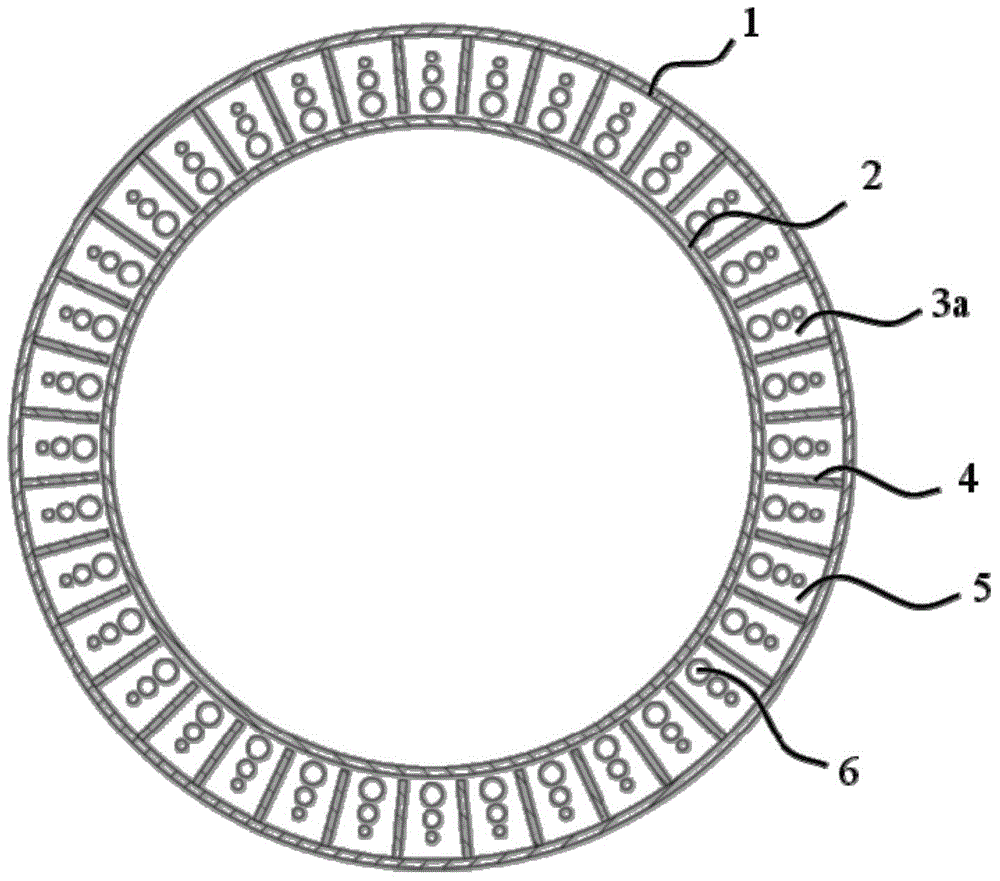

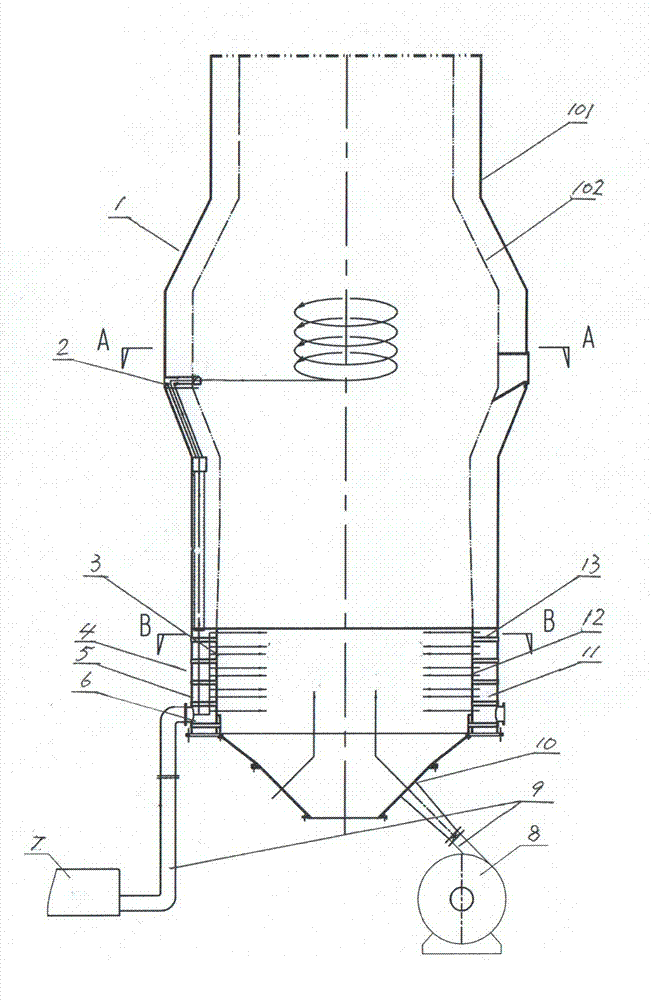

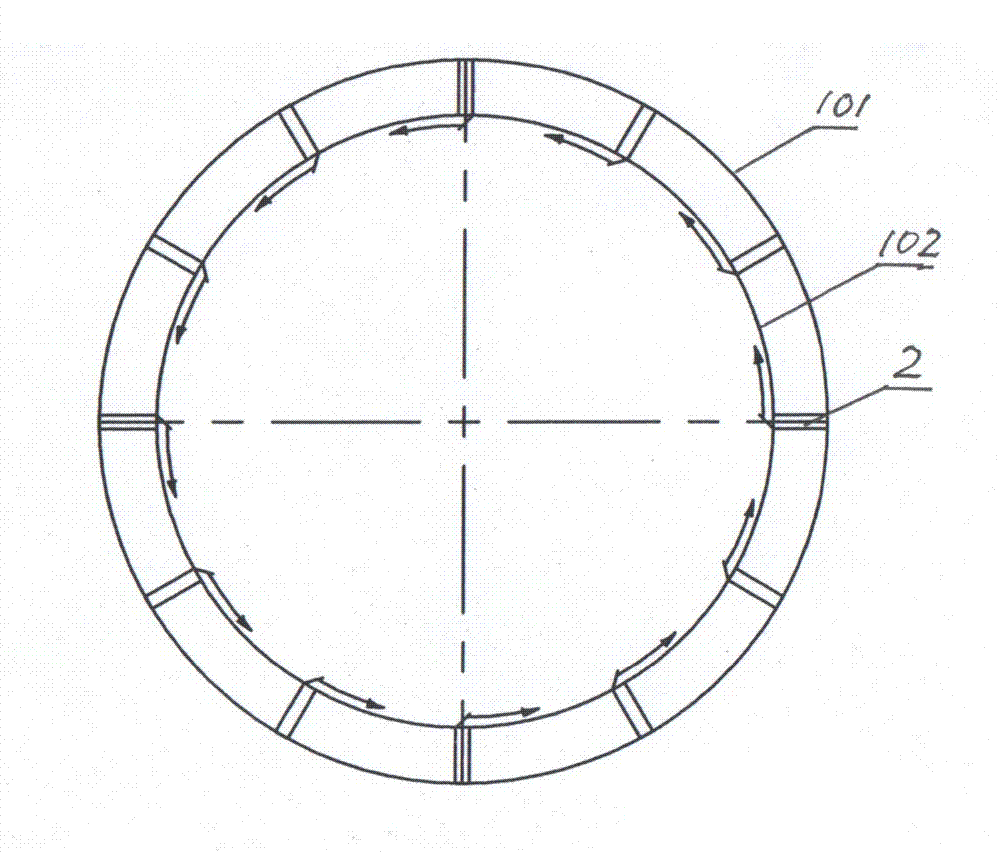

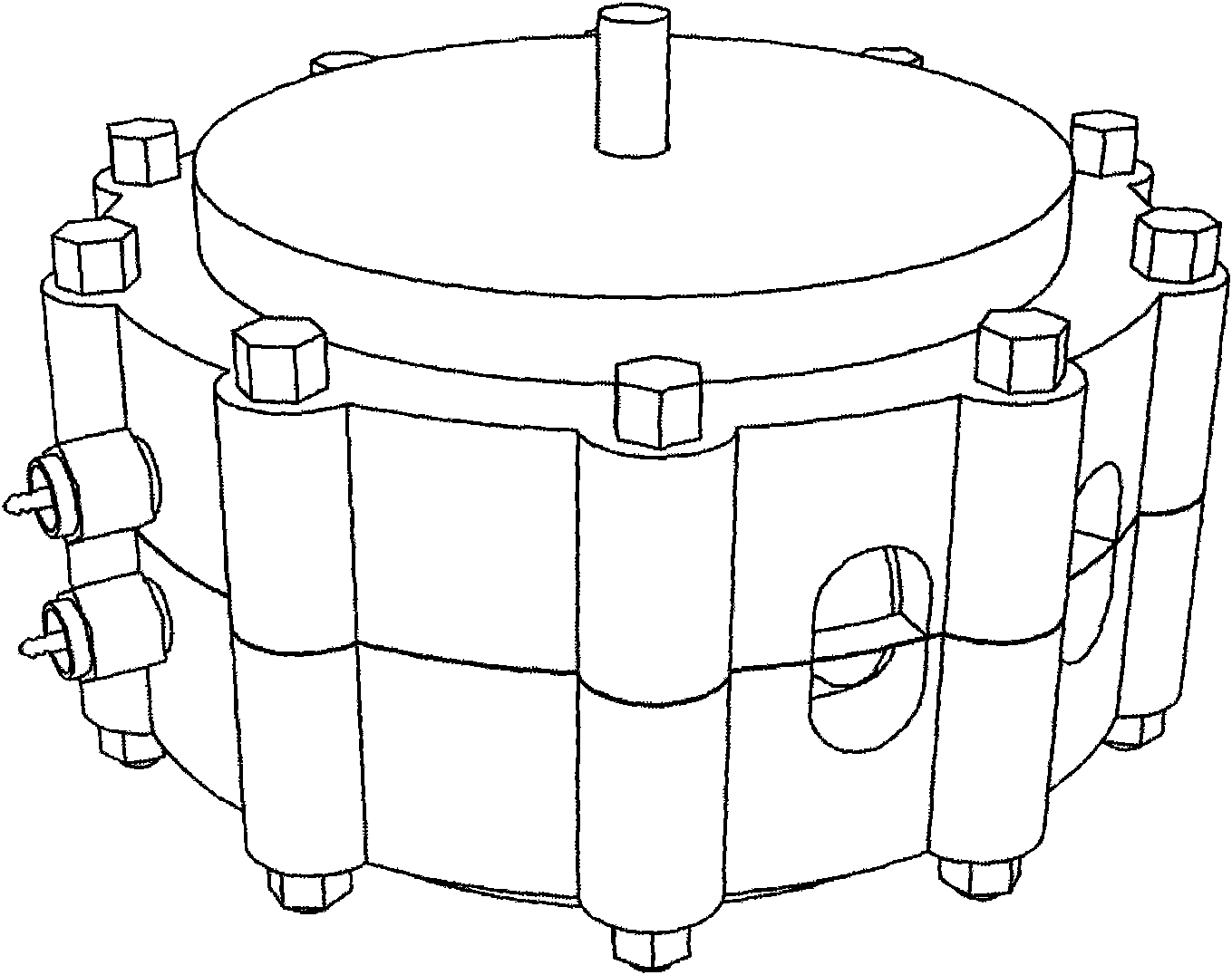

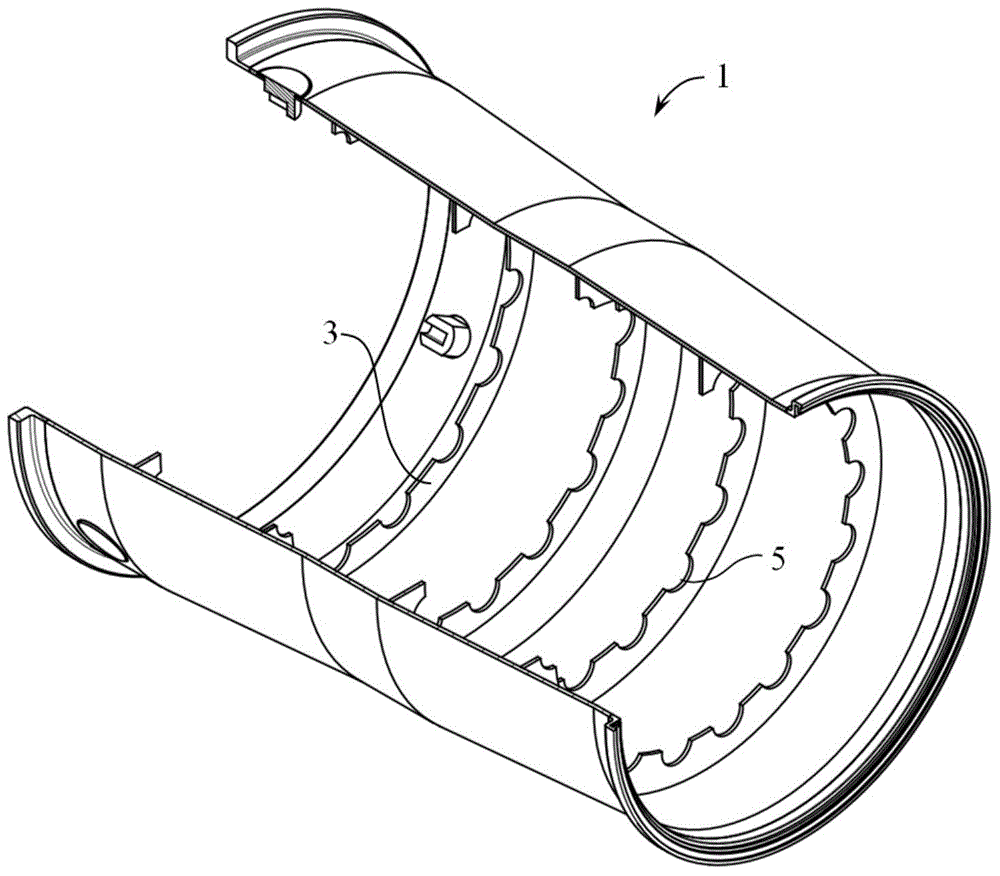

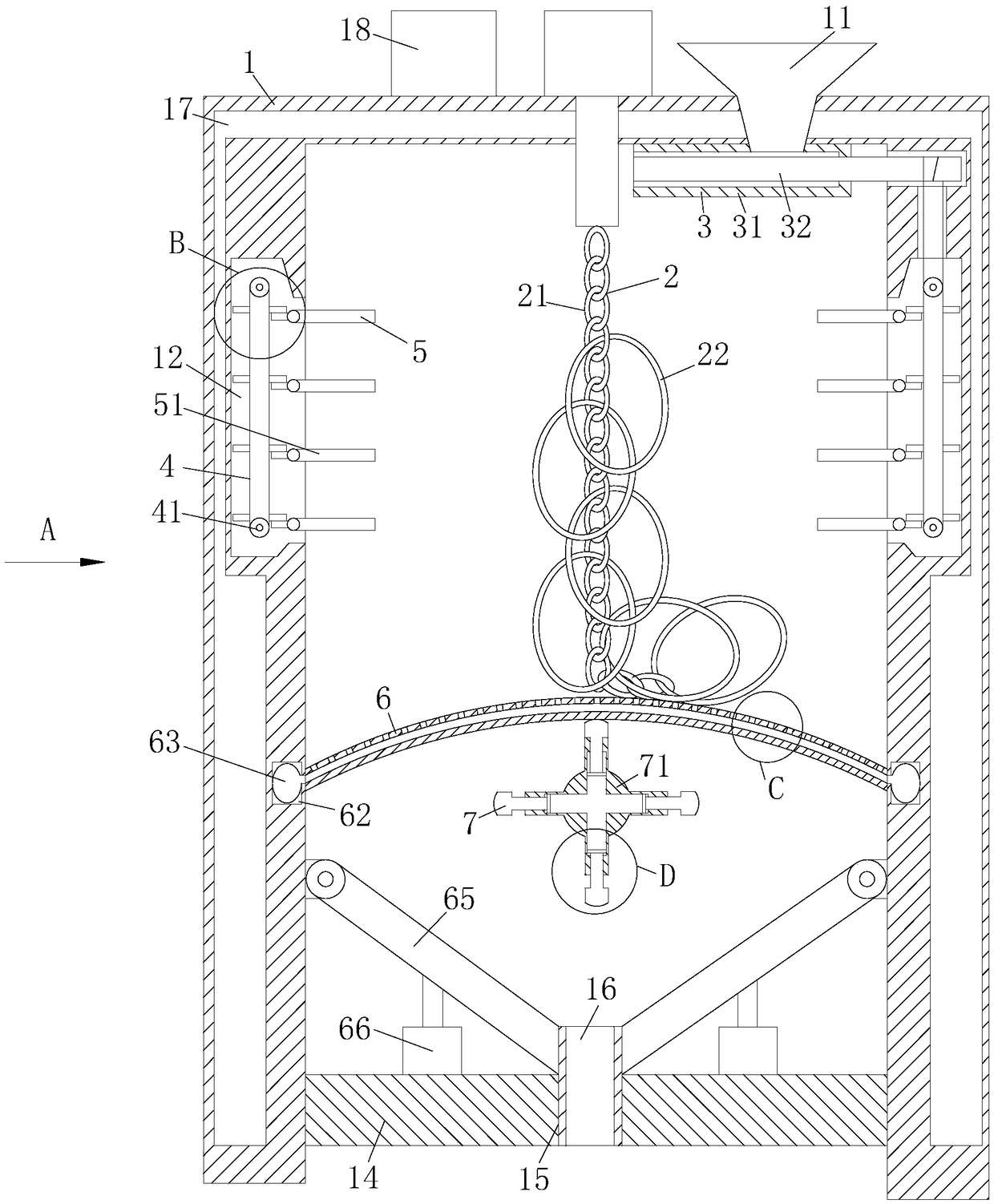

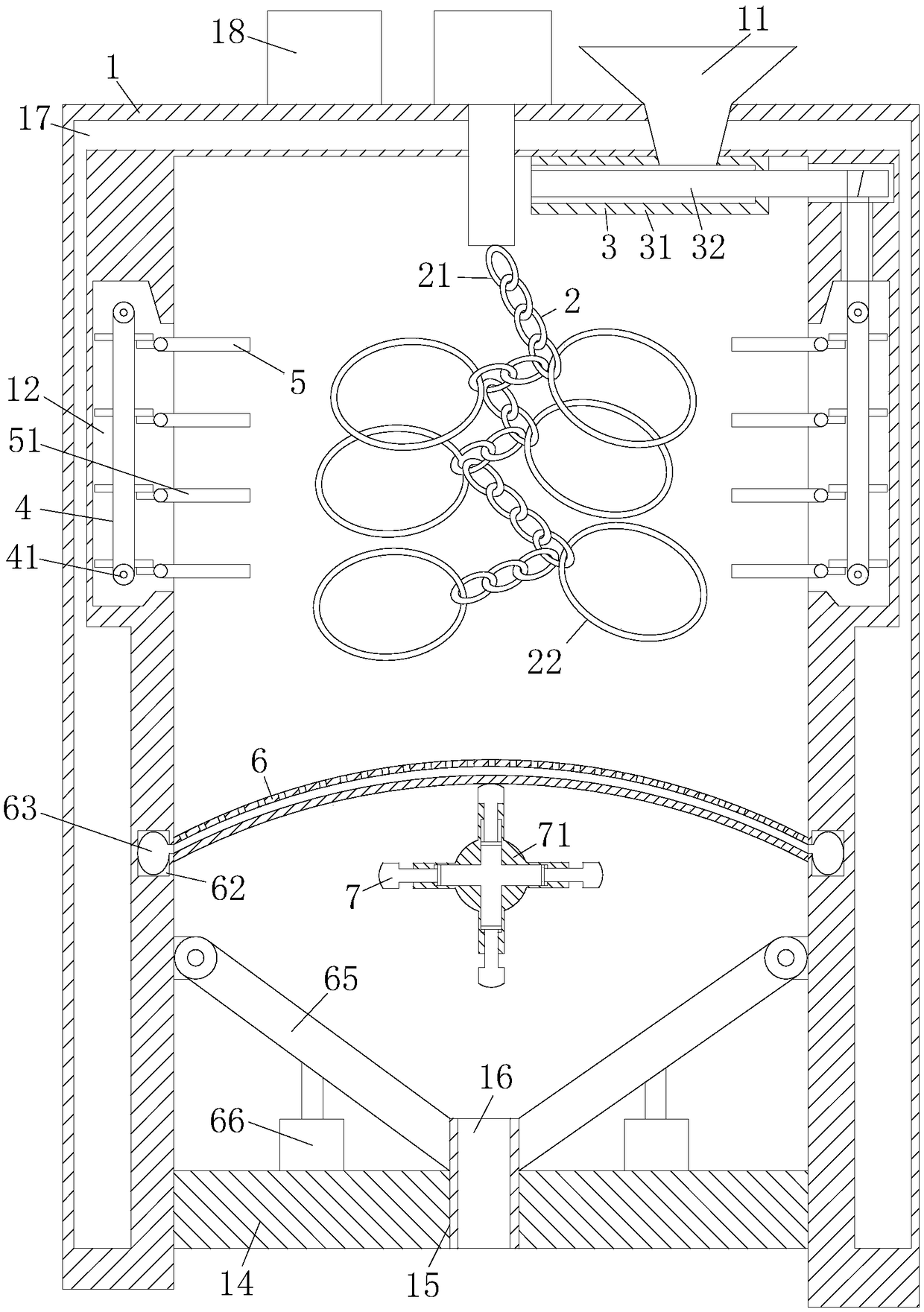

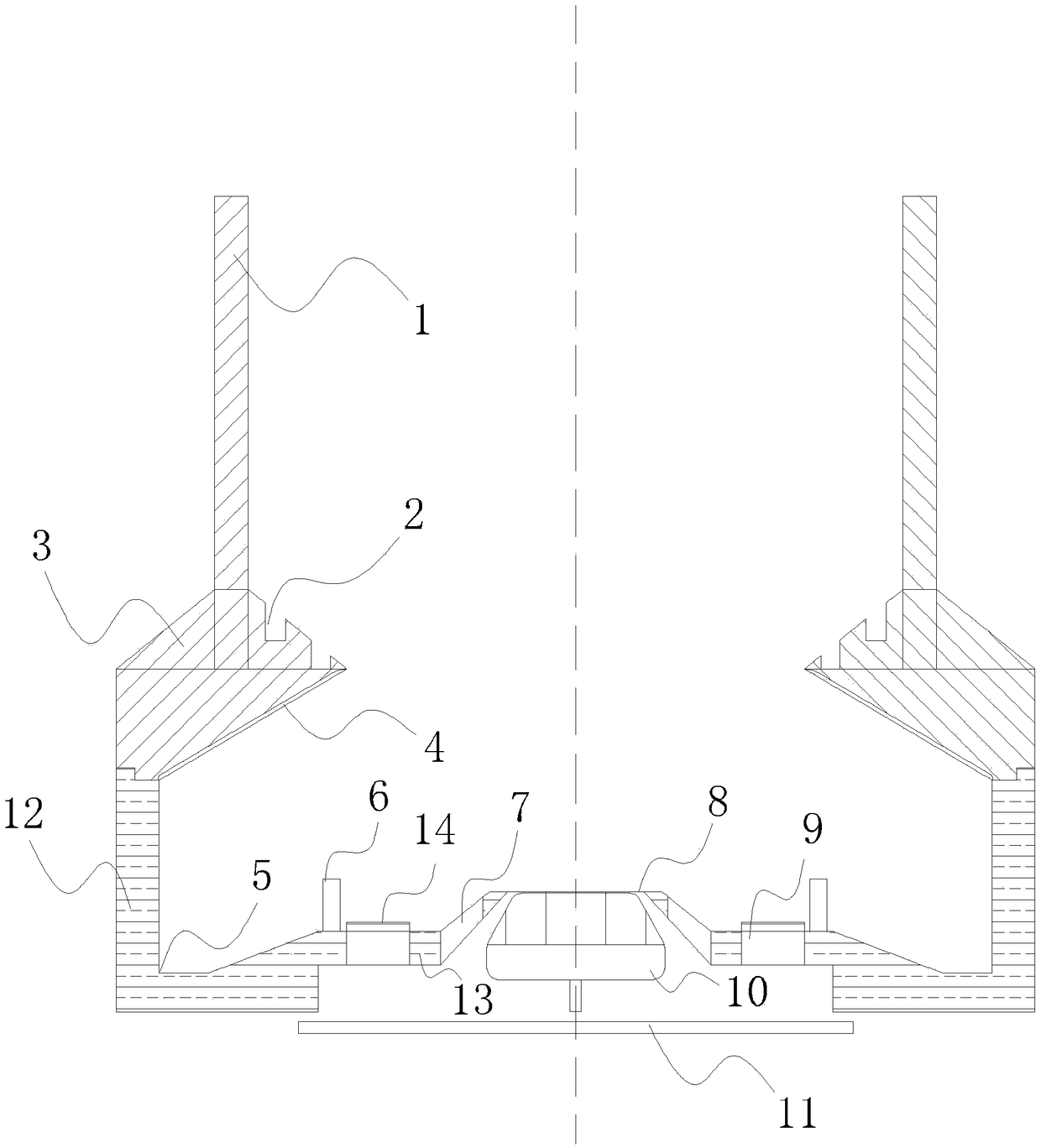

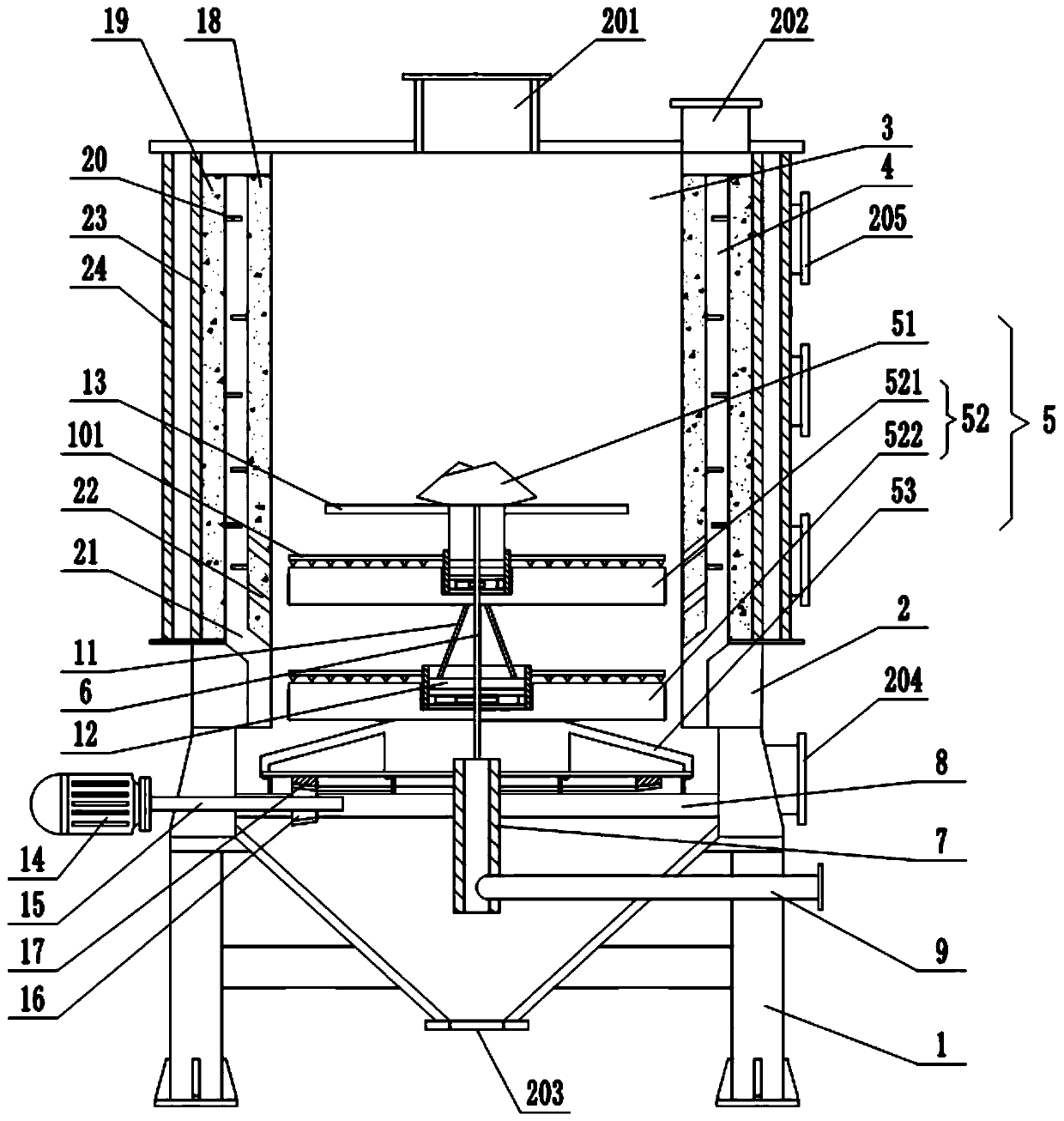

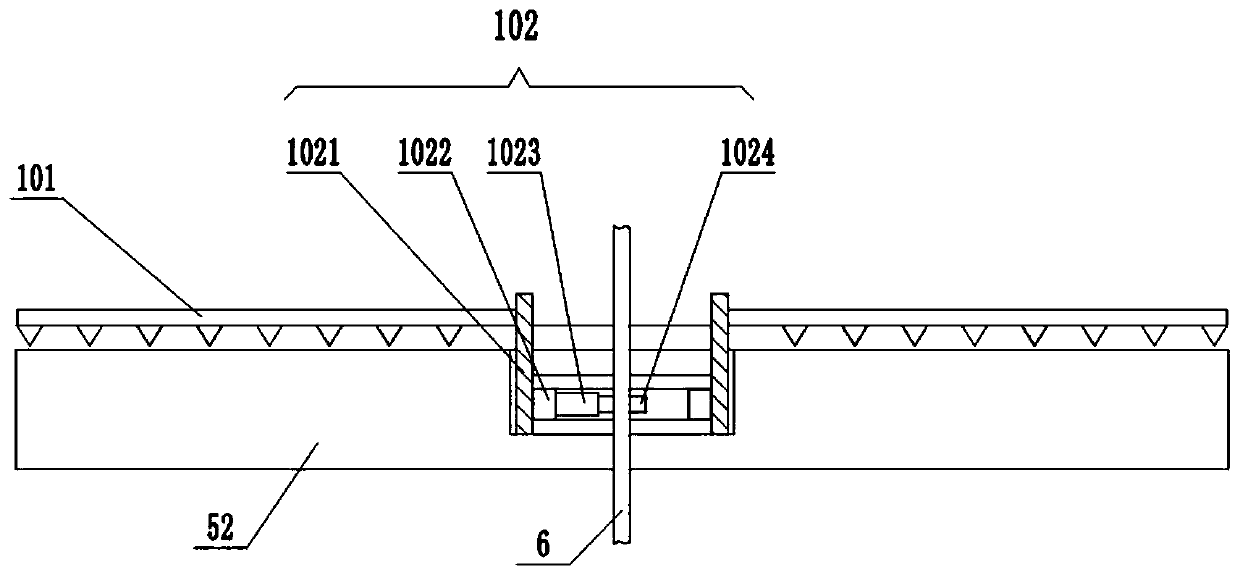

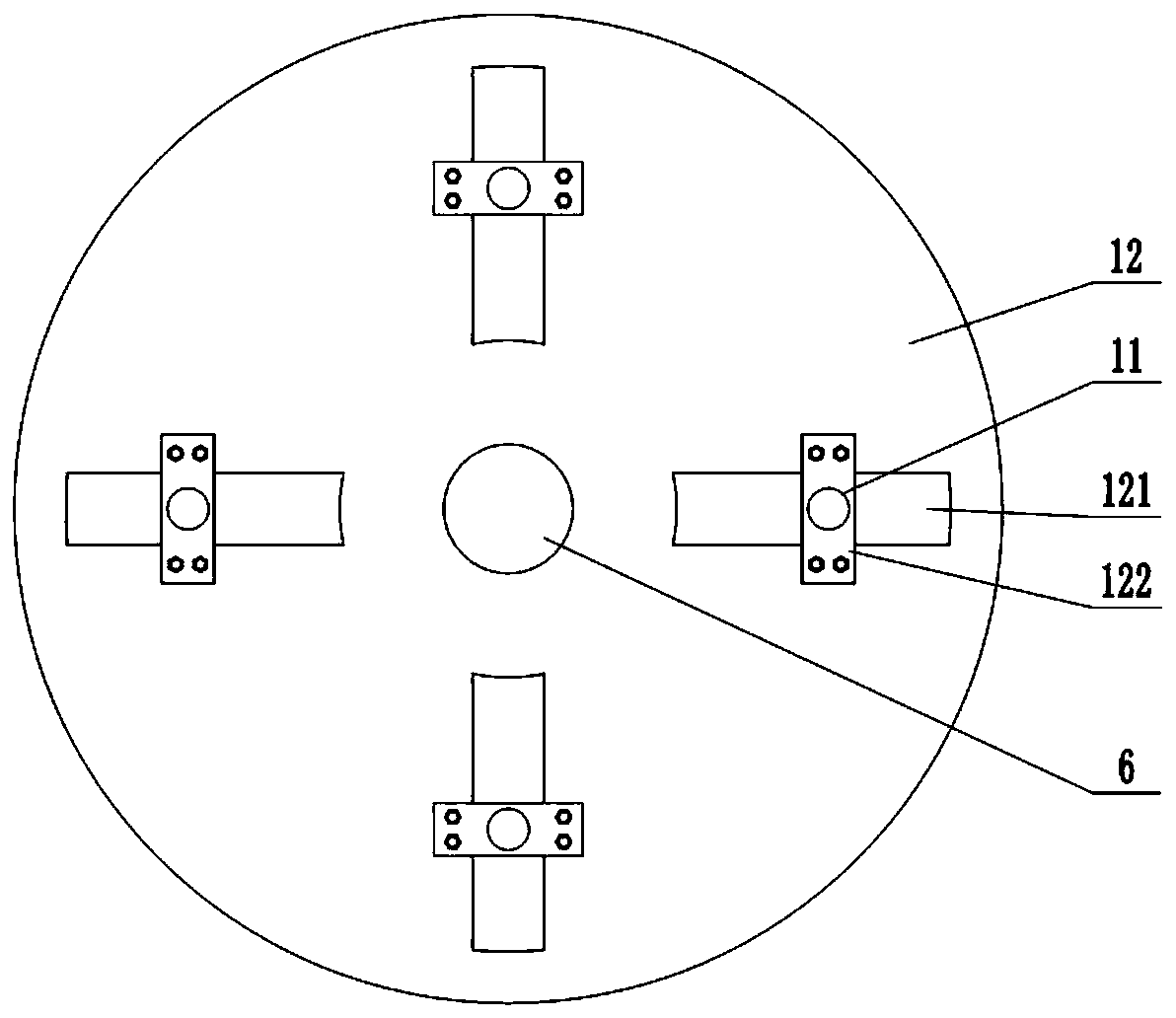

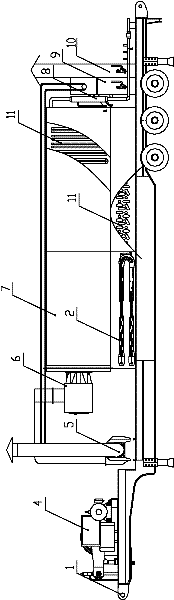

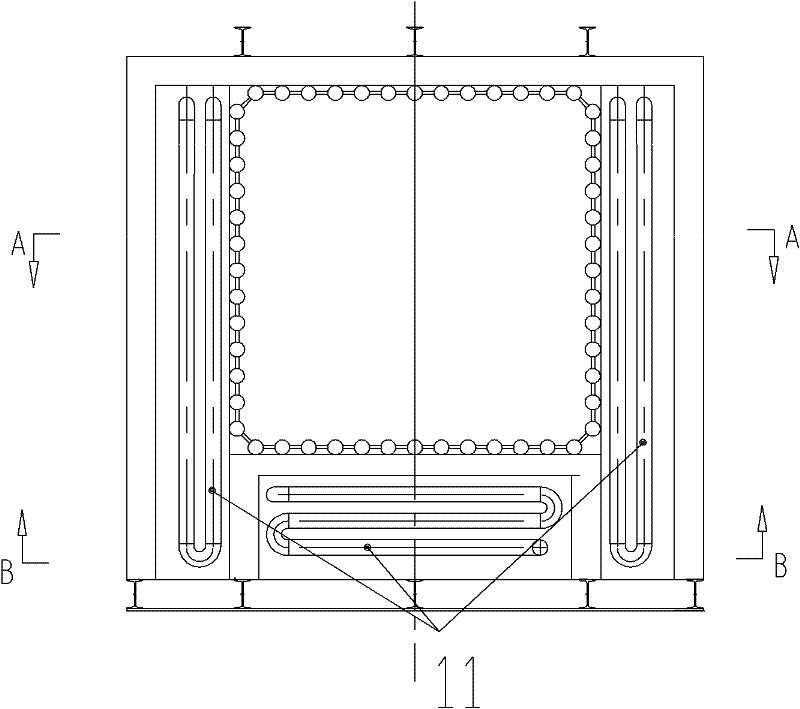

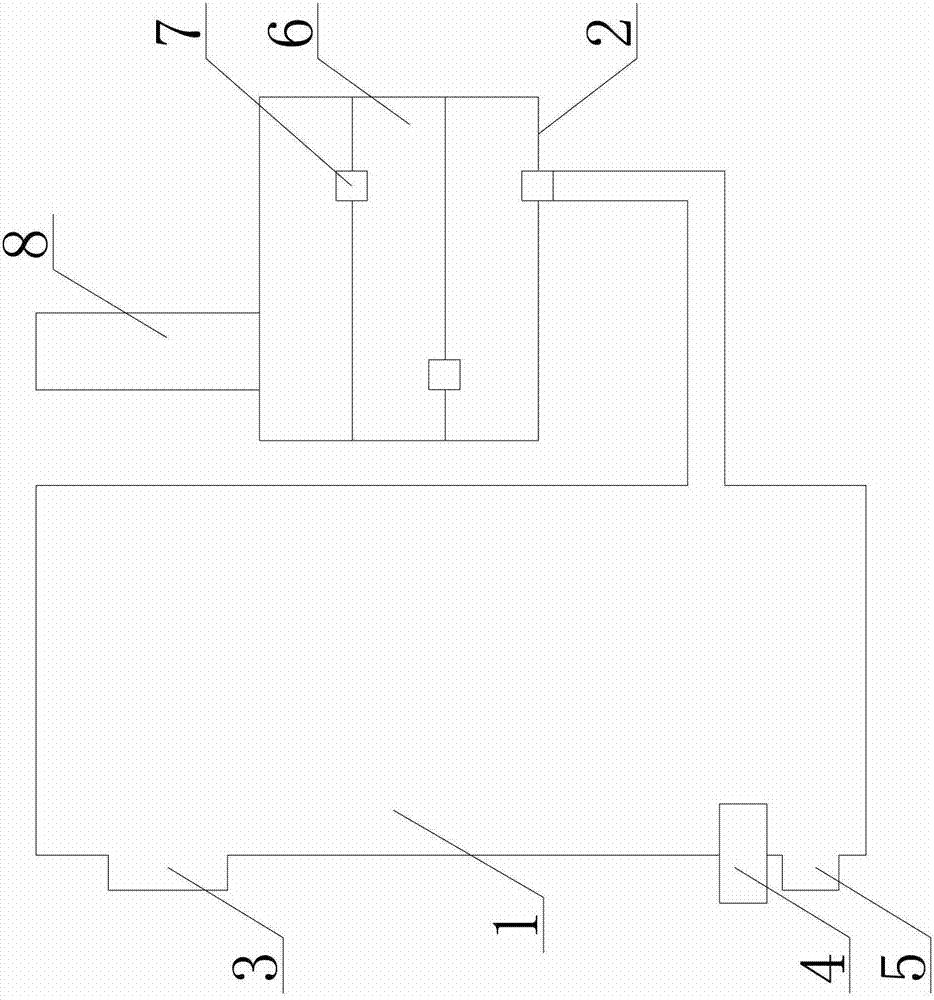

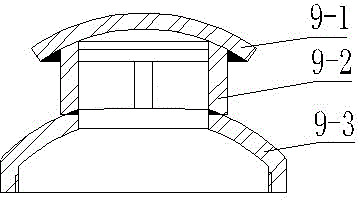

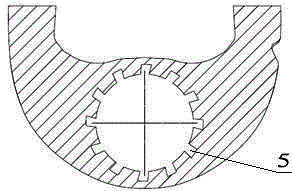

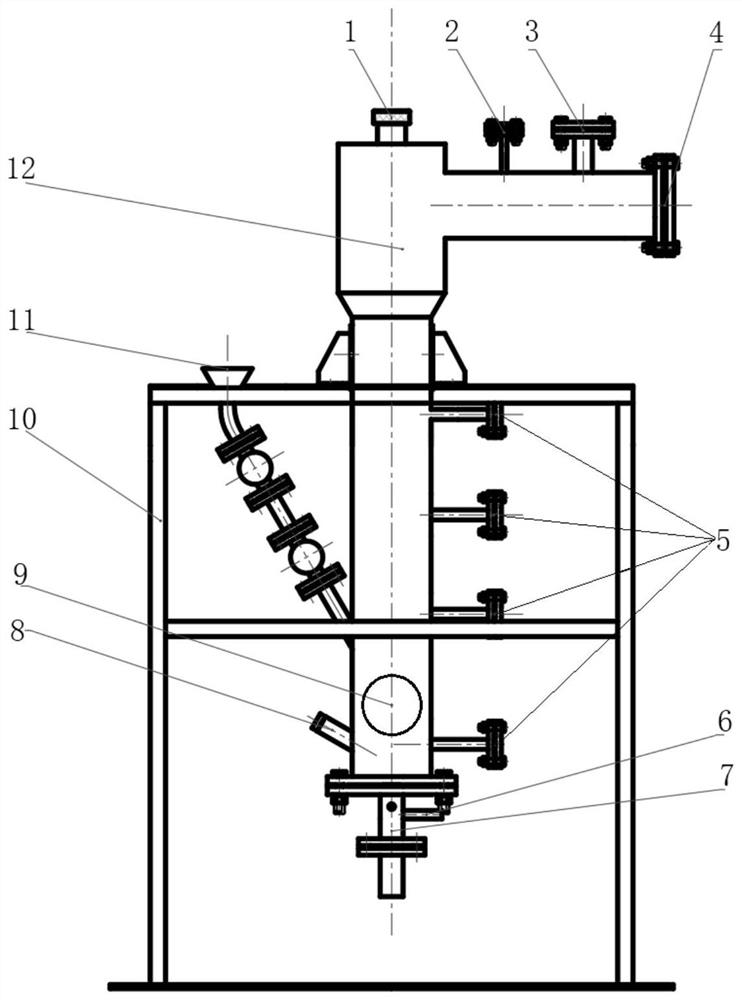

The invention belongs to the technical field of garbage disposal equipment, and particularly discloses a pyrolysis gasification furnace. The pyrolysis gasification furnace comprises a rack, a furnacebody, a furnace hearth, a secondary combustion chamber and a driving unit; the top of the furnace body is provided with a feeding port and a flue gas outlet, the bottom of the furnace body is providedwith a slag outlet, and the side wall of the furnace body is provided with a plurality of furnace doors and a plurality of observation holes; a rotatable furnace grate unit is arranged in the furnacehearth and comprises a garbage dispersing cap, a plurality layers of garbage distributing grates and a garbage furnace grate body which are sequentially connected from top to bottom; the side wall ofthe furnace body comprises an inner-side refractory layer, an outer-side refractory layer and a heat preservation layer, and the secondary combustion chamber is arranged between the inner-side refractory layer and the outer-side refractory layer; and a decoking unit is arranged in the furnace hearth and comprises a plurality of scraper blades and a power mechanism used for driving the scraper blades to do rotating motion, and the scraper blades are circumferentially distributed along the central axis and attached to the upper surface of the garbage furnace grate body. According to the pyrolysis gasification furnace, the scraper blades are arranged to remove coked materials on the furnace grate, furnace grate blocking is prevented, normal working and running of the furnace grate are guaranteed, and garbage can be fully combusted.

Owner:重庆管利仪器仪表有限公司

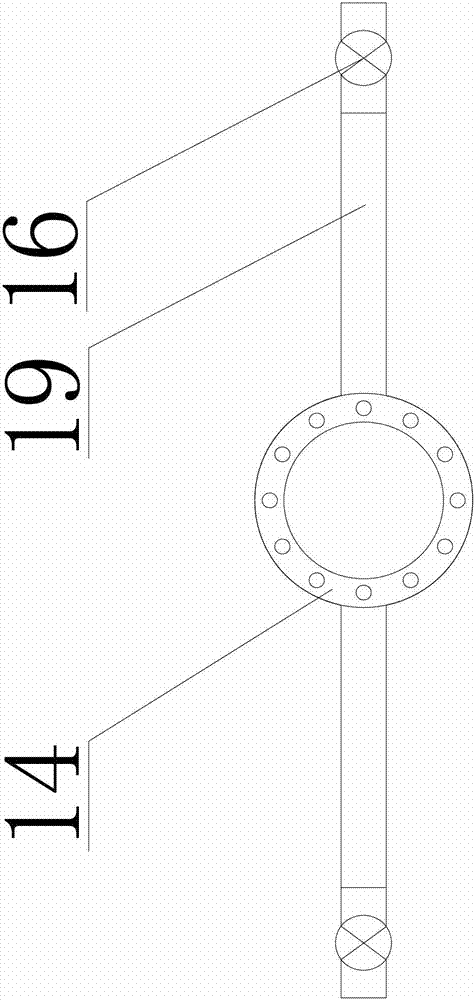

Electronic pilot burner

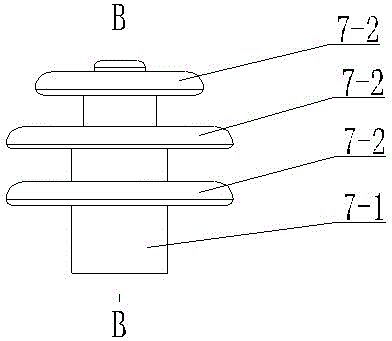

InactiveCN103062793AReduce pollutionReduce harmIncandescent ignitionCombustible gasGas supply equipment

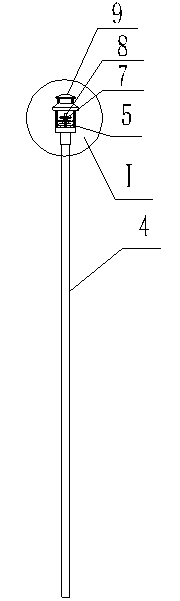

