Lithium ion battery positive electrode plate added with lithium peroxide, and preparation method thereof

A lithium-ion battery, lithium peroxide technology, applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve problems such as large consumption of positive lithium ions, irreversible capacity loss, aggravation of irreversible capacity, etc., to make up for consumption and increase capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Lithium peroxide (Li 2 o 2 ), conductive additive (Sp), and binder (PVDF) were added to the NMP solvent at a time according to the mass ratio of 80:10:10, and dispersed uniformly to form a uniform slurry; the slurry was coated on aluminum foil and placed in a vacuum oven at 85°C Dry in medium for 6 hours to obtain lithium peroxide pole piece.

[0033] Alternative scheme: Lithium peroxide (Li 2 o 2 ), conductive additive (Sp), and binder (PVDF) were added to the NMP solvent at a time according to the mass ratio of 70:15:15, and dispersed evenly to form a uniform slurry; the slurry was coated on the aluminum foil and placed in a vacuum oven at 85°C Dry in medium for 6 hours to obtain lithium peroxide pole piece.

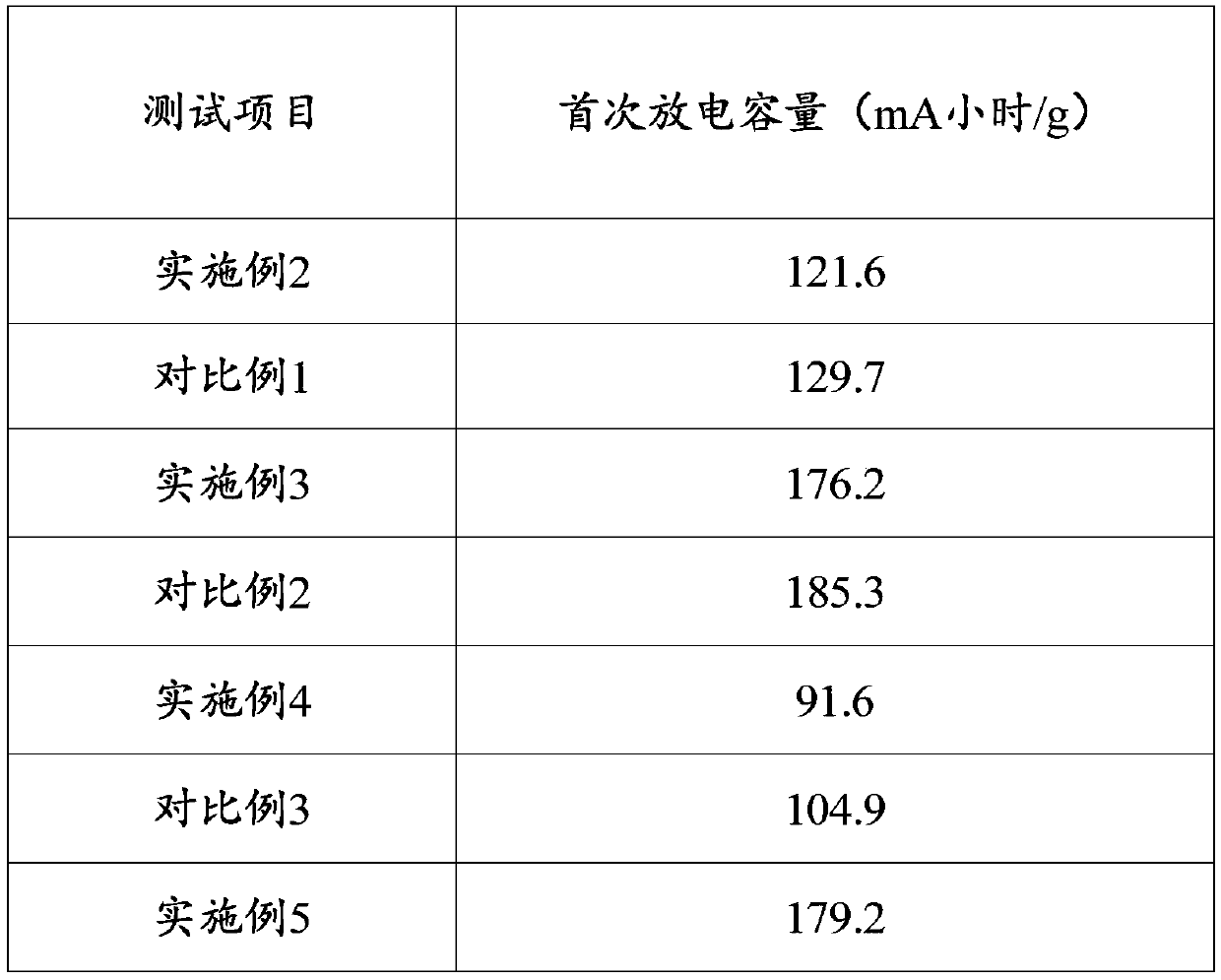

Embodiment 2

[0035] Lithium iron phosphate (LiFePO 4 ), Li 2 o 2 According to the ratio of 99:1, add in the mixing machine full of nitrogen, adjust the mixing machine speed to be 600 rpm, mix for 20 minutes to obtain composite positive electrode material a; composite positive electrode material a, conductive additive (Sp), binder (PVDF) was added to the NMP solvent at a mass ratio of 80:10:10, dispersed evenly to form a uniform slurry; the slurry was coated on an aluminum foil, and dried in a vacuum oven at 85°C for 6 hours to obtain 2 o 2 Additive LiFePO 4 Composite pole piece A.

[0036] Alternative solution: add composite positive electrode material a, conductive additive (Sp), and binder (PVDF) into NMP solvent at a mass ratio of 70:15:15, and disperse evenly to form a uniform slurry; coat the slurry Dry on aluminum foil in a vacuum oven at 85°C for 6 hours to obtain 2 o 2 Additive LiFePO 4 Composite pole piece A.

Embodiment 3

[0038] Lithium cobalt oxide (LiCoO 2 ), Li 2 o 2 According to the ratio of 97.5: 2.5, add in the mixing machine that is full of nitrogen, adjust the mixing machine speed at 800 rpm, mix for 20 minutes to obtain composite positive electrode material b; composite positive electrode material b, conductive additive (Sp), binding agent (PVDF) was added to the NMP solvent at a mass ratio of 80:10:10, dispersed evenly to form a uniform slurry; the slurry was coated on an aluminum foil, and dried in a vacuum oven at 85°C for 8 hours to obtain a Li 2 o 2 Additive LiCoO 2 Composite pole piece B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com