Quantum lead-acid accumulator

A lead-acid battery, quantum technology, applied in the direction of lead-acid battery, lead-acid battery construction, electrode carrier/current collector, etc., can solve problems such as less than 40%, small discharge capacity of lead-acid battery, and insignificant chemical activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

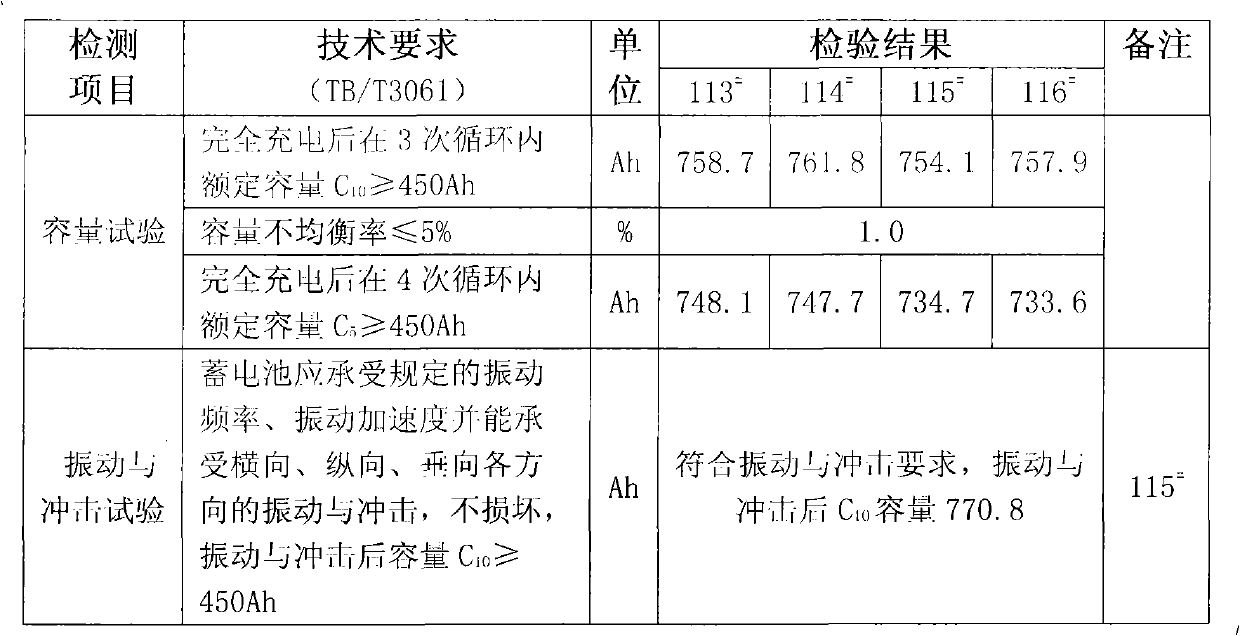

[0024] Embodiment: Quantum lead-acid accumulator comprises negative pole plate, positive pole plate and electrolytic solution, and described negative pole plate is made up of lead paste and grid, and wherein lead paste adopts lead powder (crossing 100 mesh sieves) 100kg, quantized carbon suspension (carbon Carbon particle weight percent is 0.4% in the suspension, and carbon particle particle diameter is 3nm) 5L, acrylic fiber staple fiber 50g, lignin 250g, acetylene carbon black 200g, barium sulfate (crossing 80 mesh sieves) 500g, dilute sulfuric acid (temperature 15 ℃ Time density 1.40±0.03g / cm 3 )5.72L, purified water 5L. Pour the lead powder, lignin, acetylene carbon black, and barium sulfate into the paste machine for dry mixing; add the quantized carbon suspension and acrylic short fiber into the pure water and mix well, then pour it into the paste machine again. Stir. Slowly and evenly add dilute sulfuric acid within 11 minutes (at a temperature of 15°C, the density is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com