An electronic pilot burner solves the problems of energy waste, environmental pollution and low reliability of existing pilot burner, and is characterized by comprising a metal conducting rod connected with a high-voltage device, a discharge igniting head is mounted at the top end of the metal conducting rod, a quartz protection tube is sleeved outside the metal conducting tube, a metal protection tube is mounted outside the quartz protection tube, a burner holder is mounted at the top end of the metal protection tube, high-temperature-resisting mineral sand is filled between the metal protection tube and the quartz protection tube, a tower-shaped high-voltage quartz insulator is mounted on the burner holder, burner housing support columns are arranged on a current conducting platform of the burner holder, and outer edges of the burner housing support columns are connected with a burner housing through a connecting ring. The electronic pilot burner has the advantages that electric energy can be adopted to substitute for traditional inflammable gas to form pilot burner flame, blow-off can be avoided, and corresponding gas supply equipment and pipeline systems are not need to be provided, so that investment is reduced, space is saved, reliable eternal burning is kept in all weathers, and further energy saving, environmental protection, safety and equipment investment saving are achieved.

Owner:辽宁省电子研究设计院有限公司

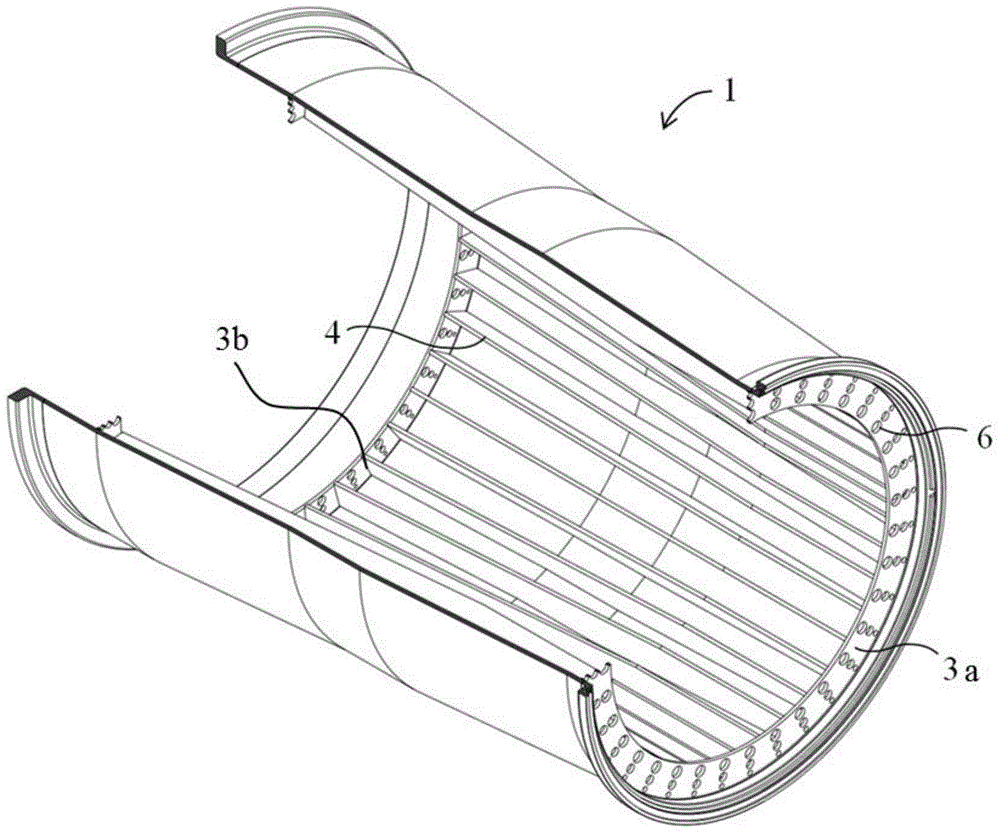

Channel type cooling structure of flame tube in combustion chamber of gas turbine

InactiveCN104359127AReduce tangential velocityImprove mobilityContinuous combustion chamberChannel typesConvective heat transfer

The invention discloses a channel type cooling structure of a flame tube in a combustion chamber of a gas turbine and belongs to the technical field of gas turbines. The cooling structure comprises a plurality of separation plates which are arranged in the axial direction of the flame tube, a front end cover plate and a rear end cover plate, wherein the separation plates are fixed on the inner wall of a diversion lining; the front end cover late is fixed on the inner wall of the diversion lining at the inlet of a ring-shaped return air channel; the rear end cover plate is fixed on the inner wall of the diversion lining at the outlet of the ring-shaped return air channel; a plurality of flow limiting holes are formed in the front end cover plate and the rear end cover plate. The ring-shaped return air channel is internally provided with a plurality of separation plates, so that the ring-shaped return air channel is divided into a plurality of axial cooling channels and the return air can flow in the axial cooling channels so as to reduce the tangential speed of the air, improve the flowing condition, bring benefit to enhance the convective heat transfer coefficient, improve the cooling efficiency, improve the uniformity of the air entering into the flame tube, improve the flowing condition in the flame tube and bring benefit to texture combustion.

