Rotary kiln pressurization ionization pole-phase separation magnetic oxygen-enriched air flow combustion-supporting system

A combustion-supporting system and ionization electrode technology, applied in the direction of oxygen preparation, rotary drum furnace, furnace, etc., can solve the problem of serious power consumption, and achieve the effect of low operating cost, fast return and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In the description of the present invention, terms such as "installation", "connection", "connection" and "fixation" should be interpreted in a broad sense unless otherwise clearly specified and limited. Disassembled connection, or integration; it can be mechanical connection or electrical connection; it can be direct connection or indirect connection through an intermediary, it can be the internal communication of two components or the interaction relationship between two components. Those of ordinary skill in the art can understand the specific meanings of the above terms in the present invention according to specific situations.

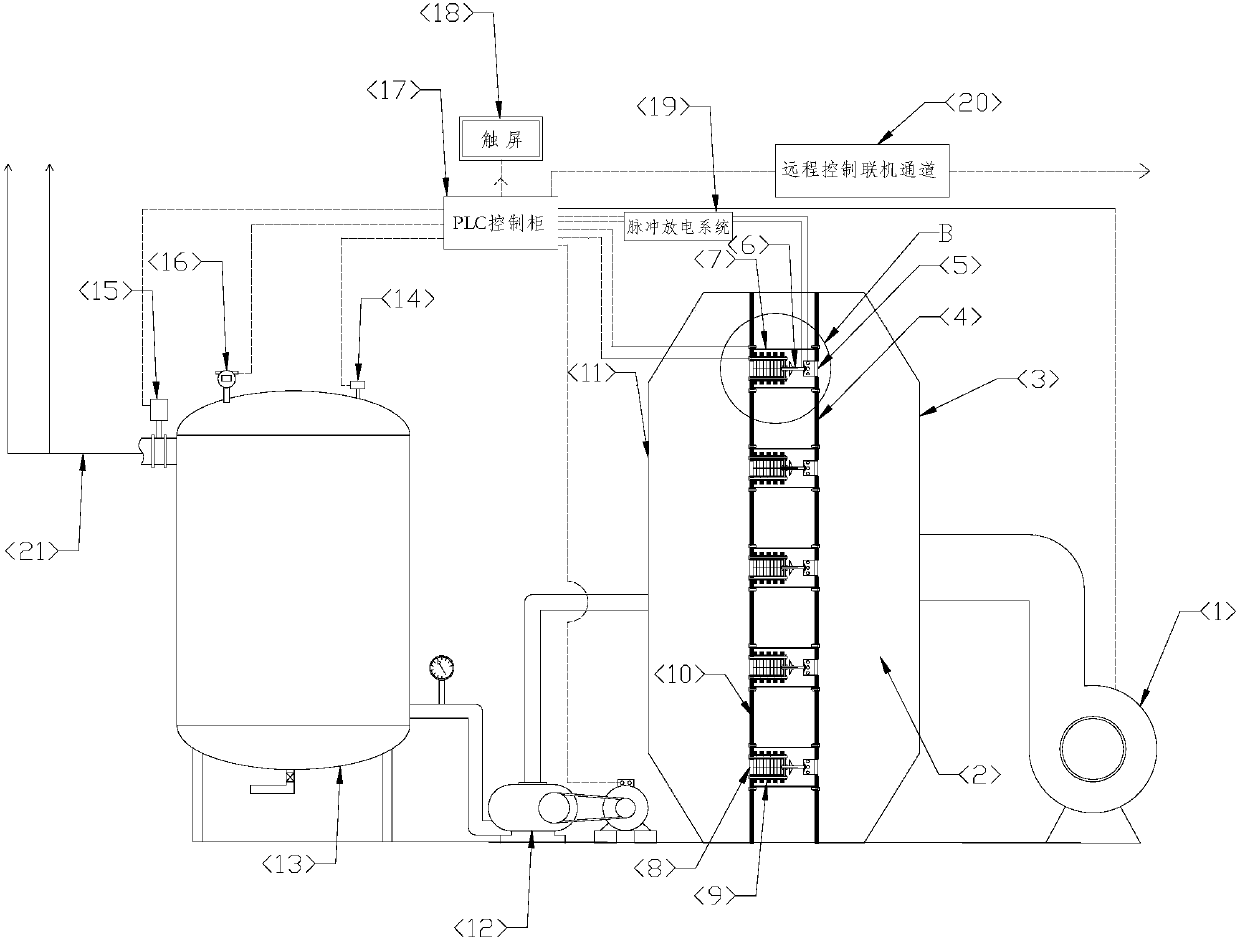

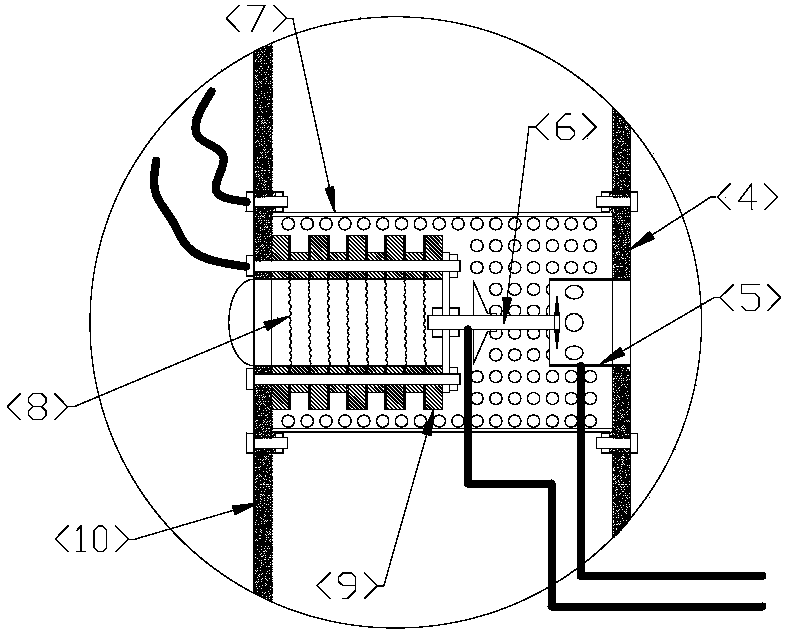

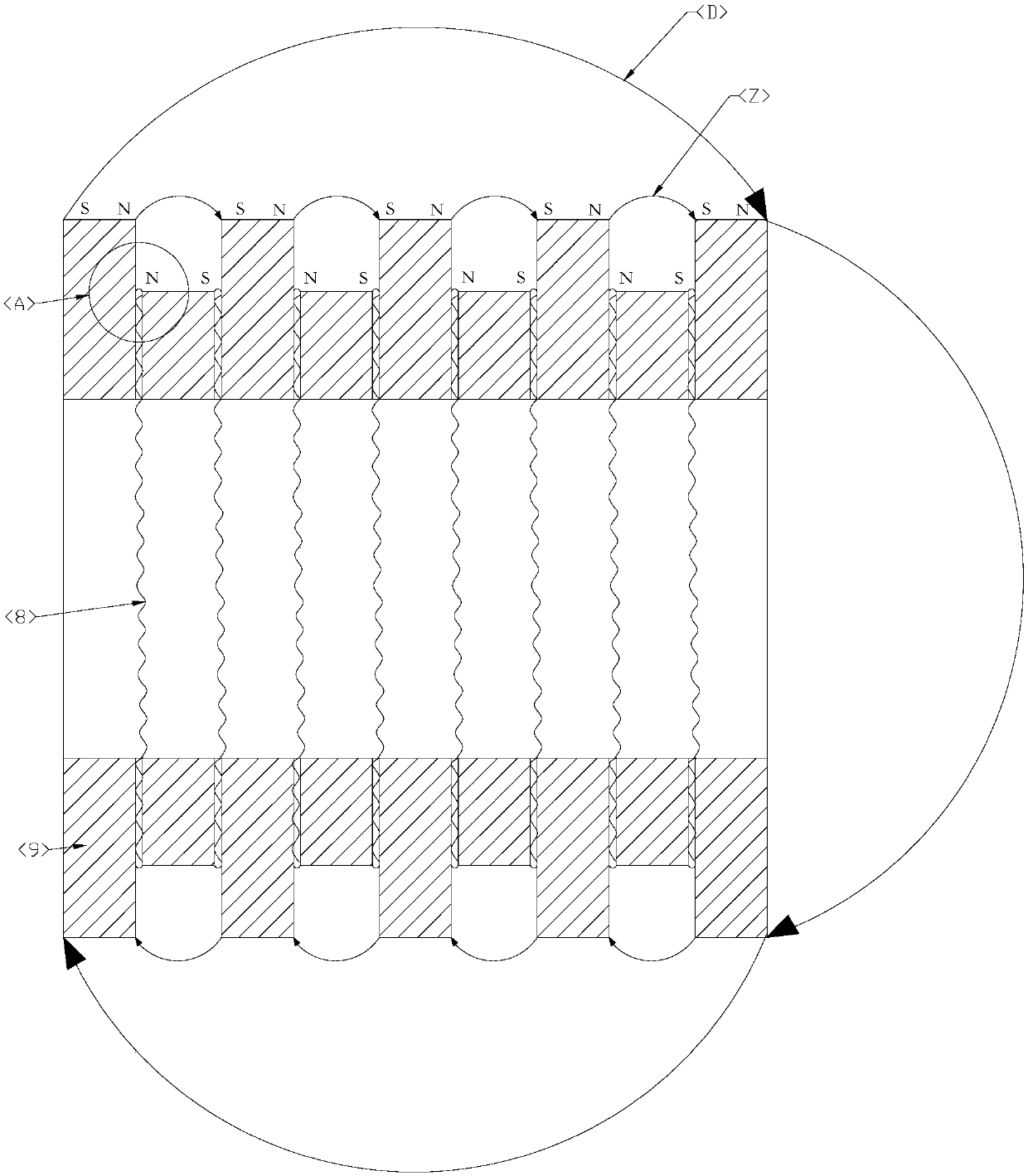

[0028] refer to figure 1 and figure 2 , Rotary kiln pressurized ionized pole separation magnetically induced oxygen-enriched flow combustion-supporting system, according to the flow direction of the air from upstream to downstream, including sequentially connected centrifugal booster supply fan 1, raw material air equalization baffle 2, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com