Patents

Literature

112results about How to "Improve charge-discharge cycle performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sulfenyl anode of lithium-sulfur rechargeable battery and preparation method thereof

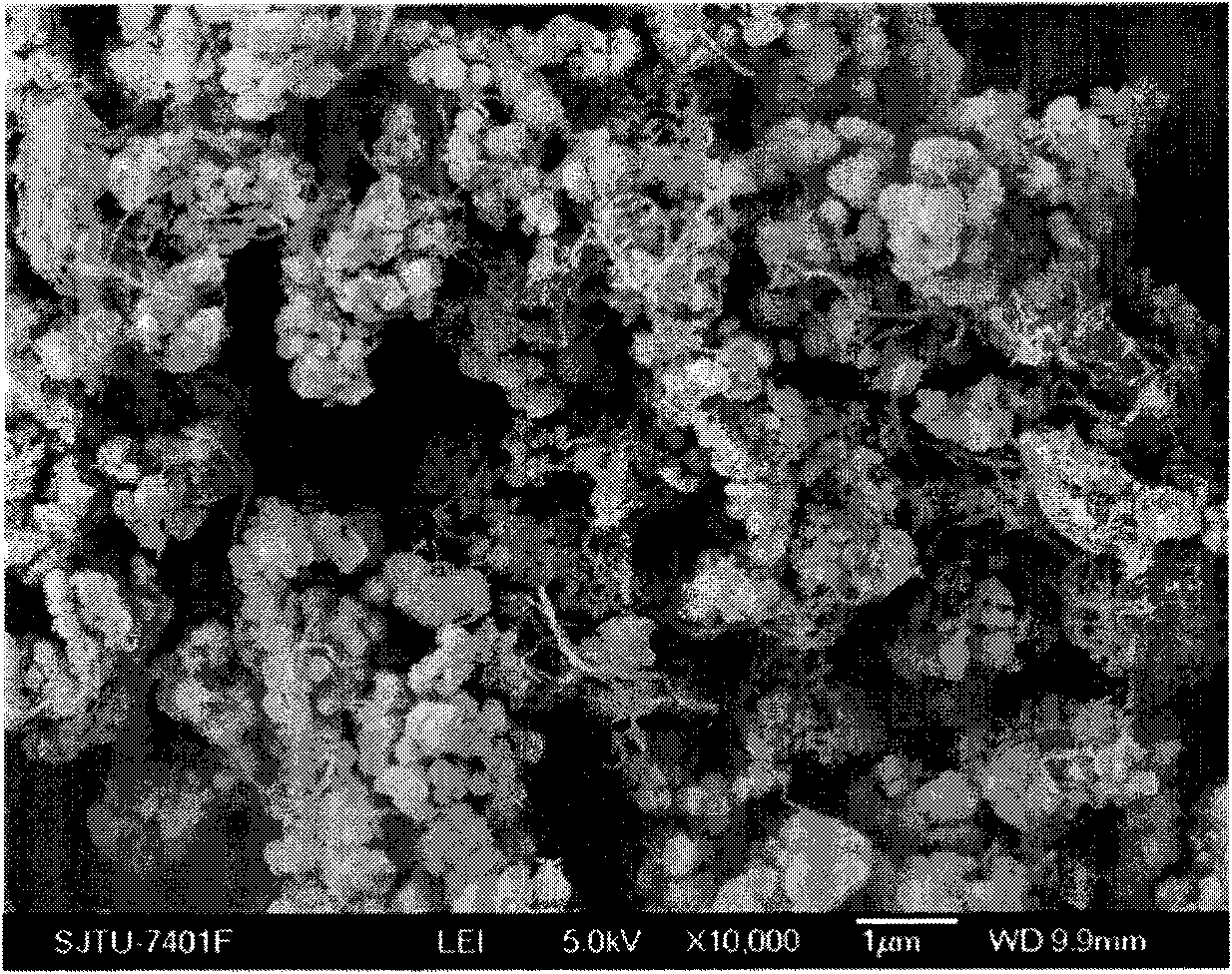

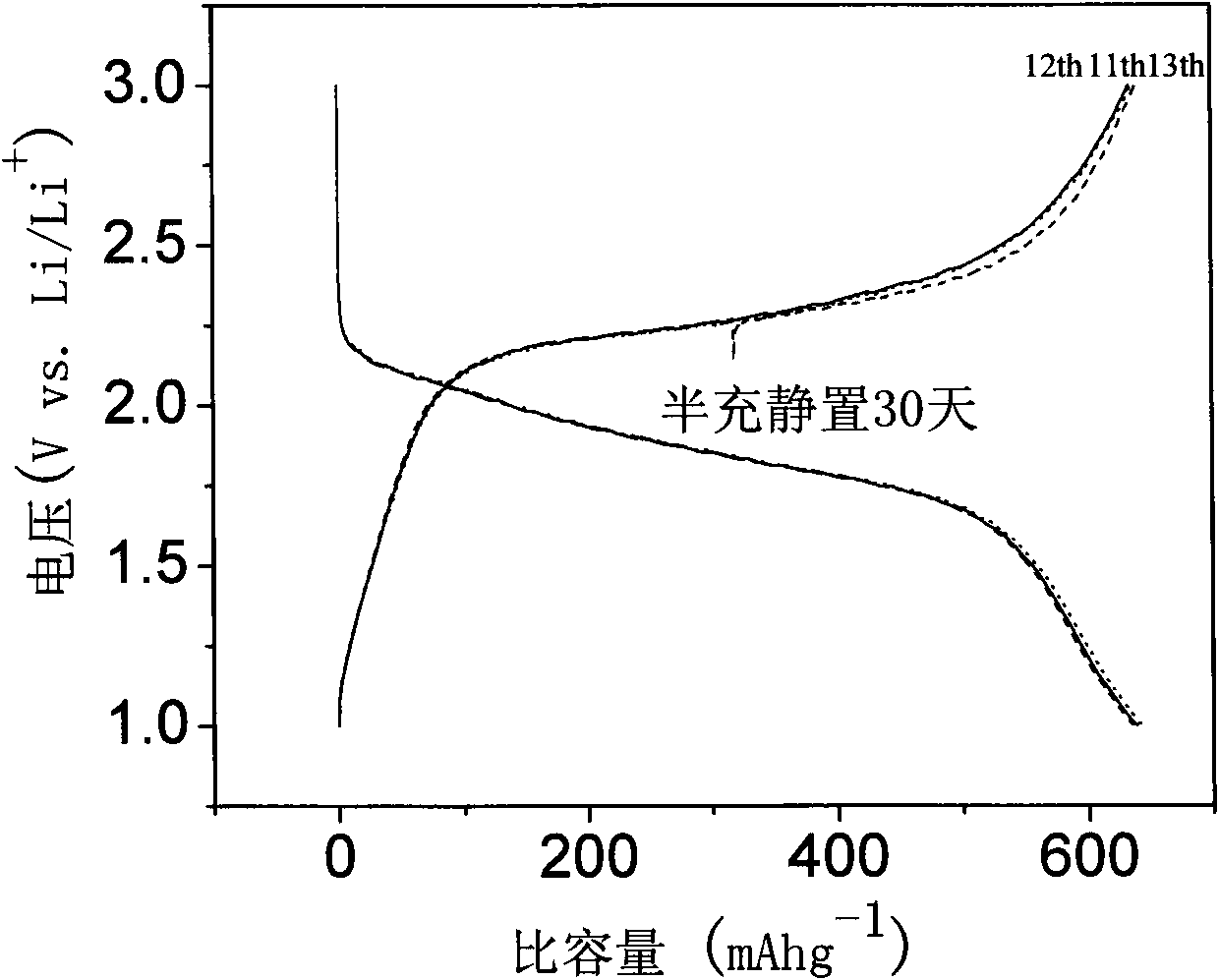

InactiveCN101577323APrevent self-dischargeImprove conductivityElectrode manufacturing processesActive material electrodesLithium metalMass ratio

The invention discloses sulfenyl anode of a lithium-sulfur rechargeable battery and a preparation method thereof. The sulfenyl anode is prepared by the steps of: equally mixing sulfenyl compound active material, cyclodextrin binder and carbon conductivity agent, coating the mixture on an aluminum foil current collector and obtaining the sulfenyl anode after drying and pressing. The coating thickness is 50 to 100 microns and the aluminum foil thickness is 20 to 30 microns; the mass ratio of the sulfenyl compound active material, the cyclodextrin binder and the carbon conductivity agent is 7 to 8:0.6 to 1:0.6 to 1.5, wherein the sulfenyl compound active material is formed by the steps of: equally mixing carbon nano tube, sulfur and polyacrylonitrile according to the mass ratio of 0.1 to 0.2:6 to 8:1 and sintering the mixture in protection of inert gas at the temperature of 300 to 320 DEG C for insulation for 6 to 8 hours. By using the lithium-sulfur rechargeable battery with the sulfenyl anode and lithium metal cathode, the reversible capacity of the sulfenyl compound active material reaches 680mAh.g under 0.1C multiplying power charge-discharge condition; and compared with the discharge capacity of second circulation, the discharge capacity after 100 times of circulation decreases less than 10 percent.

Owner:SHANGHAI JIAO TONG UNIV

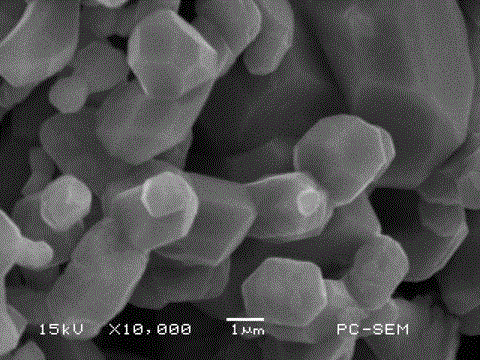

Particulate positive electrode active material for a lithium secondary cell

InactiveUS20050019662A1High safetyHigh volume capacity densityFluoride preparationPositive electrodesChemistryHigh weight

A particulate positive electrode active material for a lithium secondary cell which satisfies high charge and discharge cyclic durability, high safety, high temperature storage properties, a high discharge average voltage, large current discharge properties, a high weight capacity density, a high volume capacity density, etc. in a well-balanced manner is provided. A particulate positive electrode active material for a lithium secondary cell, which is represented by the formula LipCoxMyOzFa (wherein M is at least one element selected from Groups 2 to 8, 13 and 14 of the Periodic Table, 0.9≦p≦1.1, 0.980≦x≦0.9999, 0.0001≦y≦0.02, 1.9≦z≦2.1, 0.9≦x+y≦1 and 0.0001≦a≦0.02), wherein fluorine atoms and element M are unevenly distributed on the particle surface, the atomic ratio of fluorine atoms to cobalt atoms (a / x) is from 0.0001 to 0.02, and in powder X-ray diffraction using CuKα-ray, the half value width of the angle of diffraction on (110) plane is from 0.06 to 0.13°, and the half value width of the angle of diffraction on (003) plane is from 0.05 to 0.12°.

Owner:SUMITOMO CHEM CO LTD

Lithium secondary battery

InactiveUS7659034B2Improve charge-discharge cycle performanceElectrode carriers/collectorsOrganic electrolyte cellsCharge dischargeMaterials science

Charge-discharge cycle performance is improved in a lithium secondary battery including a negative electrode containing a negative electrode active material having silicon as its main component, provided on a surface of a current collector, a positive electrode containing a positive electrode active material, and a non-aqueous electrolyte. The positive electrode active material is a lithium transition metal oxide containing Li and Co and having a layered structure, and further containing a group IVA element of the periodic table, such as Zr, Ti, or Tf, and a group IIA element of the periodic table, such as Mg.

Owner:SANYO ELECTRIC CO LTD

Negative electrode for lithium secondary battery and lithium secondary battery

InactiveUS6946223B2Increase energy densityHigh capacity densityElectrode carriers/collectorsNegative electrodesLithium-ion batteryMaterials science

Owner:SANYO ELECTRIC CO LTD

Lithium-ion battery matching method and lithium-ion battery matching system

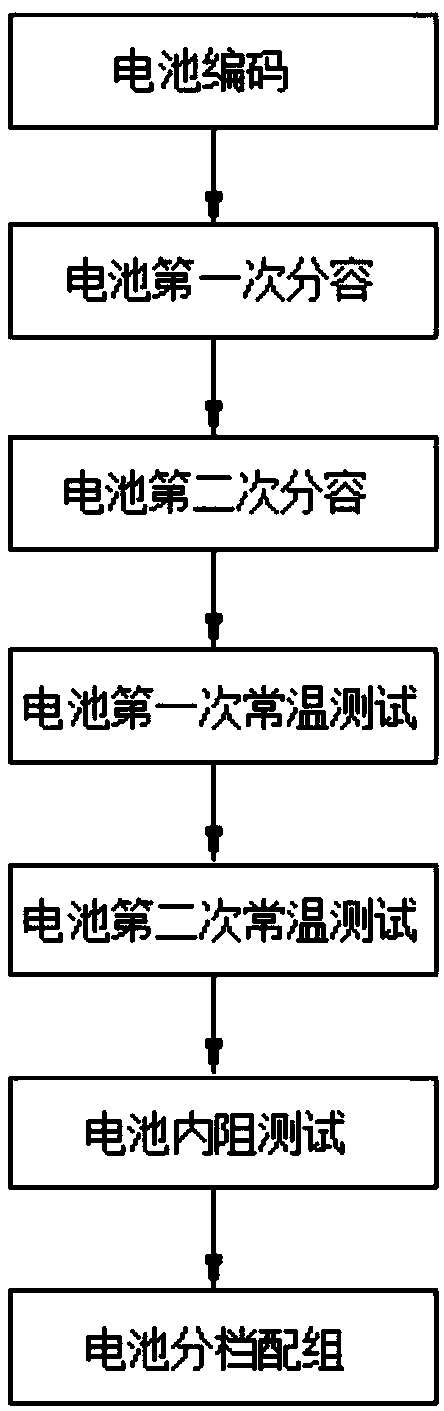

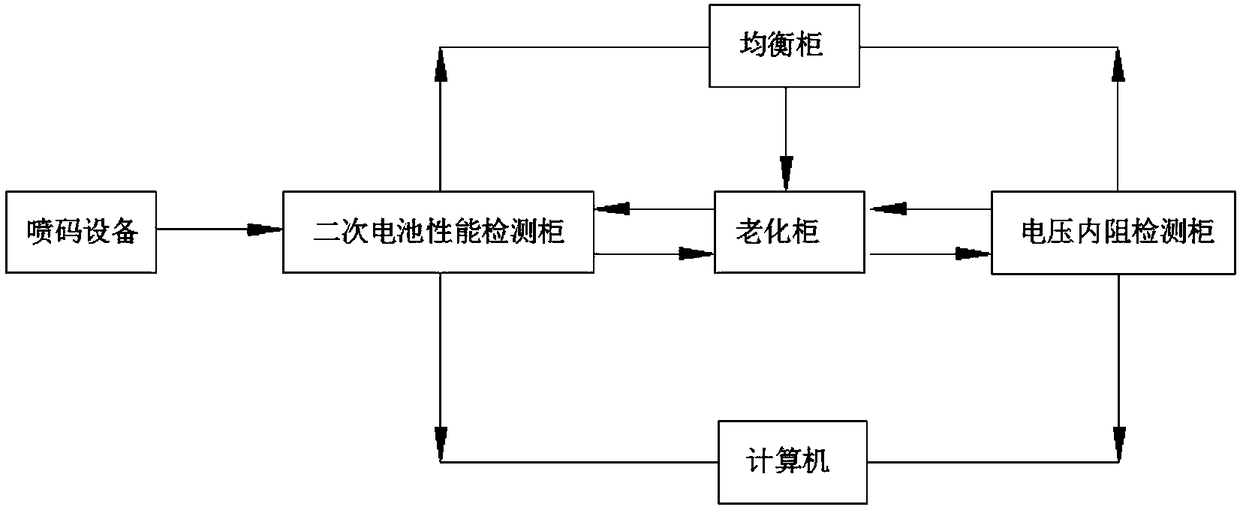

InactiveCN108306065AEasy to combineImprove consistencySecondary cells servicing/maintenanceSortingInternal resistanceElectrical battery

The invention provides a lithium-ion battery matching method and a lithium-ion battery matching system and relates to the technical field of lithium battery production technologies. The lithium-ion battery matching method comprises the steps of battery encoding, first battery grading, second battery grading, first normal temperature testing of batteries, second normal temperature testing of the batteries, internal resistance testing of the batteries and step matching of the batteries. The technical problems that a single-parameter matching method is single in basis and large in error, a multi-parameter matching method cannot present essential differences among the batteries and is poor in balance, and a method of combining the multi-parameter matching method with a charge-discharge curve matching method is complicated in operation process and low in production efficiency are solved. According to the lithium-ion battery matching method, the matched batteries are better in uniformity, the charge-discharge cycle performance is improved, furthermore, other parameters do not need to be tested in the scheme, the influence of the charged state is avoided during matching, and matching canbe carried out in the charged state of an arbitrary low-power battery pack.

