Automatic panel production line

An automatic production line and plate technology, applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problems of low production efficiency, large space occupation, unsafety, etc., to achieve increased production capacity, small occupied space, and safety The effect of increasing the coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

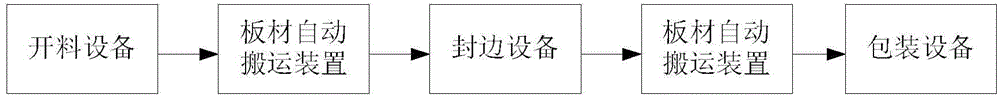

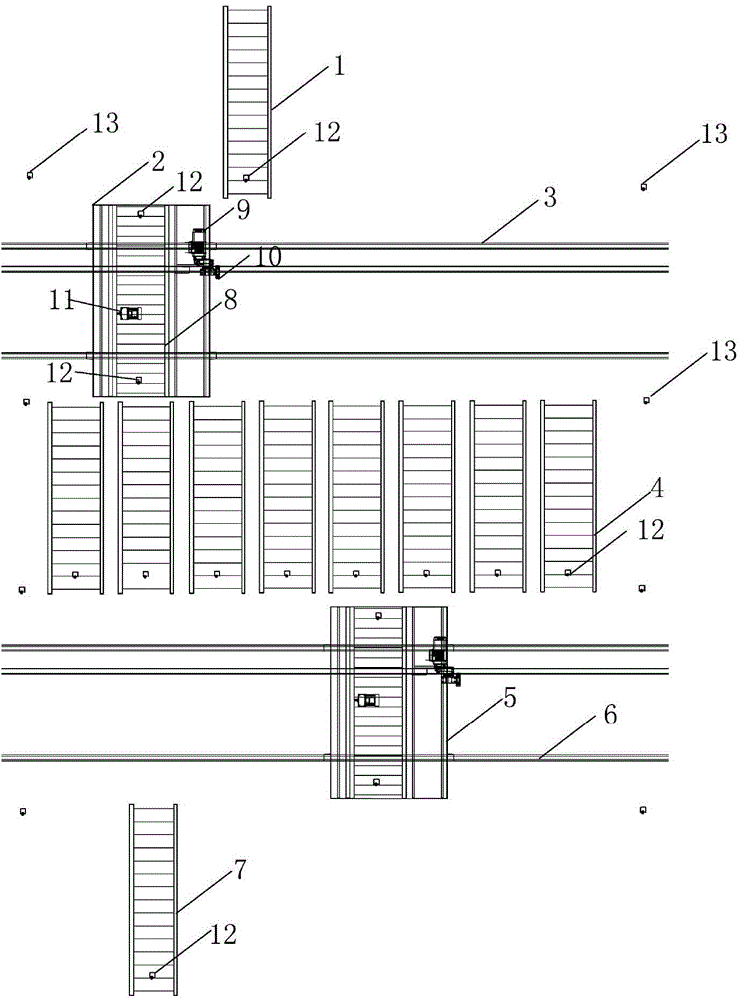

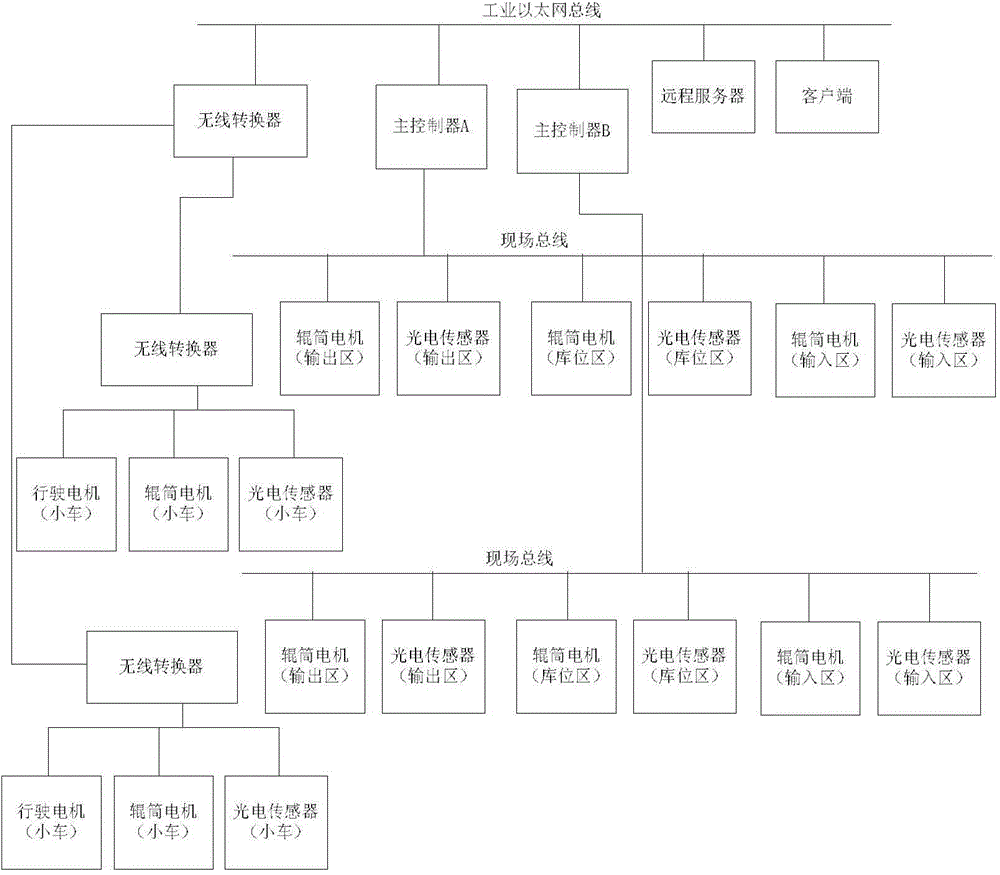

[0024] Such as figure 1 As shown, the plate automatic production line disclosed in the embodiment of the present invention includes material cutting equipment, edge sealing equipment and packaging equipment arranged along the plate processing direction, between the material cutting equipment and edge sealing equipment, and between the edge sealing equipment and packaging equipment Each room is equipped with an automatic plate handling device. Such as figure 2 As shown, the plate automatic handling device includes in sequence along the plate processing and conveying direction: the plate output area, the first conveying trolley (namely the storage trolley 2), the storage area, the second conveying trolley (ie the warehouse trolley 5) and the plate input zone, and a master controller for controlling the device. There is a first roller conveyor 1 in the plate output area, and the first roller conveyor 1 is located at the end of the upstream processing equipment (such as docking...

Embodiment 2

[0041] Such as Figure 4 As shown, compared with Embodiment 1, the plate automatic production line disclosed in the embodiment of the present invention expands the storage capacity of the plate output area, warehouse location area, and plate input area in the plate automatic handling device, and improves the single-time operation of the trolley. Transportation capacity (traveling motor and roller motor are not shown in the figure), two first roller conveyors 1 are installed in the plate output area, which are respectively located at the ends of the two output ports of the upstream processing equipment, or the output ports of different processing equipment . The plate input area is also provided with two third roller conveyors 7, which are respectively located at the beginnings of the two input ports of the downstream processing equipment, or at the input ports of different processing equipment. It can be understood that this embodiment only illustrates two sets, and the speci...

Embodiment 3

[0045] Compared with Embodiment 1, the embodiment of the present invention differs in that a vertical conveyor is added to the plate automatic conveying device. Considering that the board processing equipment takes up a lot of space, the single-floor area of the factory building is limited, and the area occupied by the storage of finished boards, etc., cross-floor production can be realized by setting up vertical conveyors between floors. For example, the cutting equipment and edge banding equipment are located on the first floor, and the packaging equipment and finished sheet stacking area are located on the second floor. Among them, the vertical conveyor can be installed in the plate output area or plate input area of the plate automatic handling device between the edge banding equipment and the packaging equipment. Taking the plate input area at the beginning of the packaging equipment as an example, the third roller in the plate output area can be The road conveyor is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com