Fabrication method of lithium-air battery and lithium-air battery

A lithium-air battery, battery cathode technology, applied in battery electrodes, fuel cell-type half-cells and secondary battery-type half-cells, circuits, etc. problem, to avoid low efficiency and achieve the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Using nano-silicon material as the negative electrode and carbon nanotubes as the positive electrode catalyst, the steps of a metal-free lithium-air battery manufacturing method are as follows:

[0040] (1) Mixing nano-silica powder, conductive agent, and binder to prepare a slurry, coating it on copper foil, and drying it in vacuum to obtain the negative electrode part of the battery;

[0041] (2) In an anhydrous and oxygen-free environment, fully mix lithium nitride, carbon nanotubes, a conductive agent, and a binder, and take the mixture and press it on the nickel foam to form the positive part;

[0042] (3) In an anhydrous and oxygen-free environment, sequentially package the positive electrode, separator, and negative electrode prepared above, and add electrolyte solution dropwise.

[0043] So far, the lithium-air battery without metal lithium has been fabricated.

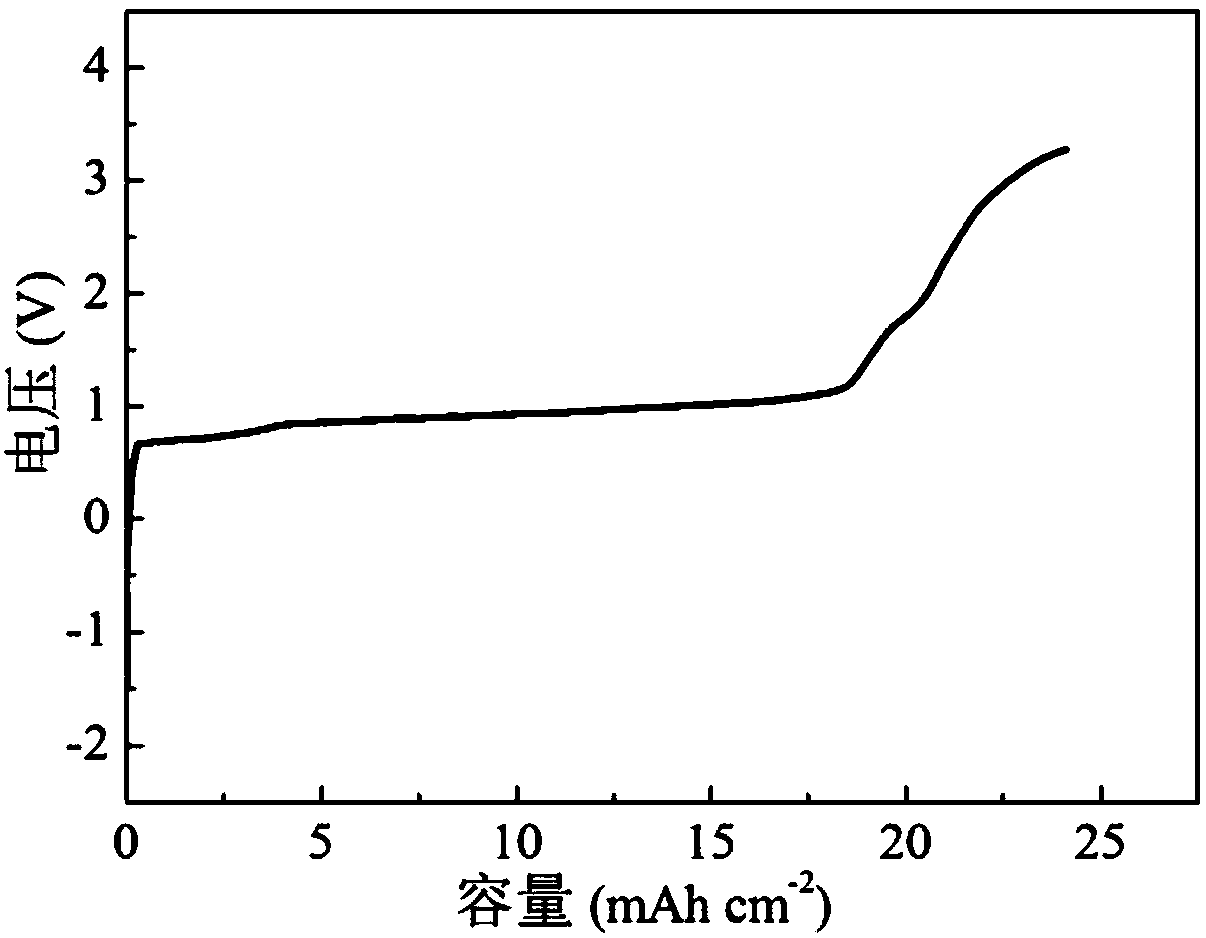

[0044] The charge-discharge curve of the metal-free lithium-air battery prepared in this example is...

