Patents

Literature

53results about How to "Large discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

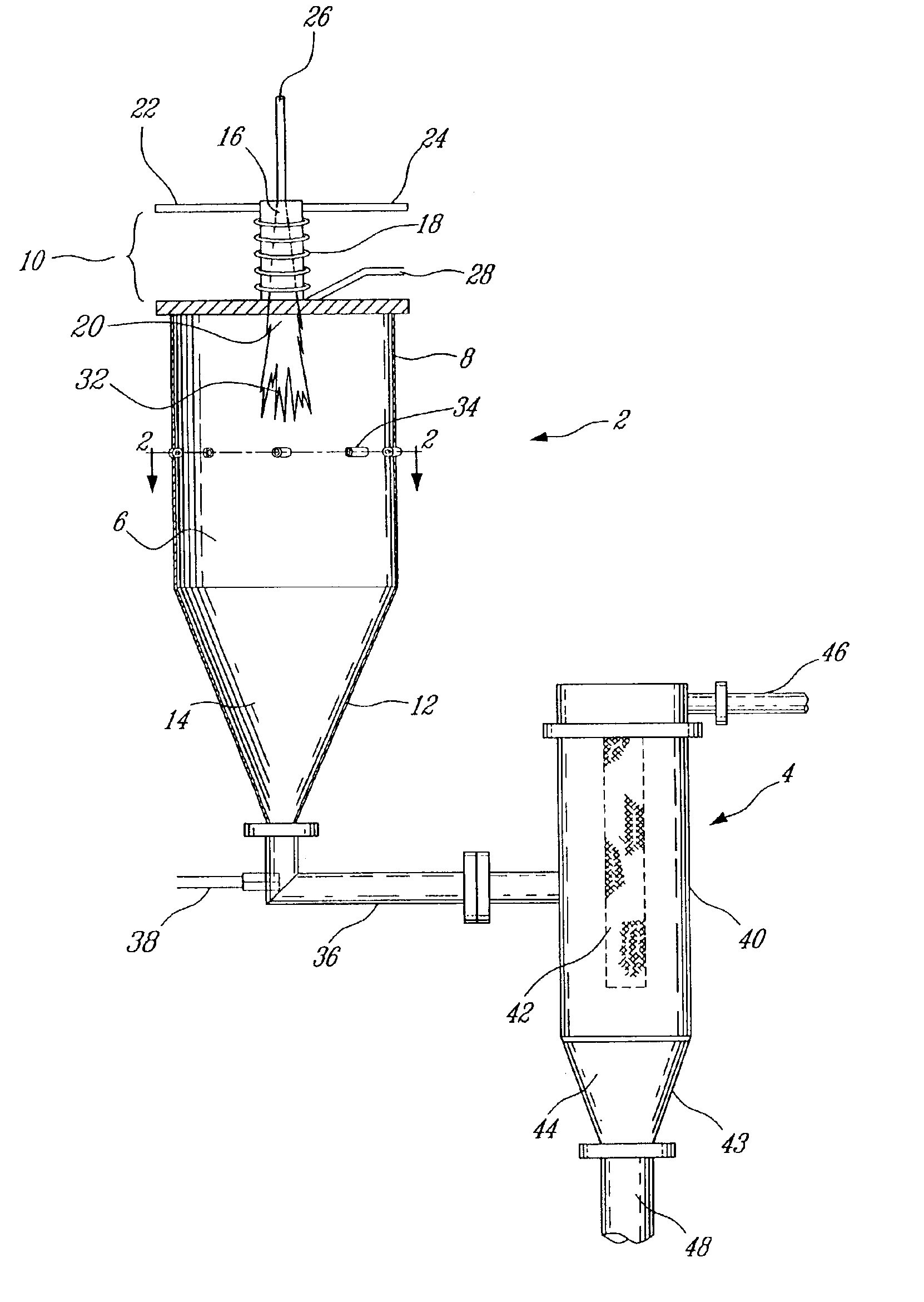

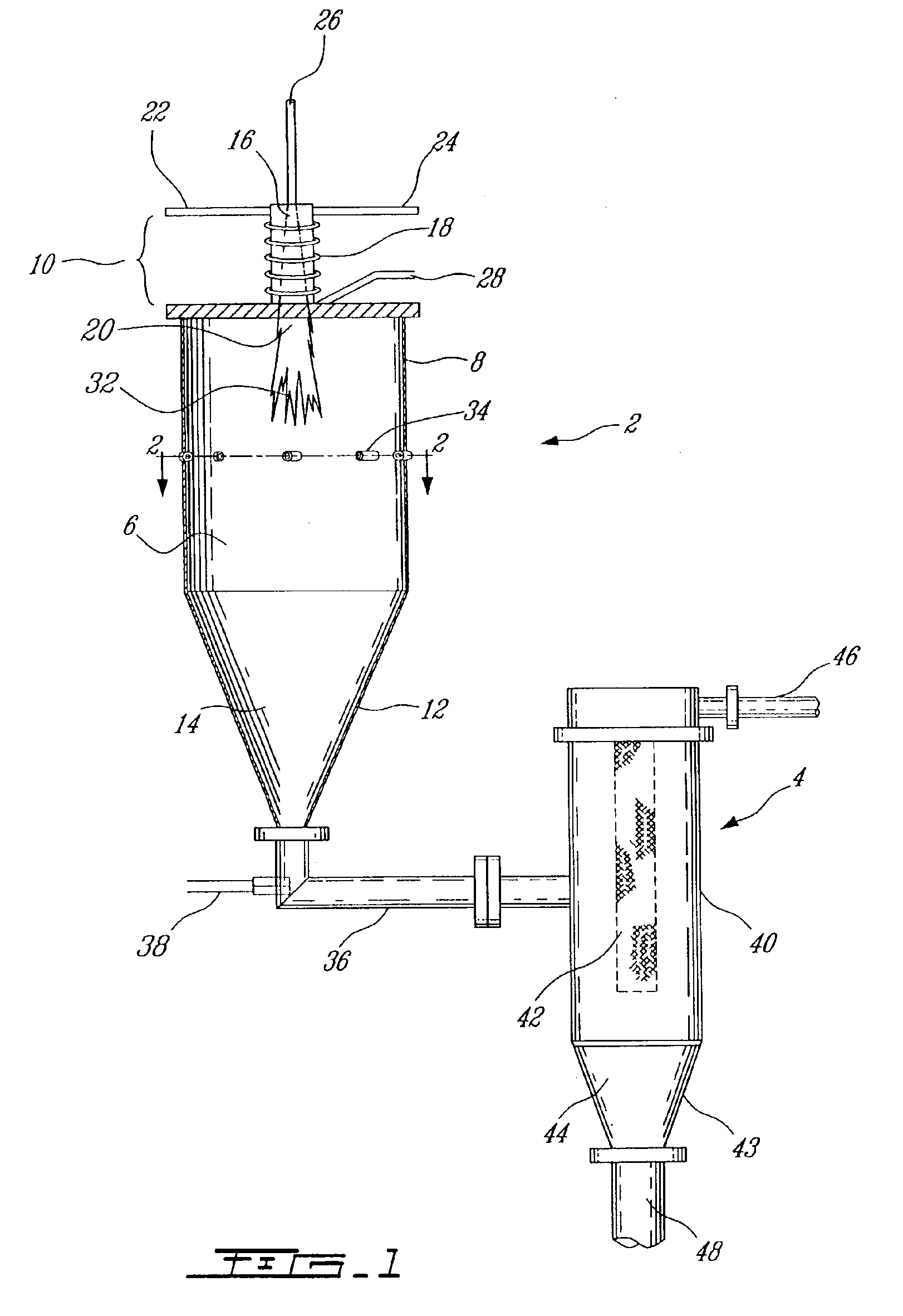

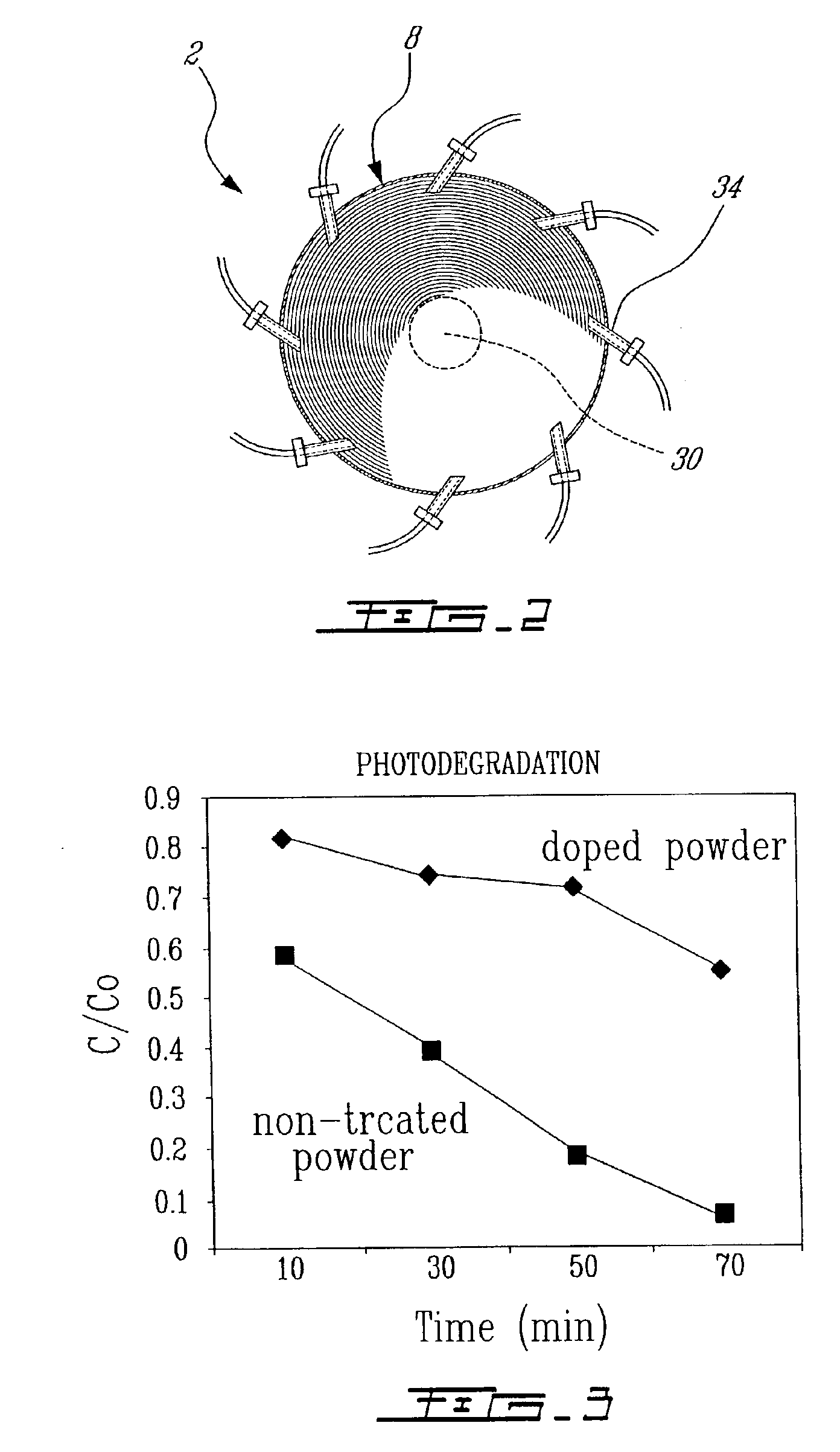

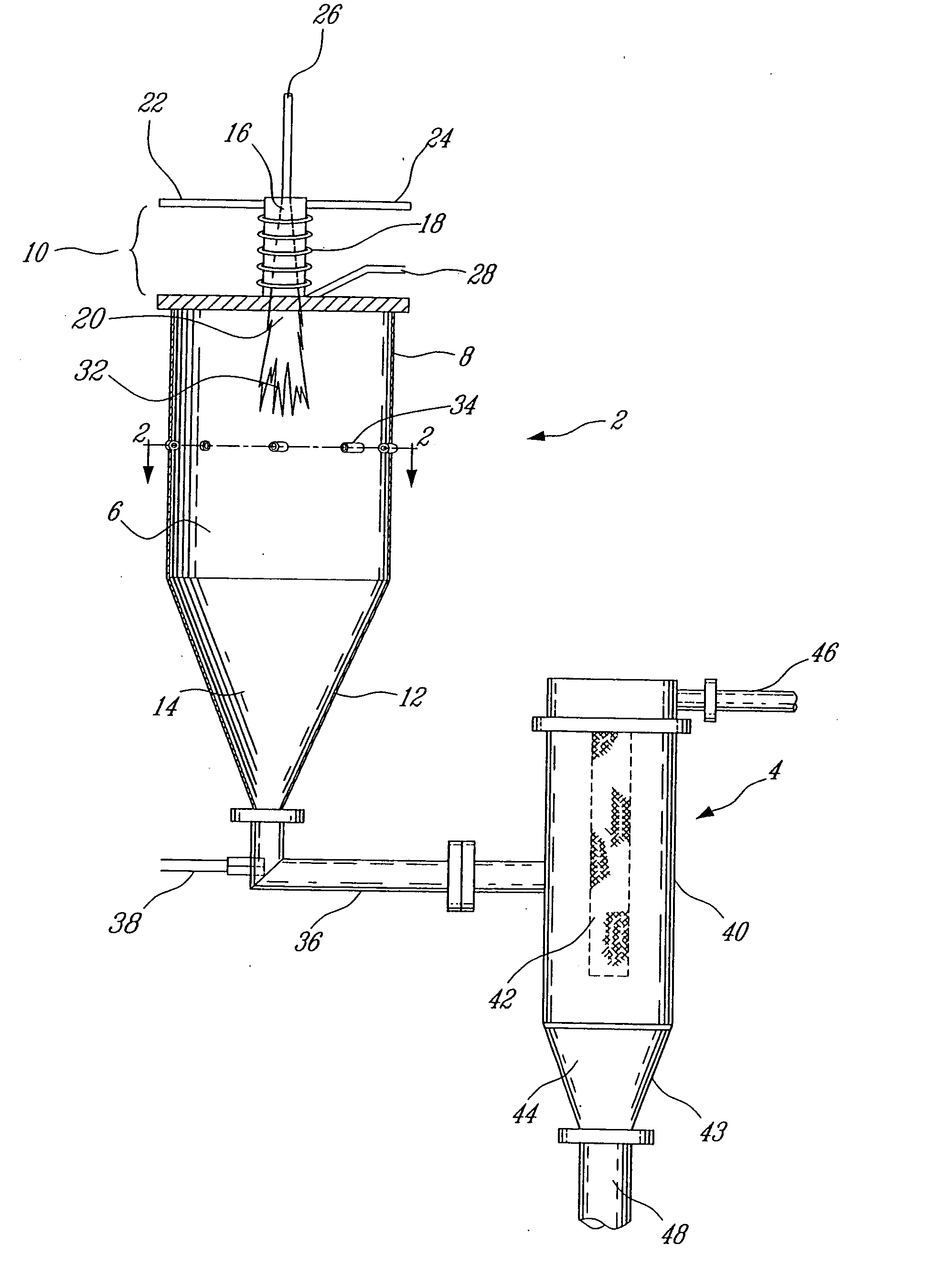

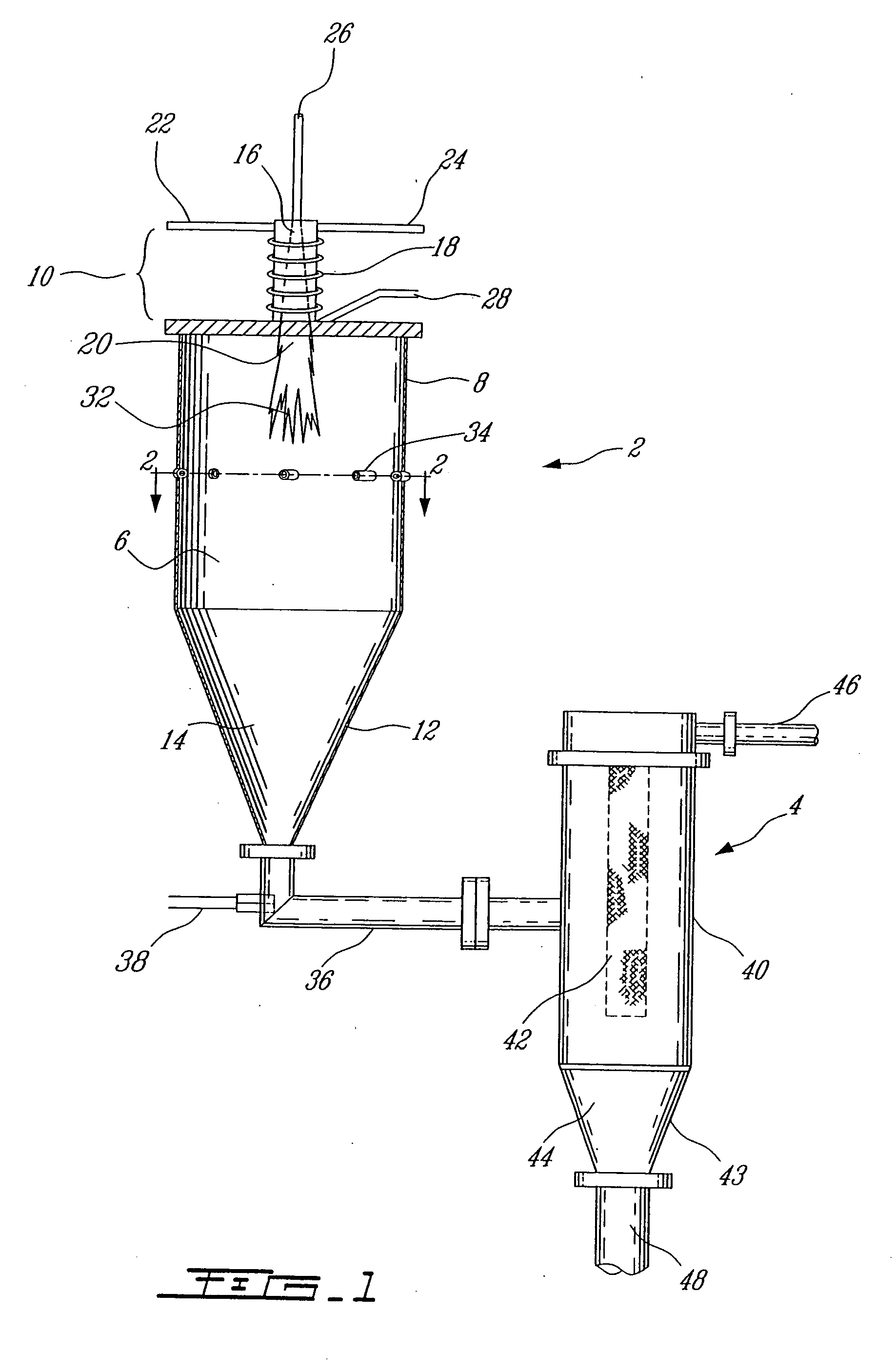

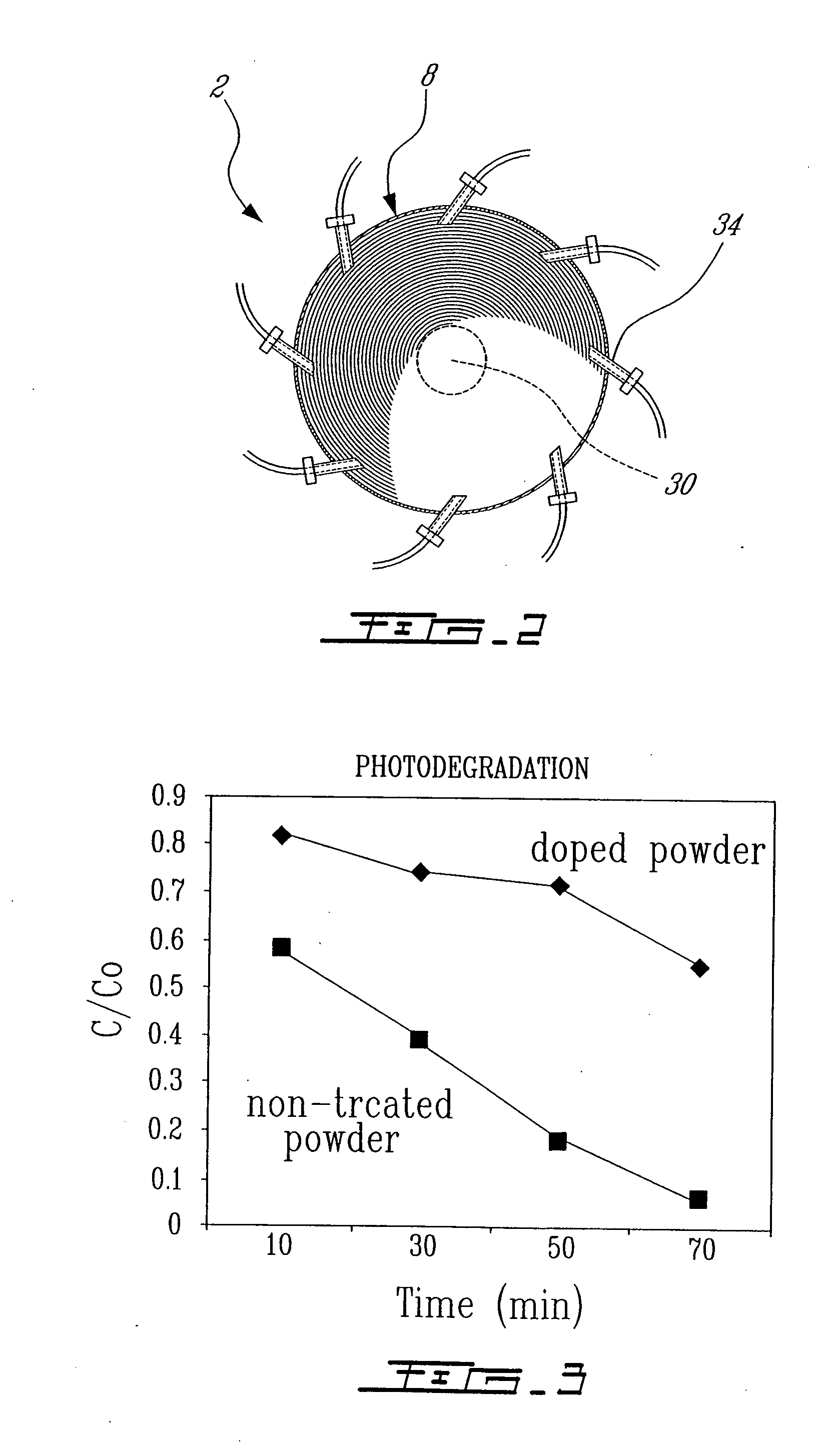

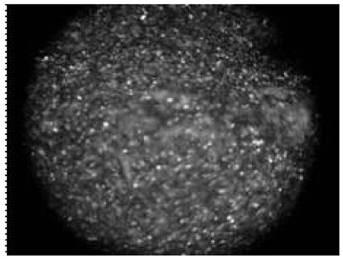

Plasma synthesis of metal oxide nanopowder and apparatus therefor

InactiveUS6994837B2Large dischargeKeep for a long timePigmenting treatmentMaterial nanotechnologyDopantPhysical chemistry

A process and apparatus for the synthesis of metal oxide nanopowder from a metal compound vapour is presented. In particular a process and apparatus for the synthesis of TiO2 nanopowder from TiCl4 is disclosed. The metal compound vapour is reacted with an oxidizing gas in electrically induced RF frequency plasma thus forming a metal oxide vapour. The metal oxide vapour is rapidly cooled using a highly turbulent gas quench zone which quickly halts the particle growth process, yielding a substantial reduction in the size of metal oxide particles formed compared with known processes. The metal compound vapour can also react with a doping agent to create a doped metal oxide nanopowder. Additionally, a process and apparatus for the inline synthesis of a coated metal oxide is disclosed wherein the metal oxide particles are coated with a surface agent after being cooled in a highly turbulent gas quench zone.

