Patents

Literature

205results about How to "Increase the amount of gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

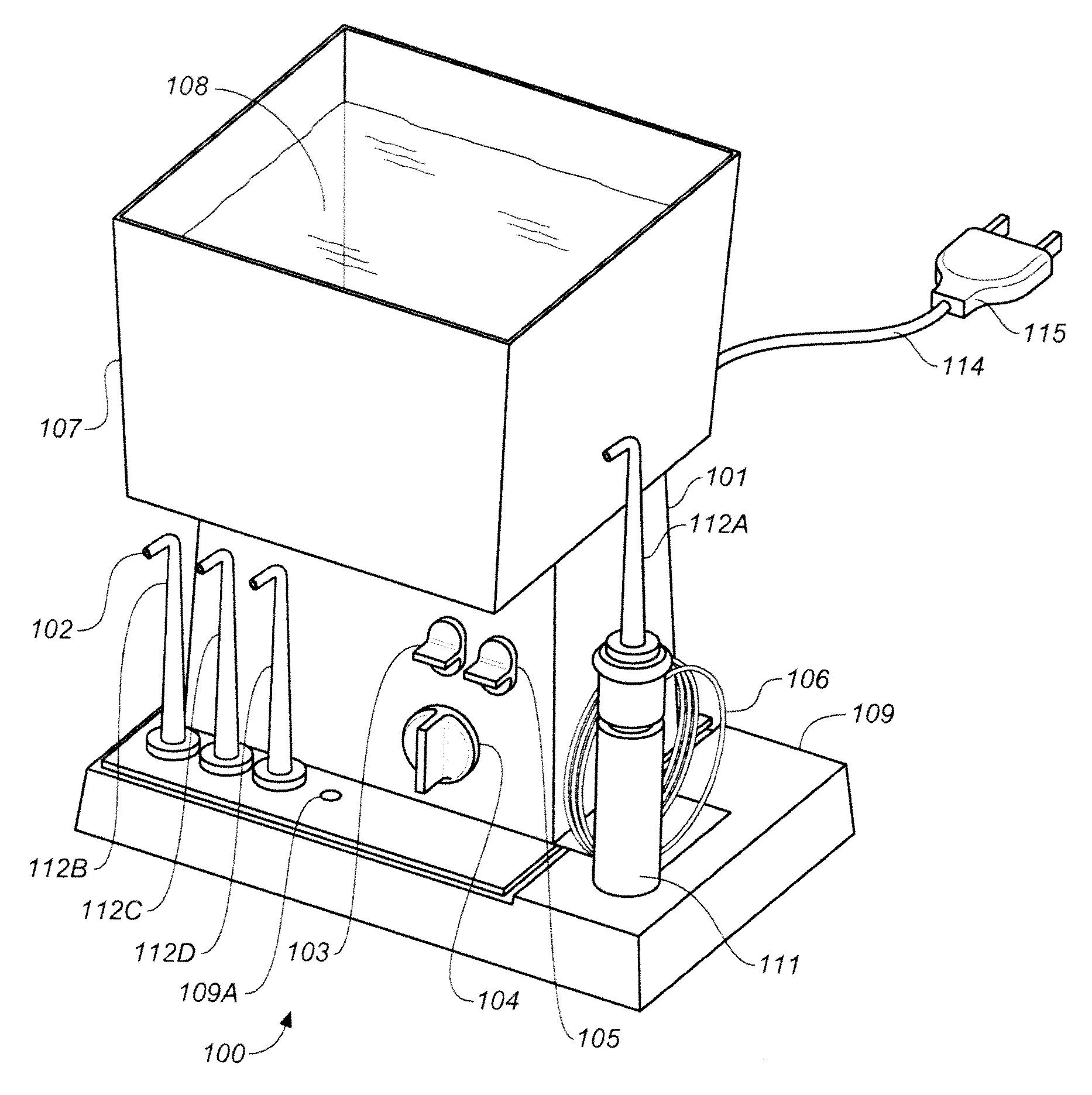

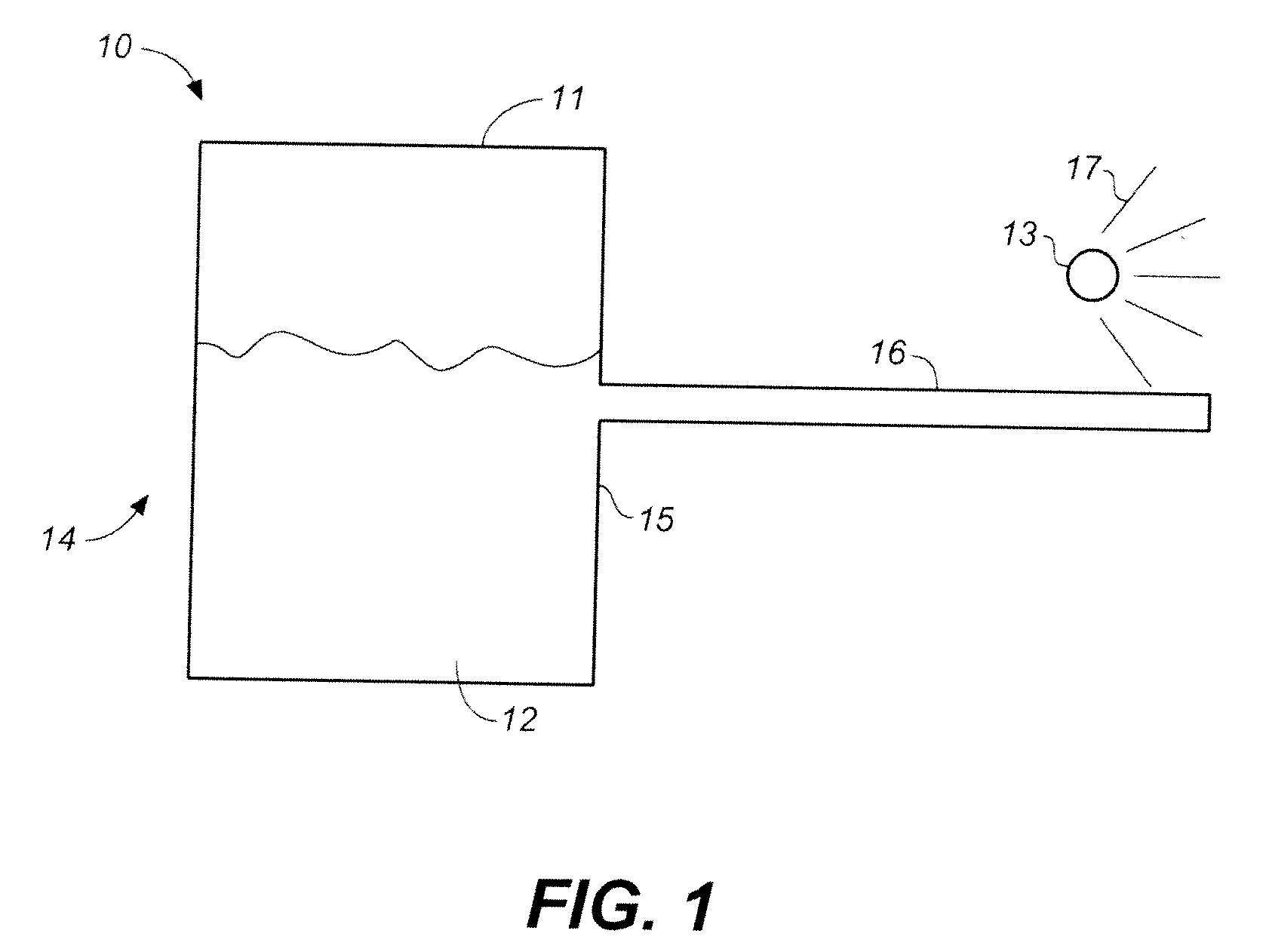

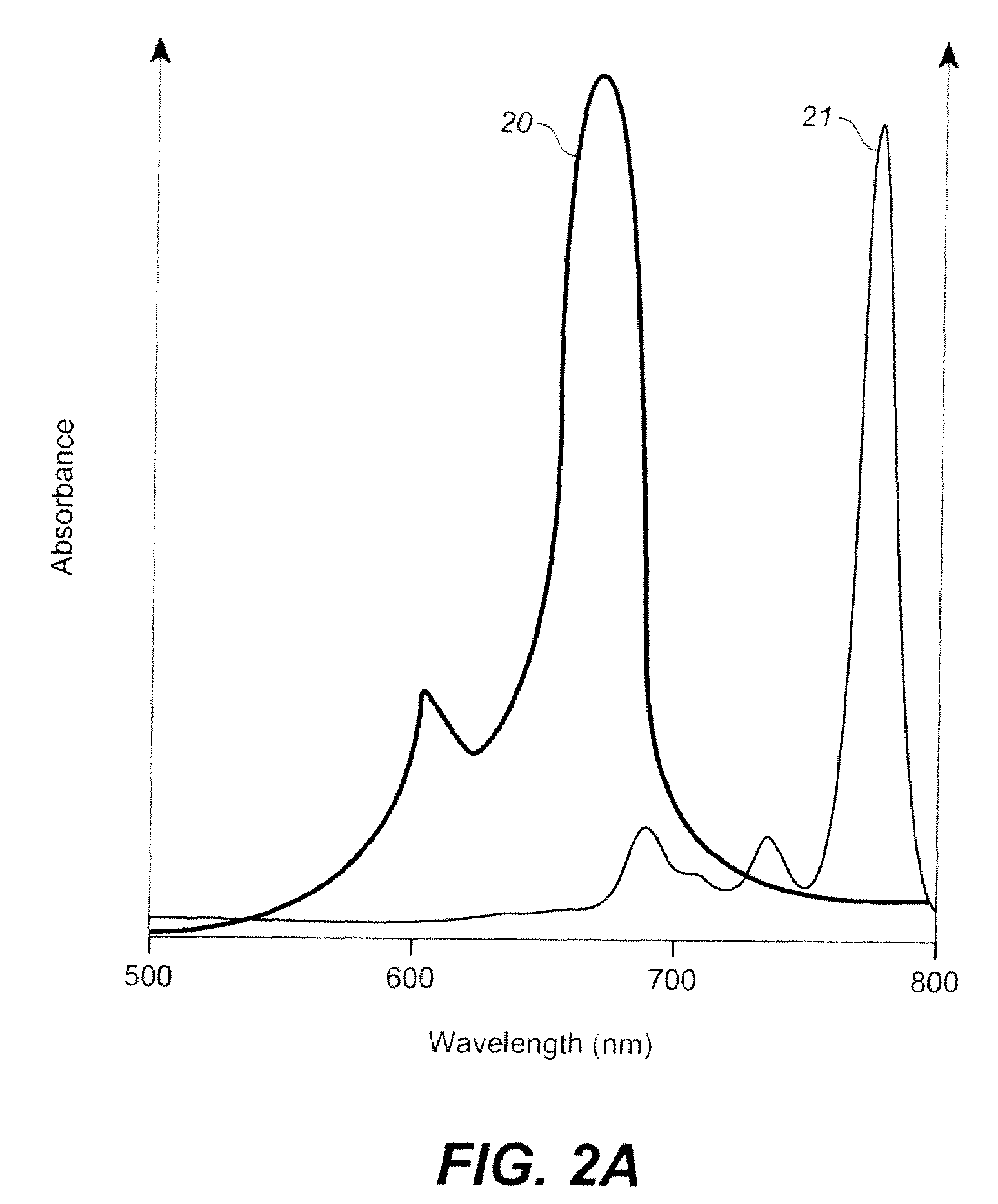

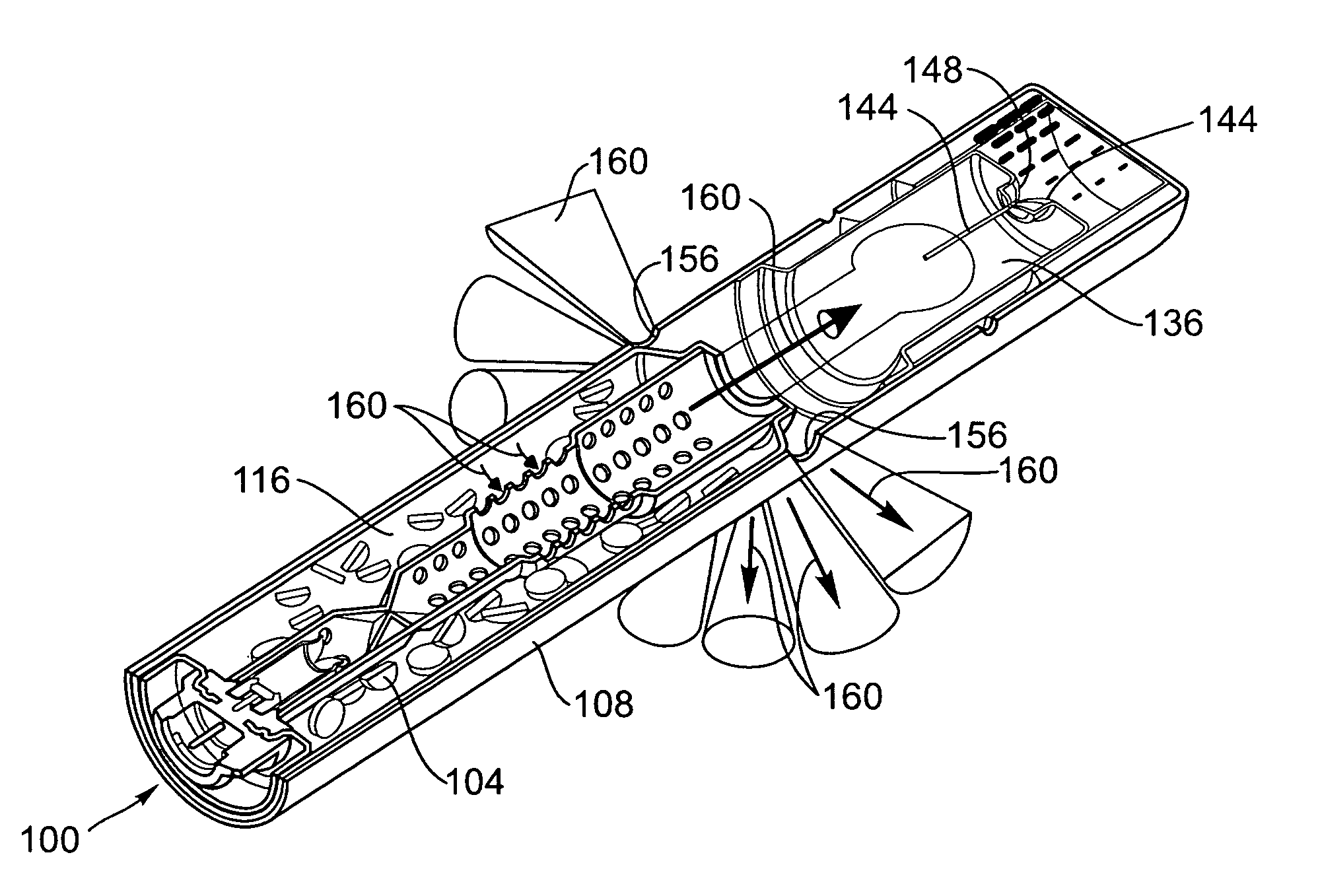

Sensitizer Solutions, Systems, and Methods of Use

InactiveUS20080255498A1Reduce riskIncreased oxygen levelsElectrotherapyPhotodynamic therapySolventChemistry

A kit cleaning system and method is disclosed. One embodiment of the present invention has a photosensitizer solution supplied by a pressurized nozzle to the target site. Specific application of the solution is to an oral or skin surface target site. The photosensitizer solution is illuminated with sensitizing light creating reactive chemical species. Pressure and a solvent having an elevated concentration of oxygen or oxygen species improve the efficiency of the killing of pathogens. Methods of using the system within an oral cavity are also disclosed.

