Patents

Literature

199results about How to "Large emissions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

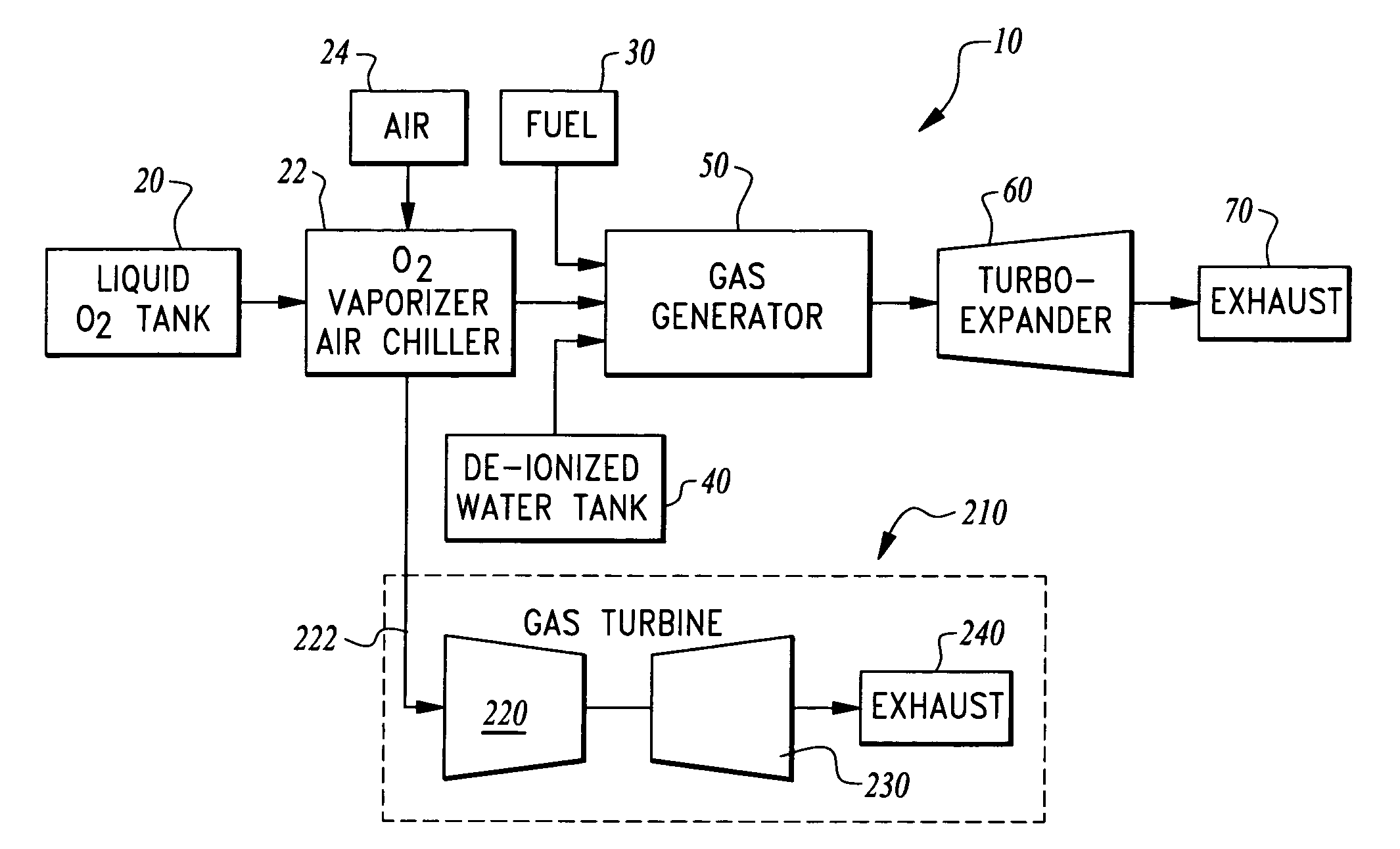

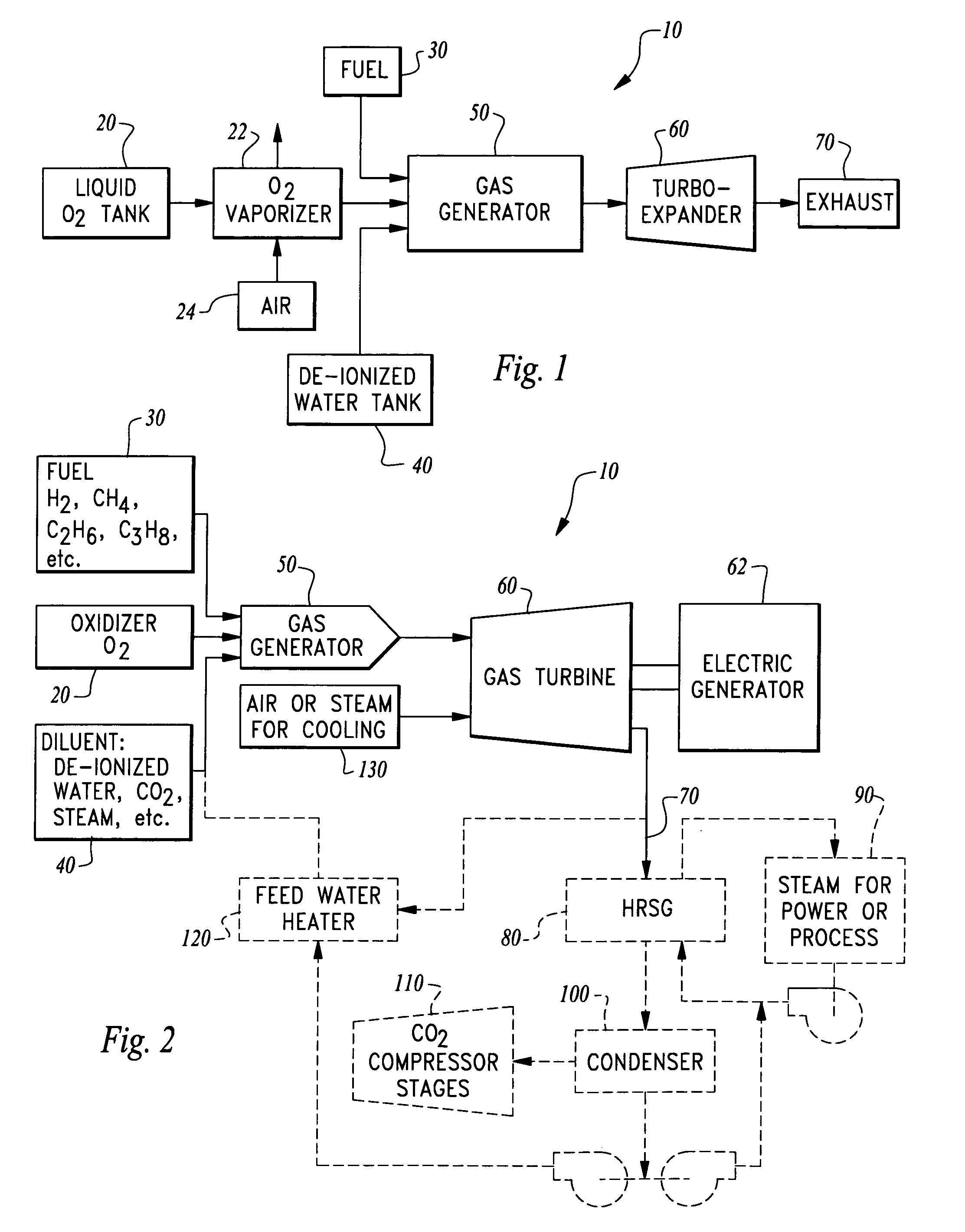

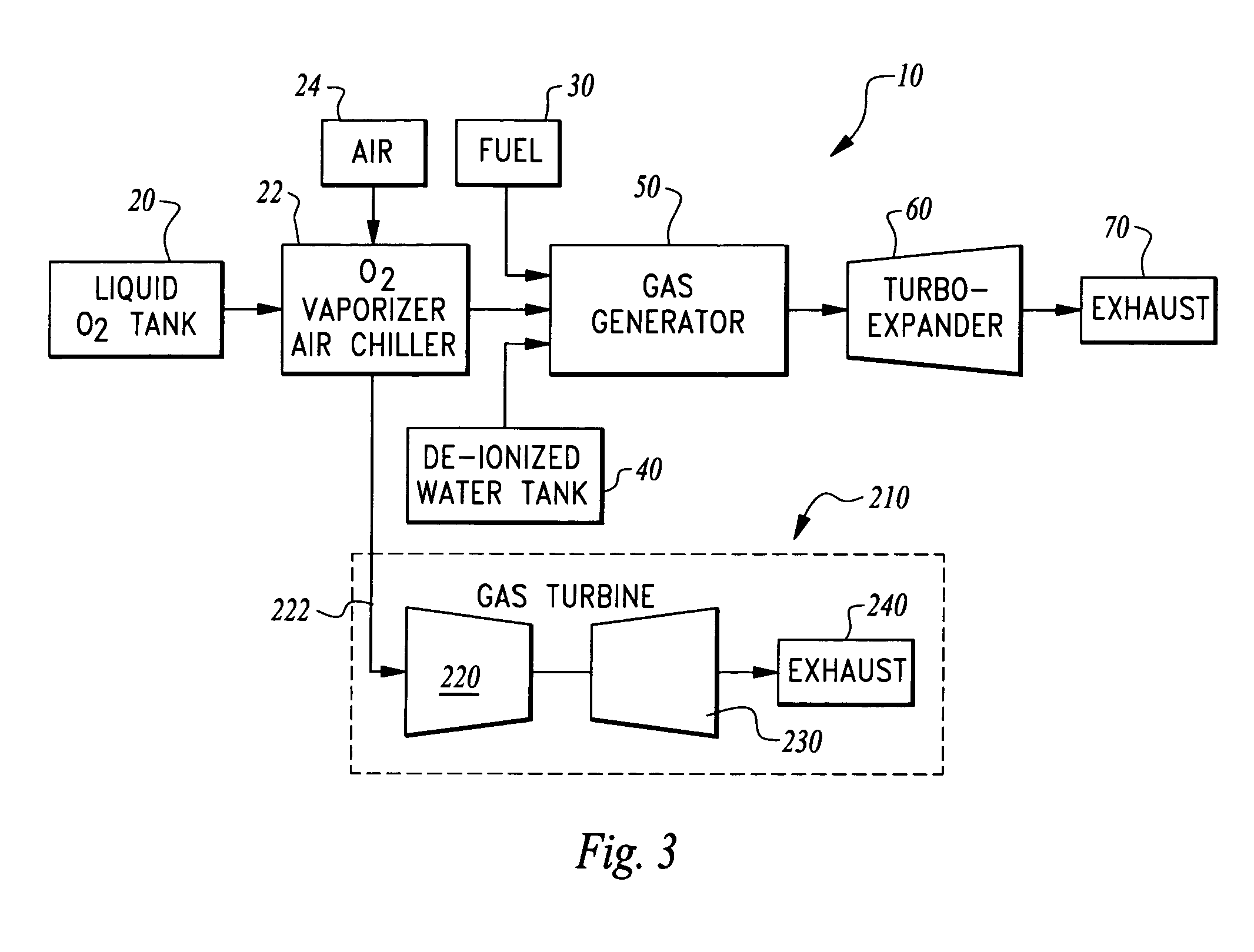

Ultra low emissions fast starting power plant

InactiveUS7827794B1Fast starting low emissionMinimal capital expenseTurbine/propulsion engine coolingGas turbine plantsNuclear engineeringLiquid fuel

The power plant combusts a hydrocarbon fuel with oxygen to produce high temperature high pressure products of combustion. These products of combustion are routed through an expander to generate power. The products of combustion are substantially free of oxides of nitrogen because the oxidizer is oxygen rather than air. To achieve fast starting, oxygen, fuel and water diluent are preferably stored in quantities sufficient to allow the power plant to operate from these stored consumables. The fuel can be a gaseous or liquid fuel. The oxygen is preferably stored as liquid and routed through a vaporizer before combustion in a gas generator along with the hydrocarbon fuel. In one embodiment, the vaporizer gasifies the oxygen by absorption of heat from air before the air is routed into a separate heat engine, such as a gas turbine. The gas turbine thus operates on cooled air and has its power output increased.