Owner:TEKNA PLASMA SYST INC

Positive electrode active material and lithium ion secondary battery

InactiveUS6872491B2Eliminate cracksLarge dischargeFluoride preparationFinal product manufactureStructural formulaComposite oxide

The present invention provides a positive electrode active material containing a composite oxide having a composition represented by a structural formula (1) given below:Lix(Ni1-yMe1y)(O2-zXz)+A (1)

Owner:KK TOSHIBA

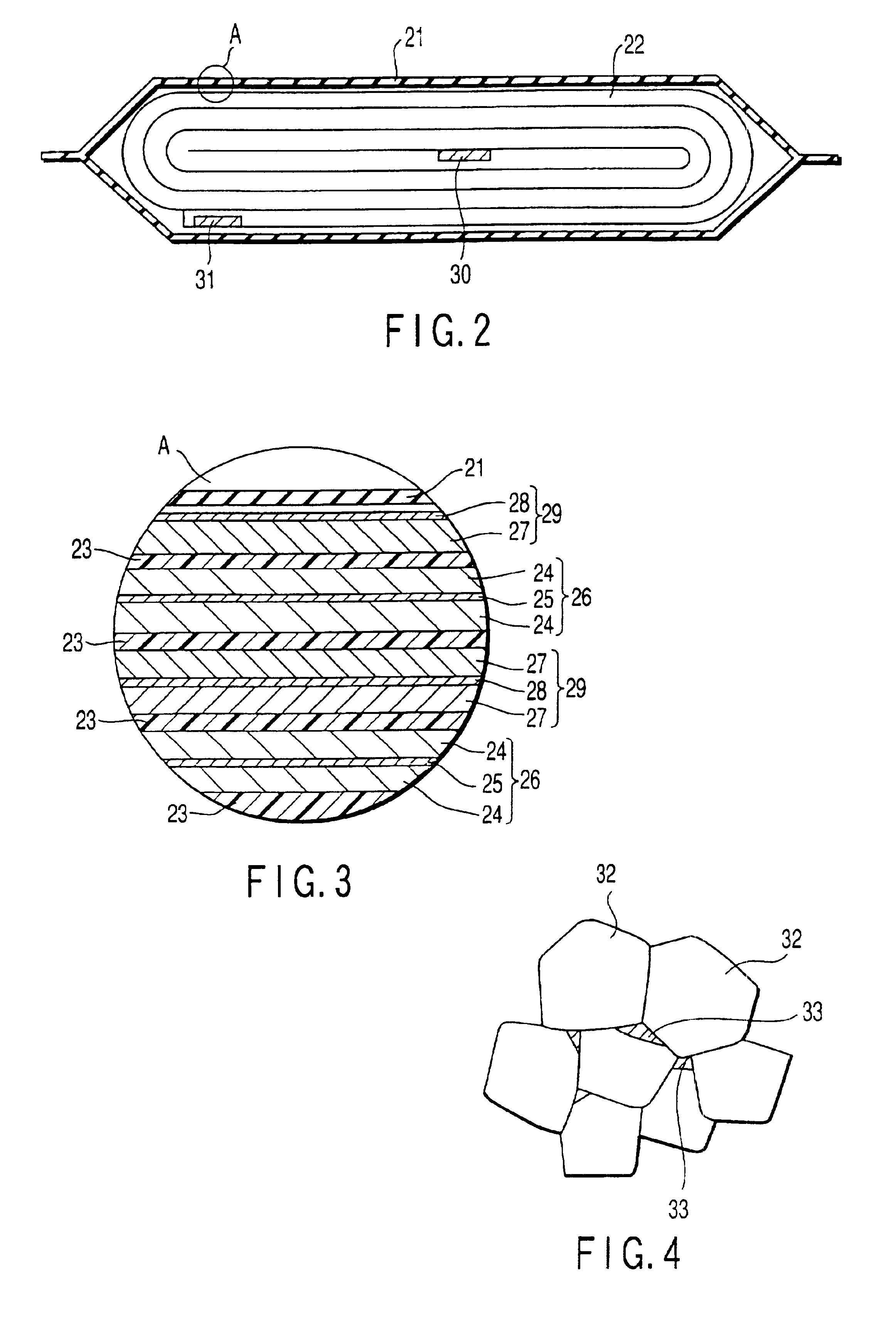

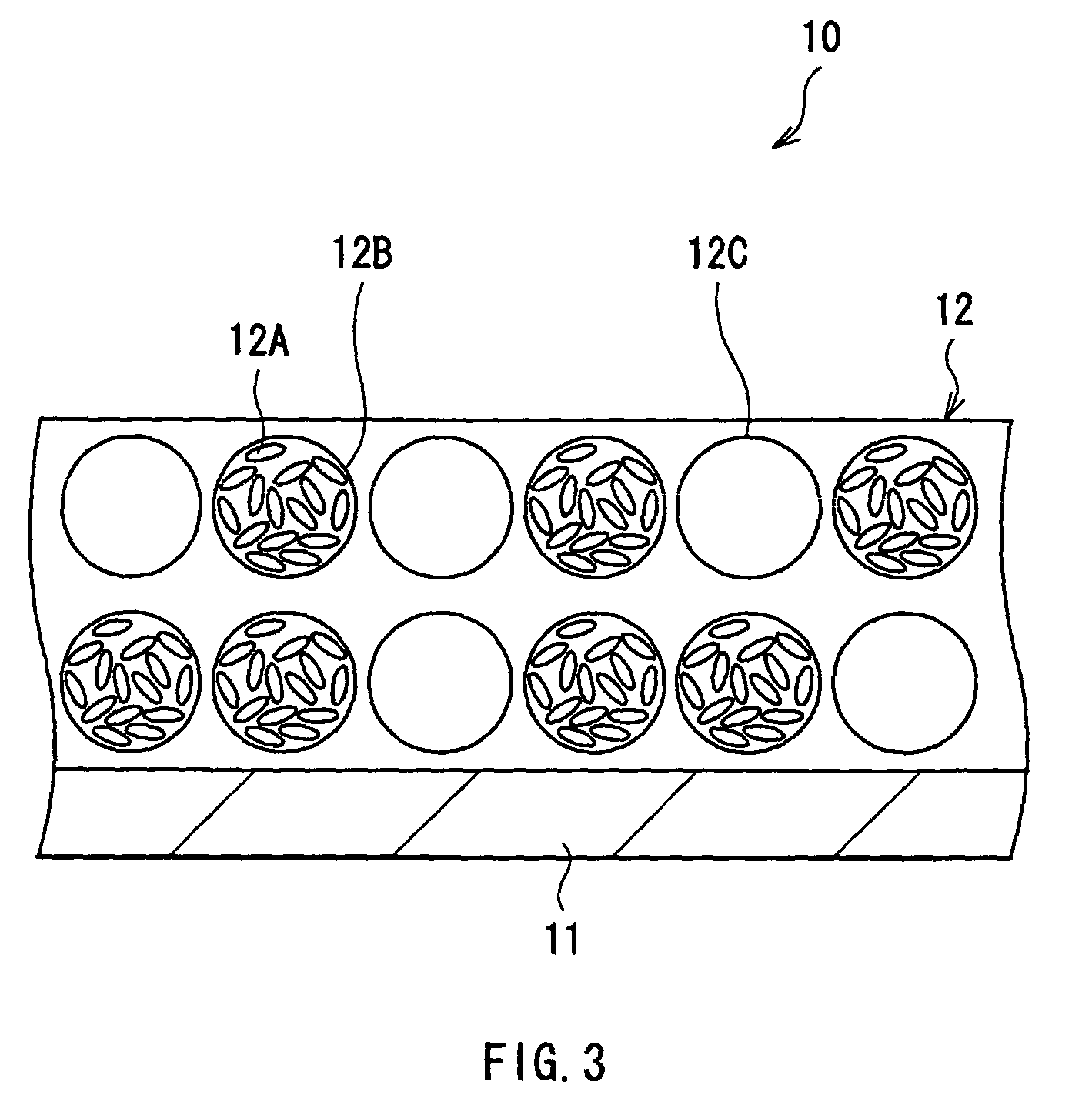

Positive electrode active material powder for lithium secondary battery

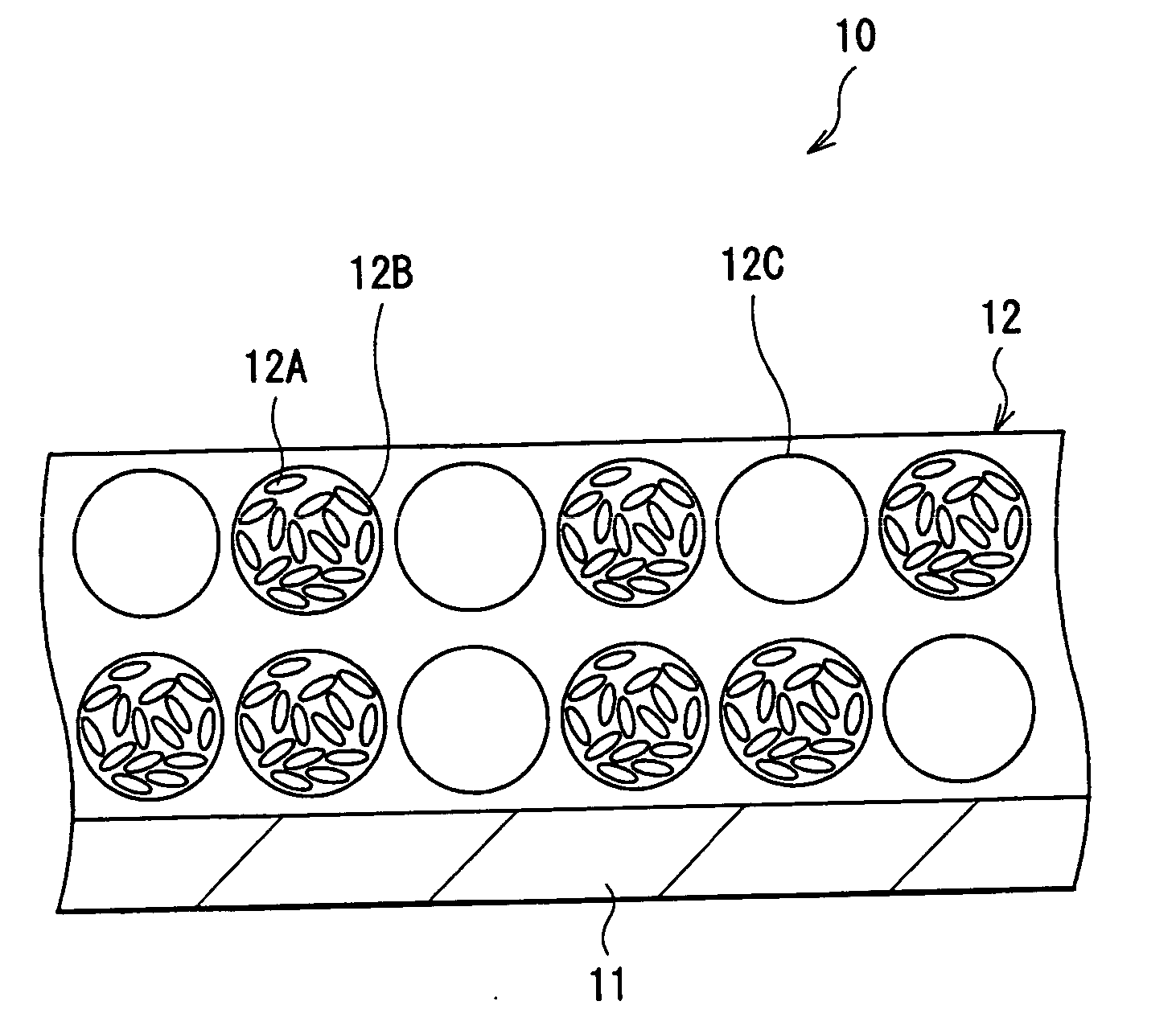

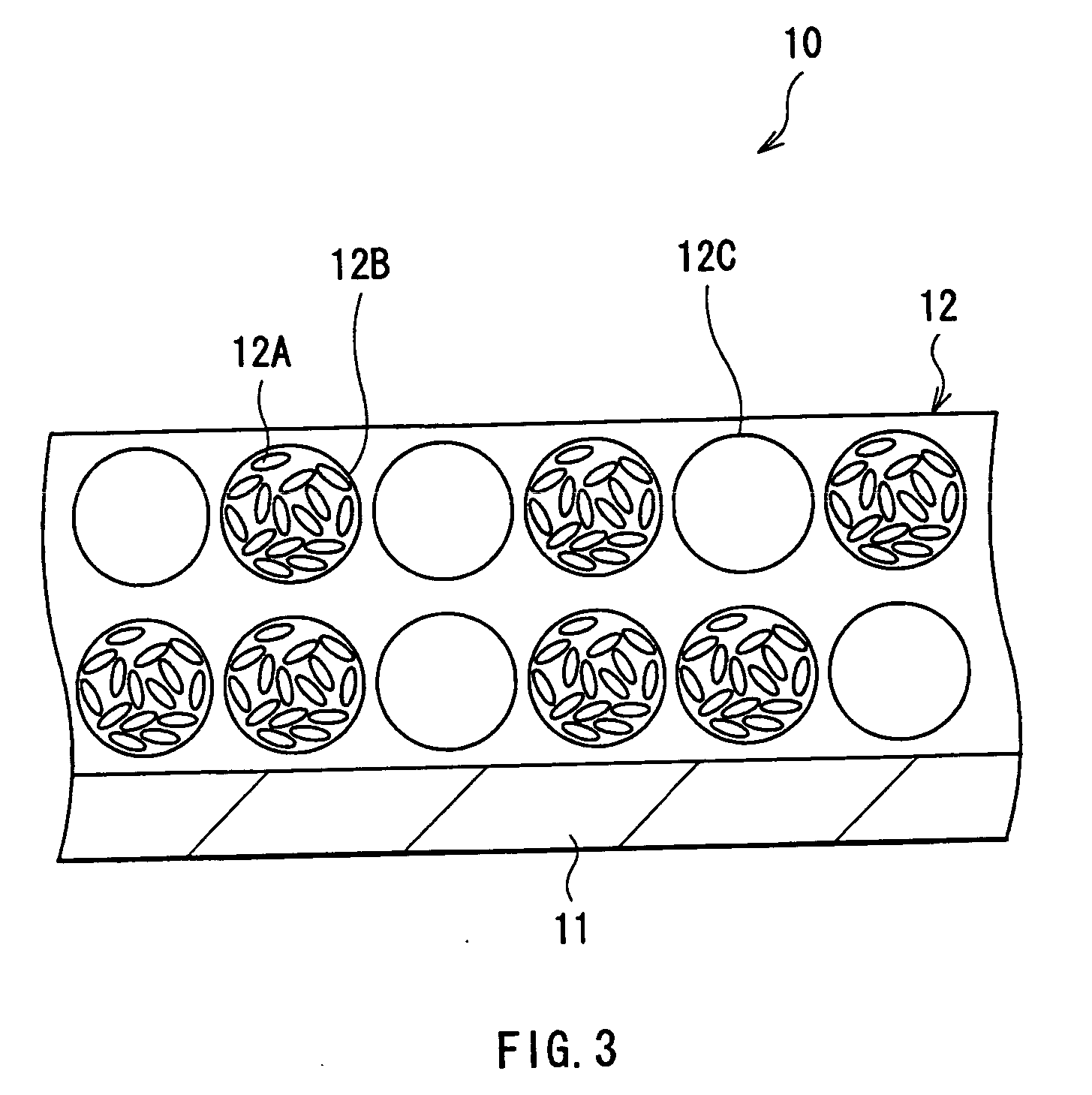

ActiveUS20050271944A1Large volume capacity densityLow compression breaking strengthAlkali metal oxidesLi-accumulatorsBreaking strengthAlkaline earth metal

To provide a lithium-nickel-cobalt-manganese composite oxide powder for a positive electrode of a lithium secondary battery, which has a large volume capacity density and high safety and is excellent in the charge and discharge cyclic durability. A positive electrode active material powder for a lithium secondary battery characterized by comprising a first granular powder having a compression breaking strength of at least 50 MPa and a second granular powder having a compression breaking strength of less than 40 MPa, formed by agglomeration of many fine particles of a lithium composite oxide represented by the formula LipNixCoyMnzMqO2-aFa (wherein M is a transition metal element other than Ni, Co and Mn, Al or an alkaline earth metal element, 0.9≦p≦1.1, 0.2≦x≦0.8, 0≦x≦0.4, 0≦z≦0.5, y+z>0, 0≦q≦0.05, 1.9≦2−a≦2.1, x+y+z+q=1, and 0≦a≦0.02) to have an average particle size D50 of from 3 to 15 μm, in a weight ratio of the first granular powder / the second granular powder being from 50 / 50 to 90 / 10.

Owner:SUMITOMO CHEM CO LTD

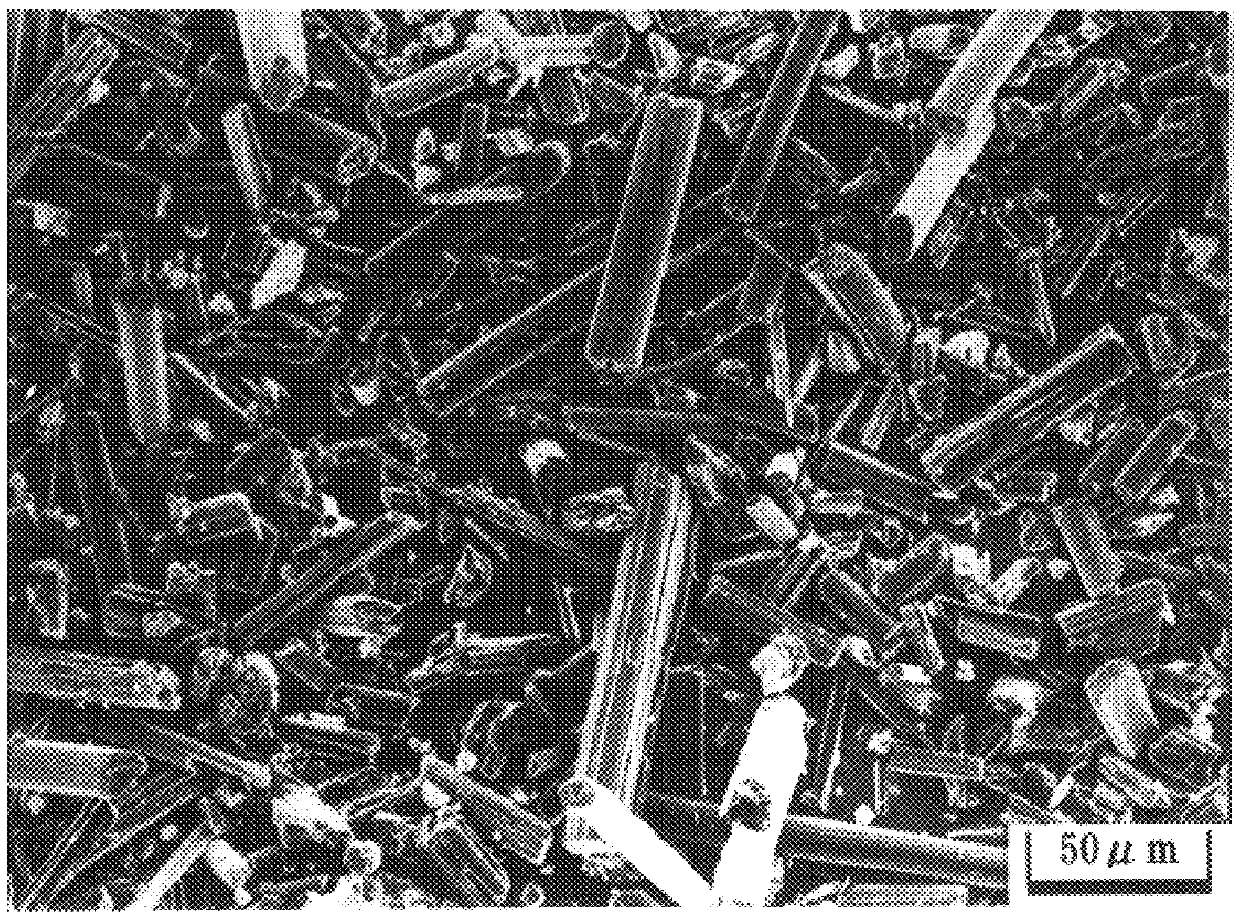

Mesophase pitch-based activated carbon fibers and electric double layer capacitor using the same

InactiveUS6118650ALower internal resistanceImprove conductivityHybrid capacitor electrodesLiquid electrolytic capacitorsActivated carbonFiber

Mesophase pitch-based activated carbon fibers which are obtained by milling infusibilized mesophase pitch fibers, as they are or after carbonizing at a temperature of 350 to 1,000 DEG C., to an average particle diameter of 5 to 50 mu m and then activating in the presence of an alkali metal compound. The activated carbon fibers have a pore distribution suitable for forming a electric double layer and is excellent as the material for an electrode of an electric double layer capacitor. The electric double layer capacitor having the electrode using the activated carbon fiber exhibits high discharge capacity.

Owner:HONDA MOTOR CO LTD

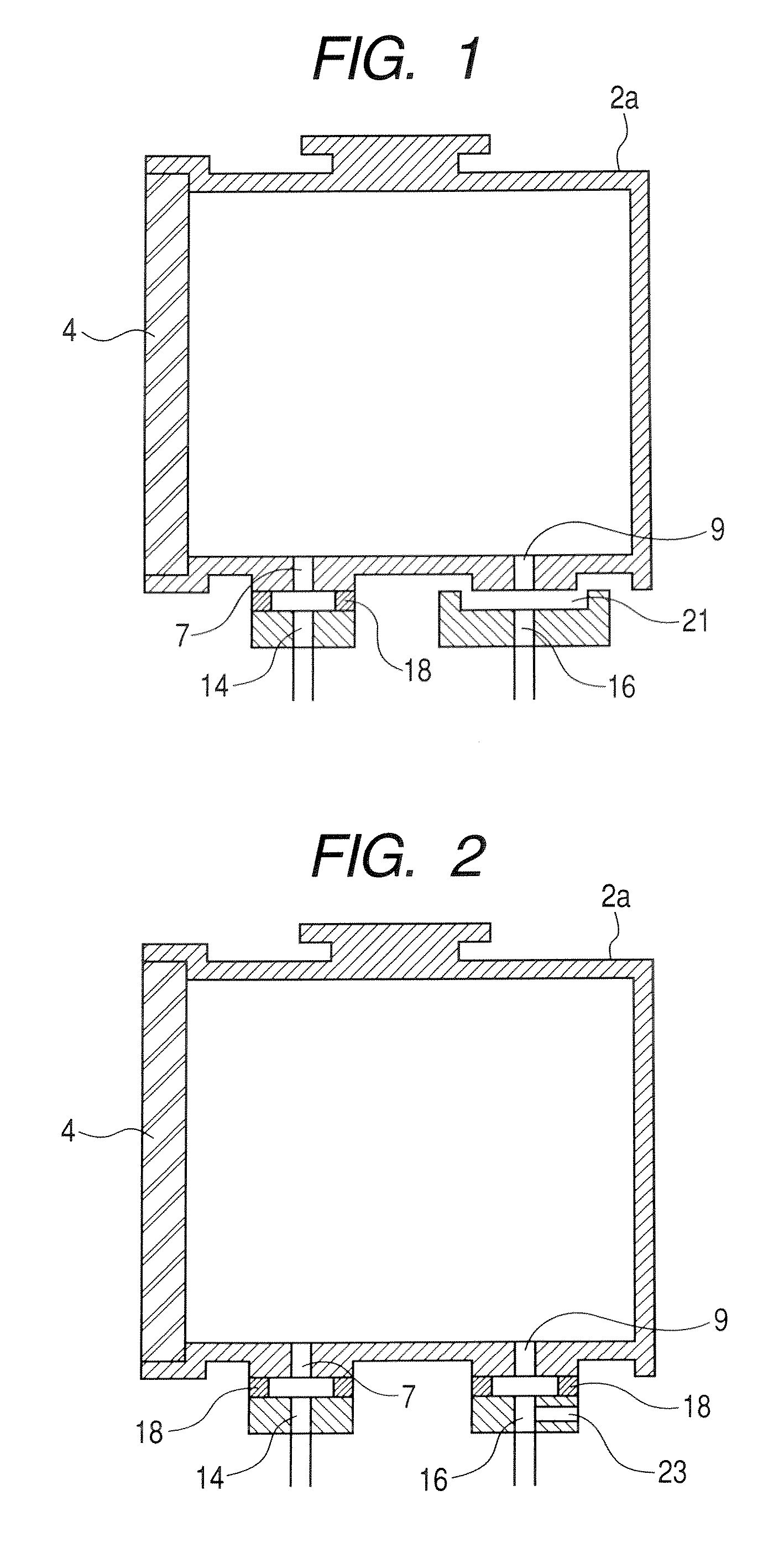

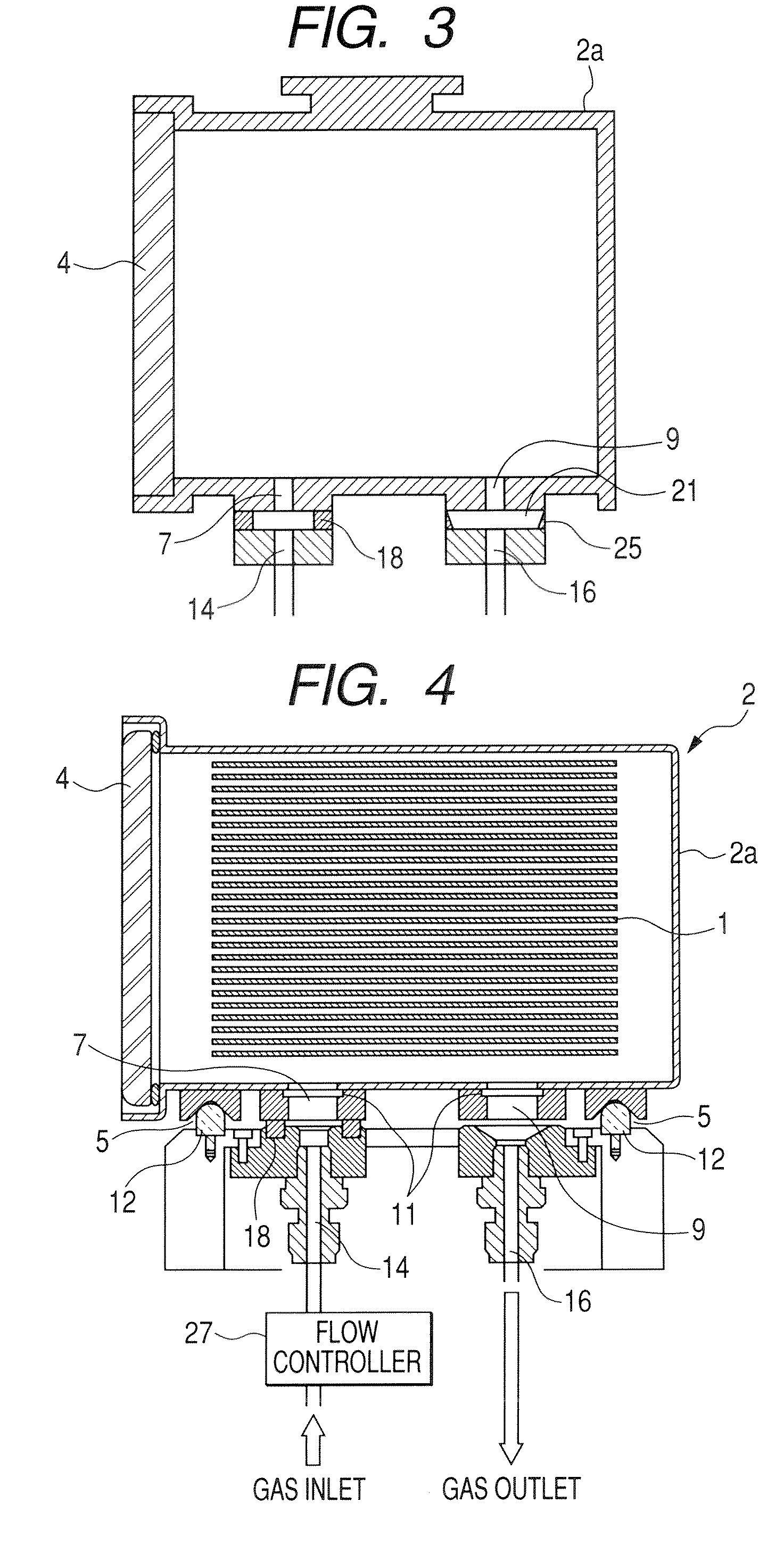

Purge system for a product container and table for use in the purge system

InactiveUS20060288664A1Avoid differential pressureSuppress pressure differenceSemiconductor/solid-state device manufacturingPackaging under special atmospheric conditionsPressure differenceAtmosphere

For the purpose of preventing a pressure difference from occurring between an interior of an FOUP and an exterior at the time of purging the interior of the FOUP, a communication path that communicates with the exterior of the FOUP and the interior of an outlet path is provided with respect to the outlet path that extends from a table side outlet port which is disposed on a table on which the FOUP is placed, and an external atmosphere is introduced to the outlet path through the communication path when a pressure difference starts occurring between the interior and the exterior of the FOUP.

