Patents

Literature

78results about How to "Avoid differential pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

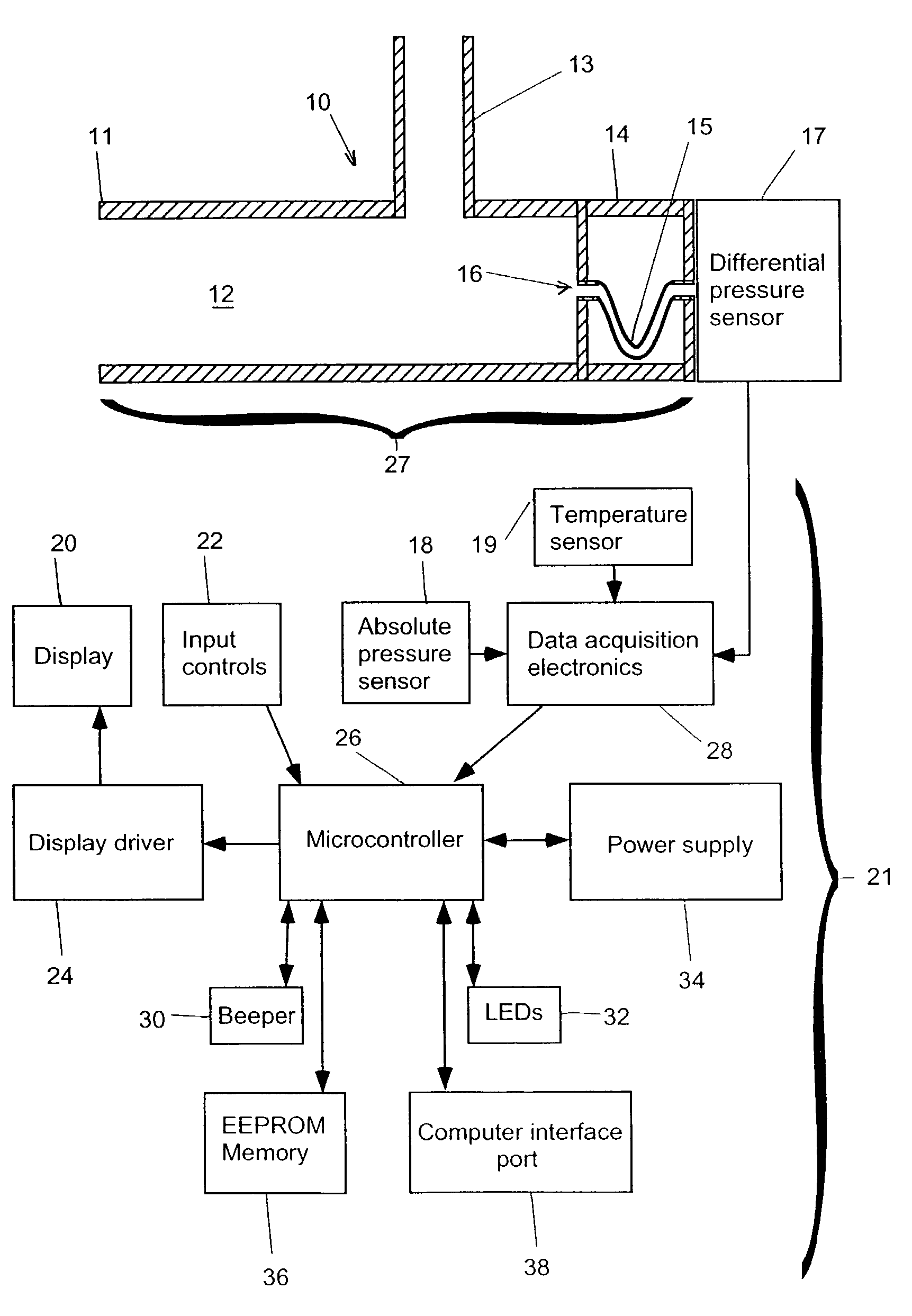

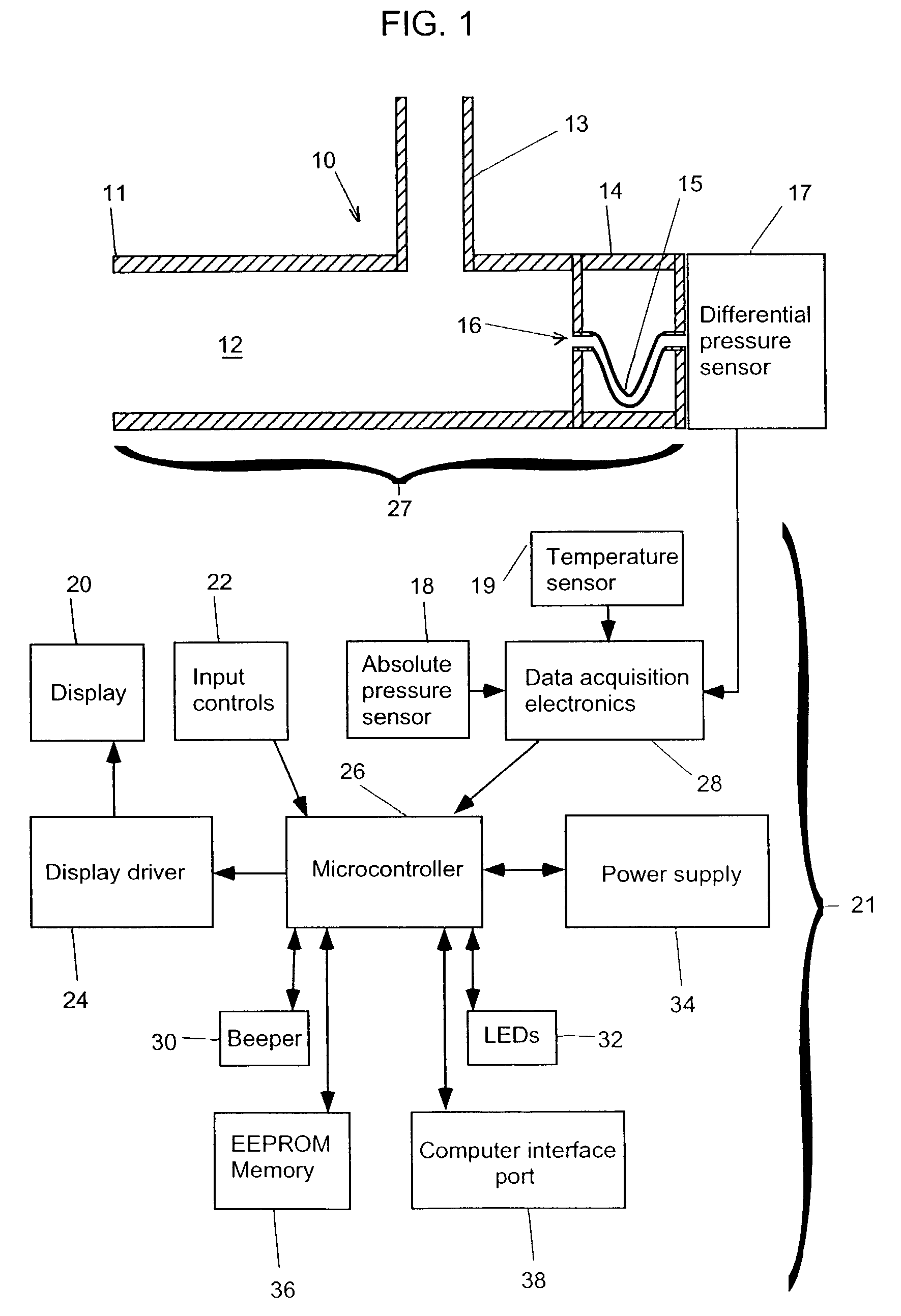

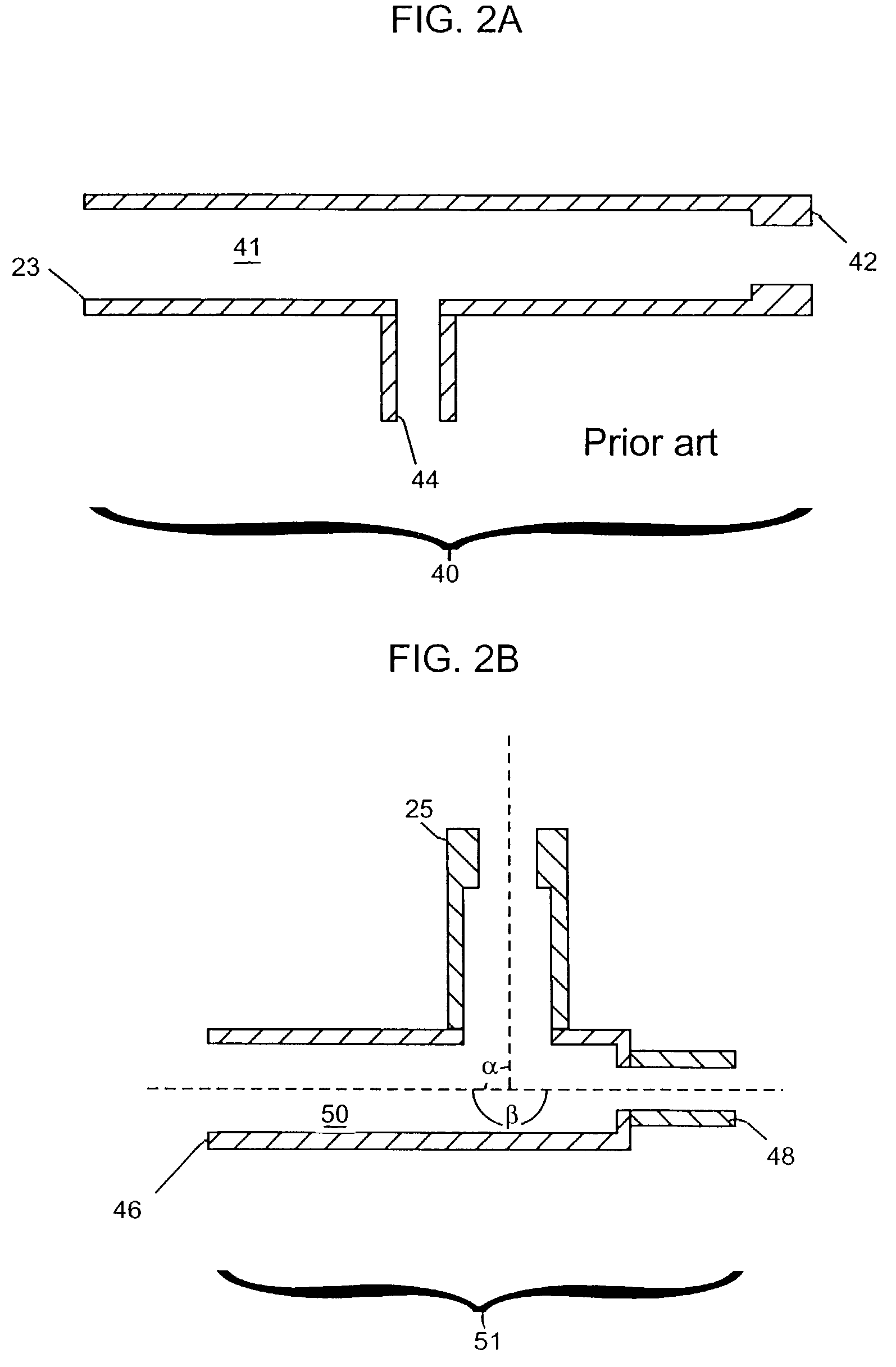

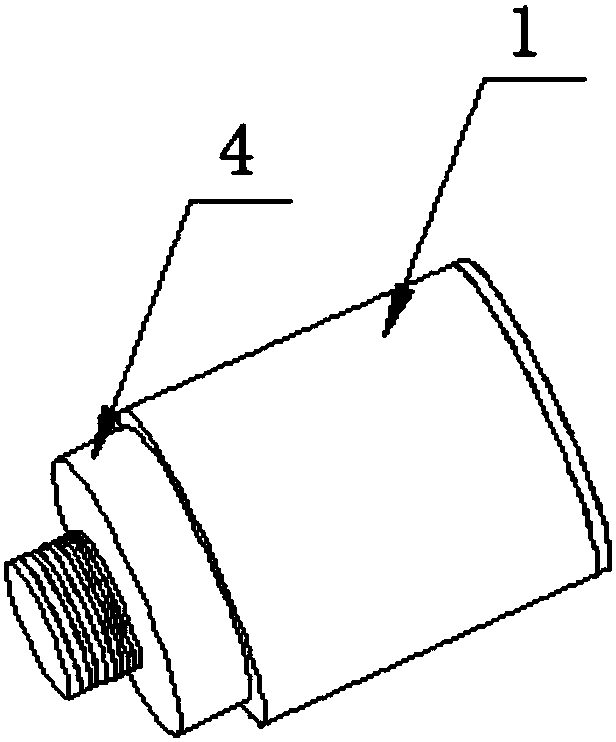

Portable electronic spirometer

InactiveUS7063669B2Increased measured air pressureAvoid signalingRespiratory organ evaluationSensorsDifferential pressurePressure sense

A spirometer having a housing with an elongated flow chamber open at one end, a pressure sensing end opposite the open end and an outlet passageway intercepting the flow chamber at an angle α and proximate the pressure sensing end. A differential pressure sensor is coupled to the pressure sensing end from a port at an angle β to an axis of the flow chamber. The angle α is substantially greater than 0° but substantially less than 180° while the angle β may range from 90° to 180°, such that a significantly increased measured air pressure results over that measured when α=180° and β=90°.

