Patents

Literature

64 results about "Lithium peroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium peroxide is the inorganic compound with the formula Li₂O₂. It is a white, nonhygroscopic solid. Because of its high oxygen:mass and oxygen:volume ratios, the solid has been used to remove CO₂ from the atmosphere in spacecraft.

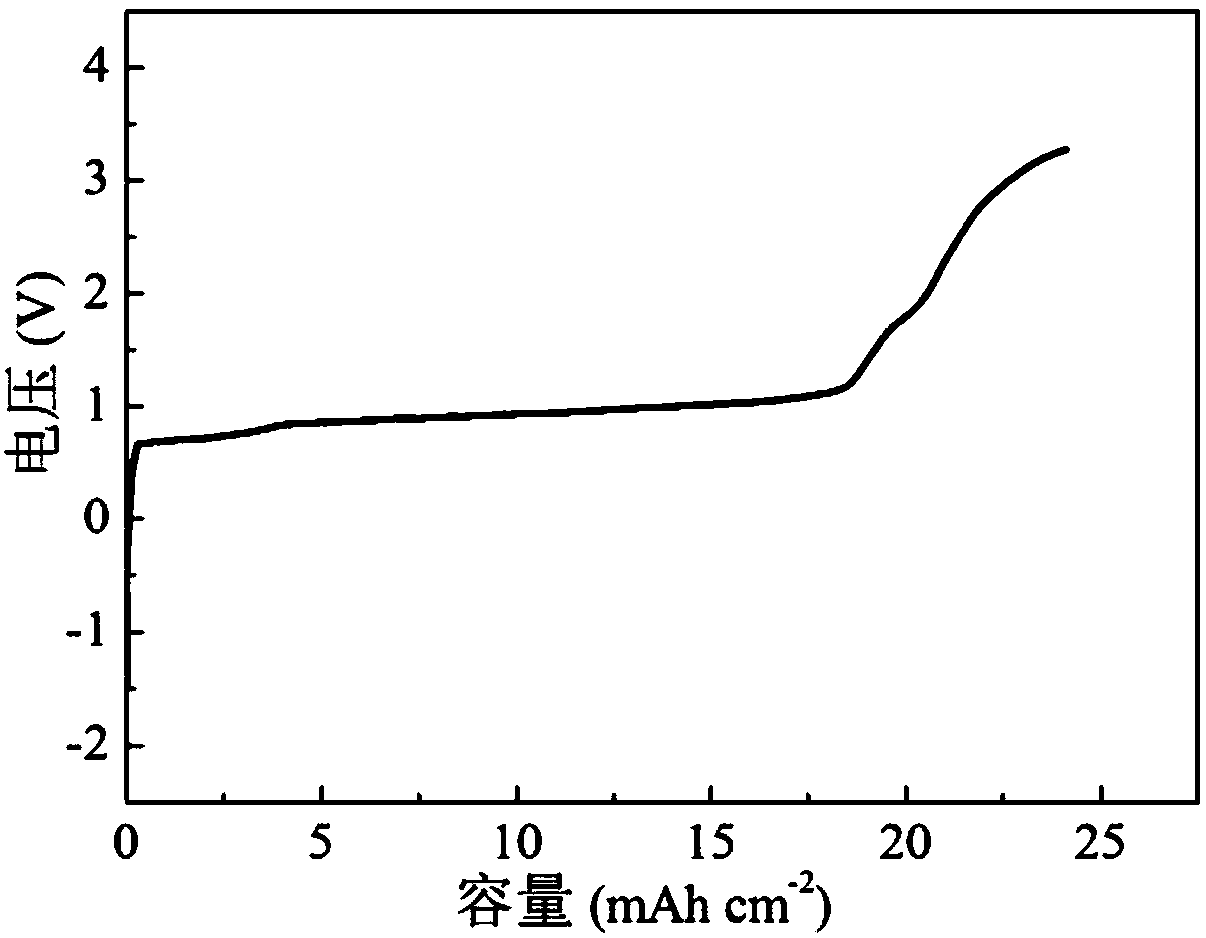

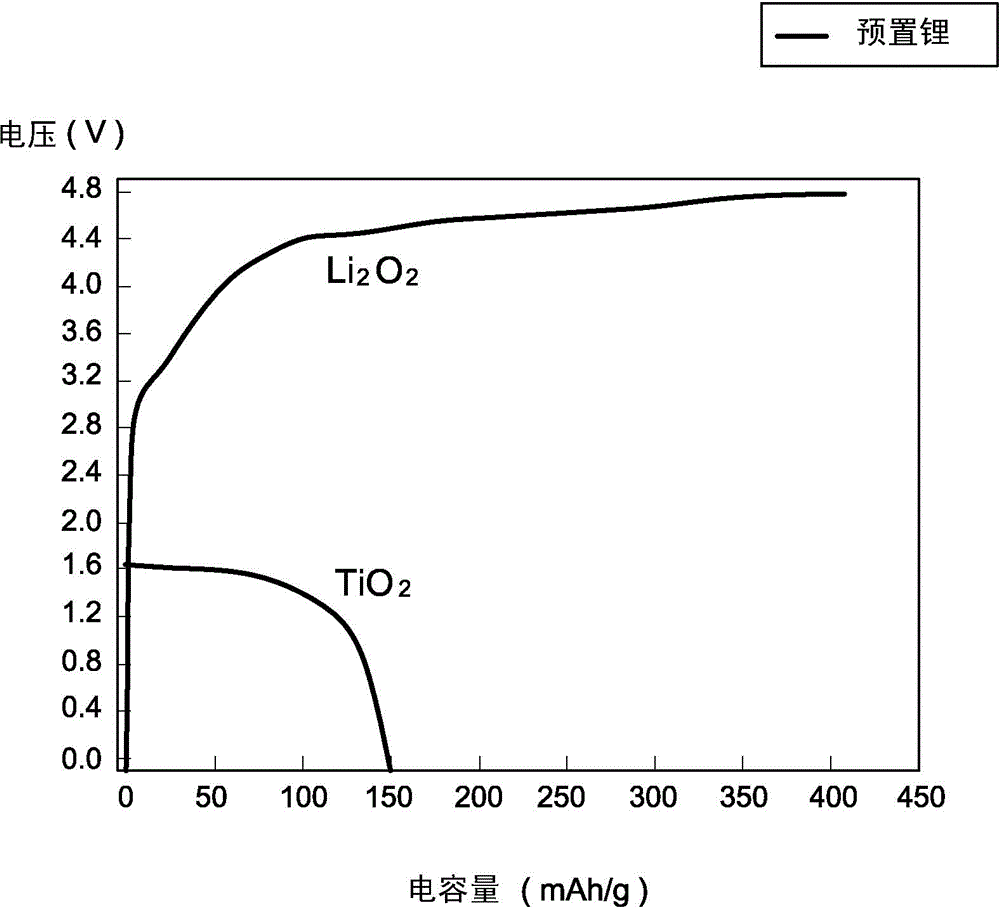

Lithium supplementing slurry as well as preparation method and application thereof

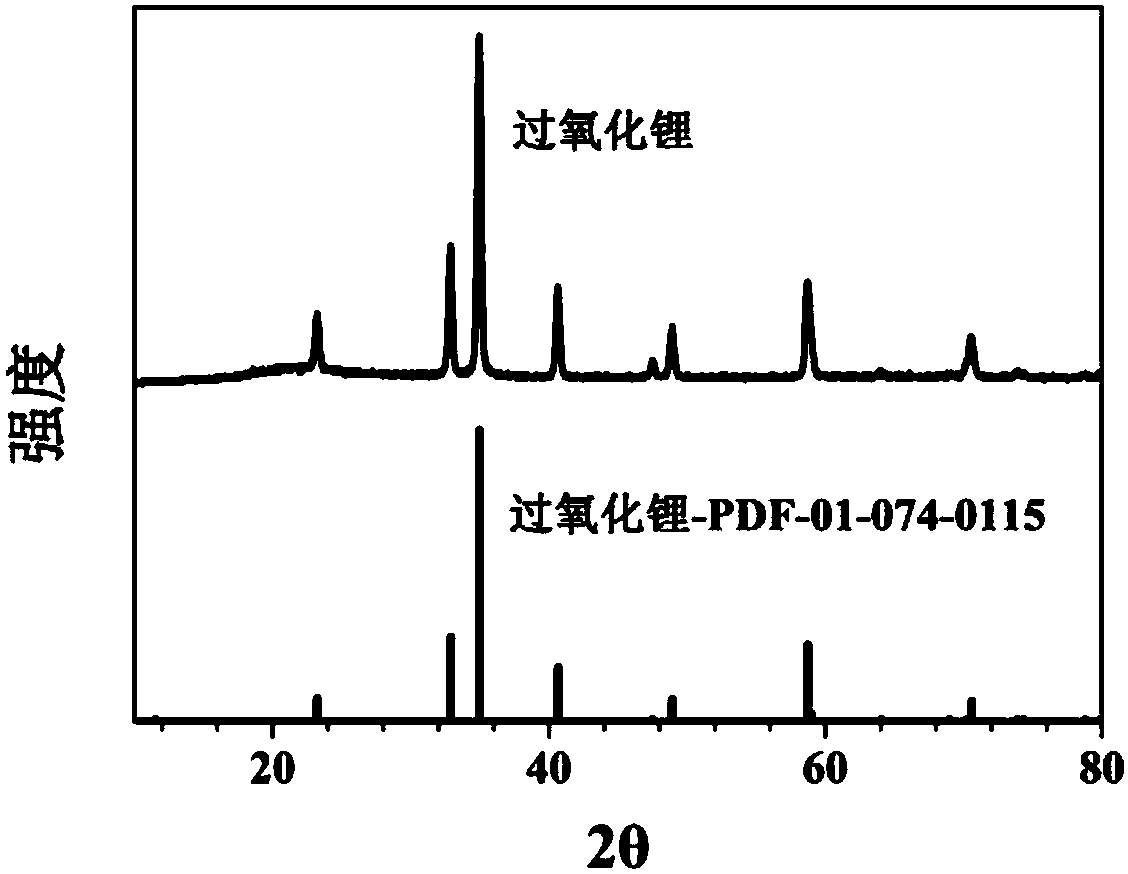

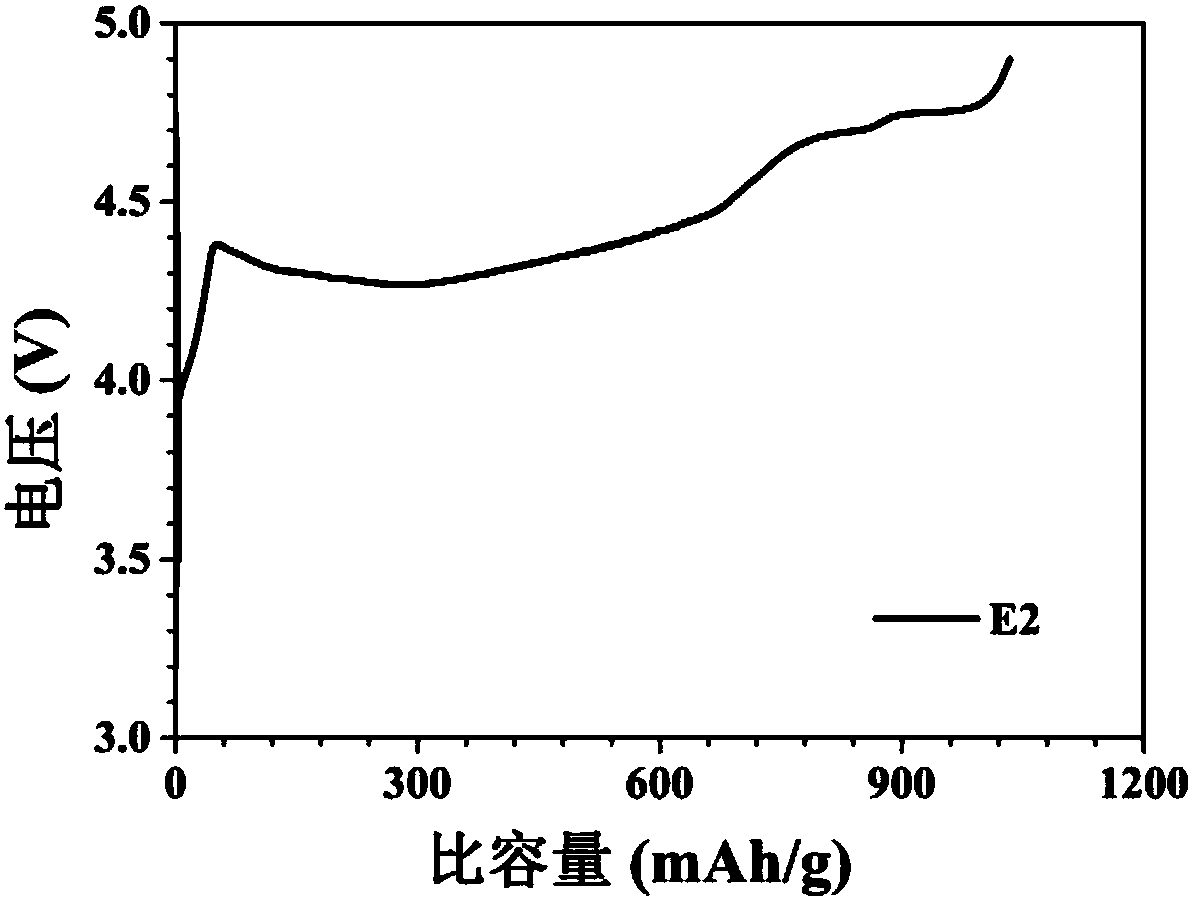

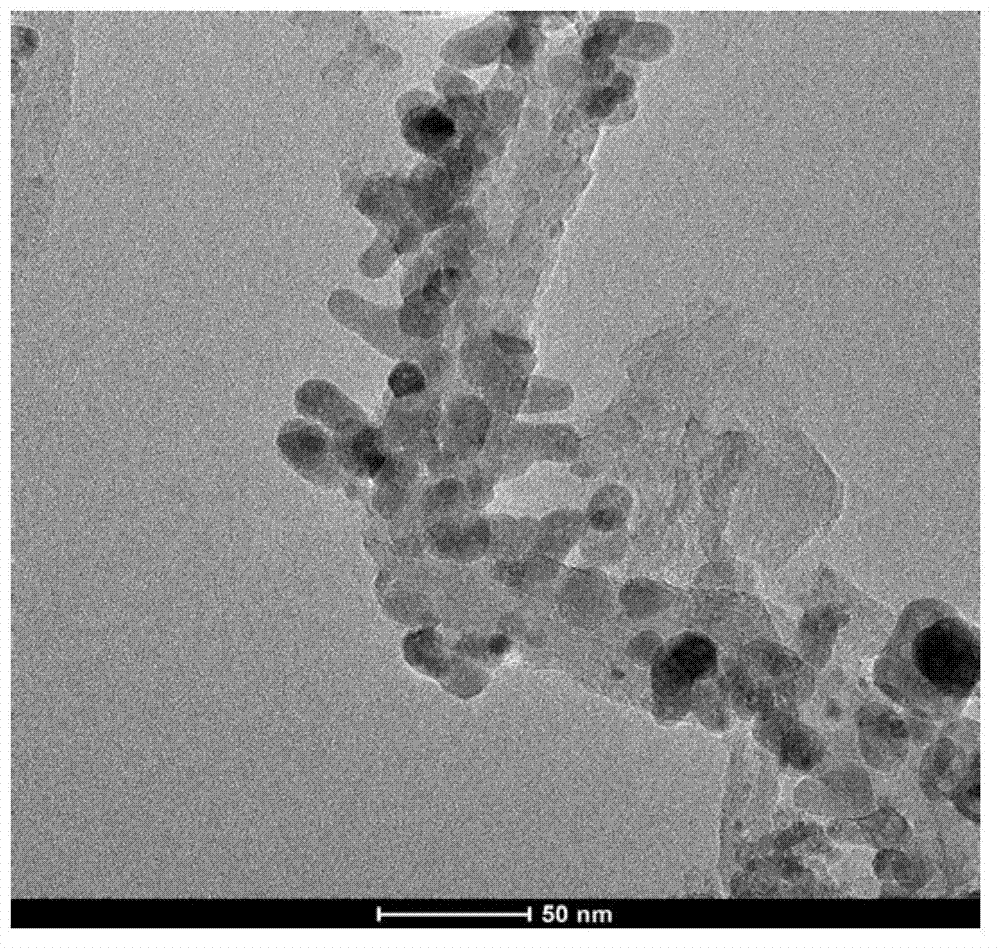

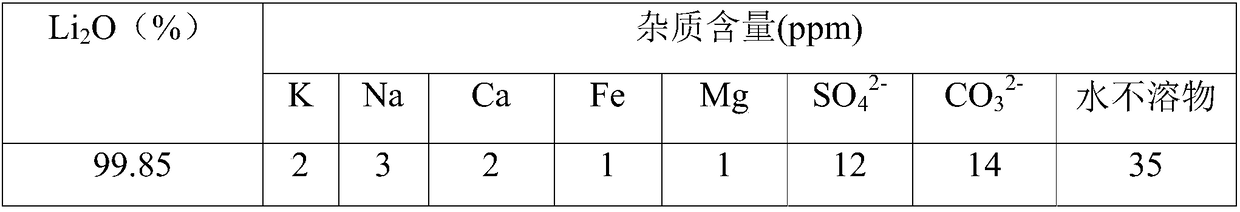

InactiveCN110350194AEasy to makeAir stabilizationCell electrodesSecondary cellsLithium peroxideSlurry

The invention provides a lithium supplementing slurry for supplementing active lithium in a lithium energy storage device as well as a preparation method and application of the lithium supplementing slurry; the lithium supplementing slurry comprises a lithium supplementing material, a liquid dispersing agent, an optional conducting material and an optional binding agent, wherein the lithium supplementing material is lithium peroxide. The lithium supplementing slurry provided by the invention is stable in air, simple to prepare, high in safety and low in cost. In addition, the lithium supplementing slurry is high in compatibility with various positive electrode materials, negative electrode materials and electrolytes of the lithium ion energy storage device, so that the lithium supplementing slurry is very suitable for various lithium ion energy storage devices.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

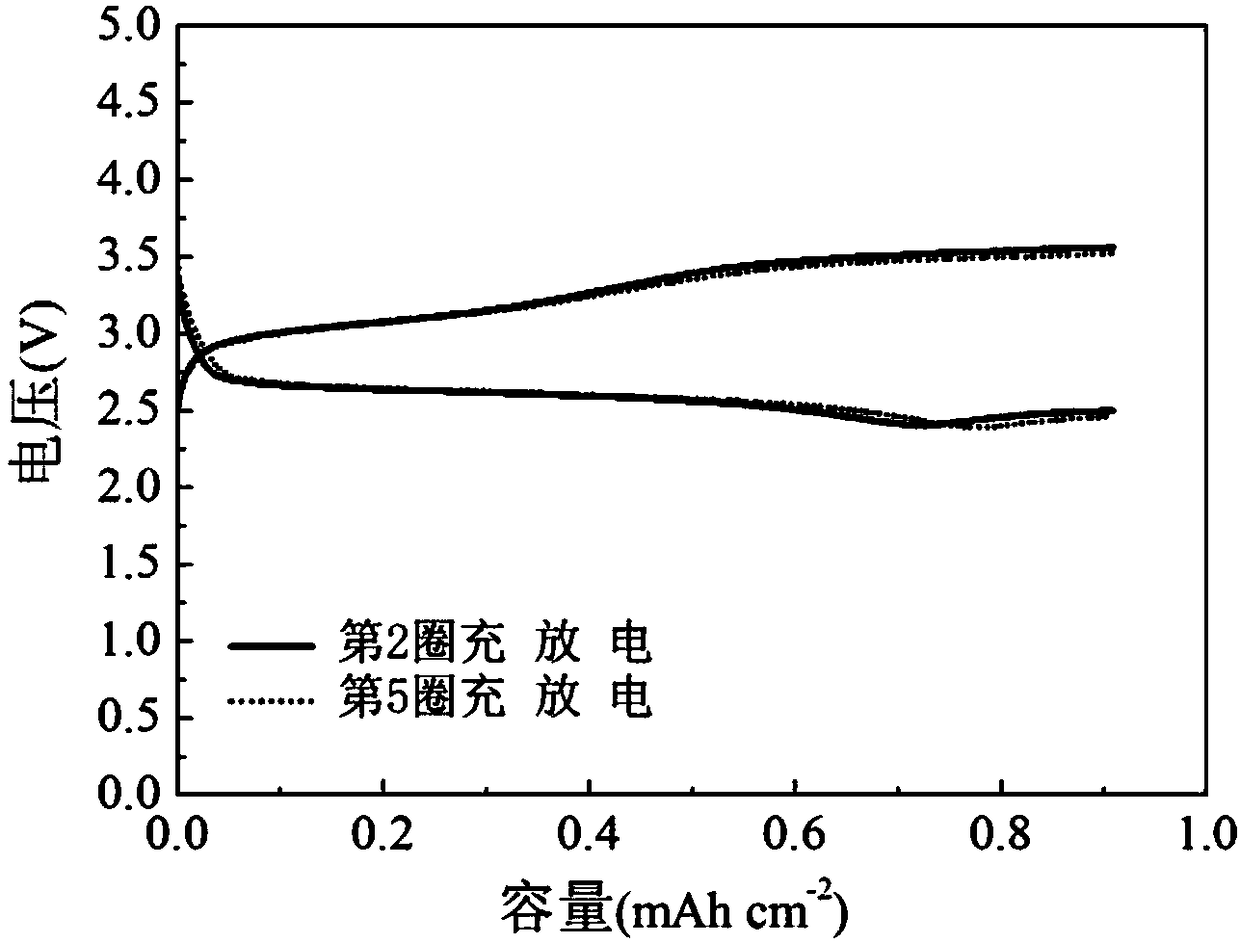

Unsymmetrical lithia battery

ActiveCN103035979AIncrease capacitySolving Safety Concerns of Piercing Battery SeparatorsFuel and secondary cellsCell electrodesPorous carbonPhysical chemistry