Owner:TDK CORPARATION

Positive electrode active material powder for lithium secondary battery

ActiveUS7381498B2Improve packaging effectSolve the small densityAlkali metal oxidesLi-accumulatorsBreaking strengthAlkaline earth metal

Owner:SUMITOMO CHEM CO LTD

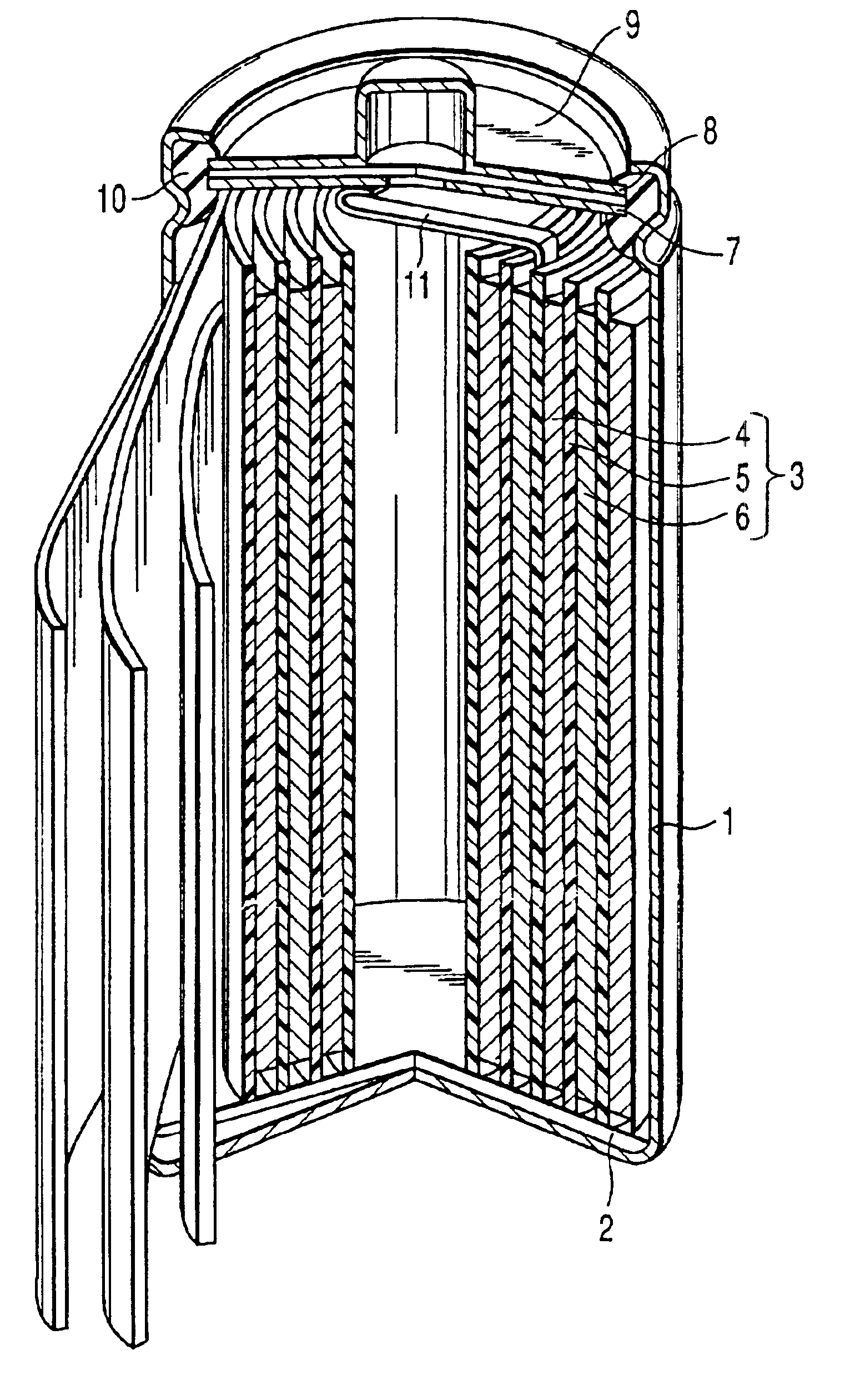

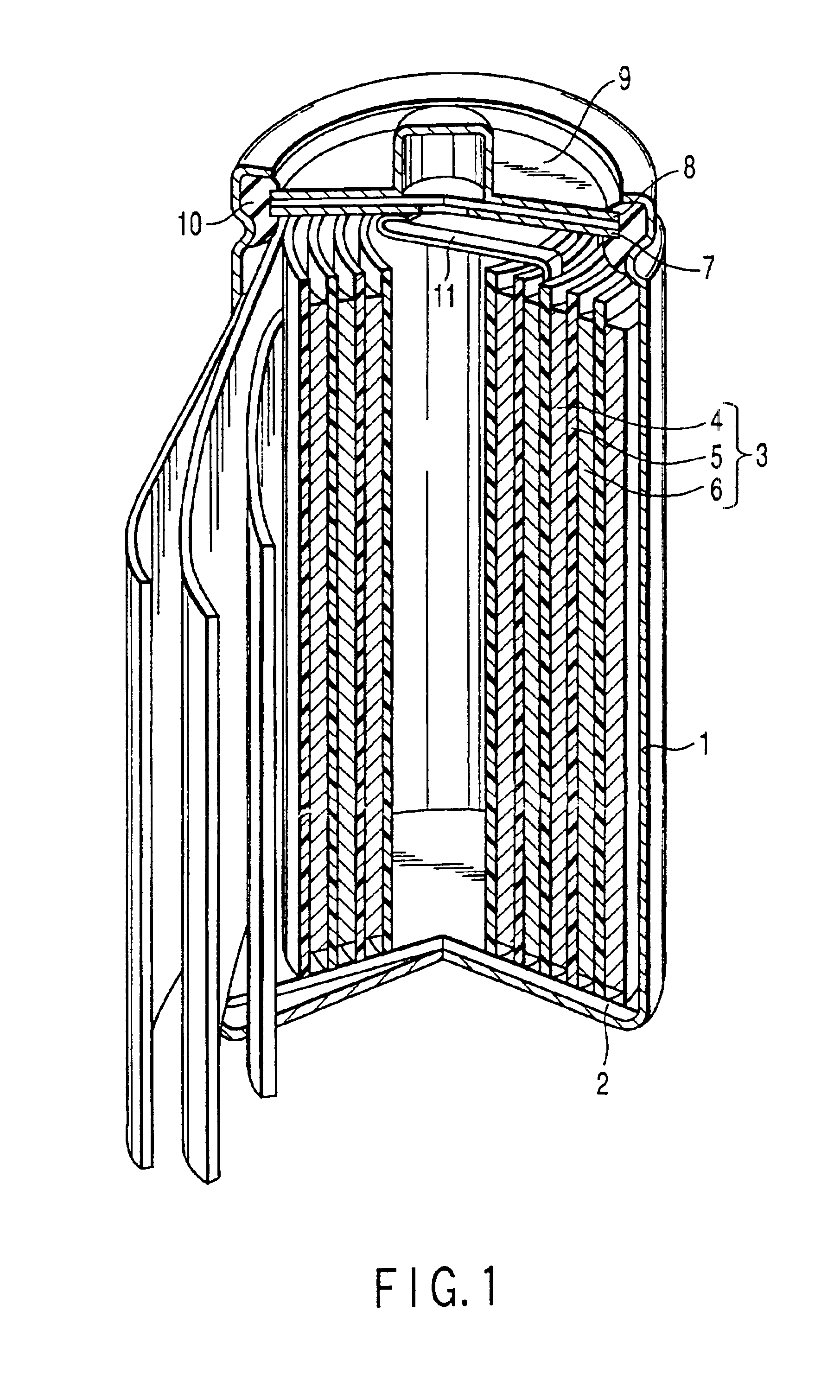

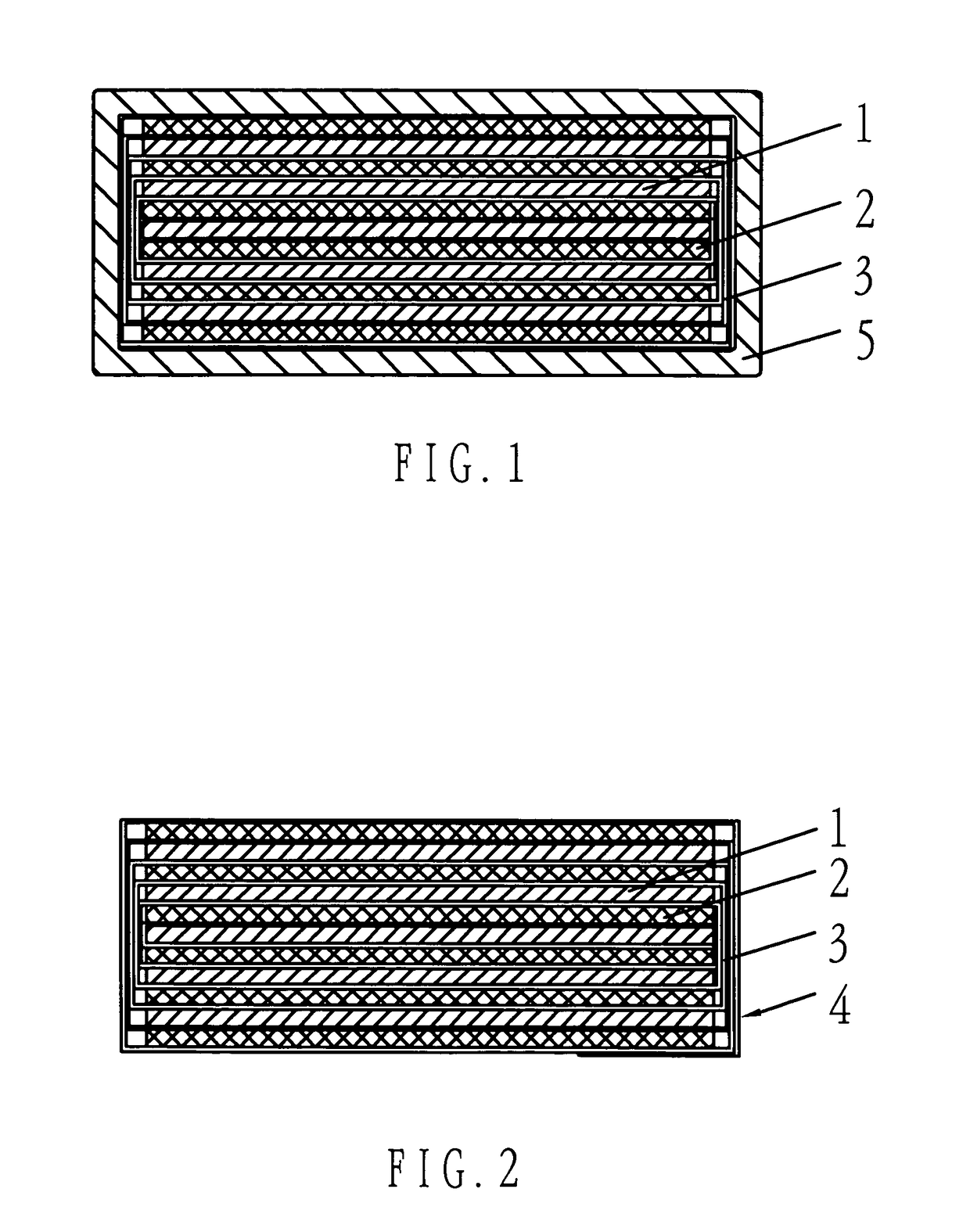

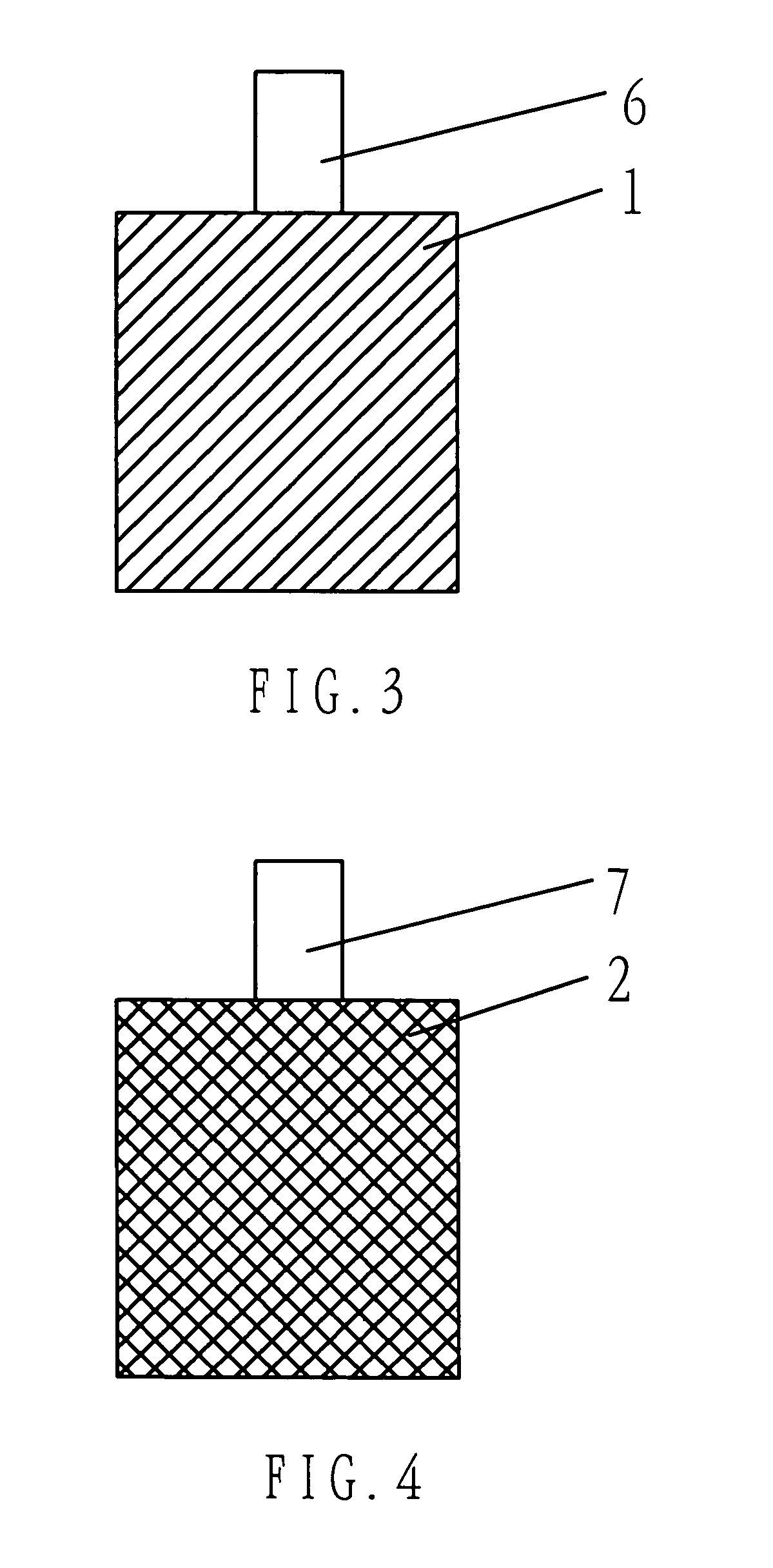

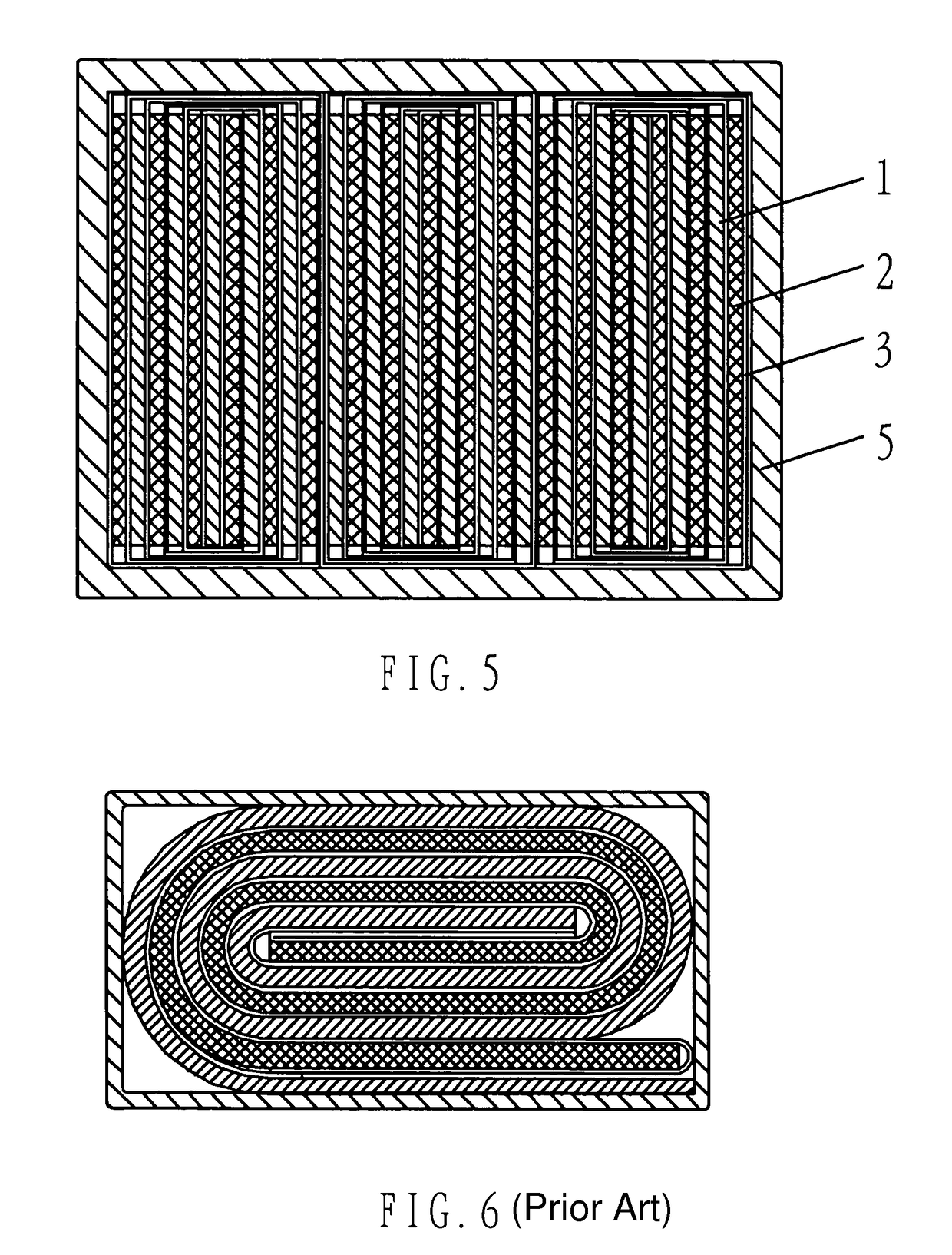

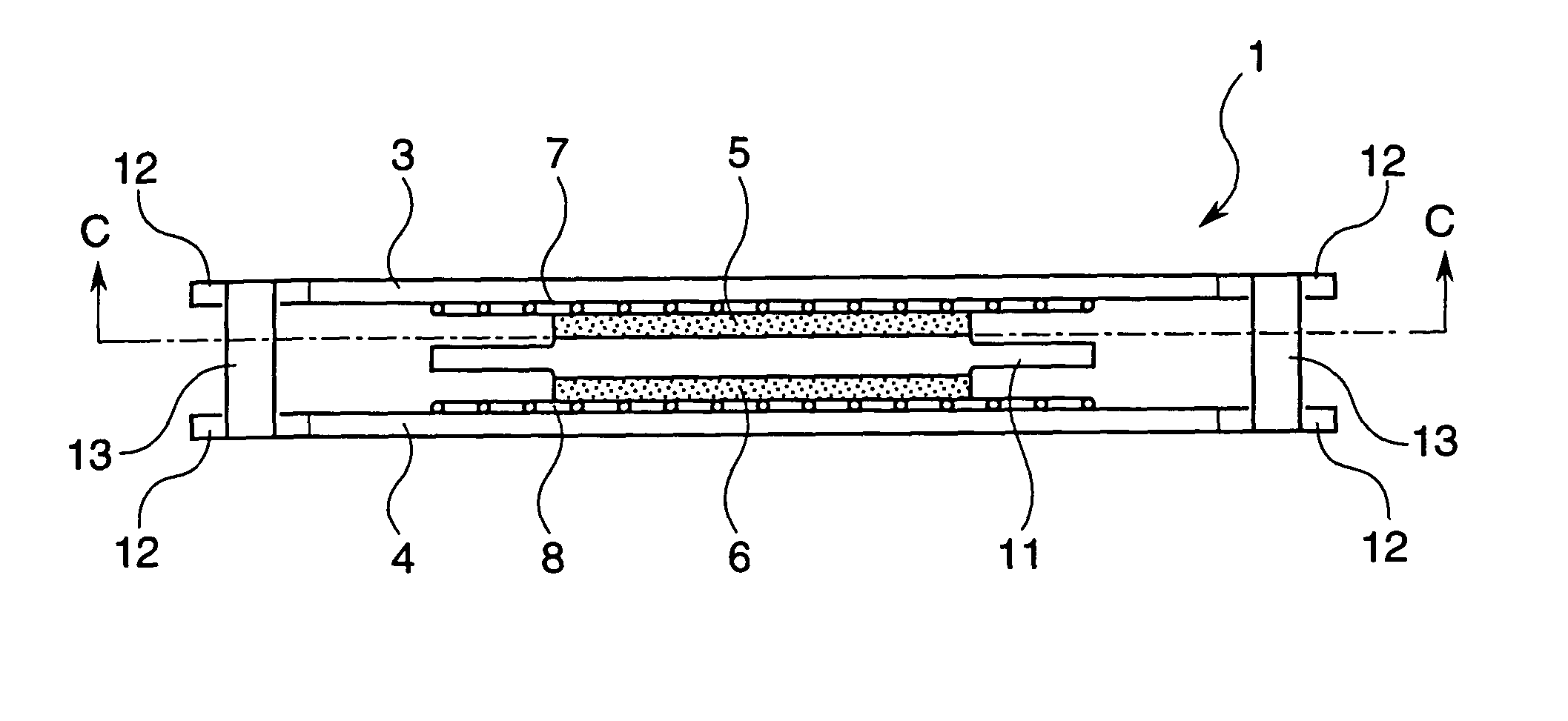

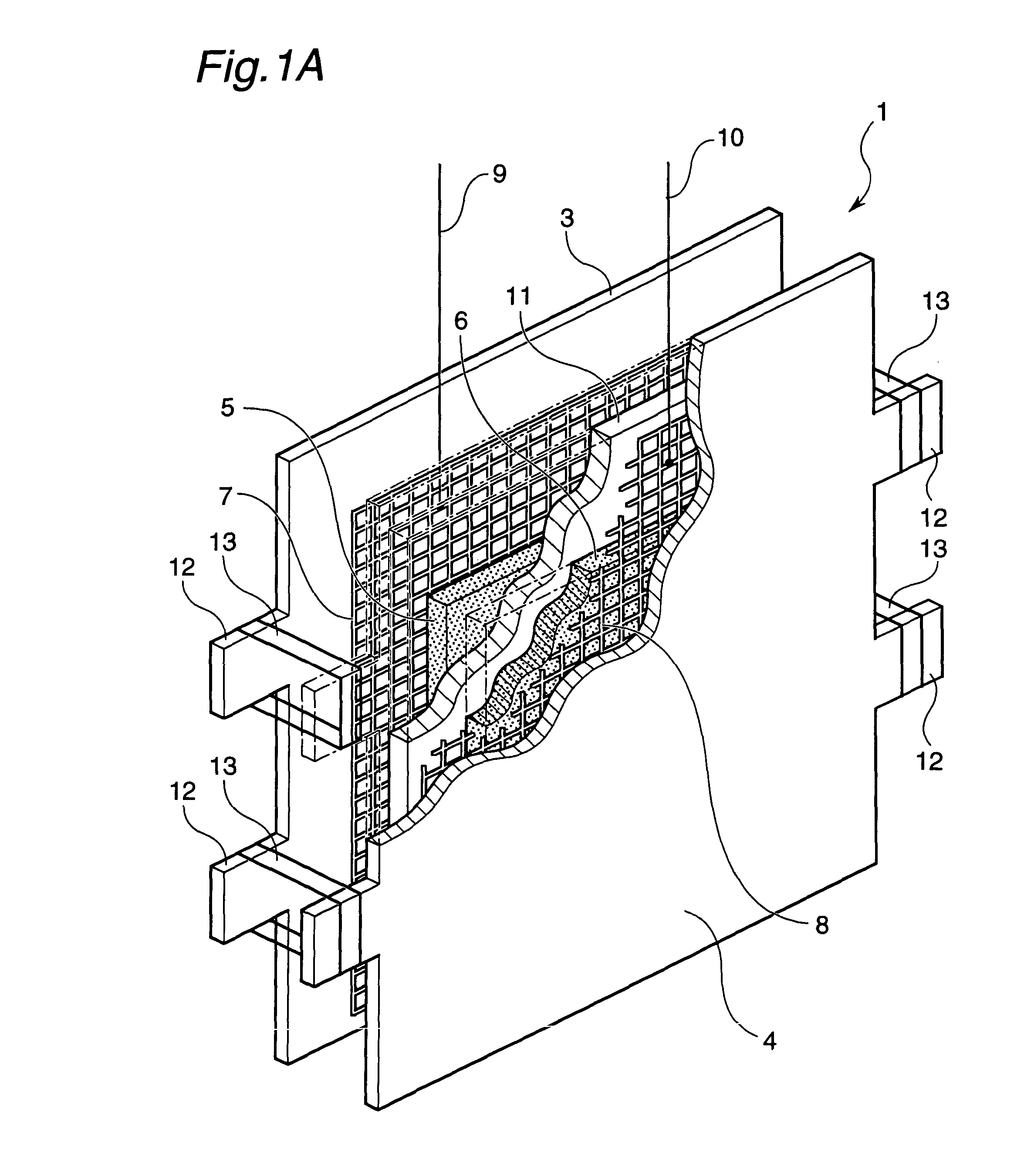

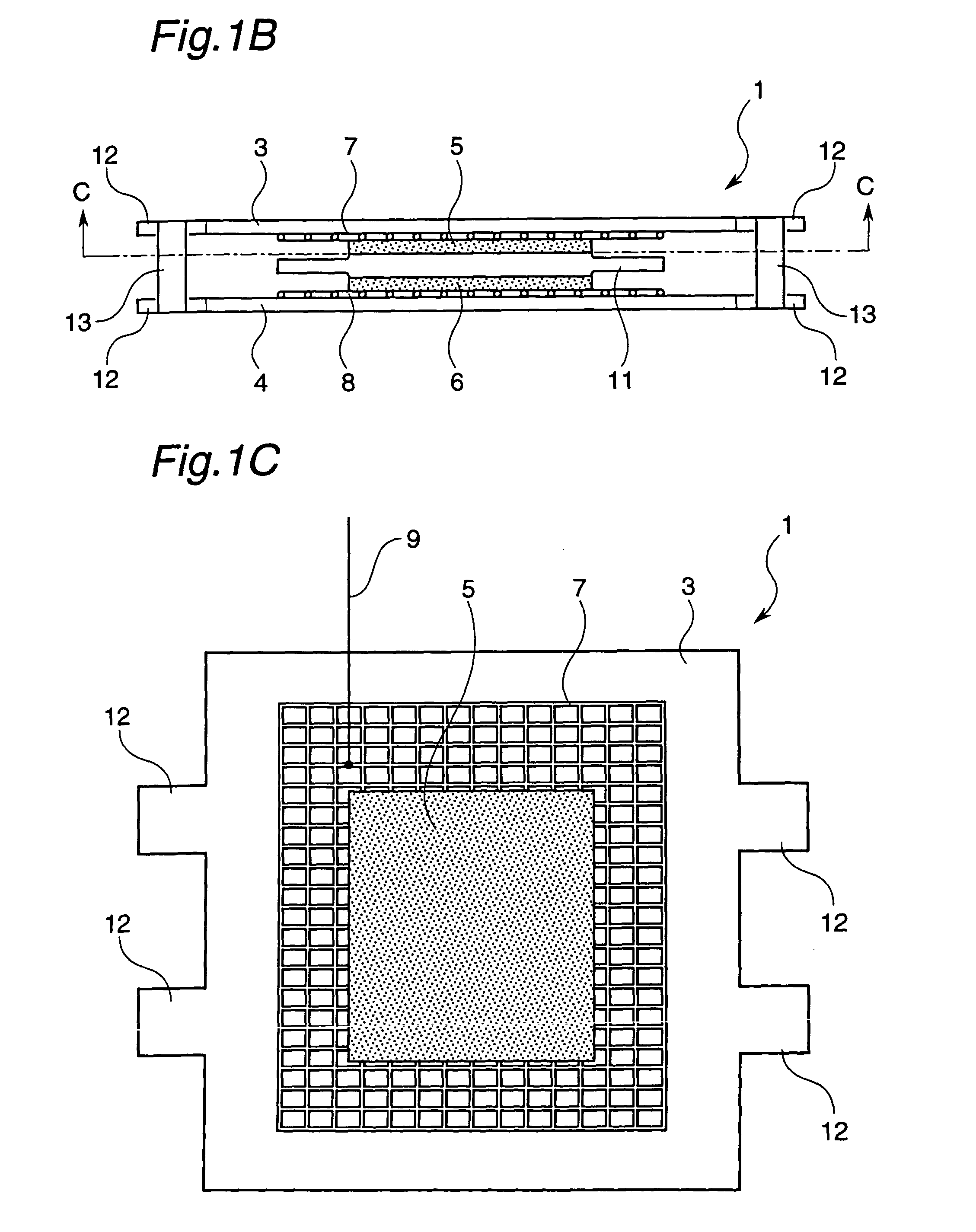

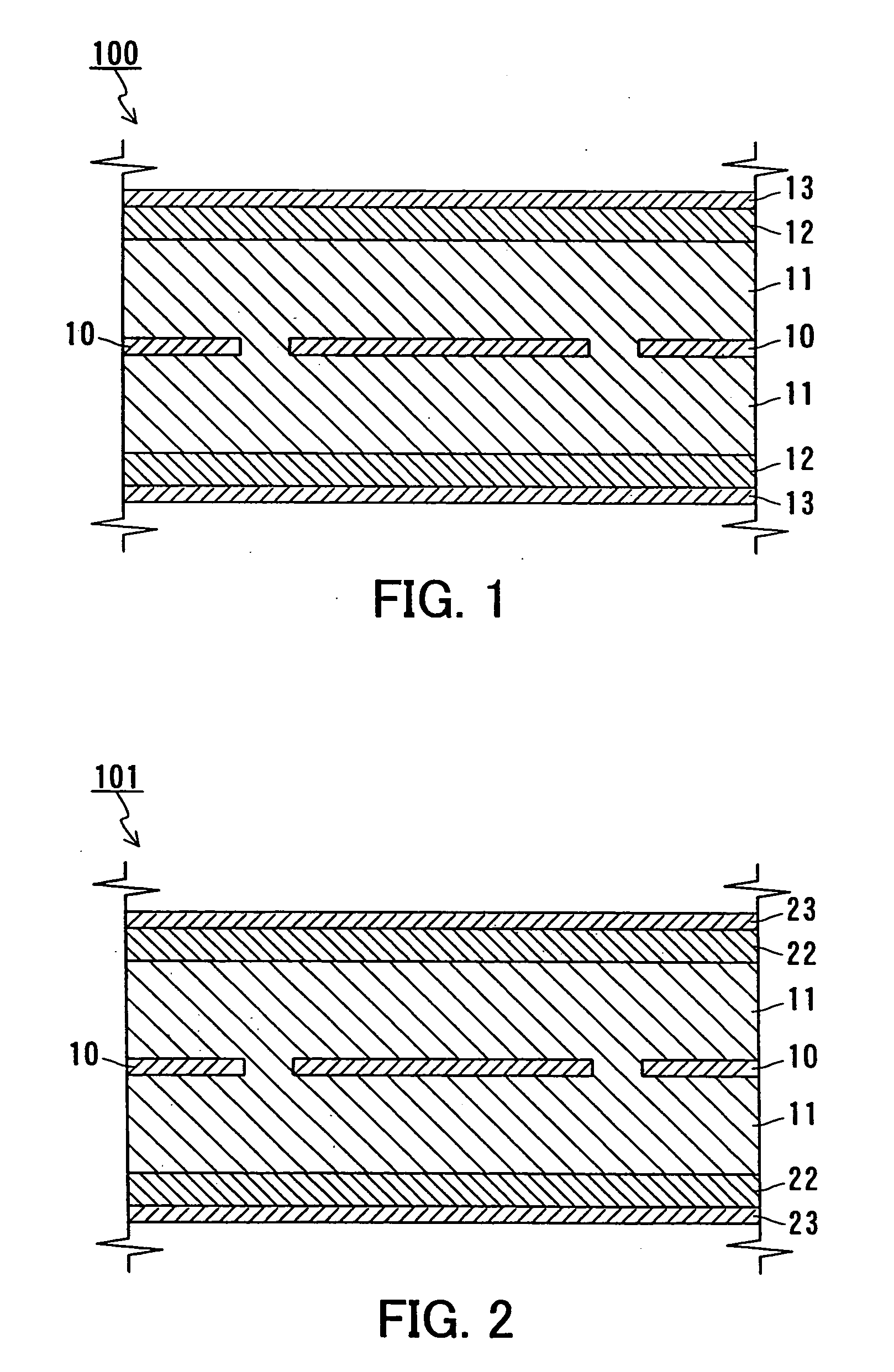

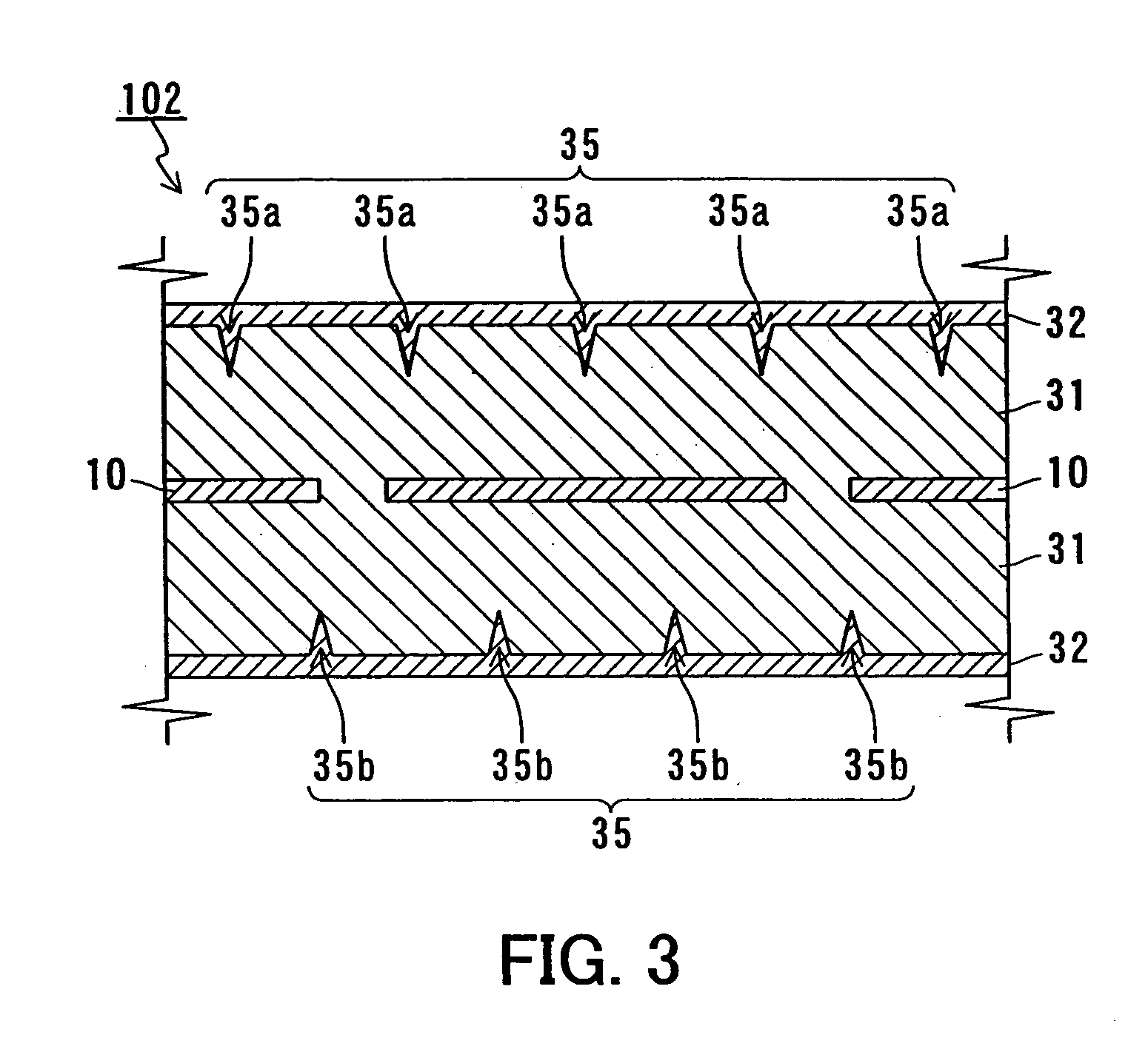

Lithium ion secondary battery

ActiveUS7906233B2Effective internal spaceHigh capacity densityElectrode manufacturing processesCell seperators/membranes/diaphragms/spacersLithiumElectrical conductor

Owner:BYD AMERICA CORP

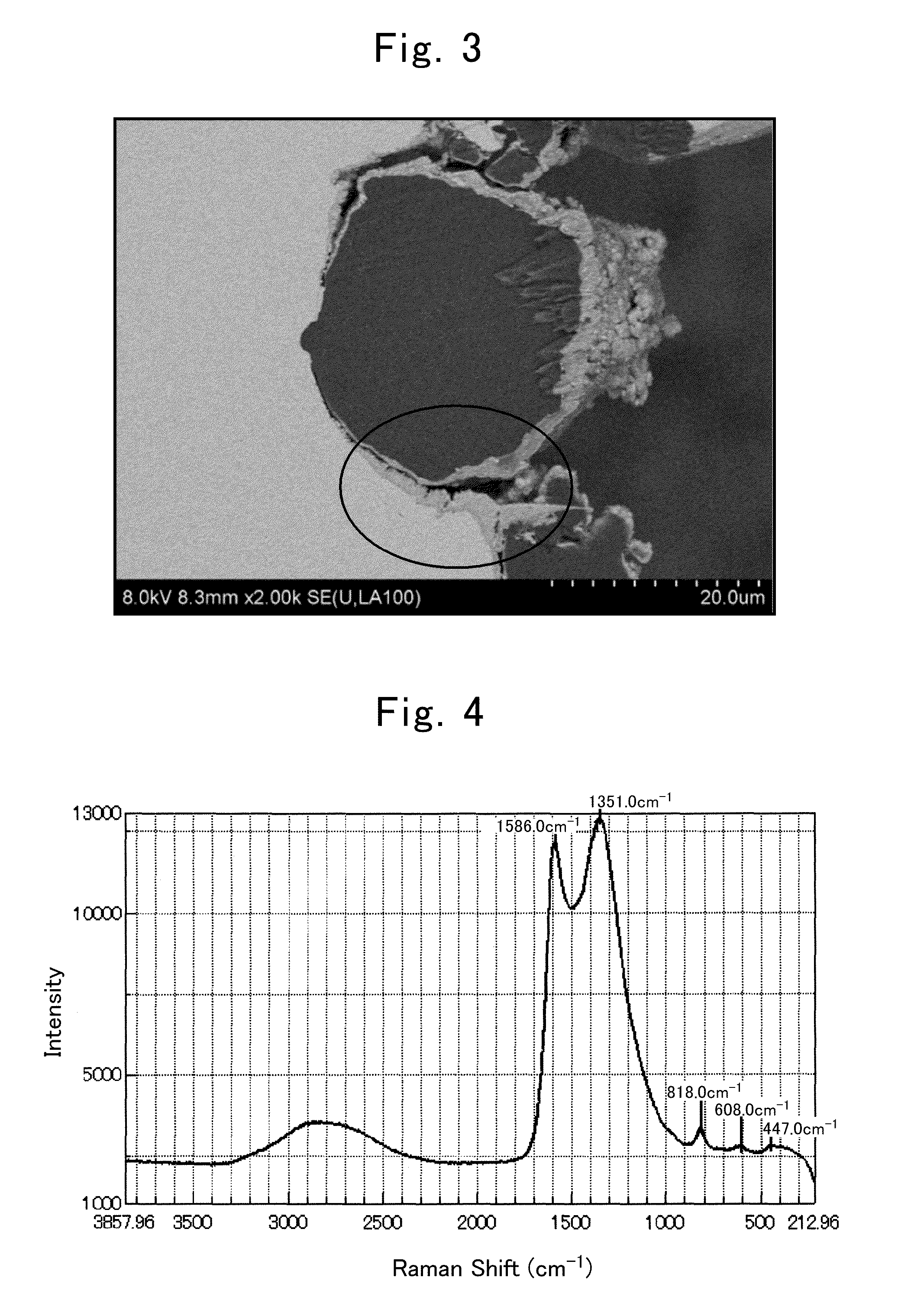

Negative-electrode material for nonaqueous - electrolyte secondary battery production process for the same, negative electrode for nonaqueous-electrolyte secondary battery, and nonaqueous-electrolyte secondary battery

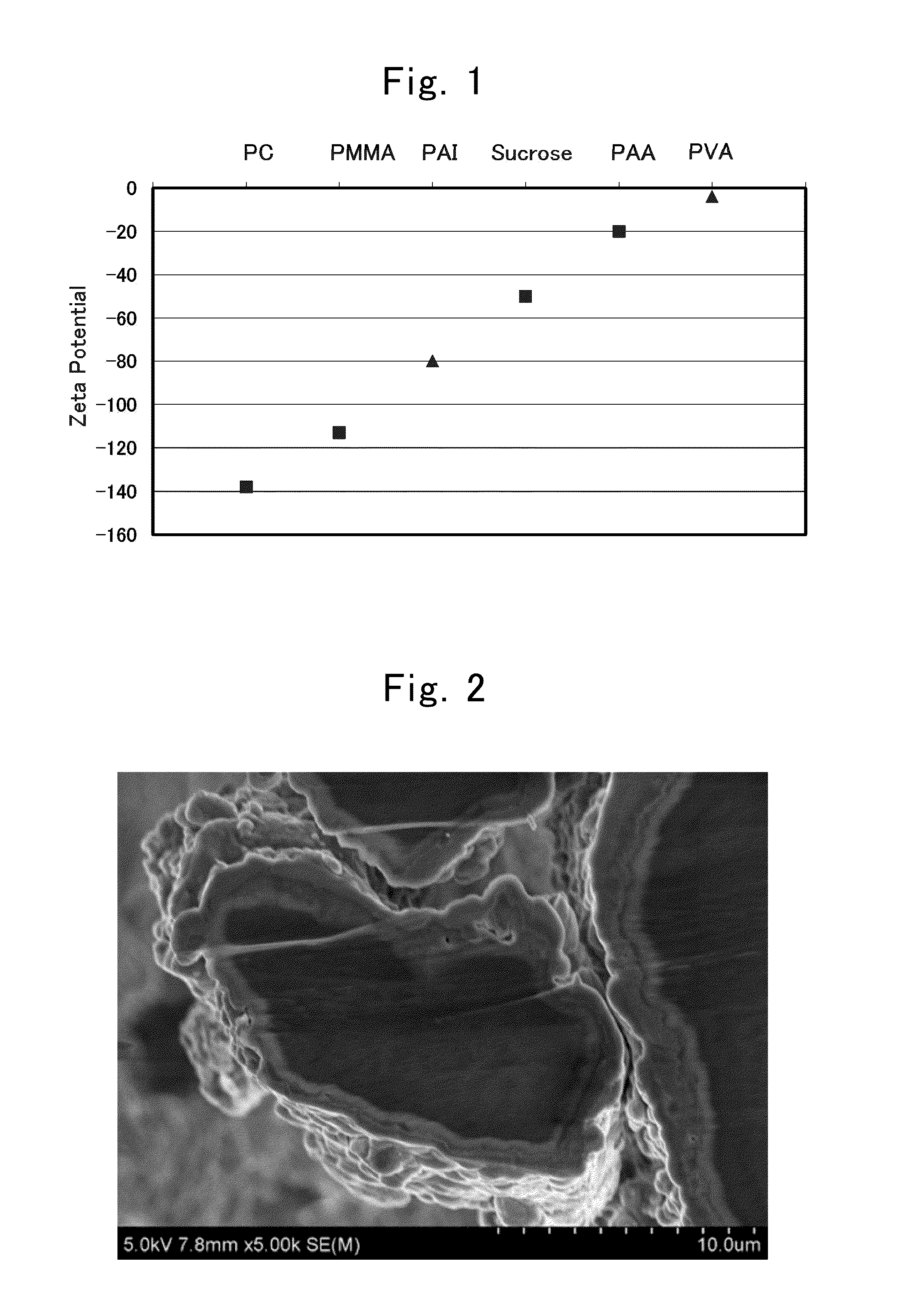

InactiveUS20150188127A1Reduce irreversible capacityLarge discharge capacityElectrode thermal treatmentNegative electrodesZeta potentialLithium

Providing a negative-electrode material for nonaqueous-electrolyte secondary battery, the negative-electrode material including lithium silicate particles coated by a carbonaceous substance, a production process for the same, a negative electrode for nonaqueous-electrolyte secondary battery, and a nonaqueous-electrolyte secondary