Lithium metal flow battery system and preparation method for same

A liquid flow battery and battery system technology, applied in the direction of regenerative fuel cells, etc., can solve the problems that dendrites are easy to pierce the diaphragm, easy to volatilize, and block the channel of oxygen transmission, etc., to achieve improved lithium polarization and high discharge specific surface area , Improve the effect of accumulation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

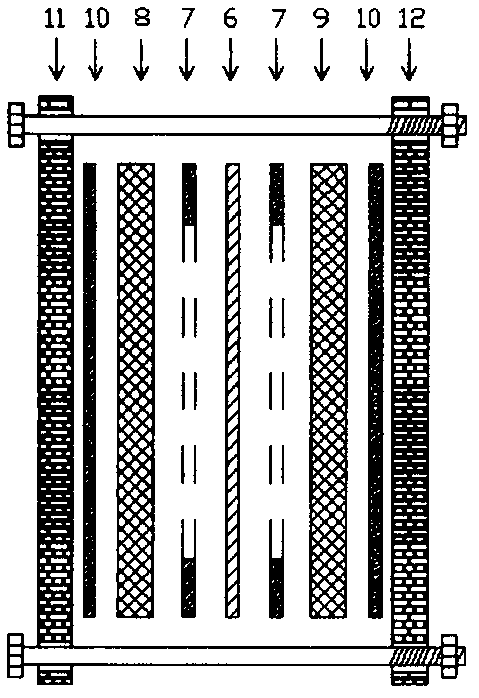

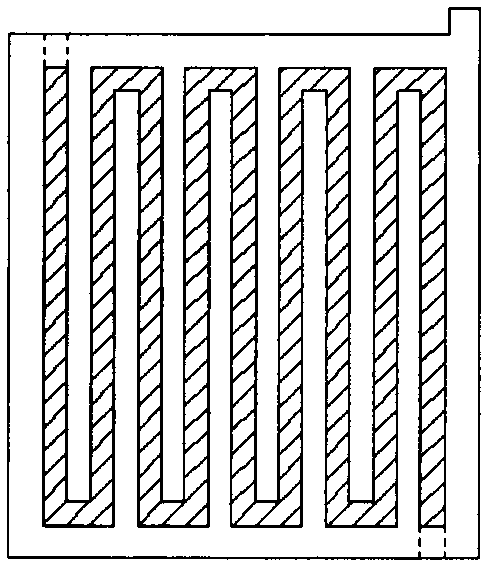

[0026] Stainless steel plate is used to process the positive and negative terminal plates, and a hole is set on the four corners of the end plate for four fixing screws. The graphite plate is used to process the positive and negative electrode collector tanks with built-in circuitous flow channels, and polypropylene is used. The composite membrane of membrane and silicon dioxide is the diaphragm, and the thickness is 0.5mm. The silicone gasket is used as the sealing gasket, and its length and width are matched with the current collector groove, such as figure 2 The sequence shown is assembled in turn, and the battery body is sealed and fixed by the screws and gaskets at the four corners; the stainless steel tubes with inner and outer diameters of 2mm and 4mm are used as the positive and negative slurry delivery tubes, and the stainless steel tank with a volume of 50mL is used as the positive and negative electrodes The slurry storage tank is tightly connected with the circulat...

specific Embodiment 2

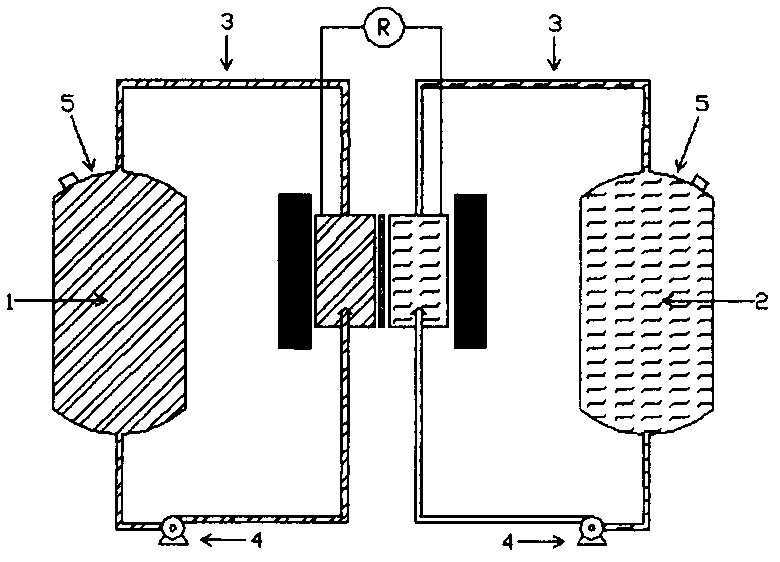

[0028] Such as figure 1 and figure 2 As shown, the lithium metal flow battery system is assembled according to the first embodiment, the positive and negative electrode slurry storage tanks 5, the circulation pump 4 and the battery body are closely connected to each other through stainless steel tubes 3 to form a complete closed circuit; the lithium-silicon alloy powder (Li 44 Si) and LiPF 6 The concentration is 1molL -1 The EC and DMC (volume ratio is 1:1) organic liquid electrolyte are mixed evenly, and the concentration of the prepared lithium alloy powder is 10molL -1 Negative electrode mixed slurry; activated carbon and the same organic liquid electrolyte used in the above-mentioned negative electrode are mixed evenly, and the concentration of activated carbon prepared is 5molL -1 The positive and negative electrode mixed slurry of the above-mentioned assembled lithium metal flow battery system is injected into the positive and negative electrode slurry storage tanks...

specific Embodiment 3

[0030] Lithium powder and LiPF 6 The concentration is 1molL -1 The EC and DME (volume ratio is 1:1) organic liquid electrolyte are mixed evenly, and the concentration of the prepared lithium powder is 10molL -1 Negative electrode mixed slurry; Prepare activated carbon-supported PdAu (marked as PdAu / C) as a positive electrode catalyst by impregnation reduction method, wherein the mass content of PdAu is 5% (Pd and Au atomic ratio is 1:1), PdAu / C Mix evenly with the same organic liquid electrolyte used in the above-mentioned negative electrode, and prepare PdAu / C with a concentration of 5molL -1 The positive electrode mixed slurry; Assemble the lithium metal flow battery system according to the first embodiment, such as figure 1 and figure 2 As shown, the positive and negative electrode slurry storage tanks 5 are closely connected with the circulation pump 4 and the battery body through stainless steel tubes 3 to form a complete closed circuit; Fill the storage tank with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com