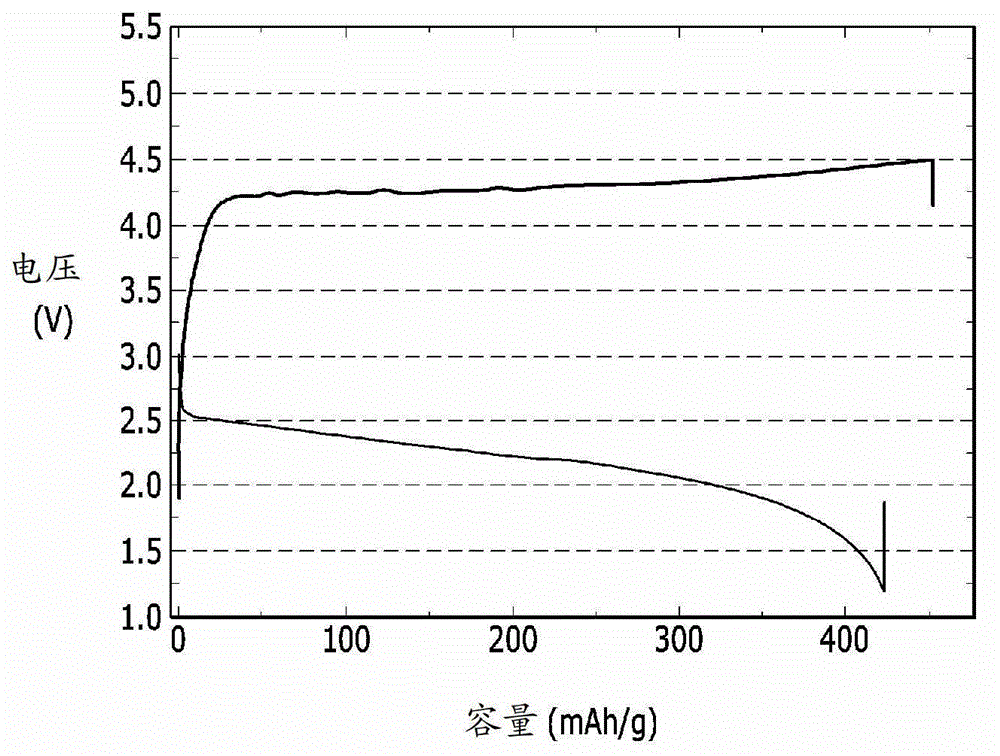

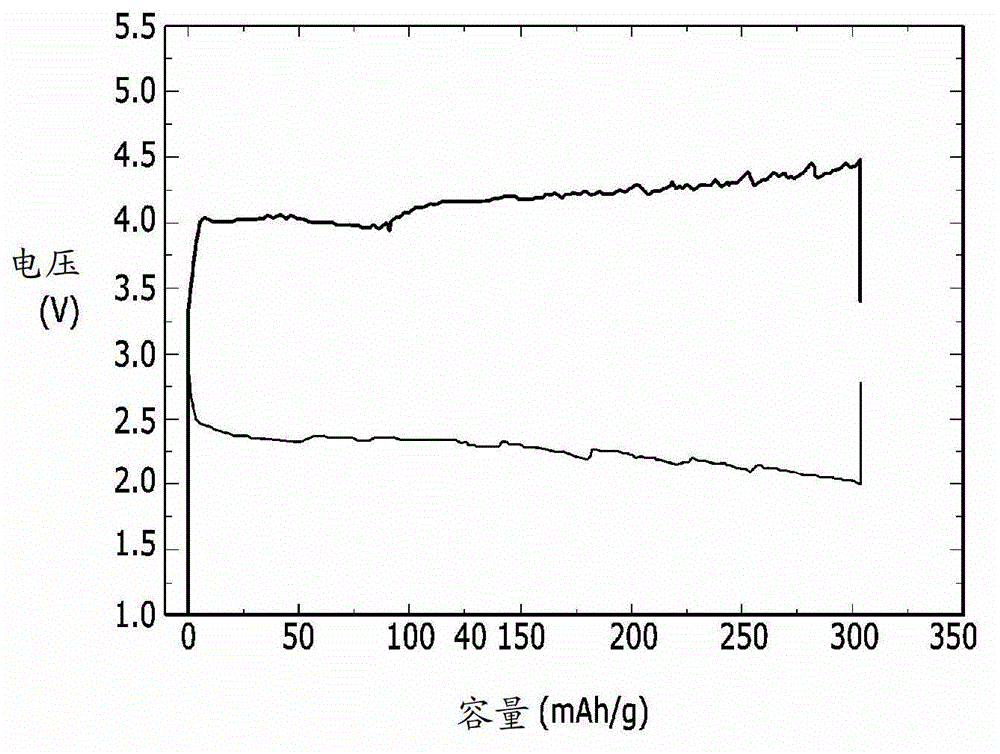

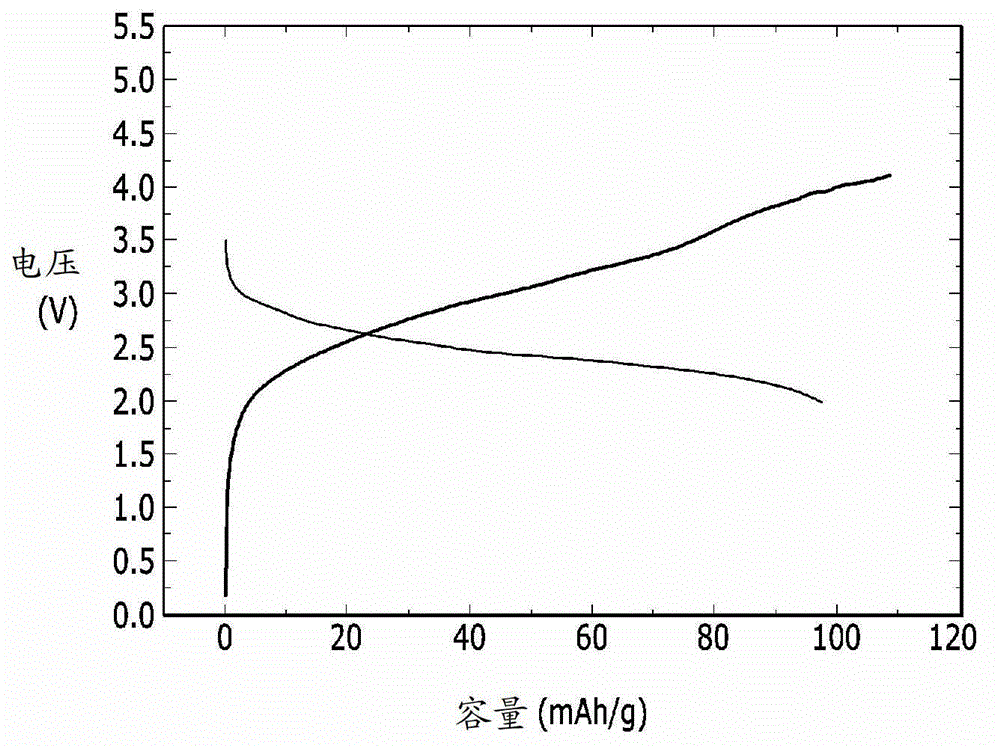

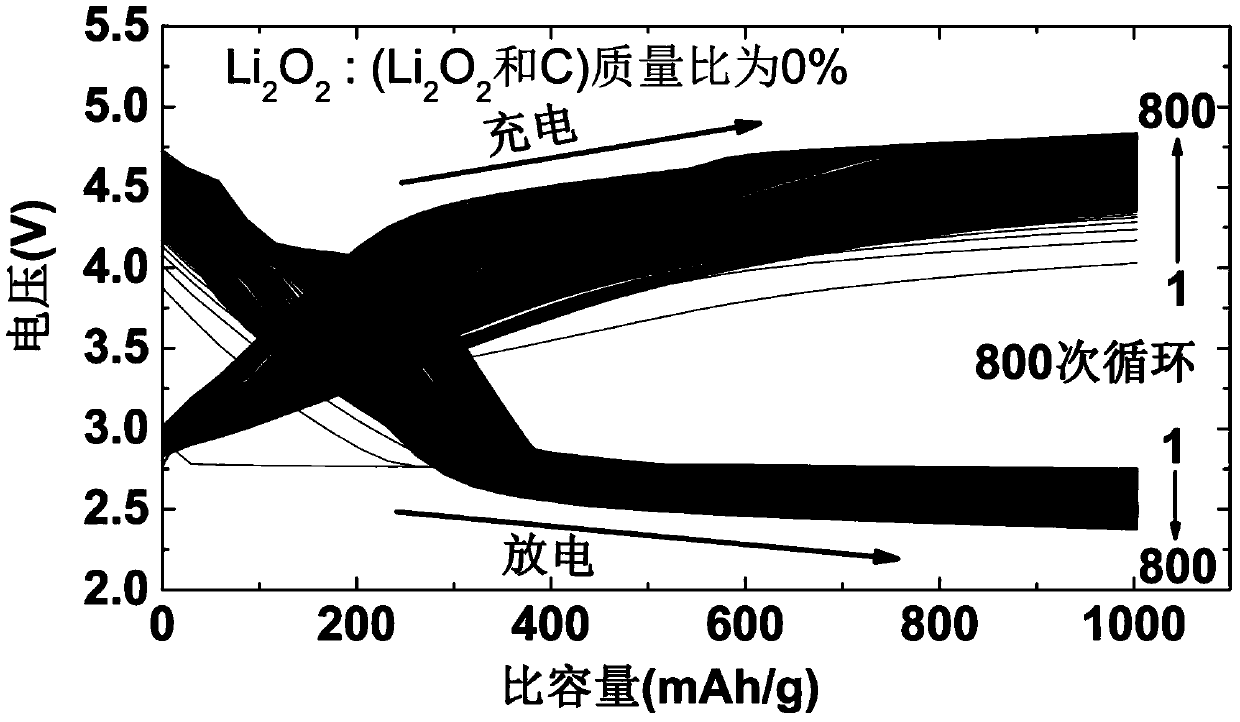

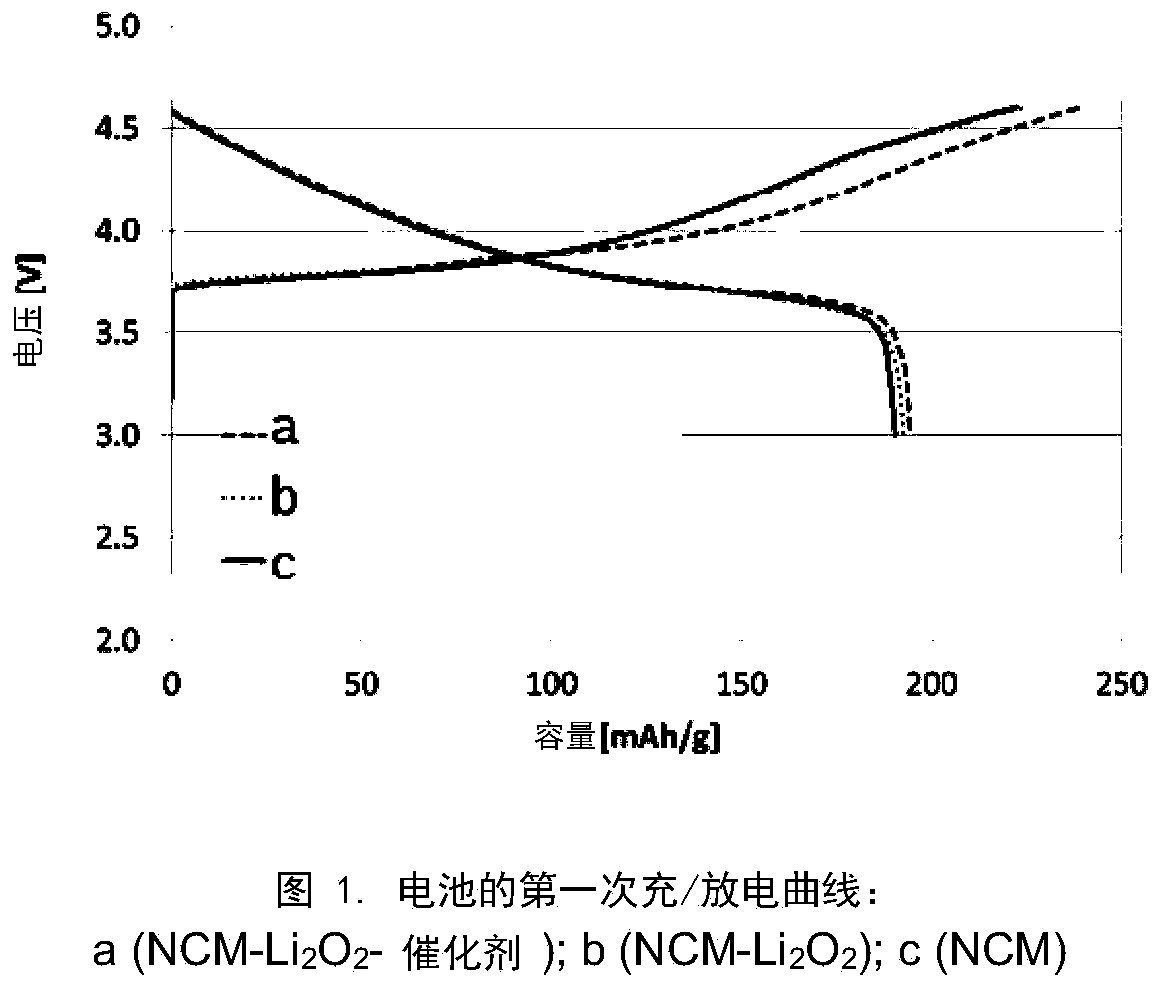

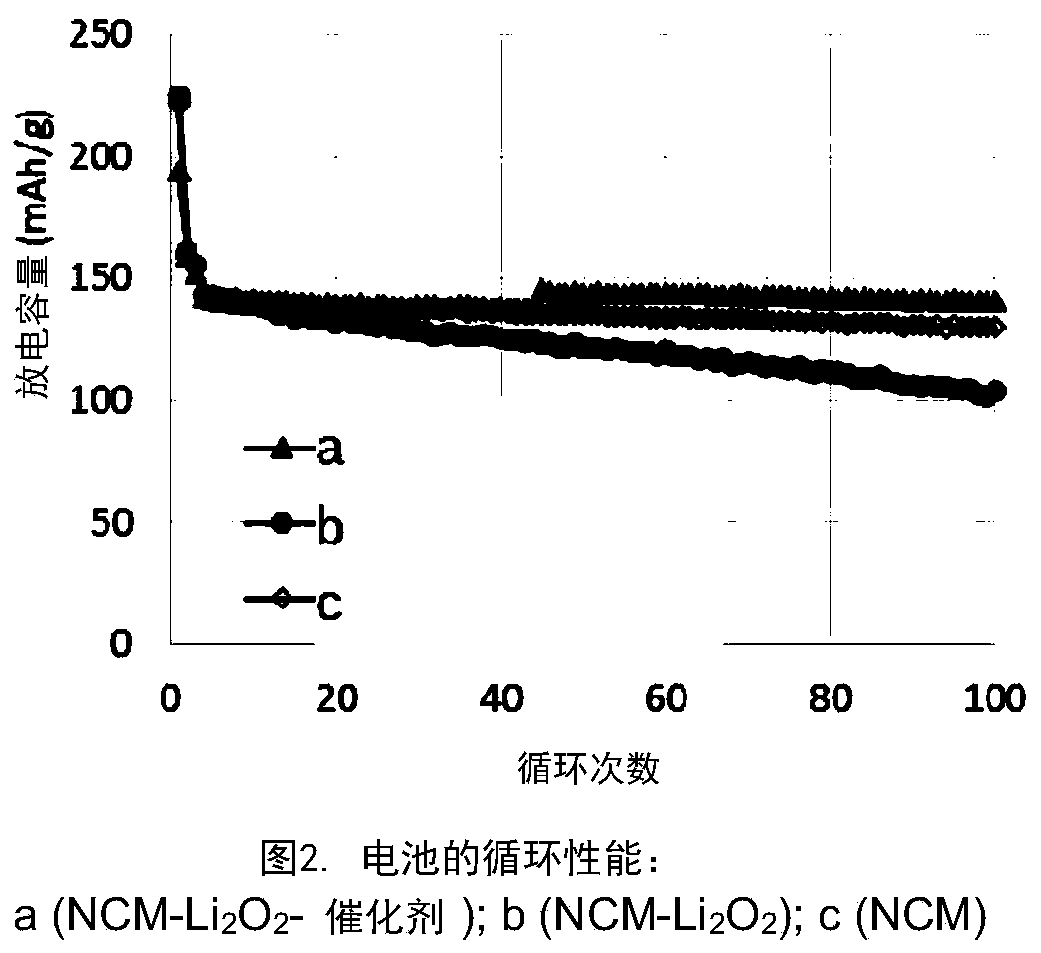

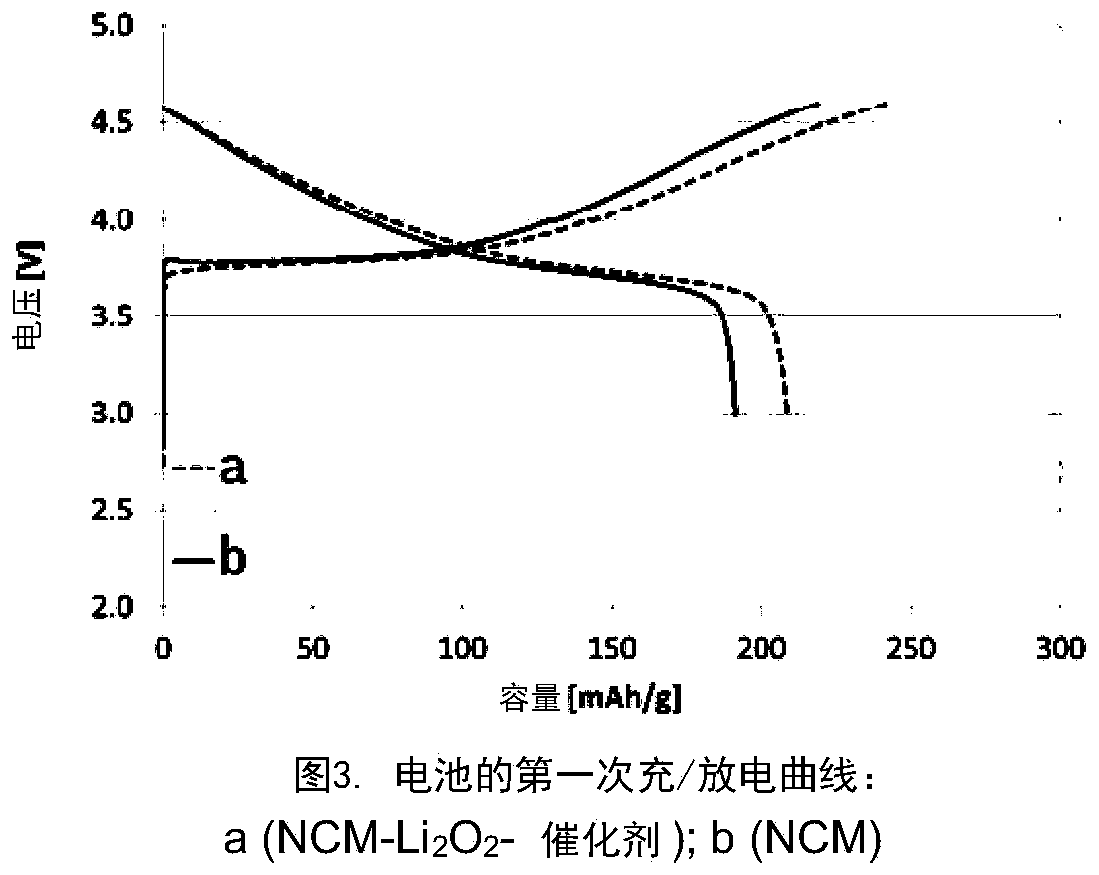

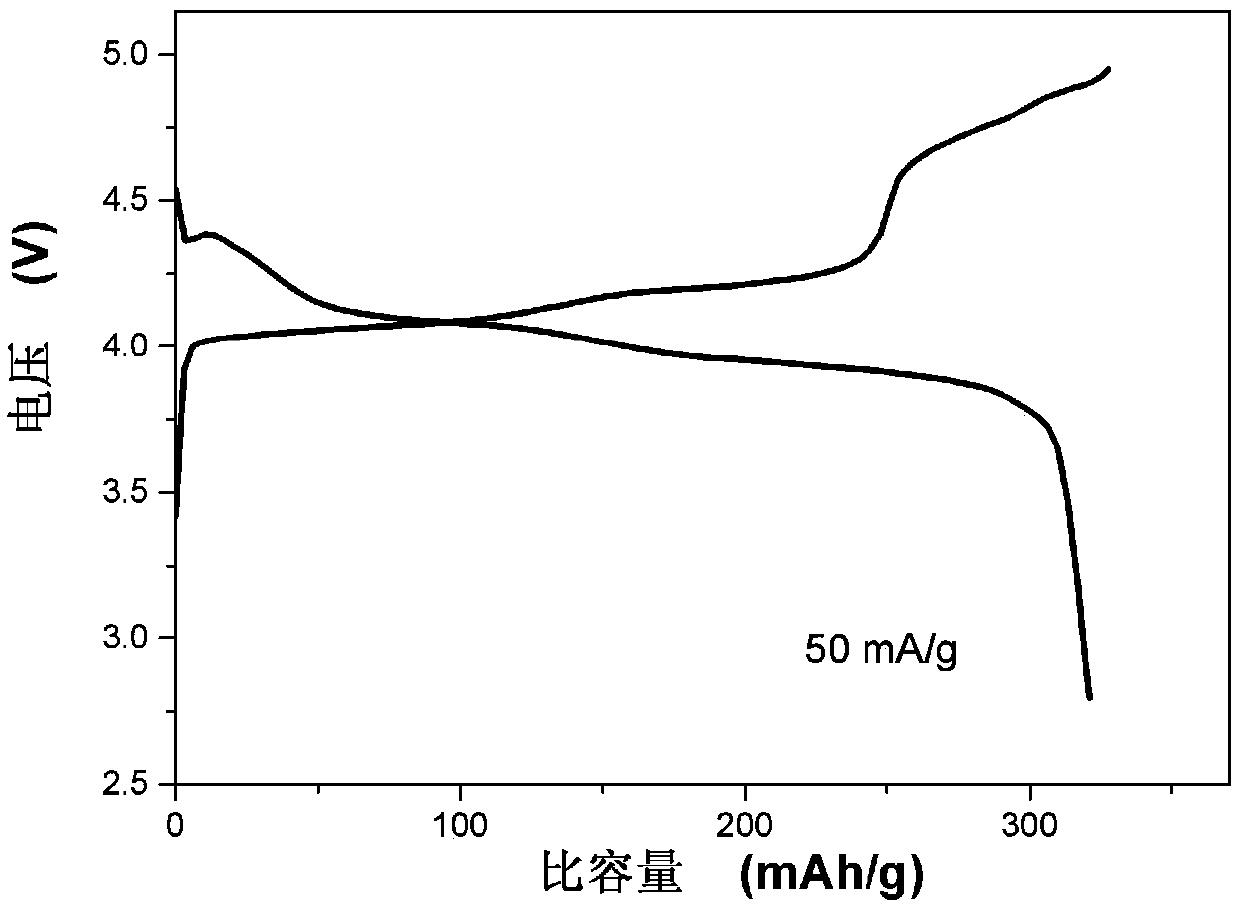

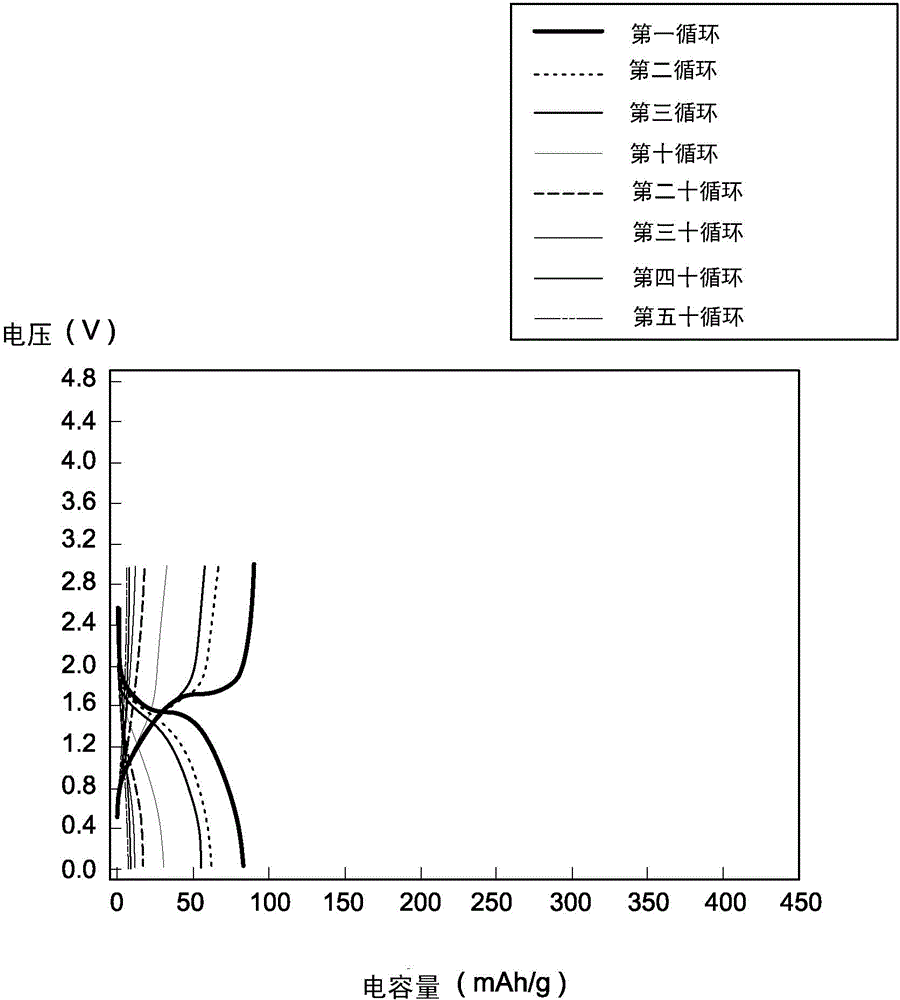

The invention discloses an unsymmetrical lithia battery. The battery takes lithium peroxide as a positive pole active material, lithium peroxide and a catalyst which are uniformly mixed are loaded on a porous carbon material so as to form a positive pole, the material capable of realizing deintercalation of lithium ions is taken a negative pole, and the weight content of lithium peroxide is 1-50% in a composite material. According to the invention, the discharging product lithium peroxide of the traditional lithia battery is directly used as the positive pole active material, the pole material of the traditional lithium ion battery, which is capable of realizing deintercalation of lithium ions, is taken as the negative pole, the damage of negative pole lithium dendrites of a lithia battery to the battery is solved, and meanwhile, the controllable distribution of the discharging product is realized, an unblocked oxygen diffusion channel is guaranteed, and the charge-discharge capacity and cycle performance of the lithia battery are effectively improved.