Owner:CLEAN ENERGY SYST

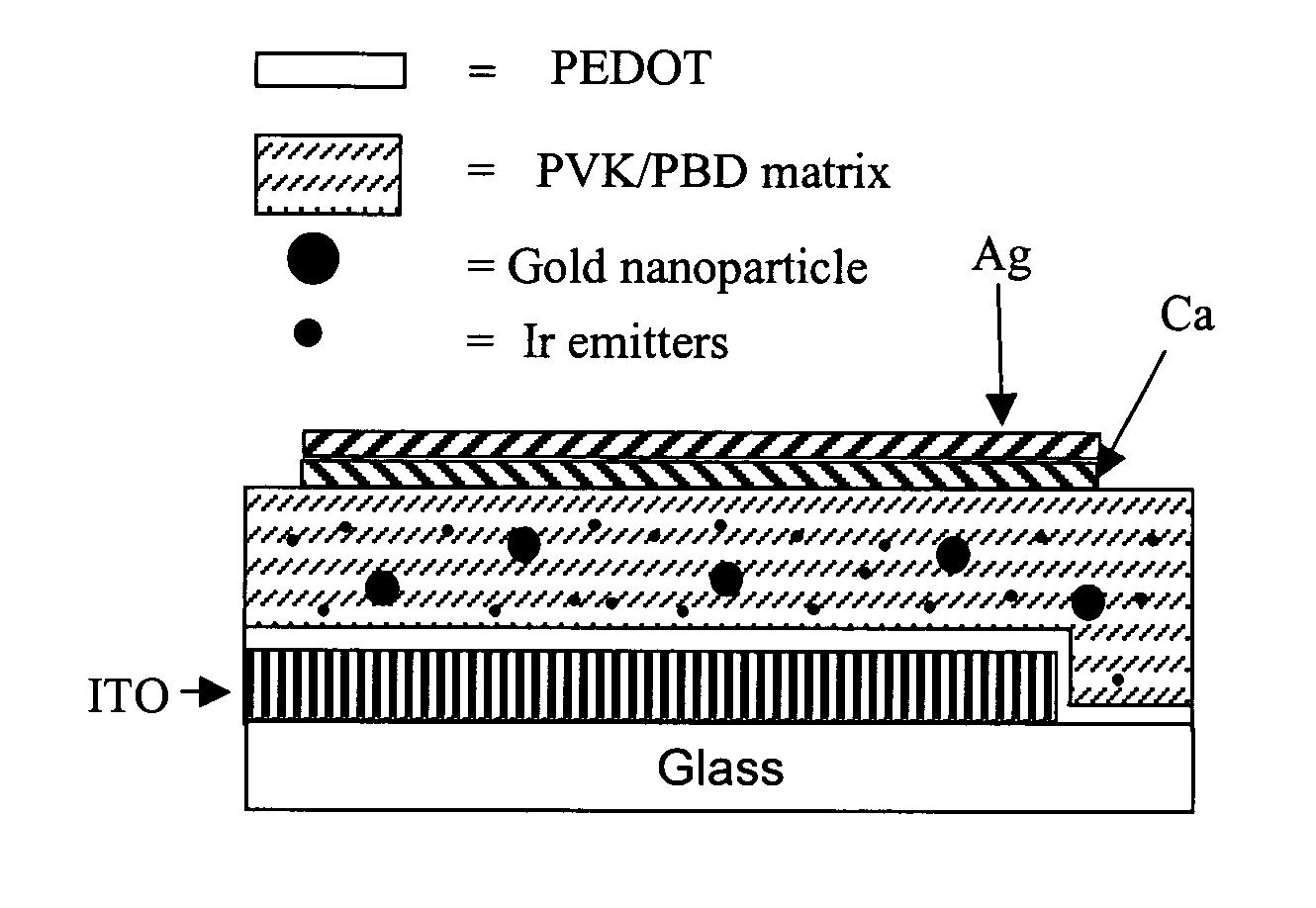

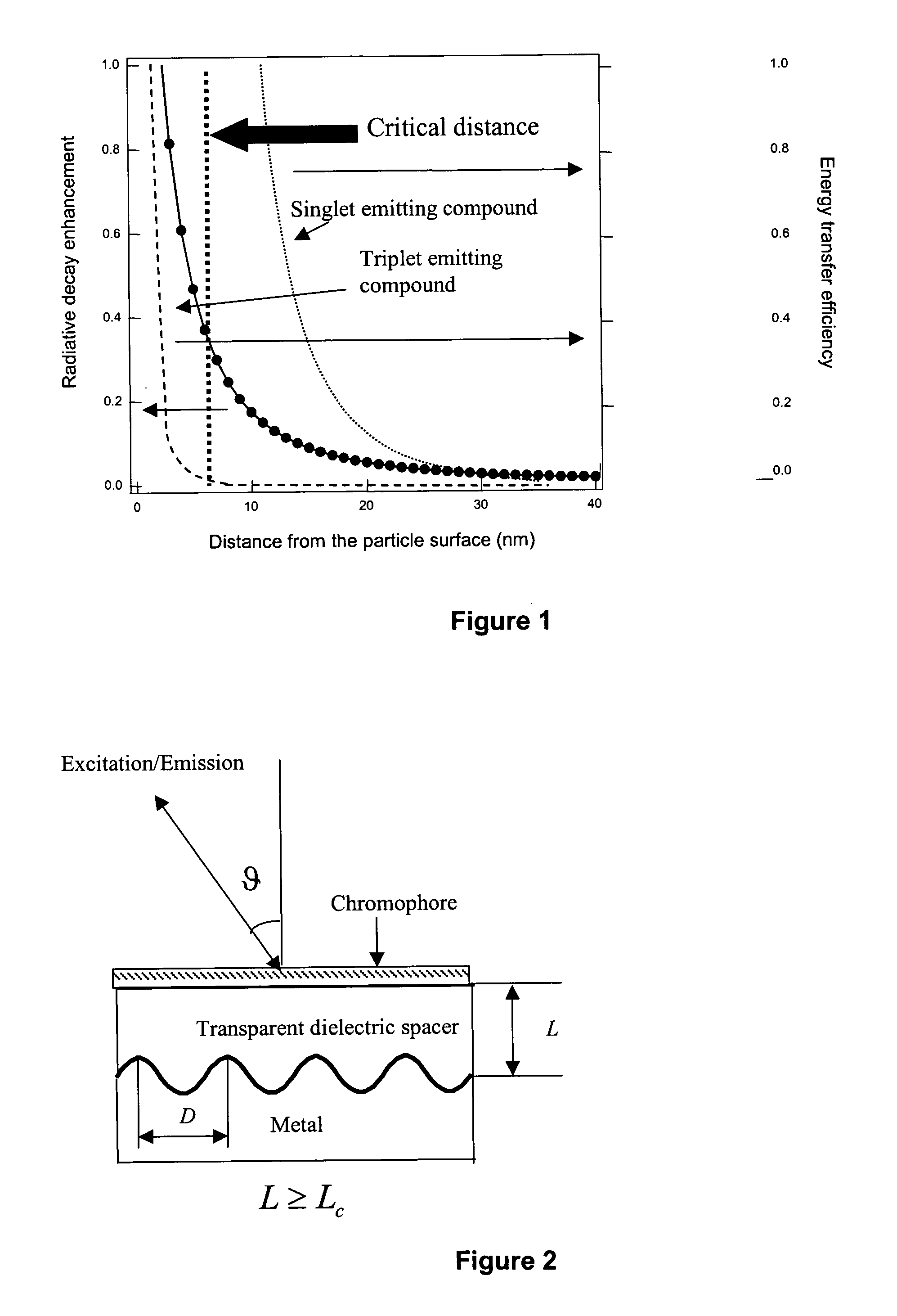

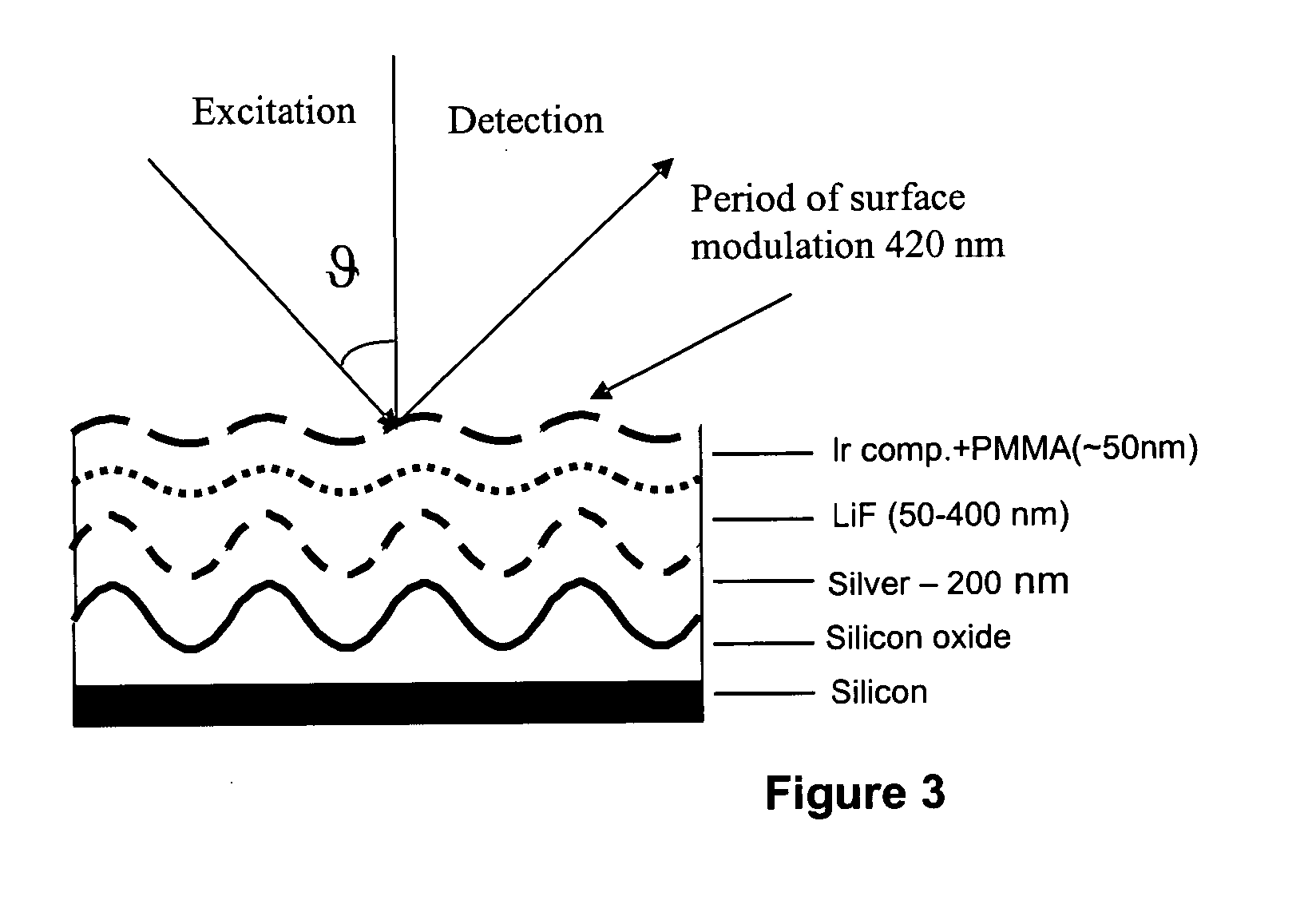

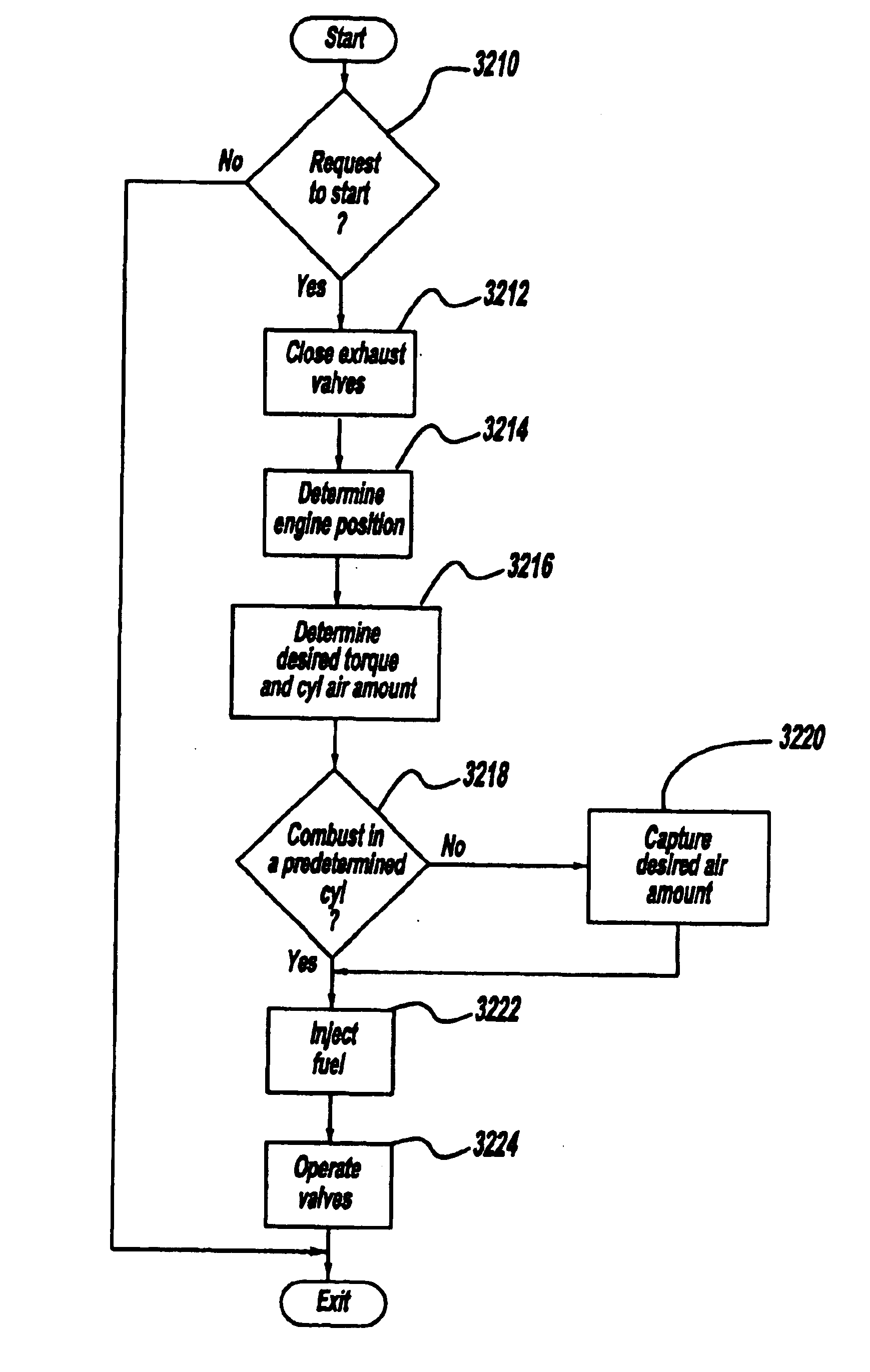

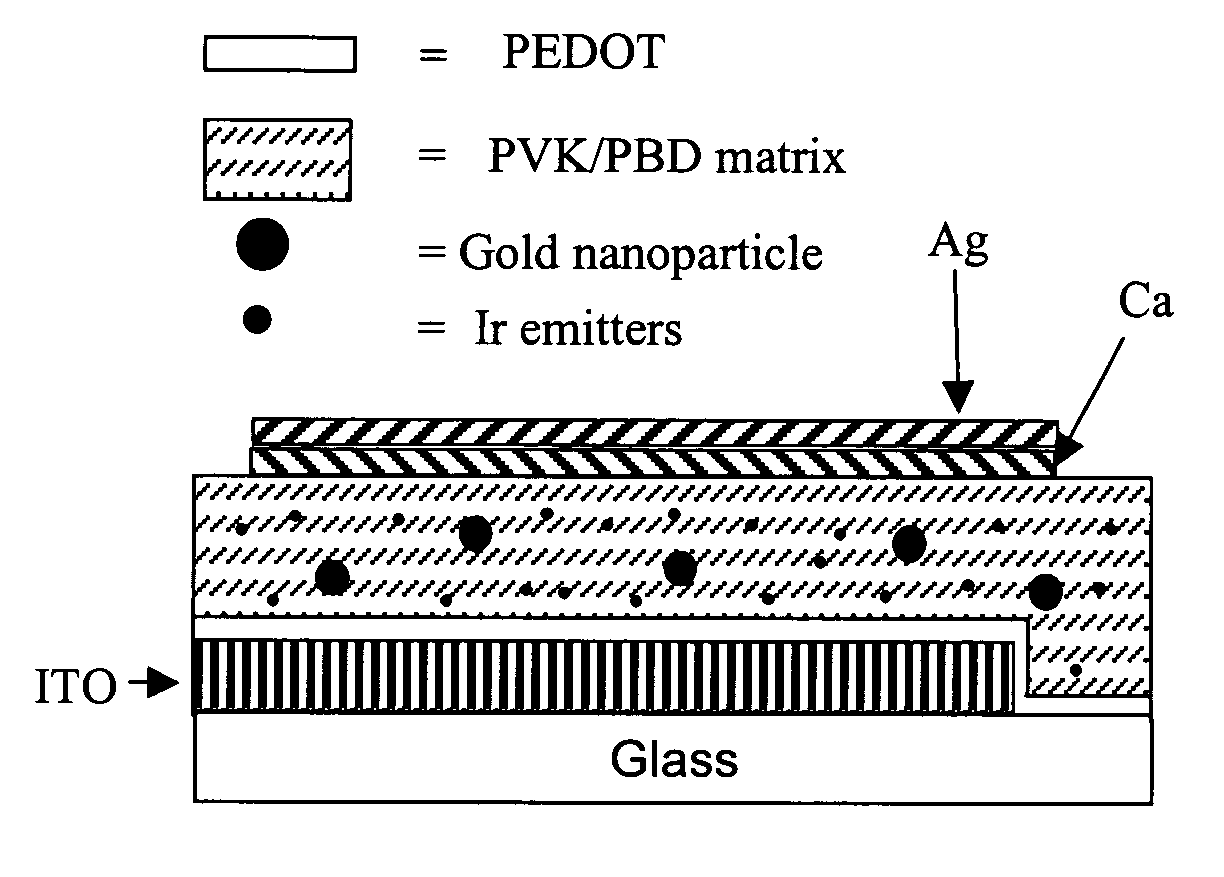

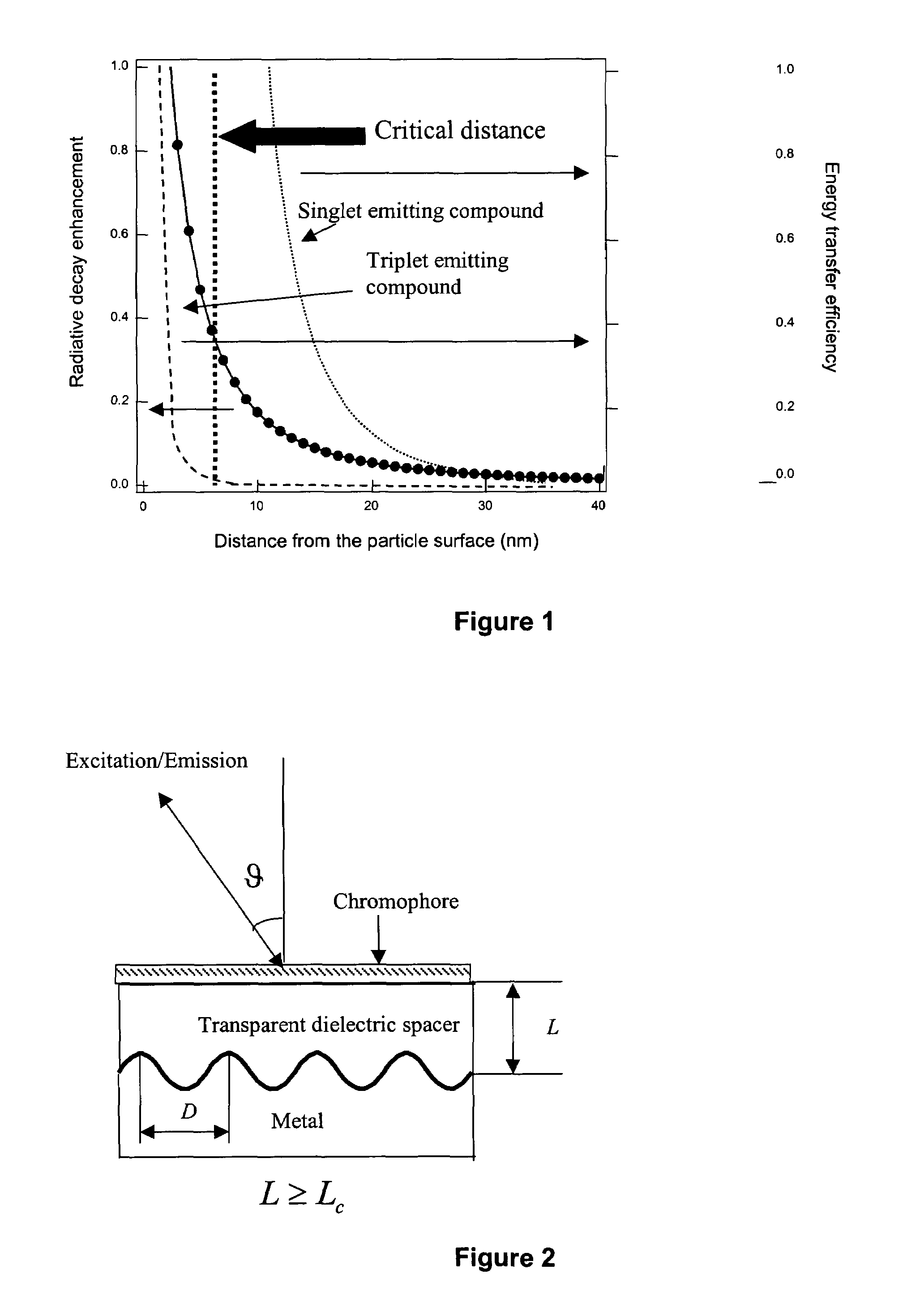

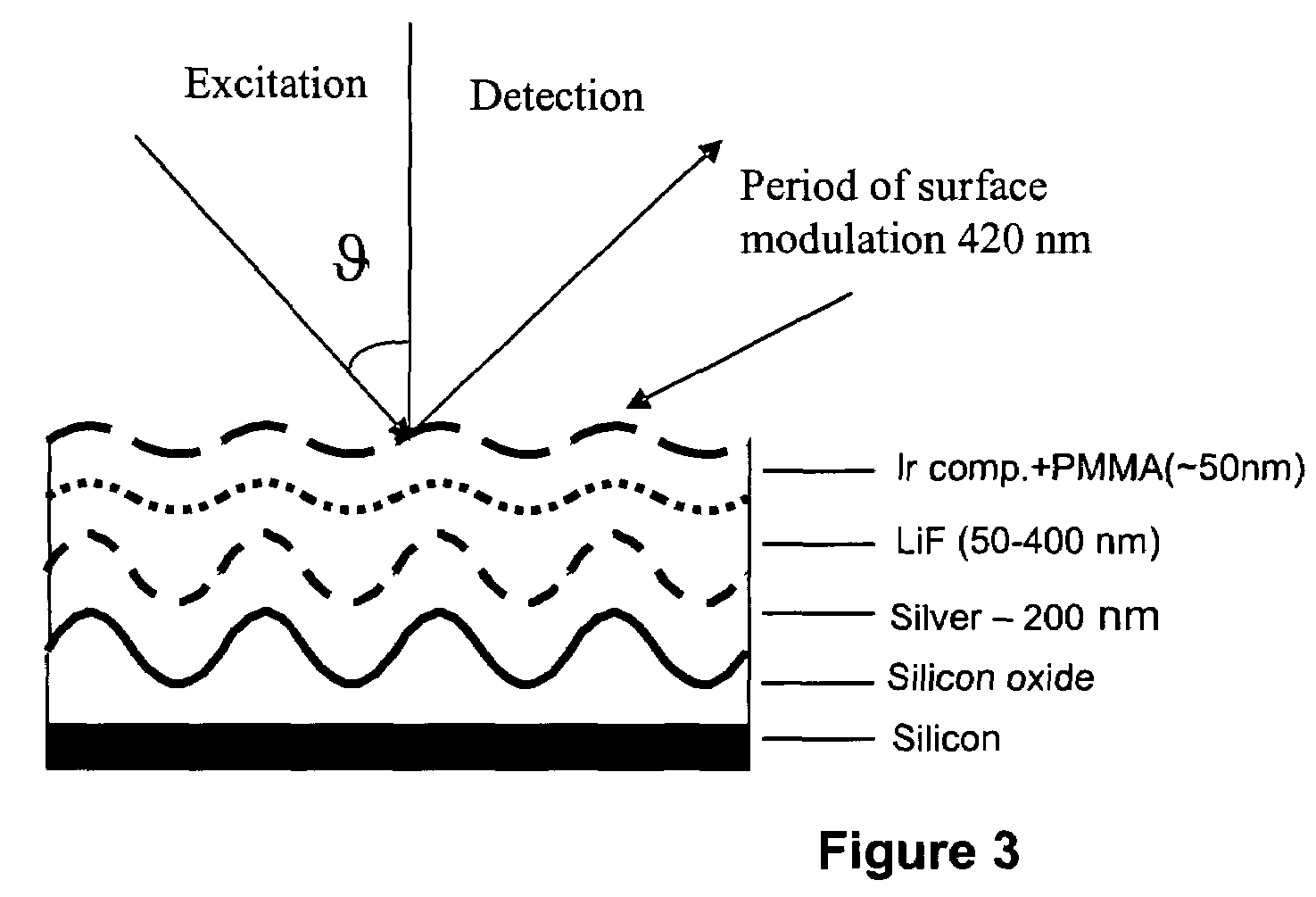

Plasmon assisted enhancement of organic optoelectronic devices

InactiveUS20050035346A1Enhanced and controllable rate of radiative relaxationImprove launch performanceMaterial nanotechnologySolid-state devicesOscillator strengthLight emitter

Optoelectronic devices and methods for their fabrication having enhanced and controllable rates of the radiative relaxation of triplet light emitters are provided exemplified by organic light emitting devices based on phosphorescent materials with enhanced emission properties. Acceleration of the radiative processes is achieved by the interaction of the light emitting species with surface plasmon resonances in the vicinity of metal surfaces. Non-radiative Förster-type processes are efficiently suppressed by introducing a transparent dielectric or molecular layer between the metal surface and the chromophore. For materials with low emission oscillator strengths (such as triplet emitters), the optimal separation distance from the metal surface is determined, thus suppressing energy transfer and achieving a significant acceleration of the emission rate.

Owner:RGT UNIV OF CALIFORNIA

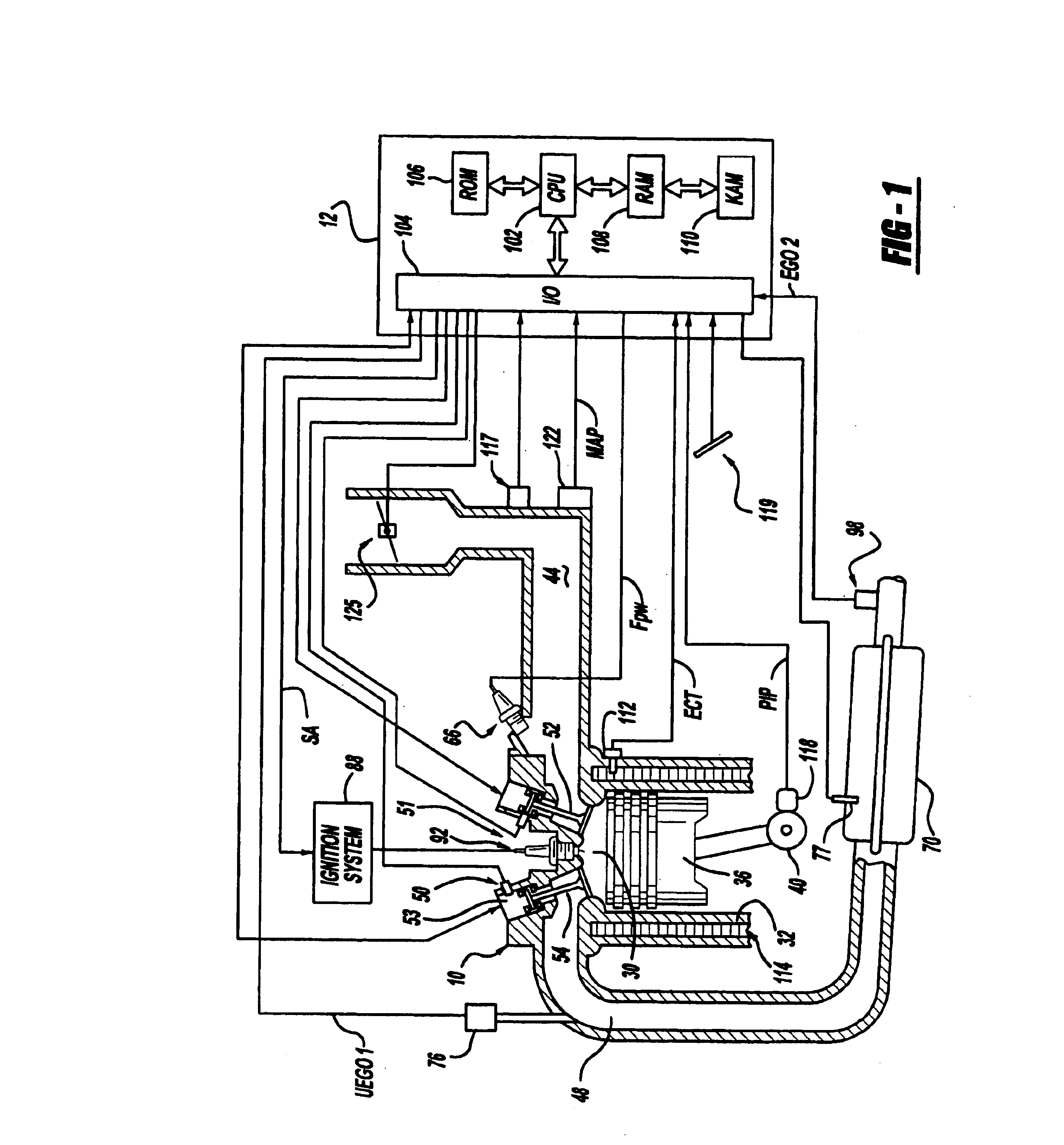

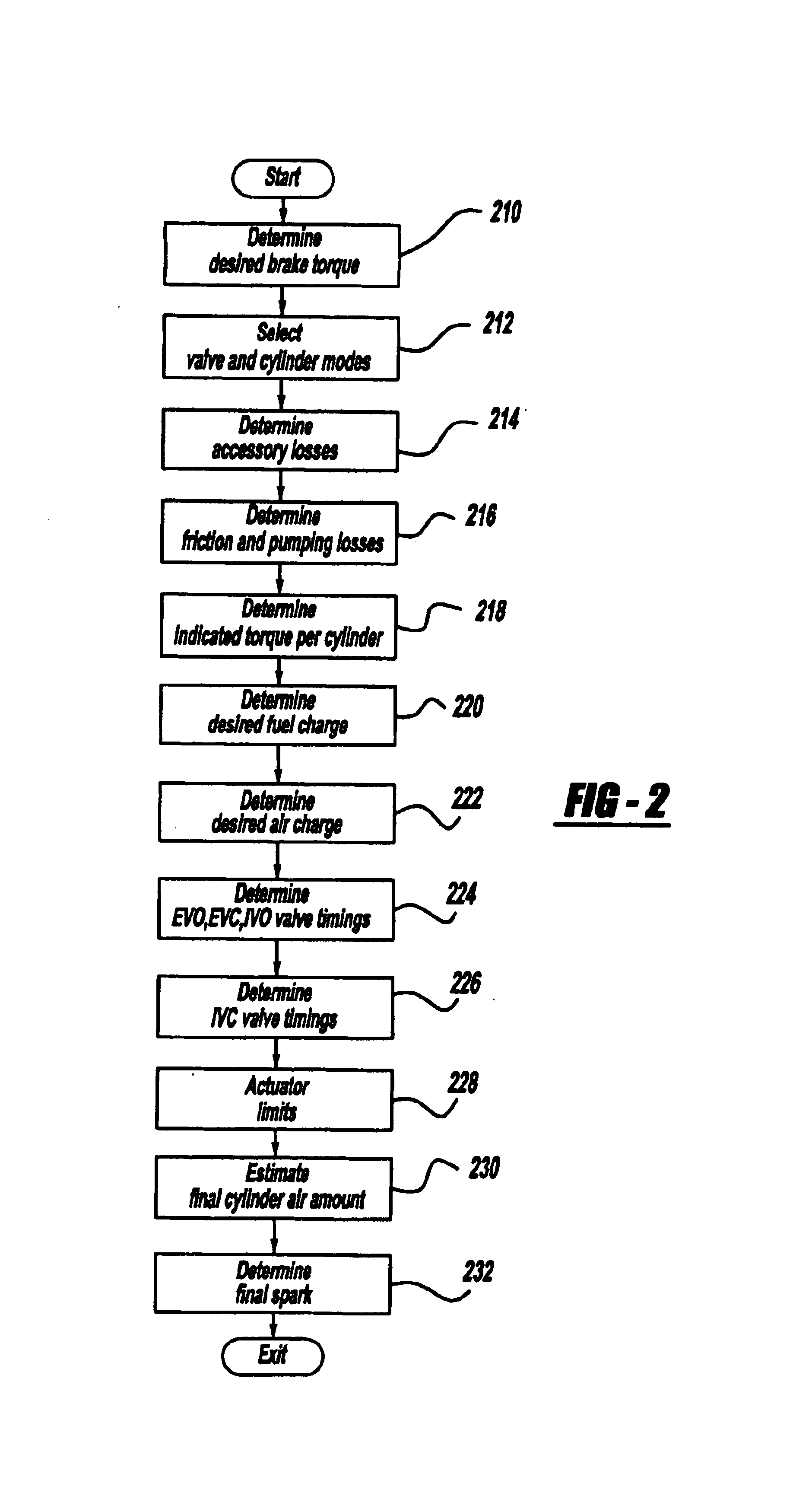

Starting an engine with electromechanical valves

ActiveUS6938598B1VariationLarge emissionsElectrical controlInternal combustion piston enginesControl mannerFour-stroke engine

A system and method to control engine valve timing to during the start of an internal combustion engine. Electromechanical valves are controlled in a manner to reduce engine vibration and hydrocarbon emissions during the start of an internal combustion engine. The method controls valves without an explicit four-stroke engine cycle during a start.

Owner:FORD GLOBAL TECH LLC

Growth of indium gallium nitride (InGaN) on porous gallium nitride (GaN) template by metal-organic chemical vapor deposition (MOCVD)

InactiveUS20090001416A1Increase indium incorporationLarge emissionsPolycrystalline material growthSemiconductor/solid-state device manufacturingIndiumGallium nitride

Si-doped porous GaN is fabricated by UV-enhanced Pt-assisted electrochemical etching and together with a low-temperature grown buffer layer are utilized as the template for InGaN growth. The porous network in GaN shows nanostructures formed on the surface. Subsequent growth of InGaN shows that it is relaxed on these nanostructures as the area on which the growth takes place is very small. The strain relaxation favors higher indium incorporation. Besides, this porous network creates a relatively rough surface of GaN to modify the surface energy which can enhance the nucleation of impinging indium atoms thereby increasing indium incorporation. It shifts the luminescence from 445 nm for a conventionally grown InGaN structure to 575 nm and enhances the intensity by more than two-fold for the growth technique in the present invention under the same growth conditions. There is also a spectral broadening of the output extending from 480 nm to 720 nm.

Owner:NAT UNIV OF SINGAPORE

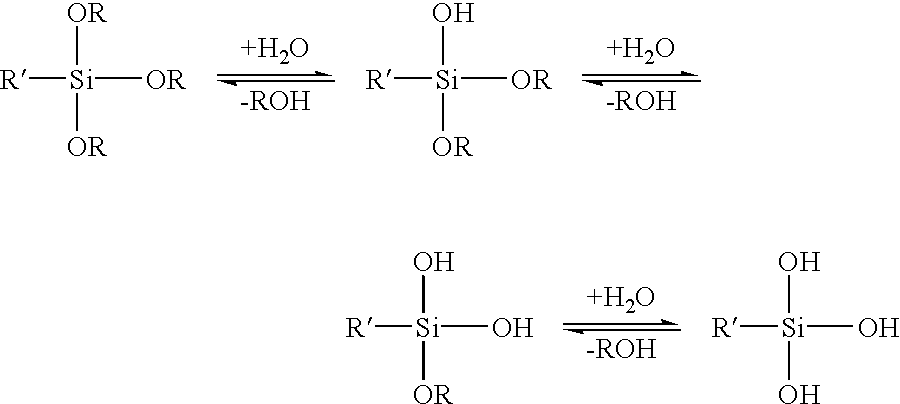

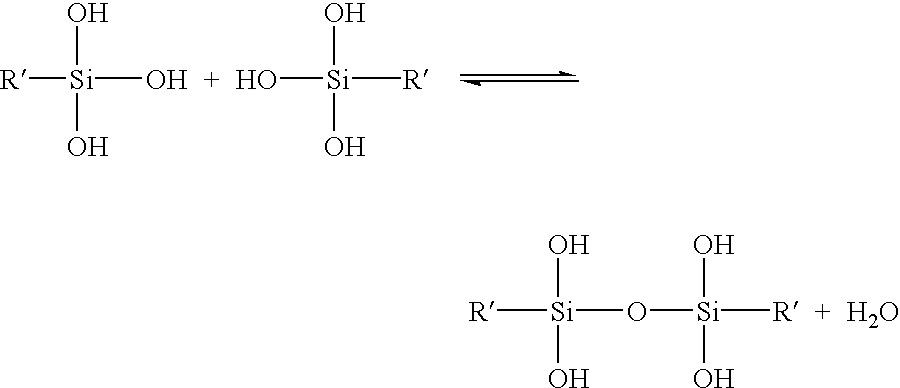

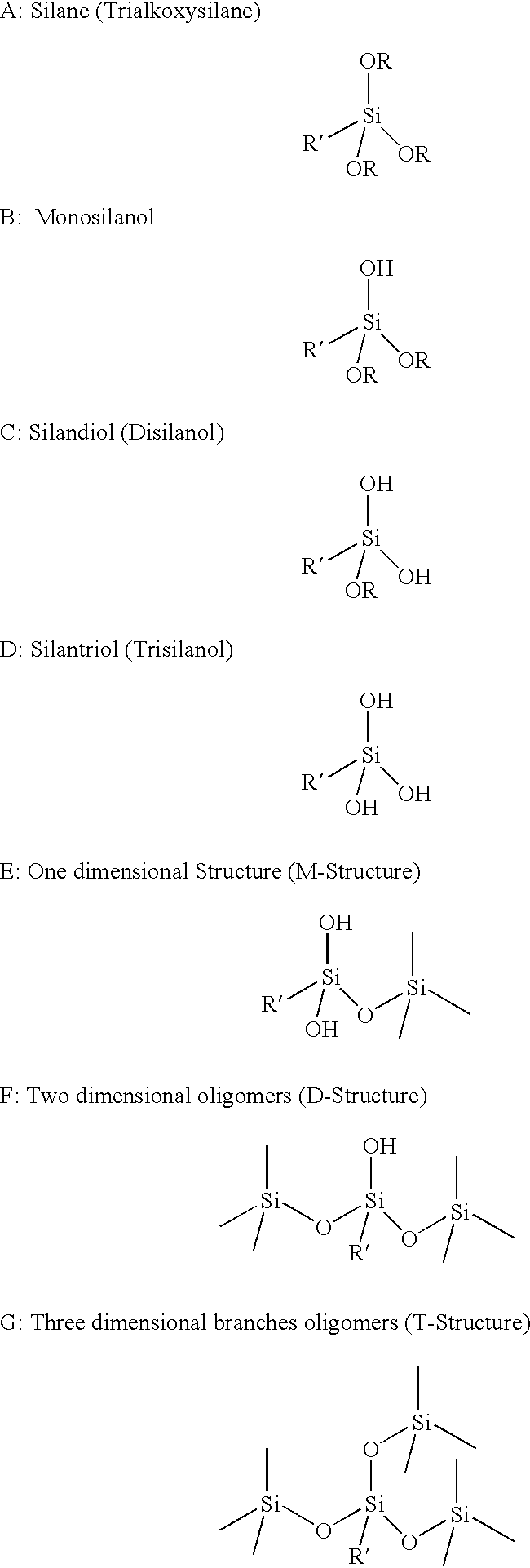

Water-based primer for promoting adhesion of polyurethane-based sealants and adhesives

InactiveUS6511752B1Improve adhesionLittle and no VOC emissionGroup 4/14 element organic compoundsOther chemical processesWater basedPolyurethane adhesive

A method is provided for adhering a polyurethane-based sealant or adhesive to a substrate. The method comprises: i) applying an aqueous primer solution onto a substrate, the primer solution comprising water, an aminotitanate compound, and preferably an epoxysilane compound having at least one epoxy group and at least two alkoxy groups; ii) applying a polyurethane adhesive or sealant to the primer-treated substrate; and iii) forming a reaction product of the primer and the polyurethane. Also provided are a substrate having a layer of a polyurethane adhesive or sealant, and a stabilized aqueous primer solution containing an epoxysilane compound and an aminotitanate compound.

Owner:SIKA AUTOMOTIVE

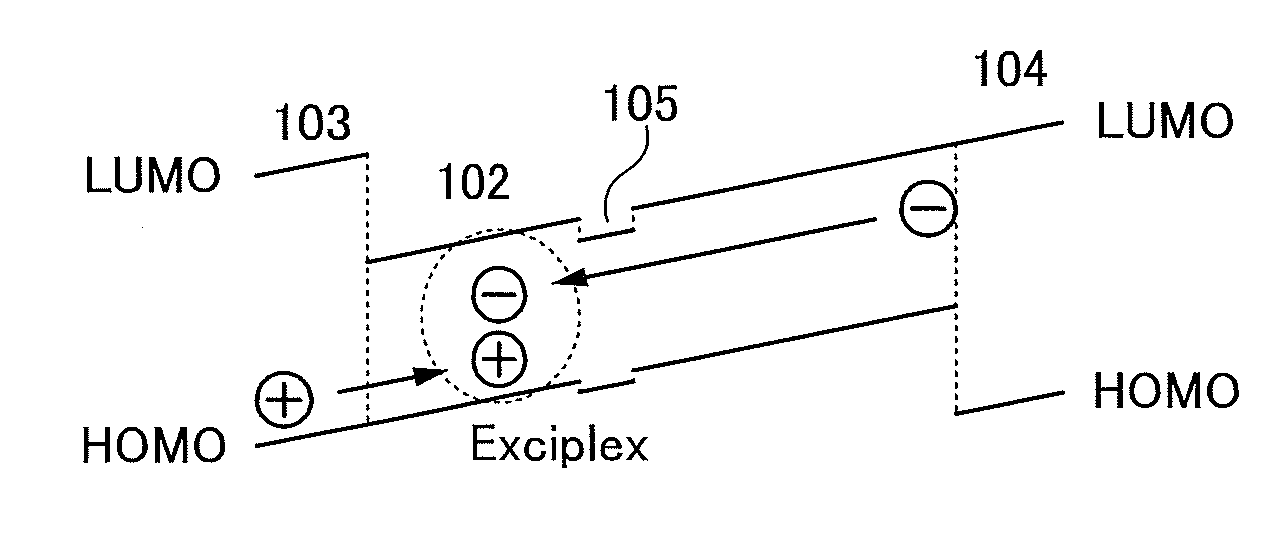

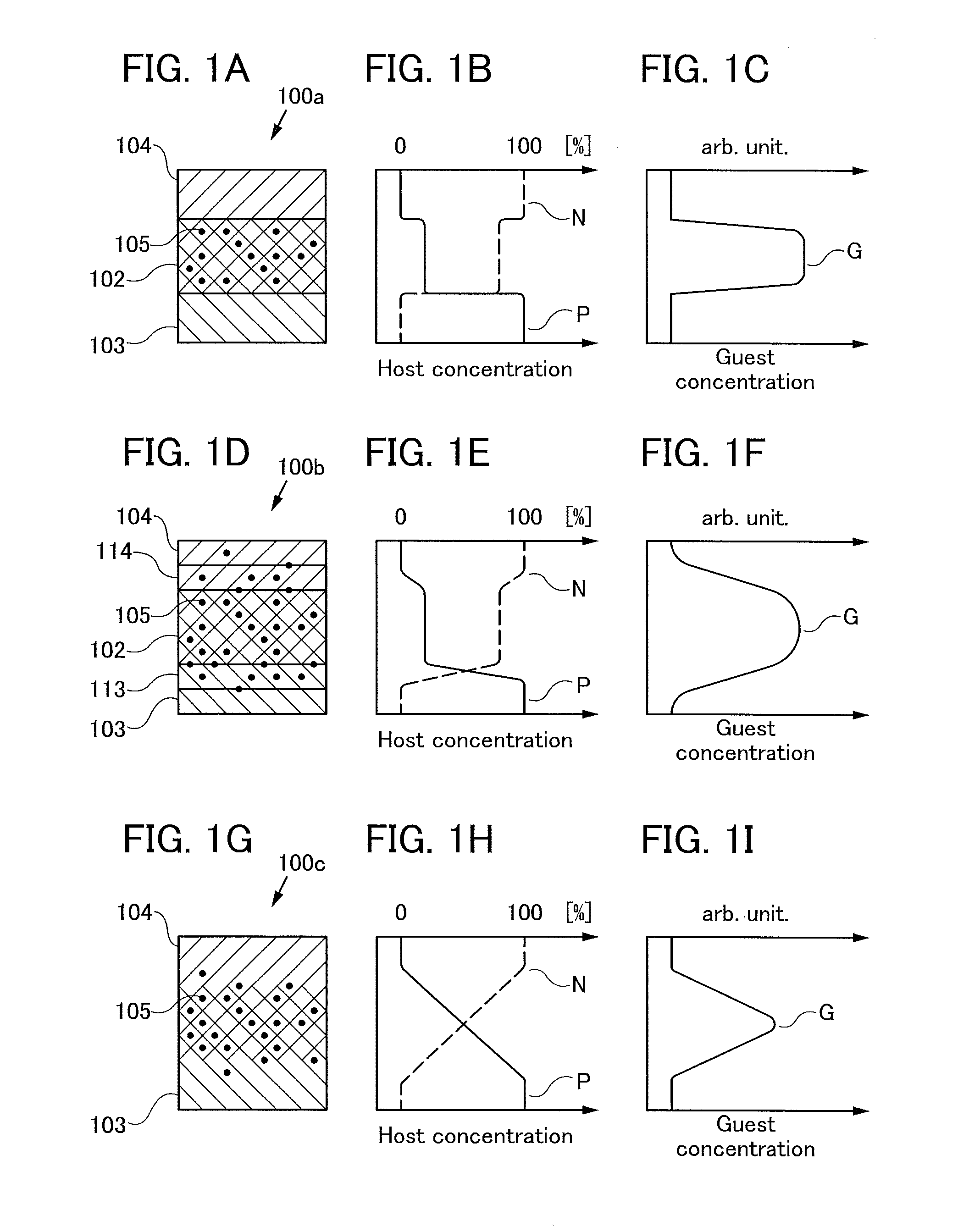

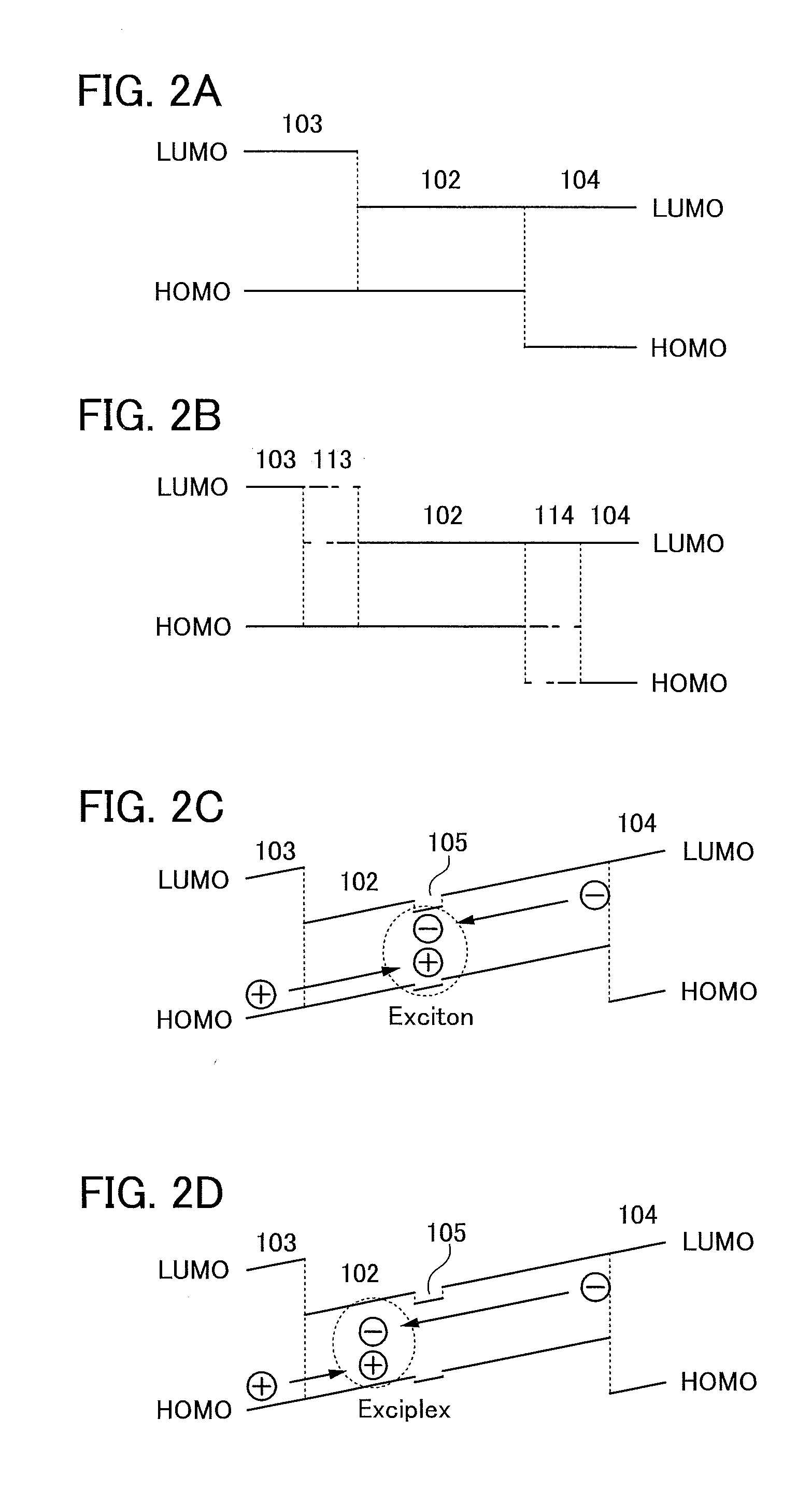

Light-Emitting Element

InactiveUS20140084274A1Efficient transferImprove emission efficiencySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringEmission efficiency

A light-emitting element with high emission efficiency is provided. The light-emitting element includes, between a pair of electrodes, a layer containing a p-type host, a light-emitting layer containing a guest, the p-type host, and an n-type host, and a layer containing the n-type host. A combination of the p-type host and the n-type host forms an exciplex. Among the layer containing the p-type host, the light-emitting layer, and the layer containing the n-type host, the light-emitting layer has the highest secondary ion intensity of the n-type host, the layer containing the n-type host has the second-highest secondary ion intensity of the n-type host, and the layer containing the p-type host has the lowest secondary ion intensity of the n-type host in analysis by a time-of-flight secondary ion mass spectrometer.