Owner:BEIJING HUAQING GAS TURBINE & INTEGRATED GASIFICATION COMBINED CYCLE ENG TECH

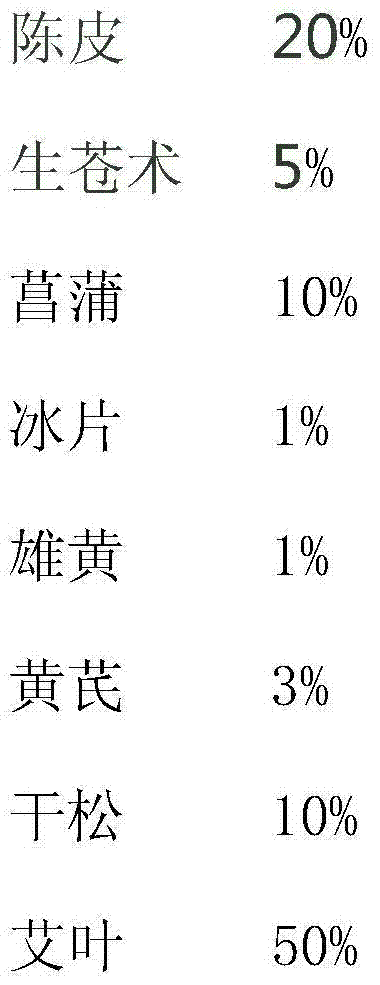

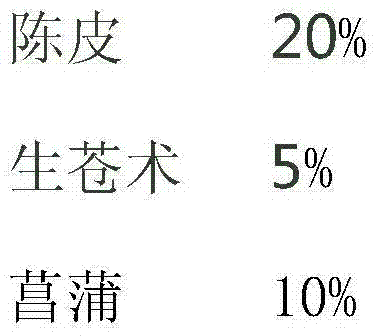

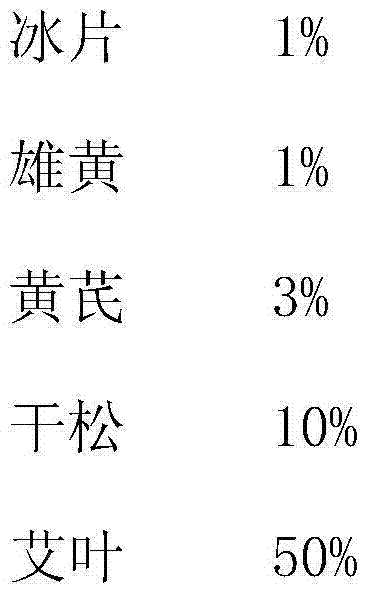

Incense formula capable of preventing cold

InactiveCN103690985AEfficient killingAvoid harmHydroxy compound active ingredientsInorganic active ingredientsSimple Organic CompoundsMedicine

The invention provides an incense formula capable of preventing cold. The incense formula consists of the following raw material in percentage by weight: 20% of pericarpium citri reticulatae, 5% of raw rhizoma atractylodis, 10% of calamus, 1% of borneol, 1% of realgar, 3% of astragalus membranaceus, 10% of rhizoma nardostachyos and 50% of folium artemisiae argyi. Moxa obtained by mixing the raw materials is favorable for burning, and smoke generated from burning is capable of effectively killing cold virus and is fragrant; and meanwhile, the incense formula is free from any organic compounds, free from any hurt to human body, and is good in effect of preventing cold.

Owner:程力

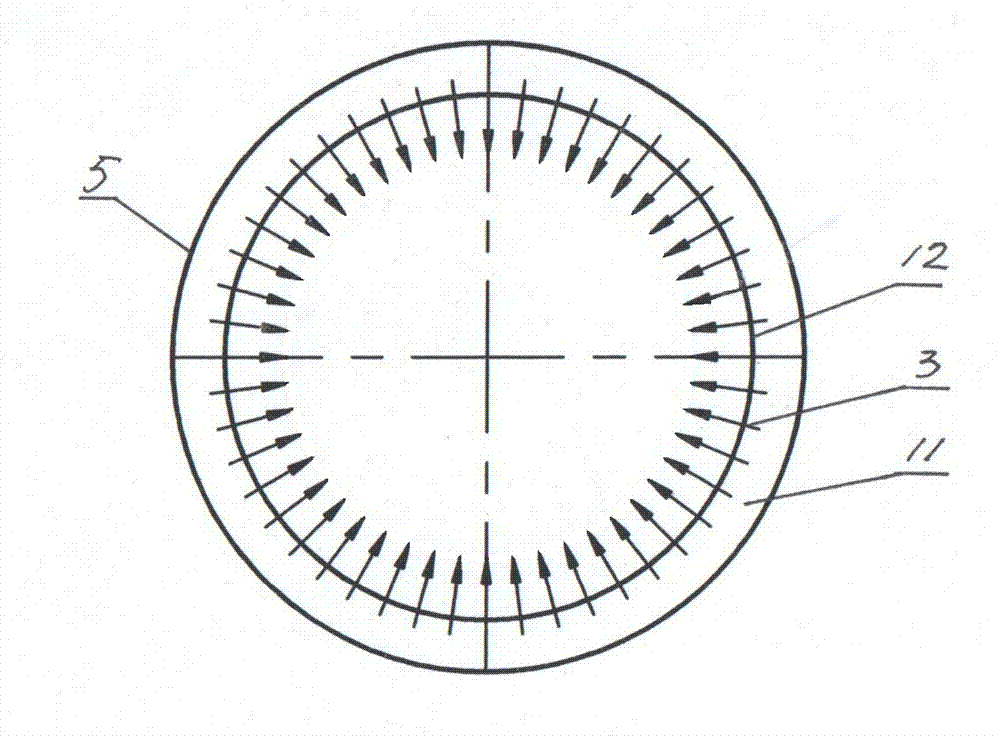

Garbage incinerator body with secondary air inlet

InactiveCN102767831ABurn fullyPlay a cooling roleIncinerator apparatusNon-combustible gases/liquids supplyTuyereHeating energy

The invention relates to a garbage incinerator body with a secondary air inlet, in particular to a large garbage incinerator body for burning urban garbage. The garbage incinerator body comprises a furnace body, the furnace body comprises an upper furnace body and a lower furnace body, and the upper furnace body is composed of a metal casing and a refractory brick lining positioned on the inner side of the metal casing. The lower furnace body comprises a metal outer wall and a metal inner wall, and an interval serving as an air chamber is reserved between the metal outer wall and the metal inner wall. The bottom of the lower furnace body is provided with a primary air inlet. The garbage incinerator body is structurally characterized in that the metal outer wall of the lower furnace body is provided with the secondary air inlet connected with an air outlet of a secondary fan, and radial holes are evenly distributed on the circumference of the inner wall of the lower furnace body. The garbage incinerator body can not only improve burning efficiency, but also avoid waste of heat energy. The garbage incinerator body is suitable for a large garbage incinerator with daily treatment quantity of over 100 tons.

