Oxygen-enriched combustion circulating fluidized bed poly-generation system and process

A circulating fluidized bed and oxygen-enriched combustion technology, which is applied in the direction of fluidized bed combustion equipment, combustion method, combustion type, etc., can solve the problems of difficult industrial application of ash content in tar products, difficult separation of tar and dust, and achieve utilization The effect of high efficiency, good tar quality and less pollutant discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

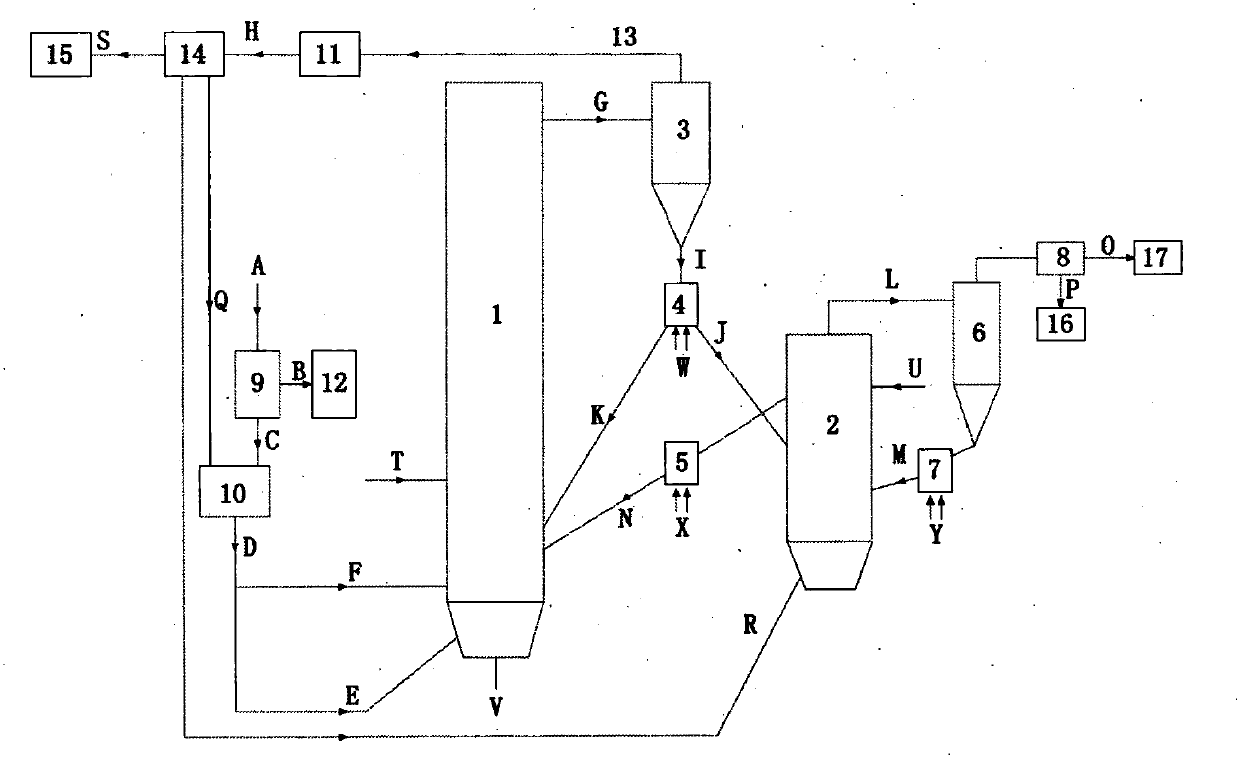

[0017] figure 1 It is a schematic diagram of the oxy-enriched combustion circulating fluidized bed polygeneration system provided by the present invention, and the described oxy-enriched combustion circulating fluidized bed polygeneration system includes a circulating fluidized bed combustion furnace 1 and a circulating fluidized bed gasifier 2, The upper part of the circulating fluidized bed combustion furnace 1 is connected to the No. 1 separator 3, the upper part of the No. 1 separator 3 is connected to the tail flue 13, the lower part of the No. 1 separator 3 is connected to the two-way feeder 4, and the two-way feeder 4 is respectively connected to the The circulating fluidized bed combustion furnace 1 is connected with the circulating fluidized bed gasification furnace 2, the circulating fluidized bed gasification furnace 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com