Embodiment 2

[0046] Using nano-silicon material as the negative electrode, and the carbon-supported Ru catalyst as the positive electrode catalyst, the steps of a metal-free lithium-air battery manufacturing method are as follows:

[0047] (1) Mixing nano-silica powder, conductive agent, and binder to prepare a slurry, coating it on copper foil, and drying it in vacuum to obtain the negative electrode part of the battery;

[0048] (2) In an anhydrous and oxygen-free environment, fully mix lithium nitride, carbon-supported Ru catalyst, conductive agent, and binder, and take the mixture and press it on the foamed nickel to form the positive part;

[0049] (3) In an anhydrous and oxygen-free environment, sequentially package the positive electrode, separator, and negative electrode prepared above, and add electrolyte solution dropwise.

[0050] So far, the lithium-air battery without metal lithium has been fabricated.

Embodiment 3

[0052] A silicon oxide material is used as the negative electrode, and carbon nanotubes are used as the positive electrode catalyst. The steps of a metal-free lithium-air battery manufacturing method are as follows:

[0053] (1) Prepare a slurry by mixing silicon oxide, a conductive agent, and a binder, apply it on a copper foil, and dry it in a vacuum to obtain the negative electrode part of the battery;

[0054] (2) In an anhydrous and oxygen-free environment, fully mix lithium nitride, carbon nanotubes, a conductive agent, and a binder, and take the mixture and press it on the nickel foam to form the positive part;

[0055] (3) In an anhydrous and oxygen-free environment, sequentially package the positive electrode, separator, and negative electrode prepared above, and add electrolyte solution dropwise.

[0056] So far, the lithium-air battery without metal lithium has been fabricated.

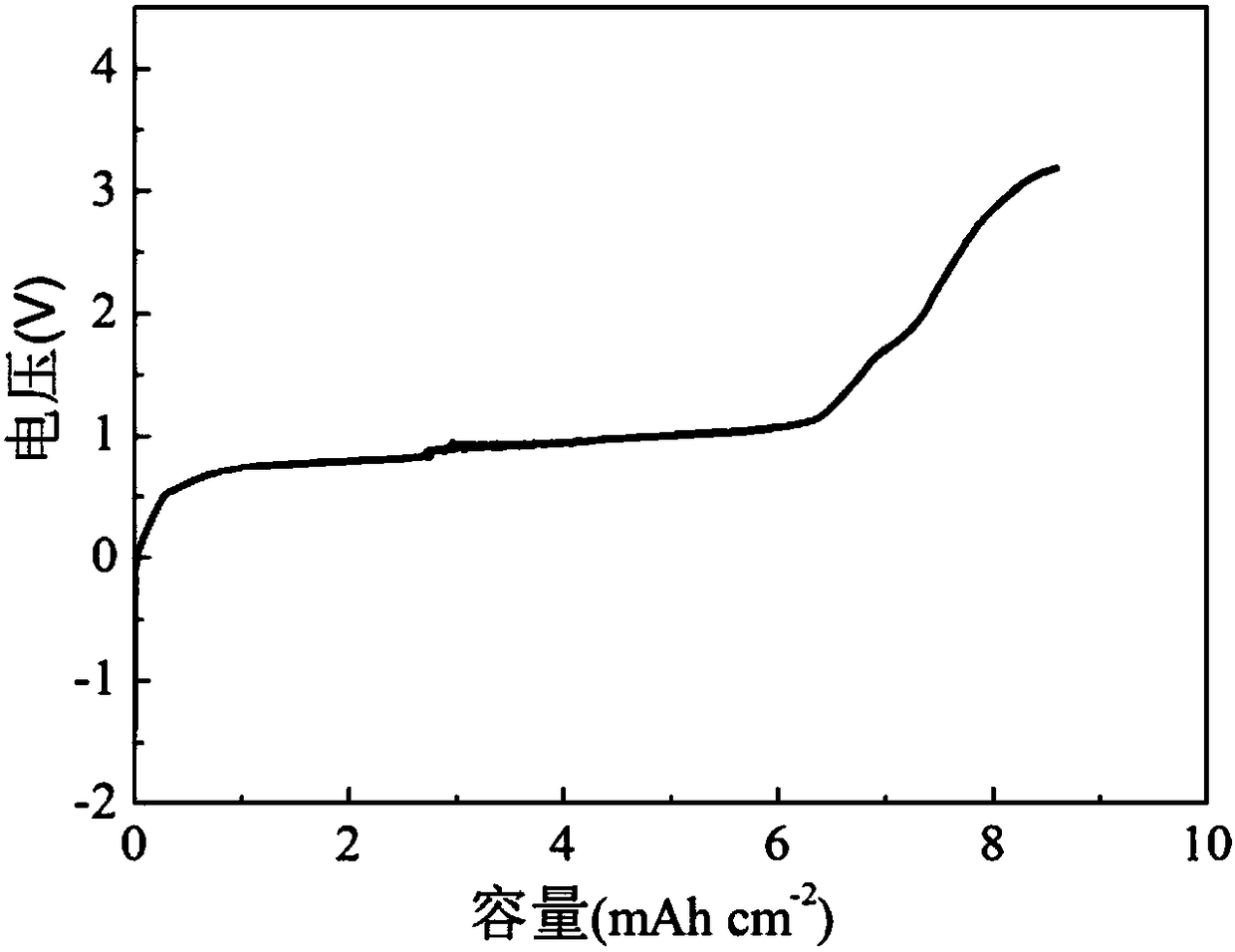

[0057] The charge-discharge curve of the metal-free lithium-air battery prepared in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com