Owner:无锡多灵环保工程设备有限公司

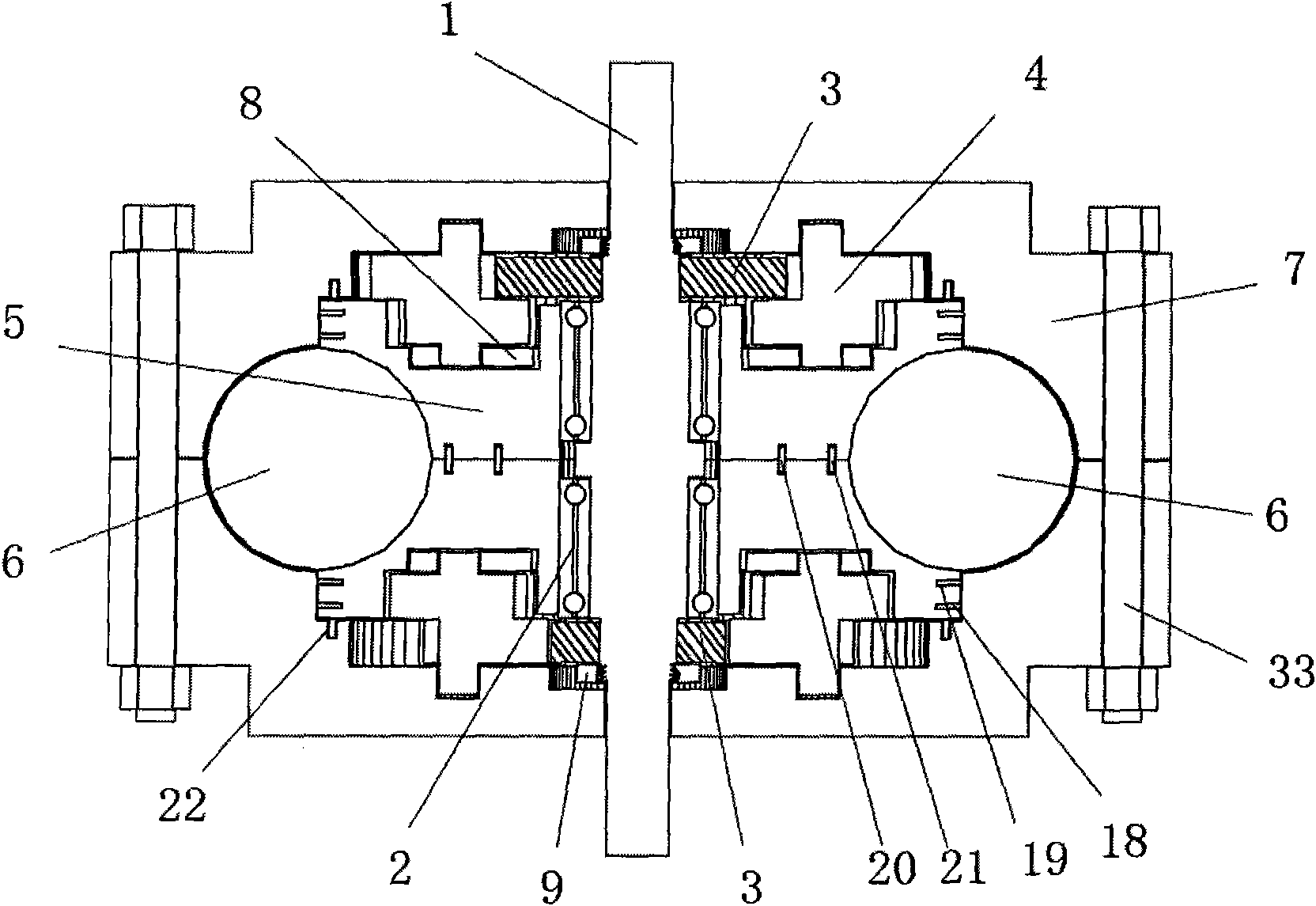

Two-way elliptic gear engine

InactiveCN101852131ANo vibrationImprove conversion efficiencyMachines/enginesCombustion chamberGear wheel

The invention relates to a two-way elliptic gear engine which is integrally in a cylindrical shape. In the two-way elliptic gear engine, an output shaft, a bearing, a disk member, a plurality of pistons and an elliptic gear form a cylindrical rotor; two shells which are arranged oppositely, an inlet valve, an outlet valve, a plurality of hot fire heads, a gear frame and a plurality of duplex eccentric gears form a stator; the space between the rotor and the stator forms an annular combustion chamber, and the plurality of pistons rotate in the annular chamber and divide the combustion chamber into a plurality of cylinders; and the elliptic gear, the duplex eccentric gears and a disk inner gear form a transmission system for carrying out one-way differential transposition rotation among the pistons, so that the volume among the cylinders is changed to realize the purpose of forming the engine by four strokes.

Owner:谢坤

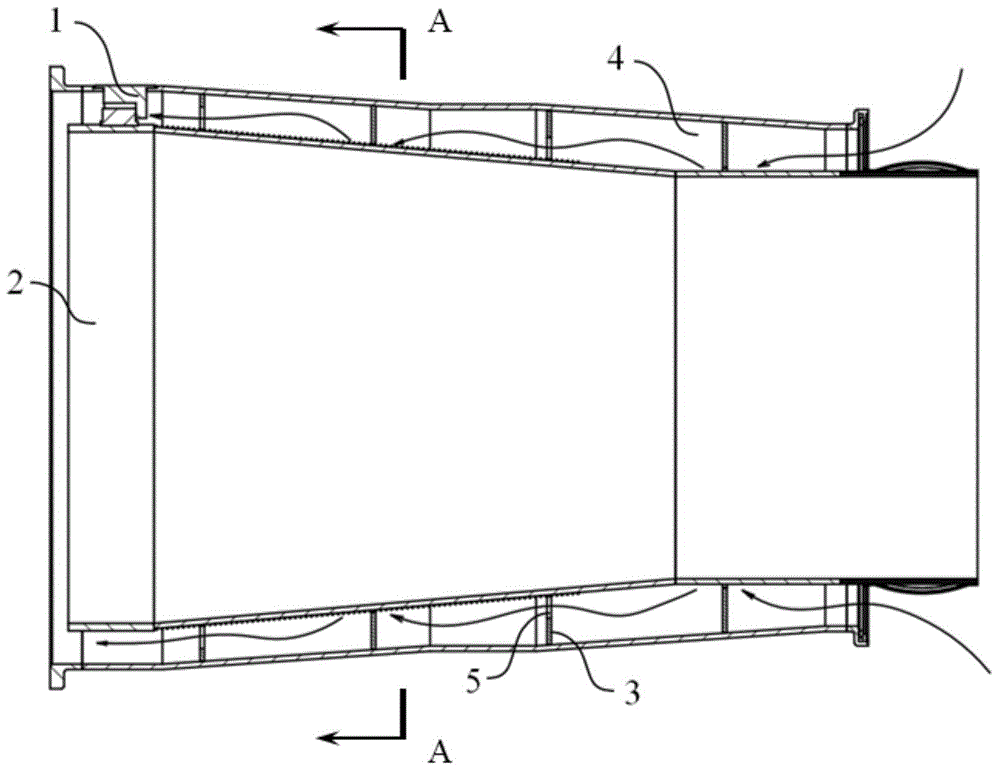

Staggered cooling structure of flame tube in combustion chamber of gas turbine

ActiveCN104359126AImprove cooling effectCooling effect limitContinuous combustion chamberCasings/liningsCombustion chamberCooling effect

The invention discloses a staggered cooling structure of a flame tube in a combustion chamber of a gas turbine and belongs to the technical field of gas turbines. The cooling structure comprises a plurality of ring-shaped flow limiting plates which are arranged in the axial direction of the flame tube, wherein the outer sides of the ring-shaped flow limiting plates are fixed on the inner wall of a diversion lining; cooling holes which are rectangular or semicircular are formed in the inner sides of the ring-shaped flow limiting plates in the circumferential direction. The cooling holes are capable of enhancing the convective heat transfer coefficient, improving the cooling effect of the flame tube and preventing the temperature of the flame tube from getting too high. The ring-shaped flow limiting plates radially extend to the flame tube; the cooling holes of every two adjacent ring-shaped flow limiting plates are distributed in the circumferential direction in a staggered manner, so that the flowing of the air can be limited, the flowing time of the return air can be increased and benefit is brought to fully cool the flame tube. Through improving the cooling, the reliability of the flame tube is improved and benefit is brought to prolong the service life of the flame tube.

Owner:BEIJING HUAQING GAS TURBINE & INTEGRATED GASIFICATION COMBINED CYCLE ENG TECH

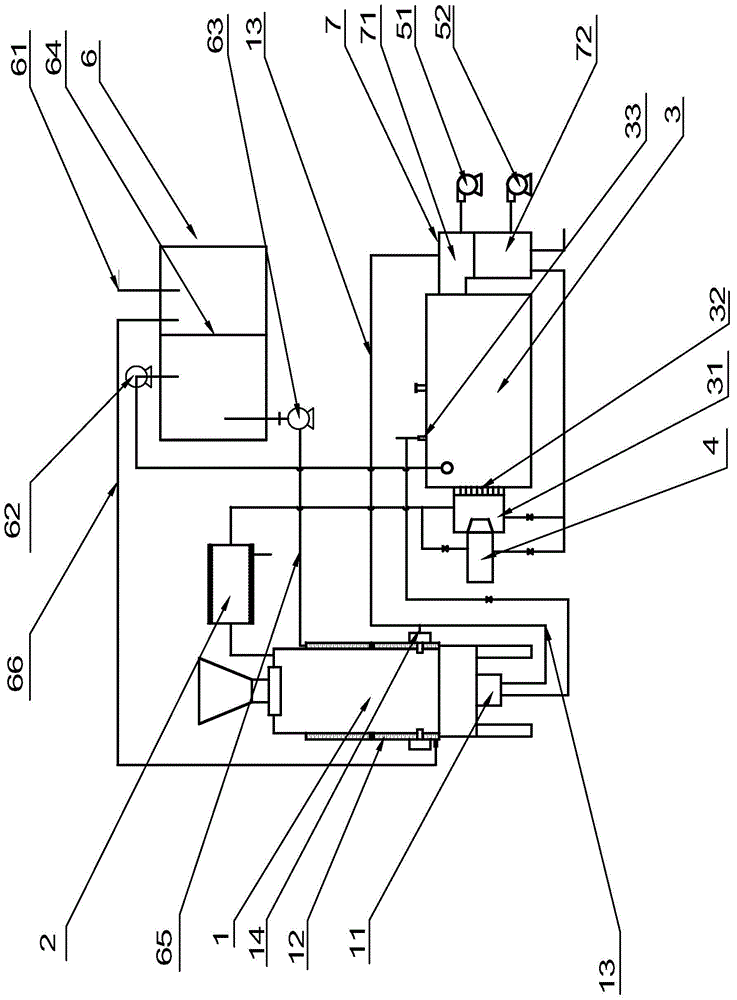

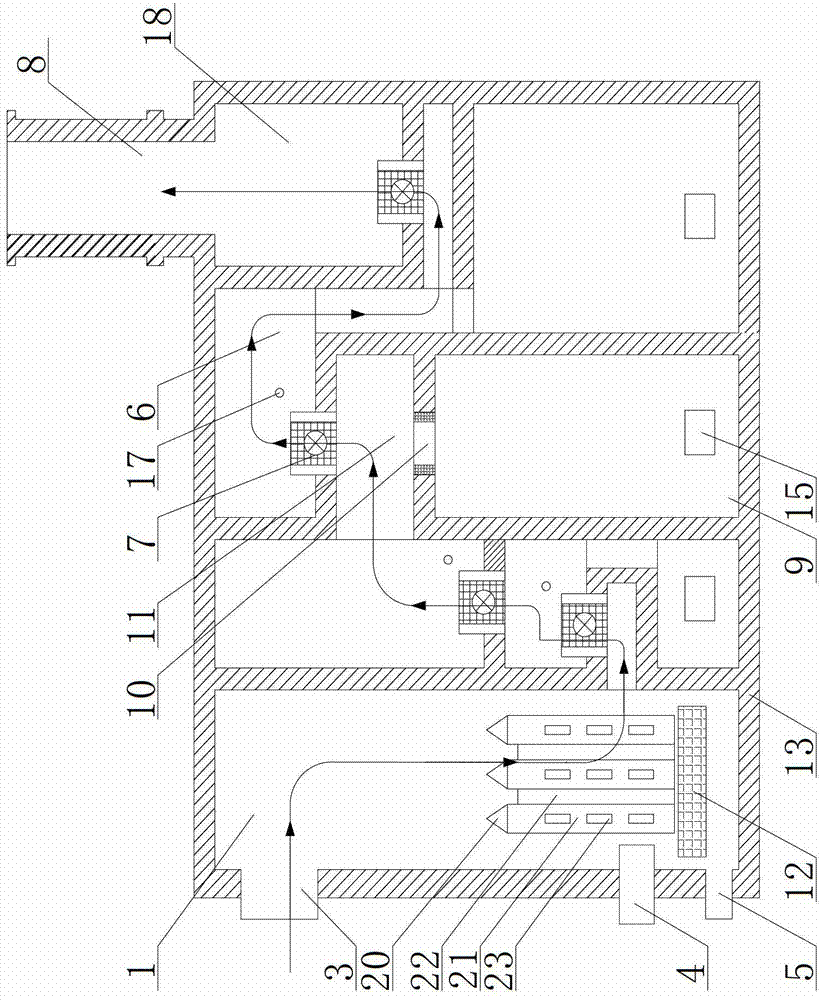

Biomass gasifier/industrial gas boiler combined high-efficiency heating system

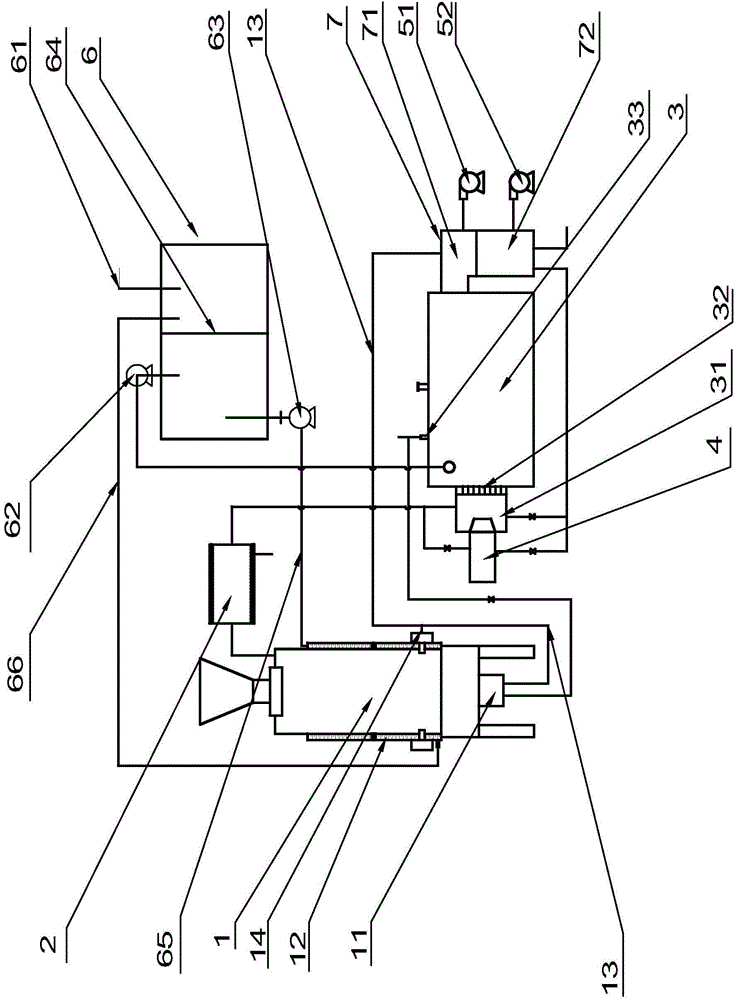

ActiveCN104560218AImprove quality and stabilityImprove efficiencyEnergy inputGasification processes detailsTarBiomass

The invention discloses a biomass gasifier / industrial gas boiler combined high-efficiency heating system. The system utilizes steam generated by the industrial gas boiler, part of the steam is supplied to the gasifier for gasification as a gasification medium, and the steam and air are combined for gasification, thereby being beneficial to enhancing the stability and quality of the biomass gas. The preheated air is supplied to the industrial gas boiler as combustion-supporting gas, thereby enhancing the overall heat efficiency. The electrolyic decoking cracking device can crack tar in the biomass gas, thereby enhancing the stability of the biomass gas and being beneficial to combustion of the biomass gas. Meanwhile, the system is subjected to water cooling through a full water cooling jacket, thereby effectively avoiding coking in the biomass gasifier. The system is applicable to the field of boiler heating systems.

Owner:GUANGDONG ZHENGPENG BIOMASS ENERGY TECH

Household boiler fuel with health effects

The invention relates to the field of processing making of boiler fuels, and especially relates to a household boiler fuel with health effects. The fuel comprises 950 parts of anthracite, 800 parts of wheat bran, 600 parts of dried firewood, 30 parts of paraffin, 10 parts of borneol, 5 parts of mint, 3 parts of wild chrysanthemum flower, 2 parts of Atractylodes lancea and 0.5 parts of sweet osmanthus essential oil. The fuel has the characteristics of low preparation cost, no smoke, environmental protection and good health effects; anthracite and paraffin are added to the fuel in order to facilitate the combustion of the fuel and reduce flue dusts, so environmental protection is realized; and wild chrysanthemum flower, mint, Atractylodes lancea and sweet osmanthus essential oil are added to make the fuel have light delicate fragrance taste and realize mind tranquilizing and health care effects, so the fuel must be loved by people.