Owner:CENT SOUTH UNIV

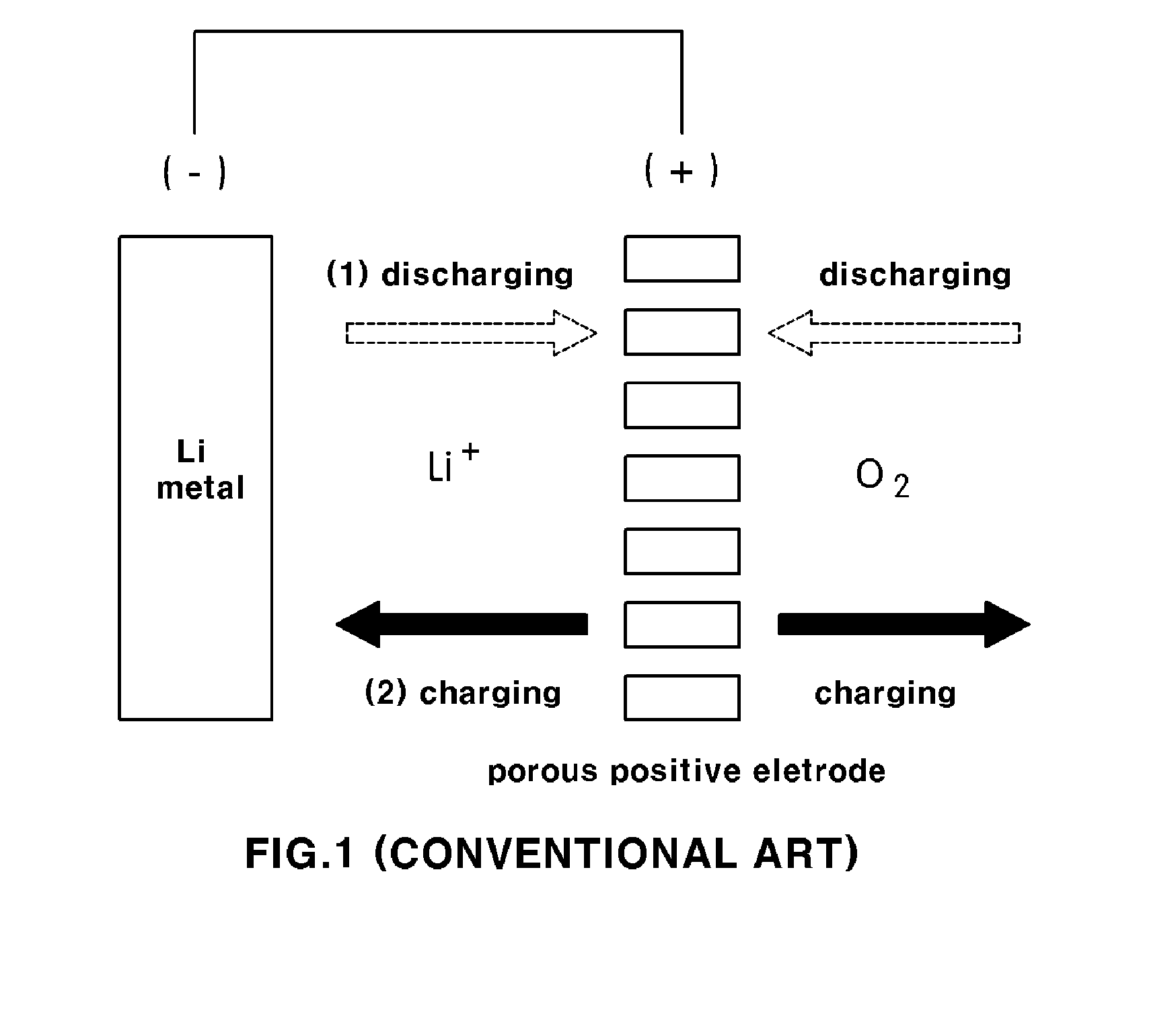

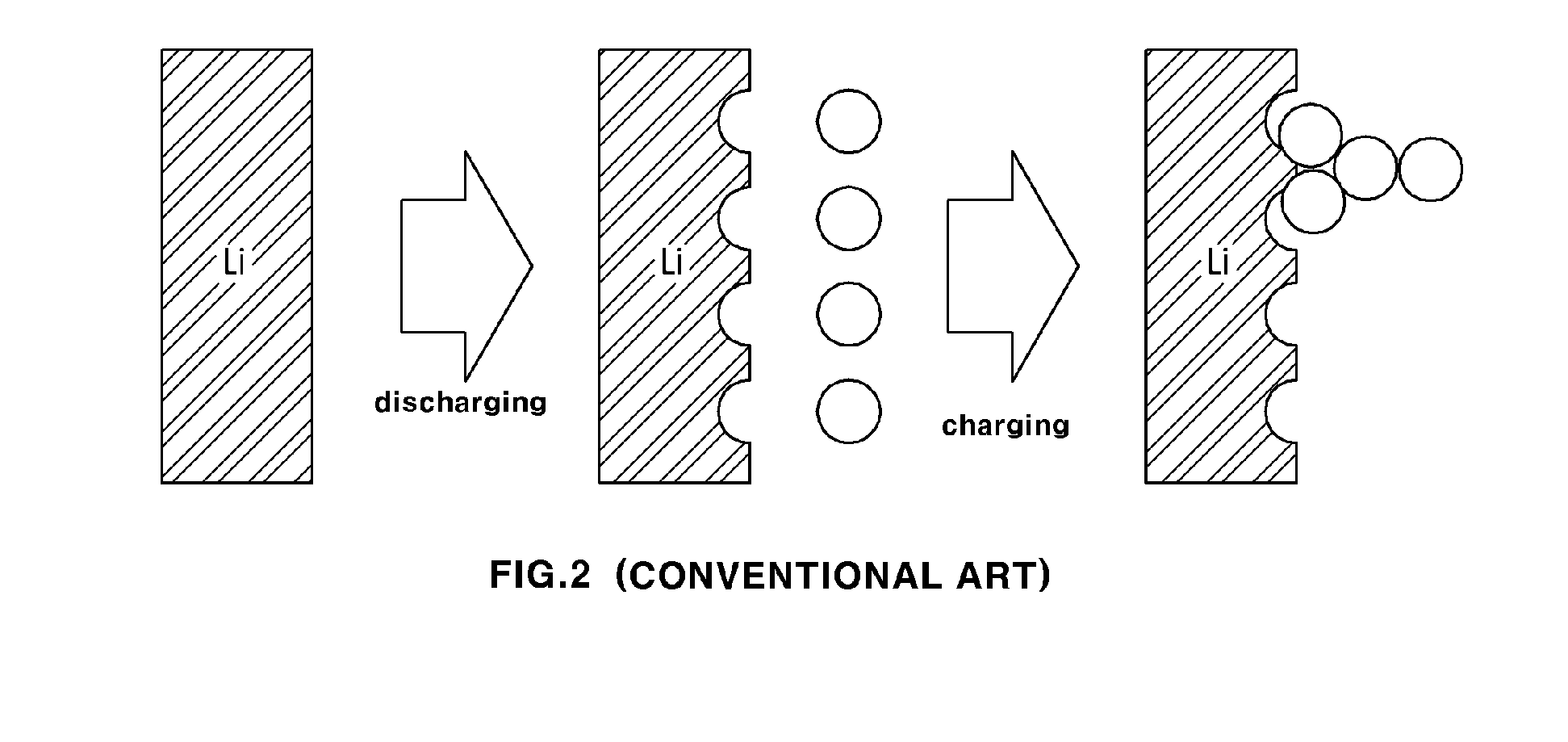

Lithium-air battery

InactiveCN102948006ACommercializationRealize large-scaleFuel and primary cellsFuel and secondary cellsLithium oxideLithium hydroxide

Provided is a lithium-air battery comprising: a positive electrode including a current collector and a positive electrode active material layer which is located on the current collector and includes a positive electrode active material; a negative electrode including a negative electrode active material; and an electrolyte, wherein the positive electrode active material includes lithium peroxide (Li2O2), lithium oxide (Li2O), lithium hydroxide (LiOH), or a combination thereof, and the negative electrode active material includes a lithium alloy, a material which can be doped or undoped with lithium, a transitional metal oxide, or a combination thereof.

Owner:IUCF HYU (IND UNIV COOP FOUND HANYANG UNIV)

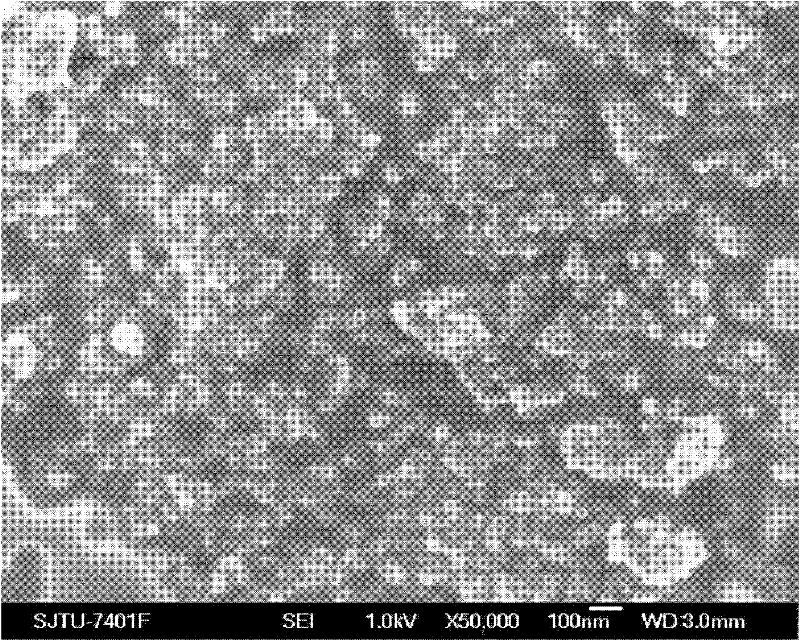

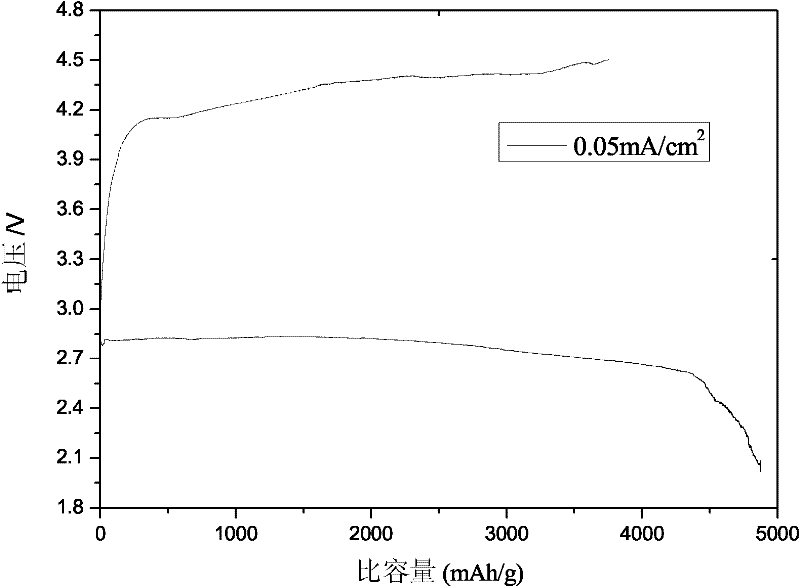

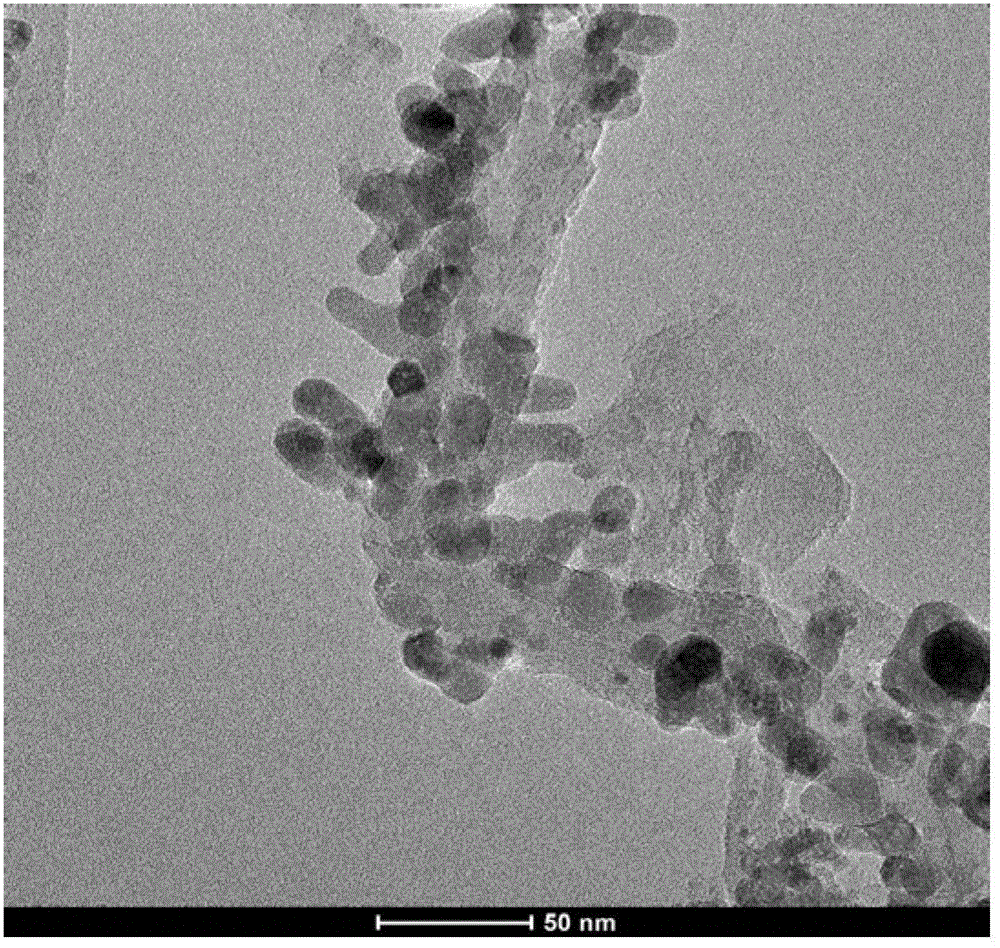

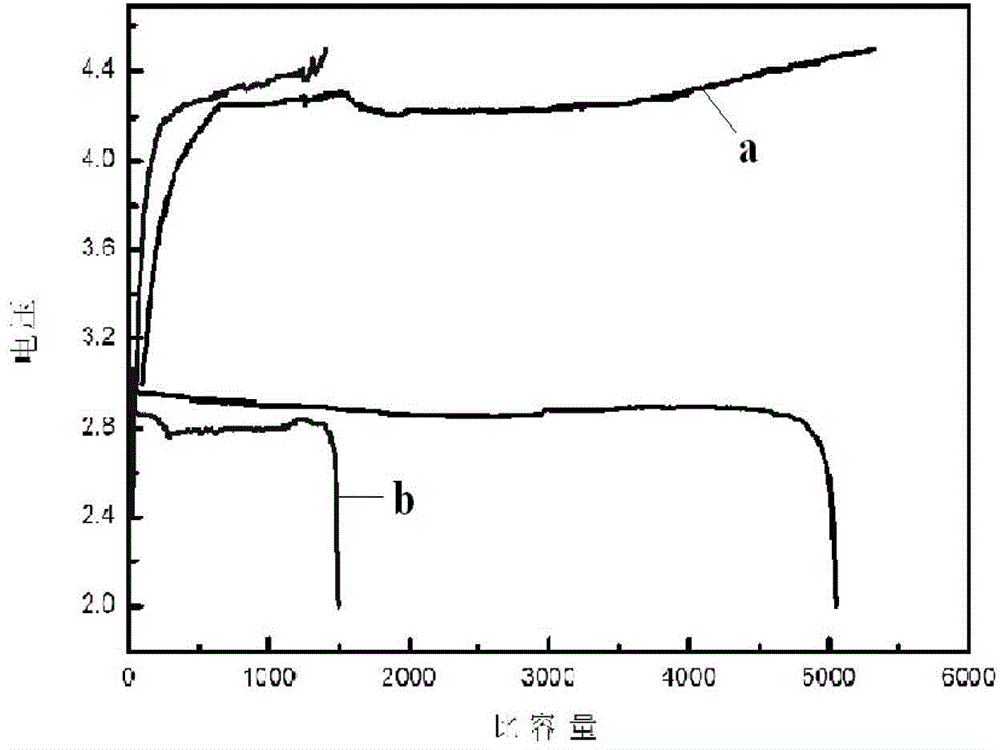

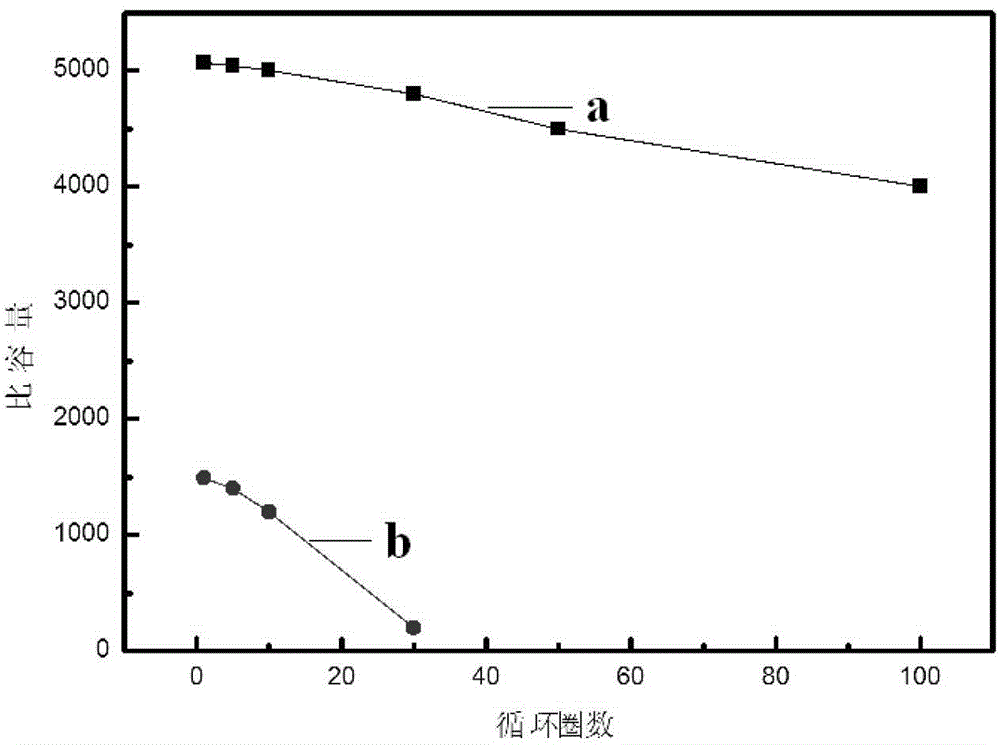

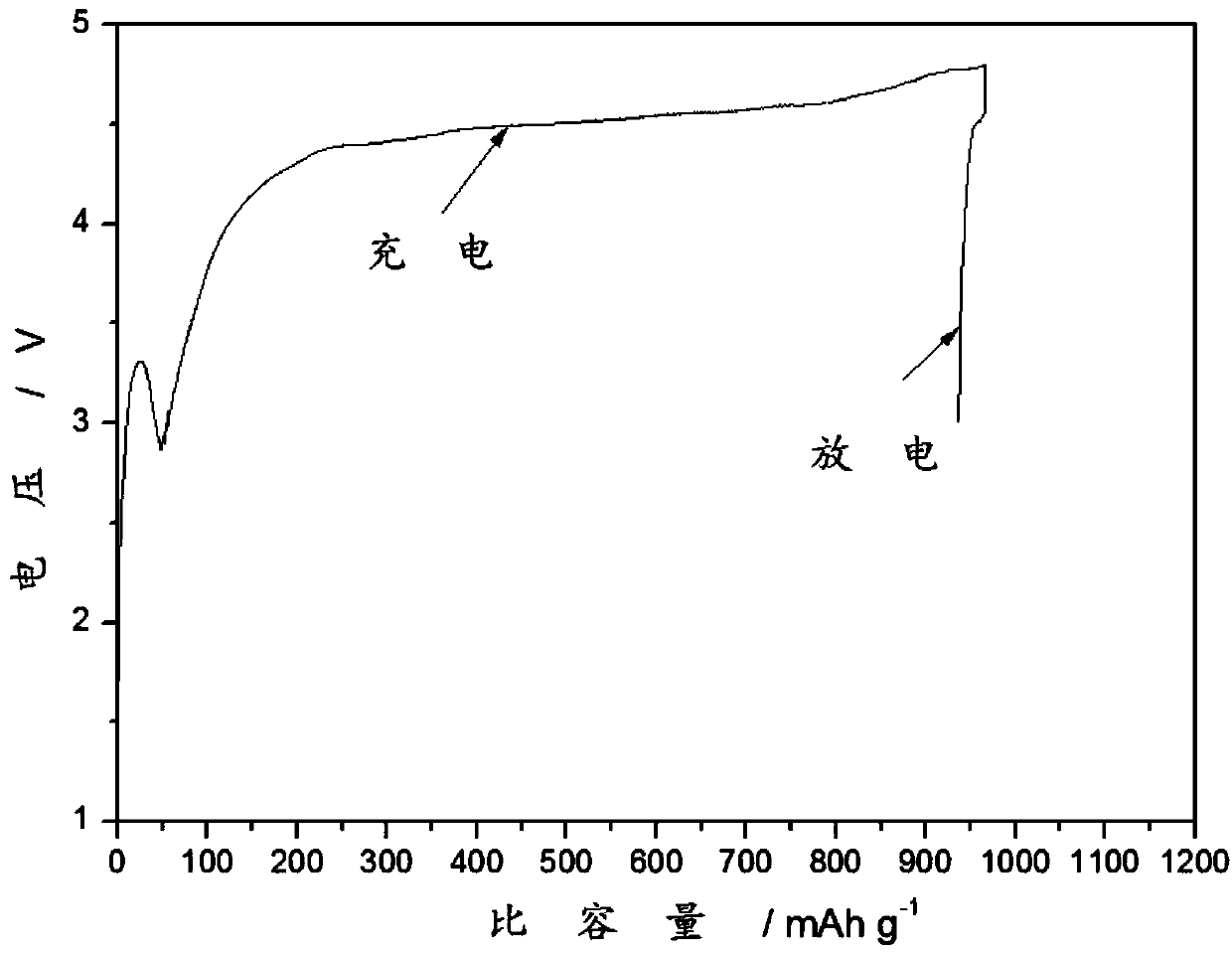

Cathodic catalyst for lithium air battery and preparation method thereof

ActiveCN102240574AFacilitated DiffusionReduce manufacturing costCell electrodesOrganic-compounds/hydrides/coordination-complexes catalystsDecompositionPorphyrin