Owner:河南国能电池有限公司

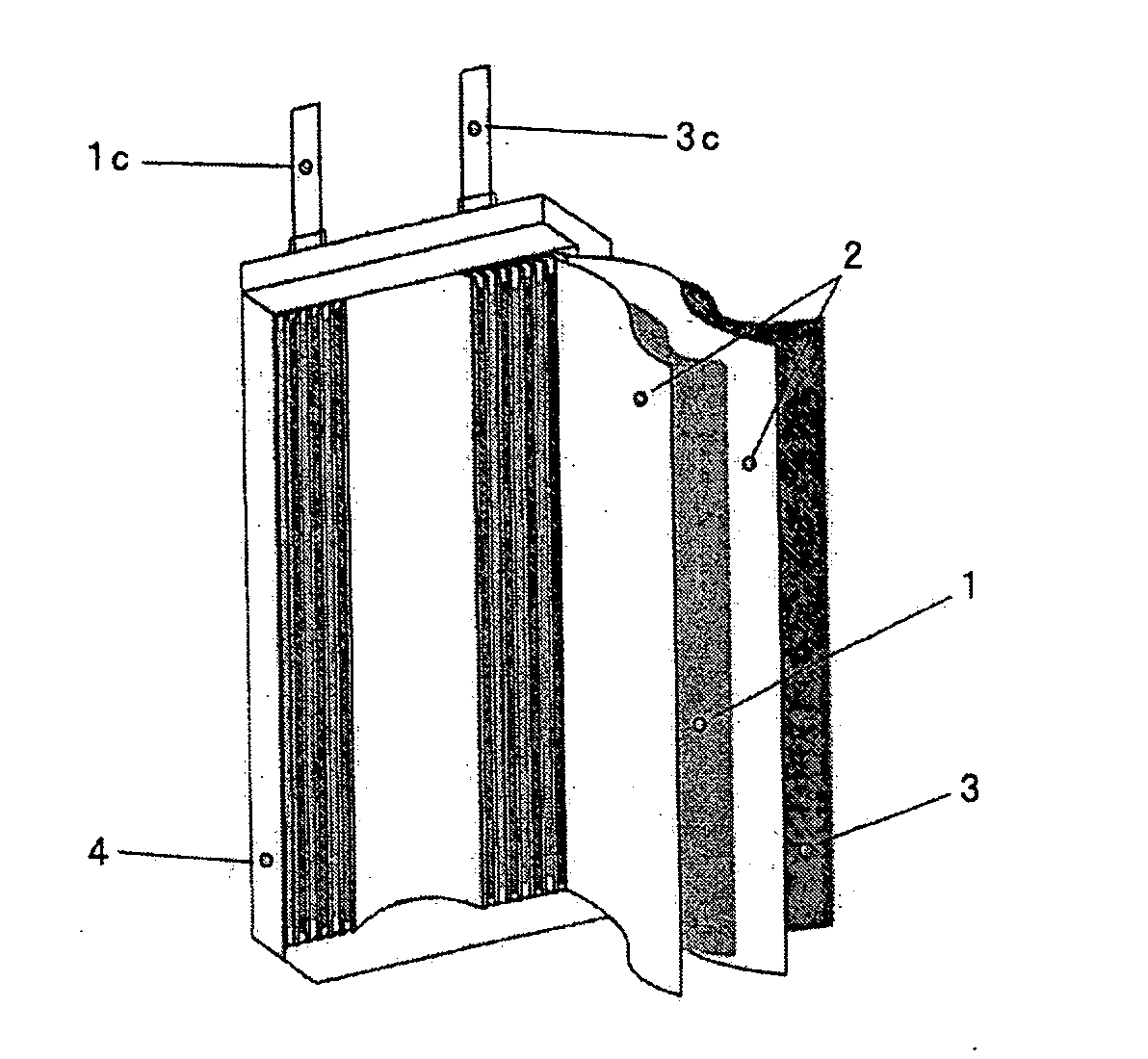

Lithium secondary battery

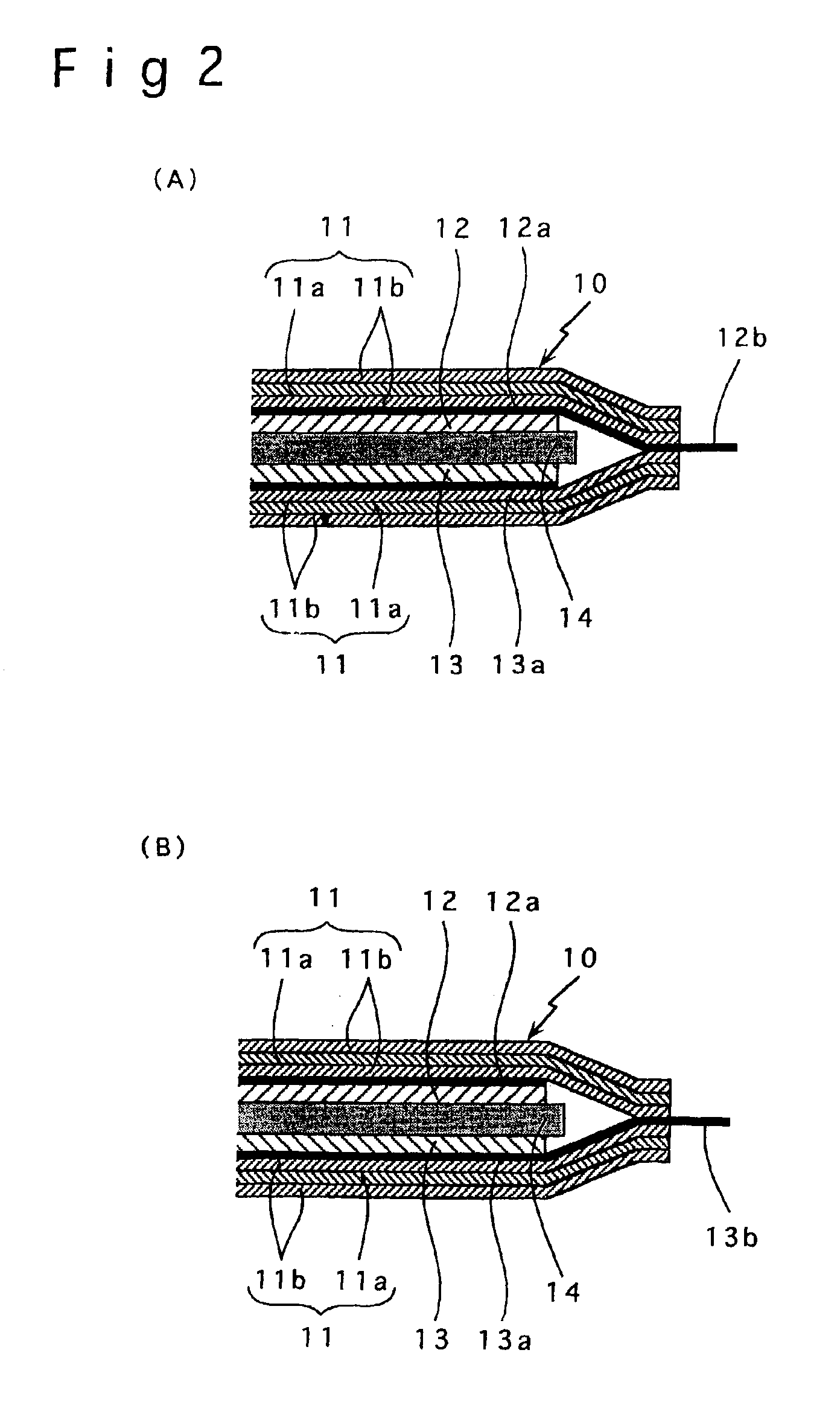

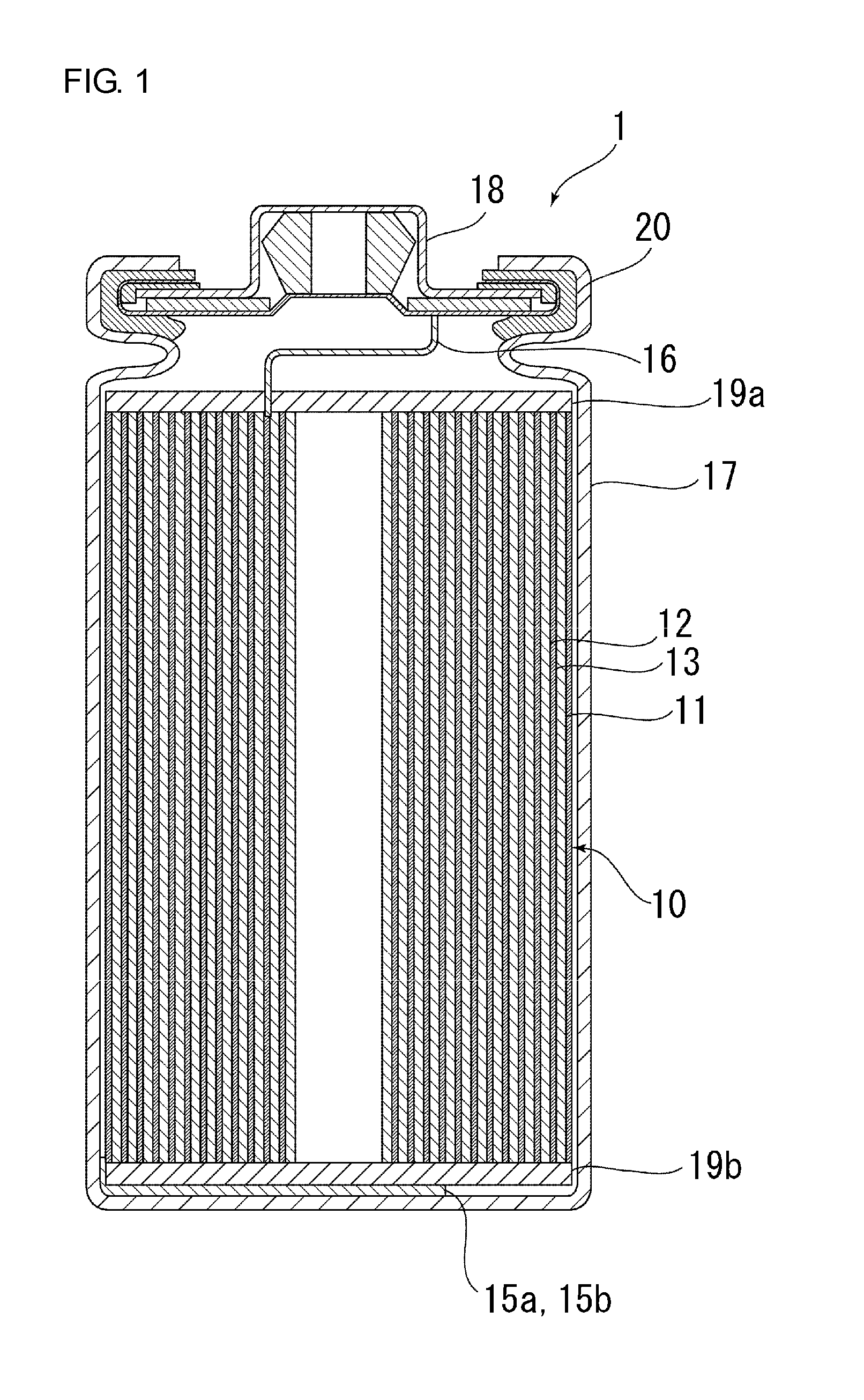

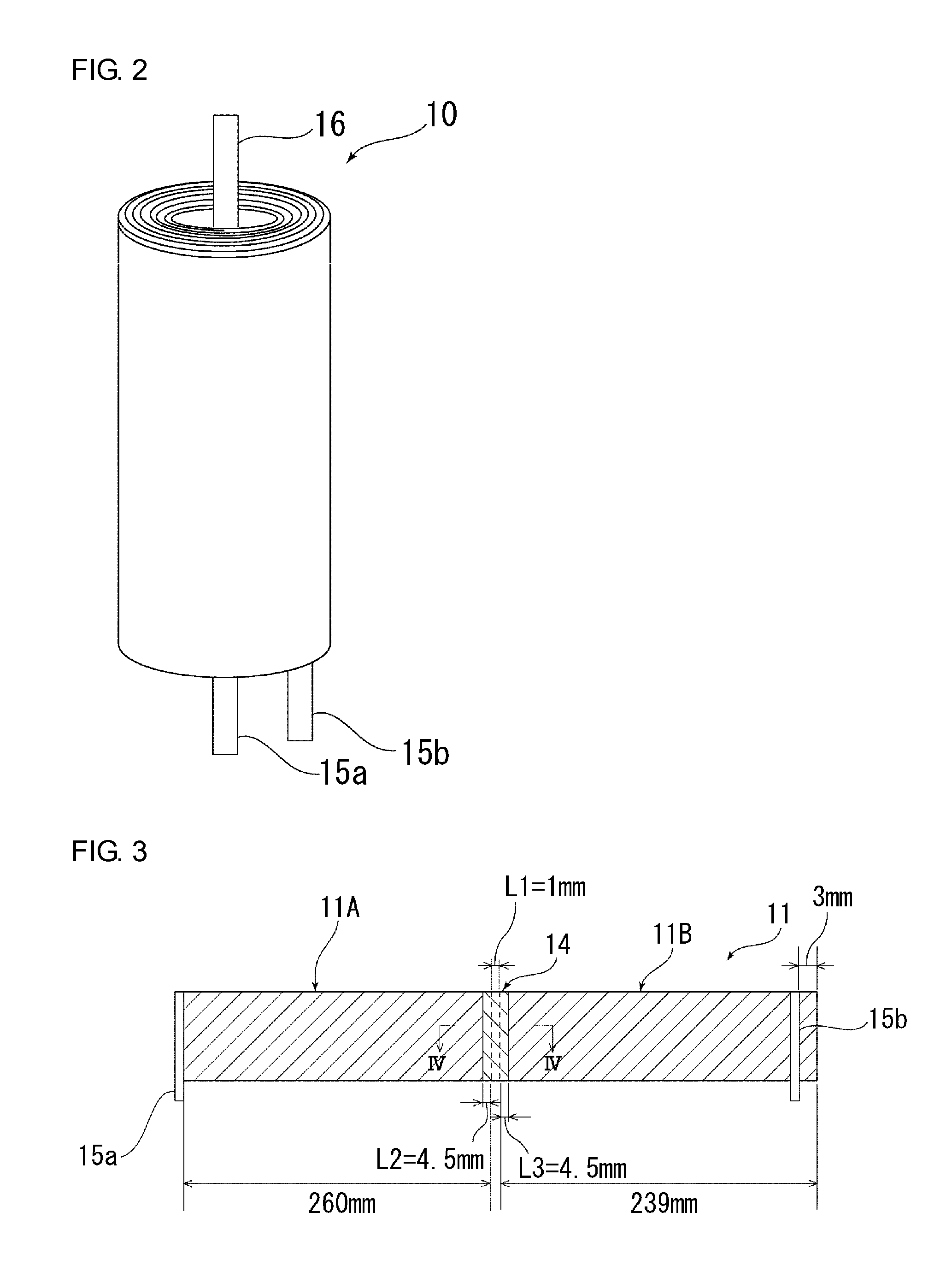

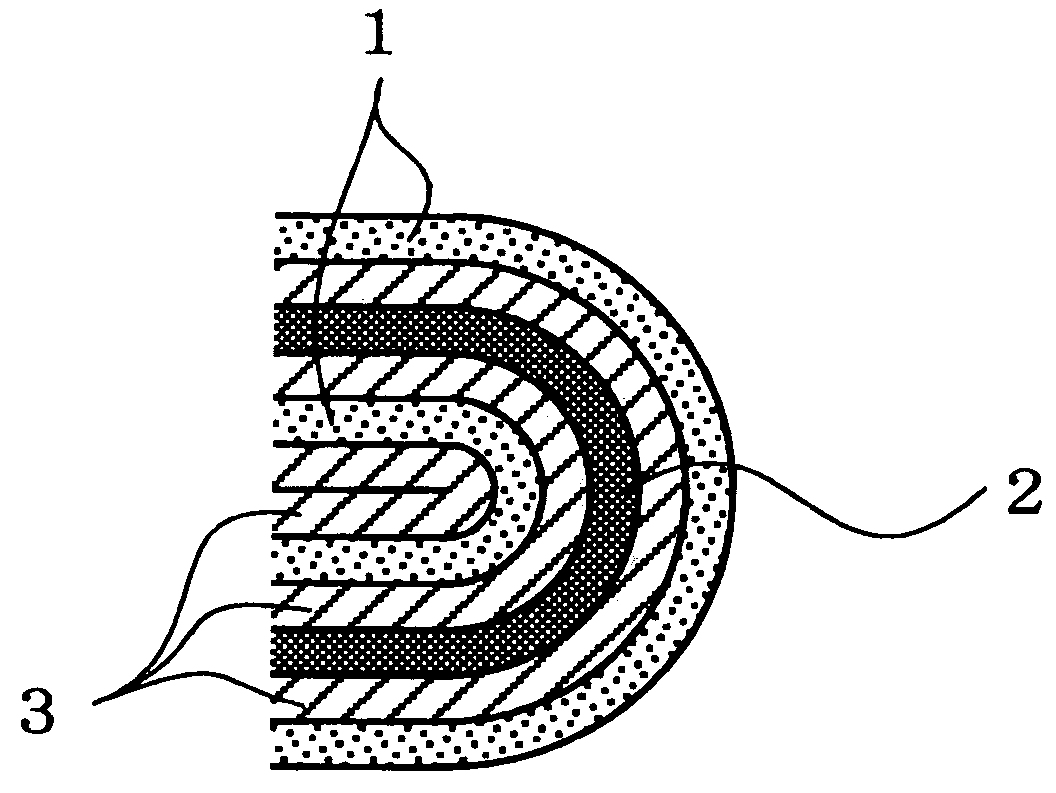

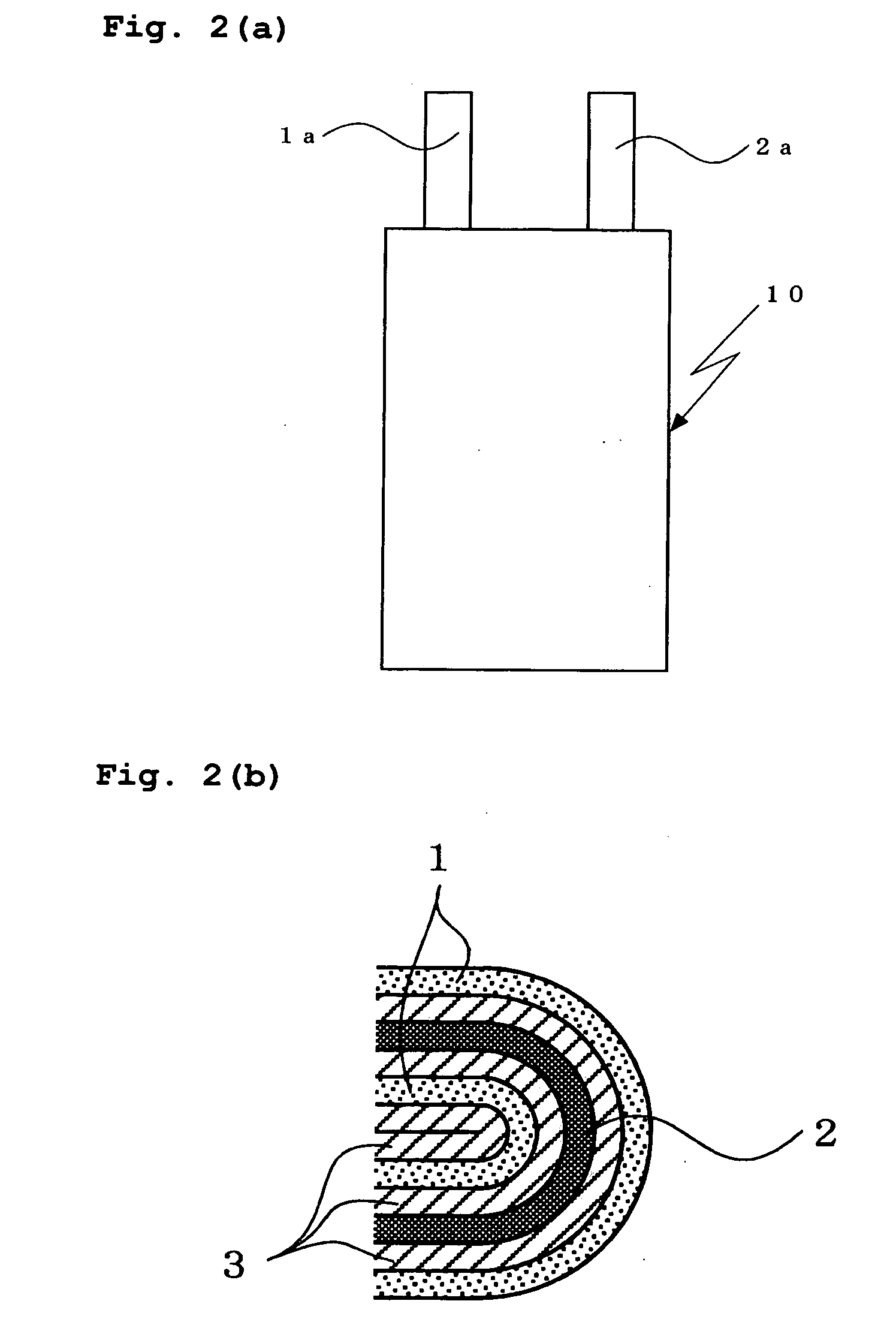

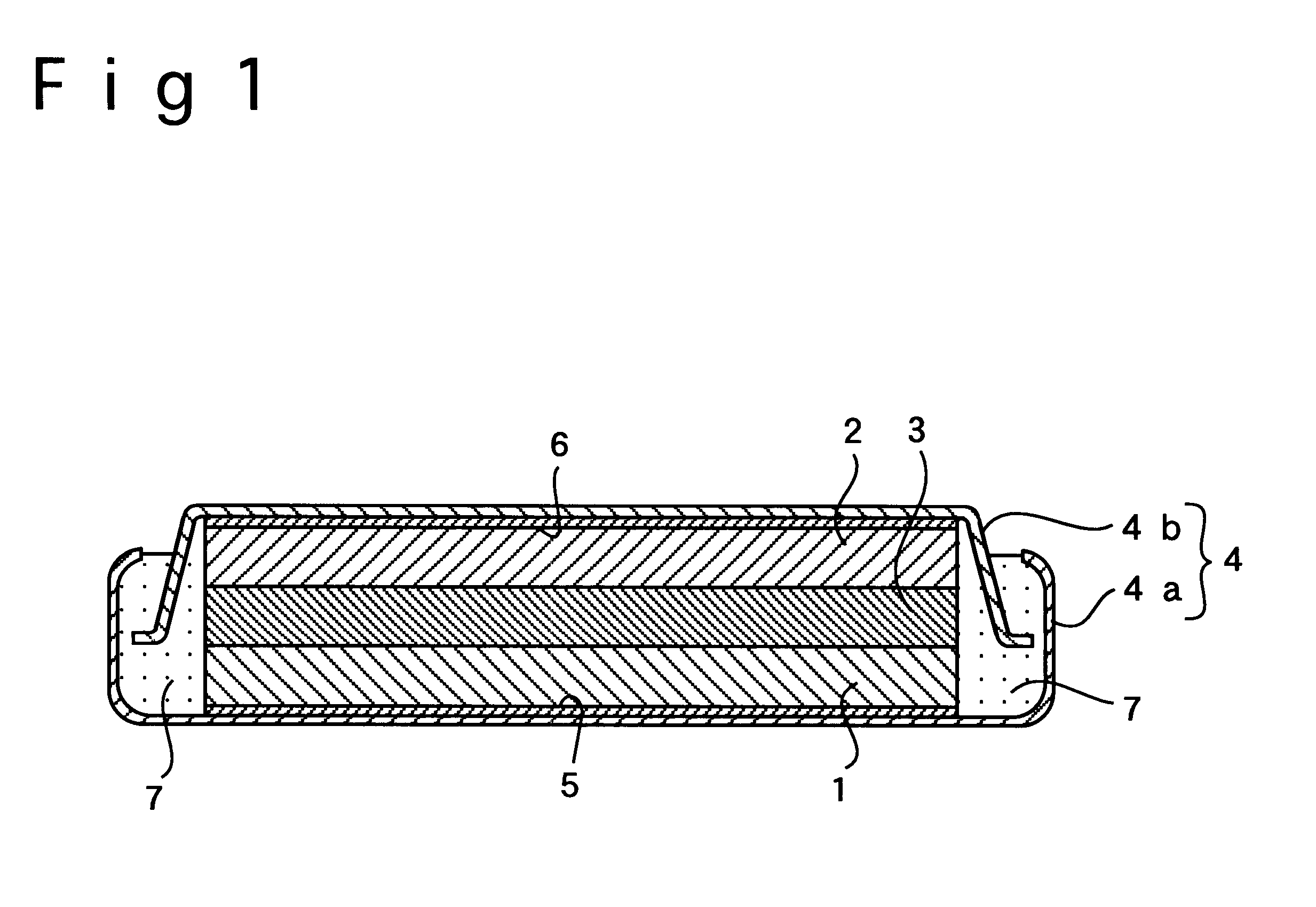

InactiveUS20110217577A1Improve charge-discharge cycle performanceDemands for higher performance of the lithium secondary batteries have been increasingly highFinal product manufactureActive material electrodesEngineeringNon aqueous electrolytes

A lithium secondary battery comprises an electrode assembly and a non-aqueous electrolyte. The electrode assembly is made by winding a negative electrode, a positive electrode, and a separator interposed between the negative and positive electrodes. The negative electrode contains a negative electrode active material that is alloyed with lithium. The non-aqueous electrolyte is impregnated in the electrode assembly. At least one of the negative and positive electrodes is divided into a plurality of electrode units which are arranged at spaces for each other along the winding direction.