Owner:QINGDAO SHENGLI BOILER

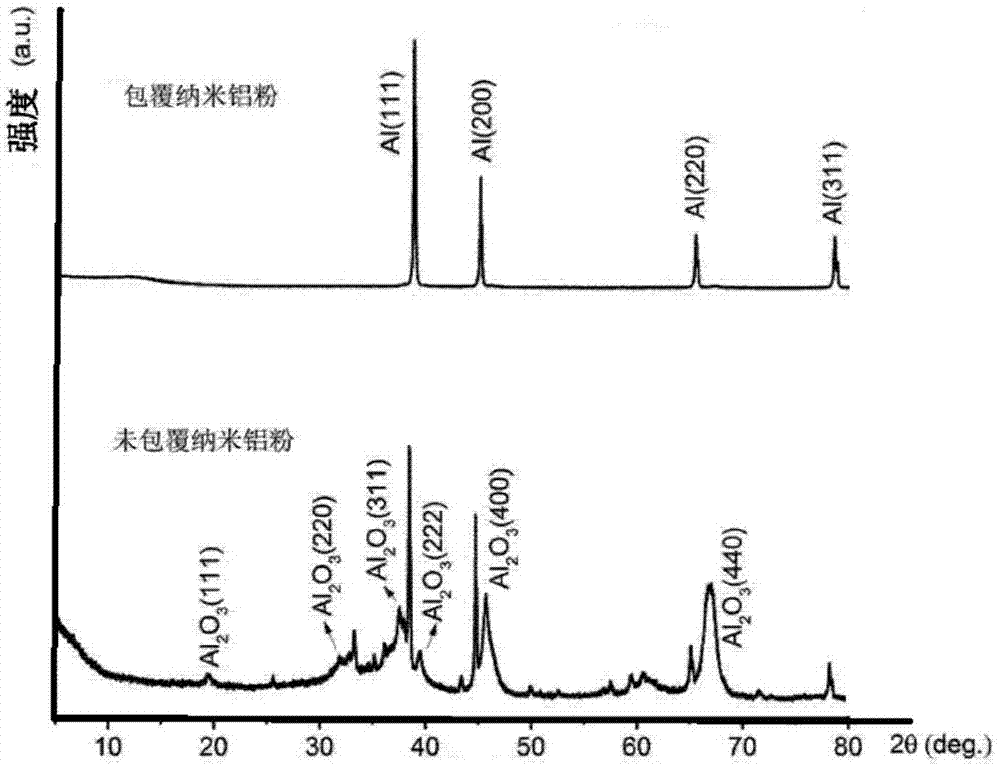

Coating method of nano-aluminum powder

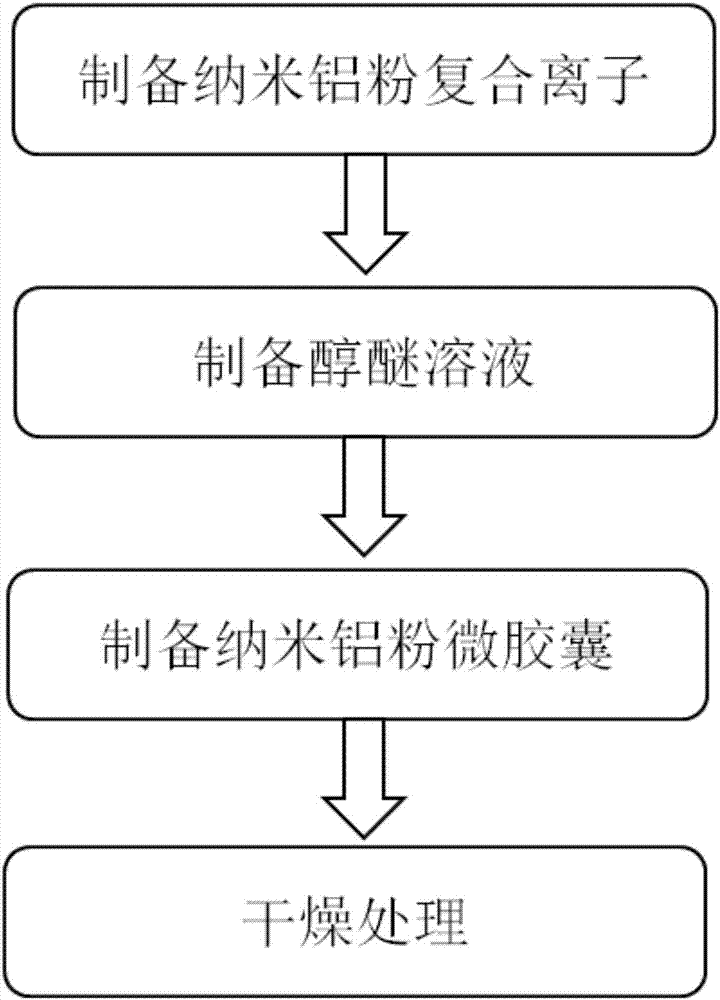

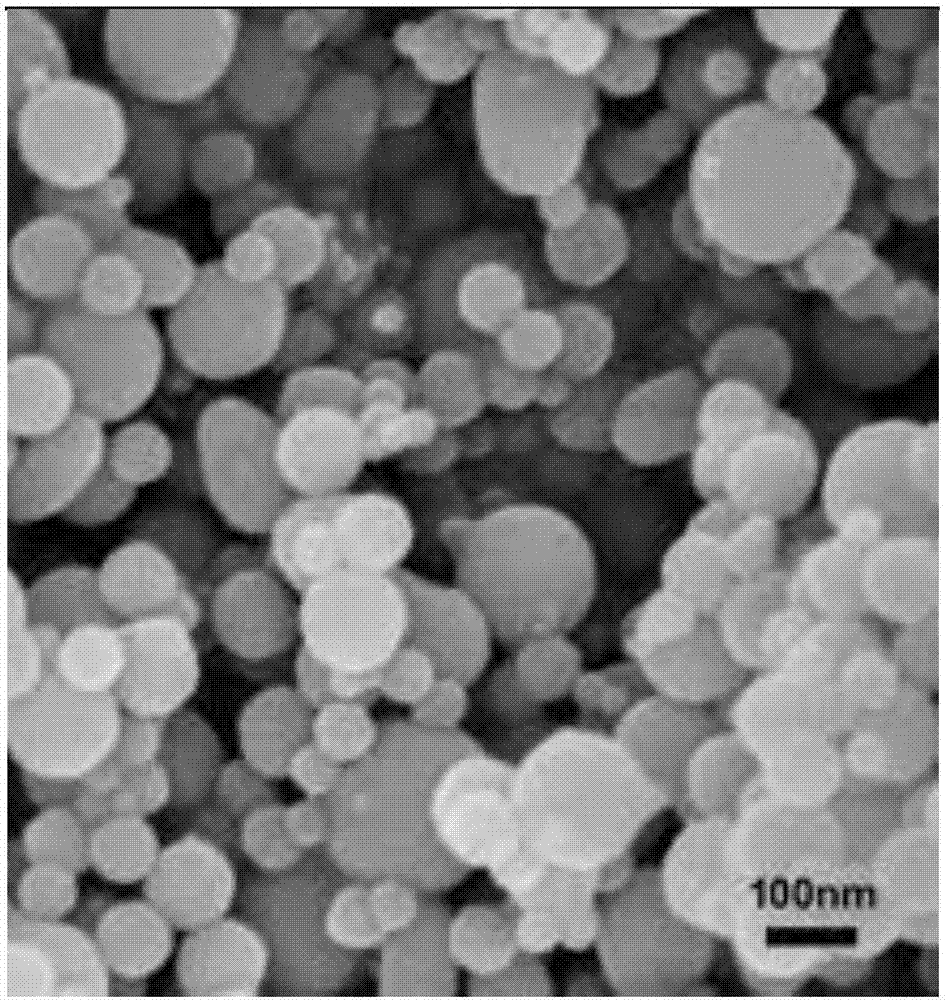

InactiveCN106984804AIncrease coverageHigh activityMaterial nanotechnologyTransportation and packagingChemical reactionAlcohol

The invention relates to the technical field of metal powder surface treatment and particularly to a coating method of nano-aluminum powder. The coating method of nano-aluminum powder comprises the following steps: preparing nano-aluminum powder compound ions and an alcohol ether solution; preparing nano-aluminum powder microcapsules by a series of chemical reactions of the obtained nano-aluminum powder compound ions and the alcohol ether solution; spreading the nano-aluminum powder microcapsules, and performing drying treatment on the nano-aluminum powder microcapsules in a vacuum drying oven, so as to obtain a composite material having a core-shell structure. According to the coating method of nano-aluminum powder, the technological process is simple and convenient to implement, large-batch coating can be completed at a time, nano-aluminum powder with a better coating performance can be directly prepared, the activity of the coated nano-aluminum powder is higher, the metal activity of the nano-aluminum powder is effectively ensured, and the problem of oxidation deactivation of the nano-aluminum powder is solved.

Owner:HARBIN ENG UNIV

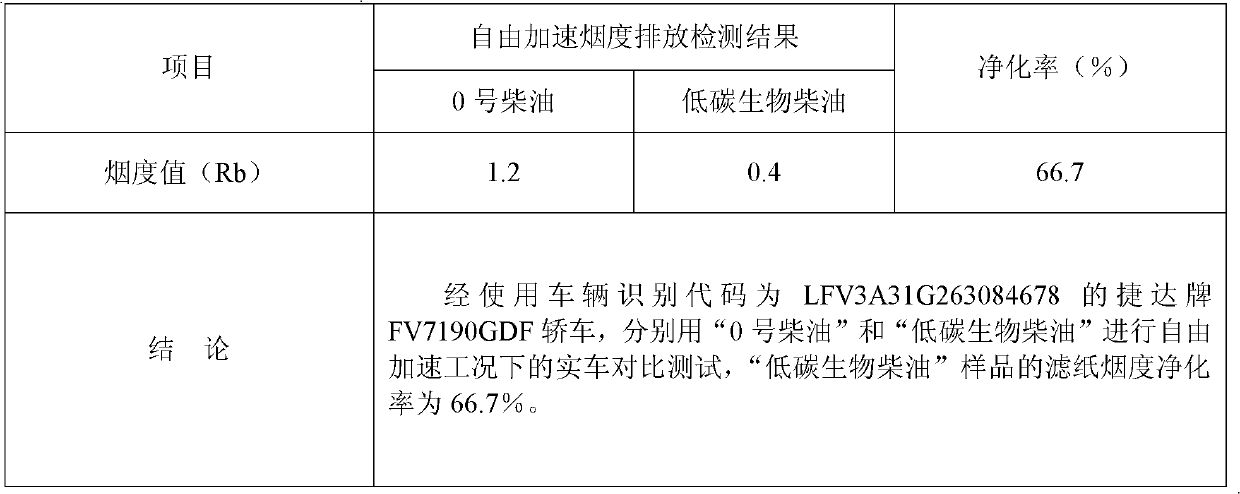

Vehicle low-carbon biodiesel

ActiveCN101768478ANo power dropNo corrosionLiquid carbonaceous fuelsPolyethylene vinyl acetateOctanol

The invention relates to a vehicle low-carbon biodiesel which uses coal methanol, butanol, octanol, oleic acid, 0# diesel and 200# solvent oil as raw materials. The preparation method comprises the following steps: firstly mixing methanol and oleic acid with octanol and butanol at room temperature under normal pressure, adding N,N'-phenylenediamine, sodium alkylsulfonate and copper naphthenate tostir evenly to inject into a preparation tank, secondly blending 200# solvent oil with 0# diesel, adding alkyl acid amide, ethylene glycol methyl ether, a mixture of chromium salt and calcium salt offatty acid, polyethylene vinyl acetate (T1804) and N,N'-bis(salicylidene)-1,2-propylene diamine, heating the obtained mixture to 55 DEG C with a fuel oil heat exchanger, injecting the mixture to the preparation tank, and using a stirred tank to stir for 1 hour to obtain the uniform low-carbon biodiesel. The vehicle biodiesel is convenient to use, the vehicle engine is not needed to modify, and the vehicle biodiesel can be used alone or mixed with vehicle diesel and biodiesel freely. The low-temperature start of fuel is good, the stability is high, the CO, HC and NOX contents of the emitted exhaust can be effectively reduced and the biodiesel of the invention is the preferred biomass vehicle fuel for energy conservation and carbon reduction now.

Owner:北京雄韬伟业能源科技发展有限公司

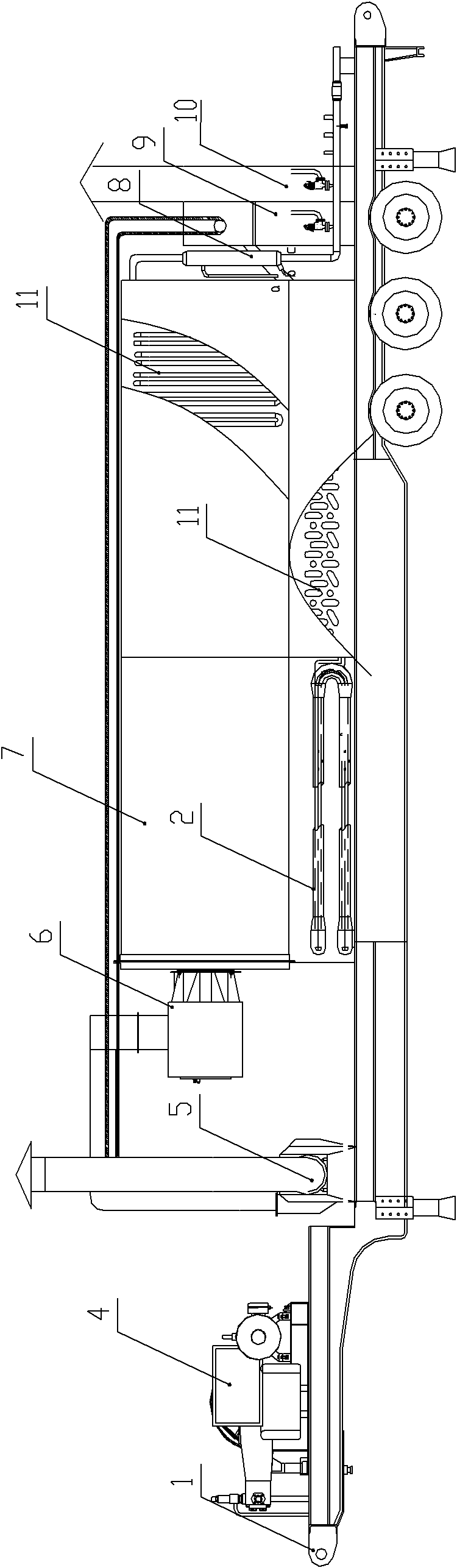

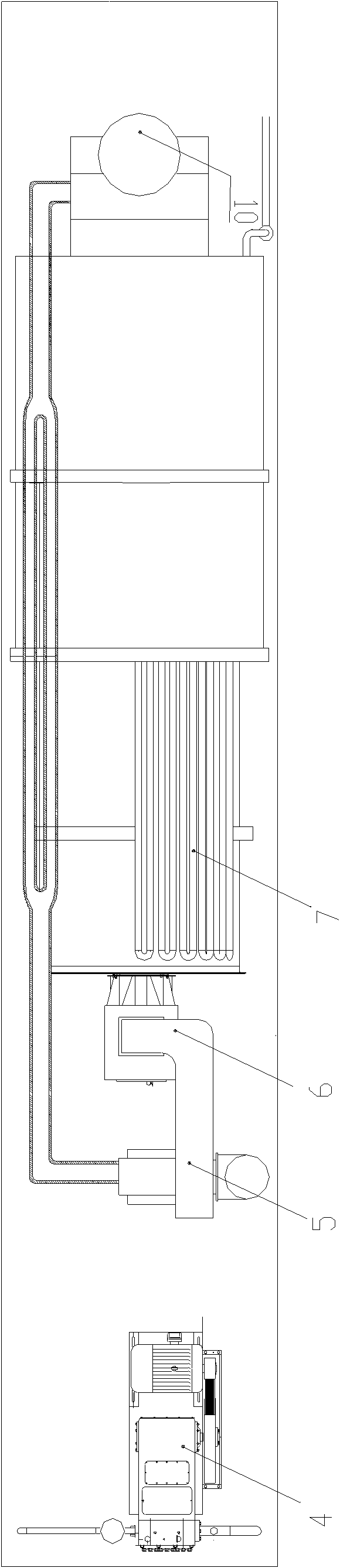

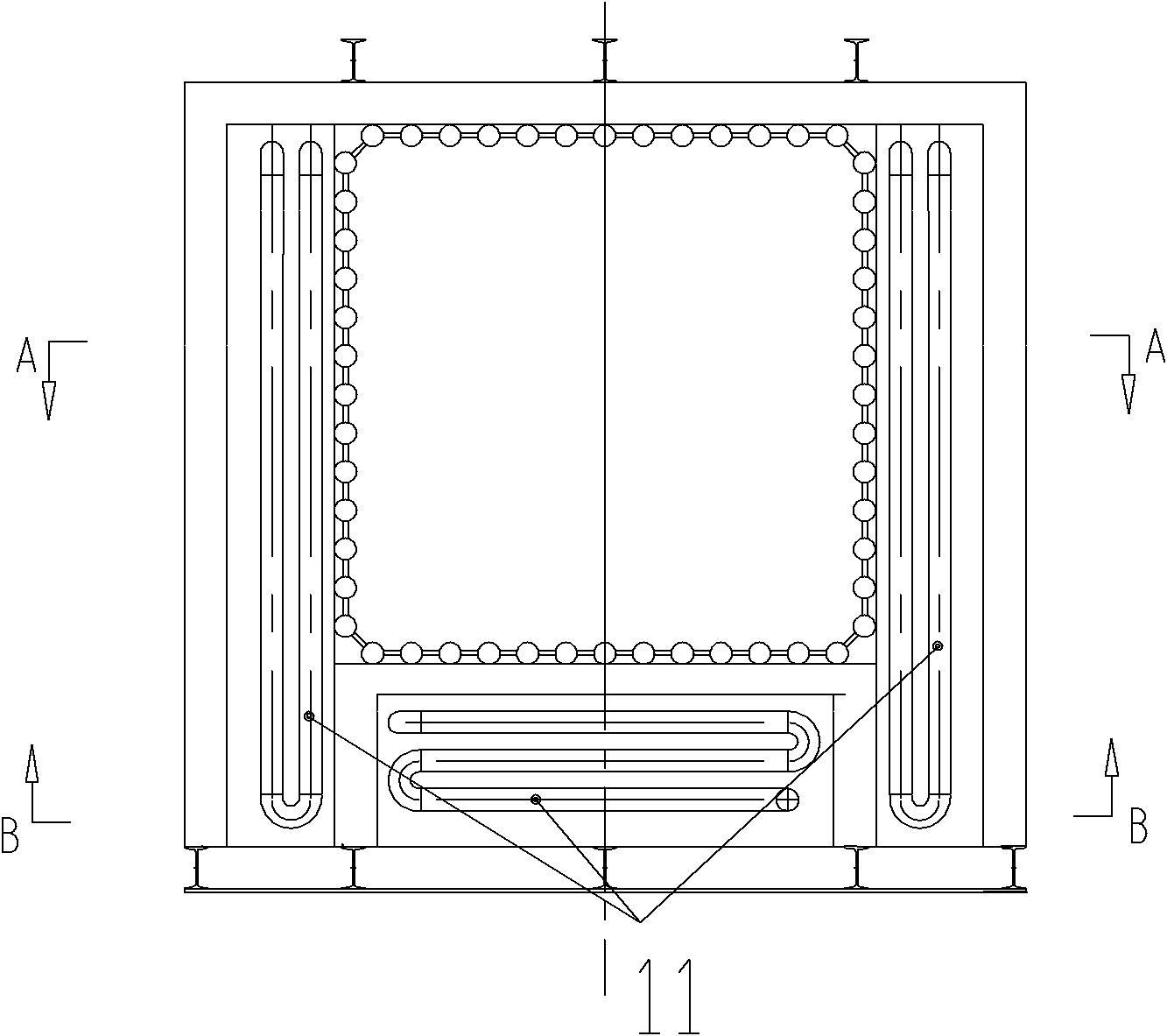

Vehicle-mounted high-pressure DC steam injection boiler system with three-pass flue gas

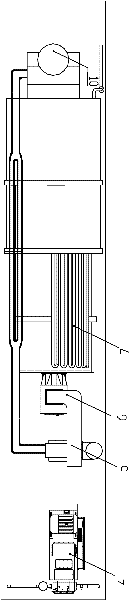

InactiveCN101881434ASmall form factorCompact structureFluid removalSteam boilersAir preheaterFlue gas

The invention relates to the field of the boiler design and manufacture, and discloses a vehicle-mounted high-pressure DC steam injection boiler system with three-pass flue gas, which is applicable to the field of thermal exploitation of heavy oil in the oil industry. The boiler system comprises a trailer, a sleeve type water-water heat exchanger, a convection section, a high-pressure water supply pump, a combustion fan, a burner, a radiation section, a steam-water separator, an air preheater and a chimney, wherein the high-pressure water supply pump, the combustion fan, the burner, the radiation section, the steam-water separator, the air preheater and the chimney are arranged on the trailer in sequence along the length direction of the trailer, the cross section of the radiation section is square, the sleeve type water-water heat exchanger is arranged outside the lower side face of the front half section of the radiation section, the convection section comprises a left rectangular flue gas channel, a right rectangular flue gas channel, a lower rectangular flue gas channel and convection tube bundles respectively arranged in the three rectangular flue gas channels, and the left rectangular flue gas channel, the right rectangular flue gas channel and the lower rectangular flue gas channel are correspondingly arranged outside the left side face, the right side face and the lower side face of the rear half section of the radiation section.