Owner:OROSCI

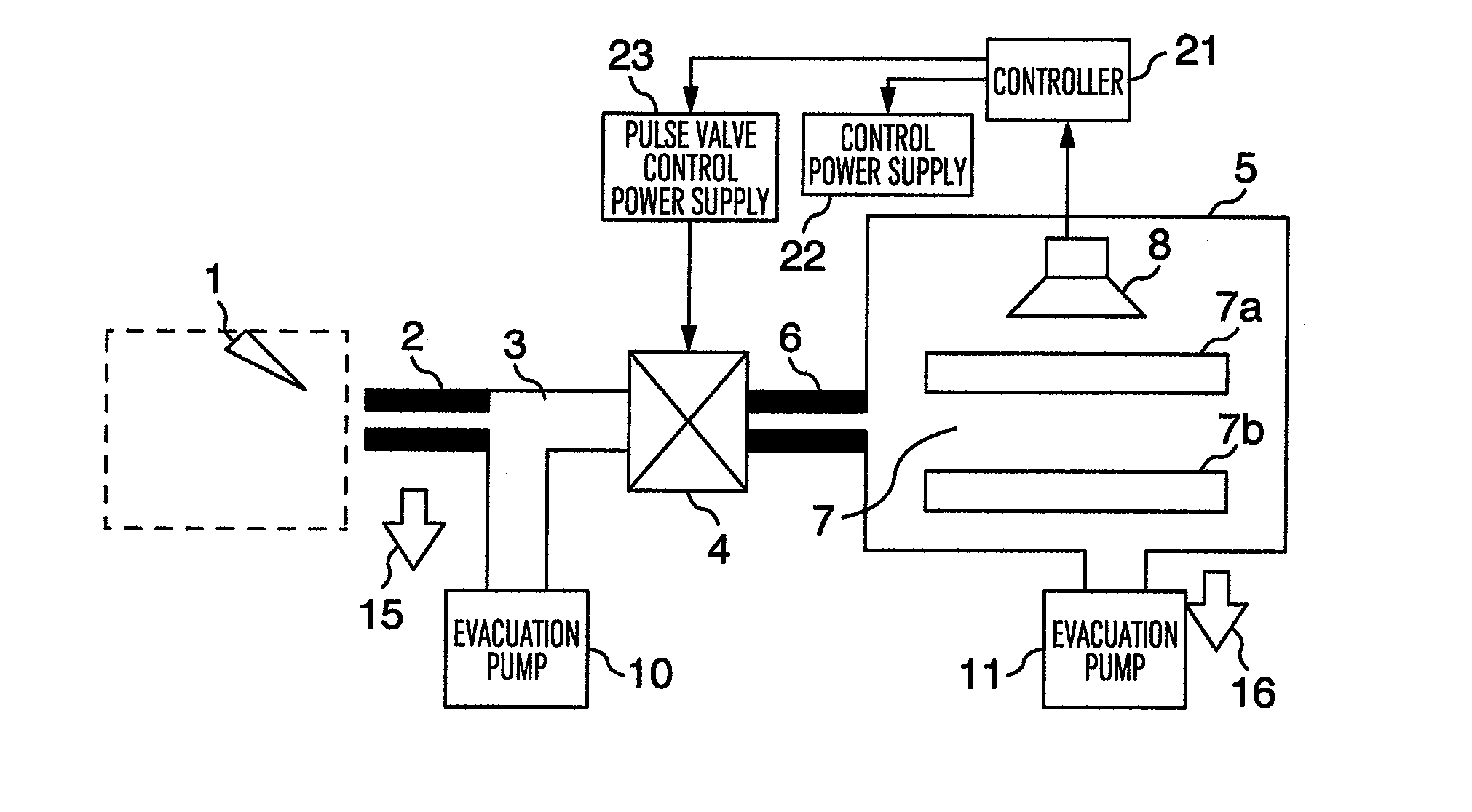

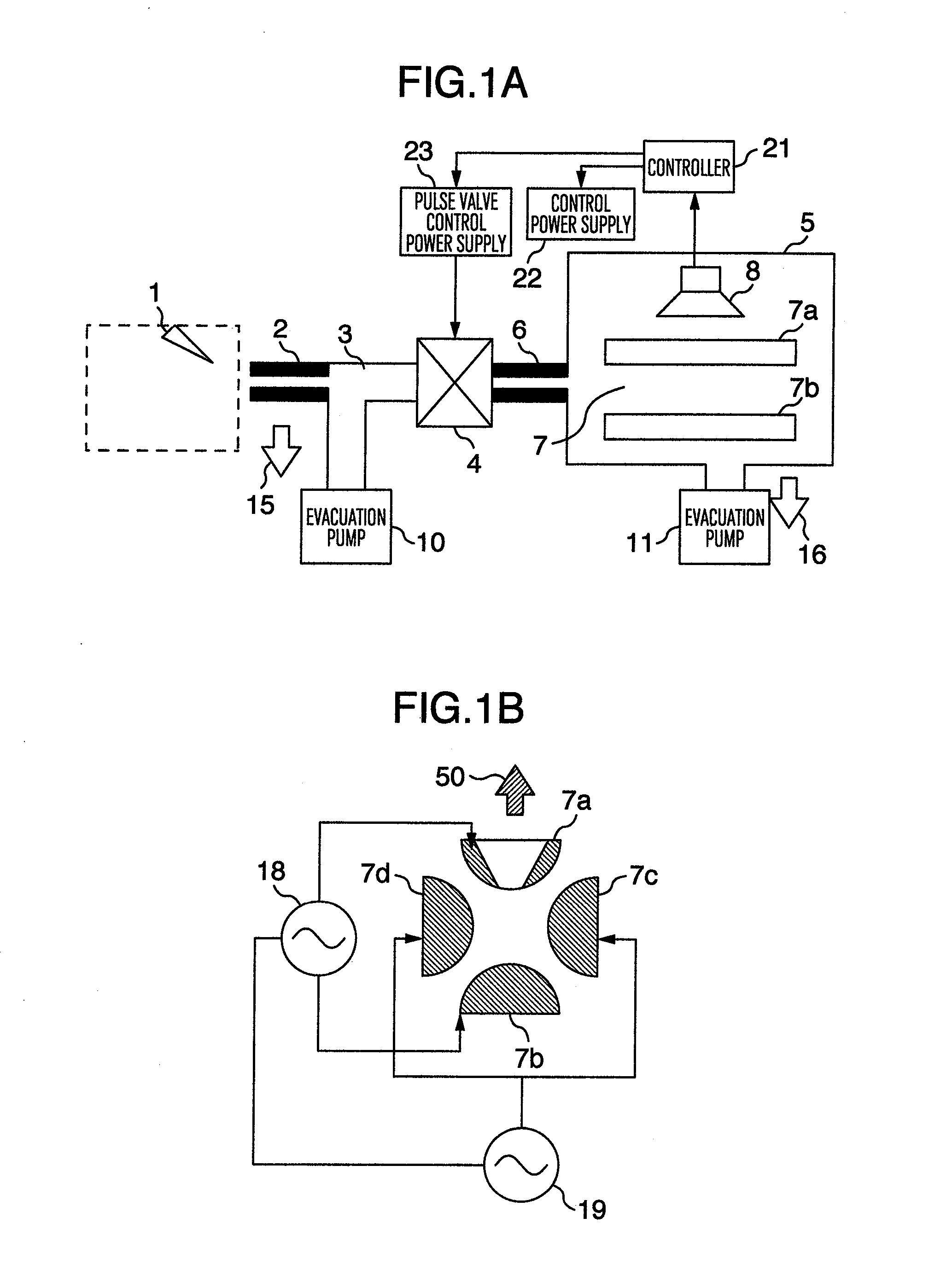

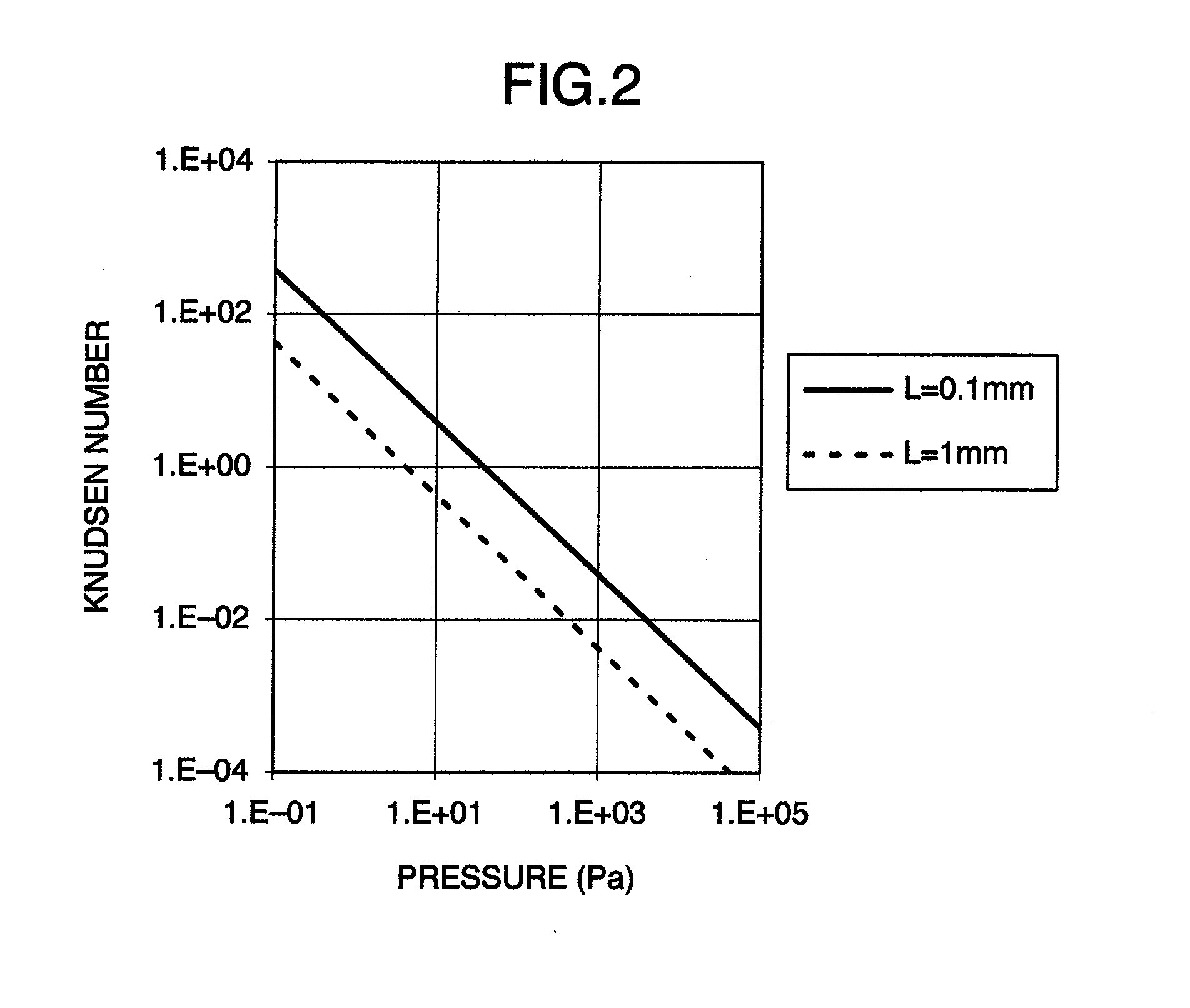

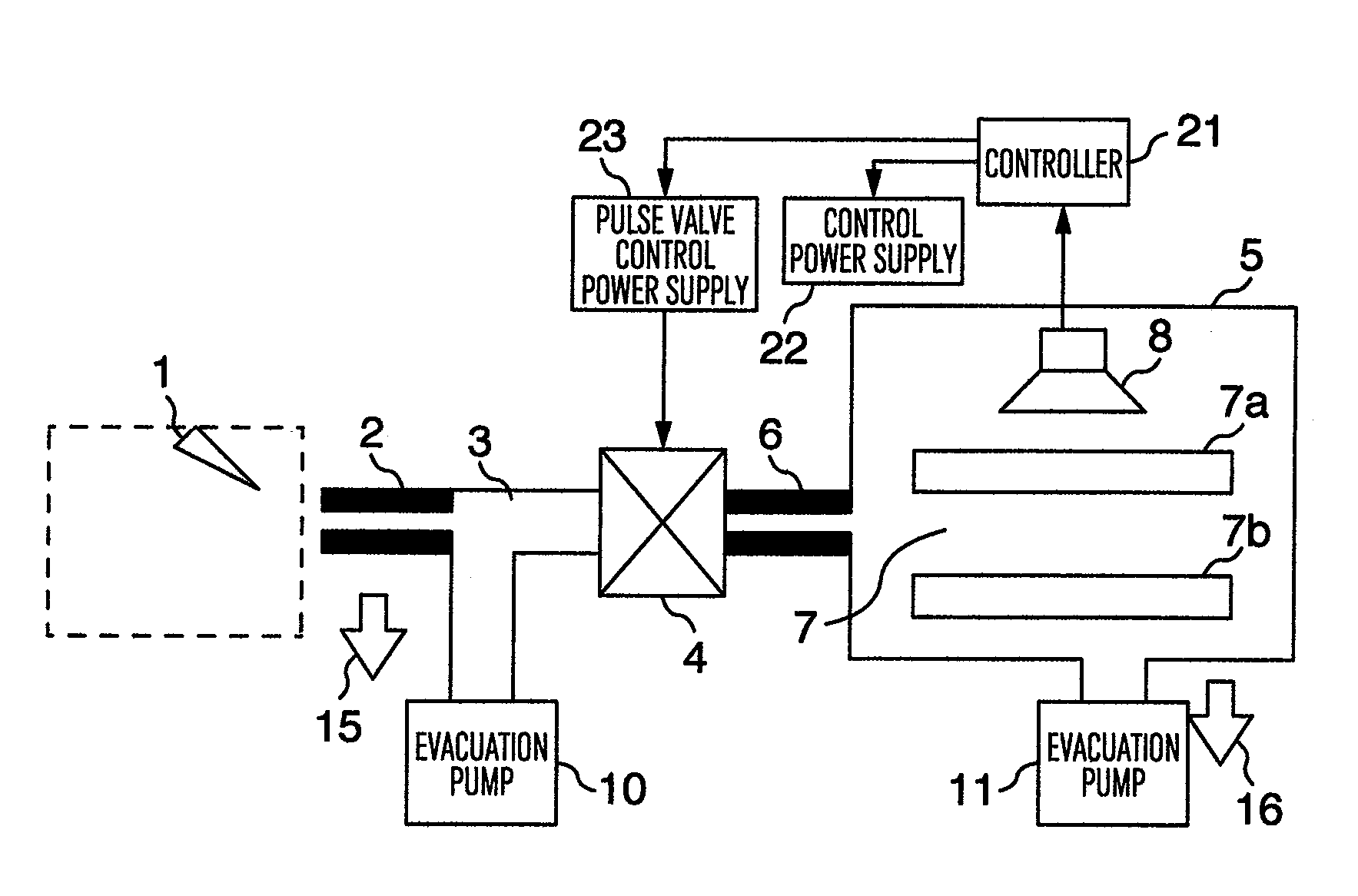

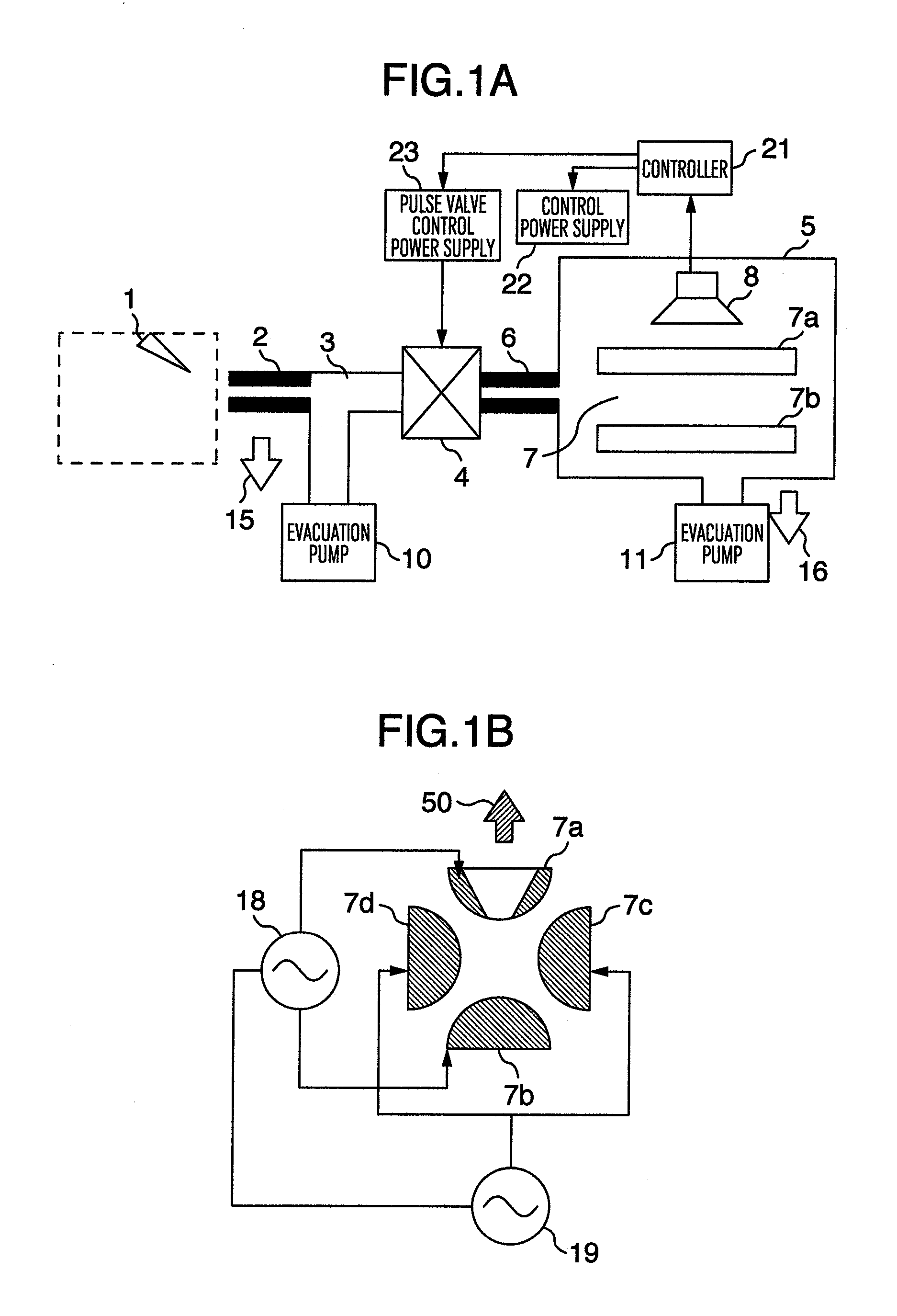

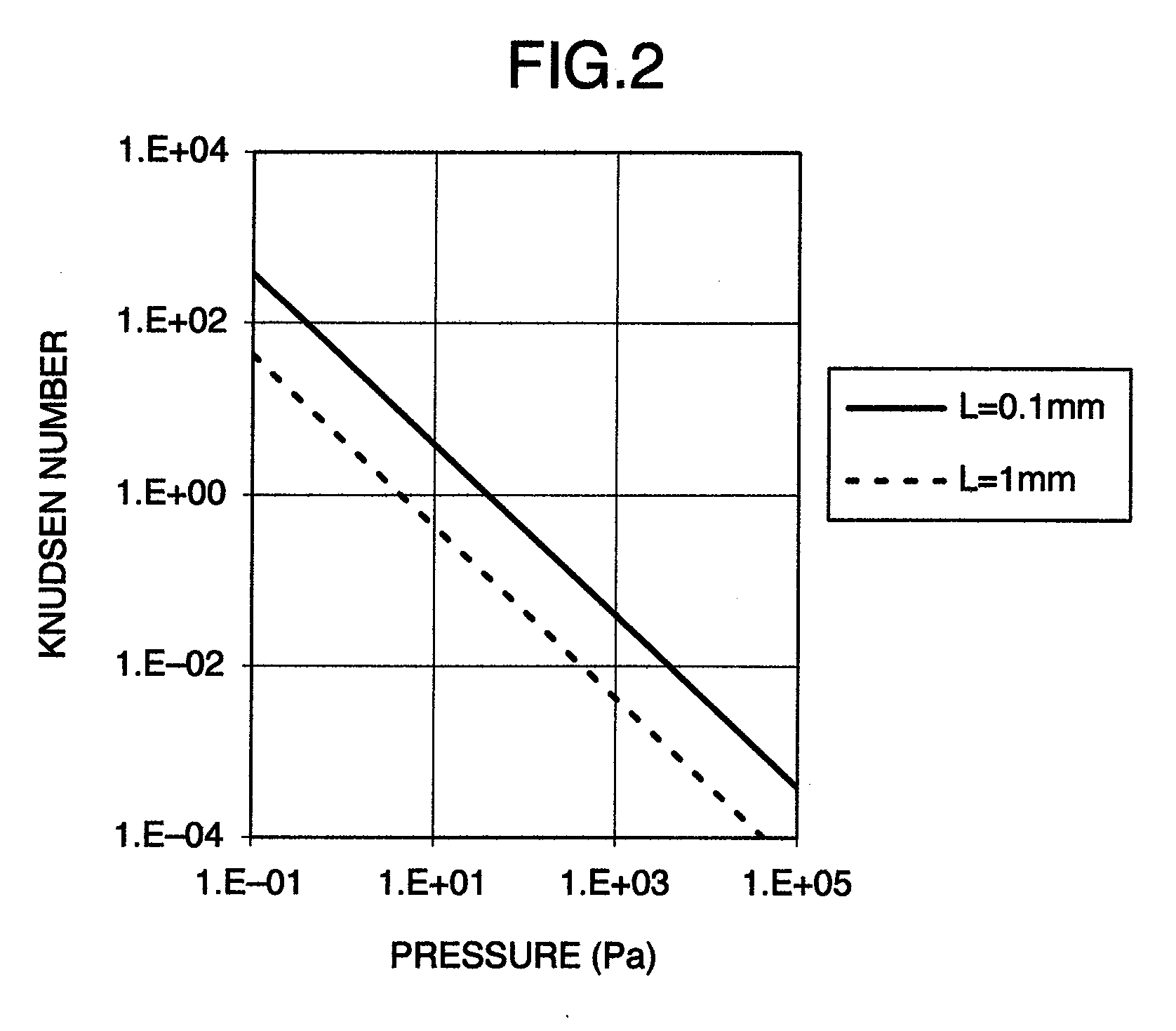

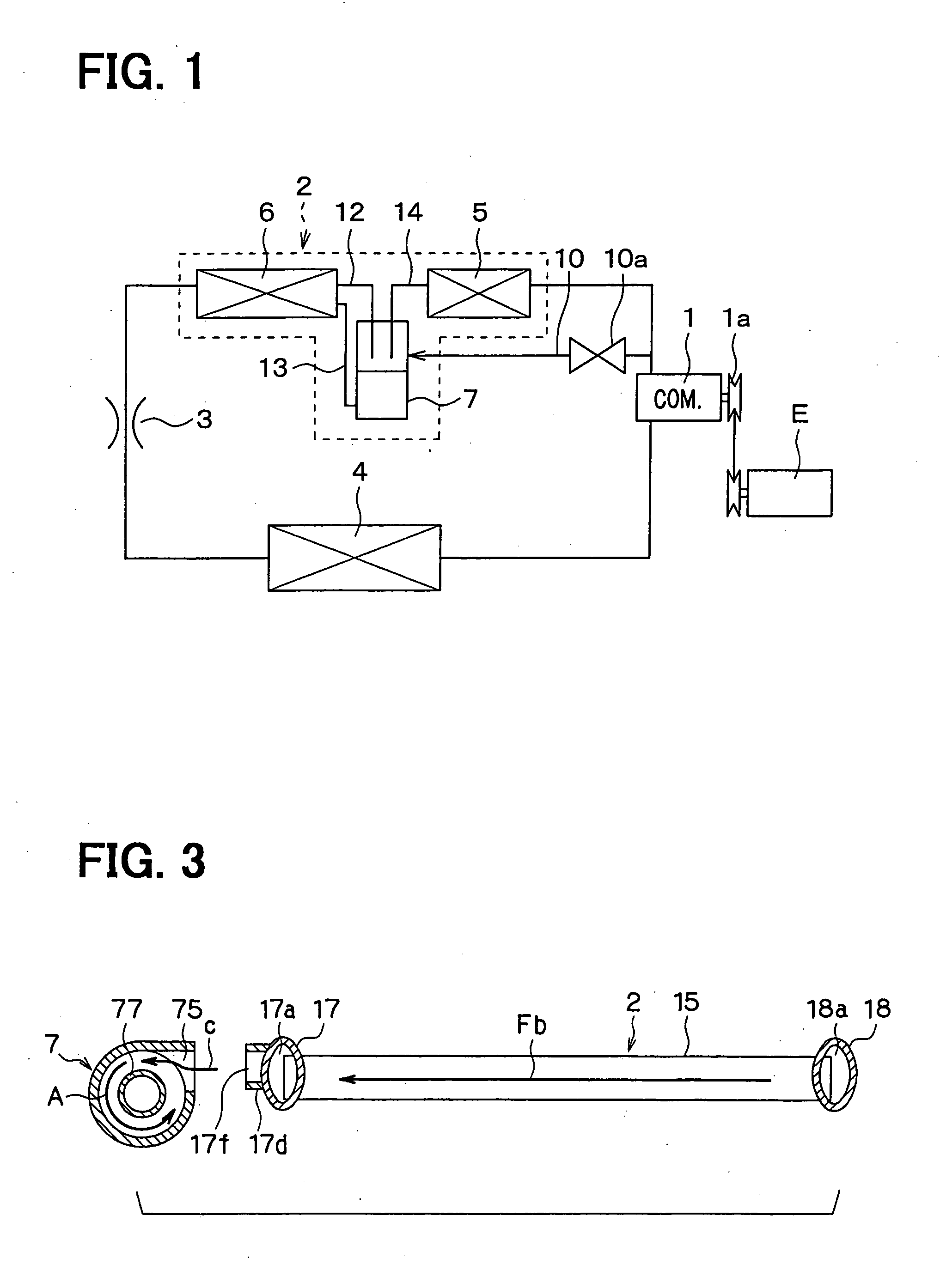

Mass spectrometer

InactiveUS20130056633A1Increase the amount of gasSmall pumping speedSamples introduction/extractionMiniaturised spectrometersMass Spectrometry-Mass SpectrometryHigh pressure

Owner:HASHIMOTO YUICHIRO +3

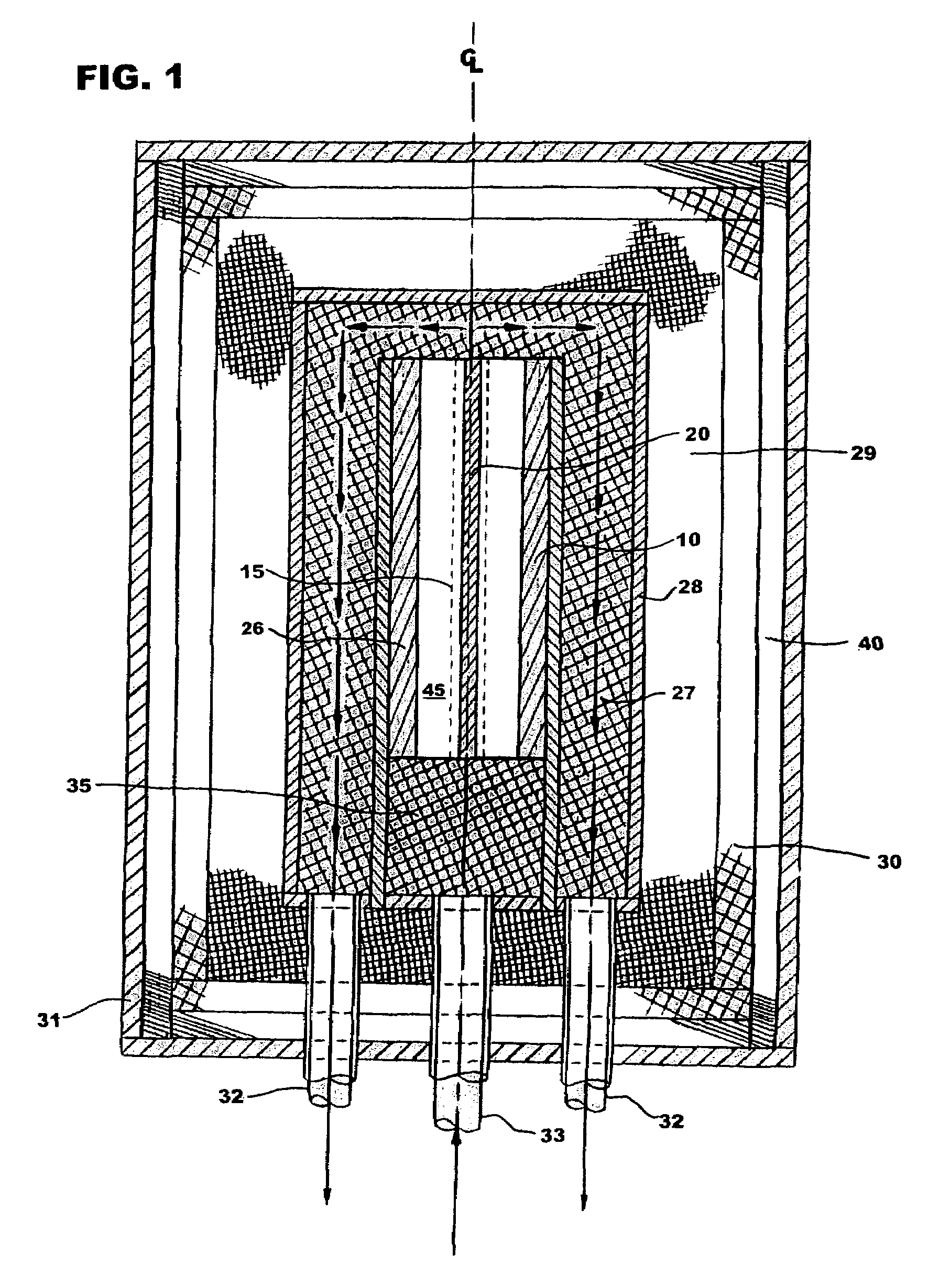

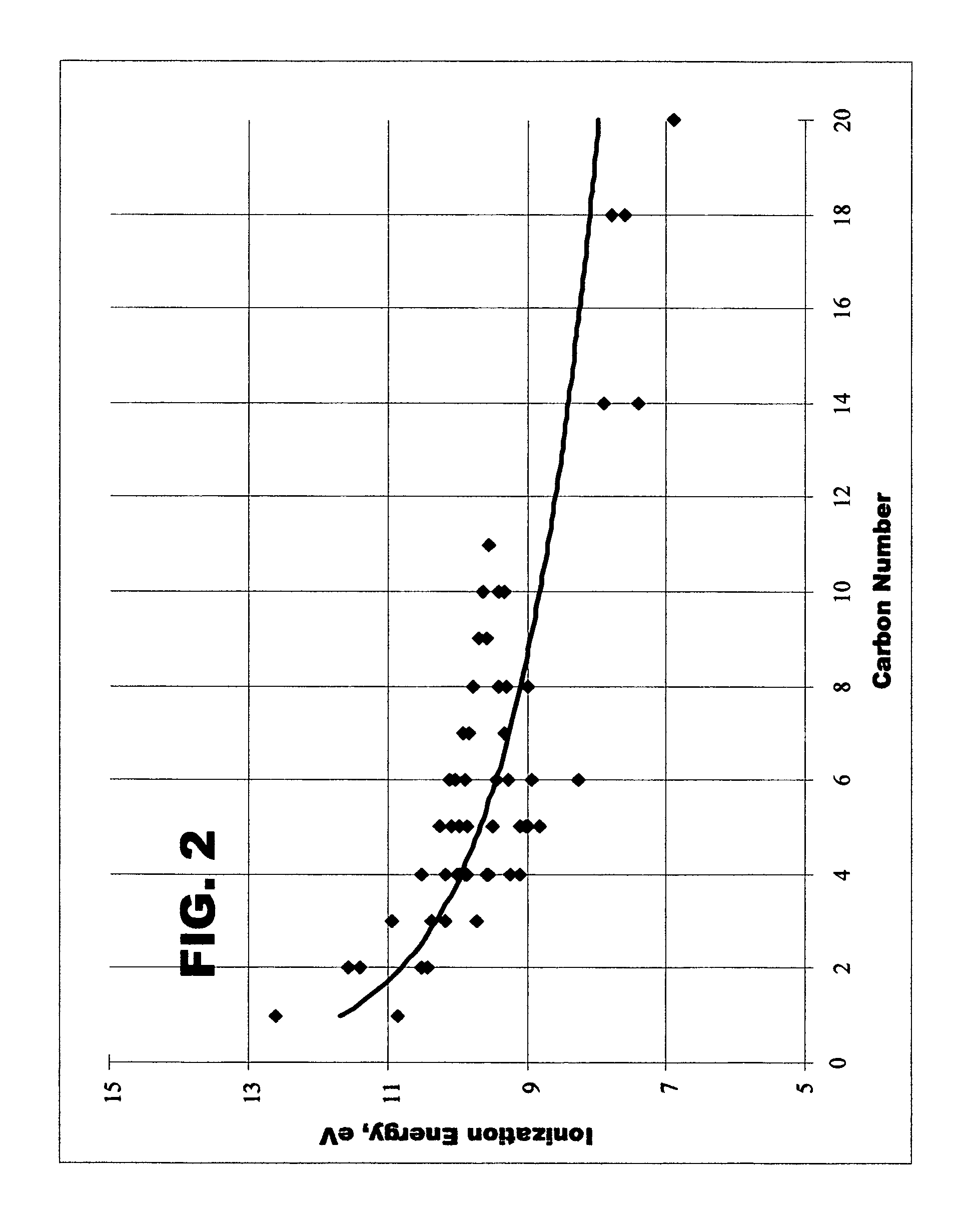

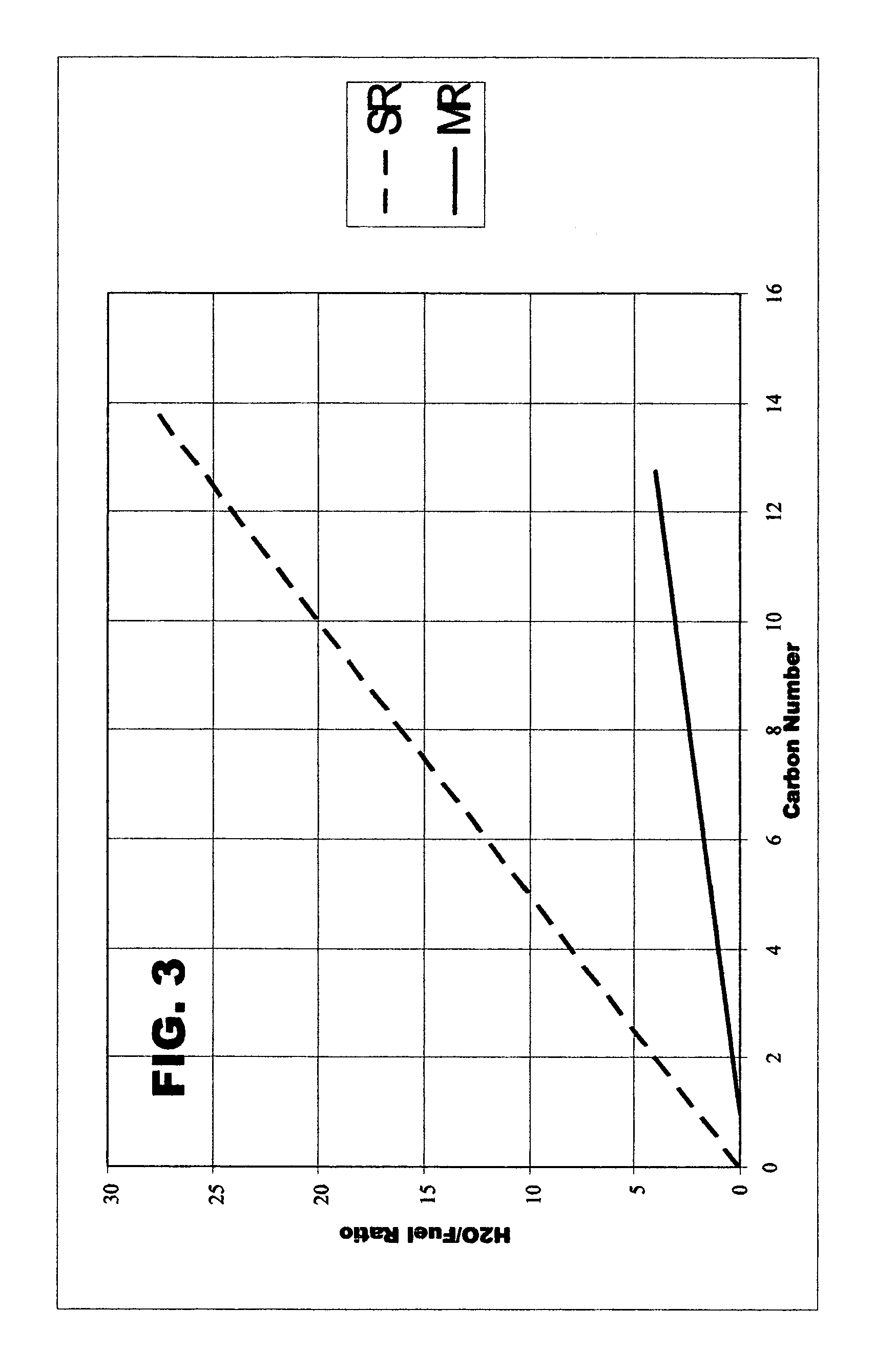

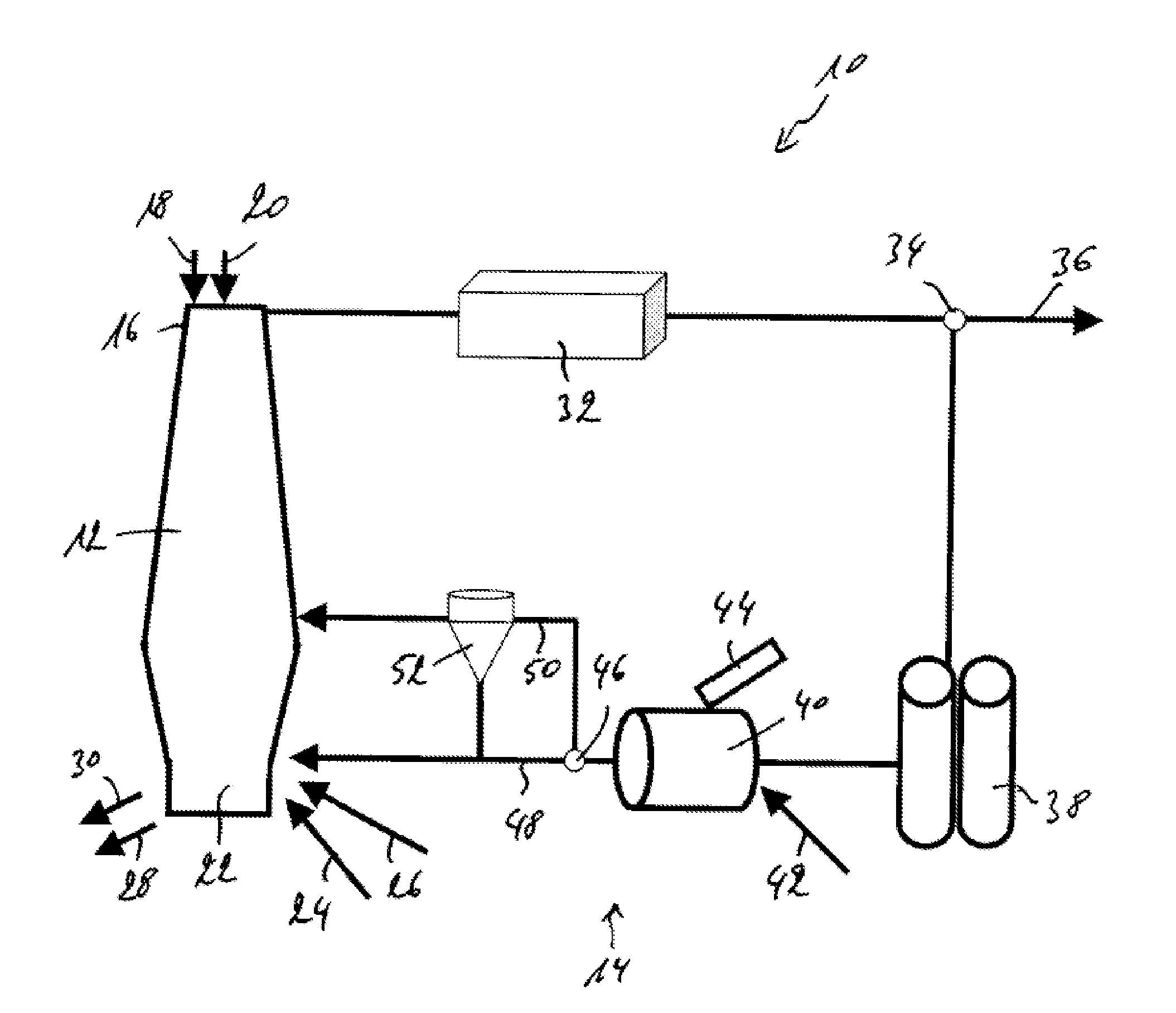

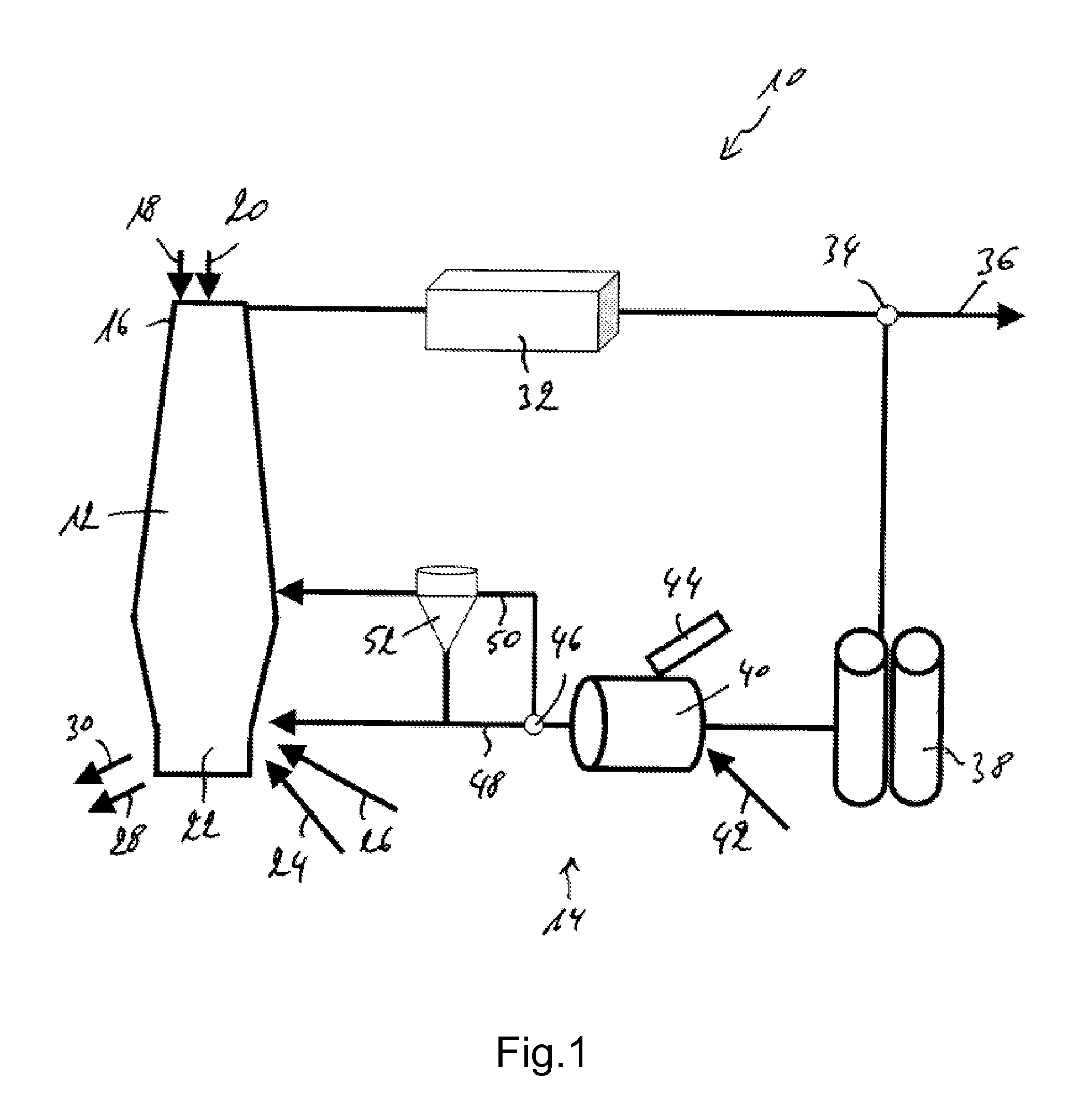

Plasma reformer for hydrogen production from water and fuel

InactiveUS7070634B1Without costReduce consumptionCombination devicesMuffle furnacesCarbon numberHigh energy

A plasma reformer for the chemical reforming of gaseous mixtures of water and hydrocarbon fuels for producing hydrogen. The reformer contains a reaction chamber with outer lateral walls containing emitter electrodes and inner lateral walls containing collector electrodes. The emitter electrodes and collector electrodes form an electric circuit. There are a multiplicity of thin needle-like extrusions on the emitter electrode from which a profusion of high energy electrons are emitted. These high-energy electrons dissociate the hydrocarbon fuel through absorption and ionization emitting low energy electrons in the process. These low energy electrons cause dissociation of water. Thus, dissociation of hydrocarbon fuel acts to initiate dissociation of water. The molar ratio of water to hydrocarbon fuel in the input mixture for reactions, and therefor the production of hydrogen from water, increases with carbon number of the hydrocarbon fuel.

