Method for operating an internal combustion engine

An internal combustion engine, crankcase technology, applied in mechanical equipment, engine components, machines/engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

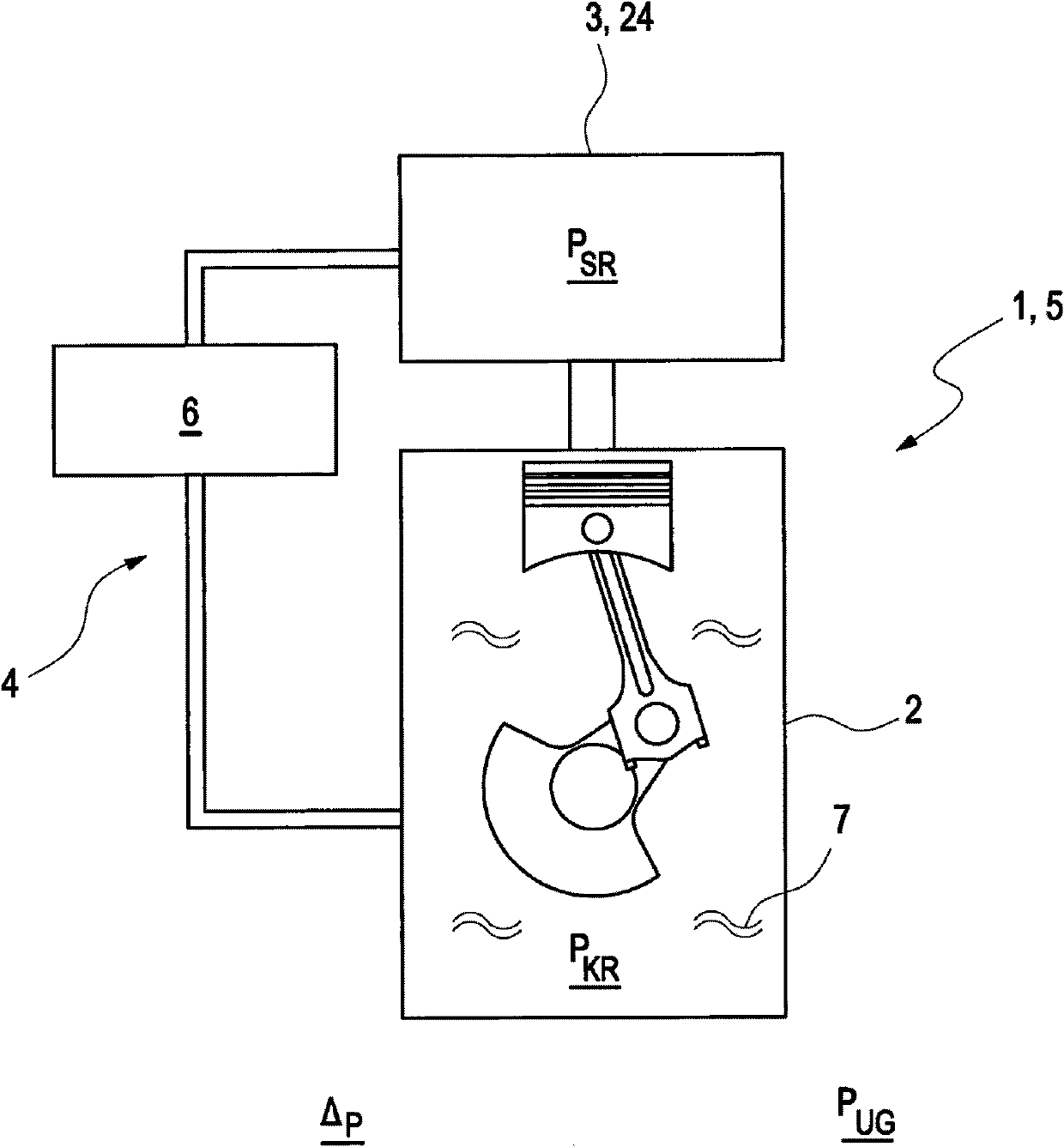

[0014] figure 1 An internal combustion engine 1 is shown schematically with a crankcase 2 and an intake manifold 3 forming an intake system 24 via which the internal combustion engine 1 is supplied with combustion air. The crankcase 2 and the intake manifold 3 are connected to one another via a crankcase ventilation device 4 . In the example shown, the internal combustion engine 1 is designed as a wet-sump naturally aspirated engine 5 . The crankcase ventilation device 4 has a pressure regulating valve 6 which makes it possible to adjust the negative pressure P present in the crankcase 2 in the following way KR Adjustment: The intake manifold negative pressure P present in the intake manifold 3 is adjusted by means of the pressure regulating valve 6 SR The crankcase 2 is loaded and the lubricant vapor 7 present in the crankcase is evacuated. The pressure regulating valve 6 is adapted here in such a way that the crankcase negative pressure P KR Relative to ambient pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com