Owner:XI AN JIAOTONG UNIV +1

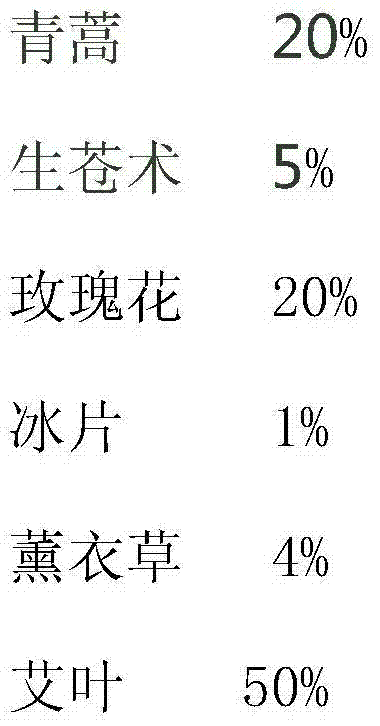

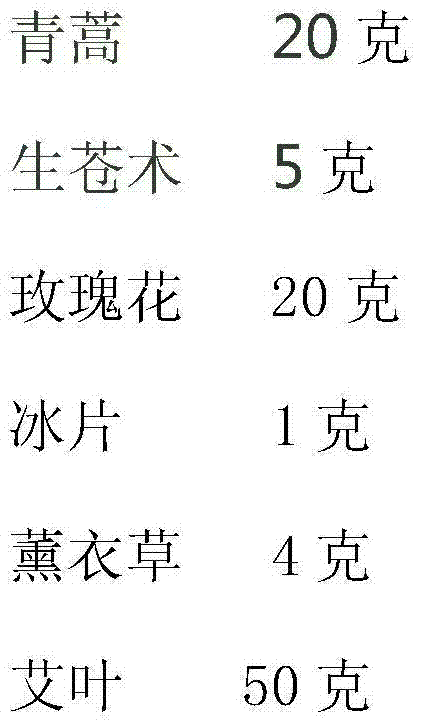

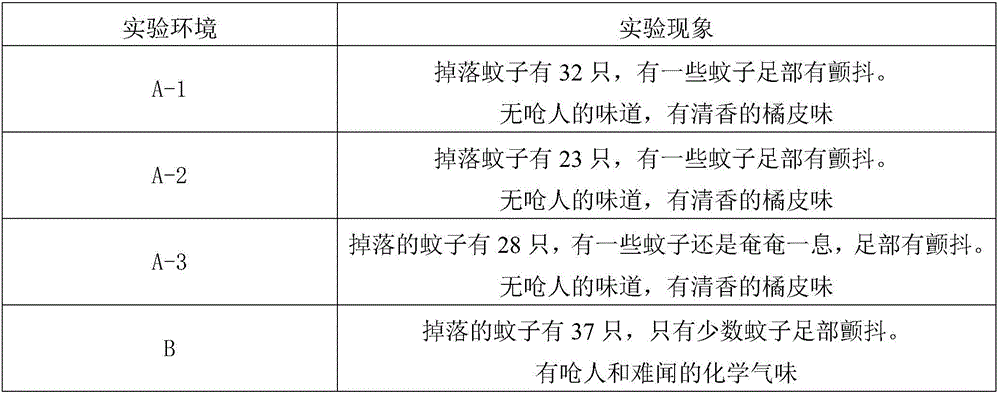

Formula of mosquito/insect-dispelling incense

The invention provides a formula of mosquito / insect-dispelling incense, wherein the adopted raw materials comprise 20wt% of sweet wormwood herb, 5wt% of raw Chinese atractylode rhizome, 20wt% of rose, 1wt% of borneol, 4wt% of lavender, and 50wt% of moxa leaf. According to the formula provided by the invention, fragrance emitted by the sweet wormwood herb, the rose, the lavender and the moxa leaf can effectively dispel mosquitoes, the raw Chinese atractylode rhizome and the borneol are used for sterilization, moxa is combustion-supporting, and the incense does not contain any organic compounds, has no harm to a human body and is good in mosquito dispelling effect.

Owner:程力

Safe and reliable nourishing vegetarian meal replacement biscuit with balanced nutrients and production method of biscuit

InactiveCN109588452AStrong expansionHigh viscosityDough treatmentModified nutritive productsLow calorieFood material

The invention discloses a safe and reliable nourishing vegetarian meal replacement biscuit with balanced nutrients and a production method of the biscuit. The meal replacement biscuit is prepared from78 raw materials. The biscuit is characterized in that firstly, rich and diversified raw materials are selected, low fat, low sugar and low calorie are guaranteed, and comprehensiveness and balance of nutrients are realized; secondarily, the biscuit contains no pigment, essence, preservatives or other artificially synthesized substances, the color, aroma and taste of the biscuit are produced naturally by reasonable matching of food materials, and the biscuit is absolutely safe, reliable, healthy and pollution-free; next, the used food materials such as konjac flour, beans, edible fungus and part of dried fruits produce strong satiety, so that the biscuit can eliminate hunger, prolong gastric emptying time and reduce intake of meals and is a meal replacement product capable of controllingweight, preventing obesity and keeping a good figure.

Owner:JILIN UNIV

Coal-fired combustion improver with high stability

The invention provides a coal-fired combustion improver with high stability. The coal-fired combustion improver is innovatively characterized by comprising the following components in percentage by weight: 20-30% of an oxidizing agent, 2-8% of a stabilizer, 20-30% of a catalyst, 2-3% of a dispersing agent, 10-20% of an emulsifier and 10-20% of a penetrating agent, wherein the stabilizer comprises 3,5-ditert-butyl-4-hydroxybenzoyl hydrazine, xylogen, silica powder, sodium sulfanilate and zinc stearate, or 3-methyl-5-tert-butyl-4-hydroxybenzoyl hydrazine, xylogen, silica powder, sodium sulfanilate and zinc stearate. According to the coal-fired combustion improver disclosed by the invention, the effect of adding the stabilizer into the coal is to mainly achieve the effects of delaying the decomposition rate after the oxidizing agent is heated and increasing the action time in the combustion system, and then the actual combustion effect is improved.

Owner:朱亚东

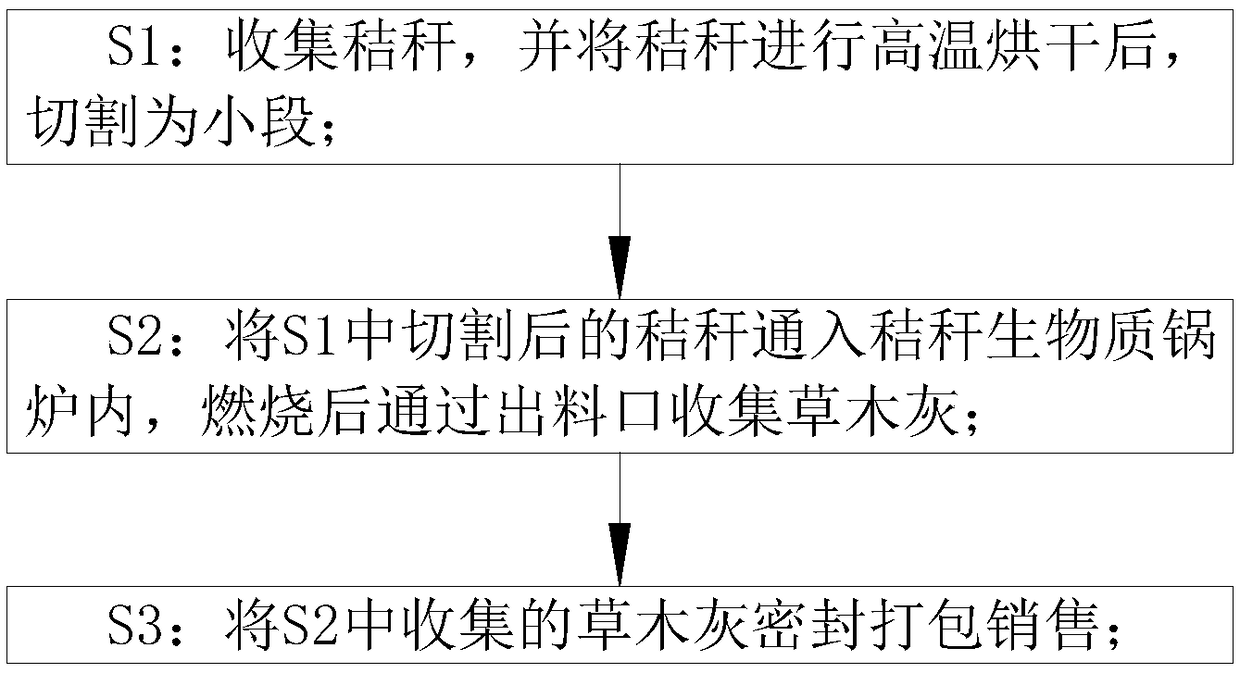

Biomass fertilizer preparation process

ActiveCN109442390AImprove combustion efficiencyBurn fullySolid fuel combustionCombustion apparatusAgricultural engineeringAluminum silicate

The invention belongs to the technical field of soil fertilizers, and particularly relates to a biomass fertilizer preparation process. According to the biomass fertilizer preparation process, straw is dried and cut so that the combustion efficiency can be improved, the straw is combusted sufficiently through the combustion of a straw biomass boiler, then plant ash does not contain straw residues,the plant ash is effectively prevented from being lost through sealing and packing of the plant ash. The applied straw biomass boiler comprises a frame body and a controller, a rotating shaft of a first motor penetrates into the frame body and is fixedly connected with a stirring unit, a crushing unit is arranged on the inner wall of the top of the frame body, transmission units are arranged in transmission grooves, the sides, close to the inner wall of the frame body, of the transmission grooves are provided with ignition units which are uniformly arranged, a filter plate is made of long-wire ultra-light aluminum silicate materials, and a rotating unit is arranged below the filter plate. According to the process, the combustion efficiency of the straw is high, the produced plant ash doesnot contain the straw residues, and then the plant ash can return to a field for reusing.

Owner:SHANDONG WANHAO FERTILIZER IND

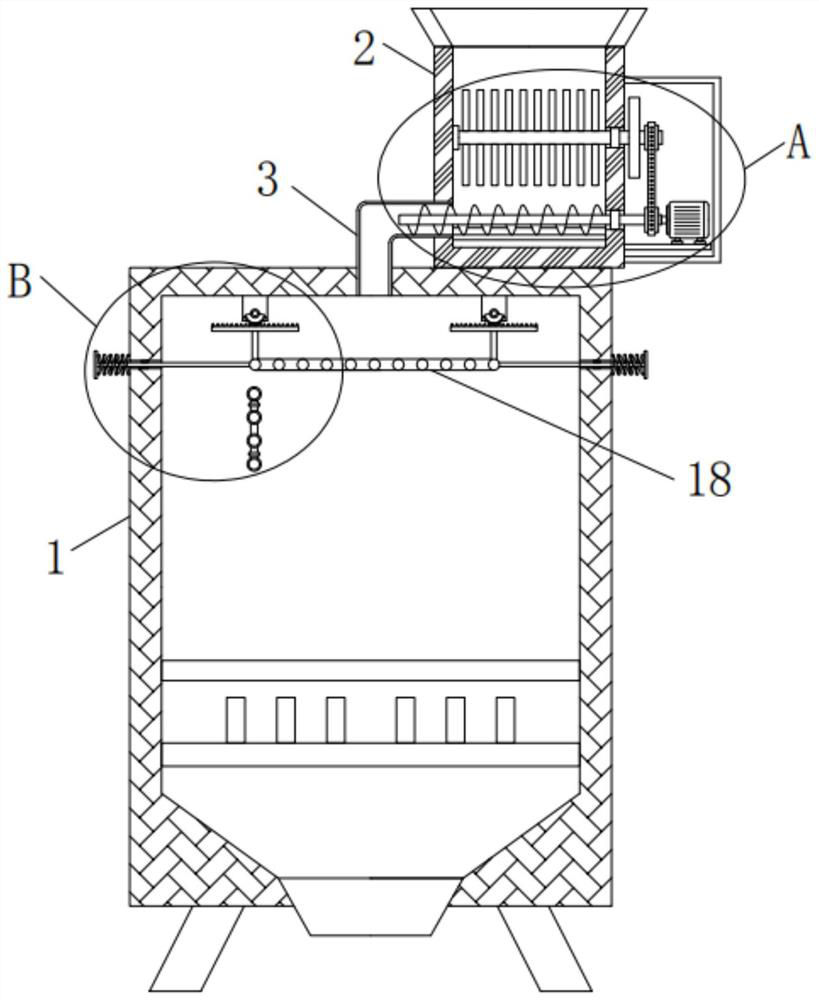

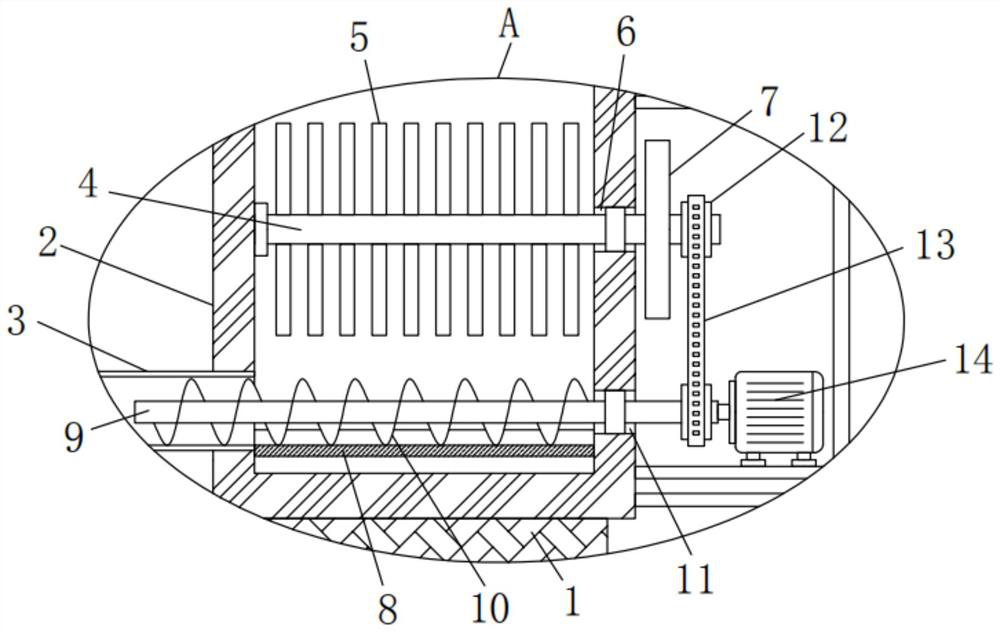

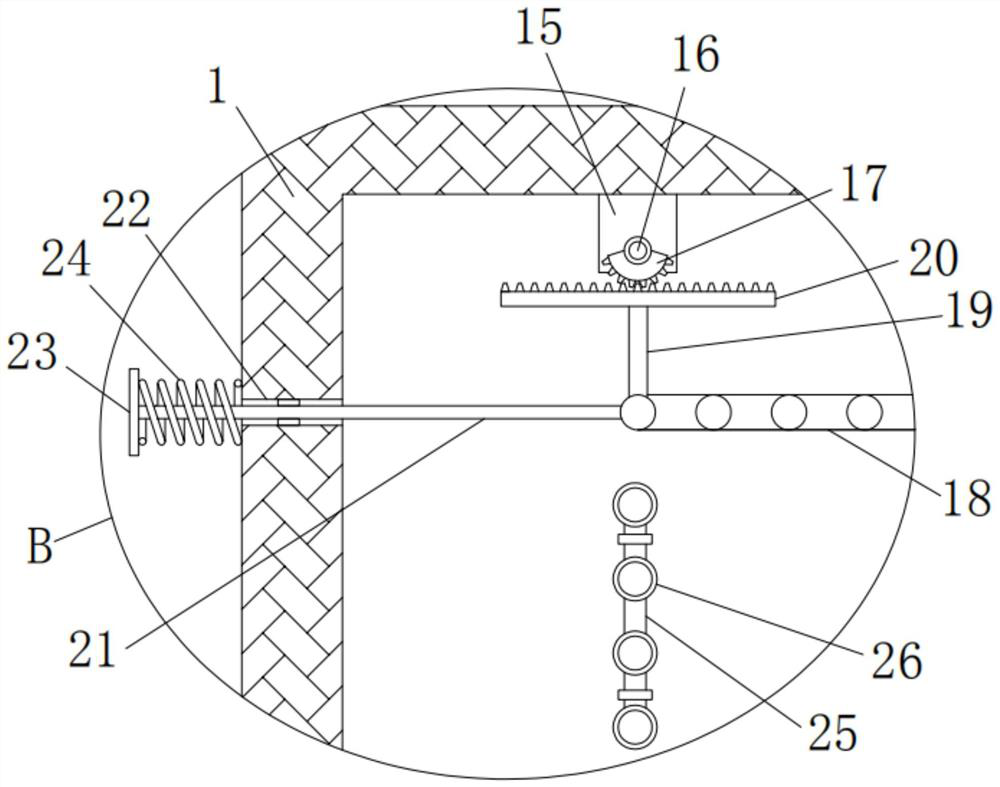

Environment-friendly waste incineration device

ActiveCN112923374AFast and efficient crushingUniform discharge at a uniform speedIncinerator apparatusCombined combustion mitigationFresh airEnvironmental engineering

The invention discloses an environment-friendly waste incineration device. The device comprises an incinerator, a smashing box is fixedly installed at the top of the incinerator, the top of the smashing box is of an opening structure, a material conveying pipe is fixedly installed at one side of the smashing box and communicates with the interior of the smashing box, and the end, away from the smashing box, of the material conveying pipe is fixedly installed at the top of the incinerator; and the material conveying pipe communicates with the interior of the incinerator, two rotating shafts are arranged in the smashing box, a plurality of smashing teeth are fixedly installed on the two rotating shafts at equal intervals, and two first installation holes are formed in the inner wall of the side, away from the material conveying pipe, of the smashing box. The environment-friendly waste incineration device is reasonable in design and good in practicability, waste can be smashed and then conveyed into the incinerator at a uniform speed and quantity, the smashed waste can be uniformly scattered into the incinerator through reciprocating horizontal movement of a falling plate, a proper amount of fresh air can be injected into the incinerator, the waste can be fully combusted, and the combustion quality and the combustion efficiency are improved.