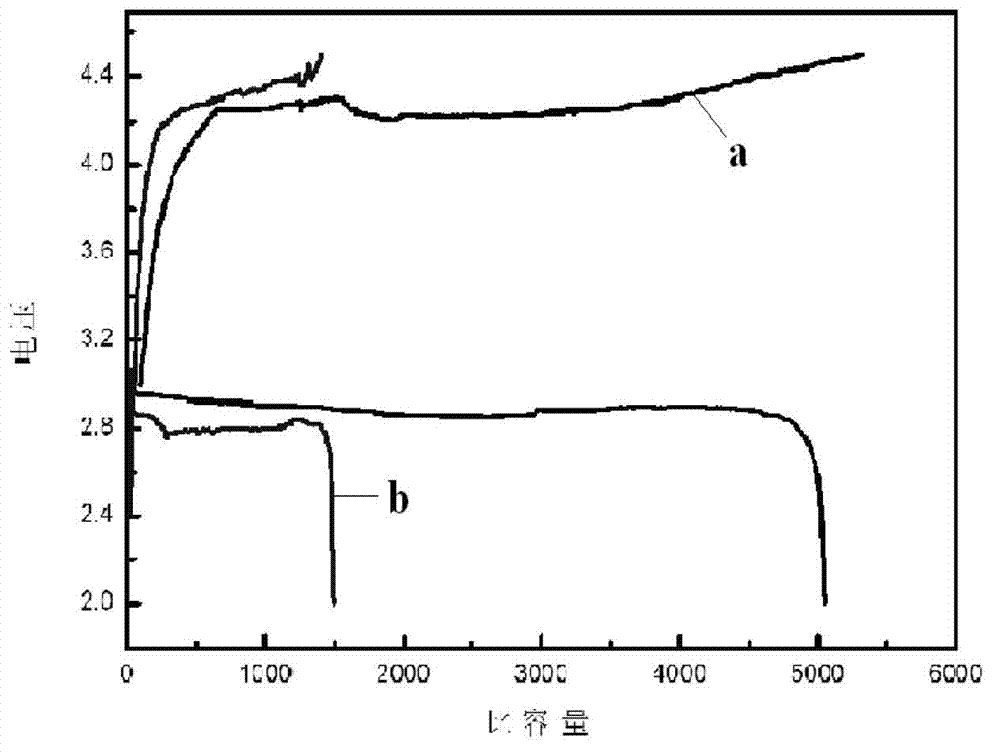

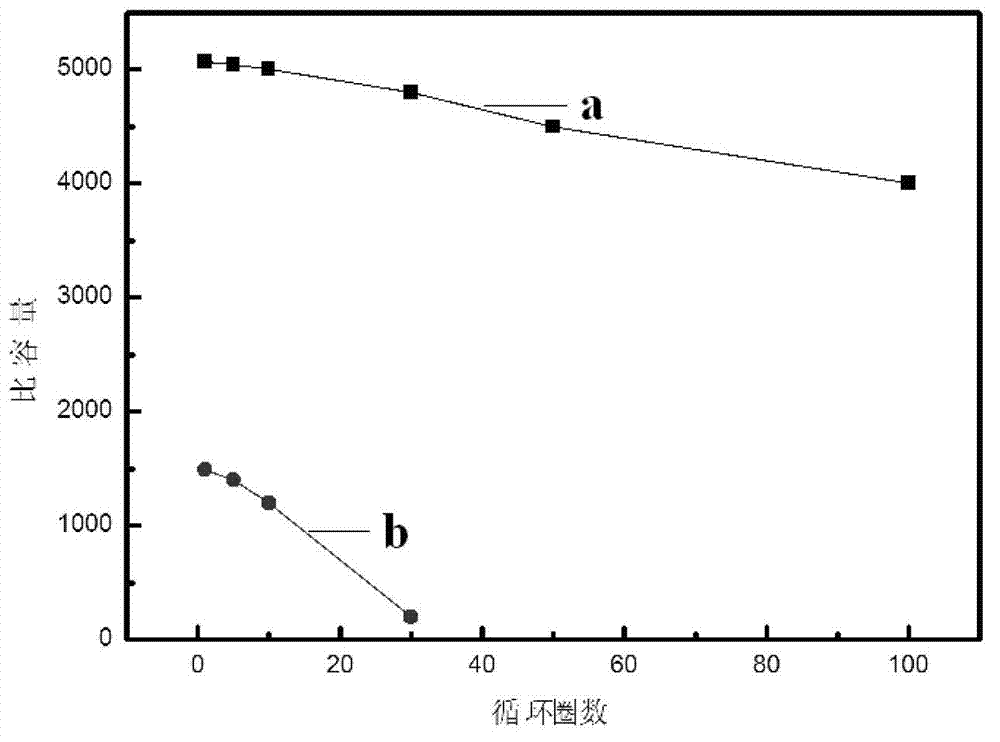

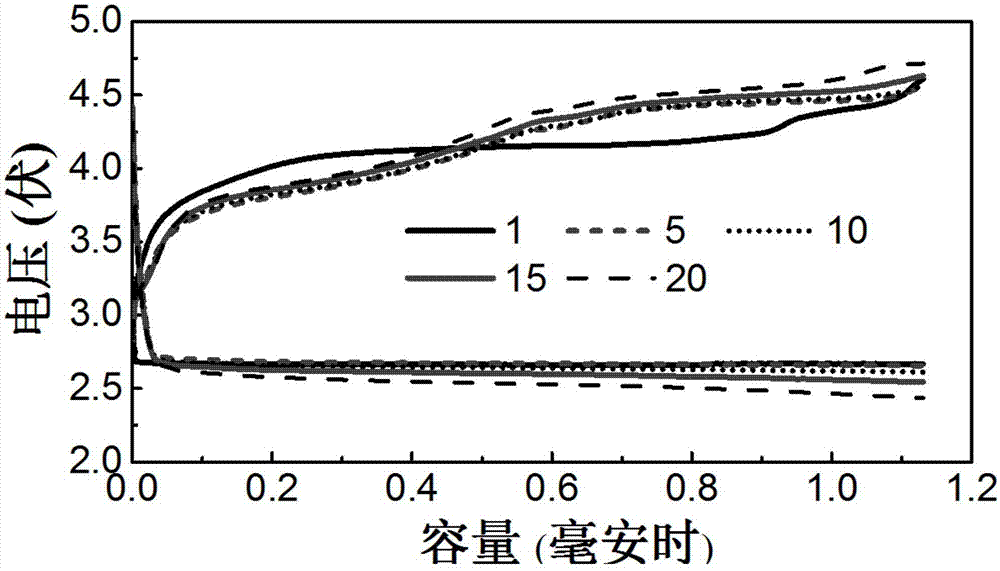

The invention discloses a cathodic catalyst for a lithium air battery and a preparation method thereof. The cathodic catalyst comprises a transition metal coordination complex and a carbon black carrier, wherein the transition metal complex is obtained by reacting cobalt salt or manganese salt with a nitrogenous ligand; the cathodic catalyst provides a catalytic center for the formation and the decomposition of lithium peroxide in the charge-discharge process of the lithium air battery; and the lithium air battery prepared by using the cathodic catalyst shows very good catalytic activity and stability, has the first circle discharge capacity reaching 4870 mAh / g<-1> (unit mass of active substances) when the current density is 0.05 mAcm<-1>, and has the discharge voltage stabilized to be 2.8 V. In the cathodic catalyst disclosed by the invention, the low-cost nitrogenous ligand is taken as a raw material; and compared with a noble metal catalyst or a macrocyclic compound catalyst generated by coordinating porphyrin and phthalocyanine with transition metal, the cathodic catalyst has the advantages of simple preparation process, good process repeatability, low cost and the like and can be used in the field of cathode materials of the lithium air battery.

Owner:浙江钠创新能源有限公司

Low carbon steel continuous casting crystallizer casting powder

The invention relates to a fusing agent for steel-making, in particular to low carbon steel continuous casting crystallizer casting powder. The low carbon steel continuous casting crystallizer casting powder mainly solves the technical problem that surface defects of a tin plate and a scouring plate cause slag entrapment during the continuous casting process. According to the technical scheme, the low carbon steel continuous casting crystallizer casting powder comprises 40-44 percents silicon dioxide, 28.5-36.5 percents calcium, 7.0-11.0 percents cerium trioxide, 3.6-8.2 percents lithium peroxide, <=2.4 percents sodium oxide and 4.0-8.0 percents fluorine. The low carbon steel continuous casting crystallizer casting powder is low in binary basicity and melting point, and high in viscosity. Meanwhile, lubricating of the casting powder is improved and surface tension of the casting powder is improved.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Electrolyte for lithium-air battery and corresponding battery product

ActiveCN103311602AImprove performanceImprove contact statusFuel and secondary cellsLithium oxideOrganic solvent

The invention discloses a lithium-air battery. The lithium-air battery comprises an air positive electrode, a lithium negative electrode and organic electrolyte which is filled between the air positive electrode and the lithium negative electrode, the organic electrolyte contains an aprotic organic solvent, lithium salt and a soluble catalyst, the soluble catalyst can select from phthalocyanine transitional metal compound and derivatives thereof, such as iron phthalocyanine and carboxylation or sulfated iron phthalocyanine. The invention also discloses electrolyte for the corresponding lithium-air battery. Through the electrolyte, a solution-phase catalytic system can be provided for the inside of the lithium-air battery, and thus even if a great amount of solid lithium oxide or lithium peroxide is formed on the surface of the air positive electrode, the favorable contact between the catalyst and a reactant can be guaranteed, the charging voltage of the lithium-air battery can be correspondently reduced, the discharging voltage can be increased, the rate capacity performance of the battery also can be improved, the capacity can be increased, and the cycling performance of the battery can be improved.

Owner:HUAZHONG UNIV OF SCI & TECH

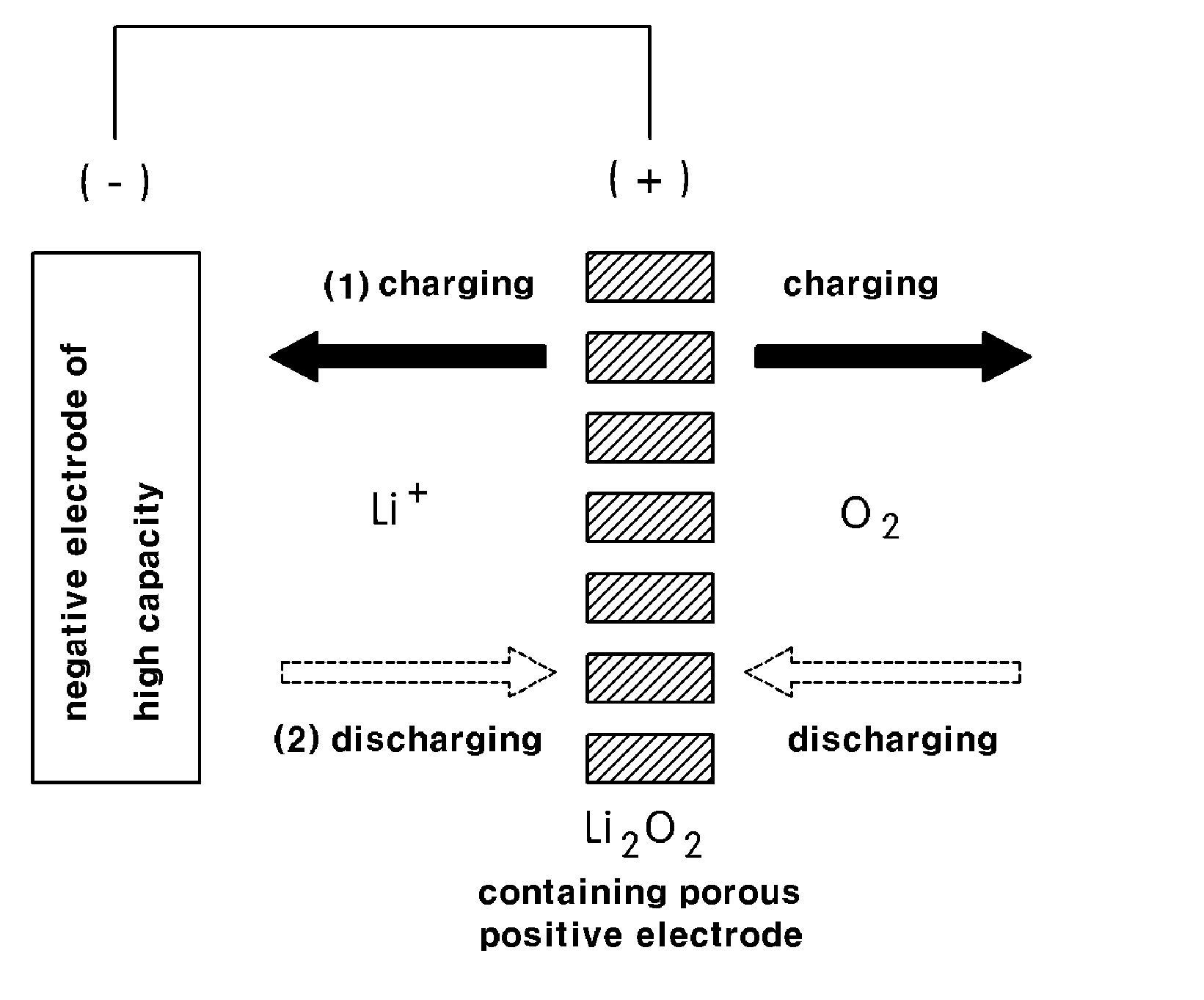

Lithium secondary battery having high capacity

InactiveUS20120328955A1Increase energy densityImprove securityNon-aqueous electrolyte accumulator electrodesLi-accumulatorsLithium oxideHigh energy

A lithium battery is formed with a combination of an increased capacity negative electrode material capable of replacing a lithium metal electrode and a high capacity positive electrode material capable of realizing a high energy density. Particularly, the lithium secondary battery includes a negative electrode, and a positive electrode containing lithium oxide (Li2O) or lithium peroxide (Li2O2) as an active material.

Owner:HYUNDAI MOTOR CO LTD

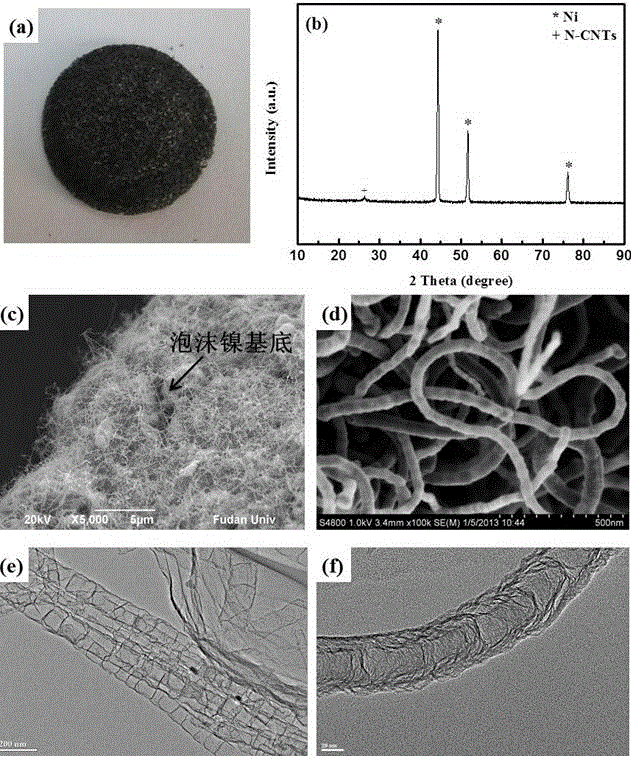

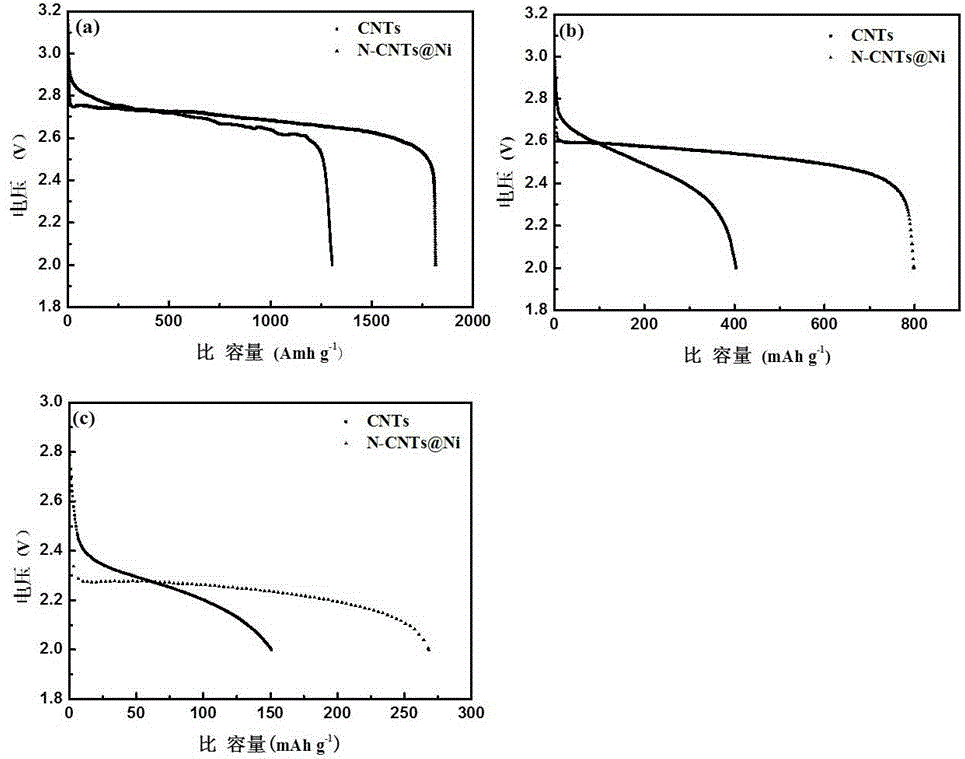

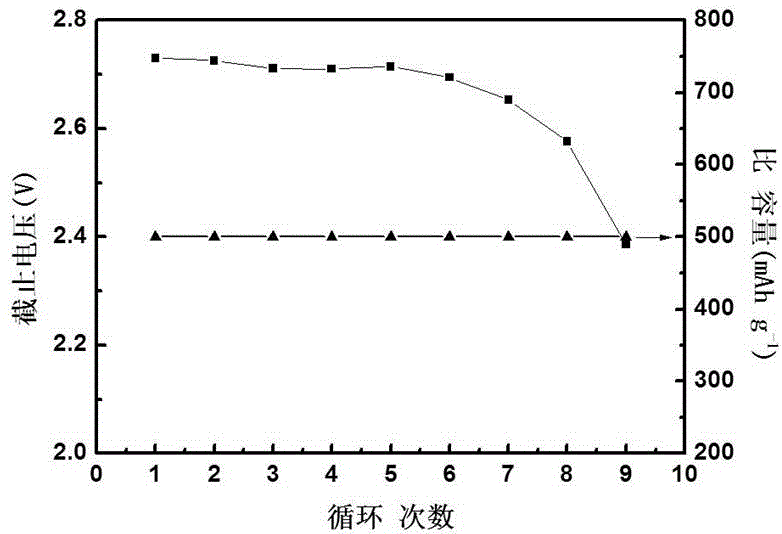

Self-supporting nitrogen-doped carbon nanotube lithium air cell cathode and preparation method thereof

The invention belongs to the technical field of lithium air cells, and particularly relates to a self-supporting nitrogen-doped carbon nanotube lithium air cell cathode and a preparation method thereof. According to the invention, a vapour deposition method is adopted; ferrocene is used as a catalyst; melamine is used as a carbon source and a nitrogen source; and a lithium air cell cathode is obtained by directly growing nitrogen-doped carbon nanotubes on a foamed nickel substrate. The method of the invention is simple in process, and good in reproducibility; the prepared carbon material is stable in structure and uniform in distribution, has a unique multistage channel three dimensional structure, prevents rigidification due to reaction between binders and intermediate products during circulation of the lithium air cell, and separates the carbon carrier from the substrate; the application of polytetrafluoroethylene with high impedance is abandoned, which greatly improves the conductivity of electrode sheets, and reduces overpotential. In addition, the multistage channel structure not only provides a gas-liquid-solid three-phase reaction site, but also accommodates lithium peroxide generated during discharging, and thus improves the electrochemical properties of the cell.

