Patents

Literature

436 results about "Organic liquids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

ORGANIC LIQUIDS ARE USED in a wide variety of industrial applications. They can be characterized as liquids that consist of one or more carbon atoms joined to other atoms via covalent bonds.

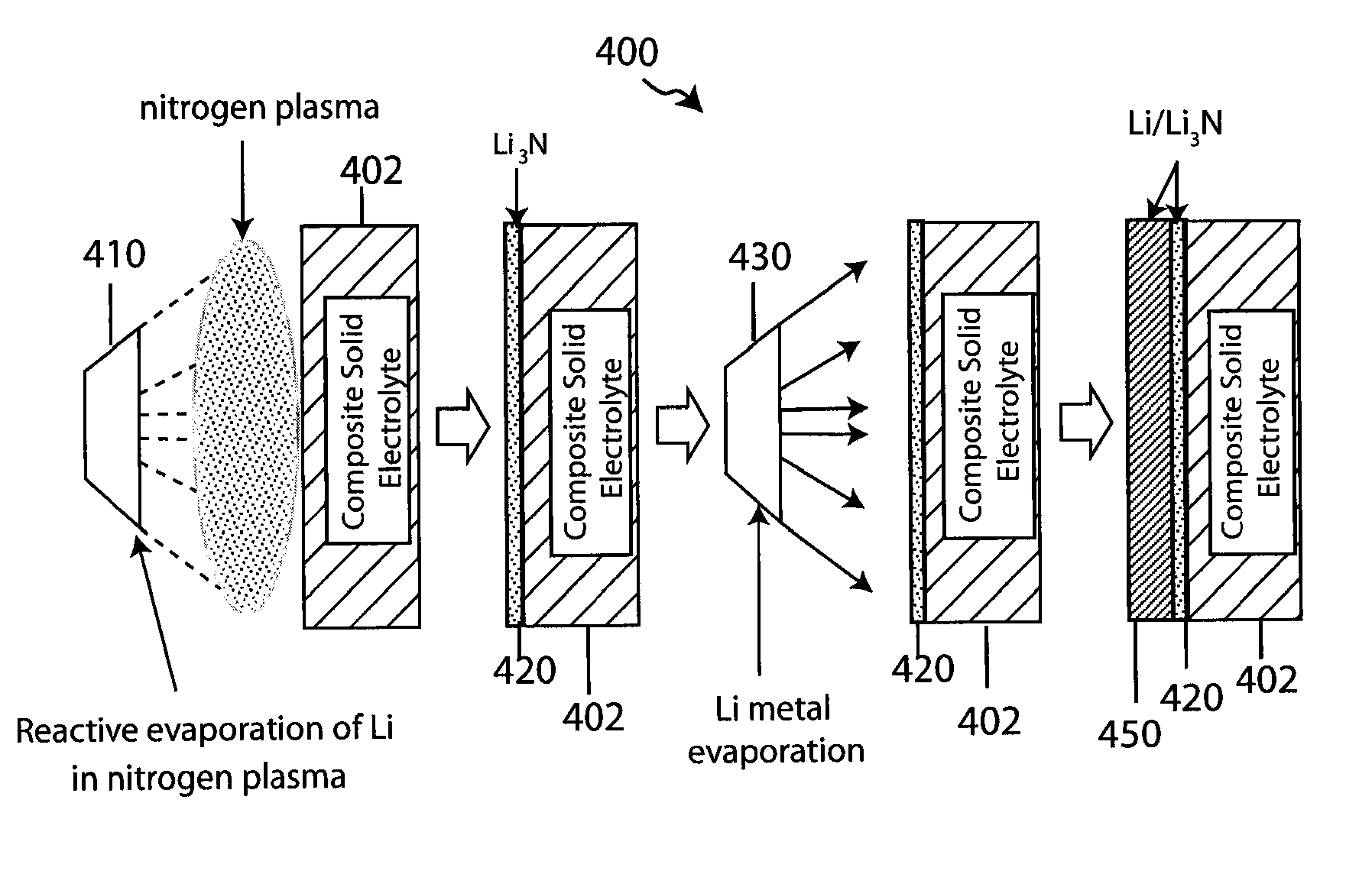

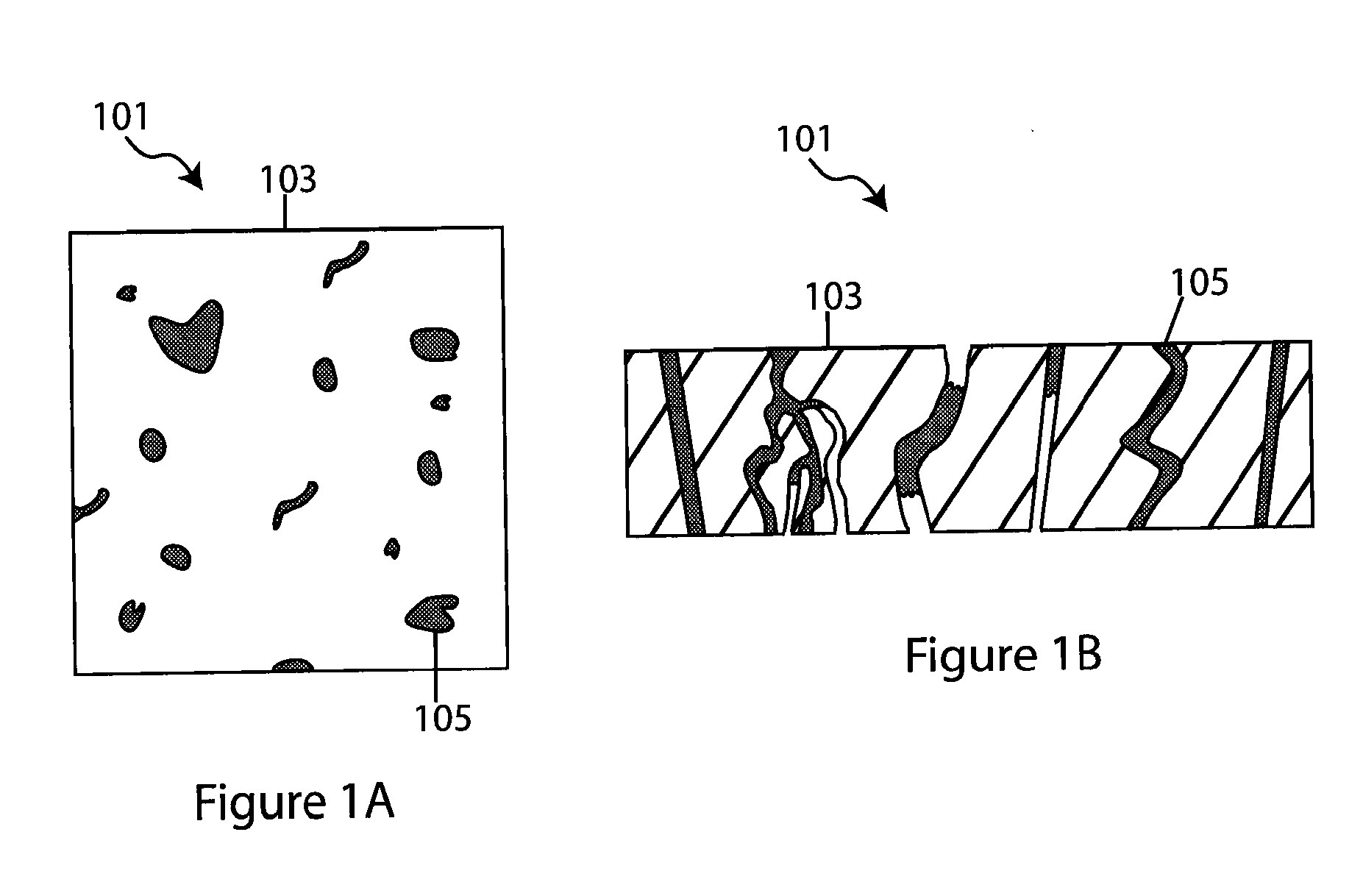

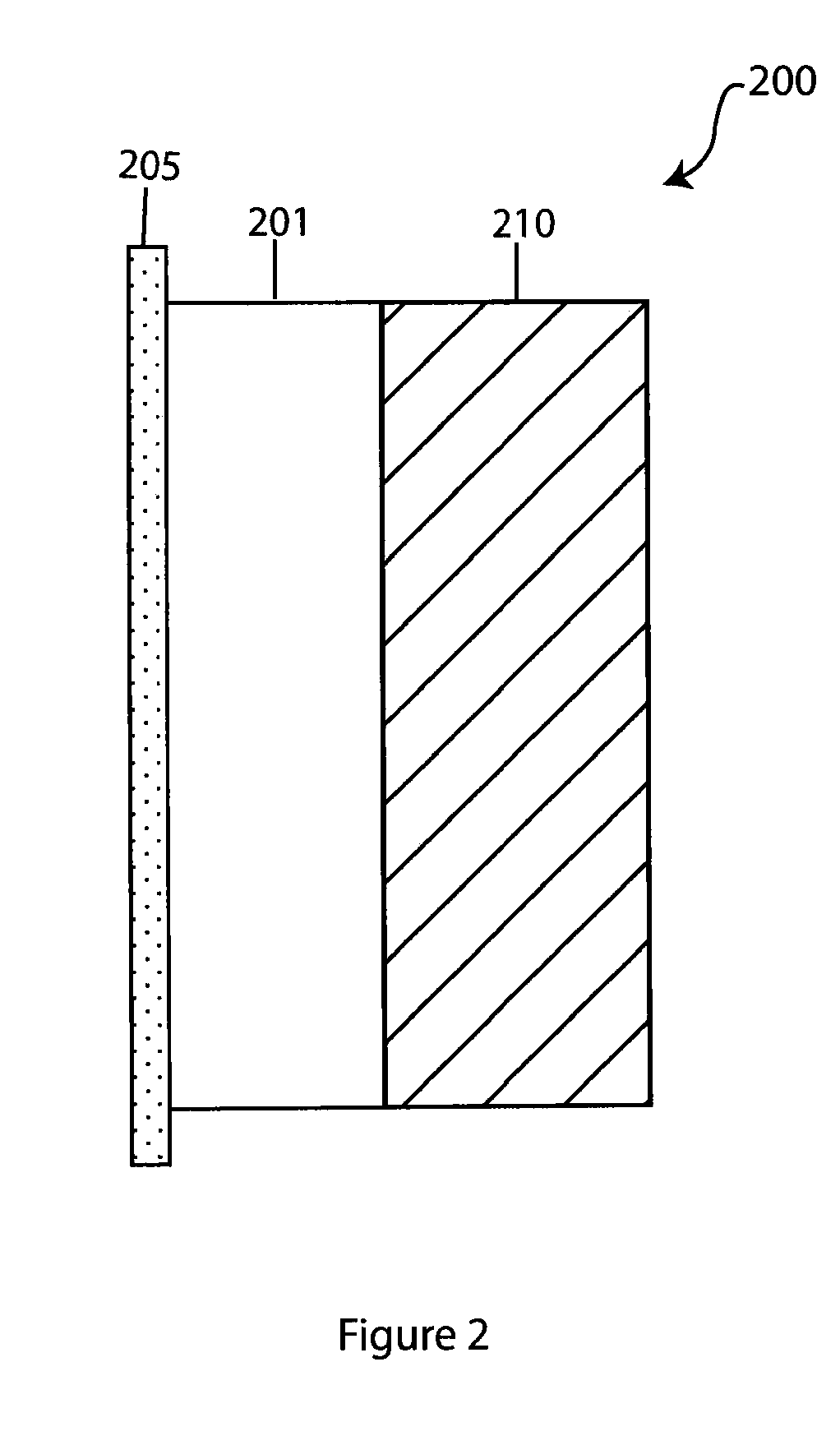

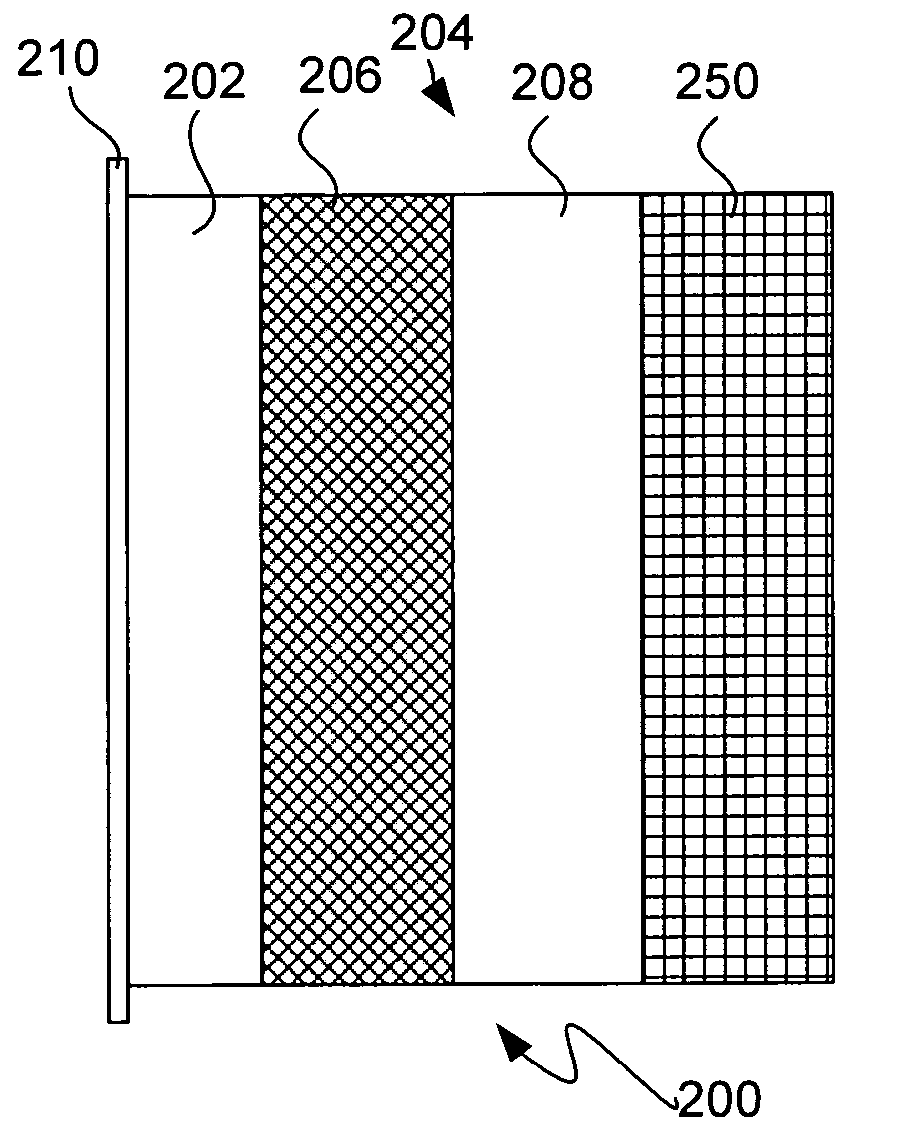

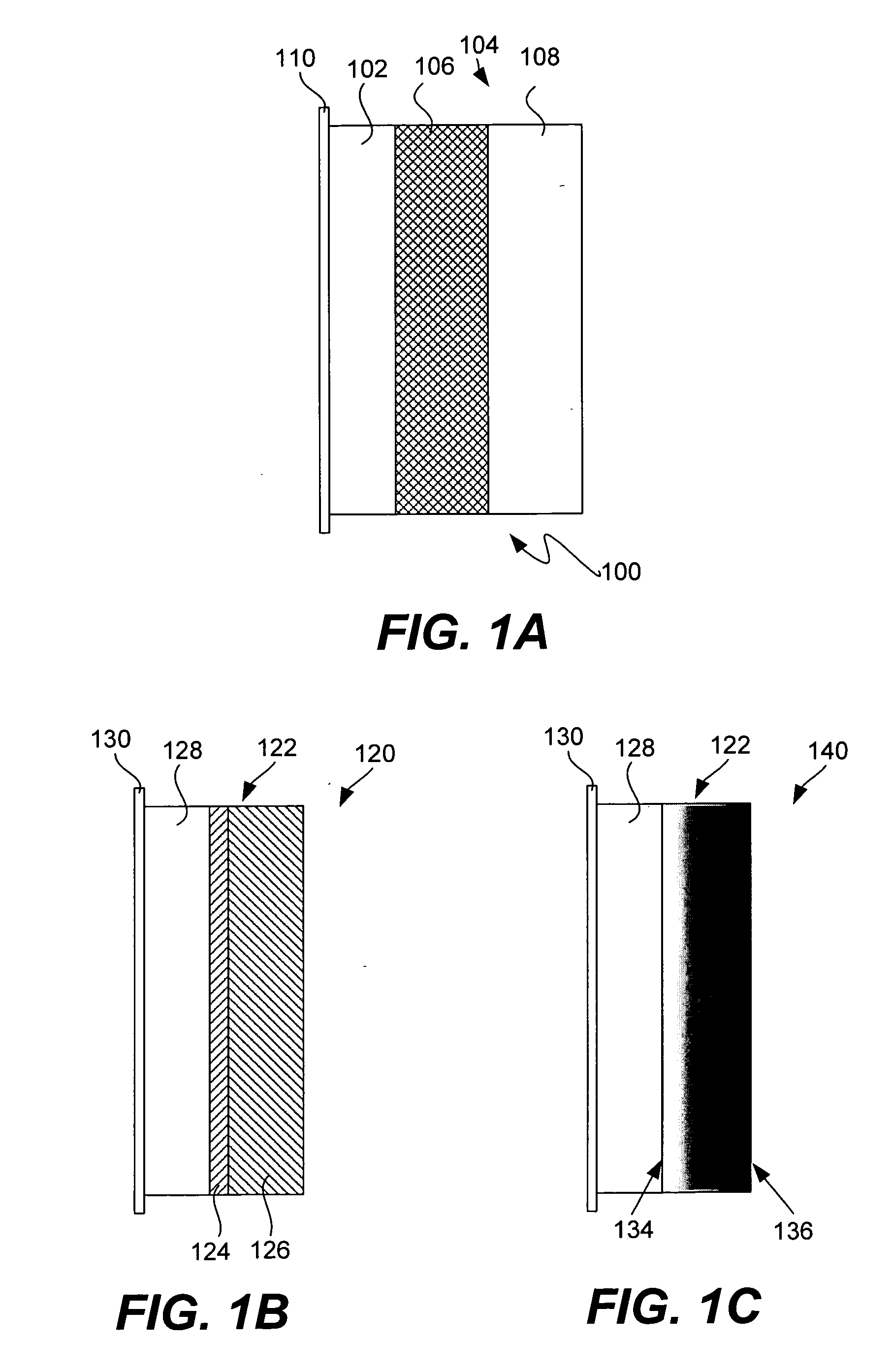

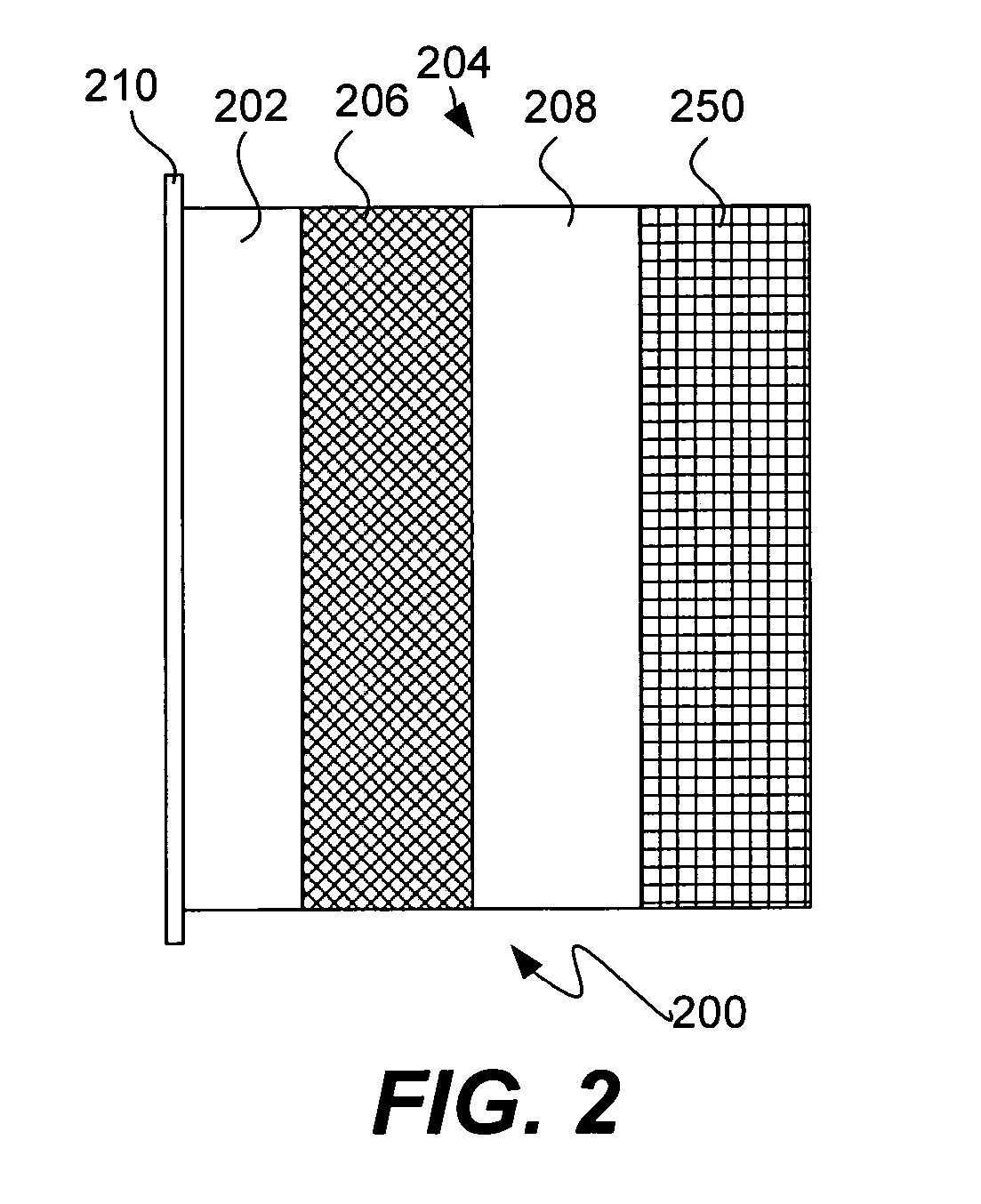

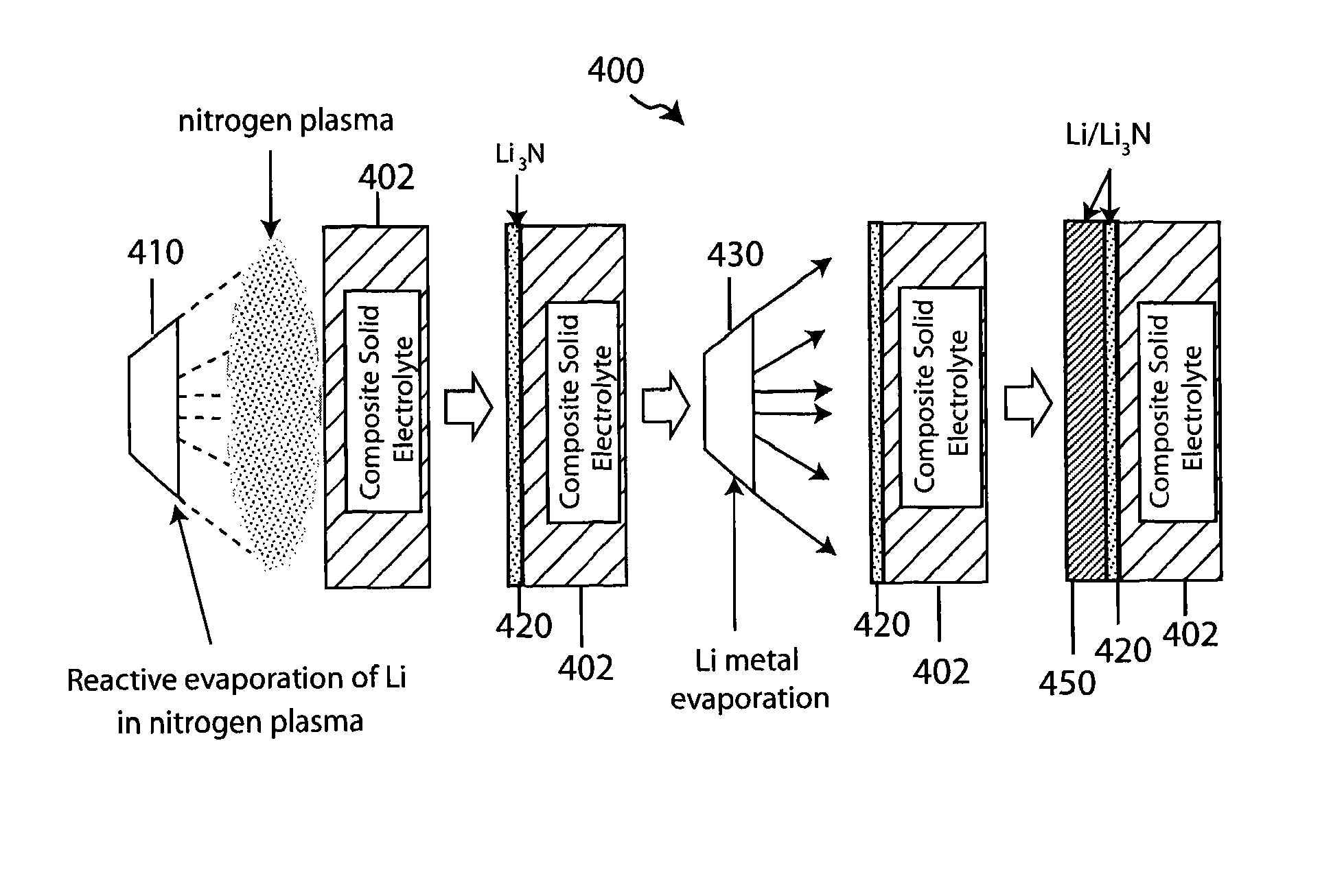

Composite solid electrolyte for protection of active metal anodes

ActiveUS20070172739A1Eliminate through-porosityHigh metal ion conductivityCell electrodesPrimary cellsPorosityTectorial membrane