Owner:SANYO ELECTRIC CO LTD

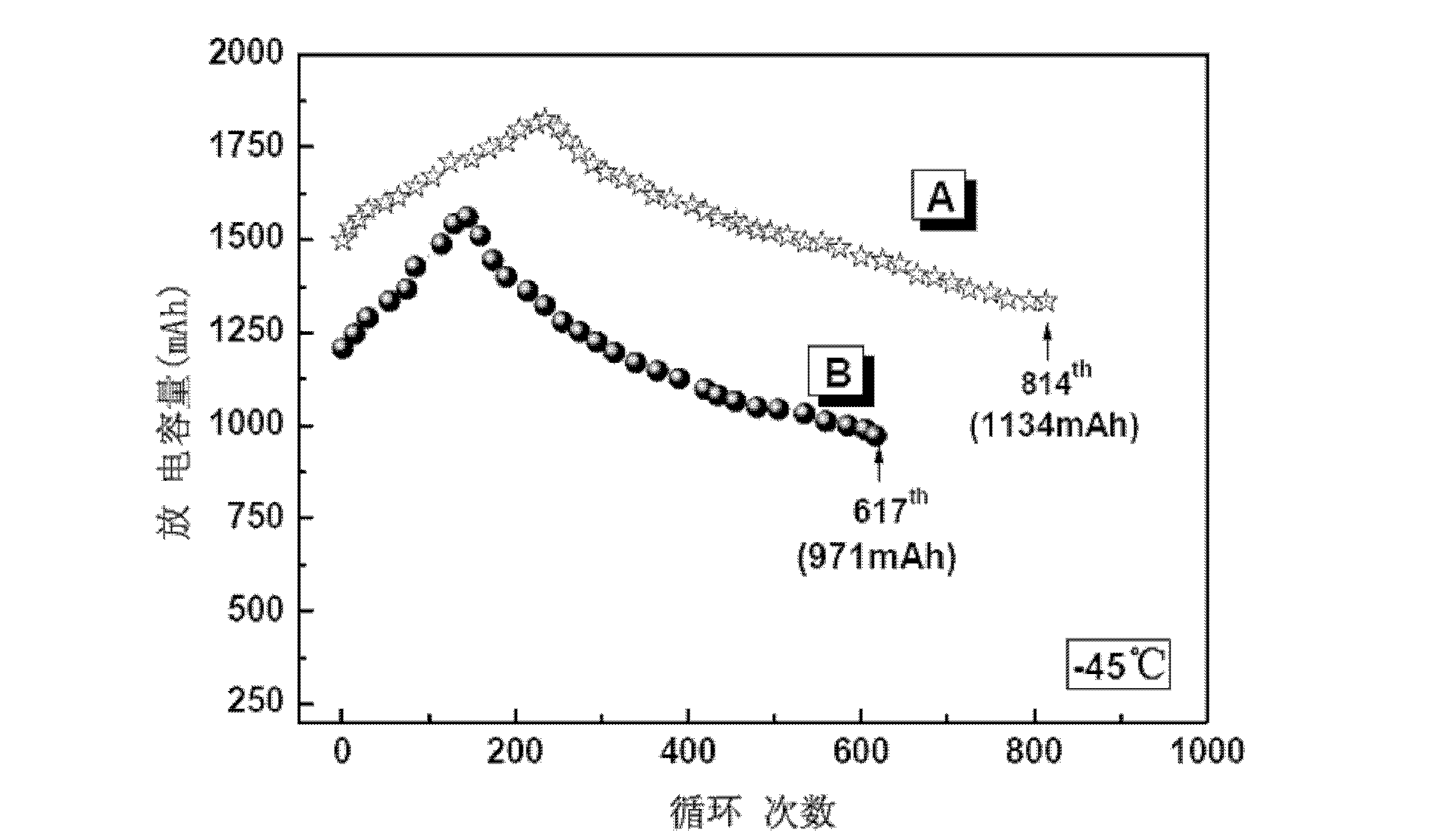

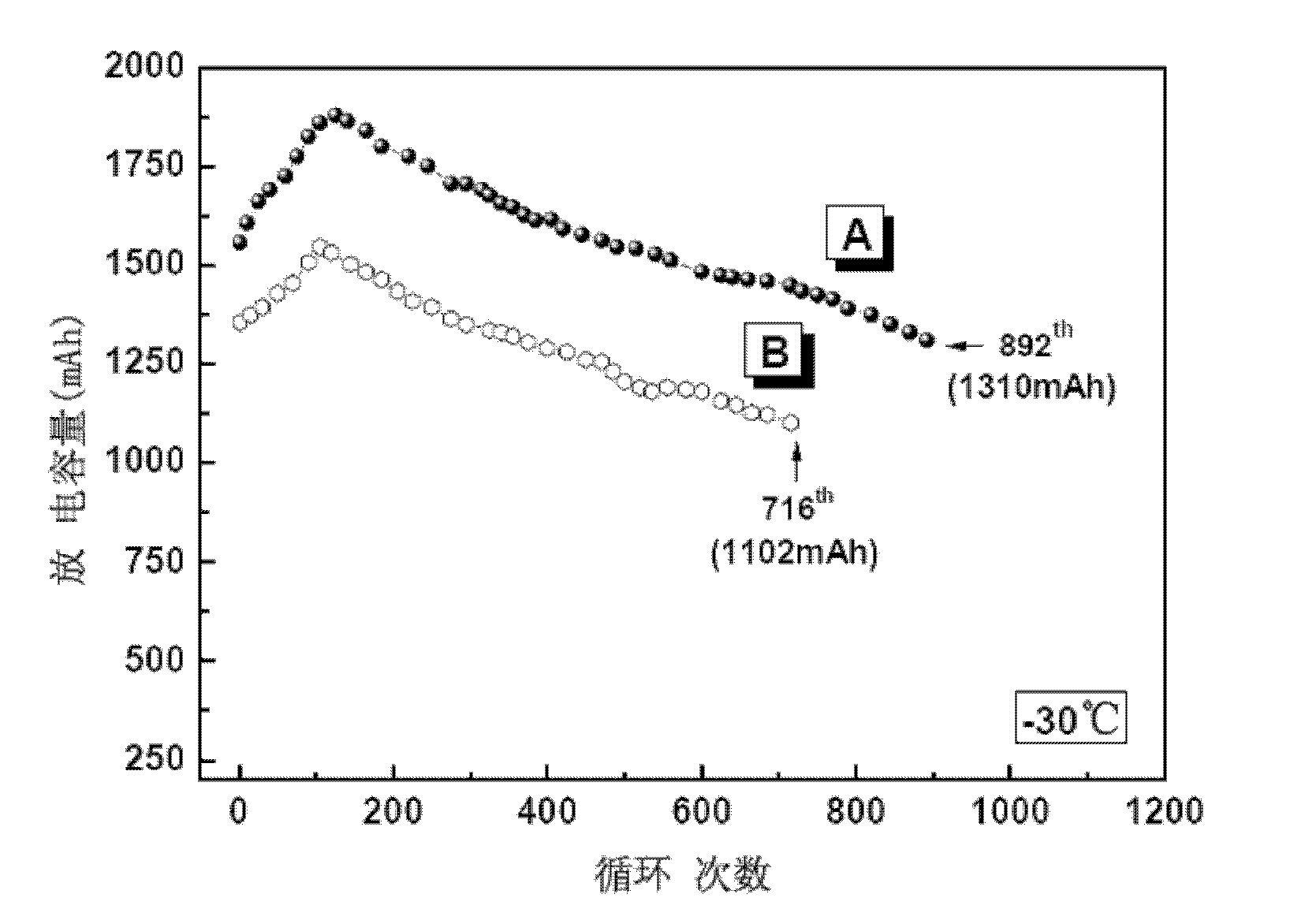

Electrolyte for lithium ion battery and preparation method thereof

ActiveCN102637901AGood effectImprove charge and discharge efficiencySecondary cellsLithium oxideLithium hydroxide

The invention discloses an electrolyte for a lithium ion battery and a preparation method thereof. The electrolyte consists of a main electrolyte, an electrolyte additive, a main solvent and a solvent additive. The preparation method comprises the following steps of: A. under the condition of vacuum or inert gas protection, respectively mixing the main solvent and the solvent additive with a drying agent (lithium oxide) which is dried to be at constant weight in advance, and mixing and filtering to remove the lithium oxide and lithium hydroxide sediment; B. uniformly mixing the dried main solvent and the dried solvent additive from the step A; and C. adding a main electrolyte mixture and an electrolyte additive into the solvent mixed in the step B, and agitating and dissolving under the vacuum and inert gas protection to prepare a solution with the mass mol concentration of the main electrolyte of 0.5-1.5 M. The electrolyte has the advantages of abundant resources, low price and no toxin, effectively improves the work temperature range of the battery and effectively prolongs the circulating service life of the battery, so that various types of the lithium ion batteries are manufactured; and the electrolyte is particularly suitable for manufacturing a lithium ion power battery with high power capacity and high multiplying power charging and discharging capacity.

Owner:广州云通锂电池股份有限公司

Particulate positive electrode active material for a lithium secondary cell

InactiveUS7018741B2High dischargeImprove securityFluoride preparationPositive electrodesParticulatesHigh temperature storage

Owner:SUMITOMO CHEM CO LTD

Graphene-cladded sulfur/microporous carbon sphere composite cathode material

InactiveCN104269543AGive full play to the advantagesImprove conductivityCell electrodesSecondary cellsComposite cathodeSulfur

The invention discloses a composite cathode material for secondary aluminum batteries. The composite cathode material is formed by compounding microporous carbon spheres, sulfur and graphene, has good electric conductivity and is capable of effectively suppressing that polysulfide dissolves in electrolyte to cause the shuttle effect. The preparation method of the composite cathode material comprises the following steps: firstly compounding the microporous carbon spheres and the sulfur, and then cladding the outer layer of the composition with a graphene sheet layer. The preparation method is simple in process and low in cost, toxic raw materials are not used, environment friendliness is achieved, the energy density is high, the utilization ratio of the sulfur is high, and the rate capability and the cycle performance of the secondary aluminum batteries are improved greatly.

Owner:NANJING ZHONGCHU NEW ENERGY

Carbon sulfur compound anode for secondary battery

InactiveCN104157879AHigh reactivityIncrease loadMaterial nanotechnologyNon-aqueous electrolyte accumulatorsCompound aElectricity

The invention discloses a carbon sulfur compound anode for a secondary battery. The anode is formed by compounding a carbon nanotube array, sulfur and graphene, is provided with a three-dimensional network conductive framework and is good in electrochemical performance. A preparation method of the anode comprises the following steps: compounding elemental sulfur in the carbon nanotube array at first and then wrapping an outer layer with few graphene sheet layers. The preparation method is simple in process, low in cost and environment-friendly due to nonuse of toxic raw materials; moreover, the compound anode does not need to be added with a conductive agent and a bonder, and is high in energy density and sulfur utilization rate, and the rate performance and the cycle performance of the secondary aluminum battery are greatly improved.

Owner:NANJING ZHONGCHU NEW ENERGY

Gel polymer electrolyte, polymer battery and preparing method

ActiveCN101747642AImprove conductivityPrevent crystallizationSecondary cellsPolymer electrolytesLithium sulphate

The present invention provides a gel polymer electrolyte. The gel polymer electrolyte comprises a polymer, an electrolyte, an organic solvent and inorganic fillers. The electrolyte, the organic solvent and the inorganic fillers are dispersed in the polymer. The inorganic fillers are lithium sulfate and / or lithium bisulfate. The present invention also provides a polymer battery containing the gel polymer electrolyte and a preparing method thereof. The preparing method of the polymer battery comprises the steps: mixed solution containing the electrolyte, the inorganic fillers, a polymerizable monomer and the organic solvent is added between the positive pole and the negative pole of the battery, the polymerizable monomer in the mixed solution is then polymerized under polymerization conditions, and a substance in a gel state is obtained. As lithium sulfate and / or lithium bisulfate are used as the inorganic fillers in the gel polymer electrolyte, the conductivity of the gel polymer electrolyte and the rate discharge performance of the battery containing the gel polymer electrolyte are obviously improved.

Owner:BYD CO LTD

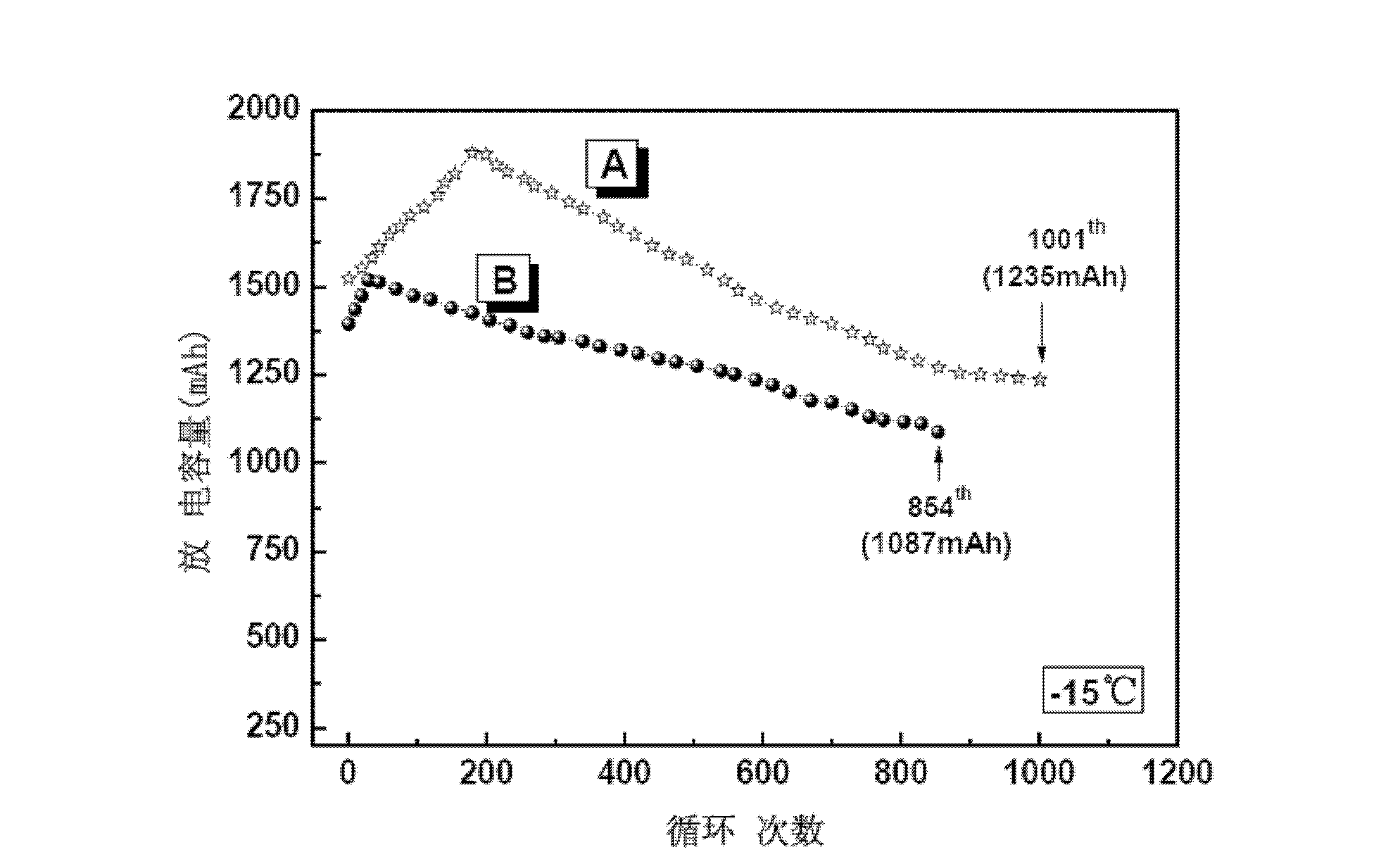

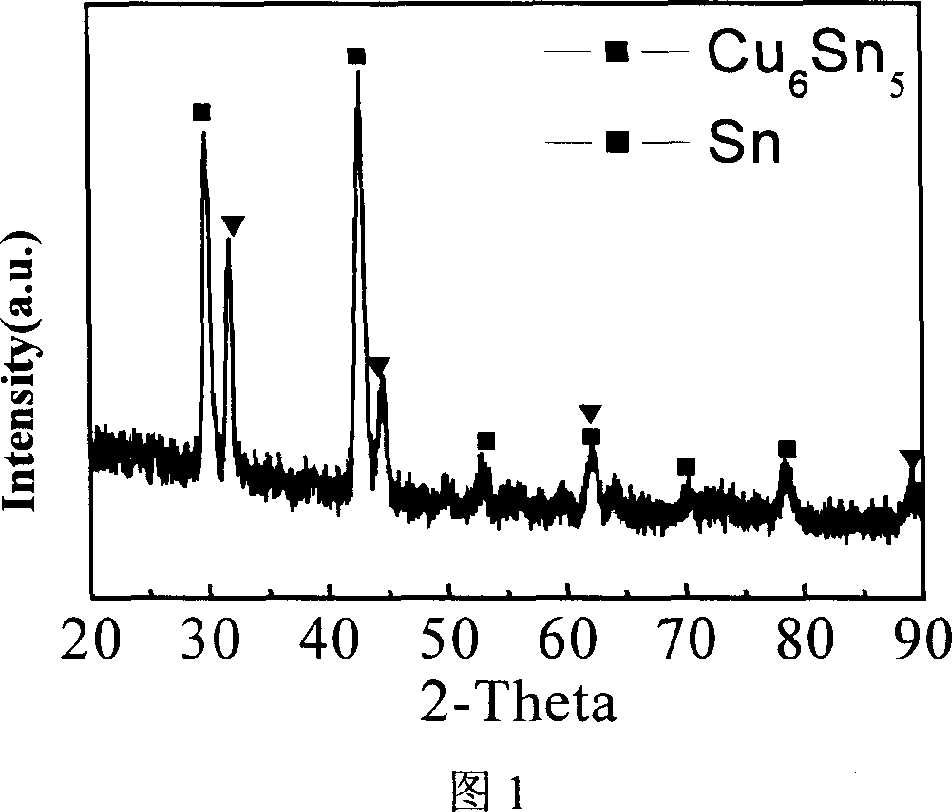

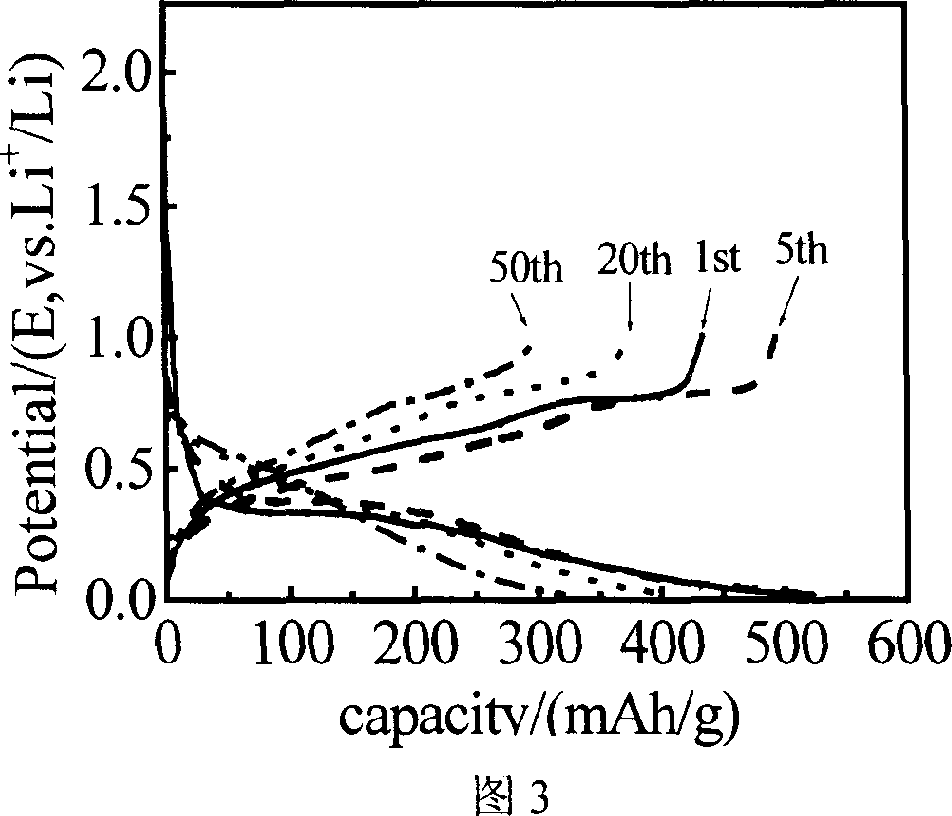

Prepn process of Sn-Cu alloy material for negative pole of lithium ion cell

InactiveCN1974869ARealize large-scale productionNo pollution in the processElectrode manufacturing processesDischarge efficiencyAlloy

The present invention relates to negative pole material for lithium ion cell, and is especially one no-cyanide electroplating process for preparing Sn-Cu alloy as negative pole material for lithium ion cell. The no-cyanide electroplating process includes the following steps: dissolving potassium pyrophosphate in water, adding stannous chloride and copper sulfate to obtain mixed solution, adding epoxy chloroalkane, triethanolamine, formaldehyde and gelatin to form electroplating solution; and electroplating on copper substrate to form silvery white bright Sn-Cu alloy. The process has low cost, no environmental pollution, and the lithium ion cell with negative pole of the Sn-Cu alloy has high initial capacity, high initial charging and discharging efficiency and good charging and discharging circulating performance.

Owner:XIAMEN UNIV

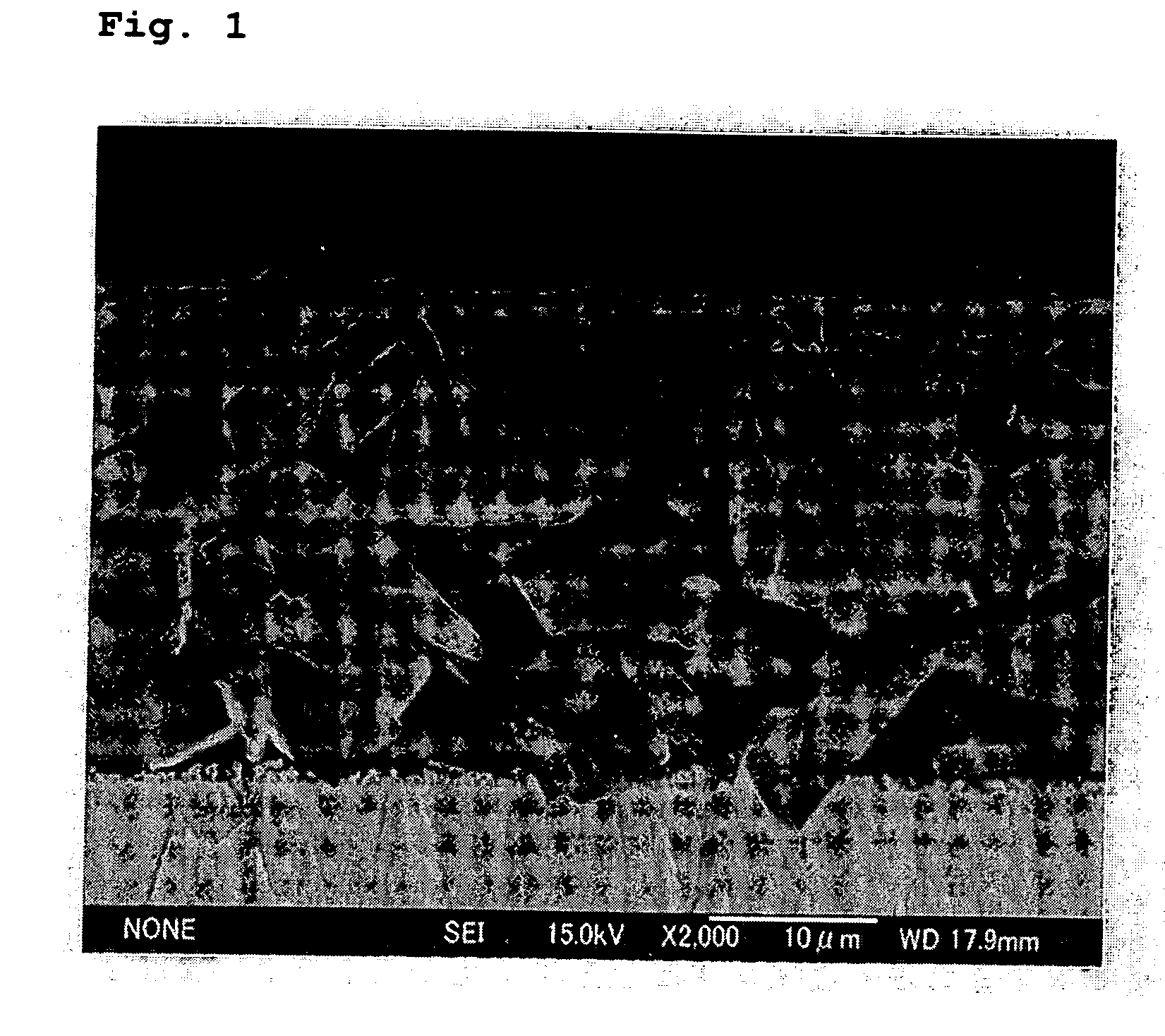

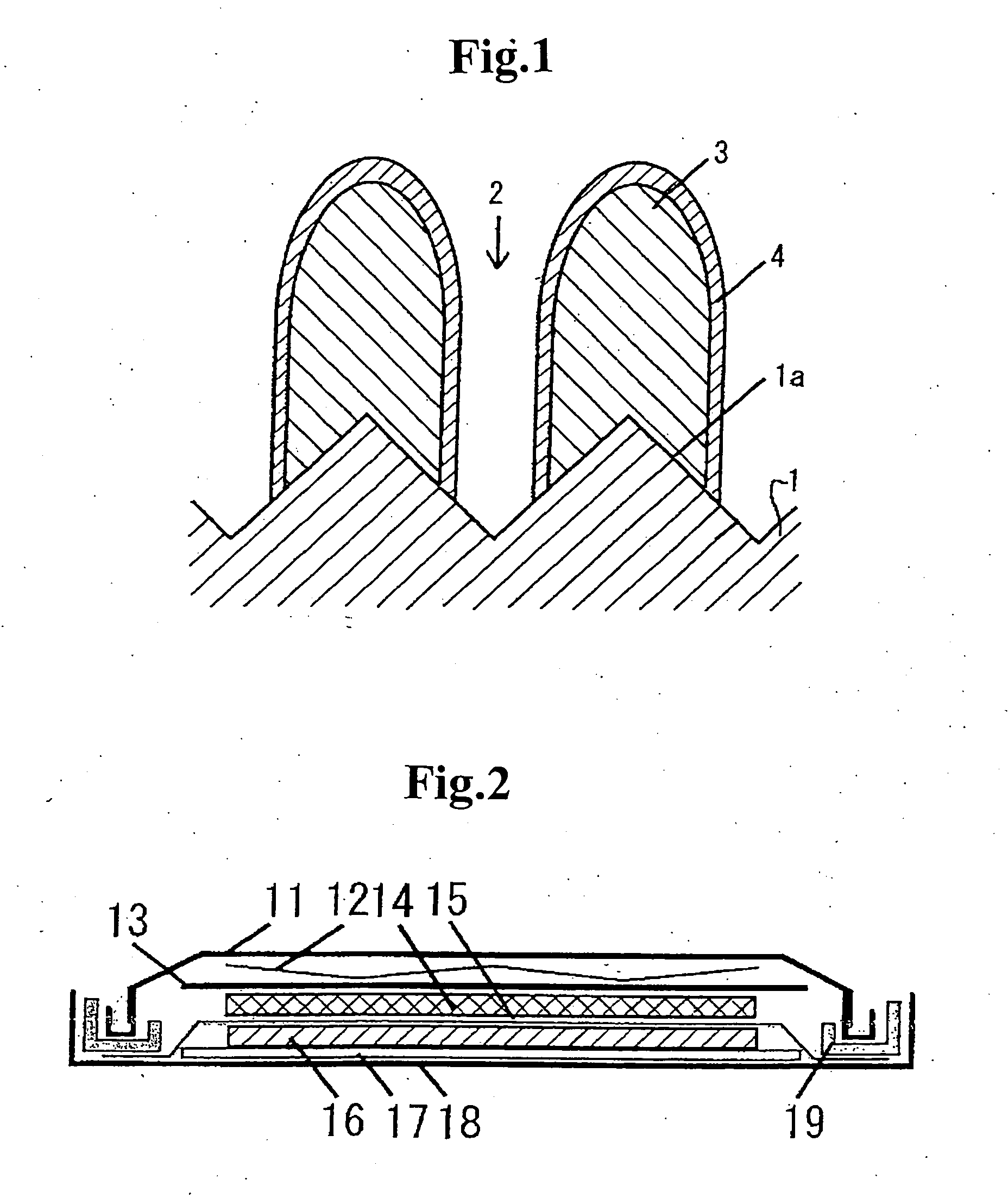

Negative electrode for lithium secondary battery, method of manufacturing the electrode, and lithium secondary battery

InactiveUS20070172733A1Improve adhesionImprove surface roughnessElectrode rolling/calenderingNon-aqueous electrolyte accumulatorsSilicon alloyCharge discharge

In a lithium secondary battery using a negative electrode having a negative electrode mixture layer formed on a surface of a negative electrode current collector, the mixture layer made of a binder and negative electrode active material particles of silicon and / or a silicon alloy, charge-discharge cycle performance is improved without degrading the capacity per unit volume, by making the negative electrode mixture layer sufficiently adhere to the negative electrode current collector. The negative electrode has a negative electrode mixture layer composed of a binder and negative electrode active material particles of silicon and / or a silicon alloy. The negative electrode mixture layer is formed on a surface of the negative electrode current collector by sintering. Negative electrode active material particles are partially embedded in the negative electrode current collector.