Owner:FUDAN UNIV

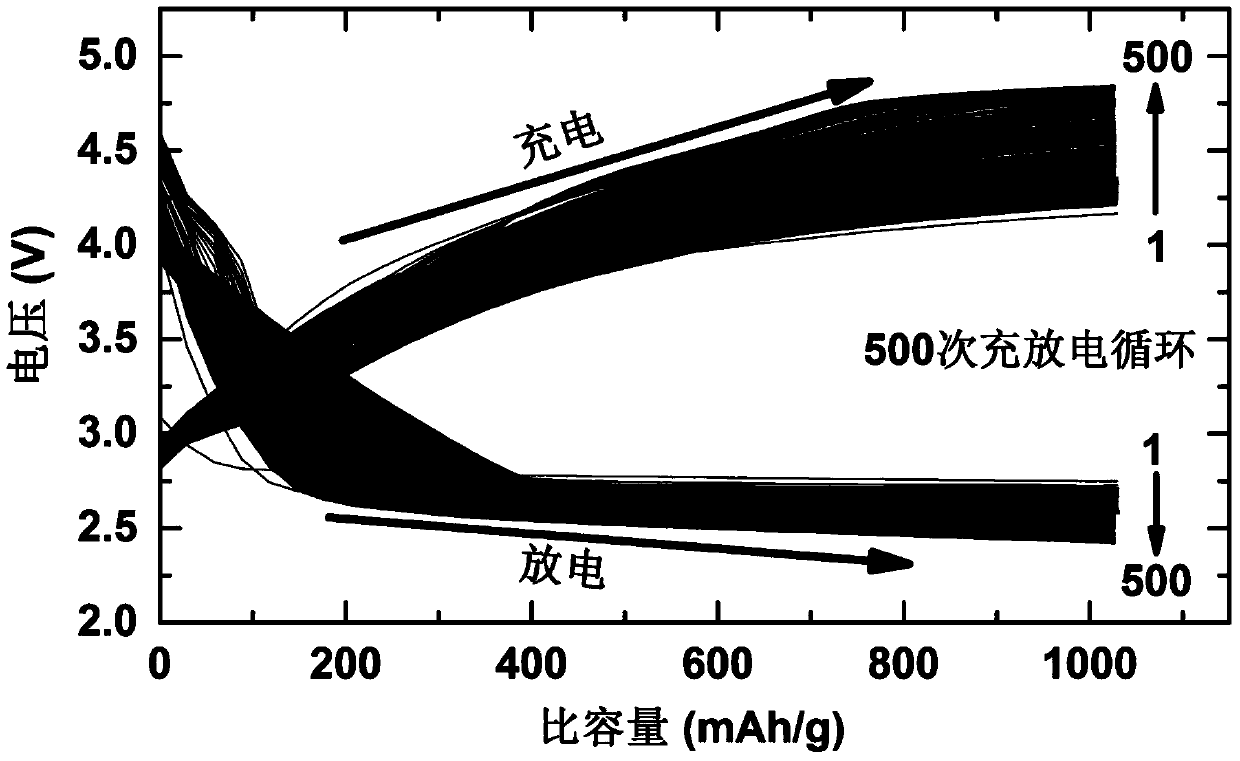

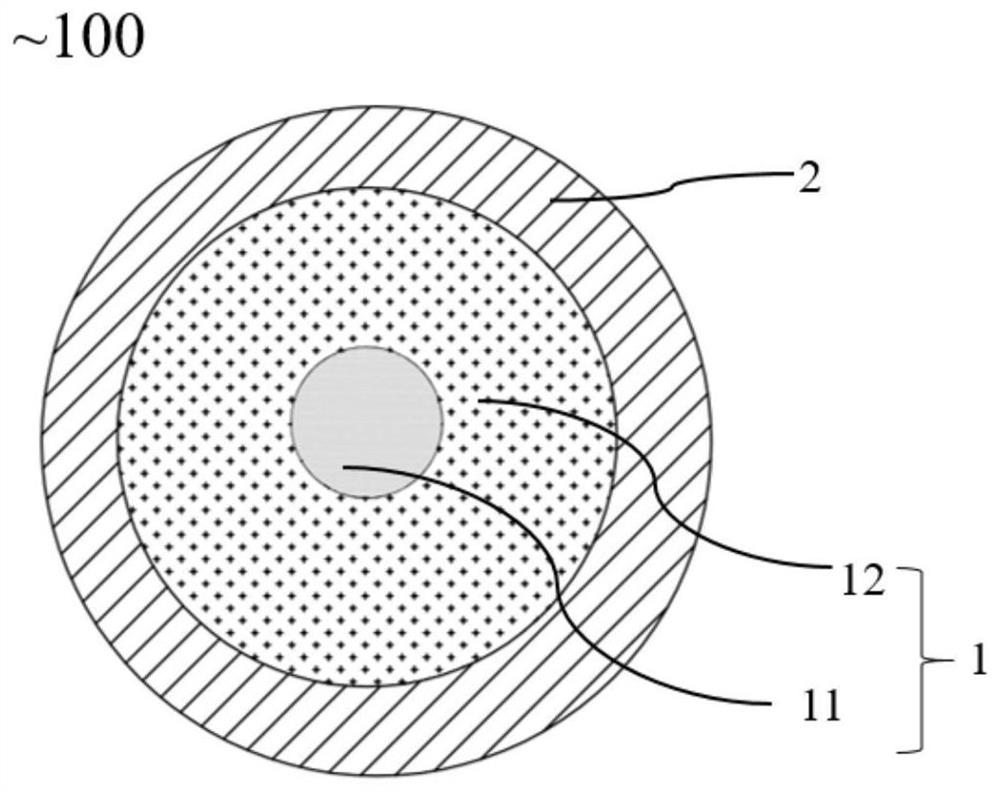

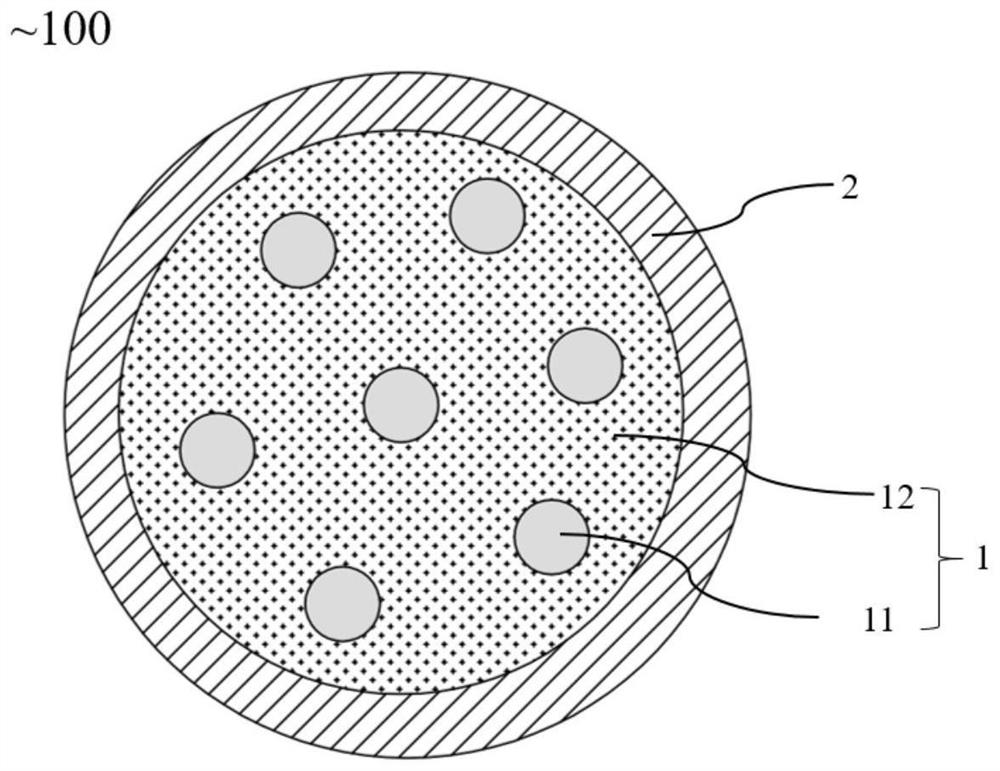

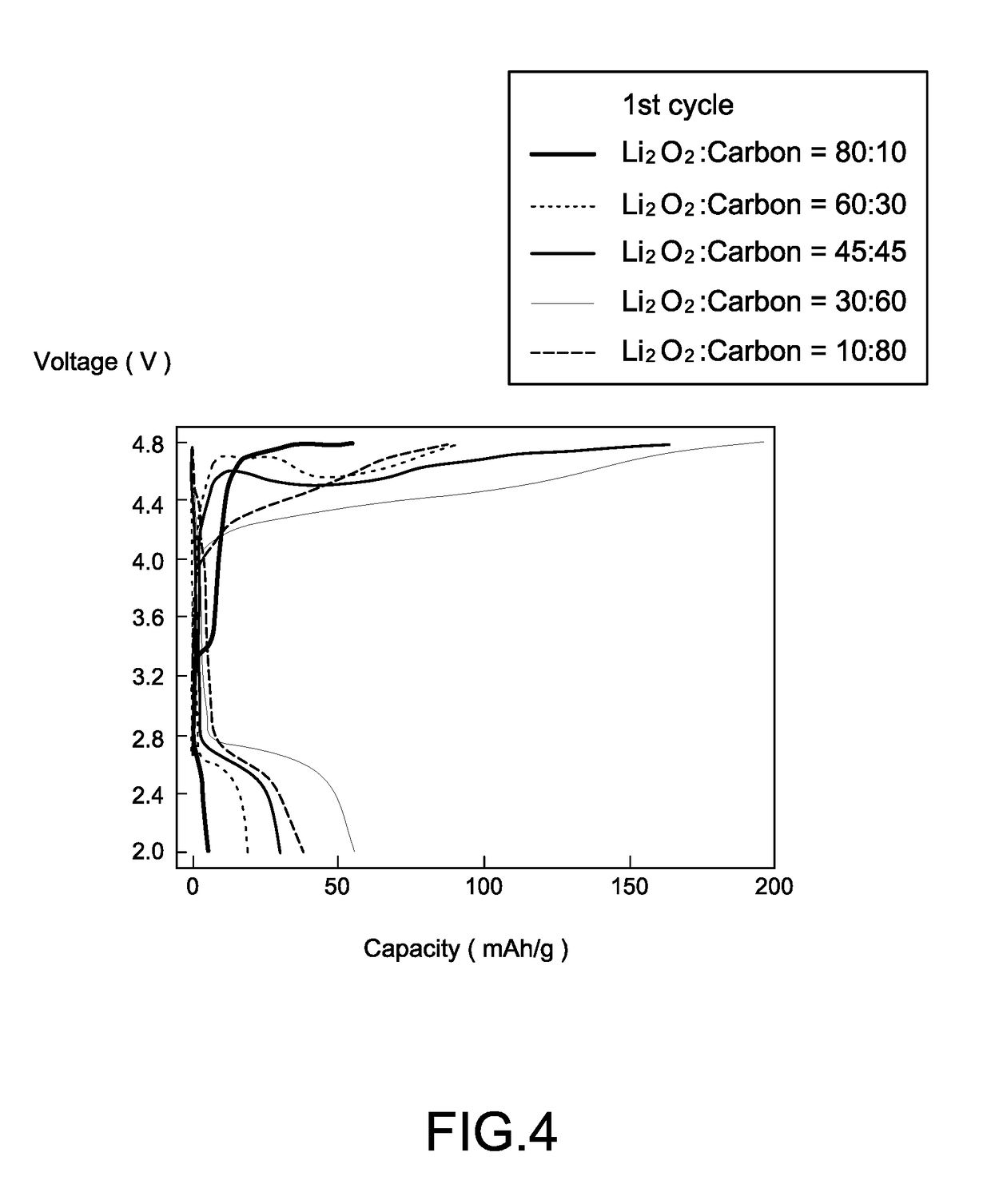

Carbon-lithium peroxide anode for lithium-air battery and preparation method of carbon-lithium peroxide anode

InactiveCN103474671AImprove stabilityImprove cycle performanceCell electrodesLithium–air batteryLithium peroxide

The invention relates to a carbon-lithium peroxide anode for a lithium-air battery and a preparation method of the carbon-lithium peroxide anode. The carbon-lithium peroxide anode comprises a carbon paper current collector and a coating layer on the carbon paper current collector, wherein the coating comprises porous electric-conduction carbon, lithium peroxide and polytetrafluoroethylene. The preparation method comprises the following steps: mixing and grinding the porous electric-conduction carbon and the lithium peroxide so as to obtain a mixture of the carbon and the lithium peroxide; mixing the mixture of the carbon and the lithium peroxide with the polytetrafluoroethylene so as to obtain a mixture I, then dispersing the mixture I in N-Methyl pyrrolidone, heating, stirring, and blending so as to obtain mixed coating slurry; coating the mixed coating slurry on one side of carbon paper, and drying so as to obtain the carbon-lithium peroxide anode for the lithium-air battery. After the anode is assembled to the battery, the primary measurement can proves that the battery can be cycled for hundreds of times, and the stability, the cycle performance and the practicability of the lithium-air battery can be improved basically. The anode can be cut in an arbitrary shape according to needs, the preparation technology is simple, the production cost is low, and the application is wide.

Owner:SHENZHEN UNIV

Metal-oxygen secondary battery

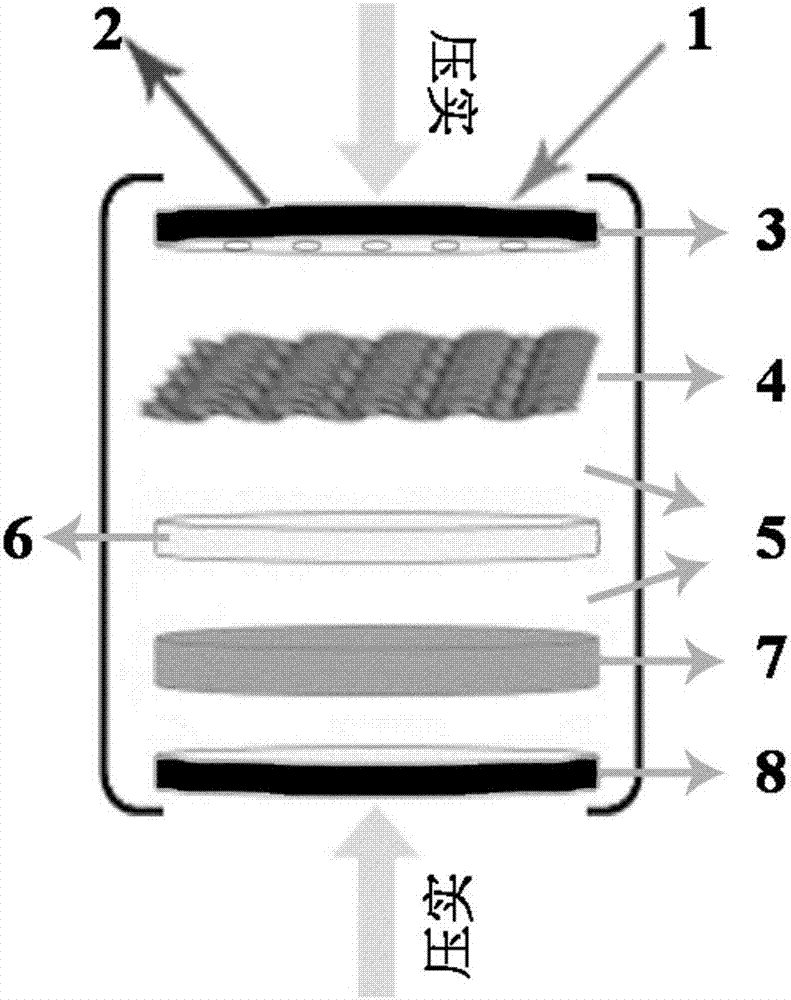

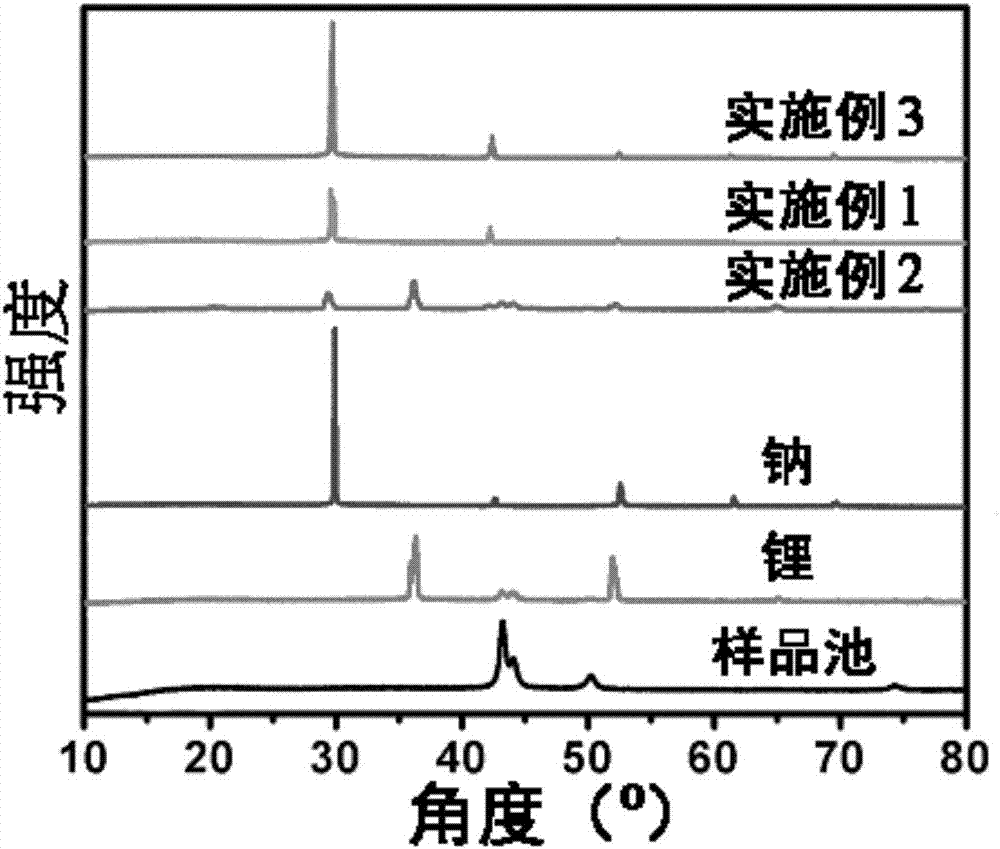

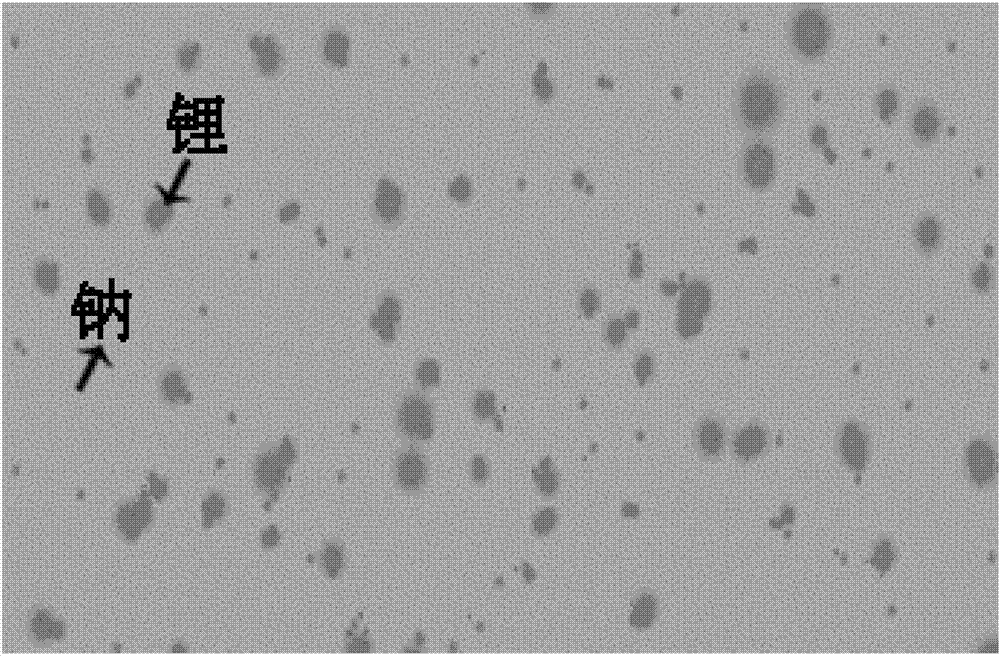

ActiveCN106935802AAchieve recyclingPromote circulationFuel and secondary cellsCell electrodesElectrical batteryMetal alloy

The invention provides a metal-oxygen secondary battery which comprises an anode, a cathode and an electrolyte, wherein the cathode comprises a lithium-sodium alloy. According to the invention, an unconventional alloy-lithium-sodium alloy is used as the cathode of the metal-oxygen secondary battery; in a discharging process, the oxygen is utilized to react and generate lithium peroxide and sodium peroxide which are attached to the anode and chemical energy is converted into electric energy; in a charging process, lithium peroxide and sodium peroxide on the anode are decomposed so as to release oxygen, so that the recycling of the oxygen is realized. The invention fills up the blank of the unconventional metal alloy applied to the technical field of an air cell and expands the research field of the air cell; the metal-oxygen secondary battery is simple and efficient; the crystal effect is solved and cracks generated by recycling are reduced; the metal-oxygen secondary battery has high stability and high use rate of atoms, meets the green chemical requirement and is beneficial to the storage and circulation of oxygen and the circular storage and utilization of large-scale renewable energy sources.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

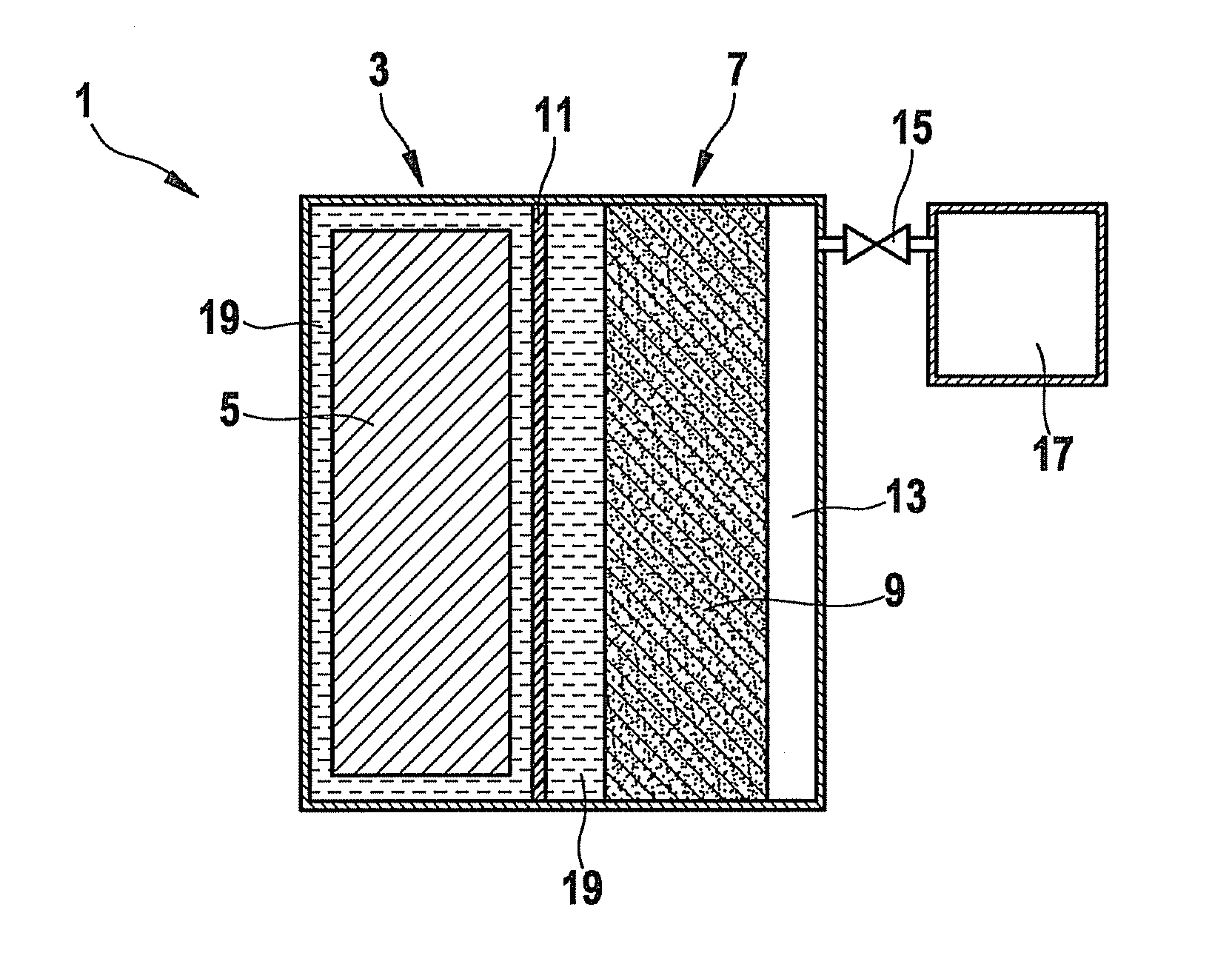

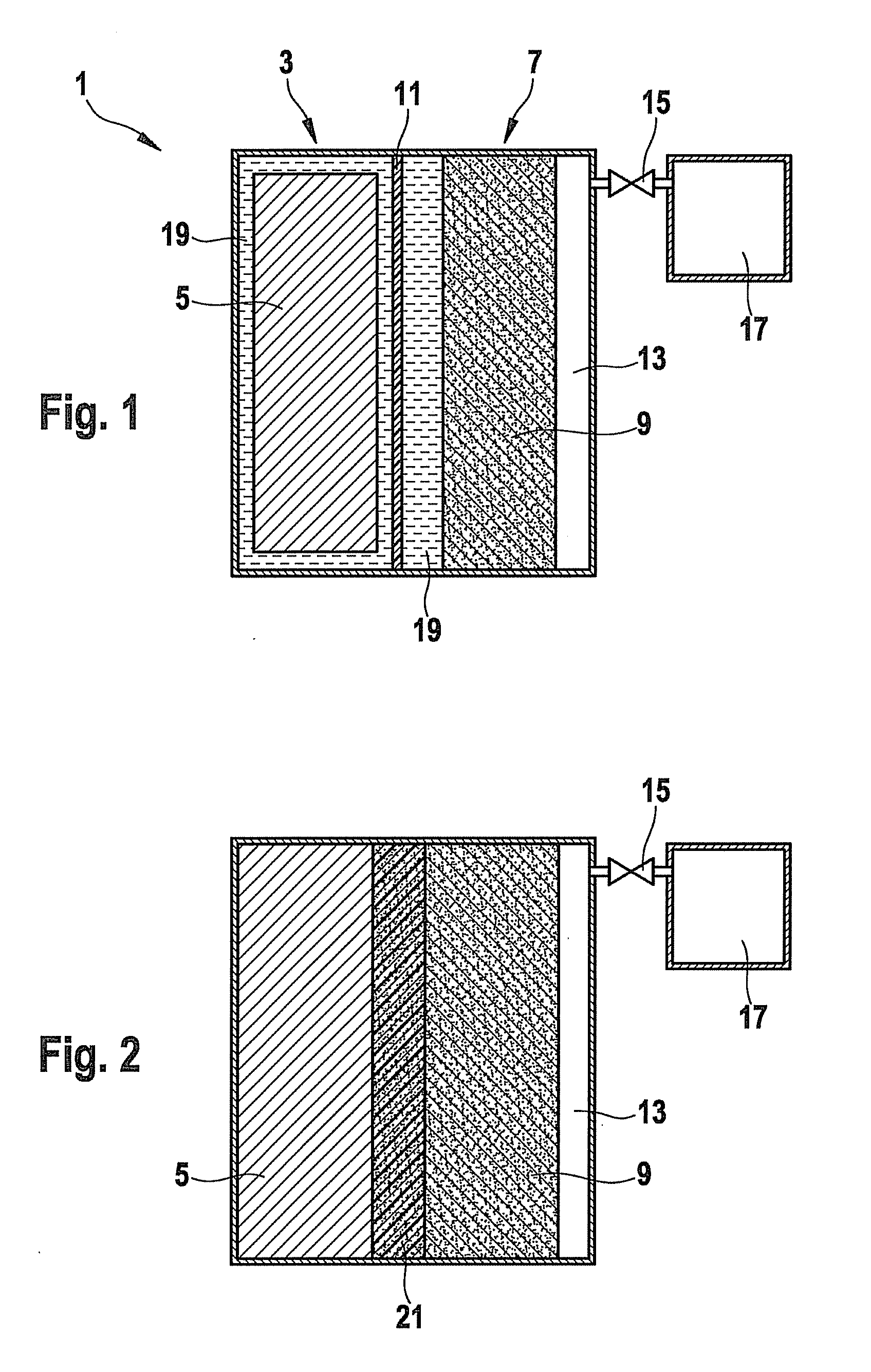

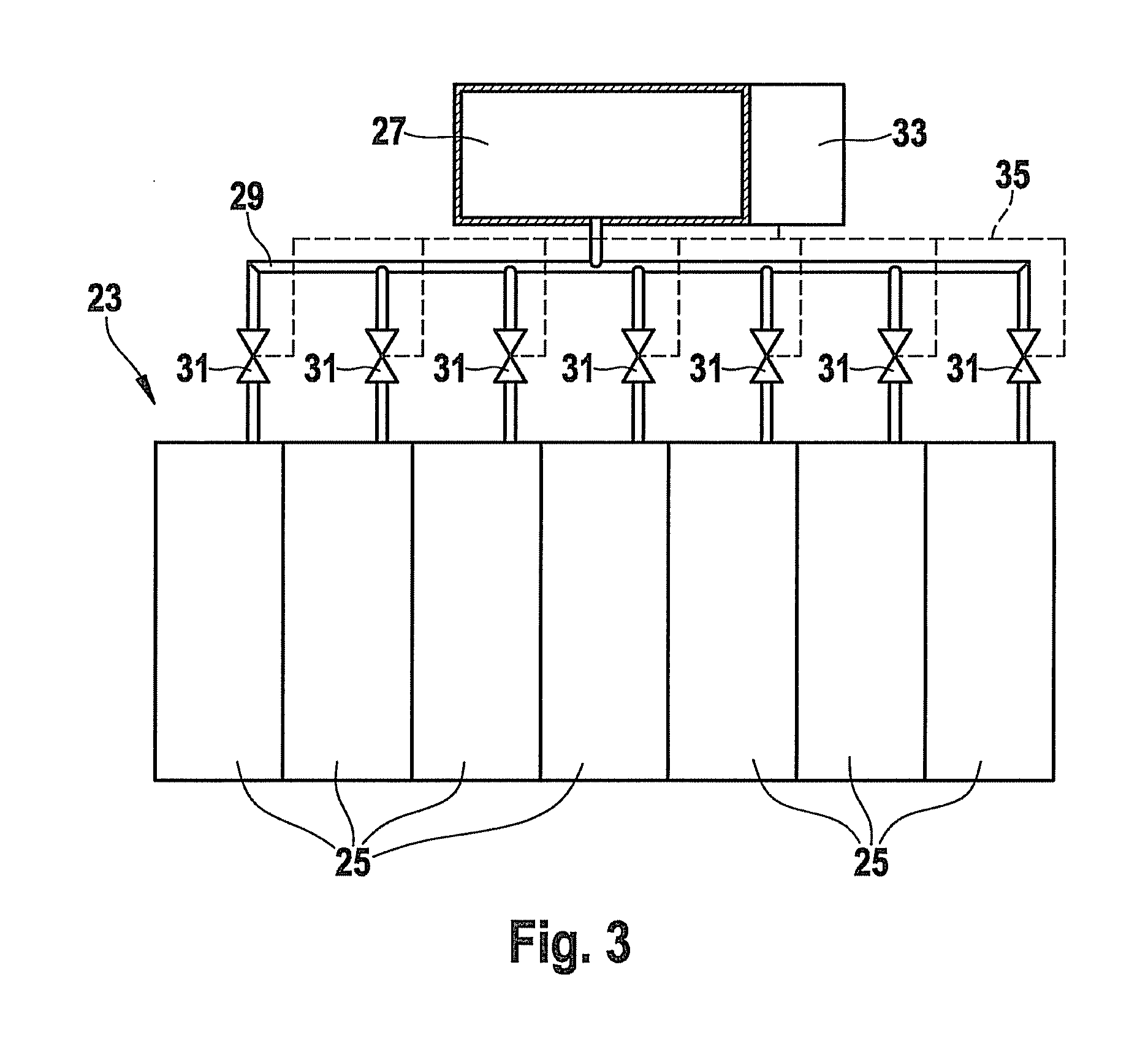

Electrochemical energy store

InactiveUS20100203397A1Inhibit side effectsFree from pollutionFuel and primary cellsFuel and secondary cellsLithium peroxideOxygen