Owner:SEMICON ENERGY LAB CO LTD

Low volatile reinforcing system

InactiveUS6211259B1Increase heat releaseImprove brittlenessOrganic-compounds/hydrides/coordination-complexes catalystsSynthetic resin layered productsThermoplasticPolyol

The present invention includes new compositions for making polyurethane and polyurethane foam compositions. These compositions comprise the reaction product of an isocyanate A-Side and a B-Side comprising: (i) a polyol having a molecular weight of about 1000 g / mol or more, and having an average functionality of 2.0 or greater; (ii) a polyol having a Tg of about -80° C. or less, and having a molecular weight of about 1000 g / mol or more, and having an average functionality of 2.0 or greater; and(iii) a polyhydric alcohol having a molecular weight of about 90 g / mol or more, and having an average functionality of 3.0 or more. In the case of polyurethane foam compositions, the system also comprises water. The invention also includes processes for making the polyurethane and polyurethane foam compositions, as well as methods of adhering the same to cosmetic layers comprising thermoplastic, acrylic, and gel coat materials. The invention also includes articles made from these reinforced cosmetic layers.

Owner:ARISTECH SURFACES

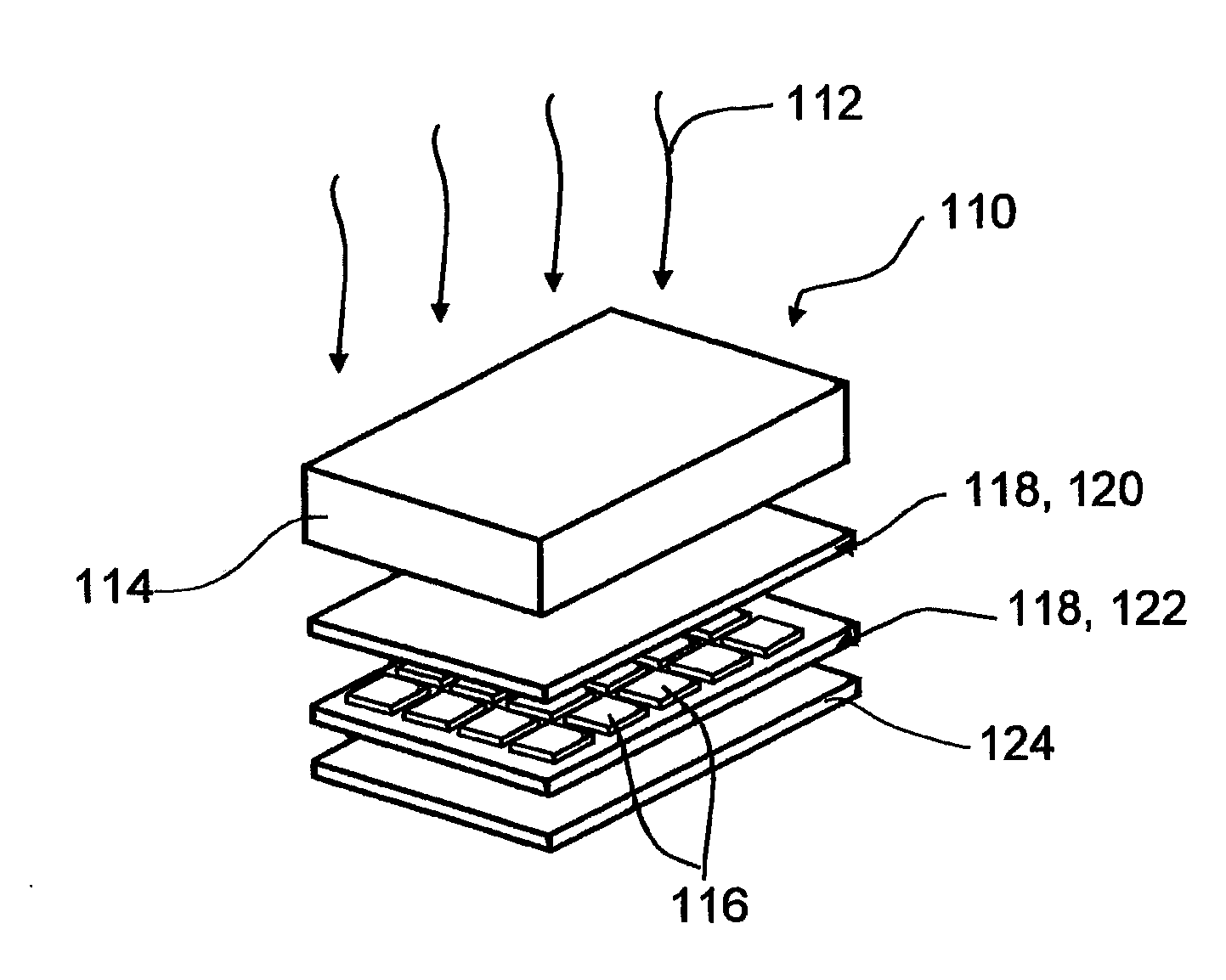

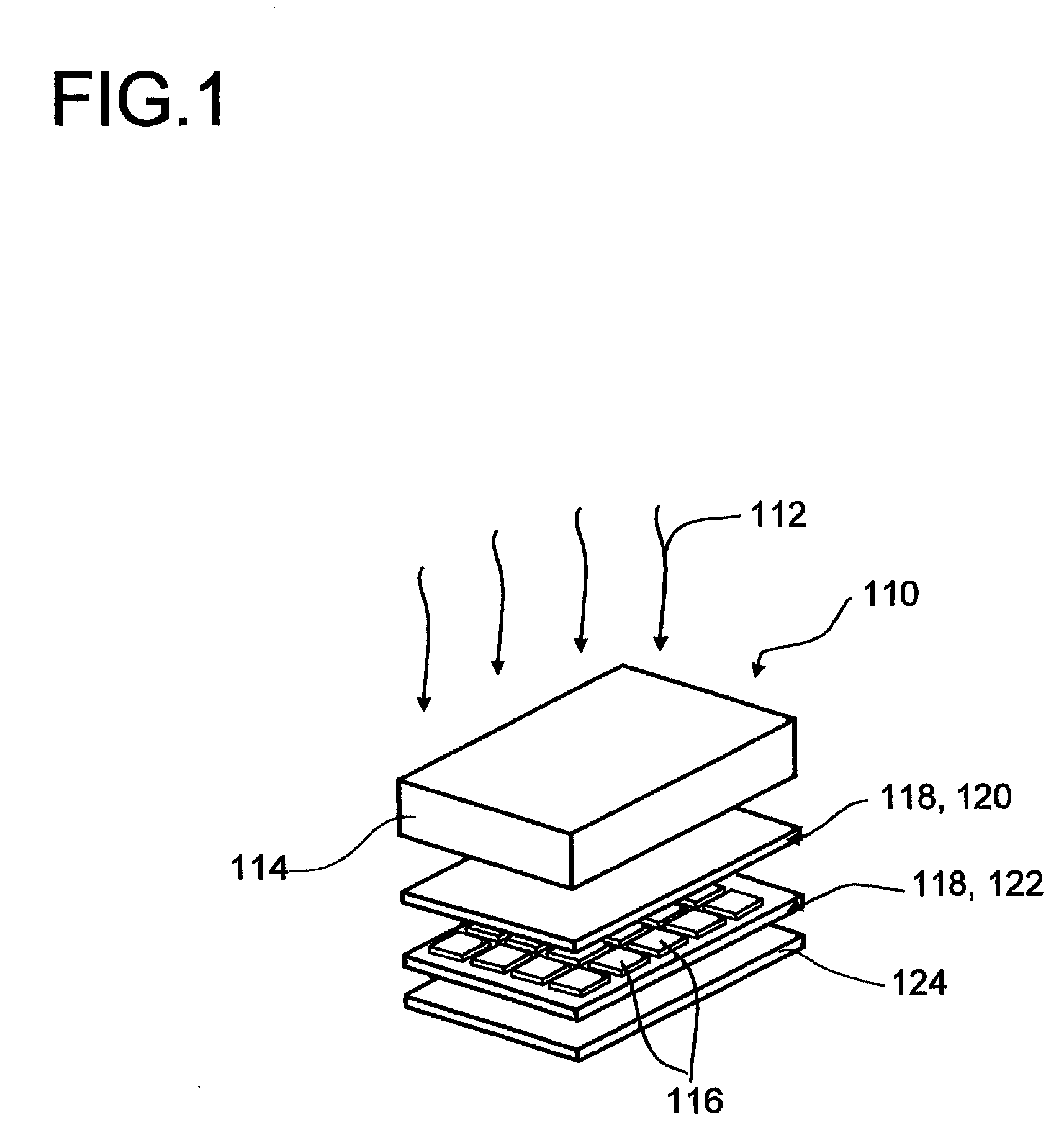

Photovoltaic modules with improved quantum efficiency

InactiveUS20100186801A1Improve quantum efficiencySuitable spectral responseSemiconductor/solid-state device manufacturingGlass/slag layered productsElectromagnetic radiationLuminescence

A photovoltaic module (110) is disclosed, which is suited for conversion of incident electromagnetic radiation (112) into electric energy. The photovoltaic module (110) comprises in order: a transparent cover sheet (114); and—at least one photovoltaic cell (116), wherein the at least one photovoltaic cell (116) is adapted to convert electromagnetic radiation (112) passing through the transparent cover sheet (114) into electric energy and wherein the photovoltaic cell (116) is accommodated within at least one encapsulation element (118) providing protection from environmental influence. The encapsulation element (118) comprises at least one luminescence downshifting material, which is adapted for at least partially absorbing the incident radiation (112) and for re-emitting radiation (112) at a longer wavelength.

Owner:BASF AG

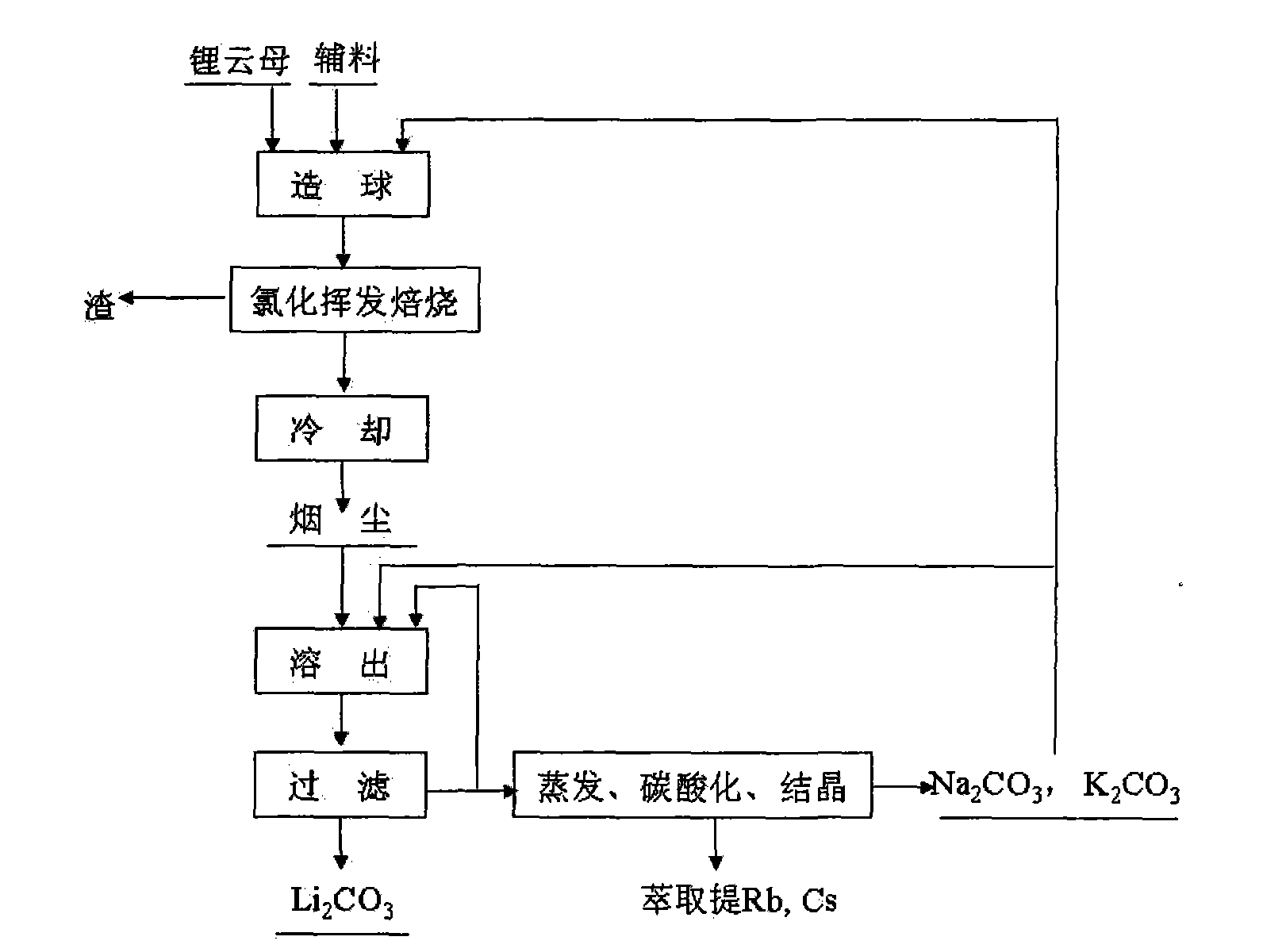

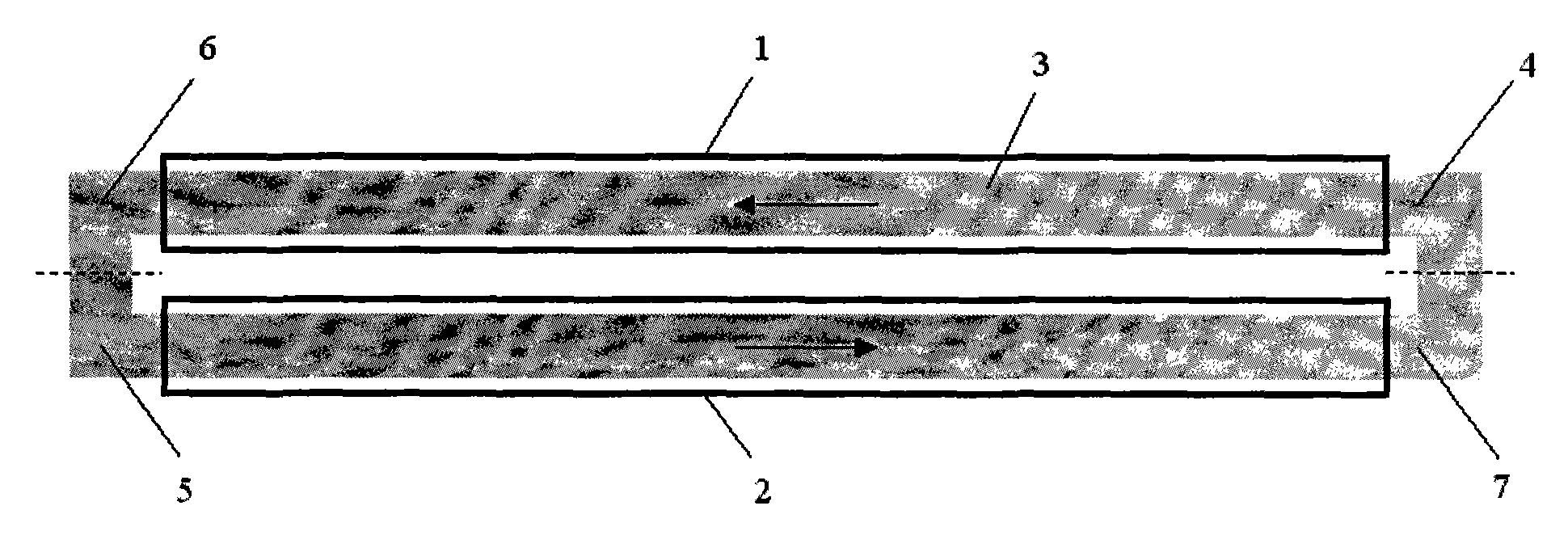

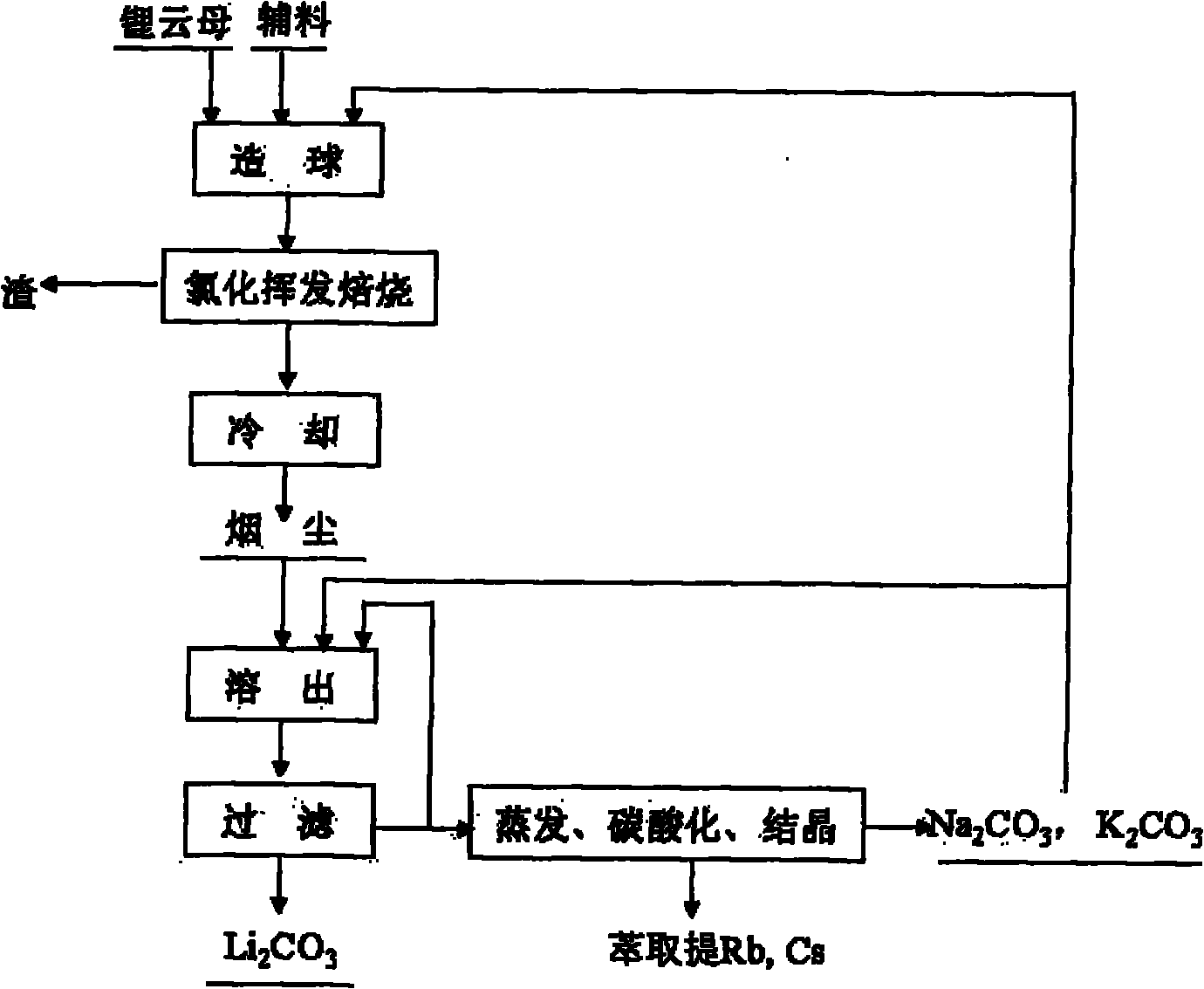

Method and device for extracting lithium from lapidolite by chloridizing roasting method

The invention discloses a method and a device for extracting lithium, which is used for preparing lithium carbonate, from a lapidolite ore by a chloridizing roasting method. The method comprises the following steps of: firstly, mixing the lapidolite ore, calcium chloride and sodium hydroxide with a compound bonding agent for pellet fabrication; secondly, performing chloridizing roasting in a square-frame shaped track type roasting furnace; thirdly, leaching out soot dust by using solution containing sodium carbonate and potassium carbonate to ensure that potassium, sodium, rubidium and cesium enter the solution and convert the lithium into lithium carbonate; fourthly, filtering the mixture to obtain a lithium carbonate solid, and circularly using the filtrated mother liquor to leach out the soot dust; fifthly, when an alkali metal salt is close to be saturated, indirectly heating the filtrated mother liquor by using the residual heat of the gas in the roasting furnace to evaporate part of water; sixthly, passing CO2 into the filtrated mother liquor to perform carbonation; and seventhly, performing cooling crystallization to separate out a mixed salt of the sodium carbonate and the potassium carbonate, returning part of the mixed salt which is used as an auxiliary material mixed and roasted with lapidolite for cyclic utilization, using another part of the mixed salt as a carbonate reagent needed in dissolution, and using the rest part of the mixed salt as byproducts of the sodium carbonate and the potassium carbonate. The method has the advantages of high lithium recovery rate, good material comprehensive utilization, large equipment productivity, high production efficiency, small water consumption in the process and less wastewater discharge.

Owner:CENT SOUTH UNIV

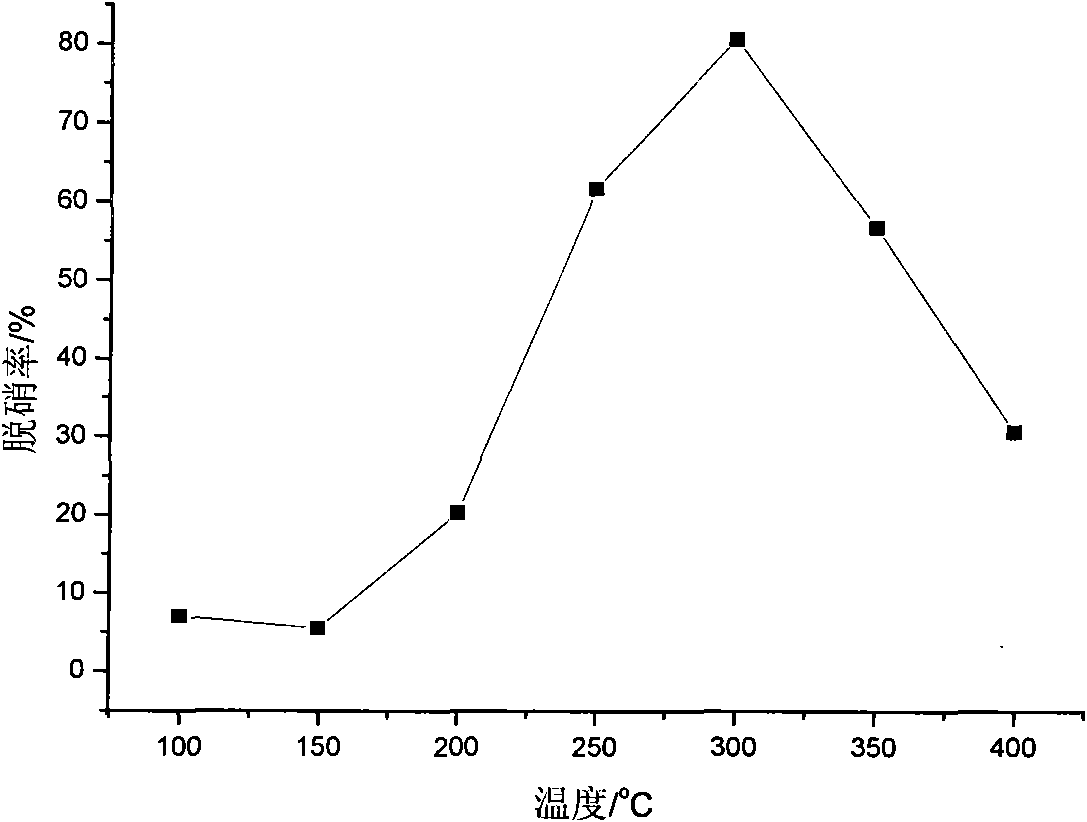

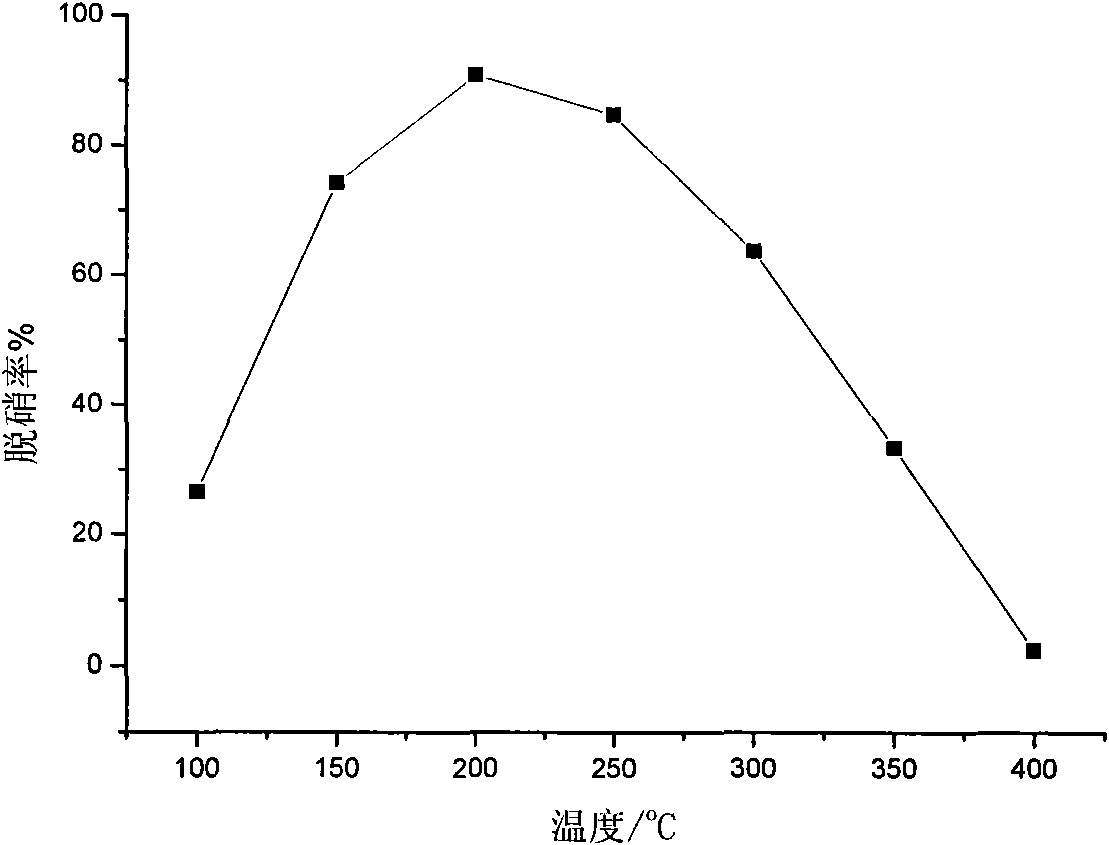

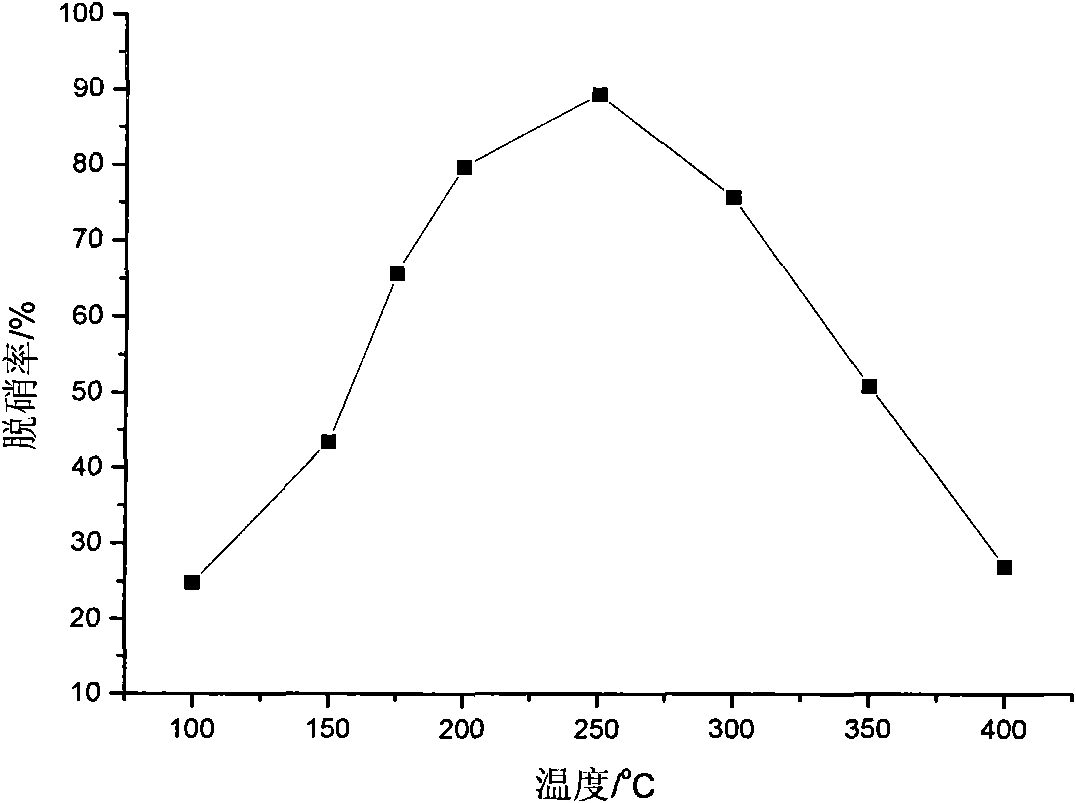

Coal ash and attapulgite compound SCR denitration catalyst and preparation method thereof

InactiveCN102000564AHigh mechanical strengthImprove thermal stabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPolymer scienceActive component

The invention discloses a coal ash and attapulgite compound SCR denitration catalyst and a preparation method thereof. Coal ash and attapulgite compound are used as catalyst carriers for carrying the compound material of manganese oxide. The preparation method comprises the following steps: mixing the coal ash with the attapulgite, making the mixture into coal ash and attapulgite compound catalyst carrier by scoring, molding, drying and burning, using the isopyknic immersion method to carry the compound carrier on the catalyst precursor, drying and burning so as to acquire the finished product. In the invention, the coal ash and the attapulgite cheaply obtained are used as the catalyst carriers, so the cost of the catalyst and the environmental loading of the catalyst are reduced, the mouldability and the heat stability are better, and the low-temperature activity of the catalyst is better because of the loading of manganese active component.