Owner:SANYO ELECTRIC CO LTD

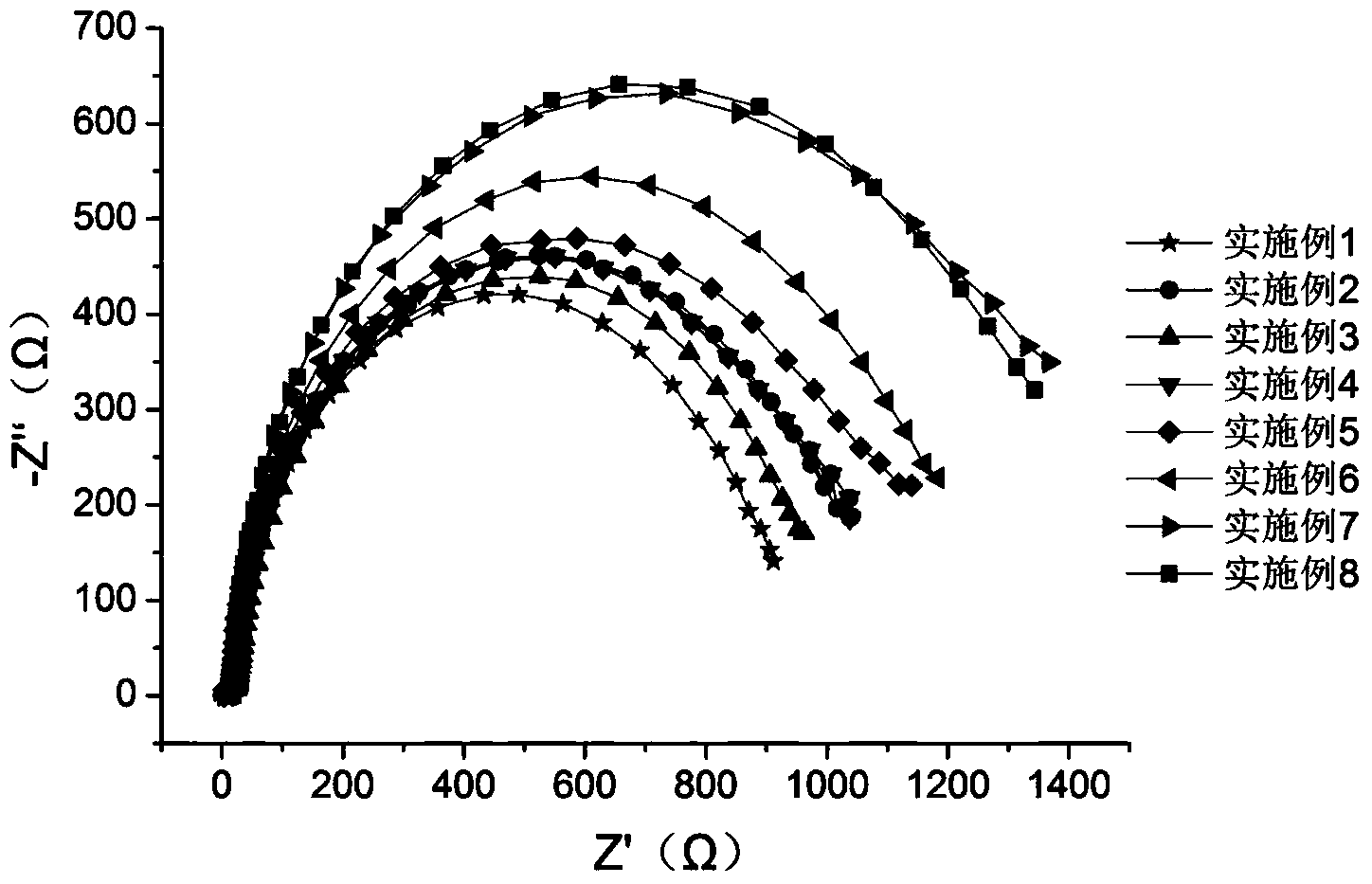

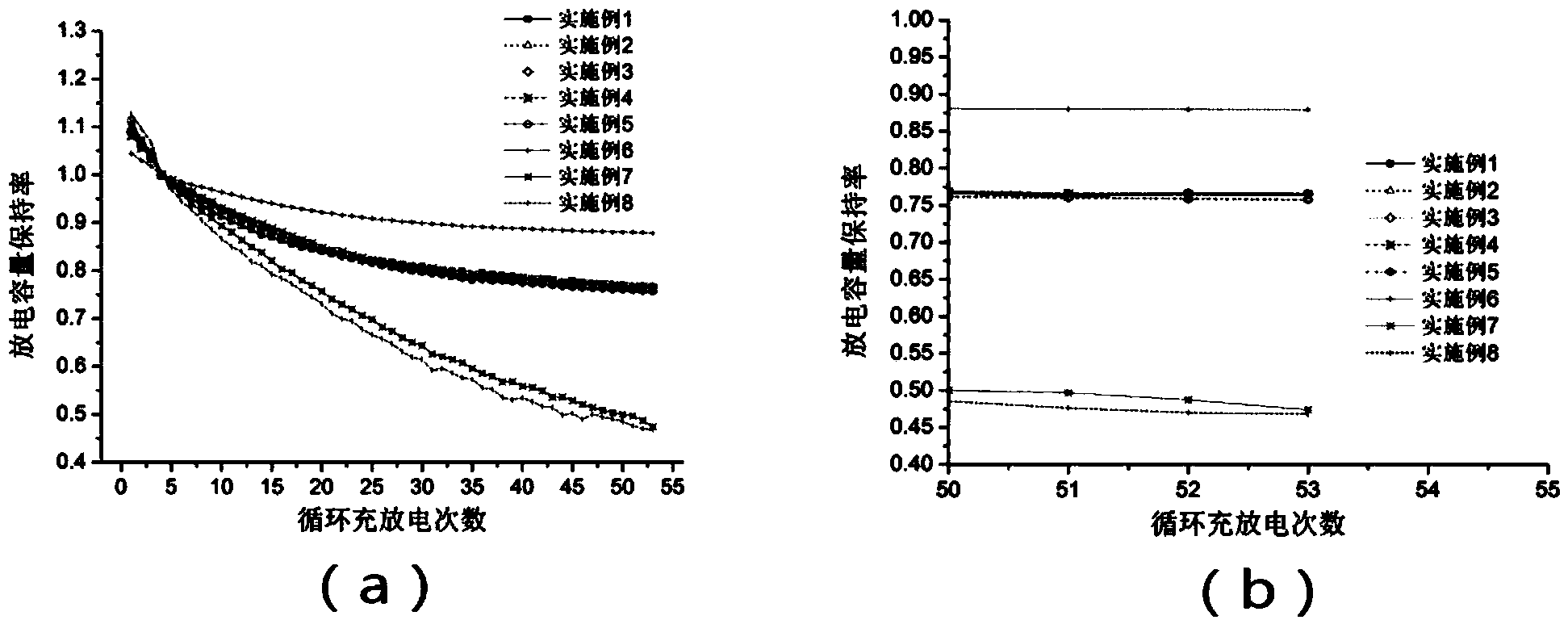

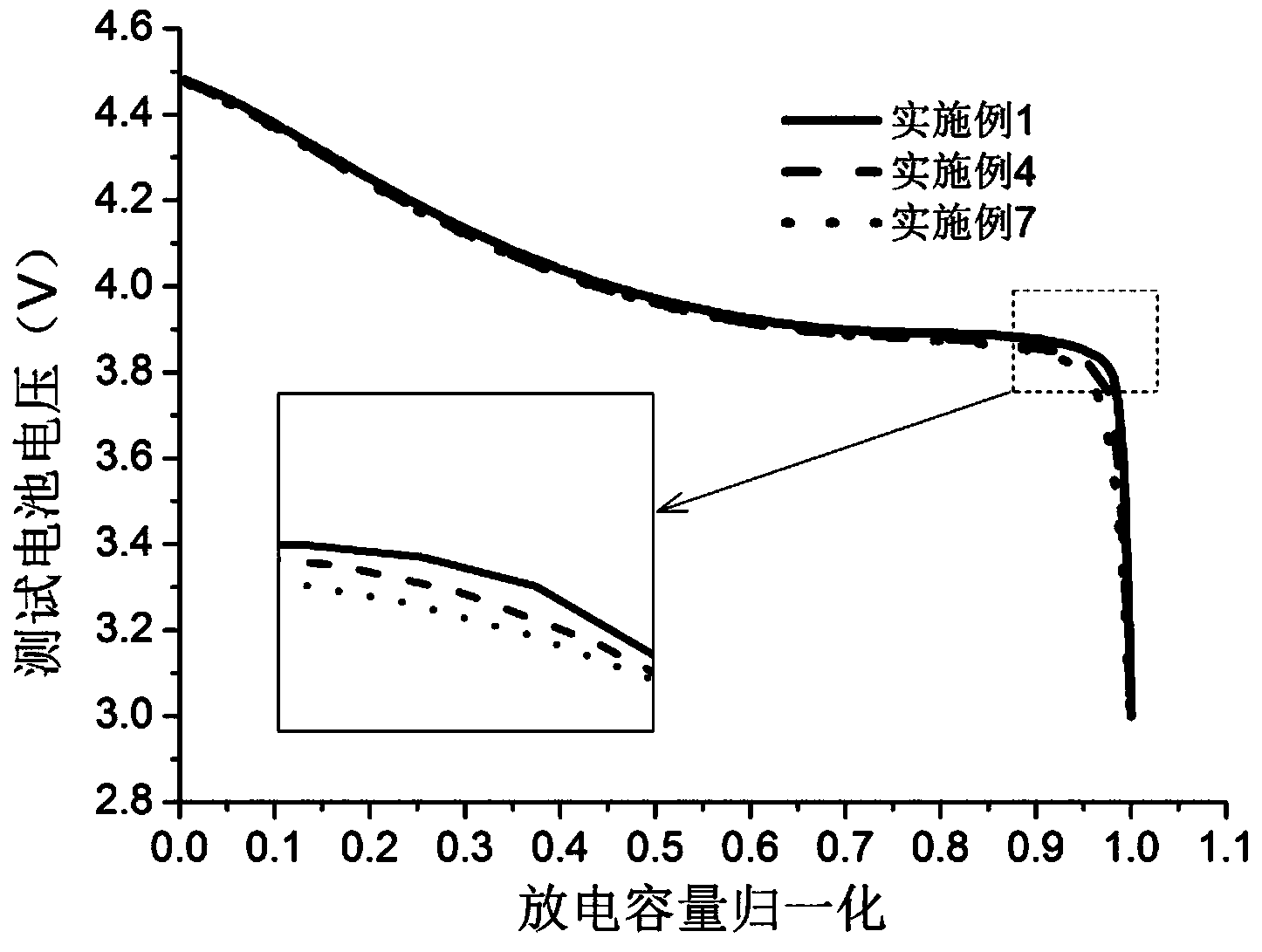

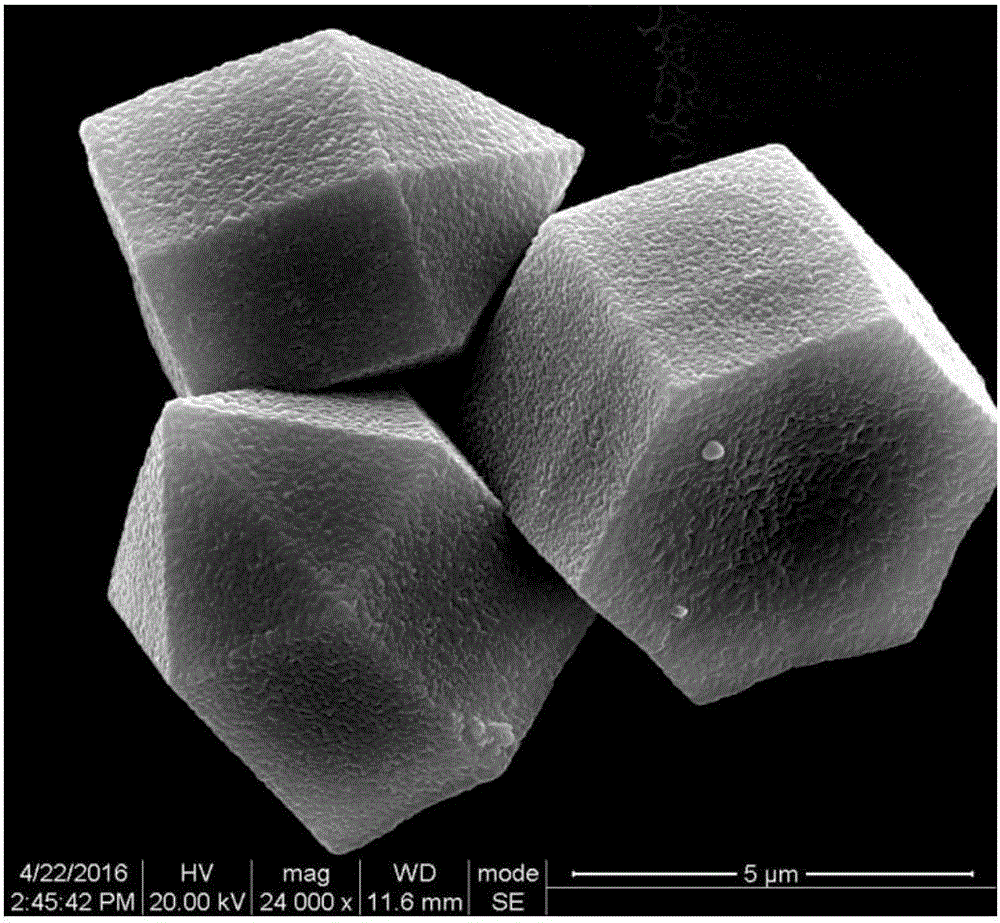

High-voltage lithium battery cathode material doped with trace amount of tungsten and preparation method thereof

InactiveCN102723481AImprove cycle stabilityImprove charge-discharge cycle performanceCell electrodesSol-gelVacuum drying

The invention discloses a high-voltage lithium battery cathode material doped with a trace amount of tungsten and a preparation method thereof. The general formula of the material is LiNi0.5Mn1.5(1-x)WxO4, wherein x is more than 0 and is less than or equal to 0.01. The material is prepared by adopting a sol-gel method, and the preparation method comprises the following steps of: dissolving a soluble lithium salt, a soluble nickel salt, a soluble manganese salt, tungsten hexachloride and ammonium oxalate in deionized water to prepare a mixed solution; heating and stirring until viscous wet gel is obtained; performing vacuum drying on the wet gel to obtain a dried gel; and finally performing pre-sintering, secondary sintering and ball milling to obtain the cathode material. The high-voltage lithium battery cathode material doped with a trace amount of tungsten has high electrochemical performance, and compared with undoped LiNi0.5Mn1.5O4, the LiNi0.5Mn1.5(1-x)WxO4 doped with a trace amount of tungsten is greatly improved in specific capacity and cycle performance.

