Method for controlling an injection process of a magnetic injector

An electromagnetic injector and injection process technology, applied in electrical control, electromagnet, engine control, etc., can solve the problems of fluid change, the difficulty of determining the precise opening and closing time of the armature, and improve the accuracy, combustion Good characteristics and precise control of injection quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

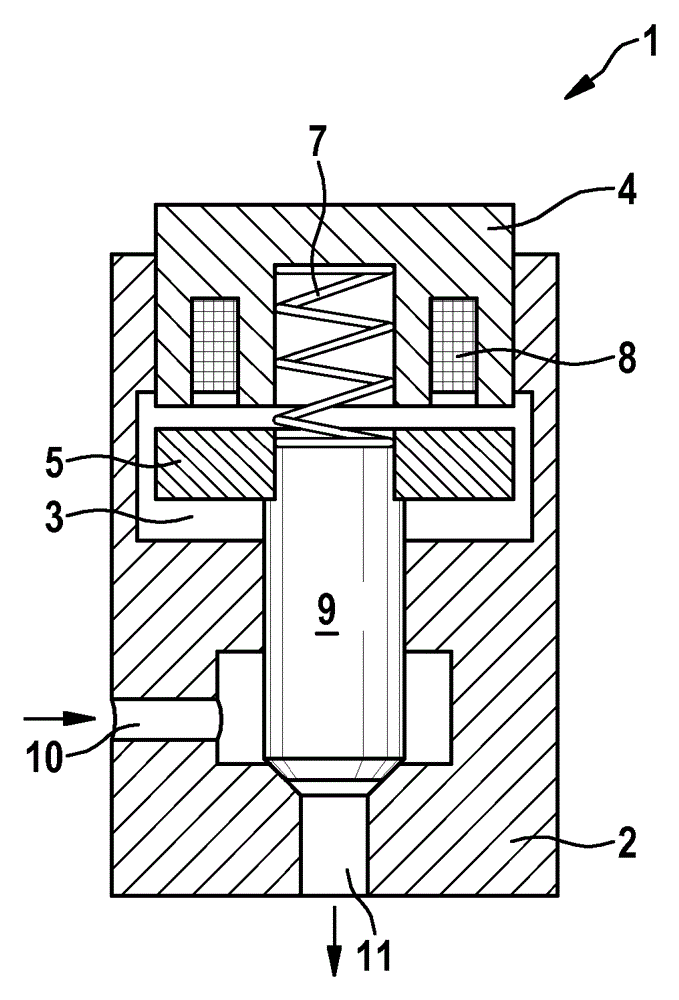

[0039] exist figure 1 An example of a non-current-closed (NC) electromagnetic injector 1 is shown in . The electromagnetic injector 1 has a valve body 2 in which an armature chamber 3 is formed. An armature 5 is arranged in this armature chamber 3 . Furthermore, a valve spring 7 is arranged in the armature chamber 3 . Furthermore, electromagnetic injector 1 has a solenoid coil 8 which surrounds valve spring 7 in an annular manner. The magnetic loop 4 serves as a yoke. A sealing element, here in the form of an injector needle 9 , is connected to the armature 5 . The electromagnetic injector 1 is equipped with an inflow port 10 and an outflow port 11 , but the directions described therein are merely exemplary directions.

[0040] So-called energization of the electromagnetic injector 1 takes place if an electric current is supplied to the electromagnetic coil 8 via an electrical line (not shown). As a result, a magnetic field is formed in the solenoid coil 8 , which causes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com