Cathodic catalyst for lithium air battery and preparation method thereof

A technology for cathode catalysts and lithium-air batteries, applied in battery electrodes, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of increased catalyst preparation costs, complex preparation processes, and long synthesis routes, and shorten the preparation time , Simplify the preparation process, the effect of uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] At 25°C, add 0.12g of manganese nitrate to 40g of water. After it is fully dissolved, add 0.206g of phenanthroline under stirring and react for 30 minutes to obtain manganese phenanthroline complex. Add 1g of carbon nanoparticles and continue stirring After 120 minutes, the water was removed by evaporation, and then heat-treated at 900° C. for 90 minutes in argon, and cooled to obtain a cathode catalyst for a lithium-air battery.

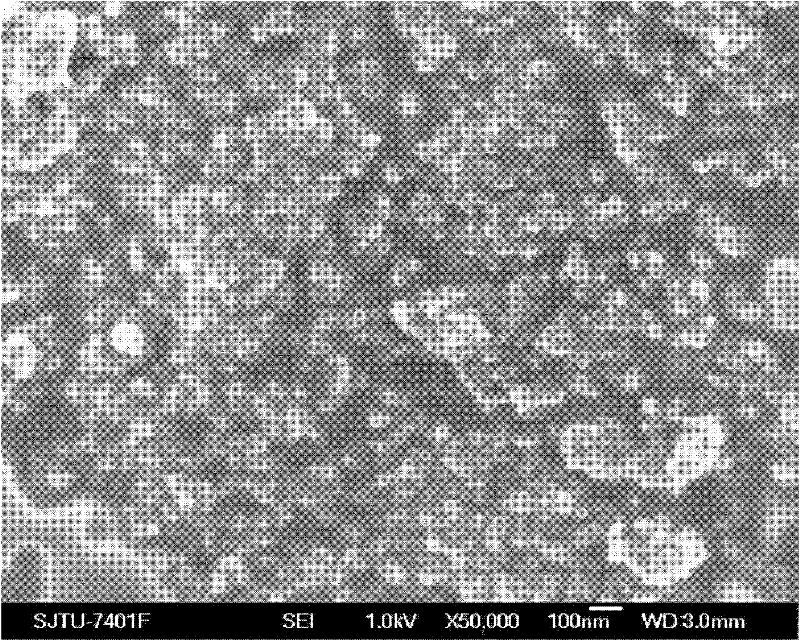

[0026] figure 1 It is the scanning electron micrograph of the lithium-air battery cathode catalyst that embodiment 1 obtains. It can be seen from the figure that the particle size of the powder is uniform, which is conducive to the contact reaction between the oxygen in the air and the active center. The first cycle discharge capacity of the lithium-air battery assembled with the cathode catalyst is 3210mAh (g active material unit mass) -1 (current density is 0.15mAcm -1 ), the discharge platform is 2.7V.

Embodiment 2

[0028] At 25°C, add 0.13g of cobalt acetate to 60g of absolute ethanol. After it is fully dissolved, add 0.206g of phenanthroline under stirring and react for 30 minutes to obtain a cobalt-phenanthroline complex. Add 1g of carbon nanoparticles , continue to stir for 120 minutes, evaporate to remove absolute ethanol, then heat-treat in argon at 900° C. for 90 minutes, and cool to obtain a cathode catalyst for a lithium-air battery.

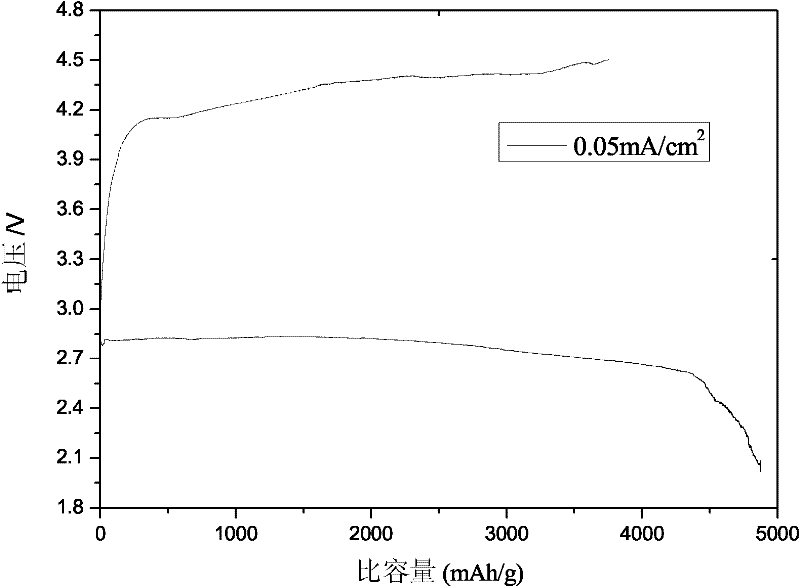

[0029] figure 2 It is the charge-discharge curve graph of the lithium-air battery prepared by the cathode catalyst for the lithium-air battery obtained in Example 2. The discharge capacity of the first cycle reaches 4870mAh (g active material unit mass) -1 (current density is 0.05mA cm -1 ), the discharge voltage is stable at 2.8V.

Embodiment 3

[0031] At 10°C, add 0.14g of cobalt oxalate to 40g of water. After it is fully dissolved, add 0.18g of bipyridine under stirring and react for 30 minutes to obtain a cobalt bipyridine complex. Add 1g of carbon nanotubes and continue stirring for 120 minutes. , evaporated to remove water, and then heat-treated at 900° C. for 90 minutes in nitrogen, and cooled to obtain a cathode catalyst for lithium-air batteries. XRD test shows that the cobalt in the catalyst is in the cubic crystal form, which is consistent with the standard card PDF 89-4307. The first cycle discharge capacity of the lithium-air battery assembled with the cathode catalyst is 3310mAh (g active material unit mass) -1 (current density is 0.1mAcm -1 ), the discharge platform is 2.75V.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com