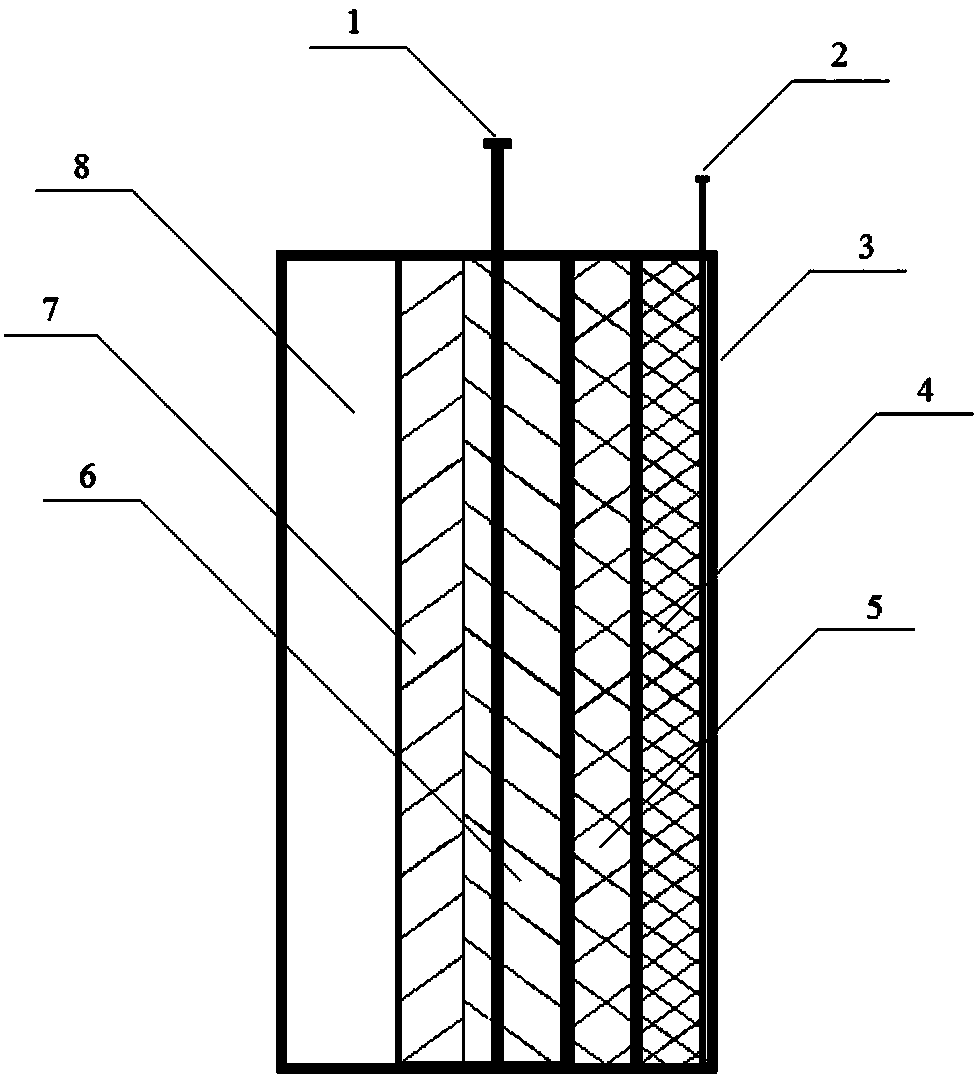

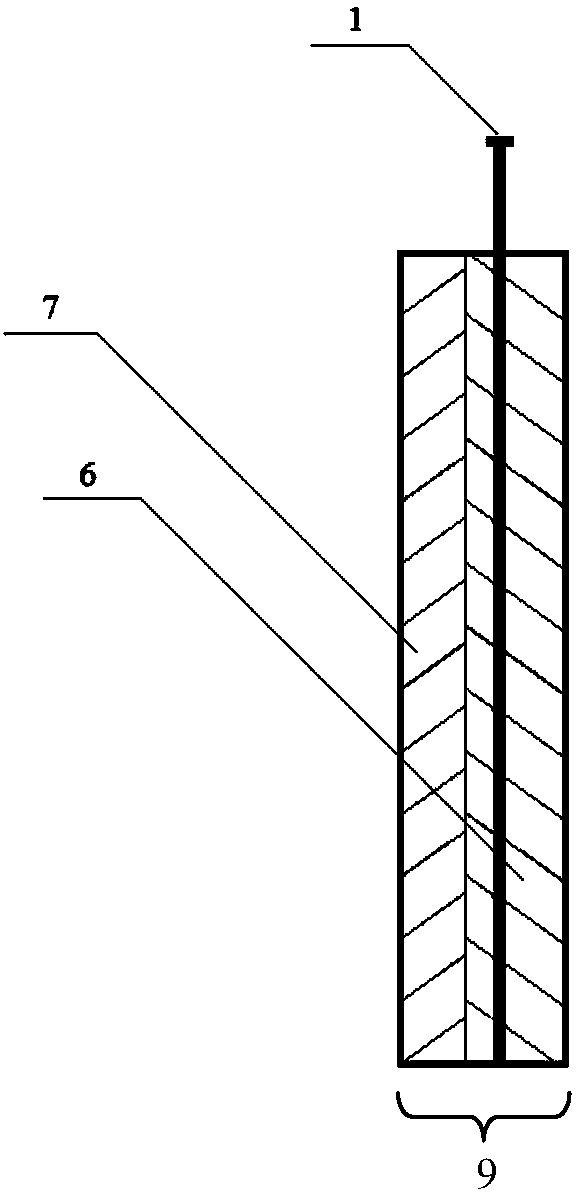

Lithium-oxygen battery and preparation method thereof

A lithium-oxygen battery and lithium peroxide technology, applied in battery electrodes, circuits, fuel cell half-cells and secondary battery-type half-cells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Take 10g of nickel carbonyl powder as conductive agent, 0.1g of sodium carboxymethylcellulose (CMC) as binder, and 0.5g of polyvinyl butyral as pore-forming agent and put them into a ball mill jar together, add 10g of deionized water, and Ball mill at a speed of 500 rpm for 60 minutes to obtain a slurry, which is coated on a 0.05 mm thick nickel-plated punched steel strip with a thickness of 0.4 mm on one side, and dried at 100°C for 6 hours to obtain Prefabricated substrates. Put the prefabricated substrate into a tube furnace, use high-purity nitrogen as the protective gas (linear flow rate 5cm / min), heat up to 1000ºC at a rate of 5ºC / min, keep the temperature at 1000ºC for 5min, cool naturally to room temperature, and cut off the protective gas to obtain the substrate . All the following operations were carried out in a nitrogen-protected glove box. The above substrates were vacuum impregnated in a 16% (mass ratio) lithium hydroxide aqueous solution at 100°C for 10...

Embodiment 2

[0074] Take 10g of nickel carbonyl powder as conductive agent, 0.1g of sodium carboxymethylcellulose (CMC) as binder, and 0.5g of polyvinyl butyral as pore-forming agent and put them into a ball mill jar together, add 10g of deionized water, and Ball milling at a speed of 500 rpm for 60 min to obtain a slurry. The slurry was coated on a 0.02 mm thick