Preparation method of nanometer-to-micrometer scale zeolitic imidazolate frameworks (ZIFs)

A technology of zeolite imidazole framework and structural material, which is applied in the directions of cobalt organic compounds, zinc organic compounds, etc., can solve the problems of restricting the large-scale industrial production of zeolite imidazole framework materials, difficult to control the crystal size, harsh reaction conditions, etc., and achieve controllable size. Wide range, reduced ligand dosage, good morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

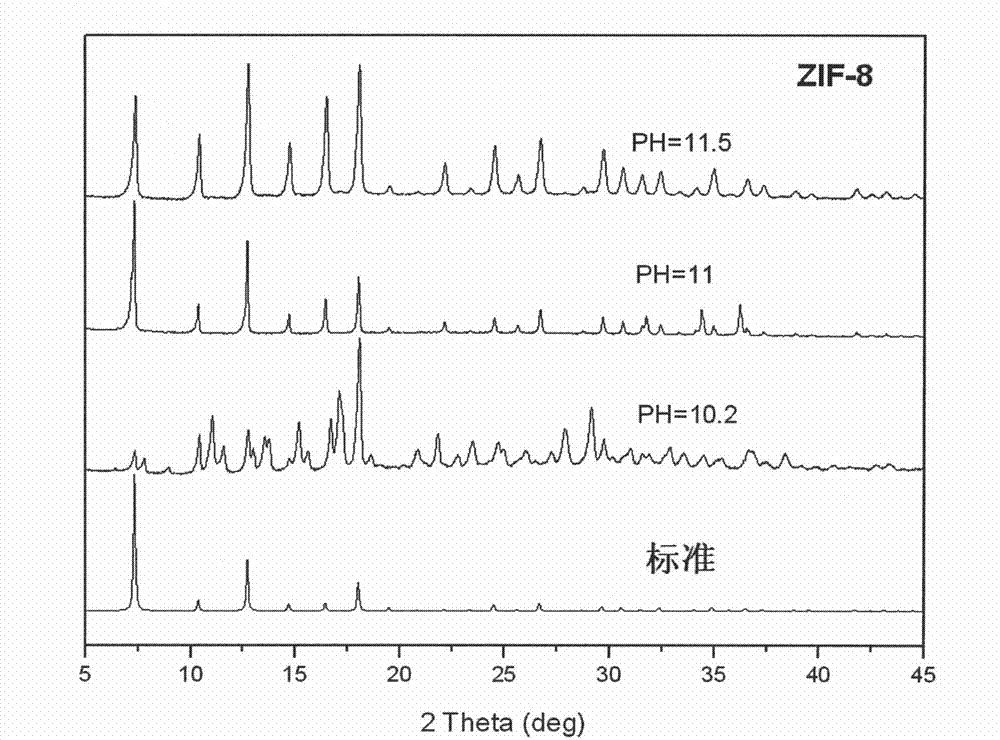

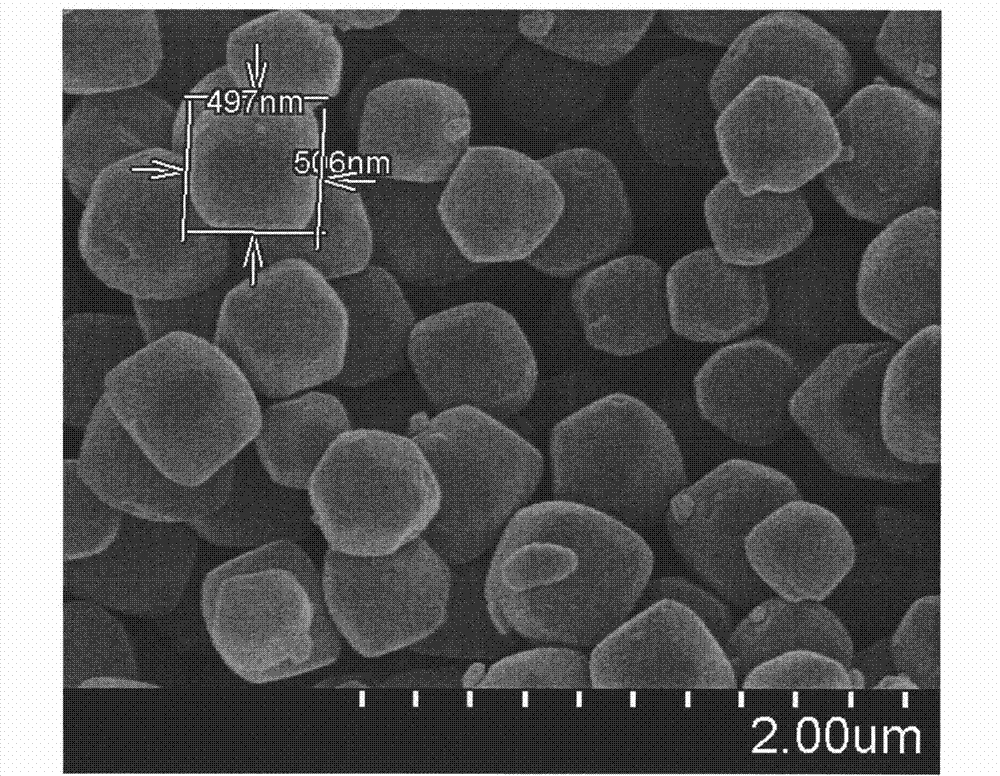

[0017] The synthetic method of zeolite imidazole framework material ZIF-8 is as follows: under room temperature, dissolve mIm (2-methylimidazole) in 20ml water, make its concentration be 0.2M, add ammonia water and adjust its pH to be 11.00, add nitric acid while stirring The zinc solid particles were adjusted to a concentration of 0.1M, stirred for 15 minutes, the obtained precipitate was washed with water and centrifuged, and the supernatant was discarded. Repeat the washing and centrifuging operation 3 times, then heat and dry at 60°C for 10 hours. Carry out XRD characterization to sample, as shown in the figure, can find out that synthesized product and ZIF-8 standard XRD spectrogram (K.Park, Z.Ni, A.Cote, J.Choi, R, Huang, F.Uribe-Romo , H.Chae, M.O'Keeffe, O.Yaghi, Prov.Natl.Acad.Sci.U.S.A., 2006, 103, 10189-10191.) coincide, the cleanliness of the surface sample is good, and the sample is pure. Some samples were taken and characterized by SEM. It can be seen that the o...

Embodiment 2