Owner:吴俊松 +3

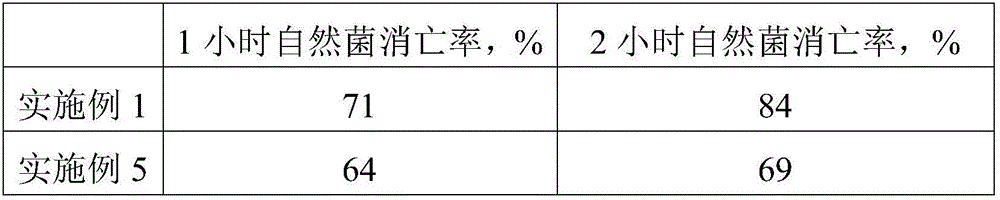

Natural plant mosquito repellent and preparation method thereof

InactiveCN106719635AImprove mosquito repellent effectGood for healthBiocidePest repellentsToxicologyToxicity

The invention relates to a mosquito repellent, in particular to a mosquito repellent prepared from natural plant materials and a preparation method of the mosquito repellent. The natural plant mosquito repellent is formed by mixing shaddock peel powder, citrus peel powder, glutinous rice flour and water, wherein the weight ratio of the shaddock peel powder to the citrus peel powder is (1:1)-(4:1), and the weight of the glutinous rice flour is 1 / 10 of the total weight of the shaddock peel powder and the citrus peel powder. The natural plant mosquito repellent is natural and environment-friendly, has no toxicity to human bodies and no harm to environment and is particularly suitable for kids, pregnant women and patients; the harm of chemical medicines contained in an insecticide, mosquito-repellent incense and the like to human bodies can be greatly reduced; and after the mosquito repellent is burnt, no environmental pollution is caused, and therefore, the mosquito repellent is very natural, environment-friendly and healthy.

Owner:陈桐

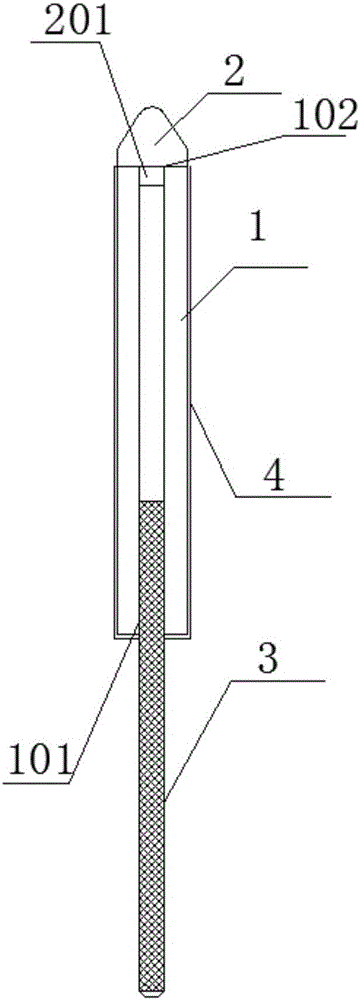

Incense and preparation method thereof

The invention discloses incense and a preparation method thereof. The incense comprises an incense body. An inserting hole is formed in the lower end of the incense body and penetrates through the incense body in the axial direction, an opening is formed in the top of the incense body by the inserting hole, a combustion-supporting head is arranged the opening position in a sealed mode, the upper portion of the combustion-supporting head is conical, the lower portion of the combustion-supporting head is cylindrical, and an insertion part is arranged on the bottom of the combustion-supporting head and inserted into the opening. The incense body is of a hollow structure, which is conductive to combustion; by means of the combustion-supporting head, ignition can be quickly achieved, continuous combustion is not needed after the combustion-supporting head is combusted, combustion supporting of the incense body can be achieved through the combustion-supporting head, and operation is easy and convenient.

Owner:SHANGHAI SHUNDU IND CO LTD

Combustion system of a fanless alcohol-based fuel cooker

ActiveCN106765349BPrevent splashSave resourcesDomestic stoves or rangesLiquid heating fuelCombustion systemCombustion

The invention discloses a combustion system for a fanless type alcohol-based fuel stove. The combustion system comprises a base. The base is a cavity with an upward opening. A backflow groove is formed in the inner side of the base. A fuel spray opening is formed in the bottom face of the base. A ventilation piece is arranged between the fuel spray opening and the backflow groove. A main air inlet is formed in the ventilation piece. A mist spray nozzle is arranged below the fuel spray opening. An air inflow locking piece is arranged at the upper end of the base. An opening cover and flow blocking grooves are arranged at the upper end of the air inflow locking piece. The flow blocking grooves are located in the opening cover. A flow diversion groove is arranged in the lower end of the air inflow locking piece and located in the inner side of the air inflow locking piece. By the adoption of the combustion system for the fanless type alcohol-based fuel stove, sufficient combustion of fuel is guaranteed, and no leakage and waste exist.

Owner:张俊

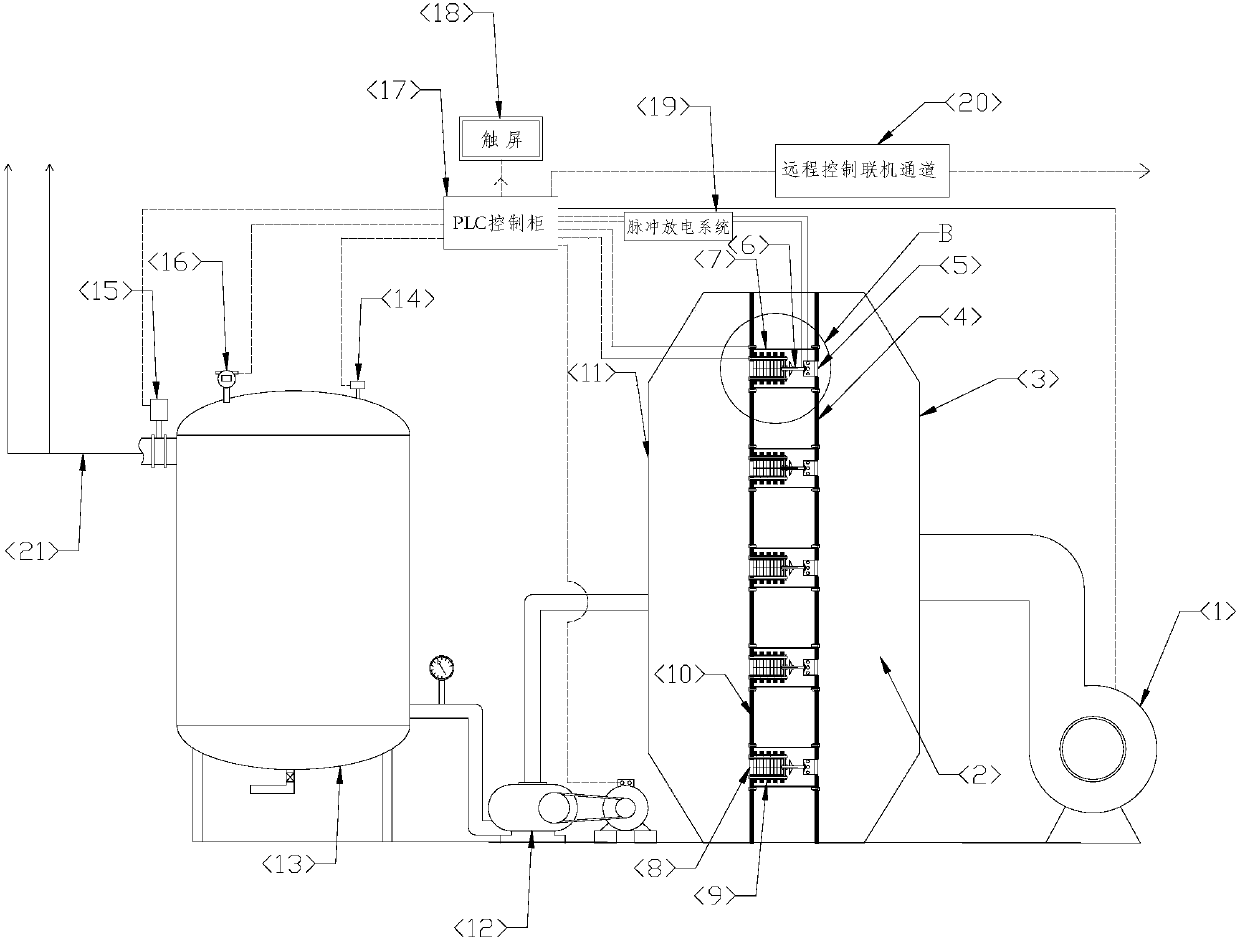

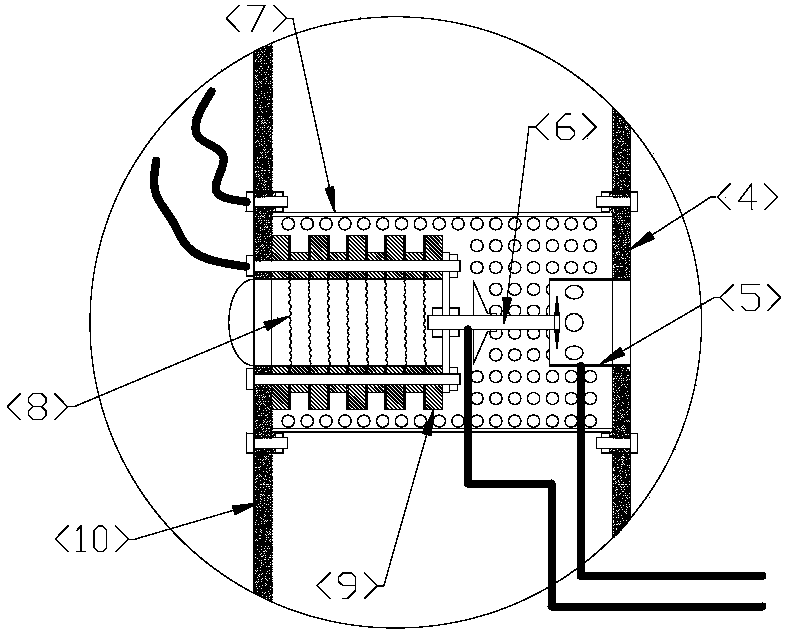

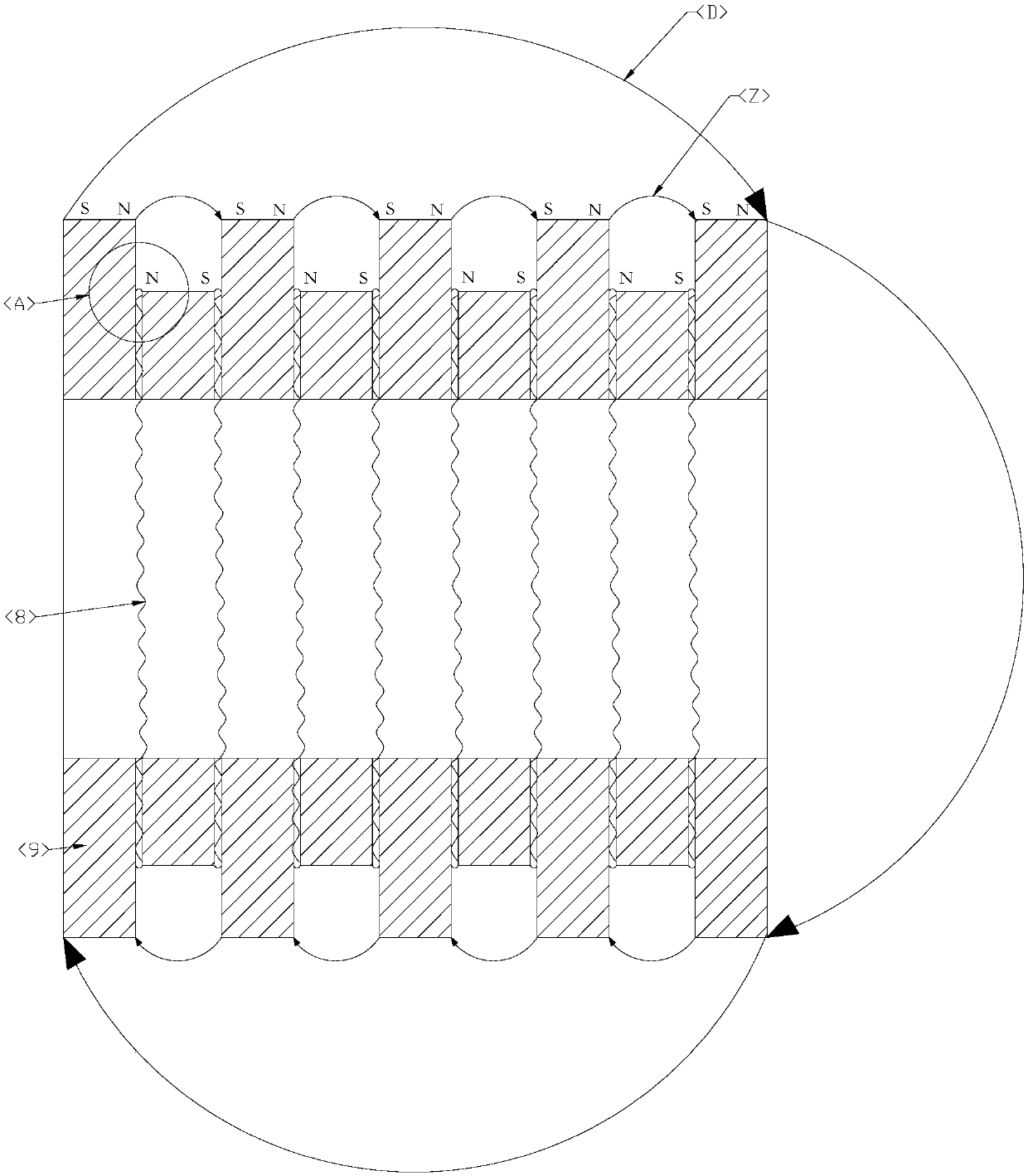

Rotary kiln pressurization ionization pole-phase separation magnetic oxygen-enriched air flow combustion-supporting system

PendingCN107588661AHigh densityLarge amount of processingRotary drum furnacesOxygen preparationOxygenEqualization

The invention provides a rotary kiln pressurization ionization pole-phase separation magnetic oxygen-enriched air flow combustion-supporting system, and aims to solve the problem that the current oxygen production method consumes more power. The rotary kiln pressurized ionization pole-phase separation magnetic oxygen-enriched air flow combustion-supporting system includes a centrifugal pressurization air supply device, a raw air balancing pressure equalization box, air ionization device components, an oxygen-enriched pre-collection adsorption warehouse, a permanent magnet Roots blower, an ionpressure equalization reducing tank and a pulse discharge system which are connected in the order. The air ionization device components include a cathode revolving vortex-type discharger, an anode star-umbrella type multi-point discharger, a net-tube-shaped negative electrode electrostatic net, a clamped positive electrode electrostatic net and a homopolar-opposite clamped grid-type gradient magnetic group. The cathode revolving vortex-type discharger and the anode star-umbrella type multi-point discharger are electrically connected with the pulse discharge system. By pressurizing the air, theair density reaches the standard during the ionization of the cathode revolving vortex-type discharger and the anode star-umbrella type multi-point discharger, thereby saving the discharge current and increasing the throughput.

Owner:中技国际工程有限公司

A combined high-efficiency heating system of biomass gasifier and industrial gas boiler

ActiveCN104560218BImprove stabilityImprove qualityEnergy inputGasification processes detailsIndustrial gasTar

The invention discloses a biomass gasifier / industrial gas boiler combined high-efficiency heating system. The system utilizes steam generated by the industrial gas boiler, part of the steam is supplied to the gasifier for gasification as a gasification medium, and the steam and air are combined for gasification, thereby being beneficial to enhancing the stability and quality of the biomass gas. The preheated air is supplied to the industrial gas boiler as combustion-supporting gas, thereby enhancing the overall heat efficiency. The electrolyic decoking cracking device can crack tar in the biomass gas, thereby enhancing the stability of the biomass gas and being beneficial to combustion of the biomass gas. Meanwhile, the system is subjected to water cooling through a full water cooling jacket, thereby effectively avoiding coking in the biomass gasifier. The system is applicable to the field of boiler heating systems.

Owner:GUANGDONG ZHENGPENG BIOMASS ENERGY TECH

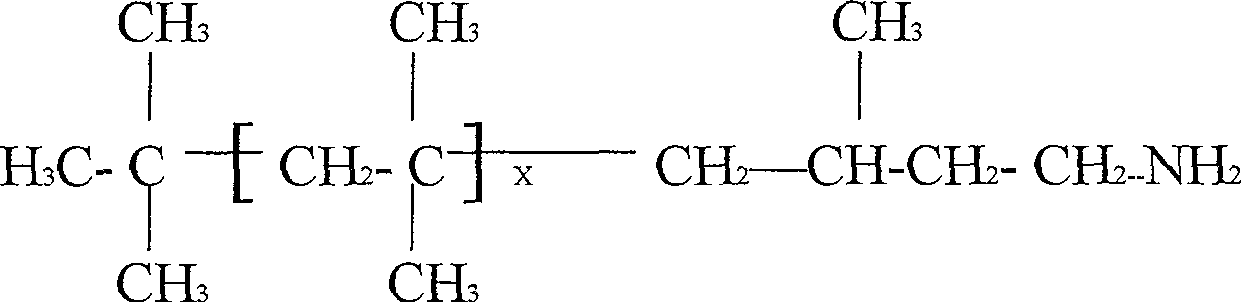

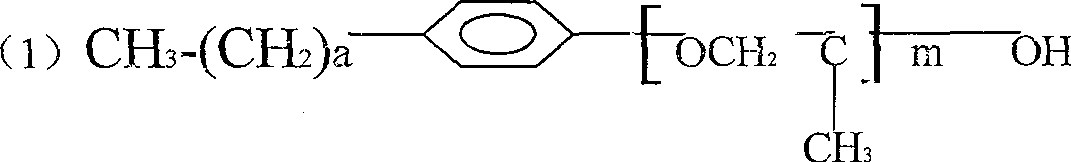

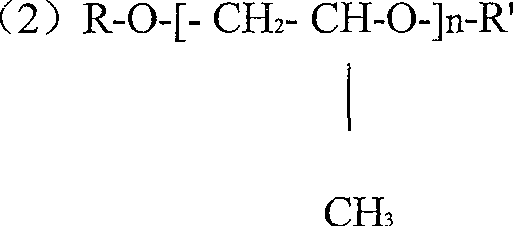

Gasoline purification agent composition

InactiveCN100487090CGood composition compatibilityReduce the probability of cloggingLiquid carbonaceous fuelsHydrocotyle bowlesioidesAlkylphenol

A composite cleaner for gasoline contains polyisobuteneamine, more than one polyether with alkylphenol and / or dihydroxy and more than two polyoxyvinyl ethers in weight ratio of (44-54):(12-22):(39-49). It can remove the oil mud and colloidal deposit in fuel oil system of engine, improve performance of engine, and decrease consumption of fuel.

