Lithium ion battery and preparation method thereof

A lithium ion battery and lithium salt technology, which is applied in the direction of lithium storage battery, battery electrode, secondary battery, etc., can solve the problems of increasing the preparation cost of lithium ion battery, and achieve the effects of improving production safety, labor saving and reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

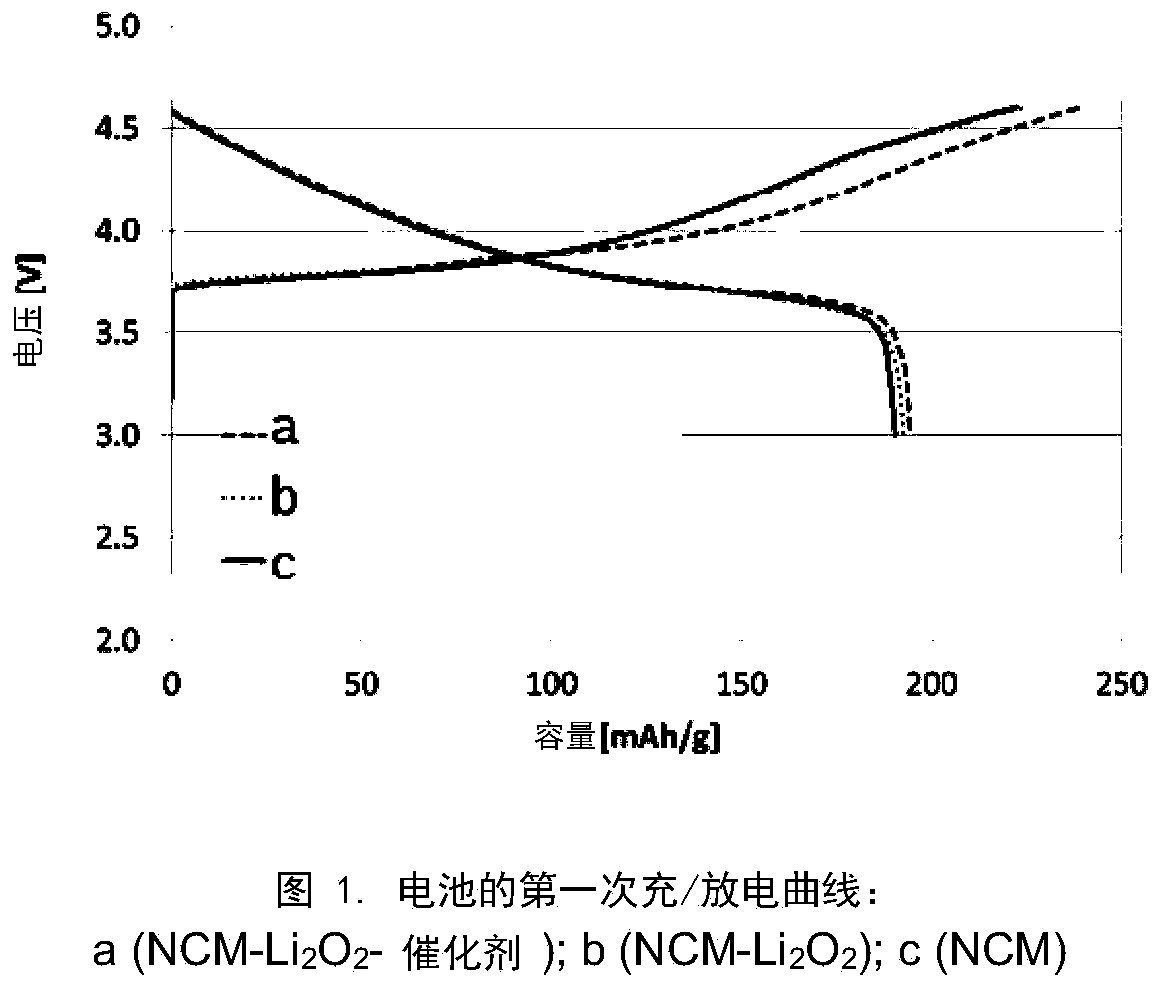

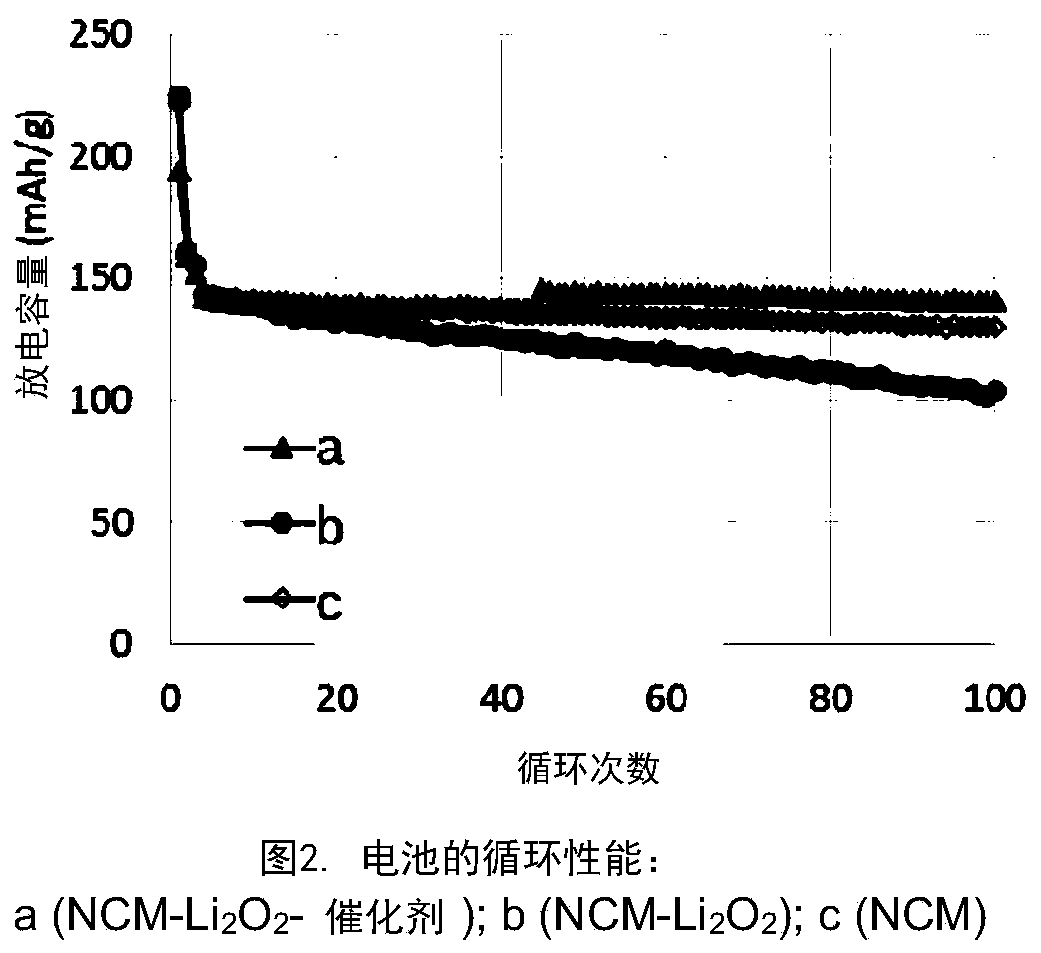

[0113] In an argon-filled glove box (MB-10compact, purchased from MBraun), 938.6 mg NCM-111, 26.4 mg lithium peroxide, 10 mg Super P, 5 mg KS6L, 20 mg PVDF were added to 450 mL NMP. After stirring for 3 hours, the resulting homogeneously dispersed slurry was coated on an aluminum foil and then dried in vacuum at 80° C. for 6 hours. The coated aluminum foil was taken out from the glove box and cut into a plurality of 12mm positive pole pieces (abbreviated as NCM-Li 2 o 2 positive pole piece).

[0114] [Preparation of battery]

[0115] In a glove box (MB-10compact, purchased from MBraun) filled with argon gas, a button battery (CR2016) was assembled using the positive electrode sheet obtained above. Pure lithium metal foil was used as the counter electrode. 1M LiPF in FEC+EMC (volume ratio 3:7, partially fluorinated carbonate electrolyte) 6 Used as electrolyte. Celgard 2325 (PP / PE / PP film) was used as separator.

