Backwash filter

A filter and backwashing technology, which is applied in the direction of fixed filter elements, filter separation, chemical instruments and methods, etc., can solve the problems of slow filtration speed, easy blockage of microporous tube filter elements, and difficulty in ensuring the clarity of filtrate, etc. Achieve the effect of increasing the filtration speed, reducing the disassembly and installation process, and improving the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

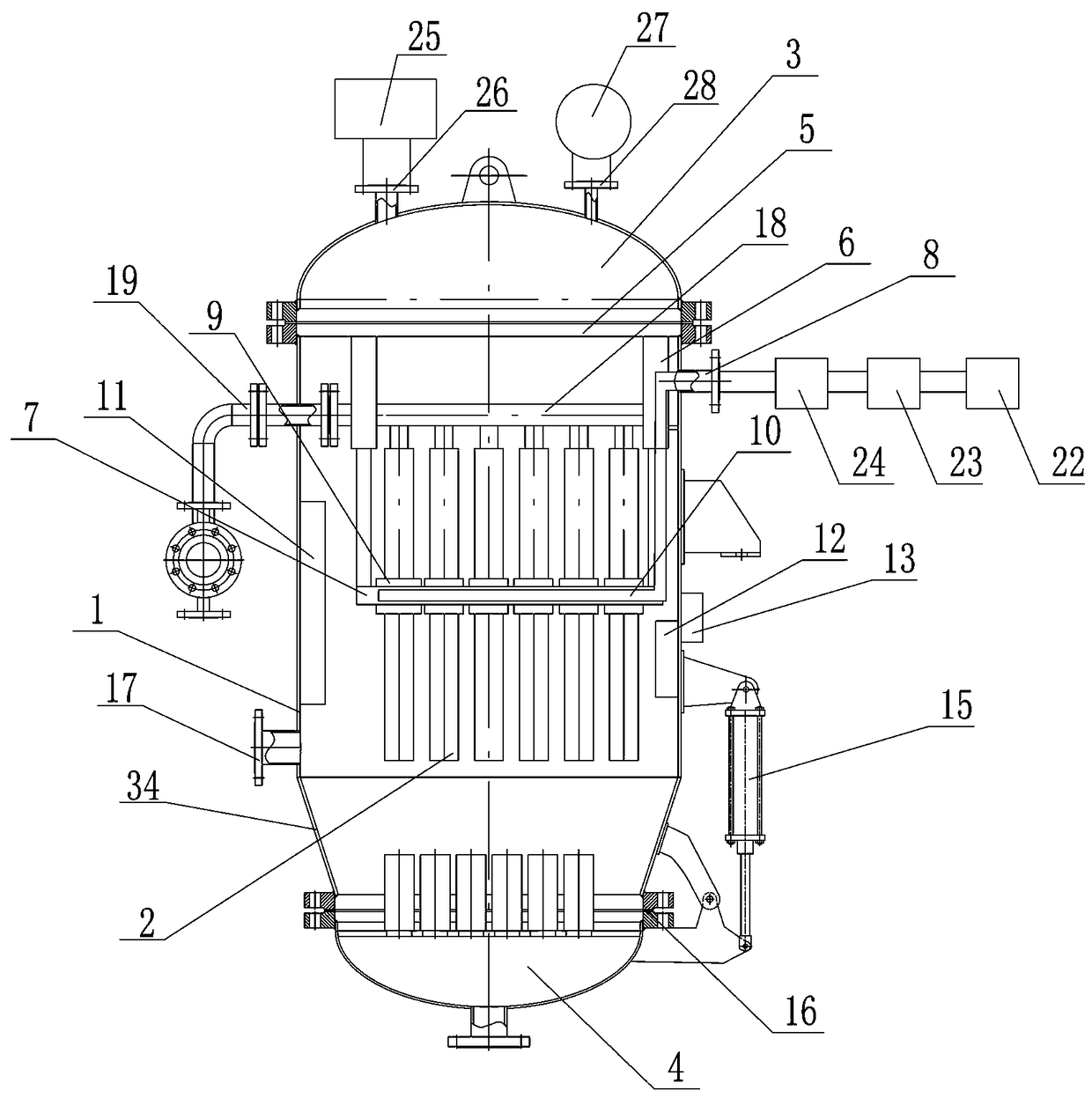