Owner:DYNAMIC MT

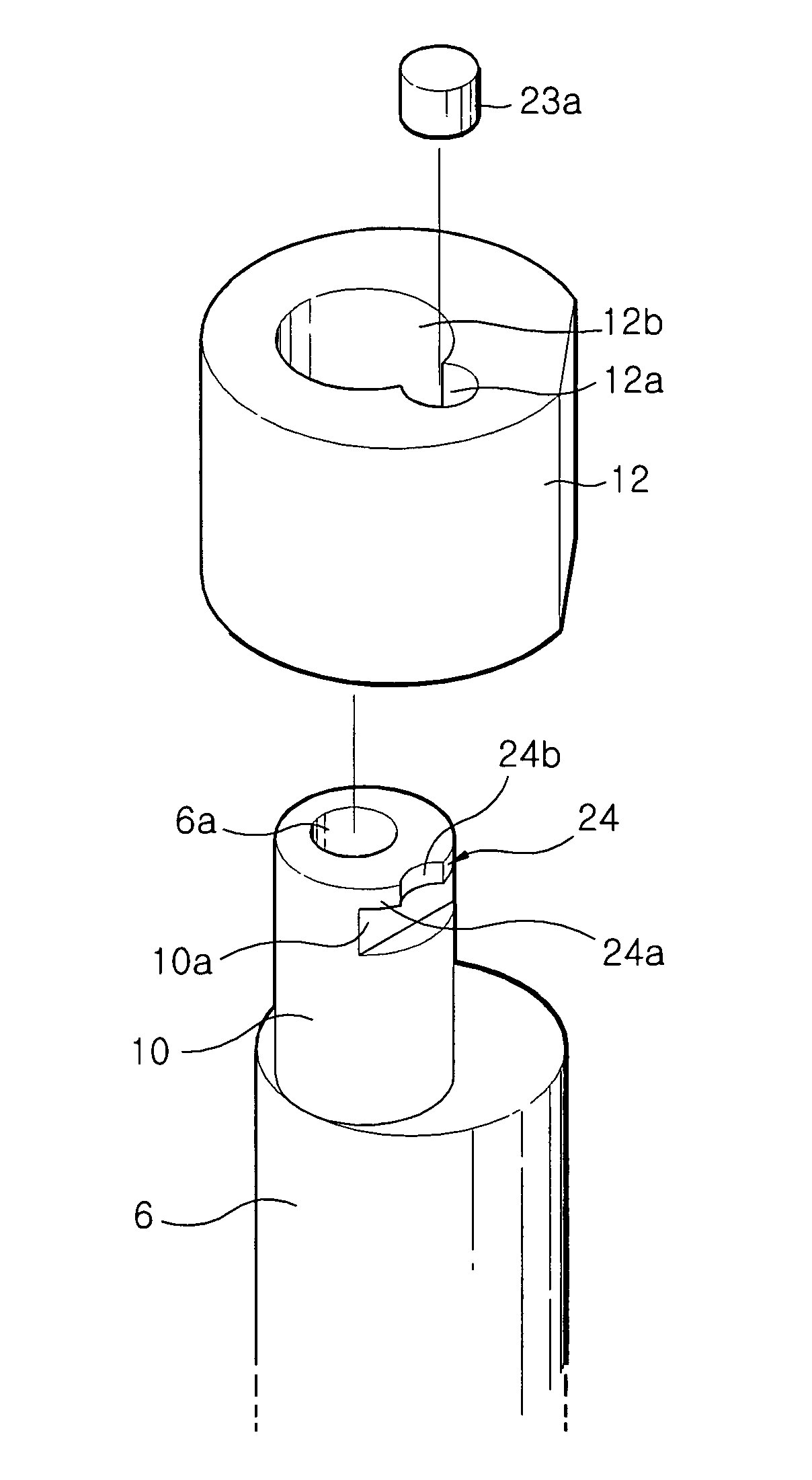

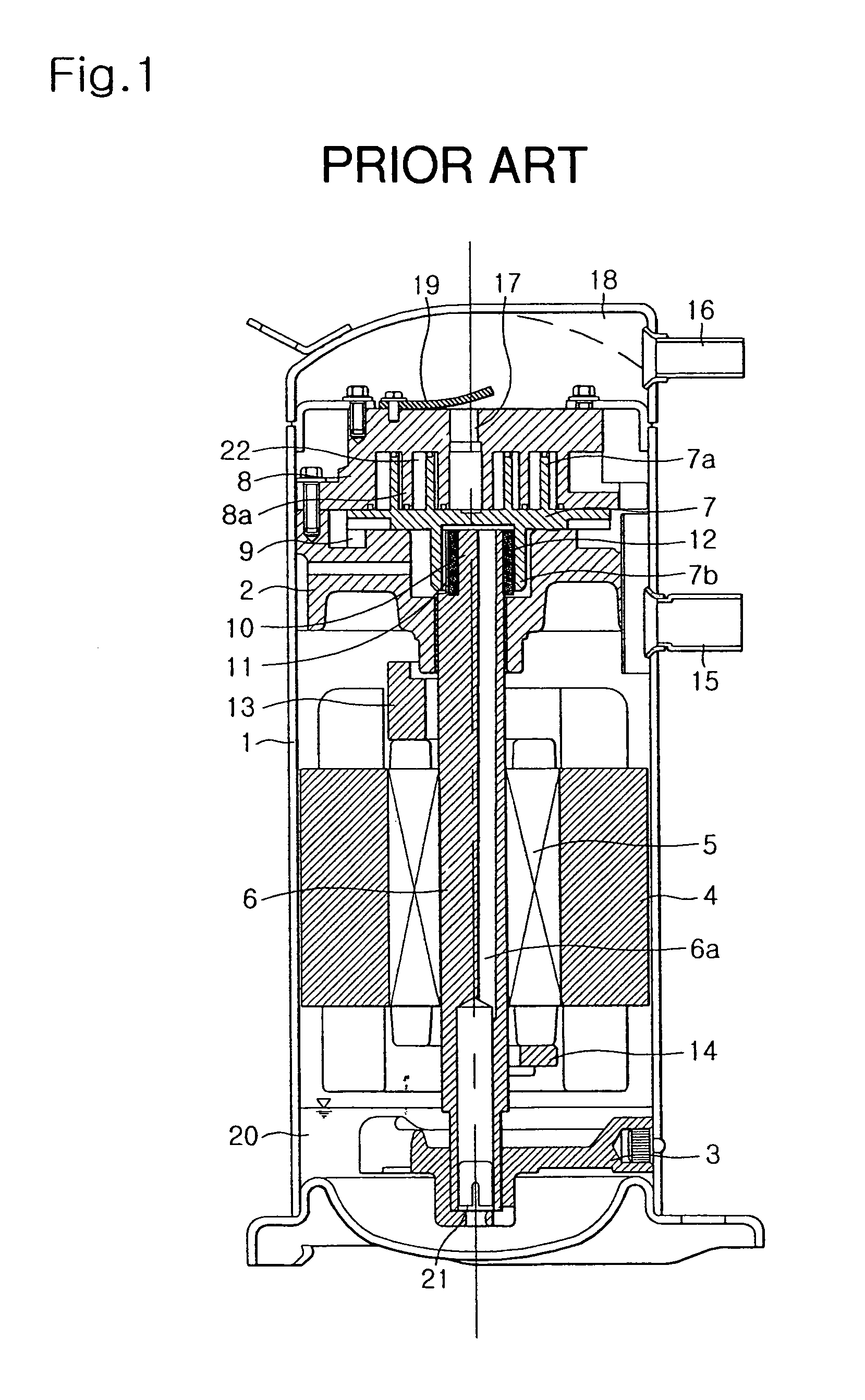

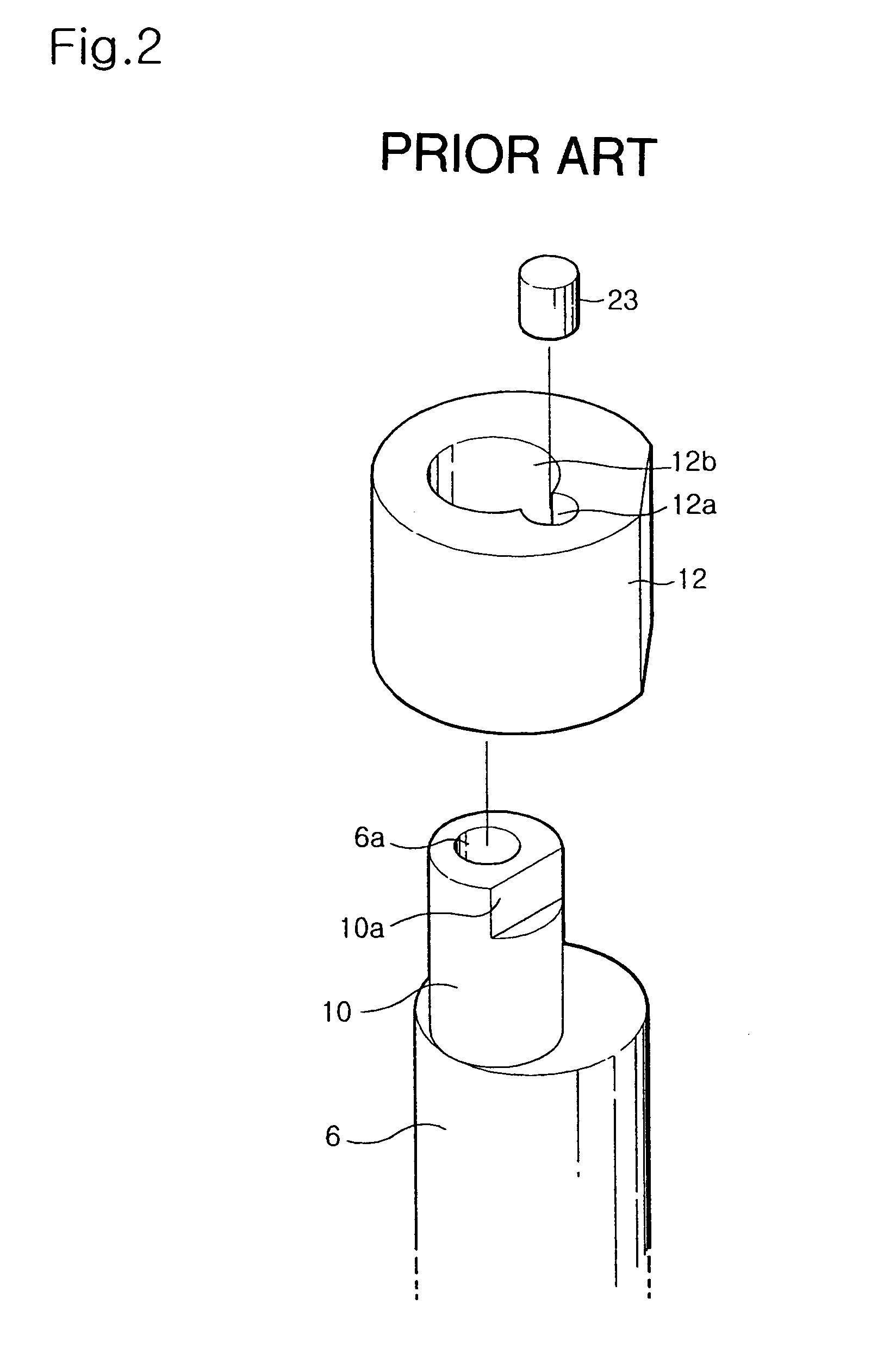

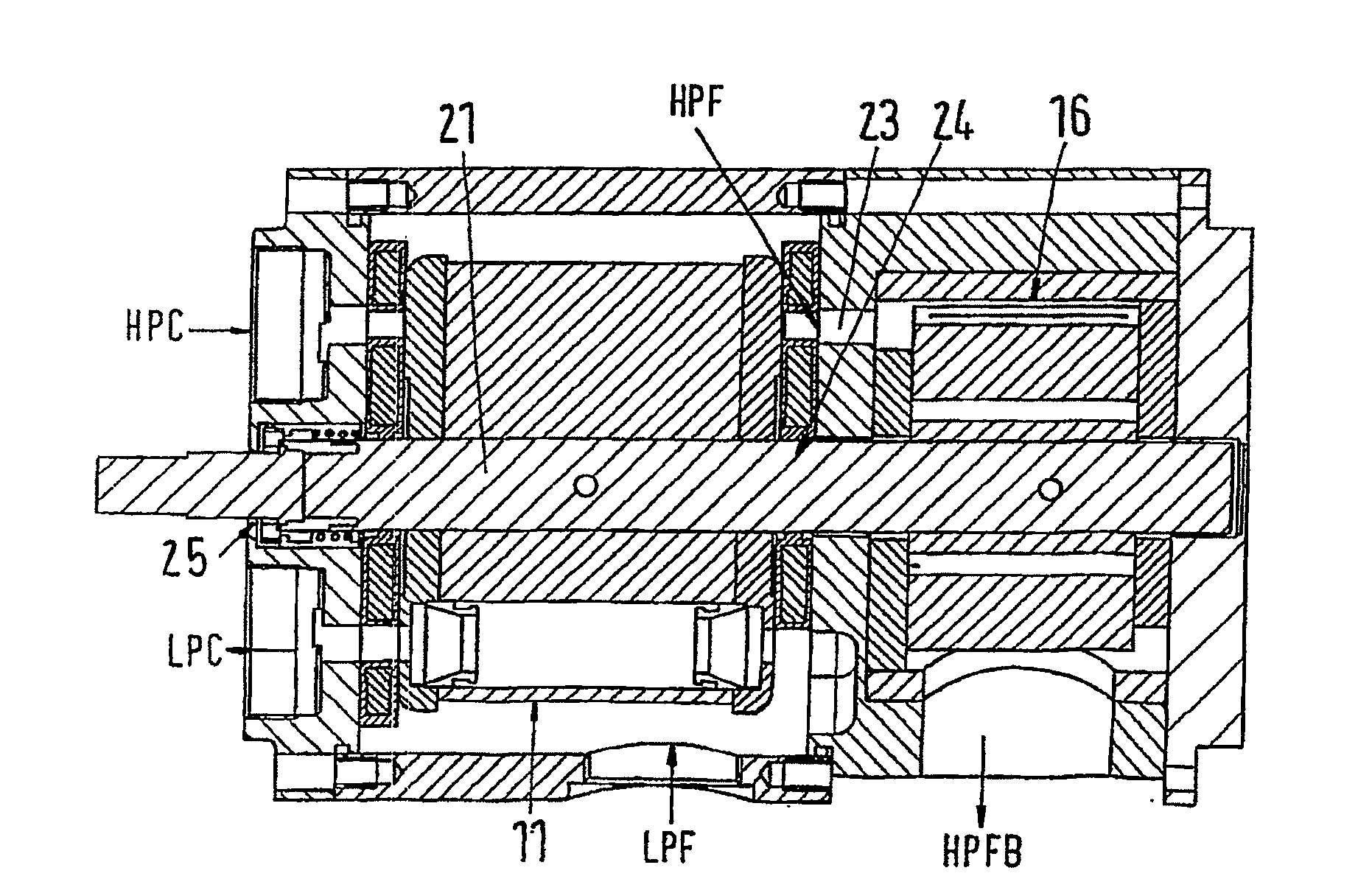

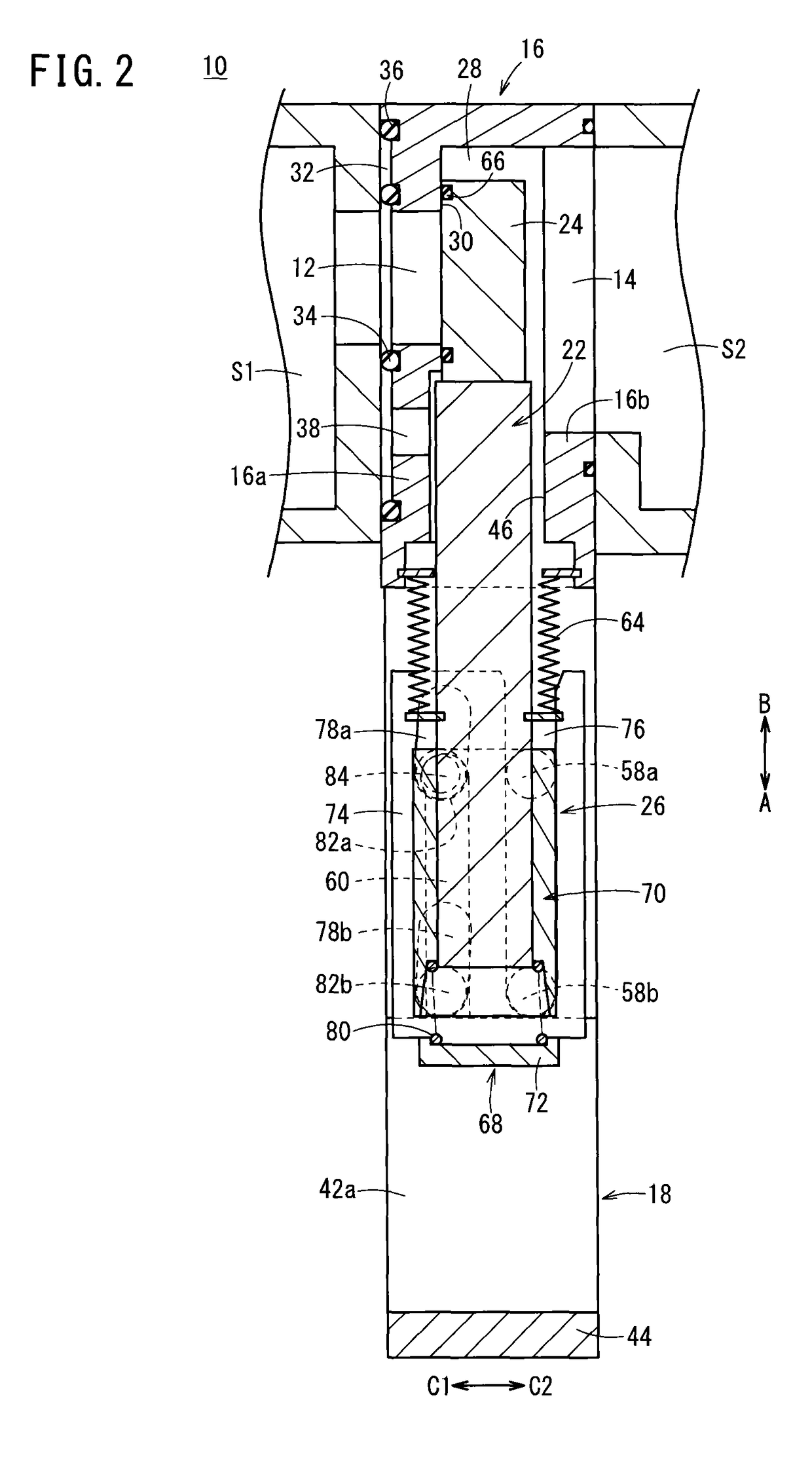

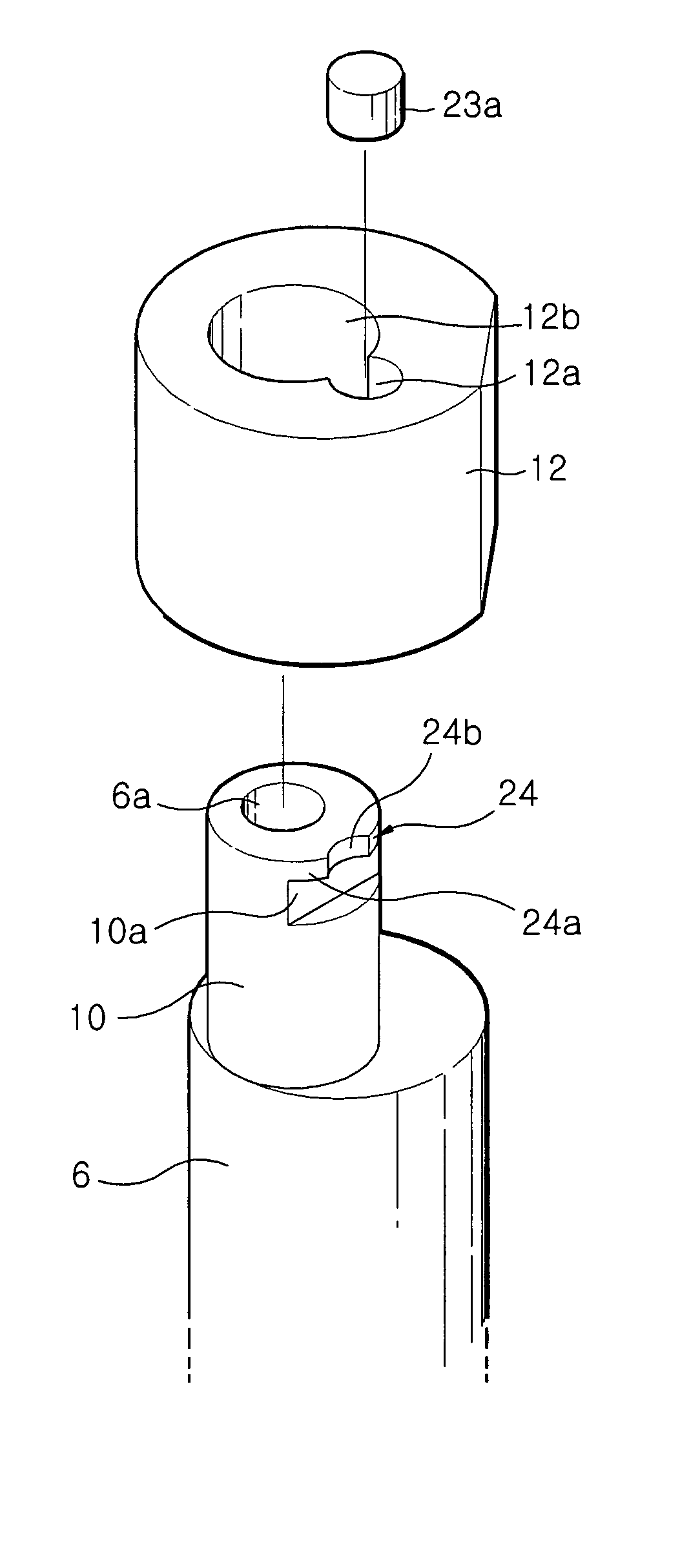

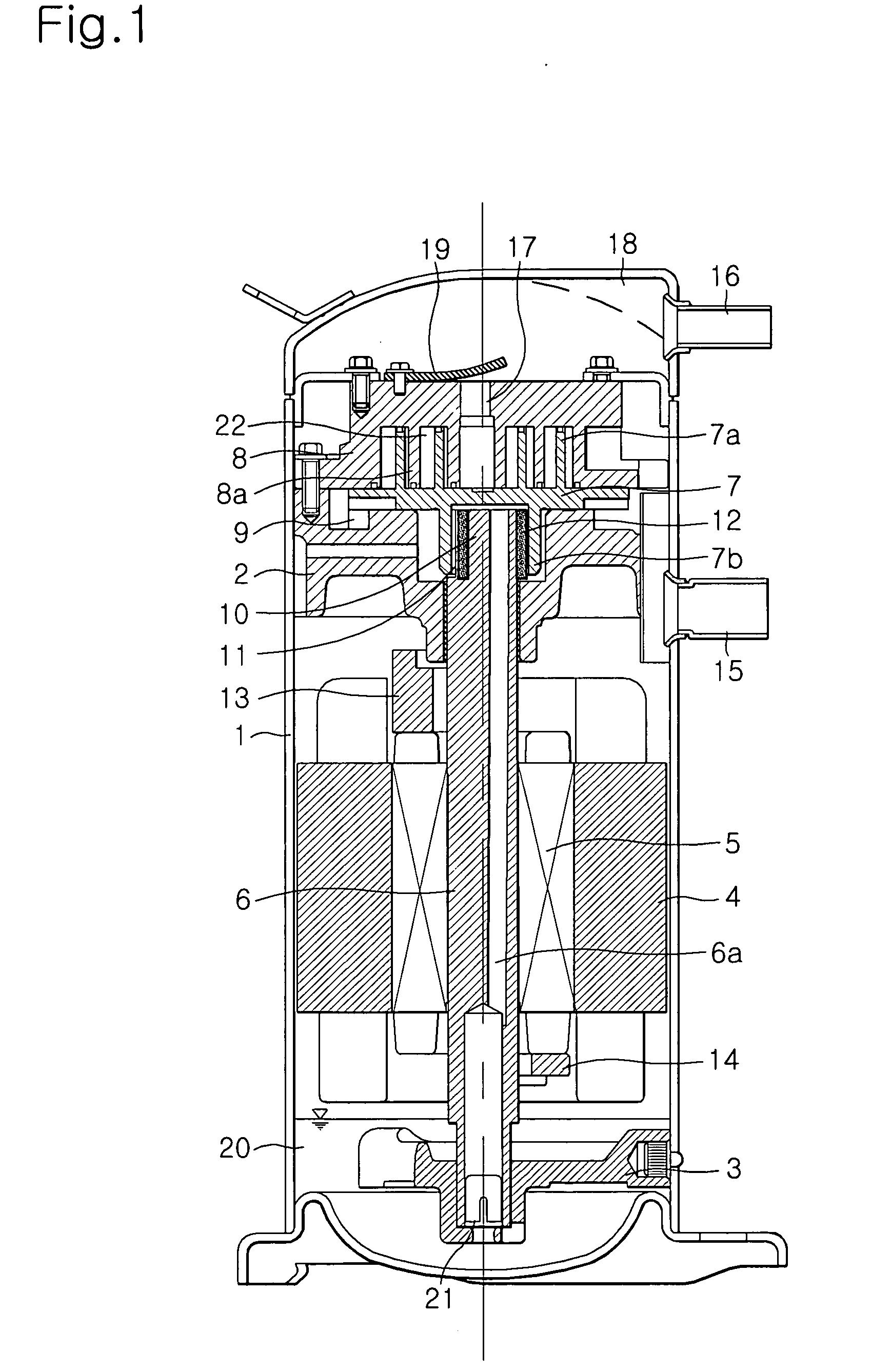

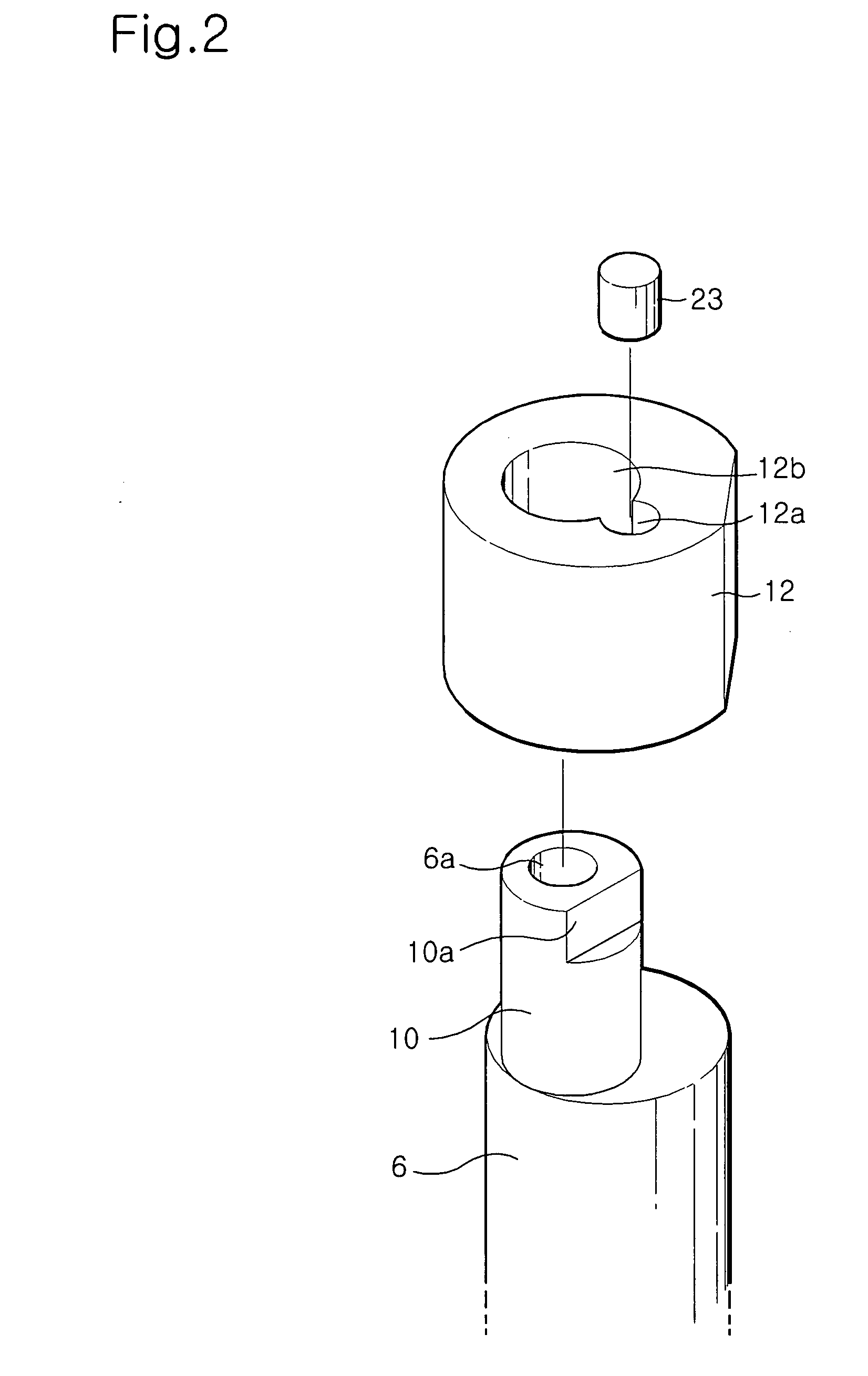

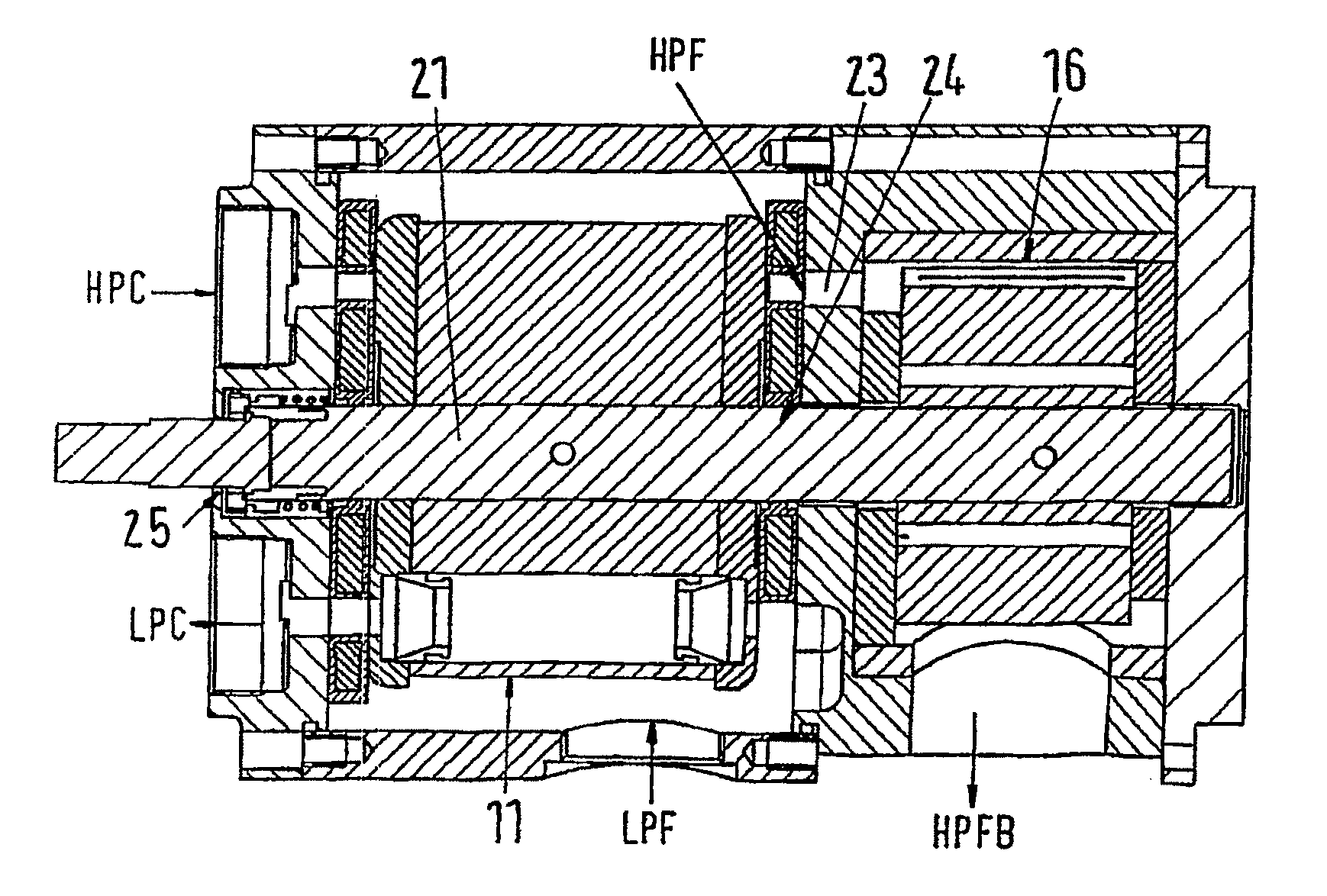

Eccentric coupling device in radial compliance scroll compressor

InactiveUS7150609B2Avoid differential pressureEasy constructionEngine of arcuate-engagement typeOscillating piston enginesCouplingEngineering

An eccentric coupling device in a radial compliance scroll compressor including a crank pin eccentrically arranged at an upper end of a crankshaft included in the scroll compressor, and provided with a vertically-extending cut surface at one side thereof, a bush fitted around the crank pin, and provided with a crank pin hole and a stopper hole, a stopper fitted in the stopper hole, and an engagement jaw adapted to prevent a vertical movement of the stopper, thereby preventing a vertical movement of the bush, the engagement jaw being provided at an upper end of the crank pin. The bush is arranged such that an upper end thereof is flush with an upper end of the crank pin. The stopper hole overlaps with the crank pin hole so that the stopper selectively comes into contact with the cut surface in accordance with a rotation of the crank pin. The stopper has a length shorter than that of the stopper hole.

Owner:LG ELECTRONICS INC

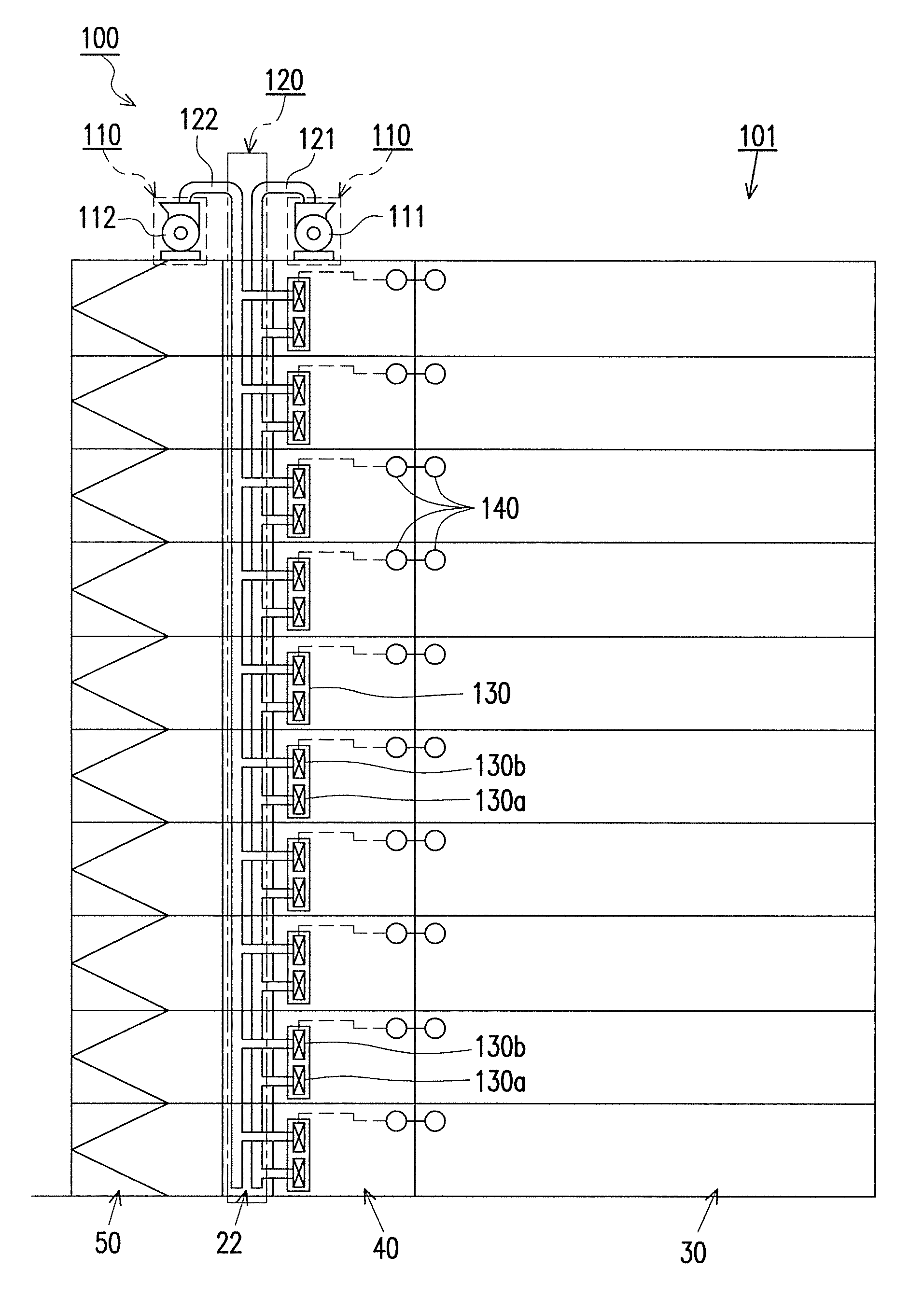

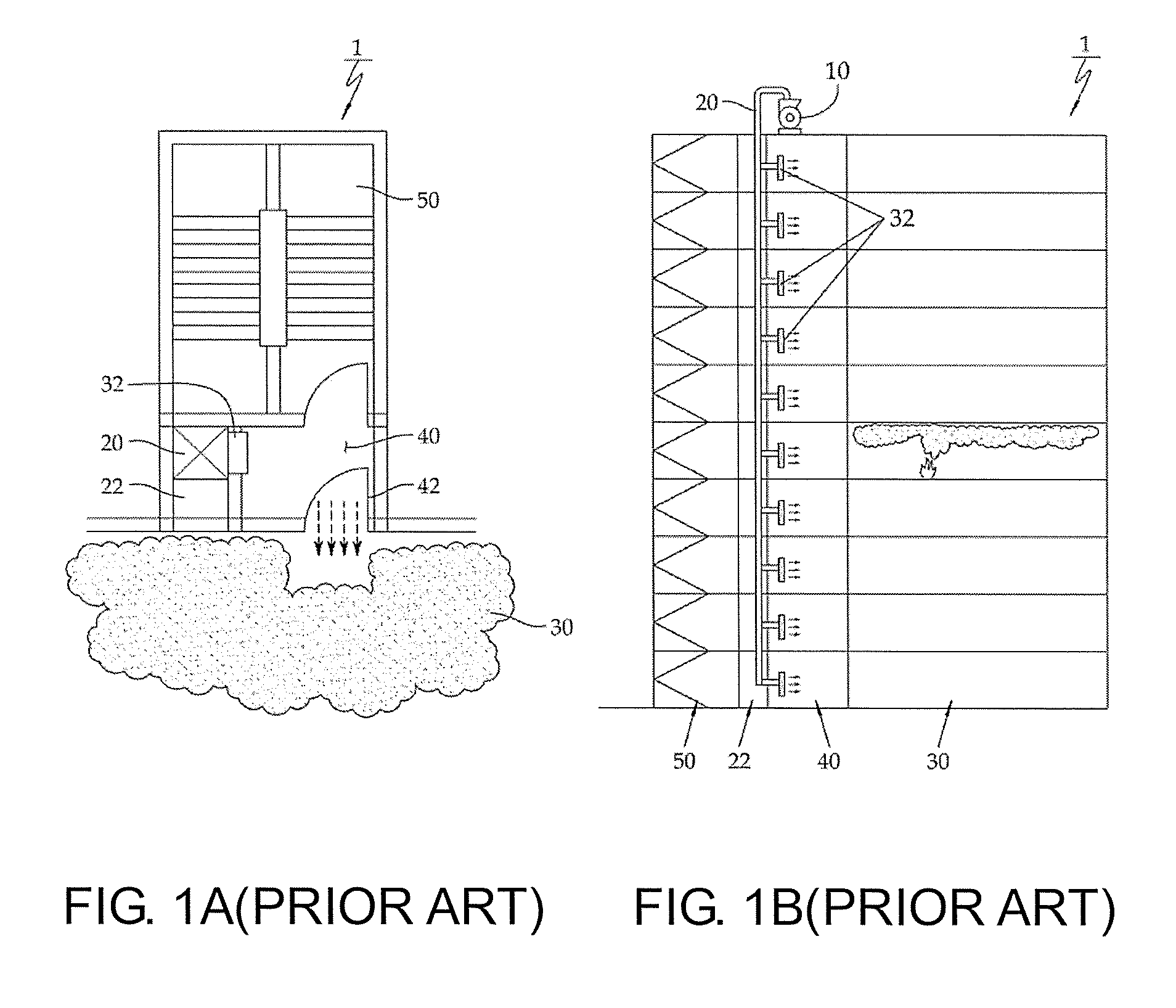

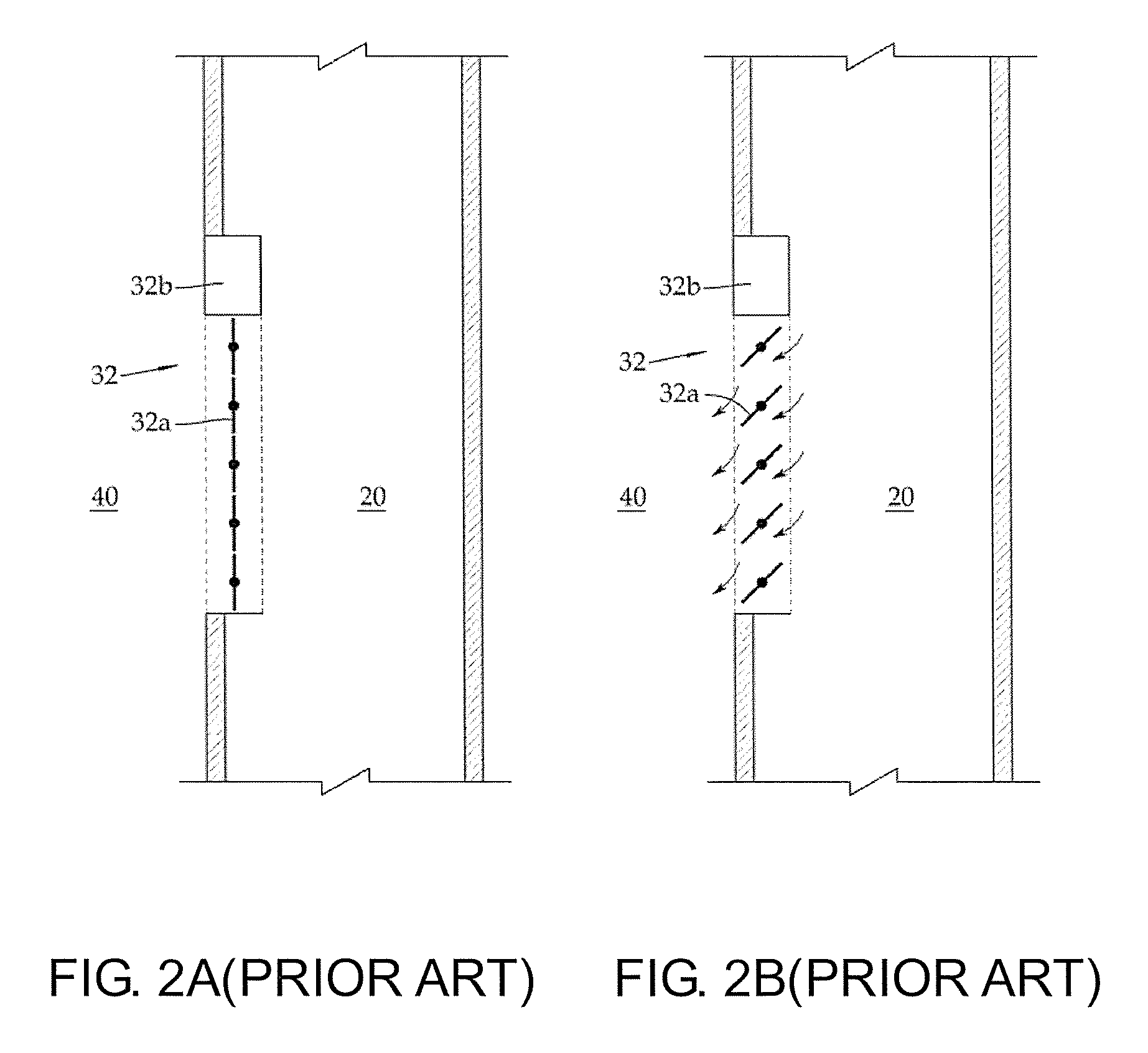

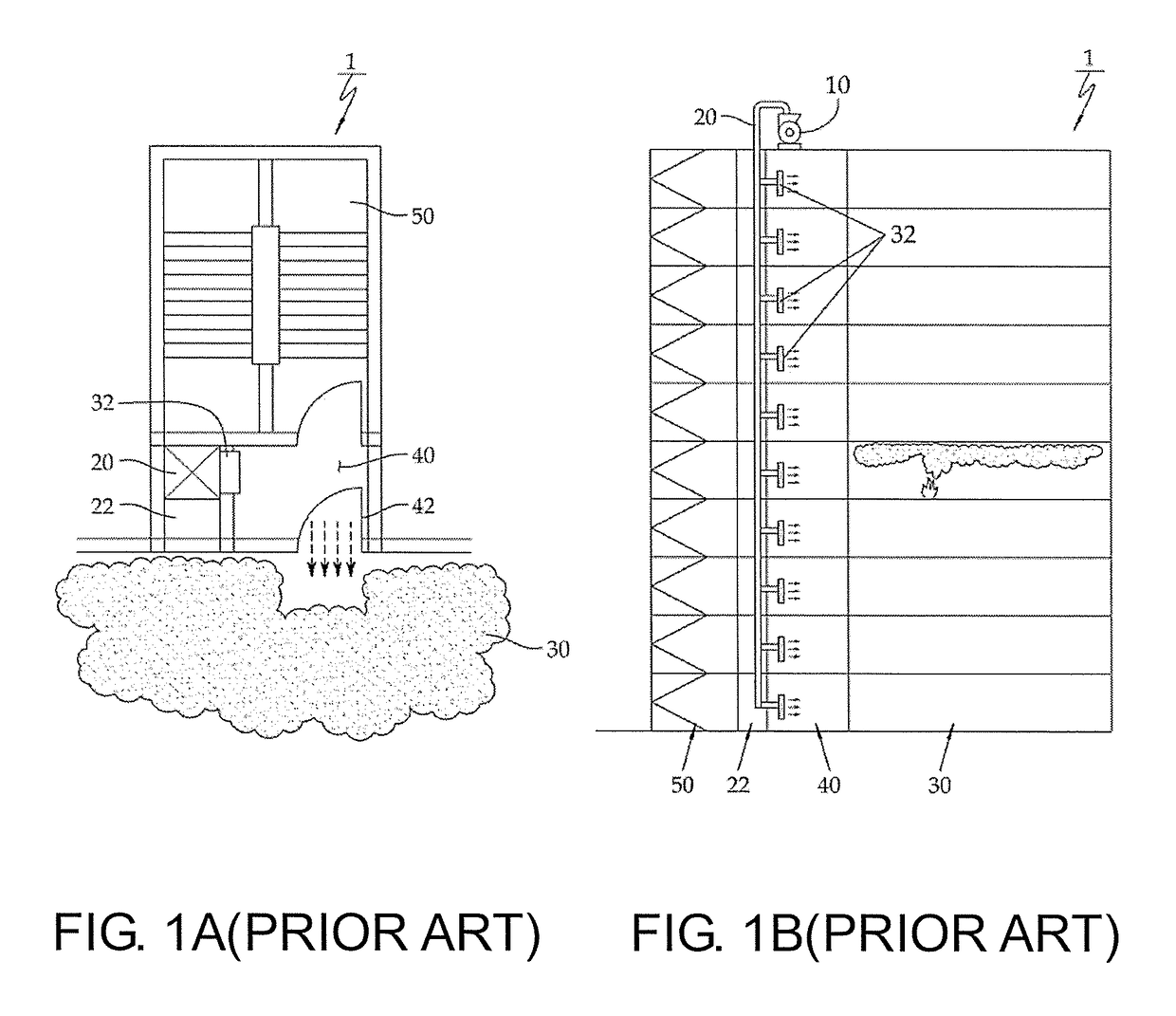

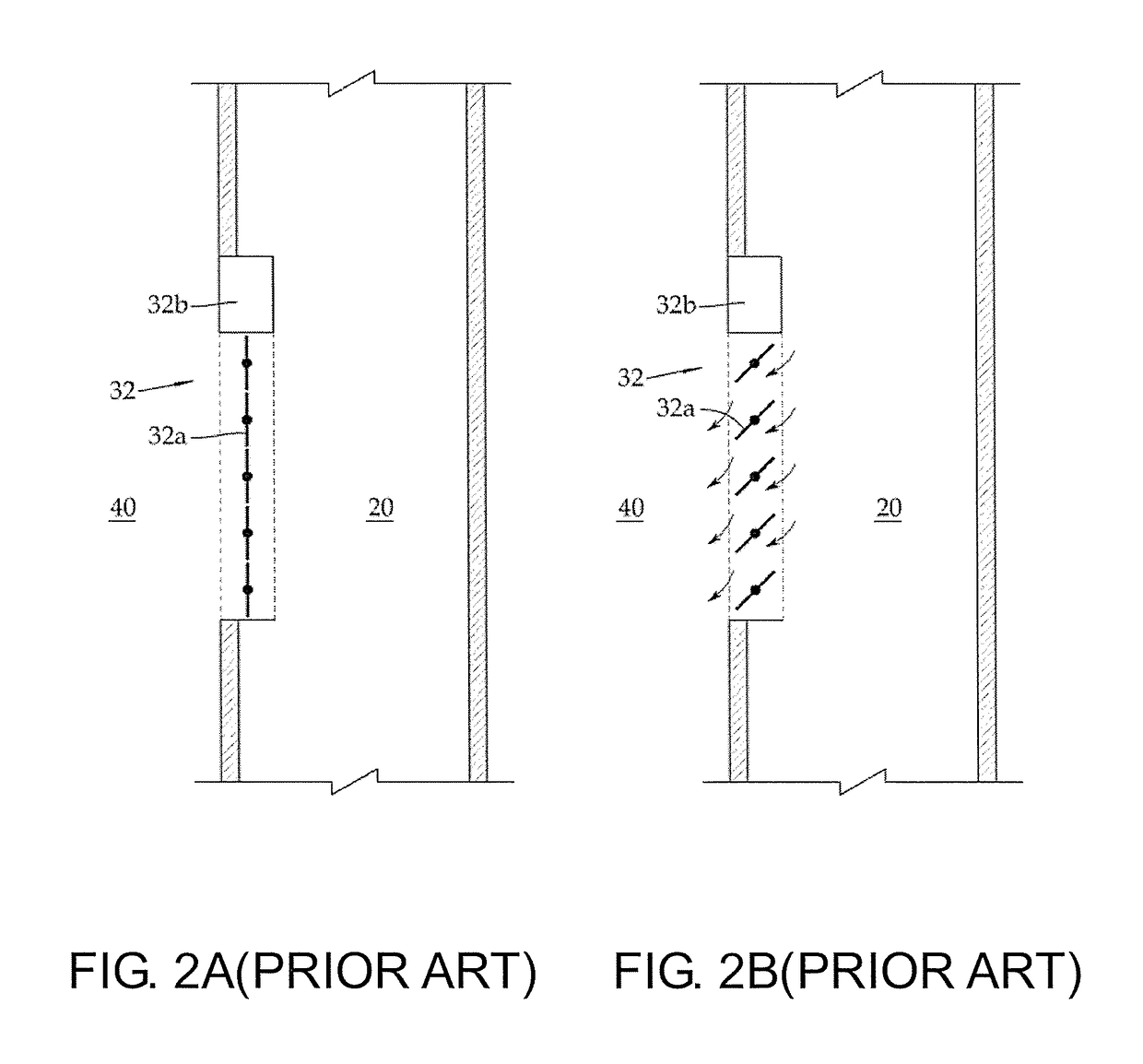

Air supply damper for separately supplying leakage air flow and supplementary air flow, method for controlling the same, and smoke control system utilizing the same

ActiveUS20130005236A1Avoid differential pressurePrecise maintenanceMechanical apparatusSpace heating and ventilation safety systemsAirflowOperating energy

Disclosed is a smoke control system provided in a high-rise building for separately supplying leakage air flow and supplementary air flow, including: a blowing means for supplying air into a building; a ventilating means having a leakage air flow supplying passage and a supplementary air flow supplying passage connected to the blowing means for introducing air; and an air supply damper connected to the leakage air flow supplying passage and the supplementary air flow supplying passage to supply air into each lobby of a building according to the leakage air flow and supplementary air flow.