battery.A negative-electrode material for nonaqueous-electrolyte secondary battery includes lithium silicate particles having a surface at least some of which is coated by a carbonaceous substance formed by heating a carbon-containing compound at a thermal decomposition temperature of the carbon-containing compound or more and 1,100° C. or less, the carbon-containing compound being a solid at ordinary temperature and exhibiting a zeta-potential absolute value being 60 or more against N-methyl-2-pyrrolidone (or NMP).

Owner:TOYOTA IND CORP

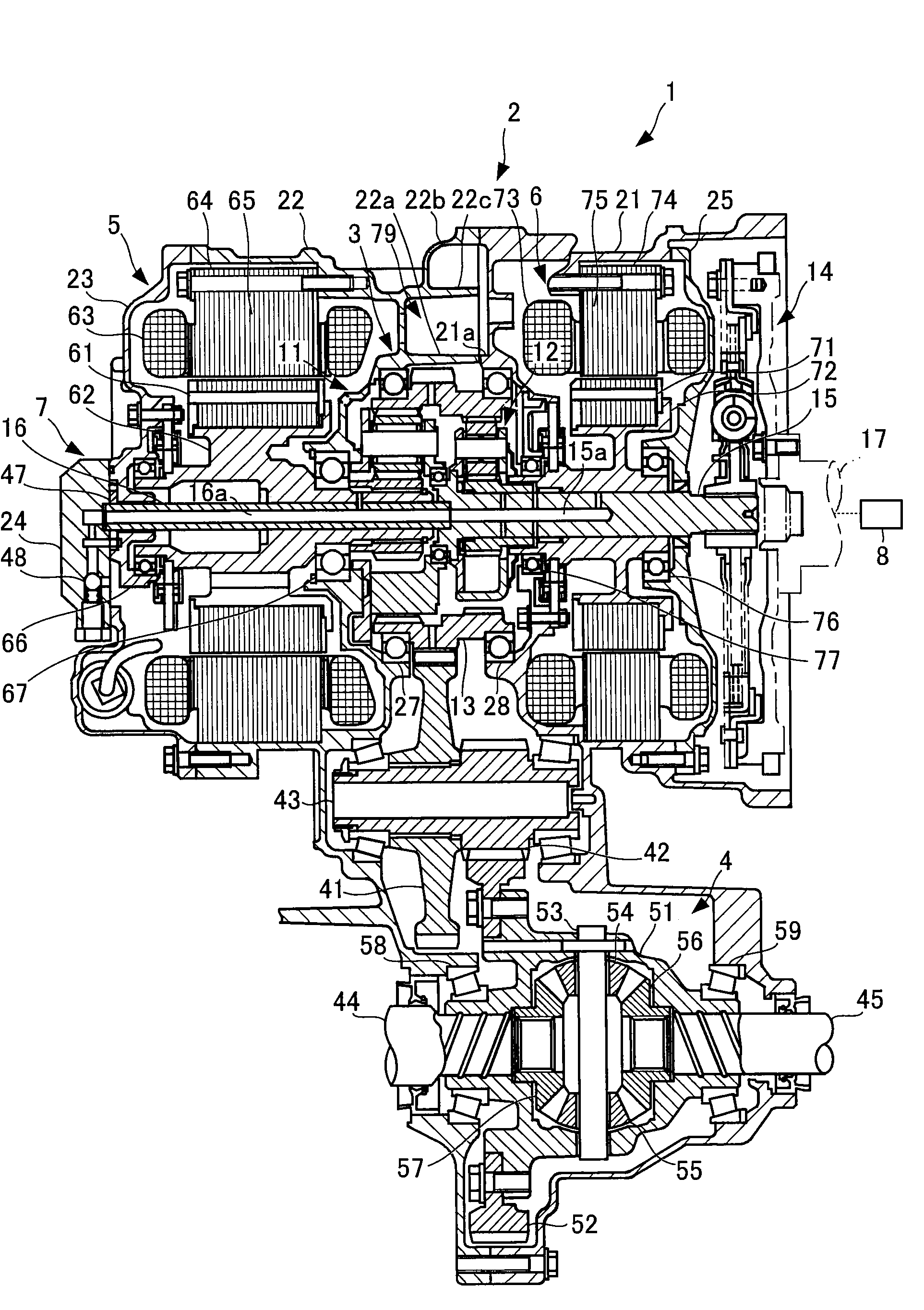

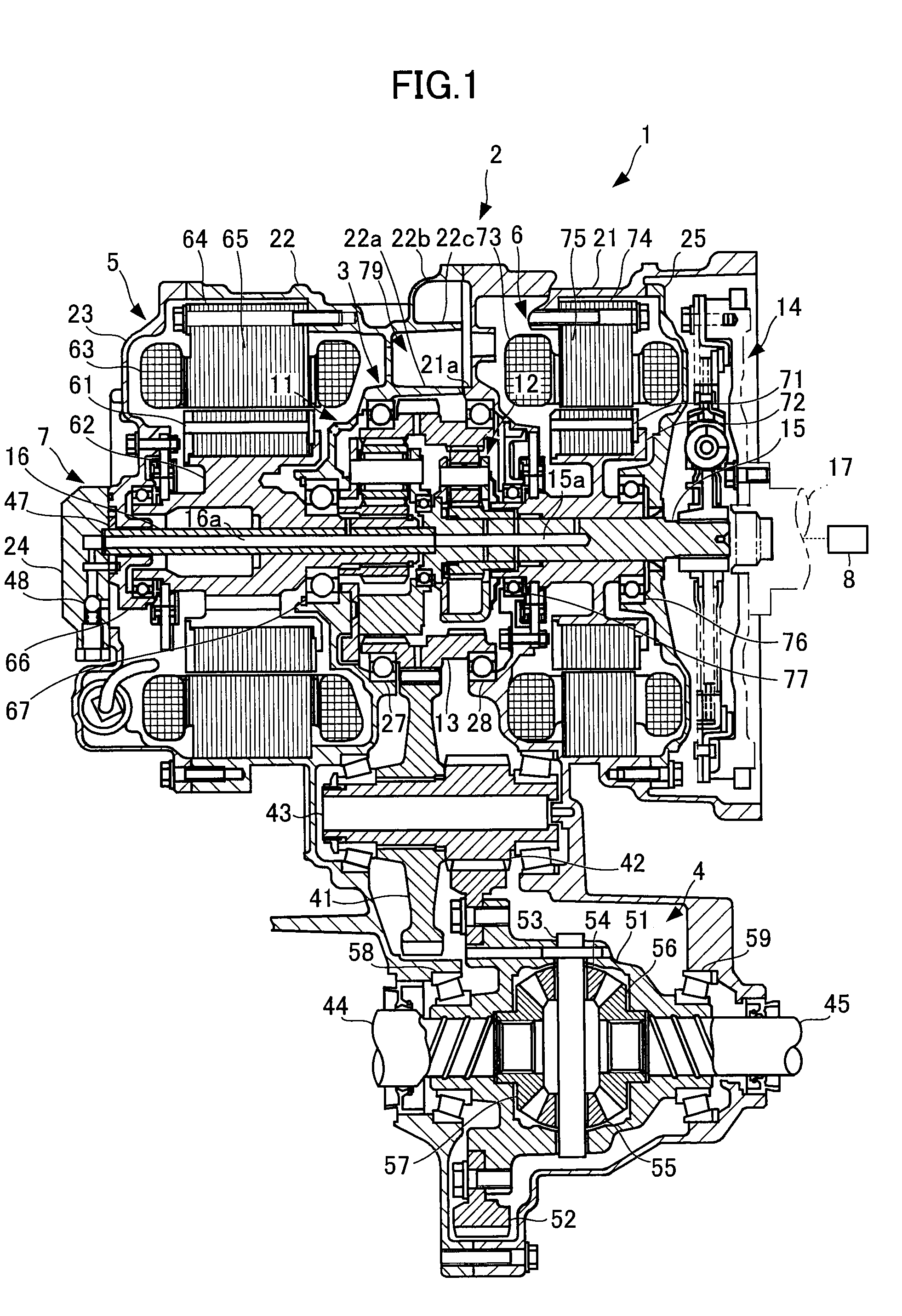

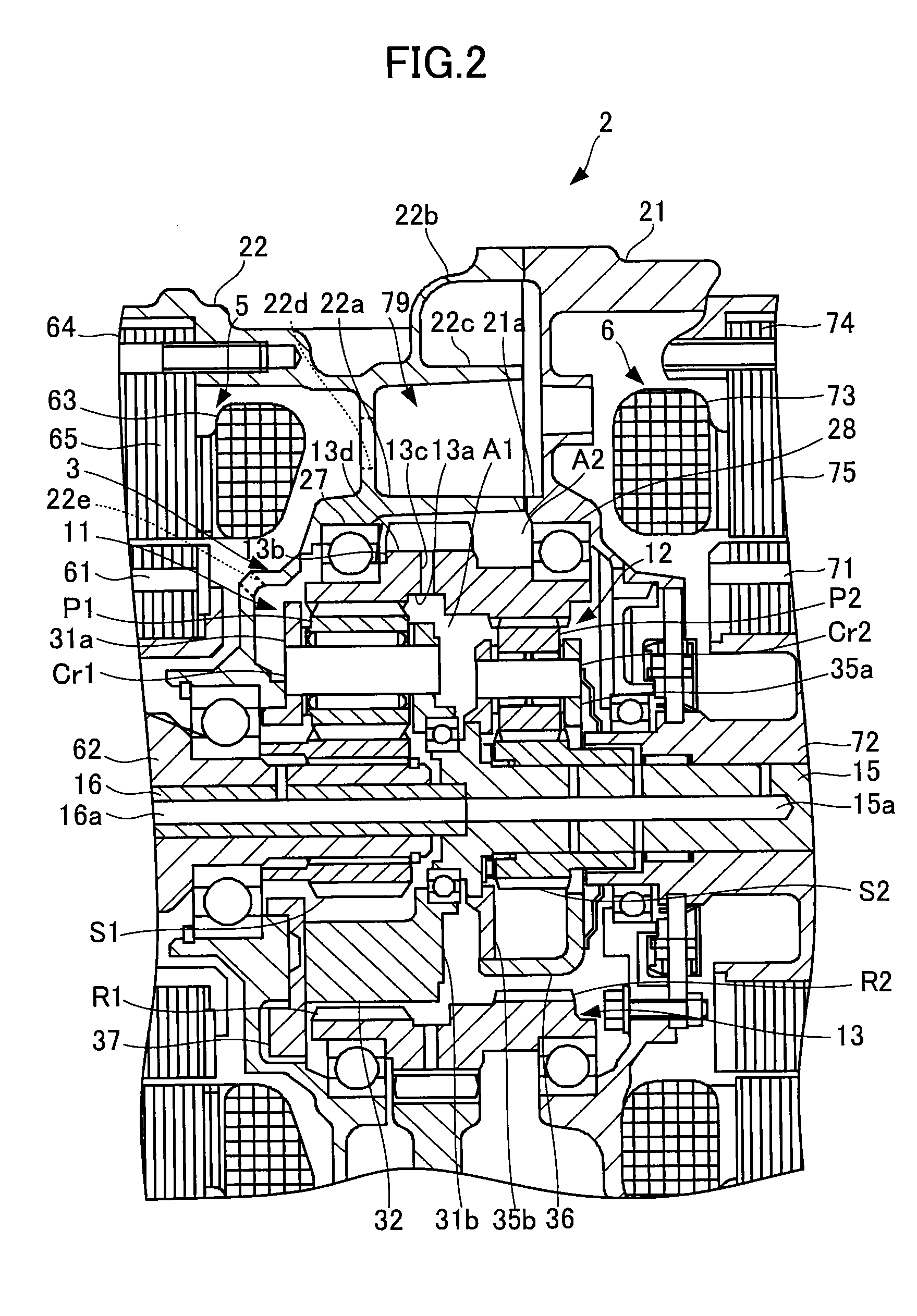

Composite planetary gear apparatus

ActiveUS20090233749A1Large dischargePrevent fuel efficiency be lowHybrid vehiclesElectric propulsion mountingEngineeringFuel efficiency

The composite planetary gear apparatus according to the present invention can bring about an advantageous effect to prevent fuel efficiency from being lowered stemming from the increased stirring loss of oil. The apparatus comprises a first planetary gear assembly 11 having a sun gear S1, pinion gears P1, and a ring gear R1, and a second planetary gear assembly 12 having a sun gear S2, pinion gears P2, and a ring gear R2. The ring gears R1 and R2 surround the pinion gears P1 and P2 and are combined together to integrally form a counter drive gear 13. The counter drive gear 13 is formed with a plurality of through bores 13c each having an inner end opened at a closed space defined by the first and second planetary gear assemblies 11 and 12, and an outer end opened at an outer space surrounding the counter drive gear 13.