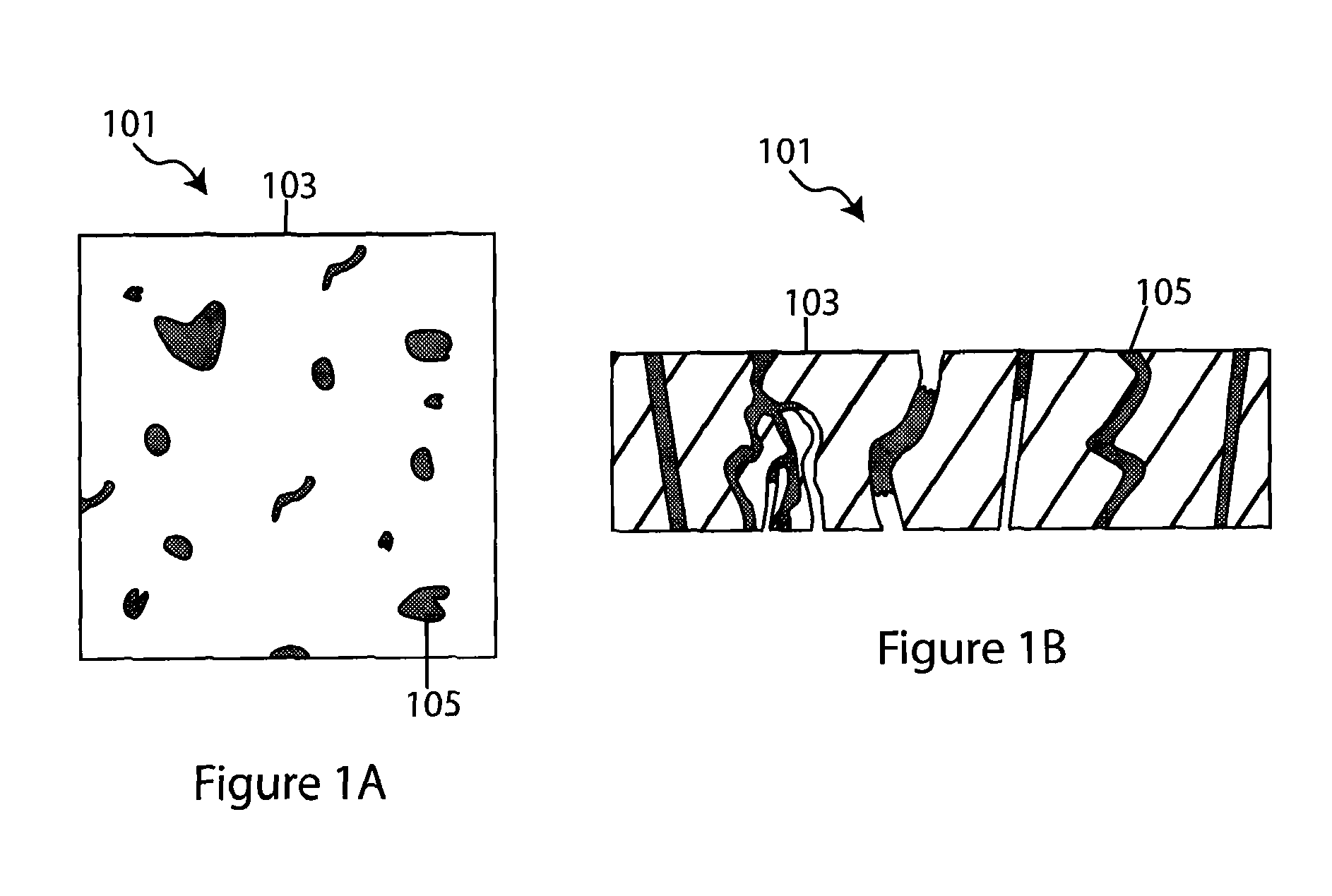

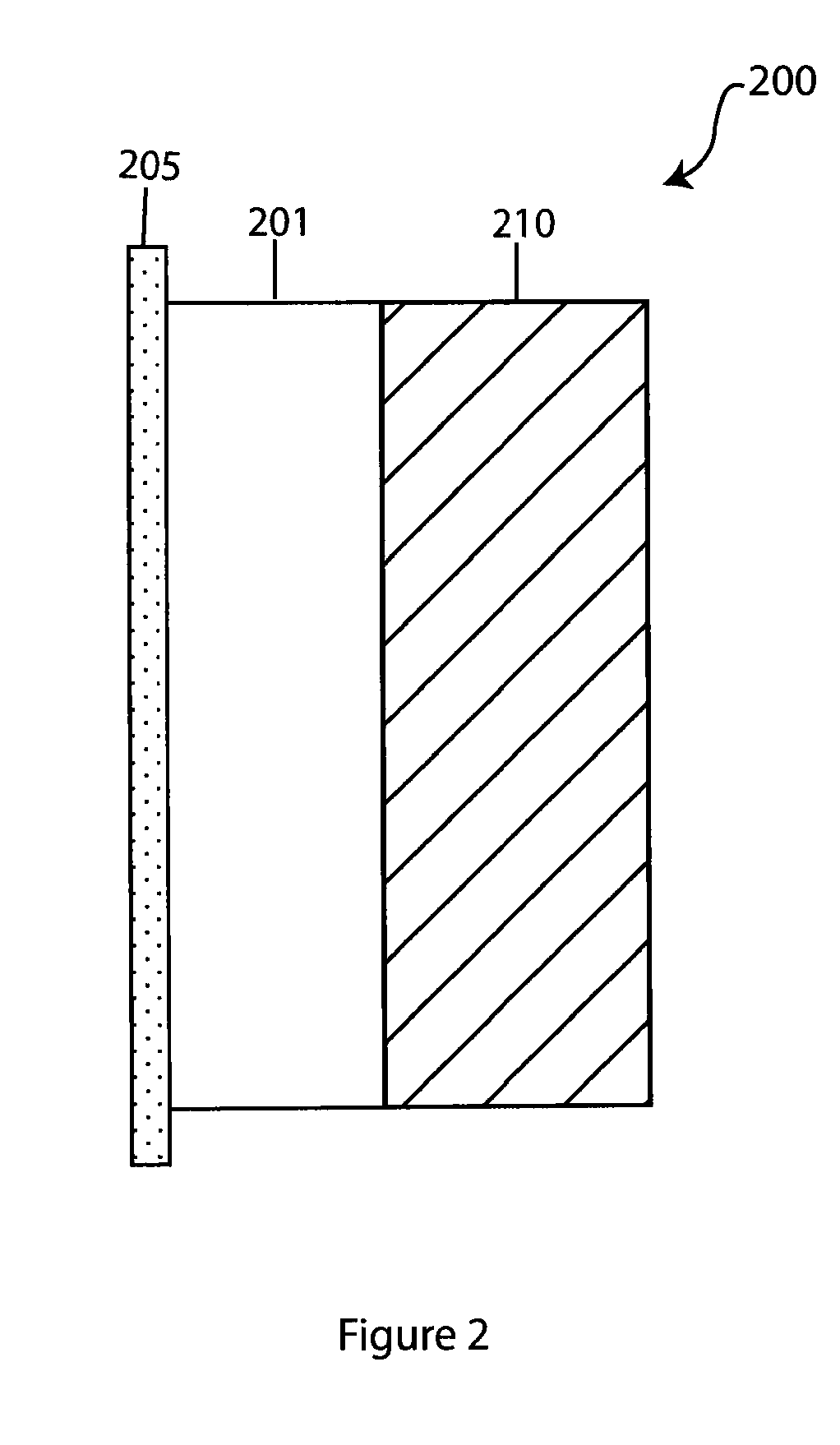

A composite solid electrolyte include a monolithic solid electrolyte base component that is a continuous matrix of an inorganic active metal ion conductor and a filler component used to eliminate through porosity in the solid electrolyte. In this way a solid electrolyte produced by any process that yields residual through porosity can be modified by the incorporation of a filler to form a substantially impervious composite solid electrolyte and eliminate through porosity in the base component. Methods of making the composites is also disclosed. The composites are generally useful in electrochemical cell structures such as battery cells and in particular protected active metal anodes, particularly lithium anodes, that are protected with a protective membrane architecture incorporating the composite solid electrolyte. The protective architecture prevents the active metal of the anode from deleterious reaction with the environment on the other (cathode) side of the architecture, which may include aqueous, air and organic liquid electrolytes and / or electrochemically active materials.

Owner:POLYPLUS BATTERY CO INC

Electrical conductors formed from mixtures of metal powders and metallo-organic decomposition compounds

The present invention relates to a thick film formed of a mixture of metal powders and metallo-organic decomposition (MOD) compounds in an organic liquid vehicle and a process for advantageously applying them to a substrate by silk screening or other printing technology. The mixtures preferably contain metal flake with a ratio of the maximum dimension to the minimum dimension of between 5 and 50. The vehicle may include a colloidal metal powder with a diameter of about 10 to about 40 nanometers. The concentration of the colloidal metal in the suspension can range from about 10 to about 50% by weight. The MOD compound begins to decompose at a temperature of approximately about 200 DEG C. to promote consolidation of the metal constituents and bonding to the substrate which is complete at temperatures less than 450 DEG C. in a time less than six minutes. The mixtures can be applied by silk screening, stencilling, gravure or lithography to a polymer-based circuit board substrate for producing rigid and flexible printed wiring boards in a single operation with negligible generation of hazardous wastes. The same mixtures can be used in place of solder to assemble circuits by bonding electrical components to conductors as well as to make the conductors themselves.

Owner:PARELEC

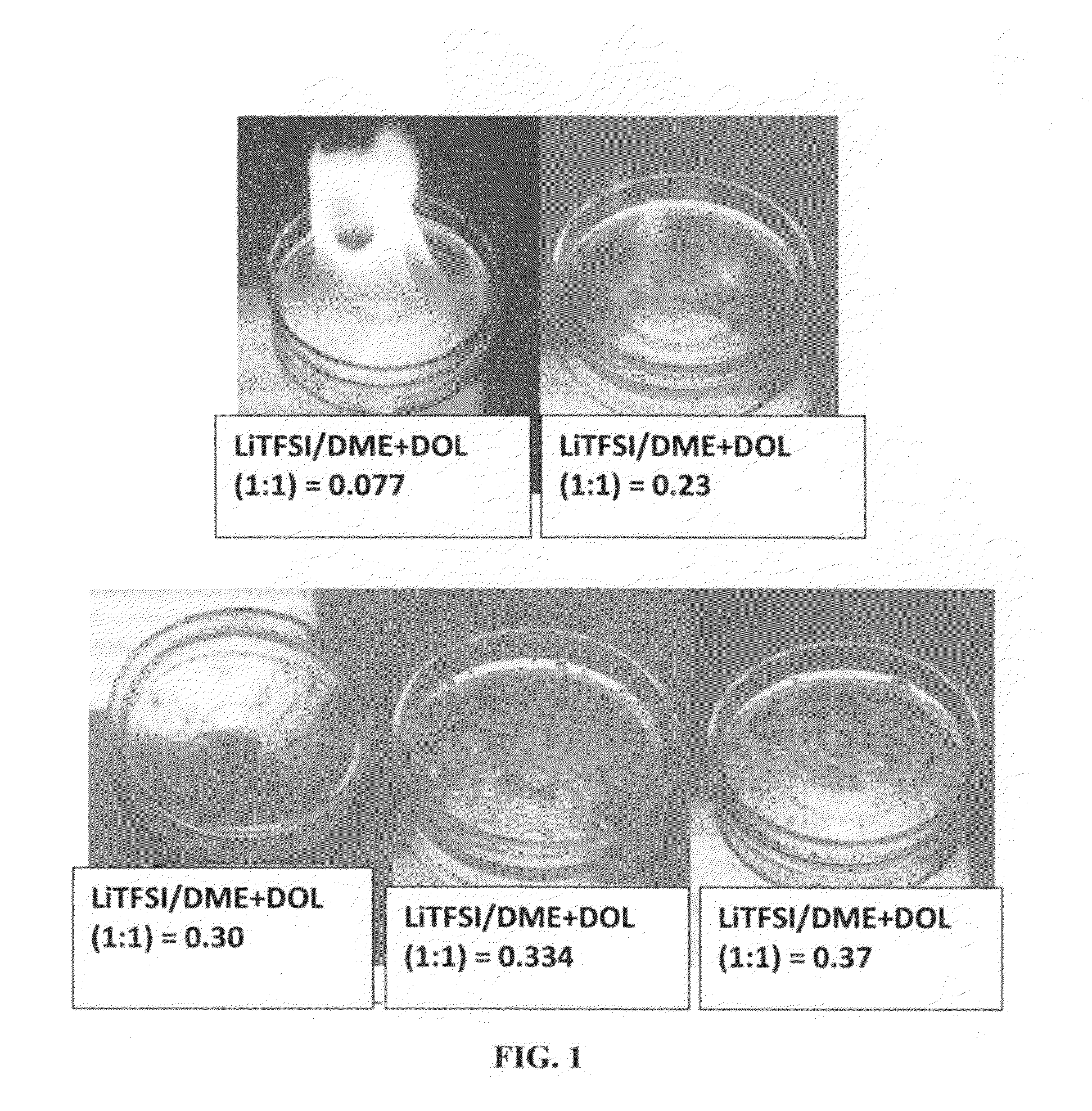

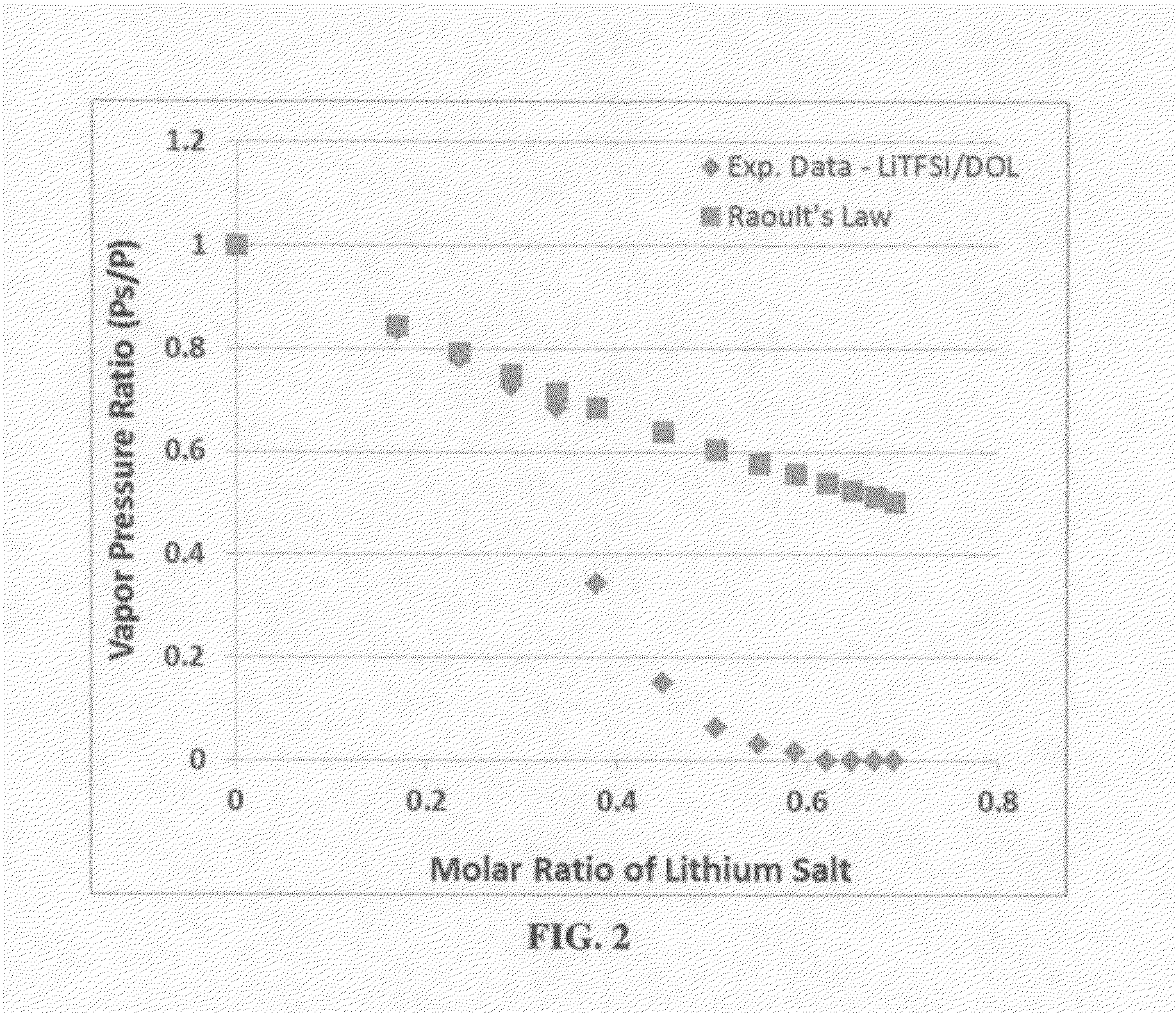

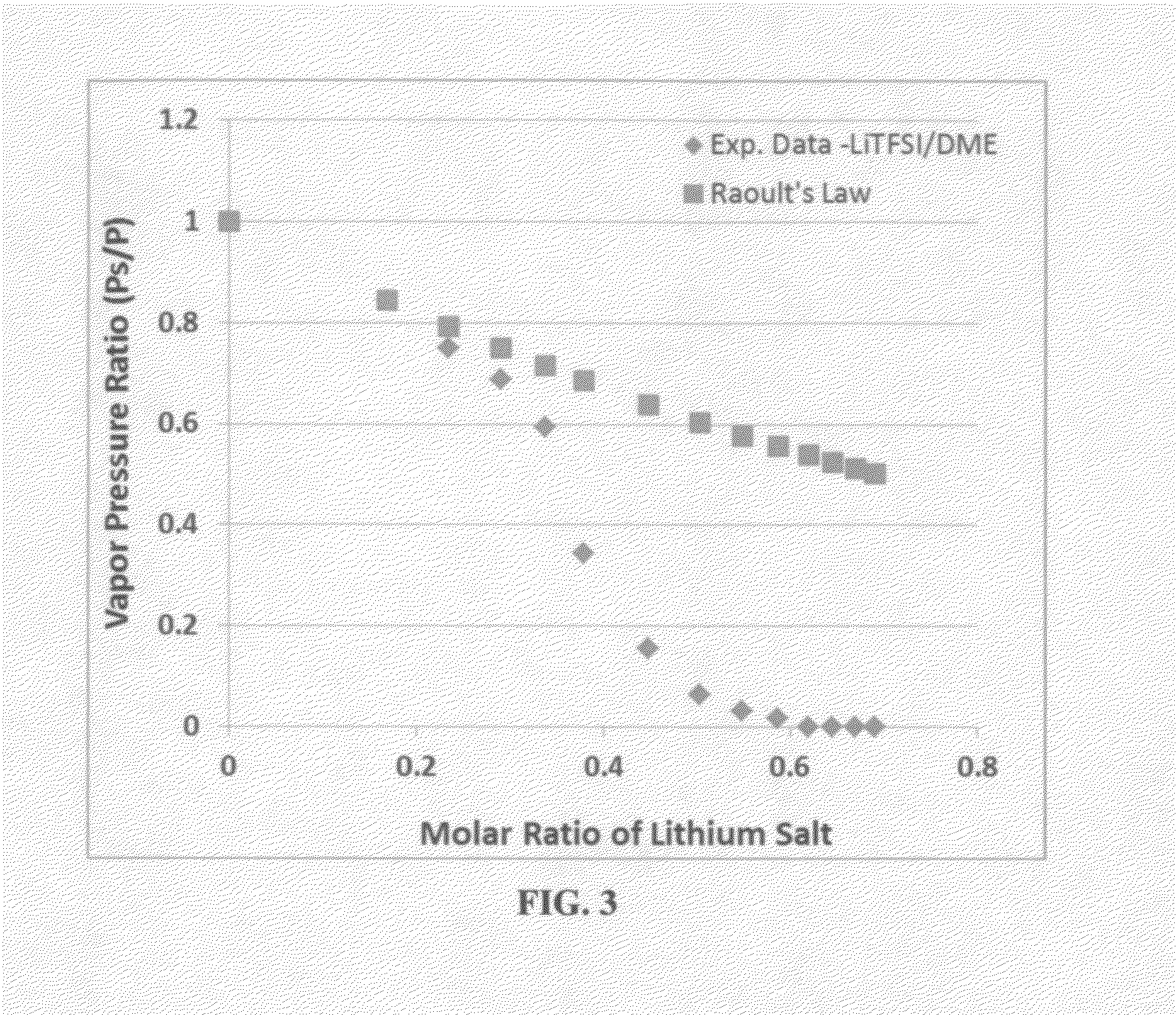

Lithium secondary batteries containing non-flammable quasi-solid electrolyte

ActiveUS20140363746A1Reduce electrical conductivityLow ionic conductivityFuel and secondary cellsSolid electrolyte cellsSolventVapor pressure

A rechargeable lithium cell comprising a cathode having a cathode active material, an anode having an anode active material, a porous separator electronically separating the anode and the cathode, a non-flammable quasi-solid electrolyte in contact with the cathode and the anode, wherein the electrolyte contains a lithium salt dissolved in a first organic liquid solvent with a concentration sufficiently high so that the electrolyte exhibits a vapor pressure less than 0.01 kPa when measured at 20° C., a flash point at least 20 degrees Celsius higher than the flash point of the first organic liquid solvent alone, a flash point higher than 150° C., or no flash point. This battery cell is non-flammable and safe, has a long cycle life, high capacity, and high energy density.

Owner:GLOBAL GRAPHENE GRP INC

Solid electrolytes based on lithium hafnium phosphate for active metal anode protection

InactiveUS20060078790A1Avoid harmful reactionsCell electrodesNon-aqueous electrolyte cellsPhosphateOrganic liquids

Active metal electrochemical structure, in particular an active metal negative electrode (anode) protected with an ionically conductive protective architecture incorporating a glassy, ceramic or glass-ceramic solid electrolyte material based on lithium hafnium phosphate, and associated electrochemical devices and methods, provides advantages over conventional structures. The protective architecture prevents the active metal from deleterious reaction with the environment on the other (cathode) side of the architecture, which may include aqueous, air or organic liquid electrolytes and / or electrochemically active materials.

Owner:POLYPLUS BATTERY CO INC

Composite solid electrolyte for protection of active metal anodes

ActiveUS8182943B2Eliminate through-porosityImprove ionic conductivityCell electrodesPrimary cellsPorosityLithium

A composite solid electrolyte include a monolithic solid electrolyte base component that is a continuous matrix of an inorganic active metal ion conductor and a filler component used to eliminate through porosity in the solid electrolyte. In this way a solid electrolyte produced by any process that yields residual through porosity can be modified by the incorporation of a filler to form a substantially impervious composite solid electrolyte and eliminate through porosity in the base component. Methods of making the composites is also disclosed. The composites are generally useful in electrochemical cell structures such as battery cells and in particular protected active metal anodes, particularly lithium anodes, that are protected with a protective membrane architecture incorporating the composite solid electrolyte. The protective architecture prevents the active metal of the anode from deleterious reaction with the environment on the other (cathode) side of the architecture, which may include aqueous, air and organic liquid electrolytes and / or electrochemically active materials.

Owner:POLYPLUS BATTERY CO INC

Cellulosic fibers with odor control characteristics

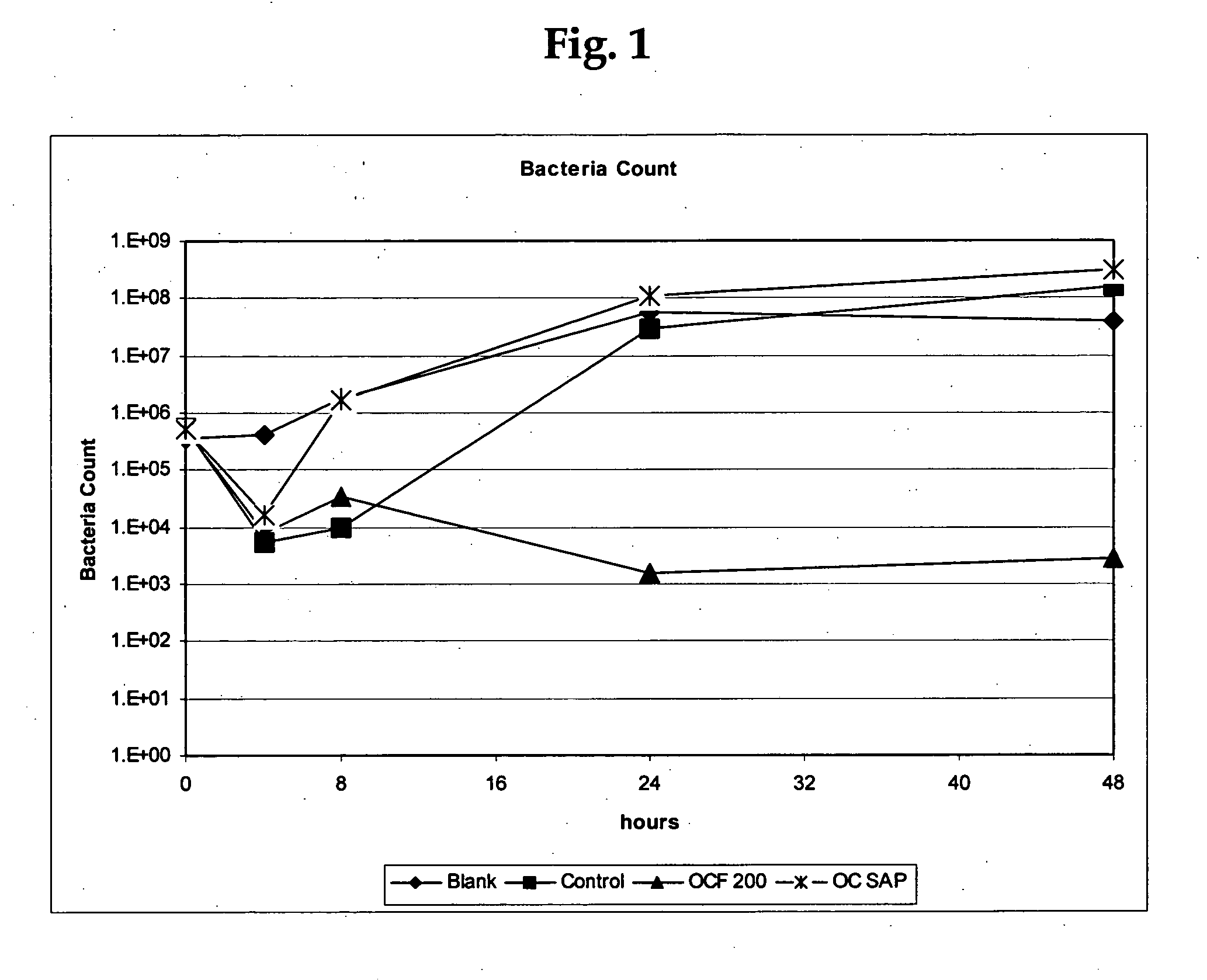

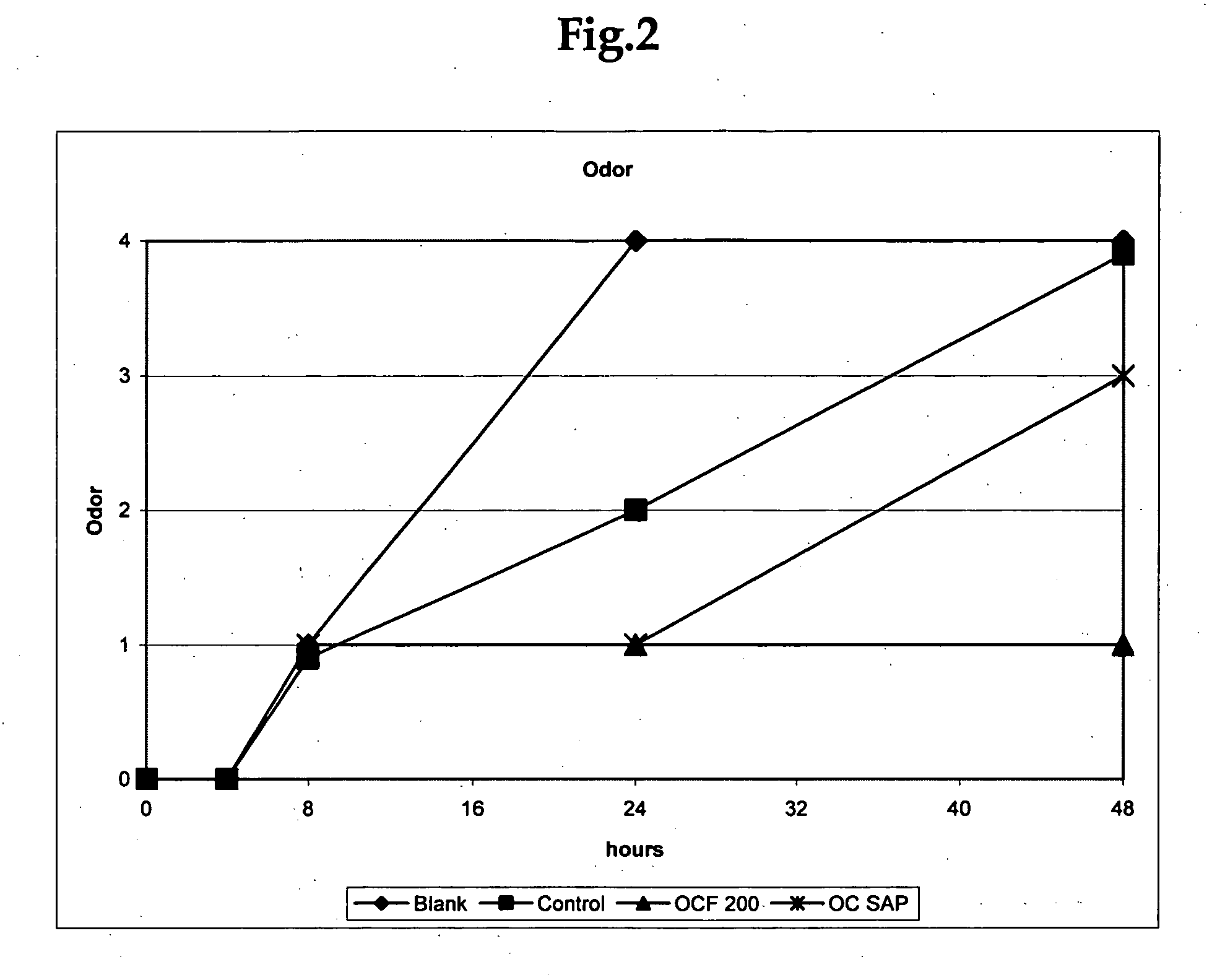

ActiveUS20070077428A1Avoid odorMaintain activityEngine sealsInorganic pigment treatmentBiotechnologyAmmonia production

An odor-inhibiting fiber having a cellulosic fiber and an odor-inhibiting formulation. The odor-inhibiting formulation may contain an odor-inhibiting agent, such as a biocide, an enzyme, a urease inhibitor. The odor-inhibiting formulation also may contain a liquid carrier such as a hydrophobic or hydrophilic organic liquid, or a mixture of a hydrophobic and hydrophilic organic liquid. The cellulosic fiber is impregnated with the odor-inhibiting formulation to produce fiber having odor-inhibiting characteristics. The resultant odor-inhibiting fiber is useful in making absorbent articles with odor-inhibiting characteristics. The fiber of the embodiments prevents odor by inhibiting bacteria growth and ammonia production, especially when used in an absorbent article such as a diaper or adult incontinence device.

