Method for controlling the injection process of an electromagnetic injector

一种电磁喷射器、喷射过程的技术,应用在电气控制、电磁体、发动机控制等方向,能够解决流体变化、电枢精确的打开时刻和关闭时刻很难确定等问题,达到提高精确性、燃烧特性好、喷射量控制精确的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

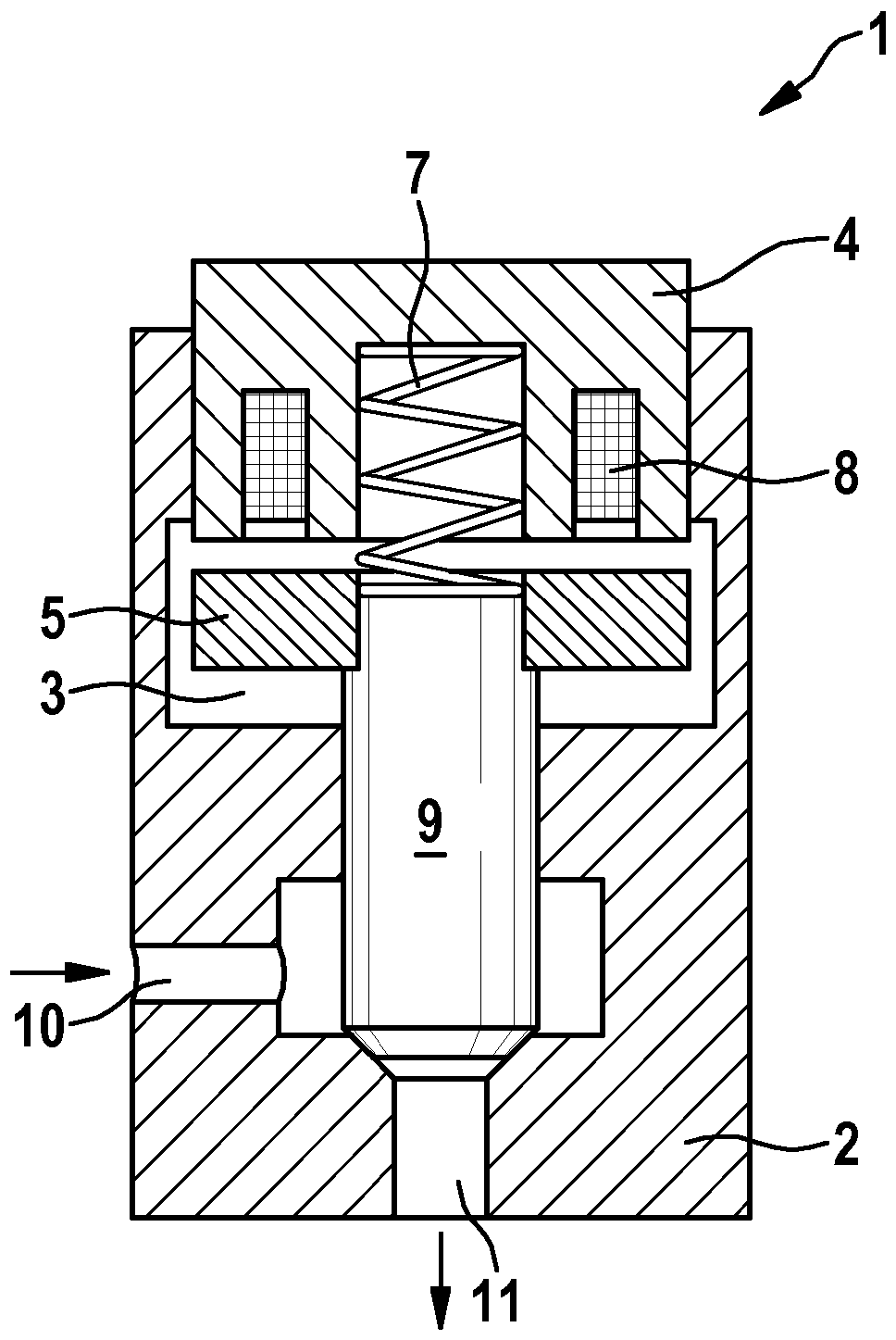

[0039] exist figure 1 An example of a non-current-closed (NC) electromagnetic injector 1 is shown in . The electromagnetic injector 1 has a valve body 2 in which an armature chamber 3 is formed. An armature 5 is arranged in this armature chamber 3 . Furthermore, a valve spring 7 is arranged in the armature chamber 3 . Furthermore, electromagnetic injector 1 has a solenoid coil 8 which surrounds valve spring 7 in an annular manner. The magnetic loop 4 serves as a yoke. A sealing element, here in the form of an injector needle 9 , is connected to the armature 5 . The electromagnetic injector 1 is equipped with an inflow port 10 and an outflow port 11 , but the directions described therein are merely exemplary directions.

[0040] So-called energization of the electromagnetic injector 1 takes place if an electric current is supplied to the electromagnetic coil 8 via an electrical line (not shown). As a result, a magnetic field is formed in the solenoid coil 8 , which causes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com