Owner:KOREA INST OF CIVIL ENG & BUILDING TECH

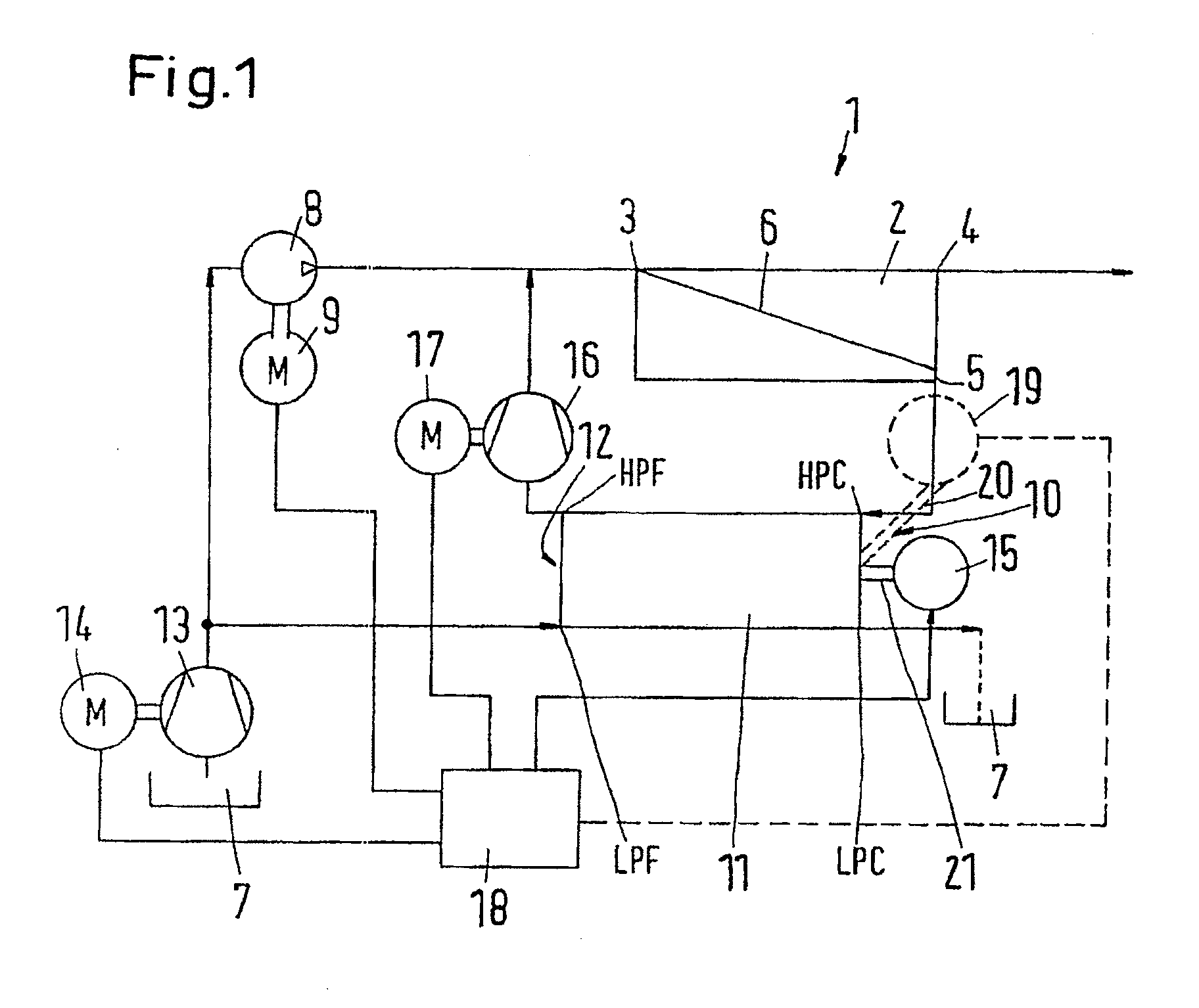

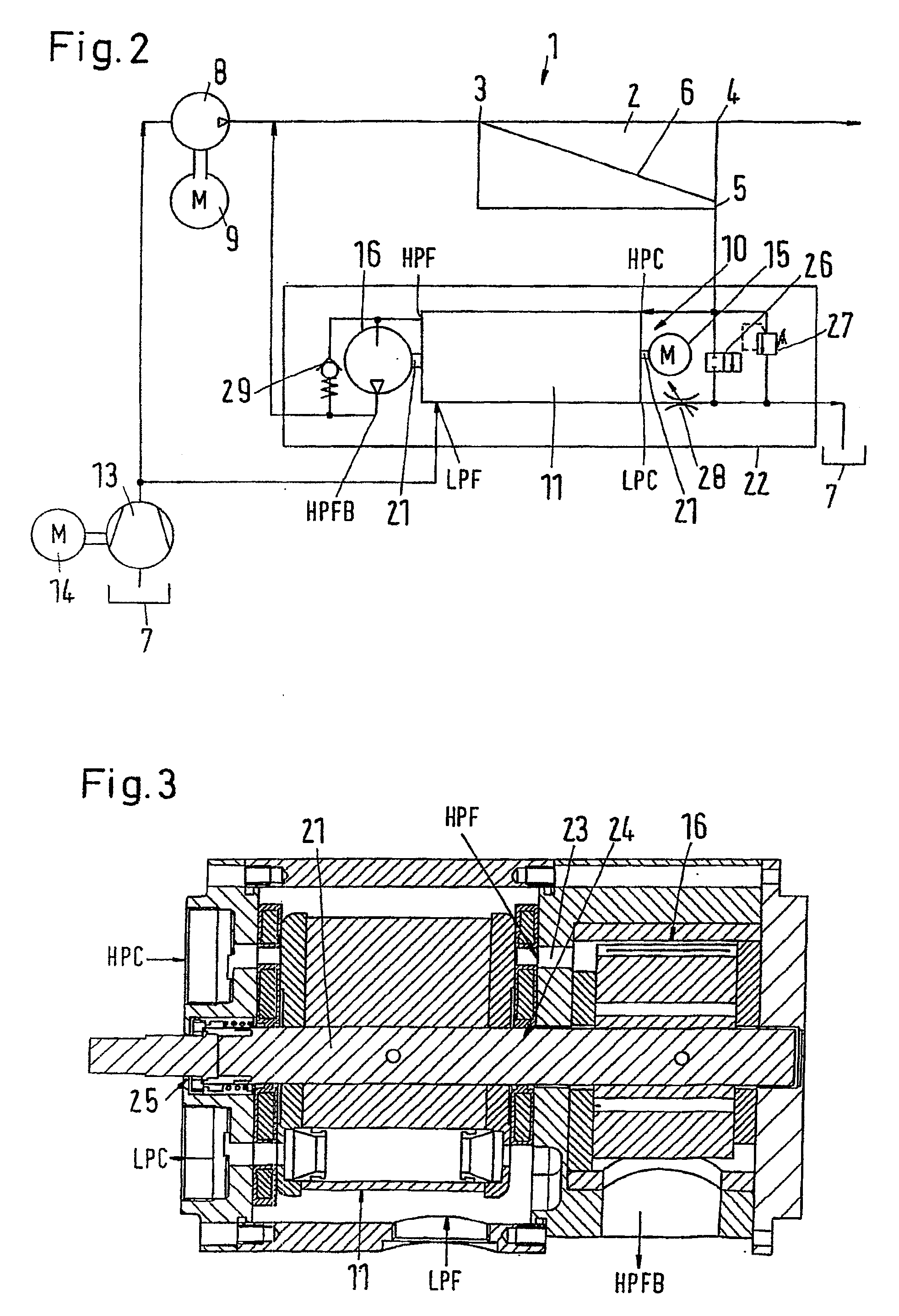

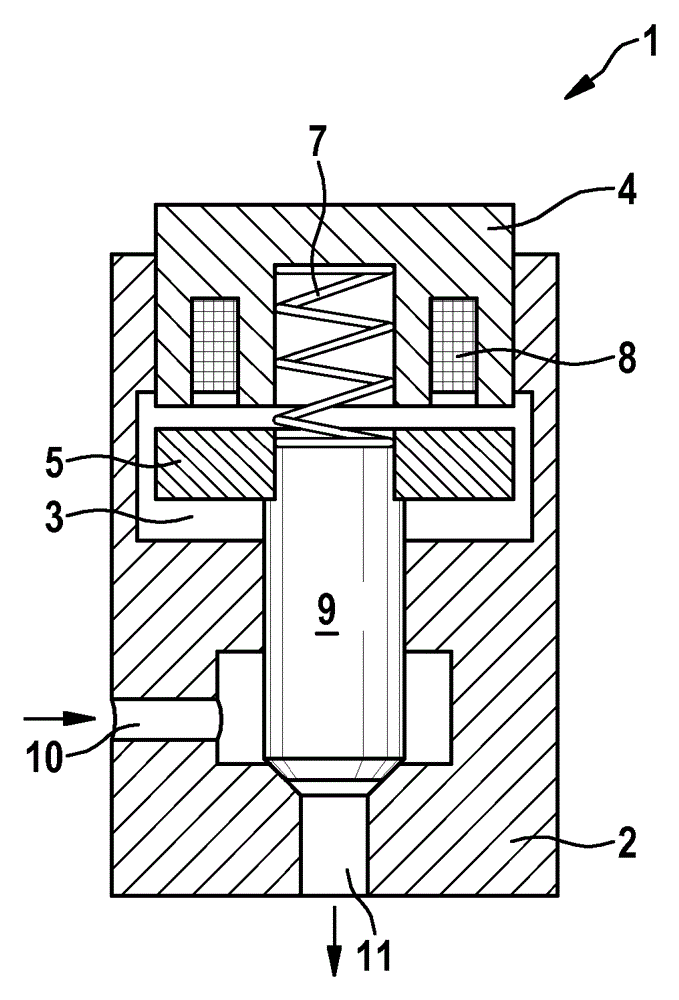

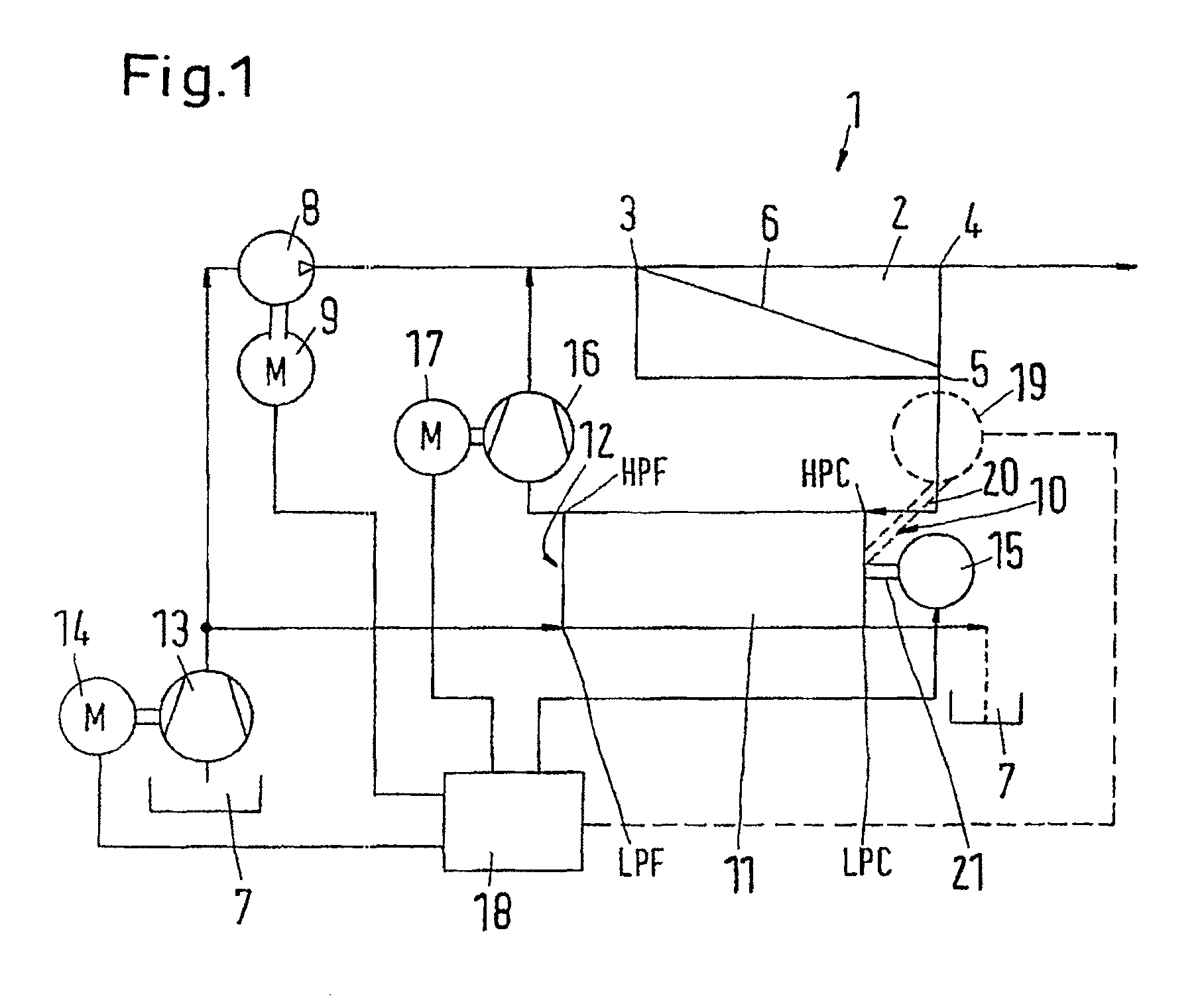

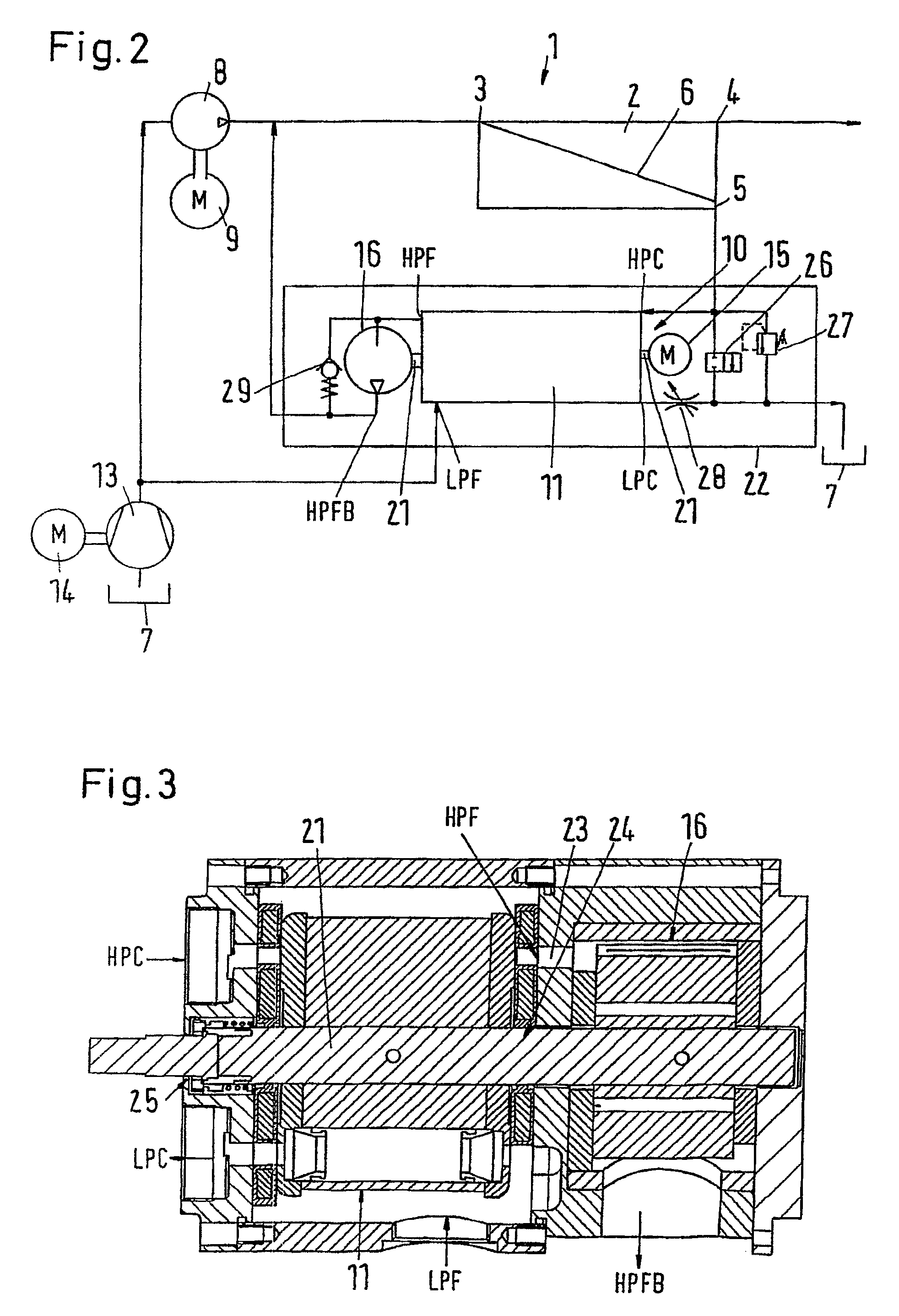

Reverse osmosis system

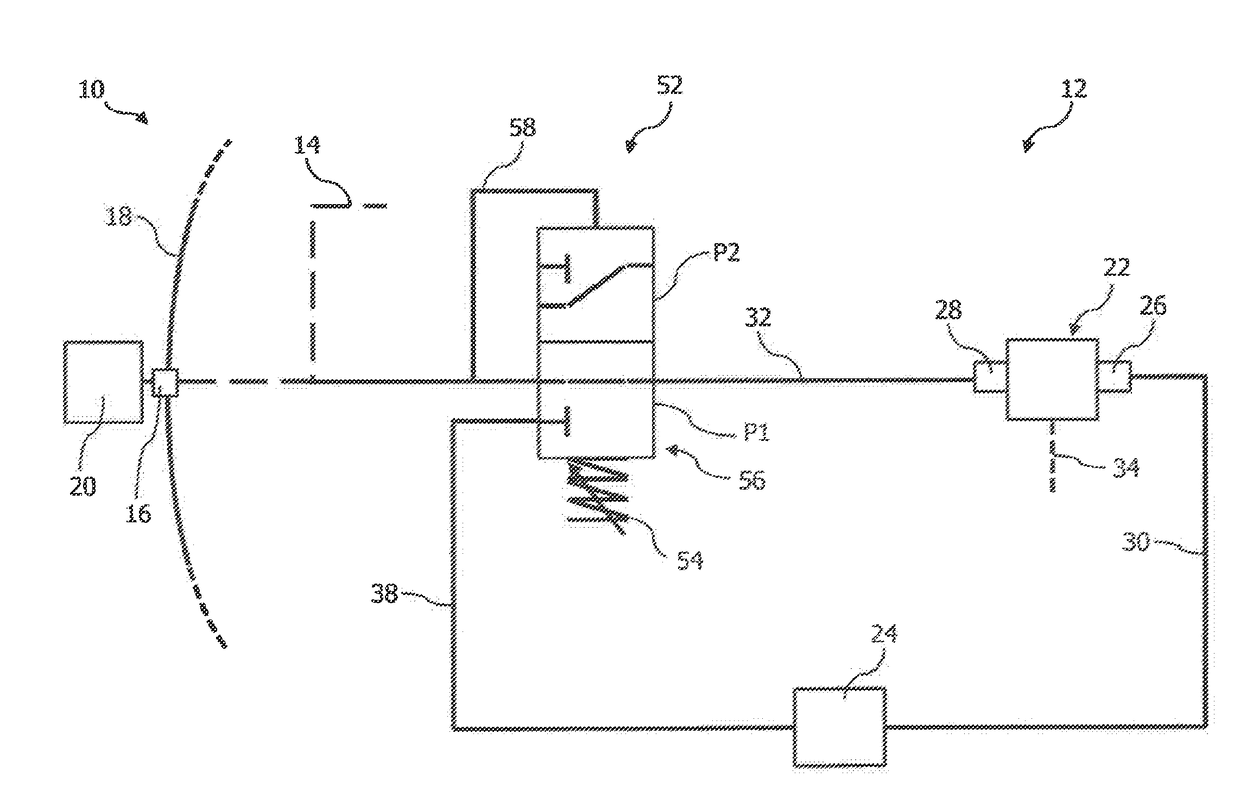

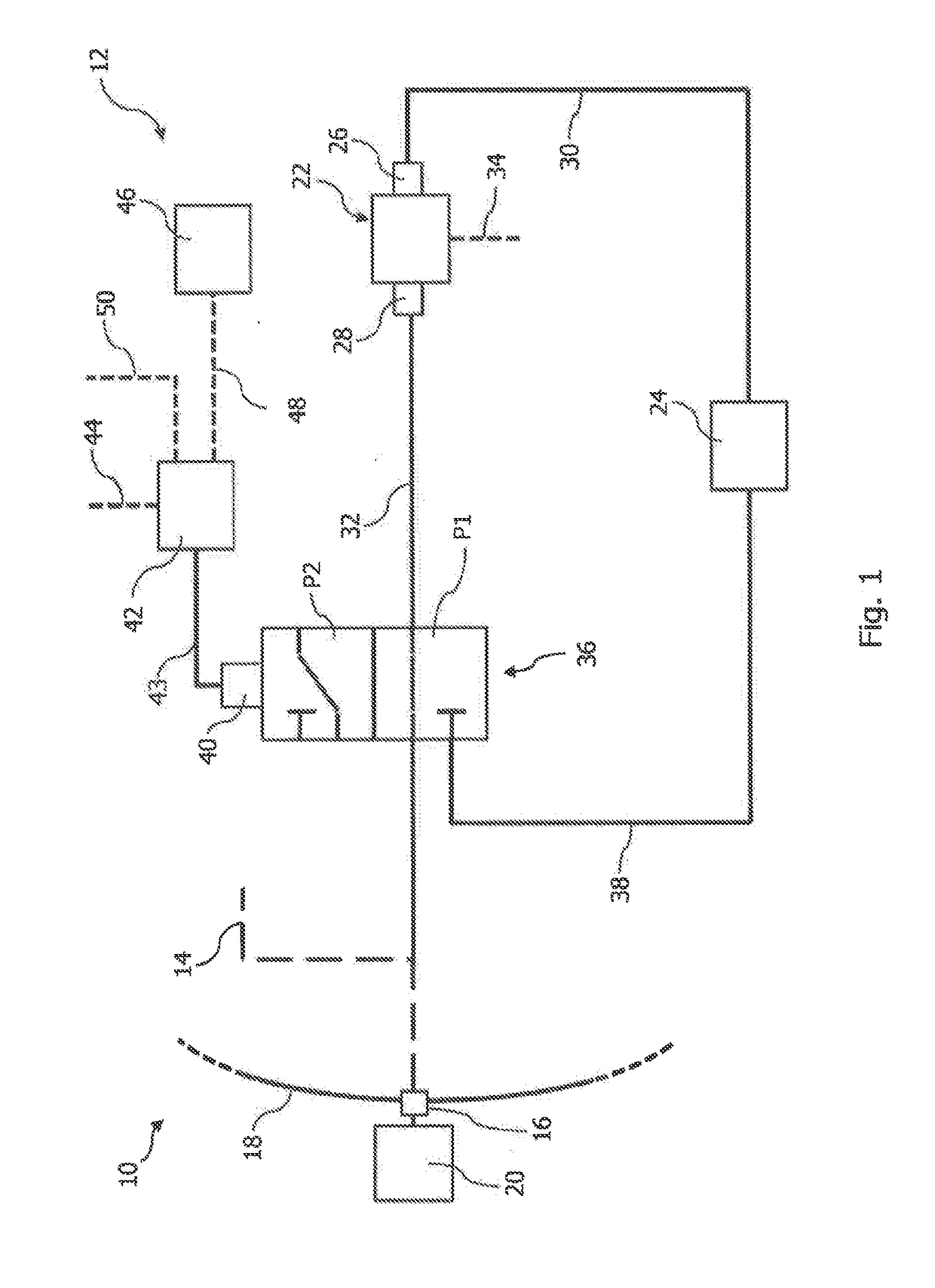

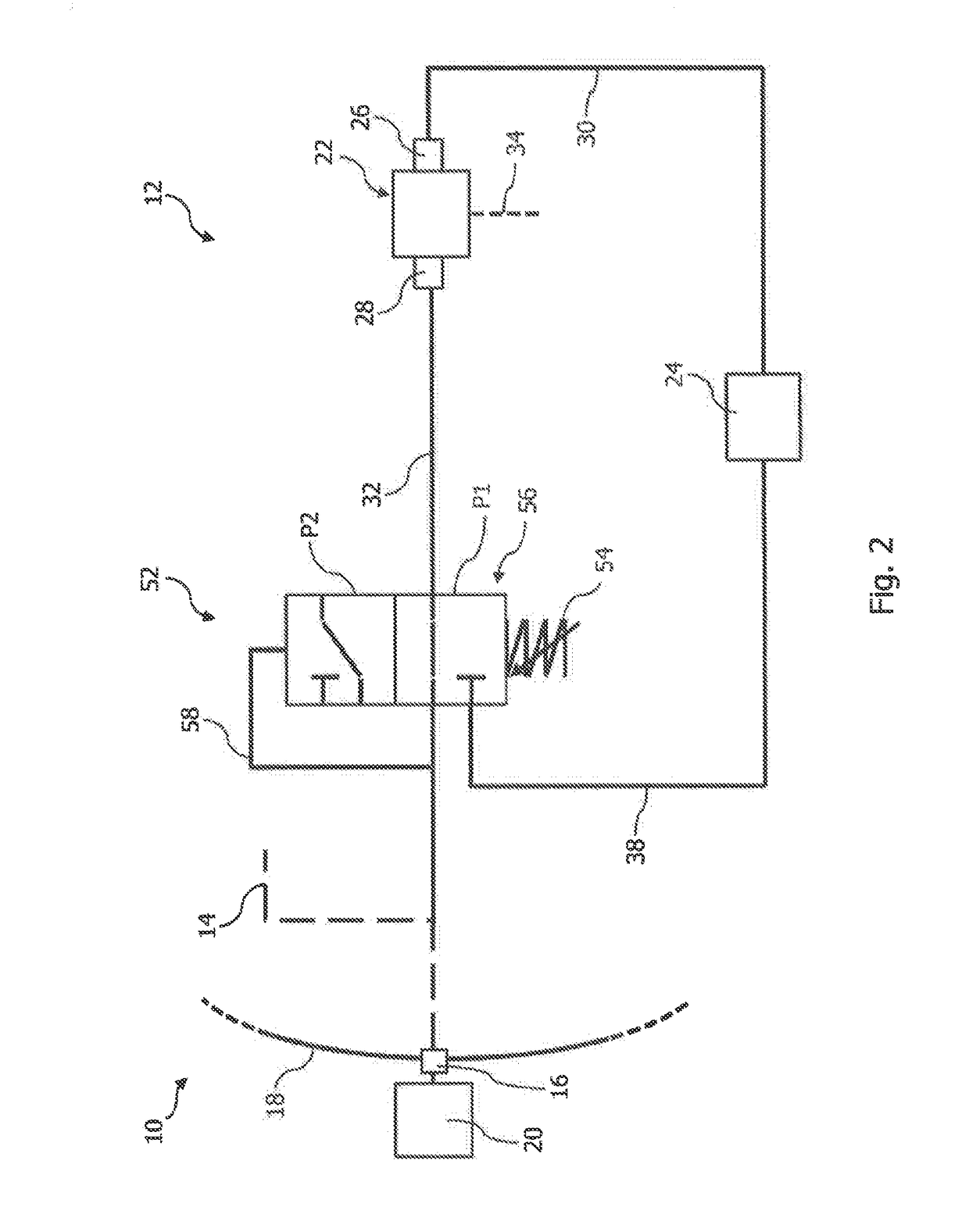

ActiveUS20110203987A1Avoid differential pressureConstant feed performanceMembranesGeneral water supply conservationReverse osmosisEngineering

The invention concerns a reverse osmosis system (1) with a membrane unit (2) comprising an inlet (3), a permeate outlet (4) and a concentrate outlet (5), a high-pressure pump (8) that is connected to the inlet (3), a pressure exchanger (11) connected on its concentrate side (10) to the concentrate outlet (5), and a booster pump between the pressure exchanger (11) and the inlet (3). It is endeavoured to make the energy consumption as small as possible. For this purpose, the booster pump is made as a displacement pump.

Owner:DANFOSS AS

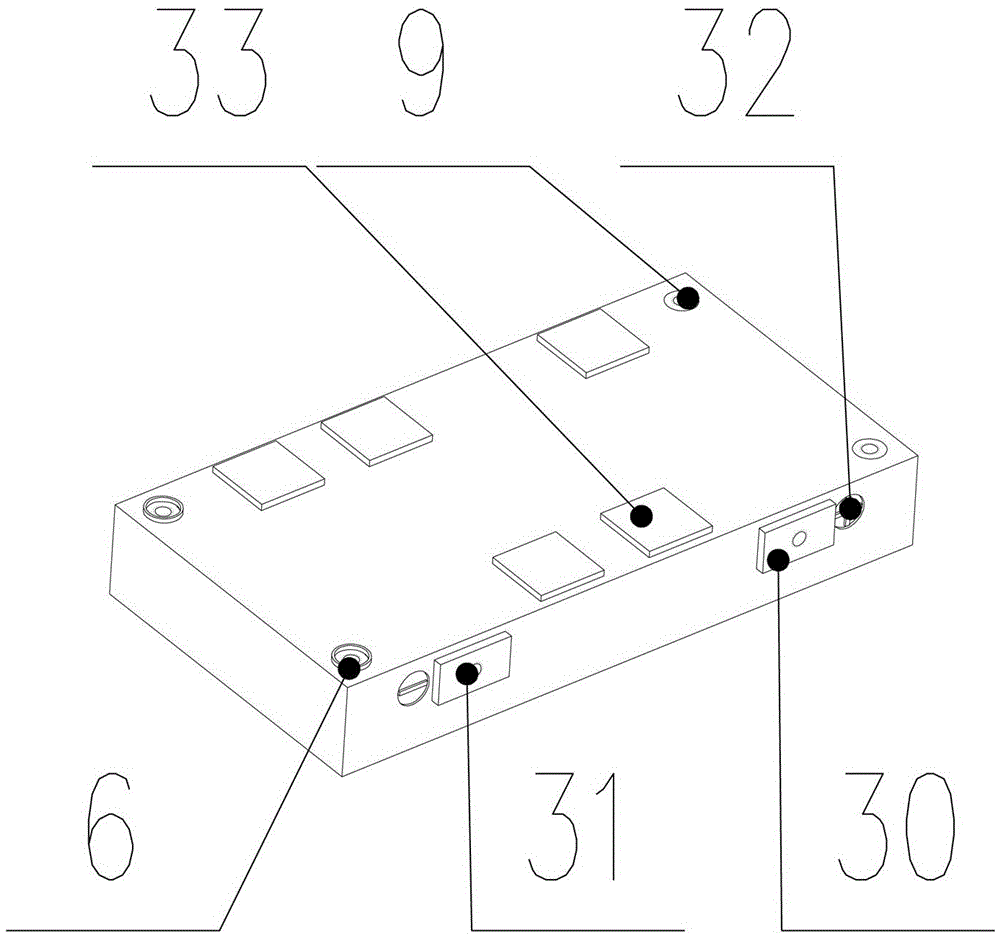

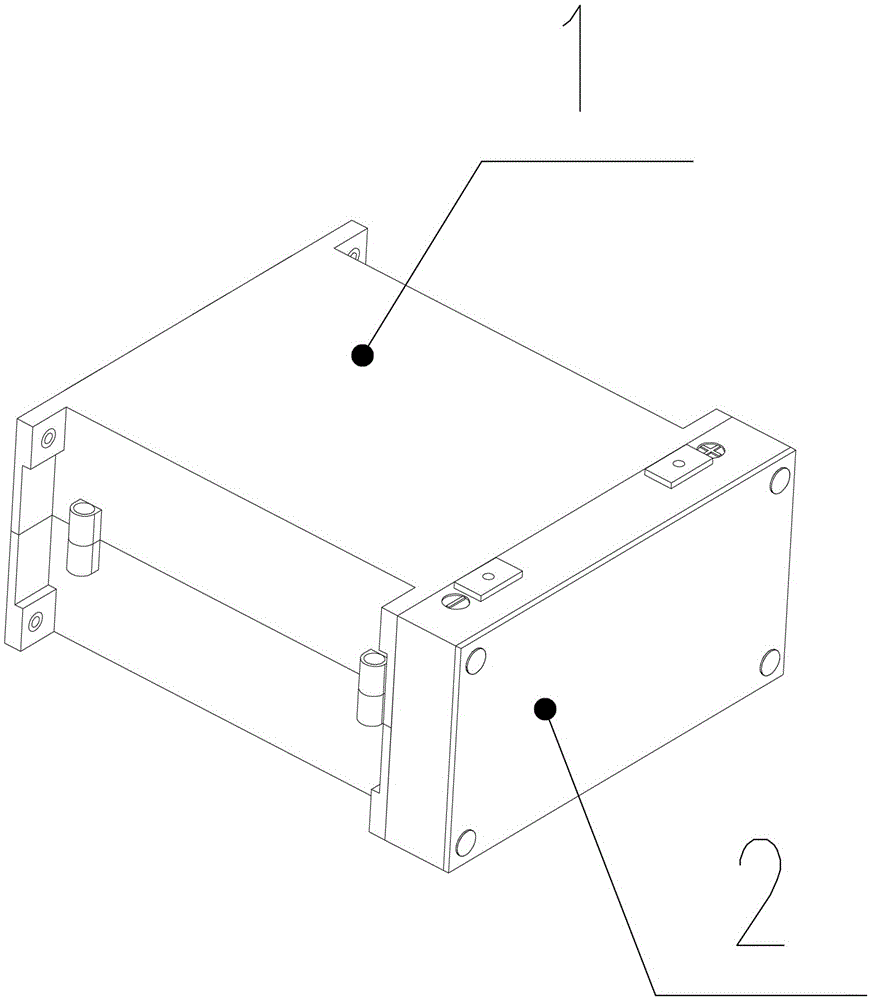

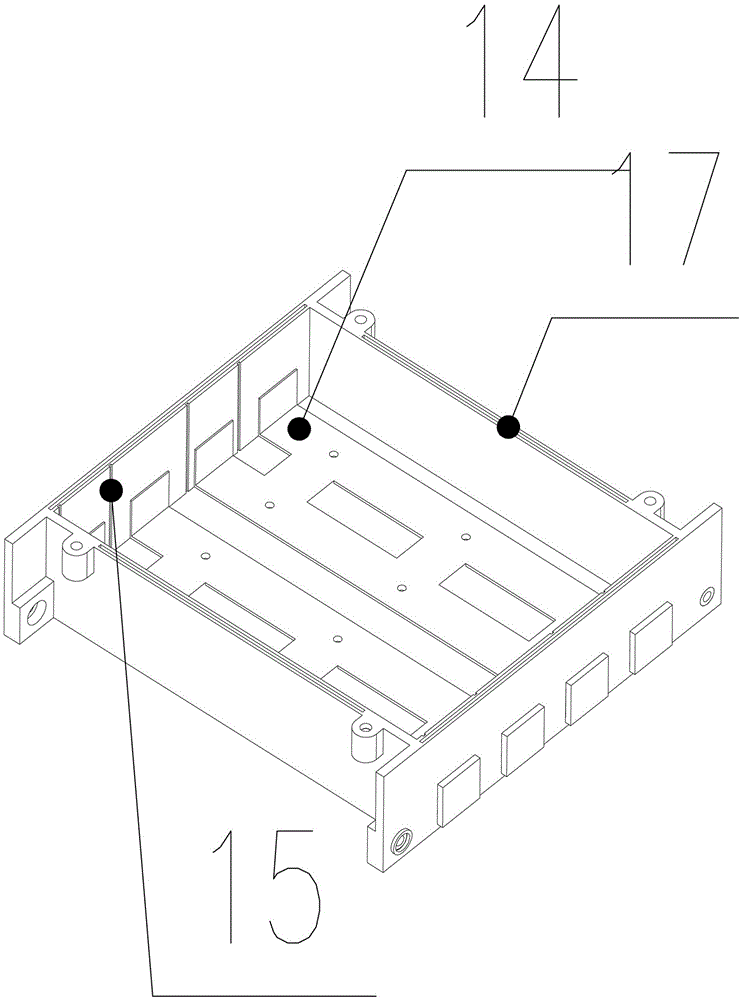

Lithium battery pack free from welding, easy to maintain and capable of being connected in parallel

ActiveCN105489799AEasy to operateEasy to check for faultsCell component detailsSingle strandSpot welding

The invention relates to a lithium battery pack free from welding, easy to maintain and capable of being connected in parallel. During the battery pack fabrication process, spot welding and welding are not needed, and the lithium battery pack is convenient to operate and maintain. In the technical scheme adopted by the invention, the lithium battery pack free from welding, easy to maintain and capable of being connected in parallel comprises a plurality of battery modules and a protection circuit module, wherein the battery modules are connected in an end-to-end way, one end of the whole battery module is connected with the protection circuit module, the battery modules are of sealed shell structures, multiple groups of single-strand battery modules are arranged in the battery modules, positive electrodes or negative electrodes of the single-strand battery modules are connected through a pole plate, the two ends of the pole plate are arranged on two opposite side surface of a shell, each single-strand battery module comprises a plurality of cylindrical monomer batteries, and the positive electrode and the negative electrode at the upper end and the lower end are provided with supports. The lithium battery pack has the advantages that the battery module and the production circuit are two independent modules and are physically pressed and connected, the lithium battery pack is convenient to operate, and a fault is easy to detect.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

