Internal structure of soft package lithium ion battery and assembly method

A lithium-ion battery and internal structure technology, which is applied to battery pack parts, secondary batteries, structural parts, etc., can solve the problems of no pressure resistance, small discharge capacity of the battery pack, and burnt out battery pack, etc., and achieve cooling Or good heating effect, large storage and discharge capacity, and the effect of preventing battery explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

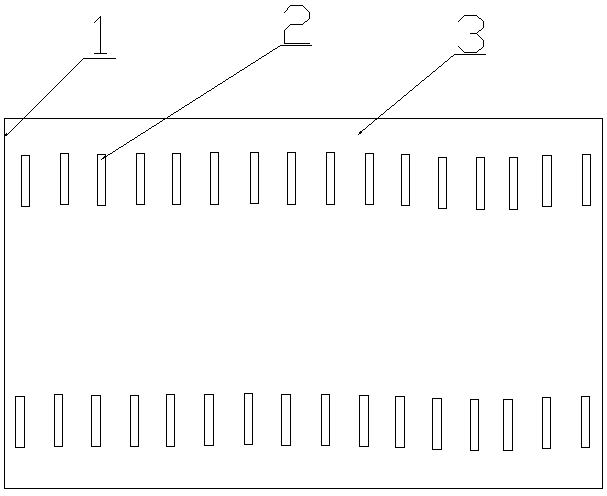

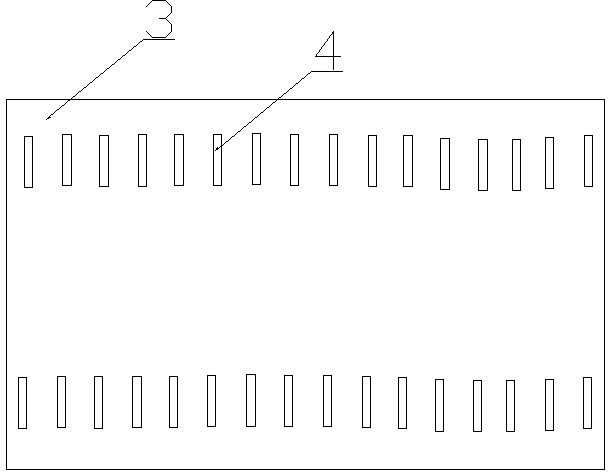

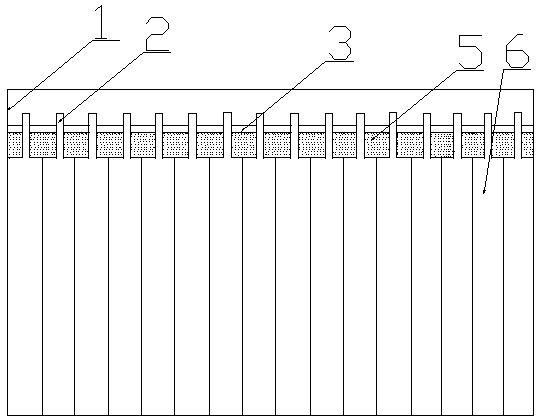

[0022] Embodiment 1: as figure 1 , 2 , 3, and 4, the internal structure of a soft-packed lithium-ion battery includes a housing 1 and a battery 6 disposed in the housing 1, EVA5 is arranged between the tabs 2 of the battery 6, and the battery 6 A PCB board 3 with a through hole 4 is arranged on the lug. The tab 2 protrudes about 10mm through the PCB. Ultrasonic welding is used for the connection between the tabs 2 of the battery 6 .

Embodiment 2

[0023] Embodiment 2: as figure 1 , 2 , 3, and 4, the internal structure of a soft-packed lithium-ion battery includes a housing 1 and a battery 6 disposed in the housing 1, EVA5 is arranged between the tabs 2 of the battery 6, and the battery 6 A PCB board 3 with a through hole 4 is arranged on the lug. The tab 2 protrudes about 10mm through the PCB. Ultrasonic welding is used for the connection between the tabs 2 of the battery 6 . A temperature sensor is arranged in the housing 1, and the temperature sensor is connected with a controller and an alarm. The controller is connected with a cooling mechanism 7 . The cooling mechanism 7 is a semiconductor cooling chip set.

[0024] A method for assembling the internal structure of a soft pack lithium-ion battery, comprising the following steps:

[0025] a. After the battery cell is assembled, the gap between the battery tabs is filled with EVA with good insulation, high temperature resistance and good formability;

[0026] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com