punched nickel strip with a coating thickness of 0.08 mm on one side, and dried at 100°C for 6 hours to obtain a prefabricated substrate. Put the prefabricated substrate into a tube furnace, use high-purity ammonia as the protective gas (linear flow rate 5cm / min), heat up to 800ºC at a rate of 5ºC / min, keep the temperature at 800ºC for 30min, cool naturally to room temperature, and cut off the protective gas to obtain substrate. All the following operations were carried out in a nitrogen-protected glove box. The above substrate was vacuum impregnated in 5% (mass ratio) lithium hydroxide aqueous solution at 10°C for 30min (vacuum...

Embodiment 3

[0077] Take conductive agent 10g nickel powder and 1g silver powder, binder 0.25g styrene-butadiene rubber latex, 0.25g sodium hydroxypropyl methylcellulose and pore-forming agent 0.5g ammonium bicarbonate and put them into a ball mill jar together, add 10g deionized Water, at room temperature with a speed of 500 rpm ball milling for 60 minutes to obtain a slurry, which is coated on a 0.05mm thick punched nickel belt with a thickness of 0.2mm on one side, and dried at 100ºC 2h, to obtain the prefabricated substrate. The prefabricated substrate is rolled to about 0.3 mm (including the total thickness of the conductive skeleton) by a roller press to obtain the substrate. All subsequent operations were carried out in an argon-protected glove box. Take the above substrate, and vacuum impregnate the above substrate in 11% (mass ratio) lithium hydroxide water ethanol solution (the volume ratio of water and ethanol is 2:8, containing lithium nitrate accounting for 1% of the mass of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com