Owner:HEFEI UNIV OF TECH

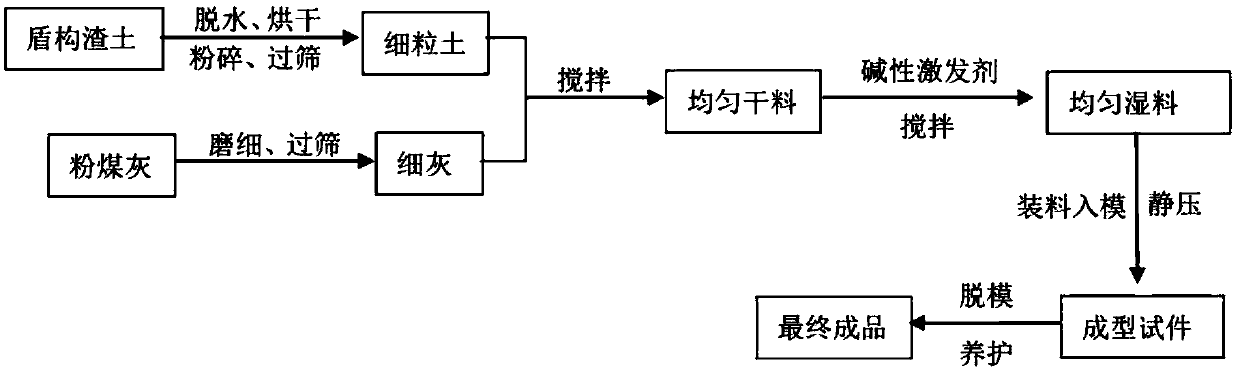

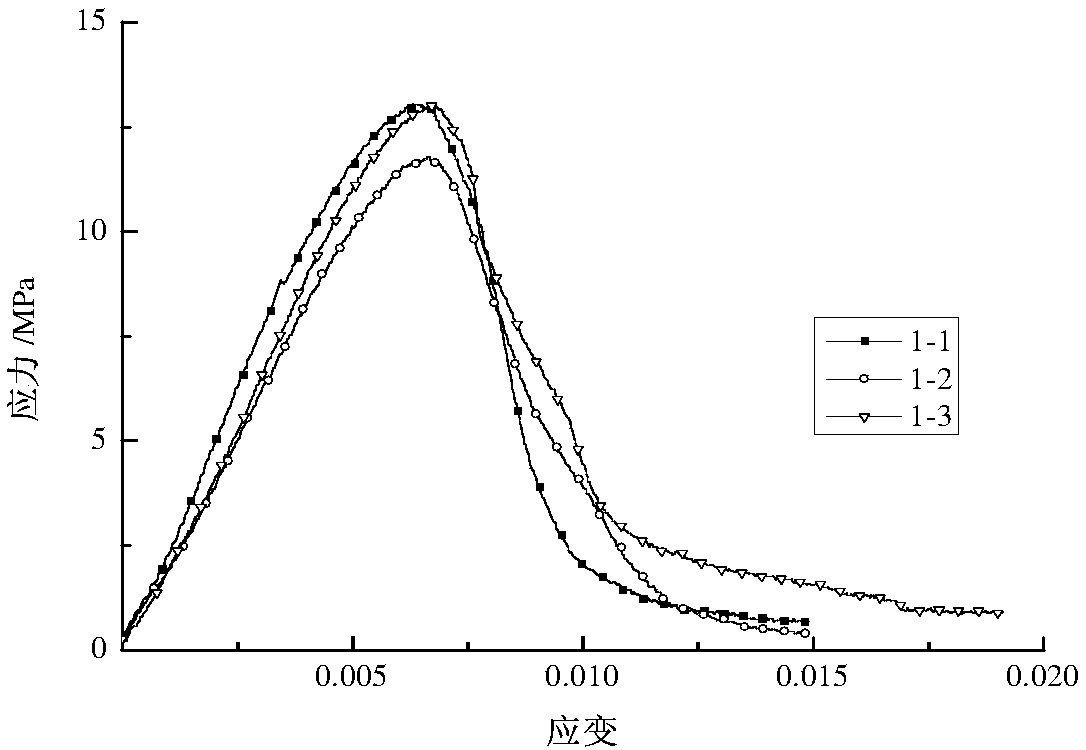

Geopolymer and preparation method and application thereof

ActiveCN108046669ALow permeability coefficientHigh strengthCement productionGeopolymerUltimate tensile strength

The invention discloses a geopolymer and a preparation method and application thereof. The geopolymer is at least prepared from fly ash, shield muck and an alkaline activator. The main component of the shield muck is clay, and the mass ratio of the fly ash to the dried shield muck is (1-2):3; the mass ratio of a mixture of the fly ash and the dried shield muck to the alkaline activator is 1:(0.14-0.18). According to the geopolymer, the high-mud-content shield muck is subjected to recycling application, and the preparation raw materials do not include any type of traditional cementing materialssuch as cement and lime, so that large carbon emission is avoided, and the cost is low. The geopolymer is high in strength and good in water resistance. The preparation method of the geopolymer includes the steps that the alkaline activator is added into the mixture of the fly ash and the shield muck through spraying to avoid large aggregates; the mixed wet material is tightly pressed in a mold,so that a geopolymer test piece has relatively high strength and water resistance.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

Plasmon assisted enhancement of organic optoelectronic devices

InactiveUS6999222B2Enhanced and controllable rate of radiative relaxationImprove launch performanceMaterial nanotechnologySolid-state devicesOscillator strengthLight emitter

Optoelectronic devices and methods for their fabrication having enhanced and controllable rates of the radiative relaxation of triplet light emitters are provided exemplified by organic light emitting devices based on phosphorescent materials with enhanced emission properties. Acceleration of the radiative processes is achieved by the interaction of the light emitting species with surface plasmon resonances in the vicinity of metal surfaces. Non-radiative Förster-type processes are efficiently suppressed by introducing a transparent dielectric or molecular layer between the metal surface and the chromophore. For materials with low emission oscillator strengths (such as triplet emitters), the optimal separation distance from the metal surface is determined, thus suppressing energy transfer and achieving a significant acceleration of the emission rate.

Owner:RGT UNIV OF CALIFORNIA

Method for three-dimensionally cultivating white mushroom by wall soil-covered cultivation process

InactiveCN101810103AMeet the requirements for fruitingImprove land utilizationHorticultureRural areaEcological environment