Owner:RAYONIER PERFORMANCE FIBERS

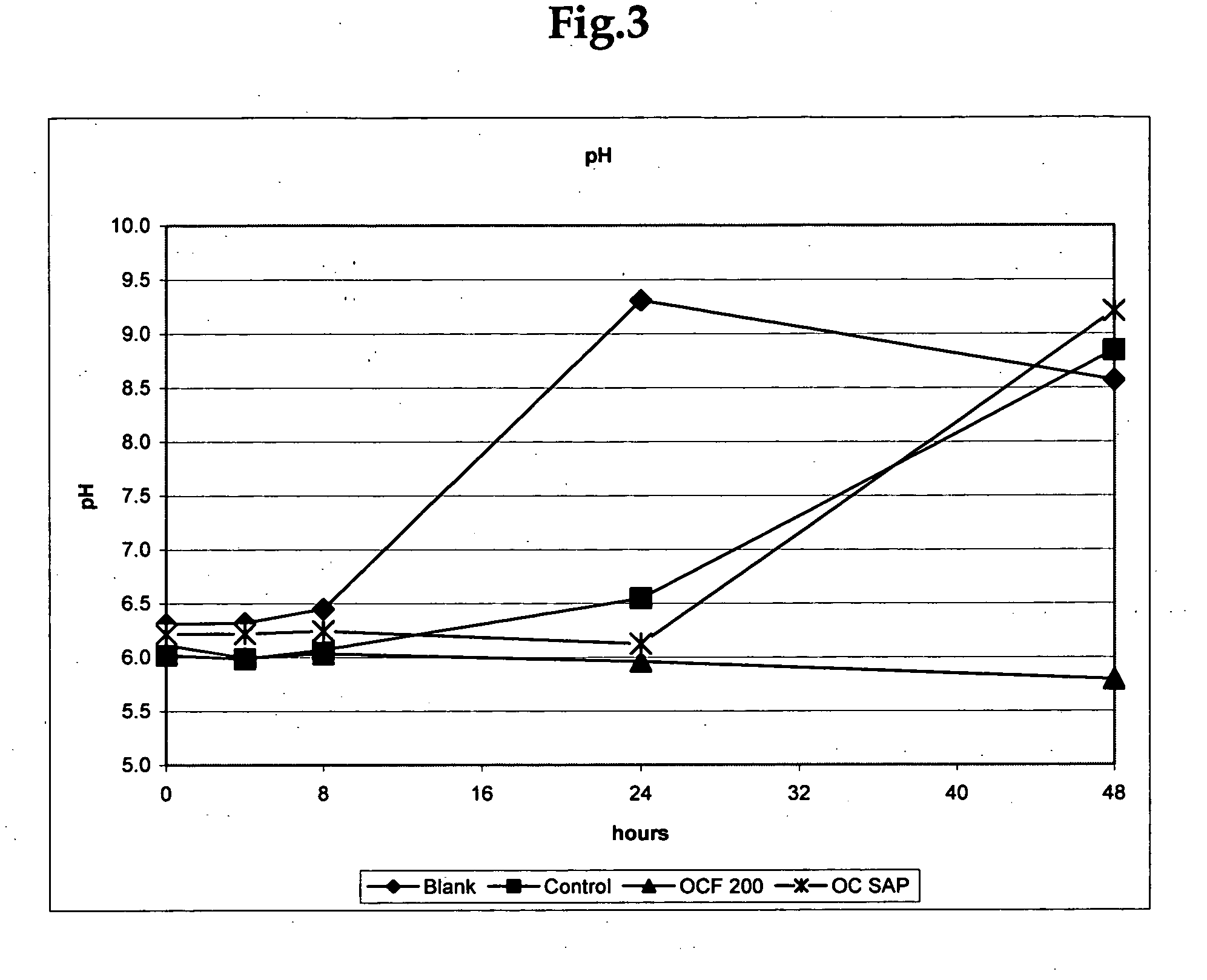

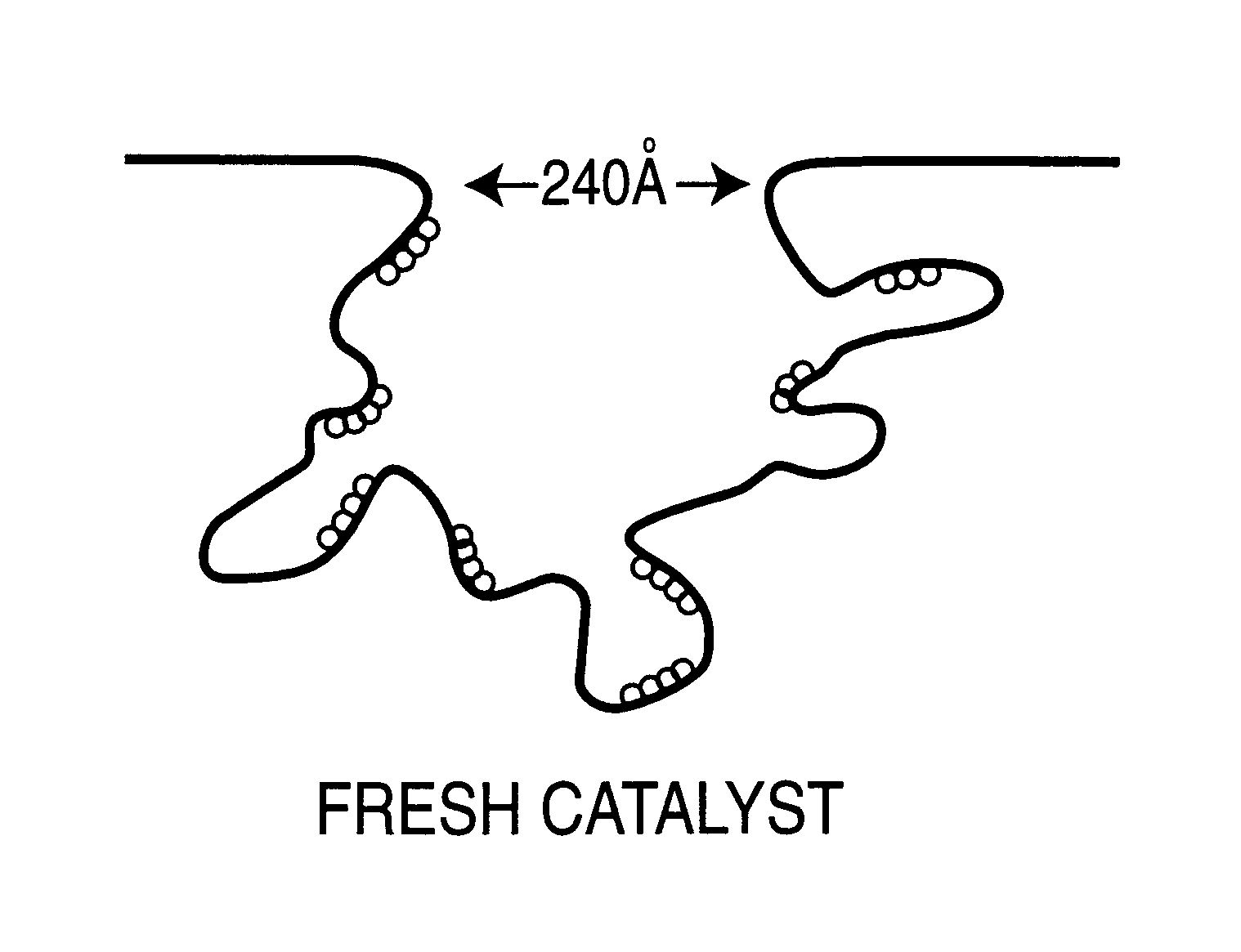

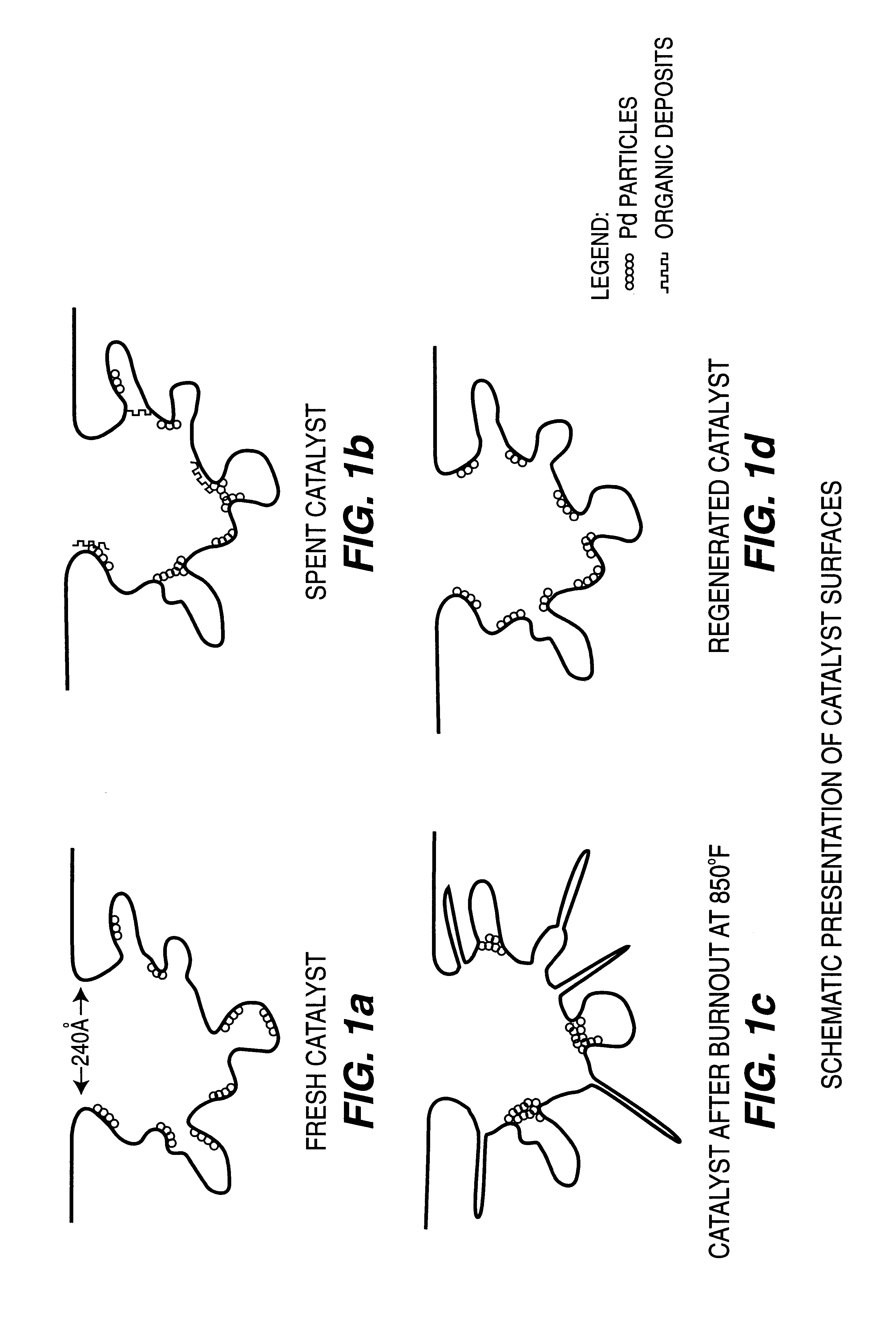

Regeneration of used supported noble metal catalysts

InactiveUS6740615B2Efficient removalImproves expositionHydrogen peroxideOther chemical processesPalladium catalystMetal particle

A method for regenerating used supported noble metal catalysts, which method includes solvent cleaning the used catalyst by contact with a suitable organic liquid cleaning solvent such as alcohols, ketones and such to remove organic deposits from the catalyst, followed by drying and calcining at elevated temperature to remove any remaining organic deposits from the catalyst, then treating the catalyst with an organo-metallic complex forming agent having ionization constant pK1 greater than about 2.5, such as glycolic acid and the like. The organic-metallic complex forming agent acts to break down large clusters of noble metal particles such as palladium (Pd) and redistributes the metal particles on the catalyst support such as alumina (Al2O3) in the same or other larger pores, so as to increase catalyst surface area and catalytic activity to provide a catalytic activity level at least 80% or even exceeding that of the fresh catalyst. This regeneration method is particularly useful for regenerating used supported palladium catalysts utilized for hydrogenation of ethyl anthraquinone (EAQ) for producing hydrogen peroxide (H2O2) product.

Owner:POROCEL INT LLC +1

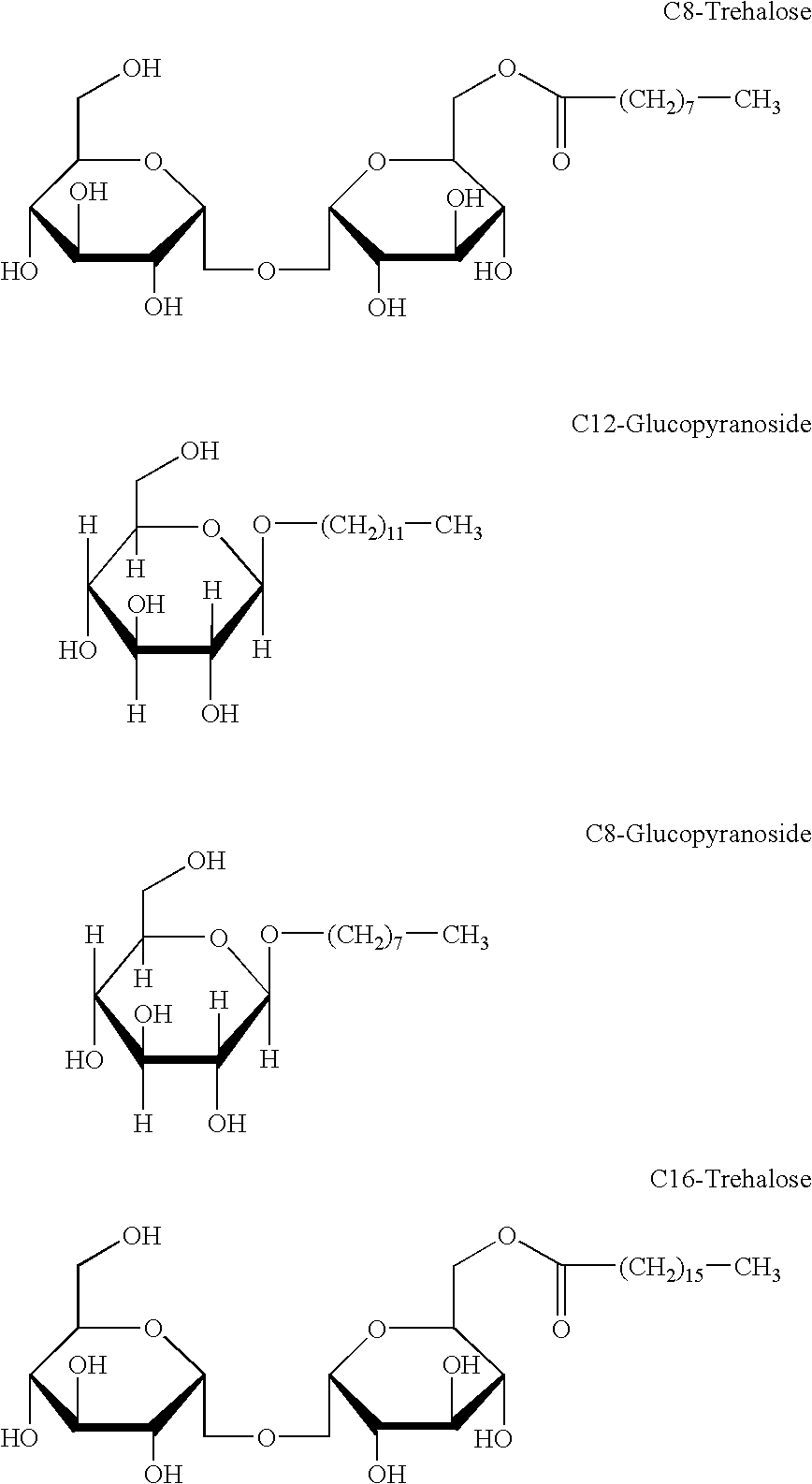

Method for stabilizing biomolecules in liquid formulations

InactiveUS20020110524A1Improve stabilityOrganic active ingredientsFactor VIIActive proteinPharmaceutical medicine

The invention is directed to a stable formulation of a biologically active protein useful for aerosol delivery to the respiratory tract of a patient in need of treatment comprising: (a) a carrier liquid comprising from about 10% to from about 100% V / V water and from about 0% to from about 90% V / V of an organic liquid; (b) a biologically effective amount of a protein suspended or dissolved in a carrier liquid; and (c) a stabilizing effective amount of a derivatized carbohydrate stabilizing agent suspended or dissolved in said carrier liquid. The stable formulations of the invention may optionally contain about 0.1% to about 5.0% W / V of a pharmaceutically acceptable excipient.