Owner:WANG CHI S

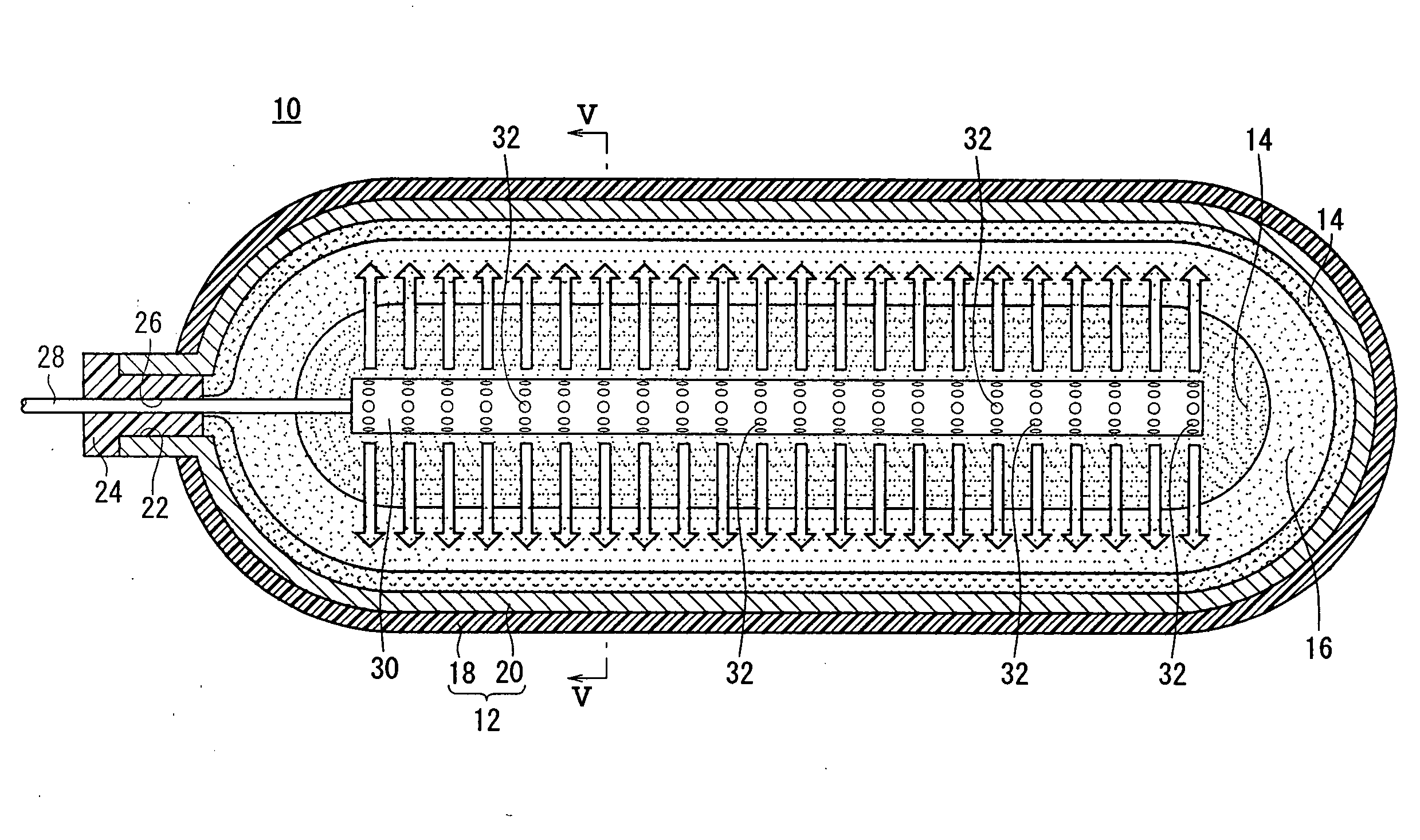

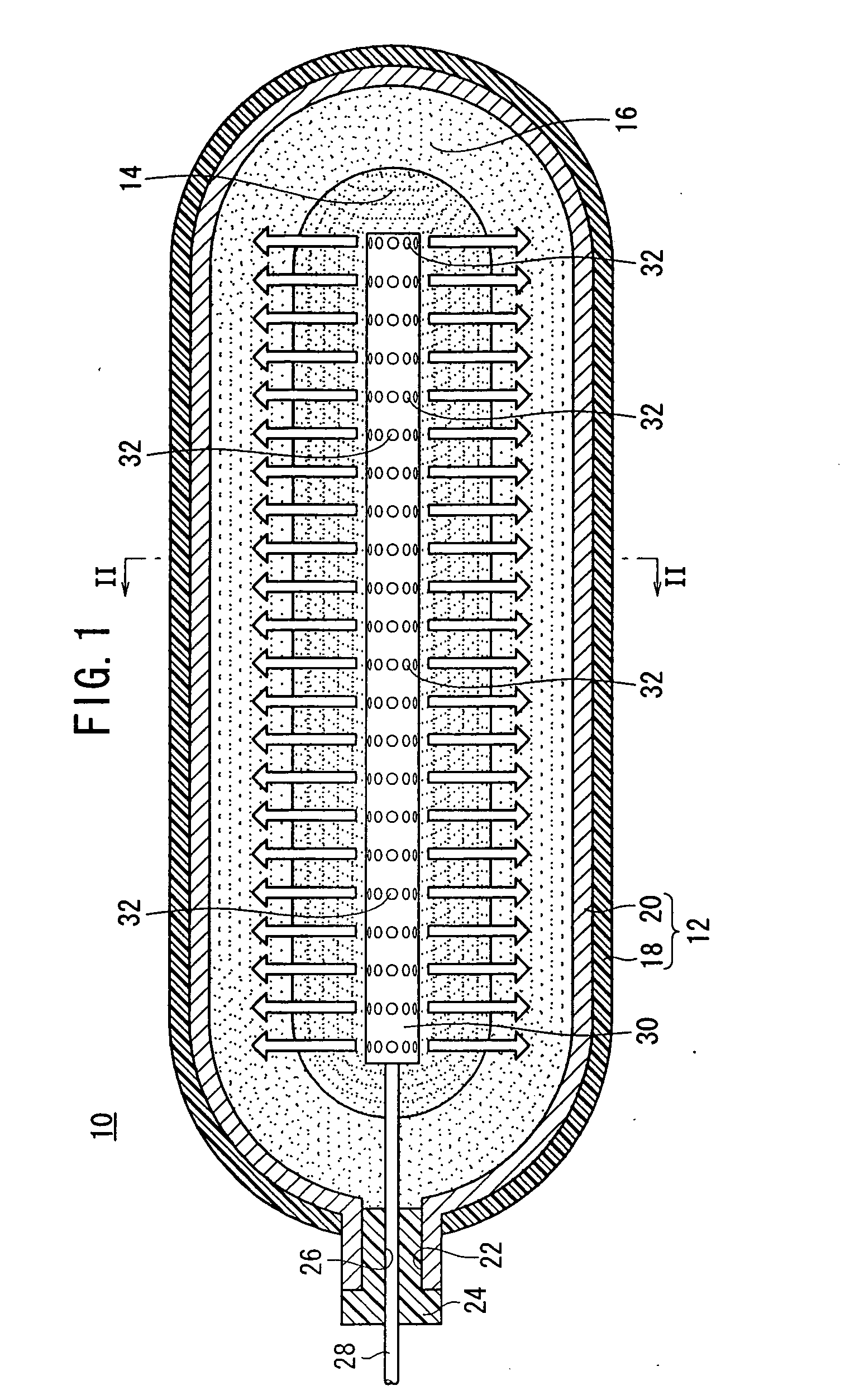

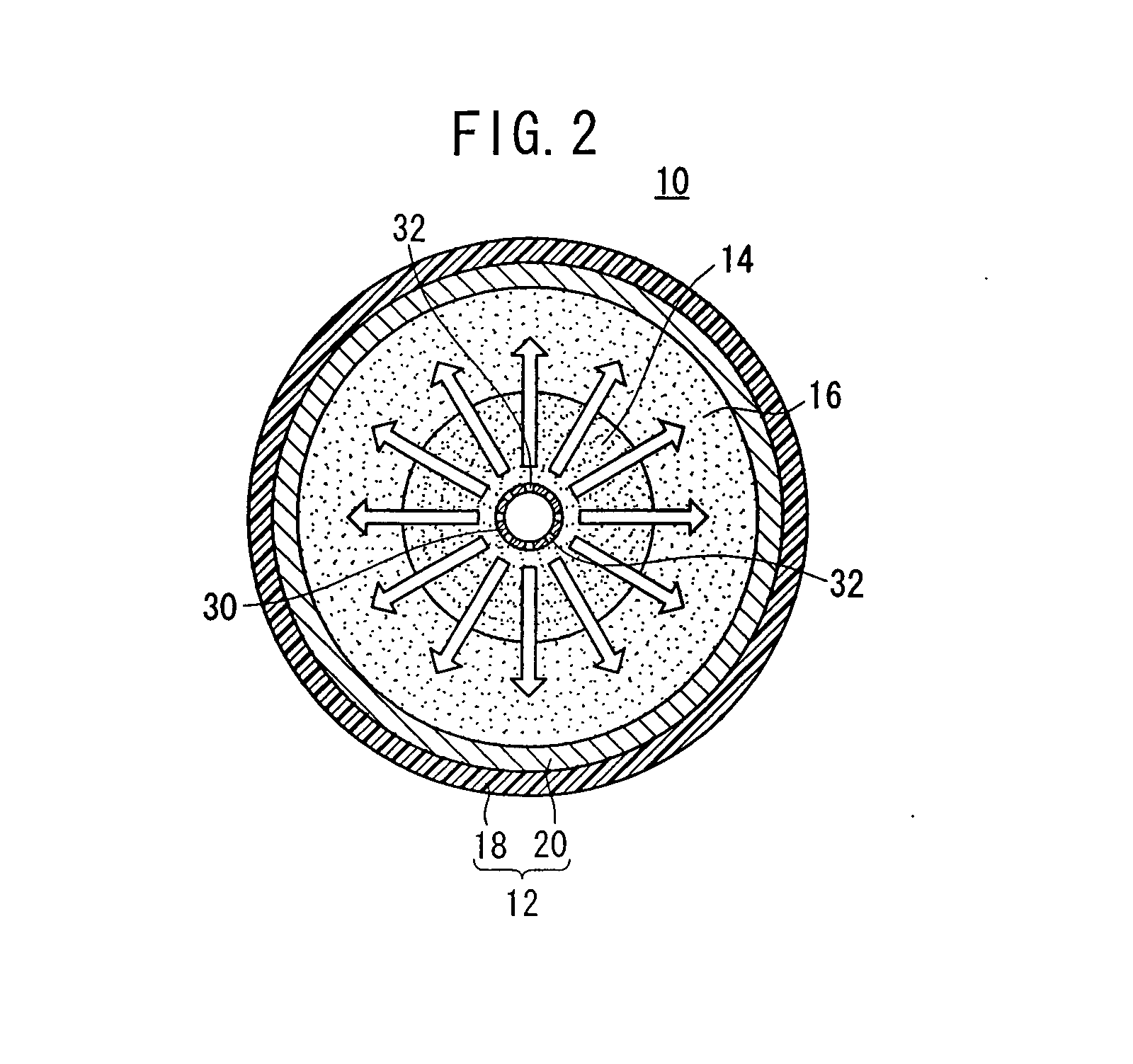

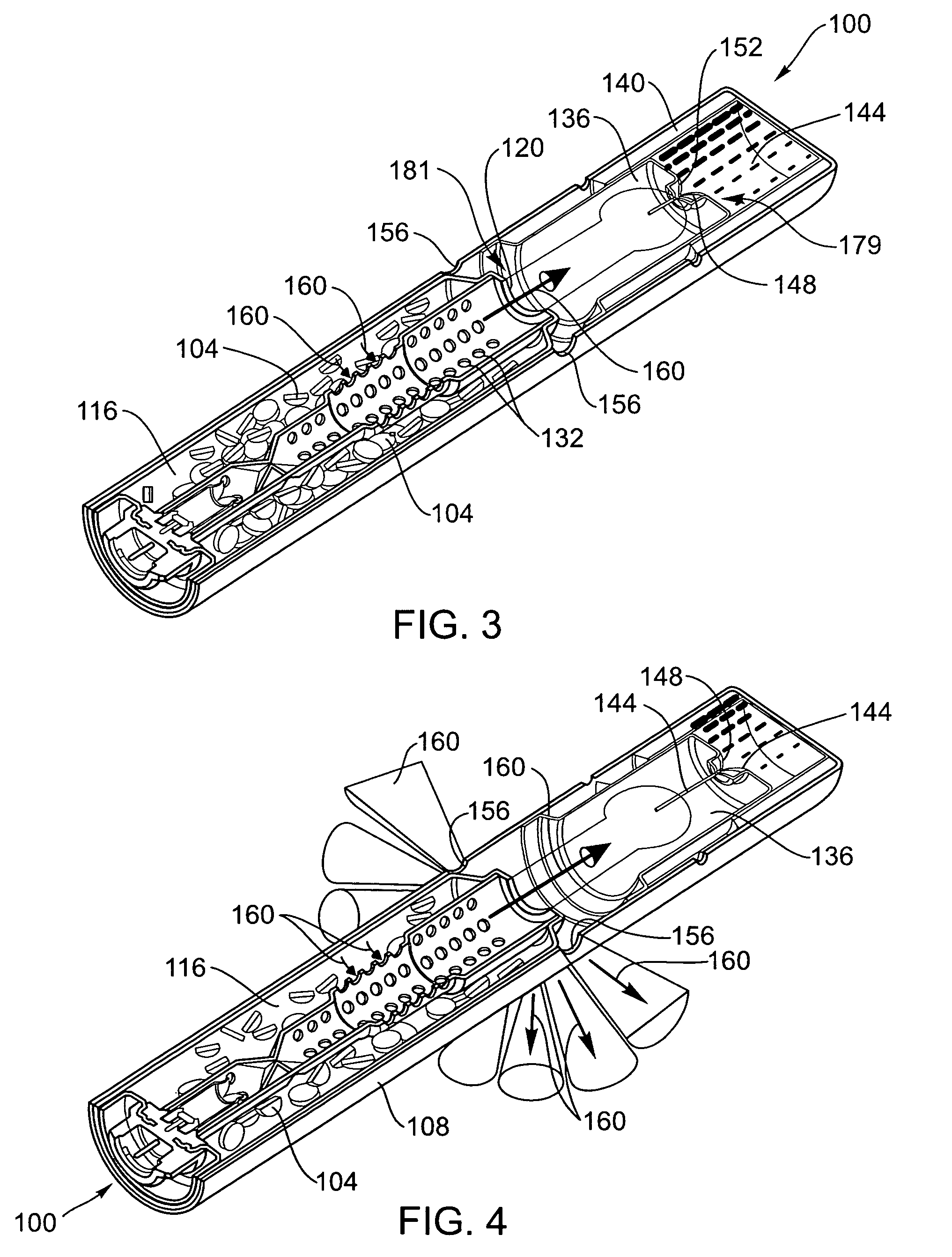

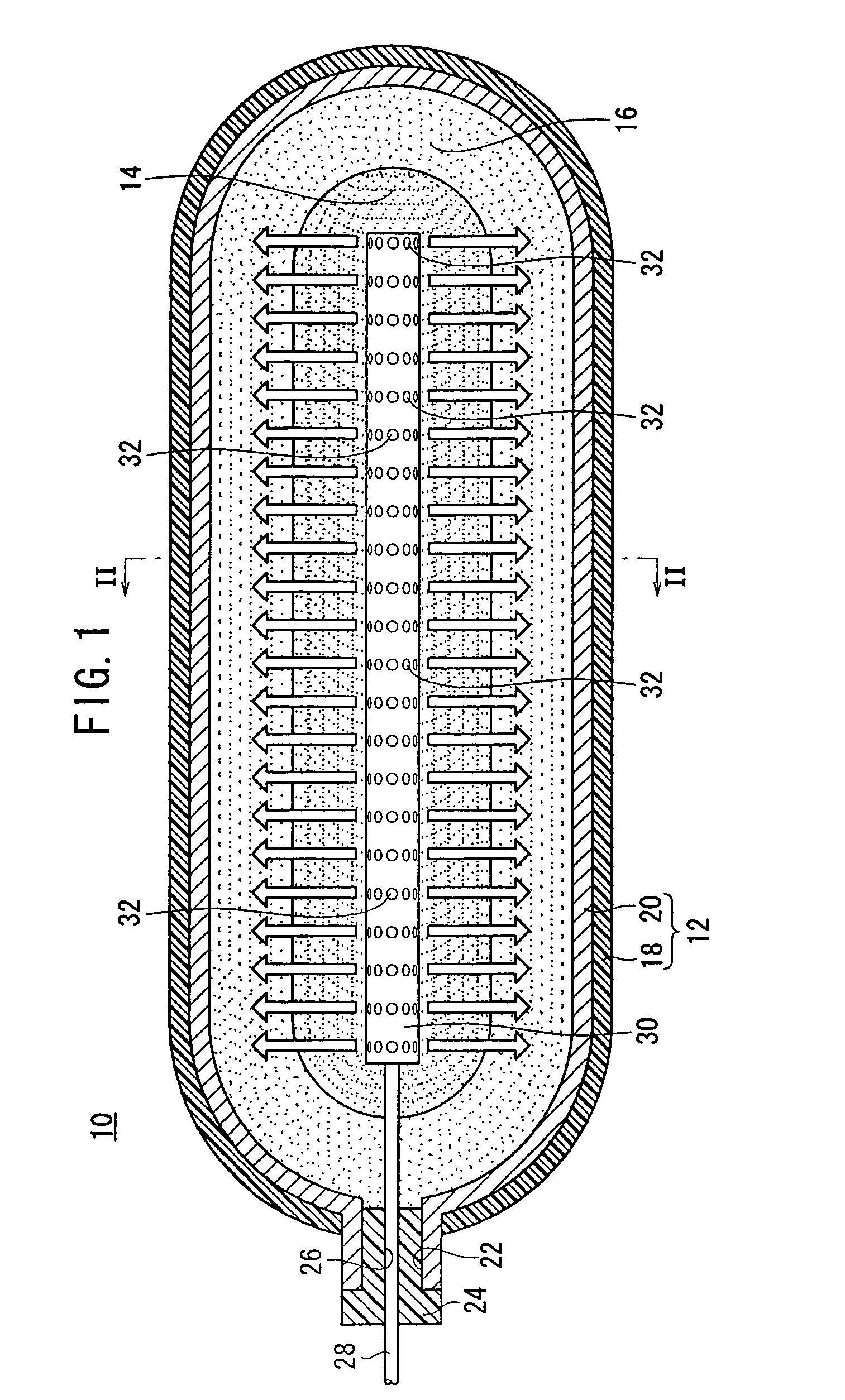

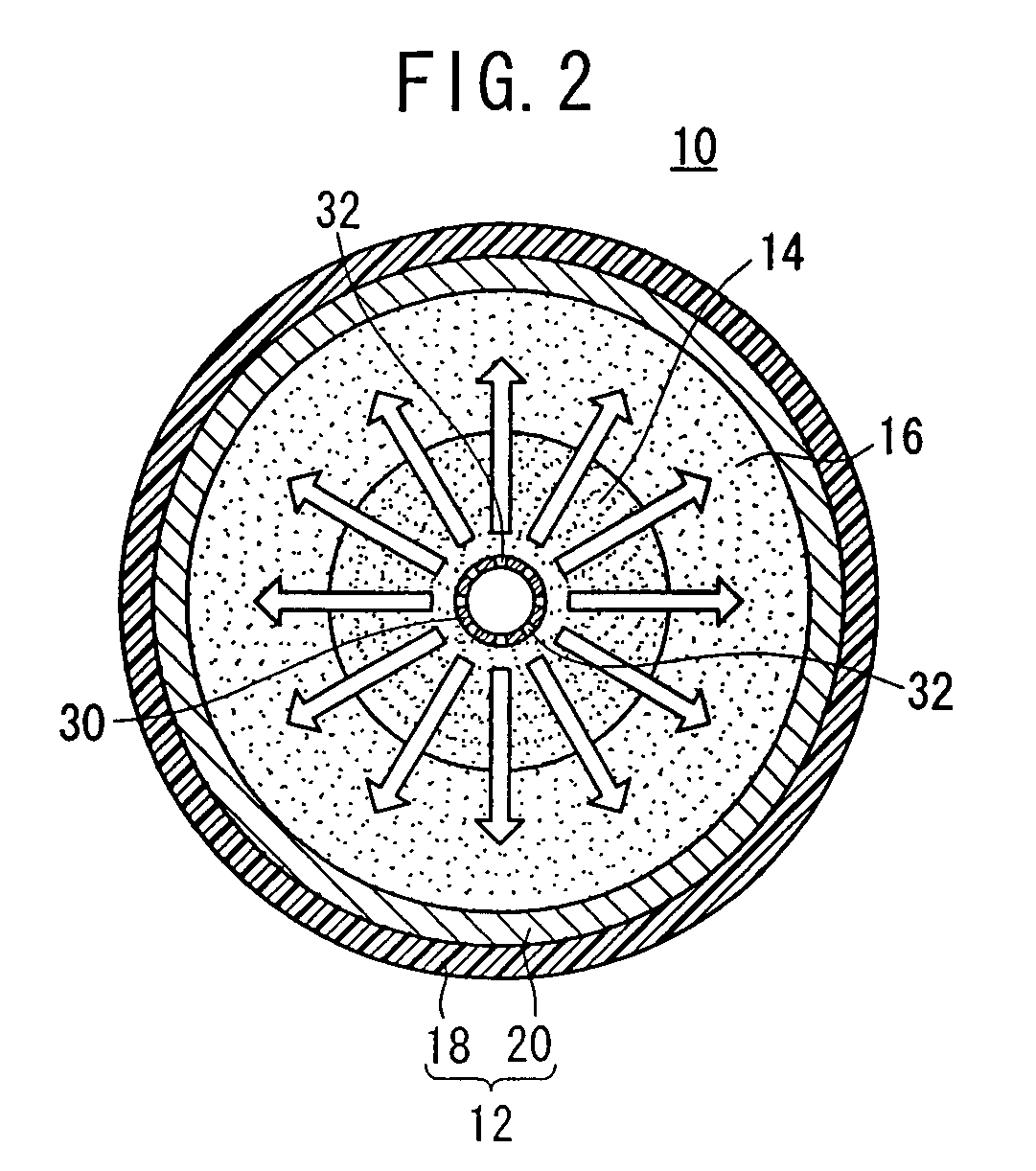

Gas storage container

InactiveUS20080142377A1Inhibit temperature riseSmall sizeReactant parameters controlDomestic cooling apparatusProduct gasHeat storage material

An elongate gas distributing tube, which extends in a longitudinal direction of a container, is accommodated within the container that constitutes a gas storage container. Discharge ports, through which the gas is discharged, are provided only on a side circumferential wall of the gas distributing tube. Therefore, the discharged gas advances while being directed toward the inner side wall of the container. The gas distributing tube is surrounded by a gas absorbing / adsorbing material. On the other hand, the gas absorbing / adsorbing material is surrounded by a mixture, which is prepared by mixing the gas absorbing / adsorbing material with a heat storage material, such that heat is absorbed by the heat storage material contained therein.

Owner:HONDA MOTOR CO LTD

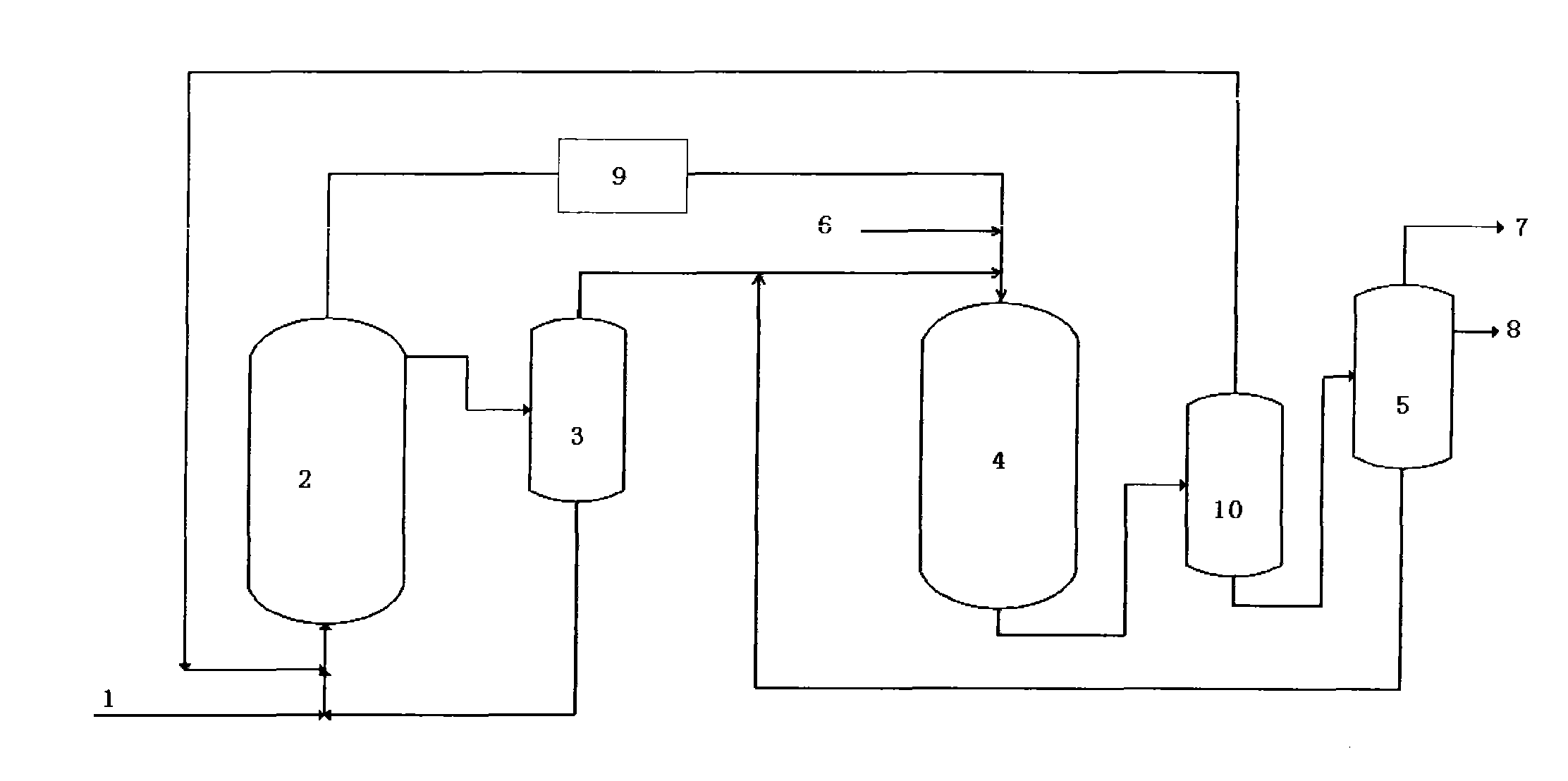

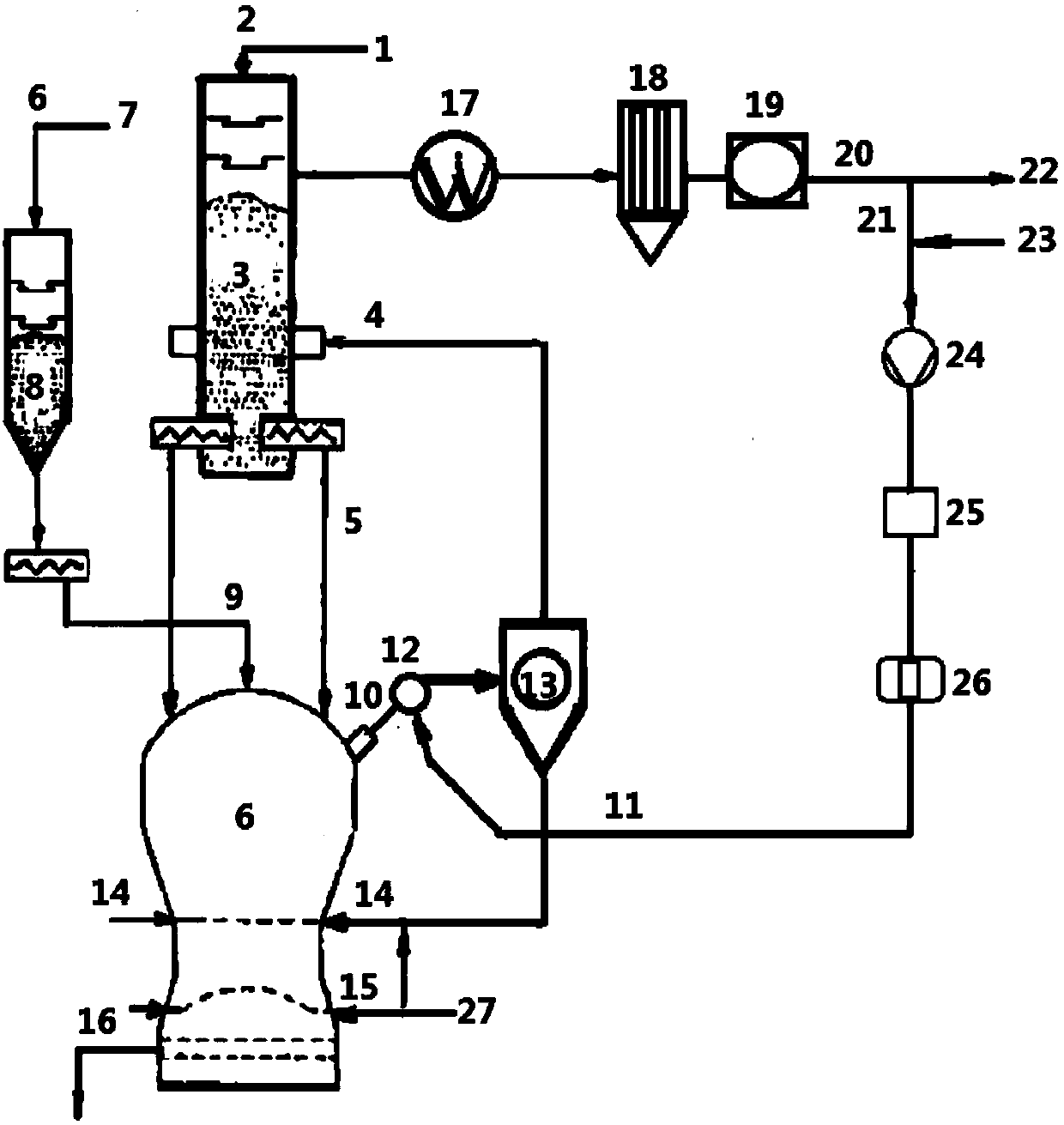

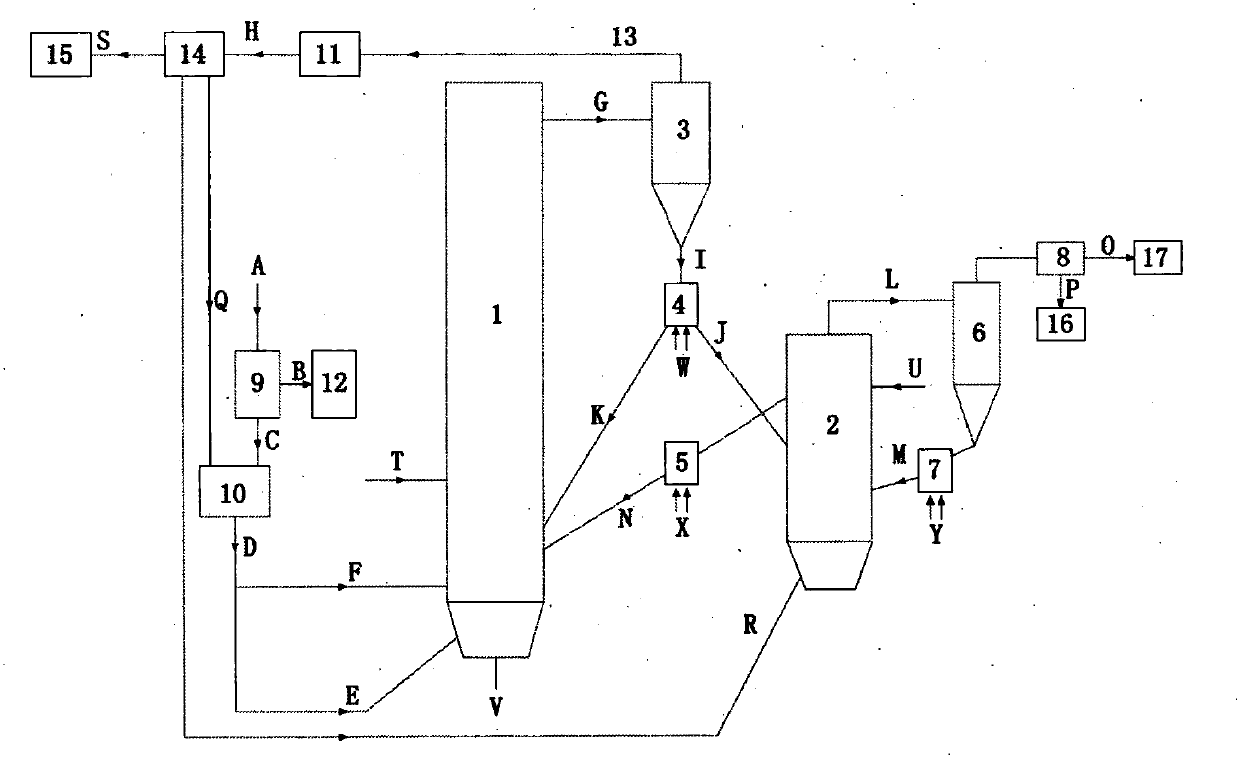

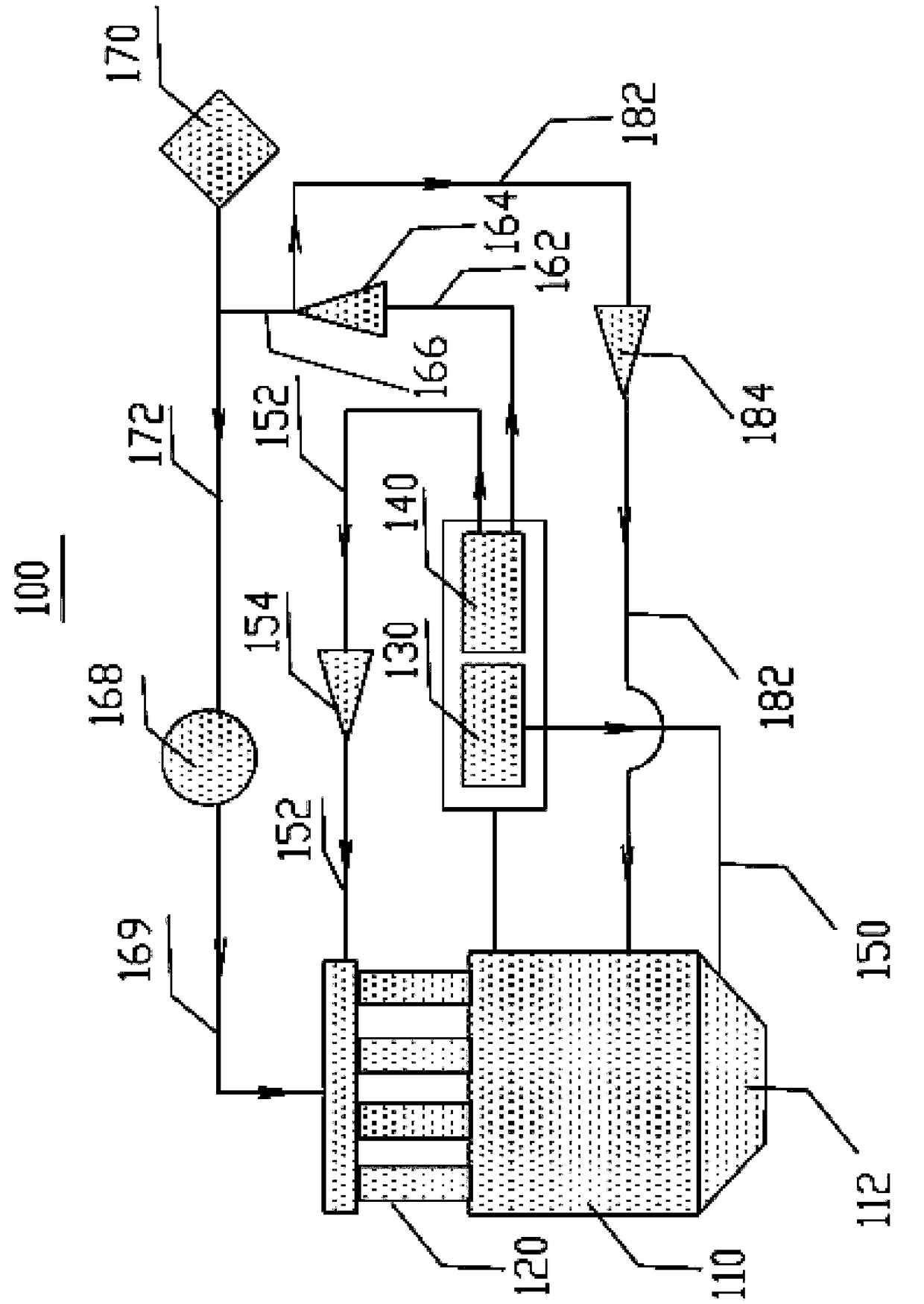

Heavy hydrocarbon hydrogenation combined process

ActiveCN102041084AWide range of processingGood quality light oil productsTreatment with hydrotreatment processesGas phaseHydrogenation reaction