Owner:TOYOTA JIDOSHA KK

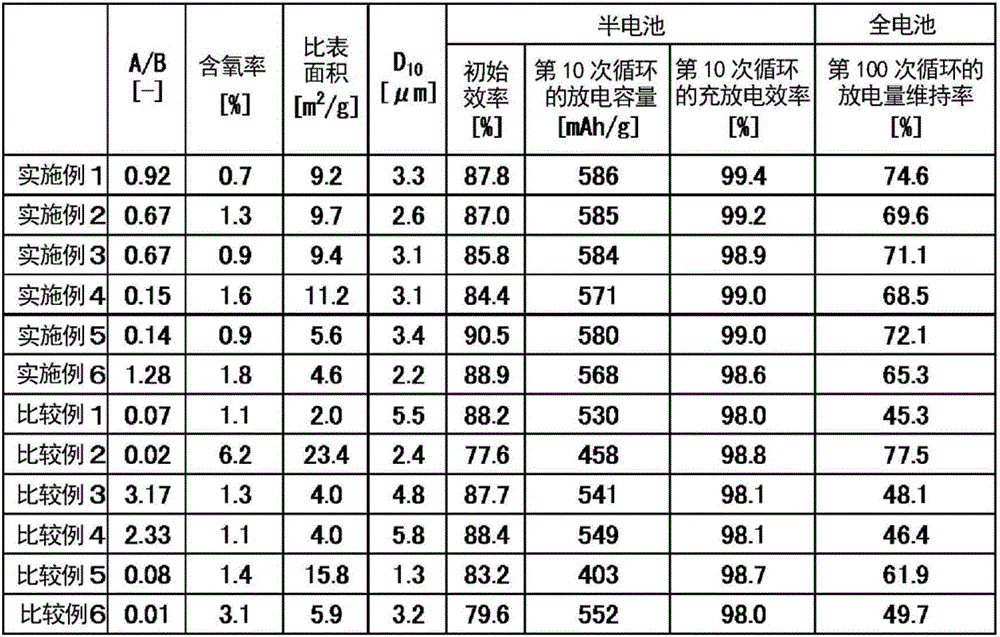

Negative electrode material for lithium-ion battery, and use therefor

ActiveUS20170040610A1Low initial irreversible capacityLarge emissionsNegative electrodesSecondary cellsSilicon oxideGraphitic carbon

A negative electrode material for a lithium ion battery containing a composite material, the composite material including silicon-containing particles, graphitic carbon material particles, and a carbonaceous carbon material, in which the composite material has a ratio (A / B) of an area (A) of a peak near 100 eV derived from metal Si to an area (B) of a peak near 103 eV derived from silicon oxide, as measured by XPS, of not less than 0.10 and not more than 2.30. Also disclosed is a paste including the negative electrode material, as well as a negative electrode for a lithium ion battery including a formed body of the paste and a lithium ion battery including the negative electrode.

Owner:UMICORE AG & CO KG

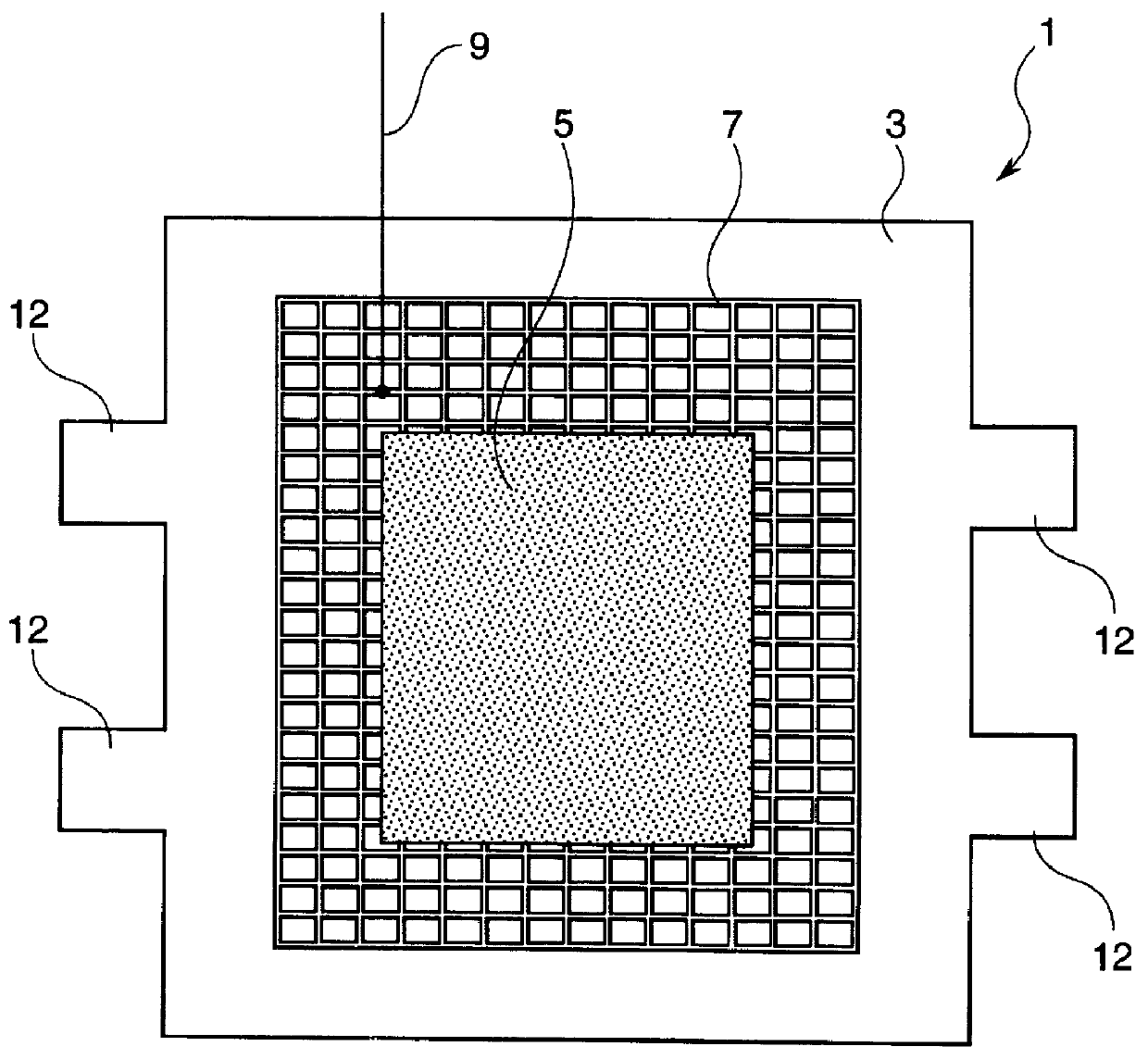

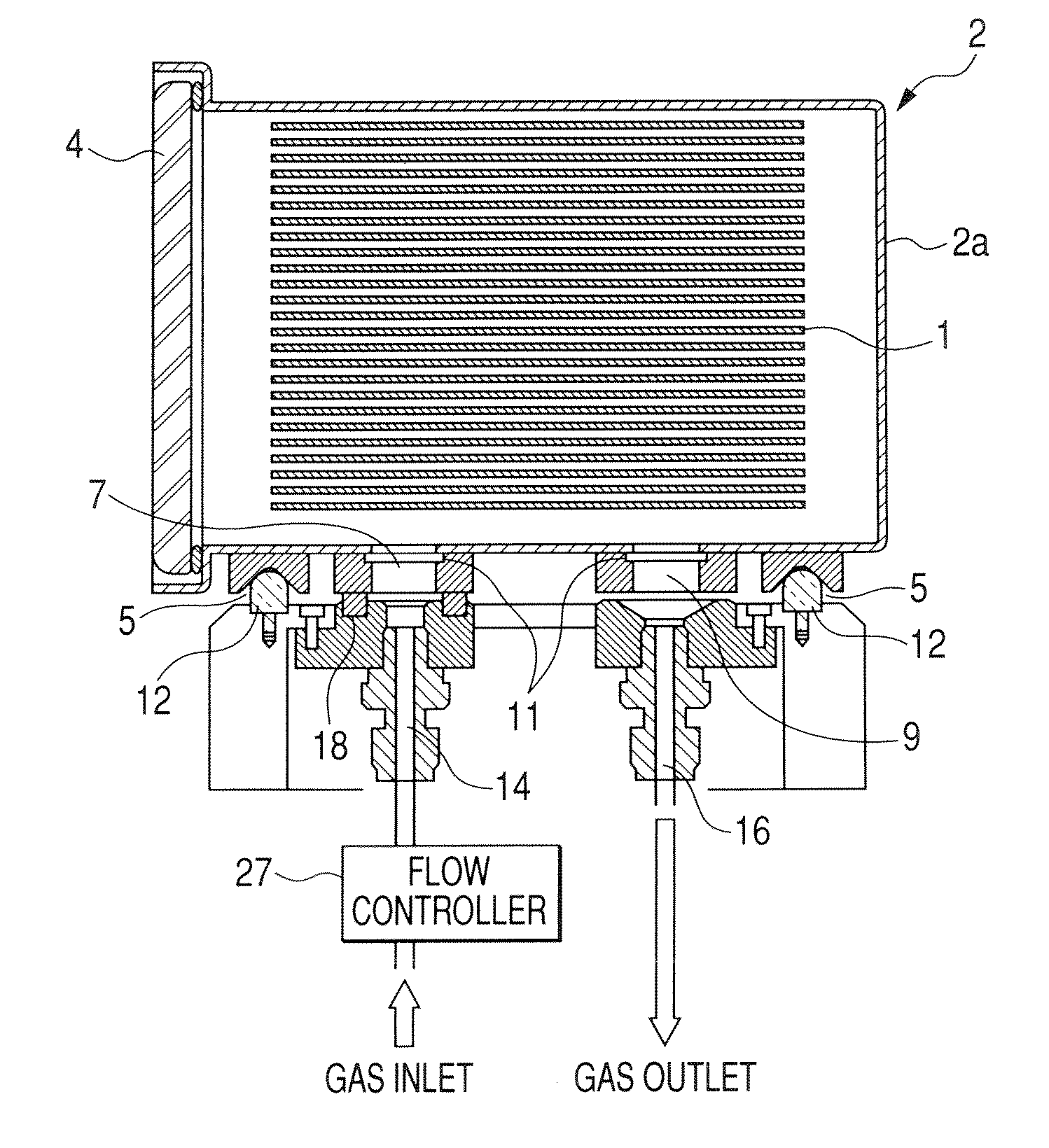

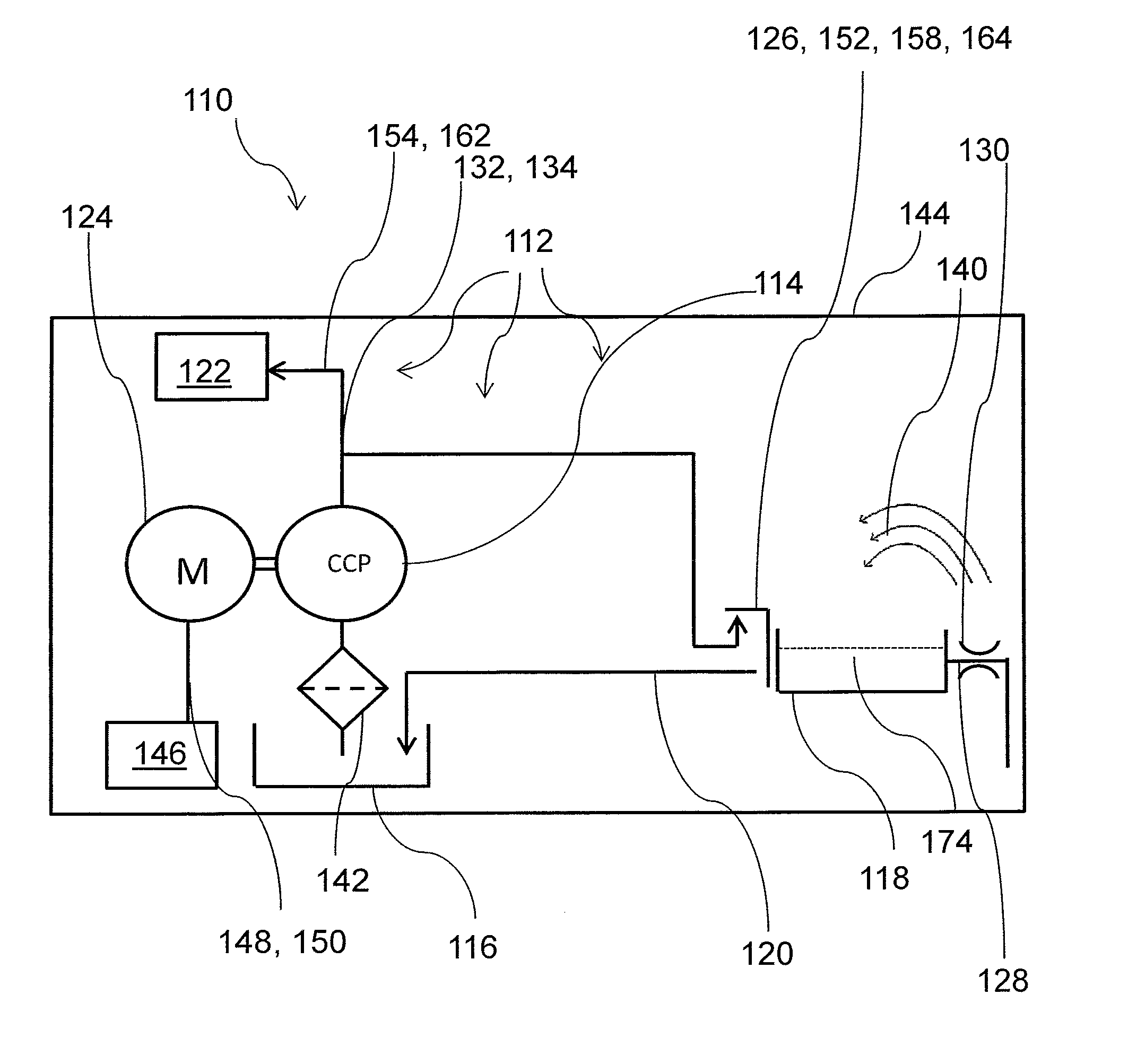

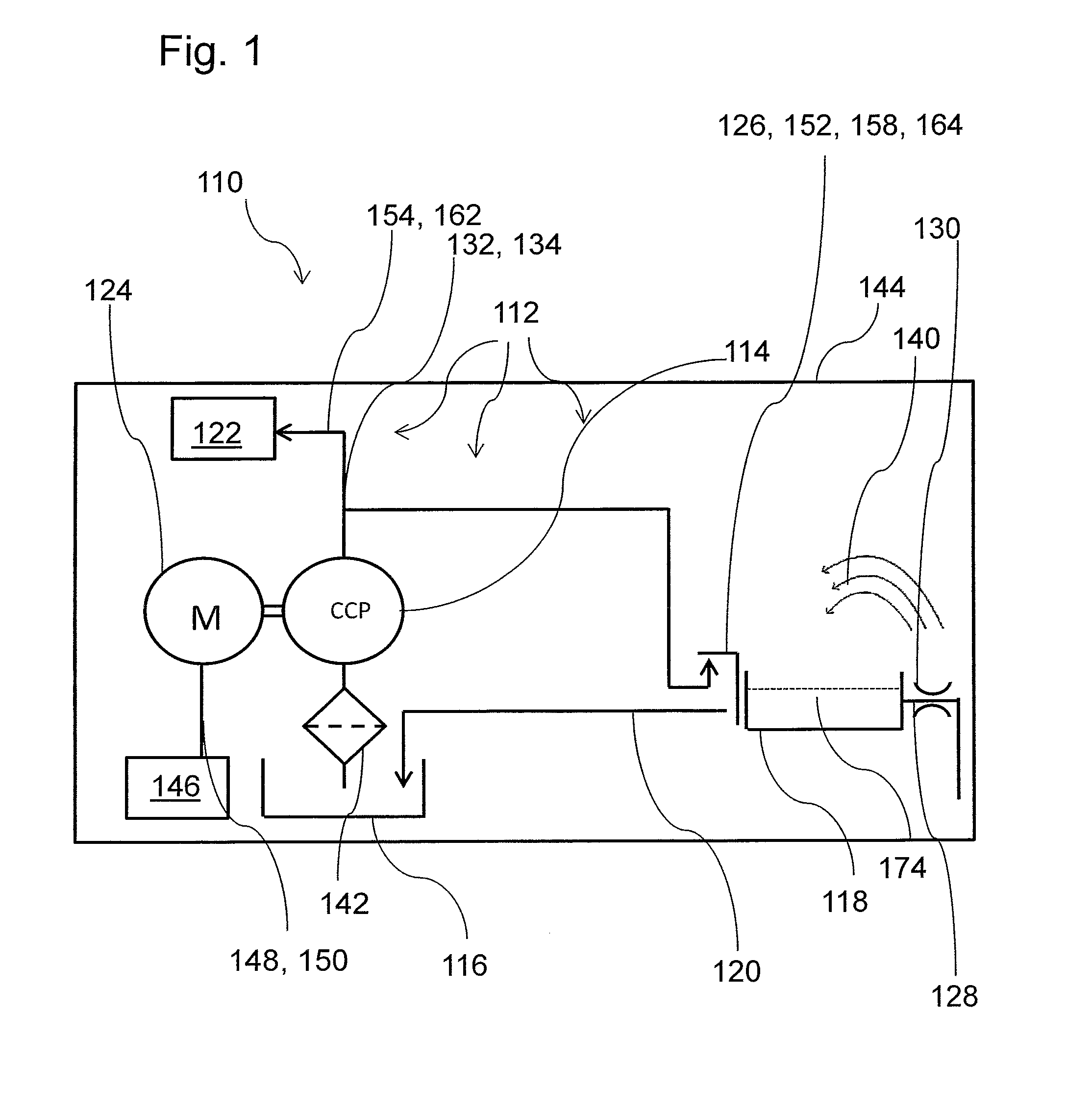

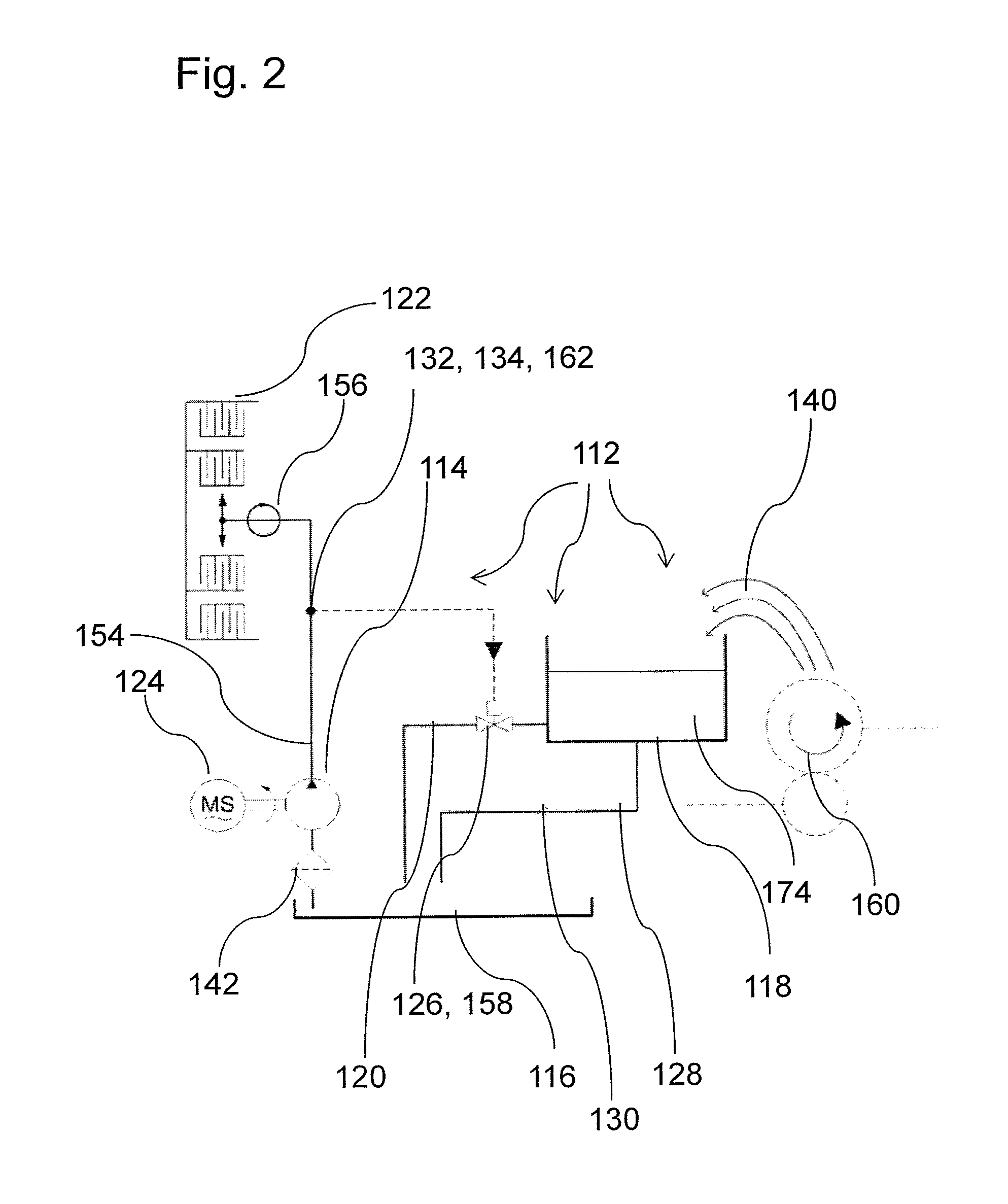

Apparatus for plasma synthesis of metal oxide nanopowder

InactiveUS20050217421A1Large volume dischargeLong residence timeMaterial nanotechnologyPigmenting treatmentProduct gasParticle growth

A process and apparatus for the synthesis of metal oxide nanopowder from a metal compound vapour is presented. In particular a process and apparatus for the synthesis of TiO2 nanopowder from TiCl4 is disclosed. The metal compound vapour is reacted with an oxidizing gas in electrically induced RF frequency plasma thus forming a metal oxide vapour. The metal oxide vapour is rapidly cooled using a highly turbulent gas quench zone which quickly halts the particle growth process, yielding a substantial reduction in the size of metal oxide particles formed compared with known processes. The metal compound vapour can also react with a doping agent to create a doped metal oxide nanopowder. Additionally, a process and apparatus for the inline synthesis of a coated metal oxide is disclosed wherein the metal oxide particles are coated with a surface agent after being cooled in a highly turbulent gas quench zone.