Owner:BEIJING DATONG HONGYE TECH DEV

A pyrolysis gasifier

ActiveCN109780548BAvoid lostUtilize concentration and fullIncinerator apparatusCombustion chamberFlue gas

The invention belongs to the technical field of garbage disposal equipment, and particularly discloses a pyrolysis gasification furnace. The pyrolysis gasification furnace comprises a rack, a furnacebody, a furnace hearth, a secondary combustion chamber and a driving unit; the top of the furnace body is provided with a feeding port and a flue gas outlet, the bottom of the furnace body is providedwith a slag outlet, and the side wall of the furnace body is provided with a plurality of furnace doors and a plurality of observation holes; a rotatable furnace grate unit is arranged in the furnacehearth and comprises a garbage dispersing cap, a plurality layers of garbage distributing grates and a garbage furnace grate body which are sequentially connected from top to bottom; the side wall ofthe furnace body comprises an inner-side refractory layer, an outer-side refractory layer and a heat preservation layer, and the secondary combustion chamber is arranged between the inner-side refractory layer and the outer-side refractory layer; and a decoking unit is arranged in the furnace hearth and comprises a plurality of scraper blades and a power mechanism used for driving the scraper blades to do rotating motion, and the scraper blades are circumferentially distributed along the central axis and attached to the upper surface of the garbage furnace grate body. According to the pyrolysis gasification furnace, the scraper blades are arranged to remove coked materials on the furnace grate, furnace grate blocking is prevented, normal working and running of the furnace grate are guaranteed, and garbage can be fully combusted.

Owner:重庆管利仪器仪表有限公司

Vehicle-mounted high-pressure DC steam injection boiler system with three-pass flue gas

InactiveCN101881434BSmall form factorCompact structureFluid removalSteam boilersAir preheaterFlue gas

The invention relates to the field of the boiler design and manufacture, and discloses a vehicle-mounted high-pressure DC steam injection boiler system with three-pass flue gas, which is applicable to the field of thermal exploitation of heavy oil in the oil industry. The boiler system comprises a trailer, a sleeve type water-water heat exchanger, a convection section, a high-pressure water supply pump, a combustion fan, a burner, a radiation section, a steam-water separator, an air preheater and a chimney, wherein the high-pressure water supply pump, the combustion fan, the burner, the radiation section, the steam-water separator, the air preheater and the chimney are arranged on the trailer in sequence along the length direction of the trailer, the cross section of the radiation sectionis square, the sleeve type water-water heat exchanger is arranged outside the lower side face of the front half section of the radiation section, the convection section comprises a left rectangular flue gas channel, a right rectangular flue gas channel, a lower rectangular flue gas channel and convection tube bundles respectively arranged in the three rectangular flue gas channels, and the left rectangular flue gas channel, the right rectangular flue gas channel and the lower rectangular flue gas channel are correspondingly arranged outside the left side face, the right side face and the lower side face of the rear half section of the radiation section.

Owner:XI AN JIAOTONG UNIV +1

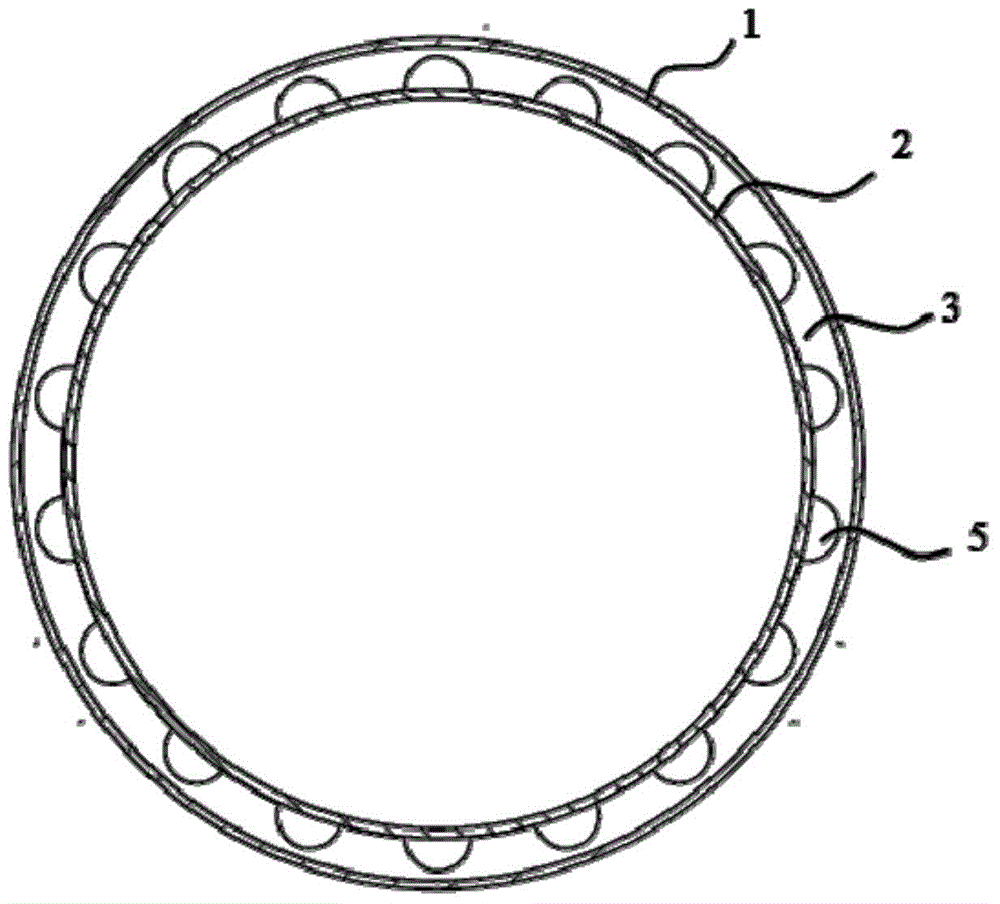

Wavy grate biofuel furnace

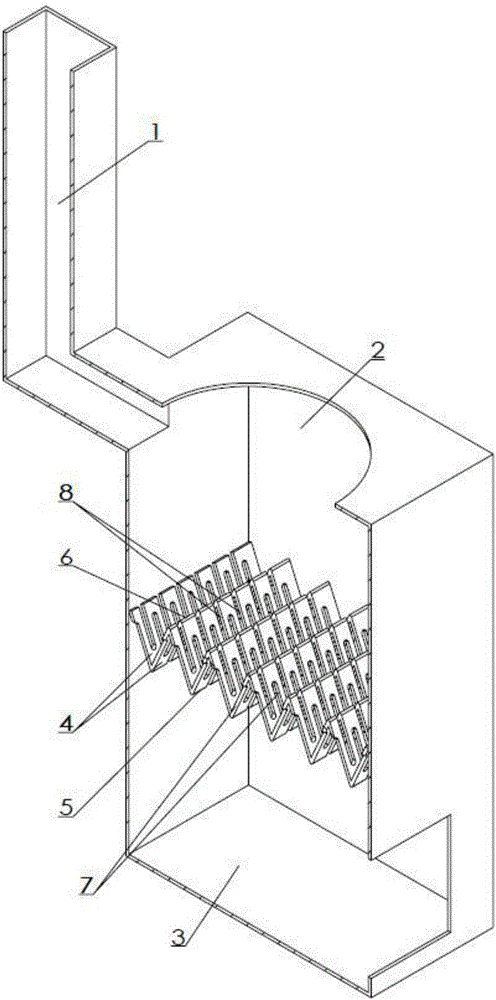

ActiveCN106482160AIncrease the ventilation areaIncrease the ash fall areaDomestic stoves or rangesLighting and heating apparatusCombustion chamberBiofuel

The invention discloses a wavy grate biofuel furnace. The wavy grate biofuel furnace comprises a furnace chamber and an exhaust pipe, and is characterized in that the furnace chamber is provided with a combustion chamber and an ash storage chamber of which the horizontal sections are rectangular; the ash storage chamber is below the combustion chamber; a grate is arranged between the ash storage chamber and the combustion chamber; the grate is composed of inclined plates which are arranged from the inner wall on one side to the opposite side wall at equal intervals and are connected end to end; the lower edges of the adjacent inclined plates are connected to form wave troughs; the upper edges of the adjacent inclined plates are connected to form wave crests; lower notches which are distributed along the wave troughs and downwards penetrate through the bottoms of the wave troughs are arranged in the bottoms of the wave troughs; and upper notches which are distributed along the wave crests, upwards penetrate through the tops of the wave crests and are staggered with the lower notches are arranged at the tops of the wave crests. According to the wavy grate biofuel furnace, the ventilation and ash falling area is increased, and combustion and ash discharge are facilitated; and besides, the V-shaped notches have inclination, ash collapses and slides during the combustion process, ash falls through the V-shaped notches more easily during the sliding process, and ash discharge is quicker and more convenient.

Owner:CHONGQING HUAWANLUN BIOLOGICAL NEW ENERGY TECH CO LTD

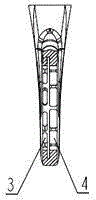

Device and method for harmless treatment of rural garbage

ActiveCN103075733BEasy to collectIncrease temperatureIncinerator apparatusCombustorCombustion chamber

The invention relates to the field of garbage disposal, in particular to a device and method for harmless treatment of rural garbage. The device comprises a pyrolysis gasification area and a combustion area, wherein the combustion area comprises a plurality of combustion chambers; the lower part of the pyrolysis gasification area is communicated with all the combustion chambers in sequence in an increasing height manner; a public side wall of two adjacent combustion chambers is provided with a combustor; and each combustor comprises a shell and an oxygen guide pipe. The method comprises the steps of: stacking combustible garbage in a closed environment to combust the combustible garbage locally; carrying out pyrolysis gasification on the garbage by using heat generated through combustion to generate combustible gas; and importing the generated combustible gas and powder into the plurality of combustors for aerobic combustion, and settling powder imported in the combustors at the same time. Compared with the prior art, the device and the method for the harmless treatment of the rural garbage, provided by the invention, can be used to decompose organic matters more completely in manners of pyrolysis gasification and multi-stage combustion, so that a harmless purpose is achieved.

Owner:四川明日得投资管理咨询有限责任公司

Electronic pilot burner

An electronic pilot burner solves the problems of energy waste, environmental pollution and low reliability of existing pilot burner, and is characterized by comprising a metal conducting rod connected with a high-voltage device, a discharge igniting head is mounted at the top end of the metal conducting rod, a quartz protection tube is sleeved outside the metal conducting tube, a metal protection tube is mounted outside the quartz protection tube, a burner holder is mounted at the top end of the metal protection tube, high-temperature-resisting mineral sand is filled between the metal protection tube and the quartz protection tube, a tower-shaped high-voltage quartz insulator is mounted on the burner holder, burner housing support columns are arranged on a current conducting platform of the burner holder, and outer edges of the burner housing support columns are connected with a burner housing through a connecting ring. The electronic pilot burner has the advantages that electric energy can be adopted to substitute for traditional inflammable gas to form pilot burner flame, blow-off can be avoided, and corresponding gas supply equipment and pipeline systems are not need to be provided, so that investment is reduced, space is saved, reliable eternal burning is kept in all weathers, and further energy saving, environmental protection, safety and equipment investment saving are achieved.

Owner:辽宁省电子研究设计院有限公司

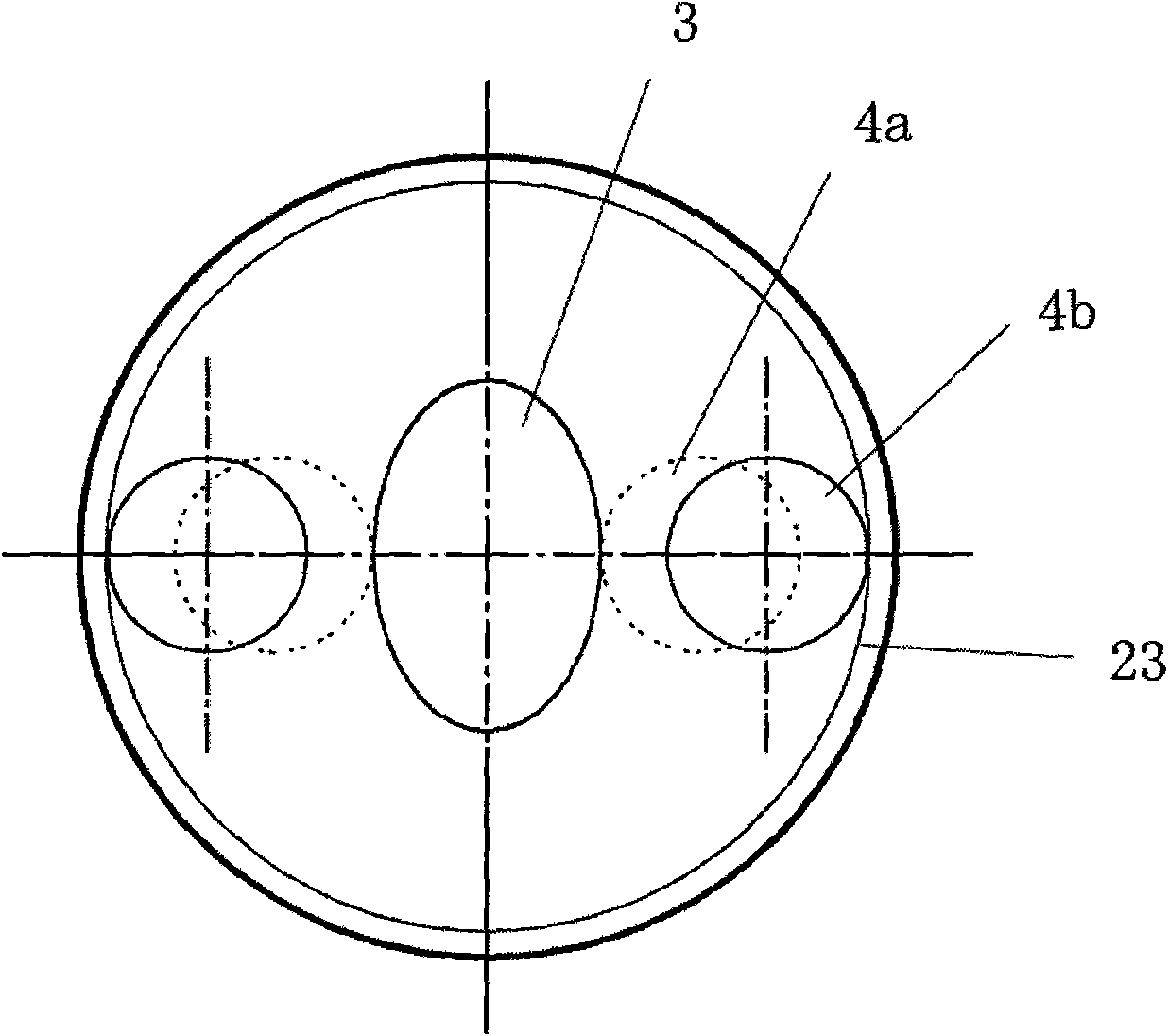

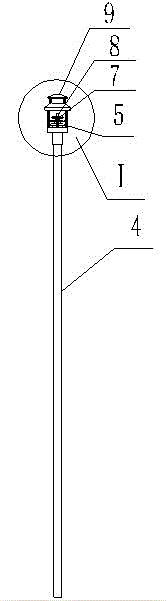

Two-stroke diesel engine admission passage

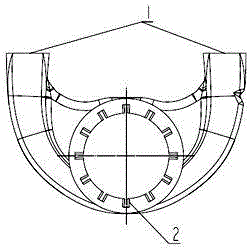

InactiveCN104314719AUniform pressure distributionInhibition of flow separationInternal combustion piston enginesCombustion-air/fuel-air treatmentTwo-stroke diesel engineMixed gas

The invention relates to a two-stroke diesel engine admission passage. The admission passage adopts a symmetrical volute structure. Inlet air pipes (1) for air to flow in are arranged on the two sides of the volute structure, the inner sides of the inlet air pipes (1) adopt rounded corner structures, a vortex air intake row (3) and a direct air intake row (4) are arranged at the middle part of the volute structure of the admission passage, the vortex air intake row (3) and the direct air intake row (4) form an air flow outlet (2), the vortex air intake row (3) is provided with 12 first air openings (5) in the circumference, the direct air intake row (4) is provided with 12 second air openings (6) in the circumference, the included angles of the first air openings (5) and the tangent lines in the peripheral directions are 6 to 9 degrees, and the included angle of every two first air openings (5) is 20 degrees, the thicknesses of the first air openings (5) on the vortex air intake row (3) are 5.5 mm, the included angle of every two second air openings (5) is 26 degrees, and the thicknesses of the second air openings (6) in the direct air intake row (4) are 9 mm. The two-stroke diesel engine admission passage provided by the invention is beneficial to forming and burning of mixed gas in a cylinder.

Owner:CHINA NORTH ENGINE INST TIANJIN

Fluidized bed reactor for treating radioactive waste graphite

PendingCN113393952ASimple structureEasy to operateRadioactive decontaminationAir preheaterCombustion

The invention relates to a fluidized bed reactor for treating radioactive waste graphite, which belongs to the technical field of radioactive waste treatment and comprises a combustion furnace, wherein a feeder and an ignition tuyere are arranged on the cylindrical surface of the combustion furnace close to the lower section, the bottom of the combustion furnace is connected with an ash discharge system, an air supply outlet is further arranged at the bottom of the combustion furnace, an air outlet is arranged at the top of the combustion furnace, and the whole reactor is fixed on a rack. Radioactive waste graphite to be treated enters the combustion furnace through a feeder, waste is ignited through the ignition tuyere, and air preheated by an air preheater is fed into the combustion furnace through the air supply outlet; and air in the combustion furnace and graphite particles form a fluidized state in the combustion furnace and are fully combusted, residue ash generated by combustion enters an ash discharging system under the action of gravity to be collected, and tail gas generated by combustion is discharged out of the combustion furnace through the air outlet. The fluidized bed reactor is simple in structure and convenient to operate, and the high volume reduction ratio can be achieved by conducting incineration heat treatment on graphite through the fluidized bed treatment technology.

Owner:CHINA INST FOR RADIATION PROTECTION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com