[0019] Check the impact of adding alkaline substances on the prepared product: under room temperature, dissolve mIm (2-methylimidazole) in 20ml water, make its concentration 0.1M, measure the pH value of the solution to 10.21, add zinc nitrate solid while stirring The pellet was brought to a concentration of 0.1 M and stirred for 15 minutes, the resulting precipitate was washed with water and centrifuged, and the supernatant was discarded. Repeat the washing and centrifuging operation at least 3 times, and heat and dry at 60°C for 10 hours. Some samples were taken for XRD characterization. As shown in the figure, it can be seen that the synthesized product does not match the standard XRD spectrum of ZIF-8 and the difference is very large, indicating that the prepared product is not the target product. Under the synthesis conditions, no alkaline Substance cannot synthesize ZIF-8.

Embodiment 3

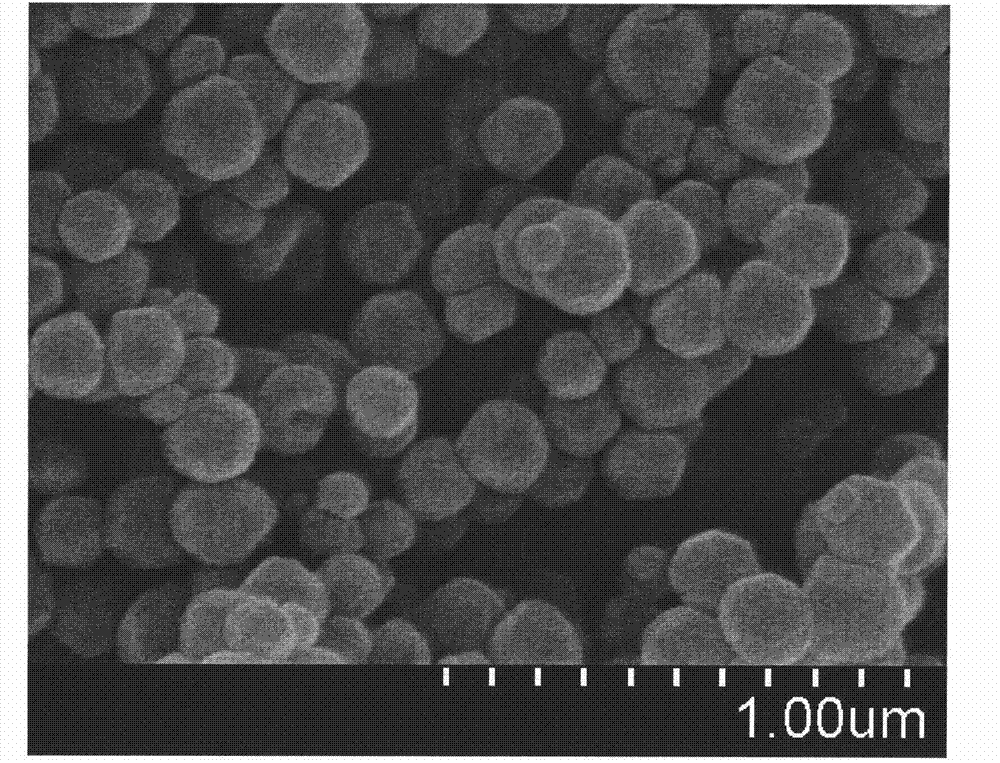

[0021] Check and adjust the pH value of the solution to affect the prepared product. At room temperature, dissolve mIm (2-methylimidazole) in 20ml water to make its concentration 0.1M. Add ammonia water to adjust the pH to 11.50, and add zinc nitrate solid particles while stirring. , so that the concentration was 0.1M, stirred for 15 minutes, the obtained precipitate was washed with water and centrifuged, and the supernatant was discarded. Repeat the washing and centrifuging operation at least 3 times, and heat and dry at 60°C for 10 hours. Some samples were taken for XRD characterization, as shown in the figure, it can be seen that the synthesized product is consistent with the ZIF-8 standard XRD spectrum, indicating that the sample is pure. Compared with Example 1, the crystallinity of the sample is improved. Some samples were taken and characterized by SEM. It can be seen that the obtained ZIF-8 material is a polyhedron with a particle size of about 100-200nm. Compared wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com