Intelligent loading robot for bagged packing materials and operating method thereof

A technology of packaging materials and robots, applied in the directions of transportation and packaging, loading/unloading, etc., can solve the problems of automatic loading, occupying a certain space, and the lack of space in the car box, so as to reduce respiratory diseases such as pneumoconiosis, improve production efficiency and improve production efficiency. Production safety, effect of reducing exposure time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

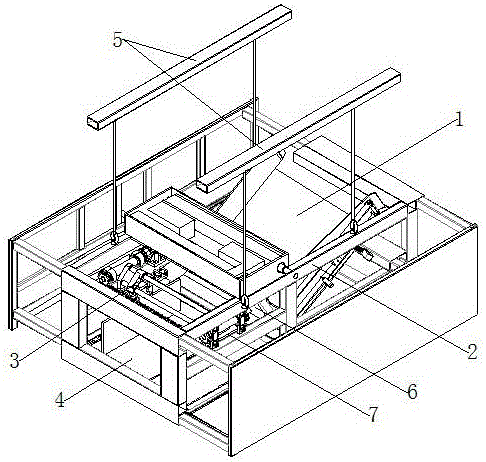

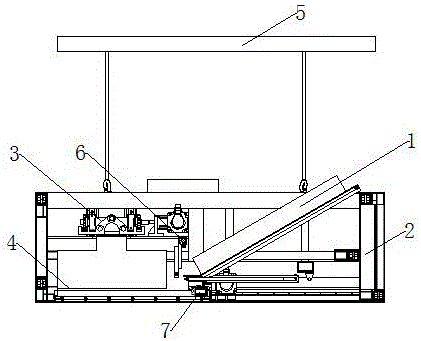

[0046] A kind of bag packing material intelligent loading robot of this embodiment, such as figure 1 , figure 2 As shown, it is mainly realized through the following technical solutions: an intelligent loading robot for bagged packaging materials, including the main body of the loading robot, an overall lifting mechanism for lifting the loading robot 5, and visual scanning measurement for data collection Detection system, data center for data processing. The main body of the loading robot includes a main body frame 2 and a feeding reversing manipulator 1, a material pushing manipulator 3, a material tongue 4, a material retaining manipulator 6, and an unloading stretching manipulator 7 installed on the main body frame 2. The main body frame 2, the code material tongue 4, and the material retaining manipulator 6 are all telescopic structures and can be telescopically adjusted along the width direction of the carriage. The code material tongue 4 is provided with a code table ...

Embodiment 2

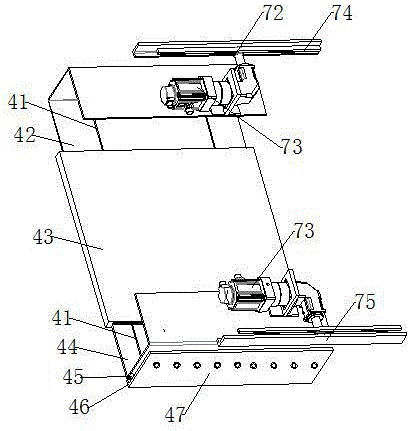

[0074] This embodiment is further optimized on the basis of the above embodiments, such as image 3 As shown, further, in order to better realize the present invention, the code material platform of the code material tongue 4 includes a fixed part 43 and a first movable part 42 and a second movable part connected to both sides of the fixed part 43 through a sliding connector 41. Activities Department 44.

[0075] The first movable part 42 and the second movable part 44 are arranged symmetrically on both sides of the fixed part 43 and telescopically connected with the fixed part 43 through the sliding connection part 41 . The first movable part 42 and the second movable part 44 are respectively connected to the main body frame 2 through the unloading stretching manipulator 7, and the telescopic adjustment of the material tongue 4 is driven by the telescopic adjustment of the main body frame 2 to make it fit the carriage The change of width improves work efficiency.

[0076] T...

Embodiment 3

[0083] This embodiment is further optimized on the basis of the above embodiments, such as image 3 As shown, further, in order to better realize the present invention, the code material tongue 4 also includes a support side plate 47, a slide rail 46 arranged on the support side plate 47, and one end connected with the first movable part 42 or the second movable part 42 The movable part 44 is connected with a sliding support wheel axle system 45 whose other end is slidingly connected with the sliding rail 46 .

[0084] Described support side plate 47, slide rail 46, sliding support wheel axle system 45 constitute an additional load-bearing seat, and its effect is to assist code material tongue 4 load-bearing. The supporting side plate 47 is fixed on the main body frame 2, and is connected with the code material table through the sliding support wheel axle system 45 in the slide rail 46: the front and rear push-pull driving device 73 is fixed in the code material table and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com