Owner:SOUTH CHINA NORMAL UNIVERSITY +1

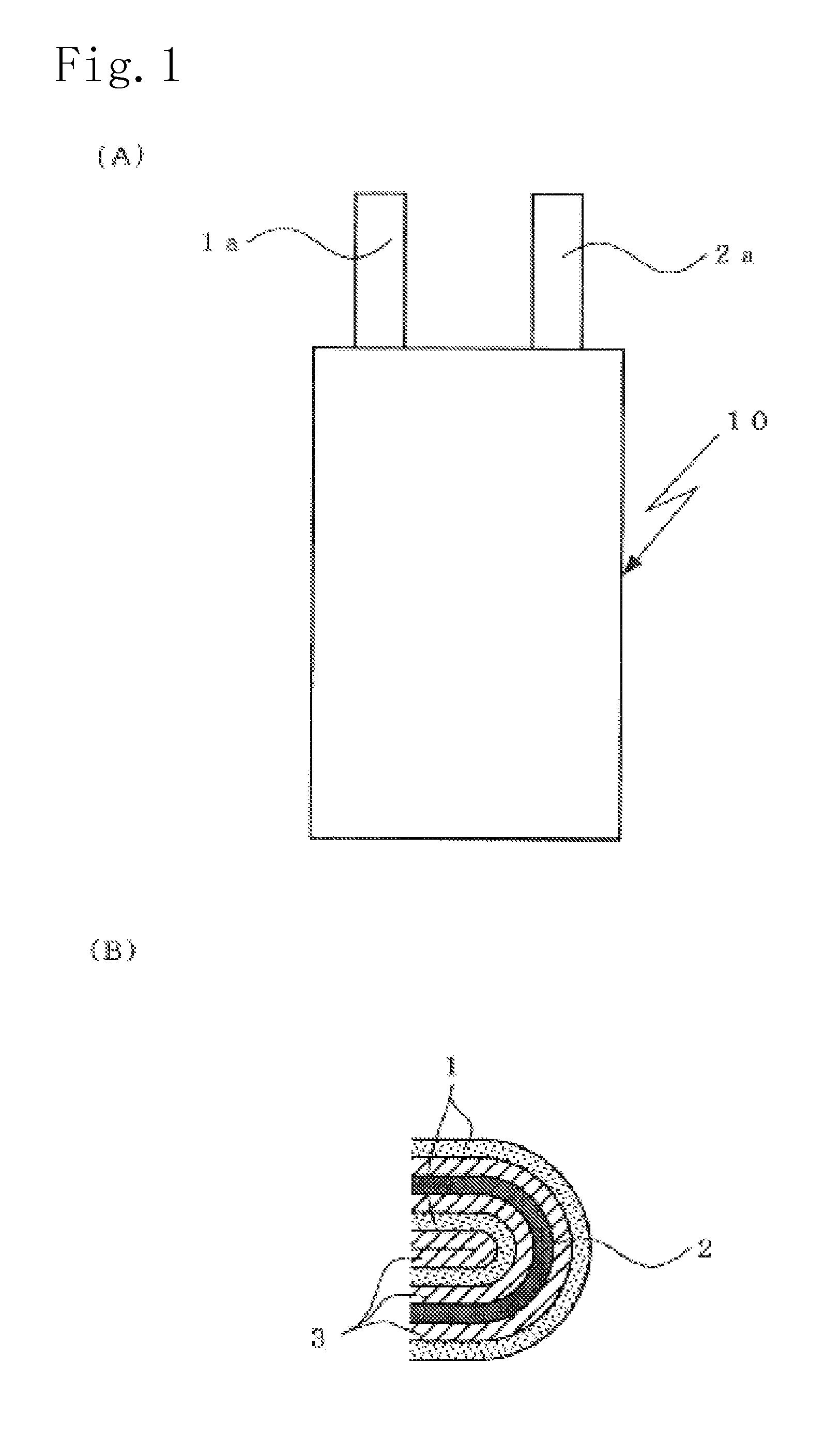

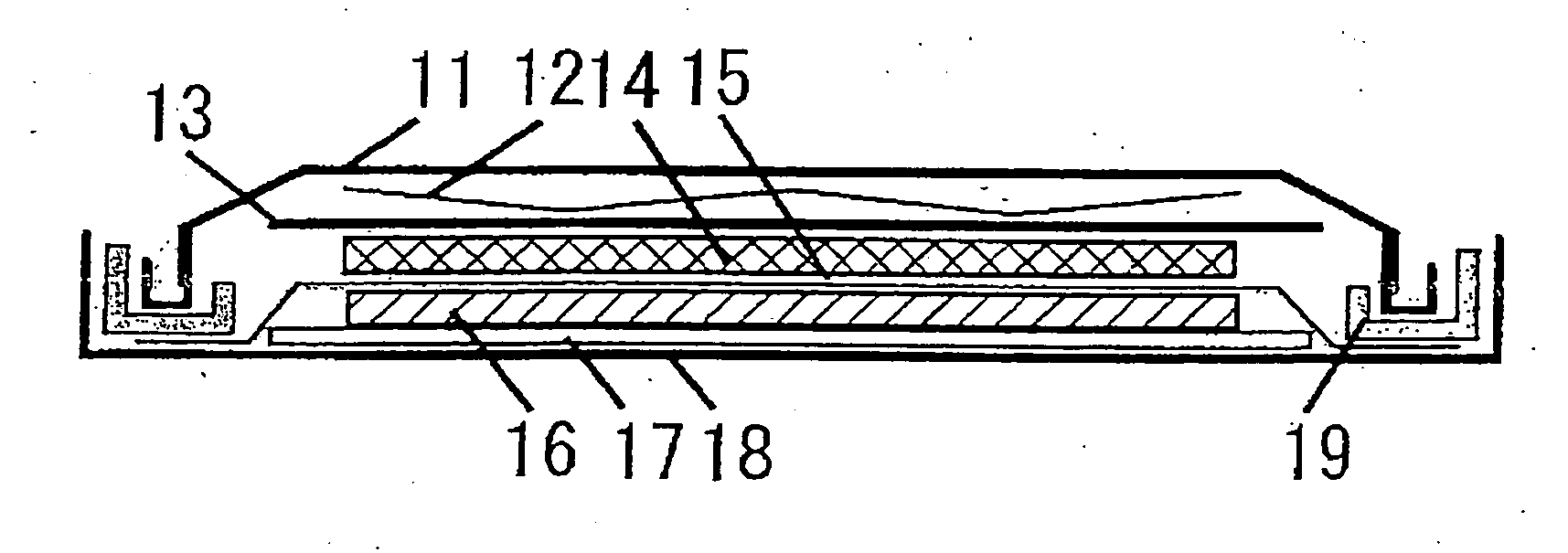

Non-aqueous electrolyte secondary battery

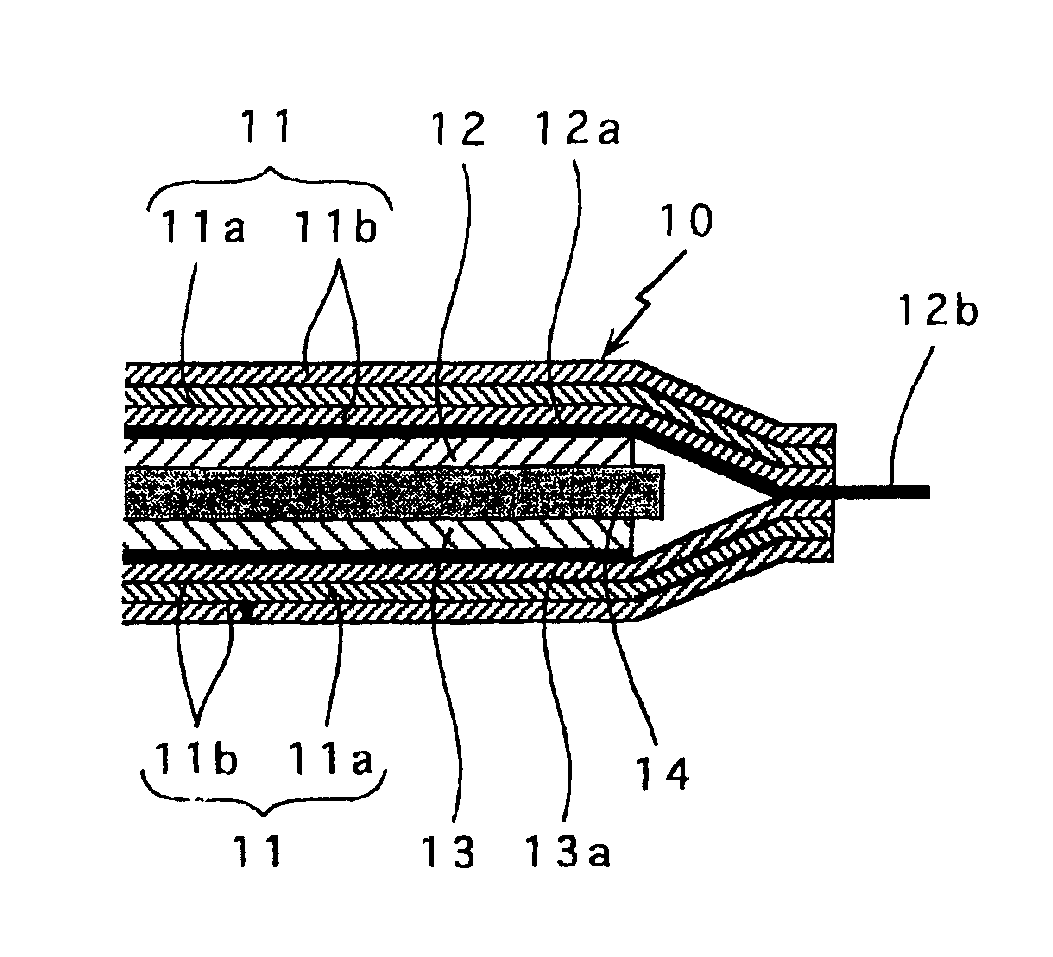

ActiveUS20110151338A1Improve charge-discharge cycle performanceProhibits deterioration of charge-discharge cycle performanceCell electrodesOrganic electrolyte cellsNon aqueous electrolytesCarbonate

The present invention is made to improve charge-discharge cycle performances under high temperature environment in a non-aqueous electrolyte secondary battery using a negative electrode containing a negative electrode active material of particulate silicon and / or silicon alloy and a binding agent.A non-aqueous electrolyte secondary battery according to the present invention includes a positive electrode 11, a negative electrode 12, a separator 13, and a non-aqueous electrolyte, wherein the negative electrode includes a negative electrode active material containing particulate silicon and / or silicon alloy and a binding agent, and the non-aqueous electrolyte contains fluorinated cyclic carbonate and a prescribed diisocyanate compound, and when Li storage volume per unit area of the negative electrode of the non-aqueous electrolyte secondary battery under charging condition is determined as A and the theoretical maximum Li storage volume per unit area of the negative electrode is determined as B, a utilizing rate (%) of negative electrode which is expressed by (A / B)×100 is 45% or less.

Owner:SANYO ELECTRIC CO LTD

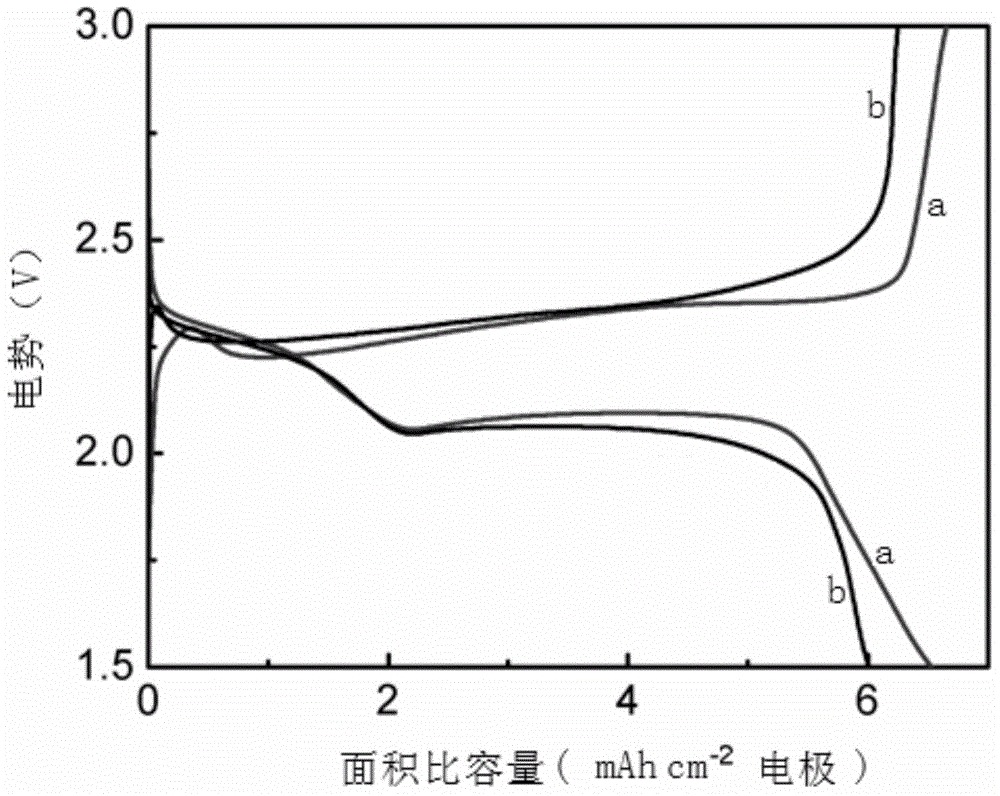

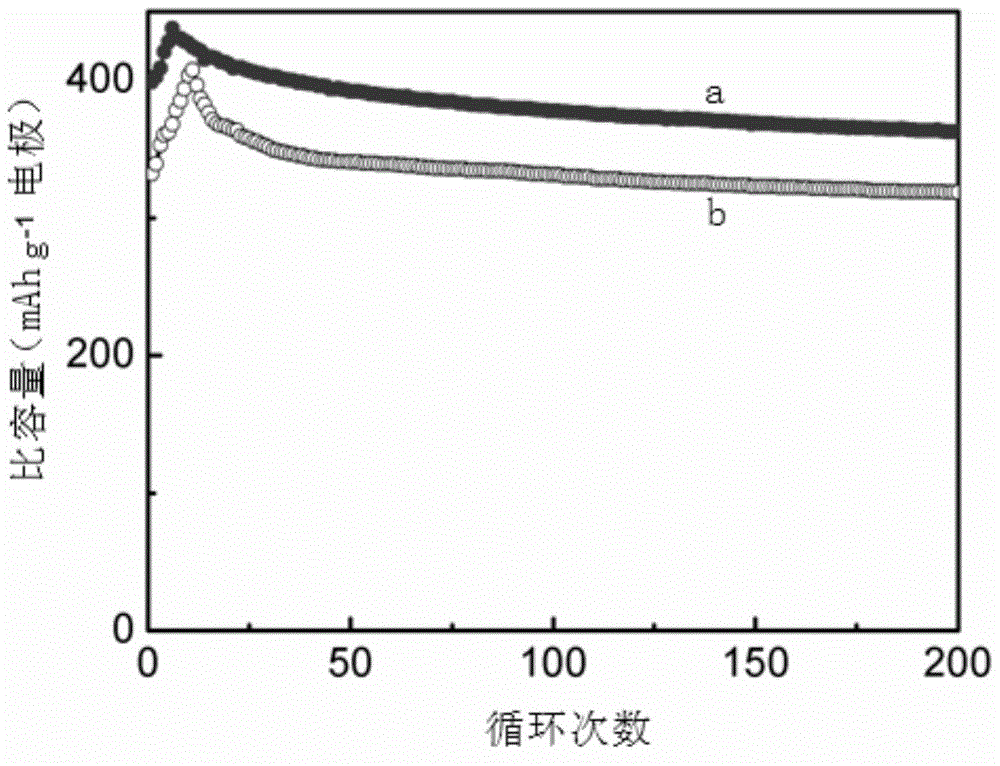

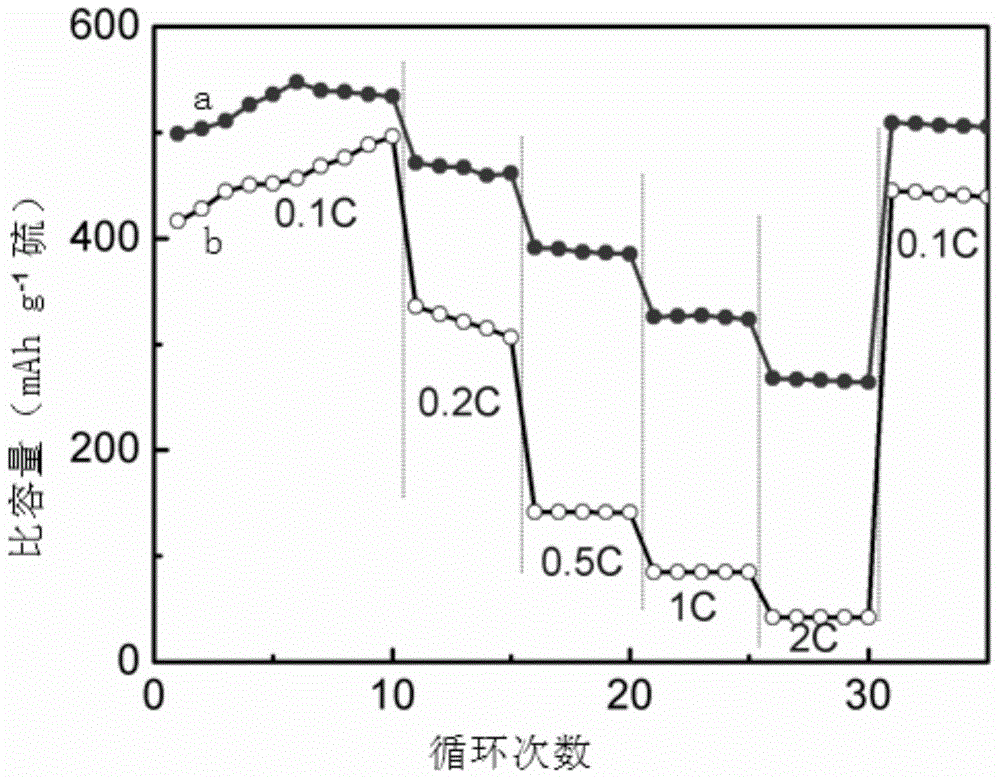

Lithium-sulfur battery carbon fiber reinforced three-dimensional graphene-sulfur positive electrode material, preparation method of material and preparation method of positive electrode

ActiveCN104617283AInhibition of agglomerationImprove conductivityElectrode manufacturing processesFiberCarbon fibers

The invention discloses a lithium-sulfur battery carbon fiber reinforced three-dimensional graphene-sulfur positive electrode material, a preparation method of the positive electrode material and a preparation method of the positive electrode, relates to a lithium-sulfur battery positive electrode material, a preparation method of the positive electrode material and a preparation method of the positive electrode, and can be used for solving the technical problem that the conventional graphene-sulfur electrode is low in area specific capacity and bad in rate capability. The positive electrode material is formed by dispersing elemental sulfur in holes of carbon fiber modified spongy graphene. The preparation method of the positive electrode material comprises the following steps: adding carbon fibers into mixed liquid of graphene oxide dispersion liquid, carrying out hydro-thermal synthesis to obtain hydrogel and carrying out freeze-drying to obtain carbon fiber modified three-dimensional spongy graphene; cutting the carbon fiber modified three-dimensional spongy graphene into slices, sprinkling the elemental sulfur on the surfaces of the slices, placing the slices in a vacuum tank and heating to obtain the lithium-sulfur battery carbon fiber reinforced three-dimensional graphene-sulfur positive electrode material. The positive electrode is prepared by slicing the positive electrode material and then pressing. The area specific capacity of the electrode material is up to 10 mAh / cm<2>, so that the electrode material can be applied to lithium ion batteries.

Owner:HARBIN INST OF TECH

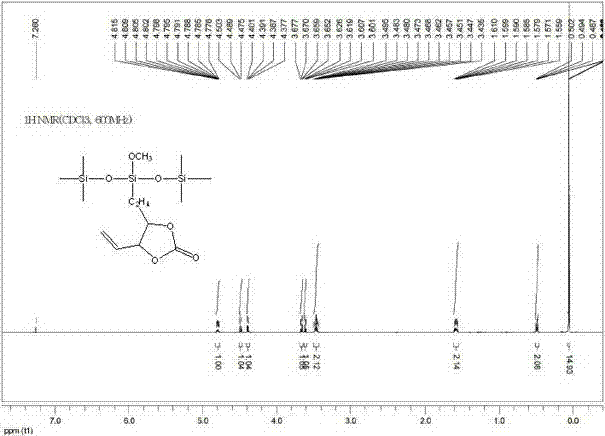

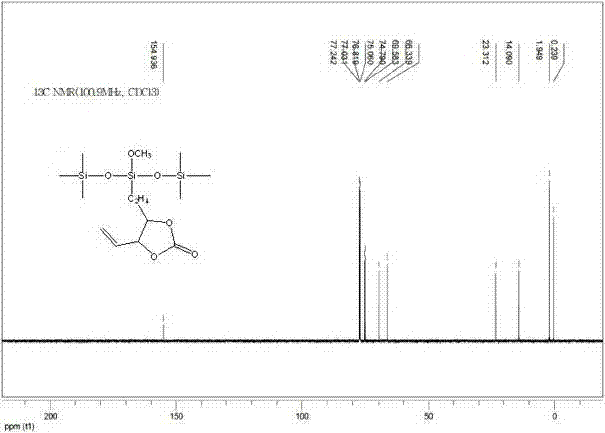

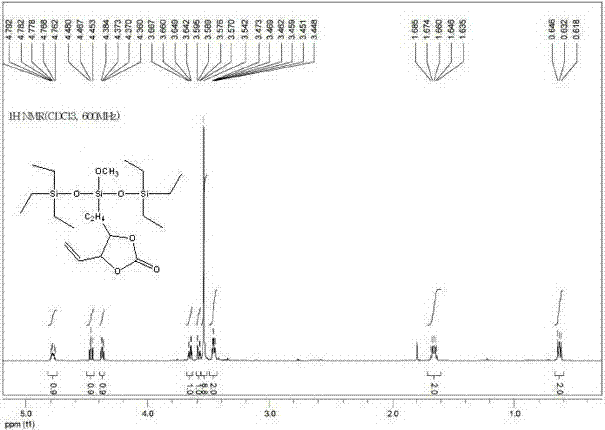

Electrolyte additive, electrolyte containing additive and lithium ion battery using electrolyte

ActiveCN104752766AAvoid damageReduce generationGroup 4/14 element organic compoundsSecondary cellsElectrolysisLithium-ion battery

The invention discloses an electrolyte additive. The additive is carbonic ester containing silicon alkyl and alkylene, wherein the silicon alkyl is connected with methoxy or ethoxy and alkyl. The invention also provides electrolyte containing the additive and a lithium ion battery using the electrolyte on the basis of the electrolyte additive. The electrolyte containing the additive can form a tough envelope on the surface of an electrode, so as to reduce the reaction between the electrode and the electrolyte, and the additive can decompose gases generated in an electrolysis process, so that high capacity and low inflation rate of the battery are maintained, and the service life of the lithium ion battery is prolonged.

Owner:BYD CO LTD

Nonaqueous electrolyte solution for secondary battery and nonaqueous electrolyte secondary battery

InactiveUS20060035155A1High charge and dischargeGood charge and discharge cycleElectrochemical processing of electrodesElectrode carriers/collectorsSolventDecomposition

Owner:SANYO ELECTRIC CO LTD +1

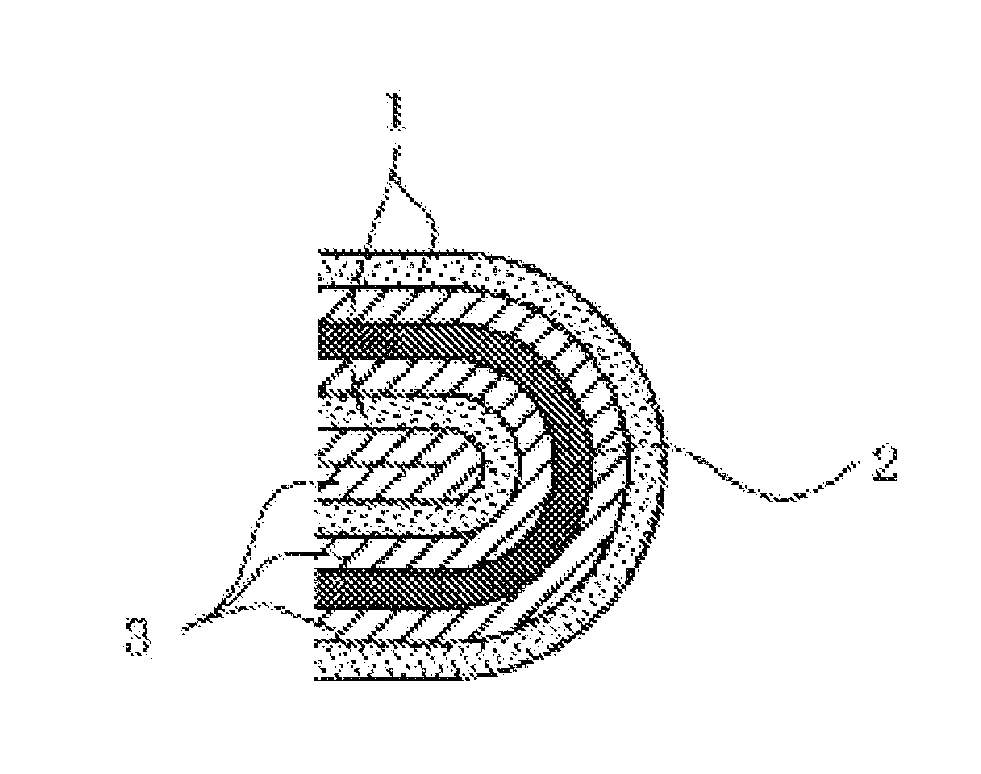

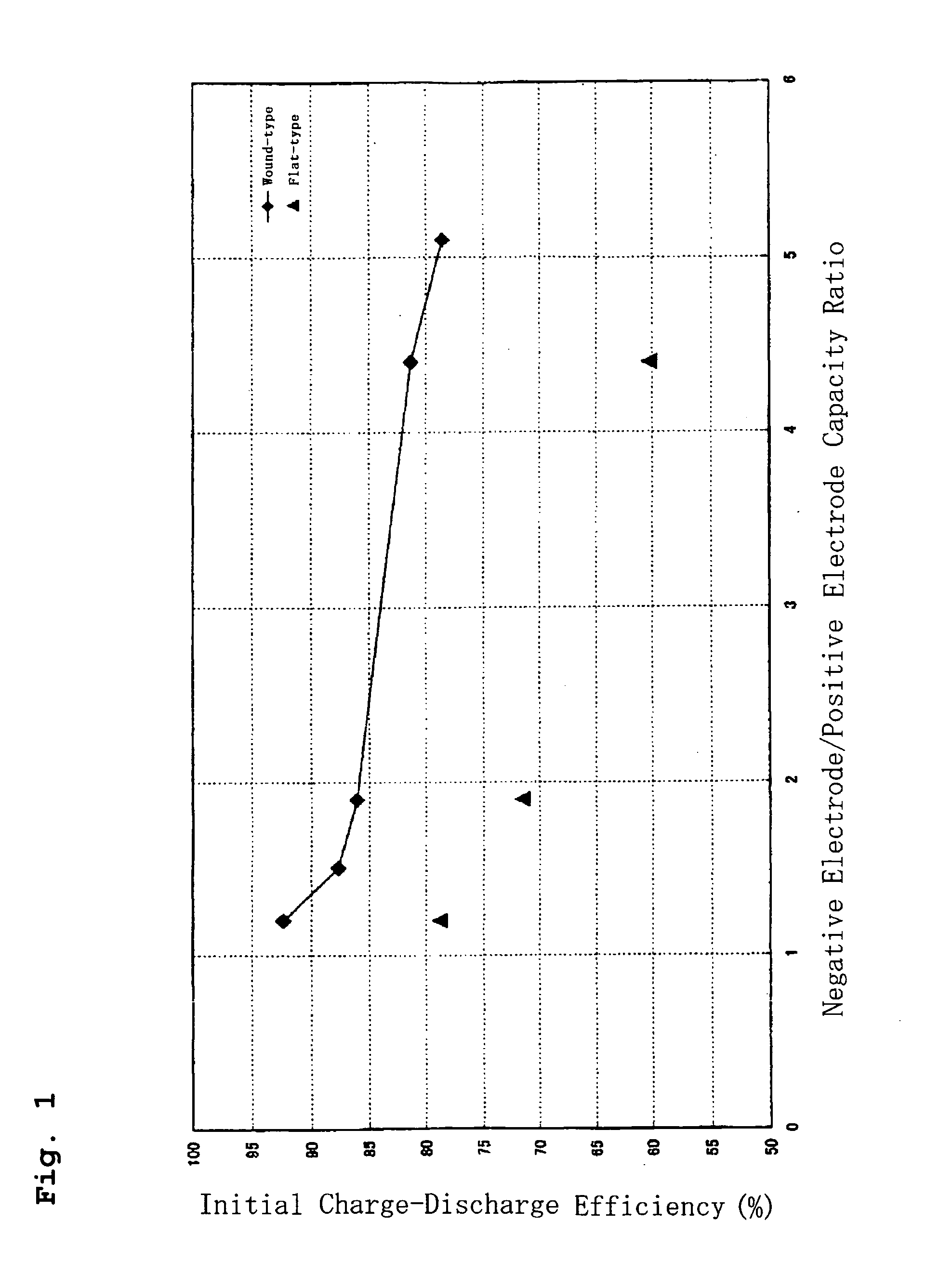

Lithium secondary battery

InactiveUS20060141359A1High charge and discharge capacityGood charge and discharge cycle performanceFinal product manufactureElectrode carriers/collectorsBattery chargeSilicon alloy

