Low-pressure casting method and equipment thereof

A low-pressure casting and equipment technology, which is applied in the field of low-pressure casting methods and equipment, can solve the problems of unfavorable quality of castings and increased difficulty in controlling the stability of rising liquid filling molds, etc., and achieve the goals of corrosion prevention, large economic and social value, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A low-pressure casting device with simple structure, convenient operation and good technical effect and a method for using the device to perform low-pressure casting operation.

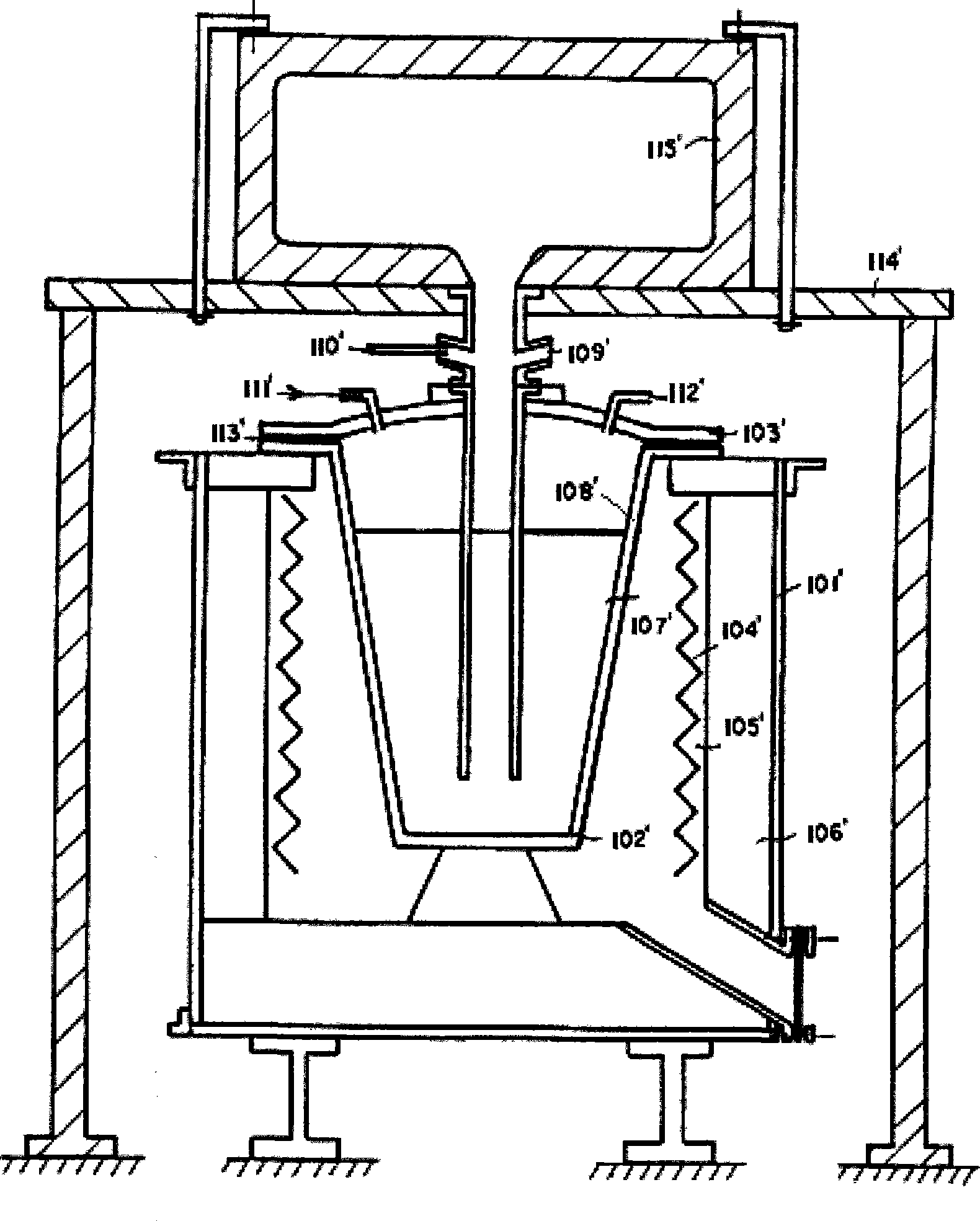

[0038] 1) Equipment used in low pressure casting method

[0039] In the special equipment, a crucible is specifically used as the core of the equipment; the feature is that the crucible in the equipment has a structure that separates its interior and exterior into two independent parts that are not connected to each other. And always keep the pressure of the two gases basically the same, that is to say, in the process of filling and pressurizing the entire casting, pressurizing and maintaining pressure after filling, and pressure relief after the casting solidifies, the gas filled inside the crucible is required to be the same as the gas filled outside the crucible. Another gas that is fed in keeps the pressure basically equal and changes basically synchronously.