Embodiment 2

[0117] Prepare the positive electrode sheet (abbreviated as NCM-Li) in the same manner as described in Example 1 2 o 2 - Catalyst positive electrode sheet), the difference is that 10 mg of NCM-111 fine particles are added as a catalyst to prepare the positive electrode slurry, and 928.6 mg of NCM-111 is used instead of 938.6 mg of NCM-111. NCM-111 fine particles have a particle size of less than 1 μm.

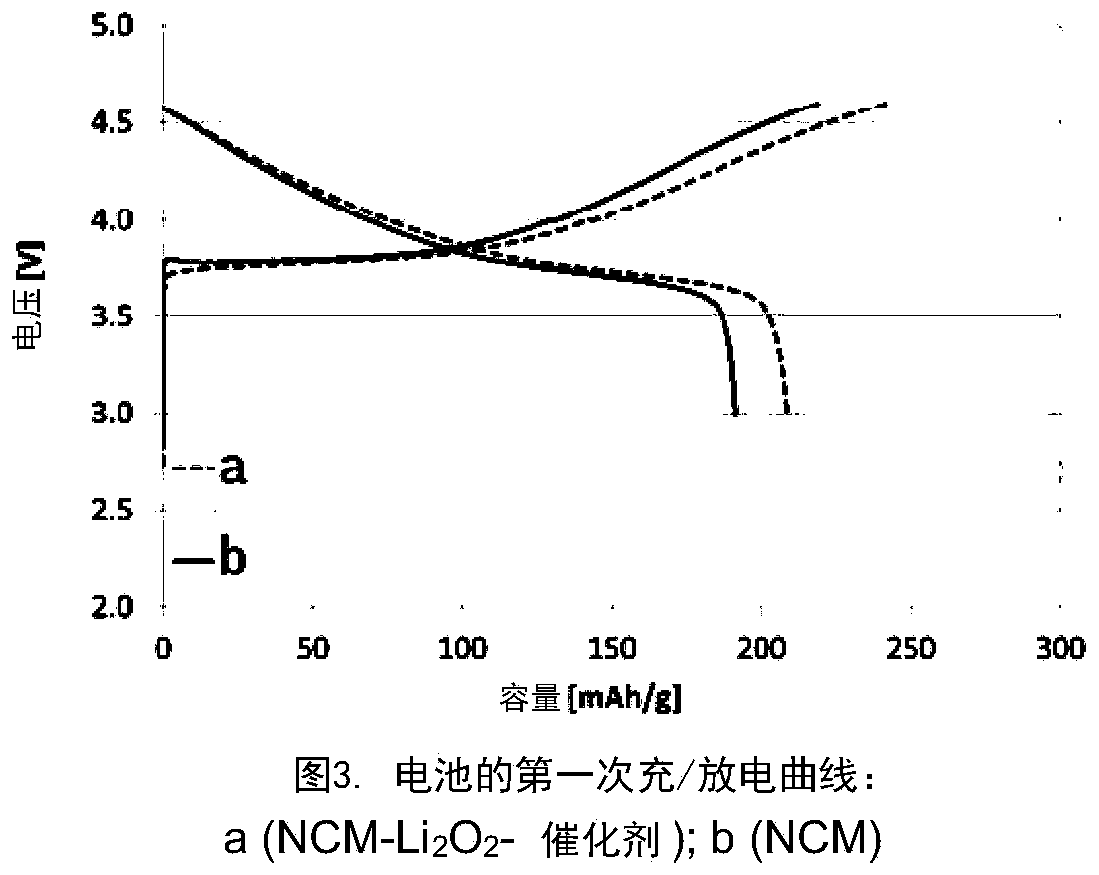

Embodiment 3

[0119] Prepare the positive electrode sheet (abbreviated as NCM-Li) in the same manner as described in Example 2 2 o 2 - Catalyst positive pole piece), the difference is that 24.1 mg of lithium peroxide is used instead of 26.4 mg of lithium peroxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com