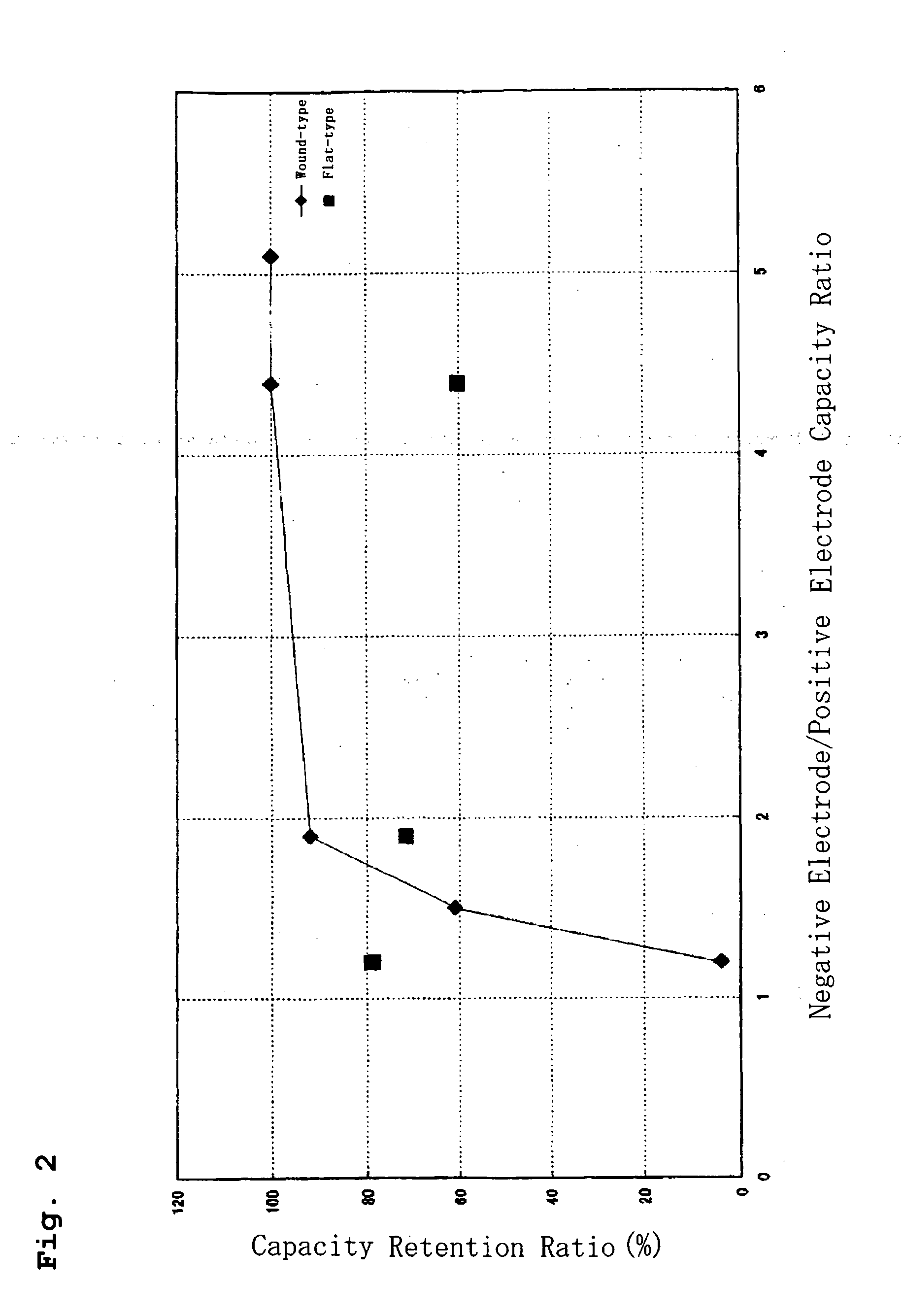

Charge-discharge cycle performance is improved in a lithium secondary battery that adopts a thin film made of silicon or a silicon alloy as its negative electrode active material and has a wound electrode structure. The lithium secondary battery includes: a negative electrode having a current collector and a thin film made of silicon or a silicon alloy as a negative electrode active material, the thin film provided on the current collector; a positive electrode; a separator; the positive and negative electrodes being overlapped with the separator interposed therebetween, and the positive and negative electrodes and the separator being wound around to form an electrode assembly; a non-aqueous electrolyte; and a battery case accommodating the electrode assembly. The ratio of charge capacity per unit area of the negative electrode to theoretical capacity per unit area of the positive electrode is within the range of from 1.9 to 4.4.

Owner:SANYO ELECTRIC CO LTD

Lithium battery with boron-containing lithium-manganese complex oxide cathode material

InactiveUS6509120B1Lower internal resistanceImprove ionic conductivityAlkaline accumulatorsElectrolytic capacitorsManganeseBoron containing

A lithium battery comprising a positive electrode comprising a positive-electrode active material of boron-containing lithium-manganese complex oxide, a negative electrode and a nonaqueous electrolyte containing a solute and a solvent, the positive-electrode active material is the boron-containing lithium-manganese complex oxide having a boron-to-manganese atomic ratio (B / Mn) in the range of 0.01 to 0.20 and a predischarge mean manganese valence of not less than 3.80

Owner:FDK CORP

Positive active material for lithium secondary battery, method for producing precursor of positive active material, method for producing positive active material, positive electrode for lithium secondary battery, and lithium secondary battery

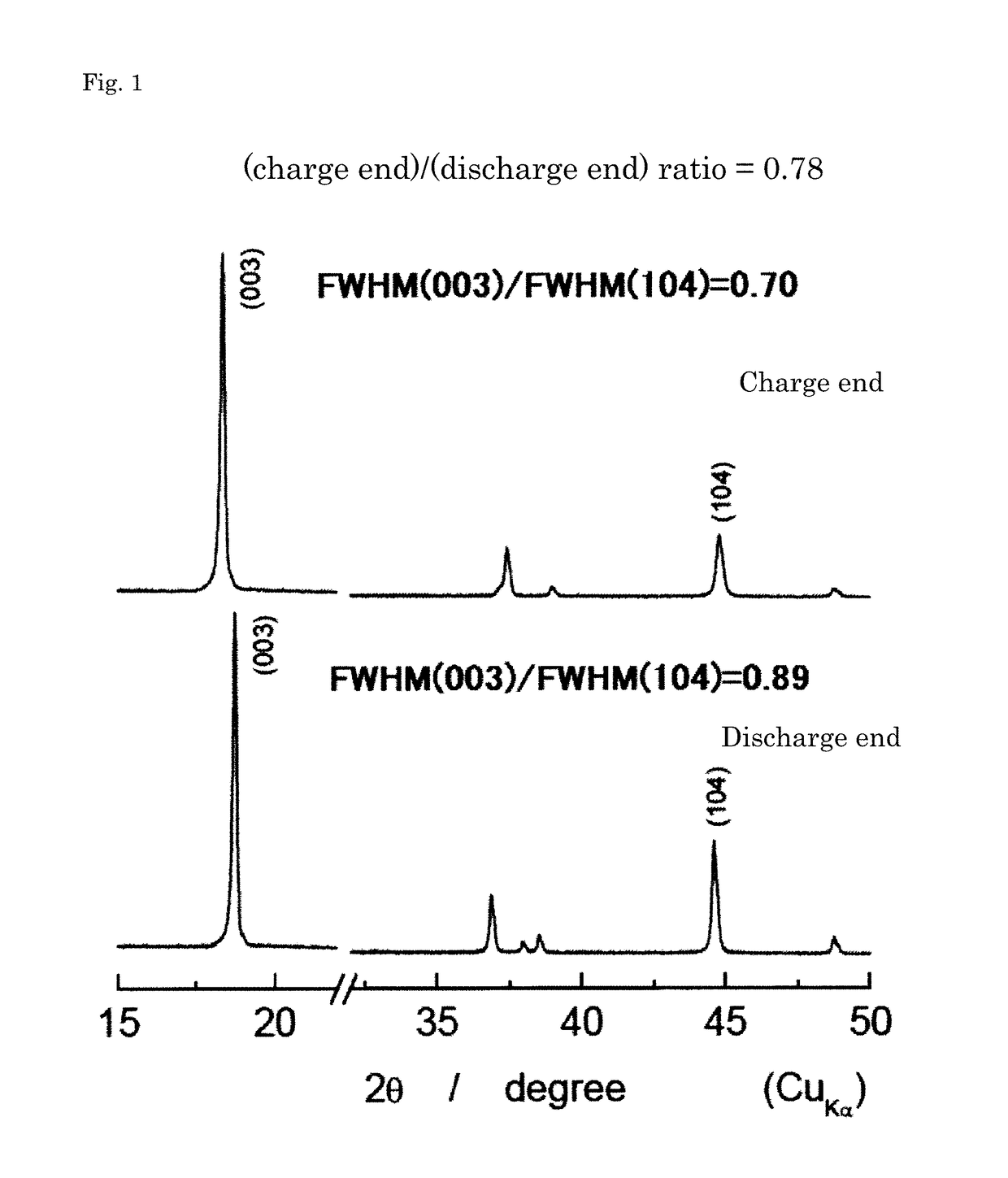

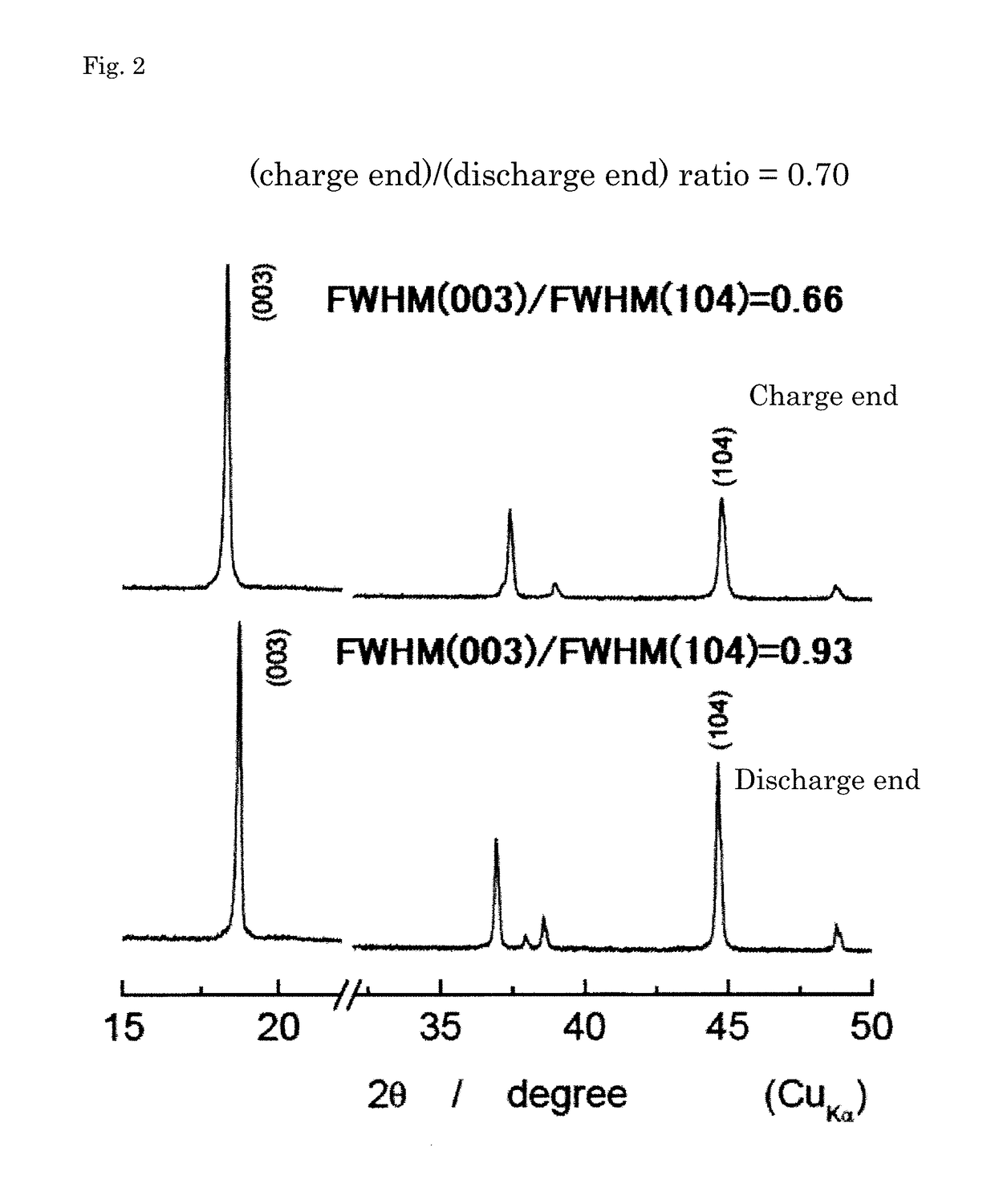

ActiveUS20180366773A1Improve charge-discharge cycle performanceCell electrodesFinal product manufactureFull width at half maximumX-ray

The positive active material for a lithium secondary battery includes a lithium transition metal composite oxide having an α-NaFeO2 structure, and having a diffraction peak at 2 θ=44±1° and a diffraction peak at 2 θ=18.6±1° in a powder X-ray diffraction diagram using a CuKα ray. In a ratio FWHM (003) / FWHM (104) of a full width at half maximum FWHM (003) for the diffraction peak at 2 θ=18.6±1° to a full width at half maximum FWHM (104) for the diffraction peak at 20 θ=44±1°, a ratio of FWHM (003) / FWHM (104) in a charge state immediately after a discharge state to FWHM (003) / FWHM (104) in the discharge state is 0.72 or more.

Owner:GS YUASA INT LTD

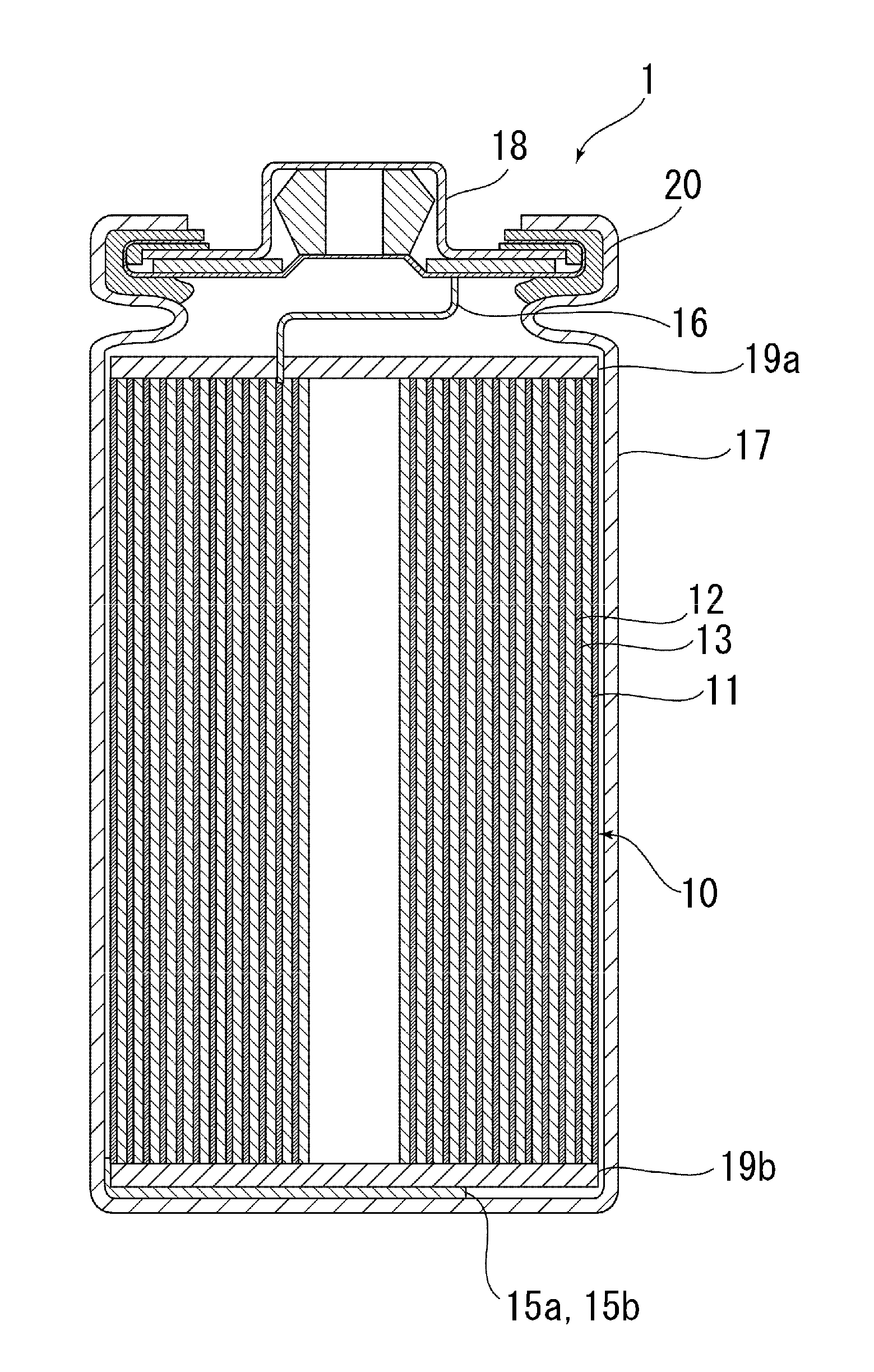

Lithium secondary battery

InactiveUS20050106464A1Improve charge-discharge cycle performanceGood charge and discharge cycle performanceElectrode carriers/collectorsActive material electrodesCurrent collectorEngineering

Charge-discharge cycle performance is improved in a lithium secondary battery that uses a material that occludes lithium by alloying with lithium as its negative electrode active material. A lithium secondary battery comprises a negative electrode having a negative electrode active material thin film provided on a negative electrode current collector, a positive electrode including a positive electrode active material, and a non-aqueous electrolyte, in which the negative electrode active material is a material that occludes lithium by alloying with lithium, the ratio of the discharge capacity per unit area of the negative electrode to the discharge capacity per unit area of the positive electrode is from 1.5 to 3, and the ratio of the thickness (μm) of the negative electrode active material to the arithmetical mean roughness Ra (μm) of the surface of the negative electrode current collector is 50 or less.

