Preparation method of rock salt type lithium ion battery cathode material, lithium ion battery cathode material, and applications thereof

A lithium-ion battery, cathode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as high price and capacity decay, and achieve the effects of cheap raw materials, high specific capacity, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

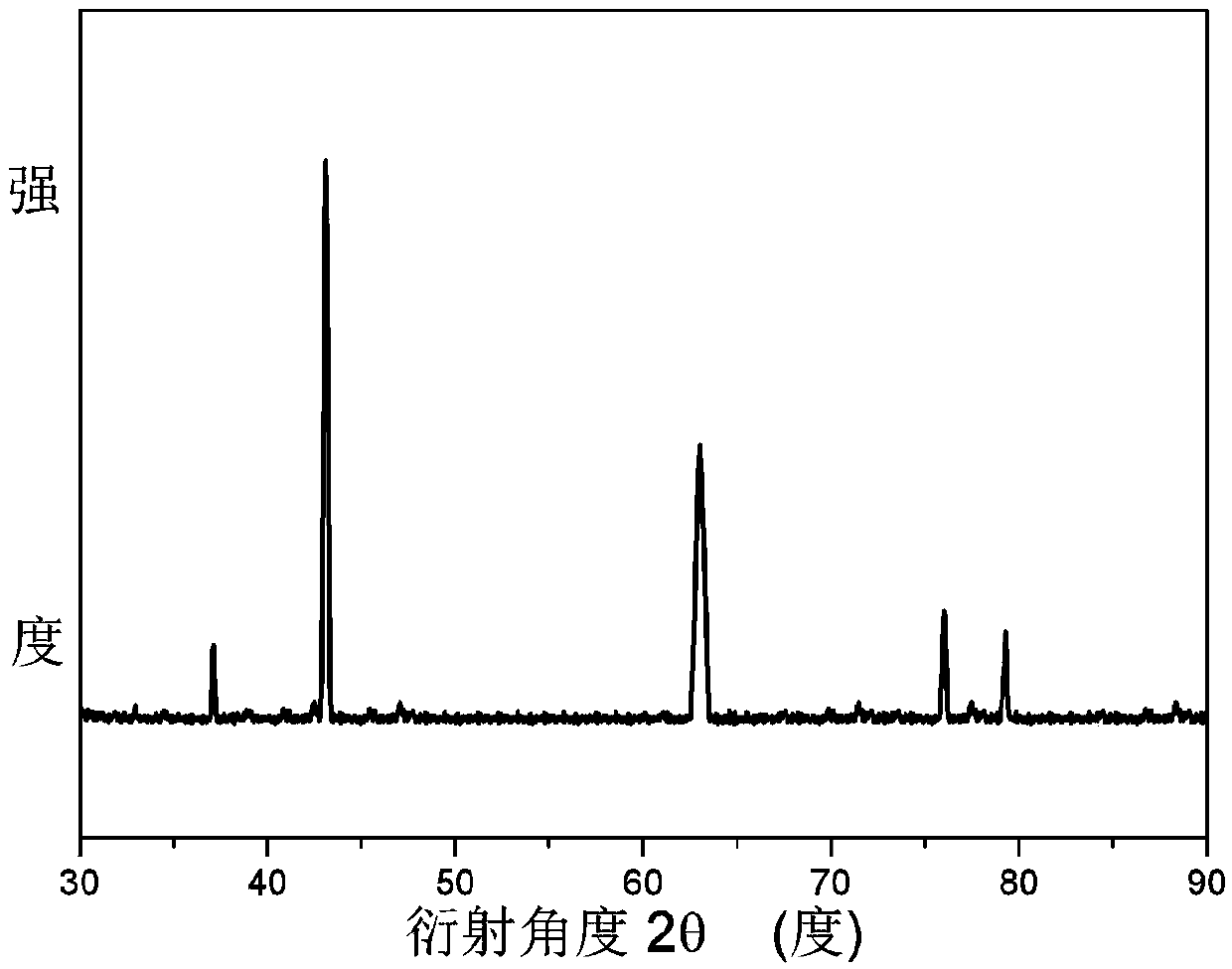

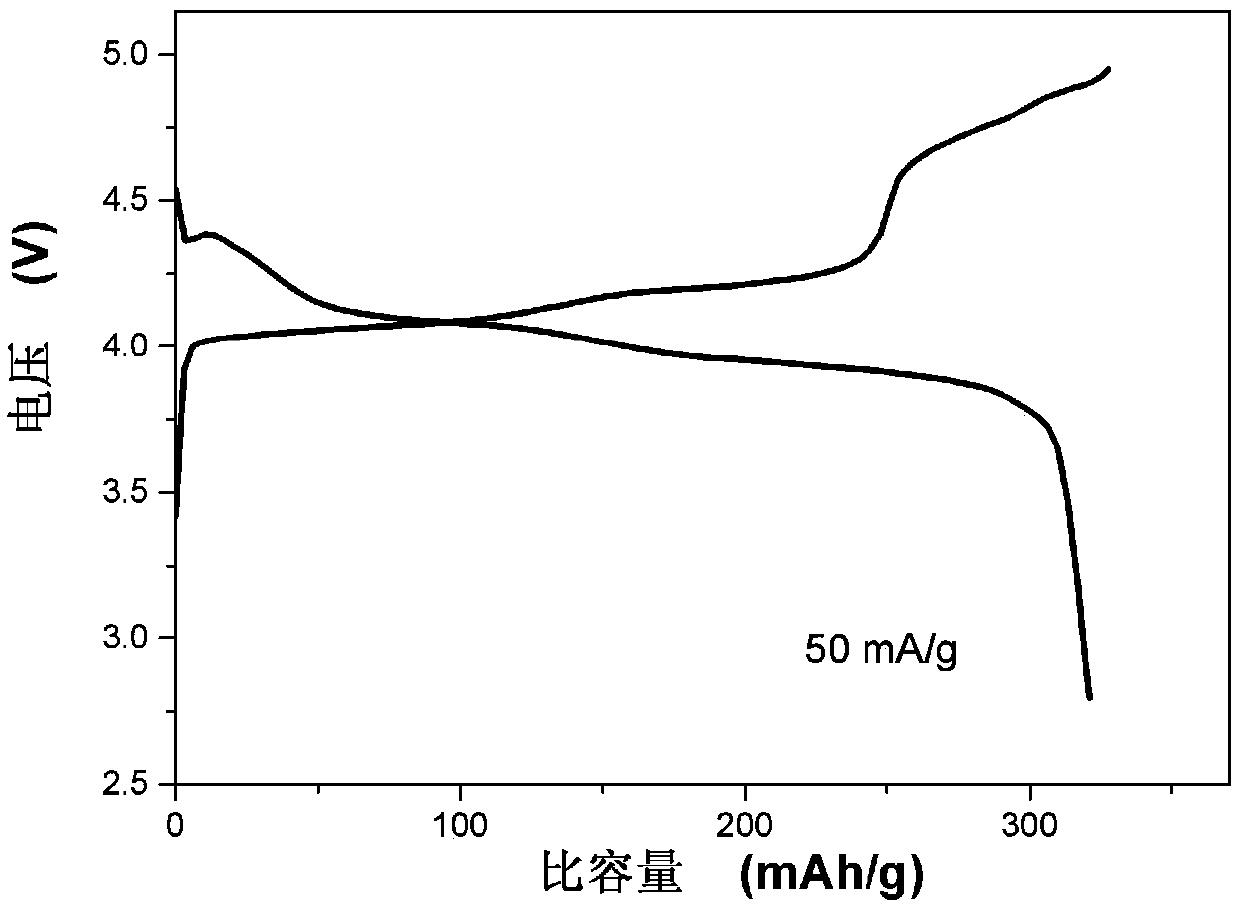

[0036] A kind of rock salt type lithium ion battery cathode material Li 4 mn 2 o 5 The preparation method comprises the following steps:

[0037] (1) Mix 9.231g of lithium hydroxide monohydrate, 8.694g of manganese dioxide, and 7.094g of manganese oxide into a planetary ball mill and grind for 30 minutes to obtain a uniform mixture;

[0038] (2) Heat the mixture obtained in step (1) to 1000°C for 8 hours in a tube furnace under a nitrogen atmosphere, and then cool naturally with the furnace after the calcination, and grind the calcined product to obtain black new LiMnO 2 Precursor;

[0039] (3) Weigh 8.000 g of the precursor obtained in step (2) and 2.535 g of lithium peroxide, place them in a planetary ball mill and grind for 30 minutes, heat up to 900 ° C for 6 hours in a tube furnace under a nitrogen atmosphere, and then cool down to Annealing treatment at 550°C for 3 hours, cooling in the furnace after annealing, and finally obtaining a black powder material, which is ...

Embodiment 2

[0047] A kind of rock salt type lithium ion battery cathode material Li 4 mn 2 o 5 The preparation method comprises the following steps:

[0048] (1) Mix 7.770g lithium carbonate, 8.694g manganese dioxide, and 7.094g manganese oxide into a planetary ball mill and grind for 30 minutes to obtain a uniform mixture;