Owner:TEKNA PLASMA SYST INC

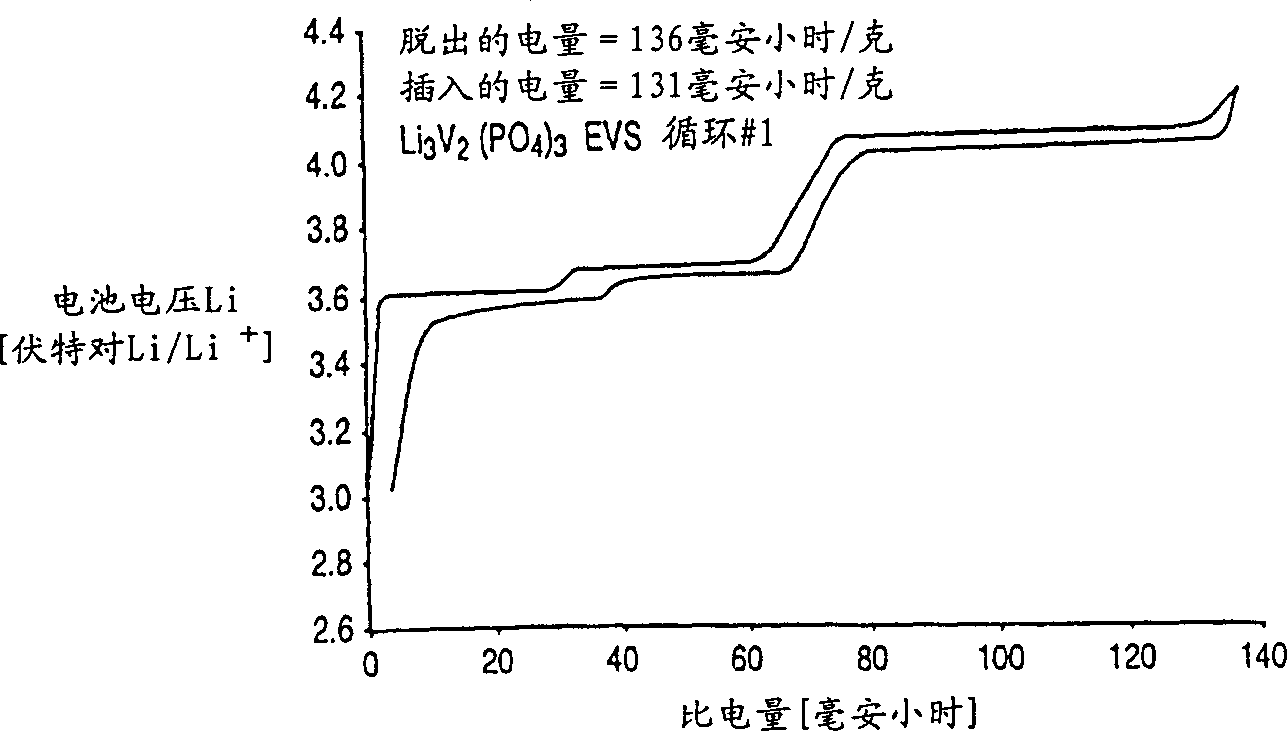

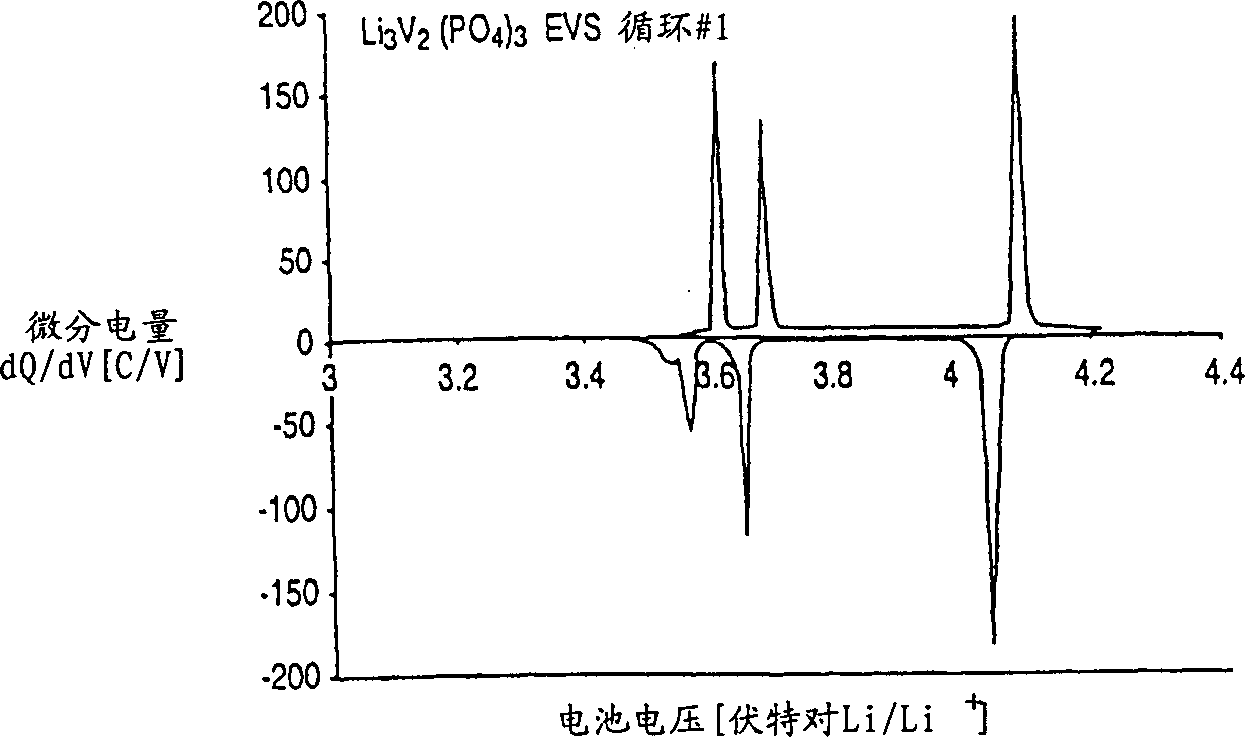

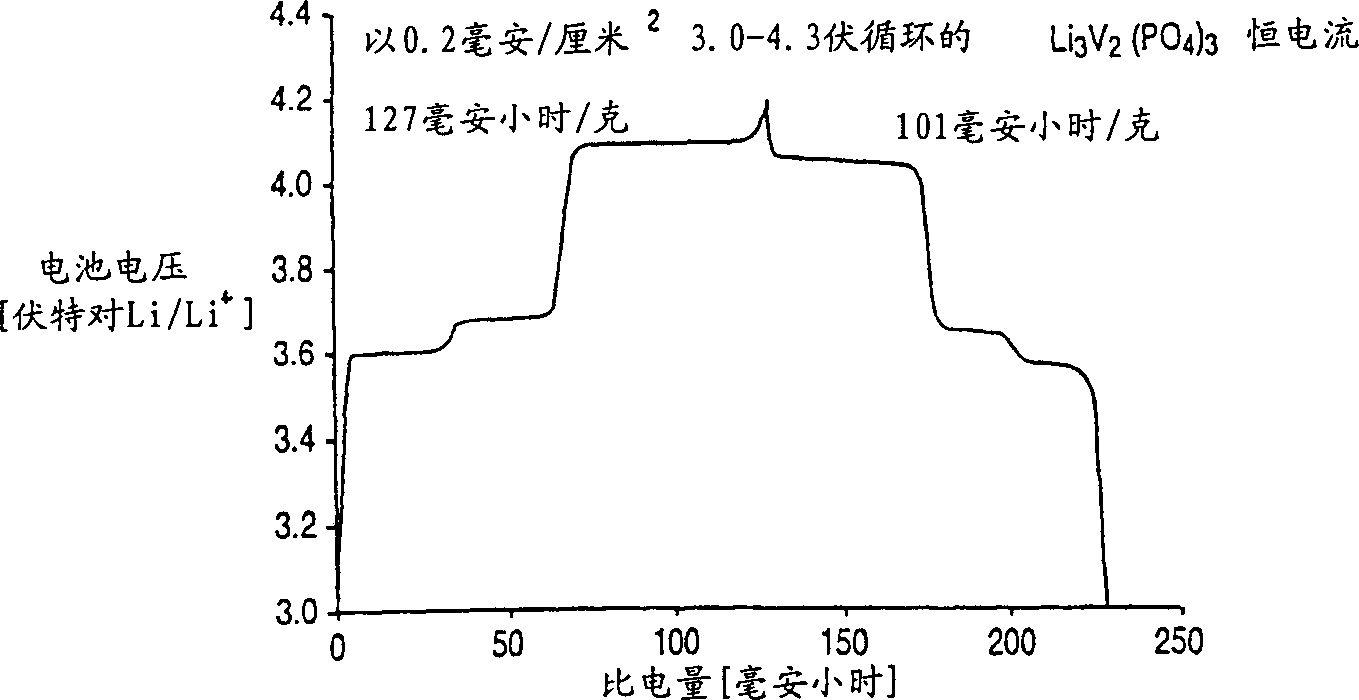

Lithium based phosphates for use in lithium ion batteries and method of preparation

InactiveCN1326595AEasy to manufactureConducive to commercial productionCell electrodesLi-accumulatorsPhosphateLithium metal

The present invention provides an electrochemical cell using an electrode containing a phosphorus compound containing lithium metal.

Owner:VALENCE TECH INC

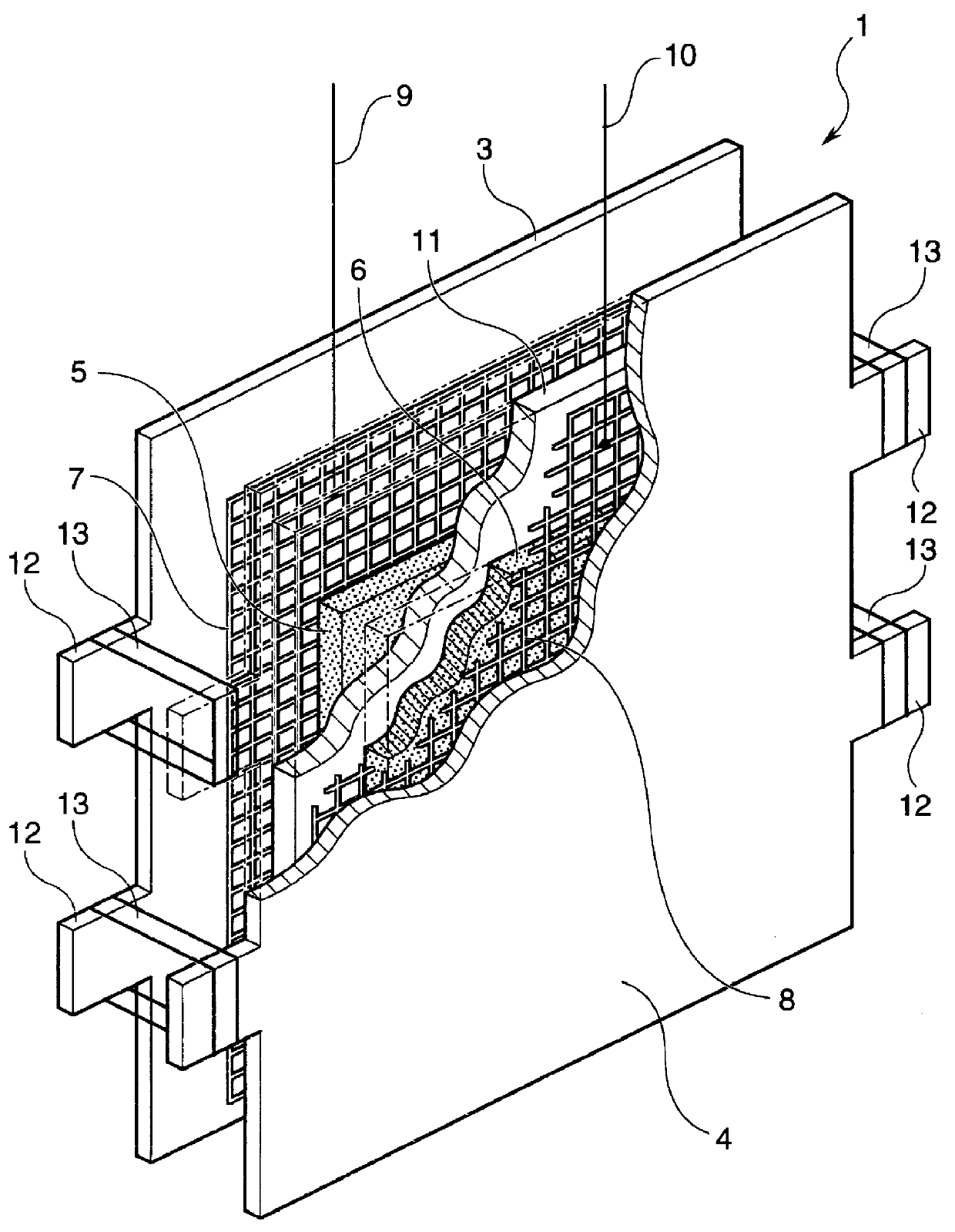

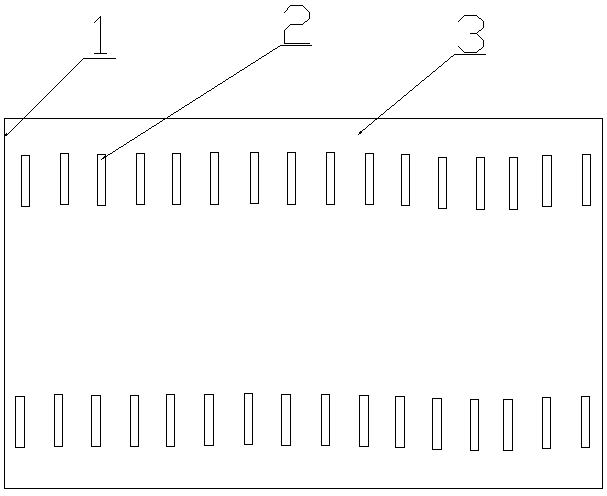

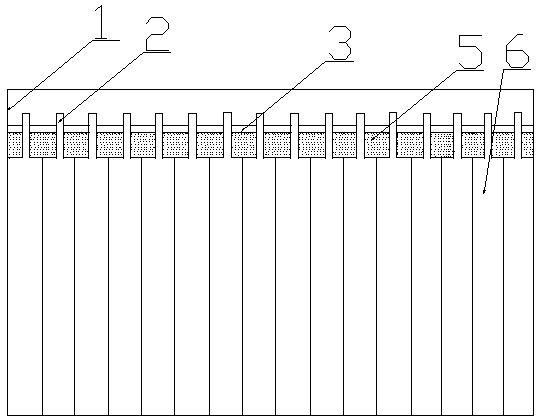

Internal structure of soft package lithium ion battery and assembly method

ActiveCN103647117AIncrease contactNot easy to fall offFinal product manufactureCell component detailsInternal resistanceUltrasonic welding

The invention discloses an internal structure of soft package lithium ion battery, which comprises a housing and a battery equipped in the housing, and EVA is equipped between tabs, and the tab of the battery is provided with a PCB board with through hole, and the tab crosses the PCB board. The invention can guarantee good contact of tab after the electrical core is connected in series connection, and simultaneously guarantee non-falling after welding, and the slit between electrical core tabs can be filled with insulated EVC with high temperature resistance and good formability, and the EVA is a plastic material which is composed of ethene (E) and vinyl acetate (VA). Ultrasonic welding of tab can play the role for reducing internal resistance between insulators and preventing falling caused by unfirm fixing of tab. After welding, scolding tin for tab can play the role for reinforcing soundness of the tab, and simultaneously facilitating link of wire harness. The tab crosses PCB with through hole, thereby reinforcing fixation of tab and increasing anti-compression property of electrical core tab position.

Owner:HENAN FUSEN NEW ENERGY TECH

Process for producing positive electrode active material for lithium secondary battery

InactiveUS20050220701A1Large volume capacity densityImprove securityAluminium compoundsElectrode thermal treatmentProduction rateLithium carbonate

To provide a process for producing a lithium-cobalt composite oxide for a positive electrode of a lithium secondary battery excellent in volume capacity density, safety, charge and discharge cyclic durability, press density and productivity, by using in expensive cobalt hydroxide and lithium carbonate. A mixture having a cobalt hydroxide powder and a lithium carbonate powder mixed so that the atomic ratio of lithium / cobalt would be from 0.98 to 1.01, is fired in an oxygen-containing atmosphere at from 250 to 700° C., and the fired product is further fired in an oxygen-containing atmosphere at from 850 to 1,050° C., or such a mixture is heated at a temperature-raising rate of at most 4° C. / min in a range from 250 to 600° C. and fired in an oxygen-containing atmosphere at from 850 to 1,050° C.

