Pyrolysis gasification furnace

A technology of pyrolysis gasification and furnace body, applied in incinerators, lighting and heating equipment, combustion methods, etc., can solve the problems of easy formation of coke on the grate, uneven distribution of garbage, insufficient combustion, etc., to reduce power Source settings, avoidance of clogging, effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following is further described in detail through specific implementation methods:

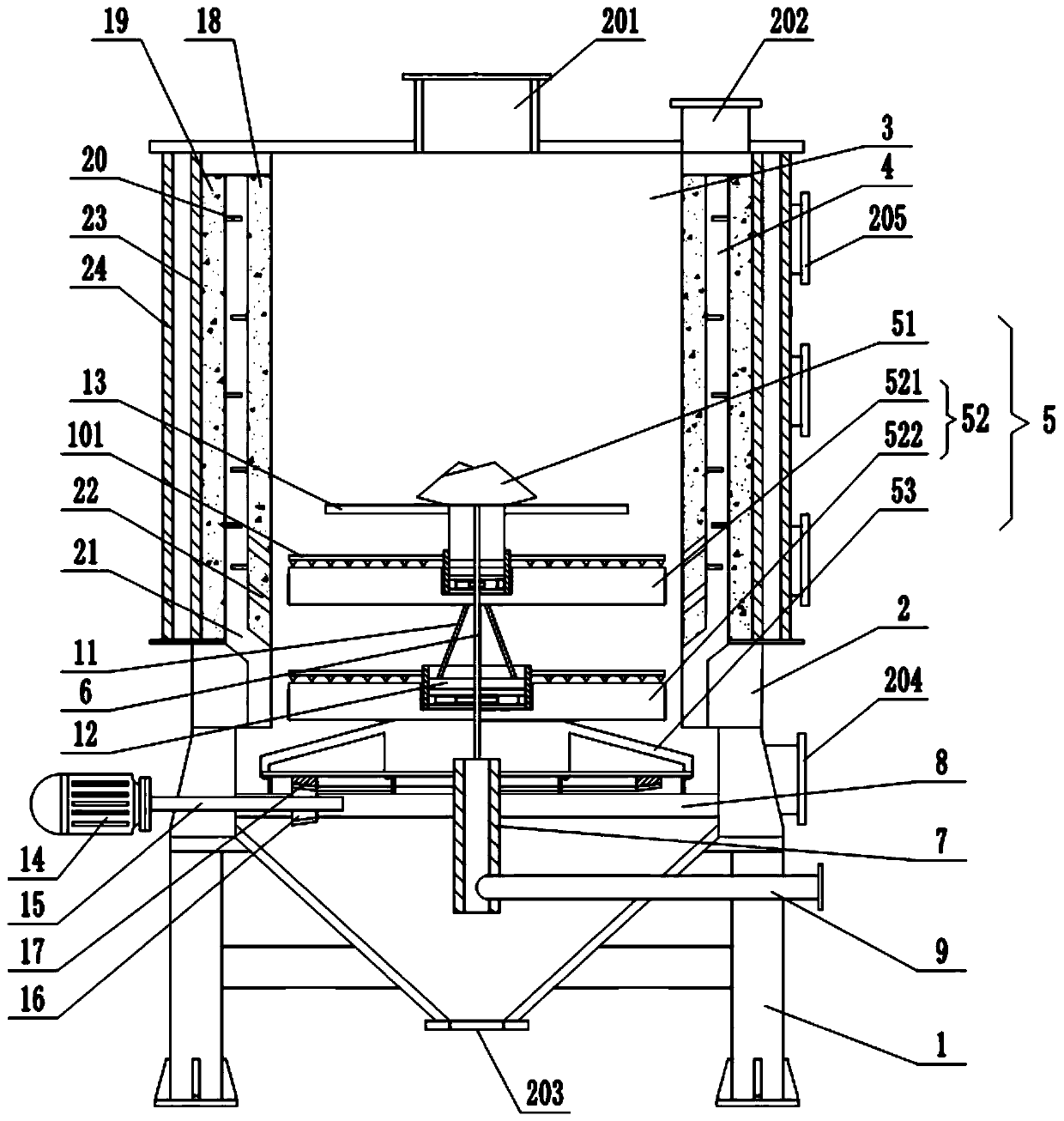

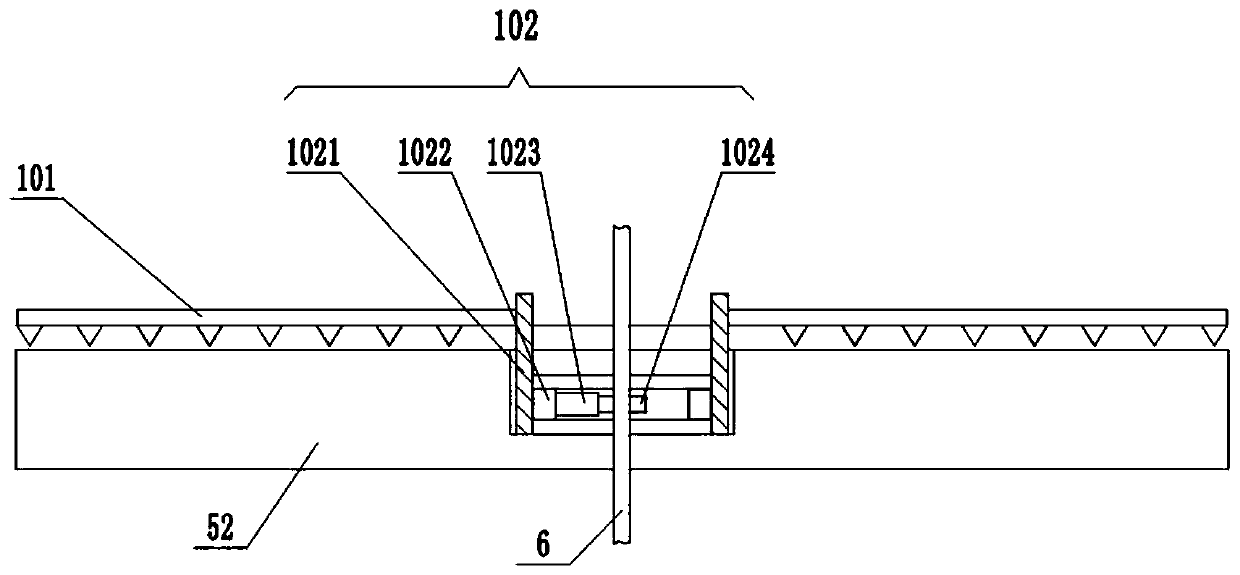

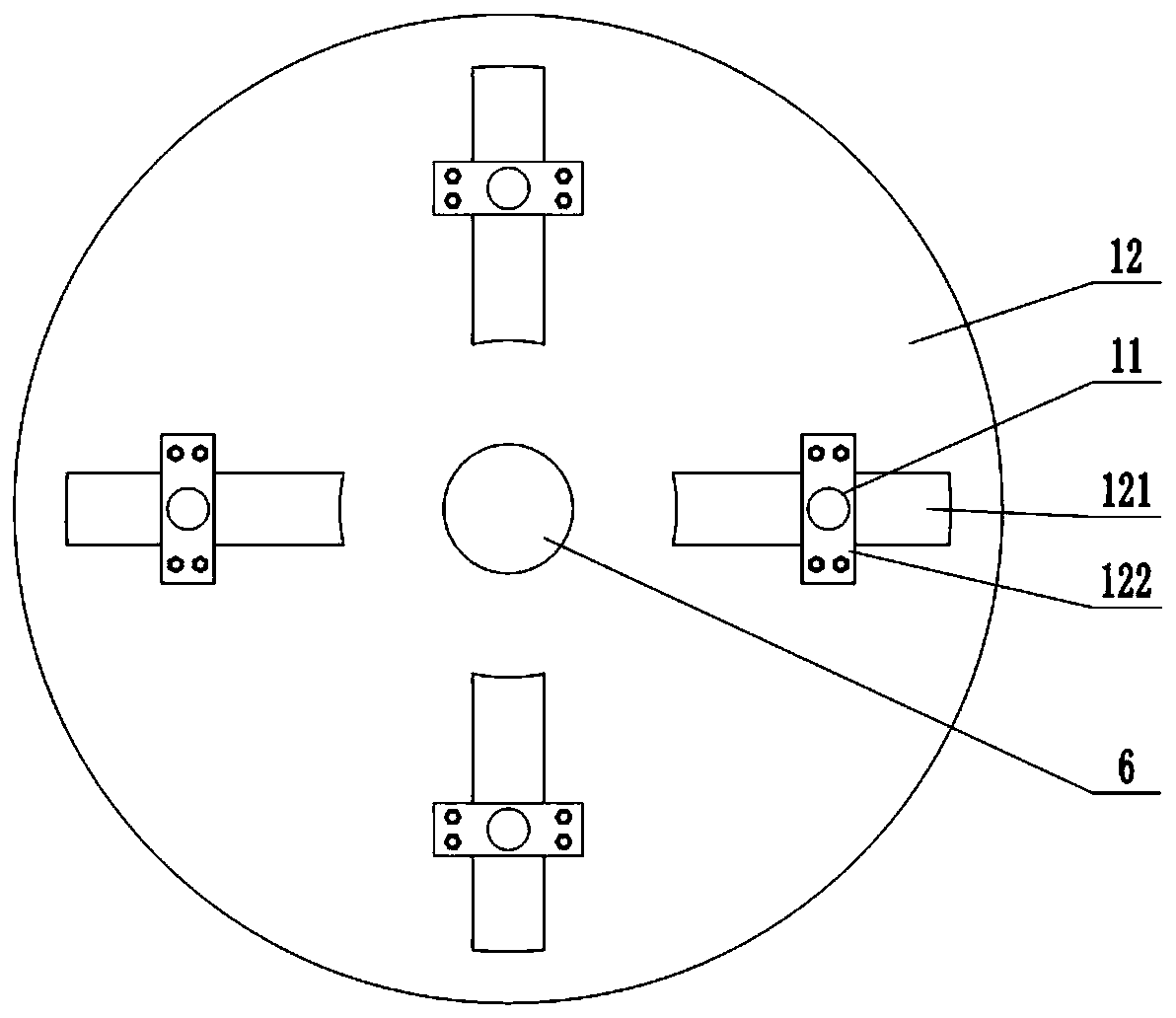

[0028] The reference signs in the drawings of the description include: frame 1, furnace body 2, feed inlet 201, flue gas outlet 202, slag outlet 203, furnace door 204, observation hole 205, furnace 3, secondary combustion chamber 4, furnace Row unit 5, garbage dispersion cap 51, garbage diversion row 52, first garbage diversion row 521, second garbage diversion row 522, garbage grate 53, support shaft 6, central shaft 7, bracket 8, oxygen supply pipe 9, scraper Plate 101, power mechanism 102, cylinder 1021, internal gear 1022, planetary gear 1023, sun gear 1024, pillar 11, mounting plate 12, slideway 121, slider 122, stirring rod 13, motor 14, rotating shaft 15, cone Gear 16, grate gear 17, inner refractory layer 18, outer refractory layer 19, baffle plate 20, flue gas inlet 21, air inlet 22, inner layer insulation layer 23, outer layer insulation layer 24.

[0029] The embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com