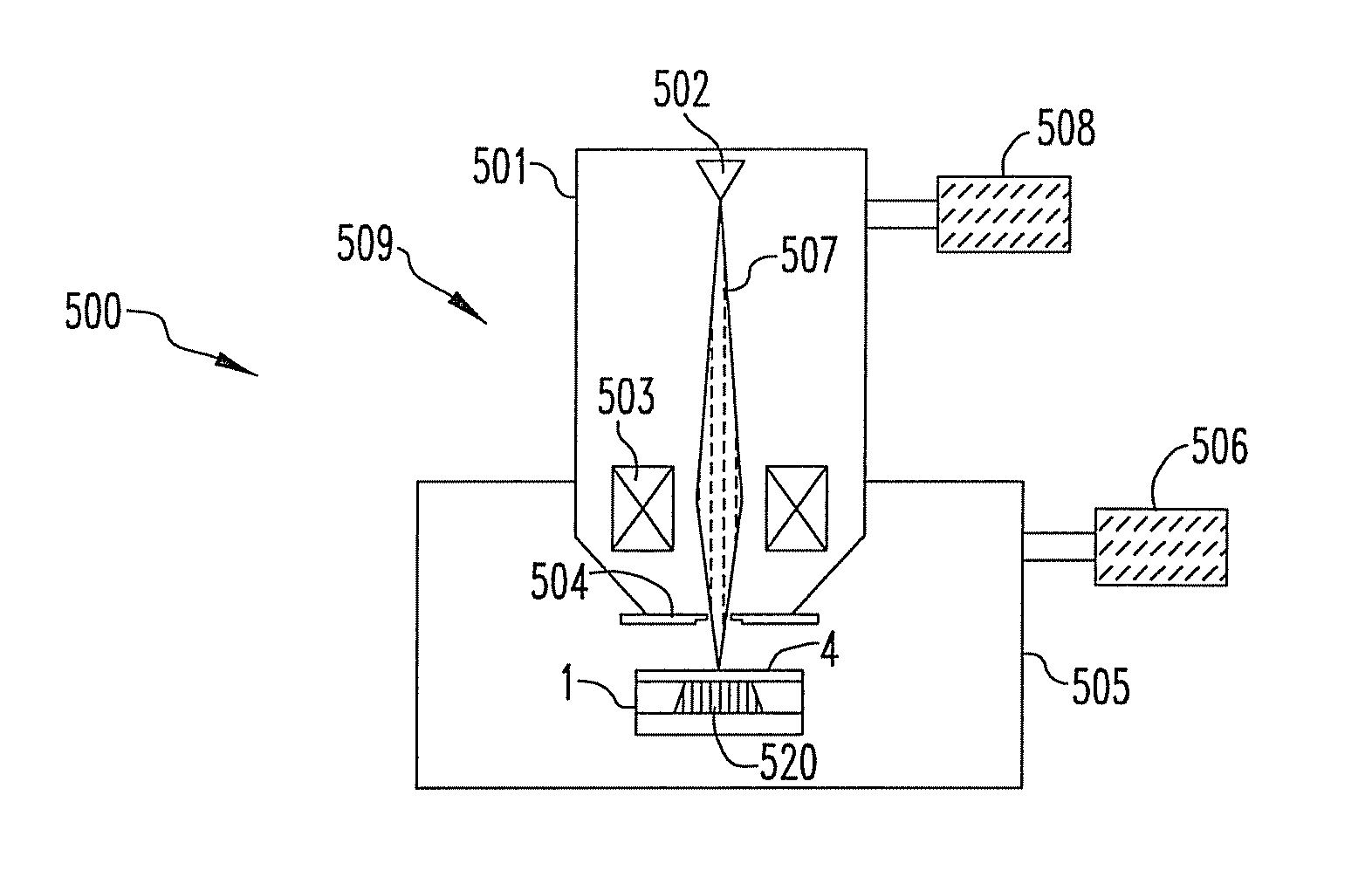

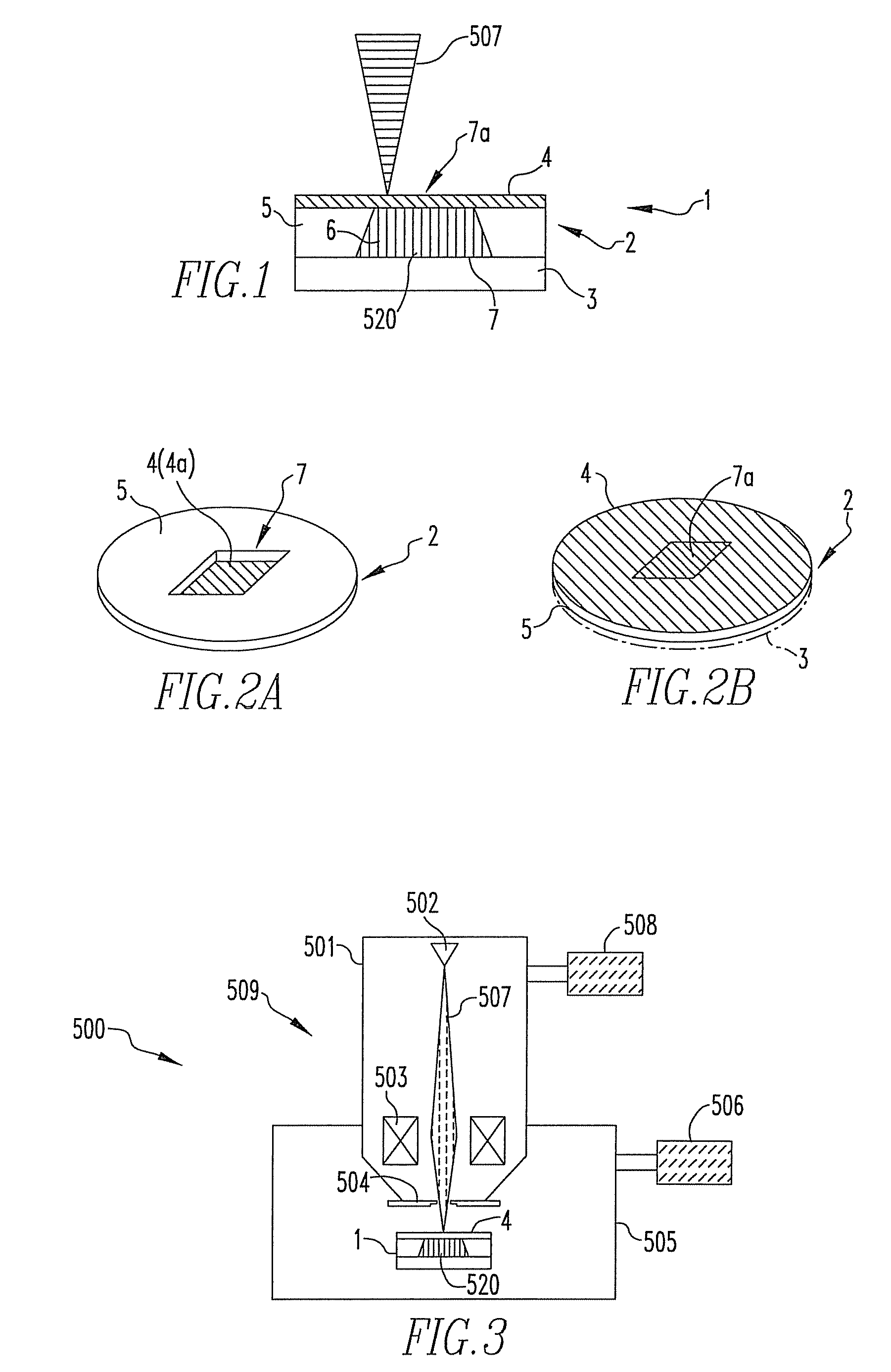

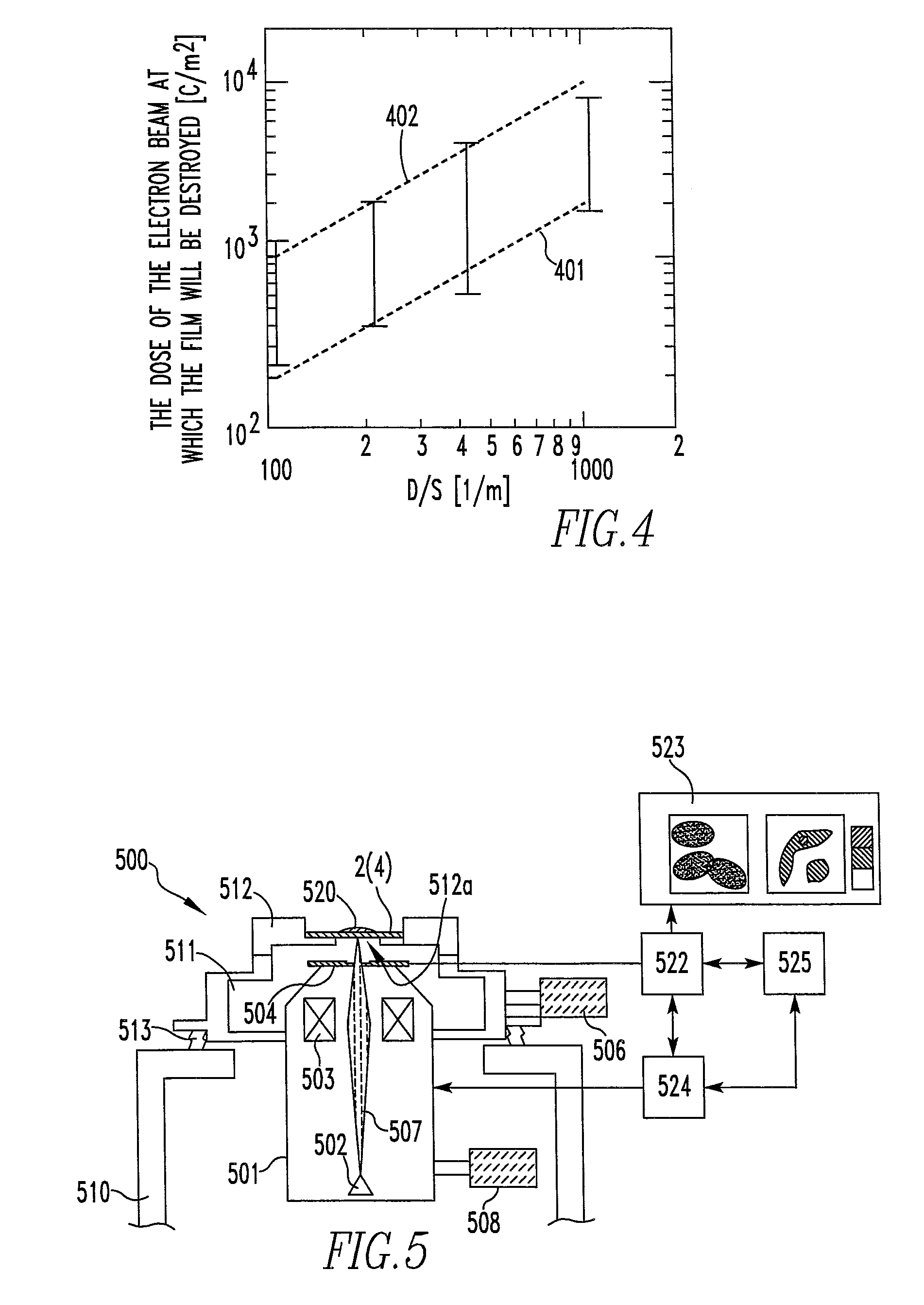

Sample inspection method, sample inspection apparatus, and sample holder

ActiveUS7745785B2Simple structureReduce sheet resistanceMaterial analysis using wave/particle radiationElectric discharge tubesLight beamPressure difference

Owner:JEOL LTD

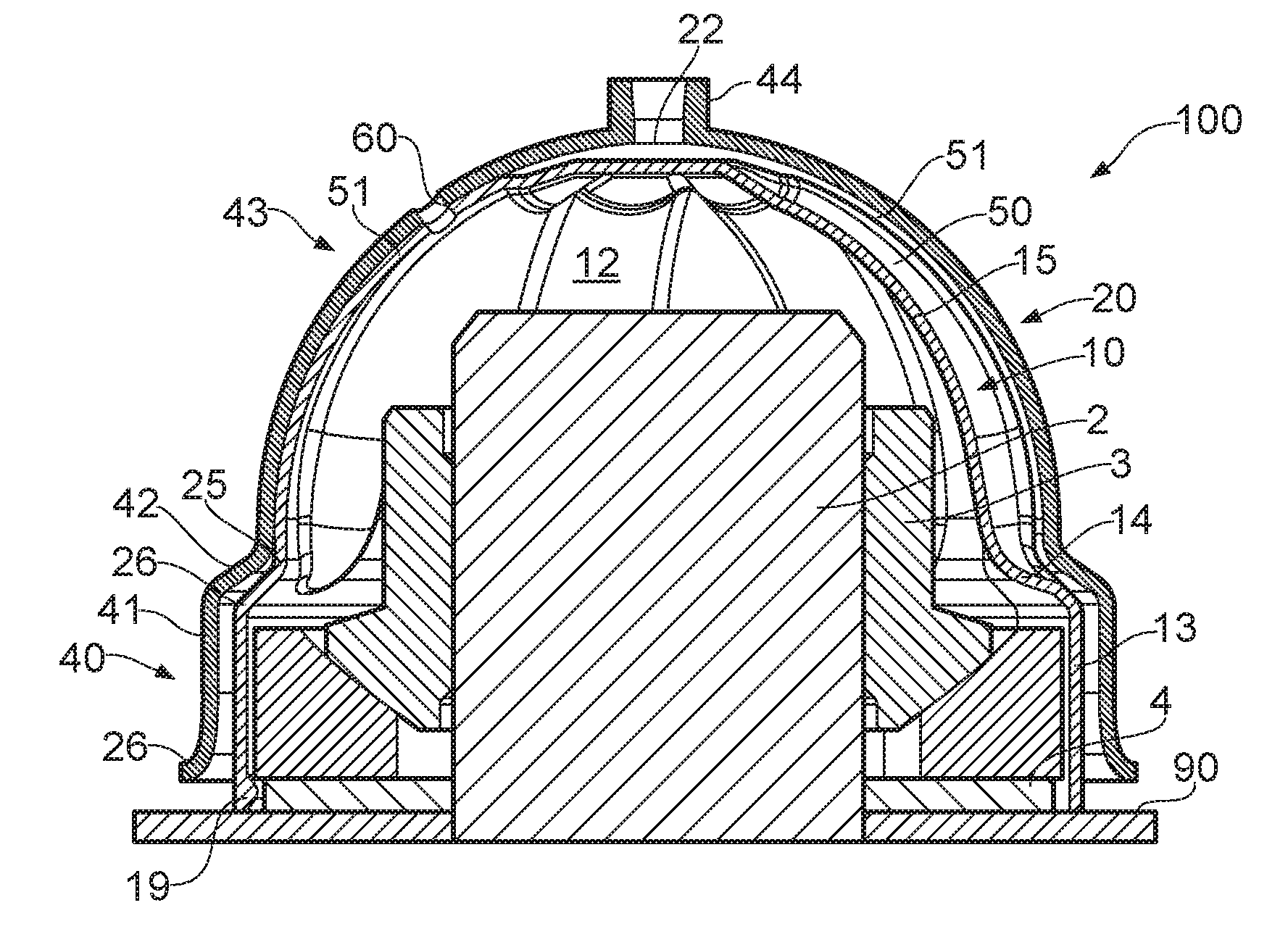

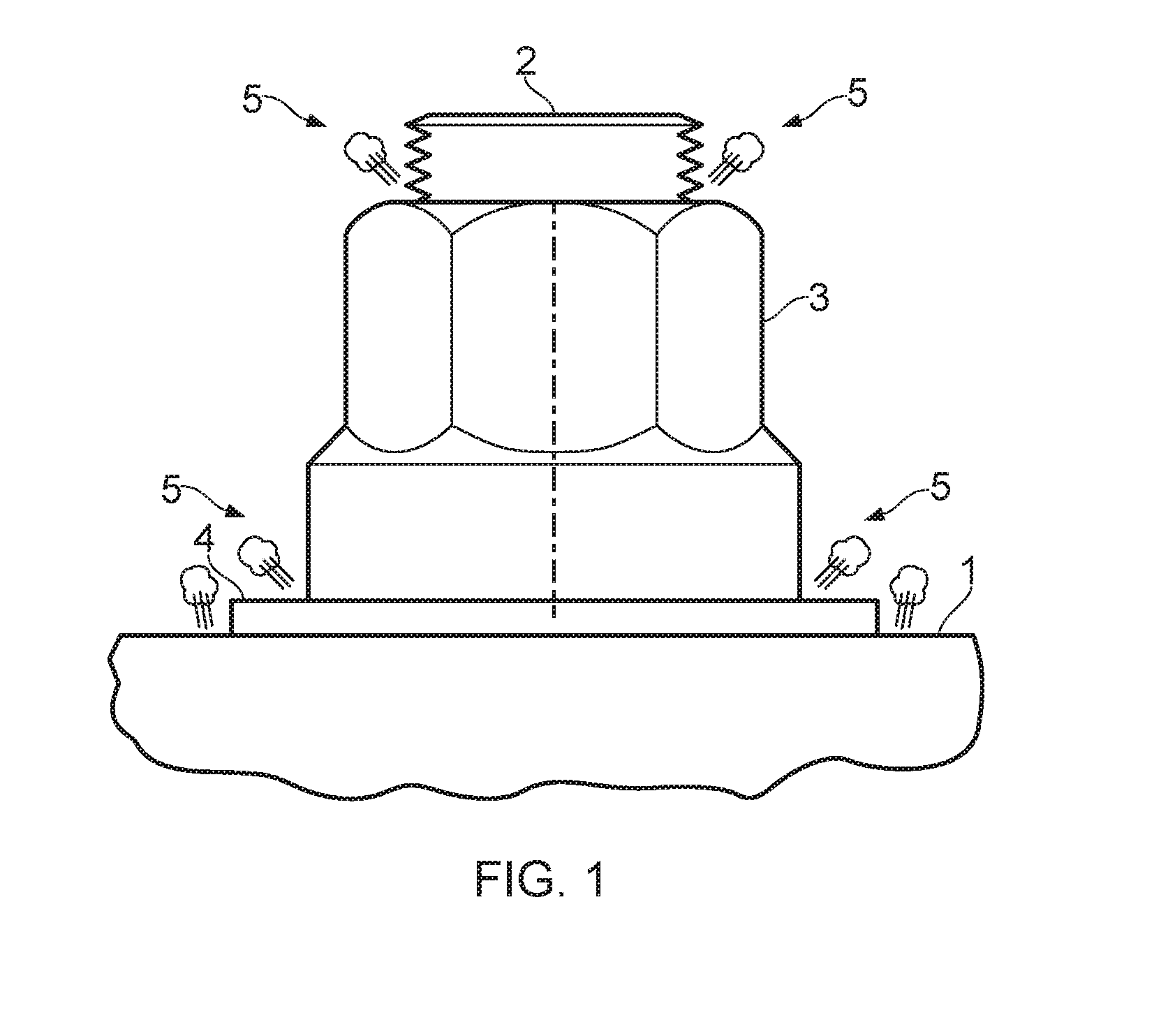

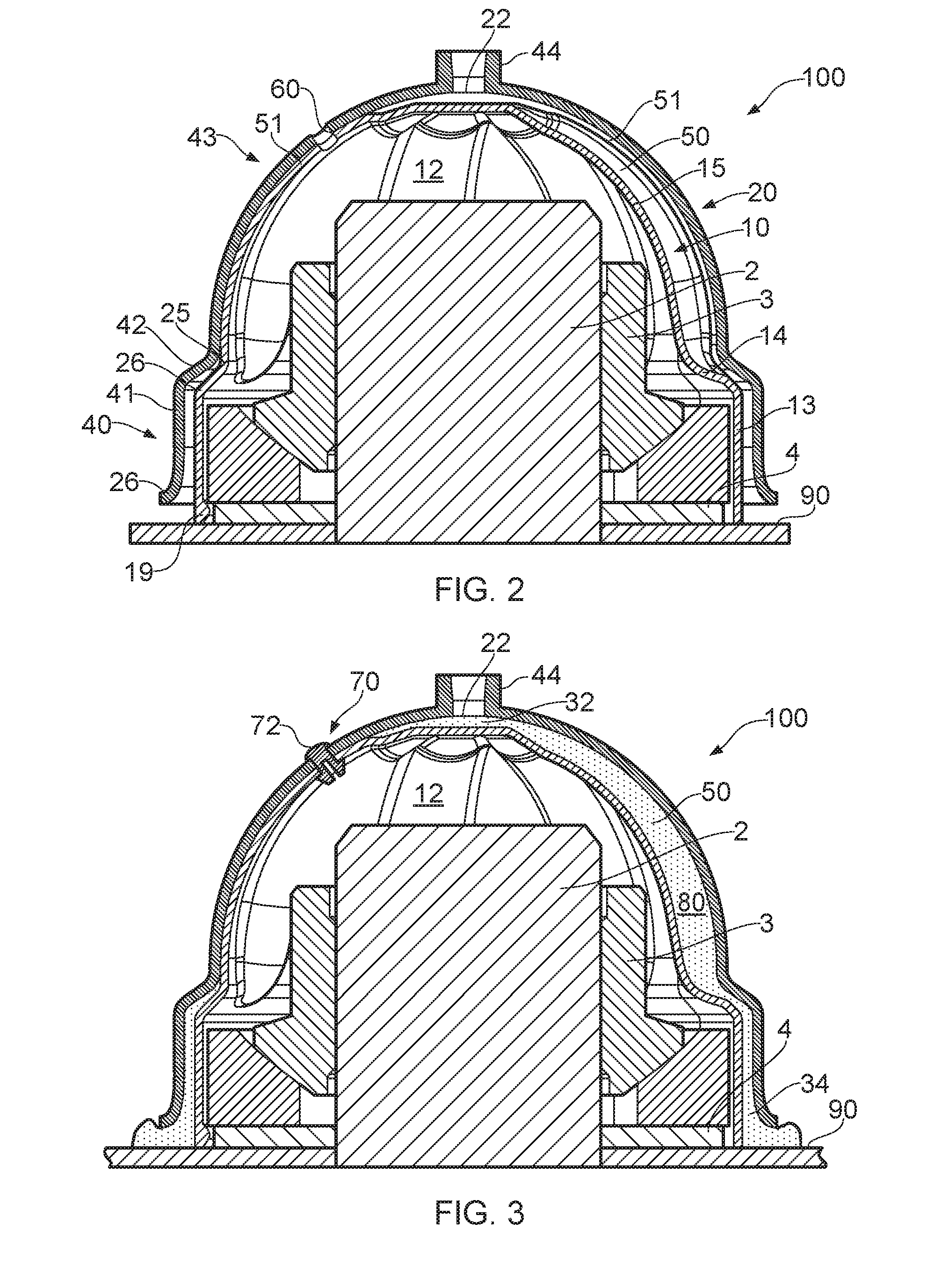

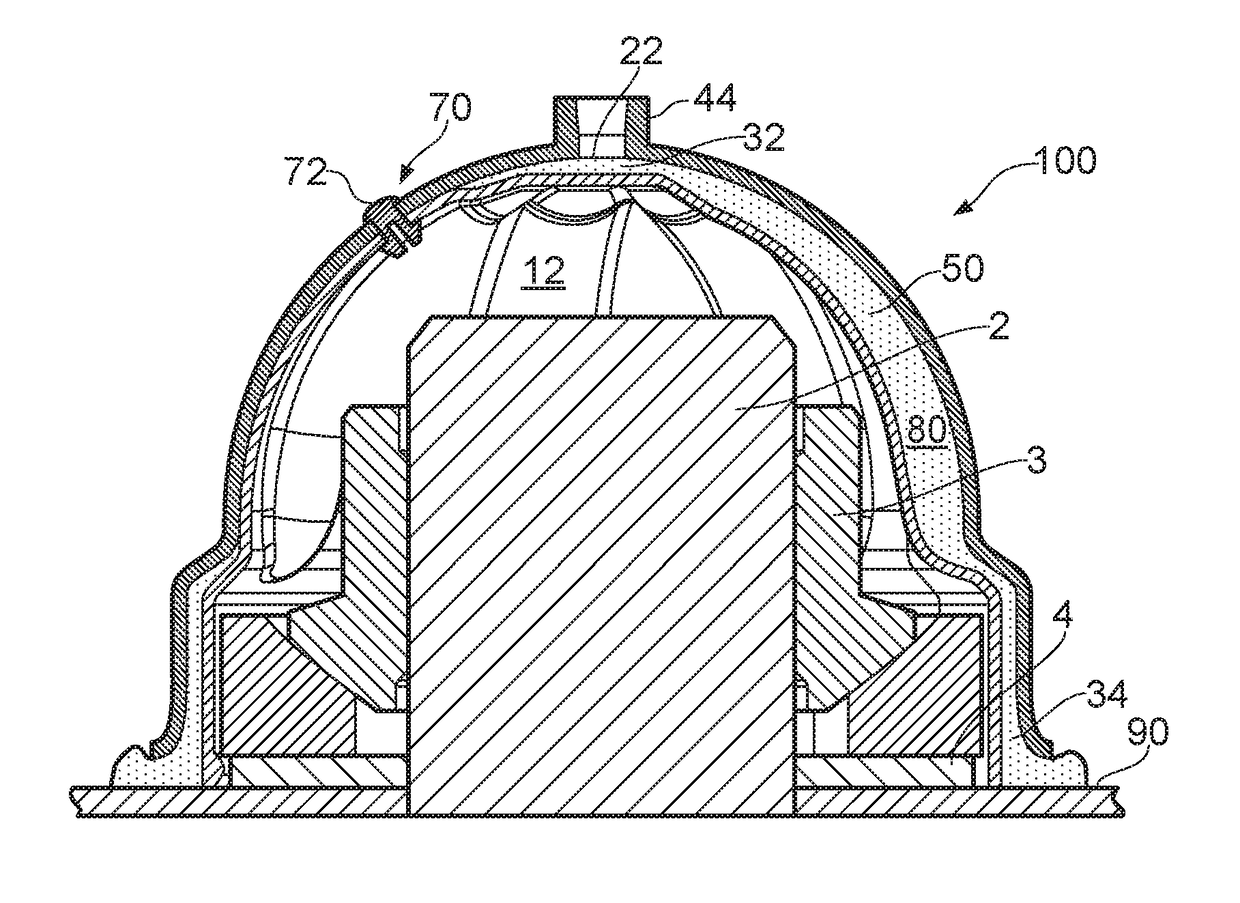

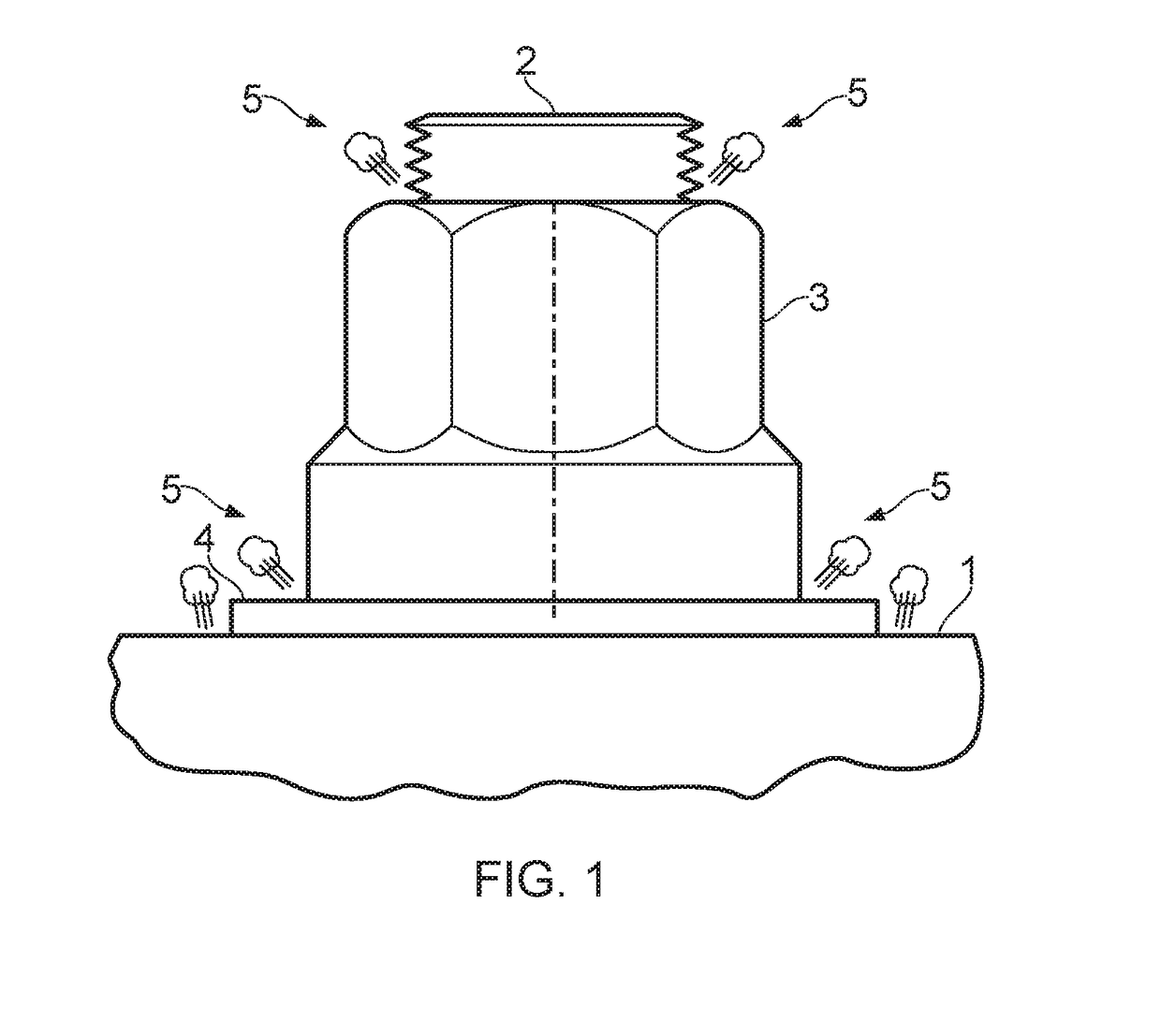

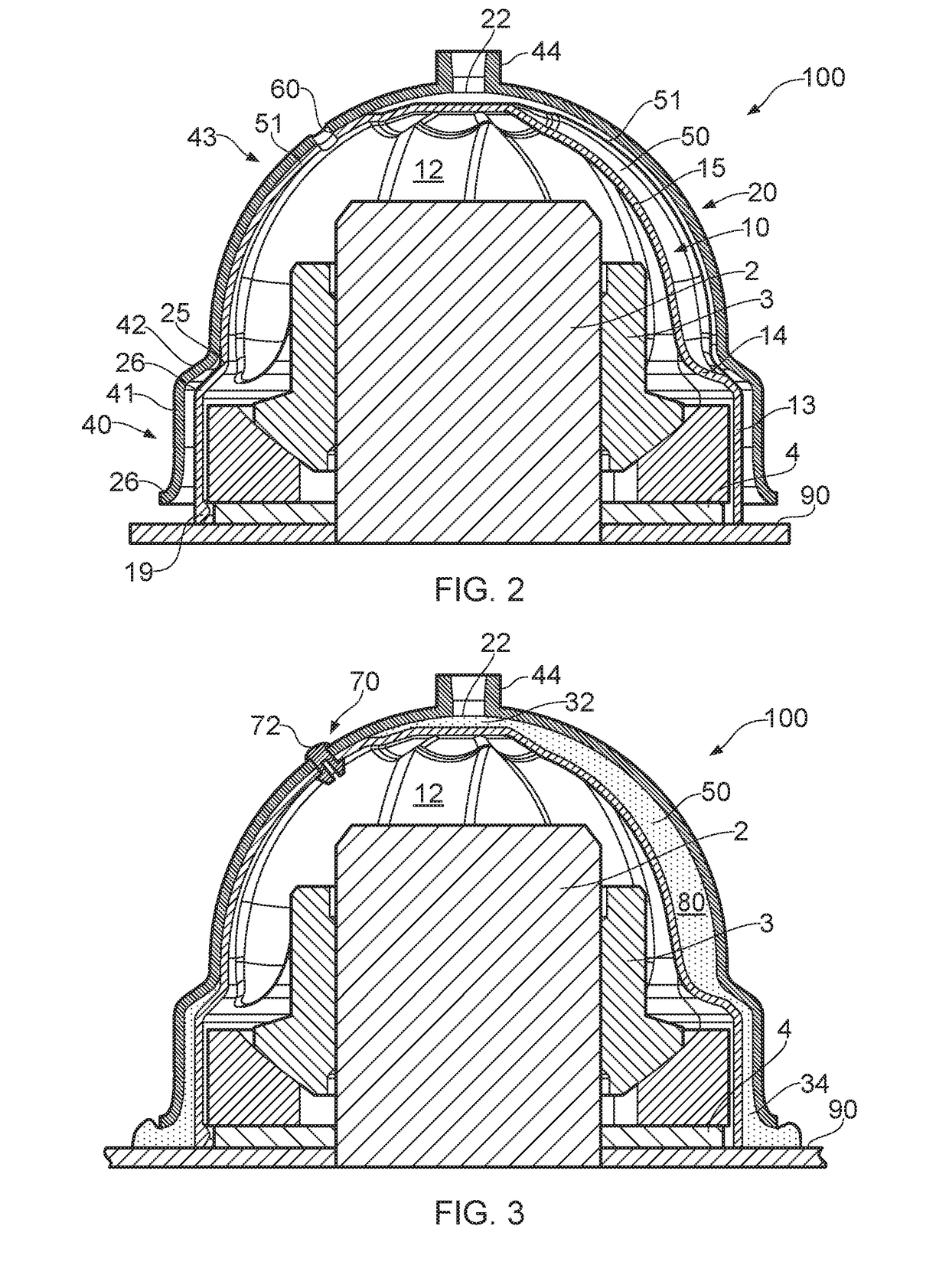

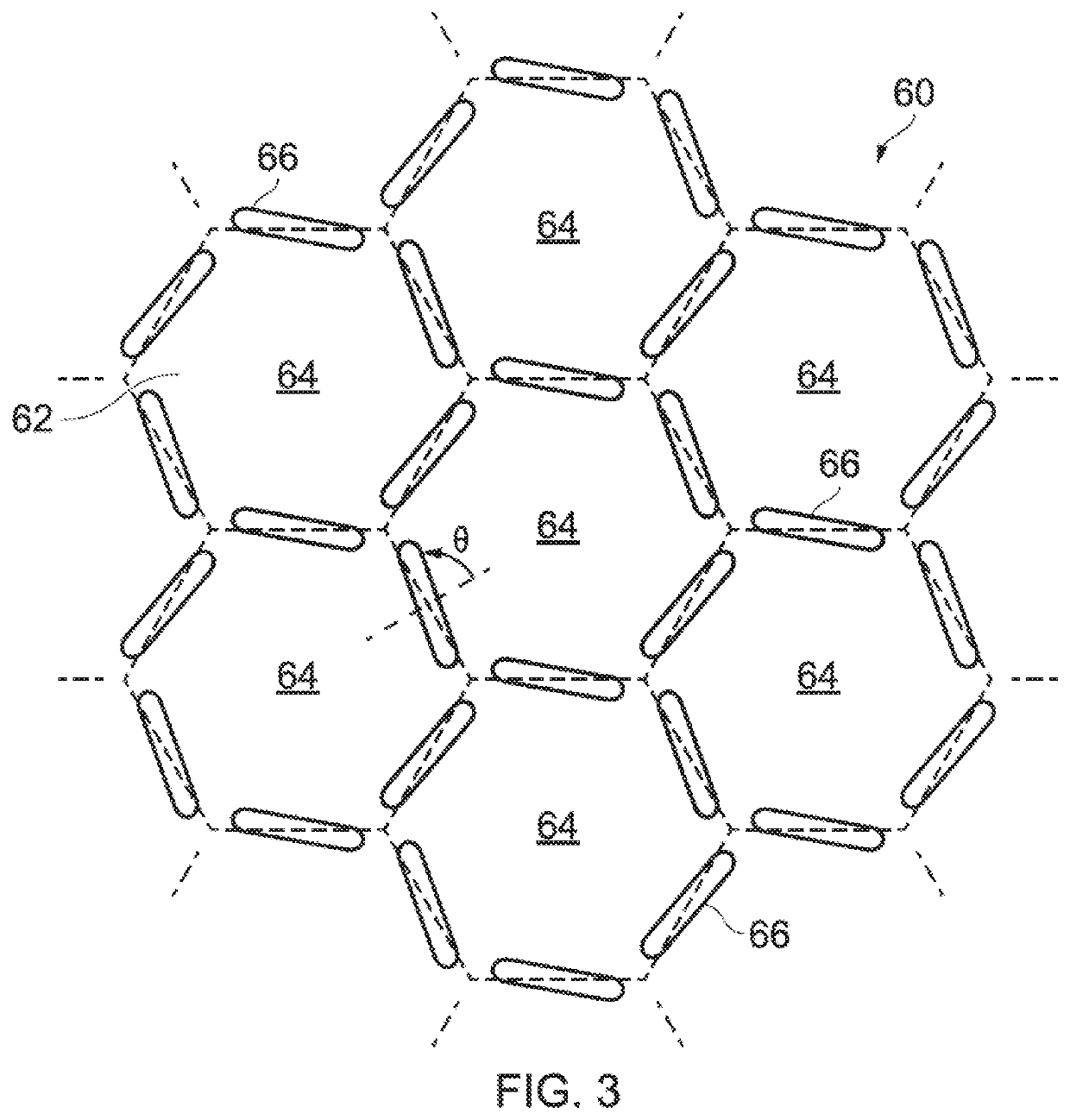

Spark containment cap

ActiveUS20160169266A1Enabling inspectionEasy to installRemovable ornamentalNutsEngineeringAir cavity

A spark containment cap is disclosed for enclosing an end of a fastener protruding from a structure. The cap includes a cap body having an annular base terminating at a rim which surrounds an opening into an air cavity arranged to enclose the fastener end and having an aperture in fluid communication with the cavity. An annular bead of uncured sealing material is provided around the opening into the cavity, the bead of sealing material being curable to provide a seal between the cap body and the structure to seal a volume of gas within the cavity. A closure member has a closed configuration in which it seals the aperture, and an open configuration in which it does not seal the aperture.