[0040] The metal liquid for ...

Embodiment 2

[0060] A low-pressure casting device with simple structure, convenient operation and good technical effect and a method for using the device to perform low-pressure casting operation.

[0061] 1) Equipment used in low pressure casting method

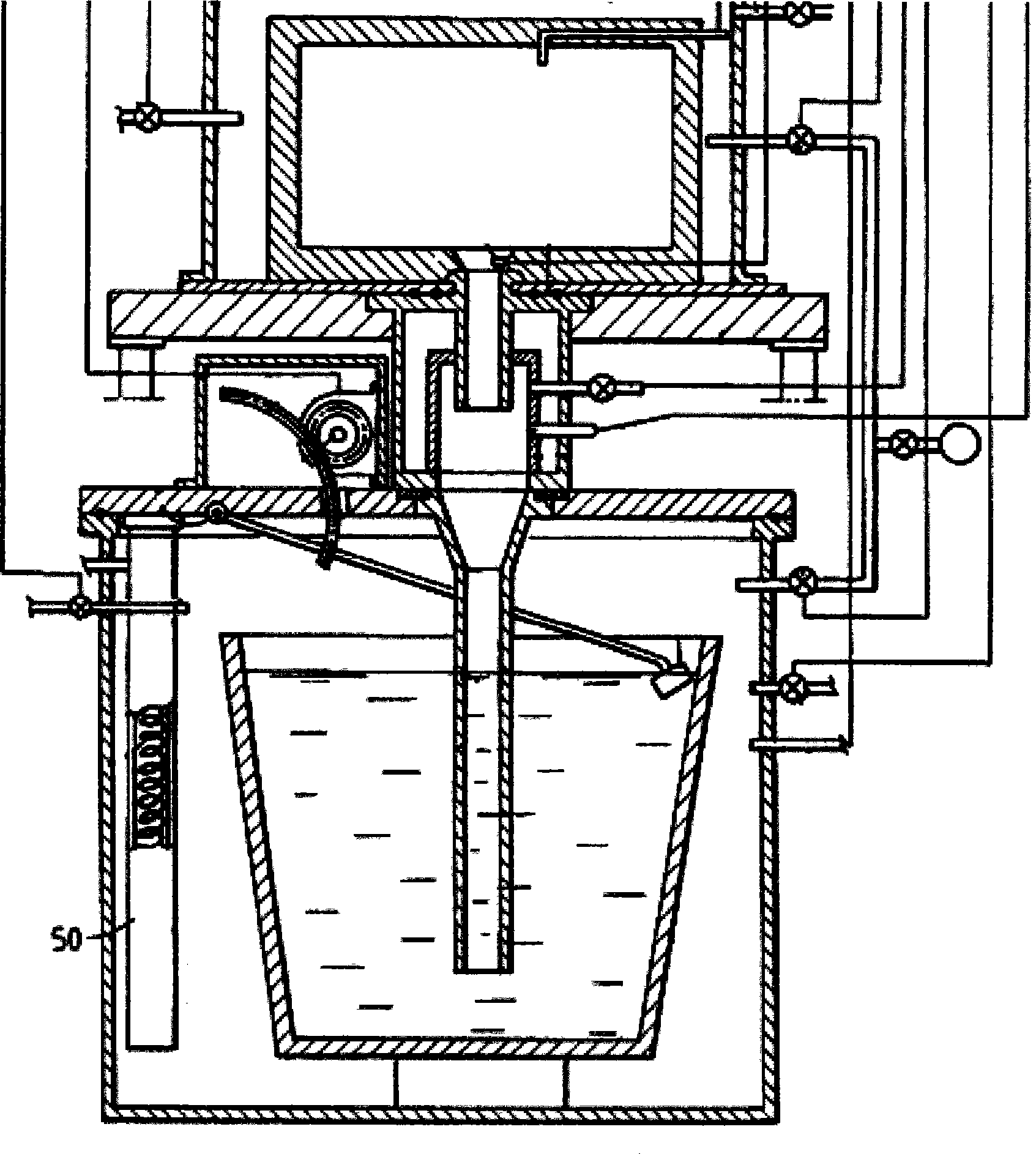

[0062] In the special equipment, a crucible is specifically used as the core of the equipment; the feature is that the crucible in the equipment has a structure that separates its interior and exterior into two independent parts that are not connected to each other. The low-pressure casting equipment includes a low-pressure casting pressure tank, a mold loading system, an air supply system and an integrated control system; wherein:

[0063] There is a holding furnace inside the low-pressure casting pressure tank, and there is a crucible inside the holding furnace, which is installed in the hearth of the holding furnace inside the low-pressure casting pressure tank. The gas supply system is connected to the following two parts that are re...