[0049] (2) Heat the mixture obtained in step (1) to 900°C for 10 h in a tube furnace under a nitrogen atmosphere, and then cool naturally with the furnace after the calcination, and grind the calcined product to obtain black new LiMnO 2 Precursor;

[0050] (3) Weigh 8.000 g of the precursor obtained in step (2) and 2.730 g of lithium peroxide, place them in a planetary ball mill and grind for 30 minutes, heat up to 800 °C for 7 hours in a tube furnace under a nitrogen atmosphere, and then cool down to Annealing treatment at 500°C for 3 hours, cooling in the furnace after annealing, and finally obtaining a black powder material, which is the rock-salt lithium-ion ...

Embodiment 3

[0055] A kind of rock salt type lithium ion battery cathode material Li 4 mn 2 o 5 The preparation method comprises the following steps:

[0056] (1) Mix 7.770g lithium carbonate, 11.495g manganese carbonate, and 7.094g manganese oxide into a planetary ball mill and grind for 30 minutes to obtain a uniform mixture;

[0057] (2) Heat the mixture obtained in step (1) to 900°C for 9 hours in a tube furnace under a nitrogen atmosphere, and then cool naturally with the furnace after the calcination, and grind the calcined product to obtain black new LiMnO 2 Precursor;

[0058] (3) Weigh 8.000 g of the precursor obtained in step (2) and 2.630 g of lithium peroxide, place them in a planetary ball mill and grind for 30 minutes, heat up to 800 °C for 8 hours in a tube furnace under a nitrogen atmosphere, and then cool down to Annealing treatment at 600°C for 4 hours, cooling in the furnace after annealing, and finally obtaining a black powder material, which is the rock-salt lithiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com