Owner:AIRBUS OPERATIONS LTD

Spark containment cap

A spark containment cap is disclosed for enclosing an end of a fastener protruding from a structure. The cap includes a cap body having an annular base terminating at a rim which surrounds an opening into an air cavity arranged to enclose the fastener end and having an aperture in fluid communication with the cavity. An annular bead of uncured sealing material is provided around the opening into the cavity, the bead of sealing material being curable to provide a seal between the cap body and the structure to seal a volume of gas within the cavity. A closure member has a closed configuration in which it seals the aperture, and an open configuration in which it does not seal the aperture.

Owner:AIRBUS OPERATIONS LTD

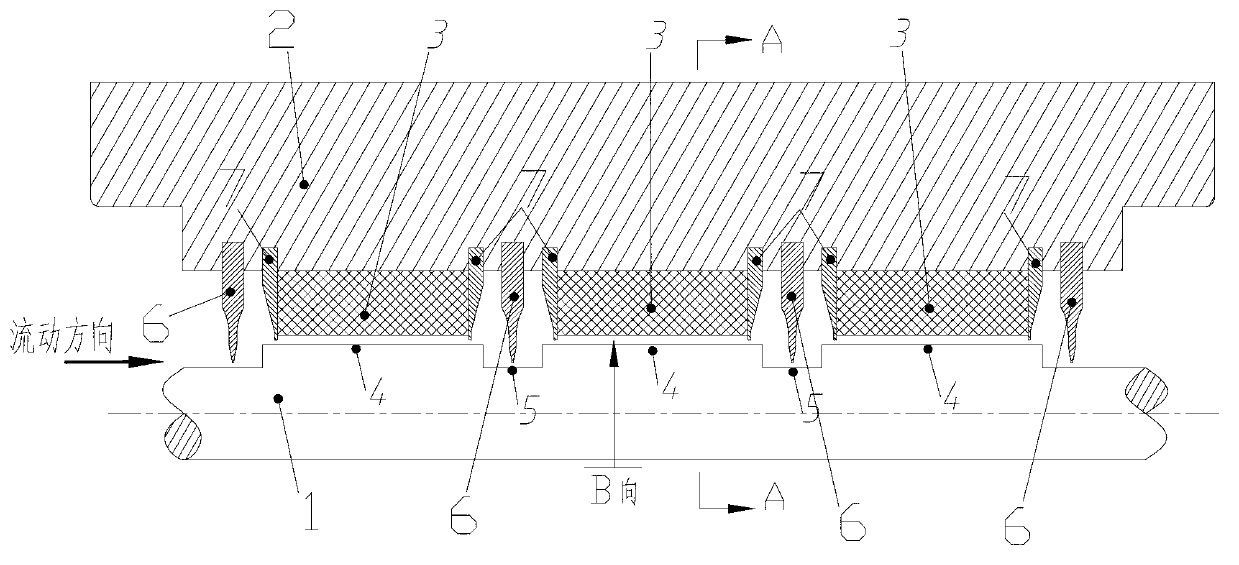

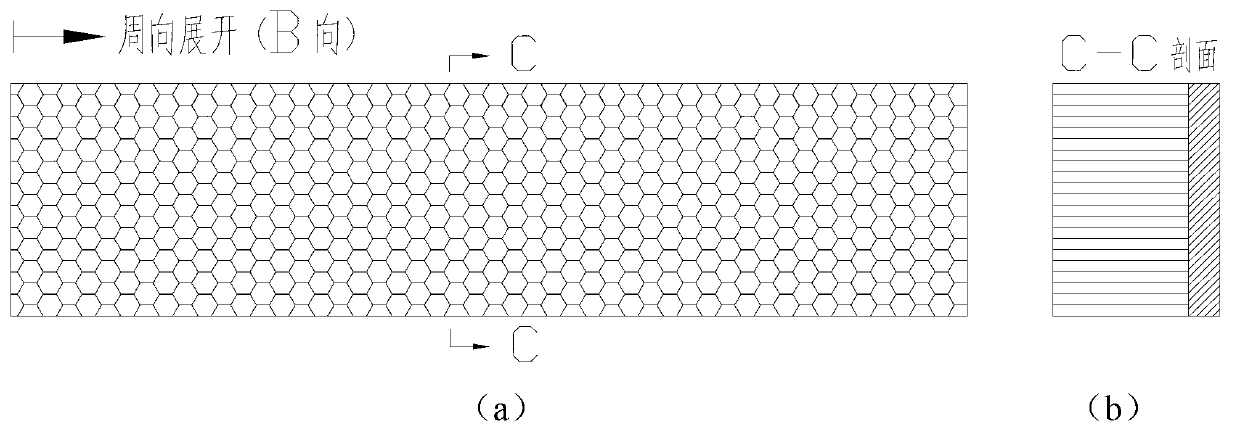

Labyrinth damping sealing device with low leakage and high damping performance

InactiveCN102953771AImprove stabilityHigh damping characteristicsPump componentsBlade accessoriesEngineeringLow leakage

The invention discloses a labyrinth damping sealing device with low leakage and high damping performance. The sealing device comprises a rotating shaft, sealing long teeth, sealing short teeth and a damping part, wherein the rotating shaft is provided with a plurality of bosses and grooves, which are axially and alternately arranged; and the sealing long teeth, the sealing short teeth and the damping part are fixed on a sealing stator ring. The damping part has the following three structures: a honeycomb structure, a hole structure and a bag structure. The labyrinth damping sealing device has the characteristics of low leakage and high damping; the possibility of causing damage to a rotor and a sealing part due to impact and rubbing between the damping sealing part (which is of a honeycomb structure or a hole structure) and the rotor is also eliminated; and not only can the energy conversion efficiency and the operation stability of a turbomachinery be further improved, but also the service life of the sealing part can be prolonged.

Owner:XI AN JIAOTONG UNIV

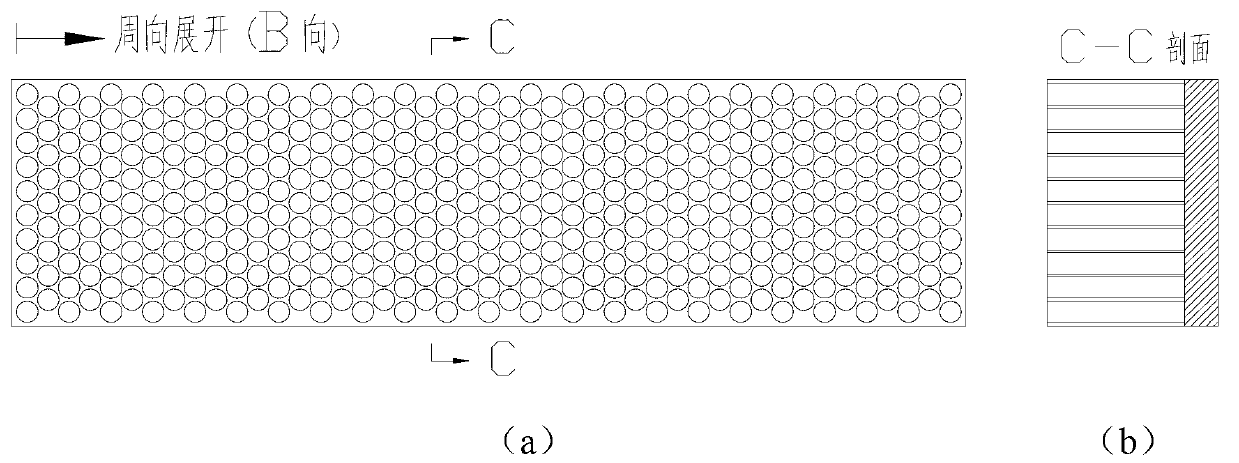

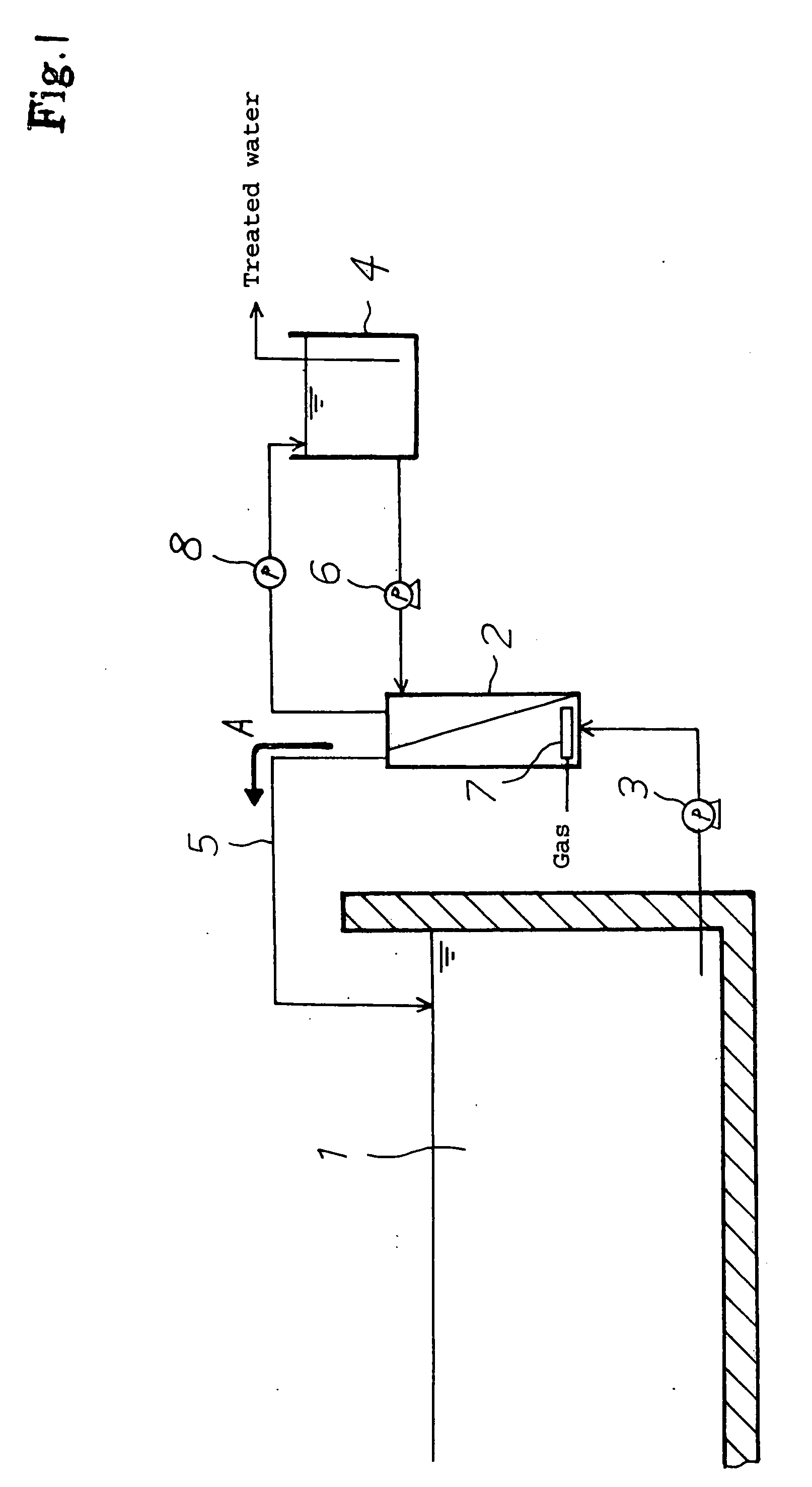

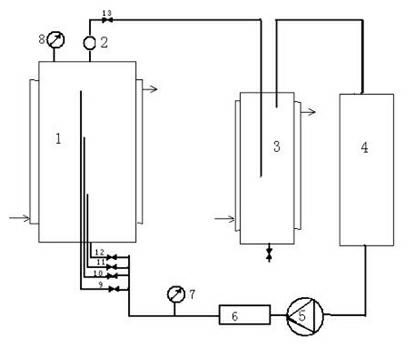

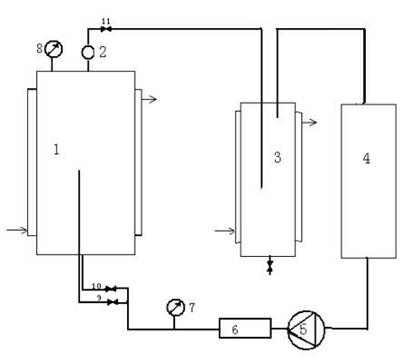

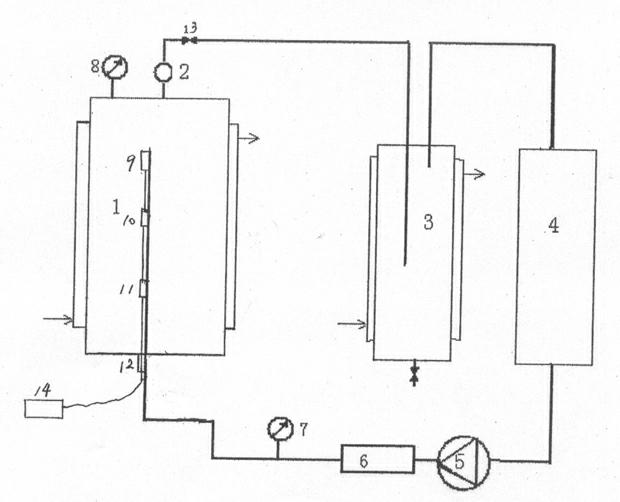

Method for cleaning separation membrane

InactiveUS20060213834A1Low costNo decrease of the operatioMembranesSemi-permeable membranesFiltrationMembrane surface

Pulse back washing for applying a back pressure from the filtrate side to the raw water side of the membrane is repeated plural times for recovering a TMP during usual main back washing applied by suspending membrane filtration, when the TMP is increased when tank water extracted out of a biological treatment tank 1 is filtrated through the membrane by a cross-flow method. Pulse back washing is applied at a stage when the TMP is 80% or less of the permissible TMP to peel the deposits on the membrane surface, and the peeled deposits are returned to the biological treatment tank concomitantly with a circulating flow. Clogging substances on the separation membrane is removed in a direction opposite to the direction of pulse back washing by selecting the destination of discharge of back wash drain to be the inlet side of the separation membrane in the main back wash step.

Owner:NGK INSULATORS LTD

Gate valve

InactiveUS9599233B2Avoid deformationWeight increaseSemiconductor/solid-state device manufacturingSlide valveFirst pathwayEngineering

In a valve box that makes up a gate valve, a balance room is disposed on one side wall that faces toward a processing chamber. In the balance room, a first seal member is provided to surround a first pathway, and a second seal member is mounted on an outer edge of the balance room. Further, a balance port is formed in the balance room. The balance port communicates with an accommodating room that is formed in the interior of the valve box. In a valve closed state in which a valve disk is seated on a valve seat of the valve box, the pressure inside the accommodating room and the pressure inside the balance room are equalized or made uniform through the balance port.

Owner:SMC CORP

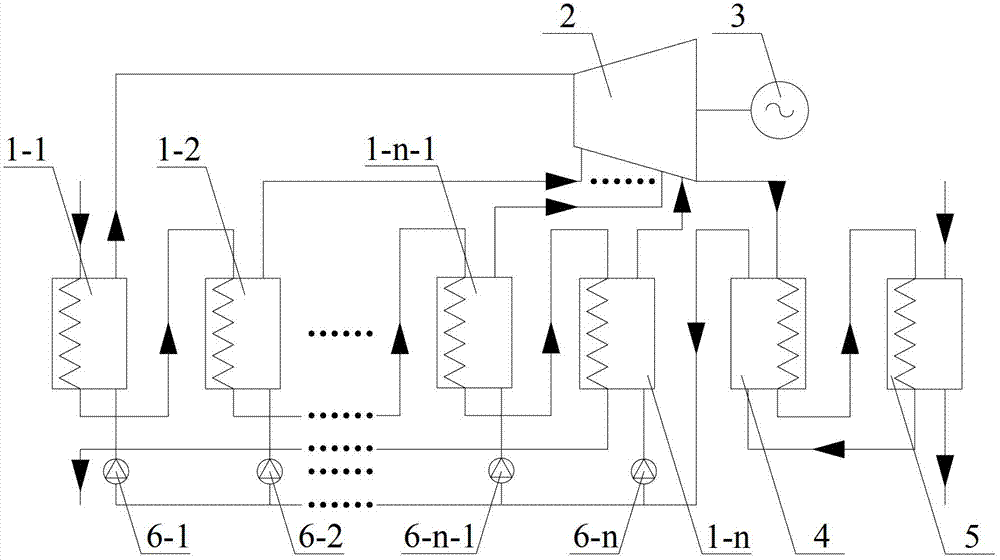

ORC (organic Rankine cycle) power generation system based on series connection of multistage evaporators

InactiveCN103195518AReduce defects with large irreversible lossesAvoid differential pressureSteam engine plantsOrganic Rankine cycleEngineering

The invention discloses an ORC power generation system based on series connection of multistage evaporators. The system comprises n evaporators , wherein the n evaporators are connected in series sequentially on a heat source side; a heat source fluid enters a first evaporator, is discharged from a last evaporator and is recharged to the underground; a working medium side of each evaporator is connected to n inlets of a steam turbine; an outlet of the steam turbine is sequentially connected with a preheater and a condenser in series; a working medium enters the preheater and the condenser, and then enters the other side of the preheater again and exchanges heat with exhaust steam exhausted by the steam turbine after working; the working medium flowing out of the preheater enters n working medium pumps in a parallel connection manner, and the n working medium pumps are connected to the n evaporators correspondingly, so that the closed cycle of the working medium is formed; a cold source side of the condenser is connected to a cooling water circulation system; a plurality of evaporator heat source sides are in series connection; and the working medium side is directly connected with the steam turbine in parallel, so that the defect that a single evaporator in a conventional ORC system is irreversible and has large loss is overcome, and the utilization efficiency and the technical economy of the system are improved.

Owner:TIANJIN UNIV

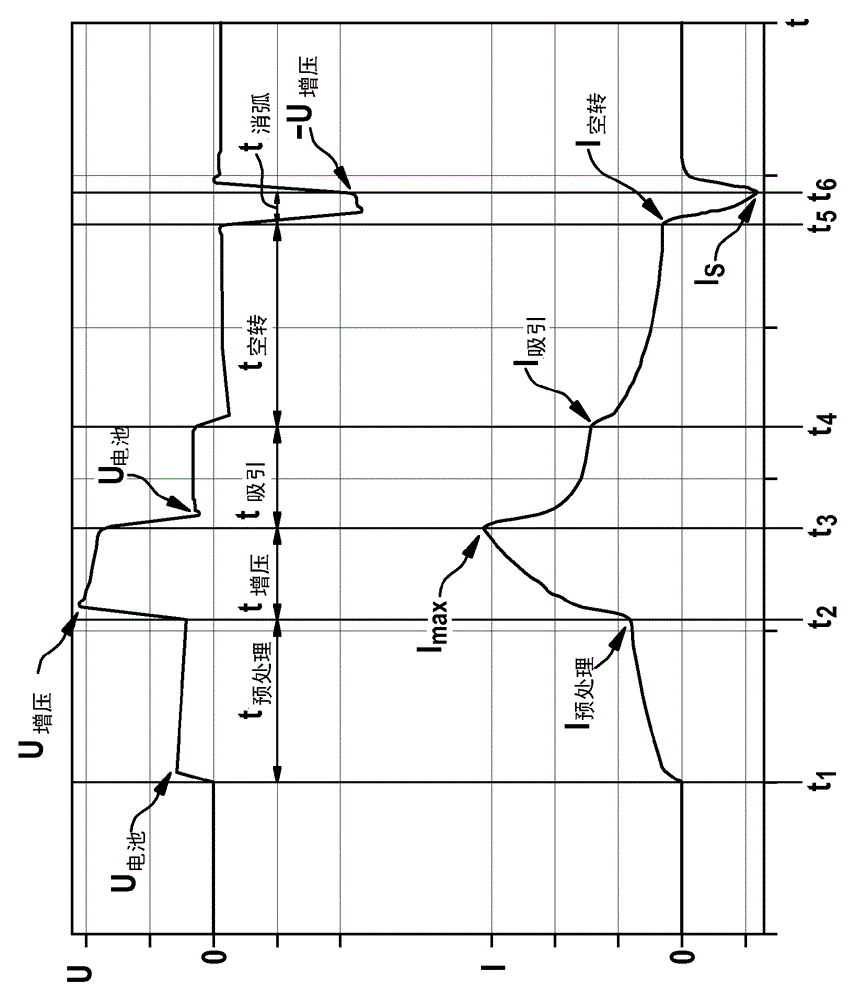

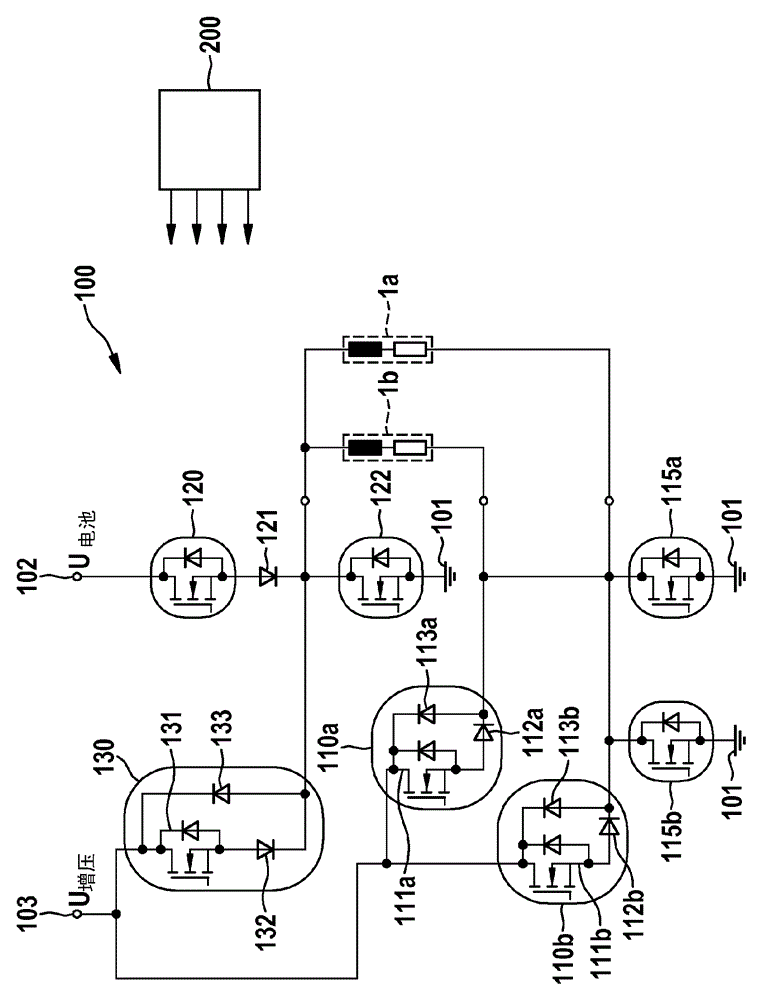

Method for controlling an injection process of a magnetic injector

ActiveCN105009232AEliminate magnetic field energyDuration determinedElectrical controlFuel injection apparatusEngineeringInternal combustion engine

The invention relates to a method for controlling an injection process of a magnetic injector of an internal combustion engine, wherein the magnetic injector has a coil. In order to open the magnetic injector, the coil is charged with a first current (IVK, Imax, Ipull). In order to keep the magnetic injector open, the coil is short-circuited, and in order to close the magnetic injector, the coil is charged with a second current (1s), wherein the second current (1s) is directed in the opposite direction of the first current (IVK, Imax, IAnzug).

Owner:ROBERT BOSCH GMBH

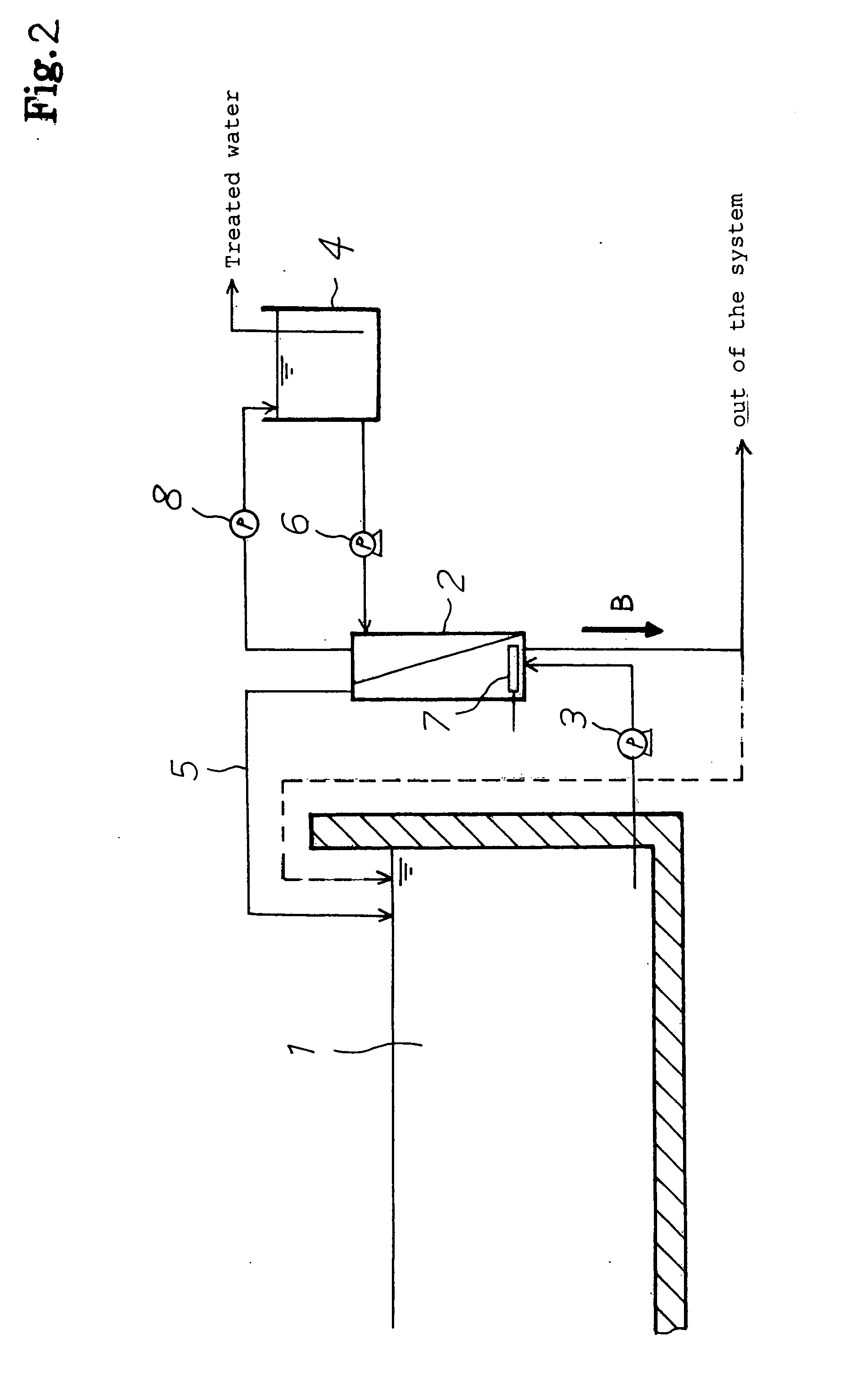

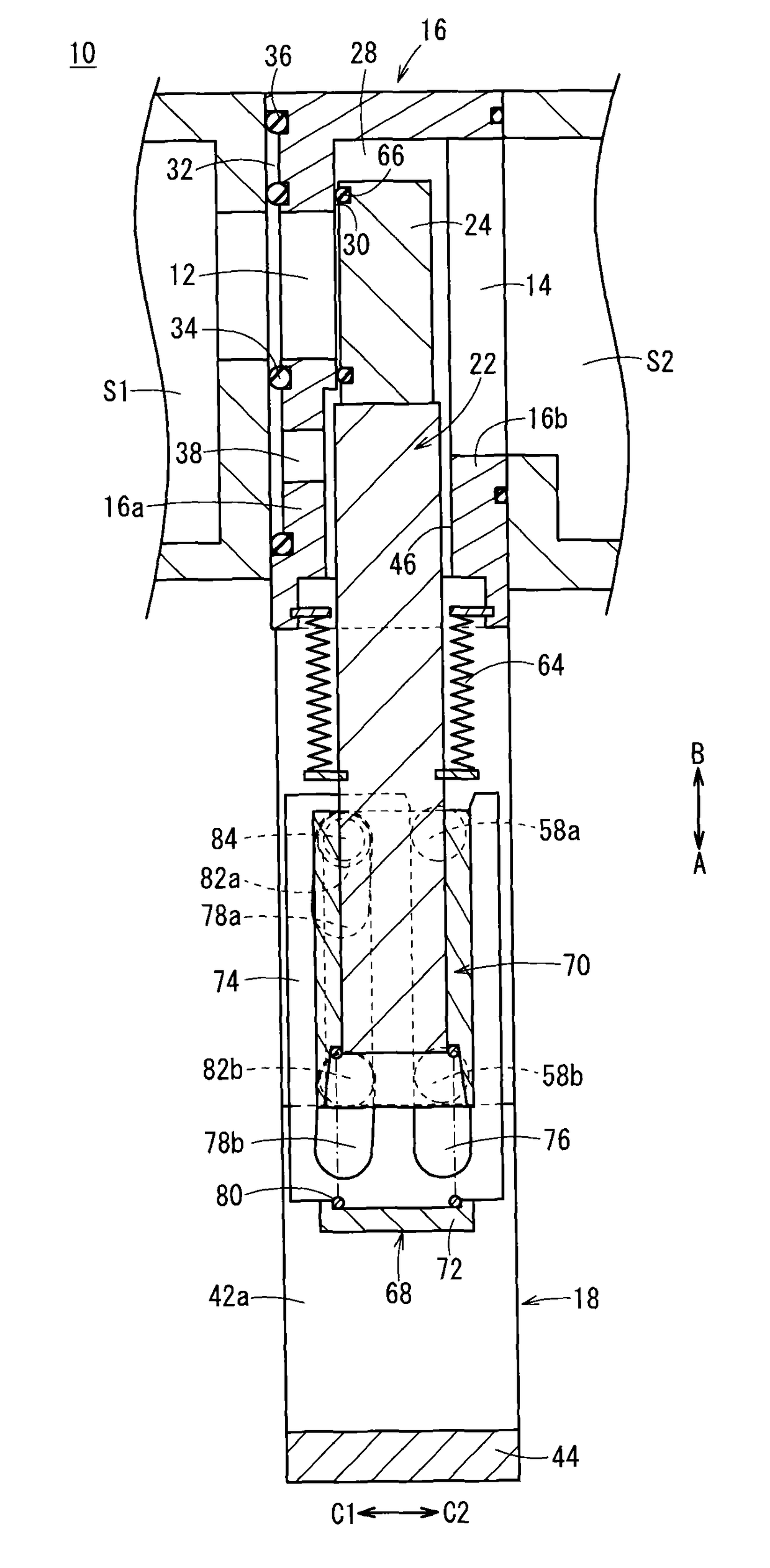

Eccentric coupling device in radial compliance scroll compressor

InactiveUS20050129552A1Avoid differential pressureEasy constructionEngine of arcuate-engagement typeOscillating piston enginesCouplingCrankshaft

An eccentric coupling device in a radial compliance scroll compressor including a crank pin eccentrically arranged at an upper end of a crankshaft included in the scroll compressor, and provided with a vertically-extending cut surface at one side thereof, a bush fitted around the crank pin, and provided with a crank pin hole and a stopper hole, a stopper fitted in the stopper hole, and an engagement jaw adapted to prevent a vertical movement of the stopper, thereby preventing a vertical movement of the bush, the engagement jaw being provided at an upper end of the crank pin. The bush is arranged such that an upper end thereof is flush with an upper end of the crank pin. The stopper hole overlaps with the crank pin hole so that the stopper selectively comes into contact with the cut surface in accordance with a rotation of the crank pin. The stopper has a length shorter than that of the stopper hole.