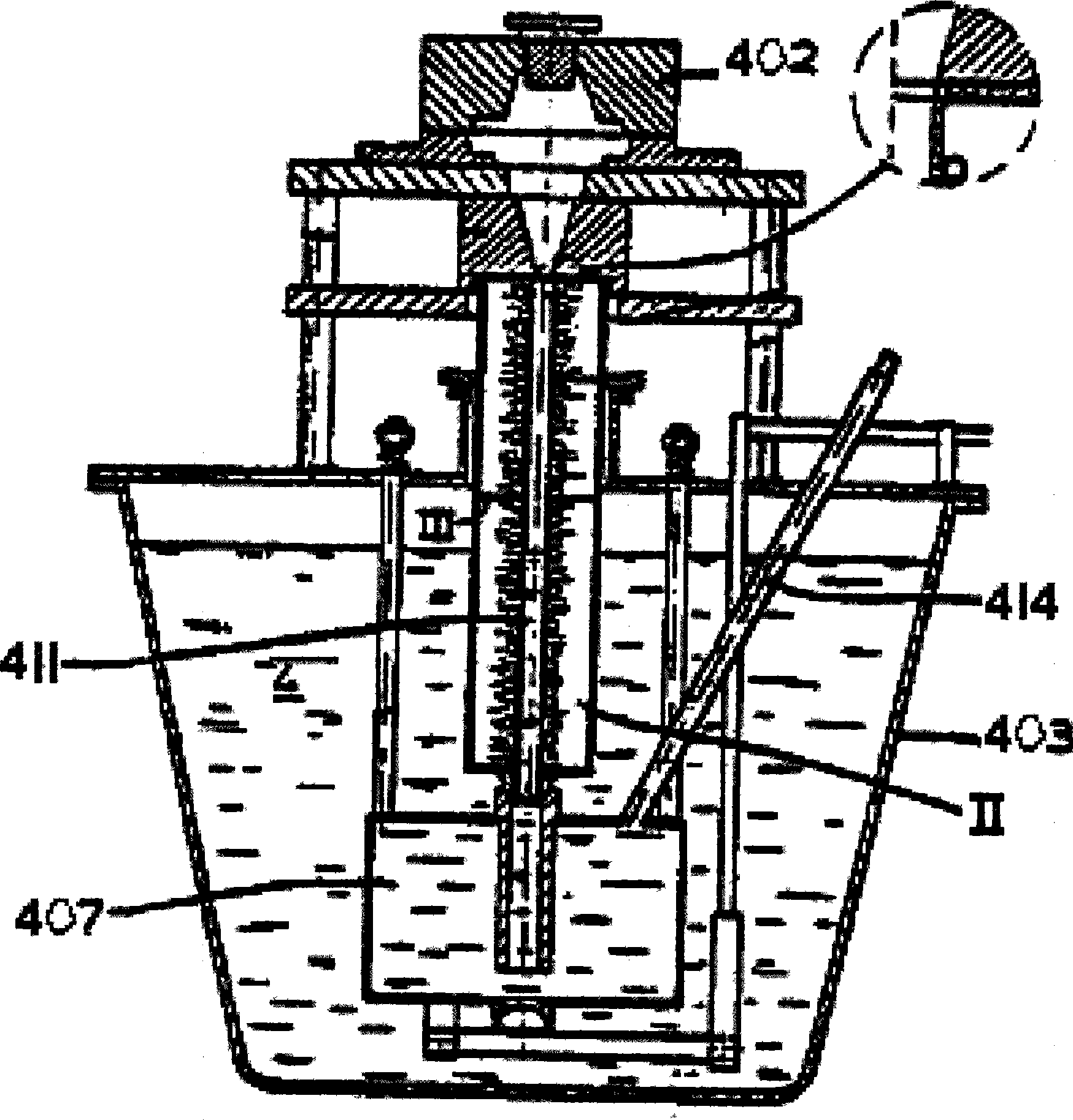

Embodiment 3

[0080] The content of this embodiment is basically the same as that of Embodiment 1, and the difference is mainly: the SF in the protective mixed gas charged inside the crucible 6 The volume fraction is about 0.3%.

[0081] The gas introduced into the closed space outside the crucible is nitrogen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com