Owner:SANYO ELECTRIC CO LTD

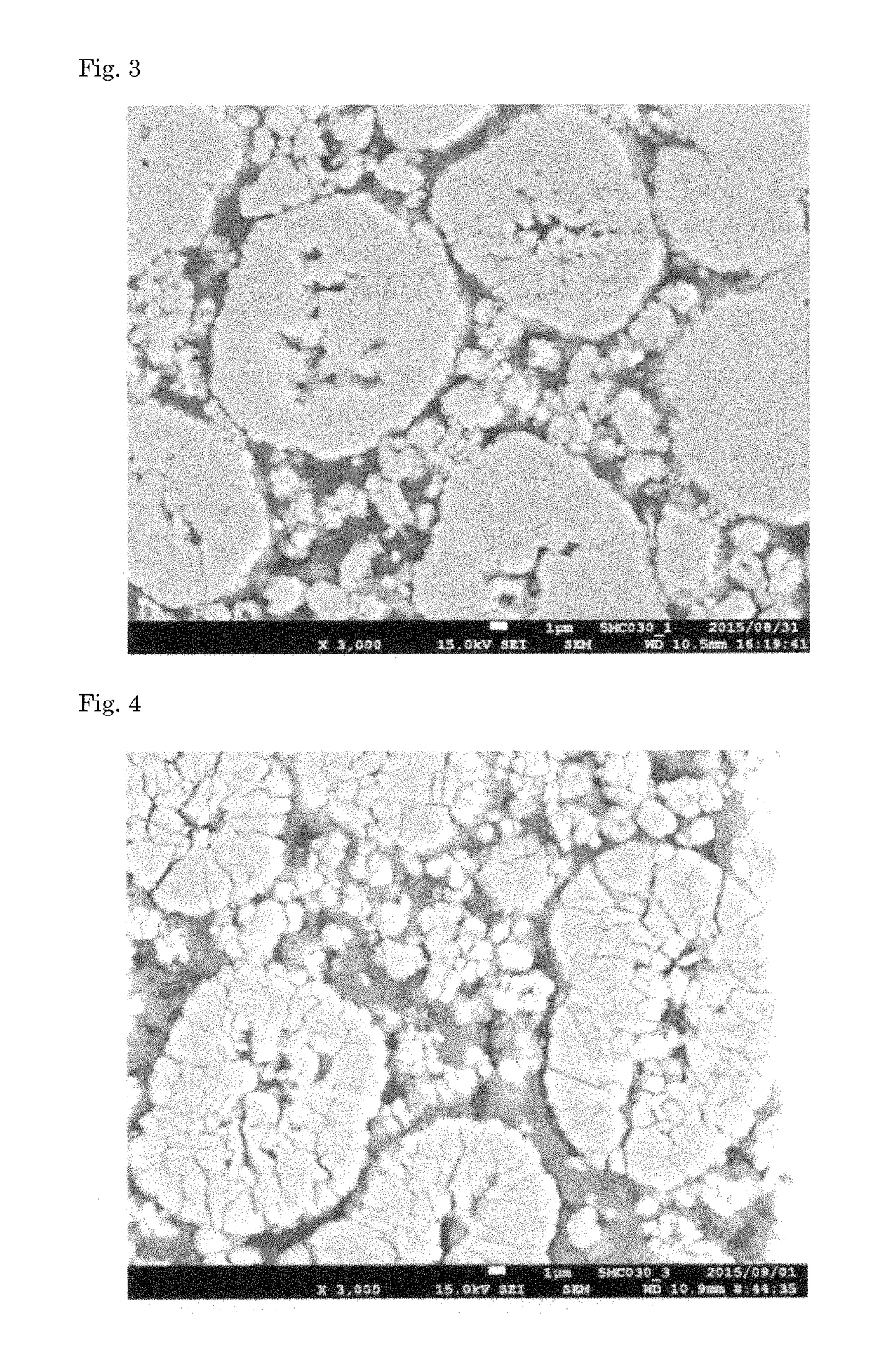

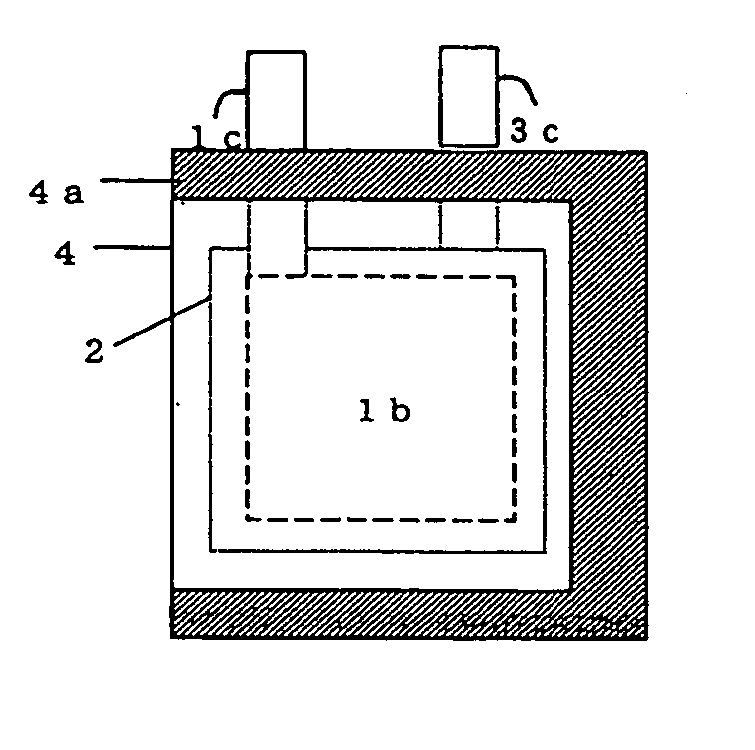

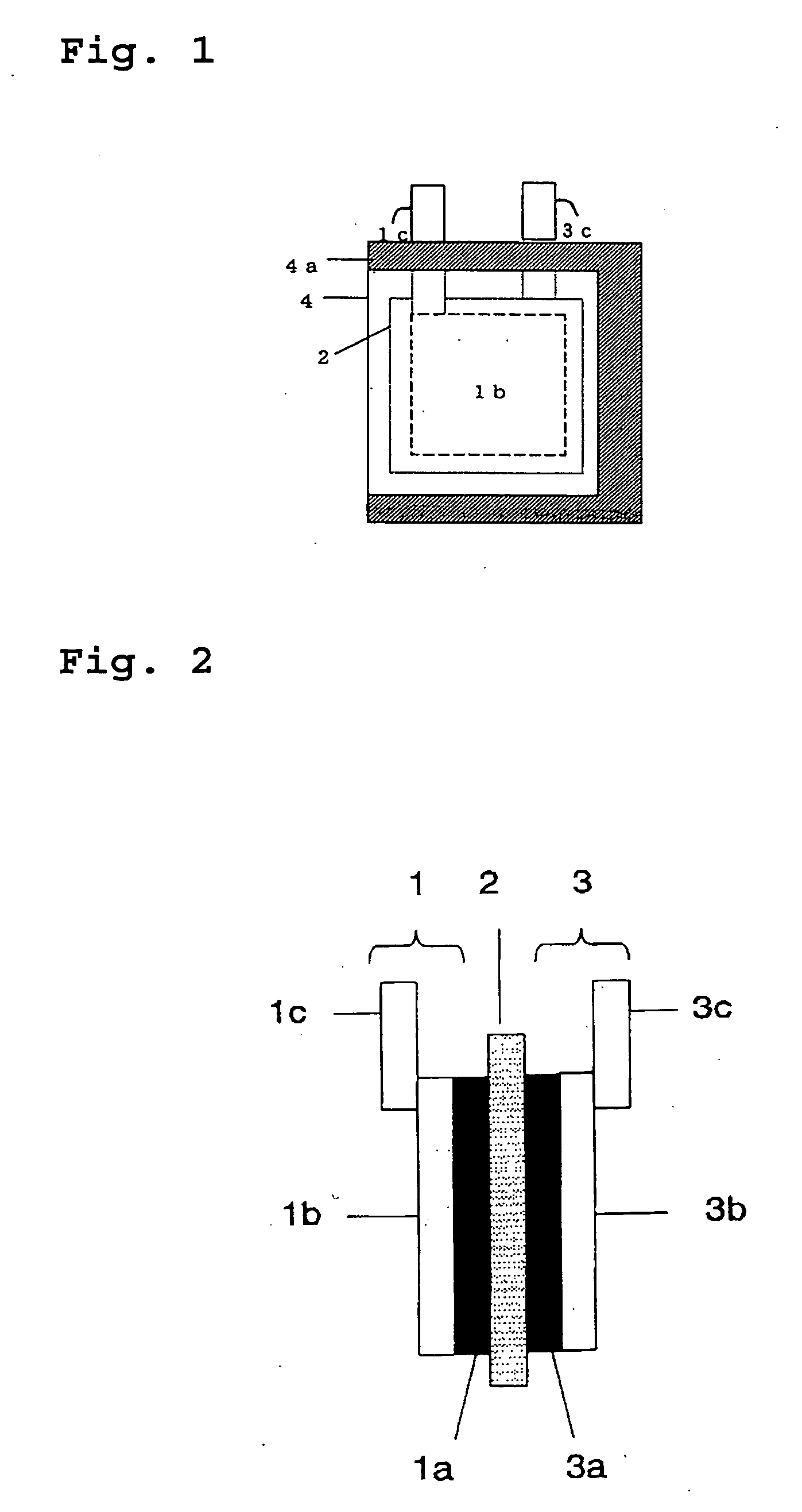

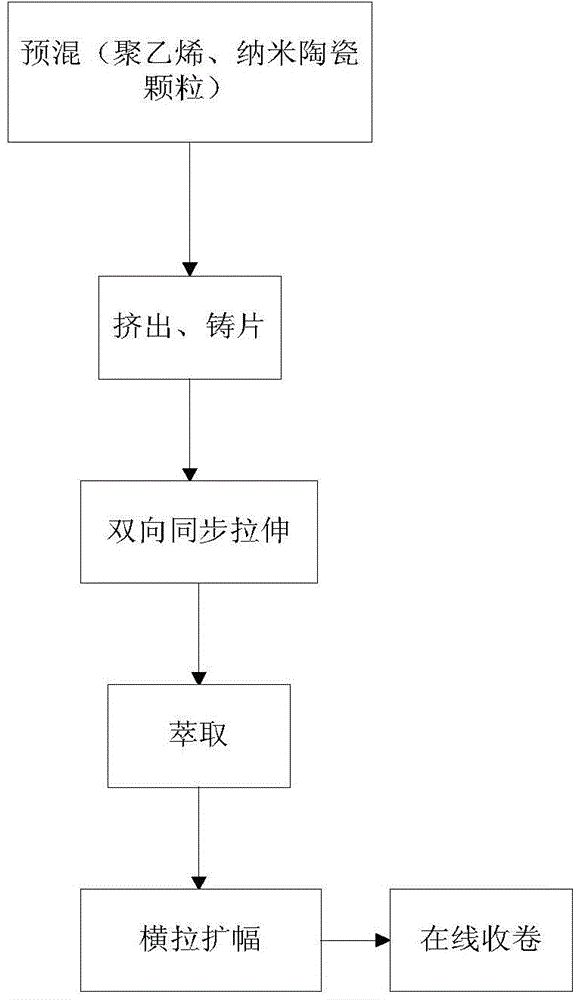

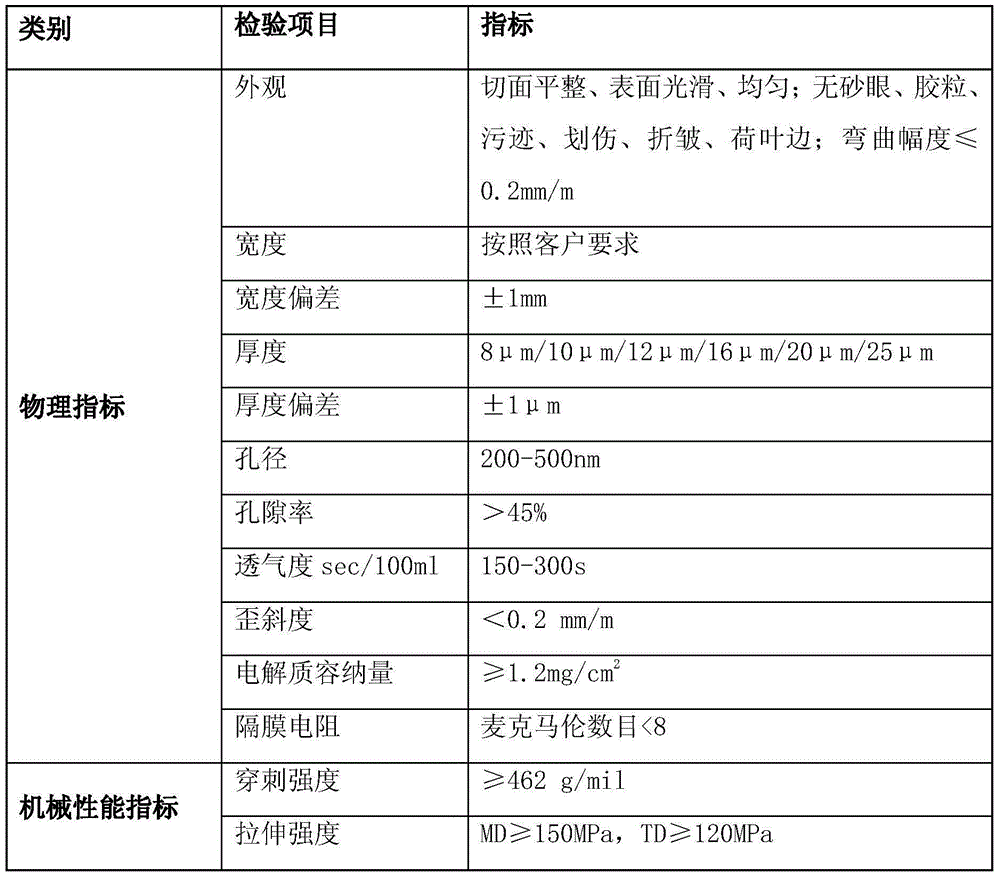

Method for preparing nanometer ceramic particle doped PE diaphragm

InactiveCN104617248AReduce production processReduce energy consumptionCell component detailsTemperature resistanceHigh rate

The invention provides a method for preparing a nanometer ceramic particle doped PE diaphragm, belonging to the technical field of high-property membrane materials. The method for preparing the nanometer ceramic particle doped PE diaphragm comprises the steps of proportioning materials, extruding cast strips, synchronously drawing towards two directions, extracting, transversely stretching for enlarging and the like; as electrochemical inactive inorganic ceramic particles are added in a skeleton material of the PE diaphragm, the PE diaphragm has better compatibility with the electrodes of a lithium ion battery than the common battery diaphragm, the high-temperature resistance and the safety of the battery can be greatly improved, the absorbability of liquid electrolytes is good, the electrolyte filling time of the battery can be shortened,the internal resistance of the battery can be reduced, and the high-rate charging-discharging properties of the batteries can be improved, so that the charging-discharging cycle properties of the battery can be greatly improved.

Owner:刘会会

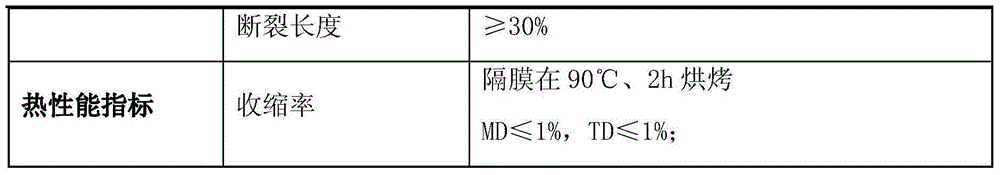

Positive pole material of nonaqueous secondary cell and producing method thereof

ActiveCN1549365AImprove thermal stabilityImprove charge-discharge cycle performanceElectrode manufacturing processesPositive electrodesCharge and dischargeEngineering

The present invention provides a positive electrode material LiNi1-xCoxO2 (x is greater than or equal to 0.15 or less than or equal to 0.30) covered by using LiCoO2 and its preparation method. Said material has good electric discharge multiplying factor specific property, charging and discharging circulating performance, safety and storage property.

Owner:BYD CO LTD

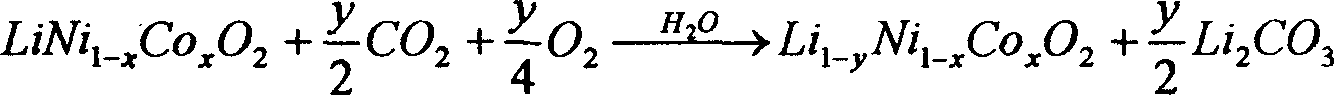

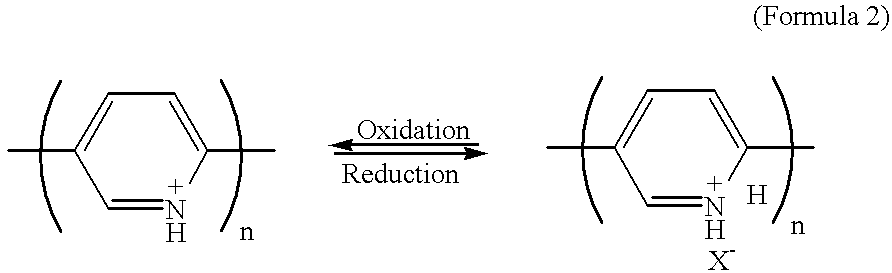

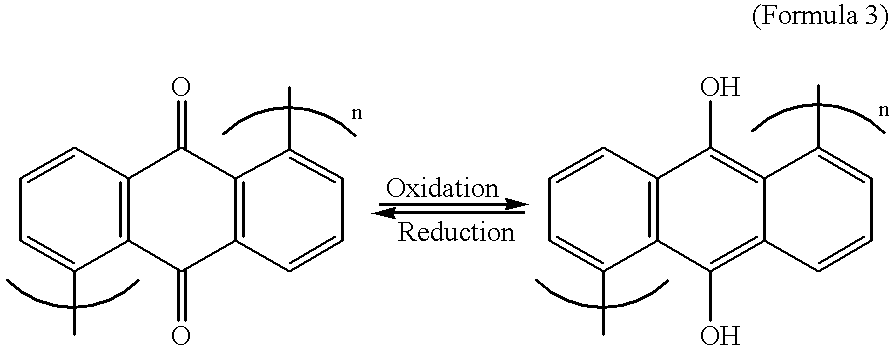

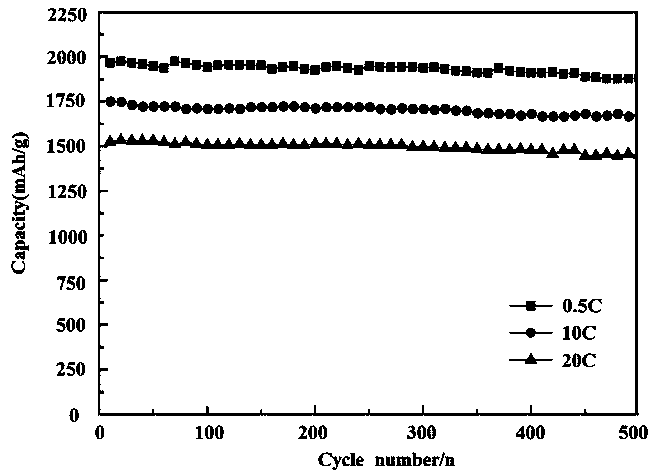

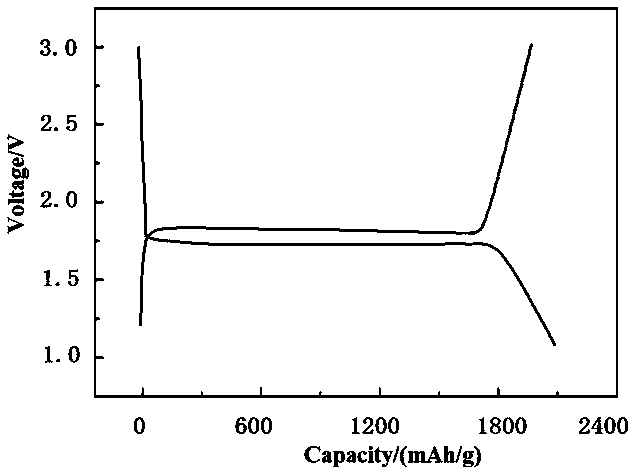

Polymer secondary battery and method of making same

InactiveUS6274268B1Improve electronic conductivityImprove efficiencyNon-aqueous electrolyte accumulatorsActive material electrodesSimple Organic CompoundsCarbon composites

A polymer secondary battery uses, for at least one of the active material of positive electrode and the active material of negative electrode, a polymer-carbon composite material including powdered carbon having its surfaces coated with an organic compound polymer capable of adsorbing and desorbing protons electrochemically. The polymer secondary battery has a high rate of appearance of capacity and excellent cycle characteristics.

Owner:TOKIN CORP

Titanium-based oxide lithium ion battery anode material and performance test method thereof

InactiveCN110336005AInhibition of agglomerationEasy transferCell electrodesSecondary cellsCarbon nanotubeEthyl acetate

The invention provides a titanium-based oxide lithium ion battery anode material and a performance test method thereof, belonging to the field of lithium ion battery materials. The method comprises the following steps of: performing ball-milling of an organic carbon source and a carbon nano tube serving as double carbon sources, high-activity silicon powder prepared from rice hulls serving as a silicon source, lithium carbonate and titanium-based oxide titanium dioxide serving as raw materials, performing ultrasonic dispersing in ethyl acetate, and performing drying in vacuum, igniting and cooling to obtain a battery anode material silicon / carbon / lithium titanate. The electrode material is subjected to battery assembling to perform electrochemical performance test, the carbon source in thematerial effectively suppresses the material agglomeration phenomenon and has the high electronic conductivity to form a conductive network facilitating fast transmission of lithium ions, and therefore, the titanium-based oxide lithium ion battery anode material has the high specific capacity, stable cycle, high conductivity and a good electrochemical performance.