Owner:SEIMI CHEM CO LTD

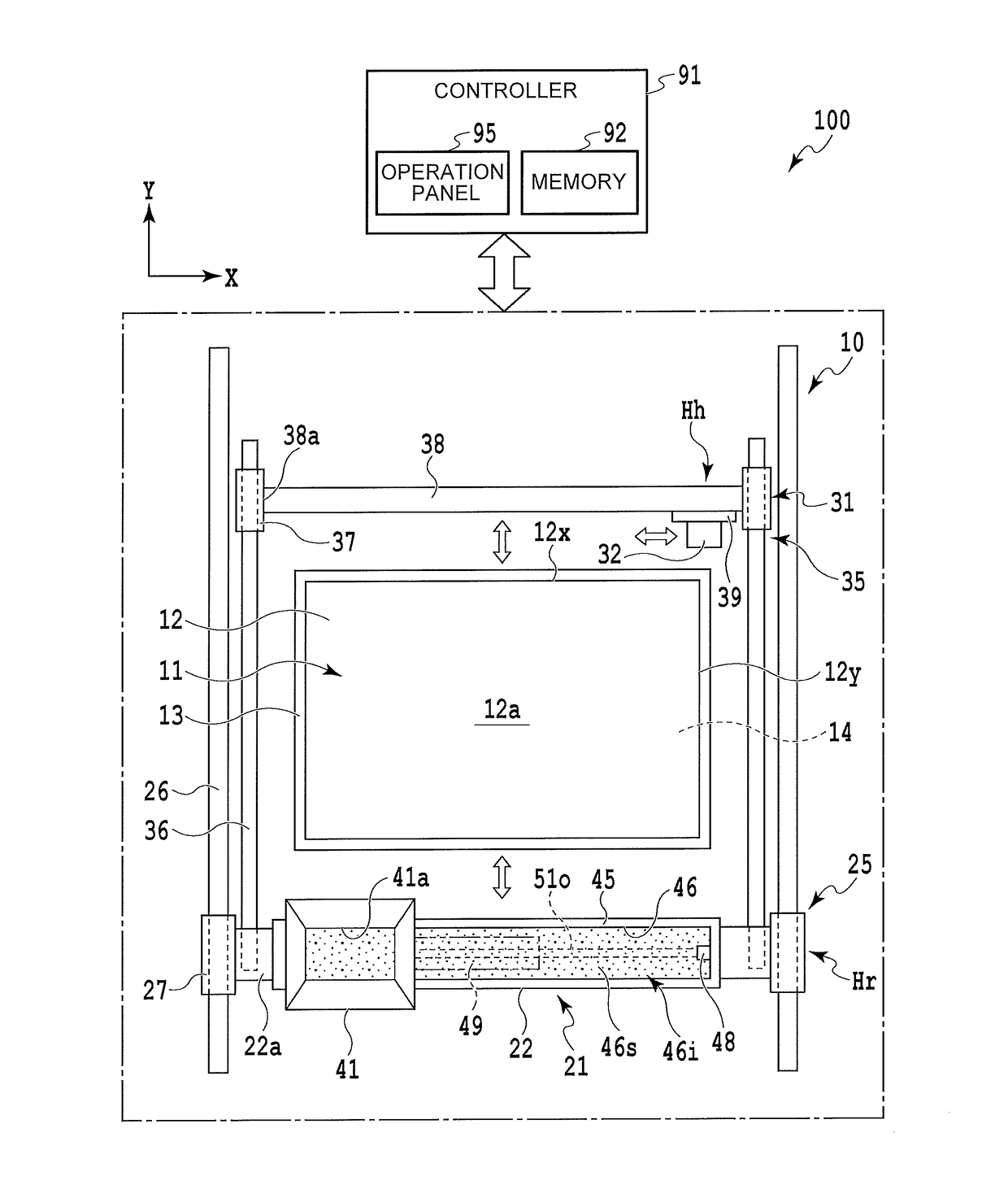

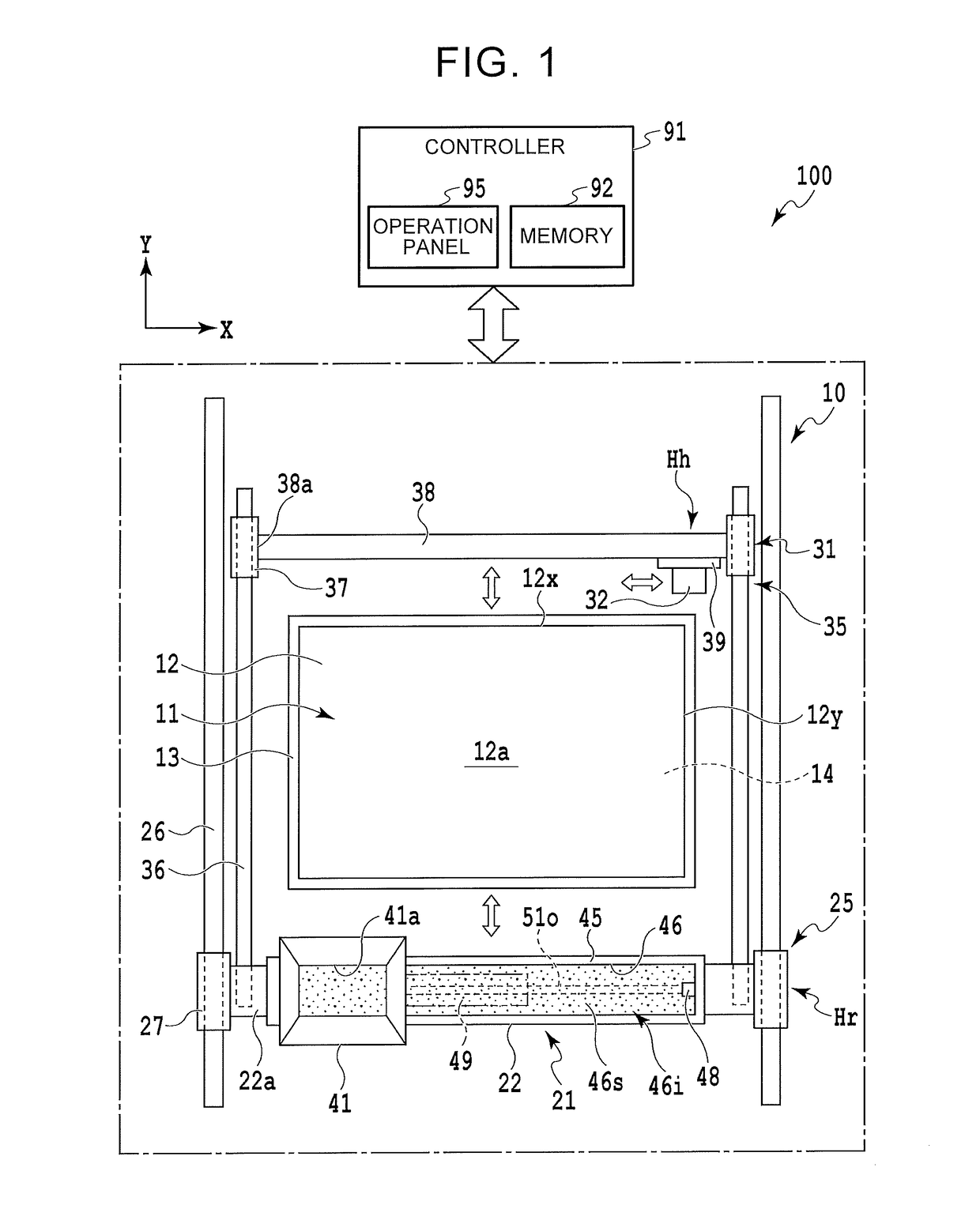

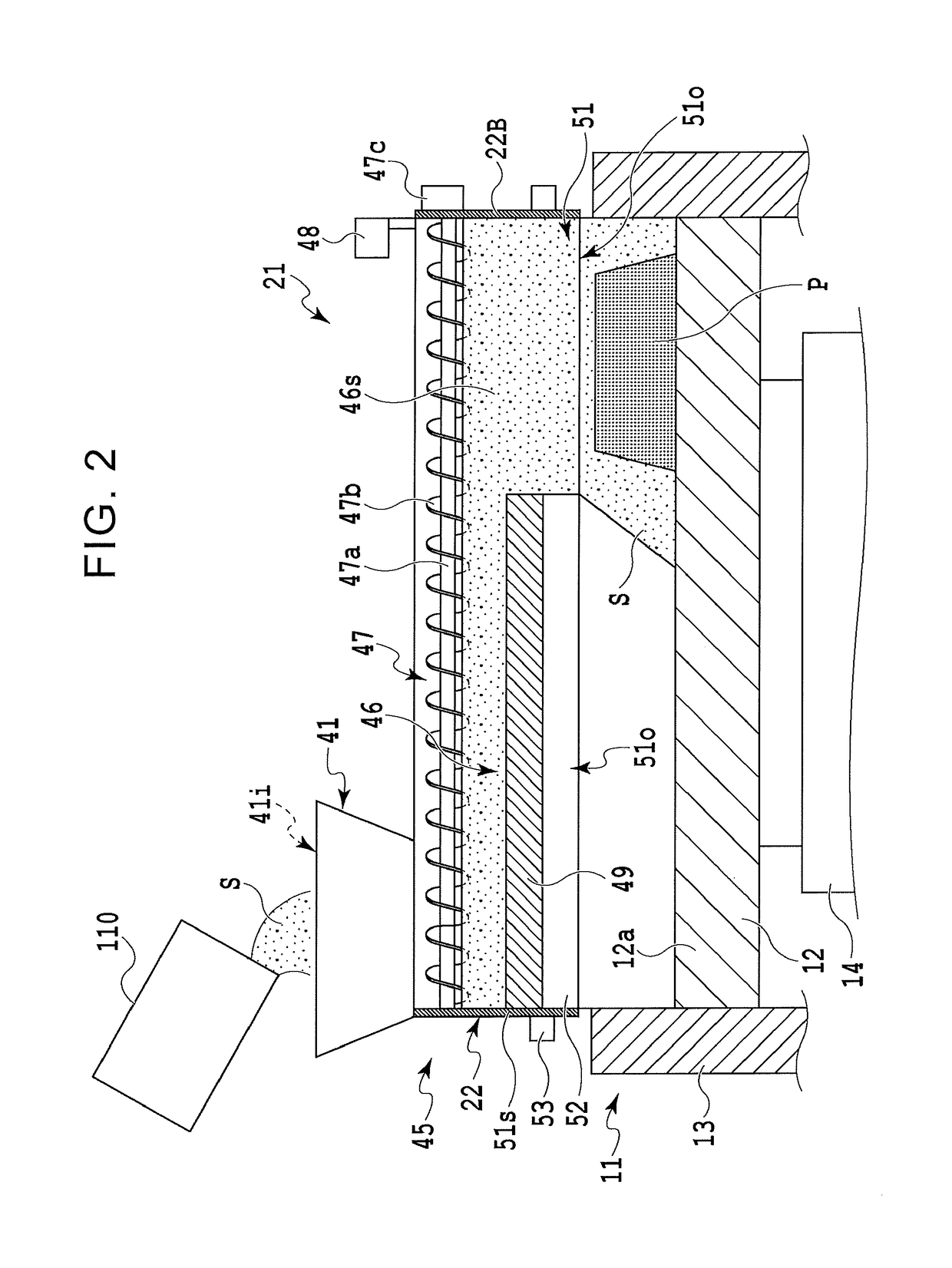

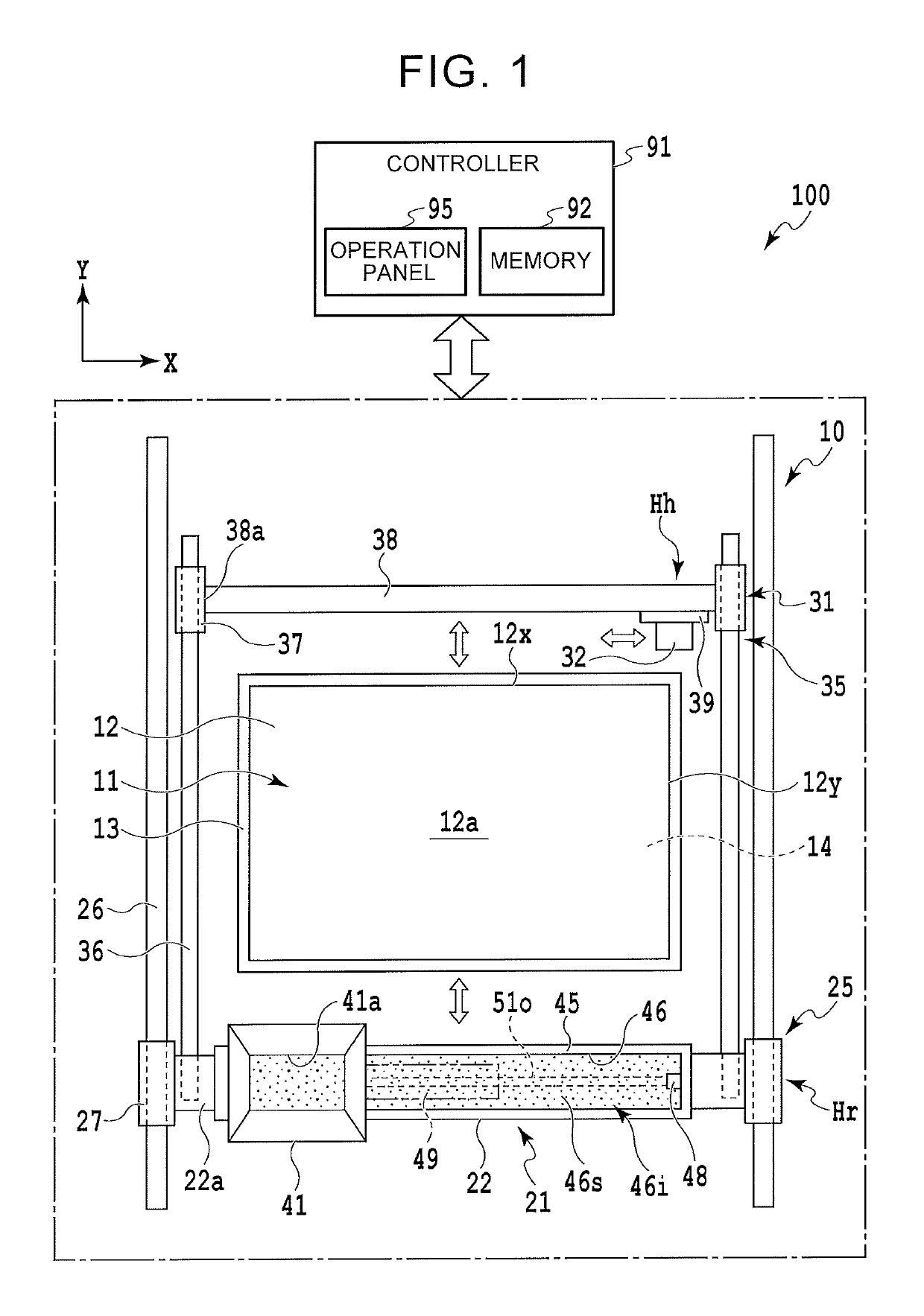

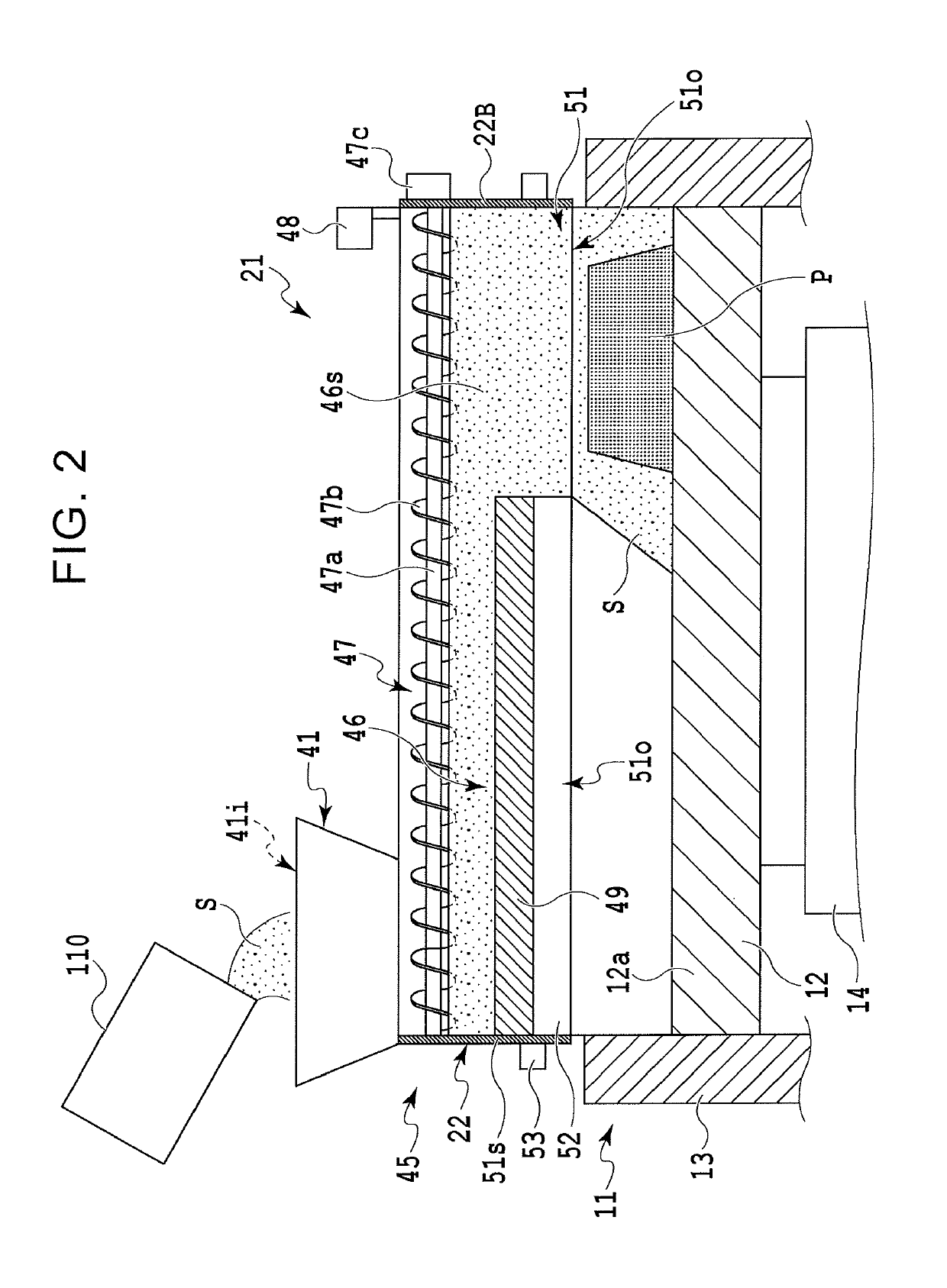

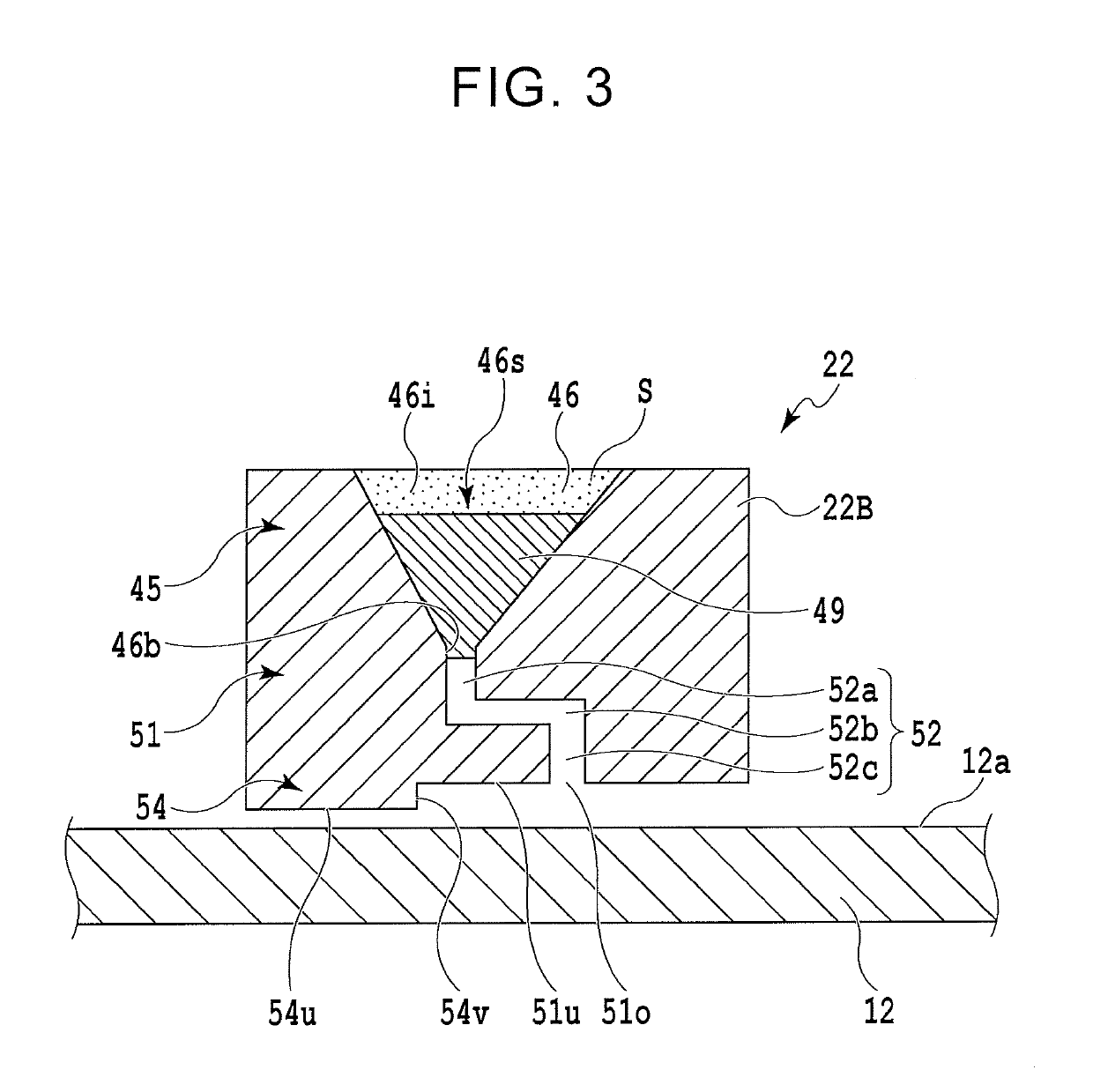

Three-dimensional molding device and three-dimensional molding method

ActiveUS20180043616A1Reduce workloadLarge dischargeManufacturing enclosures3D object support structuresReciprocating motionMaterials science

The three-dimensional molding device includes a recoater configured to discharge a granular material from a discharge port onto the molding table such that the granular material is superimposed in layer, an solidification device configured to solidify a partial region of the granular material in a plane solidification device direction of an upper surface of the molding table, a moving mechanism configured to cause the recoater to reciprocate in a plane direction parallel to the upper surface of the molding table, and at least one plug member configured to close a part of an opening in at least one location in a longitudinal direction of the discharge port of the recoater and limit a discharge range of the granular material.

Owner:TOYOTA JIDOSHA KK

Gearbox for a motor vehicle

ActiveUS20150345616A1Large dischargeAvoid small quantitiesGear lubrication/coolingEngineeringState variable

A gearbox for a motor vehicle. The gearbox comprises at least one fluid supply system. The fluid supply system comprises at least one pump. The fluid supply system comprises at least one fluid sump. The fluid supply system comprises at least one fluid reservoir. The fluid reservoir comprises at least a first fluid outflow leading into the fluid sump. The first fluid outflow can be controlled as a function of a state variable.

Owner:GETRAG GETRIEBE & ZAHNRADFABRIK HERMANN HAGENMEYER GMBH & CO KG

Waste lead-acid storage battery repair activator and preparation method thereof

ActiveCN111180805AEffective protectionNot prone to delaminationLead-acid accumulatorsSecondary cells servicing/maintenanceElectrolytic agentCarbon nanotube

The invention discloses a waste lead-acid storage battery repair activator and a preparation method thereof. The activator is prepared from 15-30 parts by weight of mother liquor, 3-5 parts by weightof carbon nano tubes, 4-7 parts by weight of sodium sulfate, 5-8 parts by weight of cobalt sulfate, 4-9 parts by weight of copper sulfate and 50-70 parts by weight of deionized water, wherein the mother liquor is prepared from 0.2-0.8 wt% of super absorbent resin, 0.5-3 wt% of fumed silica and the balance of deionized water. According to the waste lead-acid storage battery repair activator, decomposition of originally non-conductive lead sulfate is accelerated, it is guaranteed that the temperature of the storage battery is not excessively increased when high-frequency current is activated, the storage battery is effectively protected, and due to the fact that the activating agent is made of super absorbent resin according to the multi-encapsulation theory, electrolyte molecules are wrapped with one another, and the layering phenomenon is not likely to happen.

Owner:内蒙古华贵科技开发有限公司

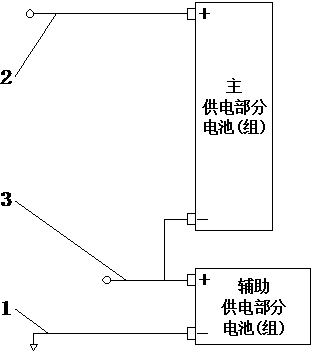

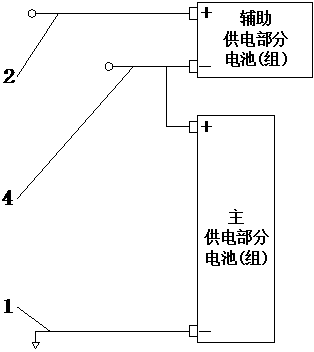

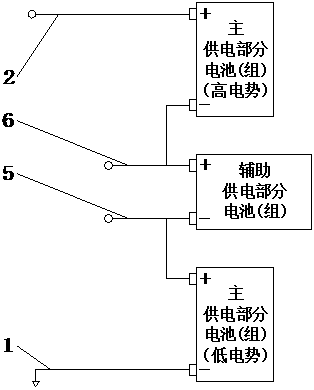

Mixedly marshaled battery pack and mixed marshaling method of battery pack

InactiveCN104638291ALarge dischargeAvoid lossFinal product manufactureSecondary cells manufactureDc dc converterElectrical battery

The invention discloses a mixedly marshaled battery pack and a mixed marshaling method of the battery pack. According to the mixedly marshaled battery pack, batteries of different capacities are connected in series or in series and in parallel in a mixed marshaling manner, or multiple batteries of same capacity are connected in series and in parallel in a mixed marshaling manner, the rated capacities of corresponding batteries (packs) of unit voltage in the whole marshaled battery pack are not completely same, and power supply leads are arranged at two ends of the batteries (packs) with relatively high capacities and are capable of supplying power outsides, so that a group of battery packs with integrated voltage can be provided for supplying power outsides, and one or multiple groups of auxiliary power supplies with voltages lower than the voltage of the battery packs are further provided for supplying power outsides. The mixedly marshaled battery pack has the beneficial effects that a DC-DC converter matched with the battery pack can be omitted, so that the electric energy loss in a voltage conversion process is avoided, meanwhile, the weight, the size and the cost of a system is reduced, and the reliability of the system is improved; the mixedly marshaled battery pack is convenient to maintain and safe to use.

Owner:BEIJING SAMEVOLT CO LTD

Negative electrode material for lithium-ion battery, and use therefor

ActiveCN106233511AImprove efficiencyImprove charge and discharge cycle characteristicsNegative electrodesSecondary cellsSilicon oxideLithium-ion battery

A negative electrode material for lithium-ion batteries that comprises a composite material that includes silicon-containing particles, graphite carbonaceous material particles, and a carbon carbonaceous material. Upon observation of the composite material by XPS measurement, the ratio (A / B) of the area (A) of the peak derived from metallic Si near 100eV relative to the area (B) of the peak derived from silicon oxide near 103eV is 0.10-2.30. A lithium-ion battery can be obtained using said negative electrode material.

Owner:UMCORE

Process for producing mesophase pitch based active carbon fiber, mesophase pitch based active carbon fiber and electric double layer capacitor

InactiveUS20040047111A1High bulk densityExcellent charging and discharging performanceElectrolytic capacitorsMagnetic/electric field screeningActive carbonCharge and discharge

A process for producing a mesophase pitch based active carbon fiber, comprising the steps of carbonizing a mesophase pitch based infusibilized fiber at 600 to 900° C., activating the thus obtained carbon fiber with alkali, and immersing the thus obtained mesophase pitch based active carbon fiber in an electrolyte and subjecting the immersed mesophase pitch based active carbon fiber to such a charge and discharge treatment that a voltage gradually increased until exceeding 2.5 V is applied at a constant current density to the mesophase pitch based active carbon fiber so that an electric double layer is formed at an interface of the mesophase pitch based active carbon fiber and the electrolyte to thereby effect a charging and thereafter a discharging is effected at a constant current density. There are further provided an active carbon fiber produced by the above process and an electric double layer capacitor including an electrode comprising this active carbon fiber.

Owner:HONDA MOTOR CO LTD

Process for producing positive electrode active material for lithium secondary battery

InactiveUS7270797B2Solve the small densityImprove securityAluminium compoundsElectrode thermal treatmentProduction rateLithium carbonate

To provide a process for producing a lithium-cobalt composite oxide for a positive electrode of a lithium secondary battery excellent in volume capacity density, safety, charge and discharge cyclic durability, press density and productivity, by using in expensive cobalt hydroxide and lithium carbonate. A mixture having a cobalt hydroxide powder and a lithium carbonate powder mixed so that the atomic ratio of lithium / cobalt would be from 0.98 to 1.01, is fired in an oxygen-containing atmosphere at from 250 to 700° C., and the fired product is further fired in an oxygen-containing atmosphere at from 850 to 1,050° C., or such a mixture is heated at a temperature-raising rate of at most 4° C. / min in a range from 250 to 600° C. and fired in an oxygen-containing atmosphere at from 850 to 1,050° C.

Owner:AGC SEIMI CHEM CO LTD

Negative electrode material for lithium-ion battery, and use therefor

ActiveUS10164257B2Low initial irreversible capacityLarge discharge amount per massSecondary cellsNegative electrodesSilicon oxideGraphite

A negative electrode material for a lithium ion battery containing a composite material, the composite material including silicon-containing particles, graphitic carbon material particles, and a carbonaceous carbon material, in which the composite material has a ratio (A / B) of an area (A) of a peak near 100 eV derived from metal Si to an area (B) of a peak near 103 eV derived from silicon oxide, as measured by XPS, of not less than 0.10 and not more than 2.30. Also disclosed is a paste including the negative electrode material, as well as a negative electrode for a lithium ion battery including a formed body of the paste and a lithium ion battery including the negative electrode.

Owner:UMICORE AG & CO KG

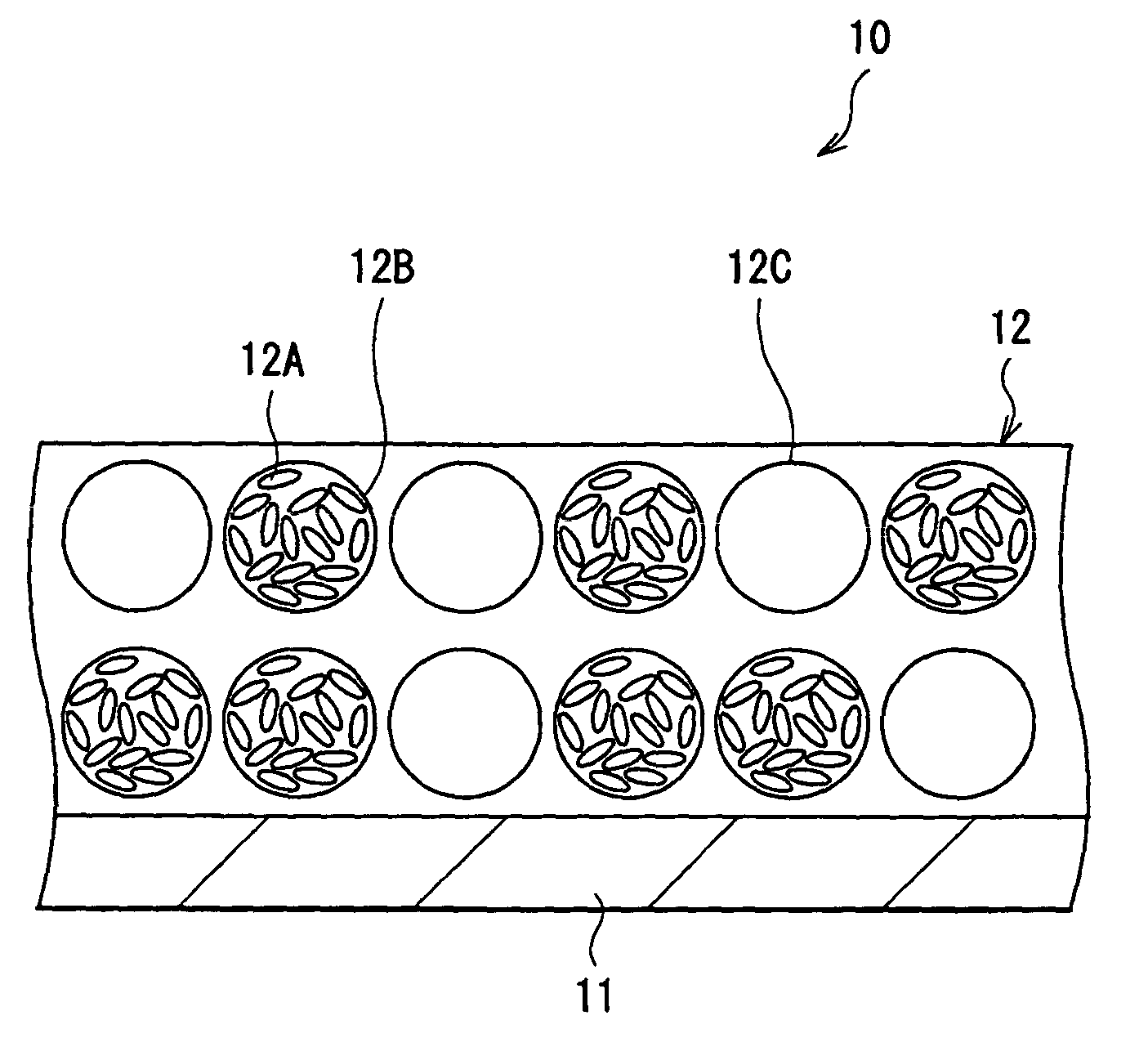

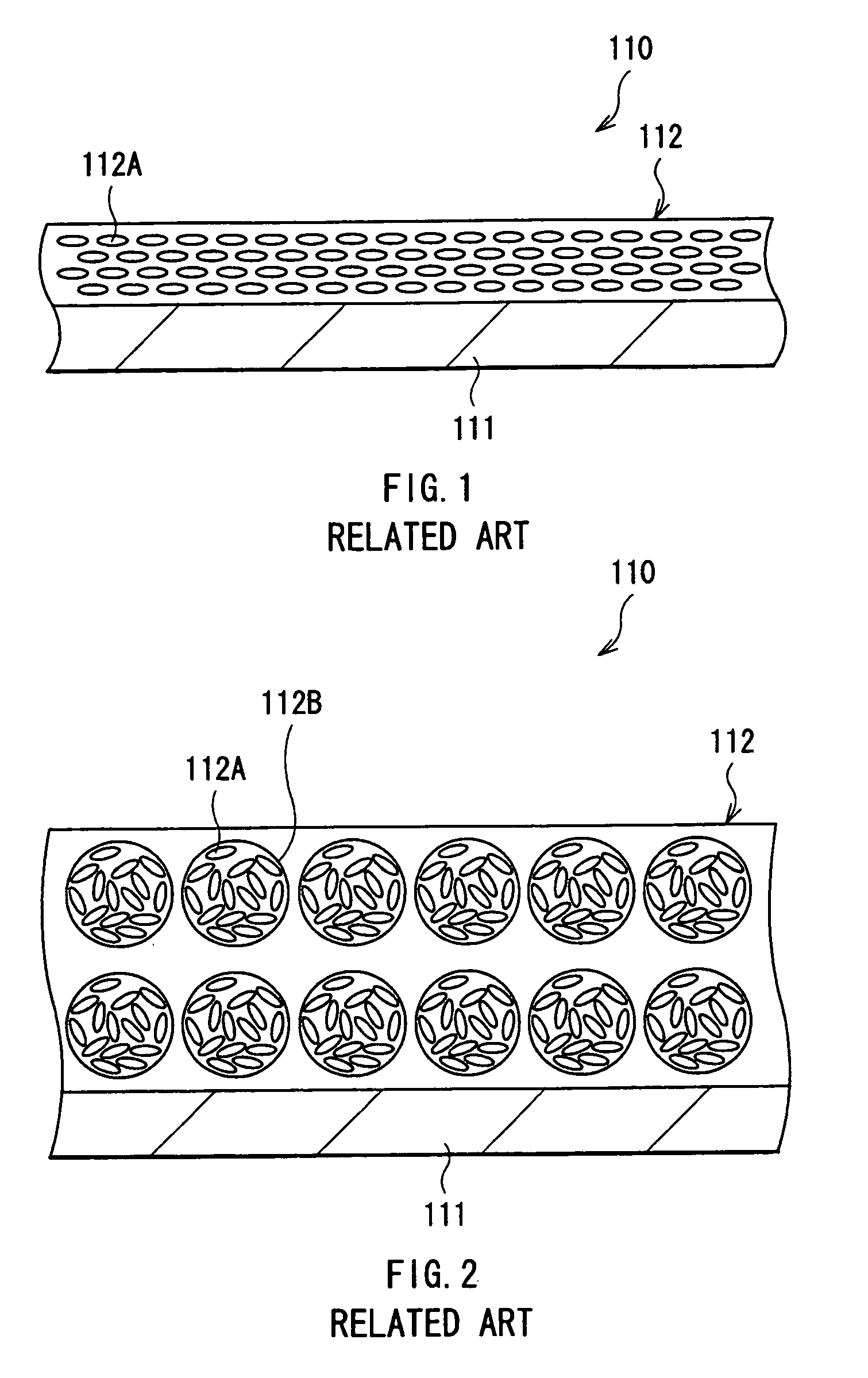

Anode and battery using same

ActiveUS20060183023A1Improve battery capacityIncrease battery capacityNon-aqueous electrolyte accumulatorsNegative electrodesCurrent collectorAnode

An anode and a battery, which have a high capacity and can improve battery characteristics such as large current discharge characteristics and low temperature discharge characteristics are provided. An anode has an anode current collector and an anode active material layer provided on the anode current collector. The density of the anode active material layer is in the range from 1.5 g / cm3 to 1.8 g / cm3. Further, the anode active material layer contains a granulated graphite material which is obtained by granulating a flat graphite particle in nodular shape and mesocarbon microbeads. Thereby, the granulated graphite material is prevented from being destroyed, and diffusion path of lithium ions is secured.