Owner:LG ELECTRONICS INC

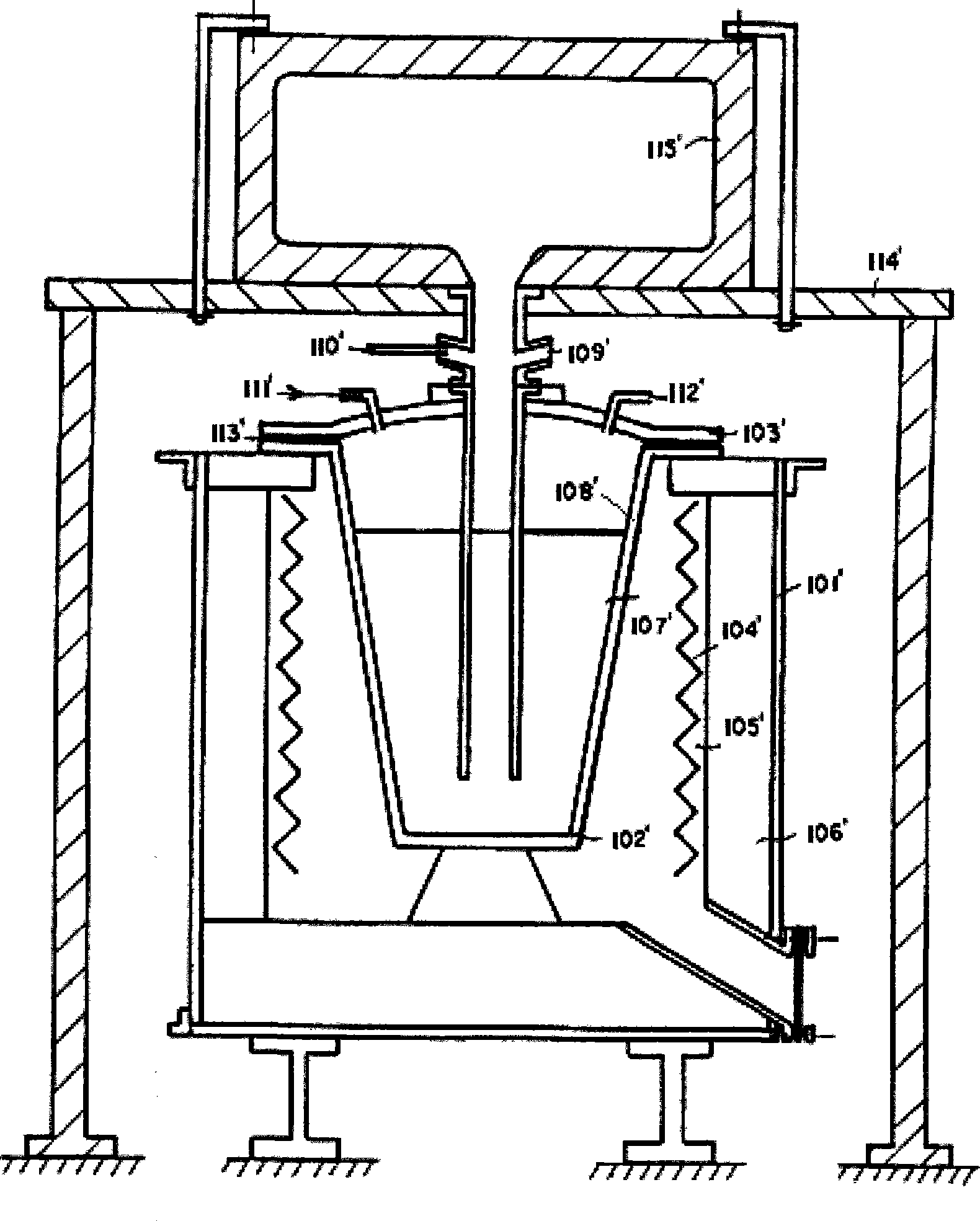

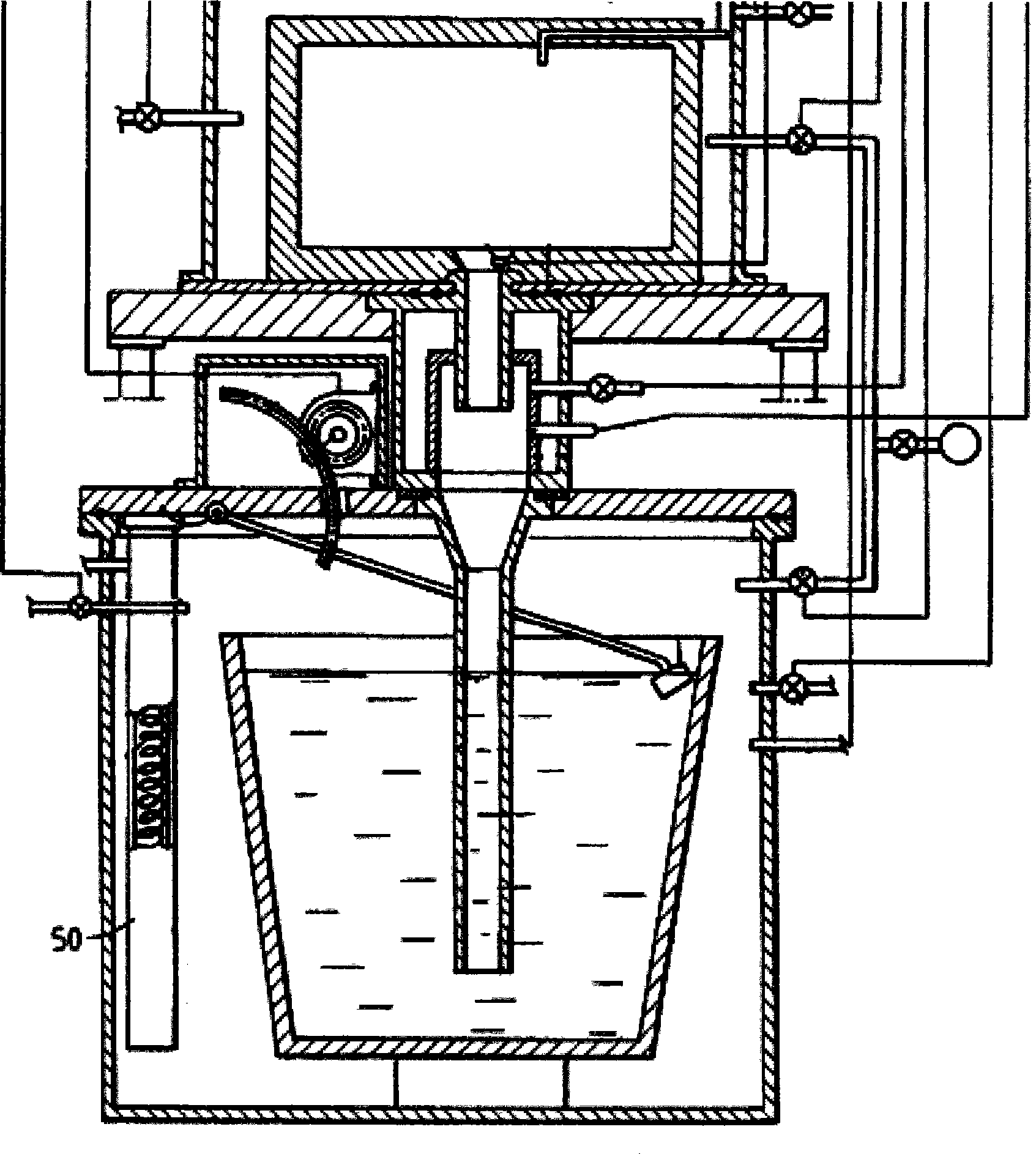

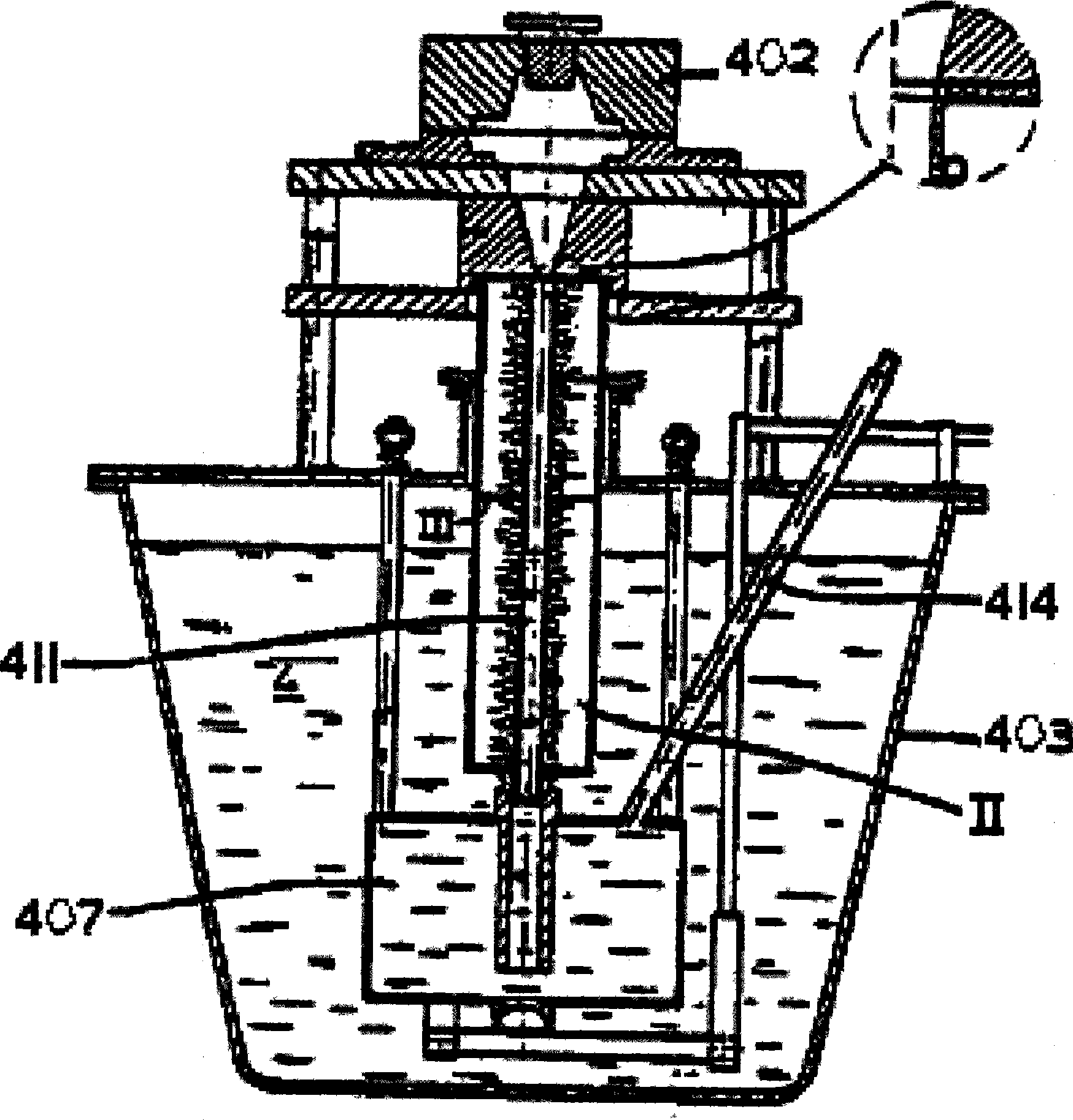

Low-pressure casting method and equipment thereof

The invention relates to a method for low-pressure casting. A crucible is a core device which is divided into an inner space and an outer space independent of each other in the crucible, gases are passed into the two spaces, and the pressures in the two spaces are basically kept equal to each other and are changed synchronously basically. The device used in the method for the low-pressure casting particularly uses the crucible as the core device; and the device is provided with a structure which separates the inner part and the outer part of the crucible into two independent parts that are not communicated with each other and can be sealed relatively. The method is particularly suitable for the low-pressure casting of a magnesium alloy and can prevent a heating element from being eroded by SF6; a low-cost silicon series refractory material can be used in a hearth; a device used in the method has the advantages of simple structure, convenient operation and good technical effect; the used casting method has a simple process and performs works in terms of a special device; and the method has greater economic and social values.

Owner:SHENYANG RES INST OF FOUNDRY

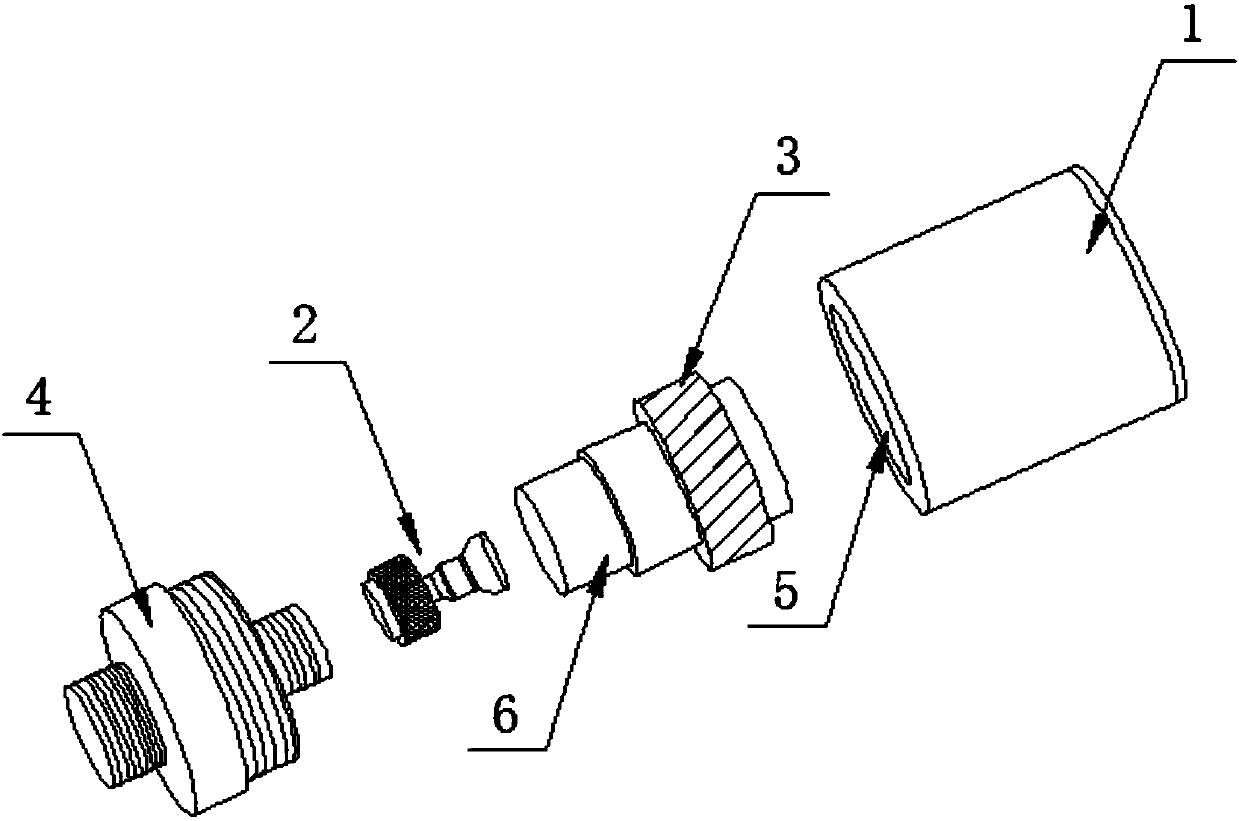

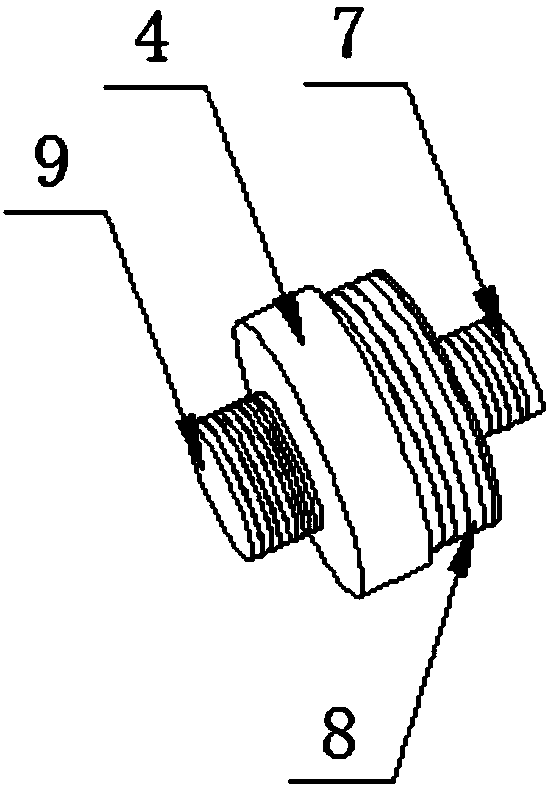

High-speed spray nozzle device

ActiveCN107755114AAvoid differential pressureExquisite structureLiquid spraying apparatusDifferential pressureSpray nozzle

The invention discloses a high-speed spray nozzle device. The high-speed spray nozzle device comprises a sprayer sleeve, a water guiding sprayer, an air guiding sprayer, a connecting distributor, an inner groove, a connecting pipe, a bulge, a thread insert, a water inlet, a swivel, a water spray nozzle, a compression chamber, a compression bar and an acceleration groove. The high-speed spray nozzle device has the following beneficial effects: the high-speed spray nozzle device is mainly composed of the sprayer sleeve, the water guiding sprayer, the air guiding sprayer and the connecting distributor, and each of the sprayer components is machined on a machine tool by adopting stainless steel bar 304 and is delicate in structure; in addition, the connecting distributor and the air guiding sprayer are additionally arranged to feed water and atomized air separately so as to prevent water and atomized air from fleeing mutually due to differential pressure; water is first self-atomized and sprayed through the water guiding sprayer and is further atomized through high-speed atomized air sprayed out of the air guiding sprayer; and water is thoroughly atomized to be high-speed vaporific, and plenty of tiny high-speed water mist liquid drops and exhaust gas are fully mixed to capture smoke dust in the exhaust gas for sedimentation, so that an excellent dust removal effect is achieved.

Owner:广西金川有色金属有限公司

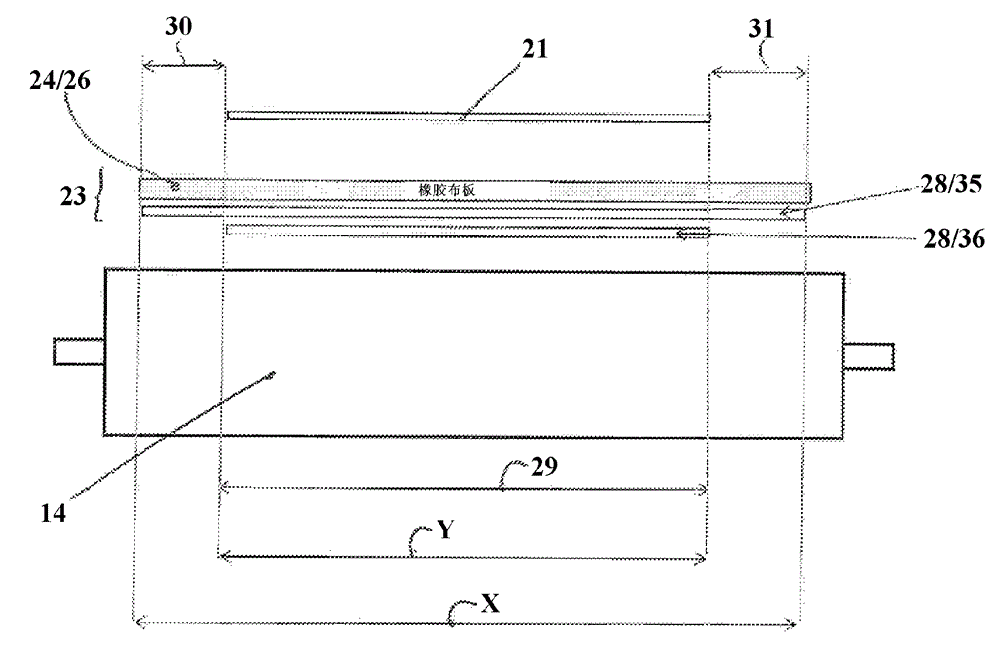

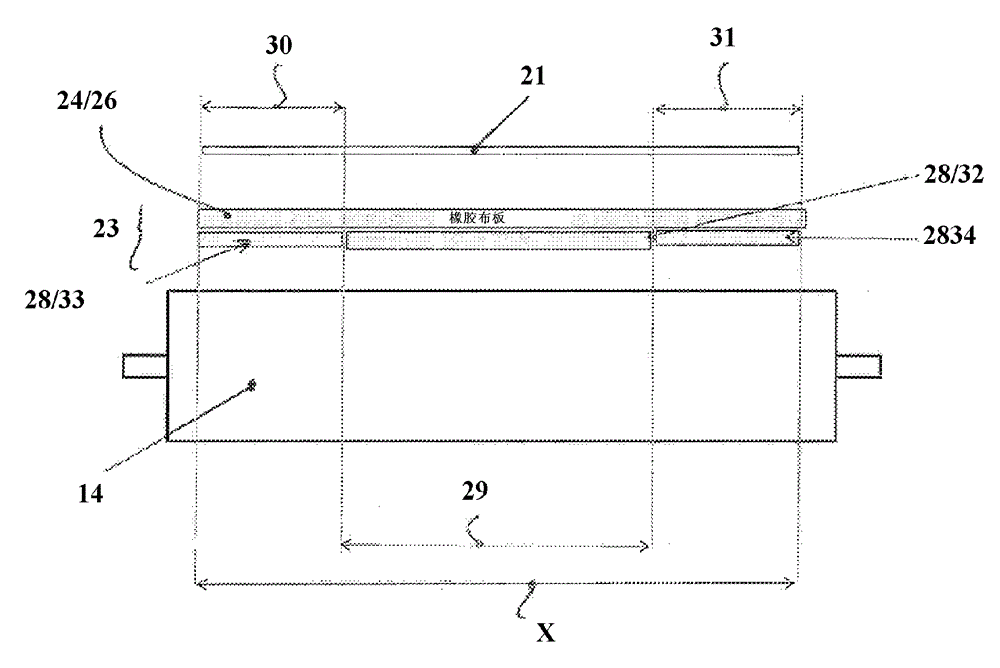

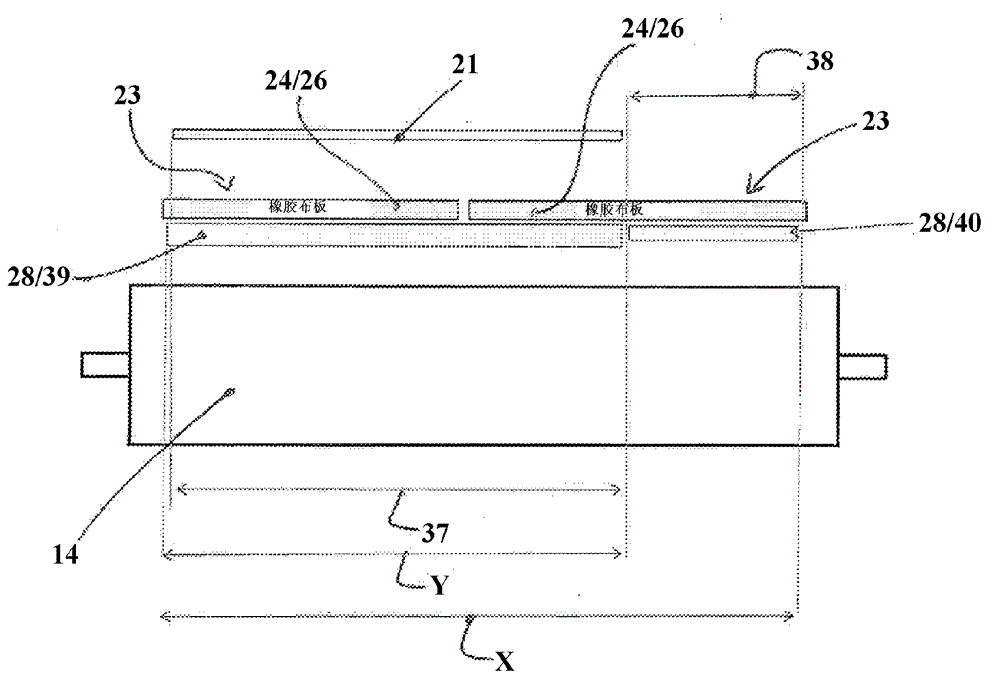

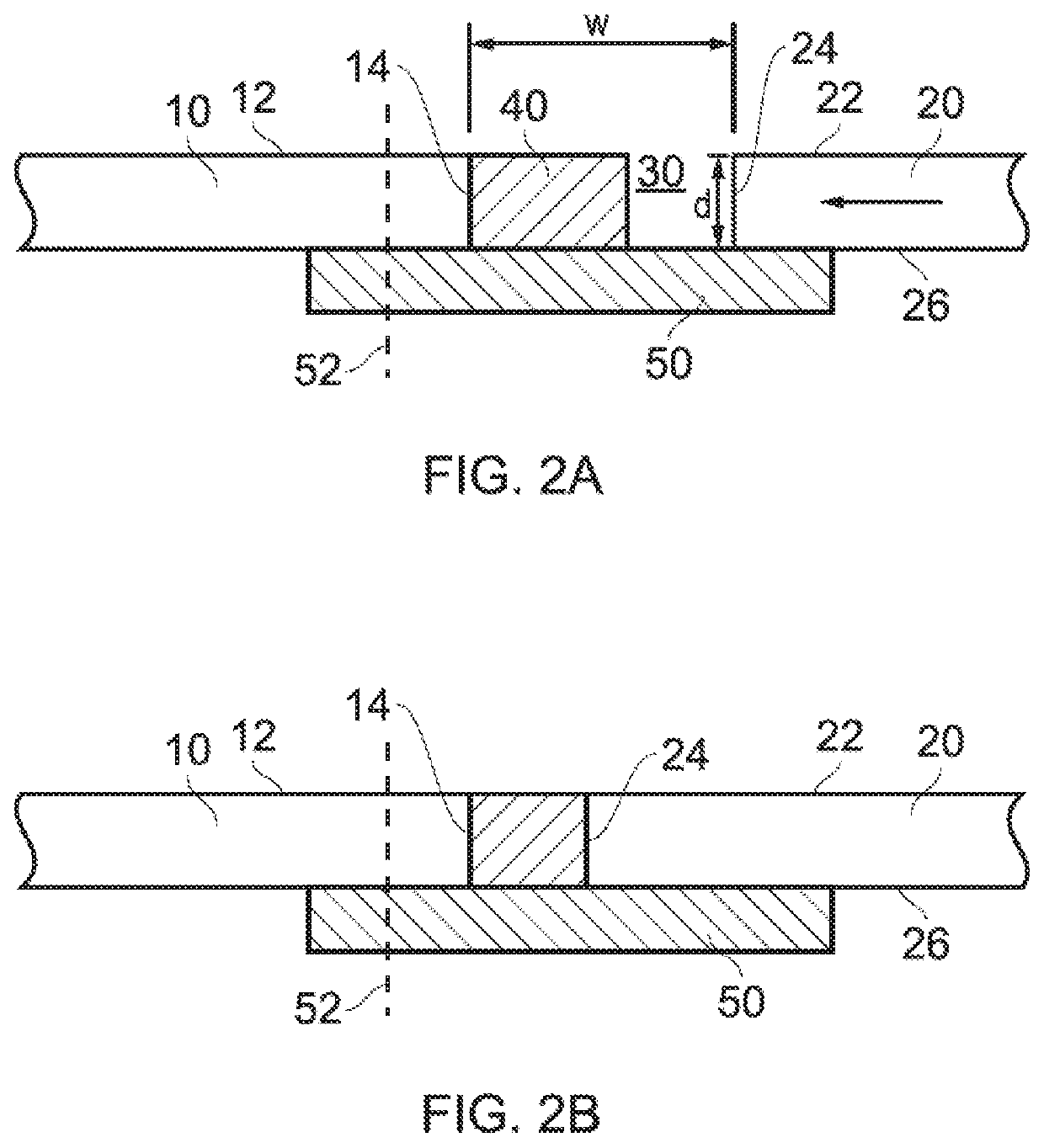

Printing unit and rubber fabric plate for the same

InactiveCN104097387AReduce differential pressureAvoid differential pressurePlate printingPrinting blanketsPrinting inkElectrical and Electronics engineering

The invention provides a printing unit for a printer, which comprises an inking unit, a transfer cylinder (14) and a forme cylinder. The inking unit is used for applying the printing ink onto at least one printing form on the forme cylinder. The printing ink positioned on the basis of each printing forme has at least one on the transfer cylinder (14) as a blanket or blanket plate (23) formed transfer form on a substrate to be printed (21) coatable, wherein between the transfer cylinder (14) and the or each blanket or between the transfer cylinder (14) and a metal support (24) of the or each blanket plate (23) a contact structure (28) is positioned, that is either with the transfer cylinder (14) or with the metallic support (24) of the respective rubber blanket plate (23) connected.

Owner:MANROLAND WEB SYST

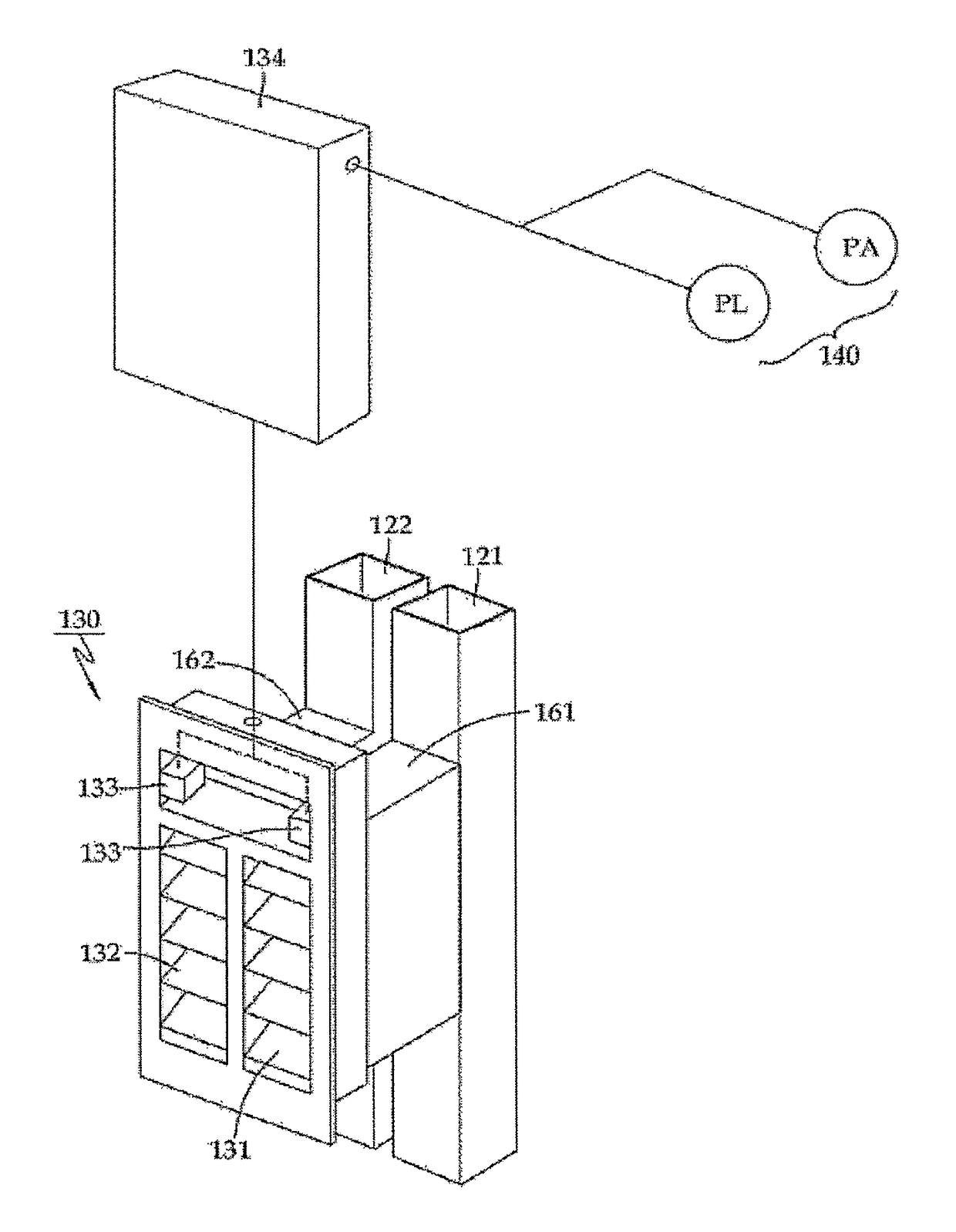

Air supply damper for separately supplying leakage air flow and supplementary air flow, method for controlling the same, and smoke control system utilizing the same

ActiveUS9784466B2Avoid differential pressurePrecise maintenanceMechanical apparatusSpace heating and ventilation safety systemsControl systemOperating energy

Disclosed is a smoke control system provided in a high-rise building for separately supplying leakage air flow and supplementary air flow, including: a blowing means for supplying air into a building; a ventilating means having a leakage air flow supplying passage and a supplementary air flow supplying passage connected to the blowing means for introducing air; and an air supply damper connected to the leakage air flow supplying passage and the supplementary air flow supplying passage to supply air into each lobby of a building according to the leakage air flow and supplementary air flow.

Owner:KOREA INST OF CIVIL ENG & BUILDING TECH

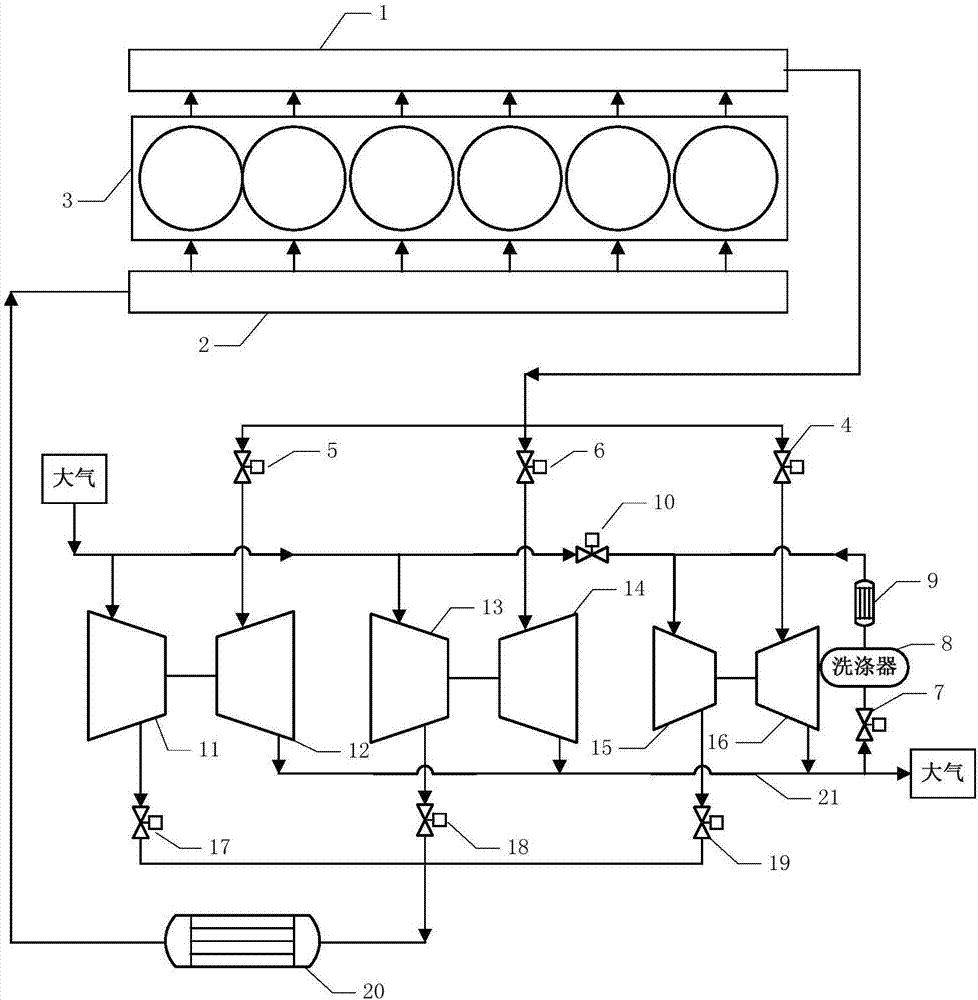

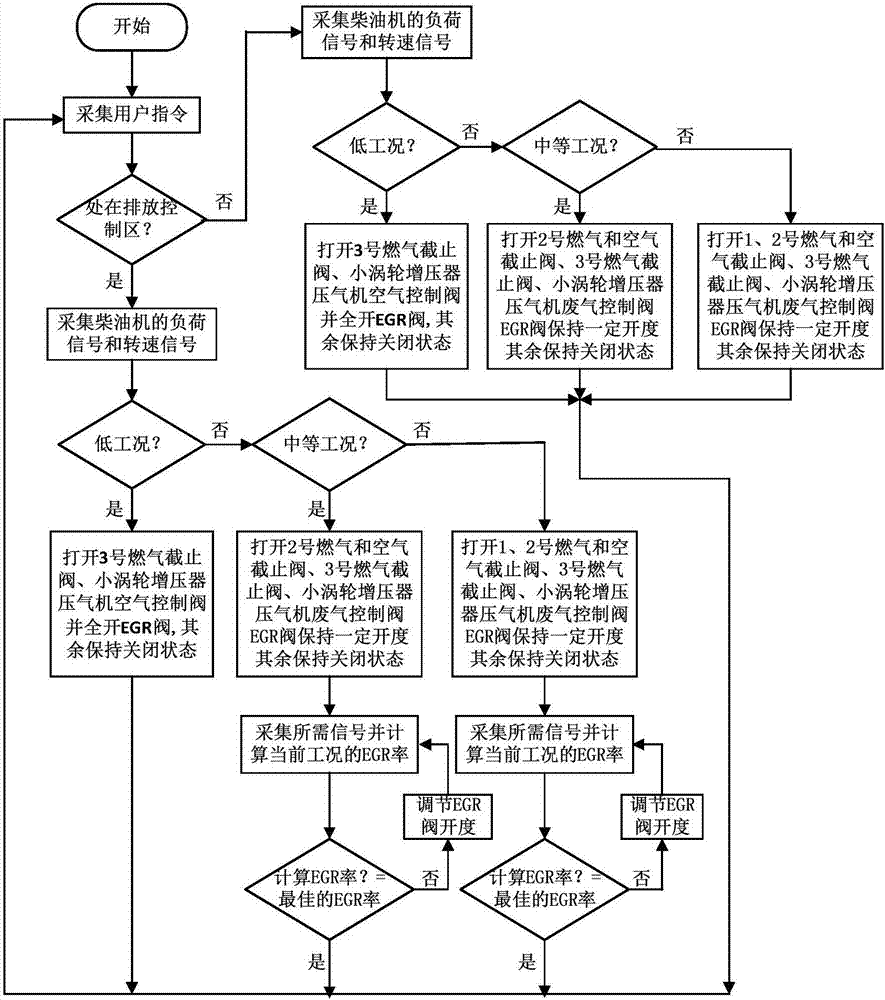

Three-turbocharger three-stage sequential turbocharging device and control method with EGR achieving function

ActiveCN107060989AStable jobReduce oxygen contentInternal combustion piston enginesExhaust gas recirculationDiesel engineControl area

The invention aims at providing a three-turbocharger three-stage sequential turbocharging device with an EGR achieving function and a three-turbocharger three-stage sequential turbocharging control method with the EGR achieving function. The sequential turbocharging device comprises an exhaust header, an air-intake header, a first big turbocharger, a second big turbocharger and a small turbocharger, wherein the inlet end of a first turbine communicates with the exhaust header, the inlet end of a second turbine communicates with the exhaust header, the inlet end of a small turbine communicates with the exhaust header, and the outlet end of the first turbine, the outlet end of the second turbine and the outlet end of the small turbine all communicate with an exhaust header pipe; and the inlet end of a first air compressor, the inlet end of a second air compressor and the inlet end of a small air compressor all communicate with an air-intake header pipe, and the outlet end of the first air compressor, the outlet end of the second air compressor and the outlet end of the small air compressor all communicate with an air outlet header pipe. According to the three-turbocharger three-stage sequential turbocharging device and control method with the EGR achieving function, the effect of performing sequential turbocharging to improve the low working-condition performance of a diesel engine can be achieved, the NOx exhaust requirement of the diesel engine in an exhaust control area can be met through EGR, and the comprehensive performance of the diesel engine can be greatly improved.