The invention discloses a heavy hydrocarbon hydrogenation combined process which comprises: (a) heavy hydrocarbon raw material and a gas-phase outflow substance from the fixed bed hydrogenation reaction are mixed and enter a boiling bed hydrogenation reactor; (b) the gas-phase outflow substance from the boiling bed hydrogenation reaction in the step (a) is subjected to hydrogen sulfide removal and then used for the fixed bed hydrogenation reaction of the gas-phase outflow substance of the boiling bed hydrogenation reaction in the step (a); and (c) the gas-phase outflow substance of the fixed bed hydrogenation reaction in the step (b) is directly used for the boiling bed hydrogenation reaction process in the step (a), and the liquid-phase outflow substance of the fixed bed hydrogenation reaction in the step (b) is fractionated to obtain a gasoline fraction, a diesel fraction and unconverted tail oil. In the combined process, the boiling bed technique and the fixed bed technique are combined by fully considering the technical characteristics of the boiling bed and the fixed bed as well as the features of the reaction materials, thereby providing a new operation mode which is flexible, efficient and energy-saving; and on the premise of ensuring the smooth operation of the device, the reaction heat is fully utilized, high product quality is provided, and the operational process can be flexibly adjusted according to the requirements of refineries.

Owner:CHINA PETROLEUM & CHEM CORP +1

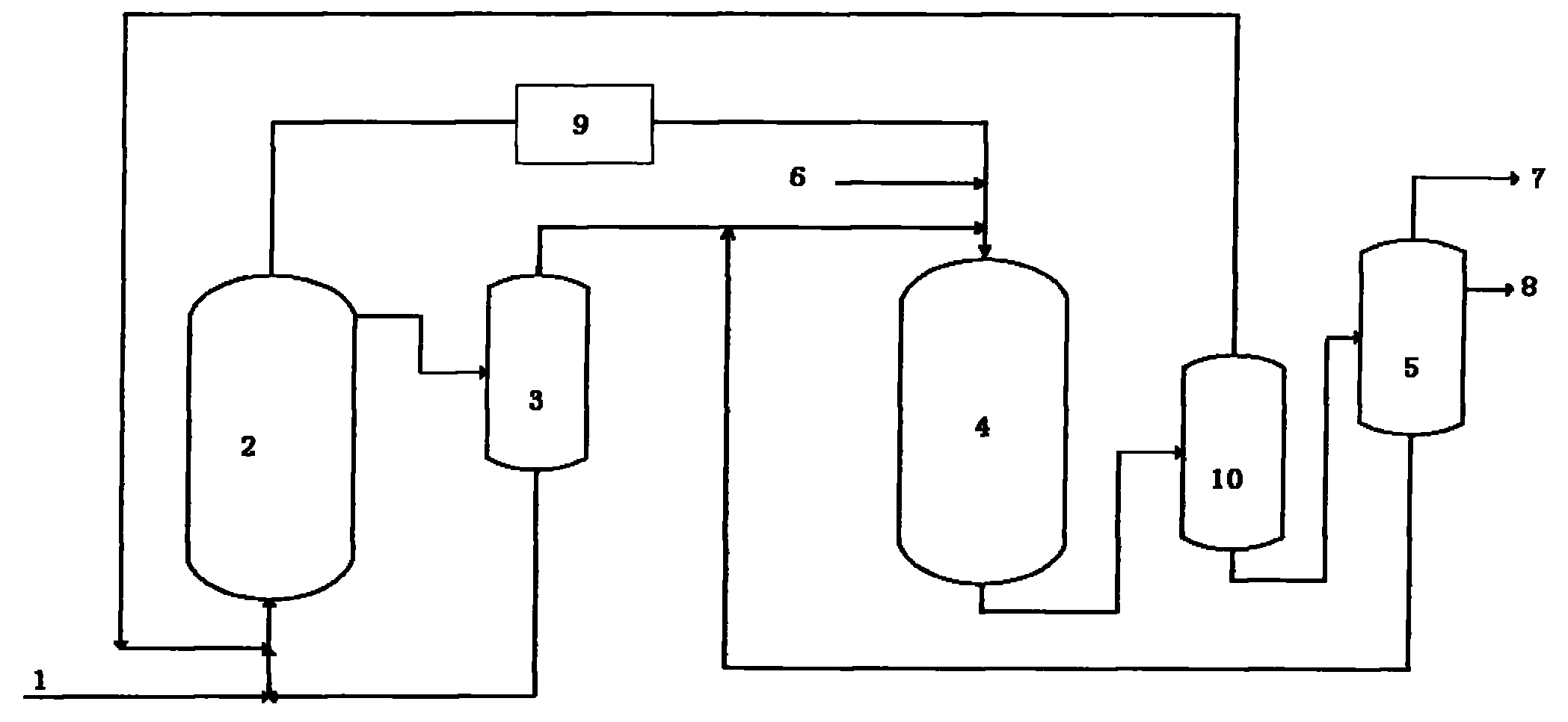

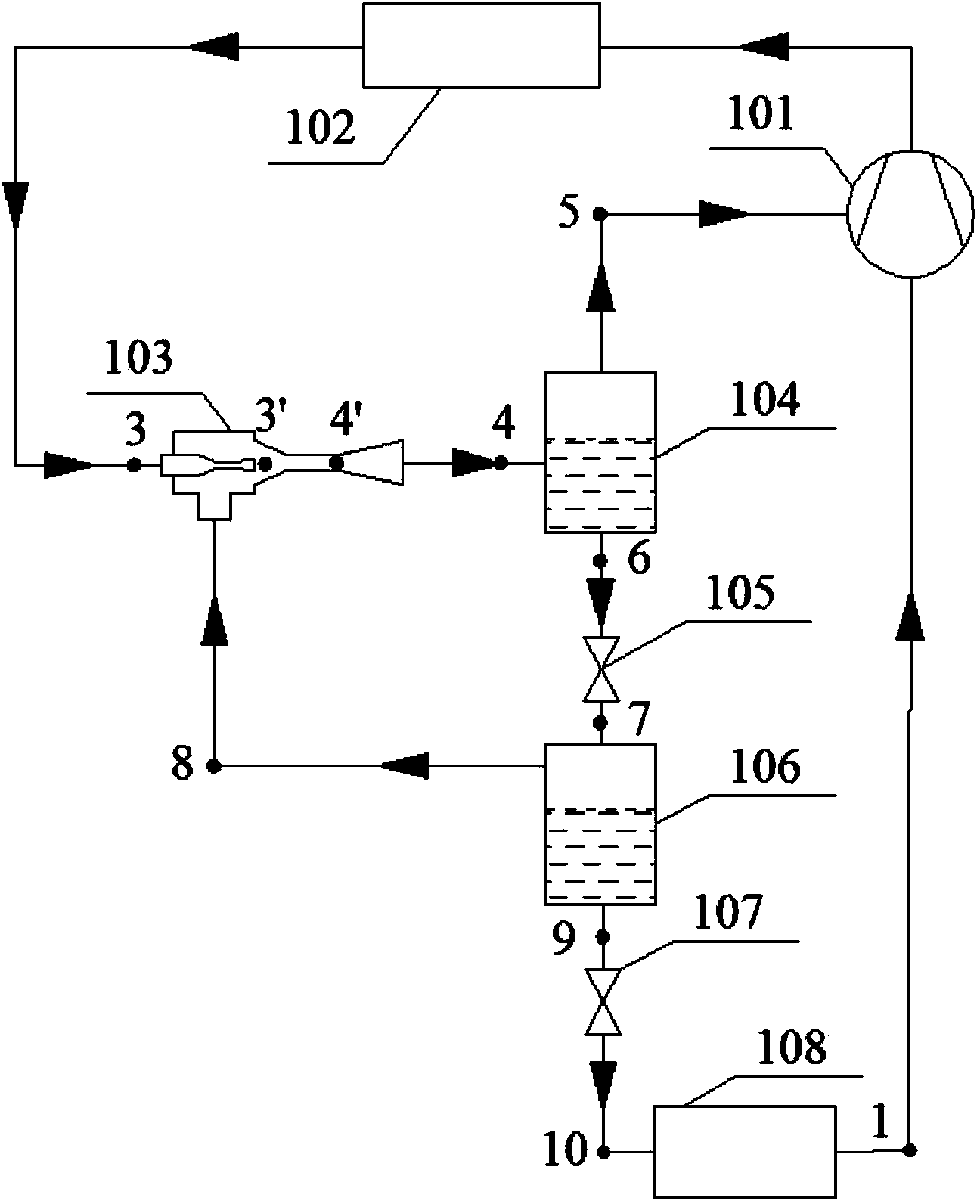

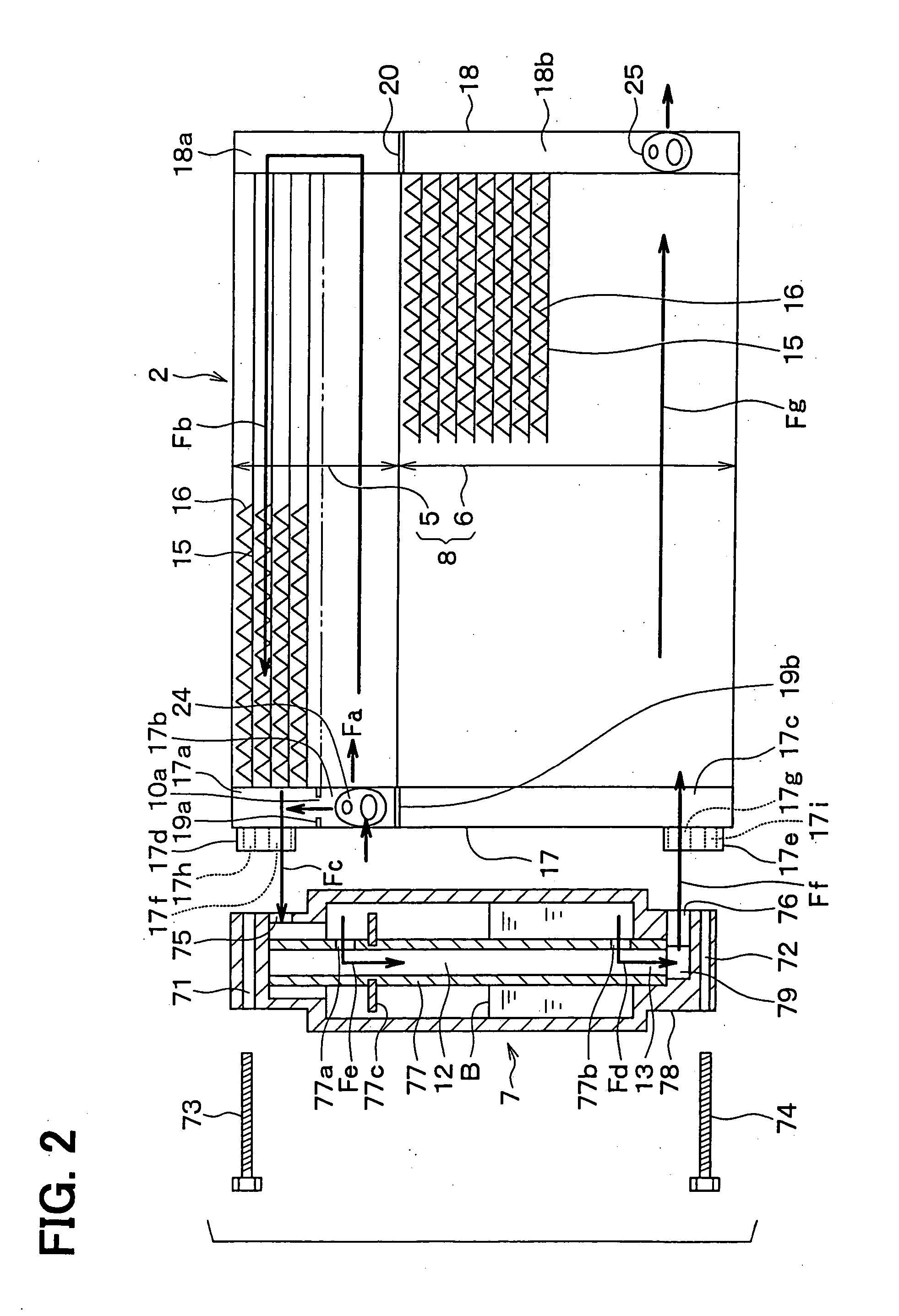

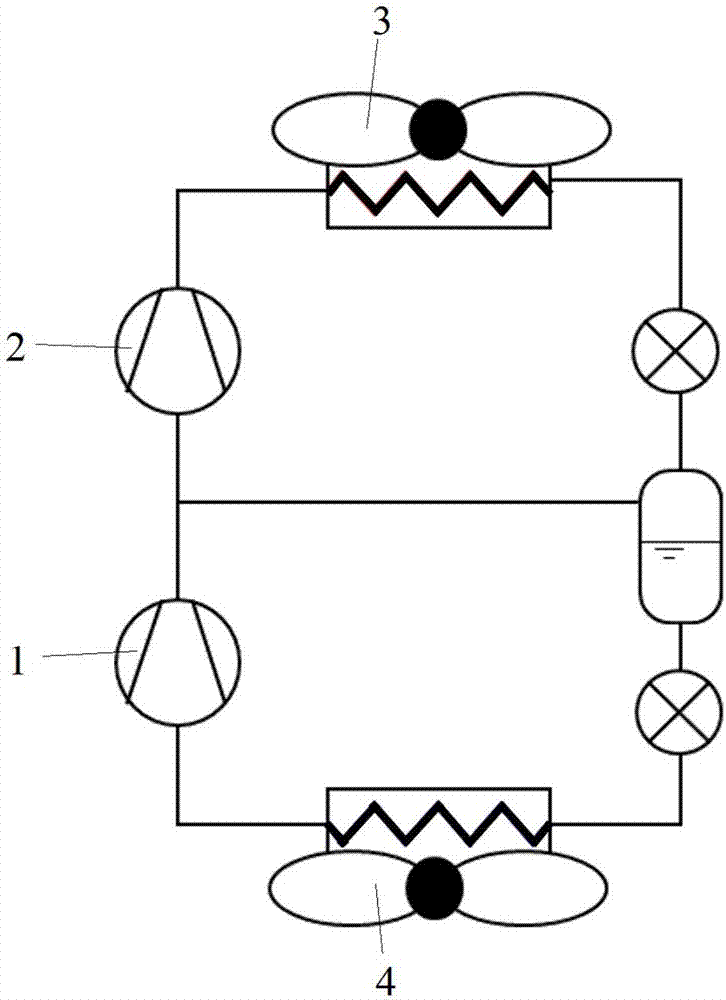

Gas-supplying enthalpy-increasing type heat pump circulating system with ejector for heat pump device

ActiveCN103776189AImprove efficiencyReduce energy consumptionCompression machinesFluid circulation arrangementIntermediate stageSpray nozzle

The invention relates to a gas-supplying enthalpy-increasing type heat pump circulating system with an ejector for a heat pump device. An outlet of a compressor is connected with an inlet of a condenser, an outlet of the condenser is connected with a nozzle inlet of the ejector, an injected refrigerating agent inlet of the ejector is connected with a gas phase outlet of a second-stage flash evaporator, and an outlet of the ejector is connected with an inlet of a first-stage flash evaporator; a saturated gaseous refrigerating agent outlet of the first-stage flash evaporator is connected with an intermediate gas-supplying port of the compressor, and a saturated liquid refrigerating agent outlet of the first-stage flash evaporator is connected with an inlet of the second-stage flash evaporator after passing through a first-stage expansion valve or a capillary tube; a saturated gaseous refrigerating agent outlet of the second-stage flash evaporator is connected with the injected refrigerating agent inlet of the ejector, and a saturated liquid refrigerating agent outlet of the second-stage flash evaporator is connected with an inlet of an evaporator after passing through a second-stage expansion valve or a capillary tube; an outlet of the evaporator is connected with an air suction port of the compressor. Through the adoption of the ejector and the auxiliary flash evaporators, the recycling of expansion work during the throttling process is realized, and meanwhile the intermediate-stage gas-supplying amount of the compressor is increased, thus the heating performance of the heat pump system is improved.

Owner:XI AN JIAOTONG UNIV

Mass spectrometer

ActiveUS20110253891A1Improve efficiencySimple configurationSamples introduction/extractionMiniaturised spectrometersMass Spectrometry-Mass SpectrometryMass analyzer

A mass spectrometer having a resolution improved by introducing ions into a mass spectrometry part with a high efficiency is provided with a small-sized, simple configuration. The mass spectrometer includes an opening / closing mechanism provided between a sample introducing piping part for introducing a sample into the mass spectrometry part and the mass spectrometry part to conduct gas introduction intermittently and control sample passage. The mass spectrometer further includes a pump mechanism to evacuate a high pressure side of the sample introducing piping part, that is, an opposite side of the opening / closing mechanism to the mass spectrometry part to have a pressure in a range of 100 to 10,000 Pa.

Owner:HITACHI HIGH-TECH CORP

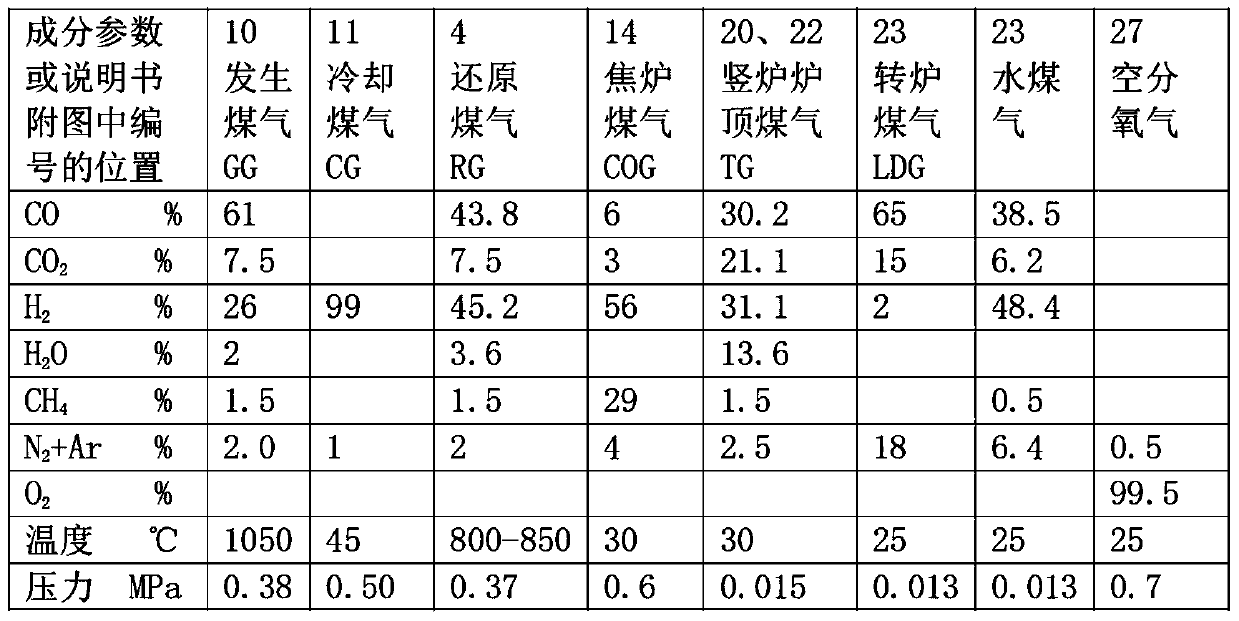

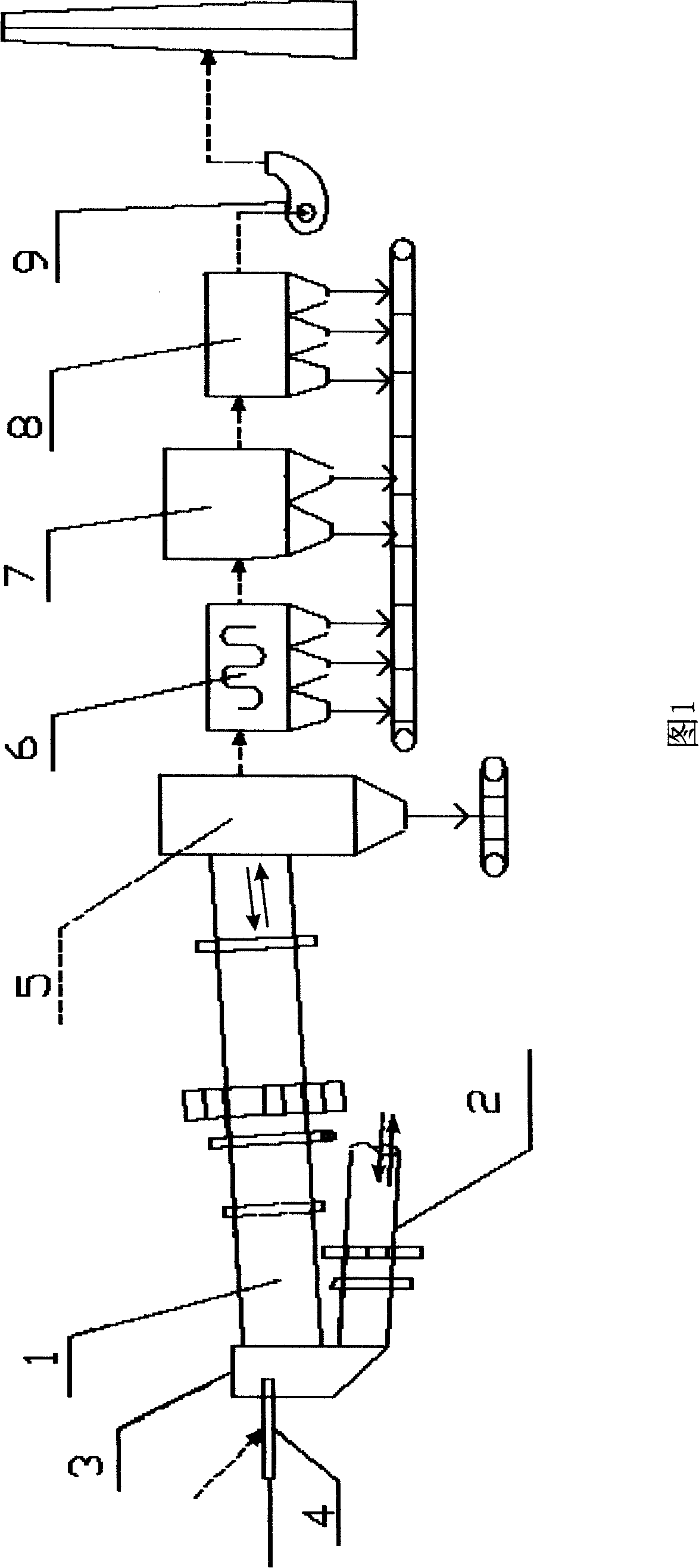

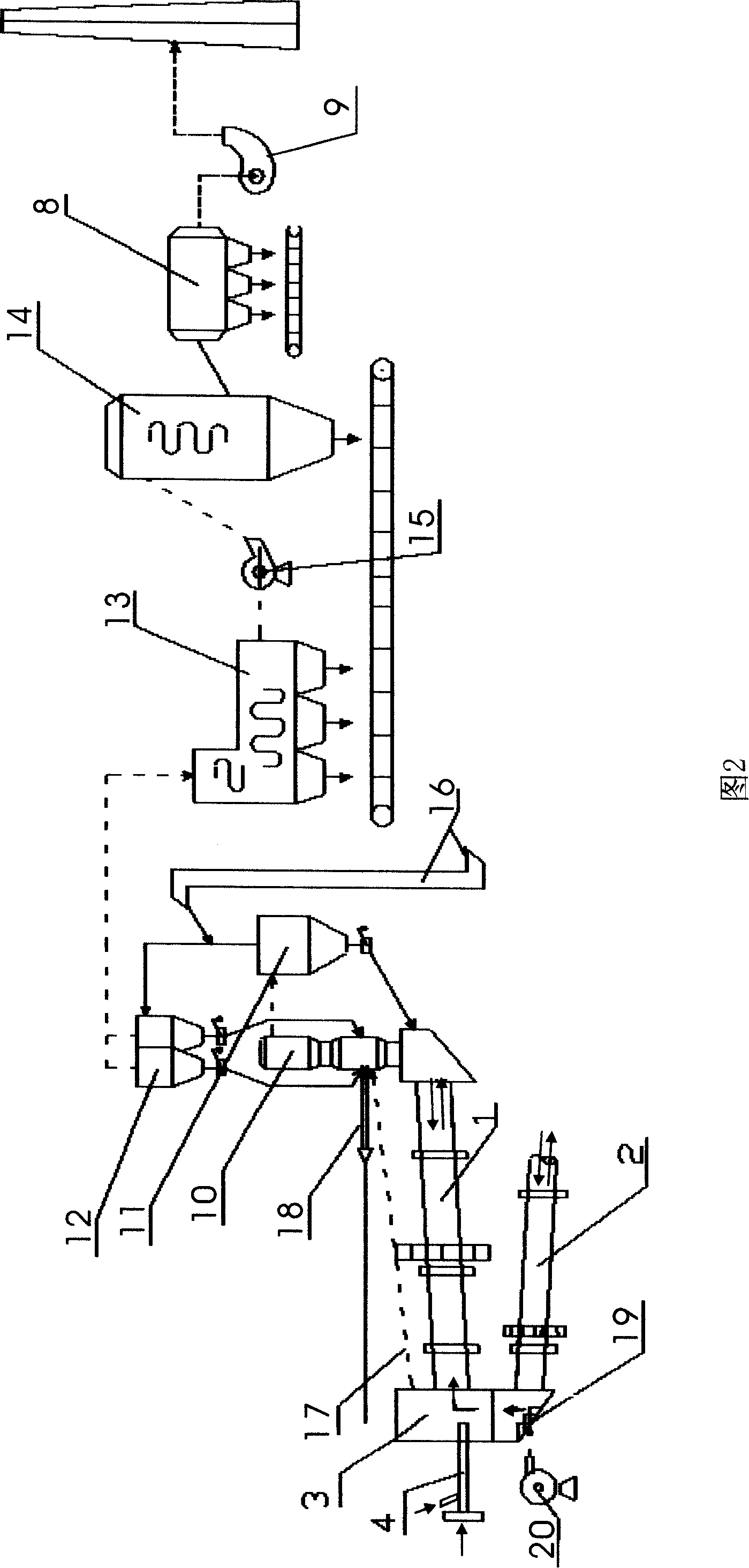

BAOSHEREX (Baosteel-Shenghua high efficiency smelting reduction) ironmaking process for smelting molten iron by two-step method

ActiveCN104212930AIncrease the amount of gasIncreased capacity to produce molten ironProcess efficiency improvementShaft furnaceThermal energySlag

The invention provides a BAOSHEREX (Baosteel-Shenghua high efficiency smelting reduction) ironmaking process for smelting molten iron by a two-step method, which belongs to the technical field of ironmaking. The steps of the process comprise vertical furnace type prereduction; and additional arrangement of a melt gasification furnace outside a vertical prereduction furnace: oxygen gas and pulverized coal are sprayed from oxygen gas tuyeres which are uniformly distributed in the middle part of a furnace cylinder of the melt gasification furnace, and generated heat meets the requirements of generating molten iron and furnace slag. In the BAOSHEREX ironmaking process, coal accounts for 80-85 weight percent of fuel, only oxygen gas containing 500-600m<3> / t of iron and carbon coke accounting for 15-20 weight percent of the fuel are used for producing high-quality hot molten iron at a temperature of 1350-1480 DEG C, pelletized water granulated slag and high-quality coal gas. The BAOSHEREX ironmaking process has the advantages of high yield, high efficiency, low energy consumption, low emission and low cost.