Owner:镇江市食用菌研究所

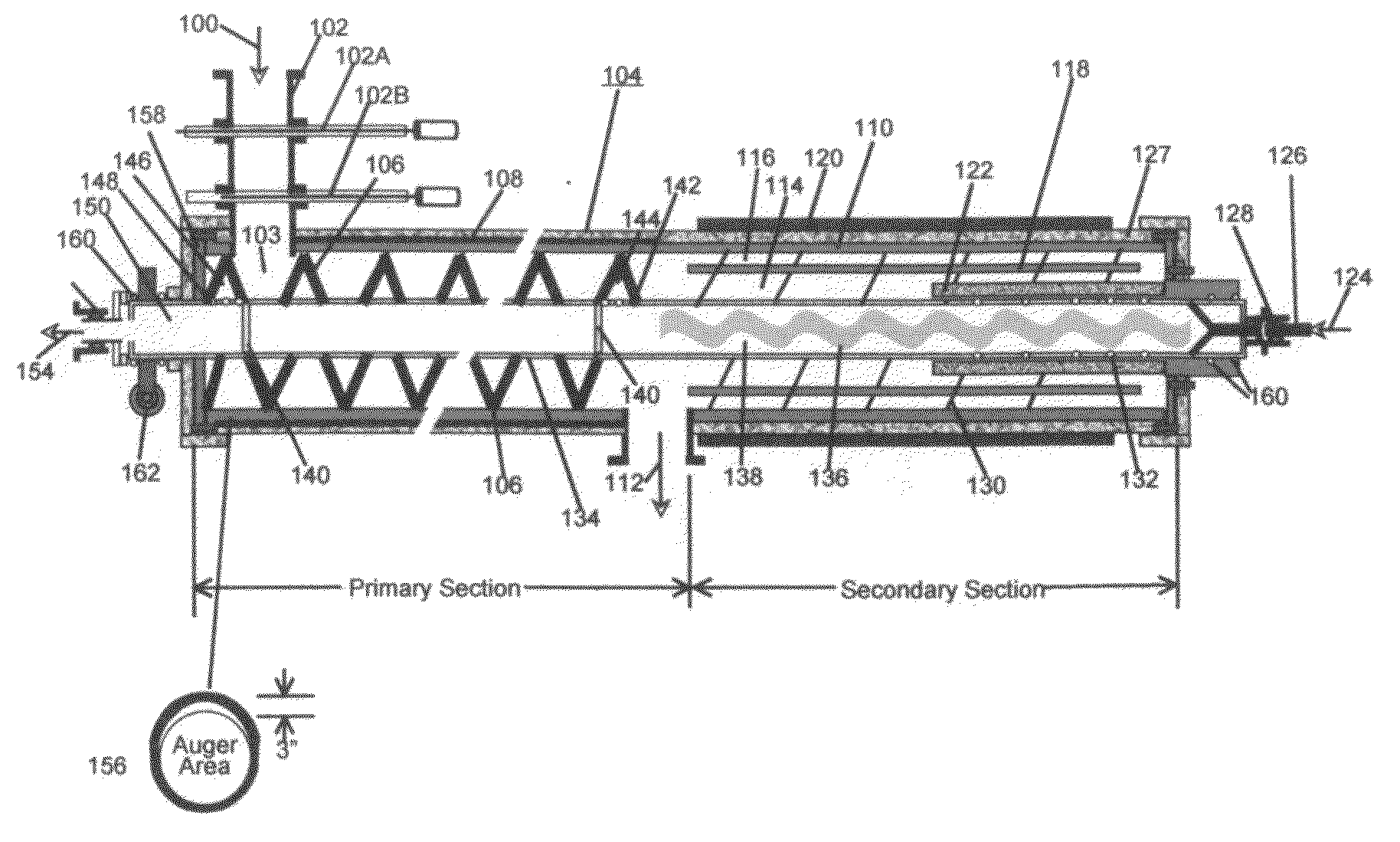

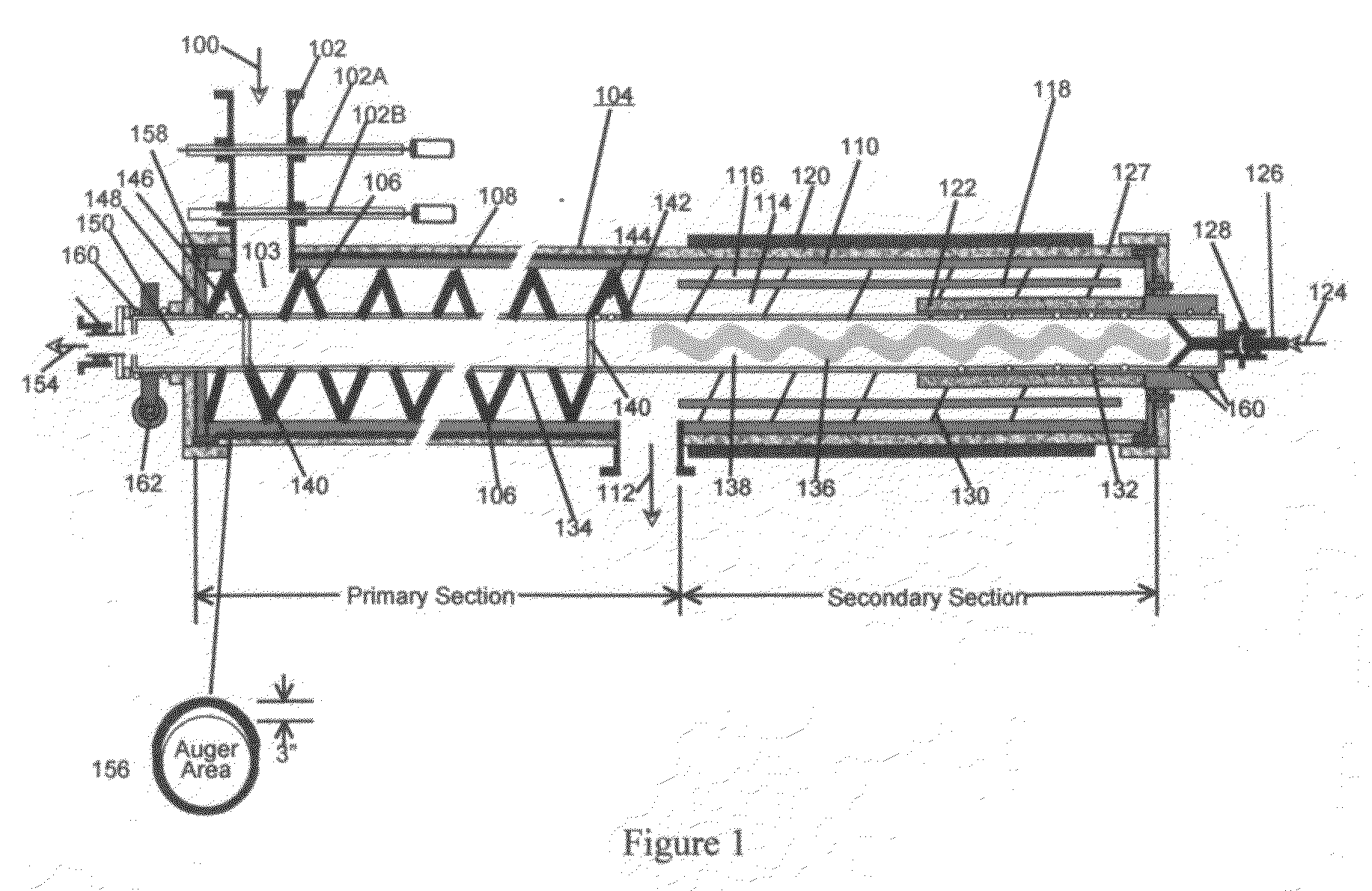

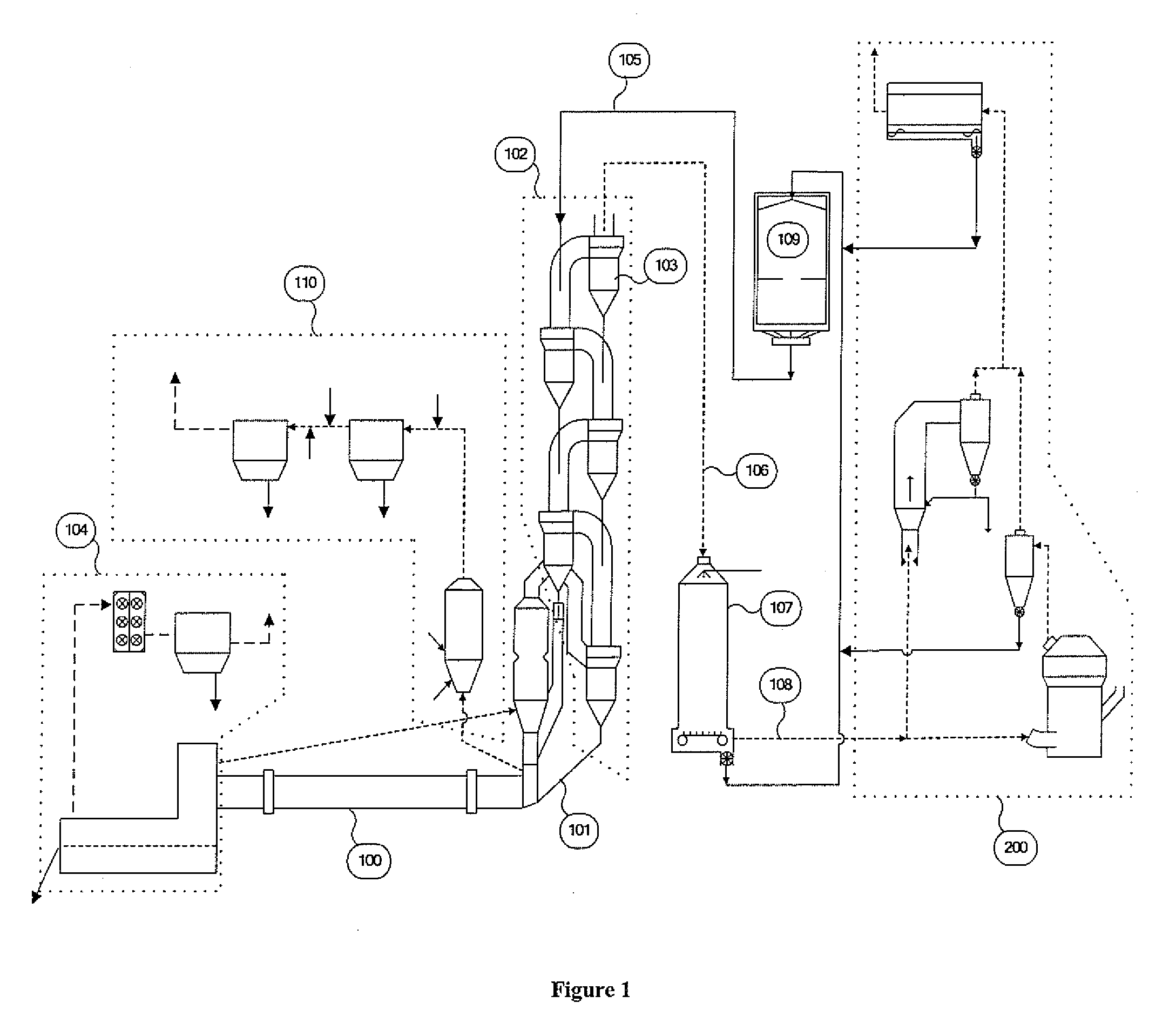

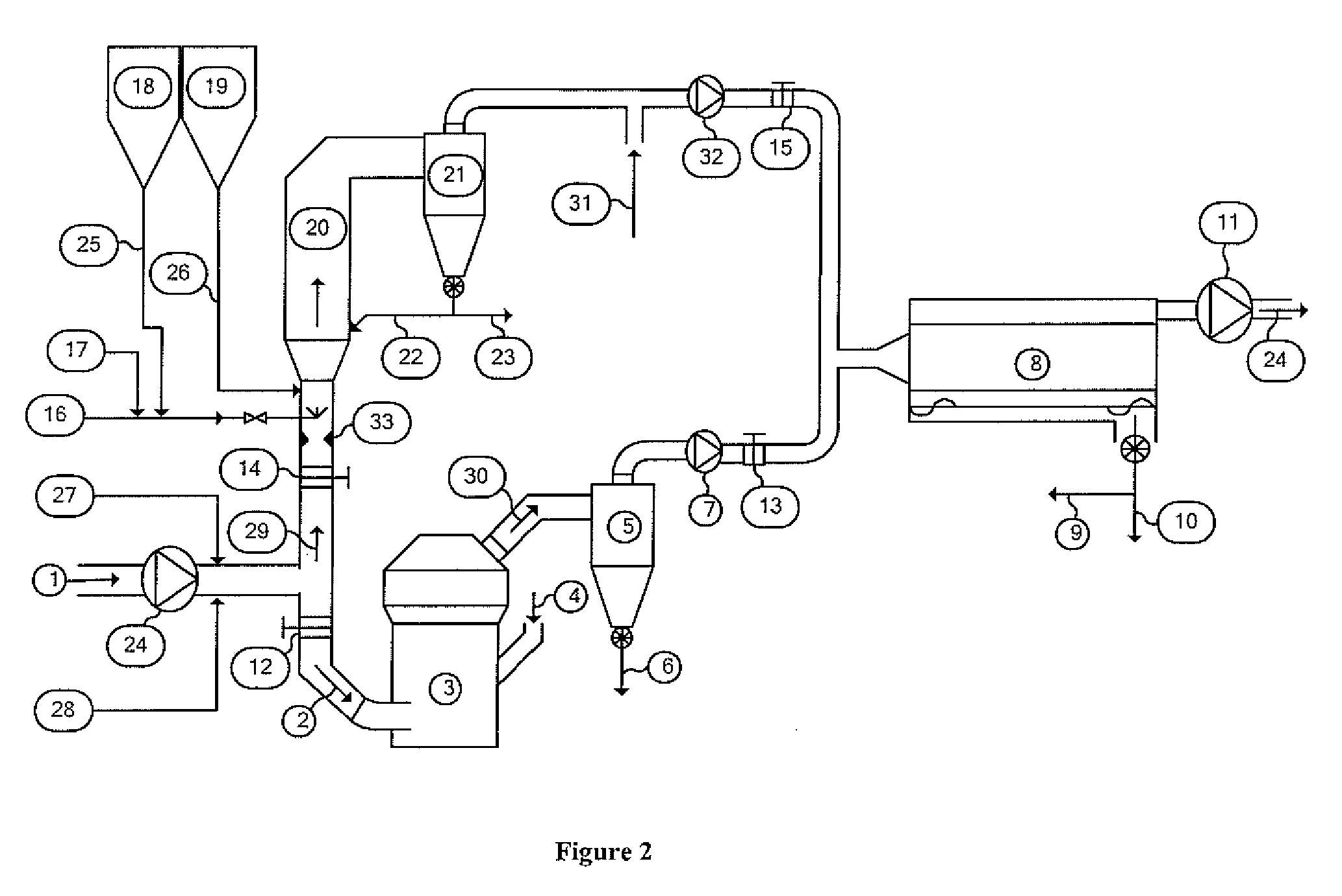

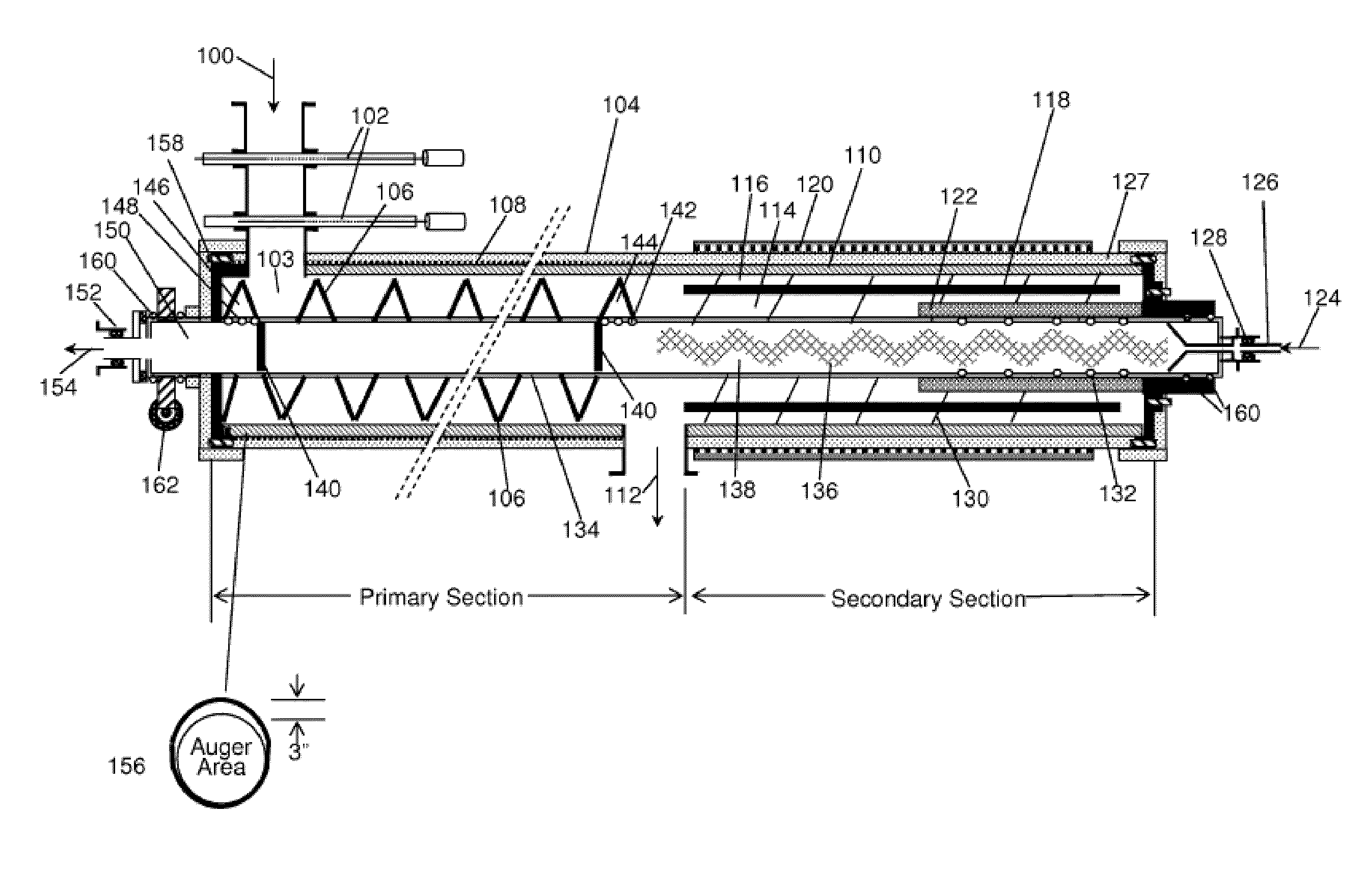

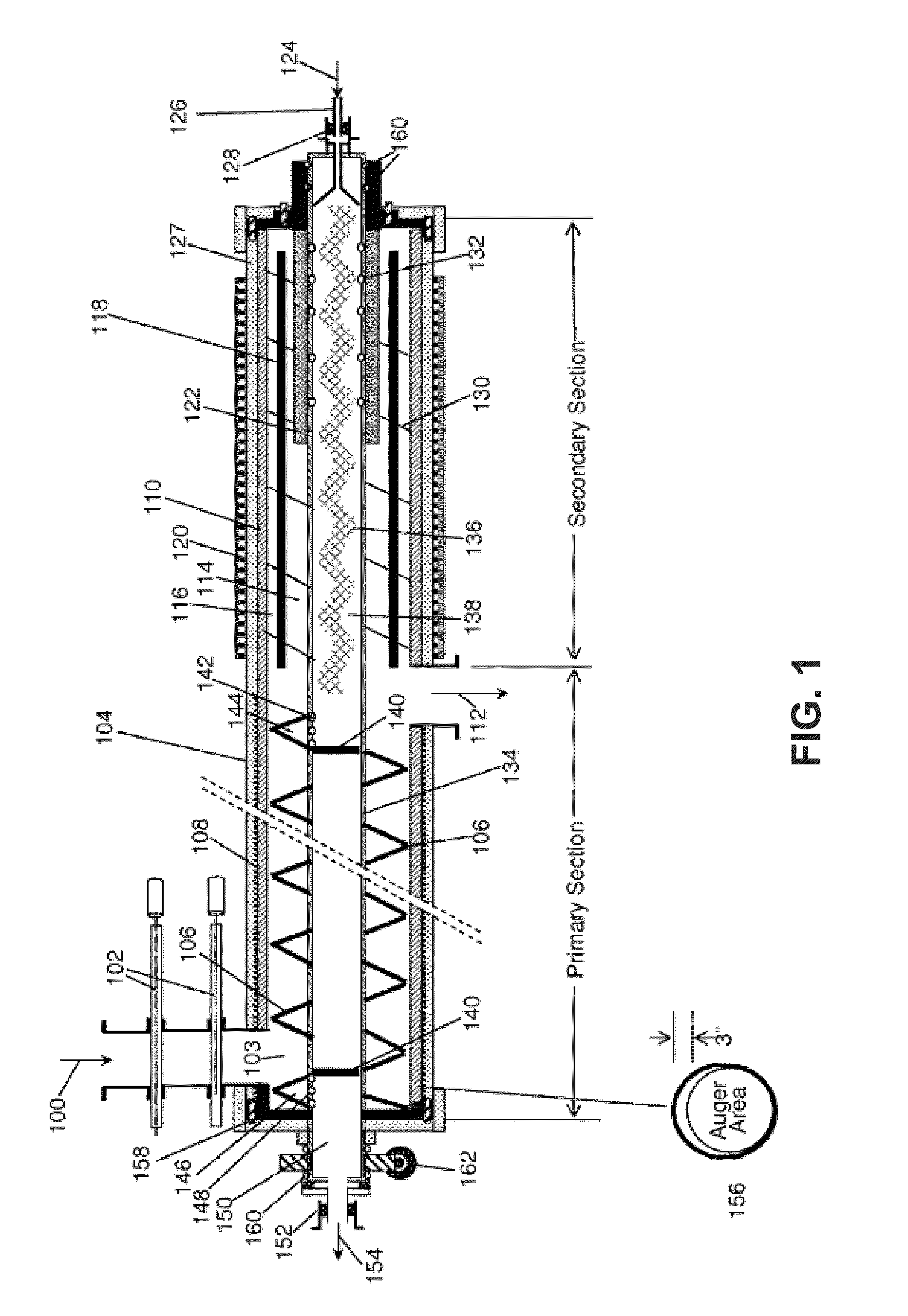

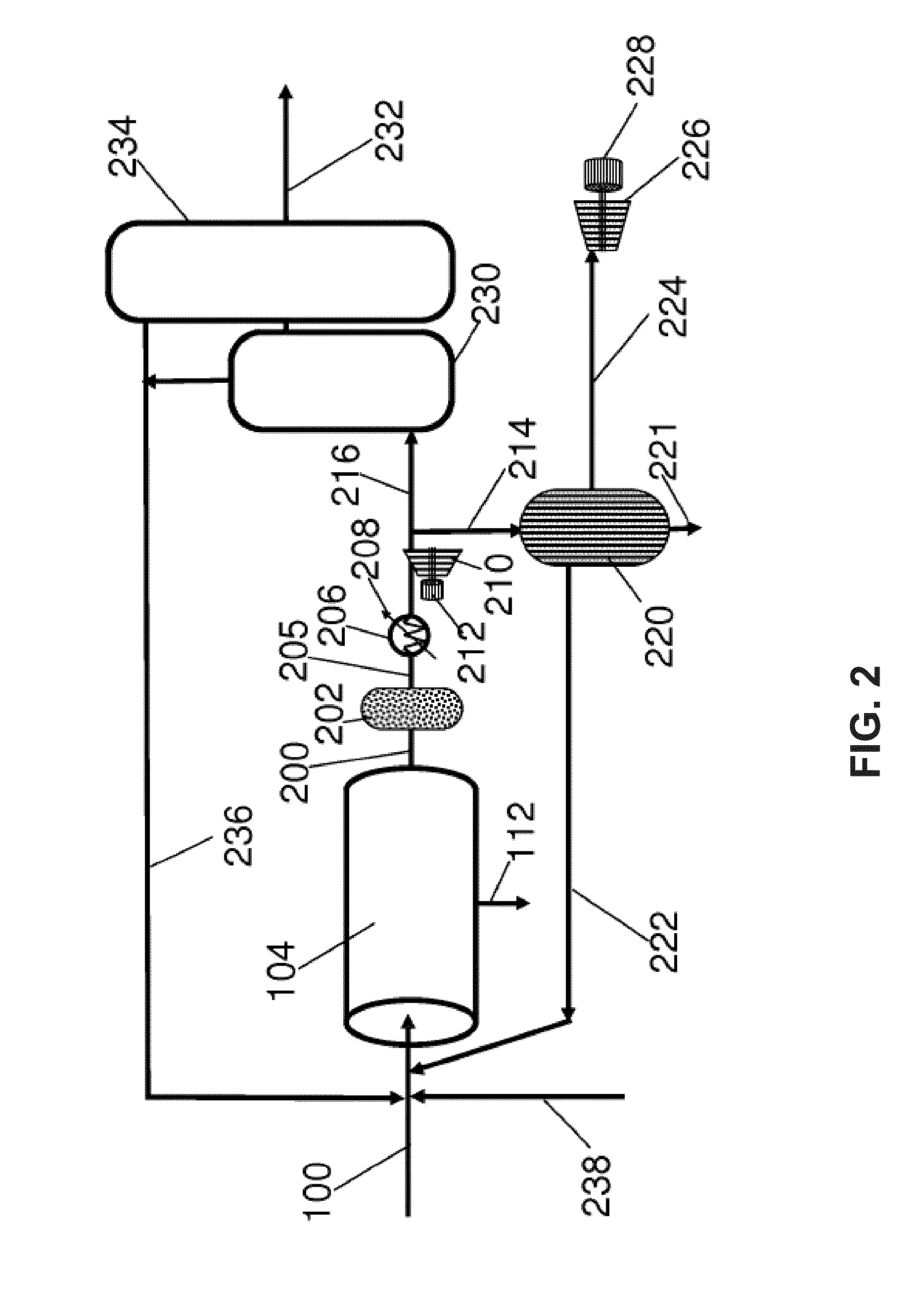

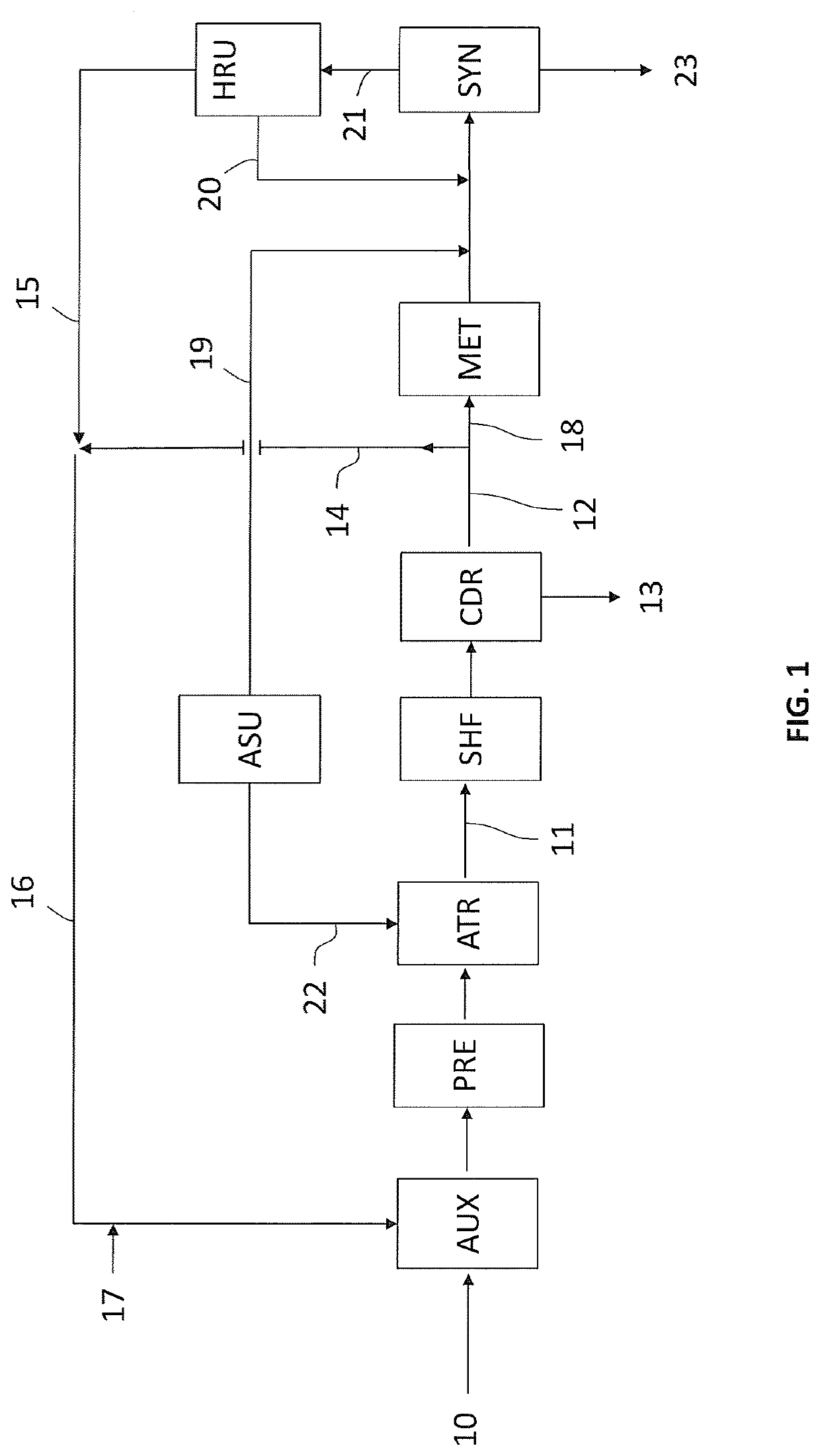

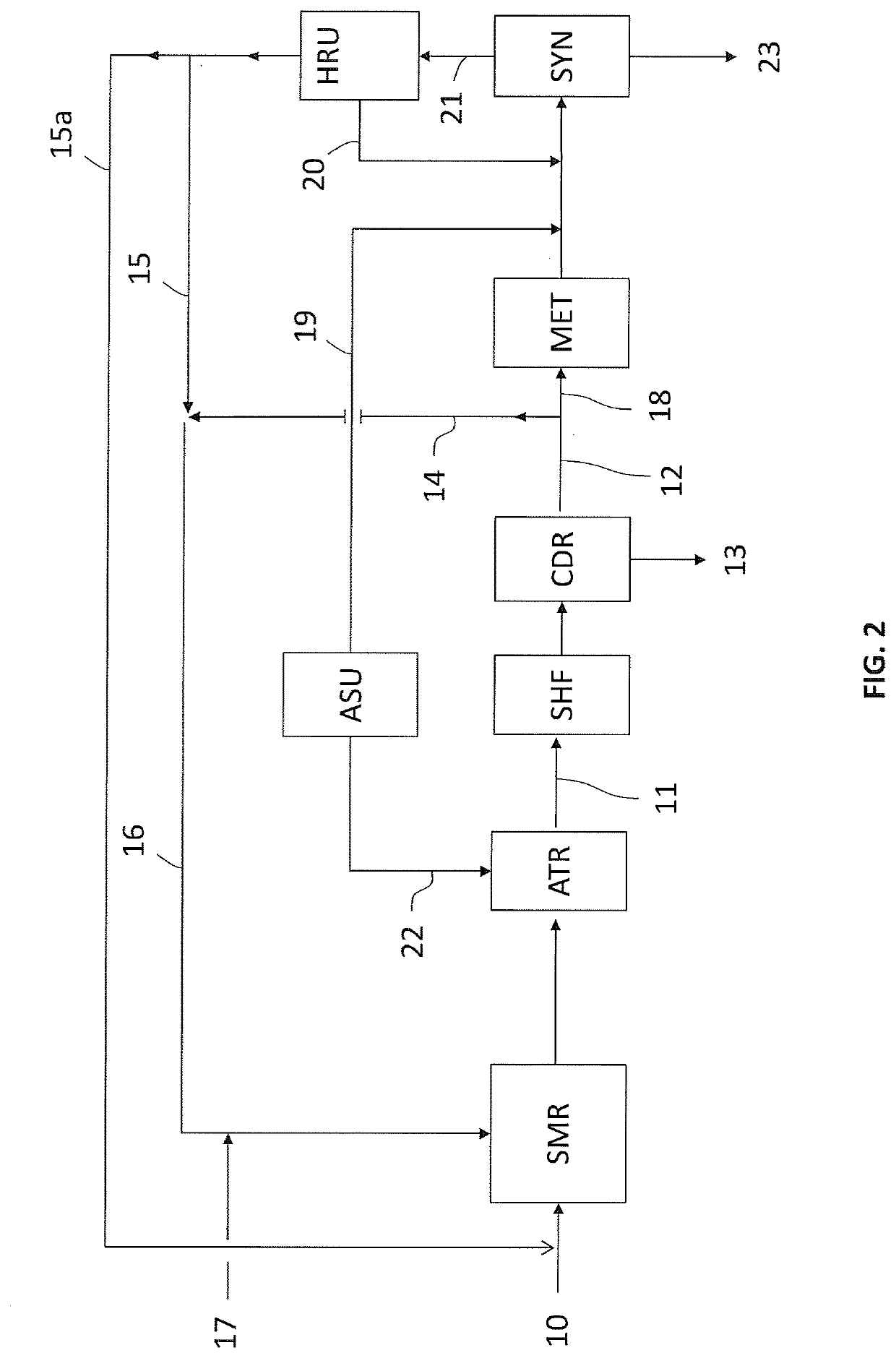

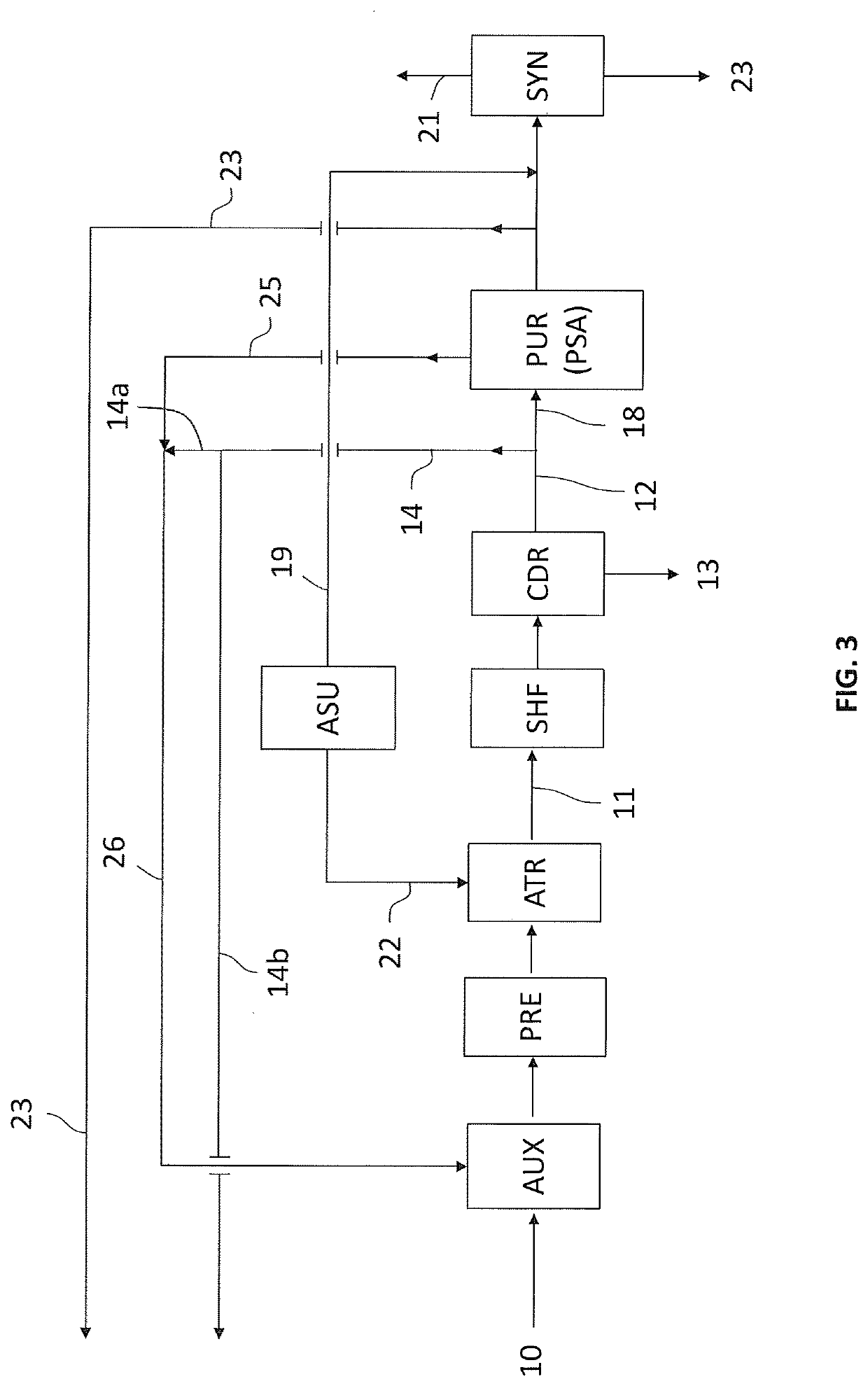

Process and System for Converting Waste to Energy Without Burning

ActiveUS20120277329A1Large emissionsGasifier mechanical detailsCombustible gas catalytic treatmentHigh carbonWaste stream

This invention relates to a power recovery process in waste steam / CO2 reformers whereby a waste stream can be made to release energy without having to burn the waste or the syngas. This invention does not make use of fuel cells as its critical component but makes use of highly exothermic chemical reactors using syngas to produce large amounts of heat, such as Fischer-Tropsch. It also relates to control or elimination of the emissions of greenhouse gases in the power recovery process of this invention with the goal of producing energy in the future carbonless world economy. A New Concept for a duplex kiln was developed that has the combined functionality of steam / CO2 reforming, heat transfer, solids removal, filtration, and heat recovery. New methods of carbon-sequestering where the syngas produced by steam / CO2 reforming can be used in Fischer-Tropsch processes that make high-carbon content compounds while recycling the methane and lighter hydrocarbons back to the reformer to further produce syngas at a higher H2 / CO ratio.

Owner:RAVEN SR INC

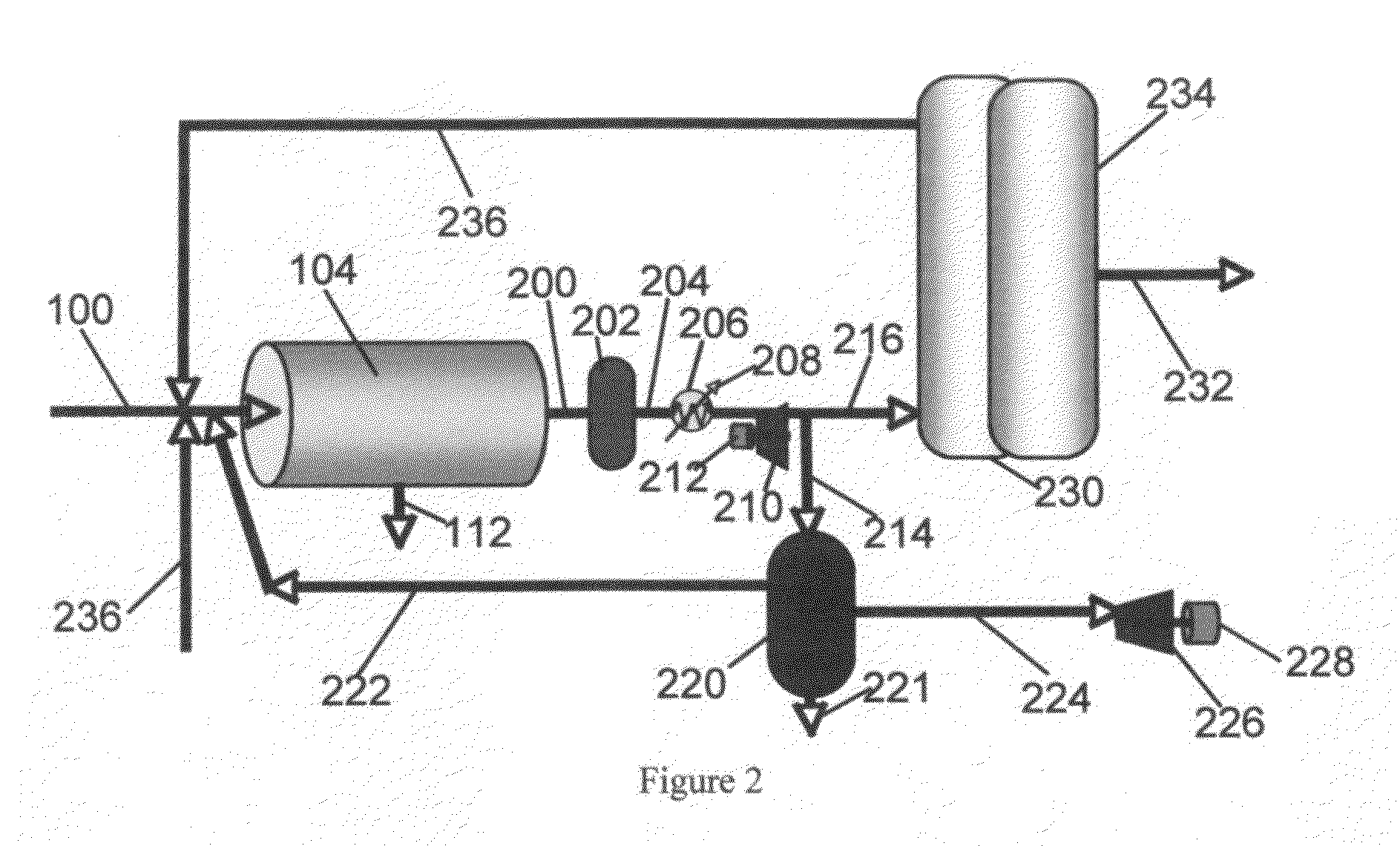

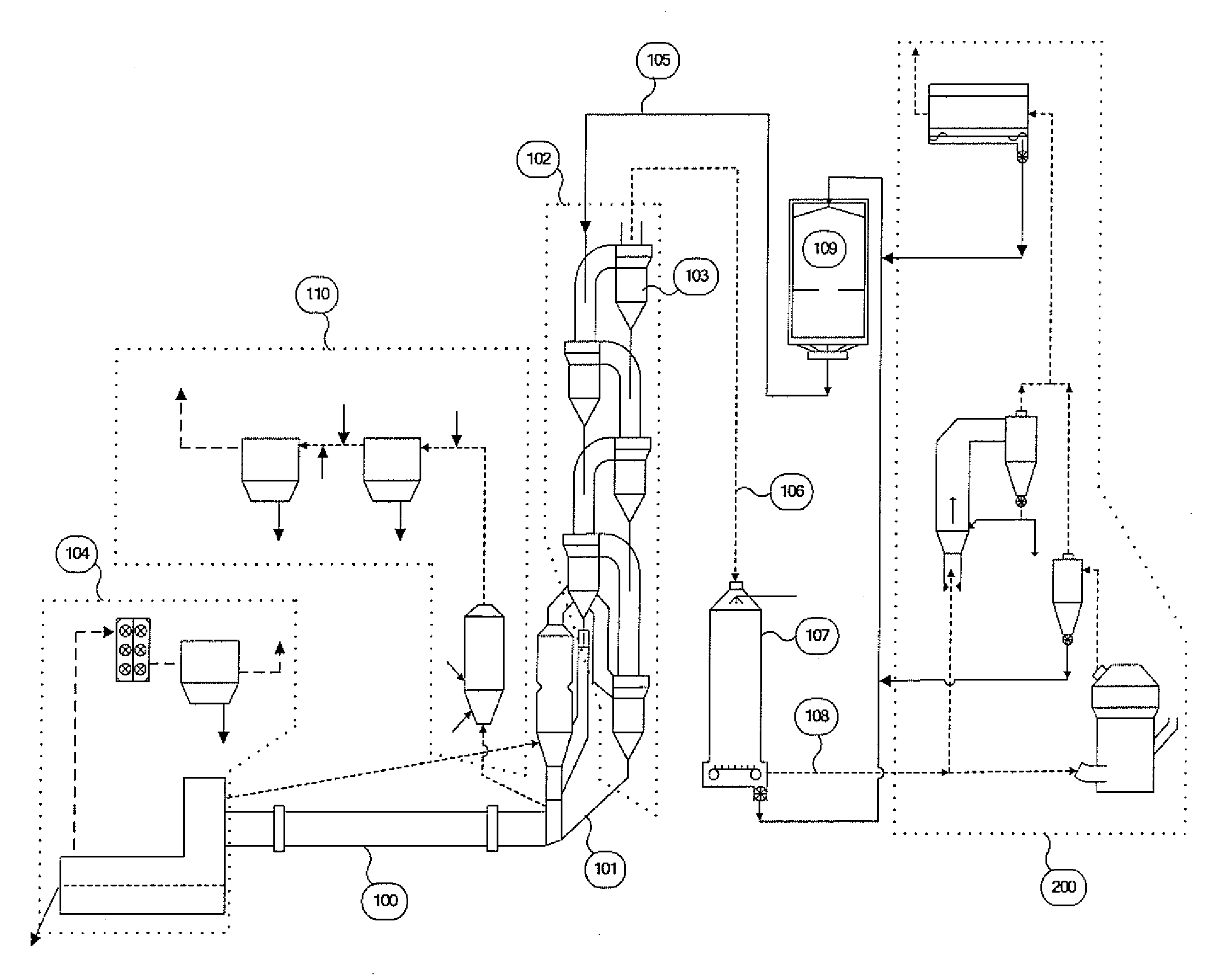

Oxygen-enriched combustion circulating fluidized bed poly-generation system and process

ActiveCN103742899AImprove utilization efficiencyIncrease operating temperatureNitrogen purification/separationFluidized bed combustionGeneration processFlue gas

The invention provides an oxygen-enriched combustion circulating fluidized bed poly-generation system. The oxygen-enriched combustion circulating fluidized bed poly-generation system comprises a circulating fluidized bed combustion furnace and a circulating fluidized bed gasification furnace, wherein the circulating fluidized bed combustion furnace is connected with a separator I, the separator I is connected with a flue at the tail and a two-way material control device, the two-way material control device is connected with the circulating fluidized bed combustion furnace and the circulating fluidized bed gasification furnace respectively, the circulating fluidized bed gasification furnace is connected with the circulating fluidized bed combustion furnace by a return feeder I, the circulating fluidized bed gasification furnace is connected with a ceramic dust collector and a coal gas purification system by a separator II, the flue at the tail is connected with a flue gas distribution valve by a glue gas dust-removal, desulfurization and denitration device, and an outlet of the flue gas distribution valve is divided into three paths. The invention also provides an oxygen-enriched combustion circulating fluidized bed poly-generation process. The oxygen-enriched combustion circulating fluidized bed poly-generation system has high fuel utilization rate, high coal gas yield, good tar quality, small pollutant discharge and low recycling cost, and fuel and flue gas at the tail can be utilized to the maximum extent.

Owner:SHANGHAI BOILER WORKS

Method for Eliminating Spikes of Mercury Emissions

InactiveUS20100300864A1Lower emission levelsLow variabilityGas treatmentPreheating coke ovensEngineeringCement kiln

A method for the reduction of mercury emissions from an industrial plant that utilizes a cement or minerals kiln that has a high level of mercury emissions during specific operating conditions. The invention reduces a large spike in mercury emissions typically seen in cement kiln systems when the in-line raw mill is shut-down and all preheater gases are vented to the stack directly. The invention diverts the preheater gases to a cooling device that functions as an adsorption reactor to provide mercury absorption during periods when the raw mill is not in operation.