Owner:BATTELLE MEMORIAL INST

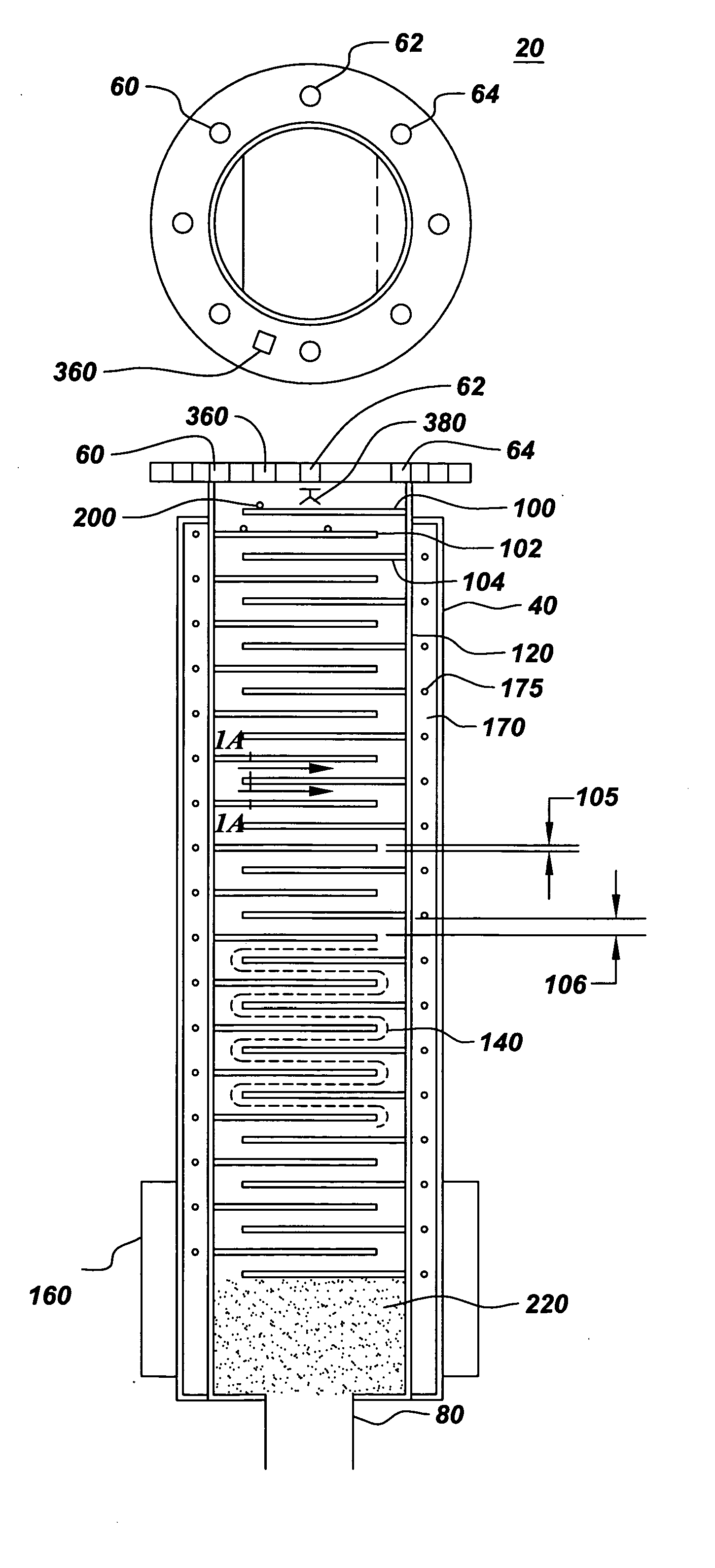

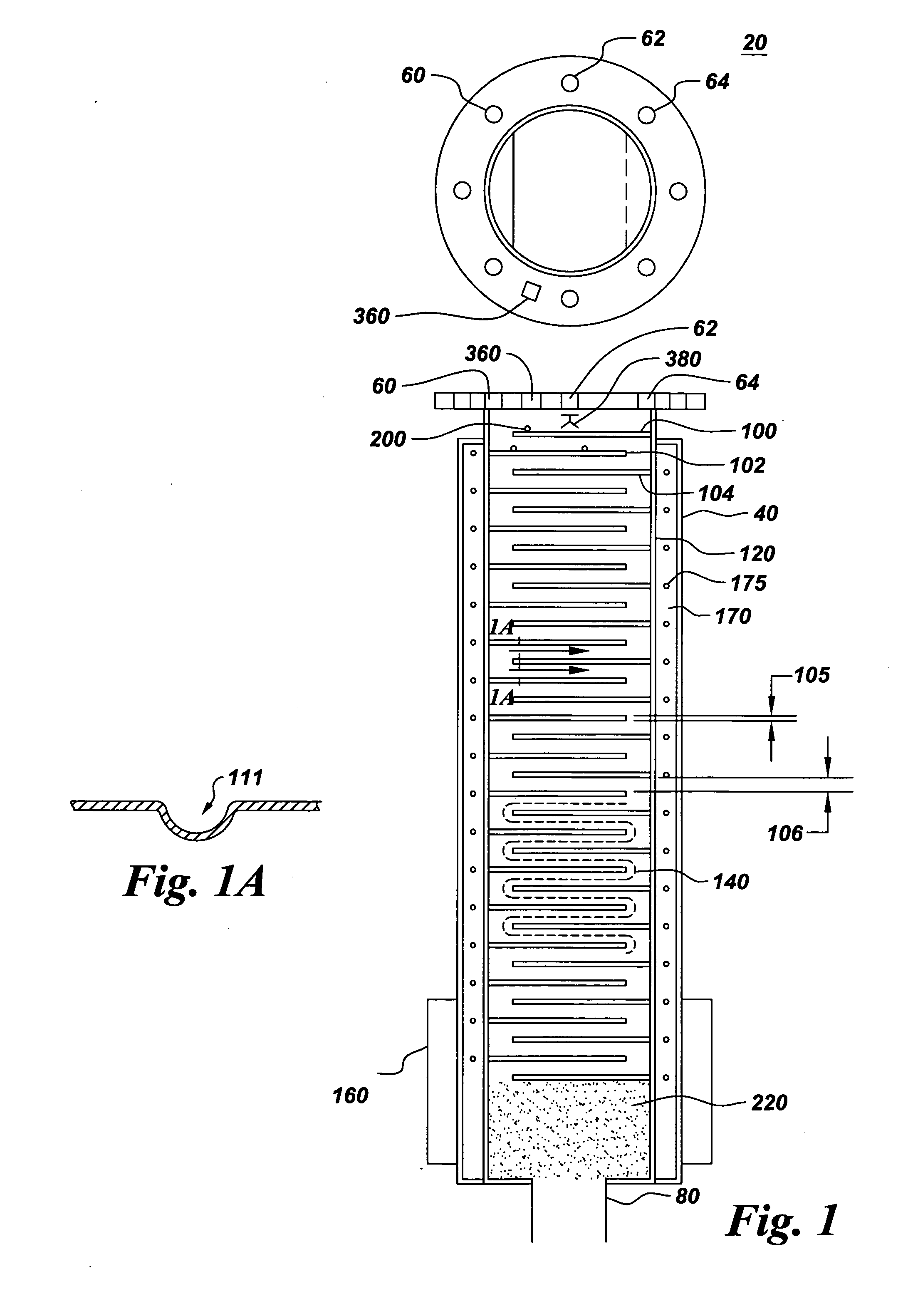

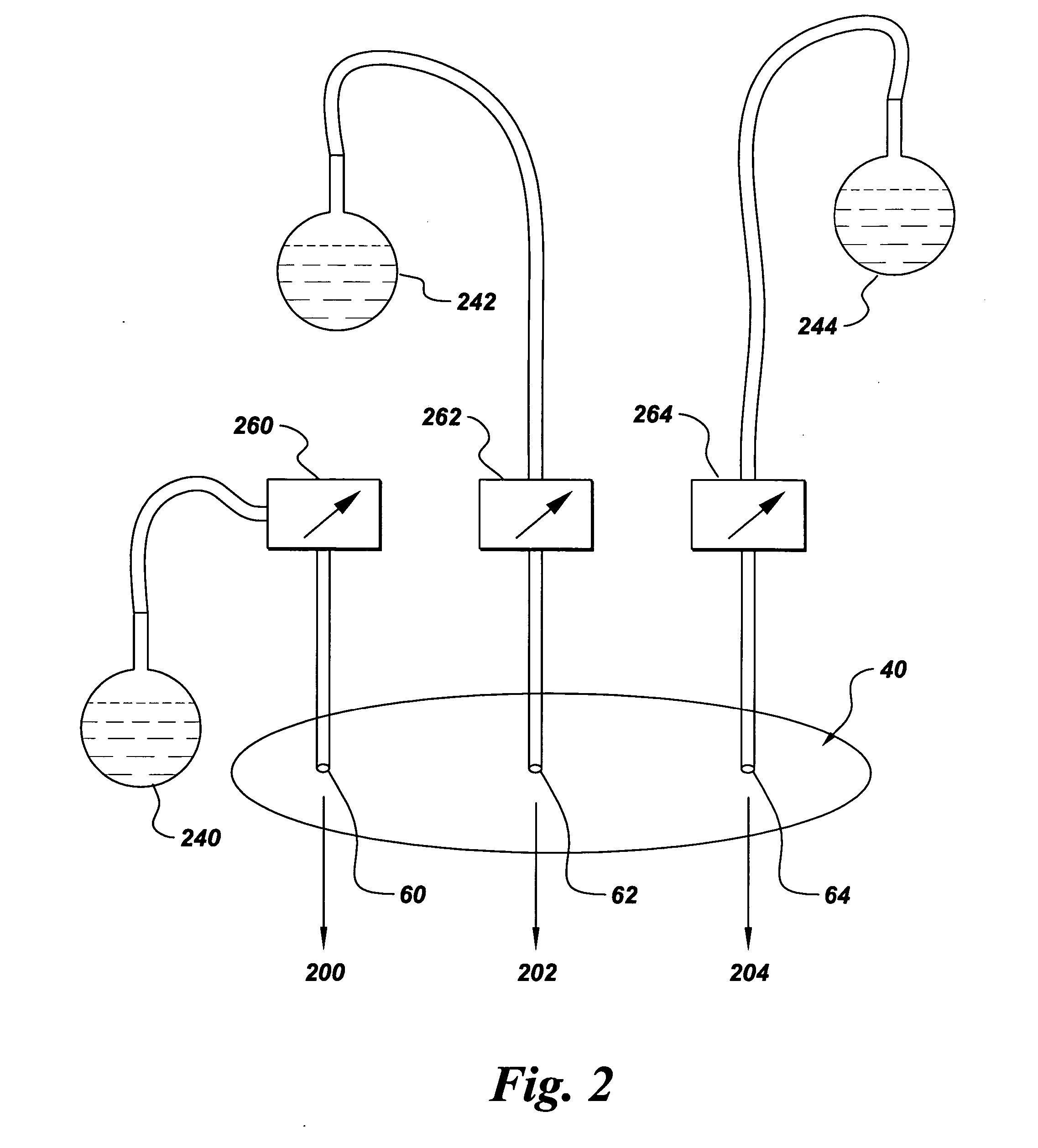

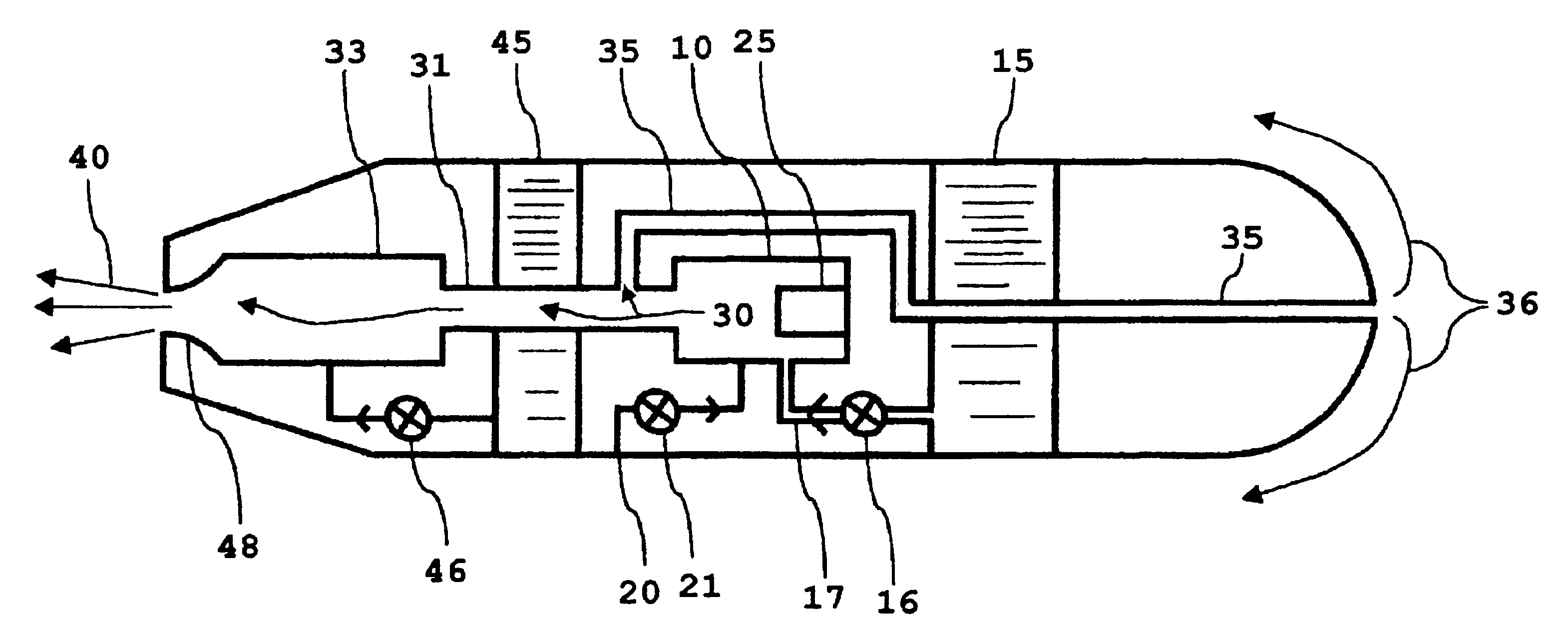

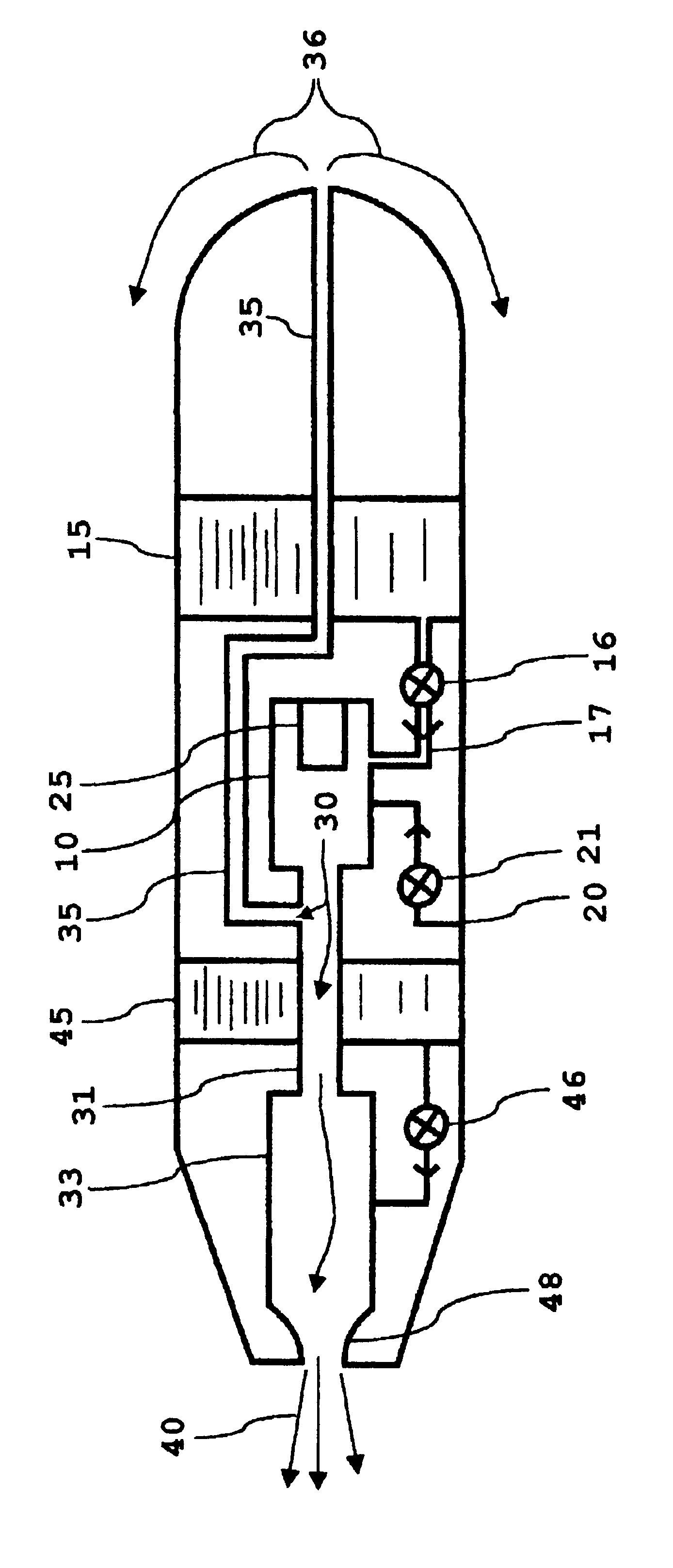

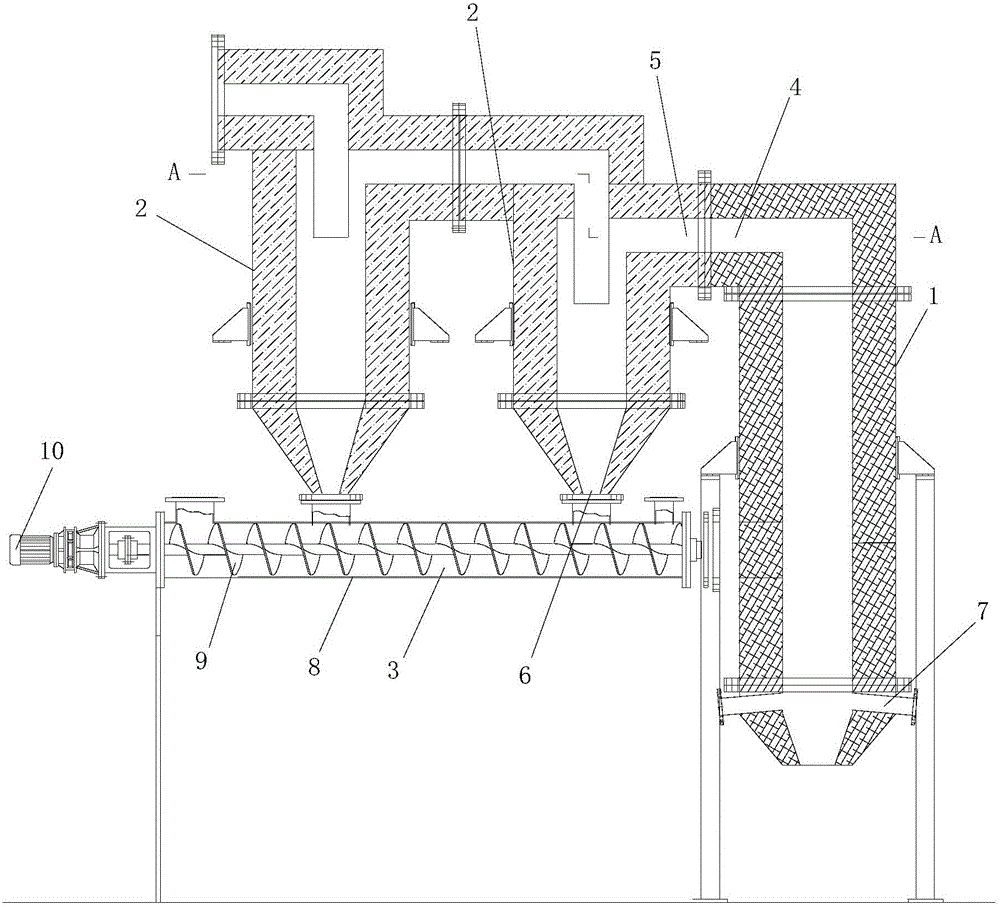

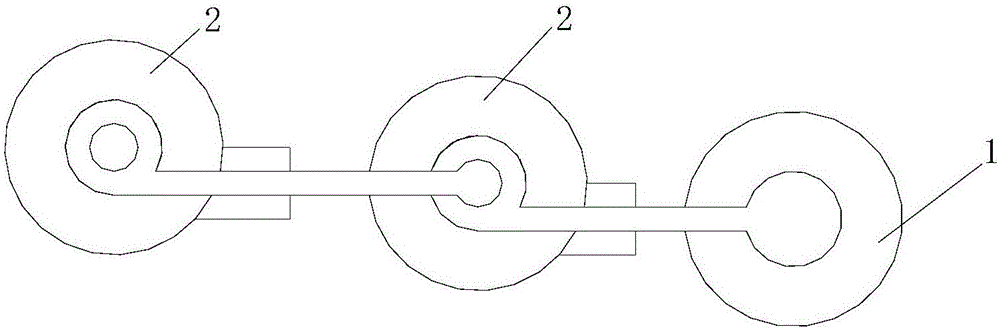

Apparatus for the evaporation of aqueous organic liquids and the production of powder pre-forms in flame hydrolysis processes

InactiveUS20050205215A1Drying using combination processesEvaporator liquid feederOrganic liquidsEvaporation

An organic liquid evaporation system is disclosed. The organic liquid evaporation system comprises a housing having at least one inlet and at least one outlet. At least a first evaporator plate radially extending from a sidewall of the housing, and at least a second evaporator plate radially extending from a sidewall of the housing define a serpentine flow path within the housing. A heating source is in thermal communication with the first evaporator plate and the second evaporator plate, wherein the heating source provides heat to the first and second evaporator plates to evaporate organic liquid introduced within the inlet to produce a vapor through the outlet. A method for preparing powder pre-forms and oxide soot using the organic liquid evaporation system is also disclosed.

Owner:GENERAL ELECTRIC CO

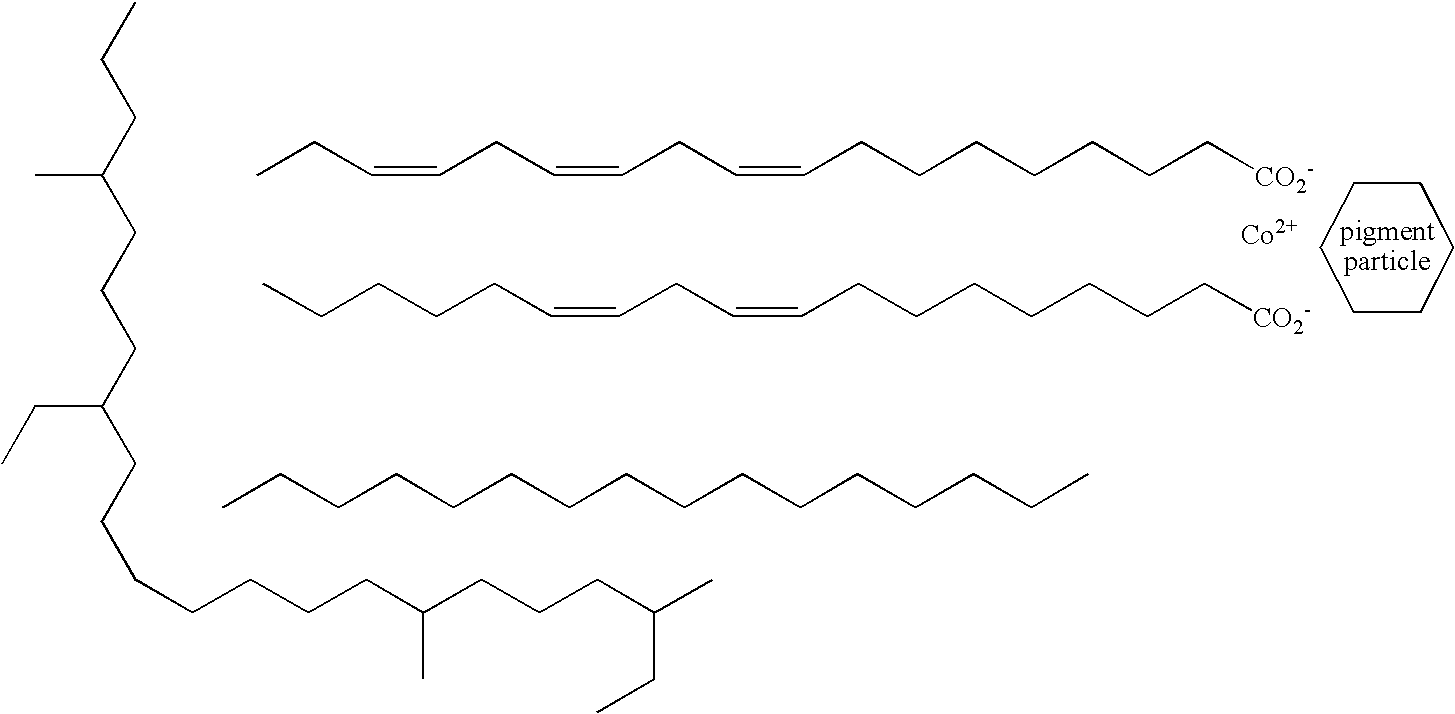

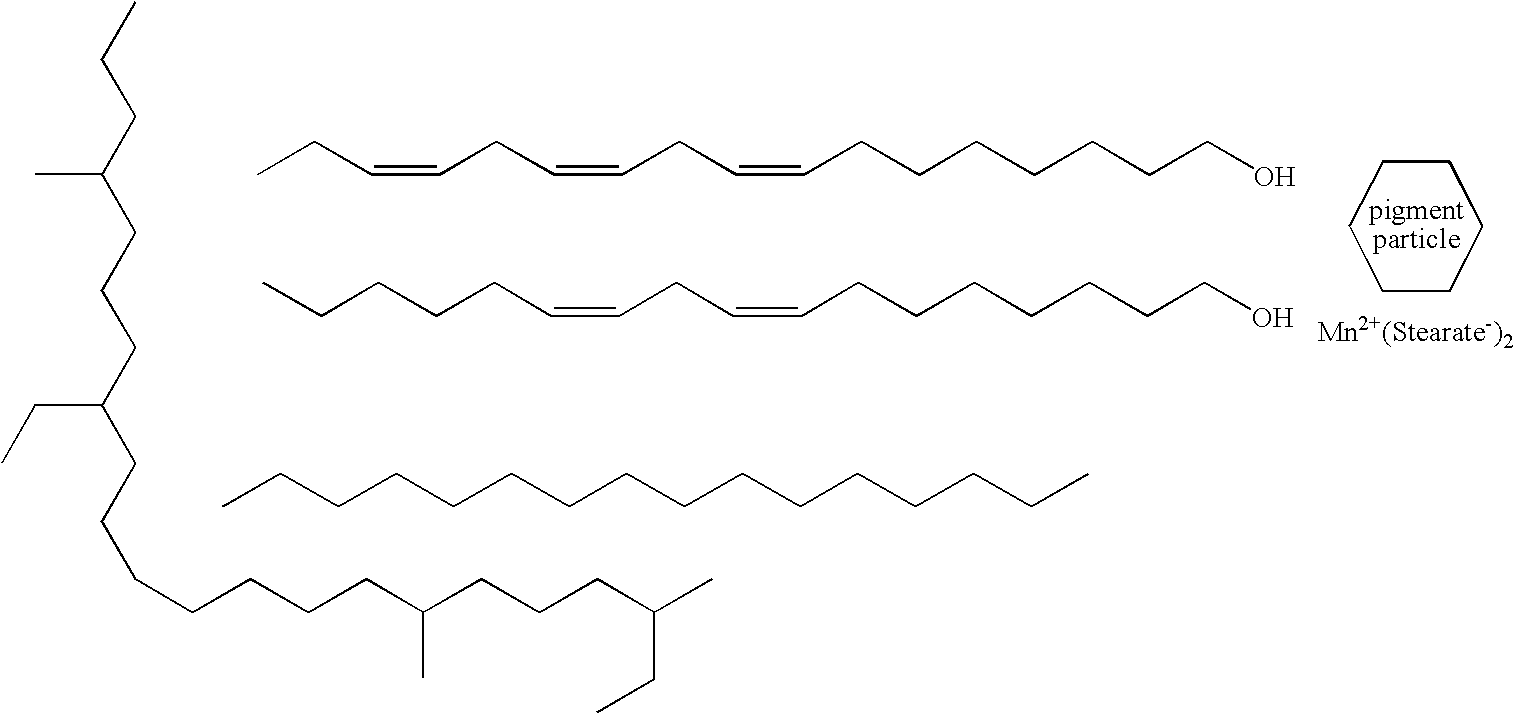

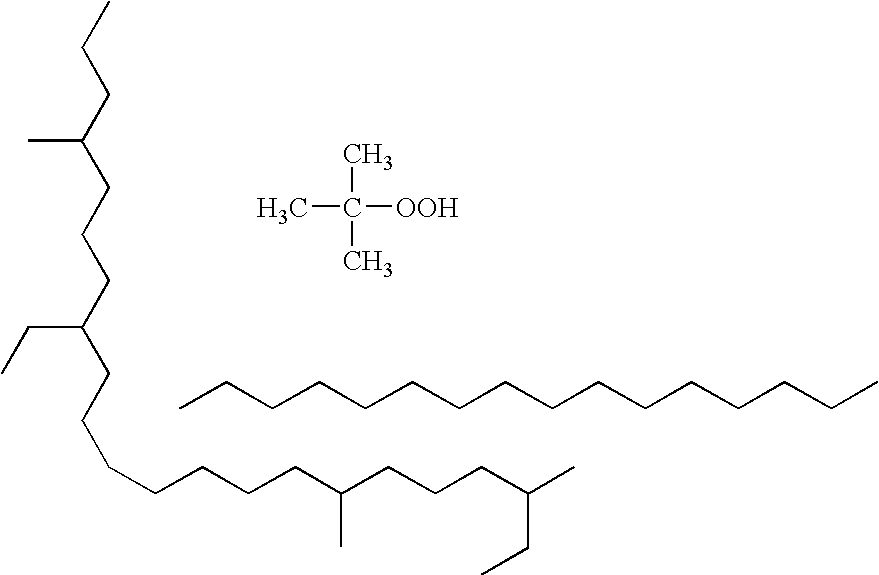

Intercalates and exfoliates formed with long chain (C6+) or aromatic matrix polymer-compatible monomeric, oligomeric or polymeric intercalant compounds, and composite materials containing same

InactiveUS6242500B1Efficient electrostatic complexingEasy to separateOrganic chemistryOther chemical processesOrganic liquidsPlatelet

Intercalates formed by contacting a layered material, e.g., a phyllosilicate, with an intercalant surface modifier selected from the group consisting of a compound having an alkyl radical containing at least 6 carbon atoms, a compound containing an aromatic ring, and mixtures thereof, said surface modifier including a matrix material-reactive functional group, to sorb or intercalate the intercalant surface modifier between adjacent platelets of the layered material. Sufficient intercalant surface modifier is sorbed between adjacent platelets to expand the adjacent platelets to at least about 10 Å, up to about 100 Å. The intercalated complex can be combined with an organic liquid into a viscous carrier material, for delivery of the carrier material, or for delivery of an active compound; or the intercalated complex can be combined with a matrix polymer to form a strong, filled polymer matrix.