Owner:钢研晟华科技股份有限公司

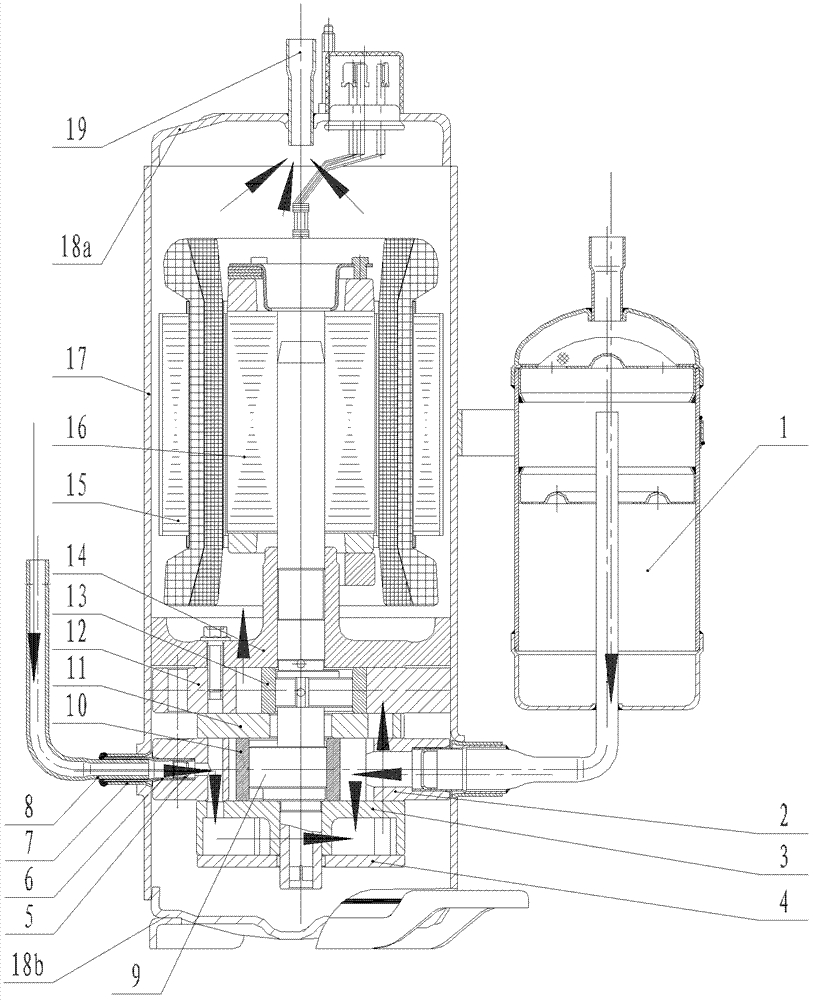

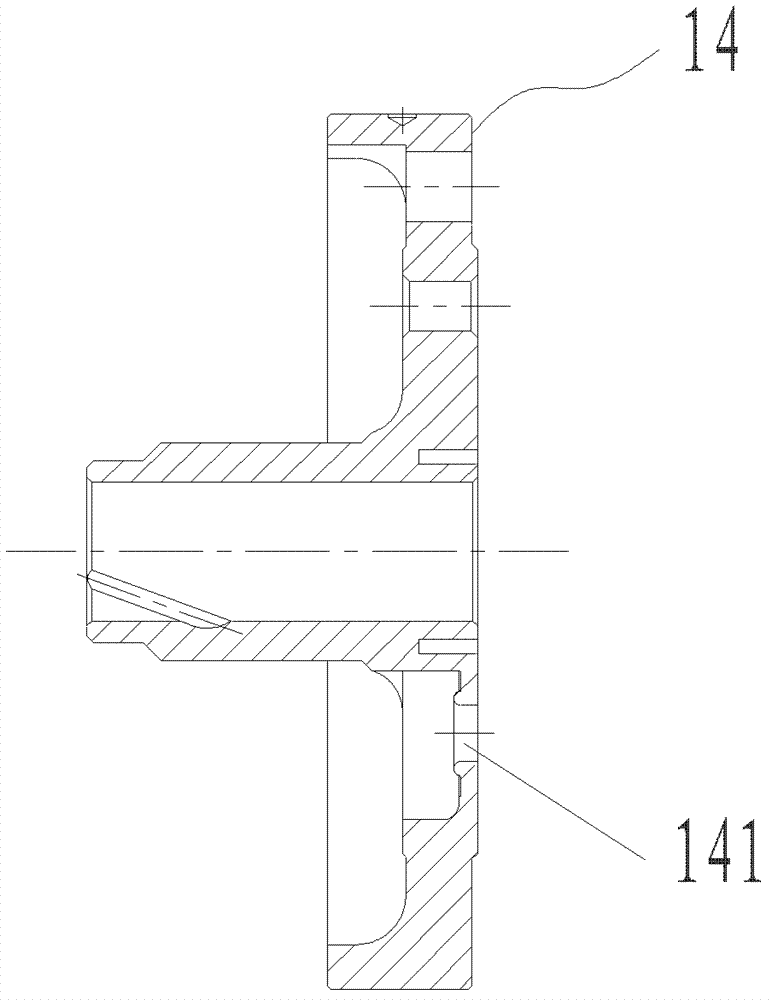

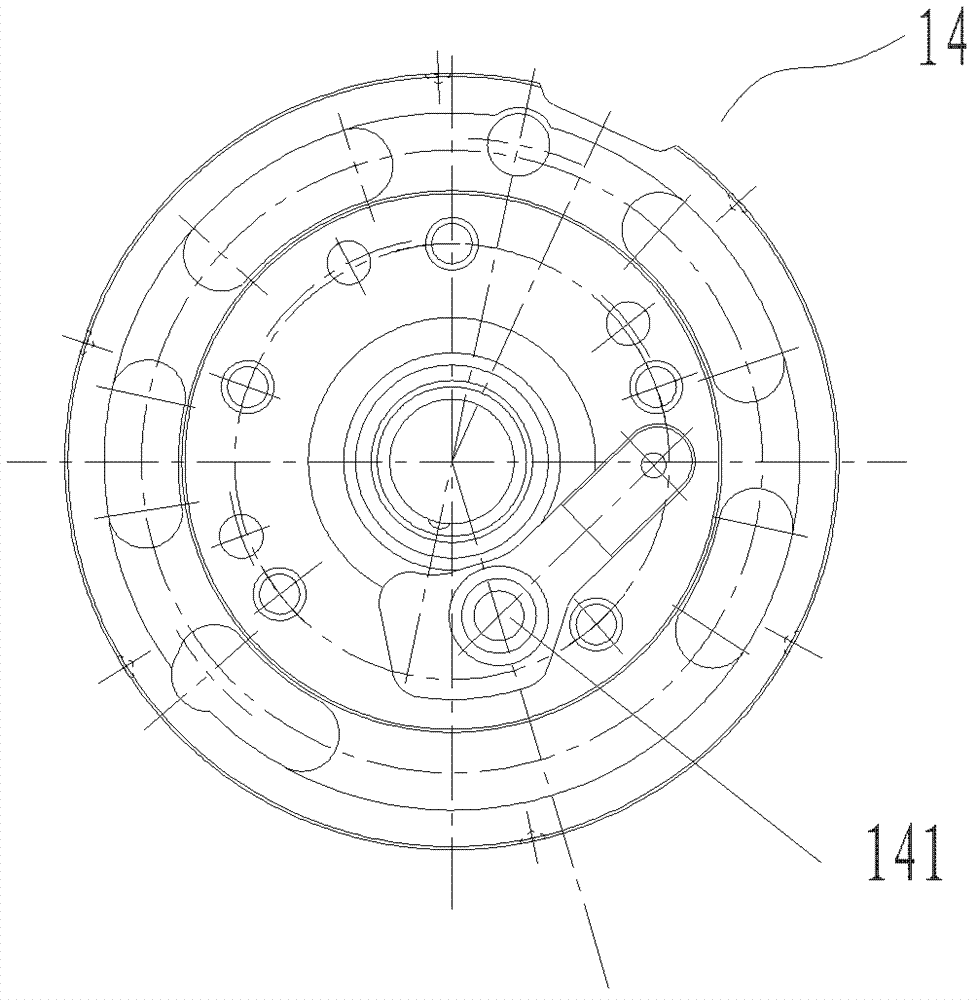

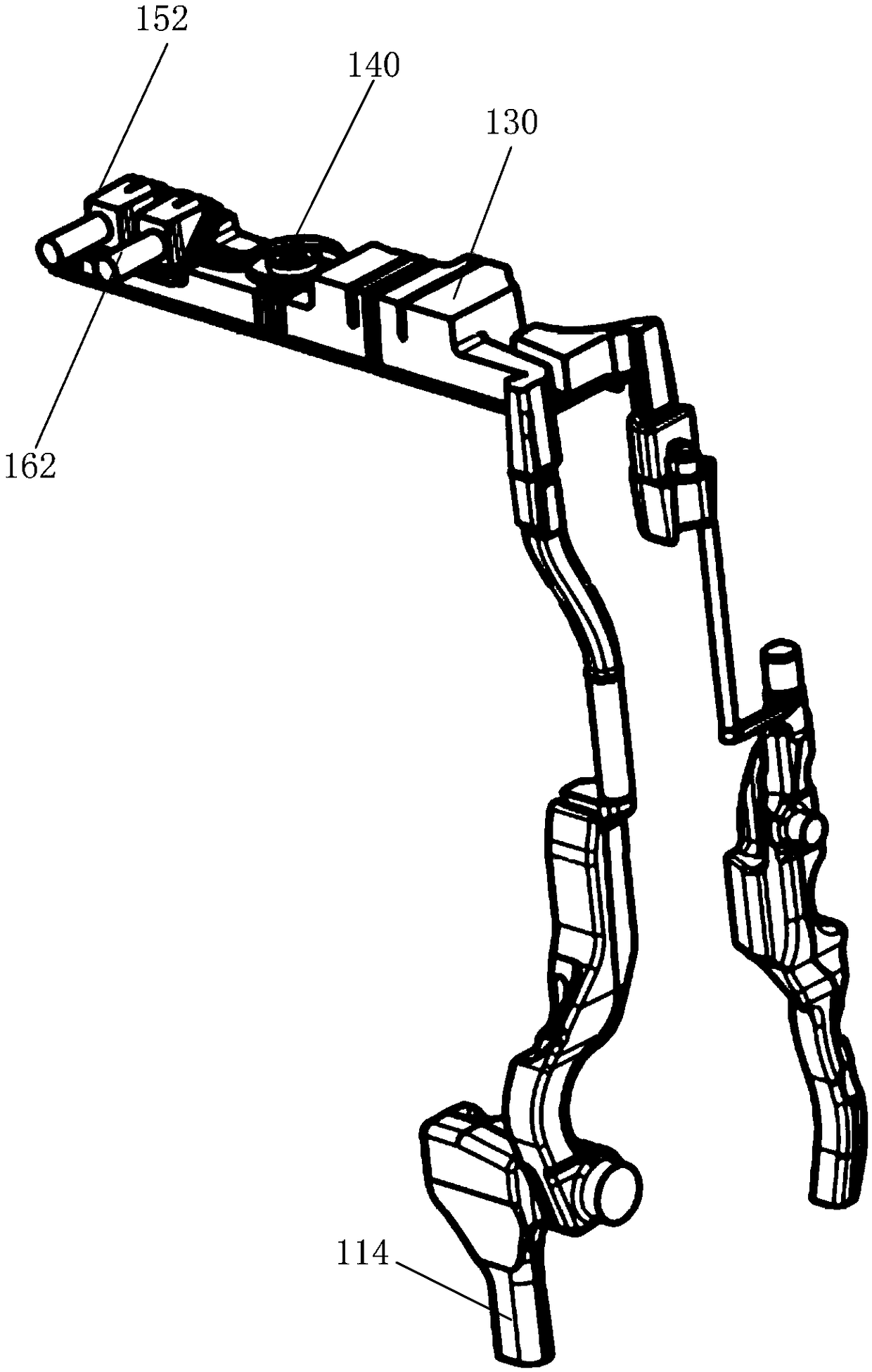

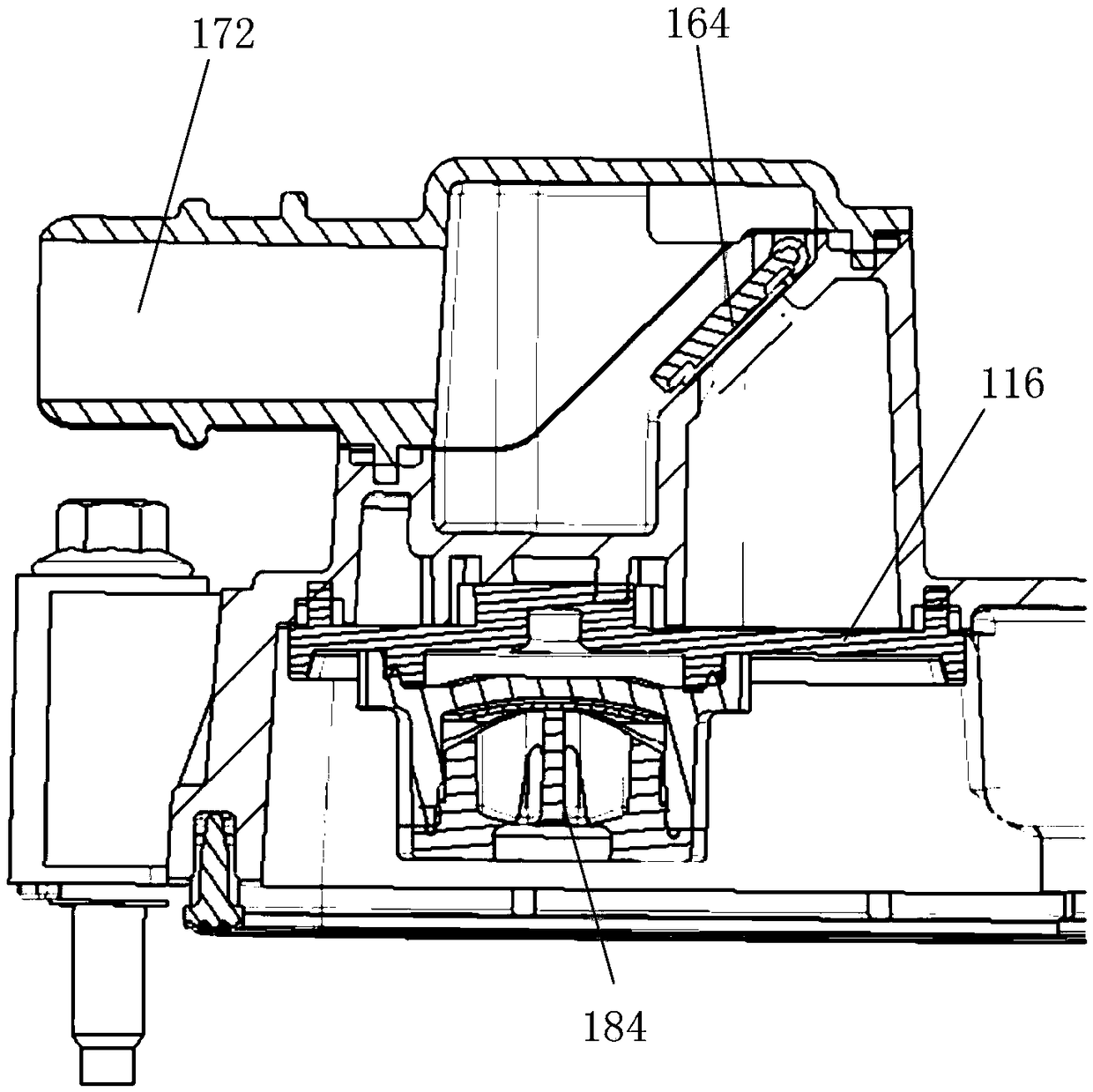

Compressor, air conditioning system with same and heat-pump water heater system

ActiveCN103362807AImprove efficiencyImprove energy efficiencyCompressorRotary/oscillating piston combinations for elastic fluidsAir conditioningHigh pressure

A compressor, an air conditioner system comprising the compressor and a heat pump water heater system. The compressor comprises: a low-pressure compression component, a medium-pressure chamber, a low-pressure chamber air discharge passageway, an enthalpy-increasing component, a high-pressure compression component, a medium-pressure air passageway and a high-pressure chamber air discharge passageway. The medium-pressure air passageway comprises a side passageway section of the low-pressure chamber air discharge passageway and a side passageway section of a high-pressure chamber air suction passageway, and a ratio between a minimum cross section area of the side passageway section of the low-pressure chamber air discharge passageway and a minimum cross section area of the side passageway section of the high-pressure chamber air suction passageway is from 1.4 to 4. In the compressor, the pressure impulse and the flow speed impulse of the refrigerant are relatively small, the first-stage air discharge plumpness and the second-stage air discharge plumpness can be improved, and the air supply quantity can be improved; therefore, the working efficiency and the energy efficiency of the compressor are enhanced, and the energy consumption is reduced.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

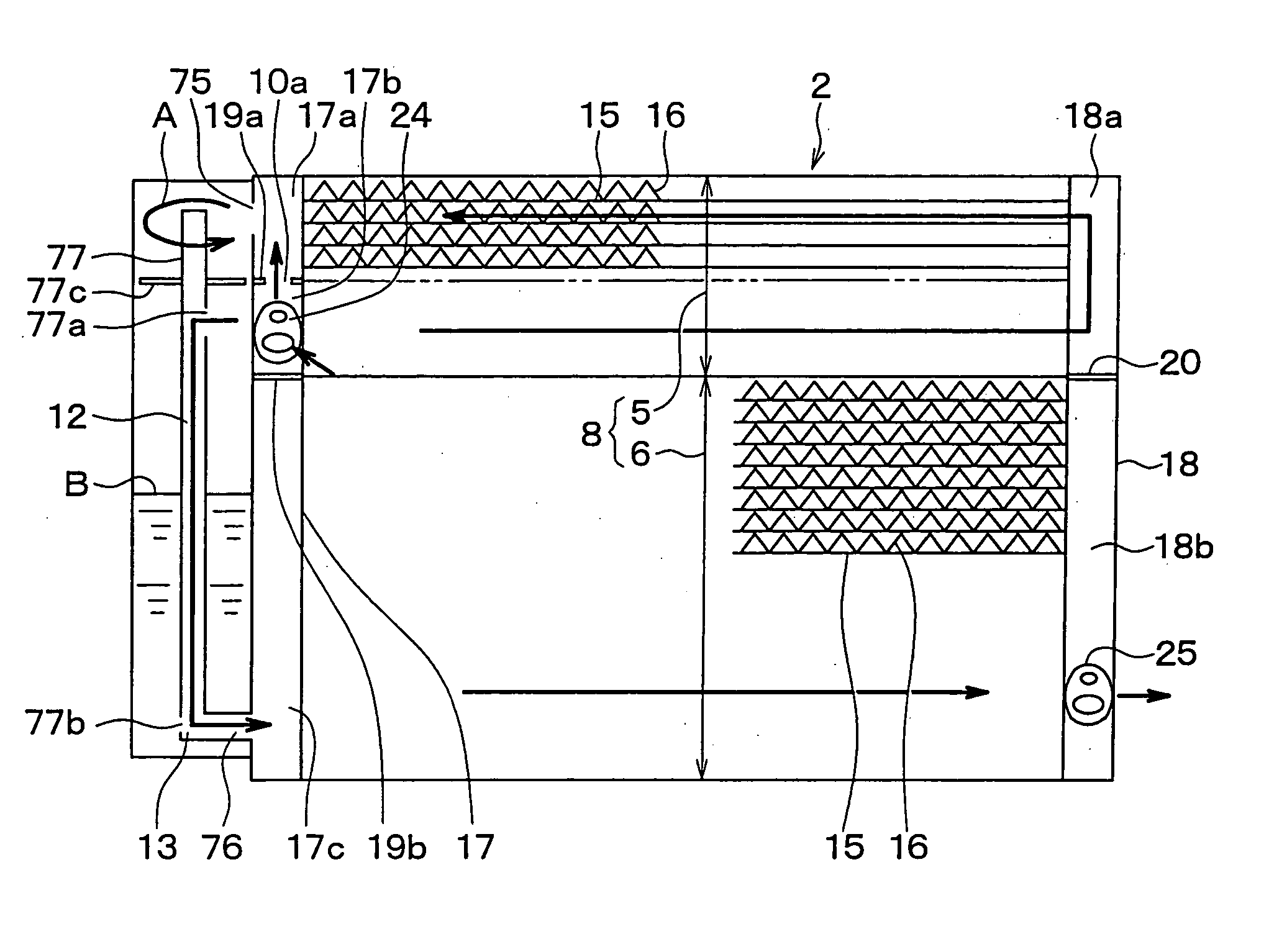

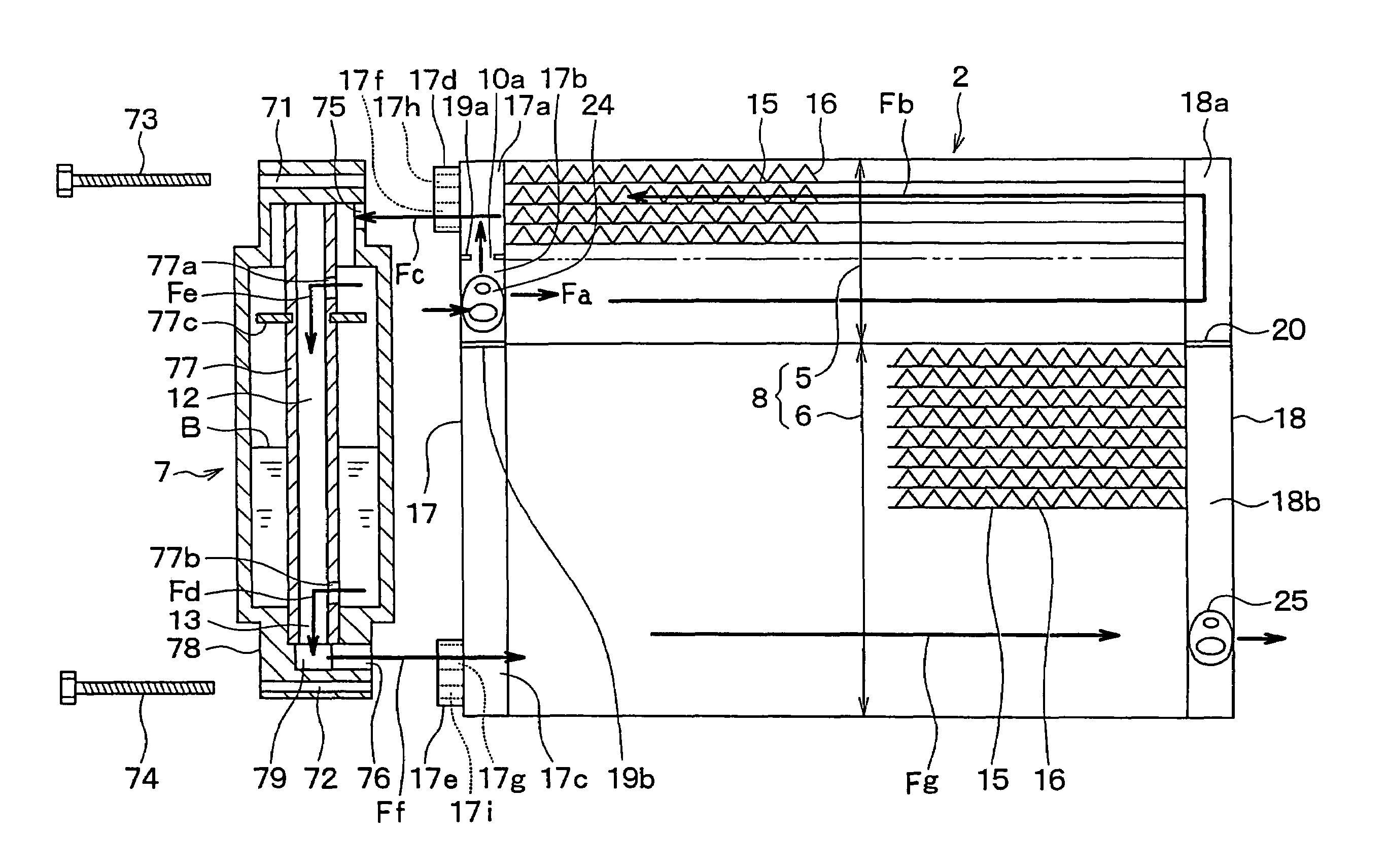

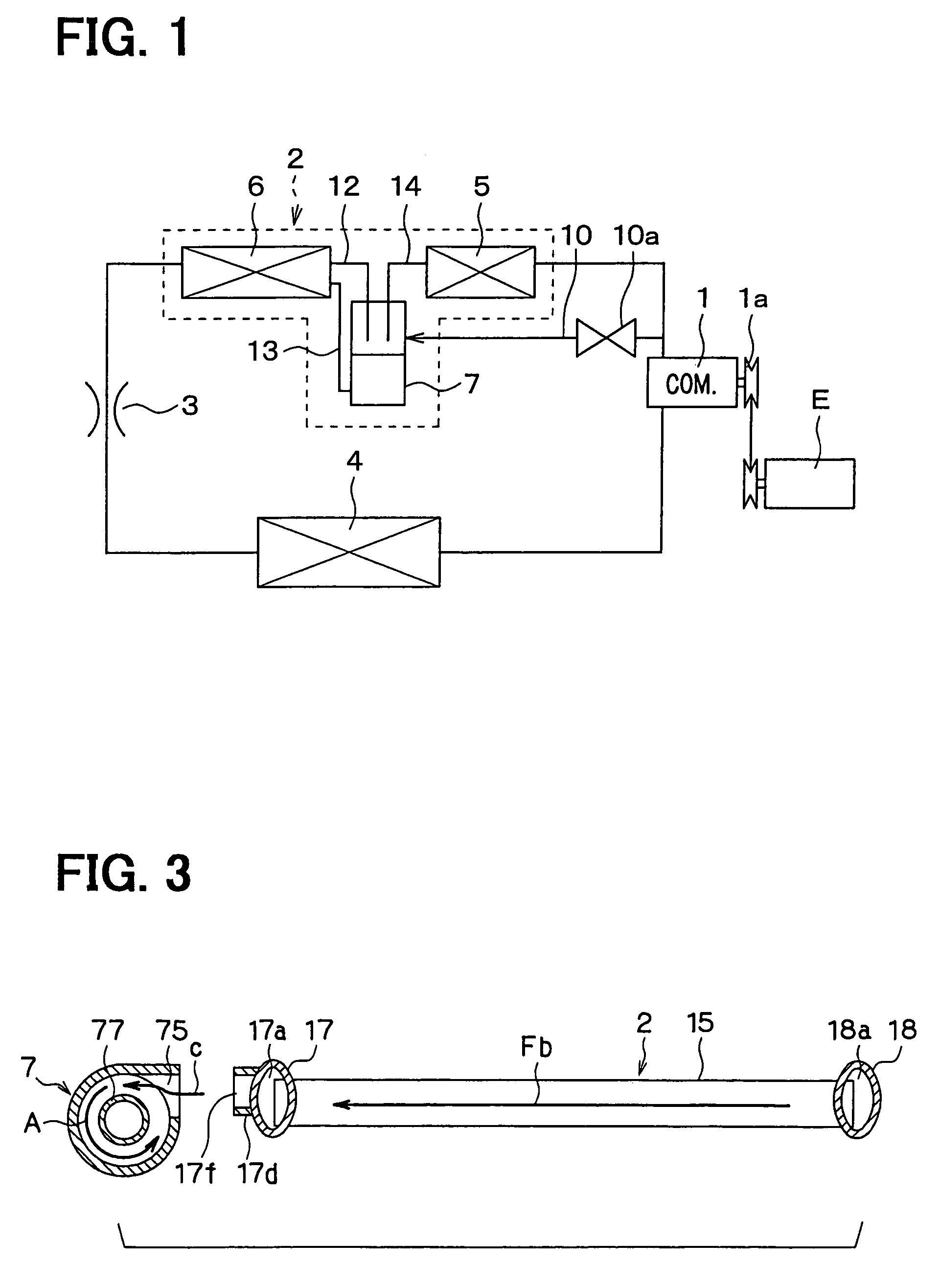

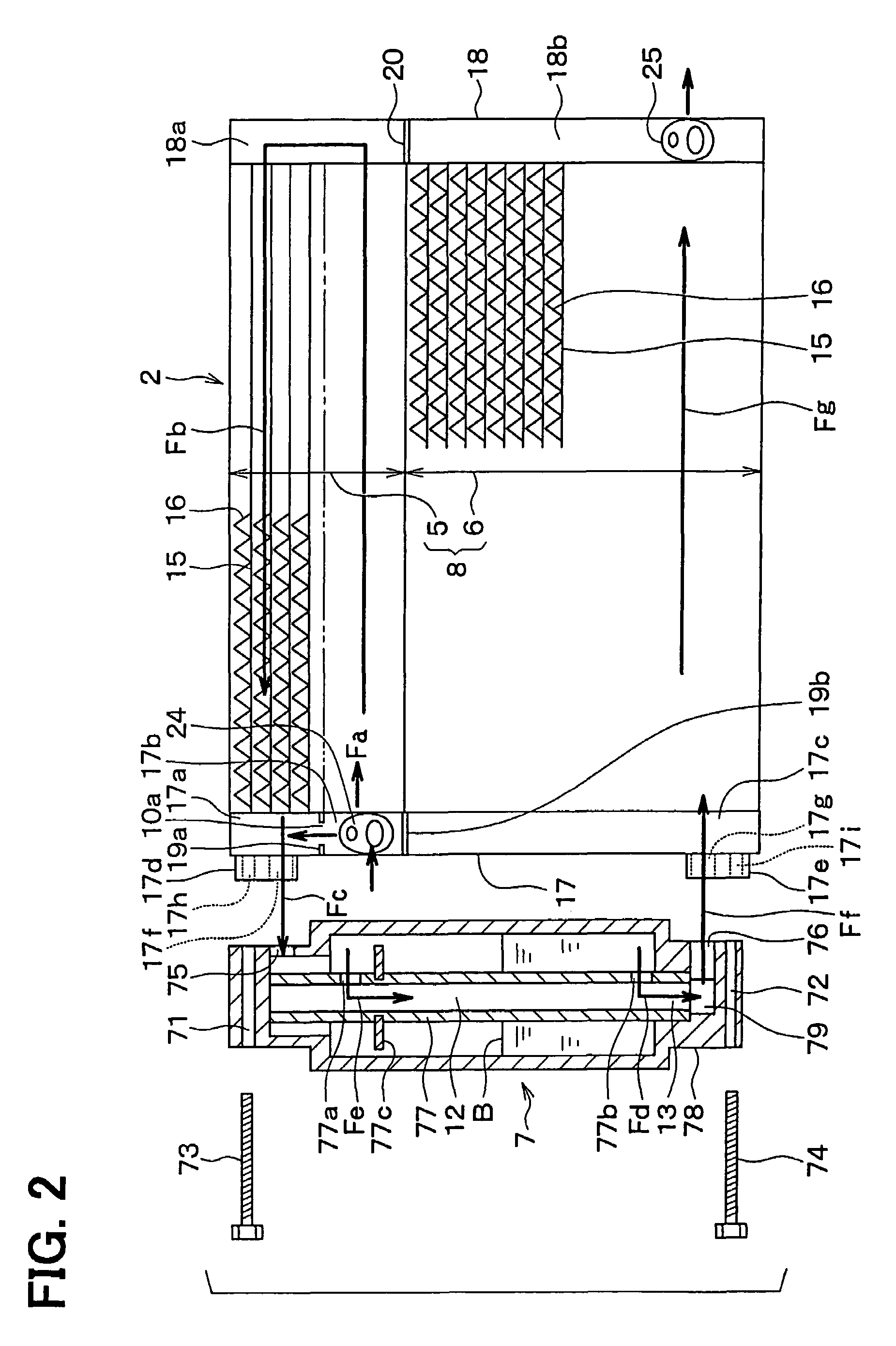

Refrigerant cycle system

InactiveUS20040118150A1Simplify refrigerant passage structureIncrease the amount of gasCompressorMechanical apparatusVapor–liquid separatorEngineering

A refrigerant cycle system includes a first heat-exchanging portion for condensing gas refrigerant discharged from a compressor, a gas-liquid separator into which all of refrigerant after passing through the first heat-exchanging portion and a part of gas refrigerant discharged from the compressor are introduced, and a second heat-exchanging portion for cooling and condensing refrigerant flowing from the gas-liquid separator. Because all of the condensed refrigerant from the first heat-exchanging portion is introduced into the gas-liquid separator, a passage area of a gas refrigerant introduction passage for introducing gas refrigerant from the compressor into the gas-liquid separator can be set relatively large. Therefore, a dimension difference of the gas refrigerant introducing passage in manufacturing is not greatly affected to an adjustment of a liquid refrigerant amount in the gas-liquid separator.