Owner:ROBERT BOSCH GMBH

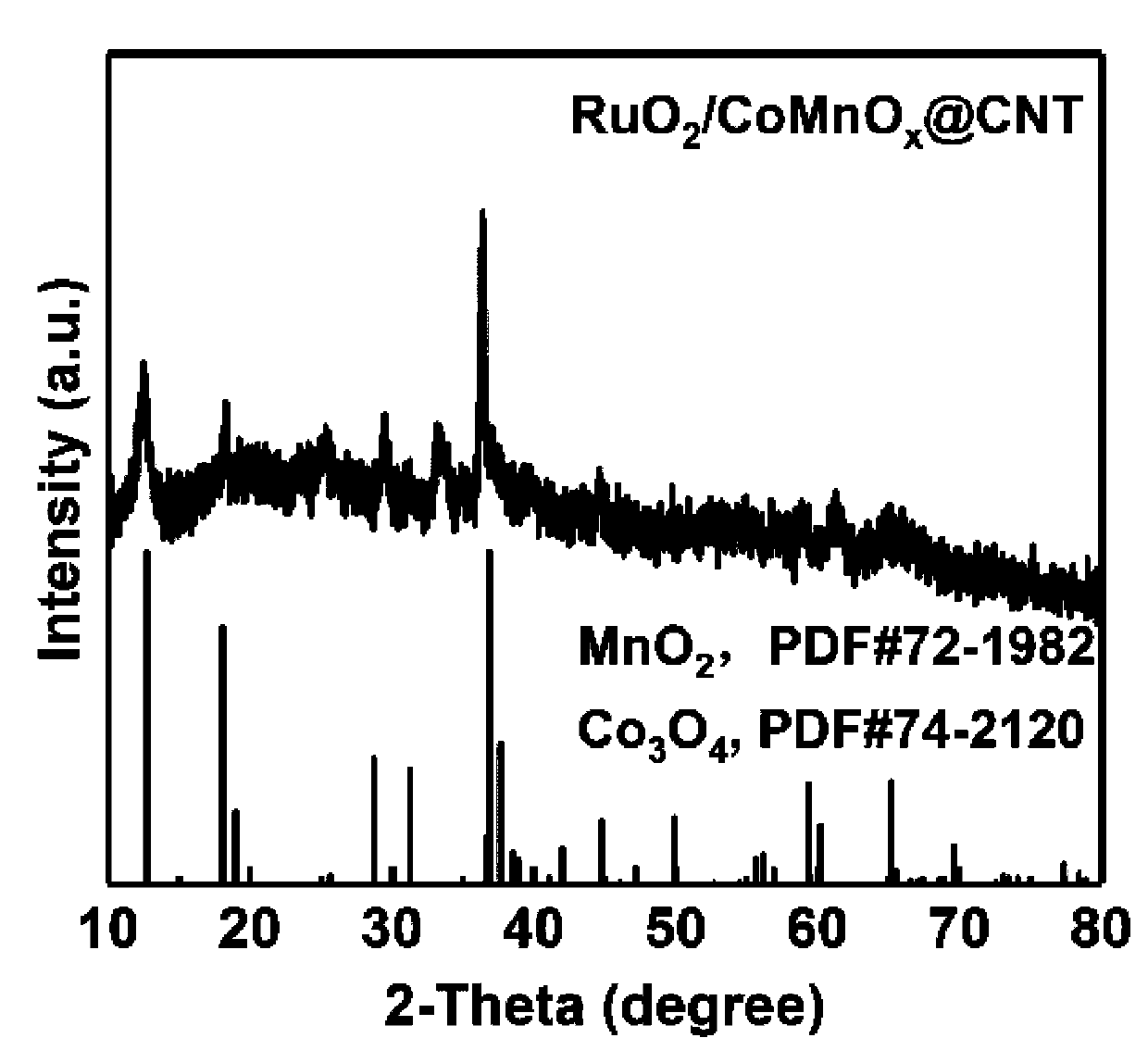

Carbon-supported noble metal oxide bifunctional catalyst and preparation method and application thereof

ActiveCN109786769AHelp with storageStable voltageFuel and secondary cellsCell electrodesDischarge efficiencyState of art

The invention discloses a carbon-supported noble metal oxide bifunctional catalyst and a preparation method and application thereof. The chemical expression of the carbon-supported noble metal oxide bifunctional catalyst is RuO<2> / CoMnO<x>@CNT; wherein Co is present in the form of Co<3>O<4>, Mn is present in the form of MnO<2>, and the content of Ru therein is 12 to 14% by weight. Through the invention, the problem that the cycle life of the lithium-oxygen battery is low caused by the unicity of the structural function of the cathode catalyst of the lithium-oxygen battery and the problems of poor charging and discharging efficiency, severe electrode polarization and bad cycle performance caused by incomplete deposition and decomposition of lithium peroxide in the prior art are solved.

Owner:XIAMEN UNIV

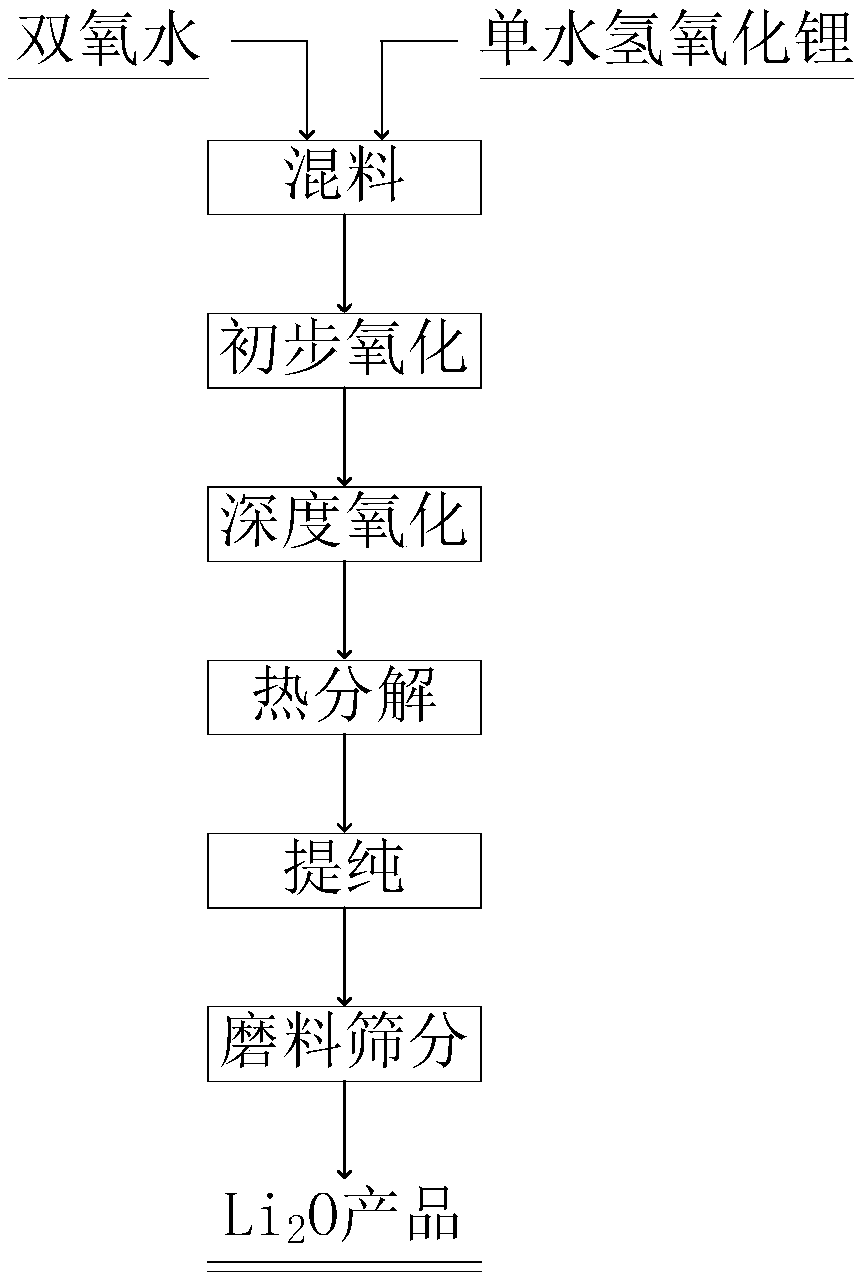

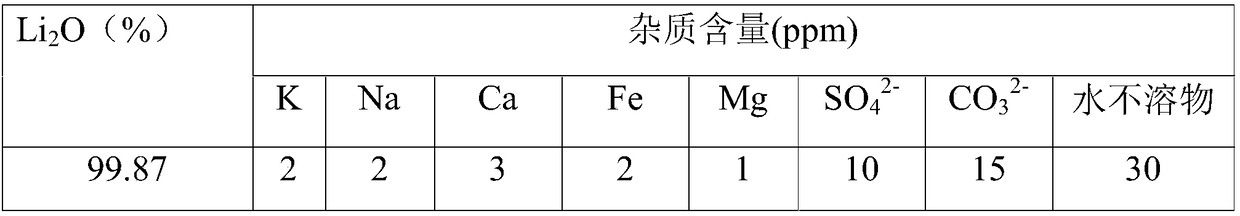

Preparation method of high-purity nano-lithium oxide

InactiveCN109336139AHigh purityReduce manufacturing costNanotechnologyLithium oxides/hydroxidesLithium oxideLithium peroxide

The invention provides a preparation method of high-purity nano-lithium oxide. The method comprises the following steps: mixing: hydrogen peroxide is added to a reactor and stirred, high-purity lithium hydroxide monohydrate is slowly added to the reactor during stirring, and a mixed solution is obtained; preliminary oxidation: the reactor is placed in a vacuum drying box and vacuumized, temperature is regulated to 80-120 DEG C and kept for a first predetermined duration, and lithium peroxide containing crystal water is obtained; deep oxidation: temperature in the vacuum drying box is regulatedto 130-120 DEG C and kept for a second predetermined duration, and lithium peroxide is obtained; thermal decomposition: the temperature in the vacuum drying box is regulated to 300-500 DEG C and keptfor a third predetermined duration, and lithium oxide is obtained; purification: the temperature in the vacuum drying box is regulated to 600-800 DEG C and kept for a fourth predetermined duration, and high-purity lithium oxide is obtained; milling and screening: high-purity lithium oxide obtained in the purification step is taken out and subjected to ball milling and screening, and nano-lithiumoxide is obtained.

Owner:天齐锂业(射洪)有限公司

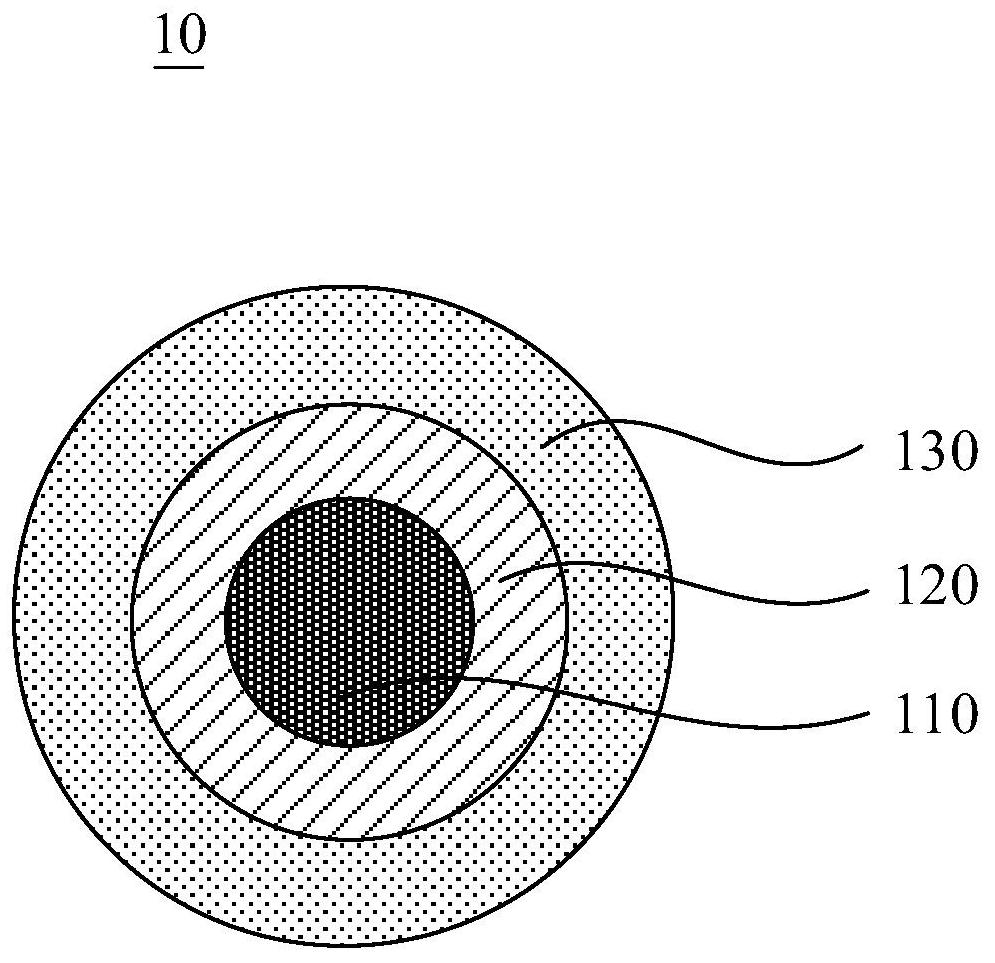

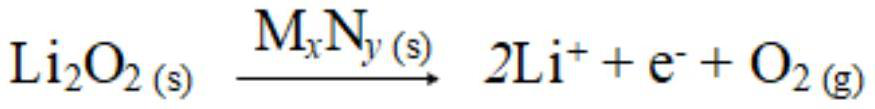

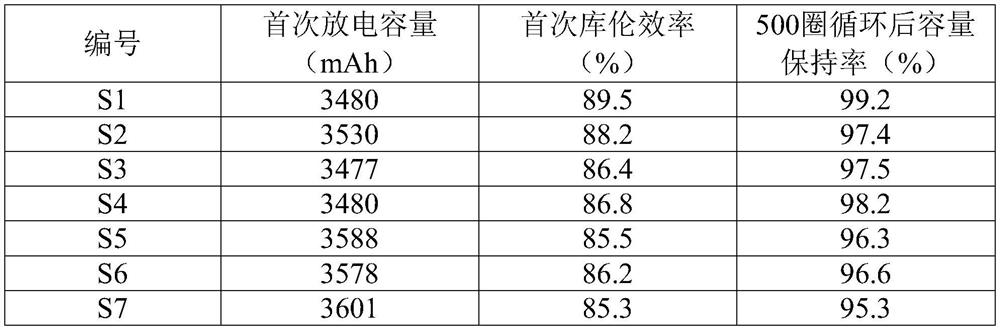

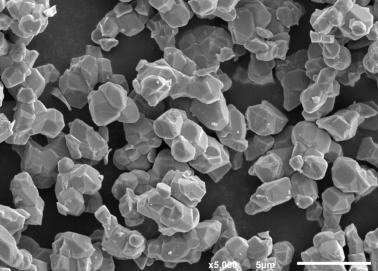

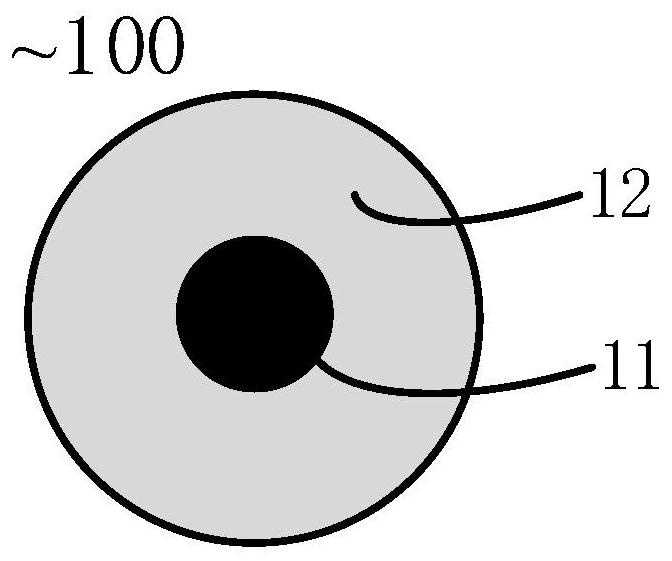

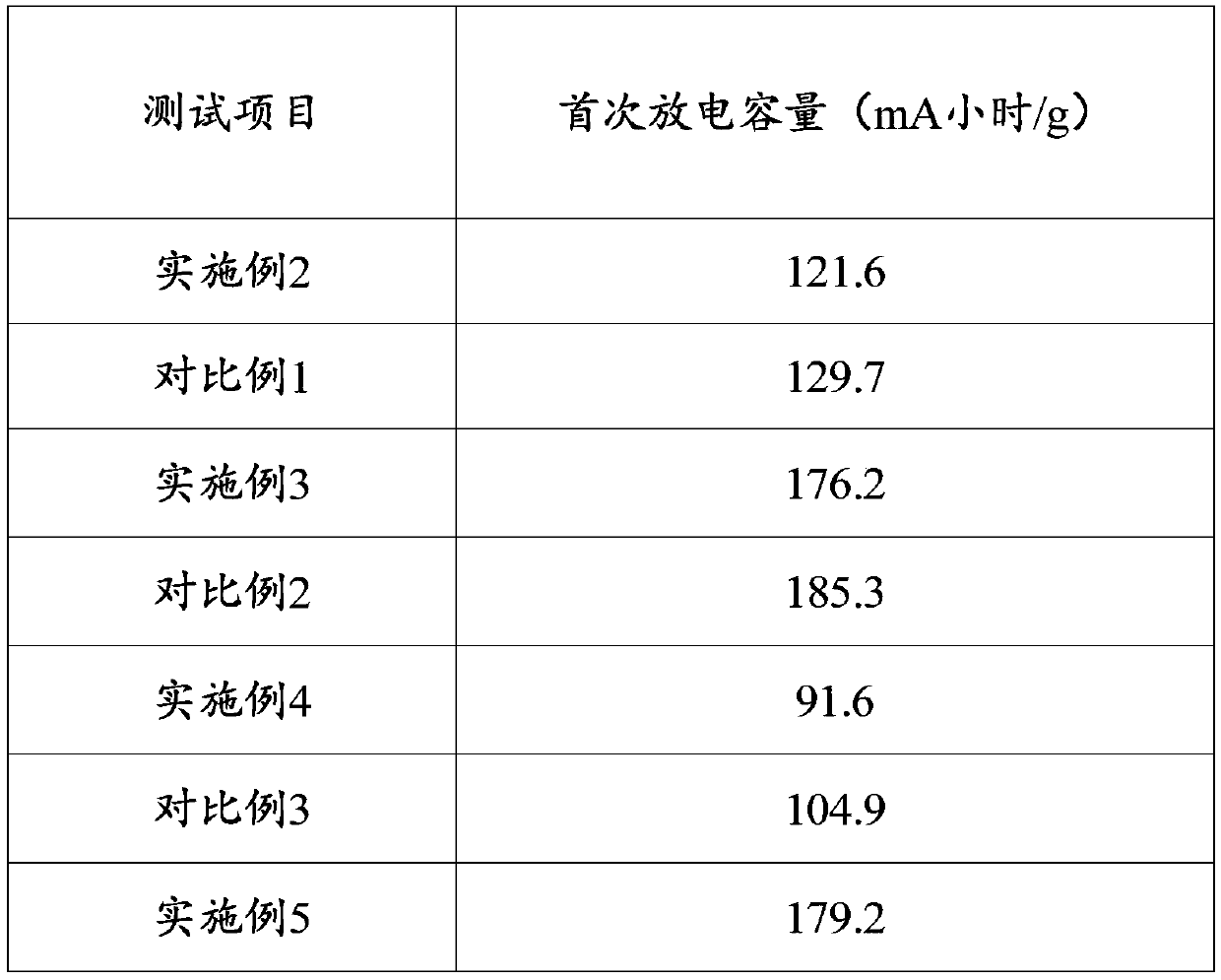

Composite cathode material and preparation method and application thereof, and lithium ion battery

ActiveCN112271281APositive electrodesSecondary cells servicing/maintenanceLithium oxideElectrolytic agent

The invention relates to a composite cathode material and a preparation method thereof and a lithium ion battery, and belongs to the technical field of batteries. The composite cathode material comprises a cathode material, a metal compound layer and a lithium peroxide layer, the surface of the cathode material is coated with the metal compound layer, and the surface of the side, away from the cathode material, of the metal compound layer is coated with the lithium peroxide layer. The metal compound layer of the composite cathode material can be used as a catalyst to reduce the decomposition potential of lithium peroxide, and in the first charging process, the metal compound can catalyze efficient decomposition of lithium peroxide and release Li+ for efficient lithium supplementation; andmeanwhile, the metal compound layer is remained on the surface of the cathode material, so that the effect of a physical barrier layer can be achieved, the cathode material is prevented from being directly contacted with the electrolyte, the interface side reaction of the cathode material is reduced, the interface stability of the cathode material and the electrolyte is improved, and the cycle performance of the battery is improved.

Owner:SUNWODA ELECTRIC VEHICLE BATTERY CO LTD

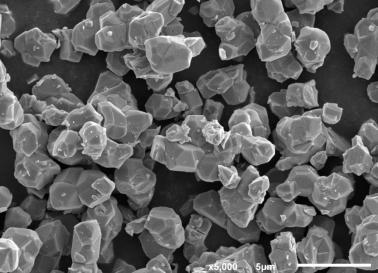

Method for preparing single-crystal ternary positive-electrode material

ActiveCN109279659AImprove consistencyImprove stabilityCell electrodesSecondary cellsLithium oxideLithium peroxide

The invention discloses a method for preparing a single-crystal ternary positive-electrode material, belonging to the technical field of lithium ion batteries. The method comprises the following steps: subjecting lithium oxide and the oxides of nickel, cobalt and manganese in a certain ratio to mixing and ball milling; performing primary sintering on a ball-milled material at 400-600 DEG C; carrying out secondary sintering on a product obtained after primary sintering at 650-780 DEG C; and finally, performing natural cooling to room temperature so as to obtain the single-crystal ternary positive-electrode material. The method of the invention directly adopts the oxides as raw materials and avoids the phenomenon of gas generation when hydroxides or carbonate compounds are used as raw materials, so the consistency of an atmosphere, the stability of heat and structural cracking are greatly improved; through direct mixing of the lithium oxide with the oxides of nickel, cobalt and manganese, uniform mixing is realized, the particle size of a sintering raw material is small, and all the elements are uniformly mixed, so a condition for forming a single crystal at a lower temperature is provided.

