Printing unit and rubber fabric plate for the same

A printing color and rubber technology, applied in the general parts of printing machinery, printing, printing machines, etc., can solve problems such as damage to printing quality, increased wear and tear of transfer printing plate 23, to reduce printing problems, reduce pressure difference, and avoid pressure. poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The invention relates to a printing color set of a printing machine, in particular to an offset printing color set of a web printing machine. Already referenced figure 1 The basic construction of such a printing color set is described.

[0060] The invention also relates to a transfer printing form formed as a blanket, wherein reference has been made to figure 2 The basic construction of the rubber cloth sheet is described.

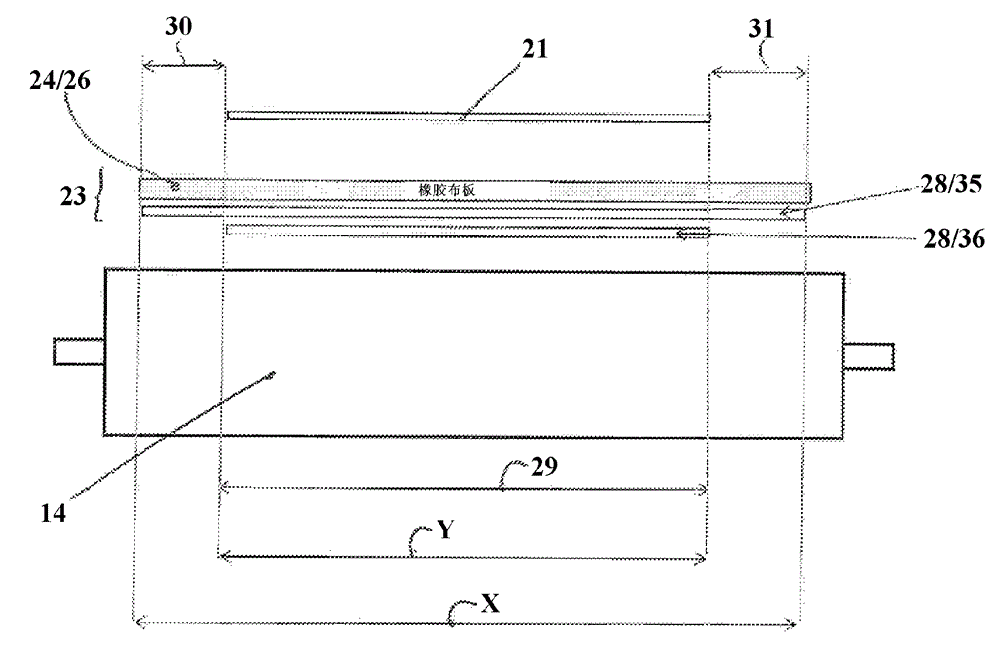

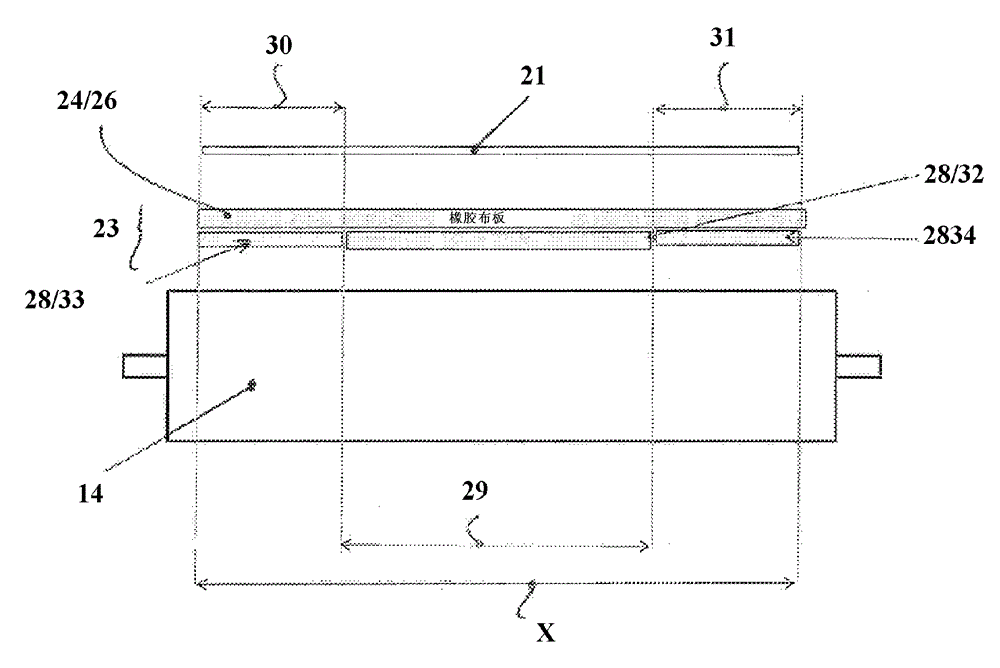

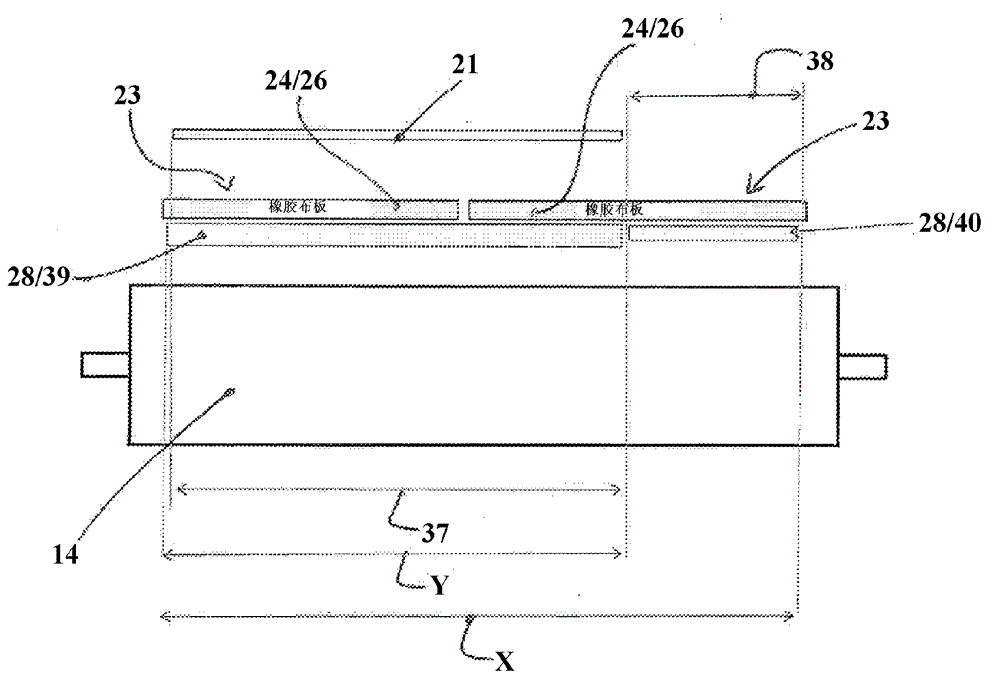

[0061] image 3 A schematic detail of the first printing group according to the invention is shown in the area of the transfer cylinder 14 , the transfer printing form positioned on the transfer cylinder 14 as a blanket 23 and the substrate 21 to be printed. exist image 3 , the maximum available for printing the axial width of the transfer cylinder 14 and thus the printing group 10 is marked by dimension X, where, in image 3 Among them, a transfer printing plate formed as a blanket 23 is arranged on the outer circumference of the transfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com