An air electrode of a lithium air battery and a preparation method thereof

A lithium-air battery and air electrode technology, which is applied in battery electrodes, fuel cell-type half-cells and secondary battery-type half-cells, circuits, etc. Stabilizing performance, controlling reaction rate, inhibiting the effect of lithium peroxide disproportionation side reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

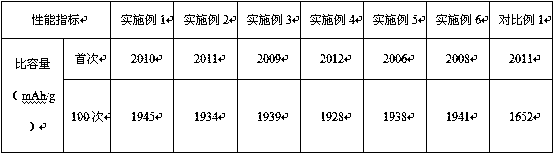

Examples

Embodiment 1

[0031] The air electrode includes a hollow porous conductive substrate, a catalyst and a coating layer; the hollow conductive substrate is a cylinder, and its hollow part is used to connect an air compressor to facilitate the injection of air or oxygen; the material of the hollow conductive substrate is a conductive carbon-based material; the catalyst is CuFeN / C composite catalyst; the cladding layer is a perovskite ceramic-based oxygen ion conductor.

[0032] The preparation process is:

[0033] (1) Add copper phthalocyanine and iron phthalocyanine to anhydrous ethanol solvent to make a solution, put the carbon-based material as a conductive substrate in the solution system for a period of time, and then evaporate the ethanol solvent under the protection of argon. Take out the remaining carbon-based material for later use; the molar concentration of the solution is 7mol / L, and the molar ratio of copper phthalocyanine to iron phthalocyanine is 1:1; the soaking time is 2h;

[...

Embodiment 2

[0036] The air electrode includes a hollow porous conductive substrate, a catalyst and a coating layer; the hollow conductive substrate is a cylinder, and its hollow part is used to connect an air compressor to facilitate the injection of air or oxygen; the material of the hollow conductive substrate is a conductive carbon-based material; the catalyst is CuFeN / C composite catalyst; the cladding layer is a metal oxide type ceramic-based oxygen ion conductor.

[0037] The preparation process is:

[0038] (1) Add copper phthalocyanine and iron phthalocyanine to anhydrous ethanol solvent to make a solution, put the carbon-based material as a conductive substrate in the solution system for a period of time, and then evaporate the ethanol solvent under the protection of argon. Take out the remaining carbon-based material for later use; the molar concentration of the solution is 5mol / L, and the molar ratio of copper phthalocyanine to iron phthalocyanine is 1:1; soaking time is 1h;

...

Embodiment 3

[0041] The air electrode includes a hollow porous conductive substrate, a catalyst and a coating layer; the hollow conductive substrate is a cylinder, and its hollow part is used to connect an air compressor to facilitate the injection of air or oxygen; the material of the hollow conductive substrate is a conductive carbon-based material; the catalyst is CuFeN / C composite catalyst; the cladding layer is a perovskite ceramic-based oxygen ion conductor.

[0042] The preparation process is:

[0043] (1) Add copper phthalocyanine and iron phthalocyanine to anhydrous ethanol solvent to make a solution, put the carbon-based material as a conductive substrate in the solution system for a period of time, and then evaporate the ethanol solvent under the protection of argon. Take out the remaining carbon-based material for later use; the molar concentration of the solution is 10mol / L, and the molar ratio of copper phthalocyanine to iron phthalocyanine is 1:1; the soaking time is 3h;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com