Owner:CNGR ADVANCED MATERIAL CO LTD

Positive electrode lithium supplement agent and preparation method and application thereof

PendingCN114530634AElectrode carriers/collectorsSecondary cells servicing/maintenanceLithium oxideElectrolytic agent

The embodiment of the invention provides a positive electrode lithium supplementing agent. The positive electrode lithium supplementing agent comprises a catalyst and a lithium-rich material, the catalyst is an oxide type positive electrode active material, the intensity ratio of a crystal face diffraction peak (003) to a crystal face diffraction peak (104) of the catalyst is smaller than or equal to 2, and the catalyst is used for catalyzing decomposition of the lithium-rich material to release active lithium. The lithium-rich material comprises at least one of lithium oxide, lithium peroxide, lithium fluoride, lithium carbonate, lithium oxalate and lithium acetate. In the presence of the catalyst, the positive electrode lithium supplementing agent can release active lithium ions at a relatively low voltage, and residues after lithium removal do not increase the risk of gas production of a battery electrolyte and do not increase the impedance of a battery cell, so that a relatively good lithium supplementing effect can be achieved. The embodiment of the invention also provides a preparation method of the positive lithium supplement agent, a battery positive plate, an electrochemical battery and a terminal.

Owner:HUAWEI TECH CO LTD

Fabrication method of lithium-air battery and lithium-air battery

ActiveCN109428138AAvoid efficiencyAvoid security issuesFuel and secondary cellsCell electrodesDecompositionSilicon alloy

The invention provides a fabrication method of a lithium-air battery without metal lithium. The fabrication method comprises the steps of (1) mixing and coating a silicon-based negative electrode material, a conductive agent and a binding agent on a negative current collector; (2) mixing and laminating a catalyst, the conductive agent, the binding agent and lithium nitride on a positive current collector in an anhydrous and oxygen-free environment; and (3) separating a positive electrode and a negative electrode by a separator in the anhydrous and oxygen-free environment, dropwise adding an electrolyte, and assembling the lithium-air battery. The lithium nitride is used as a lithium source, a silicon-based material is used as a negative electrode, a lithium-silicon alloy negative electrodeis formed during charging at initial circle, the metal lithium is substituted, lithium dendrites are prevented from being generated, and moreover, an electrical product lithium peroxide can be effectively stored in vacancies generated by the decomposition of the lithium nitride.

Owner:SHANGHAI JIAO TONG UNIV

Lithium oxygen battery electrolyte using molybdenum pentachloride as redox medium and preparation and application thereof

ActiveCN109193030AImprove cycle lifeEfficient decompositionFuel and secondary cellsSecondary cellsLithium peroxideRedox

The invention relates to a lithium-oxygen battery electrolyte using molybdenum pentachloride as redox medium and preparation and application thereof. The electrolyte includes soluble lithium salt as solute, proton-free solvent and additive molybdenum pentachloride. The concentration of solute in the electrolyte is 0.1- 1 mol / L. The concentration of molybdenum pentachloride in electrolyte is 0.01-0.1 mol / L. As that molybdenum pentachloride is use as an electrolyte additive in the lithium oxygen battery, the invention facilitates the formation of the cyclic lithium peroxide dure the discharge process, and also plays the role of stabilizing the carbon electrode. Lithium peroxide discharge products can be effectively decomposed in the charging process, and the cycle life and reversibility ofthe battery can be improved by decreasing the charging voltage. At the same time molybdenum pentachloride is stable in the battery system and no side reaction occurs. The invention has the advantagesof low cost, easy access, high efficiency and convenience.

Owner:NANKAI UNIV

Process for the chemical generation of singlet delta oxygen

This method generates the first electronically excited state of oxygen (singlet delta) at ambient temperature by a gas-solid chemical reaction involving a solid alkali metal peroxide or a solid alkaline earth peroxide and a non-radioactive-hydrogen-isotope halide gas. Singlet delta oxygen was produced from solid lithium peroxide, sodium peroxide or barium peroxide by reaction with gaseous hydrogen chloride, hydrogen bromide, deuterium chloride, or deuterium bromide. The method can be practiced in a static or a flow system, and the reaction may take place in a chemical oxygen-iodine laser. The described process avoids unstable precursors, such as basic hydrogen peroxide, and liquid phase quenching. The method is safe, compact, solvent-free, mechanically simple, requires no external energy source, and permits the generation of large quantities of singlet delta oxygen. Furthermore, since no liquid phase separations are required the process is ideally suited for zero gravitational force conditions.

Owner:ERC

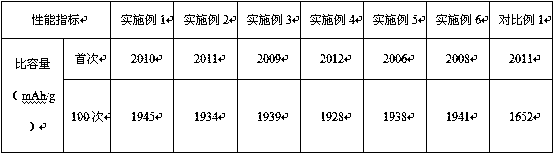

Lithium ion battery and preparation method thereof

PendingCN110100335AImprove production safetyReduce manufacturing costCell electrodesLi-accumulatorsLithium peroxideLithium-ion battery

Owner:ROBERT BOSCH GMBH

Preparation method of rock salt type lithium ion battery cathode material, lithium ion battery cathode material, and applications thereof

ActiveCN108682843AHigh specific capacityImprove electrochemical performanceCell electrodesLithium peroxidePhysical chemistry

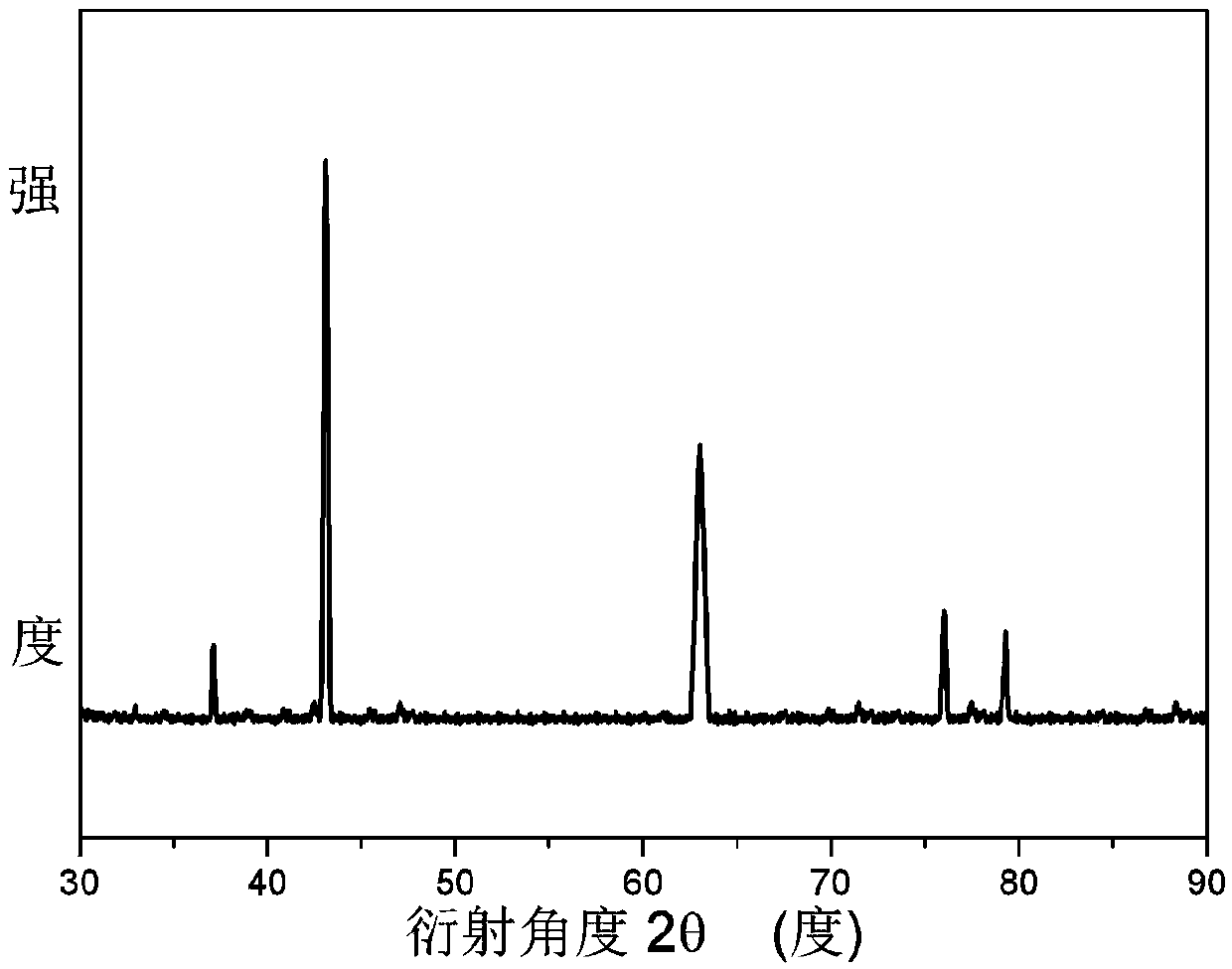

The invention discloses a preparation method of a rock salt type lithium ion battery cathode material. The preparation method comprises following steps: (1) evenly mixing a lithium source, a high-valence manganese source, and a low-valence manganese source, burning the mixture in an inert atmosphere, cooling the mixture in a furnace, and grinding the mixture to obtain a LiMnO2 precursor; and (2) evenly mixing the LiMnO2 precursor obtained in the step (1) with lithium peroxide, grinding, burning the mixture in an inert atmosphere, carrying out an annealing treatment, and cooling the mixture ina furnace to obtain the rock salt type lithium ion battery cathode material (Li4Mn2O5). The invention also provides a rock salt type lithium ion battery cathode material and applications thereof. Theprovided rock salt type lithium ion battery cathode material (Li4Mn2O5) has a pure phase rock salt structure, does not contain any purity phase, and has excellent electrochemical properties.

Owner:CENT SOUTH UNIV

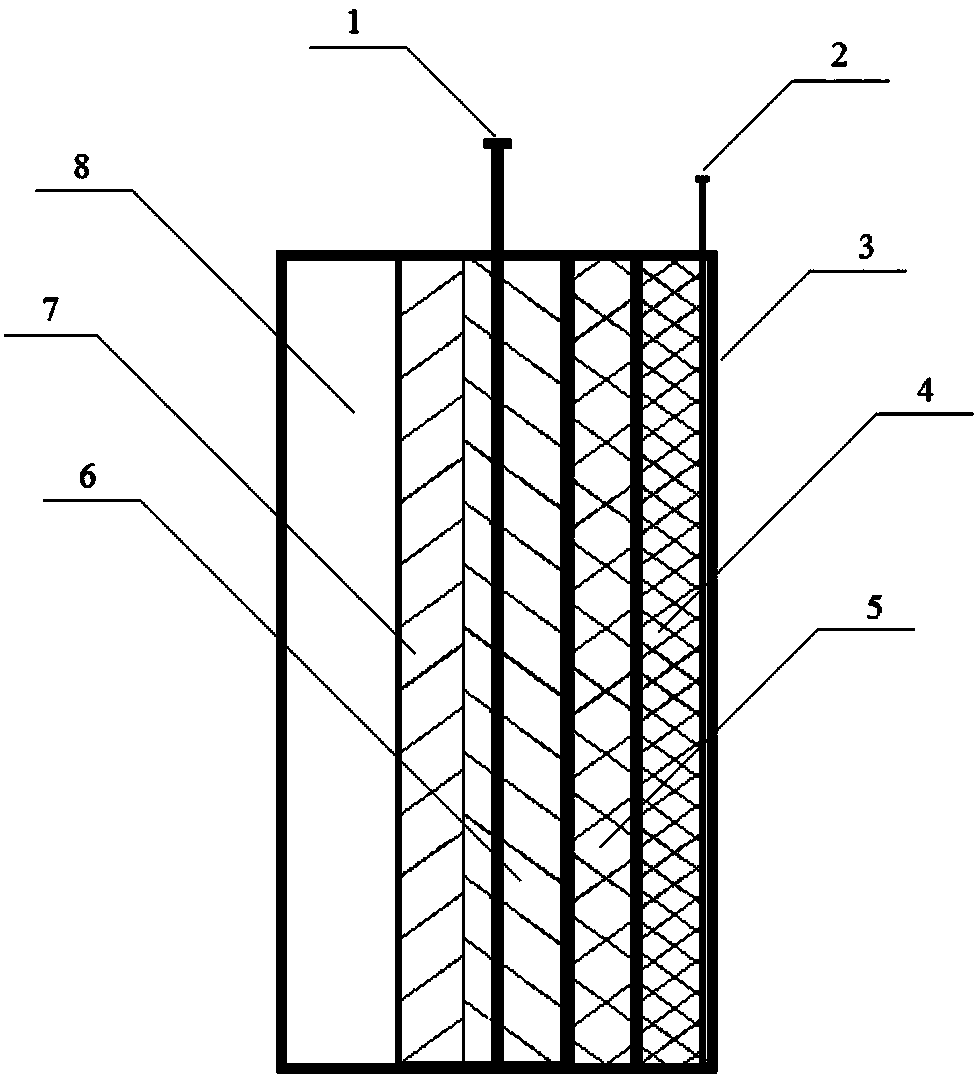

A lithium-oxygen battery

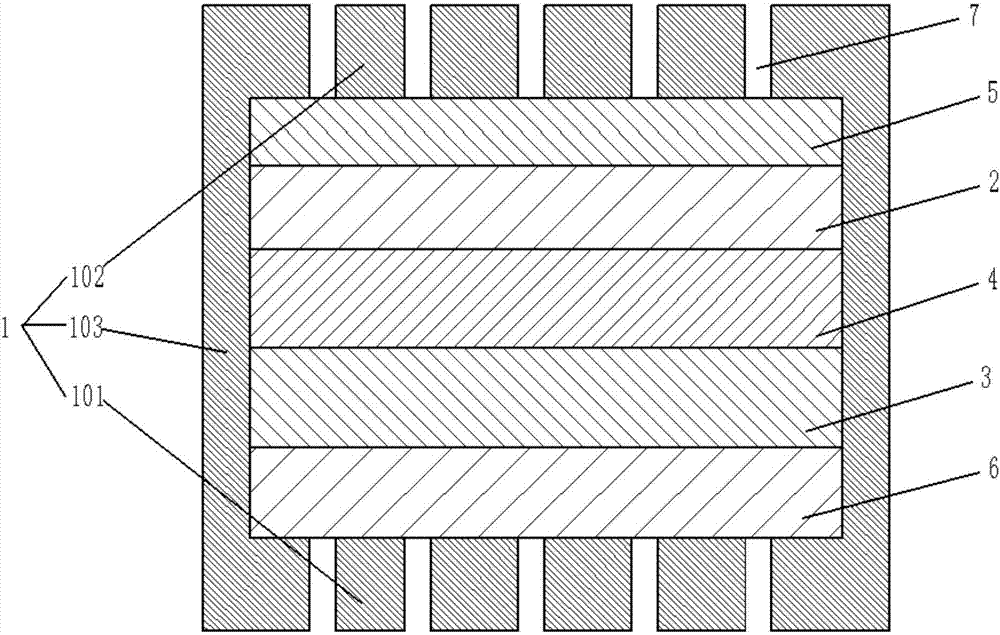

ActiveCN107482284AAvoid corrosionHigh cycle reversibilityFuel and secondary cellsSmall-sized cells cases/jacketsLithium oxideLithium peroxide

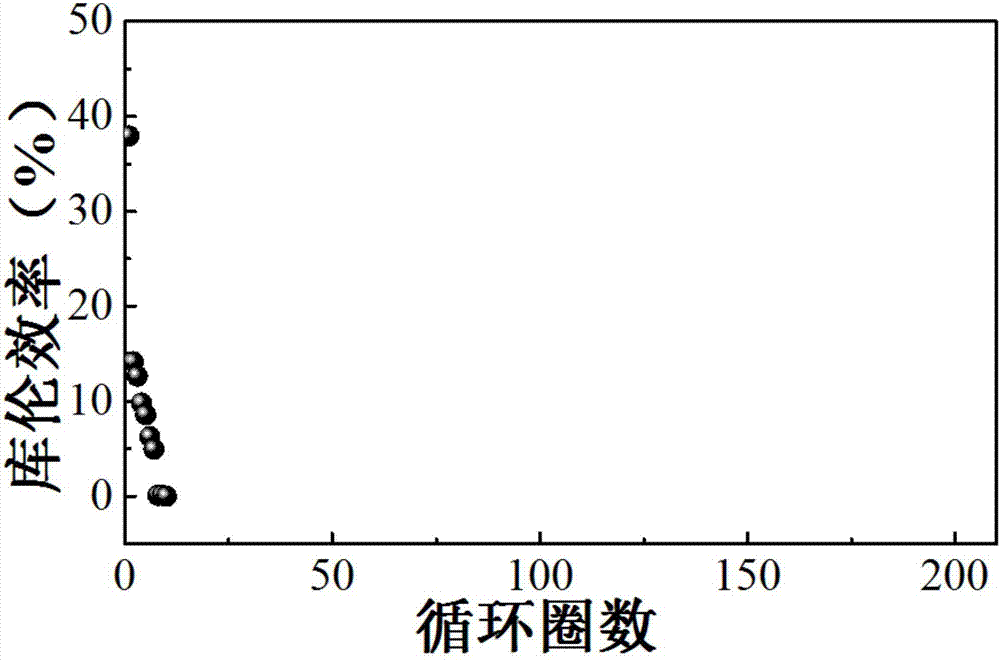

The invention relates to a lithium-oxygen battery. The battery includes shell bodies, a porous lithium anode in the shell, a porous cathode in the shell bodies, and a separating membrane disposed between the porous lithium anode and the porous cathode and provided with an electrolyte. The battery is characterized in that the battery also includes a porous anode current collector and a porous cathode current collector; the porous anode current collector, the porous lithium anode, the separating membrane provided with the electrolyte, the porous cathode and the porous cathode current collector are laminated in order; the shell body close to the porous cathode side and the shell body close to the porous lithium anode side are stainless steel shell bodies; and the stainless steel shell bodies close to the porous cathode side and the porous lithium anode side respectively are provided with a plurality of through holes from which oxygen can enter. The metal lithium anode is protected by introducing oxygen so that oxygen reacts with the metal lithium preferentially to form a dense SEI film layer rich in lithium oxide and lithium peroxide on the surface of the metal lithium, thus inhibiting metal lithium anode corrosion caused by the electrolyte, and significantly increasing cyclic stability and the coulombic efficiency of the lithium anode.

Owner:SUZHOU DISIFU NEW ENERGY TECH CO LTD +1

Unsymmetrical lithia battery

ActiveCN103035979BIncrease capacitySolving Safety Concerns of Piercing Battery SeparatorsFuel and secondary cellsCell electrodesPorous carbonPhysical chemistry