Owner:F L SMIDTH & CO AS

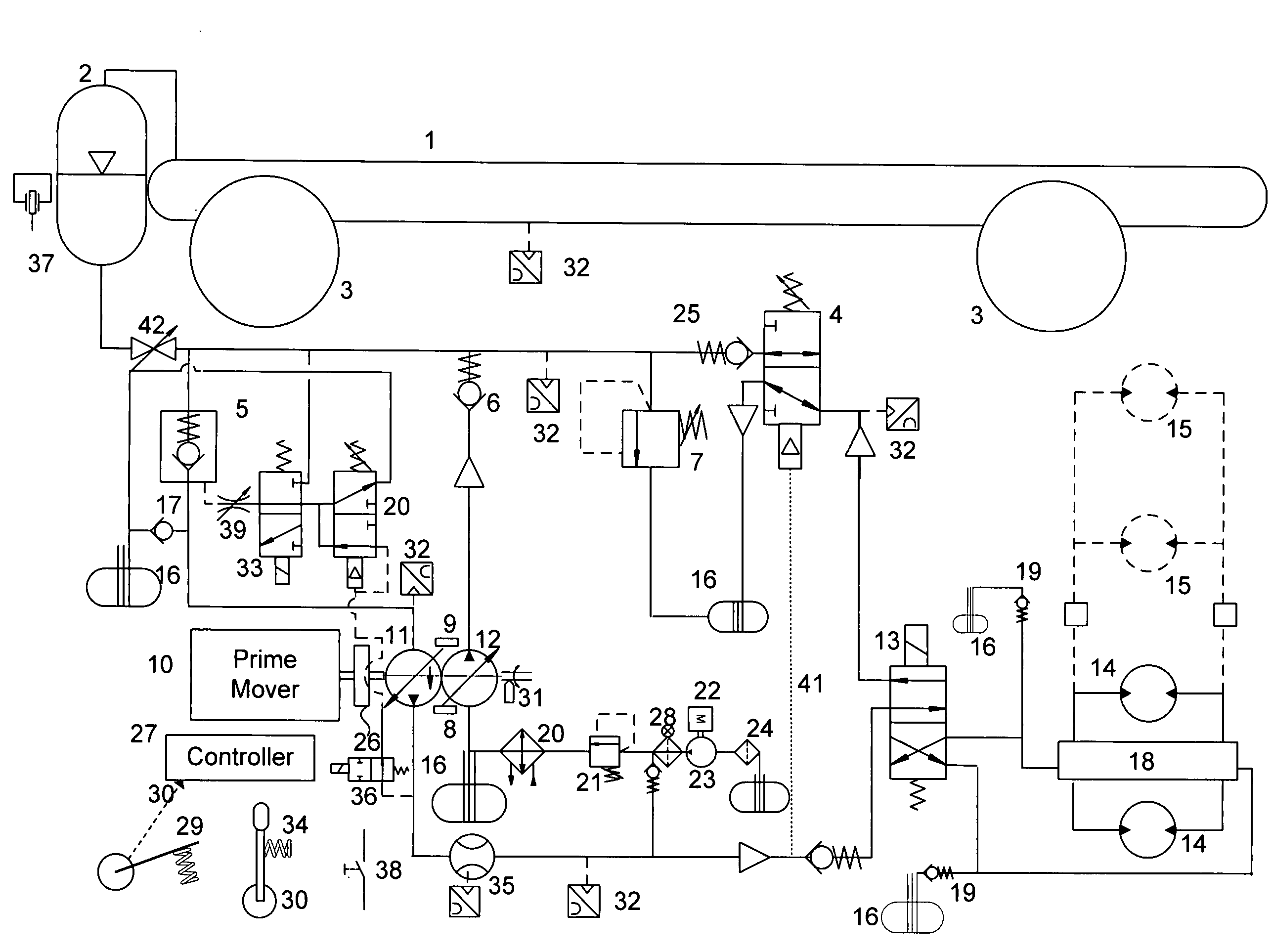

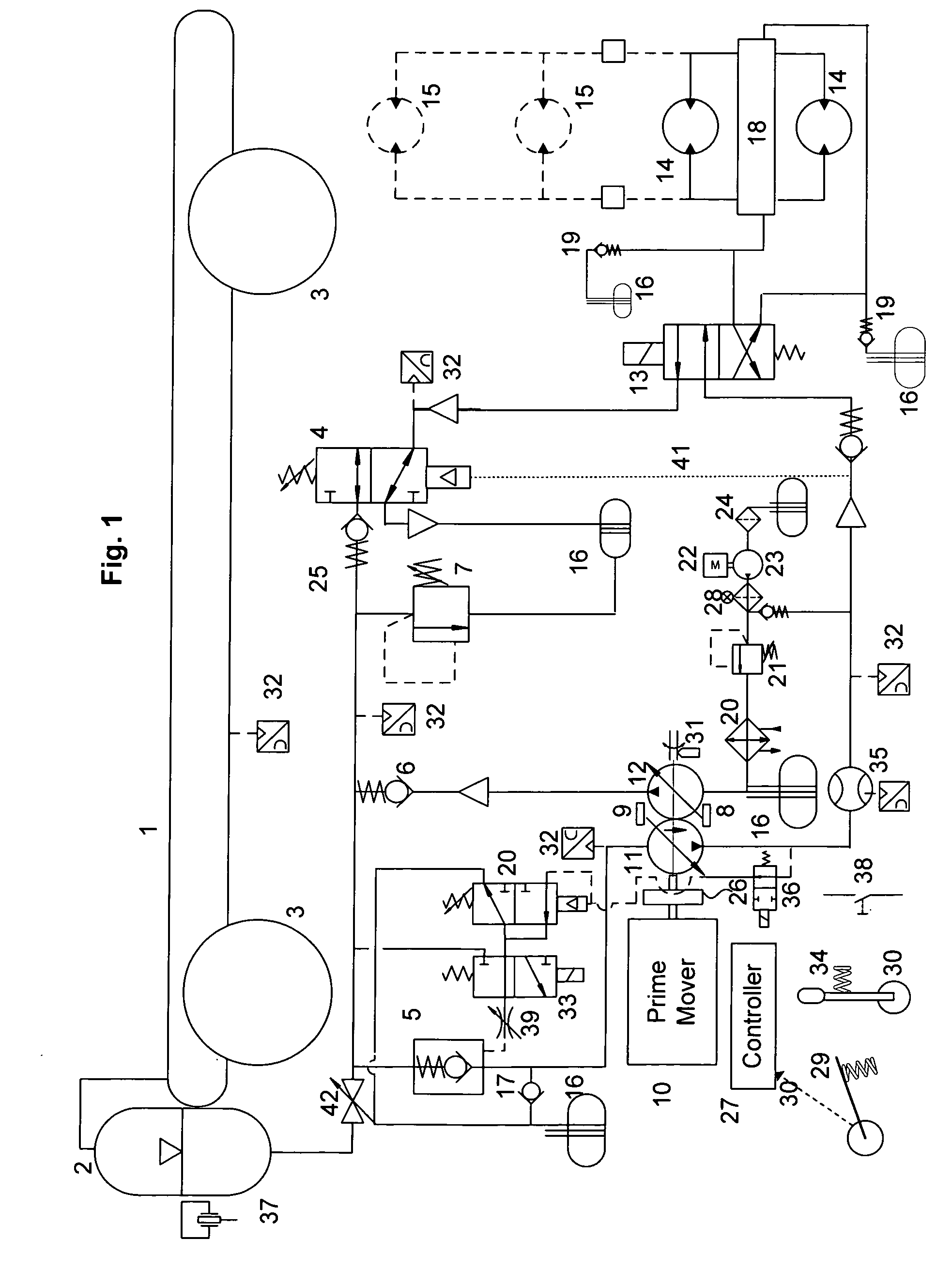

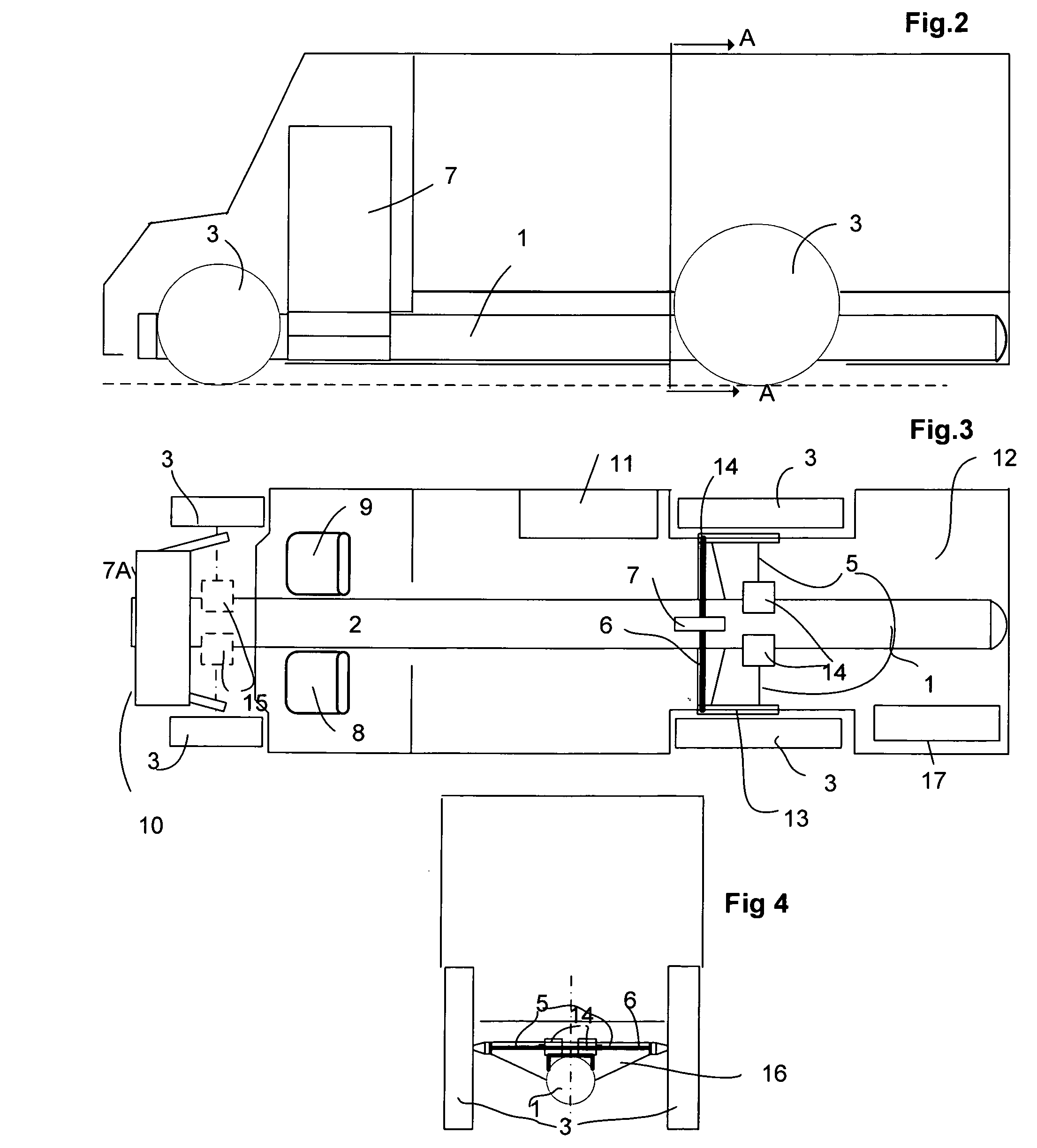

Hybrid hydraulic drive system for all terrestrial vehicles, with the hydraulic accumulator as the vehicle chassis

InactiveUS20100122864A1Large energy storageLarge emissionsAuxillary drivesFluid couplingsIntegratorJoystick

A new hybrid hydraulic drive system for all types of terrestrial vehicles, including vehicles running on rails, using as prime mover any of the ICE (internal combustion engine) available or turbine, battery propulsion, electric motors, fuel cells, etc. One special variable hydraulic pump connected to the prime mover acts as a “power integrator”, receiving hydraulic power from the accumulator and mechanical power from the prime mover, to supply the desired flow and pressure to the hydraulic motors during operation. A second variable pump, reloads the accumulator with the remnant power available, if any, during the whole cycle. The accumulator is quite large and it is also used as the chassis for all terrestrial vehicles. The braking energy is returned to the accumulator. The whole vehicle is controlled by electronics, and in one embodiment, using only one joystick or pedal to control speed, direction, acceleration, braking and in some cases including steering.

Owner:ROSMAN ALLAN

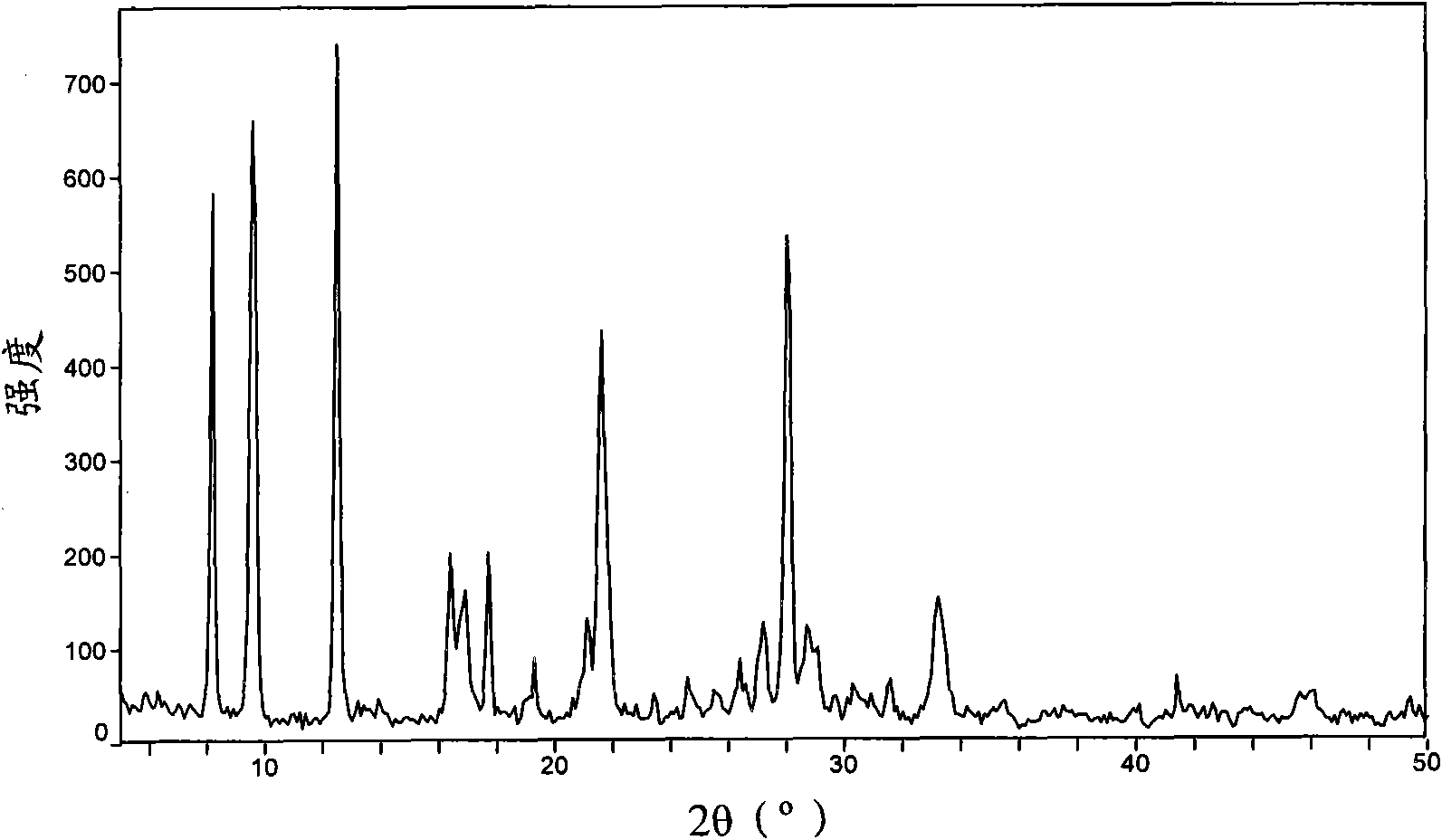

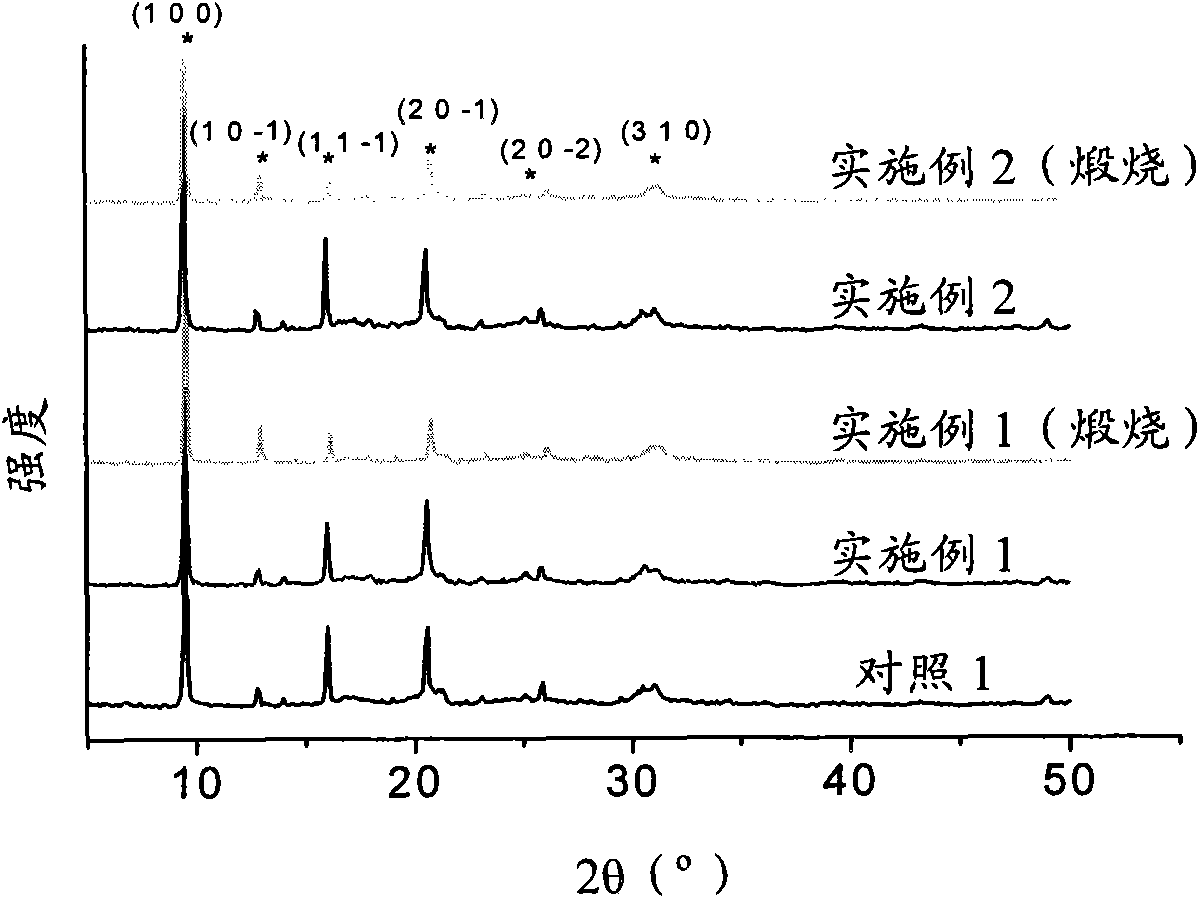

Titanium modified SAPO-34 molecular sieve and preparation method and application thereof

ActiveCN101898768AHigh catalytic activityGood catalytic lifeMolecular sieve catalystsHydrocarbon by metathesis reactionPhosphoric acidMolecular sieve

The invention discloses a titanium modified SAPO-34 molecular sieve and a preparation method and application thereof. An aluminum source and a phosphorous source are evenly mixed to form a mixed solution containing active aluminium phosphate; under the stirring state, a silicon source and template agent are added and evenly mixed; and then, titanium resource aqueous solution is added to prepare the modified SAPO-34 molecular sieve. The anhydrous chemical expression of the modified SAPO-34 molecular sieve is as follows according to the molar ratio of oxide: (0.02-0.3) TiO2. (0.8-1.15) Al2O3. (0.9-1.2) P2O5. (0.3-0.8) SiO2. The titanium modified SAPO-34 molecular sieve of the invention serves as a catalyst, is particularly suitable for the reaction of preparing low-carbon olefin by using oxygen containing raw materials, and has better catalytic activity and low-carbon olefin selectivity.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

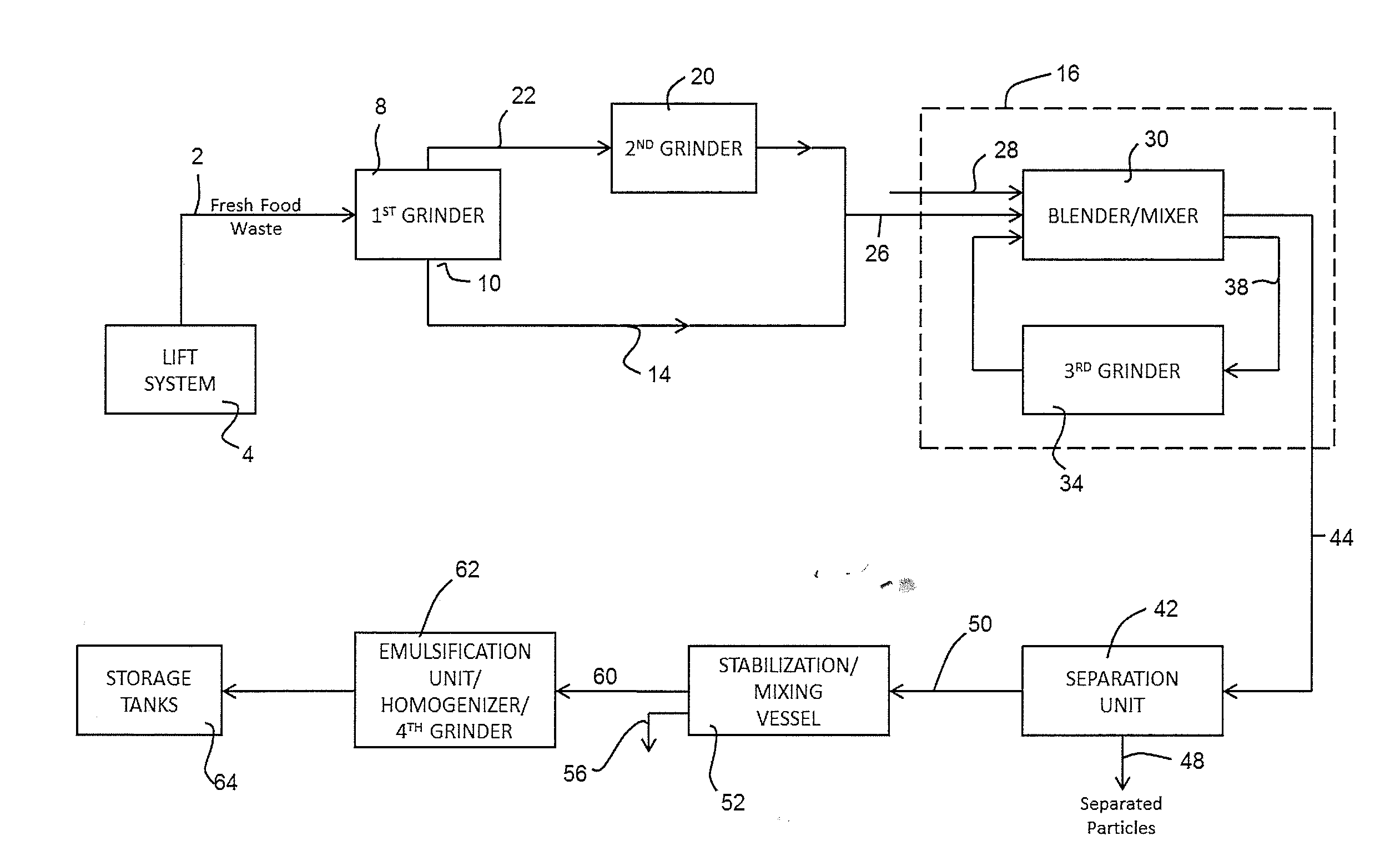

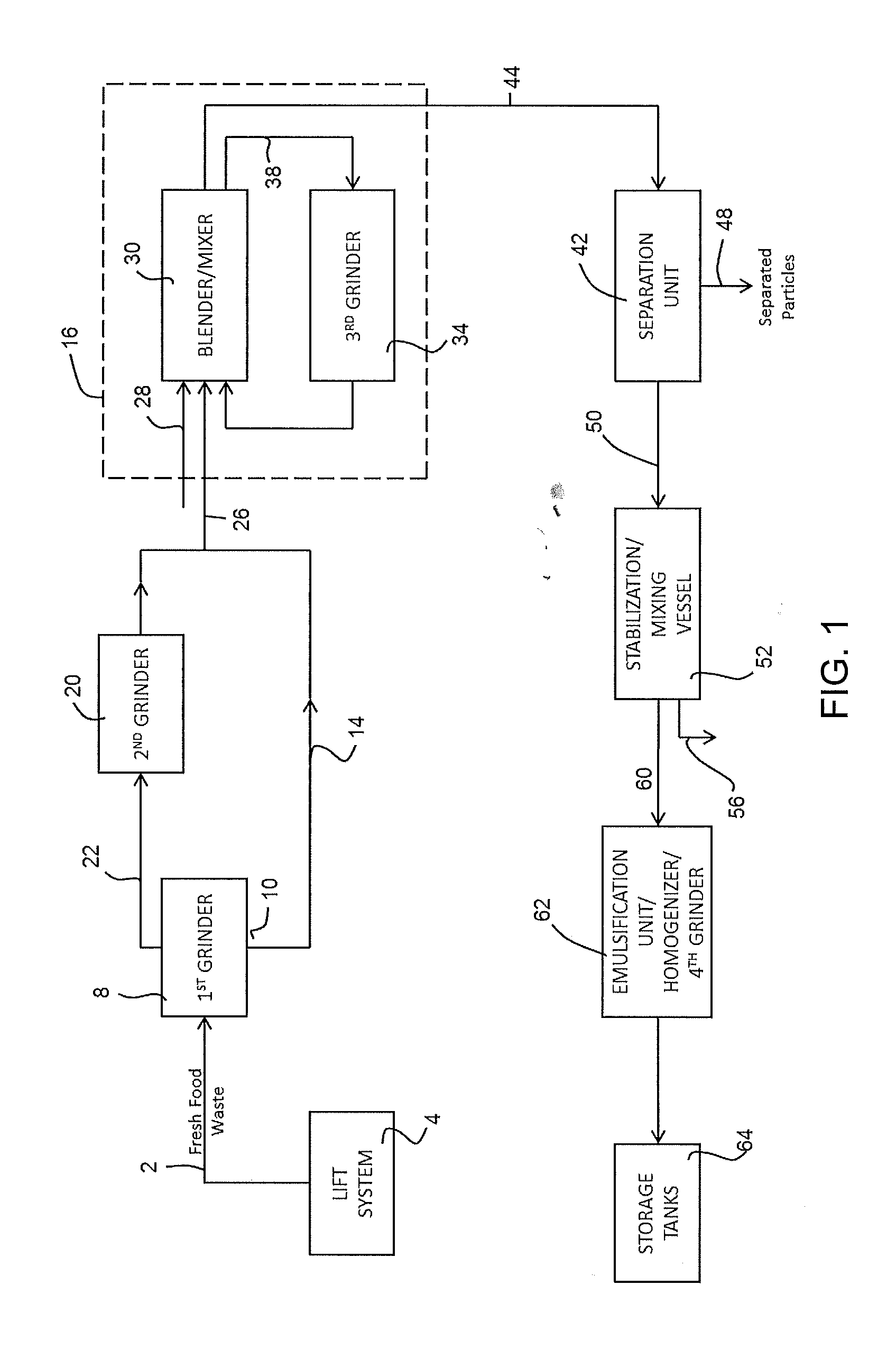

Nutrient rich compositions

InactiveUS20150315466A1Increase crop yieldReduce the amount requiredBio-organic fraction processingWorking-up animal fodderParticulatesHydrolysate

This invention relates to processes and systems for converting fresh food waste into nutrient rich hydrolysates and particulate compositions. The invention also relates to the hydrolysates and compositions useful, for example, as fertilizers, feedstock or other nutrient supplements.

Owner:CALIFORNIA SAFE SOIL LLC

Process and system for converting waste to energy without burning

InactiveUS20150122243A1Large emissionsExothermal chemical reaction heat productionOther heat production devicesWaste streamFiltration

This invention relates to a power recovery process in waste steam / CO2 reformers whereby a waste stream can be made to release energy without having to burn the waste or the syngas. This invention does not make use of fuel cells as its critical component but makes use of highly exothermic chemical reactors using syngas to produce large amounts of heat, such as Fischer-Tropsch. It also relates to control or elimination of the emissions of greenhouse gases in the power recovery process of this invention with the goal of producing energy in the future carbonless world economy. A New Concept for a duplex kiln was developed that has the combined functionality of steam / CO2 reforming, heat transfer, solids removal, filtration, and heat recovery. New methods of carbon-sequestering where the syngas produced by steam / CO2 reforming can be used in Fischer-Tropsch processes that make high-carbon content compounds while recycling the methane and lighter hydrocarbons back to the reformer to further produce syngas at a higher H2 / CO ratio.