Owner:HARBIN ENG UNIV

Method for manufacturing polyethylene microporous filter tube for secondary filtering of compressed air

InactiveCN102068866ATo achieve innovation and creationAchieve transformationDispersed particle filtrationRoom temperatureFilter media

The invention a method for manufacturing a polyethylene microporous filter tube for secondary filtering of compressed air, which comprises the steps of: A, sieving polyethylene powder with a sieving machine; B, coating silicone oil on the inner wall of an external iron tube mould and the outer wall of an internal iron tube mould for reverse mould sintering and assembling a mould body; C, pouring siftage sieved by the sieving machine between the inner wall of the external iron tube mould and the outer wall of the internal iron tube mould; D, placing the mould body in a constant temperature furnace, sintering for 5-6 hours at 250-300 DEG C; and E, cooling the mould body to room temperature and de-moulding. As a novel filtering medium, the polyethylene microporous filter tube manufactured by novel materials, with novel technology and processes, has high and stable filtering precision, long service life and easy cleaning and is non-toxic, corrosion resisting, temperature resisting at 90 DEG C and can be recycled repeatedly and is an ideal material for various industries to implement high precision gas-solid separation and oil-gas separation. In the manufacturing process, the filter core is only sintered to form at one time, thereby reducing the cumbersome multi-step manufacturing means and saving the labor.

Owner:张柏筠

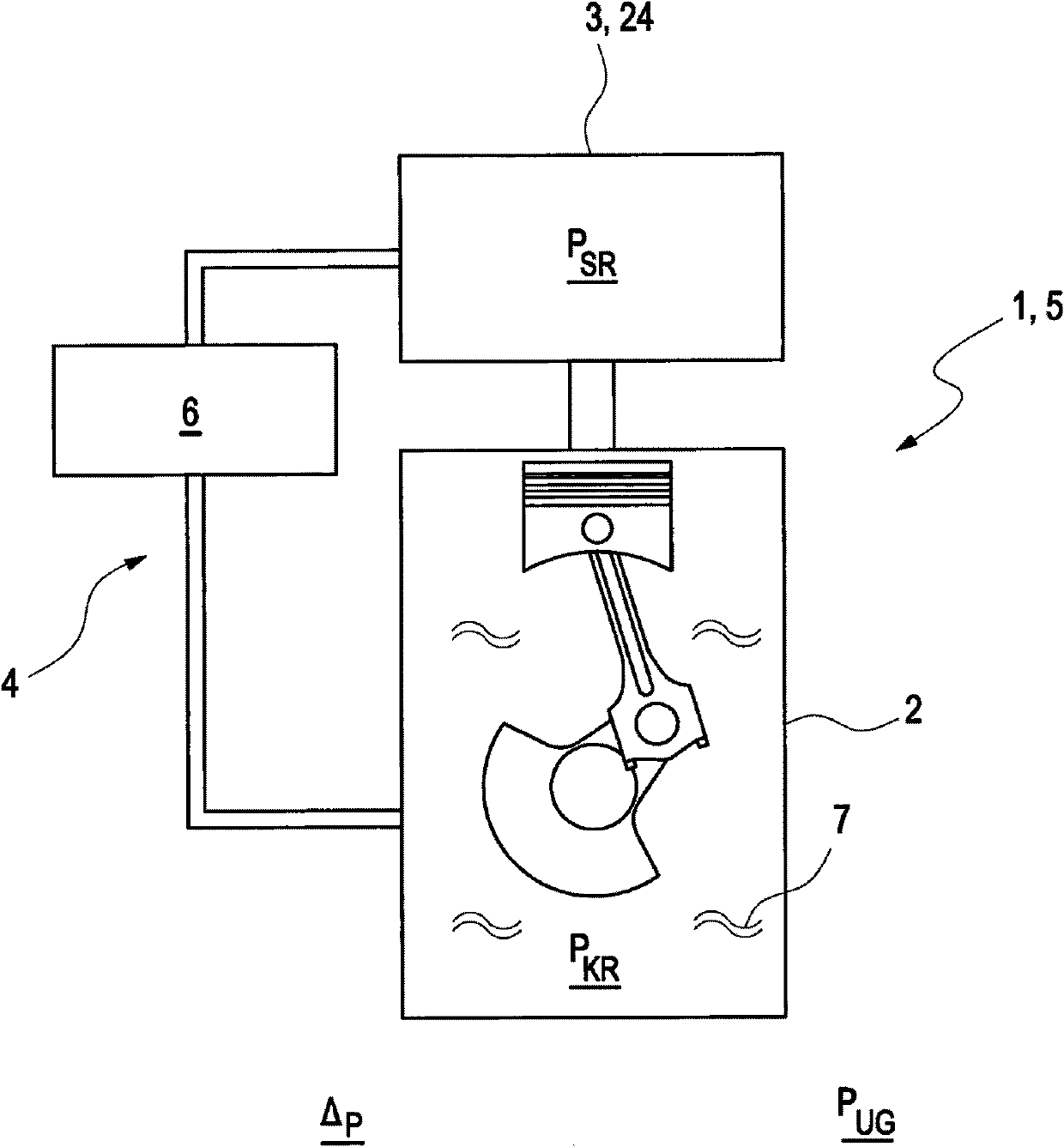

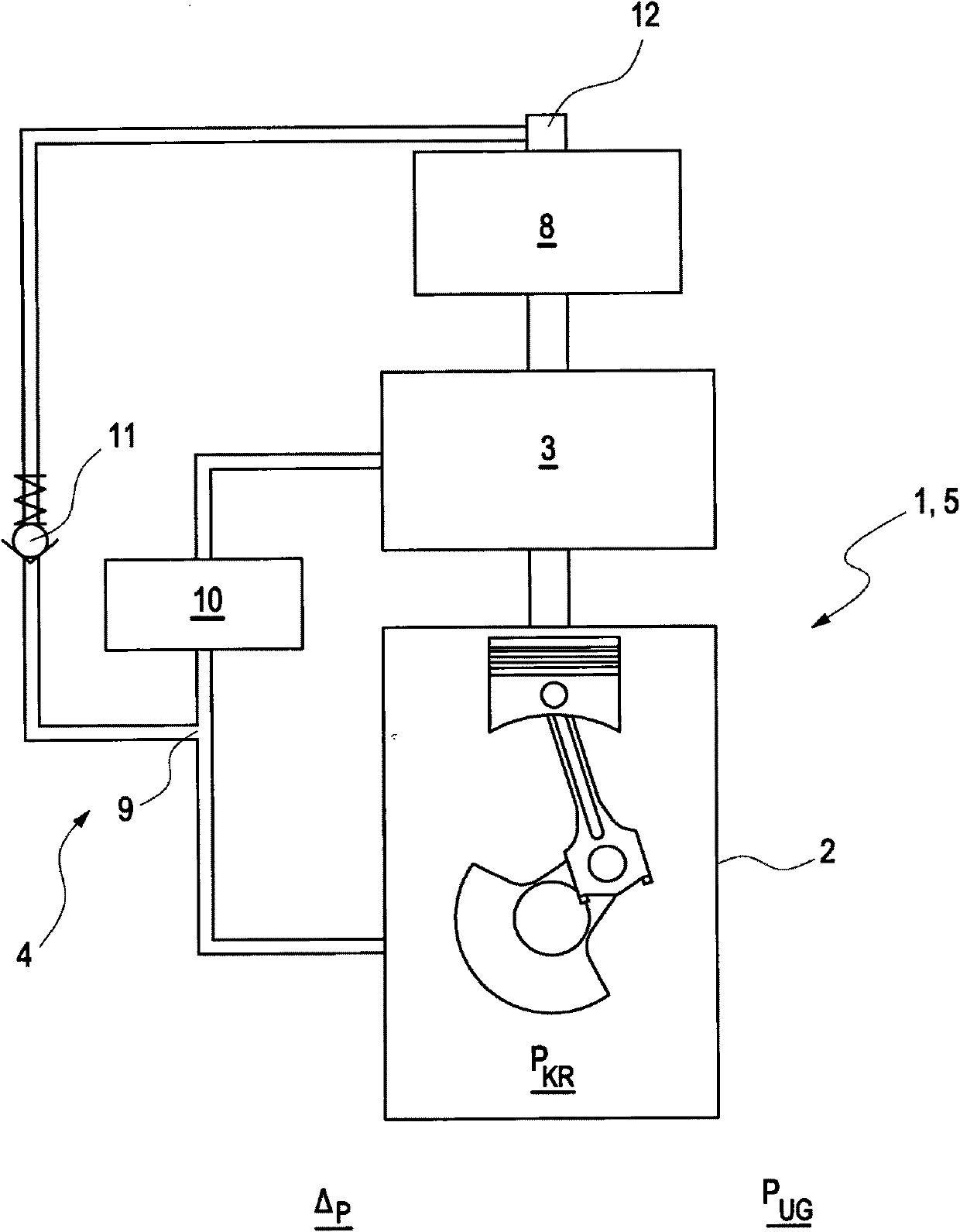

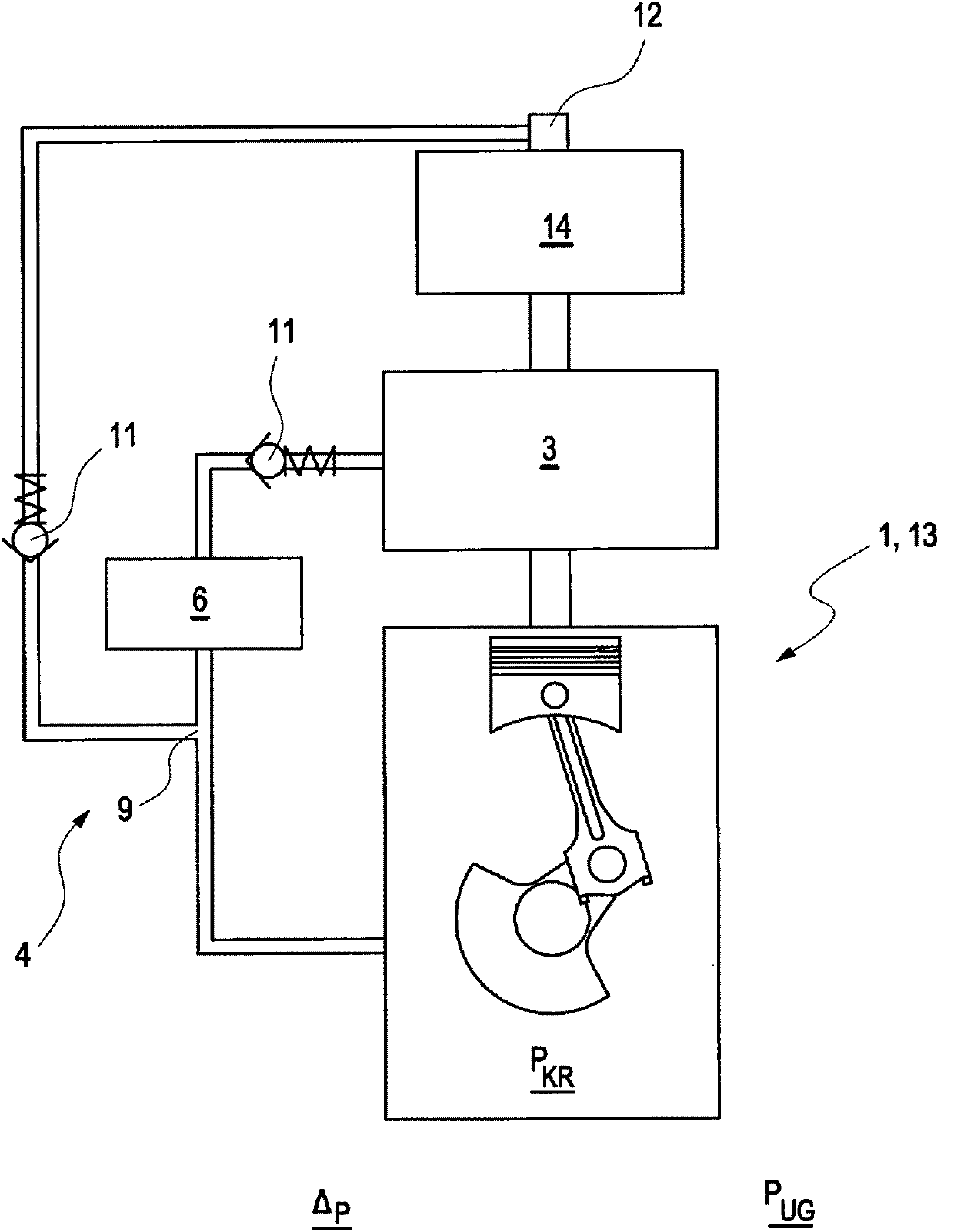

Method for operating an internal combustion engine

InactiveCN102245866AReduce differential pressureAvoid differential pressureMachines/enginesCrankcase ventillationDifferential pressureExternal combustion engine

The invention relates to a method for operating an internal combustion engine having a crankcase, a crankcase vent, and a vacuum system. According to the invention, the pressure in the crankcase can be reduced as a function of a differential pressure between the vacuum system and the crankcase to a maximum of -500 mbar, particularly a maximum of -300 mbar, relative to the ambient pressure, for reducing lubricant consumption of the internal combustion engine.

Owner:AUDI AG

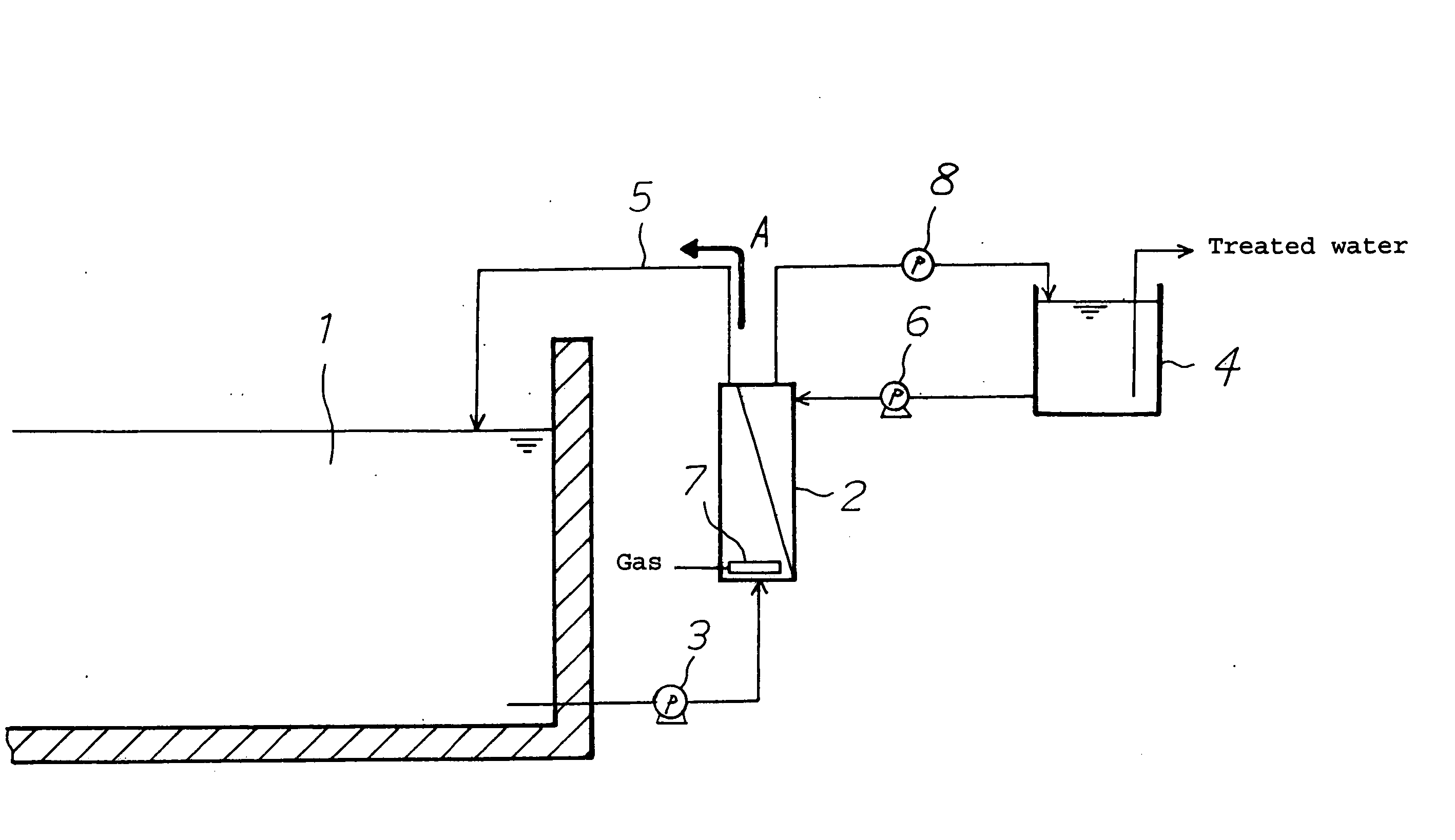

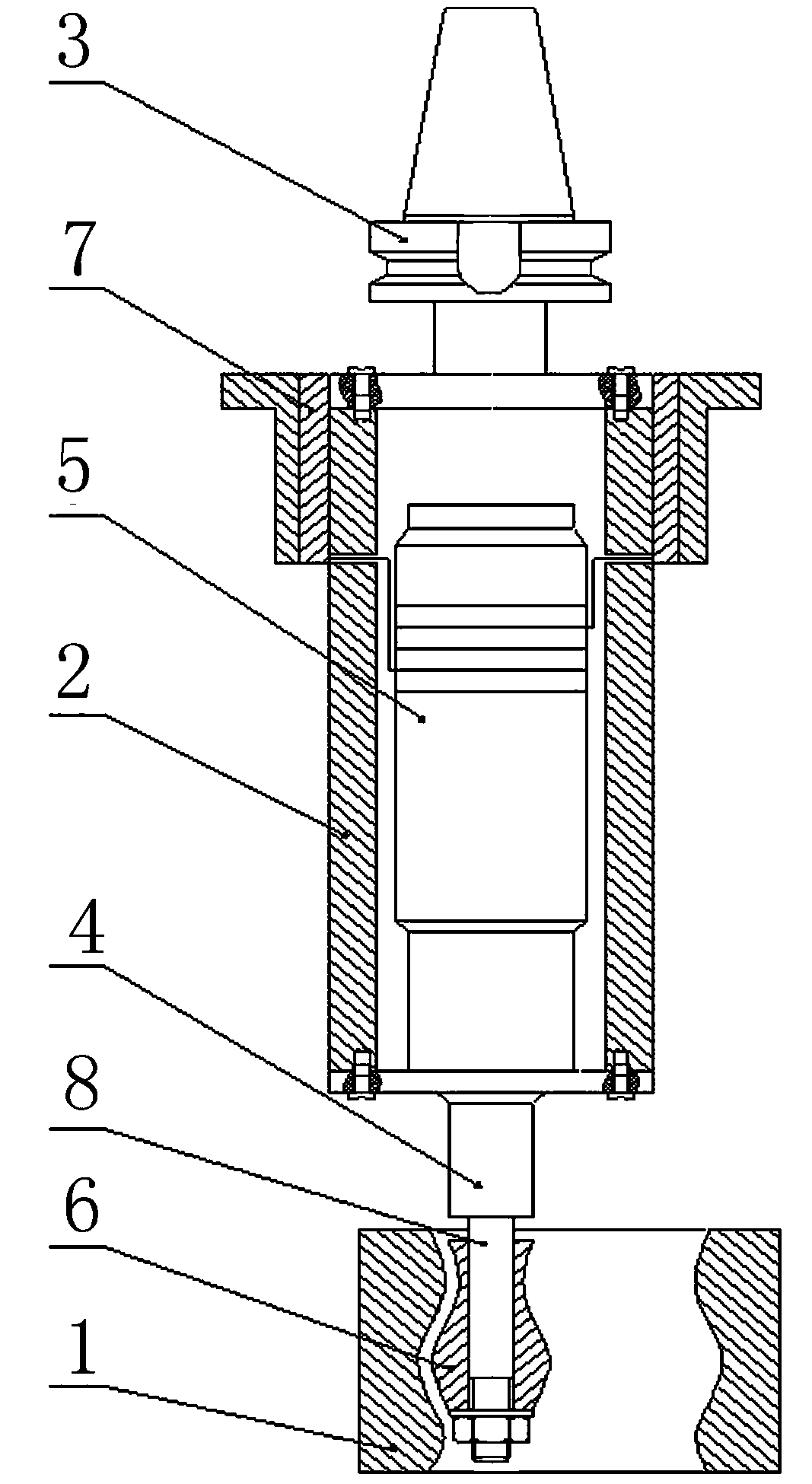

Molded surface constraint ultrasonic vibration auxiliary rotating abrasive flow finishing machining device

ActiveCN109514358AAvoid pressure difference between inlet and outletAchieve large area uniform polishingGrinding machine componentsEngineeringSurface shape

The invention belongs to the technical field of machining and particularly relates to a molded surface constraint ultrasonic vibration auxiliary rotating abrasive flow finishing machining device. Thedevice comprises a constraint molded surface, an ultrasonic vibration device, a sleeve and a spindle tool shank. The upper end of the sleeve is connected with the spindle tool shank. The ultrasonic vibration device comprises an ultrasonic amplitude change rod and an ultrasonic transducer. The ultrasonic transducer is arranged in the sleeve, and the lower end of the ultrasonic transducer is connected with the upper end of the ultrasonic amplitude change rod. The wave nodal point of the ultrasonic amplitude change rod is connected with the lower end of the sleeve. The lower end of the ultrasonicamplitude change rod is connected with a workpiece. The workpiece is located in an inner cavity of the constraint molded surface. The molded surface rotation center line of the constraint molded surface is parallel to the axis of the workpiece. The constraint molded surface is filled with fluid abrasives over the workpiece. The surface to be machined of the workpiece is matched with the inner wall of the constraint molded surface. The molded surface constraint ultrasonic vibration auxiliary rotating abrasive flow finishing machining device can avoid the inlet and outlet differential pressure,improve the machining efficiency and surface smoothness of the workpiece, shorten the machining time, save the machining cost, achieves the purpose of machining without dead angles and ensure the surface shape precision of the workpiece.

Owner:TAIYUAN UNIV OF TECH

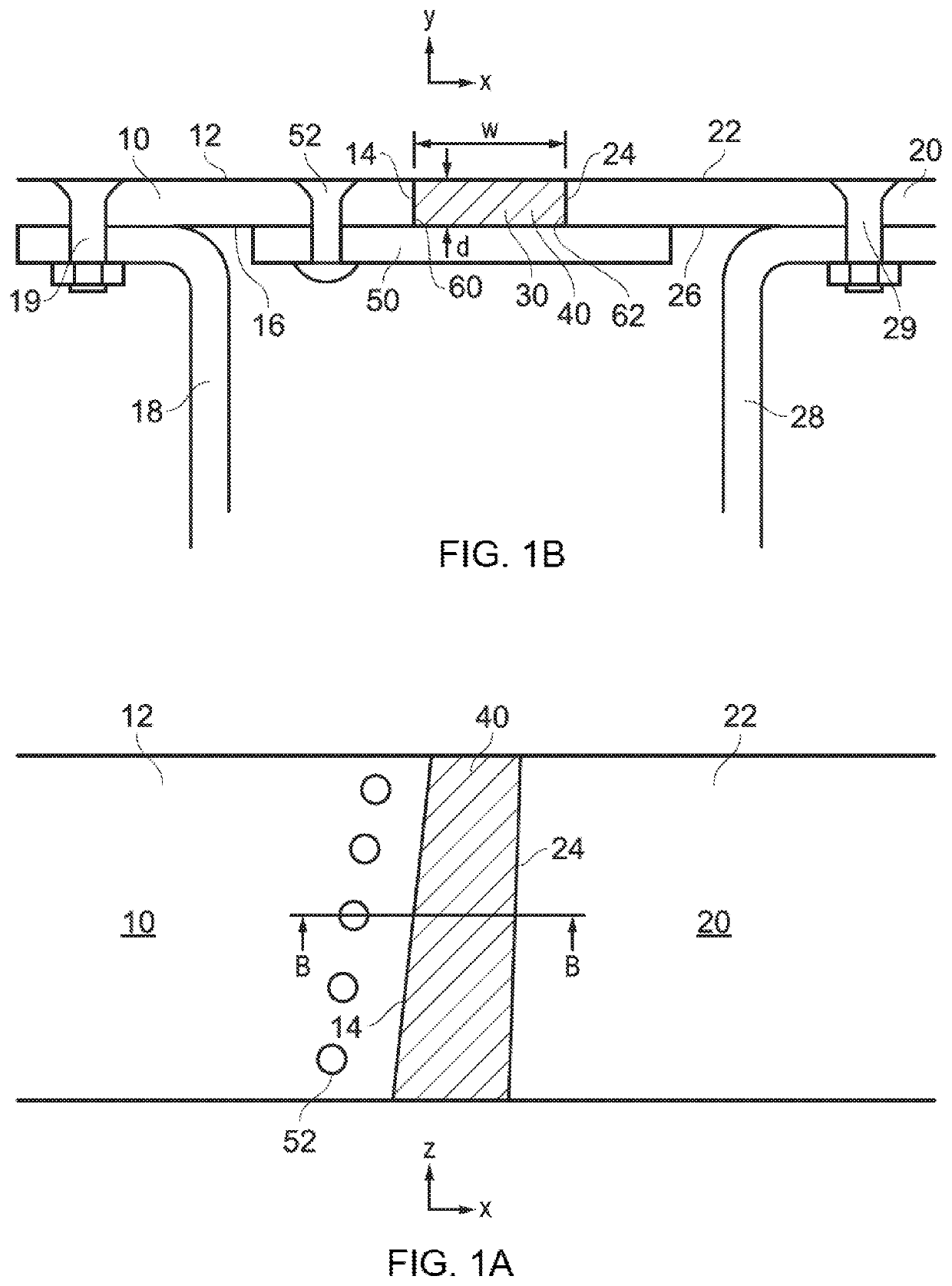

Aircraft gap seal

ActiveUS10871232B2Increase volumeAvoid differential pressureEngine sealsAircraft controlEdge surfaceStructural engineering

An aircraft assembly including: first and second external skin panels having opposing edge faces separated by a gap, the gap having a width in a first direction extending between the opposing edge faces and a depth in a second direction generally orthogonal to the first direction; and a gap seal arranged in the gap to at least partially fill the gap, wherein the gap seal is formed of a material configured such that compression of the gap seal in the first direction results in substantially no expansion of the gap seal in the second direction.

Owner:AIRBUS OPERATIONS LTD

Device and method for extracting oil-tea camellia seed oil at low temperature by taking liquefiable gas as solvent

InactiveCN102093930AReduce the problem of excessive pressure differenceAvoid differential pressureFatty-oils/fats productionEdible oils/fatsEngineeringSolvent

The invention relates to a device and a method for extracting oil-tea camellia seed oil at low temperature by taking a liquefiable gas as a solvent, which are used for extracting the oil-tea camellia seed oil. The inner side of an extracting container is at least provided with a group of more than two equal-distance or unequal-distance inlets capable of being opened and closed; the inlets are connected with a pump for inputting a solvent gas through a pipeline; the equal distance or unequal distance refers to a distance from a port end of the pipeline inserting to the inner side of the extracting container to the inner bottom surface of the extracting container; and the inlets capable of being opened and closed are connected with the pump for inputting the solvent gas through different pipelines or the same pipeline. The invention has the advantages that: the utilization rate of the camellia seed oil can be improved, the quality of crude oil is improved, a refining step is eliminated, the production period is shortened and the loss of nutrient substances in the camellia seed oil is reduced.

Owner:广州绿和缘生物科技有限公司 +1

Differential pressure sensor system, aircraft equipped with a differential pressure sensor system and method for operating a differential pressure sensor system

ActiveUS20170334573A1Less error-proneLow expenseAircraft health monitoring devicesAir-treatment apparatus arrangementsEngineeringSensor system

A differential pressure sensor system for use in an aircraft comprises a differential pressure sensor for determining a differential pressure between a pressurizable aircraft cabin and an aircraft environment, the differential pressure sensor having a first port connectable to the pressurizable aircraft cabin via a first line and a second port connectable to the aircraft environment via a second line. A shut-off device of the differential pressure sensor system is arranged in the second line which is switchable between an open position in which it opens the second line, such that a pressure prevailing in the aircraft environment acts on the second port of the differential pressure sensor, and a shut-off position in which it closes the second line, such that the second port of the differential pressure sensor is shut off from the pressure prevailing in the aircraft environment.