Owner:MURATA MFG CO LTD

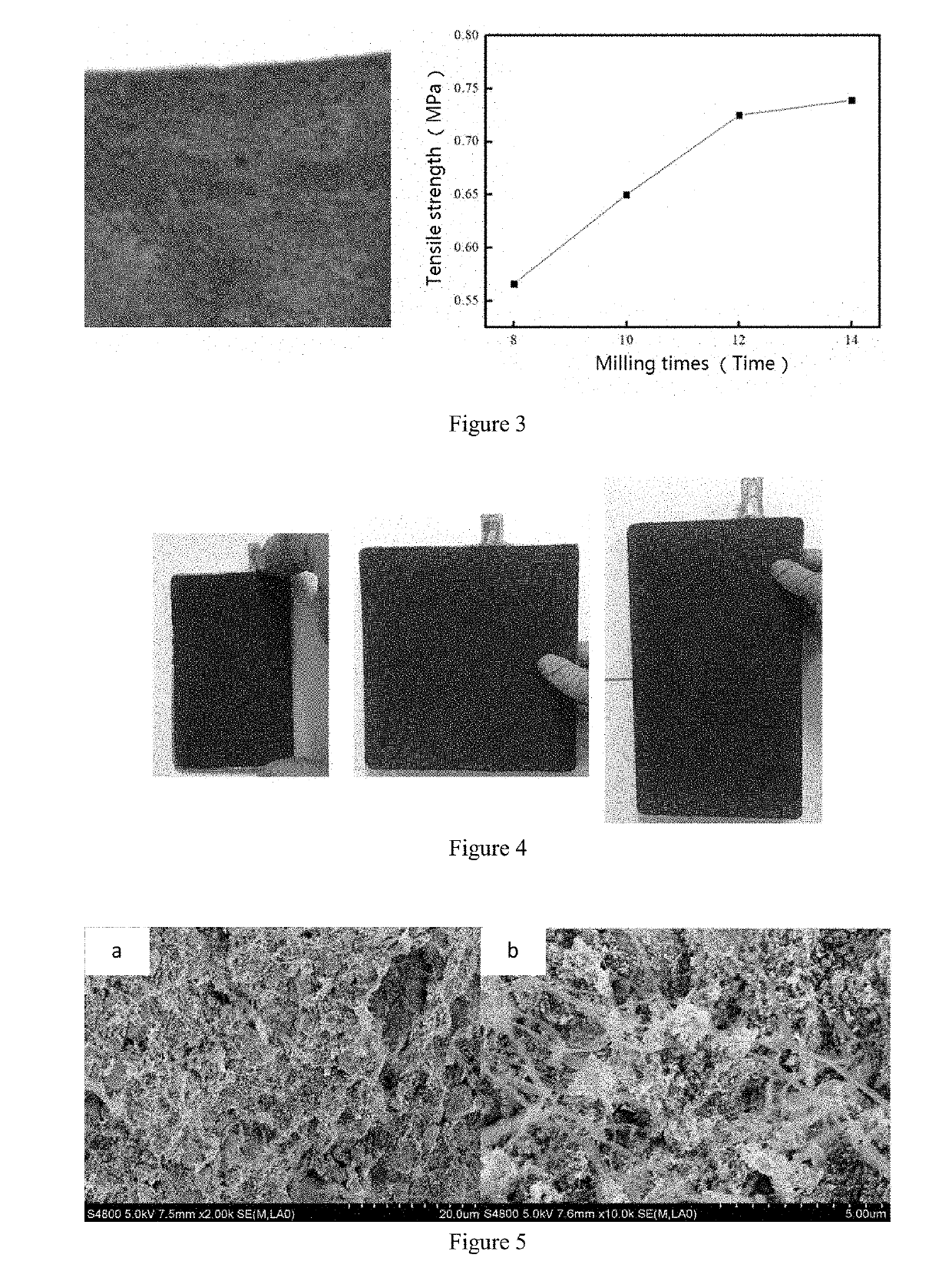

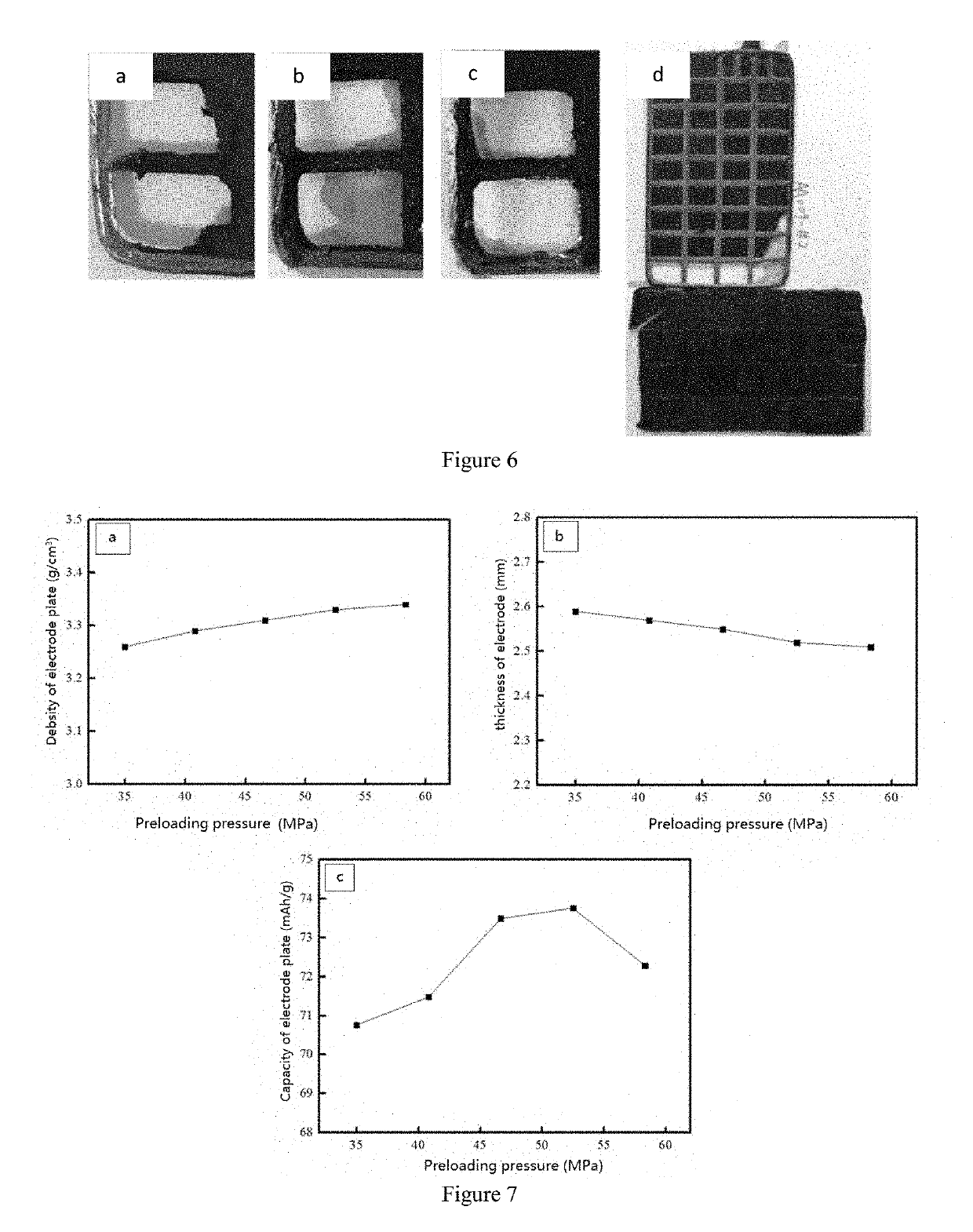

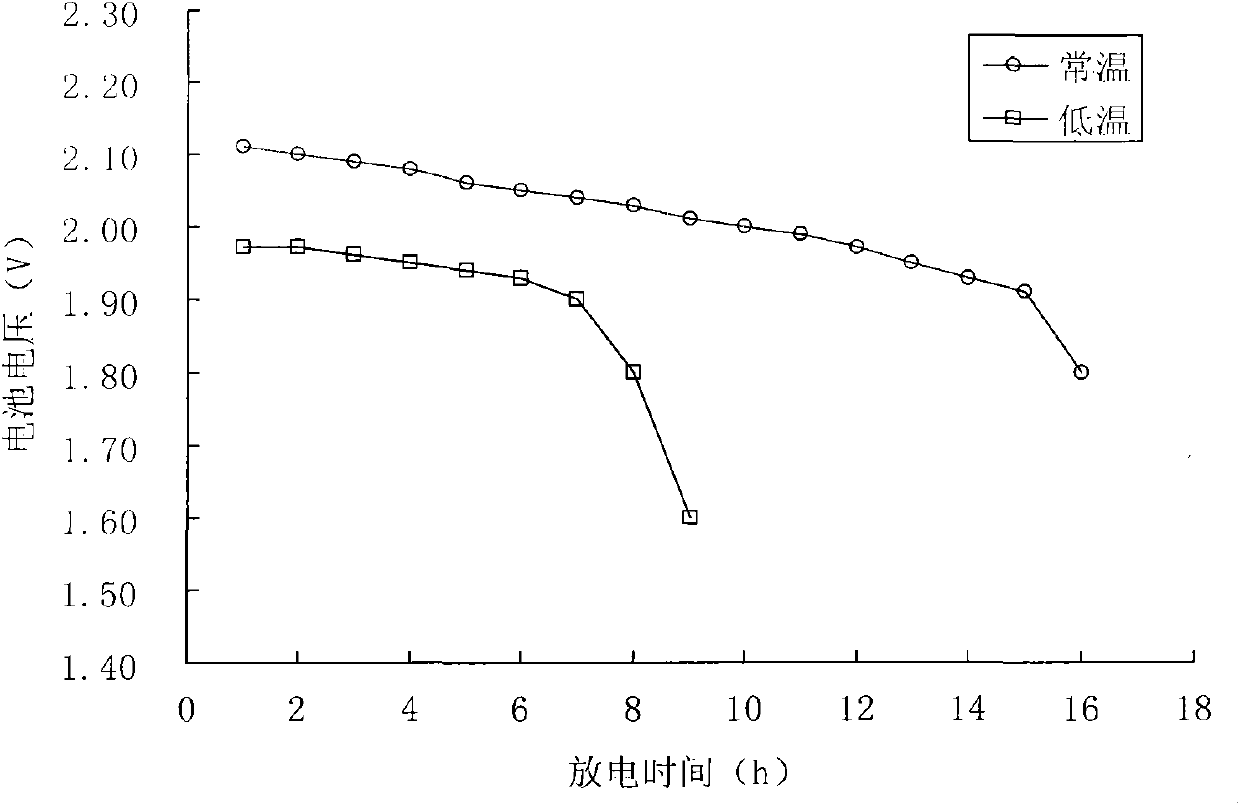

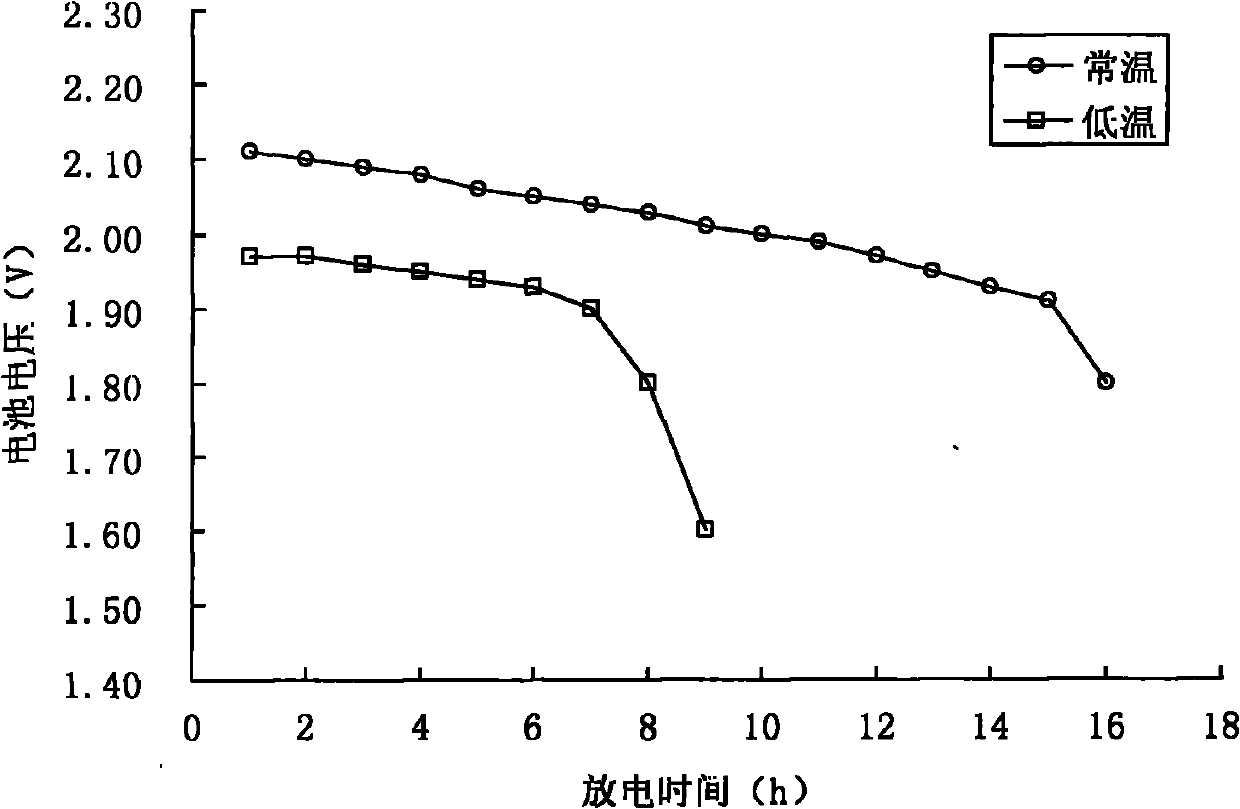

Battery electrode plate preparation method

ActiveUS20190326583A1High conductivity and capacity and active material loadingExcellent mechanical strengthElectrode thermal treatmentHybrid capacitor electrodesLithium electrodeBattery electrode

A new type of battery electrode plate preparation method is described. The method can include the following steps: a) a mixing process; b) a milling and polishing process; c) an extrusion shearing and extending process; d) cutting to obtain an electrode membrane; and e) pressing at a high temperature and a high pressure to obtain a battery electrode plate. The method can adopt the active material of different electrochemical batteries as the main body to prepare a thick type battery electrode plate with a high conductivity, a high capacity and a high active material loading, which has a viscoelastic body. The electrode plate can have a flexible organic network structure and an excellent mechanical strength, and can still exist in a variety of electrolytes after hundreds of times or even thousands of times of deep charge and discharge cycles. The thick electrode plate prepared by using the method can be applied to a variety of batteries such as lead-acid battery positive and negative electrode plates, a lead carbon battery electrode plate, a lithium ion battery electrode plate, a supercapacitor electrode plate, a Ni-MH battery electrode plate, and others.

Owner:NANTONG VOLTA MATERIALS LTD

Quantum lead-acid accumulator

InactiveCN102170025AEnhanced deep discharge performanceImprove cycle lifeFinal product manufactureElectrode carriers/collectorsWater basedPorosity

The invention relates to a lead-acid accumulator, in particular relating to a quantum lead-acid accumulator which comprises a cathode plate, an anode plate and an electrolyte, wherein the cathode plate comprises a lead plaster and a grid; the lead plaster contains 4-6% quantized carbon suspension, 0.01-0.06% of acrylic short fiber, 0.1-0.3% of lignin, 0.15-0.45% of acetylene carbon black, 0.4-0.7% of barium sulfate, 5-8% of dilute sulphuric acid and 4-5% of purified water based on the proportion by weight of lead powder; and the grid material of the anode and cathode plates adopts a Pb-Ca-Sn-Al quaternary alloy. In the quantum lead-acid accumulator provided by the invention, the quantized carbon suspension is added in the formula of the cathode plate containing the lead plaster; the particle size of the carbon particles in the suspension is uniformly less than or equal to 3nm; and in the coordinated application of the carbon particles, active substances and additives, the porosity of the active substances is improved, a cathode absorption technique is developed, the utilization rate of the active substances is enhanced, and the deep discharge performance of the accumulator is improved. A test indicates that the quantum lead-acid accumulator provided by the invention has the advantages of high quality-energy ratio, good charge-discharge performance, convenience in maintenance, long service life and suitability for being used in the severe environments such as vibration and impact, low temperature and the like.

Owner:北京三昌宇恒科技发展有限公司

Carbon material for lithium ion secondary battery, negative electrode material for lithium ion secondary battery, and lithium ion secondary battery

InactiveUS20150017539A1Improve discharge capacityImprove balanceGraphiteNegative electrodesLithiumGraphite

A carbon material for lithium ion secondary batteries of the invention contains amorphous carbon and graphite.The amorphous carbon is deposited on a surface of the graphite, the amorphous carbon content is 55% by weight to 99% by weight, and the graphite content is 1% by weight to 45% by weight.

Owner:SUMITOMO BAKELITE CO LTD

Negative electrode plate for nickel-metal hydride storage battery, method for producing the same and nickel-metal hydride storage battery using the same

InactiveUS20060194106A1Prevent an excessive increase in the internal pressure of a batteryLarge dischargeActive material electrodesAlkaline accumulator electrodesMetallic NickelSecondary layer

A negative electrode plate includes a conductive support and a first, a second and a third layer laminated on a surface of the support in this order from the support side. The first layer contains a hydrogen storage alloy powder and a first powder essentially made of a carbonaceous material. The second layer-contains a hydrogen storage alloy powder, the first powder and a second powder having conductivity. The third layer contains the second powder as a main component.

Owner:PANASONIC CORP

Anode and battery using same

ActiveUS8673501B2Increase battery capacityLarge dischargeNon-aqueous electrolyte accumulatorsNegative electrodesLithiumPower flow

Owner:MURATA MFG CO LTD

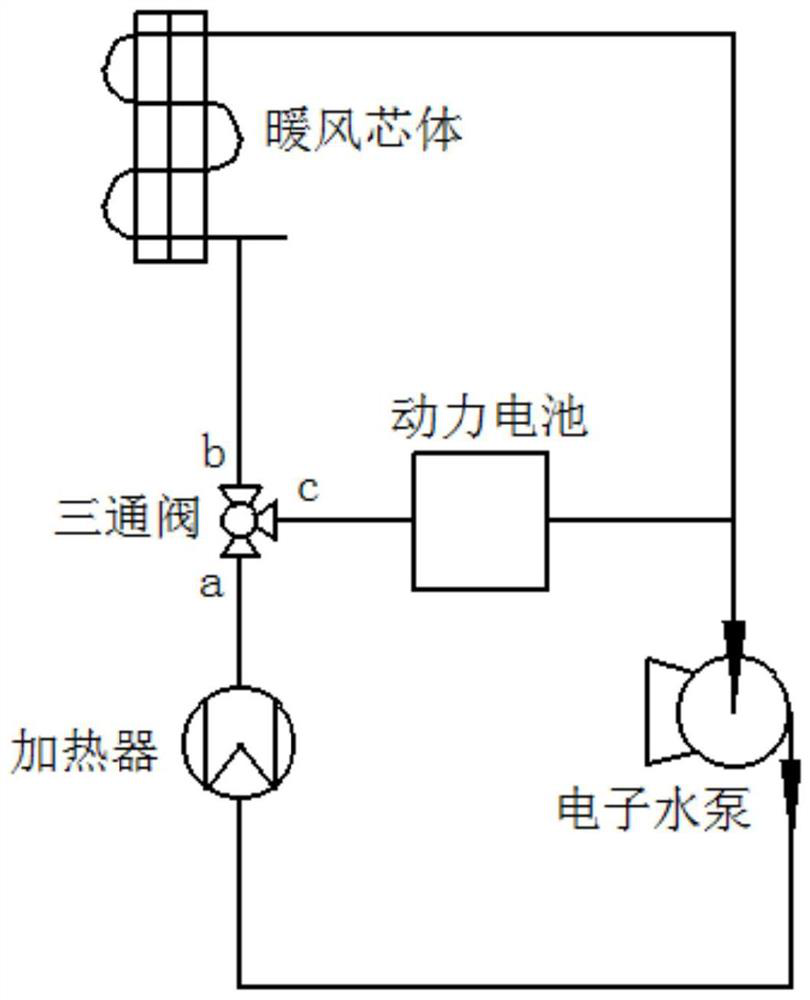

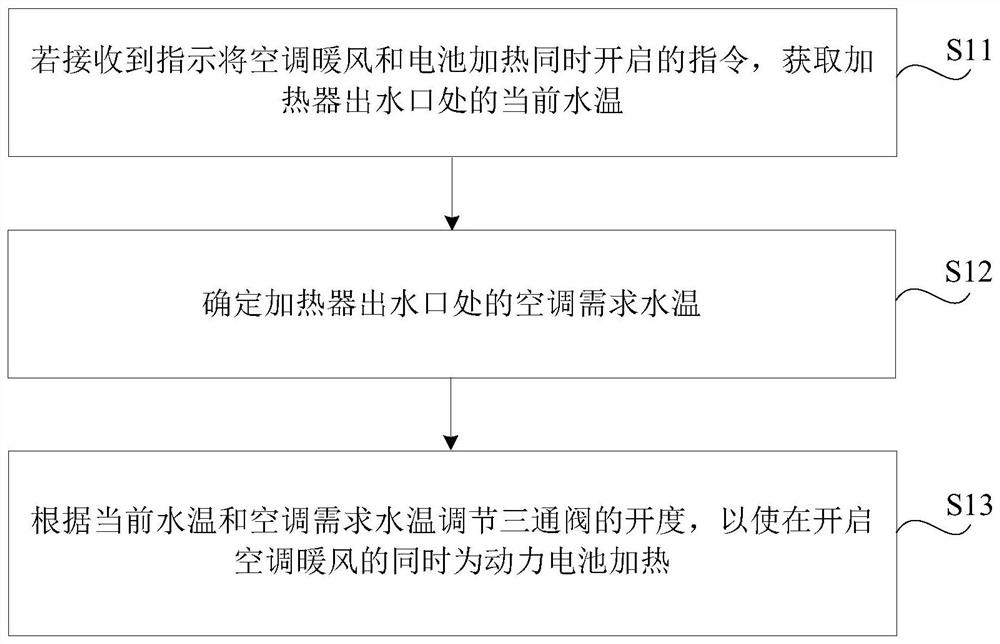

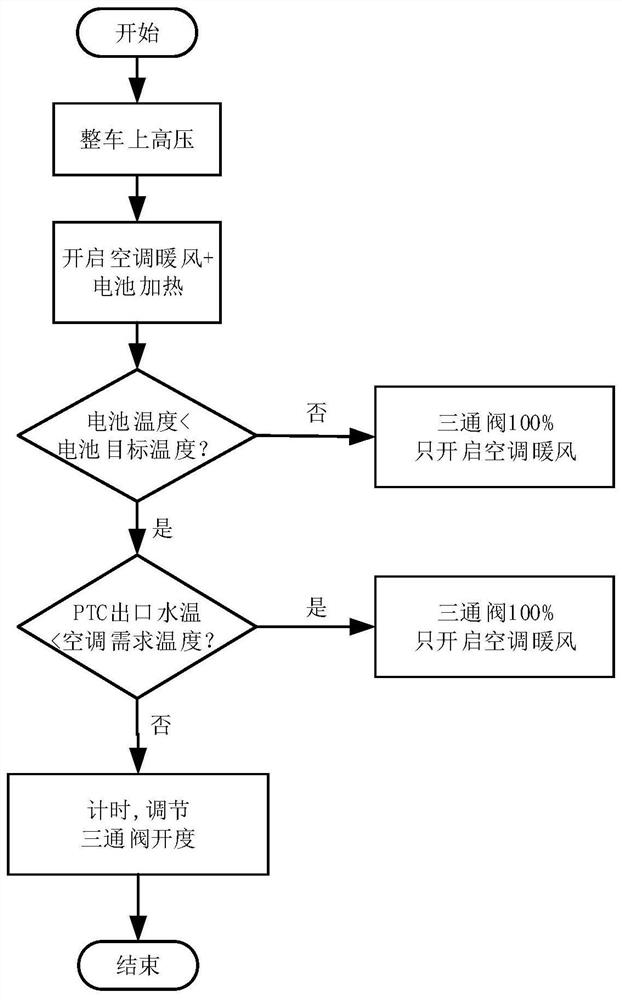

Control method of electric vehicle, medium and equipment

InactiveCN112993443AHigh activityLarge dischargeSecondary cellsVehicular energy storagePower batteryThermodynamics

The invention relates to a control method of an electric vehicle, a medium and equipment. The electric vehicle comprises a three-way valve, the three-way valve is used for guiding water heated by a heater into an air conditioner warm air core loop and a power battery loop, and the method comprises the steps that if an instruction for instructing air conditioner warm air and battery heating to be started at the same time is received, the current water temperature at a water outlet of the heater is obtained; the air conditioner required water temperature at the water outlet of the heater is determined; and the opening degree of the three-way valve is adjusted according to the current water temperature and the water temperature required by the air conditioner, so that the power battery is heated while the air conditioner is started to warm air. Thus, heat distribution between air conditioner warm air and battery heating can be automatically adjusted under the condition that basic requirements of the air conditioner are guaranteed, the activity of the power battery is improved while the comfortable temperature of a cab is achieved, and therefore the discharge capacity of the power battery is increased, the endurance mileage is increased, and the power performance of the whole vehicle is enhanced.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

Three-dimensional molding device and three-dimensional molding method

InactiveUS10414093B2Large dischargeReduce workloadManufacturing enclosures3D object support structuresReciprocating motionMaterials science

The three-dimensional molding device includes a recoater configured to discharge a granular material from a discharge port onto the molding table such that the granular material is superimposed in layer, a solidification device configured to solidify a partial region of the granular material in a plane solidification device direction of an upper surface of the molding table, a moving mechanism configured to cause the recoater to reciprocate in a plane direction parallel to the upper surface of the molding table, and at least one plug member configured to close a part of an opening in at least one location in a longitudinal direction of the discharge port of the recoater and limit a discharge range of the granular material.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com