Owner:INTELLERGY INC

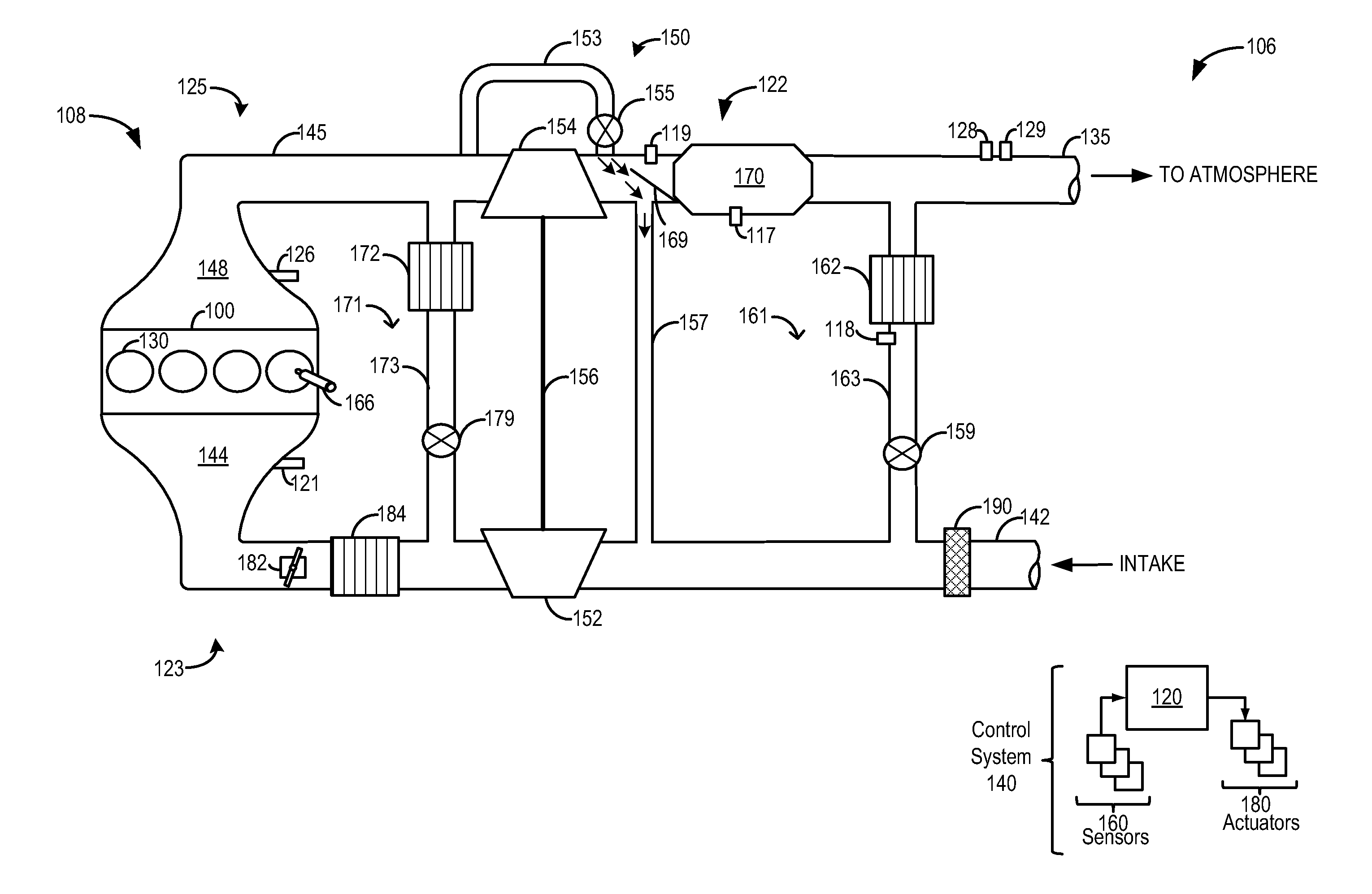

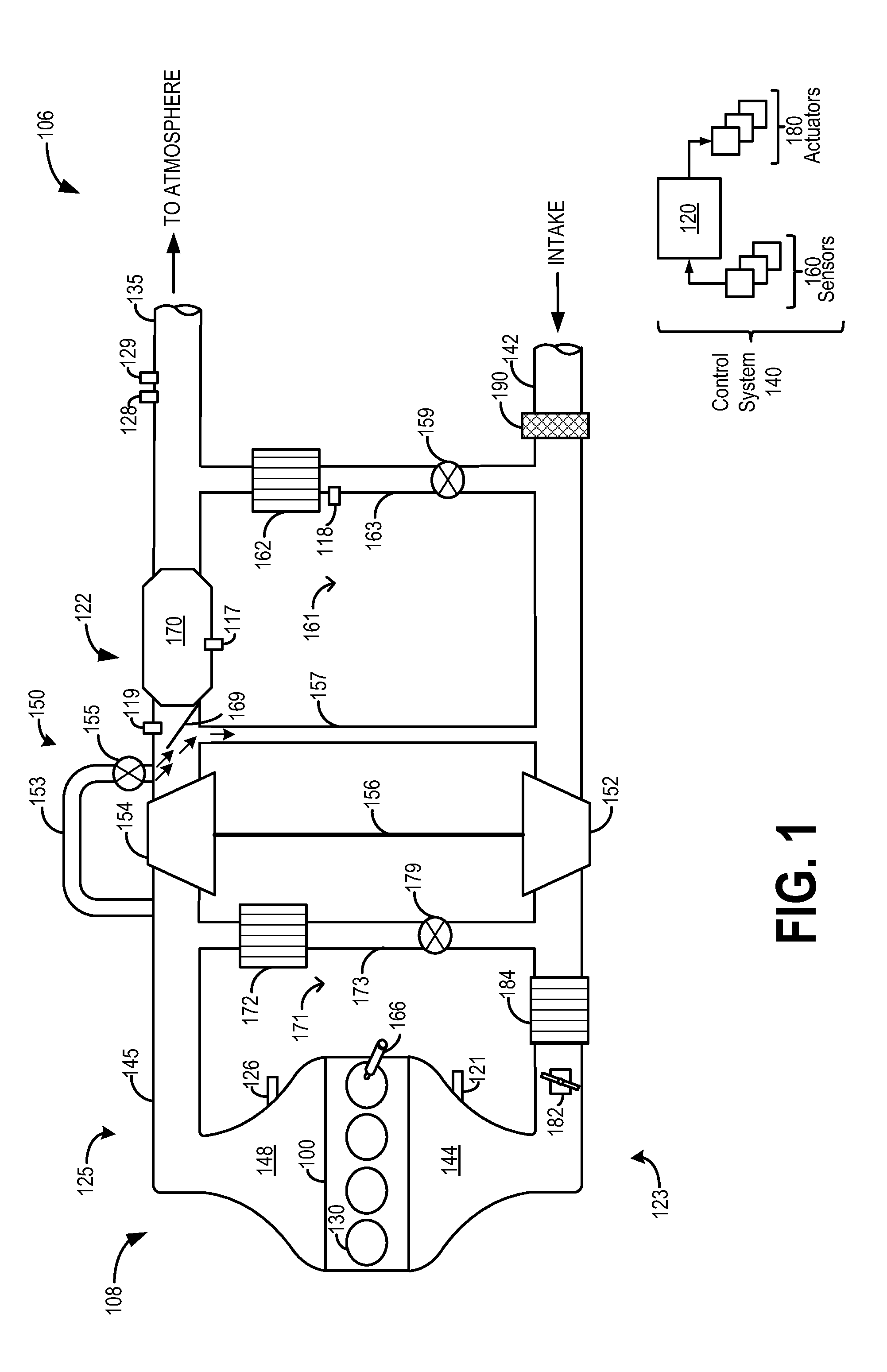

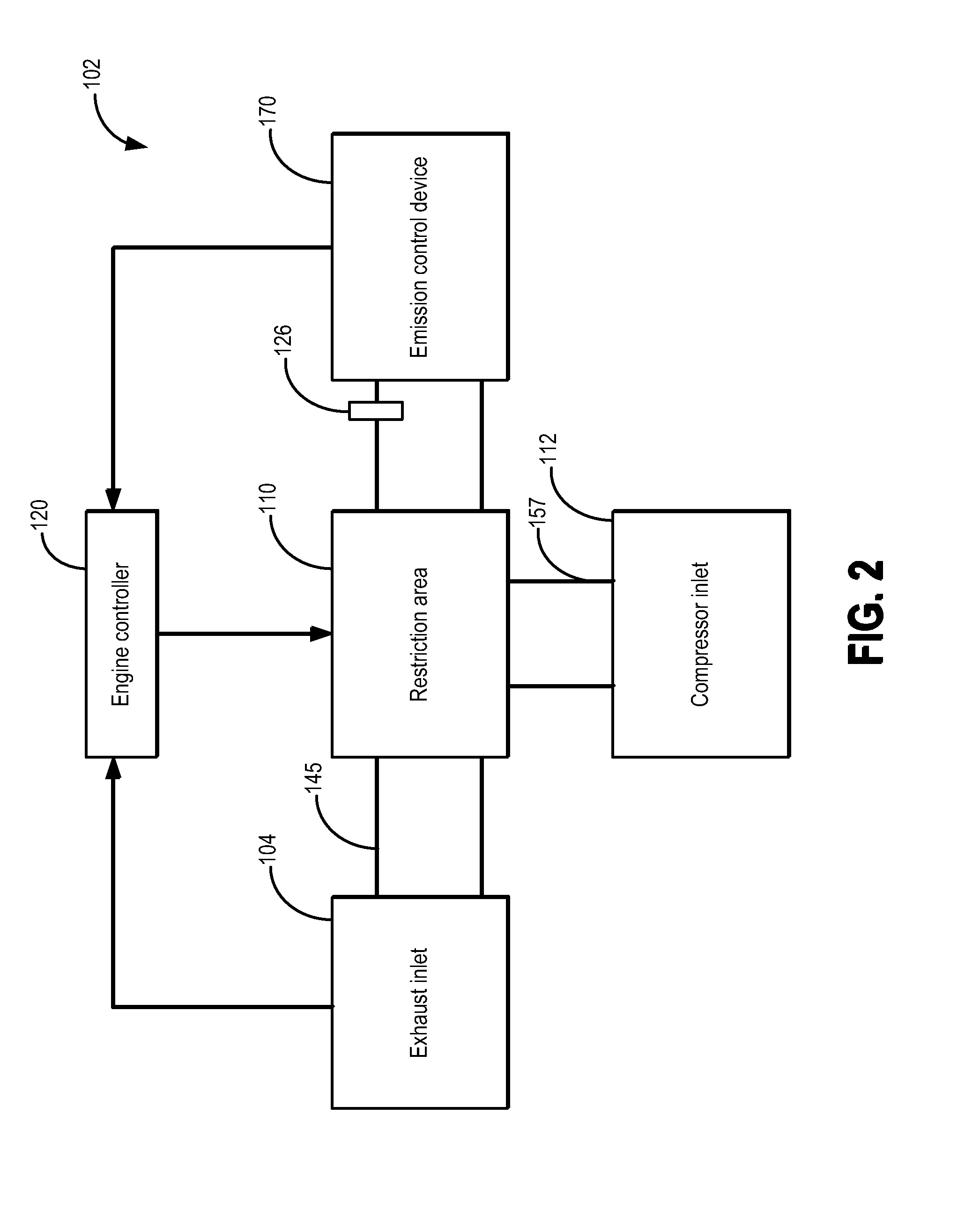

Methods and systems for recycling engine feedgas cold-start emissions

ActiveUS20150267649A1High emission reductionVehicle exhaust qualityElectrical controlNon-fuel substance addition to fuelExhaust fumesPulp and paper industry

Systems and methods are provided for recycling internal combustion engine feedgas exhaust emissions during cold-start conditions. By adjusting a restriction valve provided in an exhaust passage upstream of a catalytic converter, an amount of engine exhaust flowing through the catalytic converter prior to the catalytic converter reaching its operational temperature may be reduced.

Owner:FORD GLOBAL TECH LLC

Negative electrode material for lithium-ion battery, and use therefor

ActiveUS20170040610A1Low initial irreversible capacityLarge emissionsNegative electrodesSecondary cellsSilicon oxideGraphitic carbon

A negative electrode material for a lithium ion battery containing a composite material, the composite material including silicon-containing particles, graphitic carbon material particles, and a carbonaceous carbon material, in which the composite material has a ratio (A / B) of an area (A) of a peak near 100 eV derived from metal Si to an area (B) of a peak near 103 eV derived from silicon oxide, as measured by XPS, of not less than 0.10 and not more than 2.30. Also disclosed is a paste including the negative electrode material, as well as a negative electrode for a lithium ion battery including a formed body of the paste and a lithium ion battery including the negative electrode.

Owner:UMICORE AG & CO KG

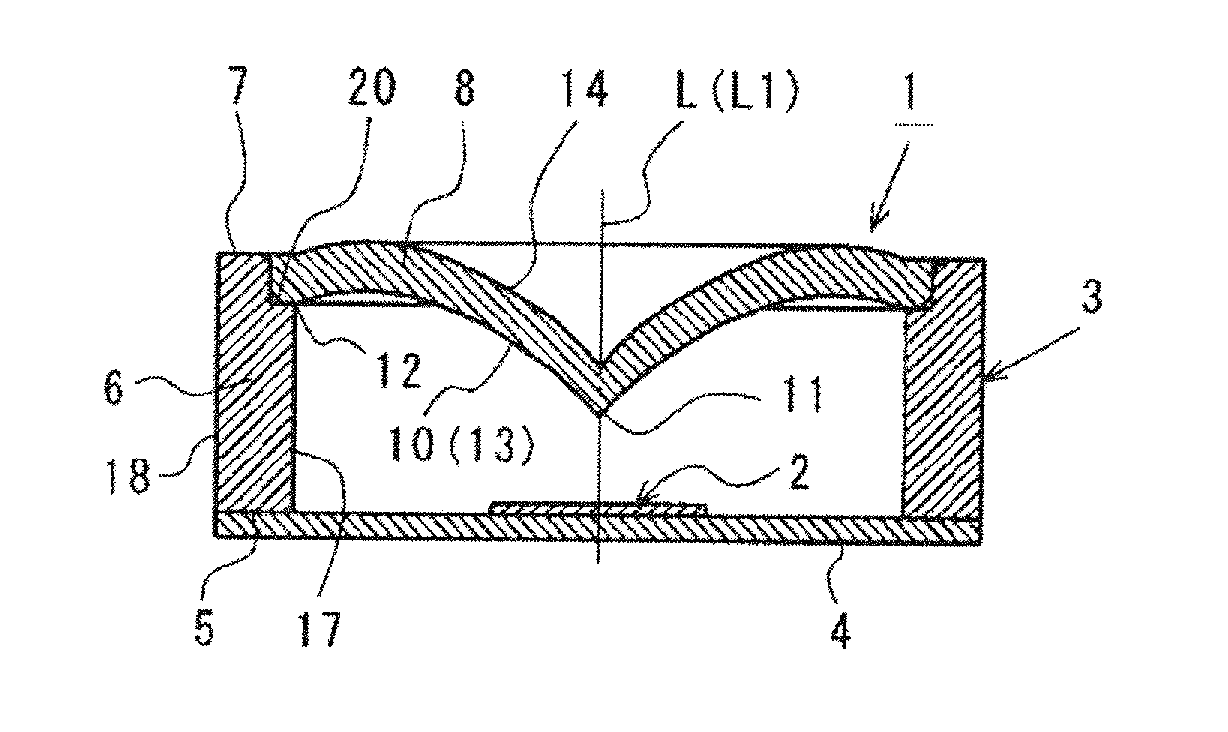

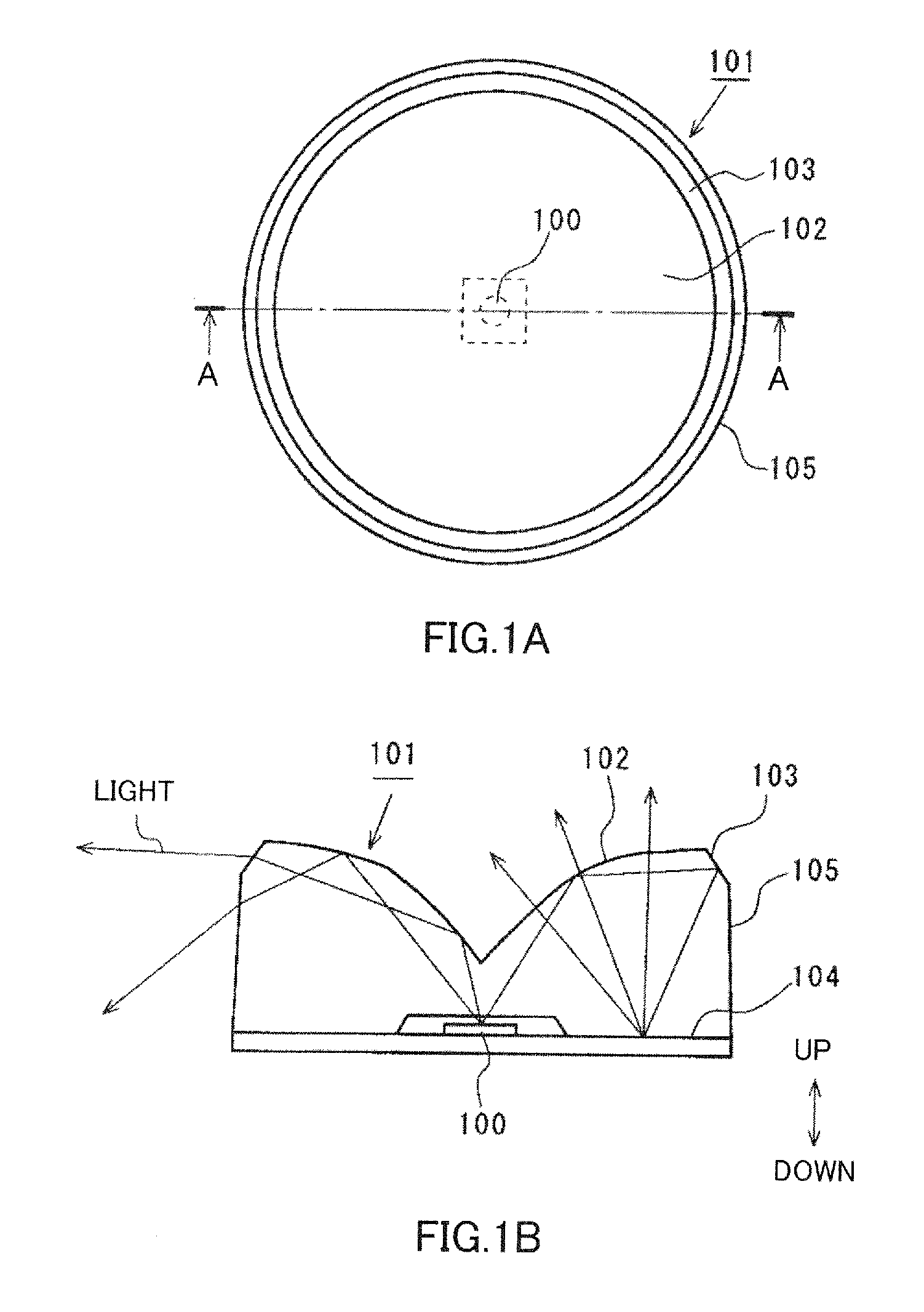

Luminous flux control member and illumination device

ActiveUS20130114254A1Inhibit coloringLarge emissionsPlanar light sourcesNon-electric lightingOptical axisLuminous flux

Disclosed is a luminous flux control member (3) comprising: a lid section (8) positioned, via an air layer, over one or two or more light-emitting elements (2) positioned on top of a substrate (4), and formed so as to intersect with the optical axis of the light-emitting elements (2); and side wall sections (6) that extend from the outer edge of the lid section (8) towards the substrate (4) side. The inner surface (10) of the lid section (8) is a concave surface with the center section thereof positioned closer to the light-emitting elements (2) than the outer peripheral section, and is covered by a transparent reflective film (13). The transparent reflective film (13) reflects some of the light from the light-emitting elements (2) towards the side wall sections (6) and allows the remaining light from the light-emitting elements (2) to pass through.

Owner:ENPLAS CORP

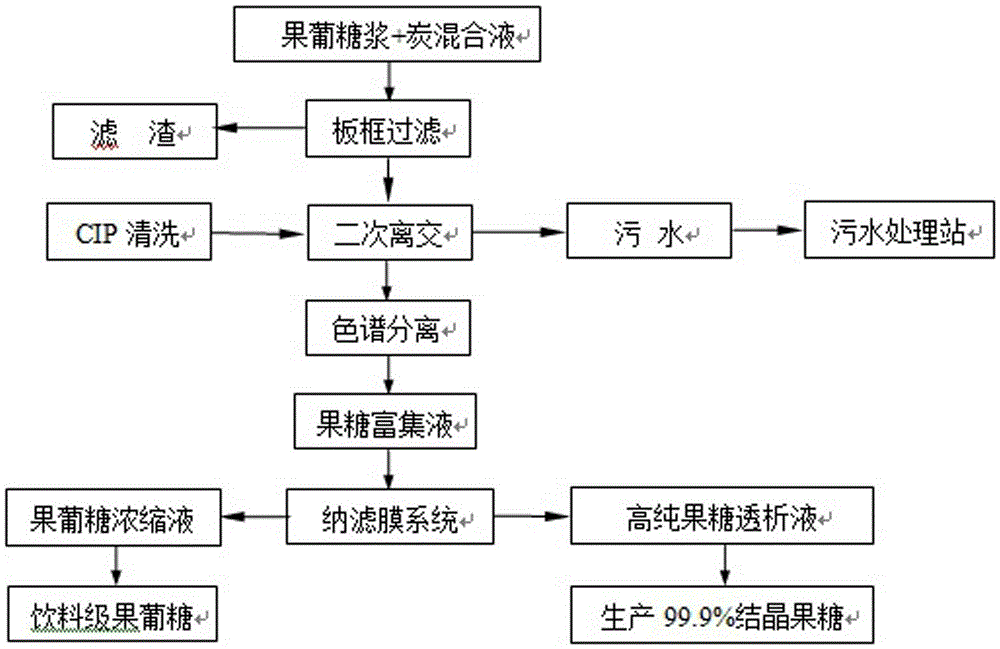

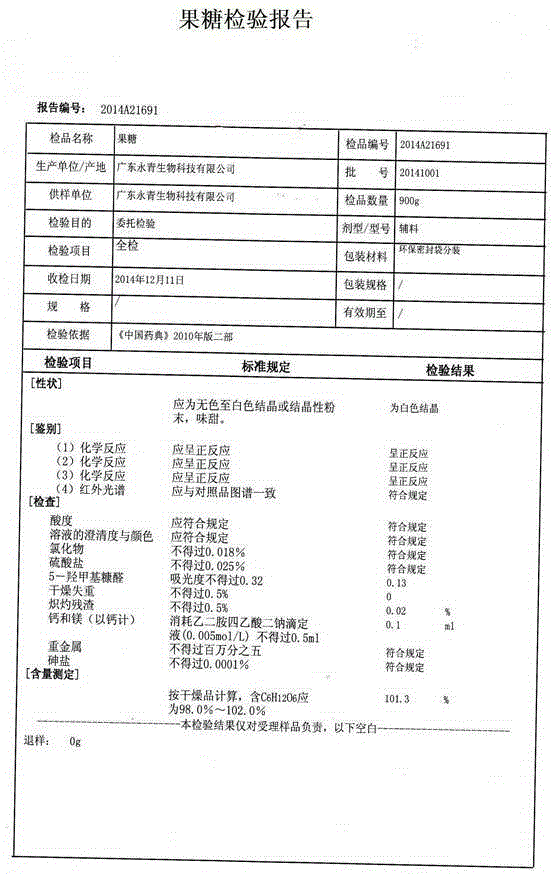

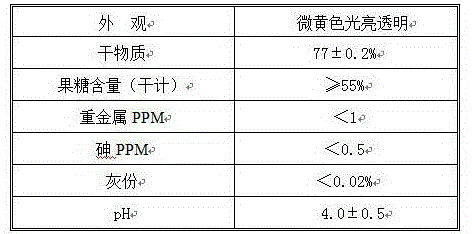

Purification method for HFCS (high fructose corn syrup) in fructose production process

InactiveCN105256079AQuality improvementImprove stabilityPurification using adsorption agentsPurification using ion-exchange materialsIon exchangeActivated carbon

The invention provides a purification method for HFCS (high fructose corn syrup) in a fructose production process. According to the purification method, the HFCS is obtained after cane juice is subjected to neutralization-hydrolysis in a medicinal anhydrous crystalline fructose production process adopting sugarcane as a raw material, the HFCS is decolorized with activated carbon, subjected to ion exchange twice and then separated through chromatography, a fructose rich liquid is obtained, the fructose rich liquid enters a nanofiltration membrane system, a high-purity fructose dialysate and a high fructose corn concentrated solution are filtered out respectively, the high-purity fructose dialysate is used for producing 99.9% crystalline fructose, and the high fructose corn concentrated solution is applied to beverage-grade high fructose corn. According to the purification method, devices and technological parameters of all working procedures are comprehensively optimized and reasonably matched to meet industrial production requirements, equipment input and production cost are greatly reduced, the one-time yield of industrially produced crystalline fructose products is up to 50%, the technical content of fructose production is increased, and the problem about the situation of heavy dependence on import of high-quality medicinal fructose is solved.

Owner:林树仁 +1

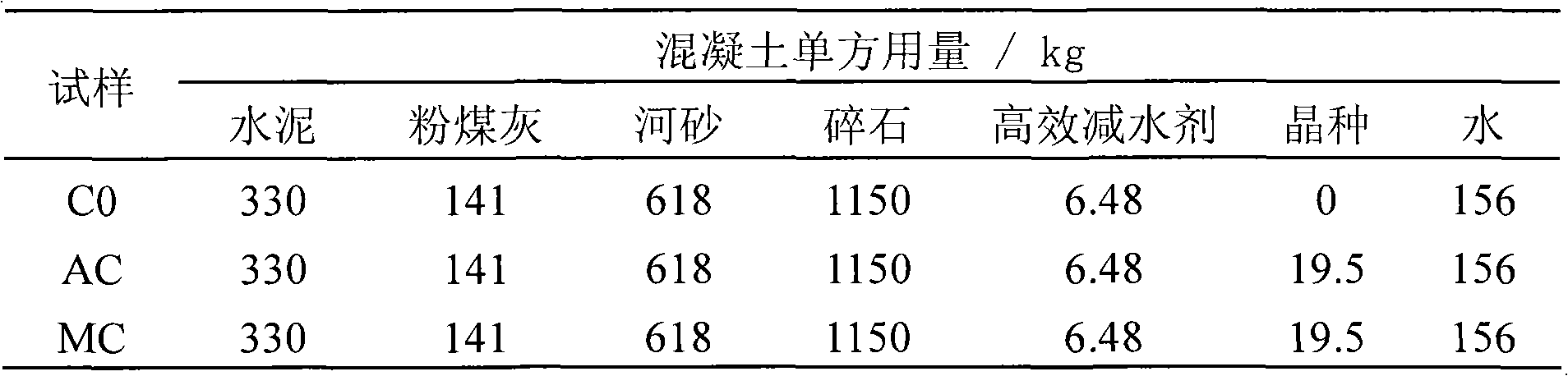

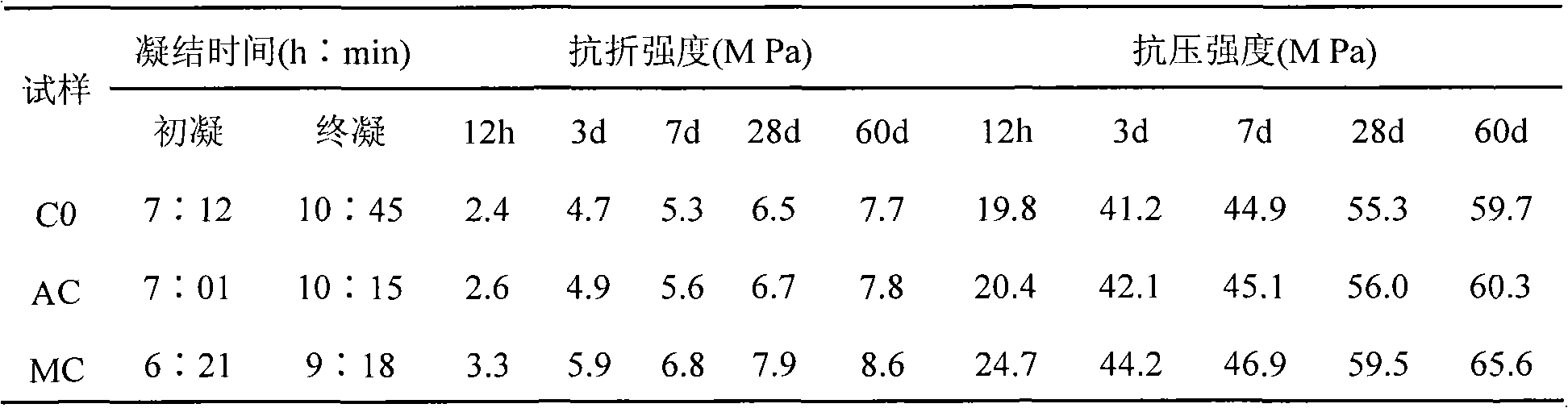

High-activity crystal seed for concrete production and preparation method thereof

InactiveCN101830660AImprove burnabilityLower firing temperatureSolid waste managementSolid waste disposalSlagSeed crystal