Owner:AMCOL INTERNATIONAL CORPORATION

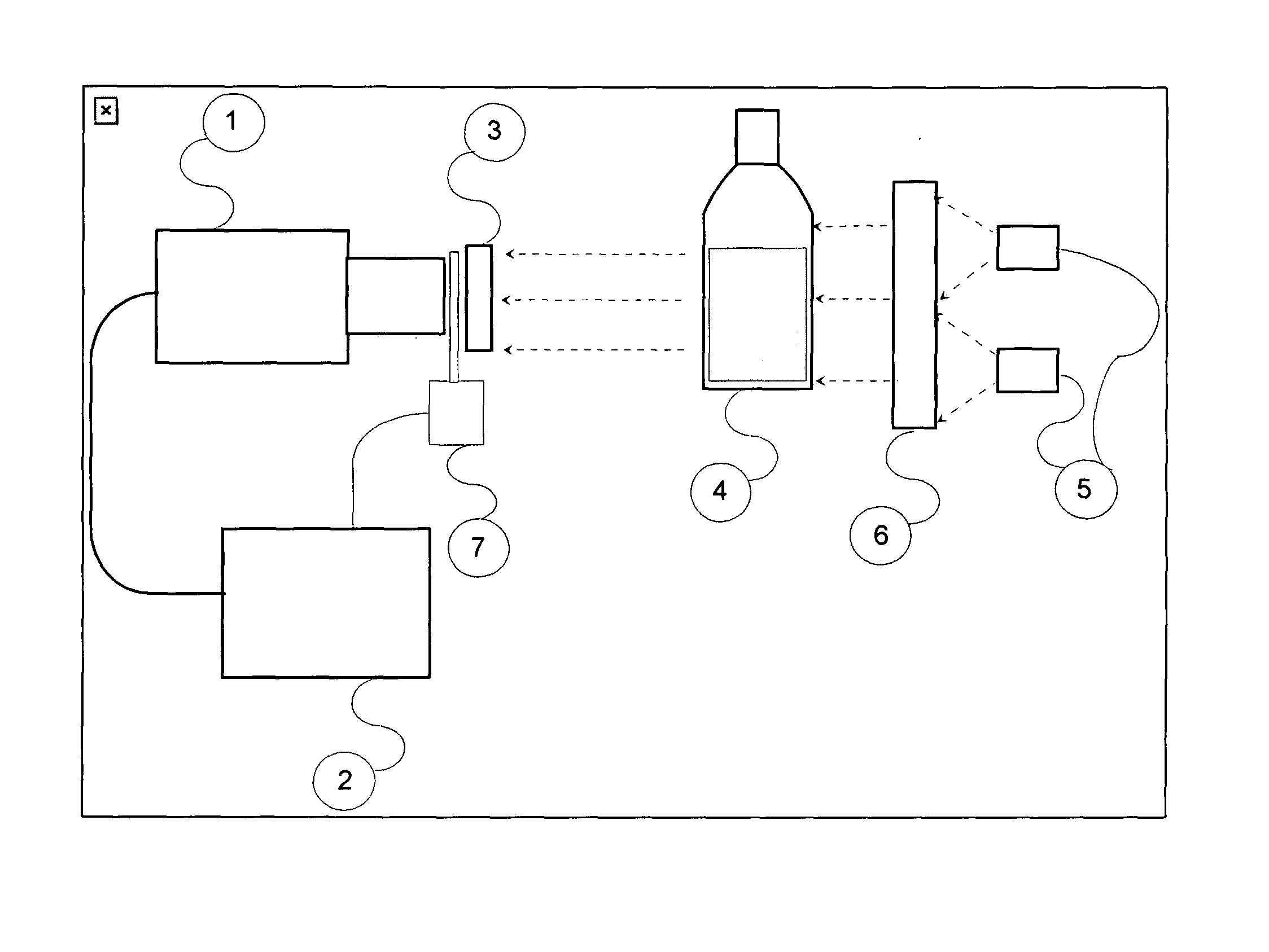

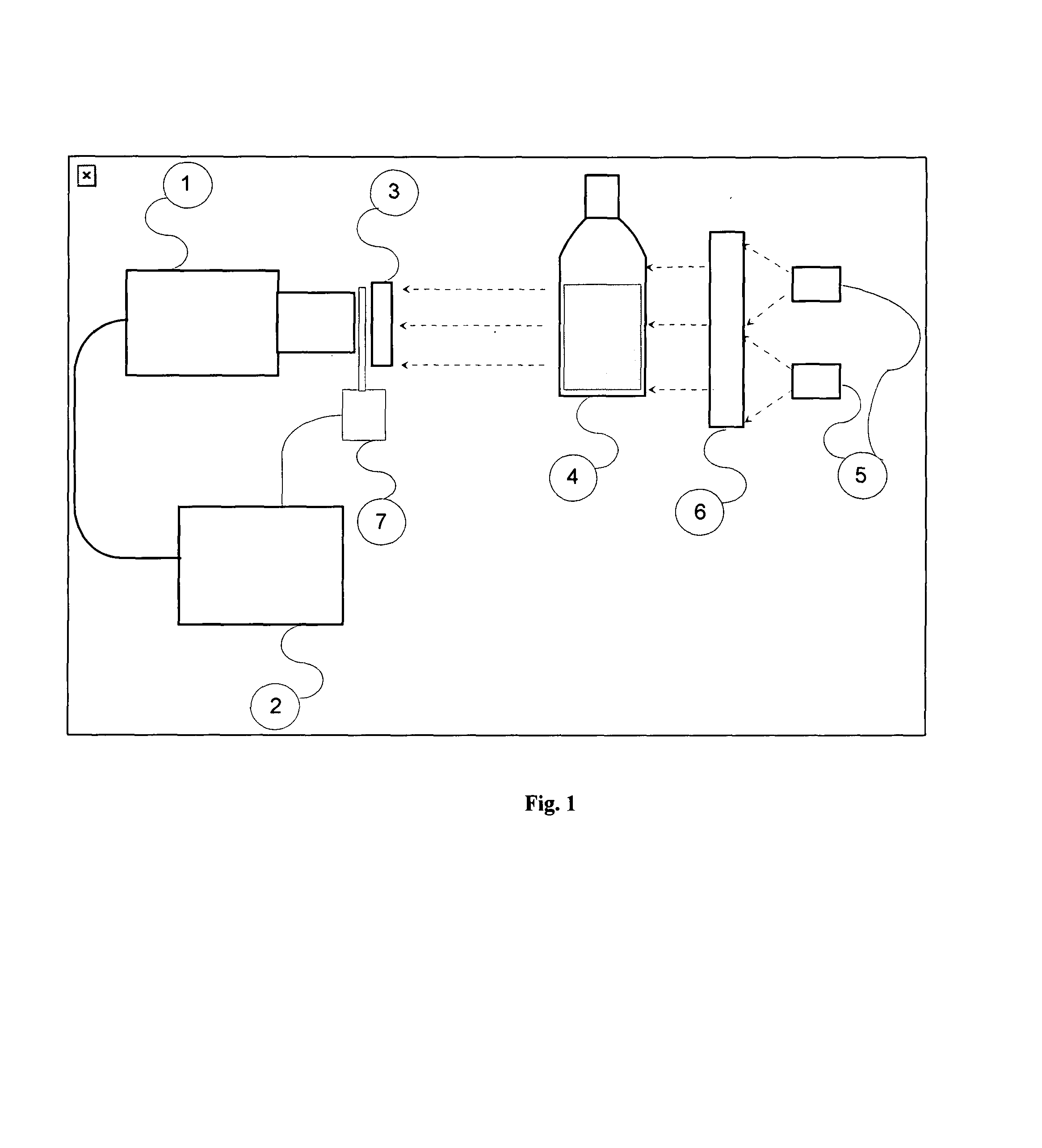

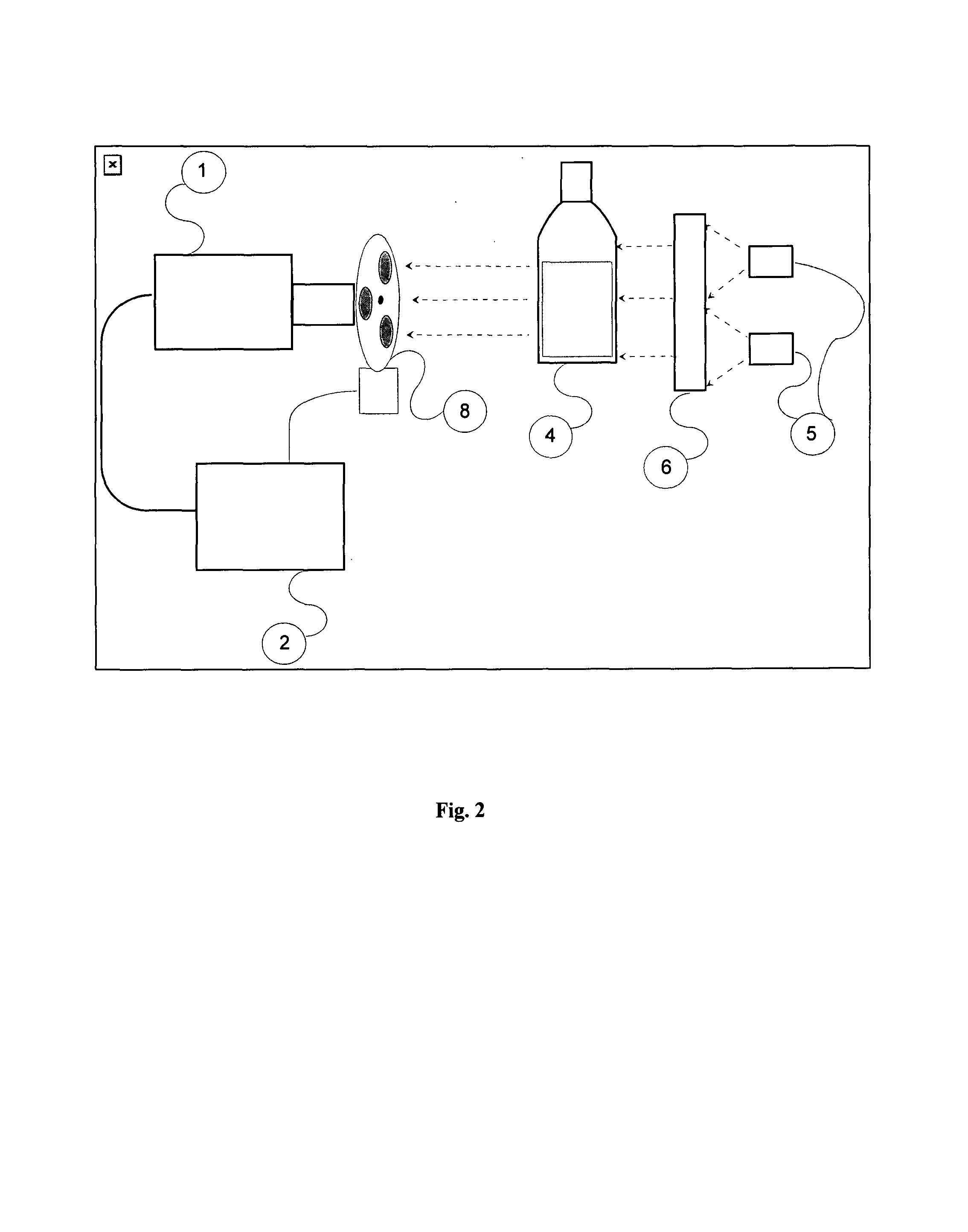

Optical system and method for inspection and characterization of liquids in vessels

A system and method for non-invasively inspecting one or more vessels capable of transmitting IR light containing liquid is provided, which uses a near-infrared (NIR) imaging device in combination with one or two NIR light sources, a diffuser plate, and an optical wavelength selecting means is provided for selecting one or more wavelength bands. In addition, the system may further comprise a computer processing means, a computer database containing known absorbance values, and a computer application, such that the system may compare the collected spectroscopic data to known spectroscopic data, and identify the liquid contained within the inspected vessel. The inspection method of the present invention measures a transmission or reflection image of one or more vessels being inspected at one or more narrow wavelength intervals in the NIR spectral range that corresponds to a peak absorbance wavelength of water, organic liquids, and explosive compositions.

Owner:POLESTAR TECH

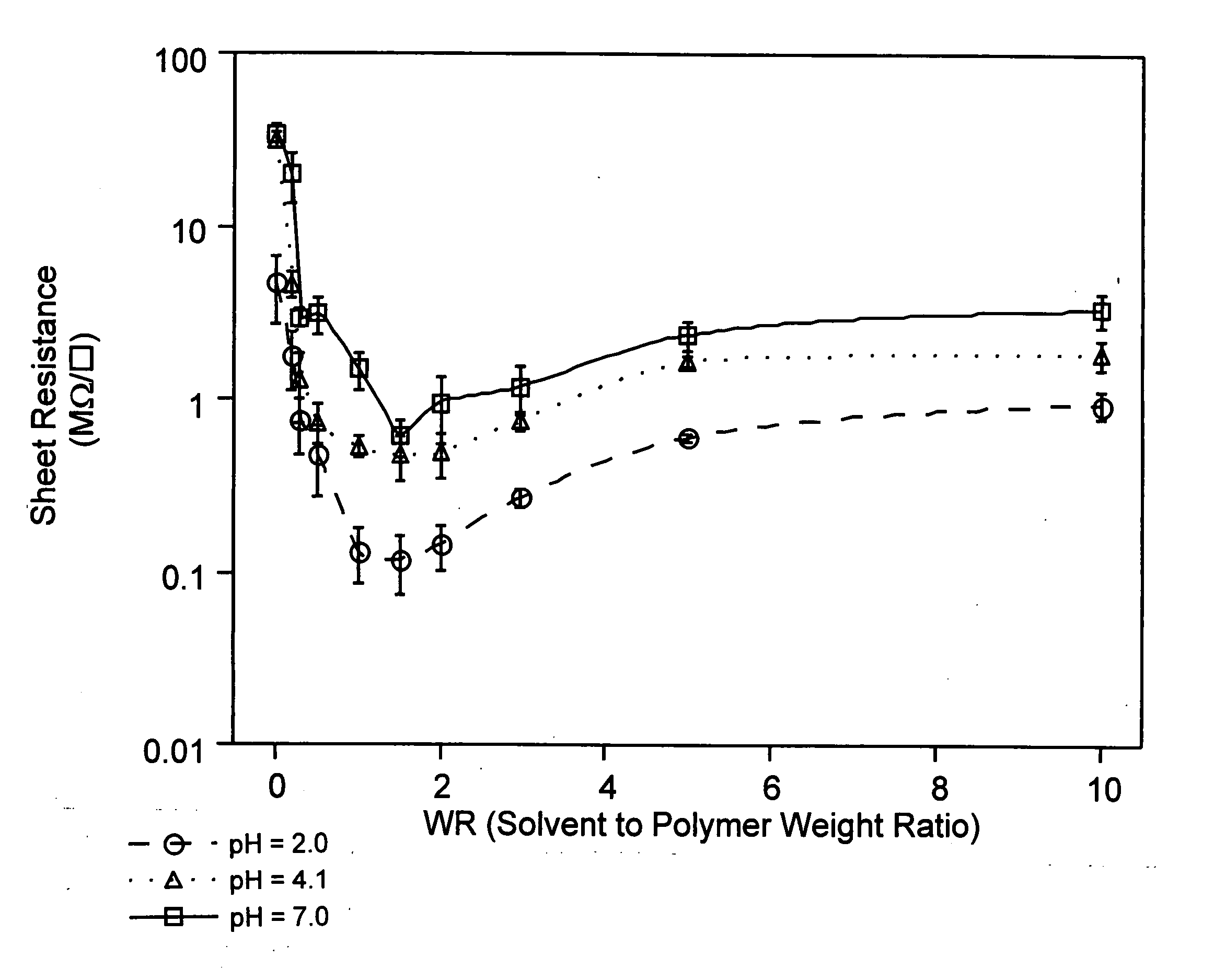

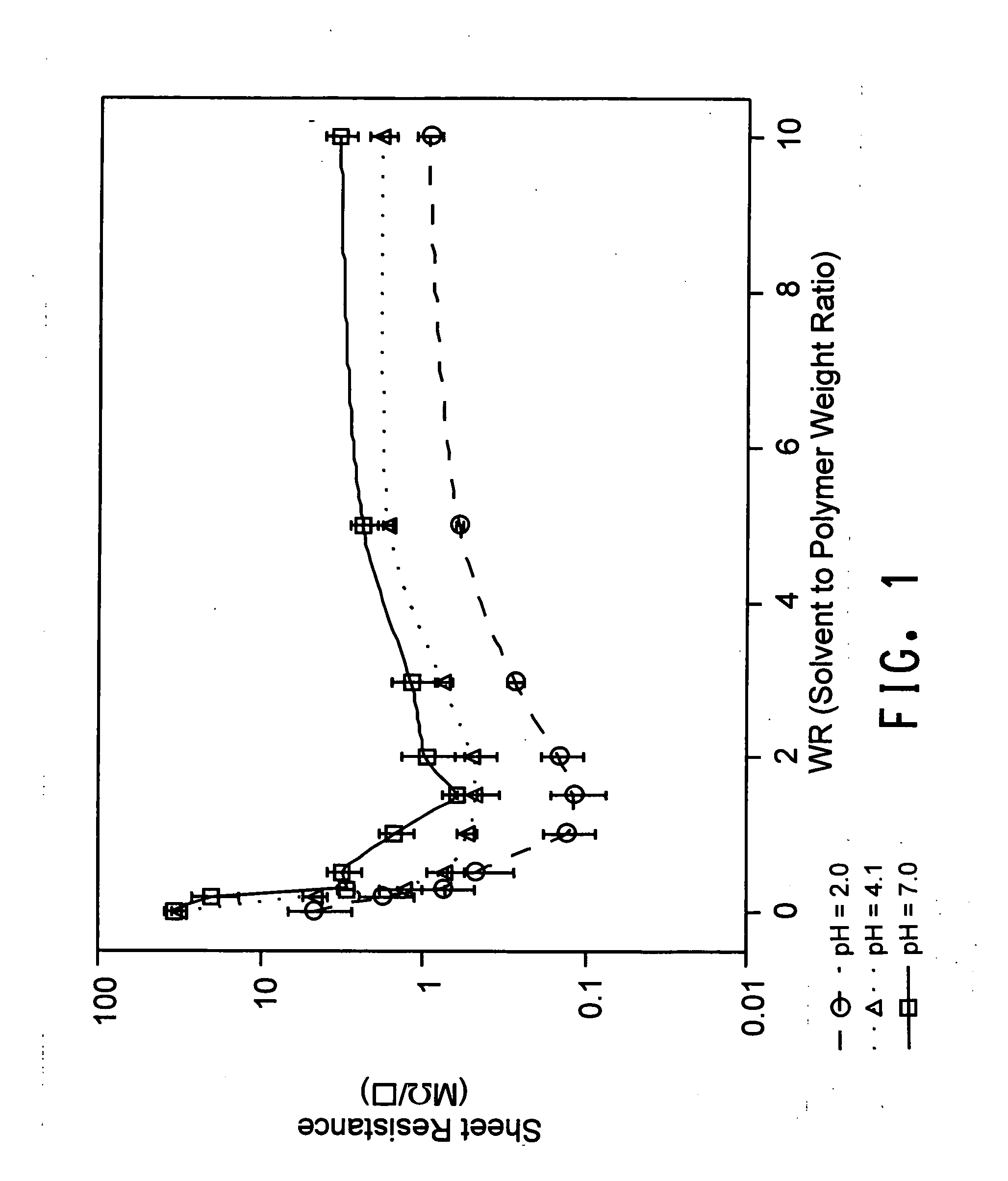

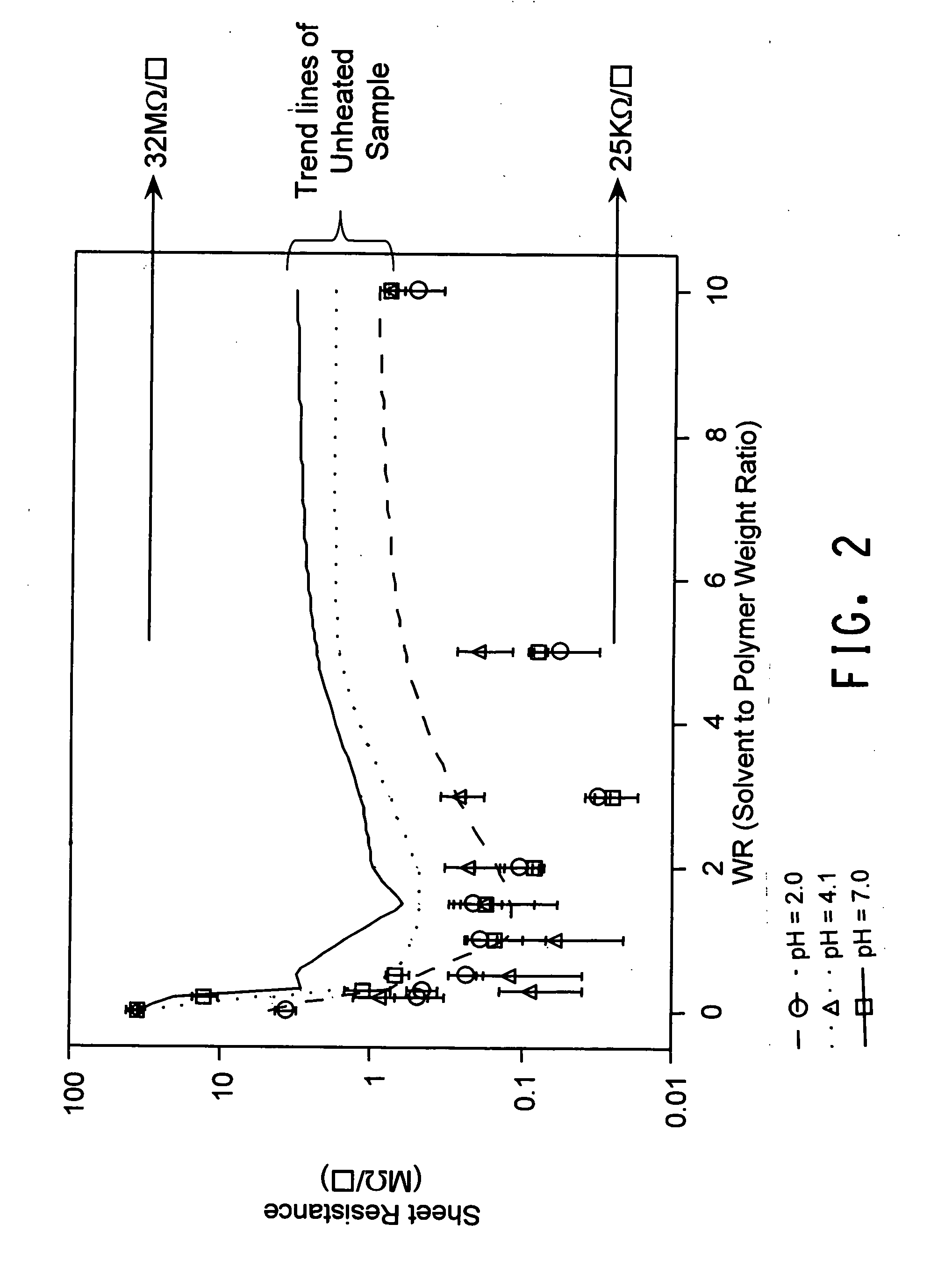

Water dispersible polydioxythiophenes with polymeric acid colloids and a water-miscible organic liquid

ActiveUS20050208328A1Material nanotechnologyHybrid capacitor electrolytesWater dispersibleOrganic liquids

Aqueous dispersion compositions of polydioxythiophene, polymeric acid colloids, and water-miscible organic liquid and methods of making such compositions. The compositions are useful in organic electronic devices.

Owner:LG CHEM LTD

Capture and Release of Mixed Acid Gasses With Binding Organic Liquids

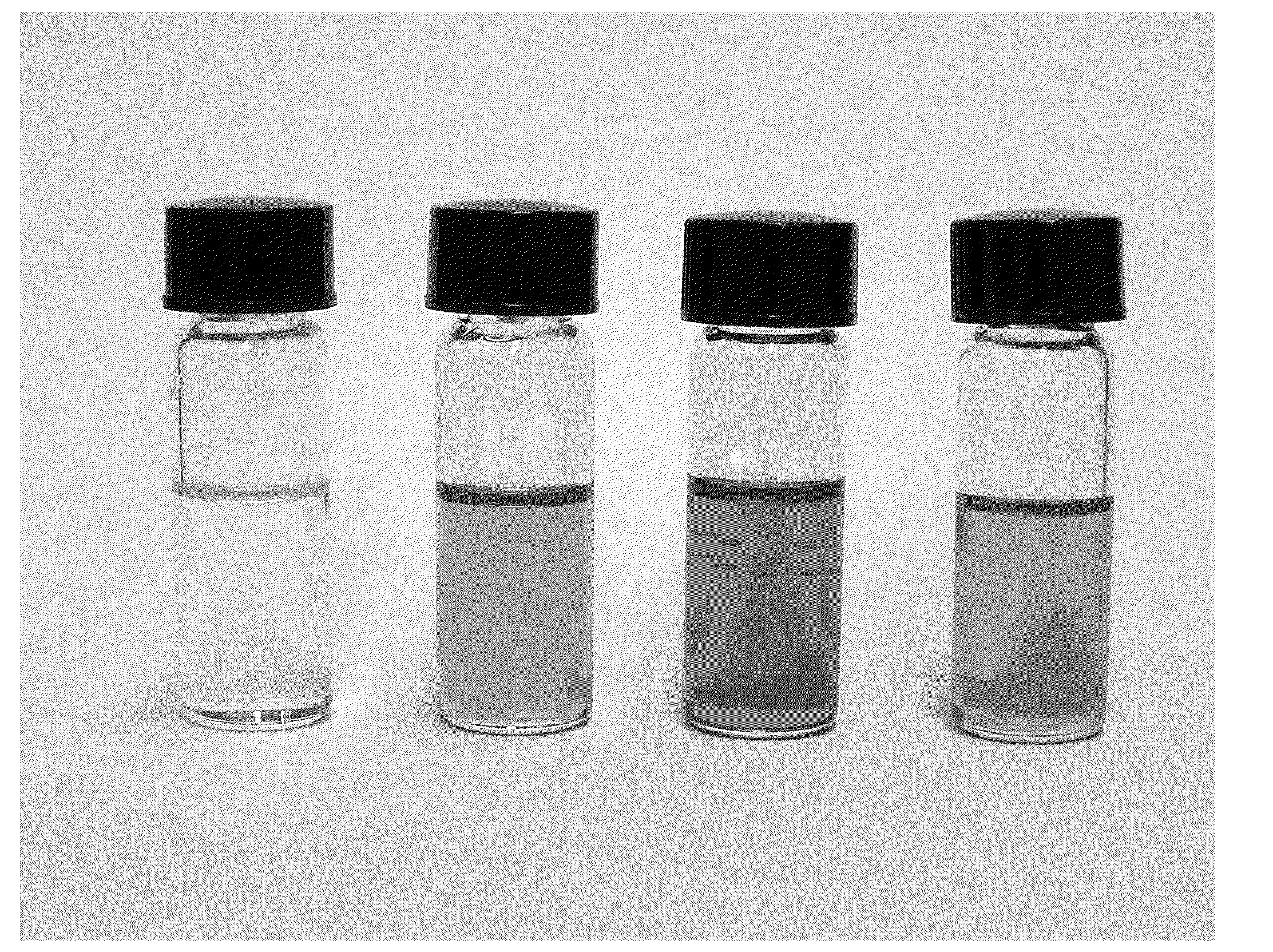

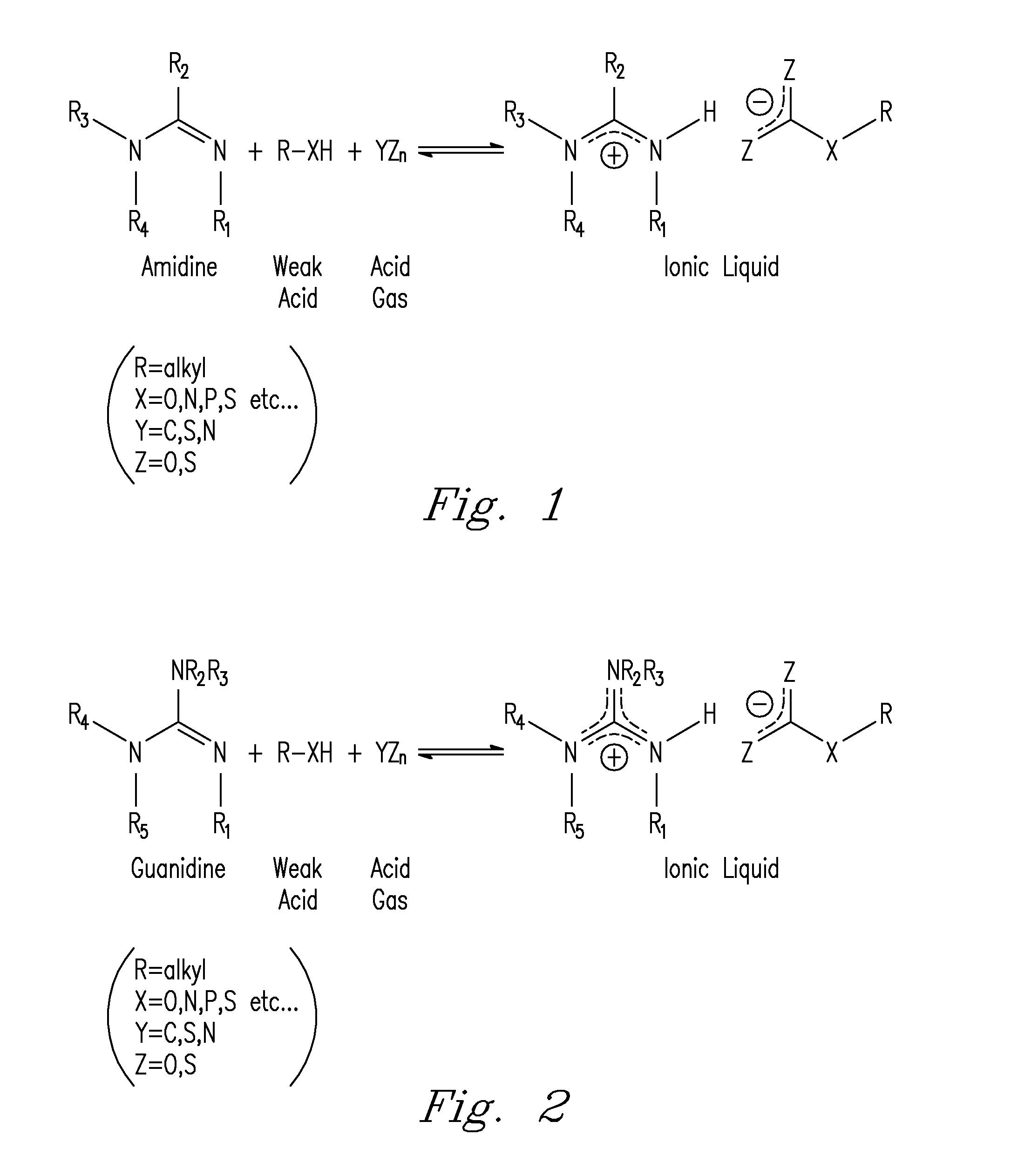

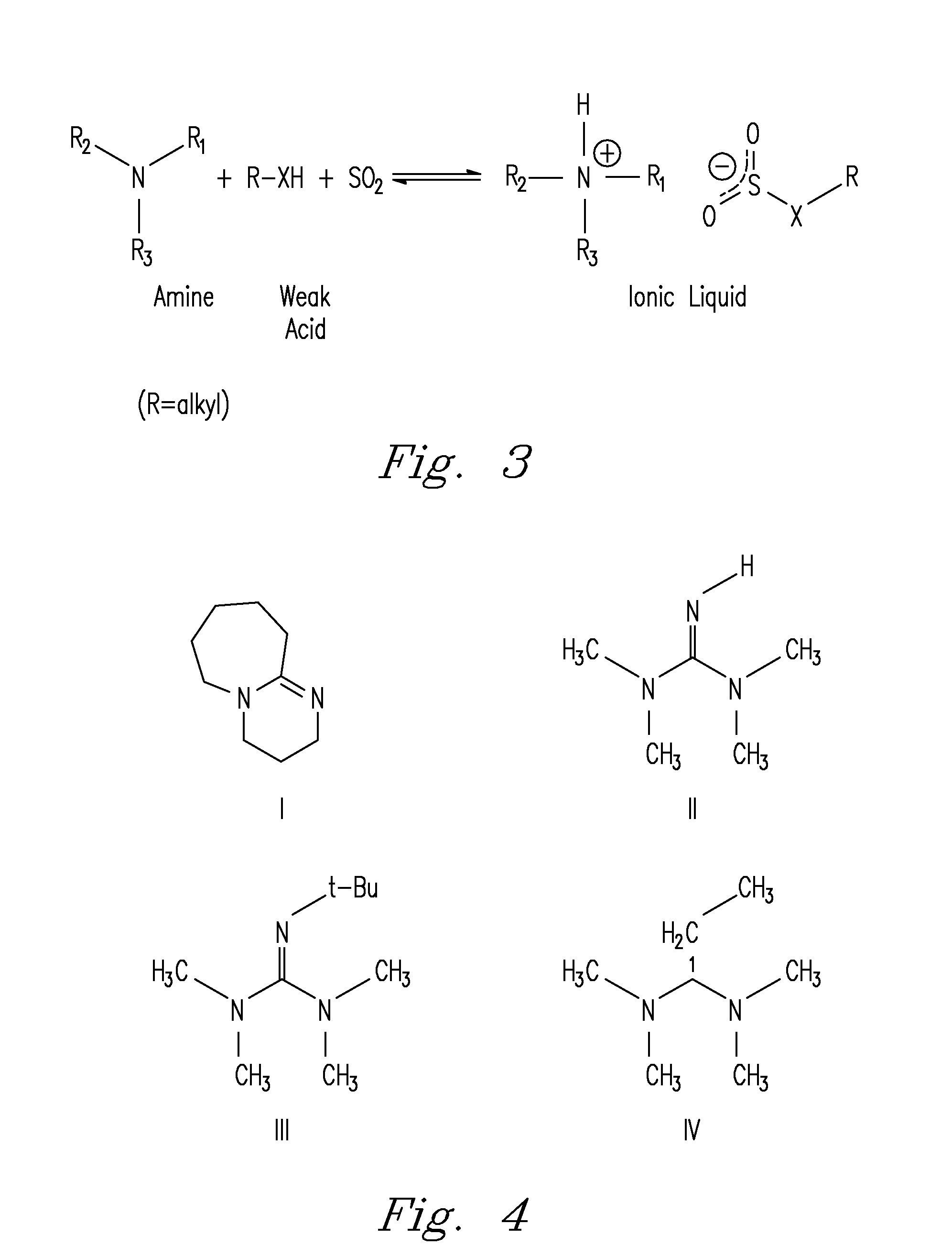

ActiveUS20090136402A1Reduced thermodynamic stabilityLess energy inputCombination devicesGas treatmentChemical reactionIonic liquid

Reversible acid-gas binding organic liquid systems that permit separation and capture of one or more of several acid gases from a mixed gas stream, transport of the liquid, release of the acid gases from the ionic liquid and reuse of the liquid to bind more acid gas with significant energy savings compared to current aqueous systems. These systems utilize acid gas capture compounds made up of strong bases and weak acids that form salts when reacted with a selected acid gas, and which release these gases when a preselected triggering event occurs. The various new materials that make up this system can also be included in various other applications such as chemical sensors, chemical reactants, scrubbers, and separators that allow for the specific and separate removal of desired materials from a gas stream such as flue gas.