Owner:AIRBUS OPERATIONS GMBH

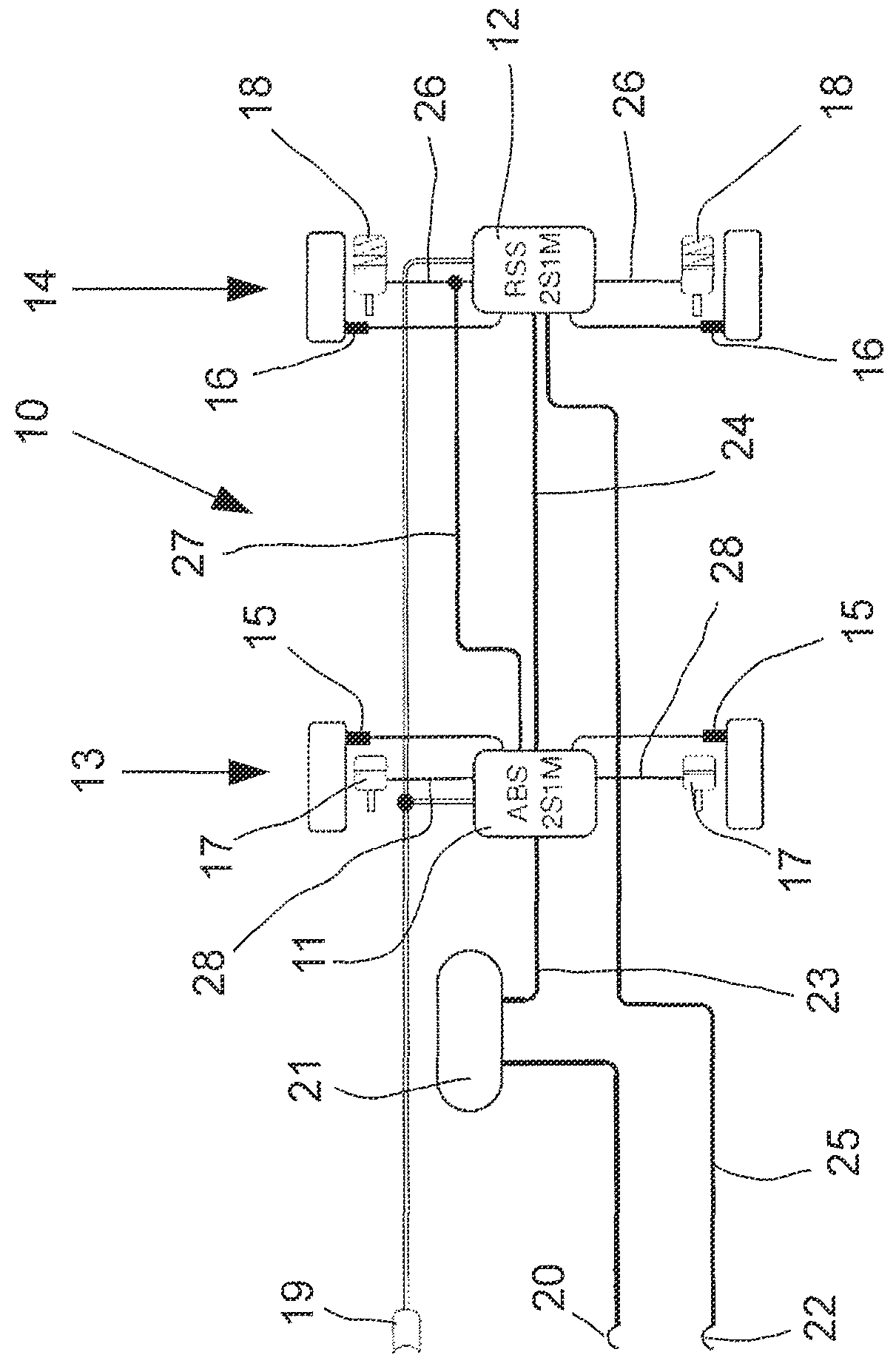

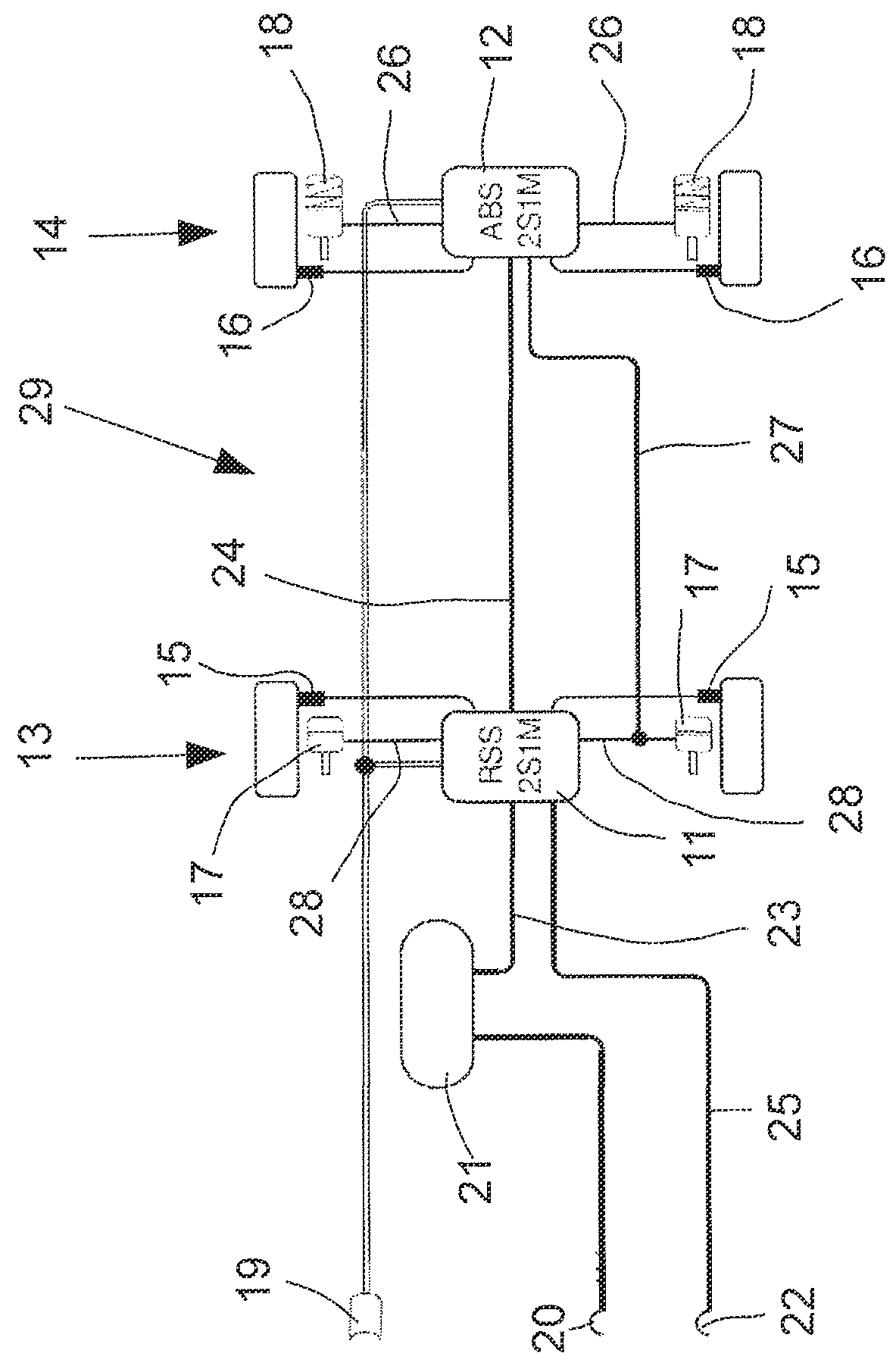

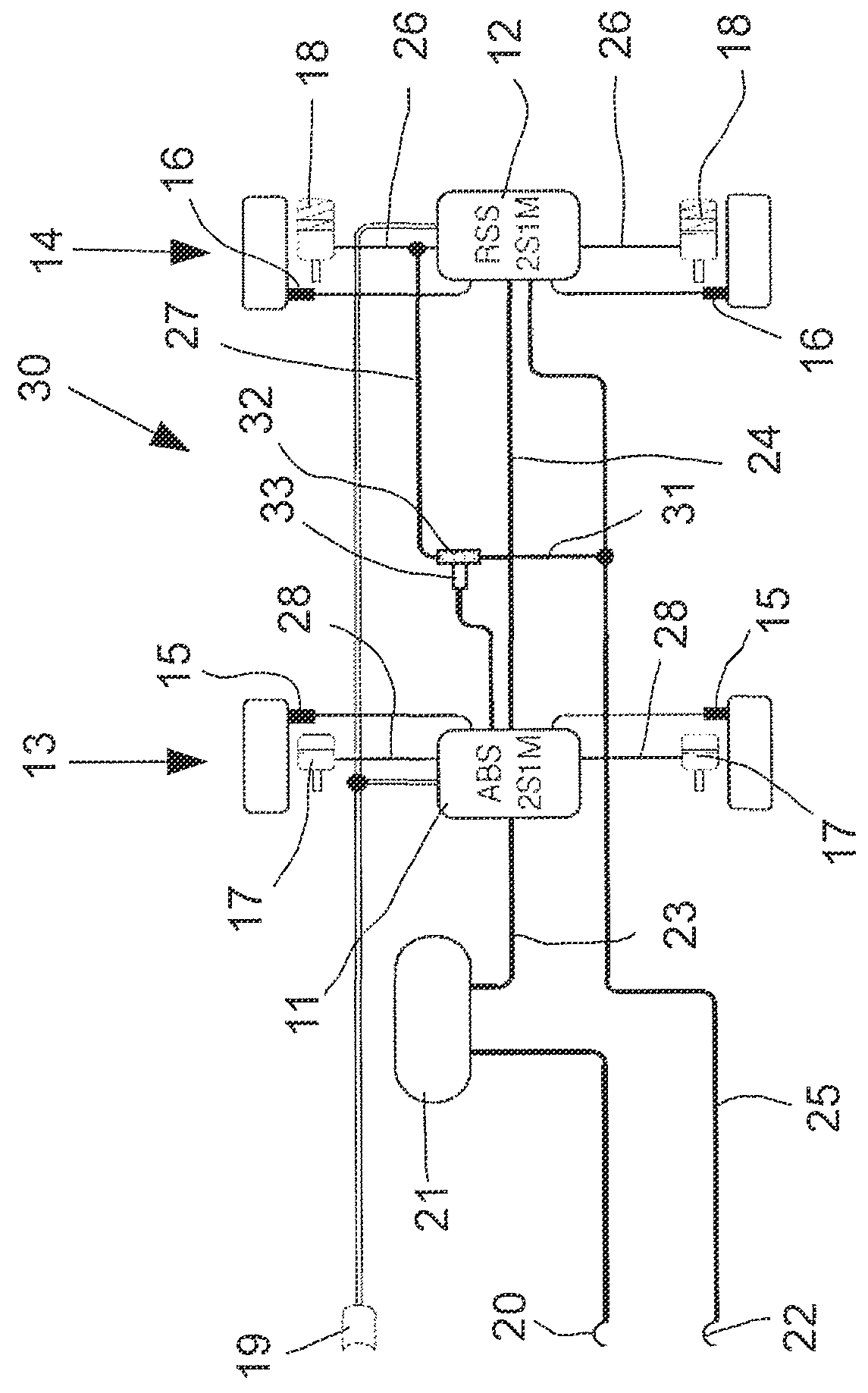

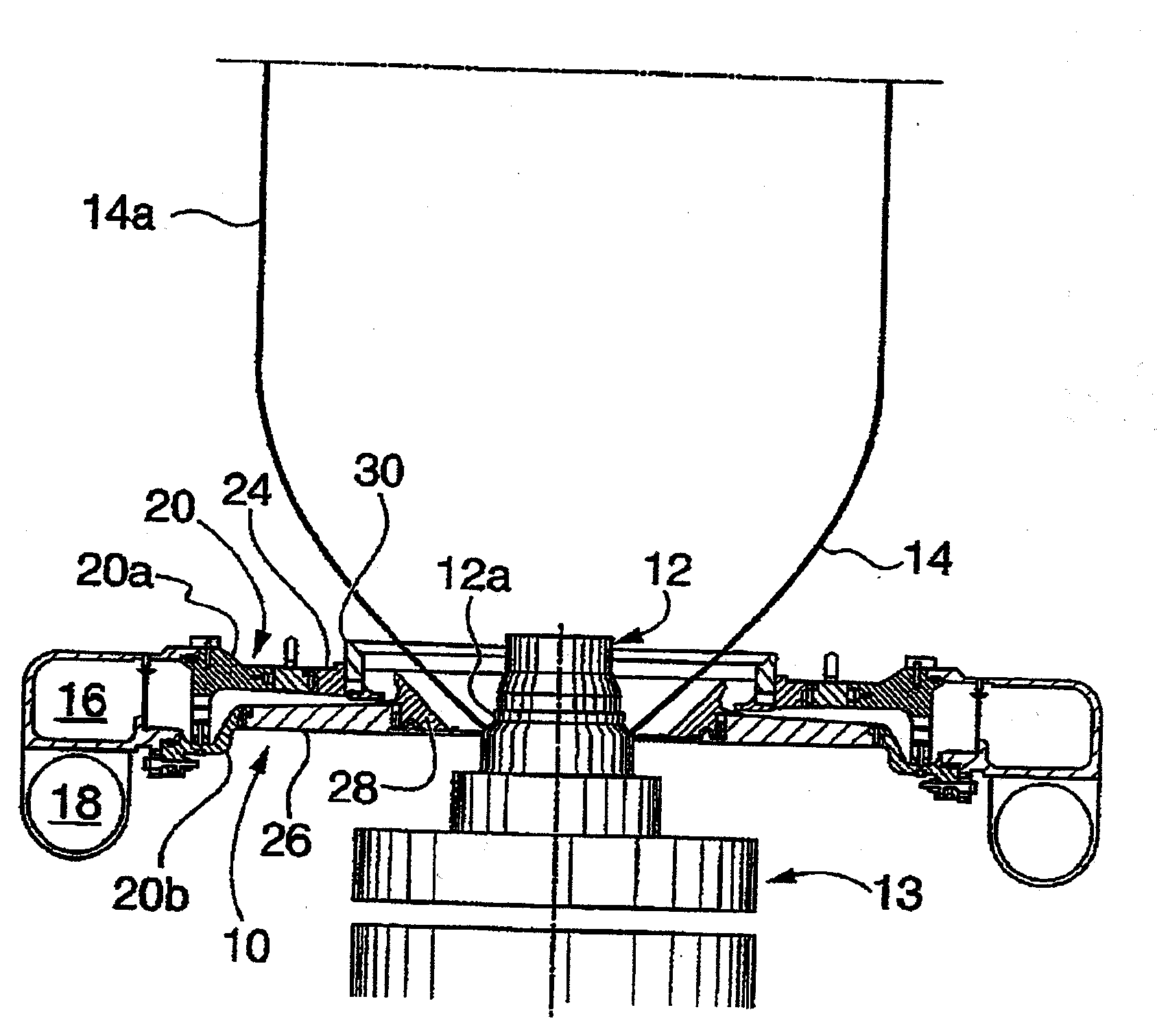

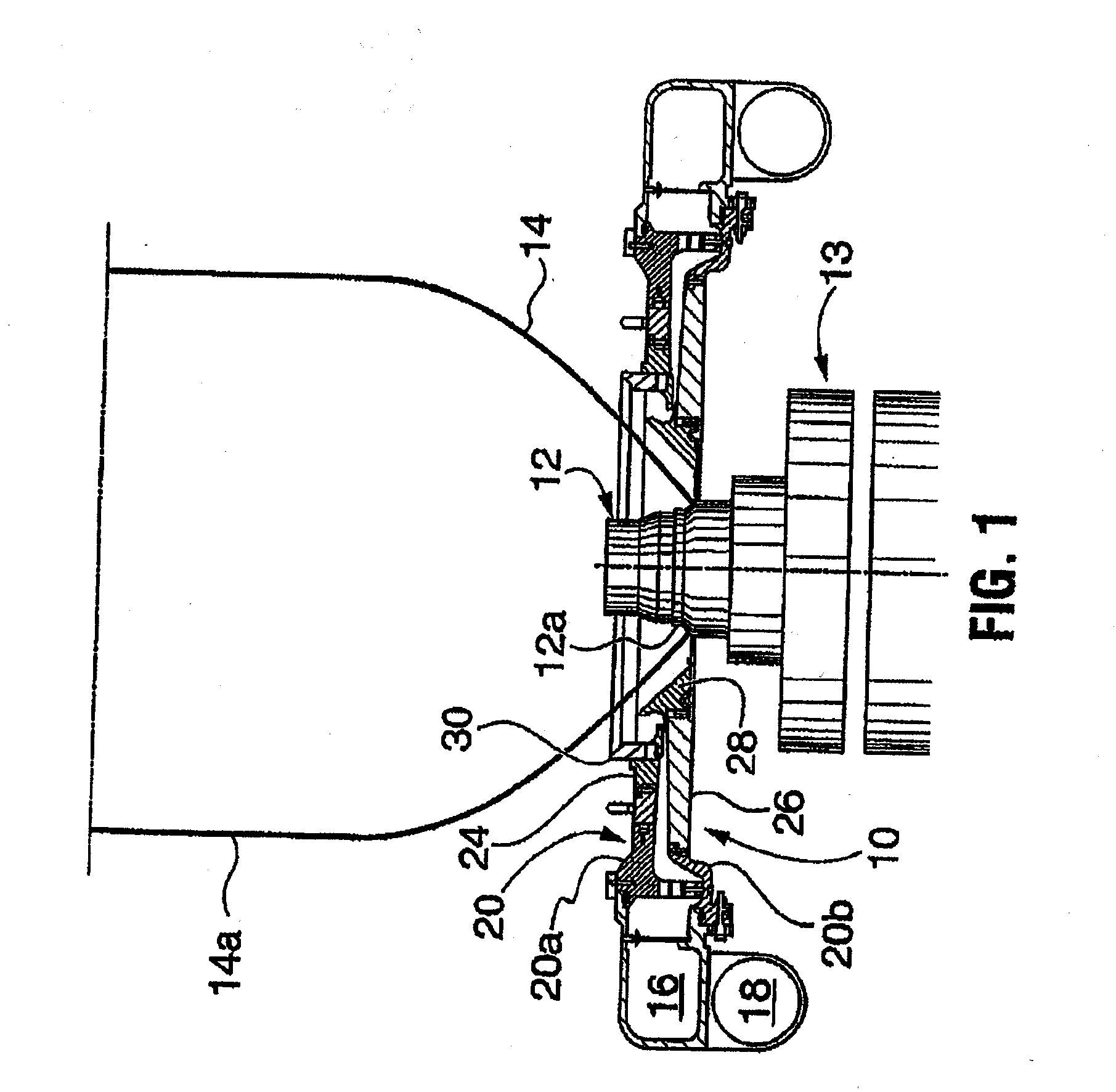

Electropneumatic brake system for a towed vehicle

In an electropneumatic brake system for a towed vehicle having at least two axles, such as a drawbar trailer, one axle is assigned a first modulator at least with an anti-lock function and another axle is assigned a second modulator at least with an anti-lock function and an additional function. Both modulators are connected to a reservoir pressure, and both modulators load wheel brake cylinders via brake pressure lines. The second modulator is connected to a control line and the first modulator has a connector for a control line. A control line leads from the connector for the control line on the first modulator to the brake pressure line between the second modulator and at least one of its wheel brake cylinders.

Owner:ZF CV SYST EURO BV

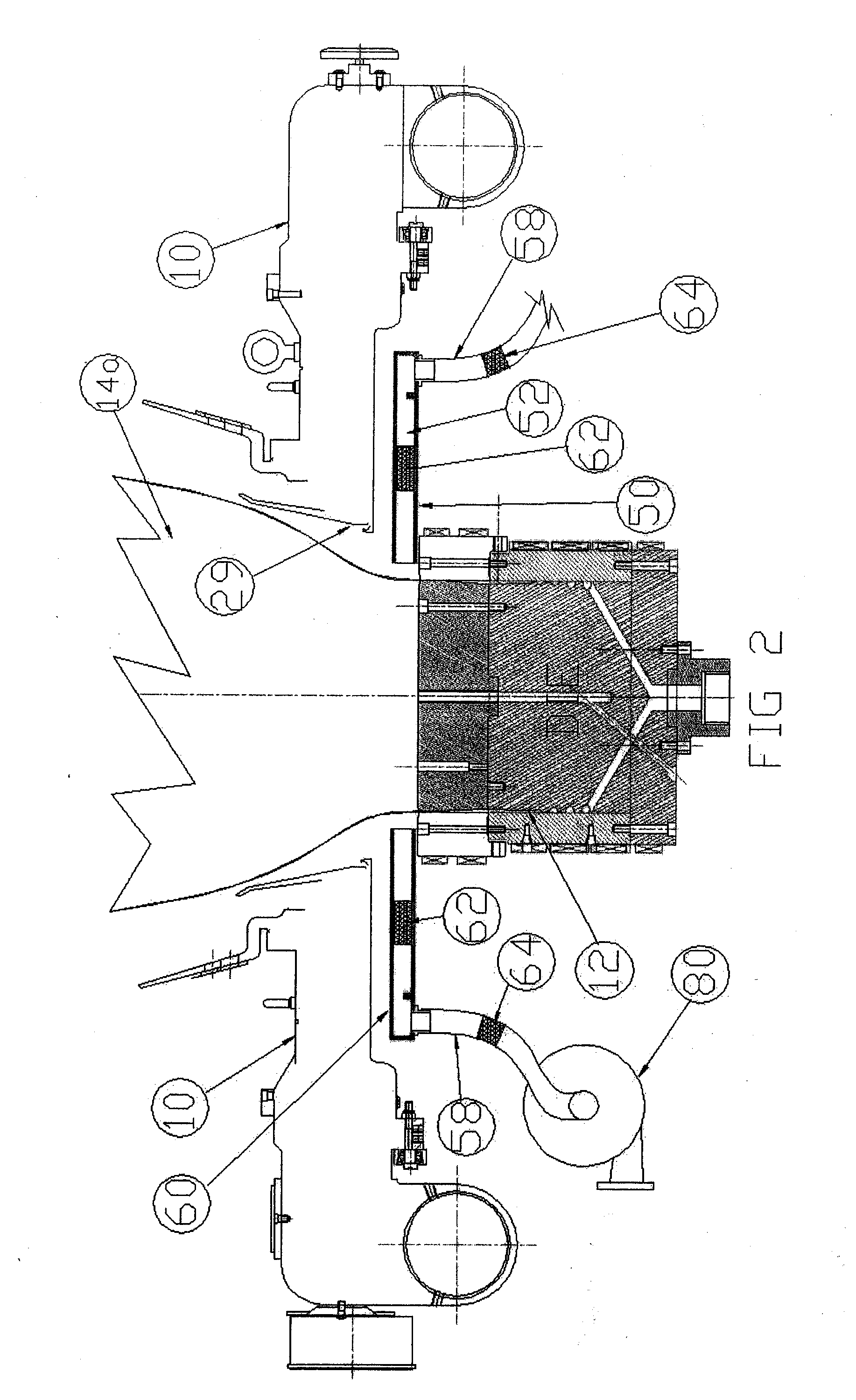

Evacuation system for plastics extrusion

ActiveUS20100086632A1Reduce unnecessary distractionsAvoid differential pressureConfectioneryFilament/thread formingAir pollutantsPressure difference

Disclosed is an evacuation system for use with plastic extrusion dies, in particular a contaminant evacuation system for removal of air borne contaminants generated at the die orifice of a plastics extrusion apparatus. The system includes an annular evacuation chamber and a suction source connected to the evacuation chamber for generating a vacuum in the evacuation chamber. The evacuation chamber has a radially inwardly directed annular air intake opening for placement about the die orifice, and a baffle structure in the evacuation chamber for equalizing suction pressure along the air intake opening and reduce or avoid localized pressure differences around the extruded product, which would lead to deformation of the product.

Owner:FUTURE DESIGN

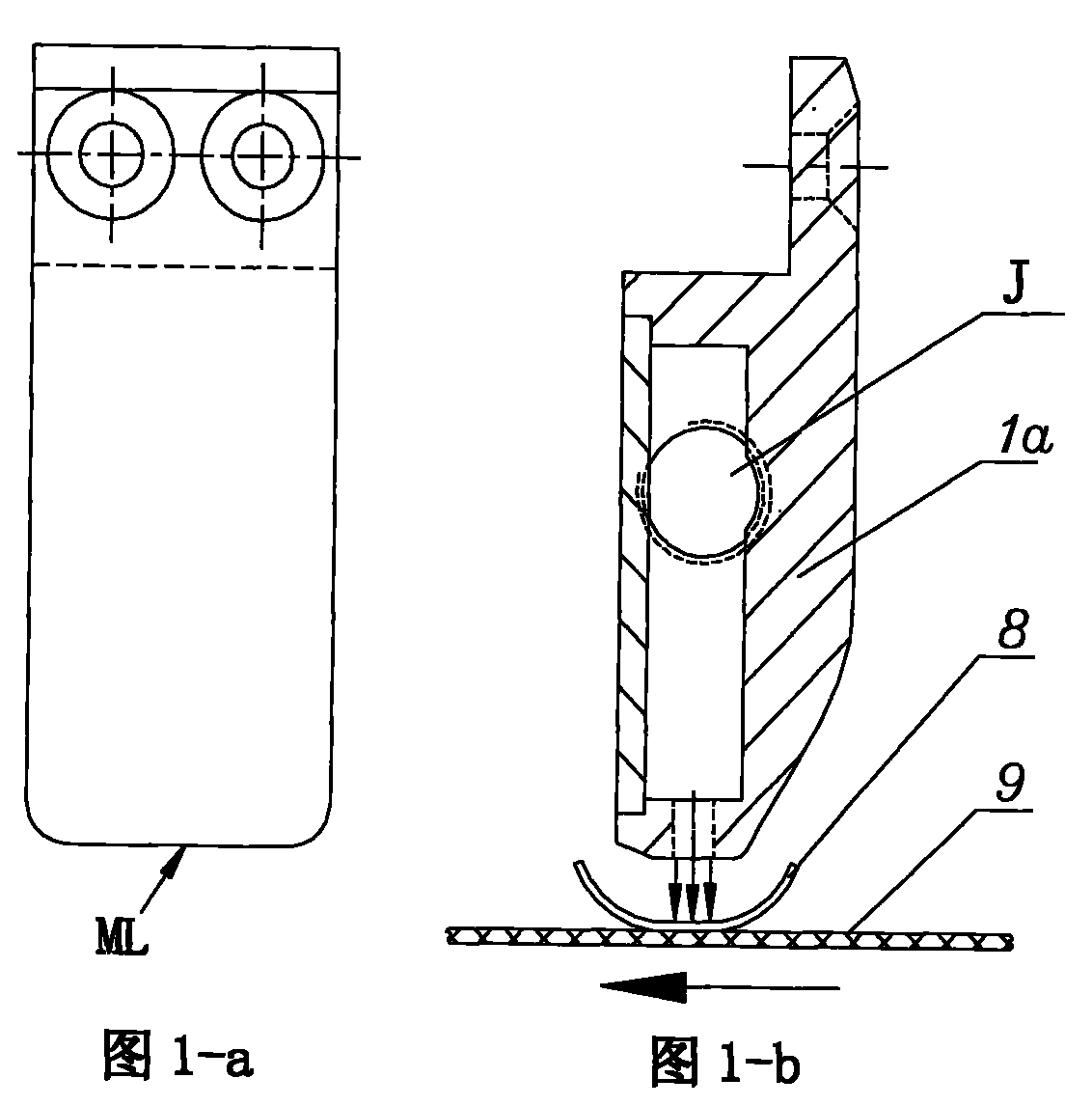

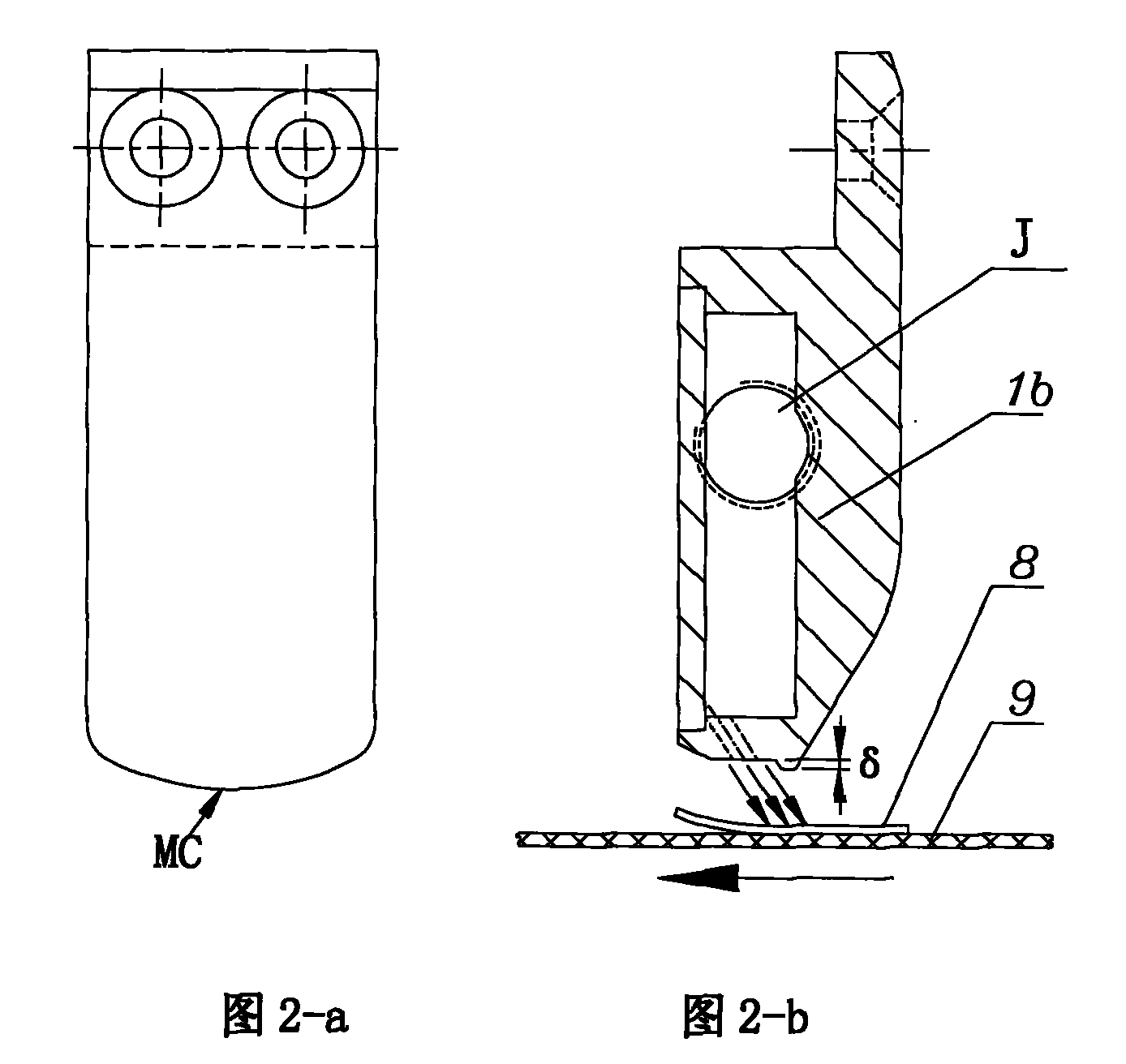

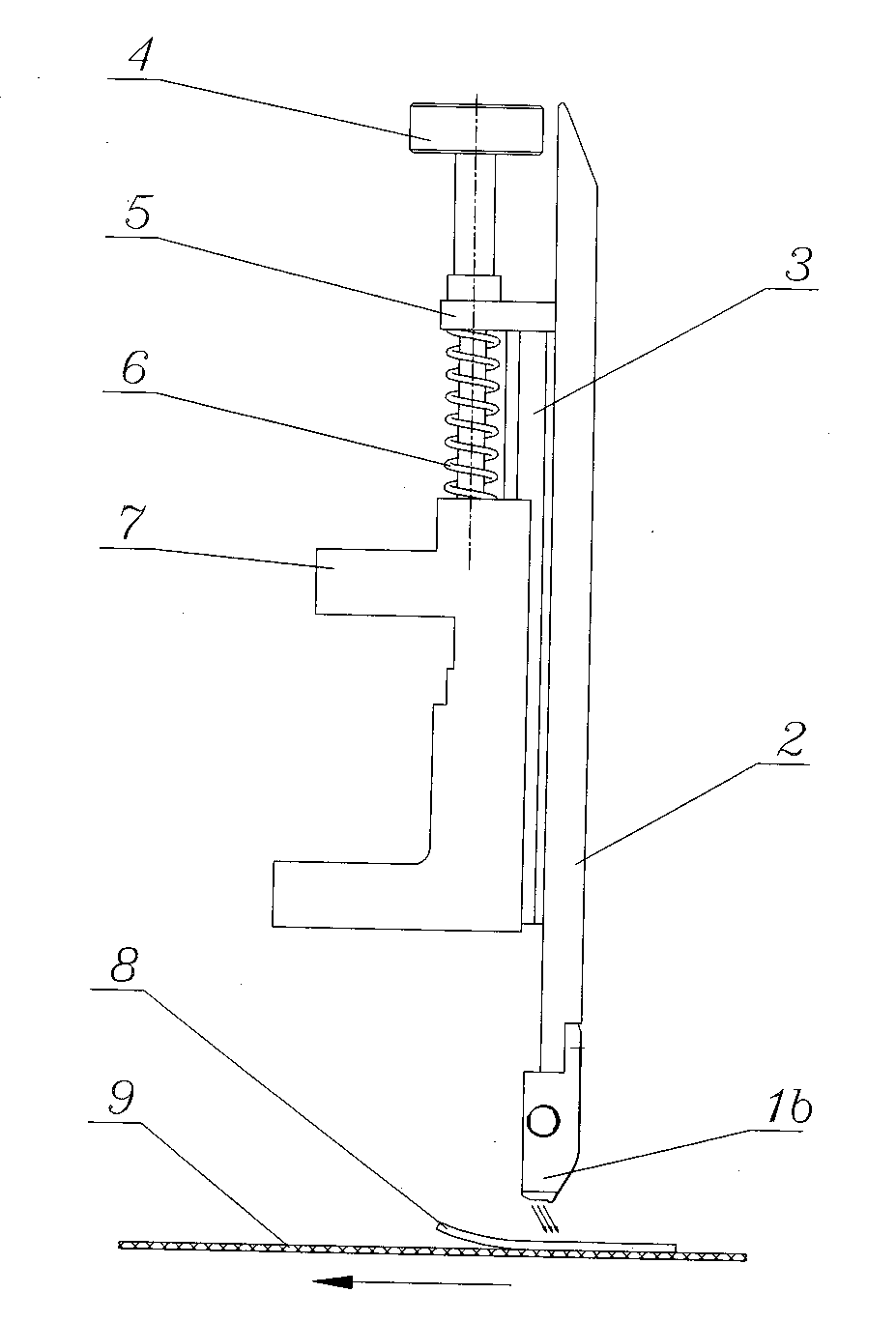

Paper feeder cutter head and paper feeder having same and working method thereof

InactiveCN101798027AAvoid scratchesAvoid differential pressureArticle feedersArticle separationPulp and paper industryPosition error

The invention relates to a paper feeder cutter head, which is characterized in that the working end surface of the paper feeder cutter head is in the shape of circular arc; a gas outlet is formed on the lower end surface of the paper feeder cutter head; the angle between a gas outlet hole and a horizontal direction of a printed product is less than 90 degrees; and the lowest position of the circular arc working surface is lower than the lower plane of the gas outlet. The invention also relates to a paper feeder having the paper feeder cutter head, which is characterized by comprising a paper feeder cutter head, a paper feeder cutter and a regulation device, wherein the regulation device consists of slide rails, a regulating handle, a double hole plate, a spring and sliders; and the working method is as follows: regulating the distance between the paper feeder cutter head and a paper conveying belt; blowing out a gas source from an inclined gas outlet of the paper feeder cutter head; and evenly acting the gas flow which is blew out from the inclined gas outlet on the printed product to lead the single printed product to smoothly stick on the paper conveying belt to be conveyed to the next working position. The invention can eliminate surface scratch of the printed product resulted from the shape and position error of mechanical processing assembly and the surface scratch of the printed product caused by warp of part of the printed product resulted from direct-blowing of the gas blowing device.

Owner:MASTERWORK GROUP CO LTD

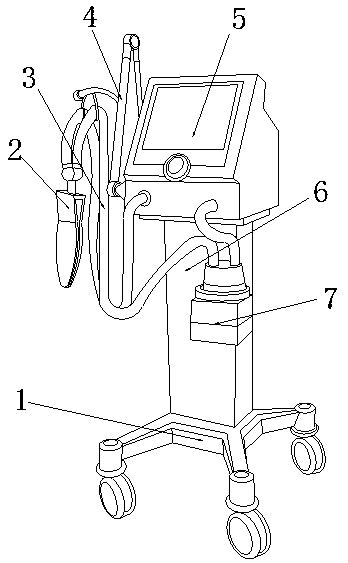

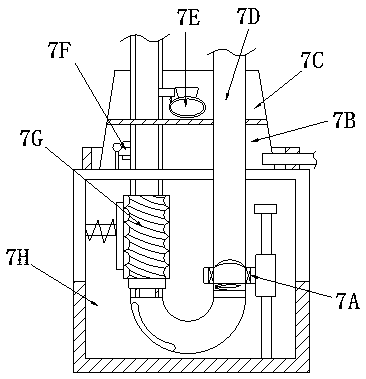

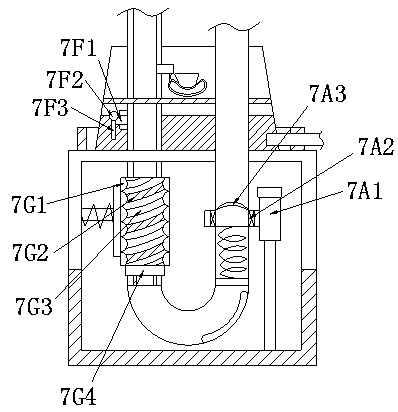

Nasal catheter fixation device for use with neonatal CPAP breathing machine

ActiveCN110327525AUniform gas volumeGuarantee the right amount of mixing precisionRespiratory masksHuman–machine interfaceTidal volume

The invention discloses a nasal catheter fixation device for use with a neonatal CPAP breathing machine. The device includes a square rod support base, a nasal intubation plate, an air duct pipe, a connecting bar rack, a human-computer interface table, a stand column plate and a liquid oxygen mixing valve seat. Through combination of the nasal intubation plate and the liquid oxygen mixing valve seat, and through treatment with a humidification water tank liquid passage and a pure oxygen storage box air passage utilizing a bent backwashing pipe connector cap of the liquid oxygen mixing valve seat, the retention amount of water vapor in the nasal intubation plate and the air duct pipe is ensured to be lowest, and recoil force allows a rotary sieve to filter condensate of the tidal volume, thus ensuring that water vapor and oxygen are mixed to achieve an oxygen supplementing wetting effect, relieving alveolar intumescence by vapor attachment, adjusting a durable dried situation of the lung passage, making respiratory muscle loose, wet and elastic, promoting increase of the functional residual volume, improving lung compliance, improving respiratory regularity of newborns, and allowingthe device to automatically match with needs of a child's body to achieve micro-adjustment and high oxygen mixing adaptability.

Owner:西昌市人民医院

Reverse osmosis system

ActiveUS9416795B2Constant feed performanceKnown efficiencyMembranesGeneral water supply conservationReverse osmosisEngineering

The invention concerns a reverse osmosis system (1) with a membrane unit (2) comprising an inlet (3), a permeate outlet (4) and a concentrate outlet (5), a high-pressure pump (8) that is connected to the inlet (3), a pressure exchanger (11) connected on its concentrate side (10) to the concentrate outlet (5), and a booster pump between the pressure exchanger (11) and the inlet (3). It is endeavored to make the energy consumption as small as possible. For this purpose, the booster pump is made as a displacement pump.

Owner:DANFOSS AS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com