Negative electrode material for lithium-ion battery, and use therefor

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of interrupted conduction path, increase in internal resistance, large volume change, etc., and achieve large discharge capacity and high charge-discharge efficiency. , the effect of large charge and discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0147] Petroleum-based coke was pulverized and heat-treated in an Acheson furnace at 3000°C to obtain a particle size of 10% (D 10 ) is 7.8μm, and the BET specific surface area is 1.9m 2 / g of scaly graphitic carbon material particles.

[0148] Silicon-containing particles (D av : 50nm; Oxygen content: 5.8% by mass; True density (theoretical value): 2.33g / cm 3 ) 10 parts by mass and 20 parts by mass of petroleum pitch (softening point: 93° C.; carbon residue rate: 28%) [based on the mass after the carbonization of petroleum pitch] were put into a detachable flask. The inert atmosphere was maintained by flowing nitrogen gas, and the temperature was raised to 150°C. The dispersion was rotated and stirred at 1000 rpm to uniformly mix the bitumen and silicon-containing particles. It was cooled and solidified to give mixture (a).

[0149] The mixture (a) was pulverized in a nitrogen atmosphere using a rod mill to obtain a pulverized product (a).

[0150] 50 parts by mass of t...

Embodiment 2

[0154] A composite material (b) was obtained in the same manner as in Example 1 except that the pulverization of the mixture (a) was performed with a rotary shredder instead of a rod mill.

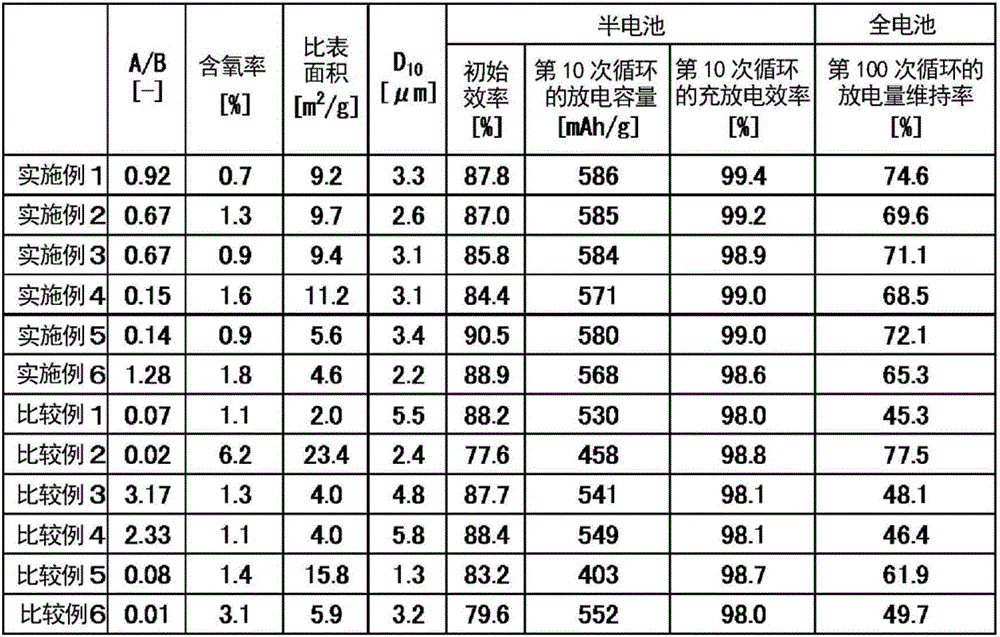

[0155] For the composite material (b), the XPS-Si2p peak area ratio (A / B), oxygen content, specific surface area and D 10 . In addition, half cells and full cells were produced using the composite material (b), and the initial efficiency, charge and discharge efficiency, discharge capacity, and discharge capacity maintenance rate were measured. The results are shown in Table 1.

Embodiment 3

[0157] A composite material (c) was obtained in the same manner as in Example 1 except that the pulverized product (a) and the graphite carbon material particles were mixed with a rod mill instead of a rotary shredder.

[0158] For the composite material (c), the XPS-Si2p peak area ratio (A / B), oxygen content, specific surface area and D 10 . In addition, the composite material (c) was used to manufacture half cells and full cells, and the initial efficiency, charge and discharge efficiency, discharge capacity and discharge capacity maintenance rate were measured. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com