Owner:DENSO CORP

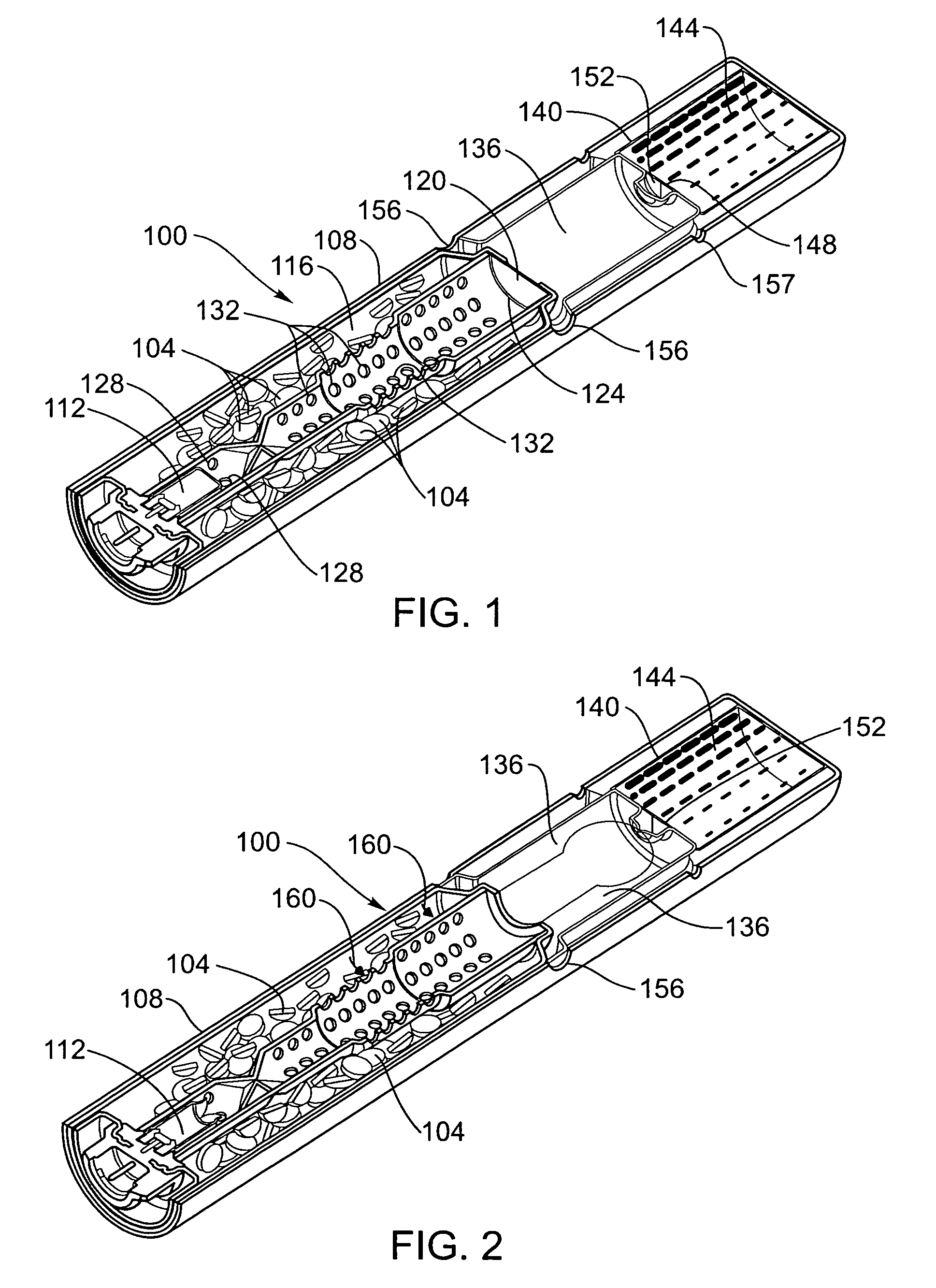

Liquid cooled hybrid

InactiveUS7770924B2Increase the amount of gasReducing size and costPedestrian/occupant safety arrangementPressure gas generationCombustionEngineering

An inflator that includes a quantity of gas generant housed within a chamber. A liquid and a piston are also housed within another chamber. This chamber is sealed by a burst disk. The piston includes an opening. During deployment of the inflator, the burst disk is ruptured and the piston moves towards the distal end of the inflator. The movement of the piston hydraulically expels the liquid through the opening in the piston such that the liquid cools and contacts the gas formed by combustion of the gas generant.

Owner:AUTOLIV ASP INC

Chemical and physical combined explosion fracturing device and manufacturing method thereof

ActiveCN103352684ASolve the limited effect of fracturingSolution rangeFluid removalInterference fitHigh pressure

The invention relates to the fracturing technology, in particular to a chemical and physical combined explosion fracturing device and a manufacturing method of the chemical and physical combined explosion fracturing device. The chemical and physical combined explosion fracturing device and the manufacturing method of the chemical and physical combined explosion fracturing device resolve the problems at the existing fracturing technology is limited in fracturing effect, narrow in application range and poor in use safety. The chemical and physical combined explosion fracturing device comprises a fracturing device outer shell, wherein the front portion of an inner cavity of the fracturing device outer shell is in interference fit with a powder chamber outer barrel, an inner cavity of the powder chamber outer barrel is provided with a powder screening pipe in a sleeved mode, a first explosion film is arranged on an opening in the rear end of the powder screening pipe in a sealing mode, an inner cavity of the powder screening pipe is filled with a powder pillar which is connected with an ignition line, a pressing nut is arranged on an opening in the rear end of the fracturing device outer shell in a sealing mode, a through hole penetrating through the front portion and the rear portion is formed between the front end surface and the rear end surface of the pressing nut, a second fracturing film is arranged on the through hole in a sealing mode, and the rear portion of the inner cavity of the fracturing device outer shell is filled with high-pressure CO2 in a sealing mode. The chemical and physical combined explosion fracturing device and the manufacturing method of the chemical and physical combined explosion fracturing device are suitable for the development of petroleum, natural gas, coal bed gas, shale gas and the like, and suitable for a pre-fracturing and permeability-increasing process of extraction of coal bed gas under a coal mine shaft.

Owner:ZHONGBEI UNIV

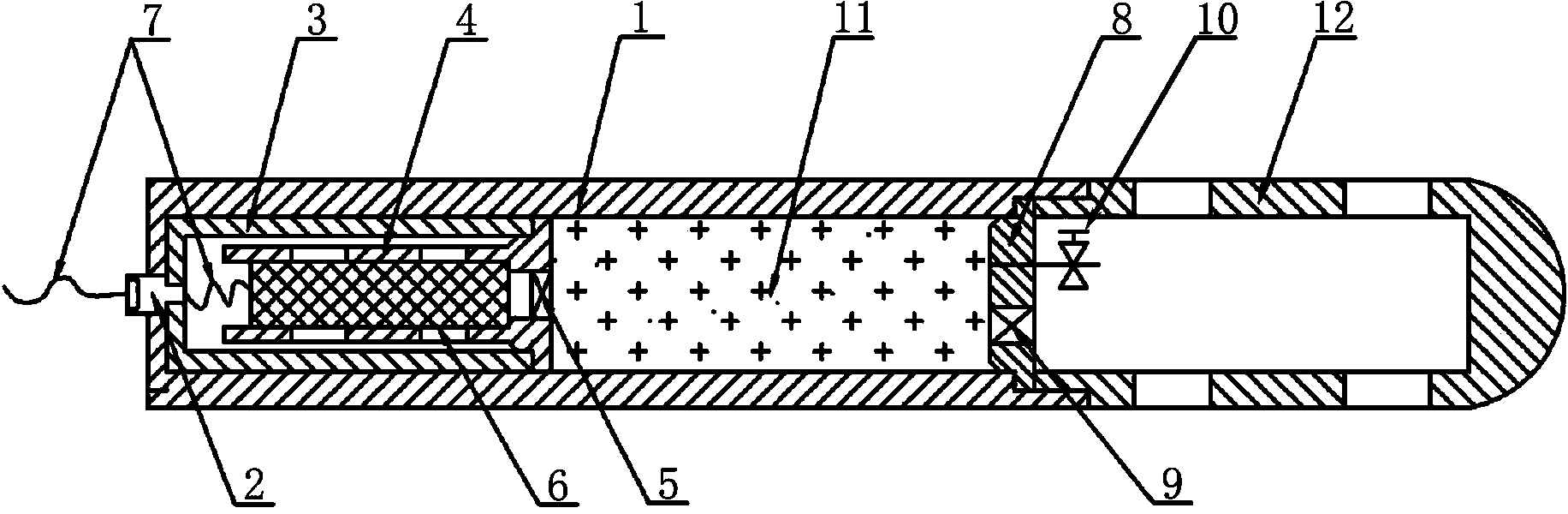

Oxygen-enriched combustion circulating fluidized bed poly-generation system and process

ActiveCN103742899AImprove utilization efficiencyIncrease operating temperatureNitrogen purification/separationFluidized bed combustionGeneration processFlue gas

The invention provides an oxygen-enriched combustion circulating fluidized bed poly-generation system. The oxygen-enriched combustion circulating fluidized bed poly-generation system comprises a circulating fluidized bed combustion furnace and a circulating fluidized bed gasification furnace, wherein the circulating fluidized bed combustion furnace is connected with a separator I, the separator I is connected with a flue at the tail and a two-way material control device, the two-way material control device is connected with the circulating fluidized bed combustion furnace and the circulating fluidized bed gasification furnace respectively, the circulating fluidized bed gasification furnace is connected with the circulating fluidized bed combustion furnace by a return feeder I, the circulating fluidized bed gasification furnace is connected with a ceramic dust collector and a coal gas purification system by a separator II, the flue at the tail is connected with a flue gas distribution valve by a glue gas dust-removal, desulfurization and denitration device, and an outlet of the flue gas distribution valve is divided into three paths. The invention also provides an oxygen-enriched combustion circulating fluidized bed poly-generation process. The oxygen-enriched combustion circulating fluidized bed poly-generation system has high fuel utilization rate, high coal gas yield, good tar quality, small pollutant discharge and low recycling cost, and fuel and flue gas at the tail can be utilized to the maximum extent.

Owner:SHANGHAI BOILER WORKS

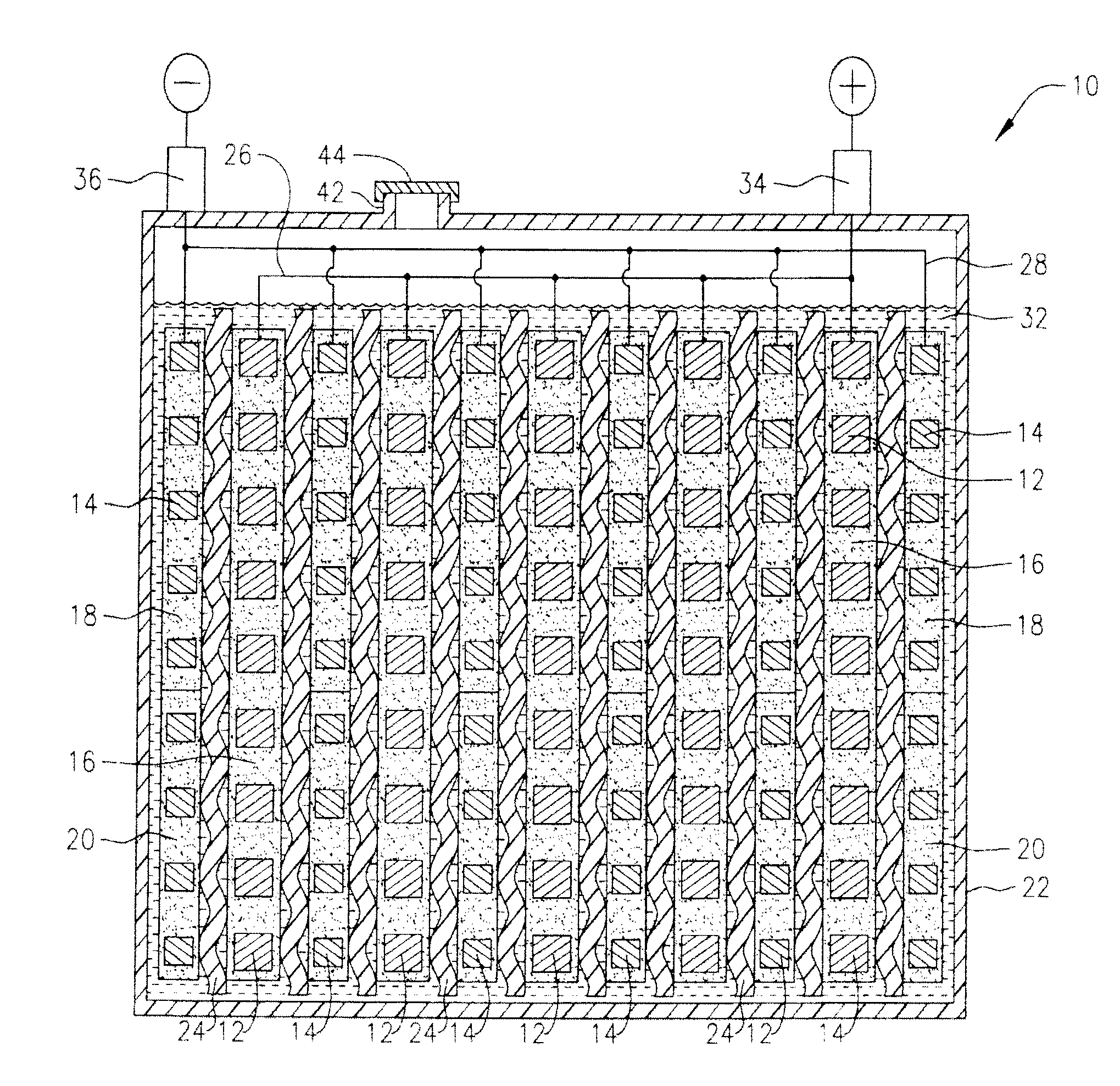

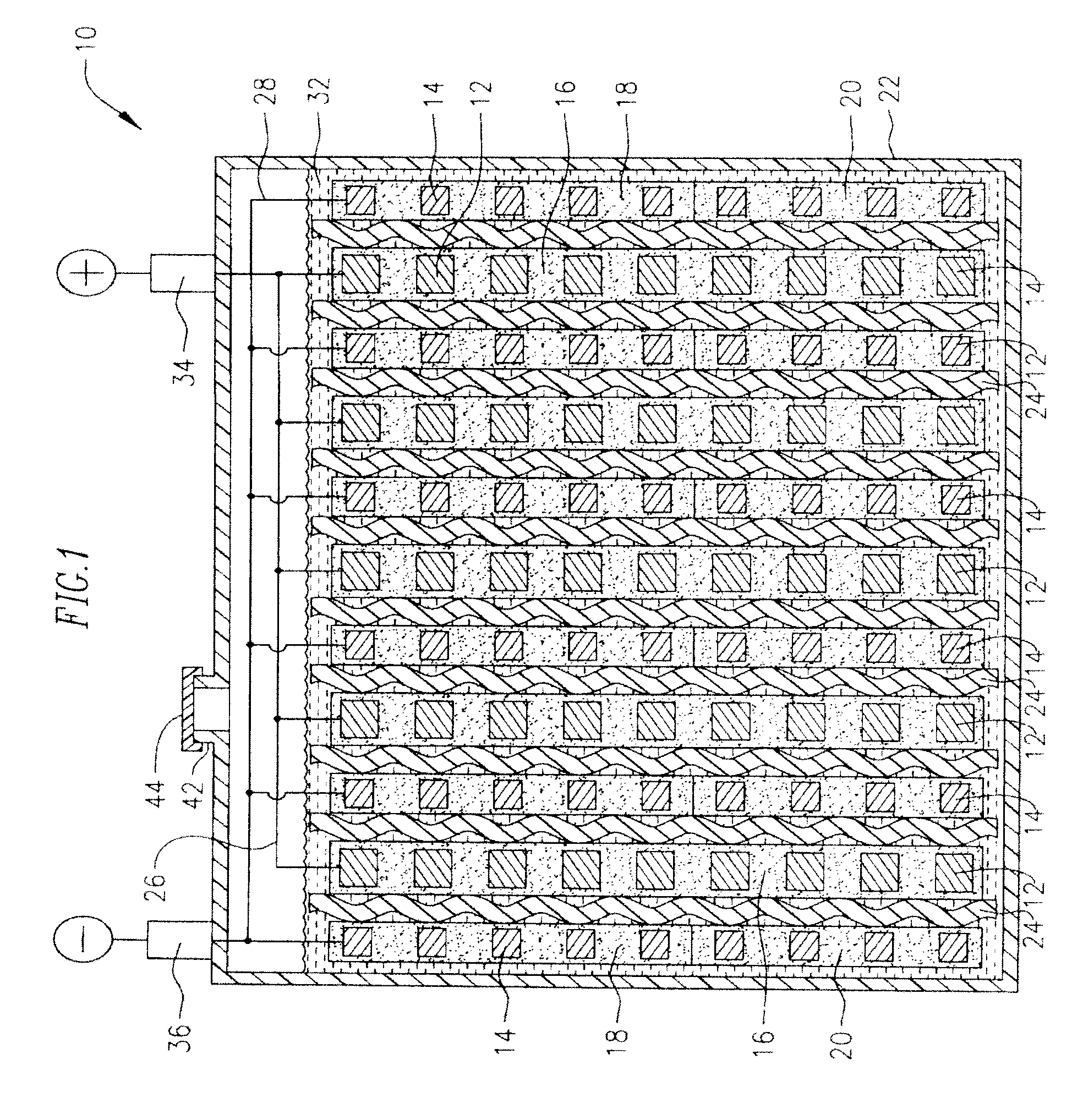

Negative plate for lead acid battery

InactiveUS20110027653A1Reduce layeringReduce maintenanceLead-acid accumulatorsElectrode carriers/collectorsCarbon AdditiveMass ratio

Capacitor pastes for flooded deep discharge lead-acid batteries include lead oxide, a carbon additive, and an aqueous acid. The capacitor paste contains lead and carbon in a lead to carbon mass ratio of about 5:1 to 82:1. Hybrid negative plates for flooded deep discharge lead-acid batteries can be made using such pastes in combination with traditional pastes. The hybrid negative plates include a capacitor paste on a bottom portion of the plate, and a traditional paste on the remainder of the plate. Batteries using the capacitor paste and hybrid plates exhibit improved performance over batteries with conventional plates and pastes and require less overcharge to prevent electrolyte stratification.

Owner:TROJAN BATTERY

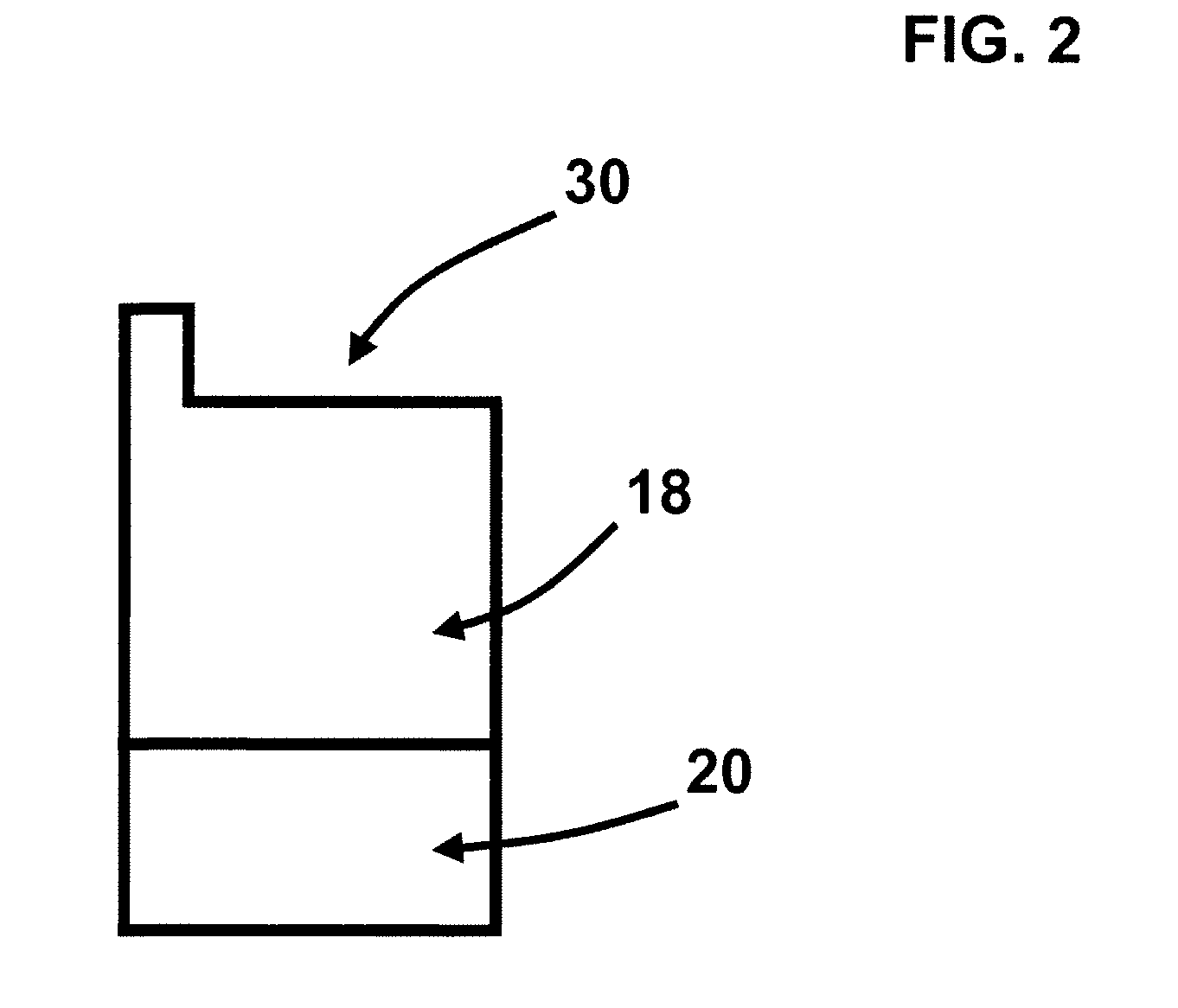

Gas storage container with gas absorbing or adsorbing material

InactiveUS7712605B2Inhibit temperature riseSmall sizeReactant parameters controlDomestic cooling apparatusProduct gasProcess engineering

An elongate gas distributing tube, which extends in a longitudinal direction of a container, is accommodated within the container that constitutes a gas storage container. Discharge ports, through which the gas is discharged, are provided only on a side circumferential wall of the gas distributing tube. Therefore, the discharged gas advances while being directed toward the inner side wall of the container. The gas distributing tube is surrounded by a gas absorbing / adsorbing material. On the other hand, the gas absorbing / adsorbing material is surrounded by a mixture, which is prepared by mixing the gas absorbing / adsorbing material with a heat storage material, such that heat is absorbed by the heat storage material contained therein.

Owner:HONDA MOTOR CO LTD

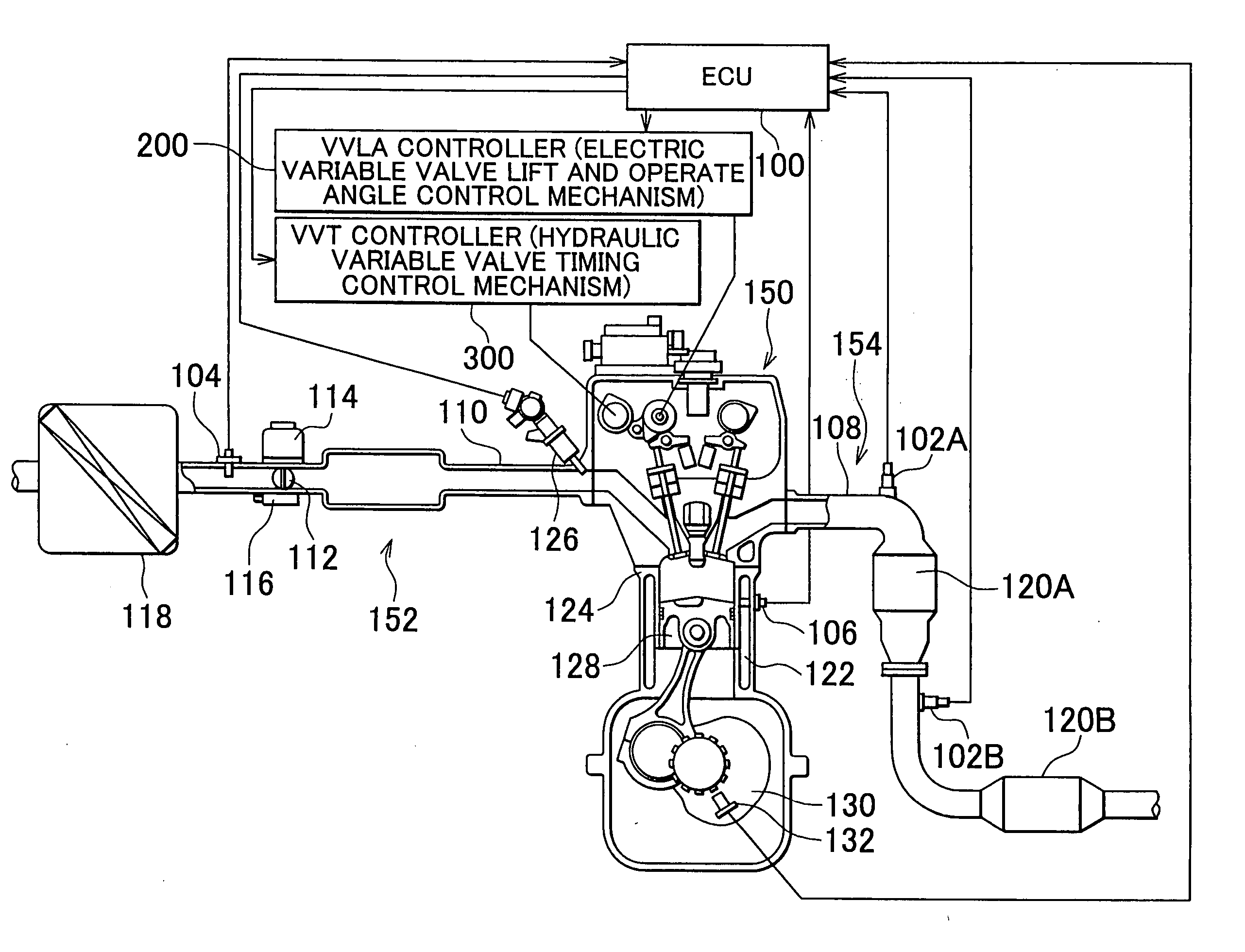

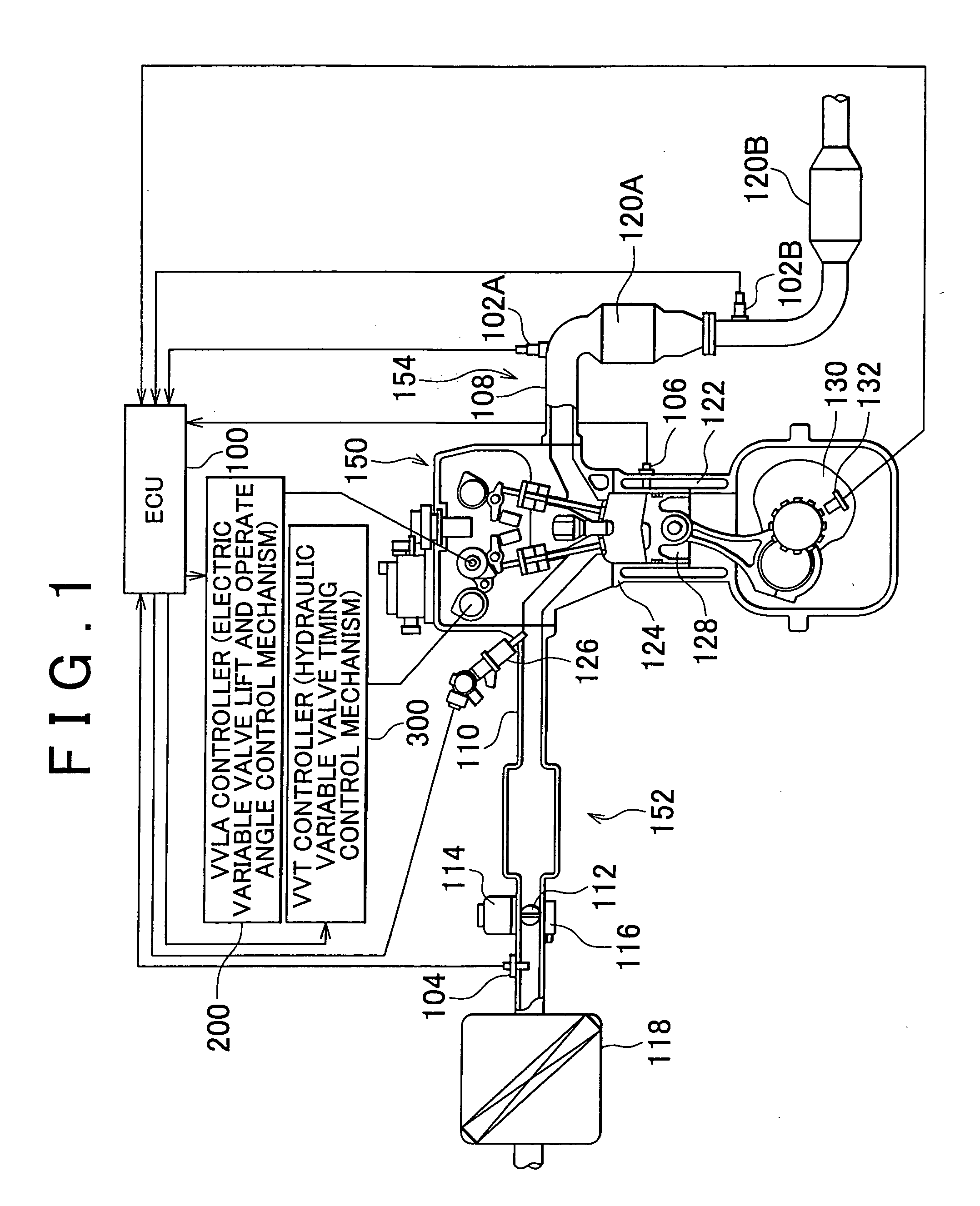

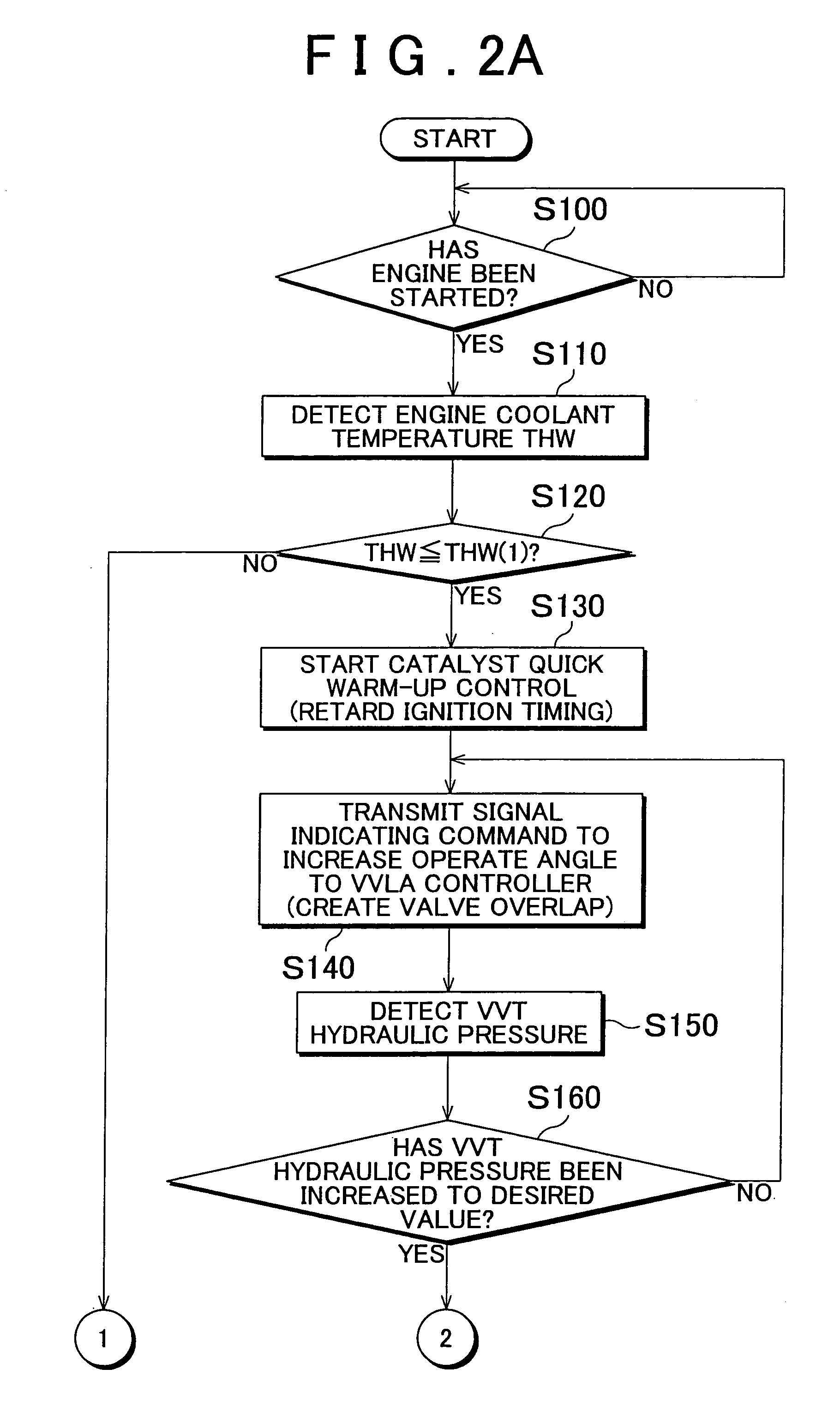

Control apparatus and control method for internal combustion engine

InactiveUS20070084425A1Extended durationUnstable combustion is avoidedElectrical controlInternal combustion piston enginesIgnition timingCoolant temperature

If it is determined that an engine has been started, an engine coolant temperature is detected. If the engine coolant temperature is equal to or lower than a threshold value, the catalyst quick warm-up control is started to retard ignition timing, and a signal indicating a command to increase an operate angle is transmitted to a VVLA controller. When a VVT hydraulic pressure is increased to a predetermined value, a signal indicating a command to decrease the operate angle is transmitted to the VVLA controller, and a signal indicating a command to advance open timing of an intake valve is transmitted to a VVT controller so that the open timing of the intake valve is not changed. If the engine coolant temperature is equal to or higher than a threshold value, the catalyst quick warm-up control ends, and the ignition timing is returned to normal timing.