Owner:BATTELLE MEMORIAL INST

Intercalates and exfoliates formed with long chain (C6+) or aromatic matrix polymer-compatible monomeric, oligomeric or polymeric intercalant compounds and composite materials containing same

InactiveUS6124365AEfficient electrostatic completingEasy to separateOrganic chemistryOther chemical processesOrganic liquidsPlatelet

Intercalates formed by contacting a layered material, e.g., a phyllosilicate, with an intercalant surface modifier selected from the group consisting of a compound having an alkyl radical containing at least 6 carbon atoms, a compound containing an aromatic ring, and mixtures thereof, said surface modifier including a matrix material-reactive functional group, to sorb or intercalate the intercalant surface modifier between adjacent platelets of the layered material. Sufficient intercalant surface modifier is sorbed between adjacent platelets to expand the adjacent platelets to at least about 10 ANGSTROM , up to about 100 ANGSTROM . The intercalated complex can be combined with an organic liquid into a viscous carrier material, for delivery of the carrier material, or for delivery of an active compound; or the intercalated complex can be combined with a matrix polymer to form a strong, filled polymer matrix.

Owner:AMCOL INTERNATIONAL CORPORATION

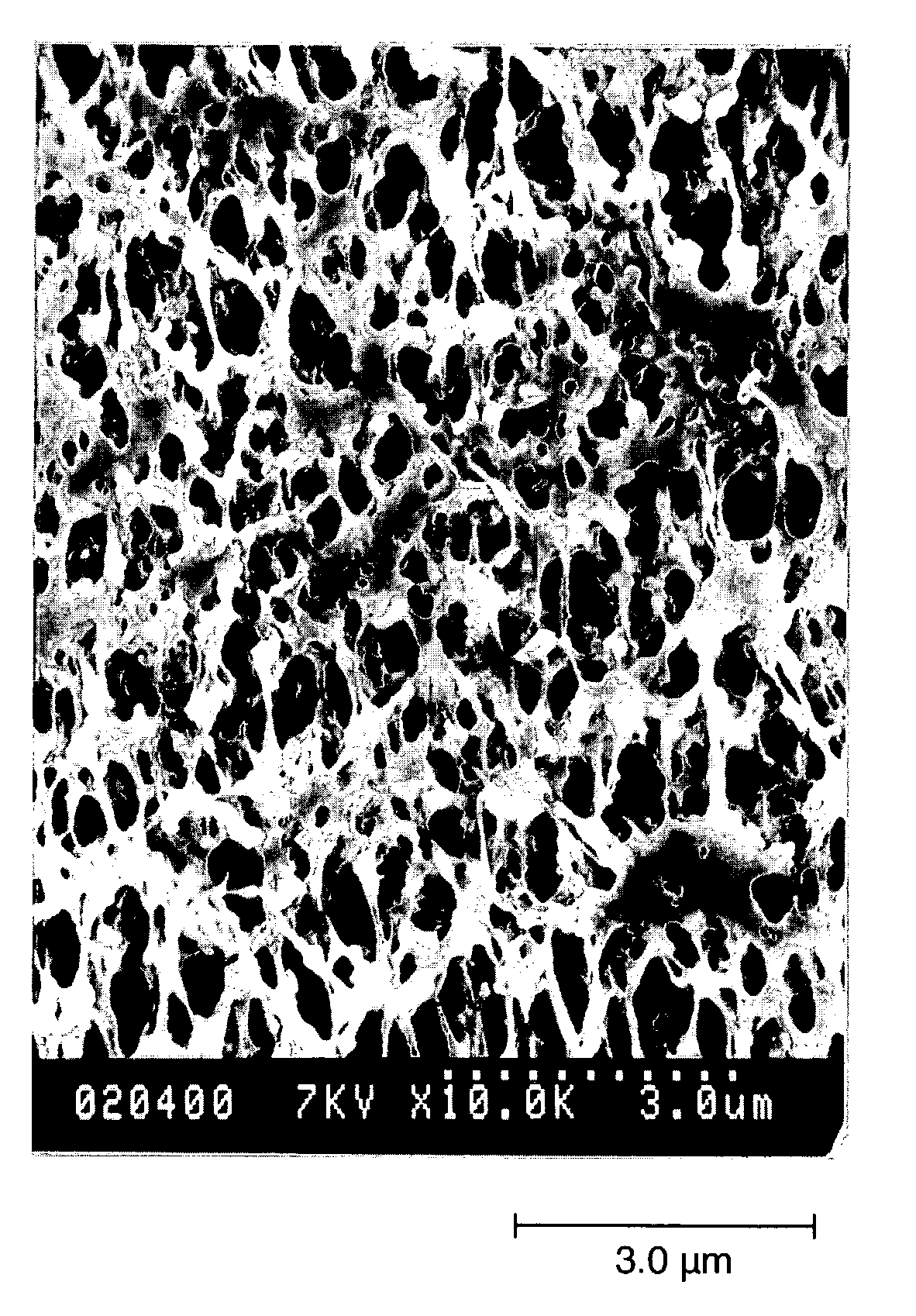

Method for producing hollow yarn film

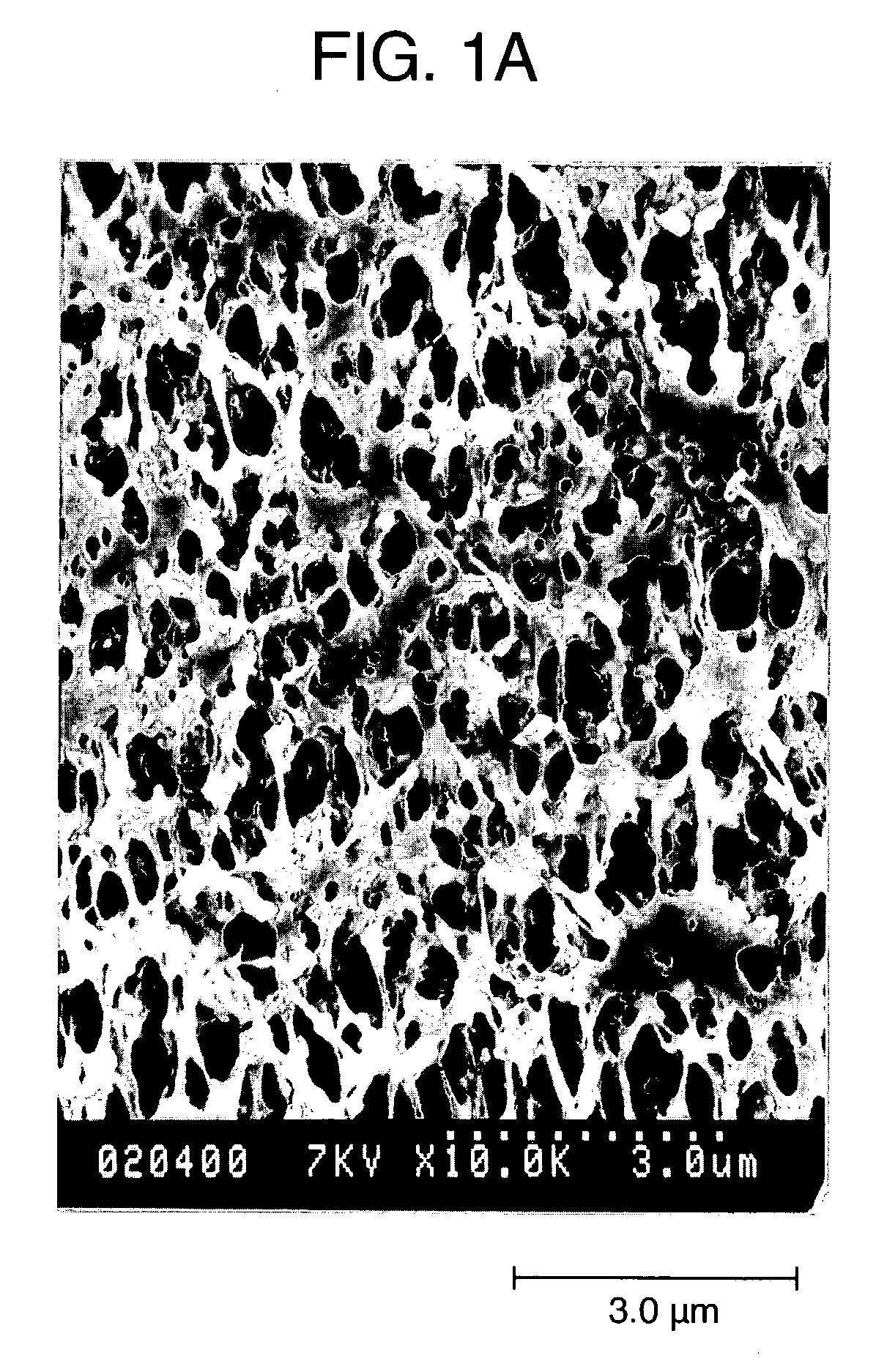

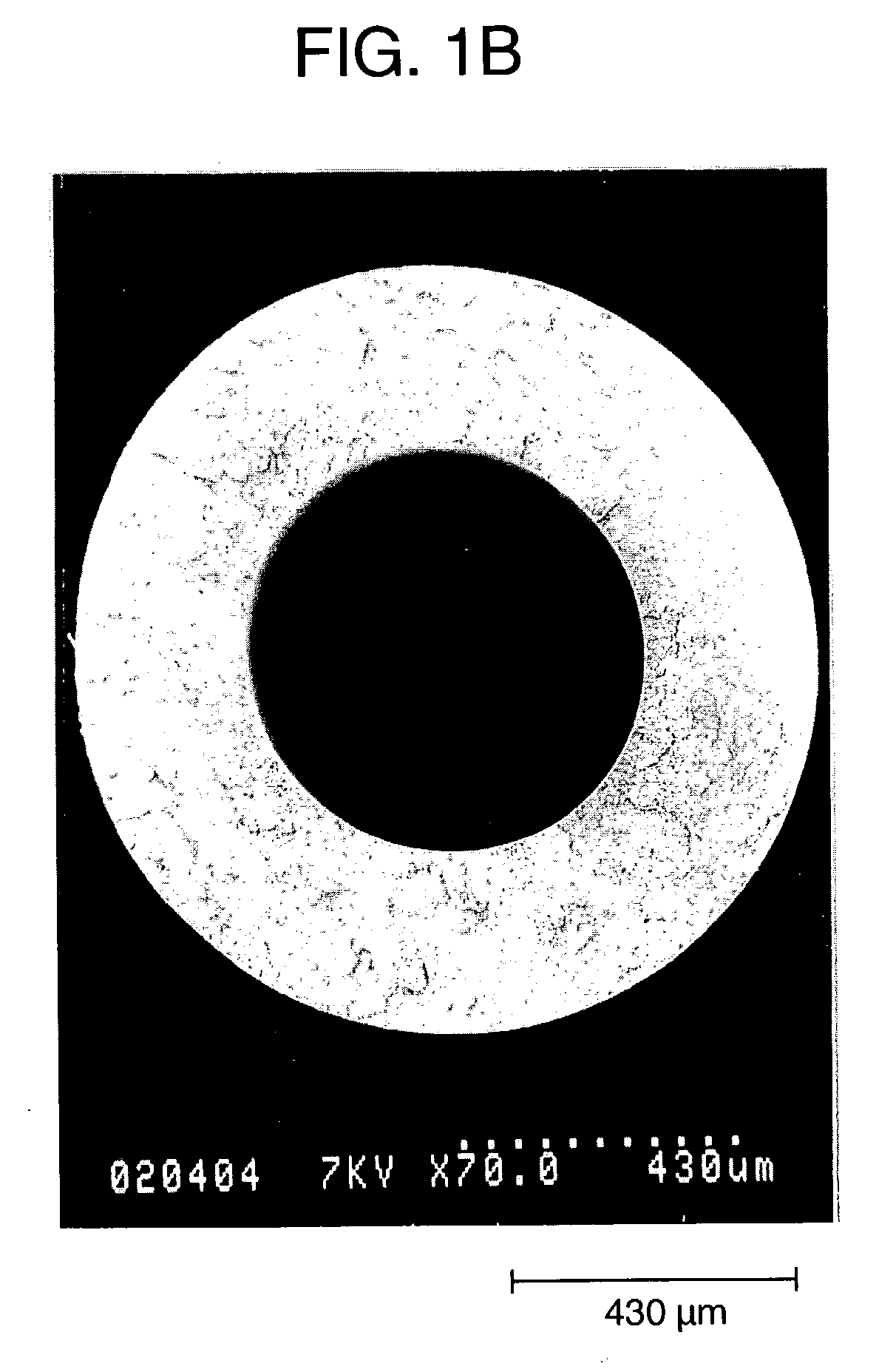

InactiveUS20030107150A1Effect of shaking is smallHigh in resistance against marringWrappers shrinkageFilament/thread formingYarnFiltration

In a method for producing hollow fiber membranes which comprises melt kneading a mixture comprising polyvinylidene fluoride and an organic liquid or a mixture comprising polyvinylidene fluoride, an organic liquid and an inorganic fine powder, extruding the kneaded mixture to form hollow fibers, and extracting the organic liquid or the organic liquid and the inorganic fine powder from the hollow fibers, which includes the steps of drawing the hollow fibers before or after termination of the extraction and then shrinking the fibers. According to this method, it is possible to stably produce hollow fiber membranes having dense pores and having a high water permeation performance, excellent endurance and stain resistance, and which are suitable for filtration uses such as removal of turbidity of water.

Owner:ASAHI KASEI KK

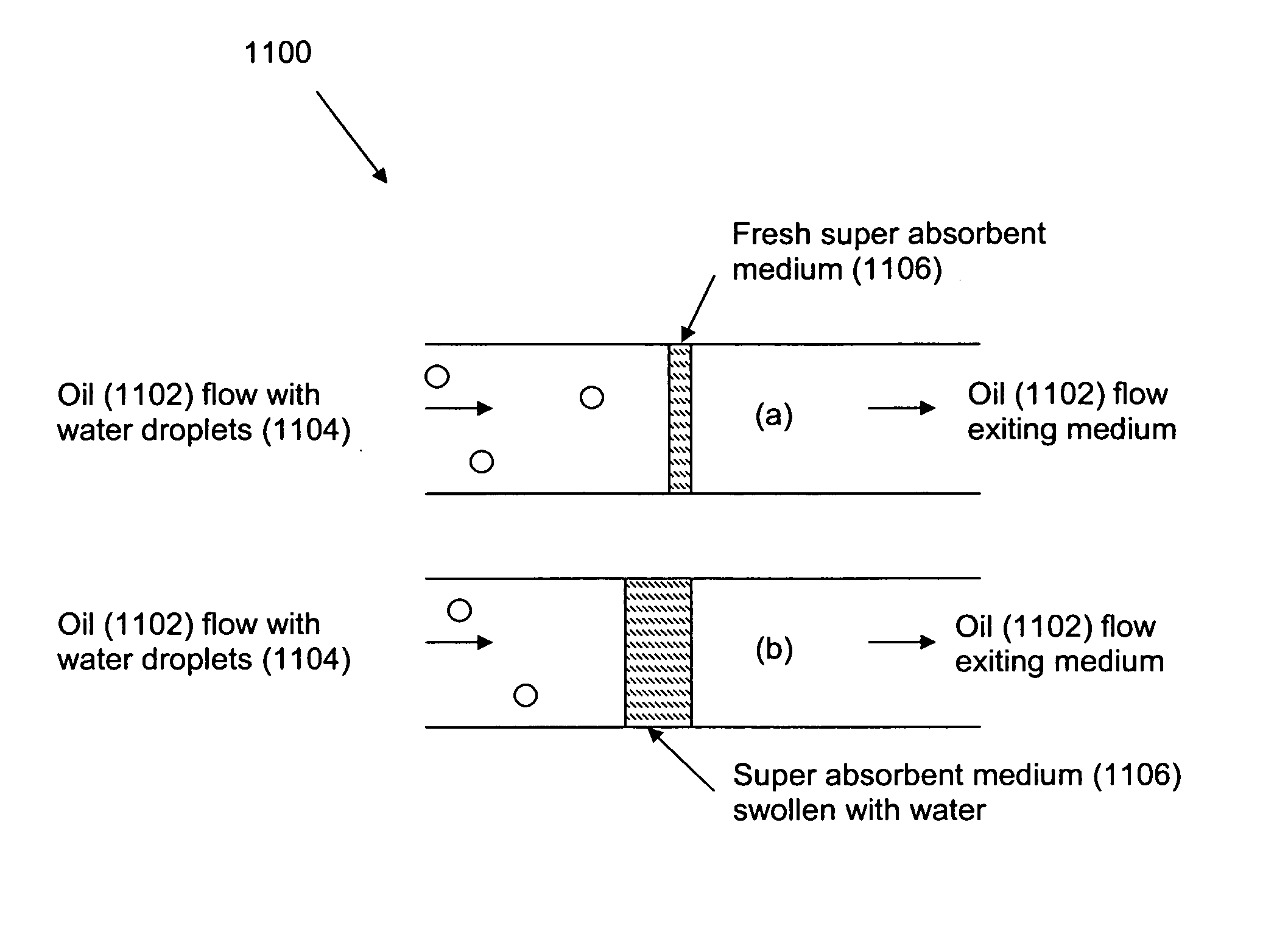

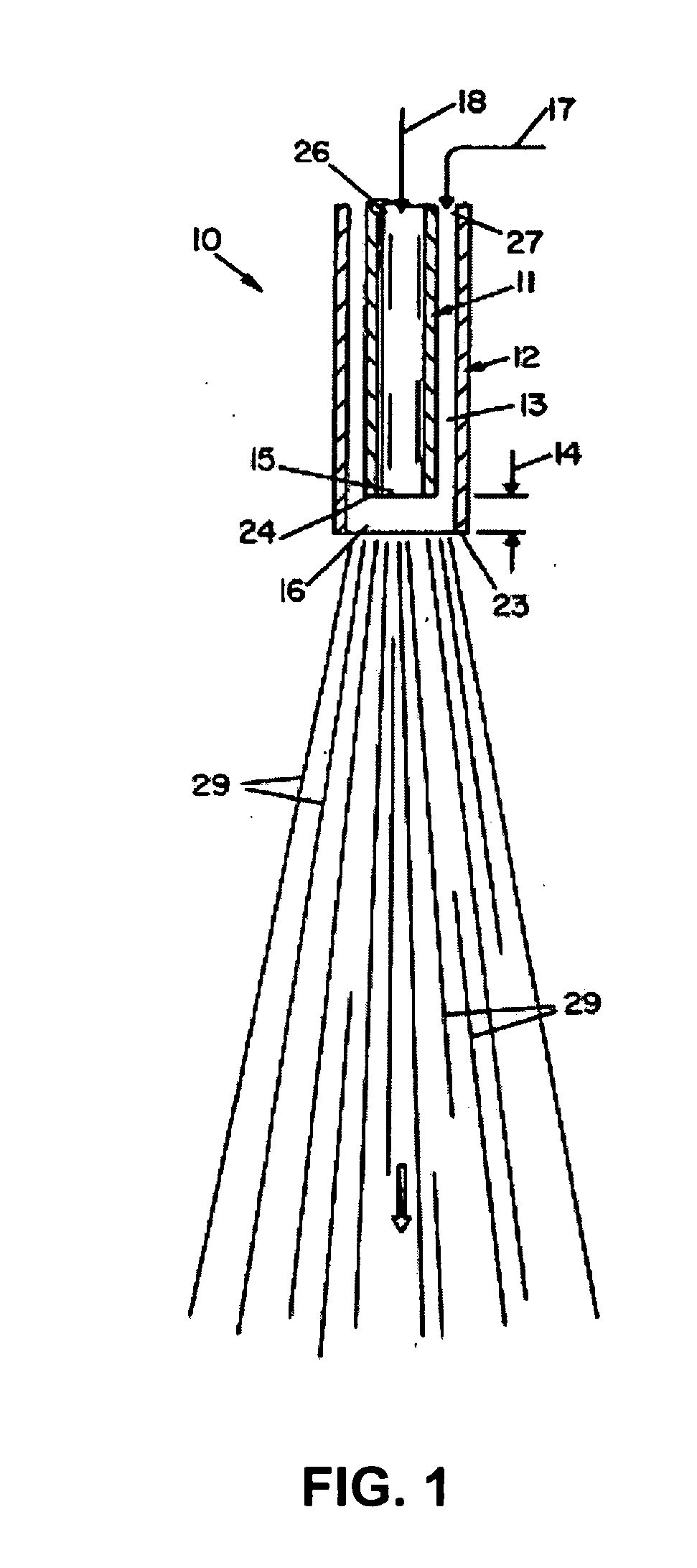

Method and apparatus for removal of water and/or water-based compounds from organic liquids or vice-versa

ActiveUS20070062855A1Efficient and complete removal of waterReduce leakageMaterial nanotechnologyWater/sewage treatment by ion-exchangeWater basedFiber

The present invention relates to methods and apparatus for removing water and / or water-based compounds from organic liquids / fluids. In one embodiment, the present invention relates to methods and apparatus that utilize fibrous media that contains, is impregnated, or is formed from at least one super absorbent compound, where the fibrous media is formed from nanofibers.

Owner:THE UNIVERSITY OF AKRON

Water dispersible polydioxythiophenes with polymeric acid colloids and a water-miscible organic liquid

ActiveUS7338620B2Material nanotechnologyHybrid capacitor electrolytesWater dispersibleOrganic liquids

Aqueous dispersion compositions of polydioxythiophene, polymeric acid colloids, and water-miscible organic liquid and methods of making such compositions. The compositions are useful in organic electronic devices.