Owner:EAST CHINA JIAOTONG UNIVERSITY

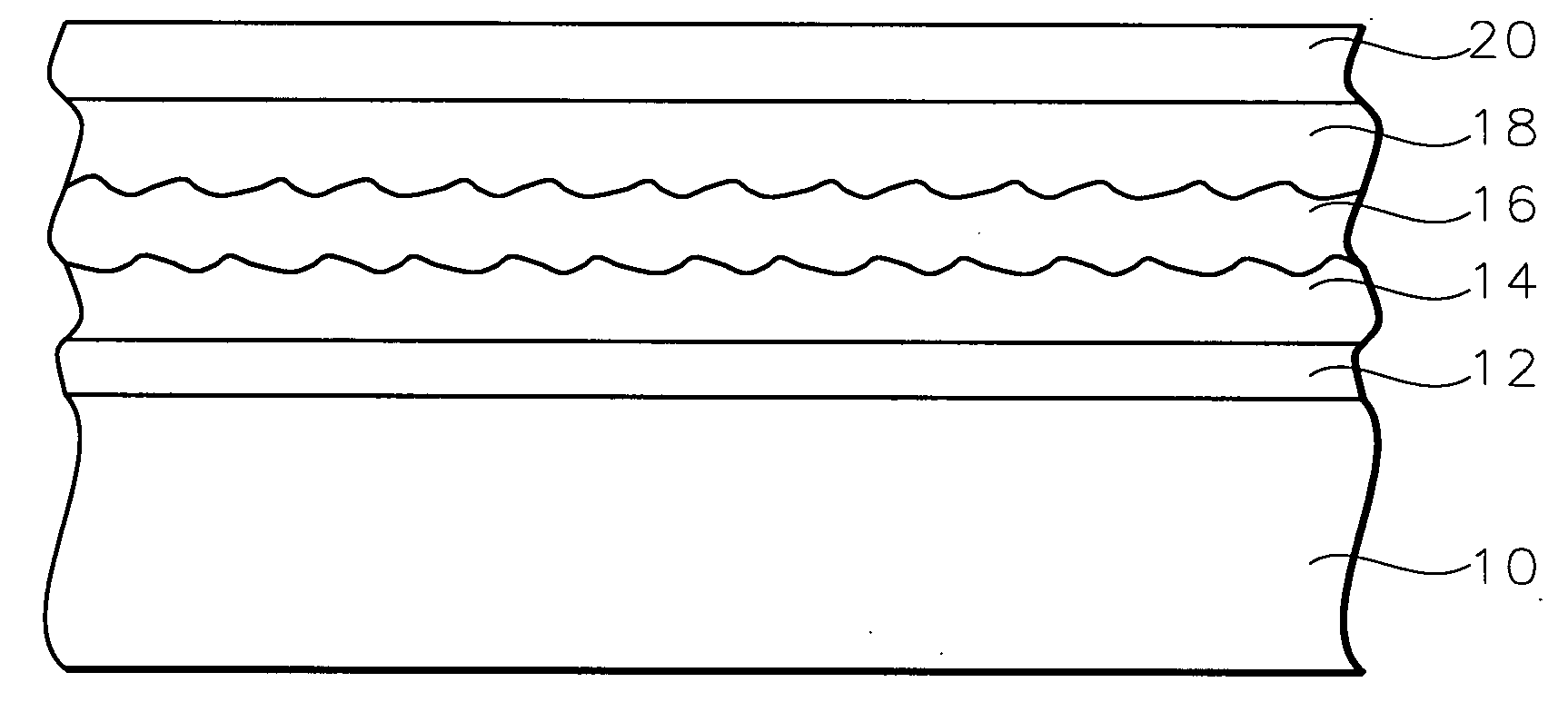

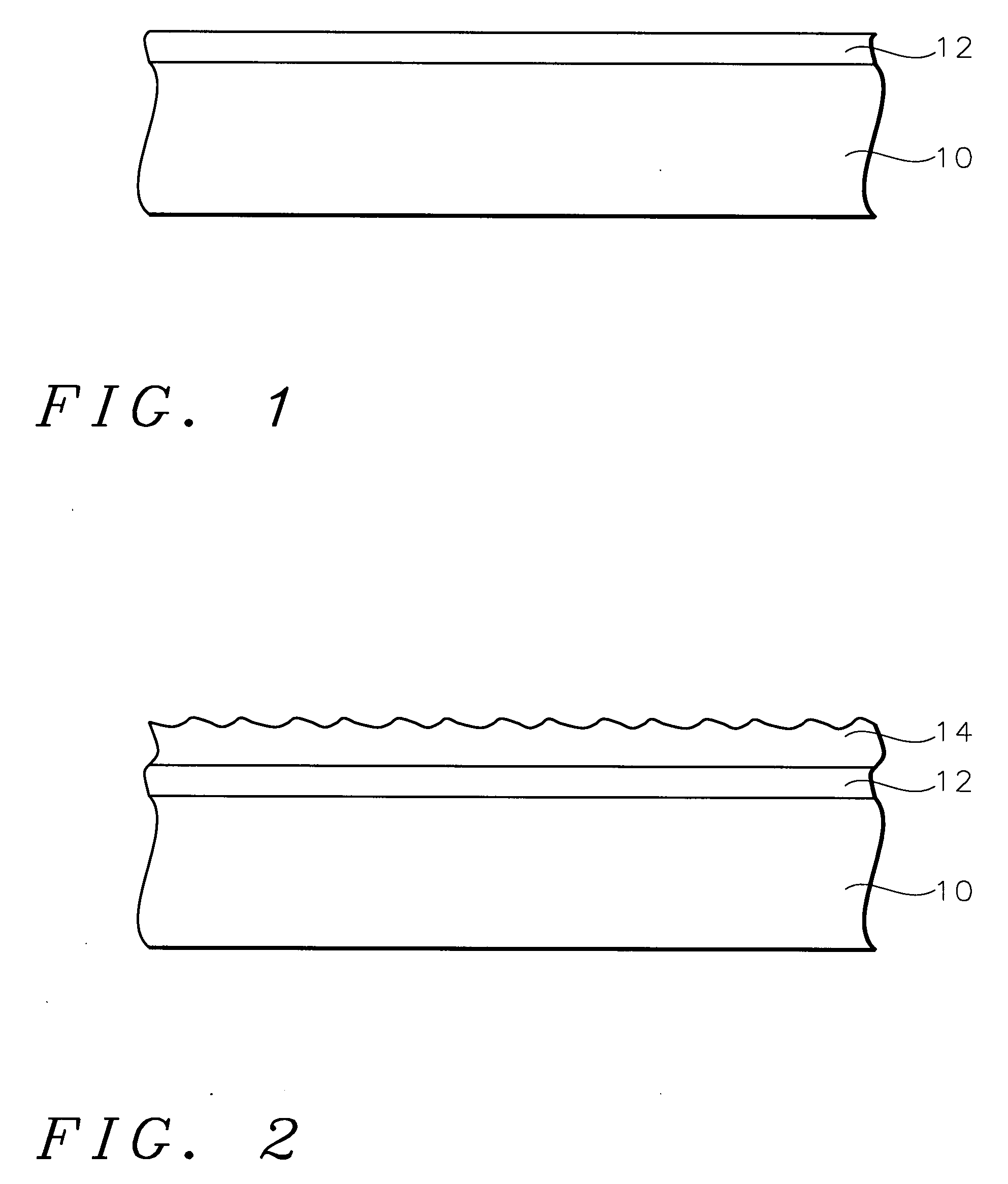

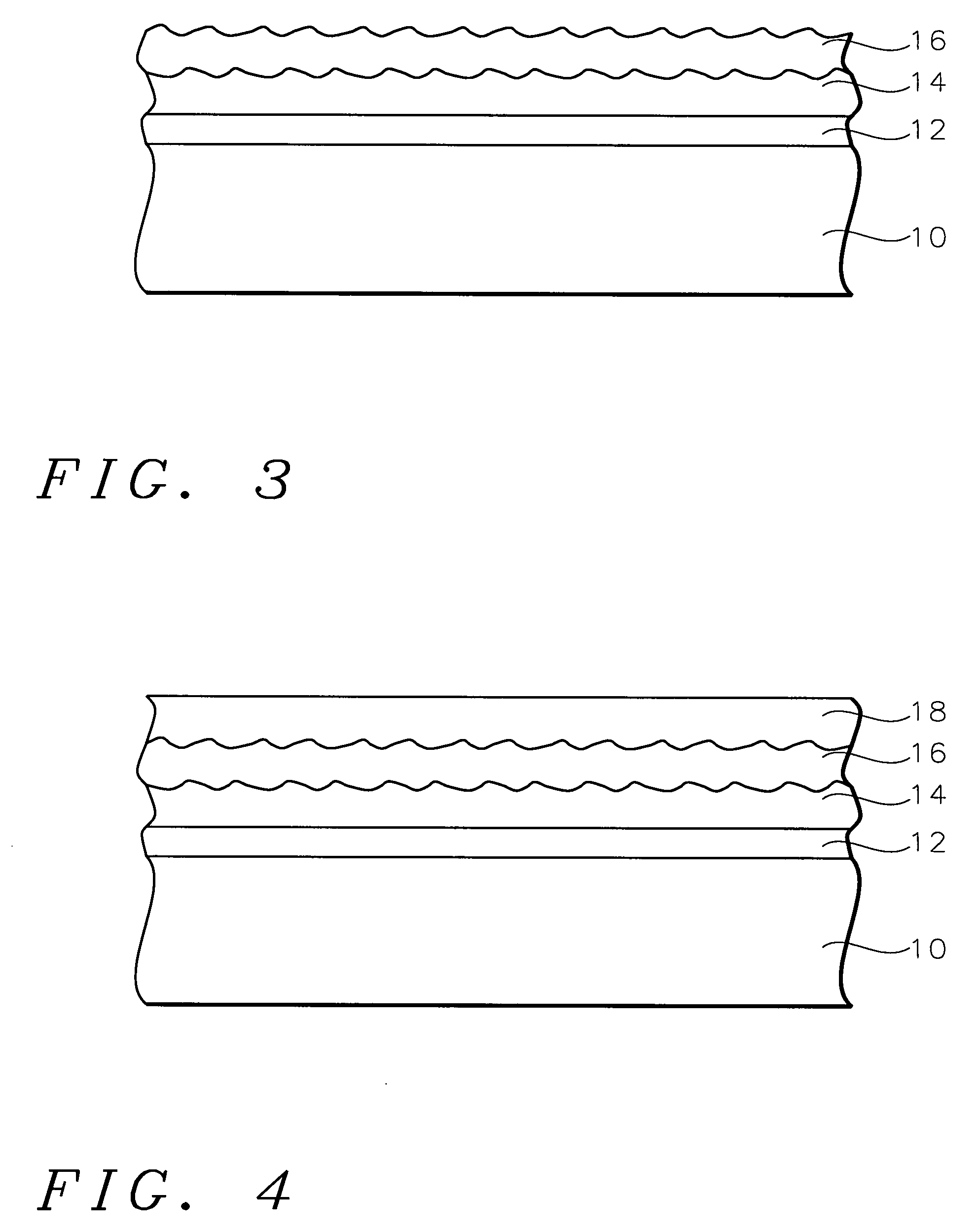

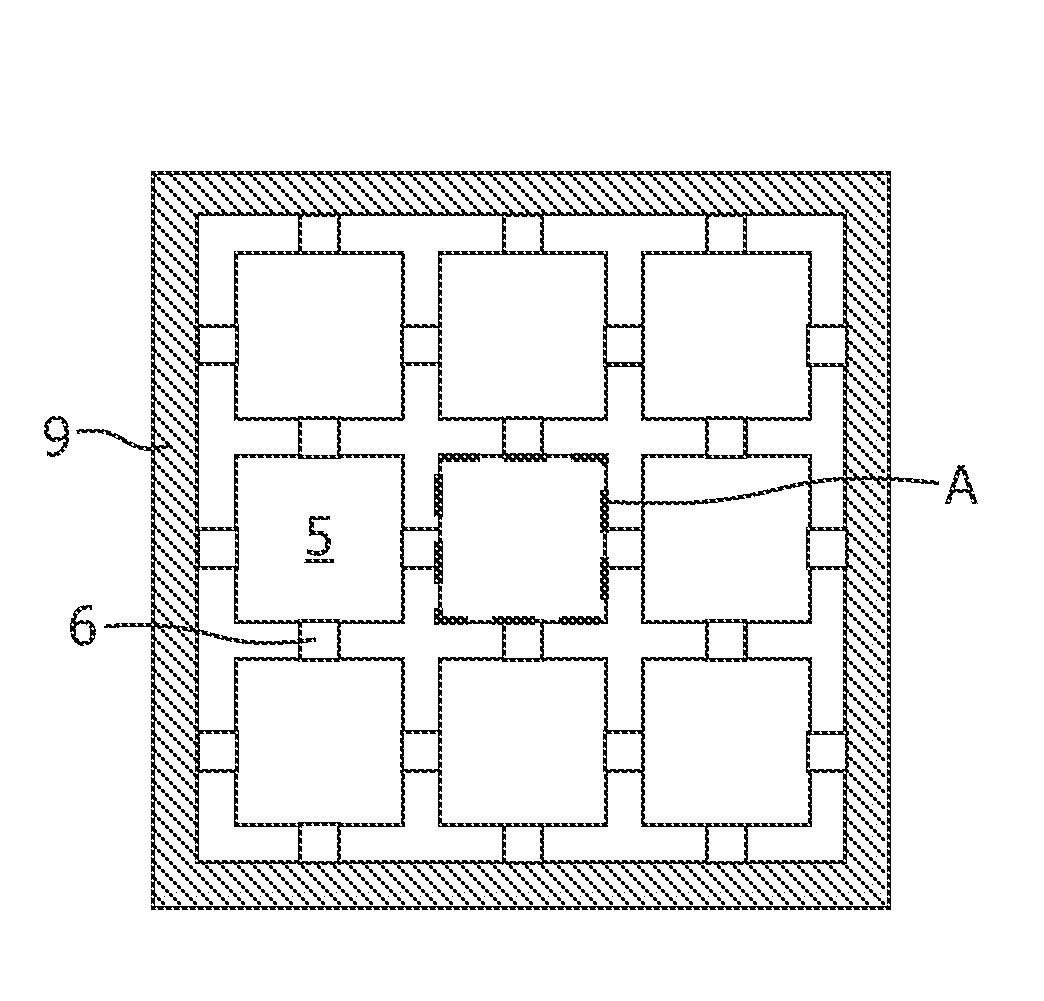

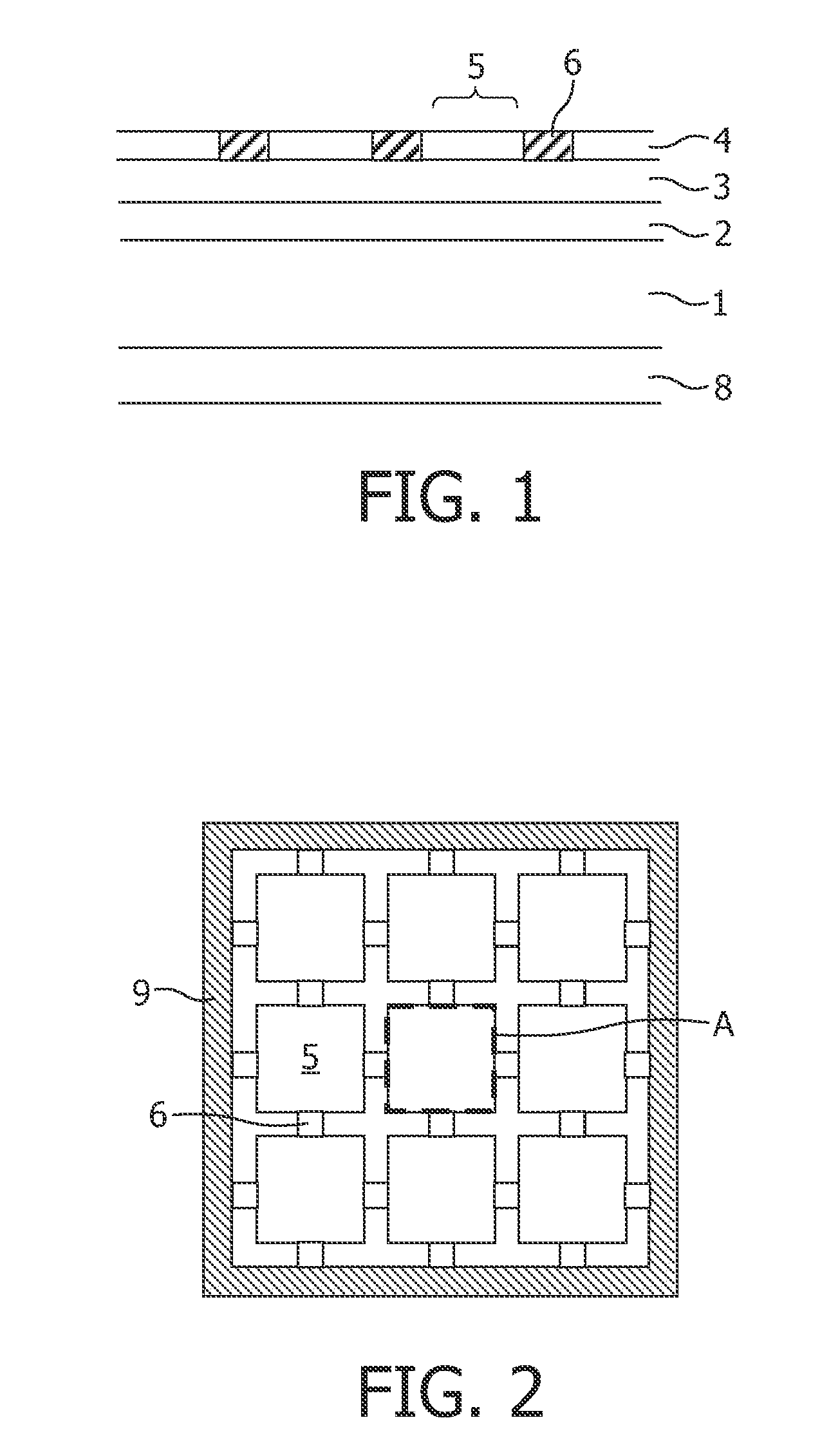

Large area light emitting diode light source

InactiveUS20100140598A1Avoid smallWithout risk of failureSolid-state devicesSemiconductor/solid-state device manufacturingNear neighborElectrical connection

The present invention relates to a LED light source comprising at least one layer of light emitting material (3), in particular organic light emitting material, sandwiched between two electrode layers (2, 4). At least one of the electrode layers (2, 4) is structured to form a pattern of electrode segments (5), each electrode segment (5) being in electrical contact with at least three of its nearest neighbor electrode segments (5) via direct electrical connections (6), which are designed to act as electrical fuses between the electrode segments (5). The invention allows the design of a large area LED light source having a homogeneous light density without the risk of failure of larger light emitting areas.

Owner:OLEDWORKS GMBH

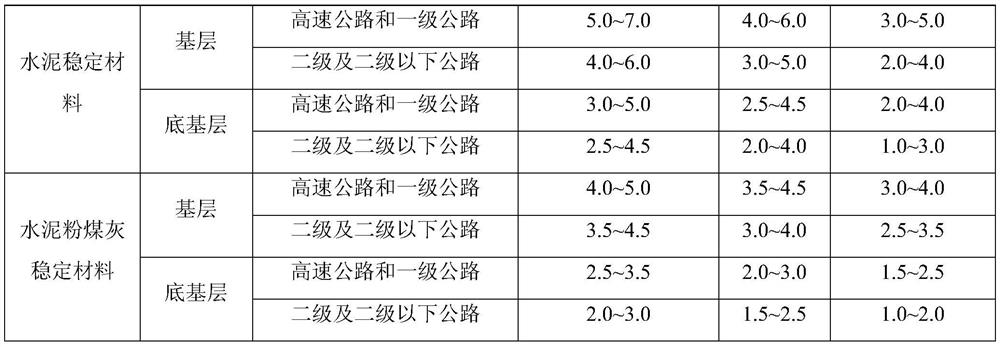

Application of household garbage incineration fly ash composite admixture in cement stabilized macadam mixture

The invention relates to application of a household garbage incineration fly ash composite admixture in a cement stabilized macadam mixture, and belongs to the technical field of crossing of environmental engineering and highway engineering. According to the invention, the household garbage incineration fly ash is used as a stable material; the cement / incineration fly ash stabilized macadam mixture is mainly prepared by blending domestic waste incineration fly ash with an active mixed material and an excitant to form a composite admixture and then forming a composite cementing system togetherwith cement to stabilize graded macadam mineral aggregate; and the cement / incineration fly ash stabilized macadam mixture can be used in highway pavement base layers and subbase layers. According to the invention, component complementation and activity excitation effects in the composite admixture are utilized; the potential gelatinization activity of the incineration fly ash is released to the greatest extent to provide a high-activity cementing effect; meanwhile, heavy metal components contained in the incineration fly ash are stably solidified through the solidification effect of the composite cementing system, so that the cement / incineration fly ash stabilized macadam mixture with good performance is prepared, the recycling and harmless disposal target of the household garbage incineration fly ash is achieved, the use amount of cementing materials is reduced for highway engineering, and the engineering cost is reduced.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +2

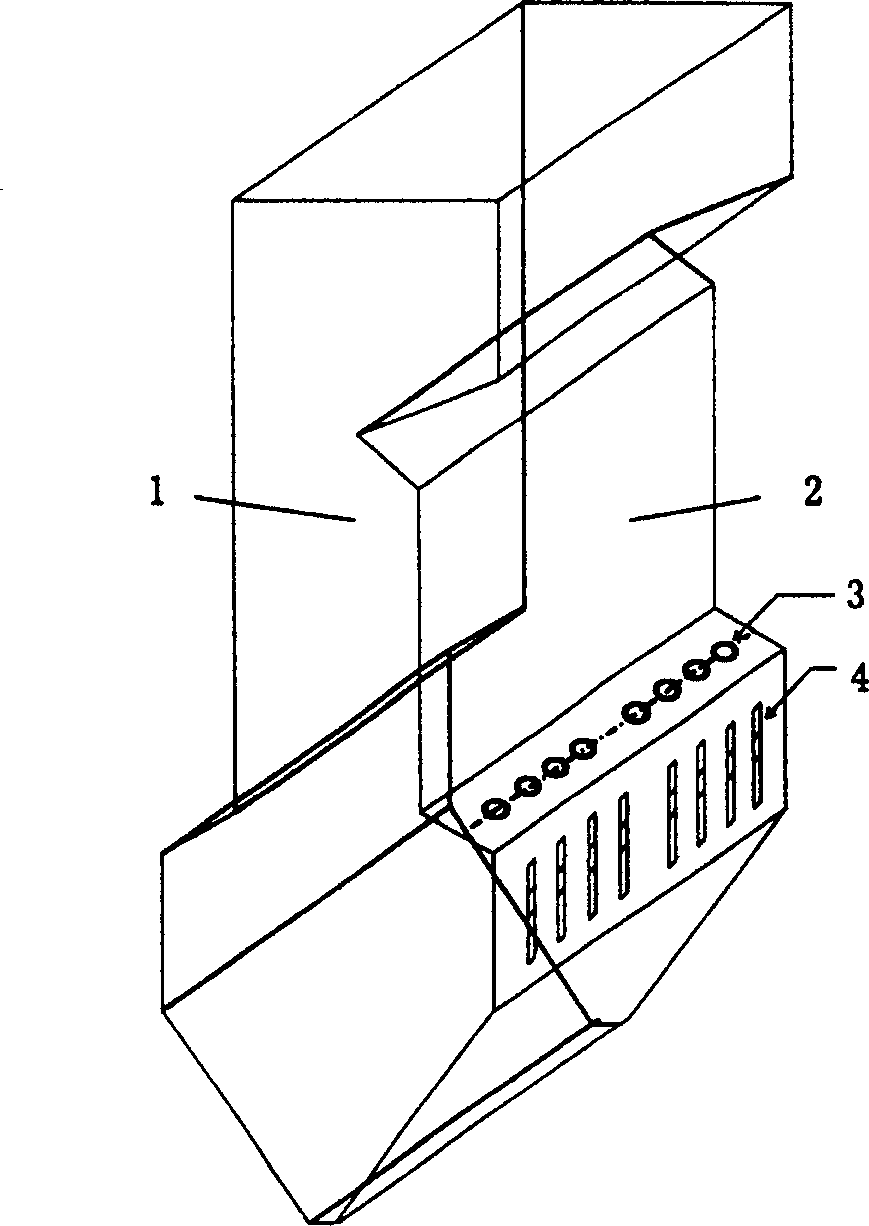

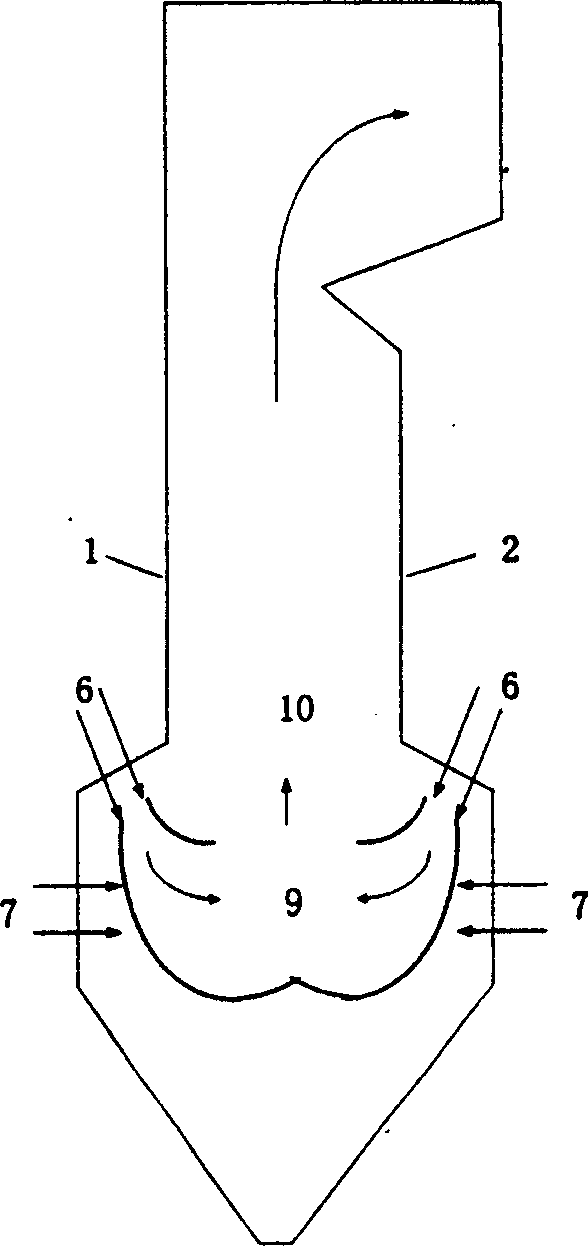

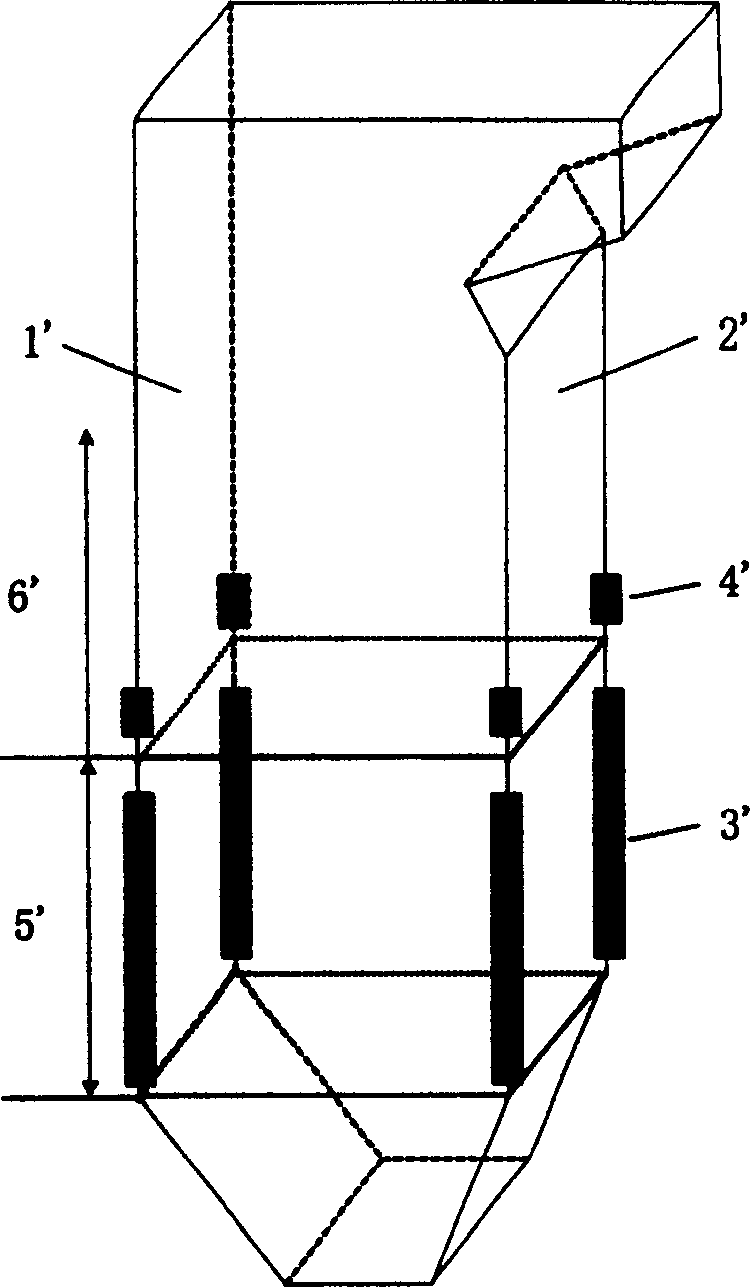

Device and method for w shape flame boiler completely burning

Owner:HUAZHONG UNIV OF SCI & TECH

Process for the synthesis of ammonia with low emissions of co2in atmosphere

ActiveUS20200055738A1Substantial elimination and zeroing of CO emissionHeat recoveryHydrogen productionHydrogen/synthetic gas productionSyngasEnvironmental engineering

Process for the synthesis of ammonia from natural gas comprising conversion of a charge of desulphurized natural gas and steam, with oxygen-enriched air or oxygen, into a synthesis gas, and treatment of the synthesis gas with shift reaction and decarbonation, wherein a part of the CO2-depleted synthesis gas, obtained after decarbonation, is separated and used as fuel fraction for one or more furnaces of the conversion section, and the remaining part of the gas is used to produce ammonia.

Owner:CASALE SA

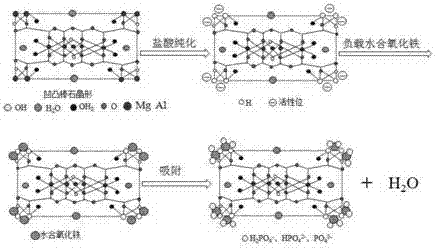

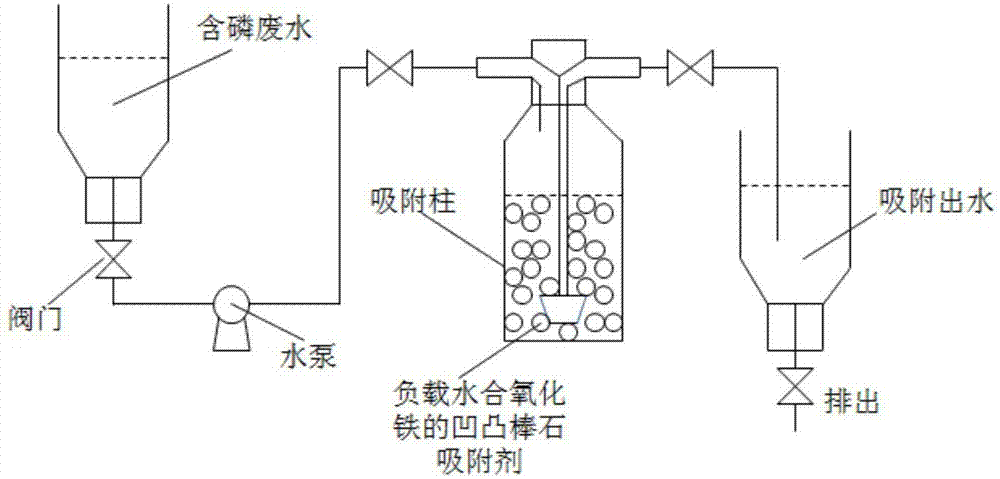

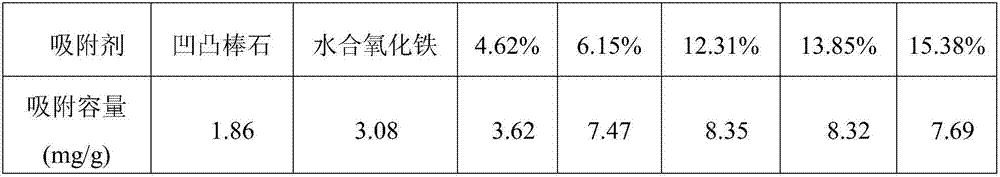

Method for deep adsorption dephosphorization through ferric oxide hydrate-carrying attapulgite

ActiveCN107265548AImprove adsorption performanceIncrease totalOther chemical processesWater contaminantsChemistryIron oxide

The invention discloses a method for deep adsorption dephosphorization through ferric oxide hydrate-carrying attapulgite. The method comprises (1) preparing a ferric oxide hydrate-carrying attapulgite adsorbent with particle diameters of 2 to 6 mm through attapulgite purification, modification and granulation, and (2) filling an adsorption device with the adsorbent particles, making phosphorus-containing wastewater flow through a dephosphorization device, adjusting and controlling inlet and outlet water amounts to ensure standing time so that the adsorbent fully contacts with the phosphorus-containing wastewater and phosphorus is adsorbed and fixed to the surface of the adsorbent, and when the adsorbing capacity is saturated, carrying out soaking in a sodium hydroxide solution so that the adsorbent is regenerated. The adsorption synthesis process is simple and has strong operability. The adsorption device is simple and easy and realizes wastewater self-flowing treatment. The treated product water has a phosphorus concentration less than 0.1ppm. Under phosphorus removal total amount quantification, the wastewater discharge capability is increased. The adsorbent can be regenerated and recycled so that requirements of environmental protection are satisfied and a treatment cost is effectively reduced.

Owner:盛隆资源再生(无锡)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com