Owner:TOYOTA JIDOSHA KK +1

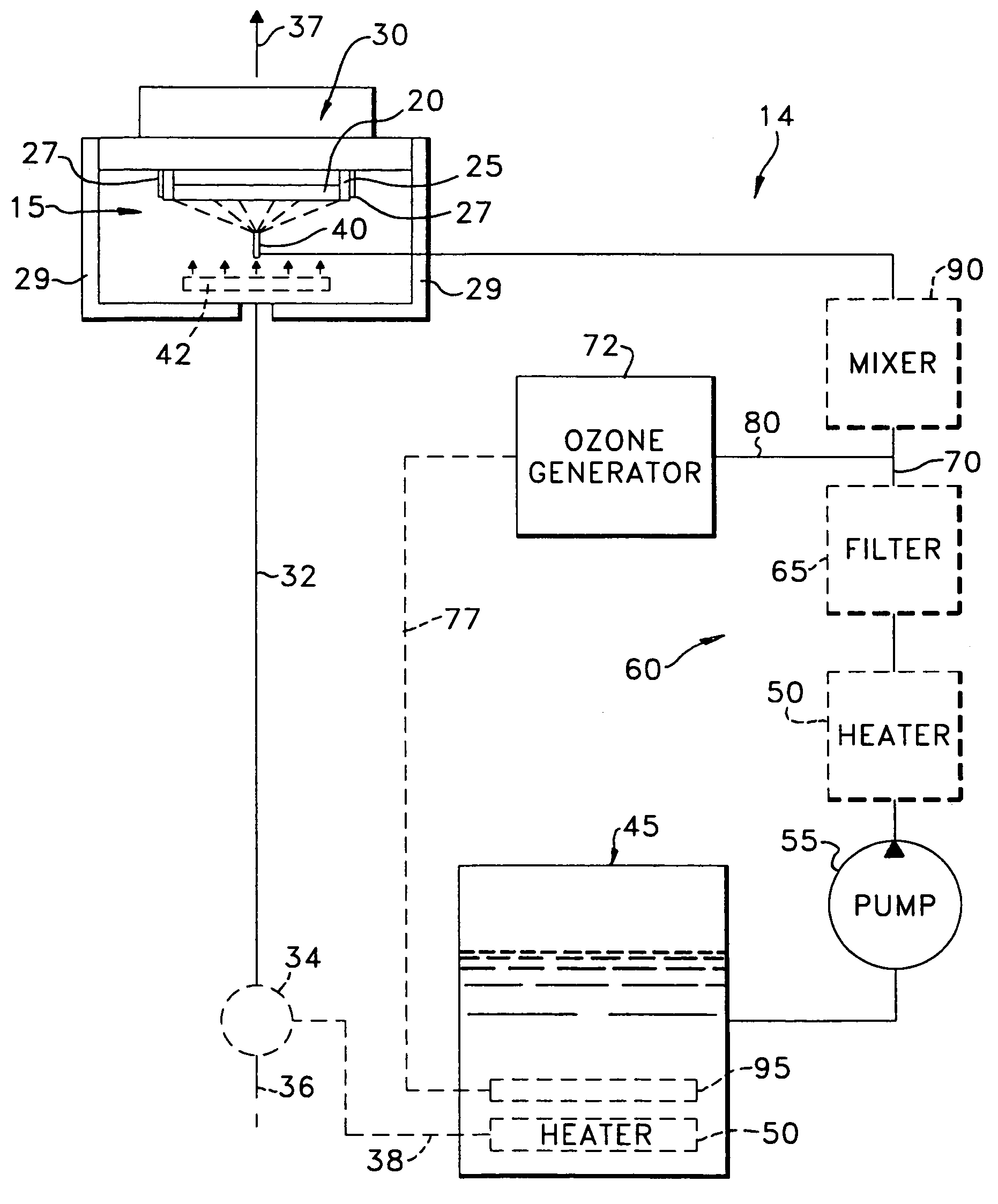

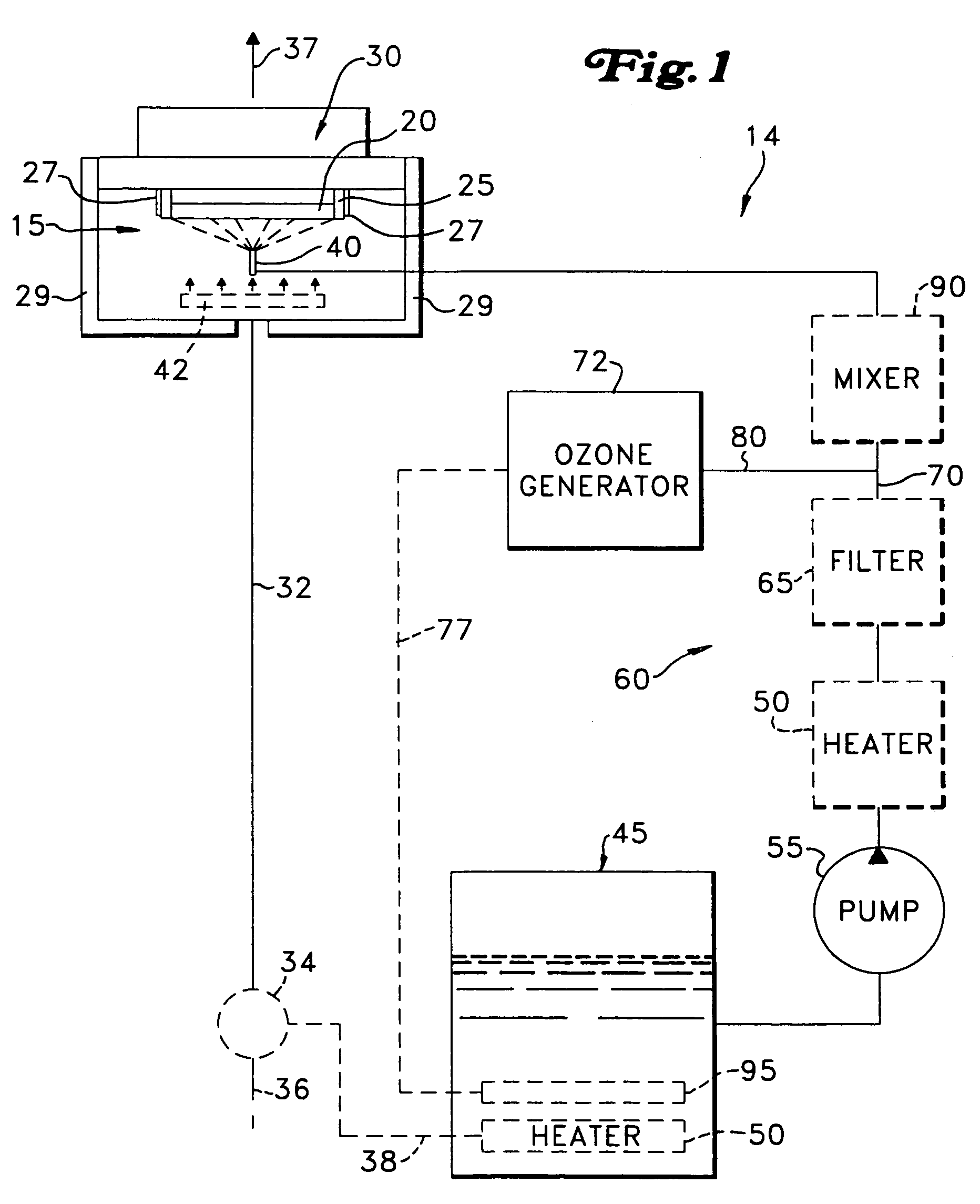

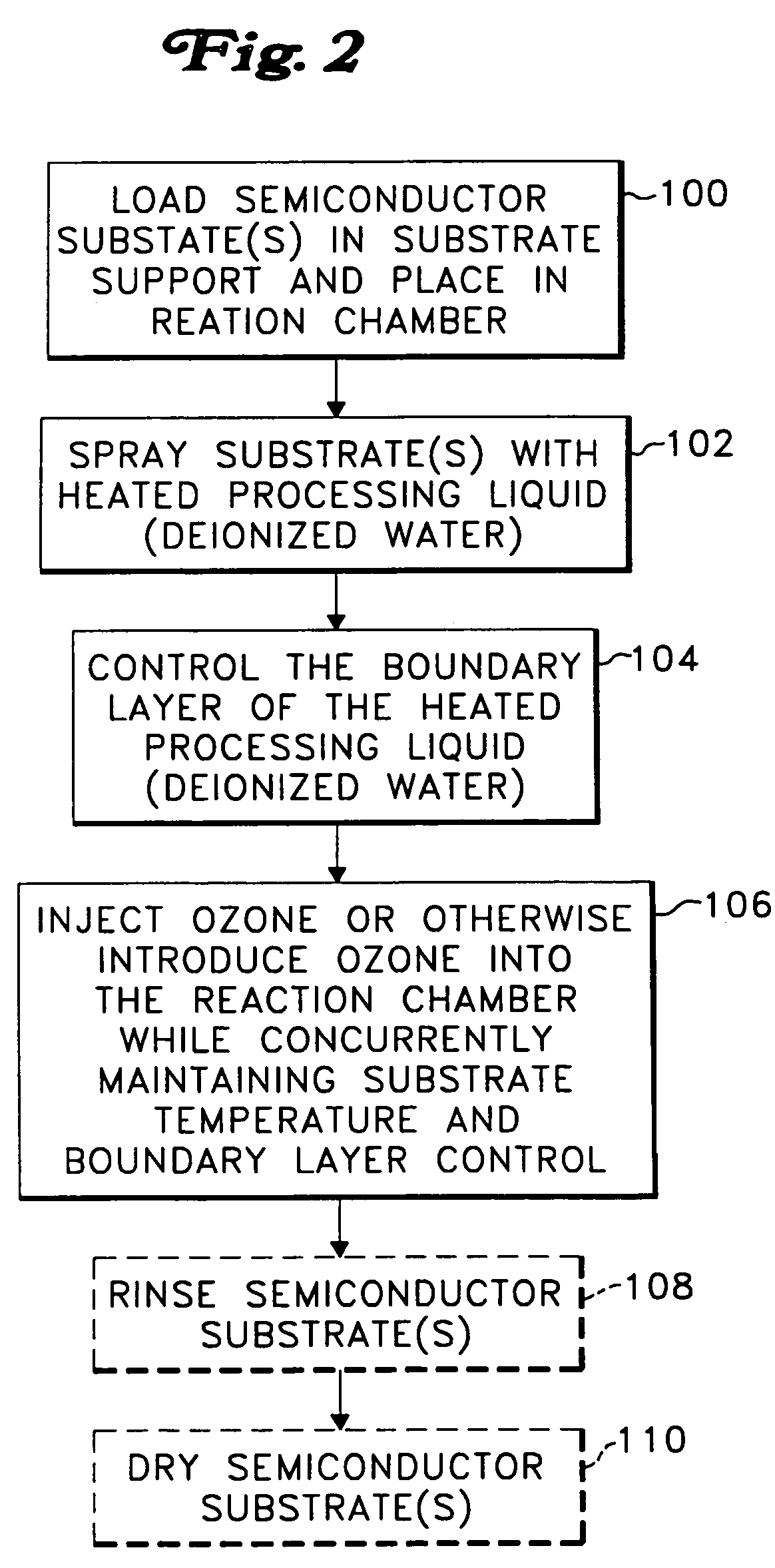

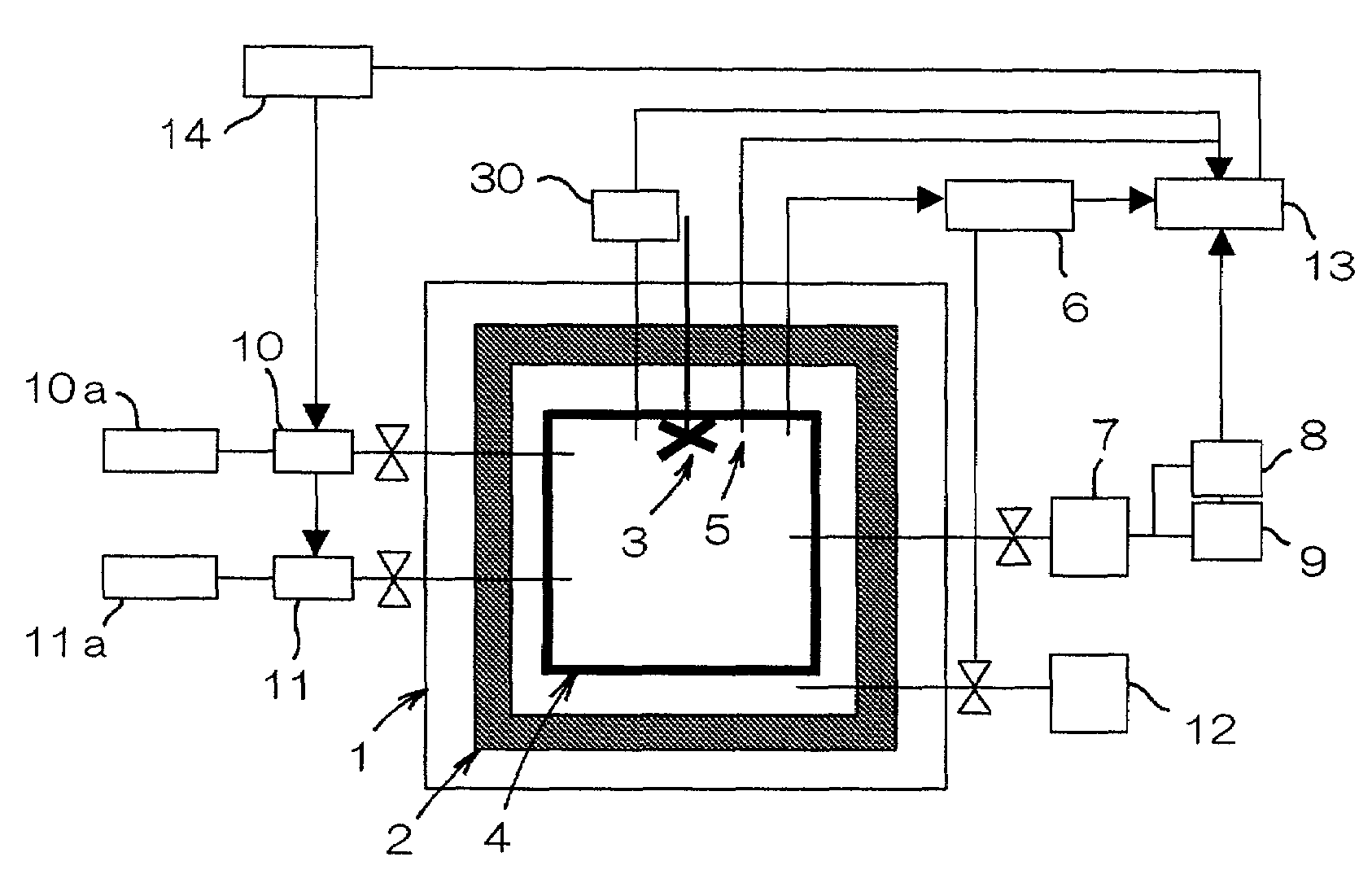

Process and apparatus for treating a workpiece with gases

InactiveUS7416611B2Increase the amount of gasReduce processing timePrinted circuit assemblingLighting and heating apparatusLiquid layerReaction rate

In a method and apparatus for cleaning or processing a workpiece, a process gas is brought into contact with the workpiece by diffusion through a heated liquid layer on the workpiece, and by bulk transport achieved by entraining the gas in a liquid stream, spray or jet impinging on the workpiece. The process gas, which may be ozone, is entrained in the liquid via entrainment nozzles. Use of entrainment and diffusion together increases the amount of gas available for reaction at the workpiece surface, increases the reaction rate, and decreases required process times.

Owner:OEM GRP LLC

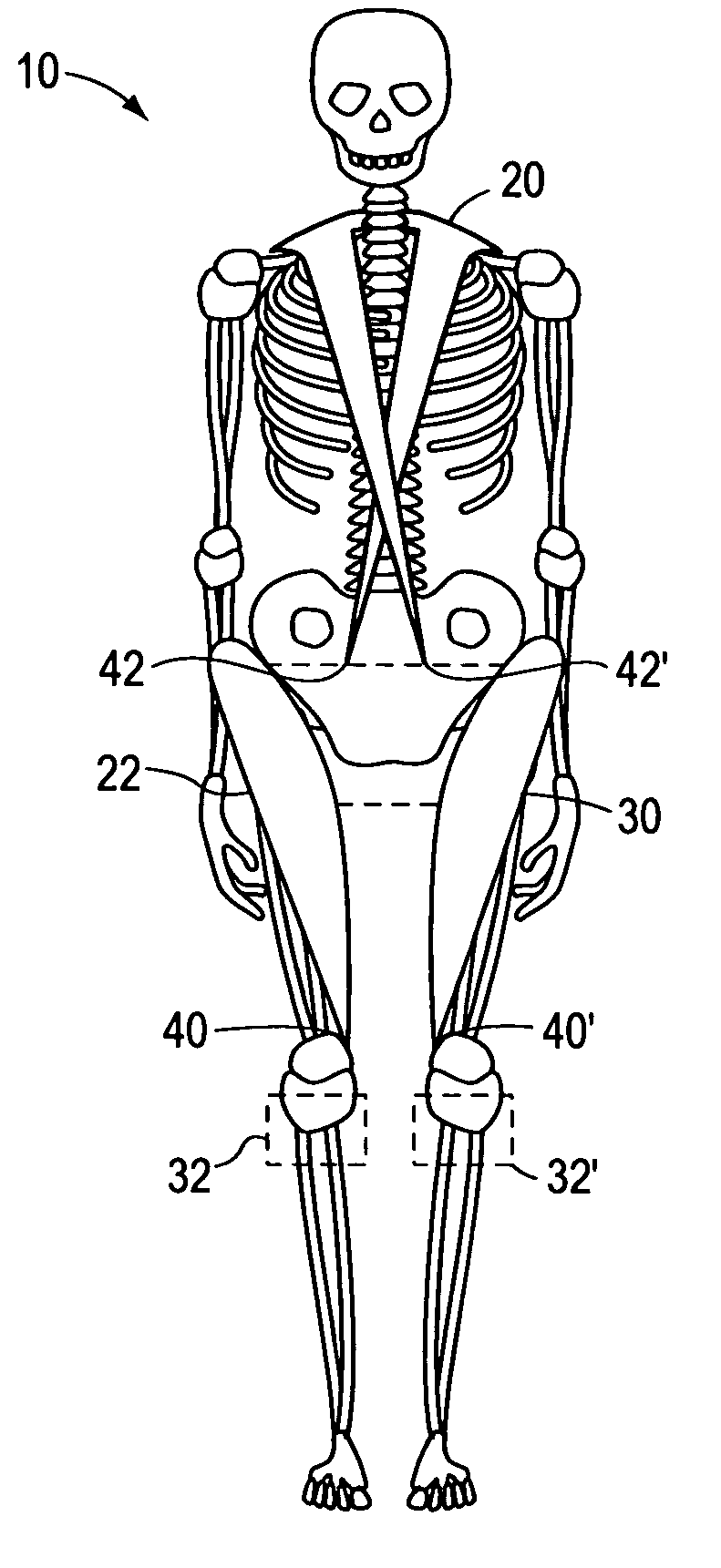

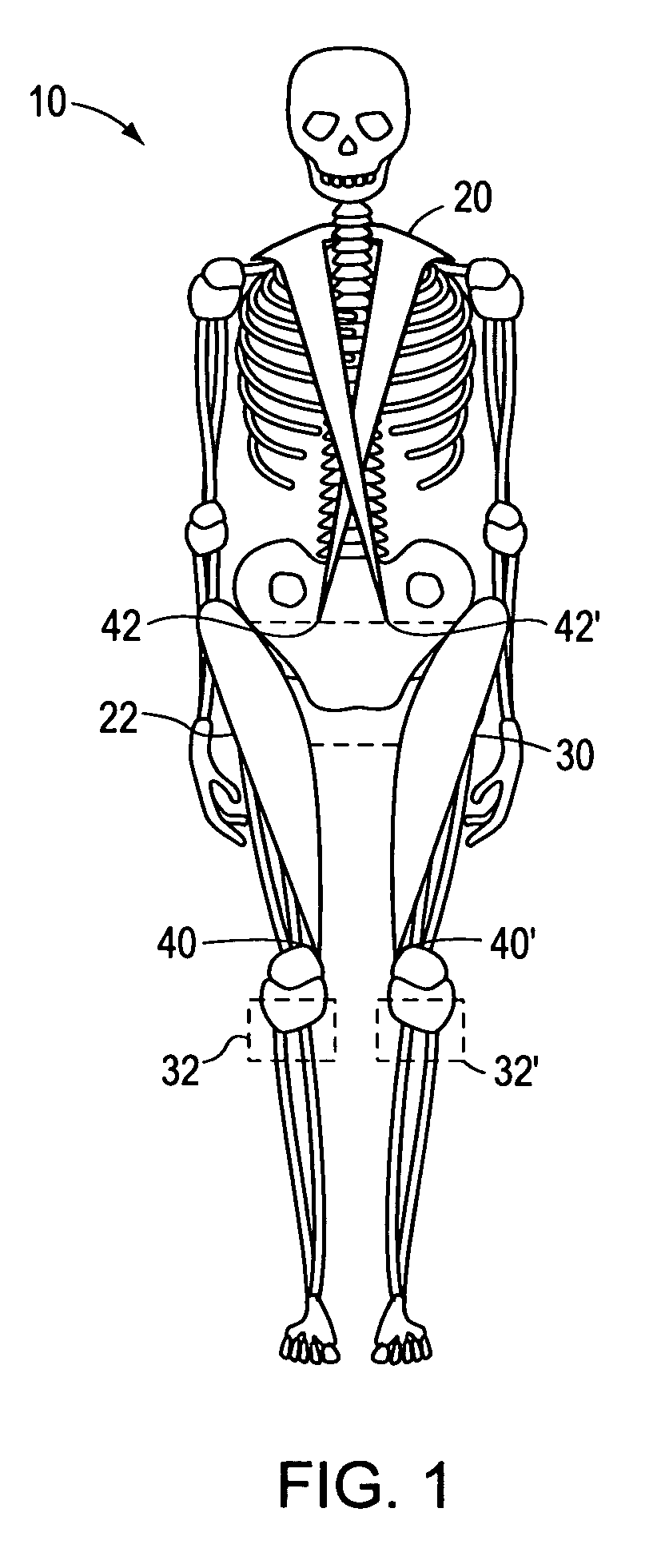

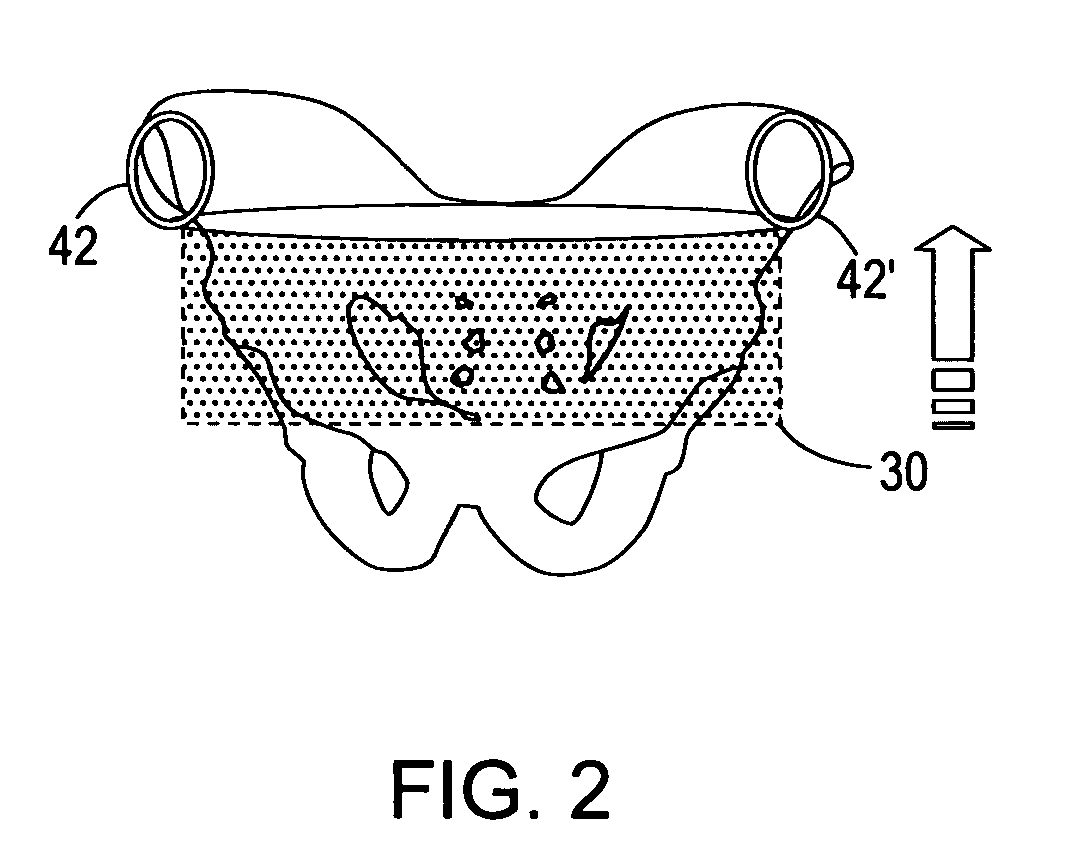

Resistance fitness suit

InactiveUS20050255975A1Increased energy expenditureMinimal resistiveResilient force resistorsDeltoid muscleThigh musculature

A fitness system including a suit, a fixation system, and attachment locations on the fixation system. The attachment locations are located at the neck, shoulders, chest, waist, and knees. The fitness system also includes bands that are attached to the attachment points on the upper and lower torso. The upper torso band traverses behind the neck or posterior shoulders to the front waist to engage the rear deltoid, the upper back and the lower back. The upper torso band may also traverse under the armpit to the rear waist to engage the front deltoid, the chest, and the abdominals. The lower torso band traverses the rear waist over the front of each thigh to below the knee to engage the gluteus, the hamstring and the flexion of the upper leg, or under the thigh to below the knee to engage the quadriceps and the extension of the upper leg.

Owner:RIPPED

Method for operating a blast furnace and blast furnace installation

InactiveUS20110209576A1Easy to installSimple methodDirect heating destructive distillationBiofuelsMaterials scienceBlast furnace

A method for operating a blast furnace and a corresponding blast furnace, the method including recovering top gas from the blast furnace, submitting at least a portion of the top gas to a recycling process, and feeding the recycled top gas back into the blast furnace, where the recycling process includes feeding the recovered top gas to a reformer unit, feeding volatile carbon containing material to the reformer unit, proceeding to flash gasification of the volatile carbon containing material in the reformer unit, at a temperature between 1100 and 1300° C., and thereby producing devolatised carbonaceous material and synthesis, and allowing the devolatised carbonaceous material and synthesis gas to react with the recovered top gas.