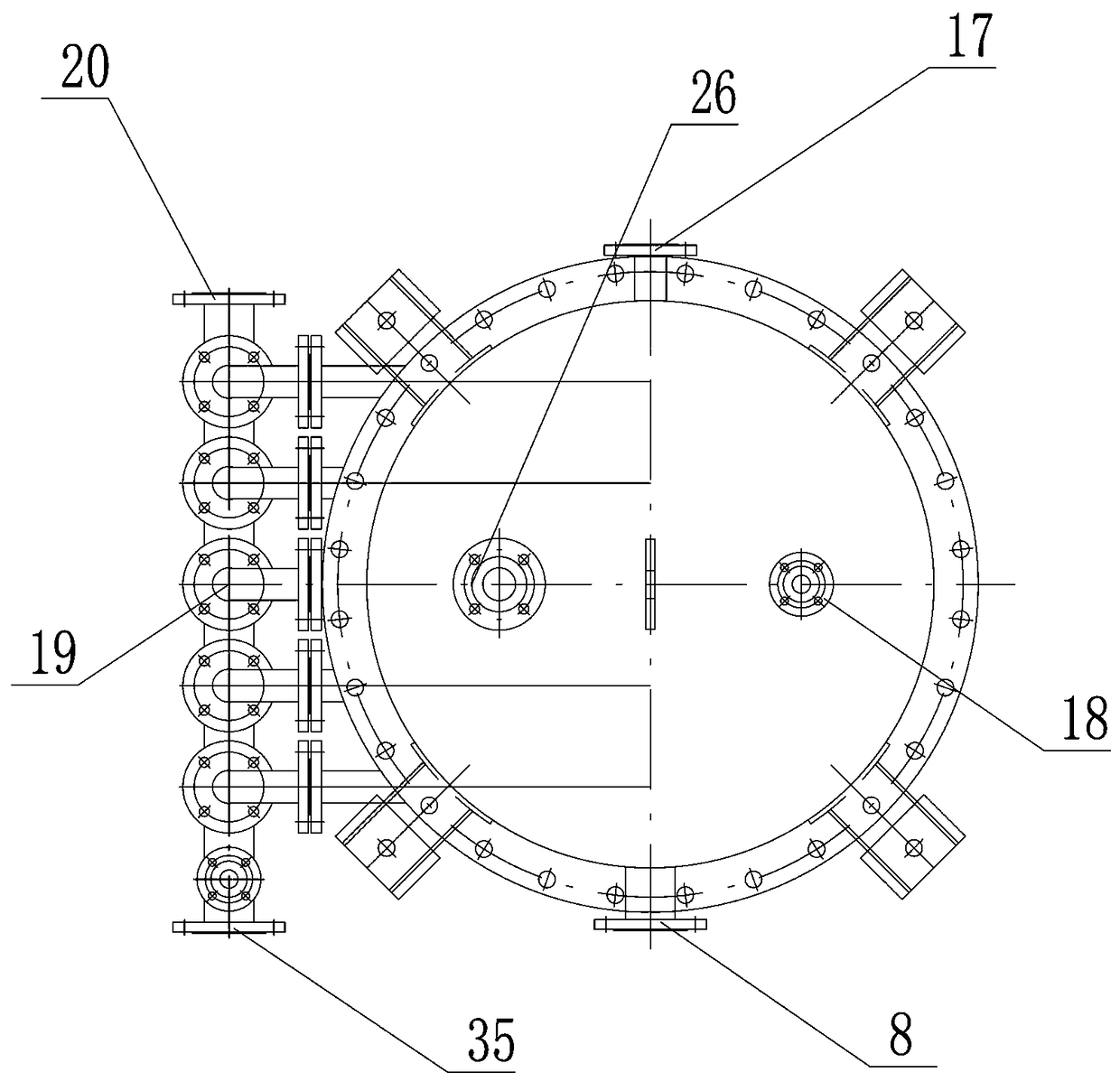

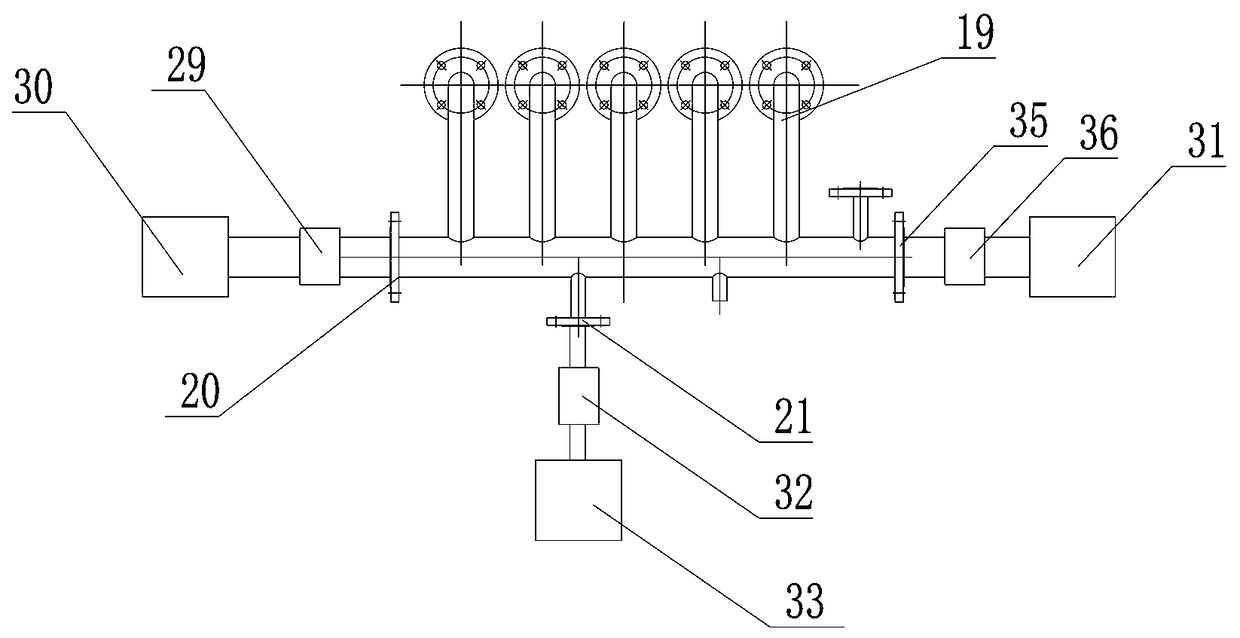

[0029] Combine below Figure 1-4 To further describe the present invention.

[0030] The present invention adopts following technical scheme:

[0031] The present invention provides a backwash filter, which includes a housing 1, a microporous filter element 2 fixedly arranged inside the housing 1, an upper cover 3 arranged on the upper part of the housing 1, and an upper cover 3 arranged on the The lower cover 4 of the lower part of the housing 1, the lower side of the housing 1 is provided with a feed port 17, and the upper part of the microporous filter element 2 is provided with a filter branch pipe 18 communicating with the microporous filter element 2, and the filter element is divided into The road pipe 18 is communicated with the discharge pipe 19, and the discharge port 20 is arranged on one side of the discharge pipe 19, and the discharge port 20 is communicated with the receiving container 30 through the first electromagnetic valve 29, and the discharge pipe 19 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com