Owner:CENT SOUTH UNIV

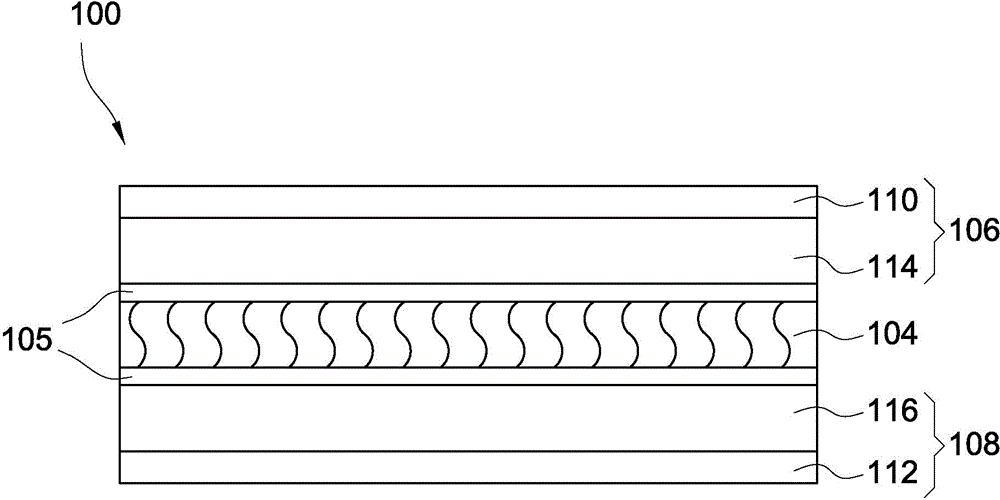

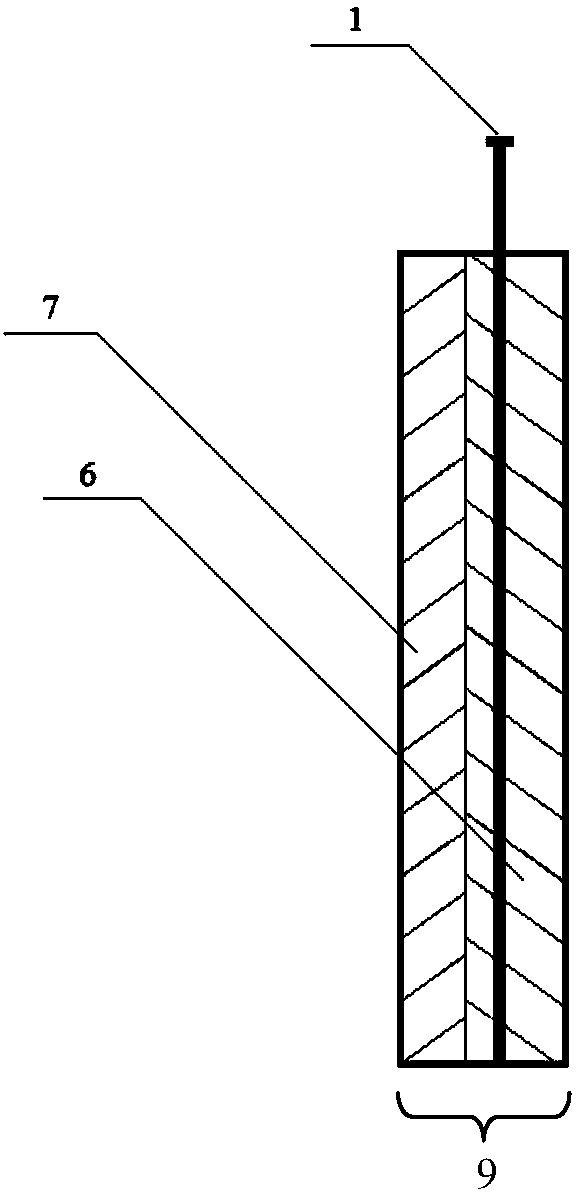

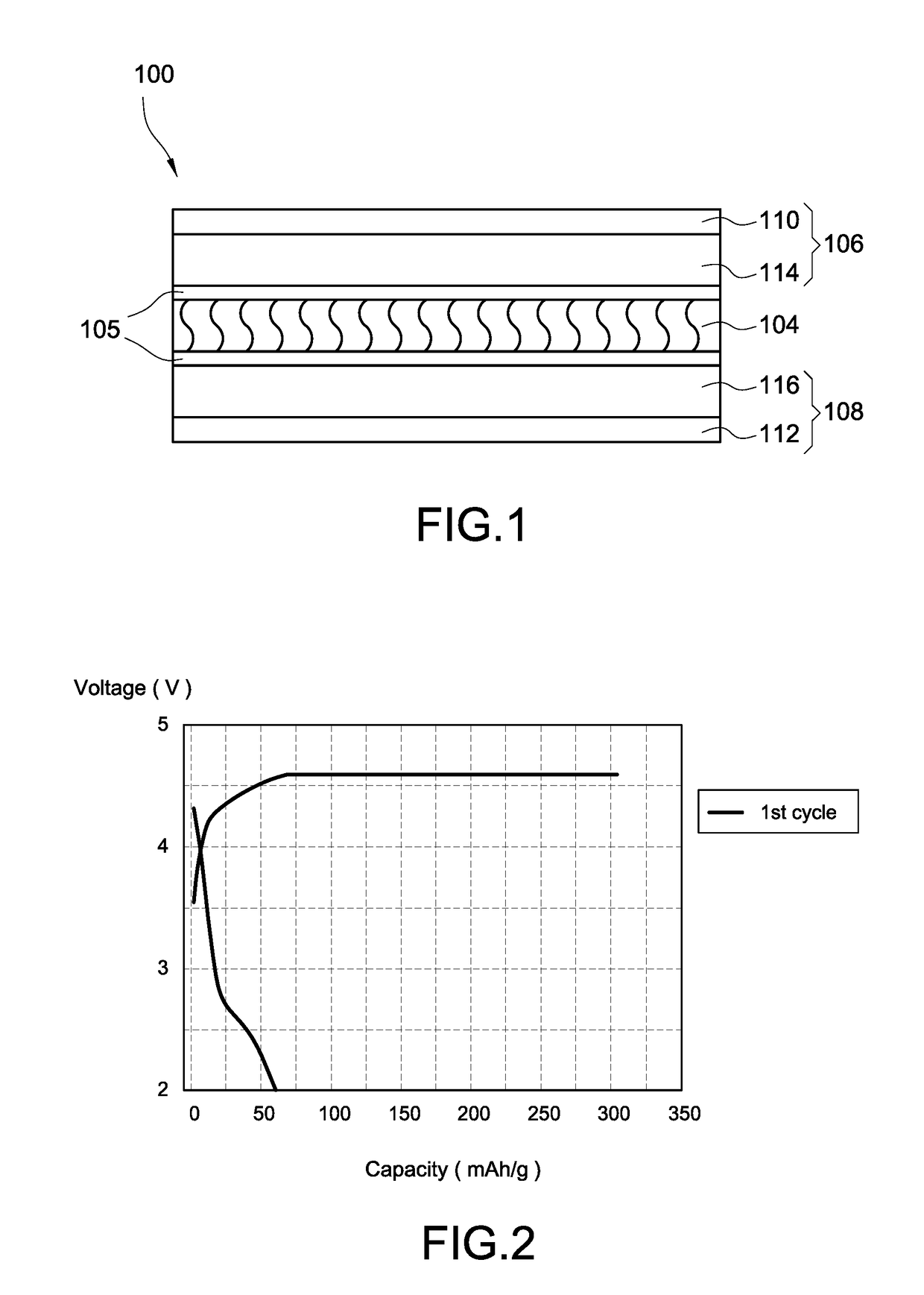

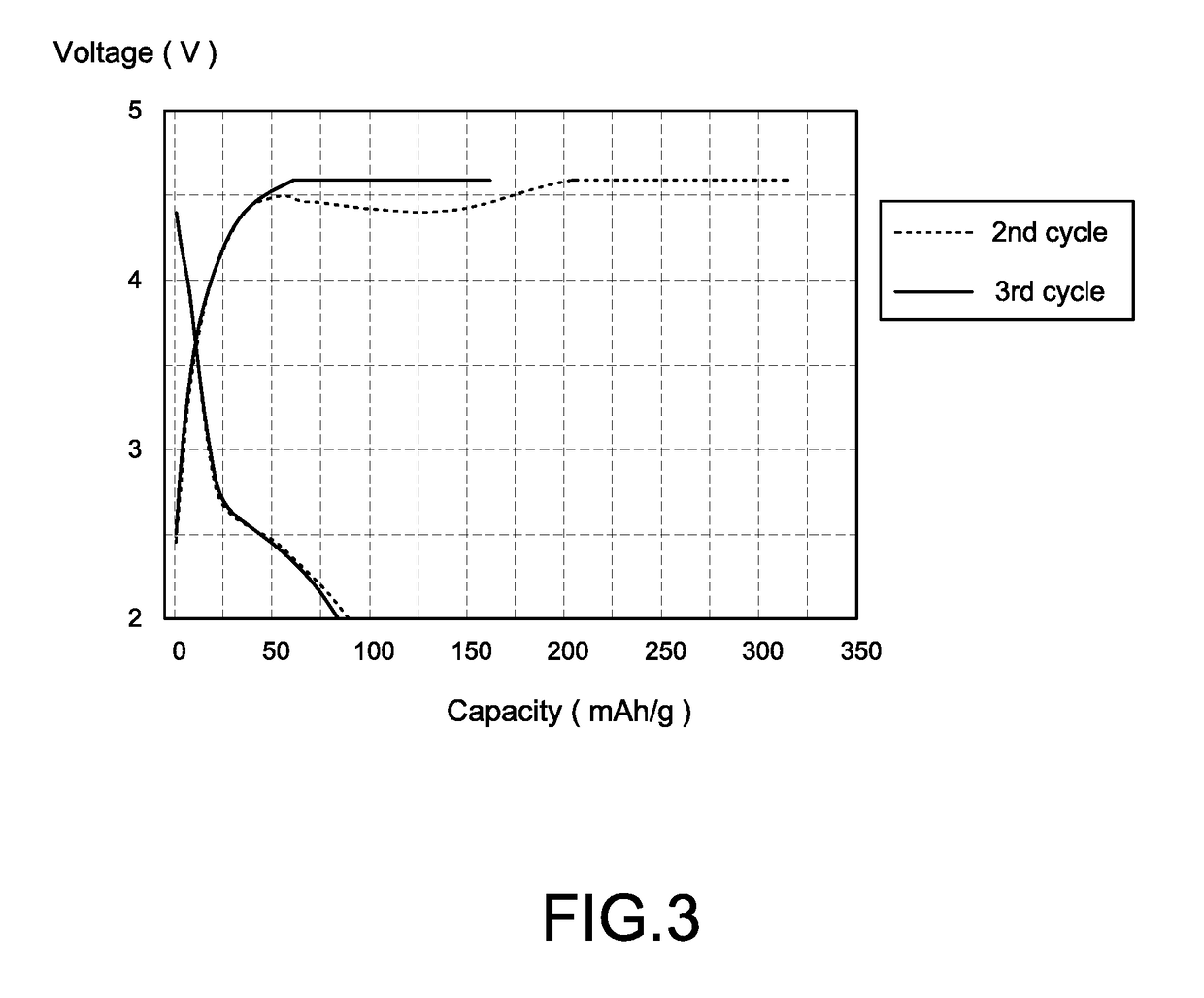

Lithium ion energy storage element and manufacturing method thereof

InactiveCN105655646AHigh unit capacityFinal product manufactureElectrolyte accumulators manufactureLithium oxideLithium peroxide

The present invention provides a lithium ion energy storage element, which comprises: a positive electrode, wherein the positive electrode comprises a first current collection sheet and a positive electrode active material on the first current collection sheet; a negative electrode, wherein the negative electrode comprises a second current collection sheet and a negative electrode active material on the second current collection sheet, and the negative electrode active material is selected from a group comprising a carbon-containing material, a Si alloy and a Sn alloy; and an electrolyte, wherein the positive electrode active material comprises a lithium ion provider and a positive electrode frame active material, and the lithium ion provider is lithium peroxide, lithium oxide, or a mixture of lithium peroxide and lithium oxide. The present invention further relates to a manufacturing method of the lithium ion energy storage element.

Owner:AMITA TECH

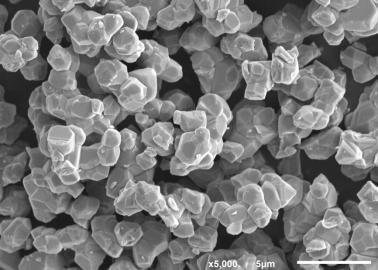

Lithium ion battery positive electrode plate added with lithium peroxide, and preparation method thereof

InactiveCN109659533AIncrease capacityMake up for consumptionSecondary cellsElectrode collector coatingLithium peroxideLithium-ion battery

The invention provides a lithium ion battery positive electrode plate added with lithium peroxide. The lithium ion battery positive electrode plate comprises the following components by weight: 70-80%of lithium peroxide, 10-15% of conductive additive, and 10-15% of binder. The invention further provides another lithium ion battery positive electrode plate added with lithium peroxide. The lithiumion battery positive electrode plate is characterized by comprising the following components by weight: 70-80% of composite positive electrode material, 10-15% of conductive additive, and 10-15% of binder, wherein the composite positive electrode material comprises a positive electrode material and lithium peroxide, and the weight percentage between the positive electrode material and the lithiumperoxide is: 90-99% of the positive electrode material, and 1-10% of lithium peroxide. The invention further provides a preparation method of the lithium ion battery positive electrode plate added with lithium peroxide. Compared with the prior art, the lithium ion battery positive electrode plate can effectively compensate for the consumption of lithium ions of the positive electrode material andincrease the capacity of the battery.

Owner:SUZHOU YOULION BATTERY INC

Co3O4/MXene composite catalyst, and preparation method and application thereof

PendingCN113224329AHigh catalytic activityLarge specific surface areaFuel and primary cellsCell electrodesLithium oxidePtru catalyst

The invention provides a Co3O4 / MXene composite catalyst, and a preparation method and application thereof. The preparation method of the Co3O4 / MXene composite catalyst comprises the step of preparing the Co3O4 / MXene composite catalytic material from MXene, cobalt salt and a precipitator through an in-situ hydrothermal method. The preparation method of the catalyst is simple and low in cost, MXene provides good conductivity for the catalyst, meanwhile, the diffusion rate of lithium ions is increased, and Co3O4 provides abundant catalytic active sites. The catalyst disclosed by the invention is used for preparing the positive electrode material of the lithium air battery, so that the decomposition of the lithium air battery product lithium peroxide (Li2O2) is effectively promoted, the problem of positive electrode blockage is avoided, and the cycle performance of the lithium air battery is greatly improved.

Owner:NANJING UNIV OF TECH +1

An air electrode of a lithium air battery and a preparation method thereof

InactiveCN109088074AInhibition of disproportionation side reactionsImprove cycle stabilityFuel and secondary cellsCell electrodesIron phthalocyanineReaction rate

The invention provides an air electrode of a lithium air battery and a preparation method thereof. The air electrode comprises a hollow porous conductive substrate, a catalyst and a coating layer. Theair electrode is mainly prepared by immersing the carbon-based material of the conductive matrix into a mixed solution of copper phthalocyanine, iron phthalocyanine and absolute ethanol, then evaporating and drying the ethanol to take out the carbon-based material, uniformly applying the ceramic slurry on the surface of the carbon-based material, preheating at a low temperature, treat at a high temperature and performing washing and drying after heat preservation. A surface of the hollow electrode is coated with a uniform and compact layer of ceramic-based oxygen ion conductor, and the reaction rate of the lithium-air battery can be further controlled by adjusting the thickness of the ceramic film, so as to prevent the internal temperature of the battery from being too high due to the reaction too fast and improve the cycle stability of the battery. The invention can effectively suppress the side reaction of the lithium peroxide disproportionation caused by the catalyst and solve theproblem of the lithium peroxide blocking the positive electrode channel.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Lithium-oxygen battery and preparation method thereof

PendingCN108110385AAvoid problems such as cloggingAffect performanceFuel and secondary cellsCell electrodesElectrical batteryLithium peroxide

The invention relates to a lithium-oxygen battery and a preparation method thereof. The lithium-oxygen battery comprises a shell, a positive pole, a negative pole, a separator located between the positive pole and the negative pole, a positive terminal connected with the positive pole and led out of the shell as well as a negative terminal connected with the negative pole and led out of the shell,wherein the positive pole and the negative pole are arranged in the shell; the positive pole comprises a gas diffusion layer allowing oxygen to pass and a lithium peroxide loading layer which is located between the gas diffusion layer and the separator; the lithium-oxygen battery further comprises a gas chamber for storing oxygen, and the gas chamber is formed in the side, opposite to the side where the lithium peroxide loading layer is located, of the gas diffusion layer and communicated with the gas diffusion layer; the negative pole is a collector electrode formed by copper, a copper-zincalloy, nickel, a nickel-zinc alloy or a nickel-copper alloy; the lithium-oxygen battery further comprises an electrolyte filling space between the positive pole and the negative pole and in the separator. The lithium-oxygen battery is high in specific energy, high in charge-discharge cycle performance and low in cost, facilitates large scale production and has broad application prospect in the energy-storage aspects of electric tools, electric vehicles, power grids and the like.

Owner:CHAOWEI POWER CO LTD

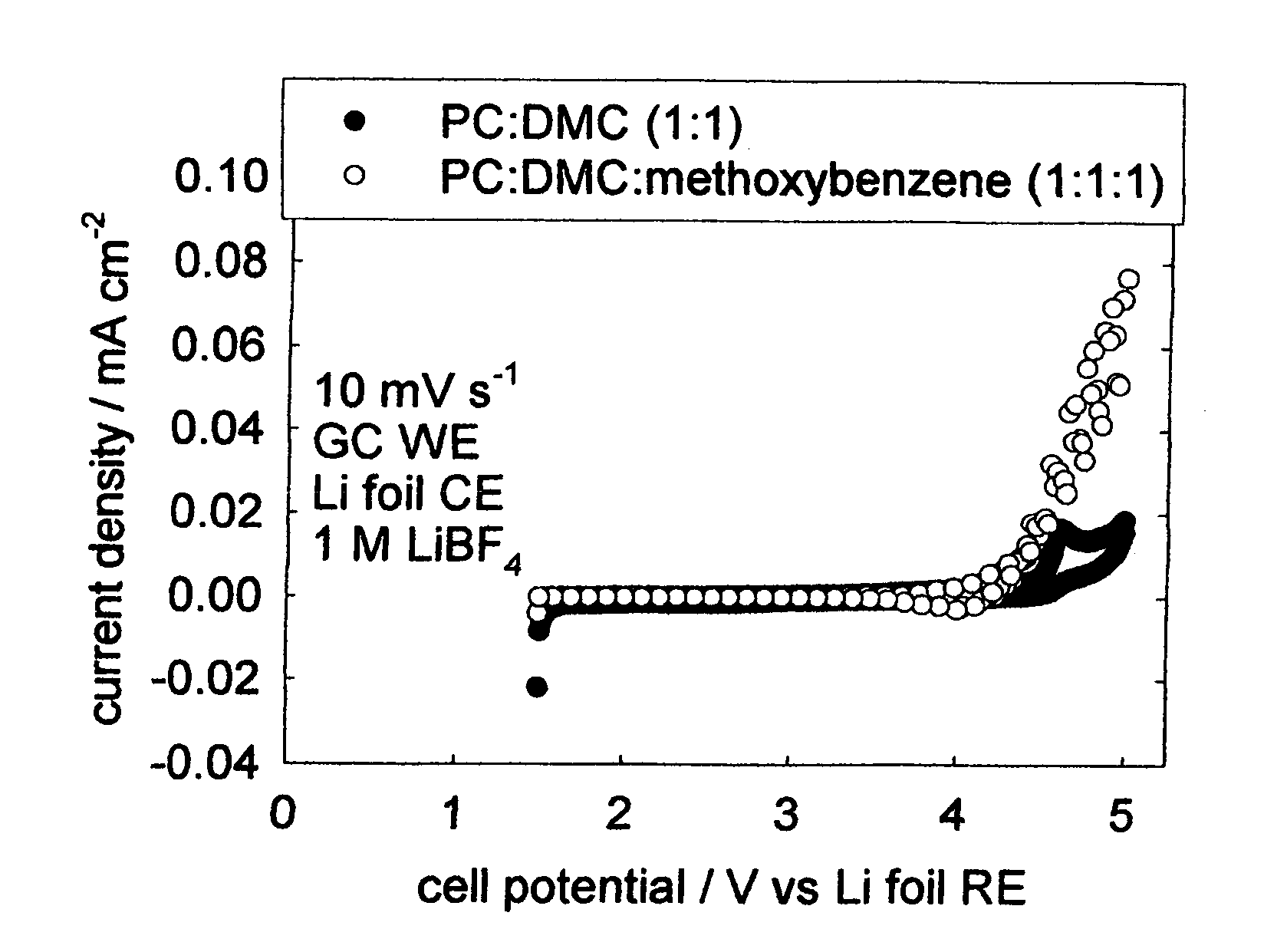

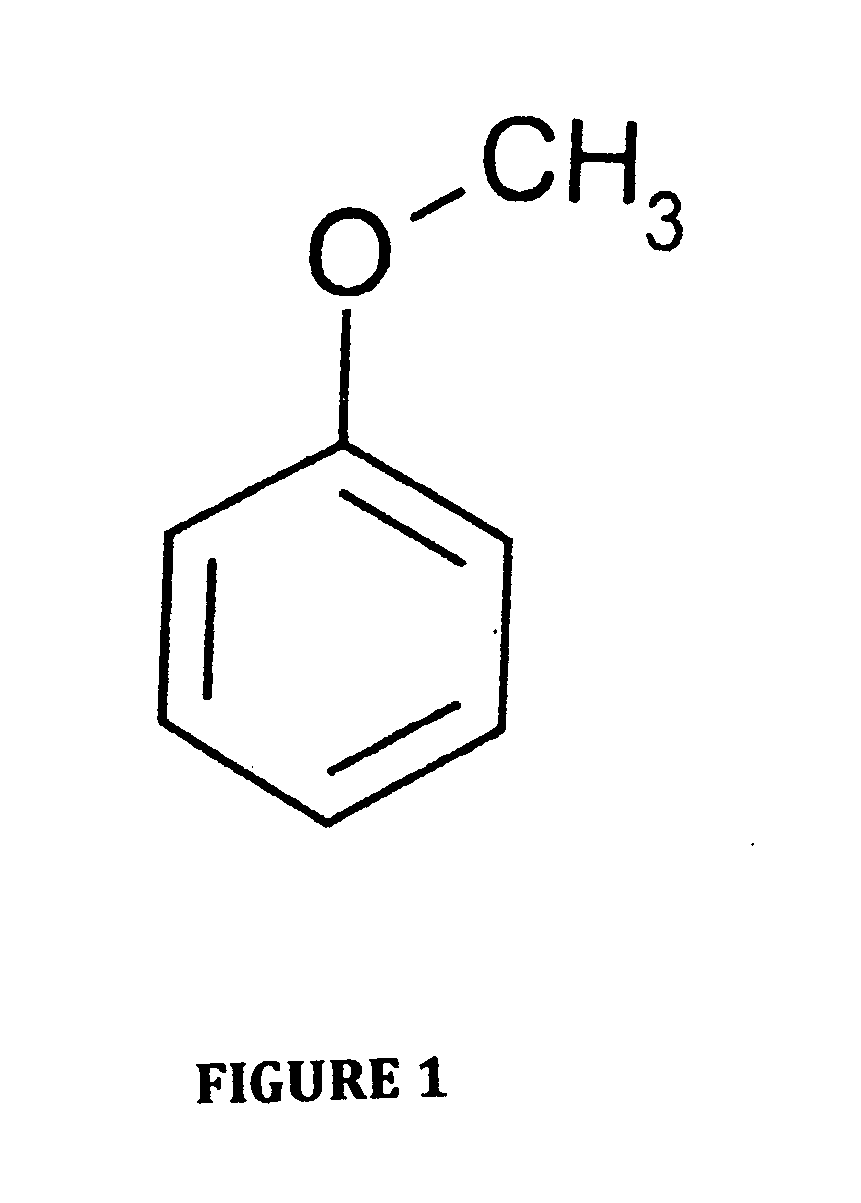

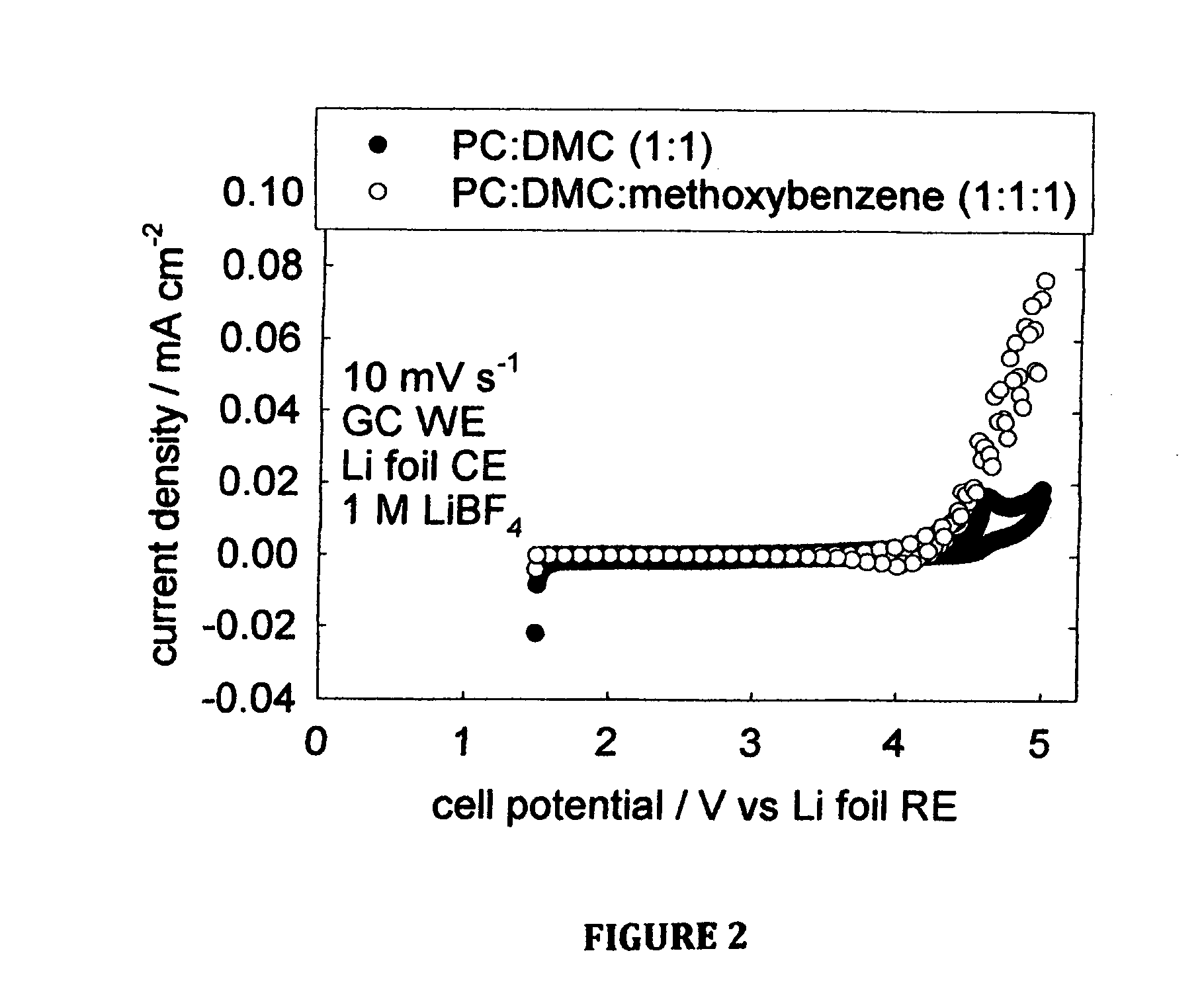

Electrolyte containing methoxybenzene for use in lithium-air semi-fuel cells

InactiveUS20120121993A1Long operating timeIncrease energy densityFuel and primary cellsCell electrodesSolubilityMetallic lithium

Disclosed herein are electrolyte formulations containing methoxybenzene (also known as anisole or phenoxymethane) for use in lithium-air semi-fuel cells. Lithium-air semi-fuel cells contain a metallic lithium anode and an air (oxygen) fuel cell type porous carbon cathode. The reaction product in the cathode is lithium oxide (Li2O) and / or lithium peroxide (Li2O2). This reaction product is sparingly soluble in common lithium-air cell solvents, and therefore the cathode pores become blocked over time, leading to cell end-of-life. Methoxybenzene is an organic solvent that demonstrates an increased solubility of Li2O, which minimizes the clogging of the cathode. Lithium-air semi-fuel cells with electrolytes containing methoxybenzene demonstrate higher discharge capacities per the same weight, than the cells having electrolytes without methoxybenzene. Higher energy density semi-fuel cells are thus achieved.

Owner:CHUA DAVID +3

Method for making lithium ionic energy storage element

ActiveUS20190020014A1Large capacityElectrode thermal treatmentFinal product manufactureLithium oxideLithium peroxide

A method for making a lithium ionic energy storage element, the method includes the steps of: (a) mixing a lithium ion donor, a positive electrode frame active substance and a binder with a predetermined weight ratio to form a mixture, and adding the mixture into a dispersant to form a positive electrode active substance, wherein the lithium ion donor includes lithium peroxide, lithium oxide or a combination thereof; (b) coating the positive electrode active substance on an aluminum foil to form a film, and baking the film to form a positive electrode; and (c) forming a lithium ionic energy storage element by assembling the positive electrode, a negative electrode having a negative electrode active substance and a porous separate strip interposed between the positive electrode and the negative electrode, and filling an electrolyte into the porous separate strip.

Owner:AMITA TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com