Owner:LG CHEM LTD

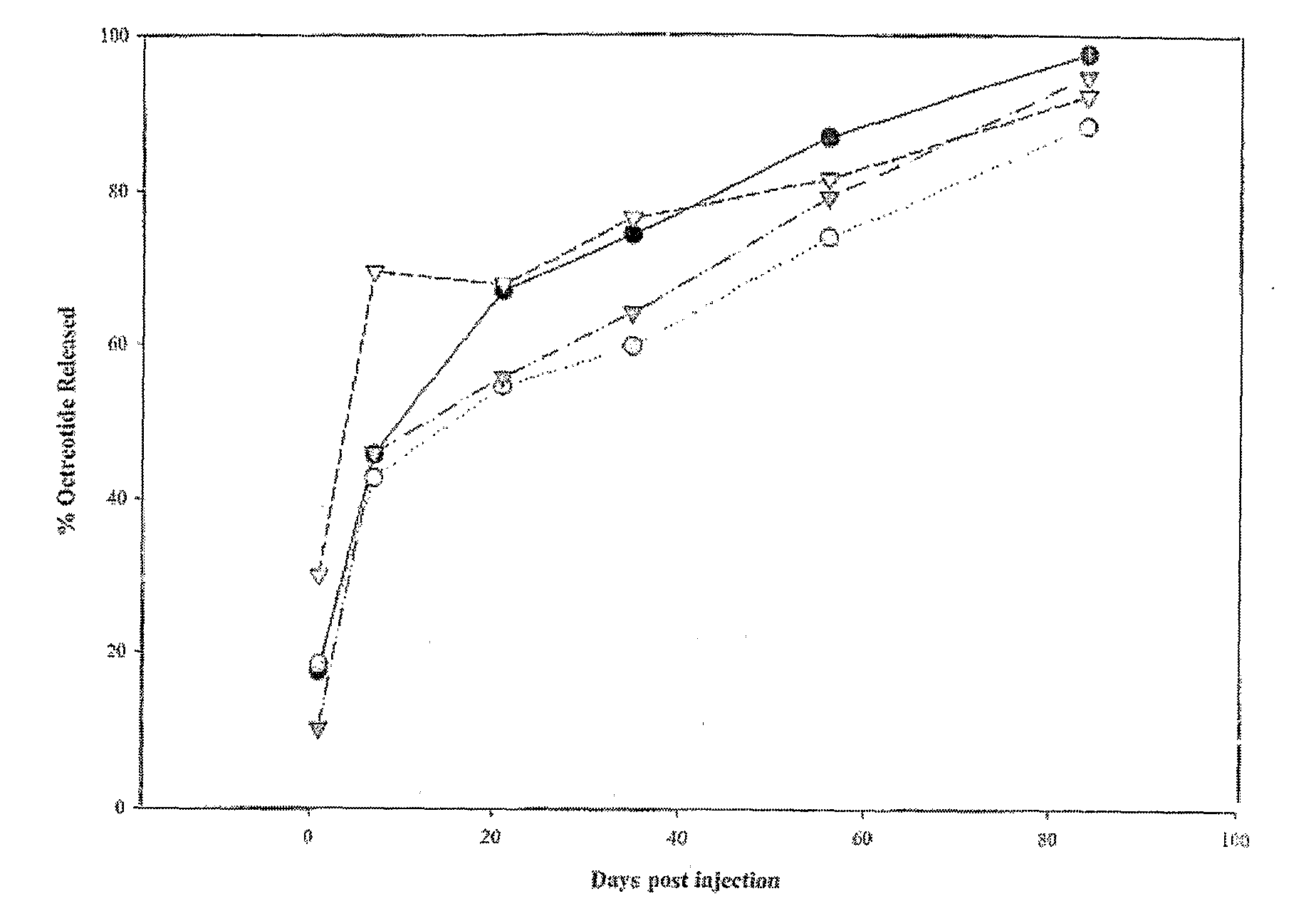

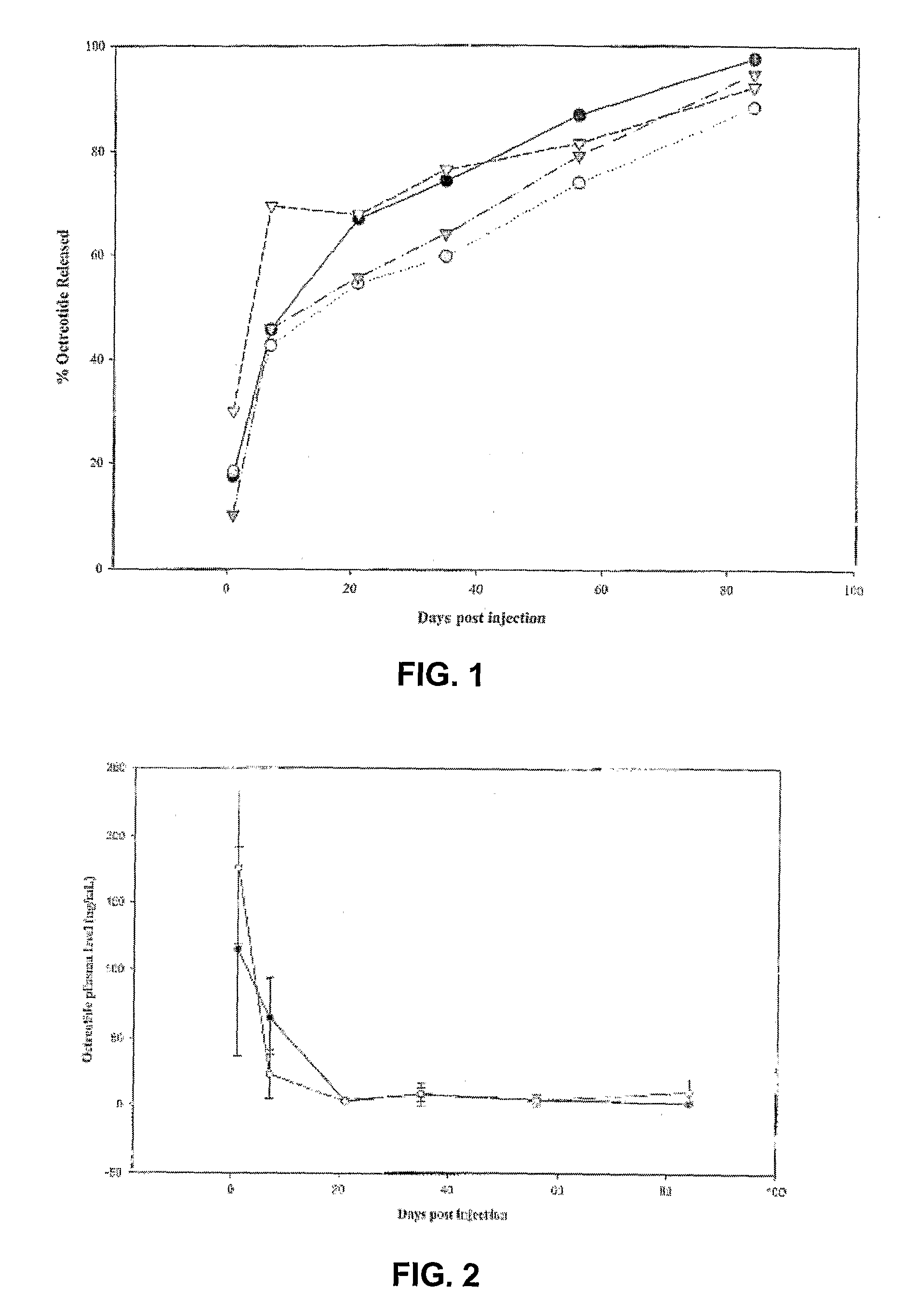

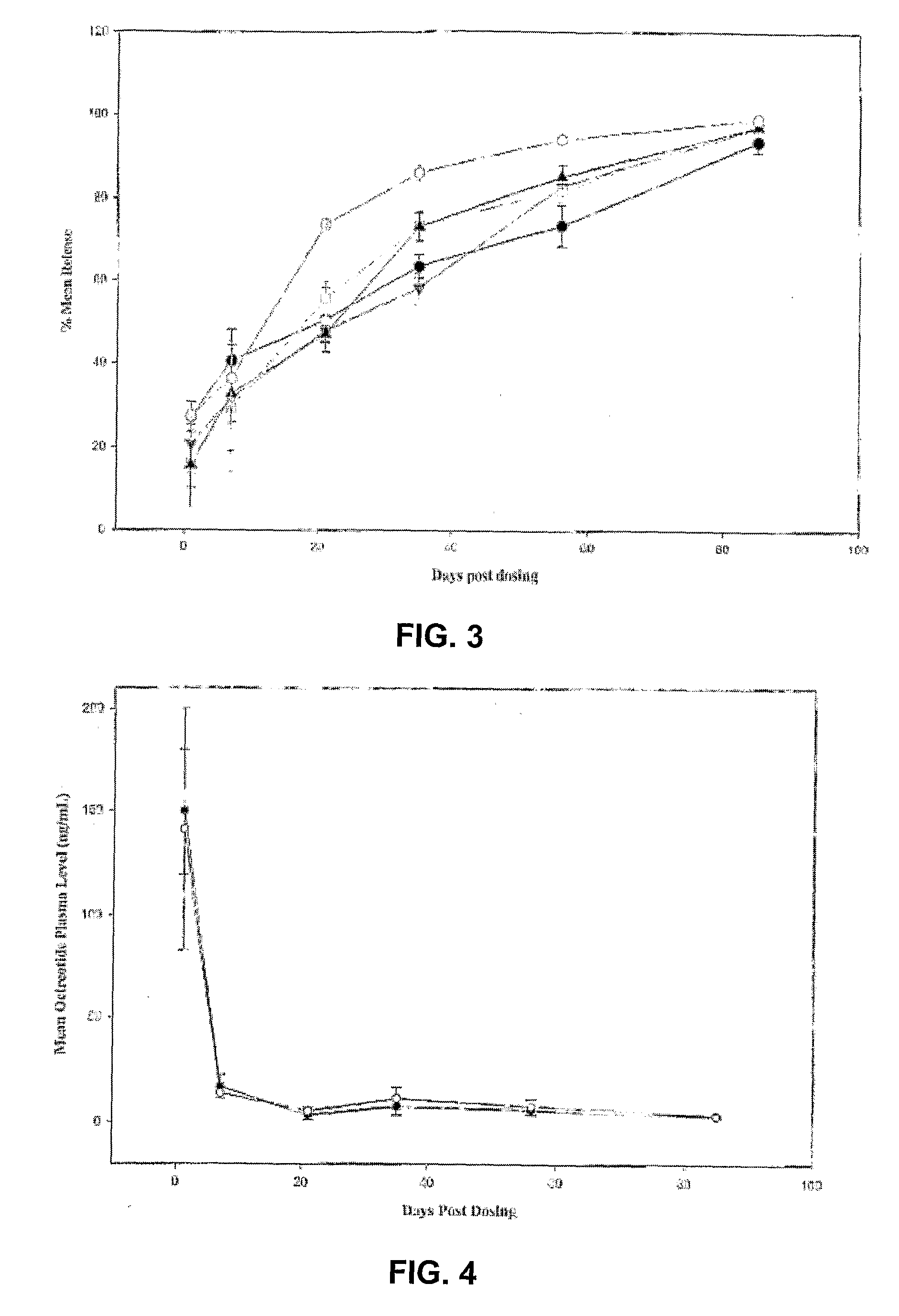

Sustained Delivery Formulations of Octreotide Compounds

InactiveUS20090092650A1Improve bioavailabilityLeast riskSenses disorderPeptide/protein ingredientsMedicineOrganic liquids

The present invention relates to an octreotide sustained release delivery system for treatment of diseases relating to somatotropin and / or somatostatin. The sustained release delivery system of the invention includes a flowable composition containing an octreotide compound, and an implant containing the octreotide compound. The flowable composition may be injected into tissue whereupon it coagulates to become the solid or gel, monolithic implant. The flowable composition includes a biodegradable, thermoplastic polymer, an organic liquid and an octreotide compound.

Owner:QLT USA INC

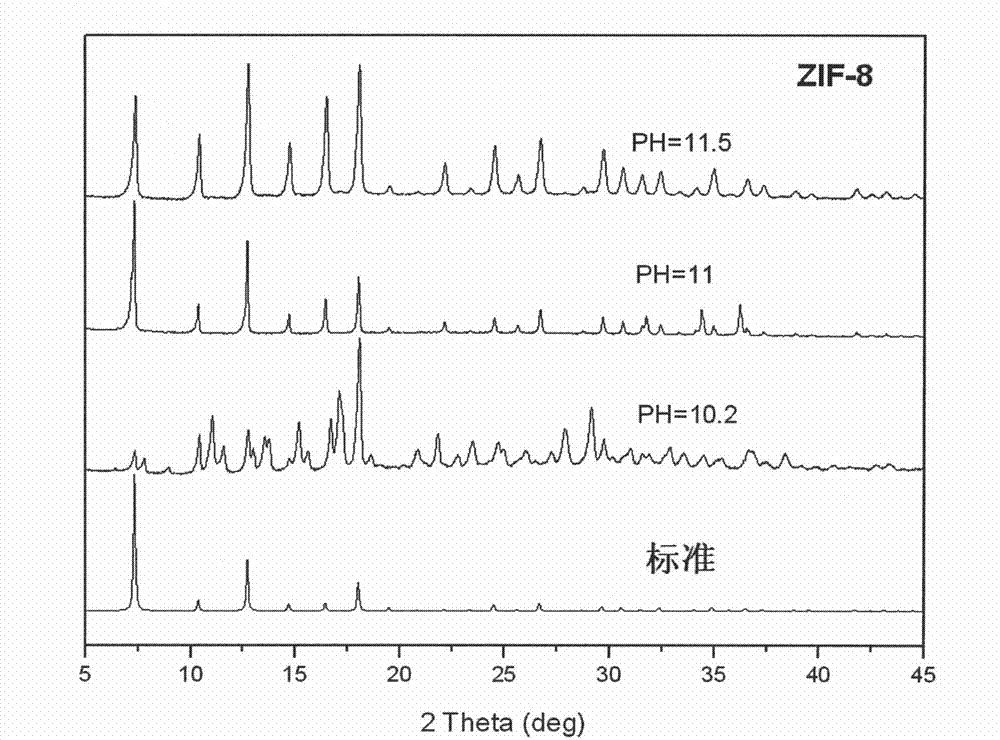

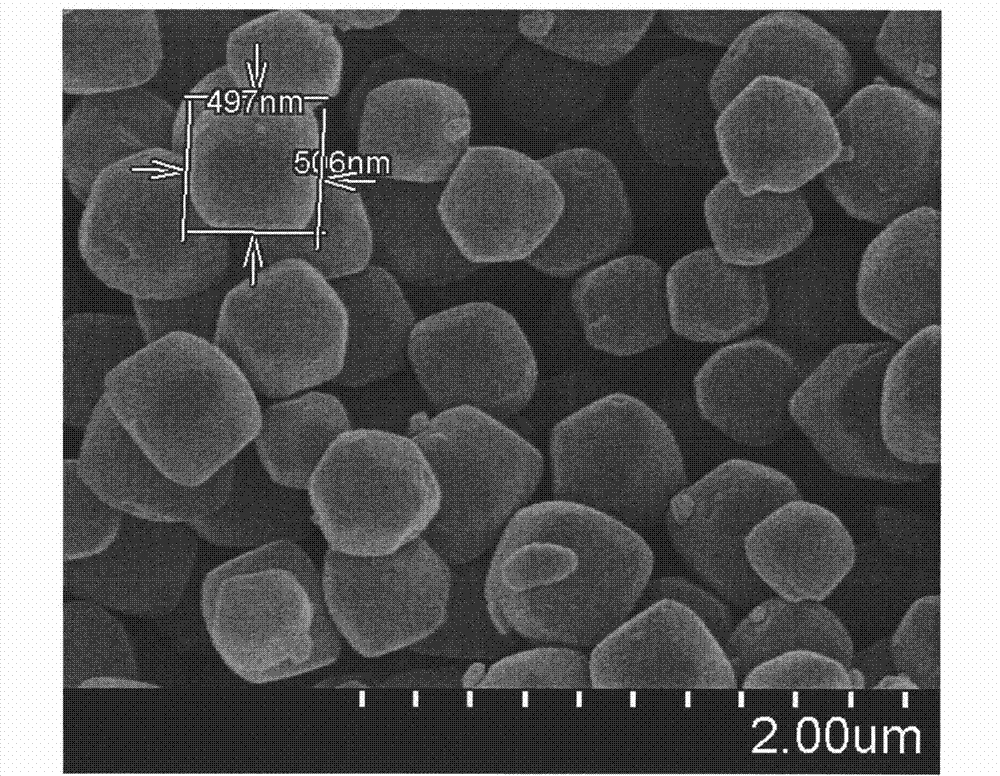

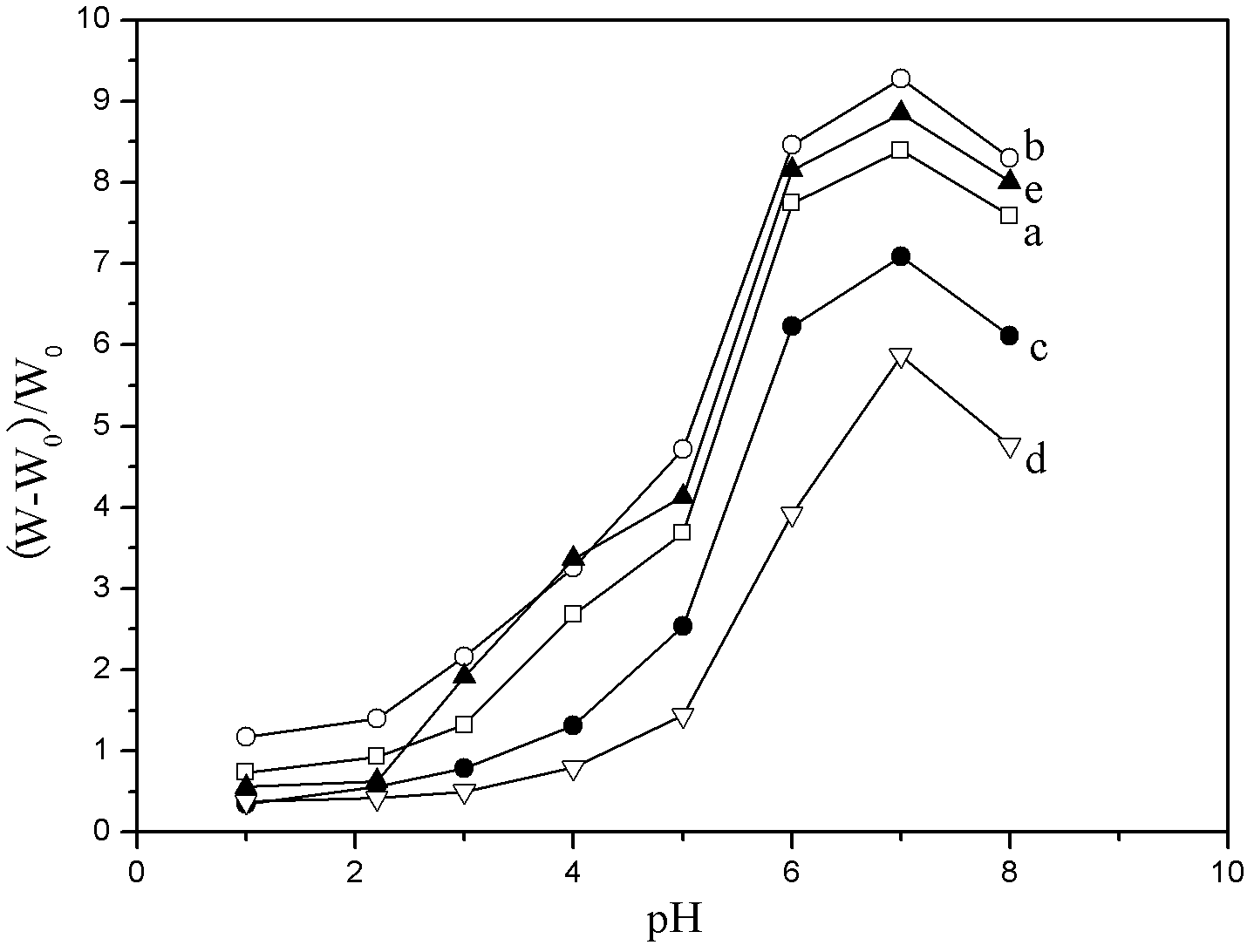

Preparation method of nanometer-to-micrometer scale zeolitic imidazolate frameworks (ZIFs)

ActiveCN102731538AGood lookingPromotes deprotonationCobalt organic compoundsZinc organic compoundsOrganic fluidSolvent

The invention which belongs to the technical field of new materials relates to a synthetic method of ZIFs, and concretely discloses a method for synthesizing nanometer / micrometer scale ZIFs based on imidazole and its derivatives at room temperature in a concise, efficient and green manner. The method comprises the following steps: dissolving a single imidazole ligand or a mixture of two imidazole ligands in water or an organic liquid to form a solution, adding an alkaline substance to adjust the pH value of the solution, adding a metal salt to form a reaction system, and reacting to obtain the nanometer or micrometer scale ZIFs. The method which allows routine reactants to be utilized and the alkaline substance to be added to adjust the pH value of the system has the advantages of ligand application amount reduction, controllable product size, and high purity of the nanometer / micrometer scale ZIFs. The synthetic method has the characteristics of cheap and easily available raw materials and solvent, and no pollution, and has important meanings to the production and the application of the ZIFs.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

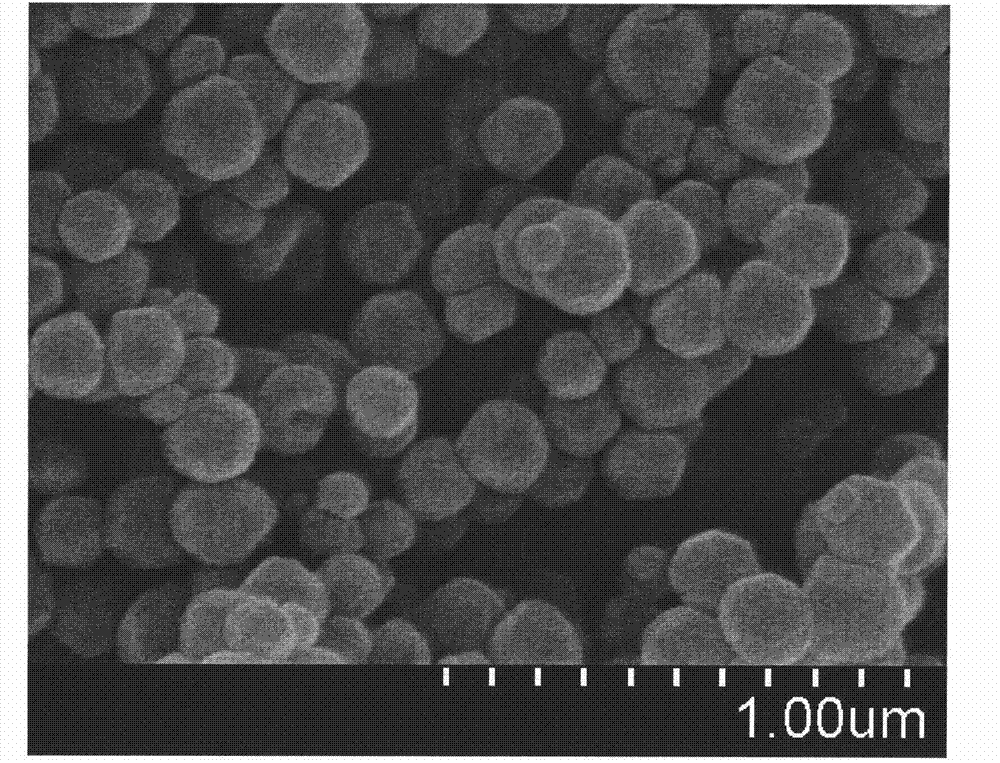

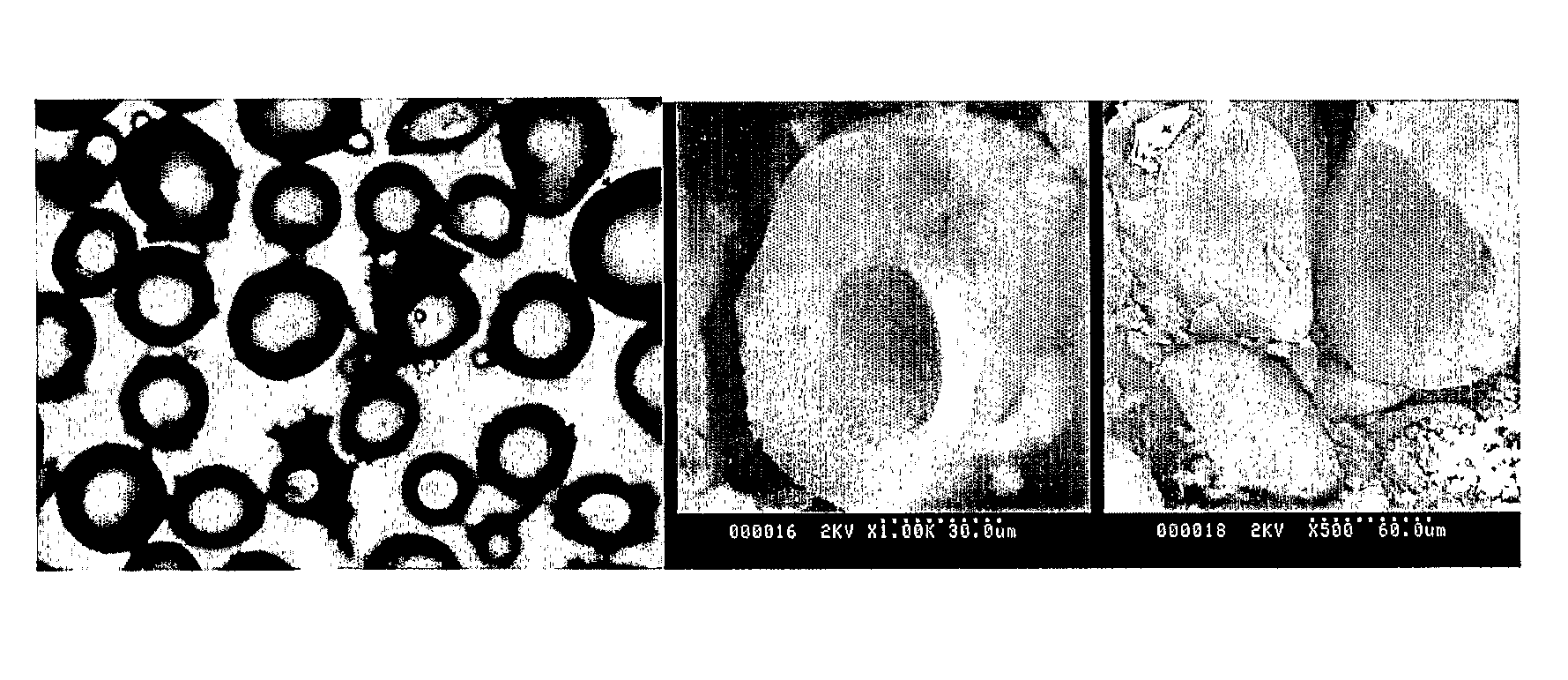

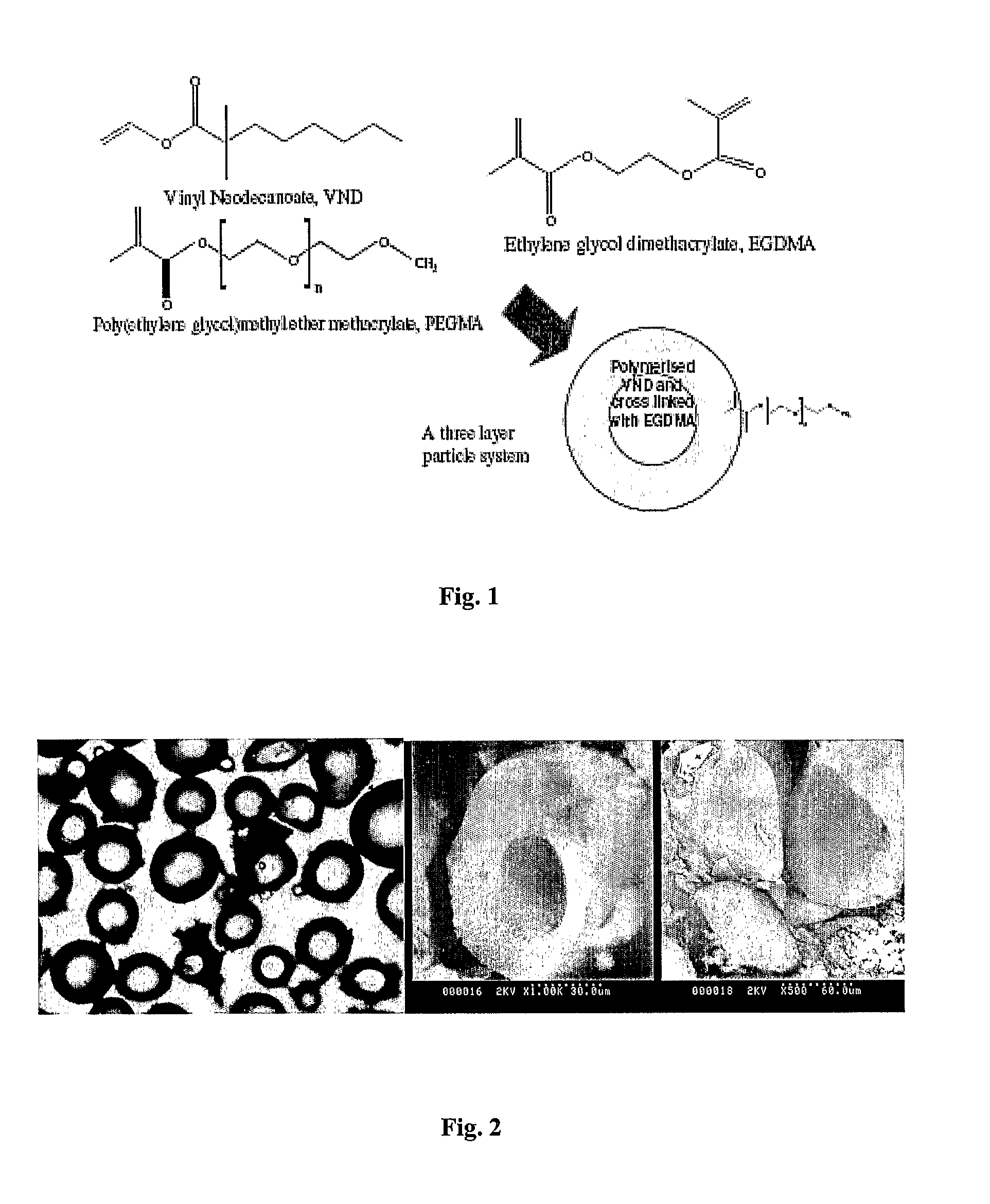

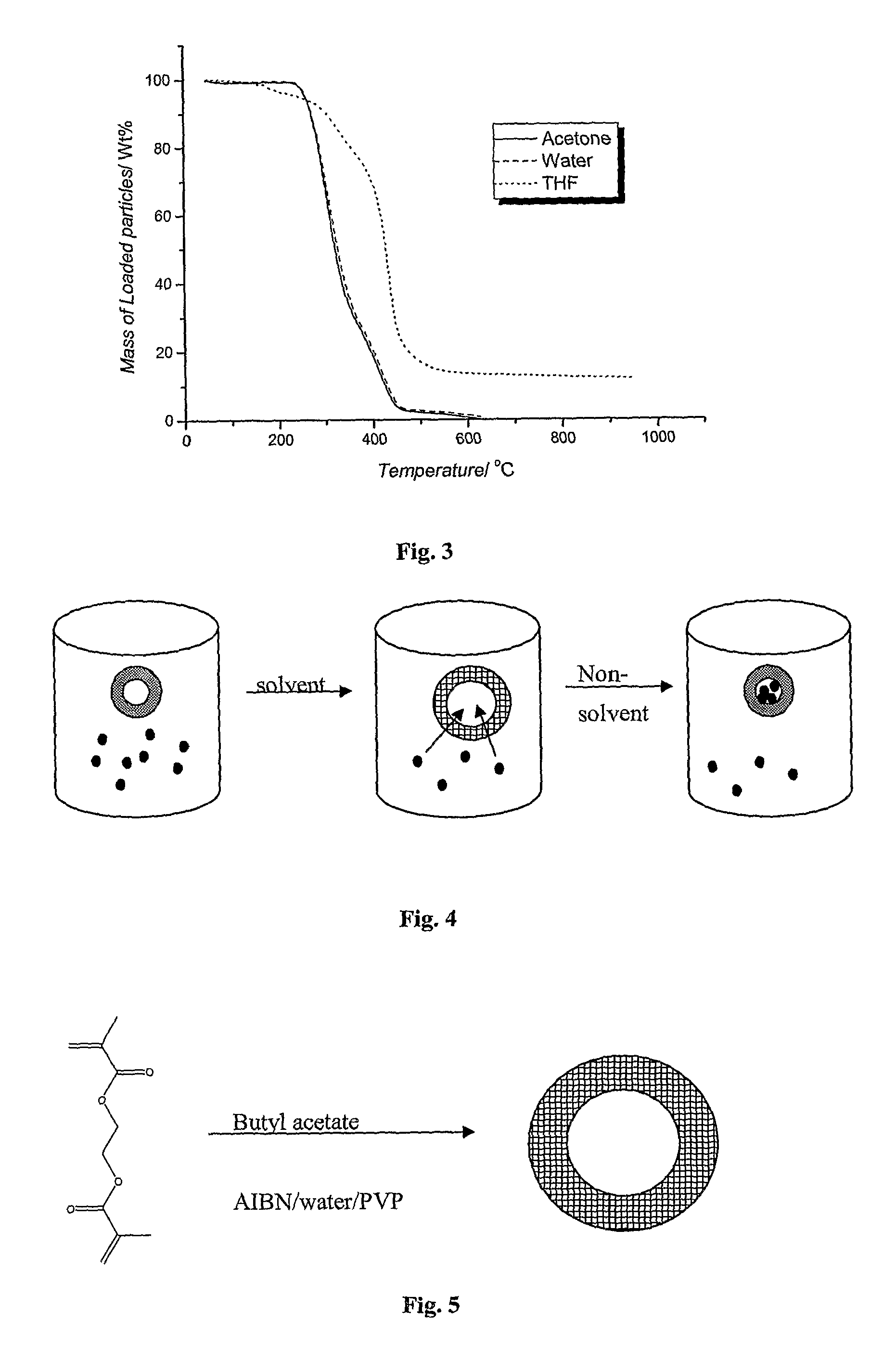

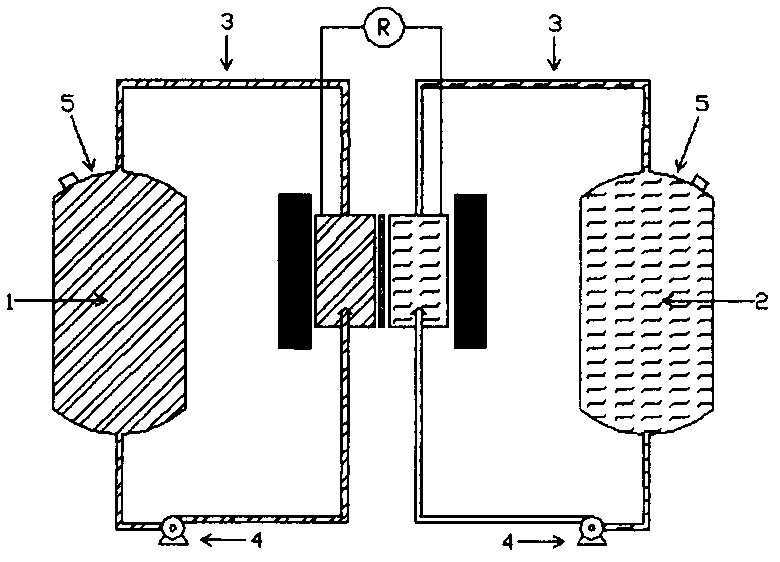

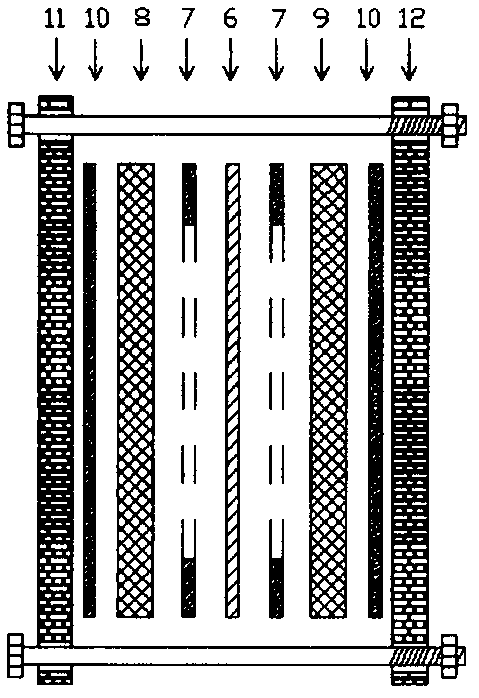

Hollow microparticles

InactiveUS20100104647A1Overcome disadvantagesPrevent and inhibit coagulationPowder deliveryOrganic active ingredientsOrganic fluidMicroparticle

The invention provides a process for making hollow microparticles. The process comprises providing a dispersion having a continuous aqueous phase and a discontinuous organic phase and polymerising a monomer in the dispersion to form hollow polymeric microparticles. The continuous aqueous phase of the dispersion comprises a stabiliser and the discontinuous organic phase of the dispersion comprises the monomer and an organic liquid. The monomer has two or more polymerisable groups per molecule. Prior to the step of polymerising the monomer, the discontinuous organic phase does not contain a polymer.