Owner:DONGGUAN UNIV OF TECH

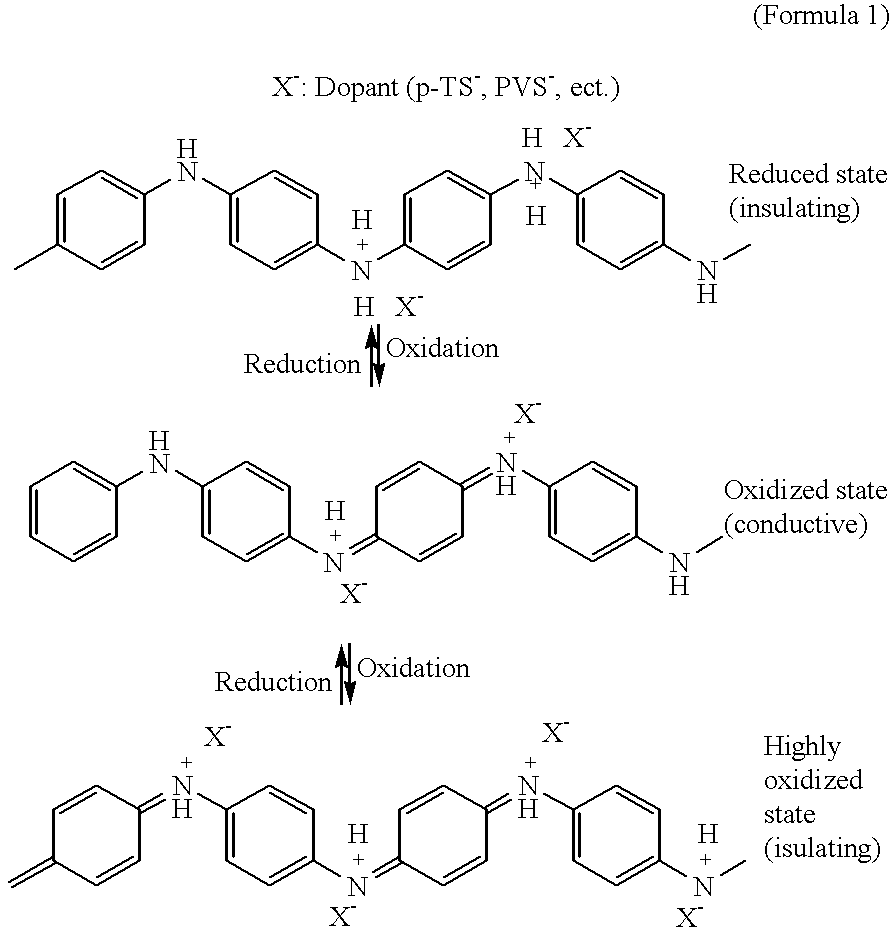

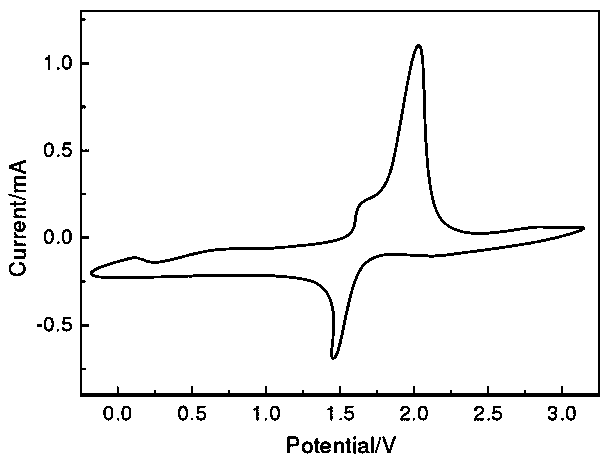

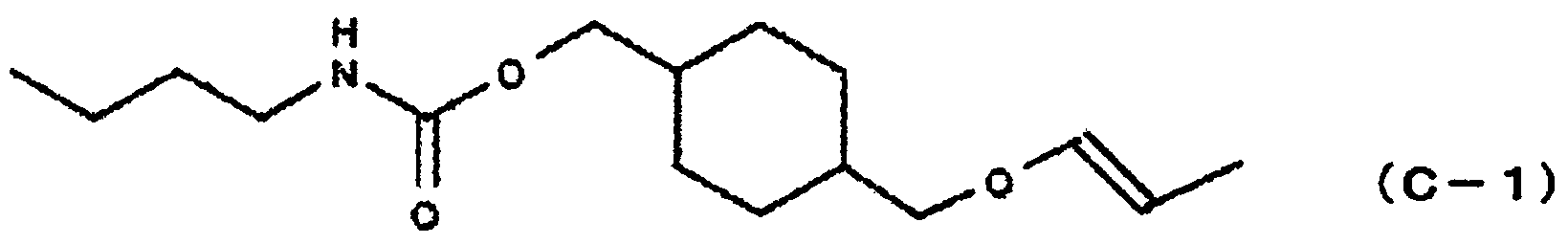

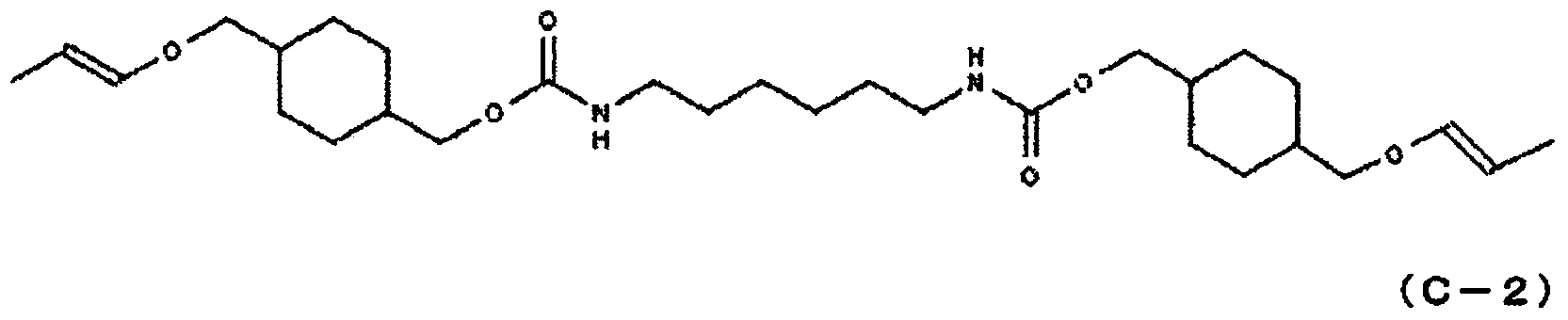

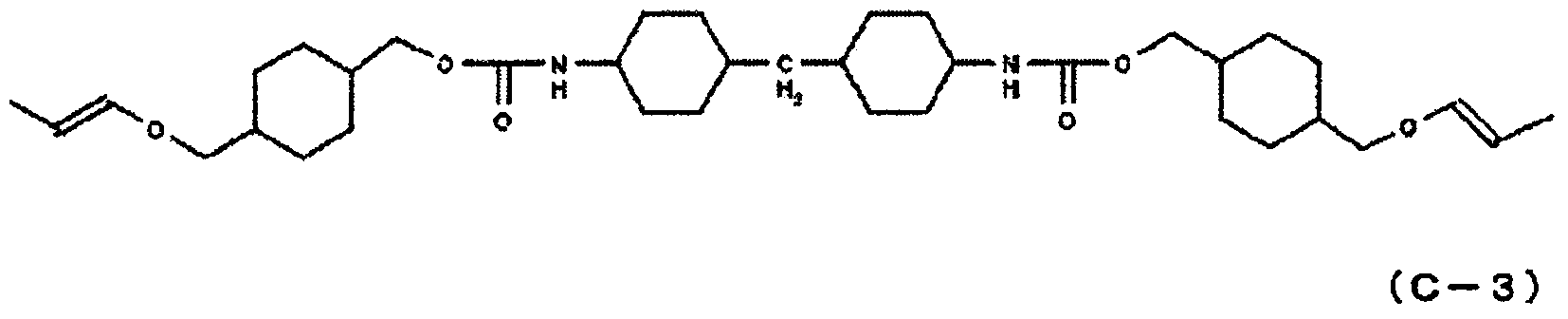

Agent for forming electrode protection film

InactiveCN104364948AImprove long-term stabilityImprove charge-discharge cycle performanceHybrid capacitor electrolytesOrganic chemistryElectrolytic agentPolymer science

The purpose of the present invention is to provide an electrode or electrolyte solution for electrochemical devices, which has excellent long-term stability and can be used in a wide temperature range. An agent for forming an electrode protection film, which contains a compound that has a urethane bond and a polymerizable unsaturated bond and that is preferably represented by general formula (1). (In formula (1), A represents (i) an n-valent hydrocarbon group having 2-42 carbon atoms, (ii) a trivalent residue that is obtained by removing three isocyanate groups from a trimer of a diisocyanate (B) having 2-42 carbon atoms or (iii) a divalent residue that is obtained by removing two isocyanate groups from a urethane prepolymer having isocyanate groups at both ends, said urethane prepolymer being a reaction product of a diisocyanate (B) having 2-42 carbon atoms and a diol (N) having 2-20 carbon atoms; X represents a monovalent organic group having a polymerizable unsaturated bond (b) and 3-42 carbon atoms; and n represents an integer of 1-6, and in cases where n is 2 or more, the plurality of X moieties may be the same as or different from each other.) A(-NHCO2-X)n (1)

Owner:SANYO CHEM IND LTD

Lithium cobaltate for positive electrode of lithium ion battery and preparation method of lithium cobaltate for positive electrode of lithium ion battery

InactiveCN104241627AReduce contact areaImprove charge-discharge cycle performanceCell electrodesSecondary cellsLithium electrodeMetal

The invention discloses lithium cobaltate for a positive electrode of a lithium ion battery and a preparation method of the lithium cobaltate for the positive electrode of the lithium ion battery. The proportional formula of the lithium cobaltate prepared by adopting the method is shown as LixCoyMzO2, wherein M represents for one or two of transition metal elements except Co or alkaline earth metals elements; S represents for an average valence of all metal elements of the lithium cobaltate except lithium and cobalt; a mole ratio of four elements in the positive material-lithium cobaltate is x to y to 2 to 2; S is greater than or equal to +2 and less than +2.5; x is greater than or equal to 0.9 and less than or equal to 1.1; y is greater than or equal to 0.8 and less than or equal to 1.1; x plus 3y plus S*z is equal to 4. The lithium cobaltate prepared by adopting the method has the high volume capacity density, the high safety, the stable charge-discharge cycle performances and the high compaction density.

Owner:PULEAD TECH IND

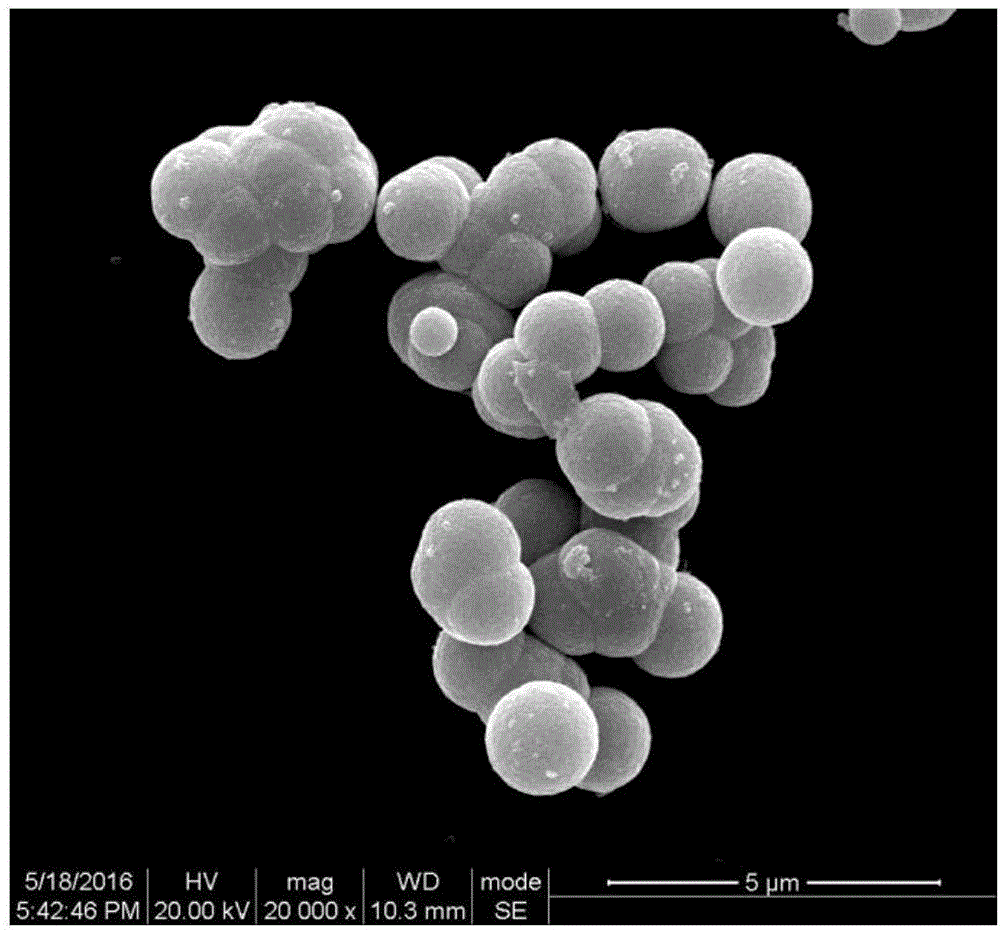

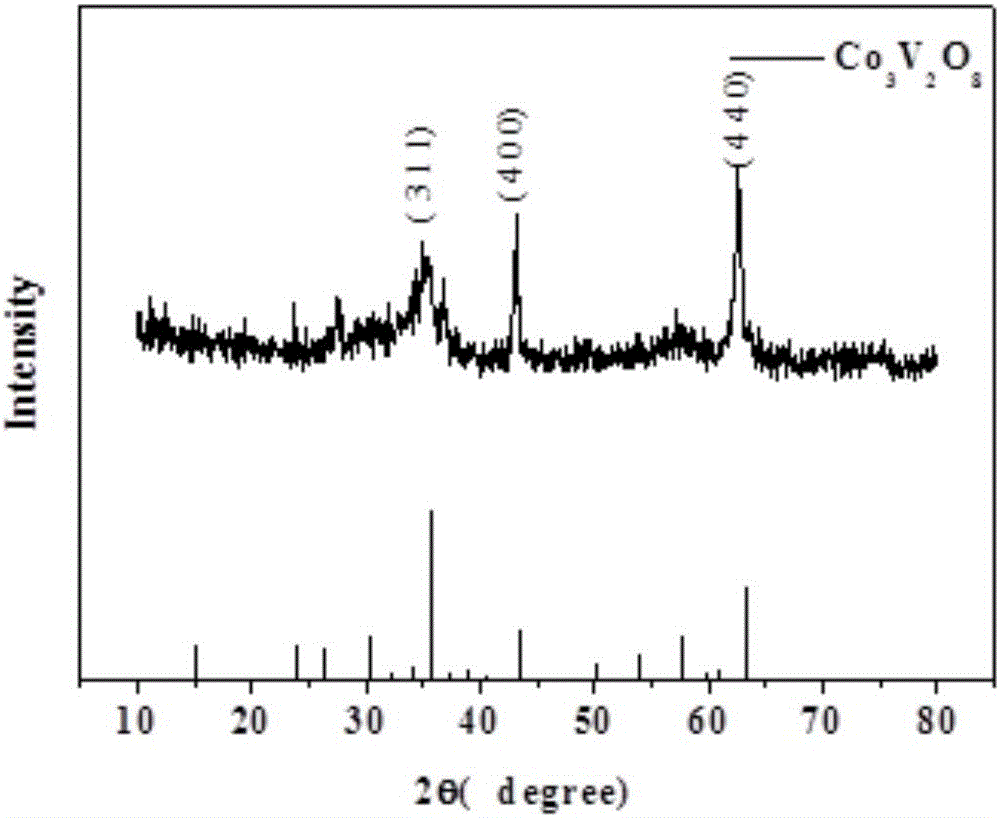

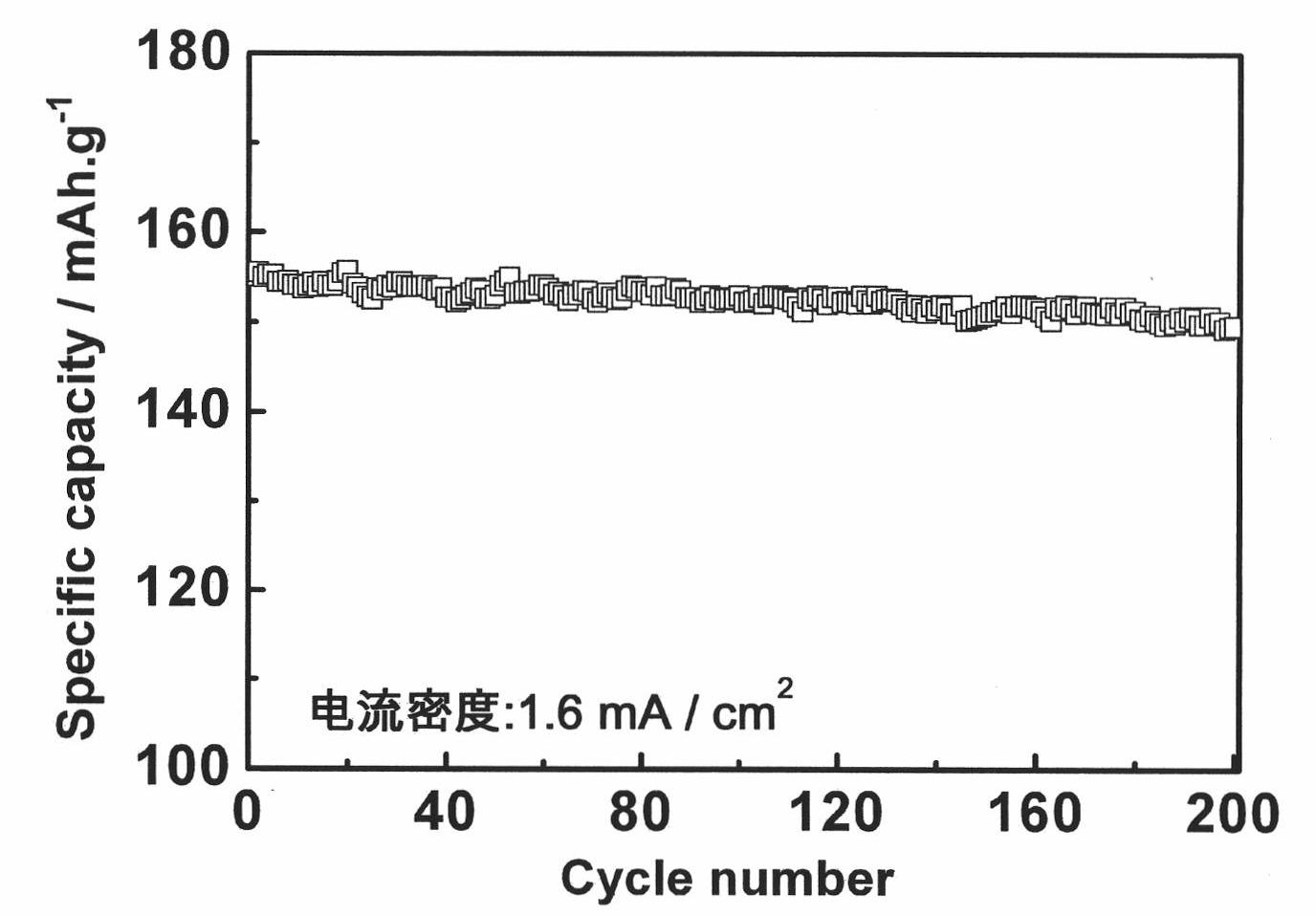

C-layer-cladding Co3V2O8 composite material and preparation method thereof

ActiveCN106384814AWell mixedRich materialCell electrodesSecondary cellsSource materialHazardous substance

The invention provides a C-layer-cladding Co3V2O8 composite material and a preparation method thereof. The method comprises the steps of mixing Co3V2O8 with a carbon source; adding deionized water; performing grinding; drying a sample; after the drying, grinding and dispersing the sample; performing firing at the temperature of 600 to 700 DEG C for 6 to 8h; cooling the materials to room temperature; obtaining the C-layer-cladding Co3V2O8 composite material. The C-layer-cladding Co3V2O8 composite material provided by the invention has the advantages that source materials of the carbon source are rich; the price is low; in the whole process, toxic or harmful substances are not generated; a final product is of a composite structure; the specific surface area is large; the surface active points are many; the material is used as an electrode material; the contact between active substances and an electrode is increased; the internal resistance of a battery is reduced; the electron and ion diffusion performance is obviously improved; high discharging specific capacity and good discharging performance are realized; meanwhile, the C layer on the surface effectively reduces the stress deformation and peeling phenomena of Co3V2O8; the charging and discharging circulation performance of a lithium battery can be effectively improved by the material; cleanness and environment protection are realized; the operation is simple.

Owner:SINOCAT ENVIRONMENTAL TECH

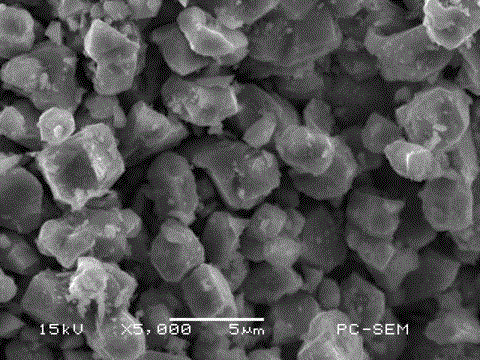

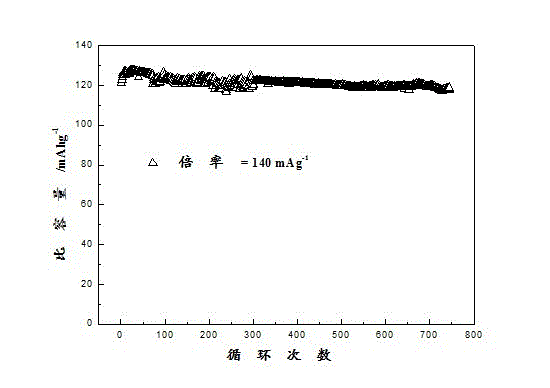

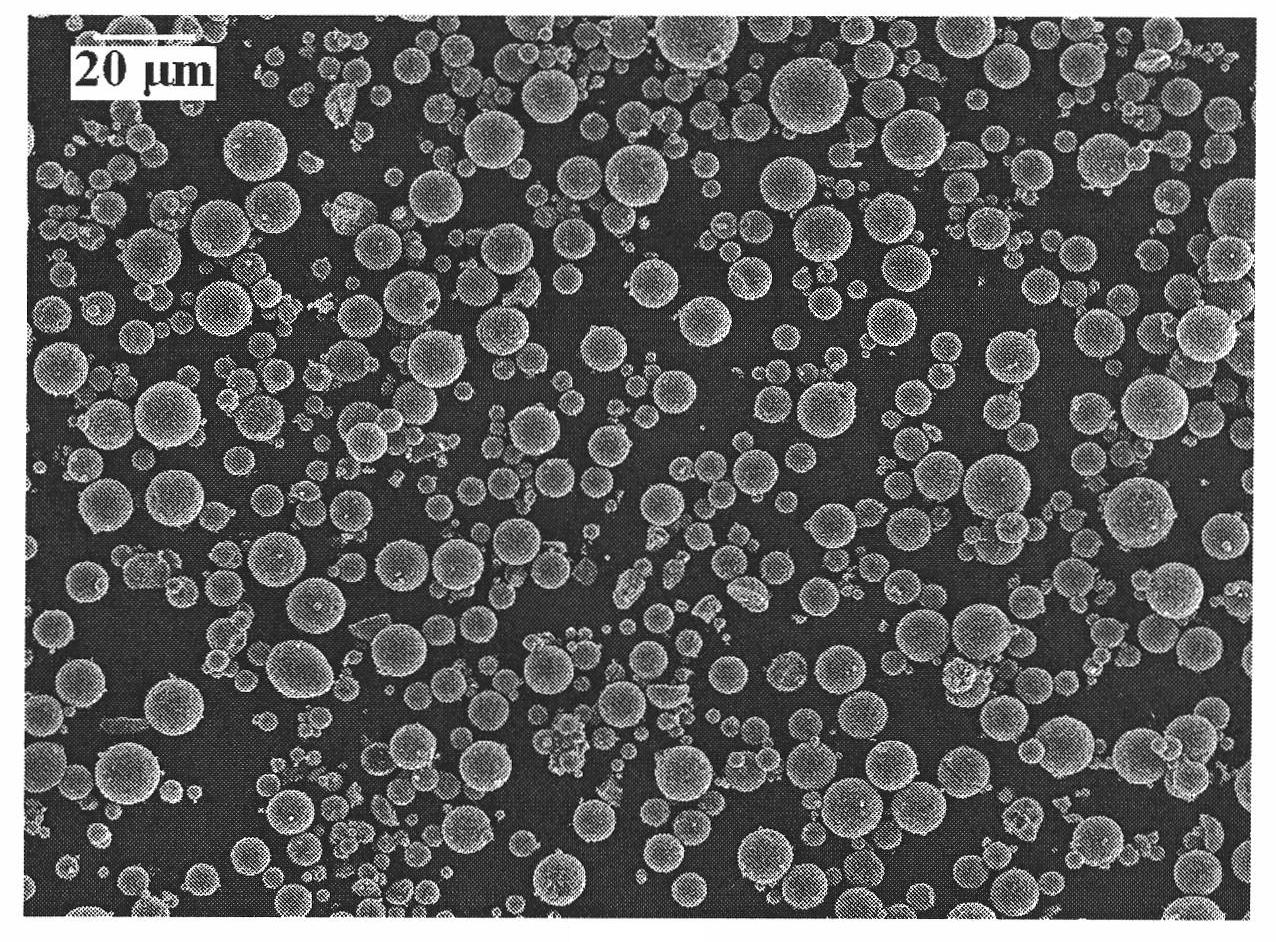

Ion-doped spherical Li4Ti5O12/C lithium ion battery anode material and preparation method thereof

InactiveCN102104142AImprove conductivityStable crystal structureCell electrodesCrystal structurePhysical chemistry

The invention discloses an ion-doped spherical Li4Ti5O12 / C lithium ion battery anode material and a preparation method thereof. The method comprises the following steps of: 1) uniformly dispersing a lithium source compound and a carbon source compound into ion-doped titanium oxide sol and spray-drying to obtain spherical powder; and 2) under the protection of an inert gas, performing heat treatment on the spherical powder to obtain the ion-doped spherical Li4Ti5O12 / C lithium ion battery anode material. The method for preparing the ion-doped spherical Li4Ti5O12 / C lithium ion battery anode material provided by the invention improves the electric conductivity of the material by compounding Li4Ti5O12 with carbon and stabilizes the crystal structure of the material by doping ions so as to further improve the charge-discharging cycle performance of the material. The method has a simple process flow; and the obtained lithium ion battery anode material is spherical, and has suitable particle sizes and reasonable particle diameter distribution, high stacking density and a very good application prospect in the field of lithium ion batteries.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com