Owner:NEWSOUTH INNOVATIONS PTY LTD

Preparation method of anti-creeping and anti-corrosive titanium or titanium alloy material

ActiveCN102051615AMaintain superamphiphobic propertiesImprove corrosion resistanceSurface reaction electrolytic coatingChemical vapor deposition coatingTemperature resistanceTitanium alloy

The invention discloses a preparation method of an anti-creeping and anti-corrosive titanium or titanium alloy material with a super-hydrophobic and super-oleophobic surface. The preparation method comprises the following steps: microprocessing the surface of metal titanium or titanium alloy through laser etching to obtain a roughened surface with a micron structure; then, forming a layer of titanium dioxide nanotube array film on the surface of the micron structure through anodic oxidation treatment; and finally, modifying by perfluorosilane or perfluorosiloxane to obtain the super-hydrophobic and super-oleophobic surface. The microstructure on the surface of the prepared metal titanium and titanium alloy is very stable and has good high temperature resistance; and after the chemical modification, the surface has super-hydrophobic (acid, base and salt solution) and super-oleophobic property, namely the contact angles to most of organic liquids and aqueous solutions are more than 150 degrees.

Owner:甘肃中安瑞科科技有限公司

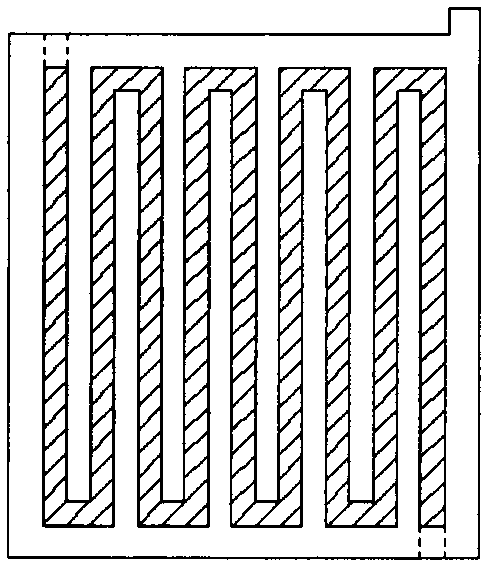

Lithium metal flow battery system and preparation method for same

InactiveCN102637890AIncrease capacityContinuous operationRegenerative fuel cellsMetallic lithiumPtru catalyst

A lithium metal flow battery system and a preparation method for the same belong to the field of electrochemical power sources. A cathode of a lithium metal flow battery is made of slurry formed by mixing lithium metal powder or lithium alloyed powder with organic liquid electrolyte containing lithium salt, an anode of the lithium metal flow battery is made of mixed slurry formed by the same organic liquid electrolyte and carbon catalyst or carbon-loaded catalyst, high-purity oxygen saturated in the slurry serves as oxidizer, a polymer composite membrane for separating the anode from the cathode is arranged in the middle, a lithium ion migrates between the two electrodes by means of the organic liquid electrolyte and the membrane, and an electron flows on an external lead connected with the anode and the cathode and a load to generate current. The novel lithium metal flow battery can be continuously used only by means of circulating feeding, and lithium metal can be regenerated by recovering discharge products in anode slurry and reused as cathode materials. The lithium metal flow battery system has the advantages of high energy density, continuous and stable operation, simple structure, long cycle life, high safety, high power density, and capability of realizing quick charge and discharge.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Working substance pair for absorptive thermal cycling system with heat source temperature ranging from 60 to 130 DEG C

ActiveCN102965082AImprove solubilityLow saturated vapor pressureHeat-exchange elementsAlkaneOrganic liquids

The invention provides a working substance pair for an absorptive thermal cycling system with heat source temperature ranging from 60 to 130 DEG C. The working substance pair comprises a working substance and an absorbing substance, wherein the working substance is one or the mixture of more than two substances selected from hydrofluoroalkane, fluoro olefin, fluoro-ether, non-substituted alkane or olefin; the absorbing substance is the mixed liquid consisting of 1 to 50% by mass of ionic liquid and 50 to 99% by mass of organic liquid; and the working substance and the absorbing substance are mixed at 20 to 80 DEG C. The working substance pair can overcome the shortcomings of the conventional working substance pair, and has the characteristics of nontoxicity, safety, and environment conservation.

Owner:WUHAN IND TECH RES INST OF GEO RESOURES ENVIRONMENT CO LTD

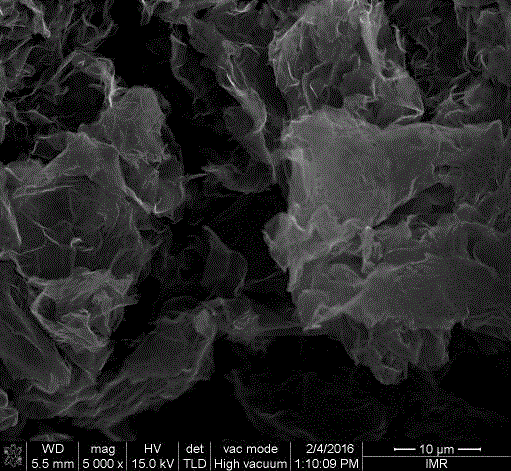

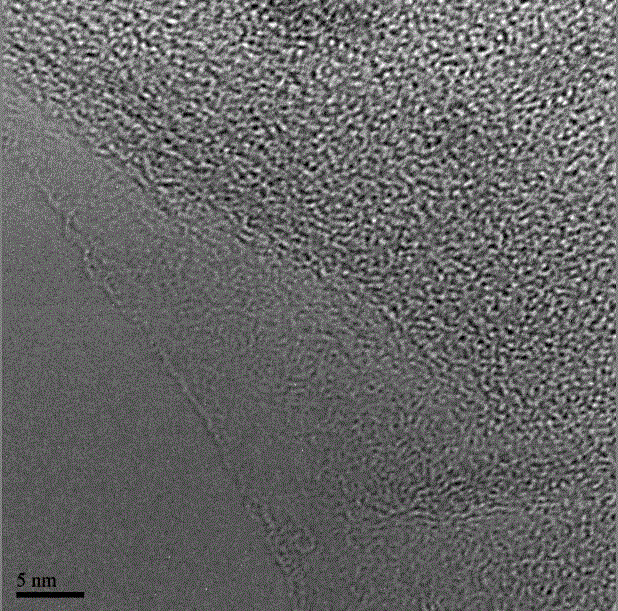

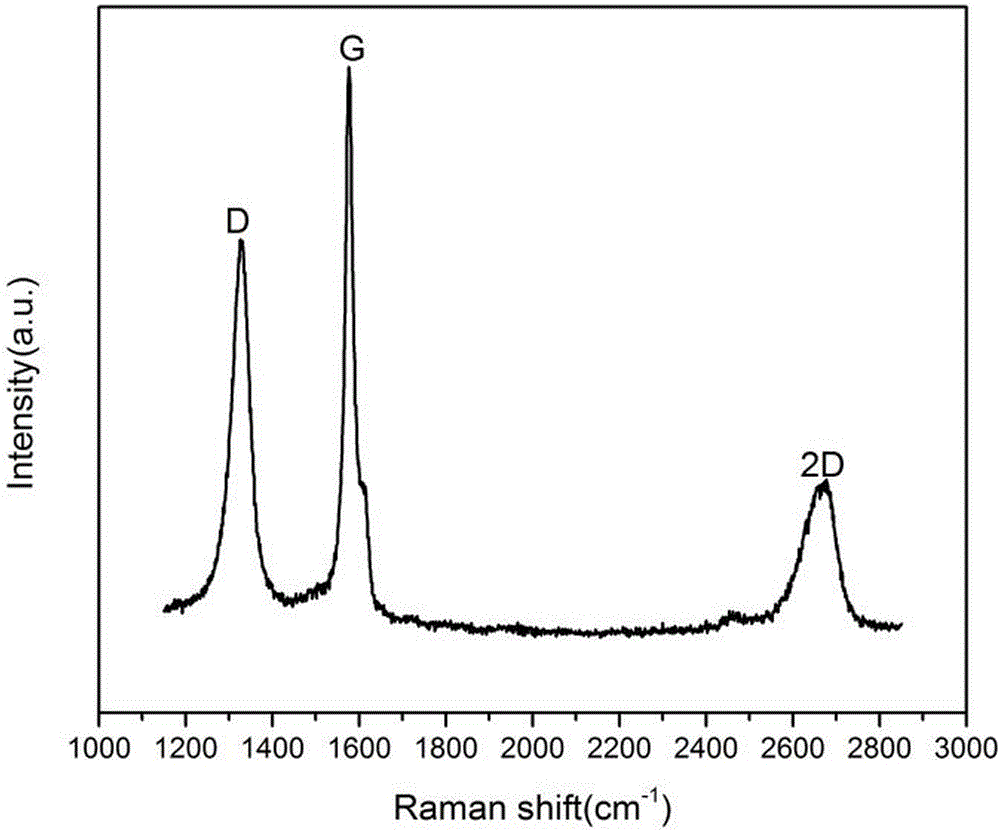

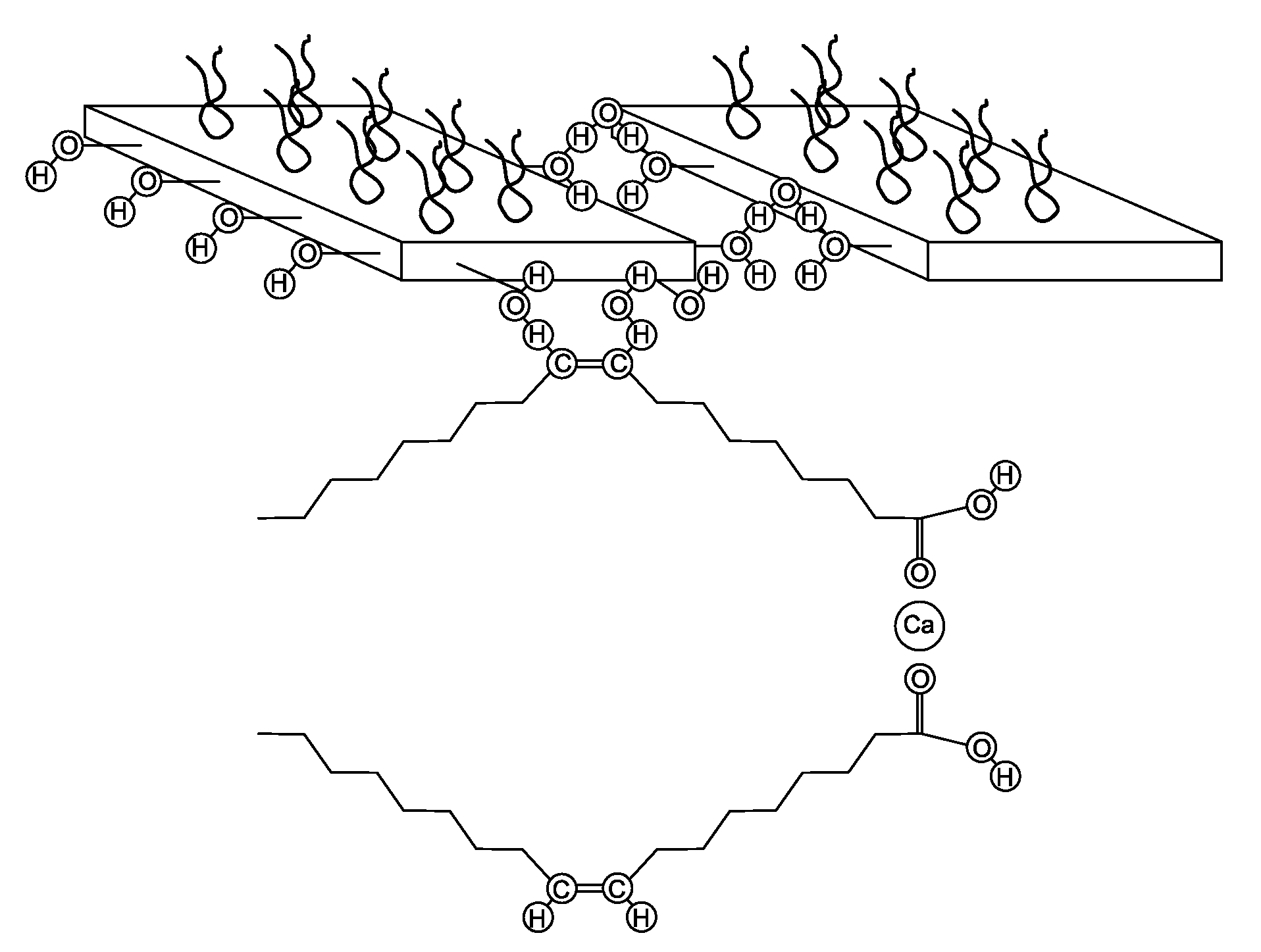

Method for electrochemically preparing graphene

The invention discloses a method for electrochemically preparing graphene. The method comprises the following steps: 1, intercalating and expanding graphite paper by adopting graphite paper as a positive electrode and an aqueous intercalator solution as an electrolyte to obtain expanded graphite; 2, filtering and washing the expanded graphite, and carrying out ultrasonic peeling treatment on the expanded graphite to obtain a flocculent graphene slurry; and 3, filtering the graphene slurry, and drying the graphene slurry through adopting a microwave vacuum drier to obtain fluffy graphene powder. The electrochemical method solves the problem of use of heavy metal-containing reagents, strong acids, strong oxidants and expensive organic liquids in the graphene preparation process in the prior art, and has the advantages of simple preparation technology, low energy consumption and low cost.

Owner:DEYANG CARBONENE TECH

Methods Of Preparing Hydrocarbon, Water And Organophilic Clay Emulsions And Compositions Thereof

InactiveUS20090260885A1Low viscosityPerformance maximizationTransportation and packagingMixingPolyesterFoundry

This invention relates to compositions and methods for improving the performance of organophilic organic-clay complexes, which are dispersible in organic liquids to form a gel therein. Depending on the composition of the gel, such gels may be useful as lubricating greases, oil-based muds, oil base packer fluids, paint-varnish-lacquer removers, paints, foundry molding sand binders, adhesives and sealants, inks, polyester laminating resins, polyester gel coats, cosmetics, detergents, and the like.

Owner:ENGINEERED DRILLING SOLUTIONS

Gas generating process for propulsion and hydrogen production

InactiveUS6849247B1Reduce the temperatureProducing energyLoomsHydrogen productionMetallic materialsSlurry

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

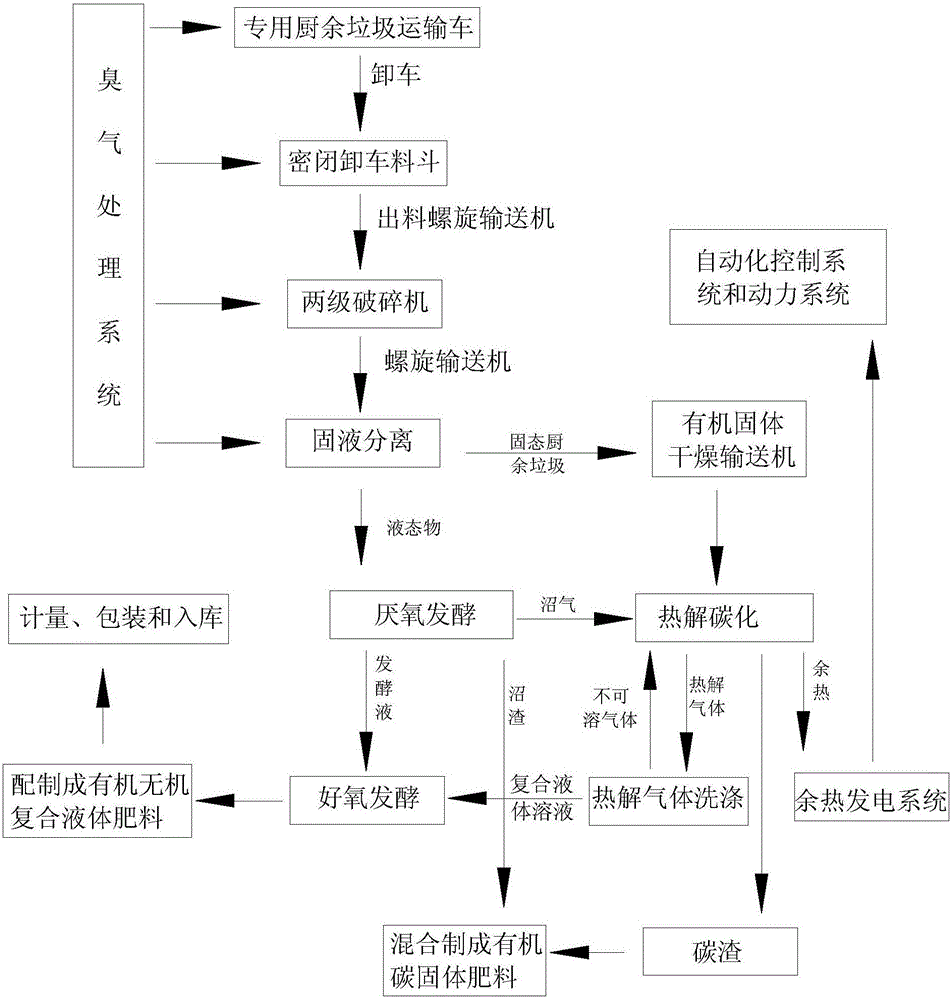

Method and device for preparing fertilizer from kitchen garbage

ActiveCN105060946AImprove efficiencySave spaceBio-organic fraction processingClimate change adaptationLitterOrganic liquids

The invention discloses a method and device for preparing fertilizer from kitchen garbage. The method comprises crushing kitchen garbage, carrying out solid-liquid separation, carrying out pyrolysis carbonization on the separated solid kitchen garbage to obtain pyrolysis gas and carbon residue, washing the pyrolysis gas, carrying out anaerobic fermentation on the separated liquid to obtain a broth, biogas residue and biogas, carrying out aerobic fermentation on the broth, then preparing organic-inorganic composite liquid fertilizer from the obtained liquid, mixing the biogas residue and the biogas residue obtained by the pyrolysis carbonization, adding composite microbe engineering bacteria into the mixture, and carrying out solid state fermentation to obtain the organic carbon solid fertilizer. The method and device respectively carry out resourceful treatment on the solid kitchen garbage and the organic liquid, the organic liquid is treated by a biotechnology so that the organic-inorganic composite liquid fertilizer is produced, and solid kitchen garbage is subjected to pyrolysis carbonization so that energy and biochar are produced.

Owner:GUANGZHOU YINGHAO ENVIRONMENTAL PROTECTION TECH CO LTD

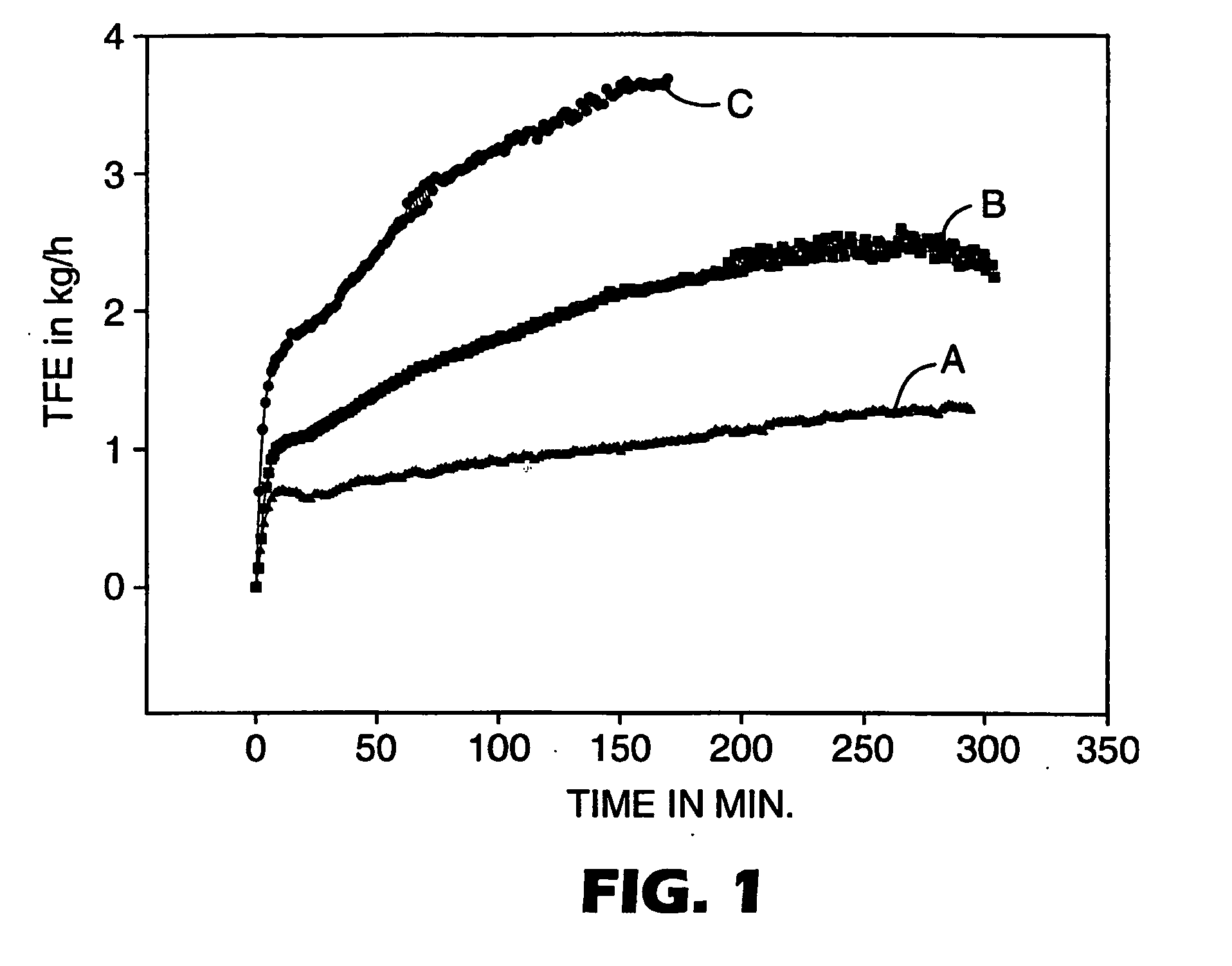

Aqueous emulsion polymerization process for producing fluoropolymers

InactiveUS20040072977A1Reduced coagulumThe polymerization process is simpleFibre treatmentPolymer scienceEmulsion polymerization

The present invention provides a method of making a fluoropolymer through emulsion polymerization of one or more fluorinated monomers in an aqueous phase in the presence of a fluorinated surfactant. At least part of the fluorinated surfactant is added to the aqueous phase as an aqueous mixture with at least one organic liquid that is not miscible with water and that is selected from halogenated and non-halogenated organic liquids, the mixture having droplets having an average droplet diameter of not more than 1000 nm and the mixture being added to the aqueous phase in such an amount that the total amount of the fluorinated surfactant is not more than 1% by weight based on the weight of the aqueous phase and the total amount of said organic liquid is not more than 1% by weight based on the weight of said aqueous phase. The invention allows for an improvement of the efficiency of an aqueous emulsion polymerization process. In particular, the polymerization time can be reduced and the polymer yield may be improved.

Owner:3M INNOVATIVE PROPERTIES CO

Overcoat compositions, oil-based ink compositions, and processes for ink-jet recording using overcoat and oil-based ink compositions

Overcoat compositions include film-forming resins and organic liquids. Overcoat compositions are included in ink sets that also include oil-based ink compositions. Methods for ink-jet printing use oil-based ink compositions and overcoat compositions.

Owner:XEROX CORP

In-situ crosslinked alginate hydrogels and preparation method thereof

InactiveCN102408496AGood biocompatibilityGood water solubilityAerosol deliveryOintment deliveryNitrogen gasOxygen

The invention relates to in-situ crosslinked alginate hydrogels with an active ingredient of disulfide bond disulfide bond alginate derivative. The preparation method thereof is as follows: the organic liquids of carbodiimide hydrochloride and N-hydroxysuccinimide eater are added into the alginate aqueous liquid of the alginate to activate the carboxyl of the alginate aqueous liquid; then the organic liquid of 4-aminothiolphenol is added under the conditions of keeping in dark place under 10 DEG C and nitrogen protection, so that the amino of the 4-aminothiolphenol and the carboxyl of the alginate aqueous liquid form an amido bond. The proportions of each matter adjusted and the pH value of muriatic acid is adjusted to 6.0, ethanol is deposited, frozen and dried to obtain sulfhydrylation alginates of different sulfydryl contents. The alginate aqueous liquid of the alginate oxidizes the sulfydryl thorugh the oxygen in the liquid under a room temperature to crosslink and form a disulfide bond, thus obtaining the crosslinked alginate hydrogels. The hydrogels prepared through the method has pH sensitivity and reduction responsiveness, and has potential application values in drug delivery field.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com