Owner:PAUL WURTH SA

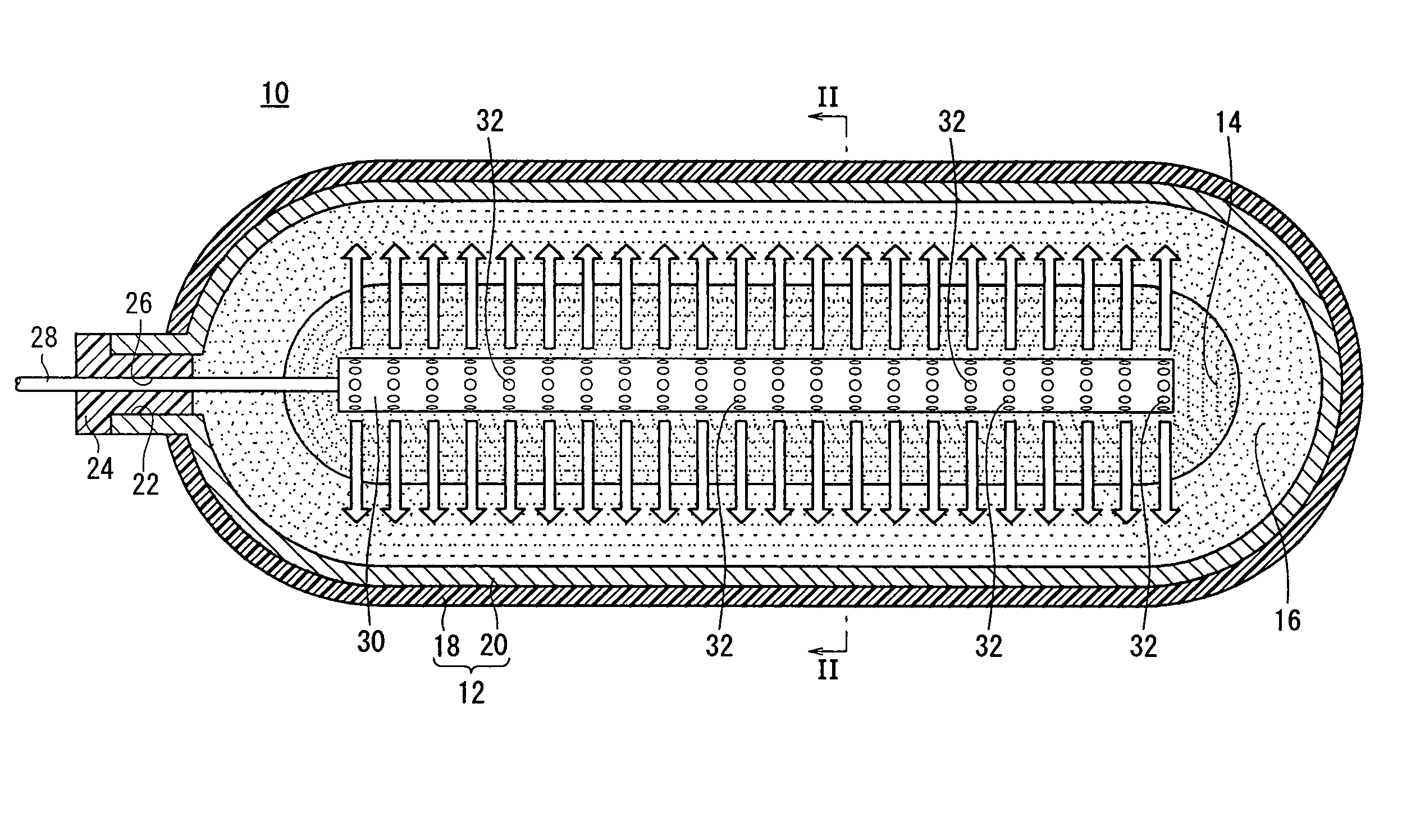

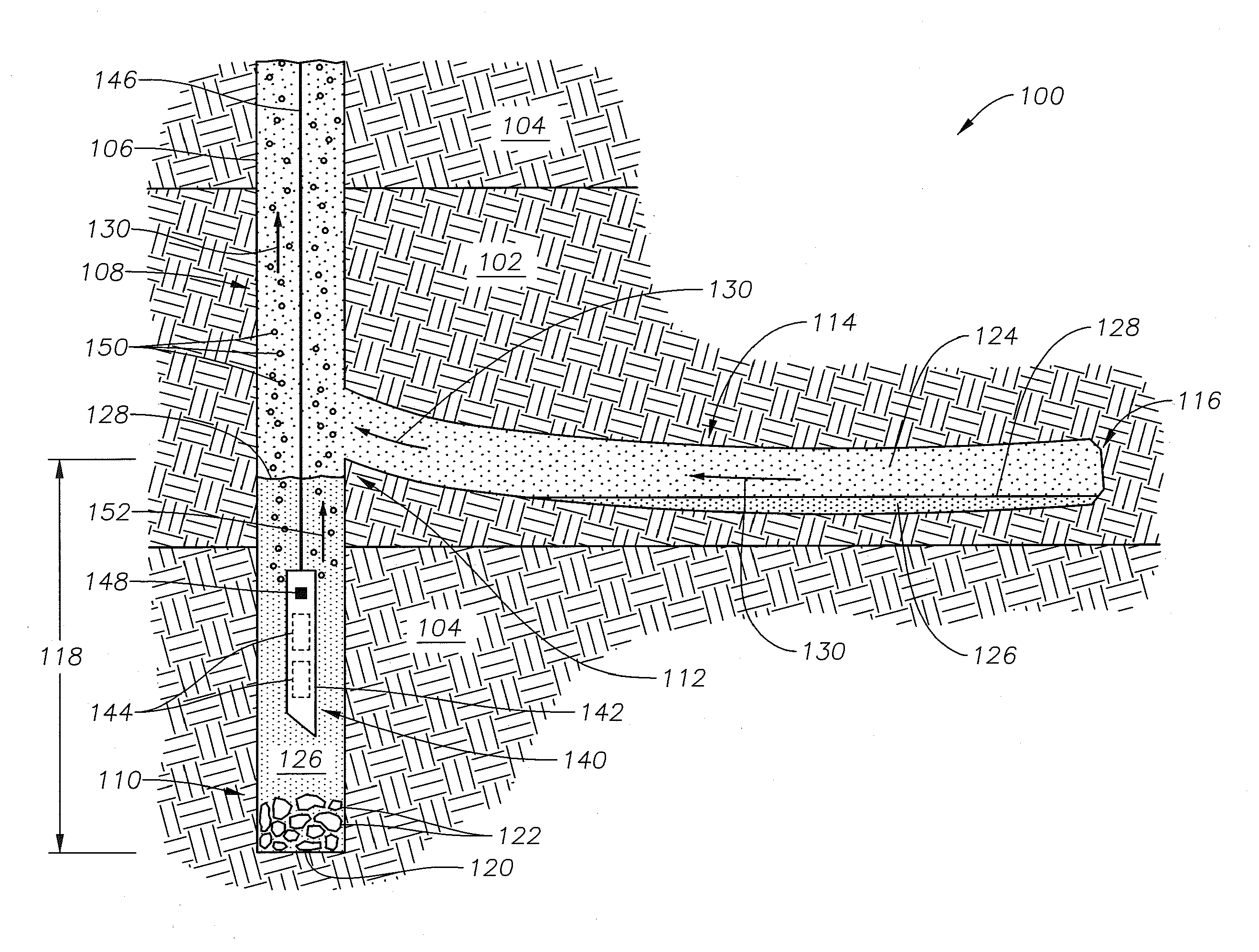

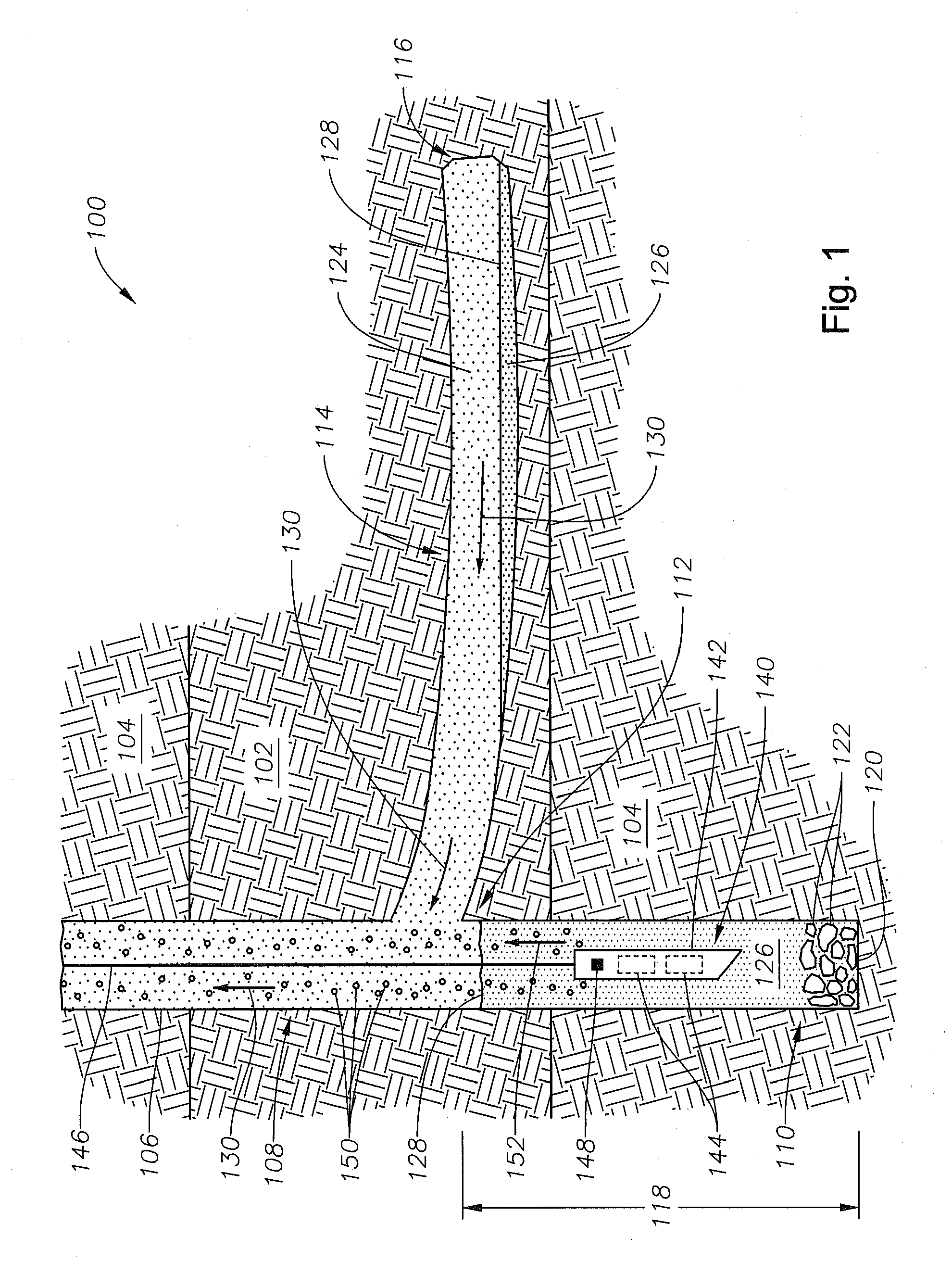

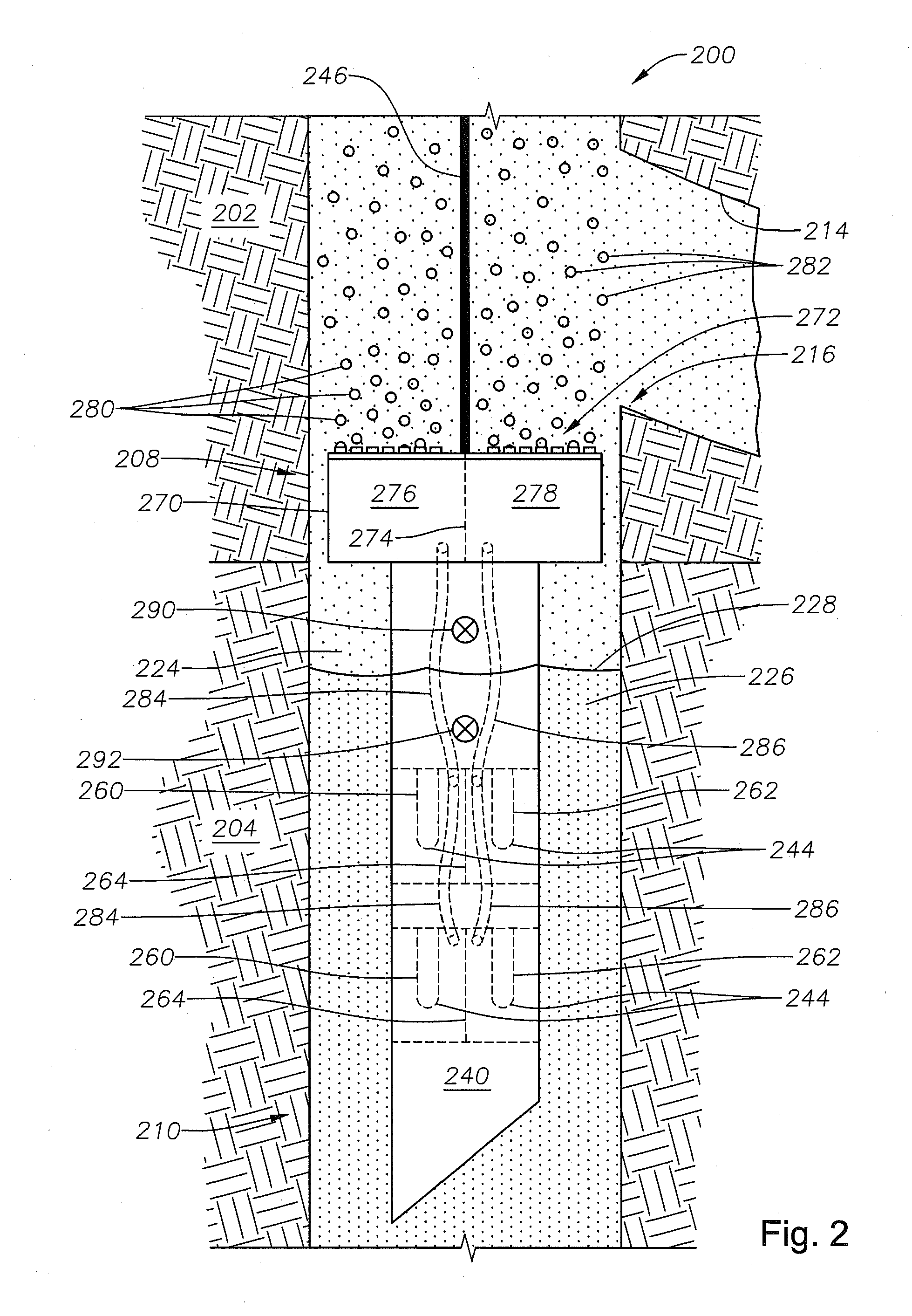

Method and apparatus for artificial lift using well fluid electrolysis

ActiveUS20130105174A1Artificial liftDecrease in fluid densityFluid removalElectrolysisHorizontal wells

An artificial lift device is useful for inducing artificial gas lift in a well bore fluid present in a horizontal well bore system using electrically conductive aqueous solution. The artificial lift device includes an ion exchange membrane, an electrode pair having an anode and a cathode separated by the ion exchange membrane, a sensor operable to detect the presence of solution and a power relay operable to selectively permit the electrode pair to receive electrical power. The artificial lift device is operable to form hydrogen product gas bubbles from hydrogen product gas. A method for providing artificial gas lift using the artificial lift device includes forming a horizontal well bore system having a well boot, introducing the artificial lift device into the well bore system, introducing electrical power to the electrode pair, and operating the device to introduce hydrogen product gas bubbles into the horizontal well bore system.

Owner:SAUDI ARABIAN OIL CO

Refrigerant cycle system

InactiveUS6981390B2Simplify refrigerant passage structureIncrease the amount of gasCompressorMechanical apparatusVapor–liquid separatorEngineering

A refrigerant cycle system includes a first heat-exchanging portion for condensing gas refrigerant discharged from a compressor, a gas-liquid separator into which all of refrigerant after passing through the first heat-exchanging portion and a part of gas refrigerant discharged from the compressor are introduced, and a second heat-exchanging portion for cooling and condensing refrigerant flowing from the gas-liquid separator. Because all of the condensed refrigerant from the first heat-exchanging portion is introduced into the gas-liquid separator, a passage area of a gas refrigerant introduction passage for introducing gas refrigerant from the compressor into the gas-liquid separator can be set relatively large. Therefore, a dimension difference of the gas refrigerant introducing passage in manufacturing is not greatly affected to an adjustment of a liquid refrigerant amount in the gas-liquid separator.

Owner:DENSO CORP

Crankcase ventilation system

InactiveCN108894851ASpeed up the flowEasy to diluteMachines/enginesCrankcase ventillationAir filterPressure controlled ventilation

The invention provides a crankcase ventilation system which comprises an engine body, an intake manifold, an oil and gas separating system, a pressure control valve and an oil loop. The intake manifold and the oil and gas separating system are connected with the engine body separately, the pressure control valve is connected with the oil and gas separating system, and the oil and gas separating system is connected with the engine body through an oil loop; the crankcase ventilation system further comprises a first crank ventilation access, a second crank ventilation access and a gas supplementing access, the first crank ventilation access is a gas access under the small-load working condition, and the two ends of the first crank ventilation access are connected with the pressure control valve and the intake manifold respectively; the second crank ventilation access is connected with the first crank ventilation access in parallel and is a gas access under the large-load working condition, and the two ends of the second crank ventilation access are connected with a booster front pipeline and the pressure control valve respectively; the two ends of the gas supplementing access are connected with an air filter rear pipeline and the engine body respectively. The crankcase ventilation system can solve the problems that engine oil is diluted and engine oil is emulsified.

Owner:ZHEJIANG GEELY HOLDING (GROUP) CO LTD +1

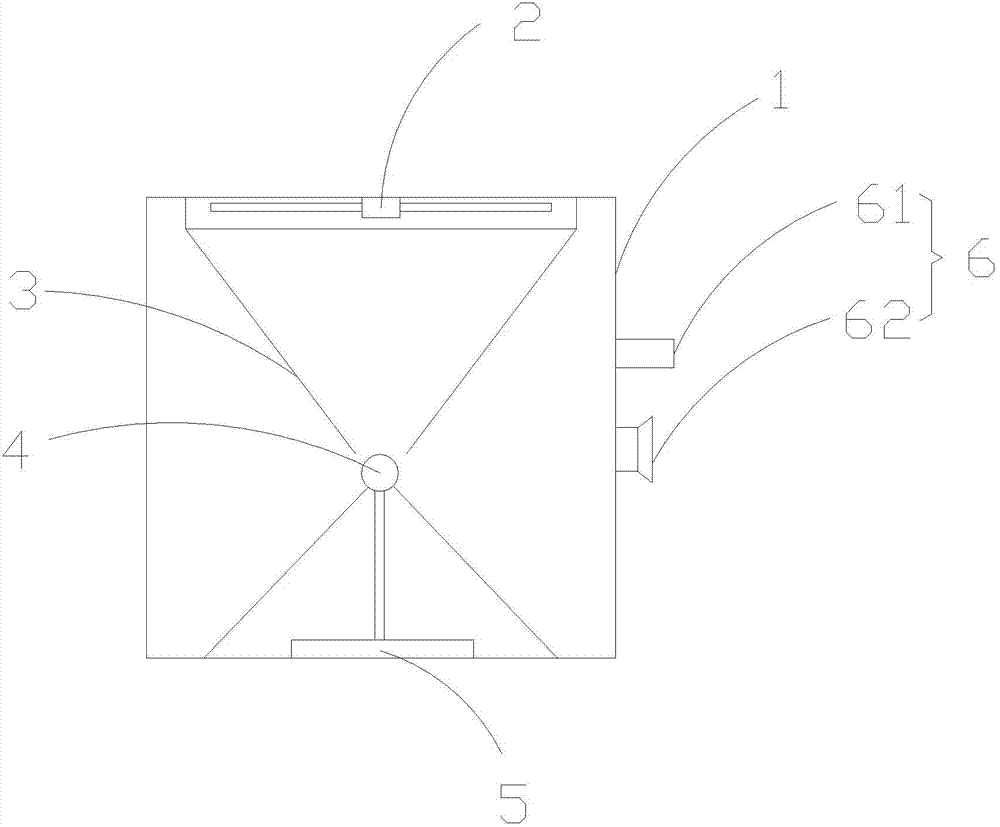

Initiative absorbing type flammable and explosive gas detection alarm

The invention provides an initiative absorbing type flammable and explosive gas detection alarm. The alarm comprises a machine frame, an initiative gas absorbing device, a gas inlet pipe, a gas detection device, a control device and a warning device, wherein the gas inlet pipe is fixed on the machine frame, a gas inlet of the gas inlet pipe is larger than a gas outlet of the gas inlet pipe, the initiative gas absorbing device is arranged on the gas inlet of the gas inlet pipe, the gas detection device is arranged on the gas outlet of the gas inlet pipe, the gas detection device is electrically connected with the control device, and the control device is electrically connected with the warning device. The initiative absorbing type flammable and explosive gas detection alarm can absorb gas initiatively, and therefore the problems that gas molecule diffusion is low in speed and random in direction during flammable and explosive gas detection are solved; due to the fact that a semiconductor gas sensitive device is adopted to serve as the gas detection device, sensitivity is high; due to the fact that an automatic amplifying circuit is added to amplify signals of the semiconductor gas sensitive device, the sensitivity of the instrument is greatly improved; furthermore, a thermostat is adopted to overcome the influence of temperature on the semiconductor gas sensitive device.

Owner:FUJIAN MEIYING AUTOMATION TECH

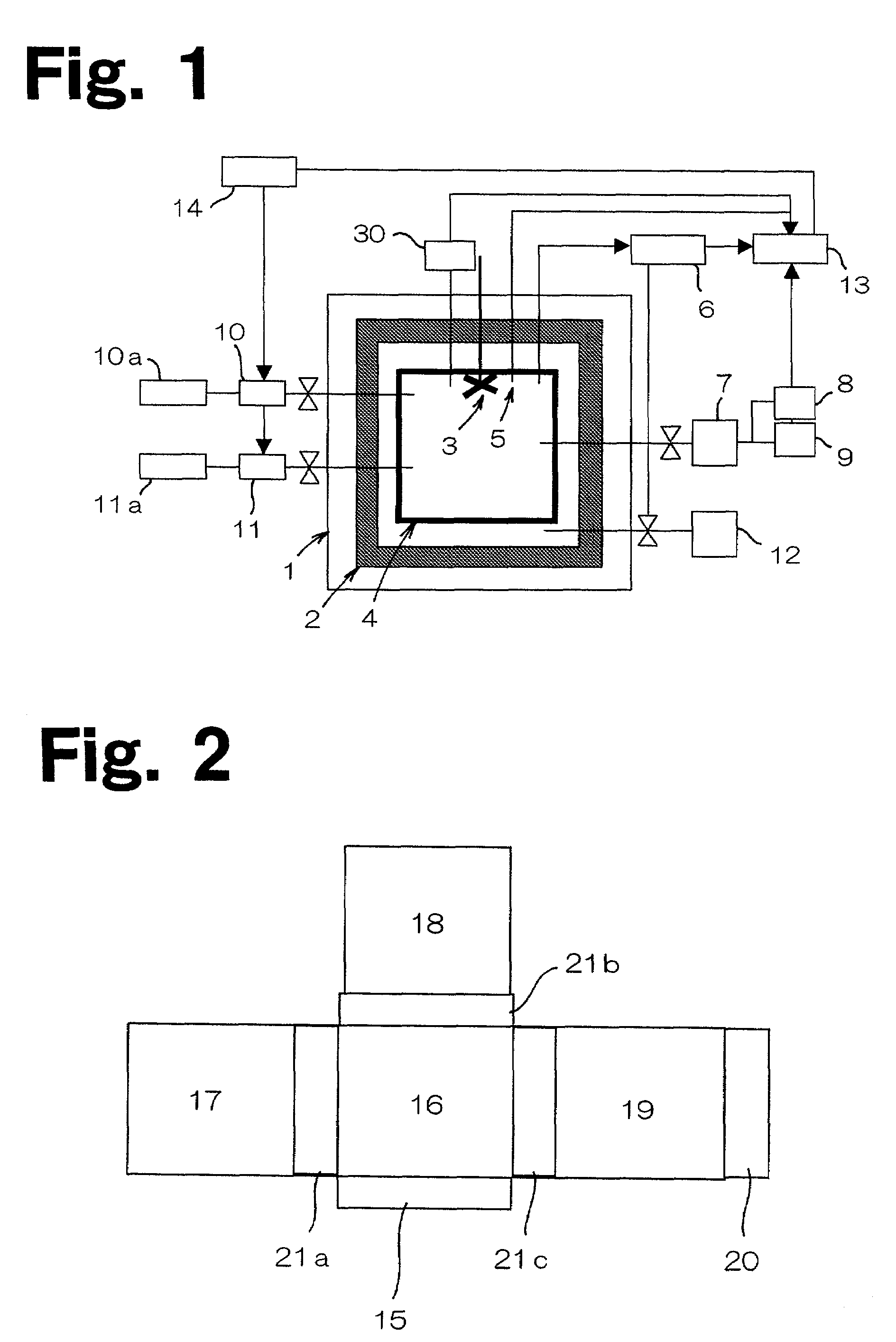

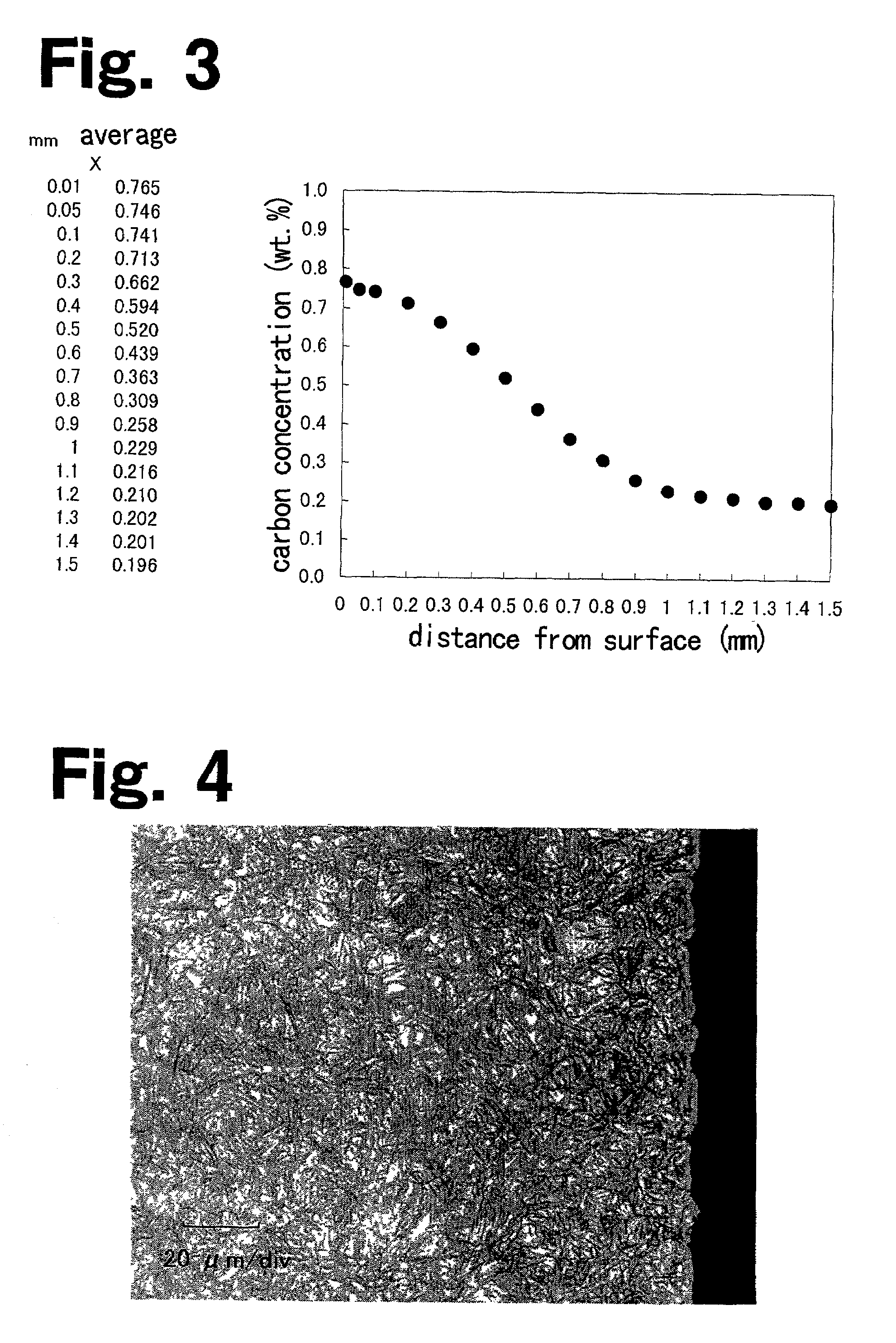

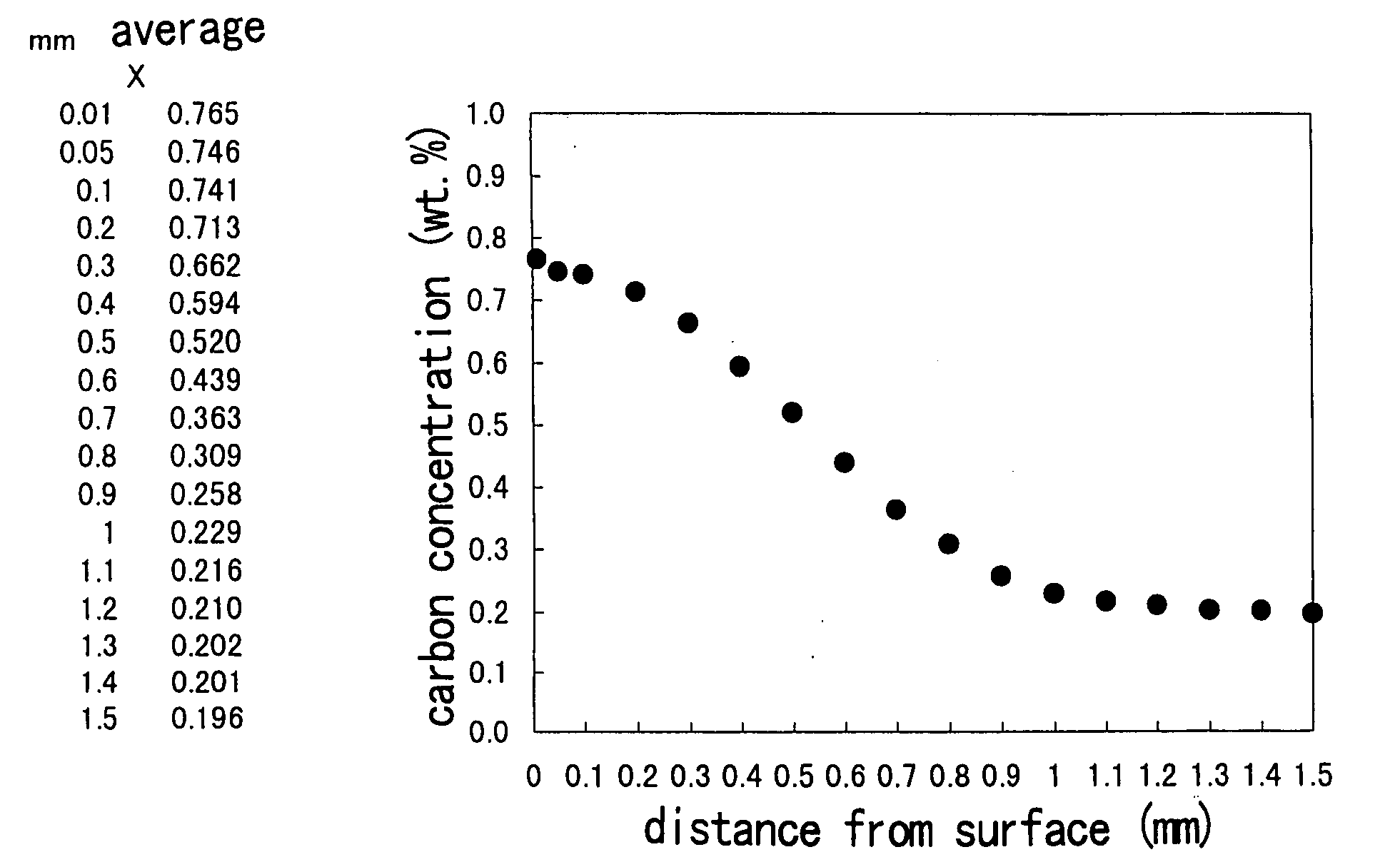

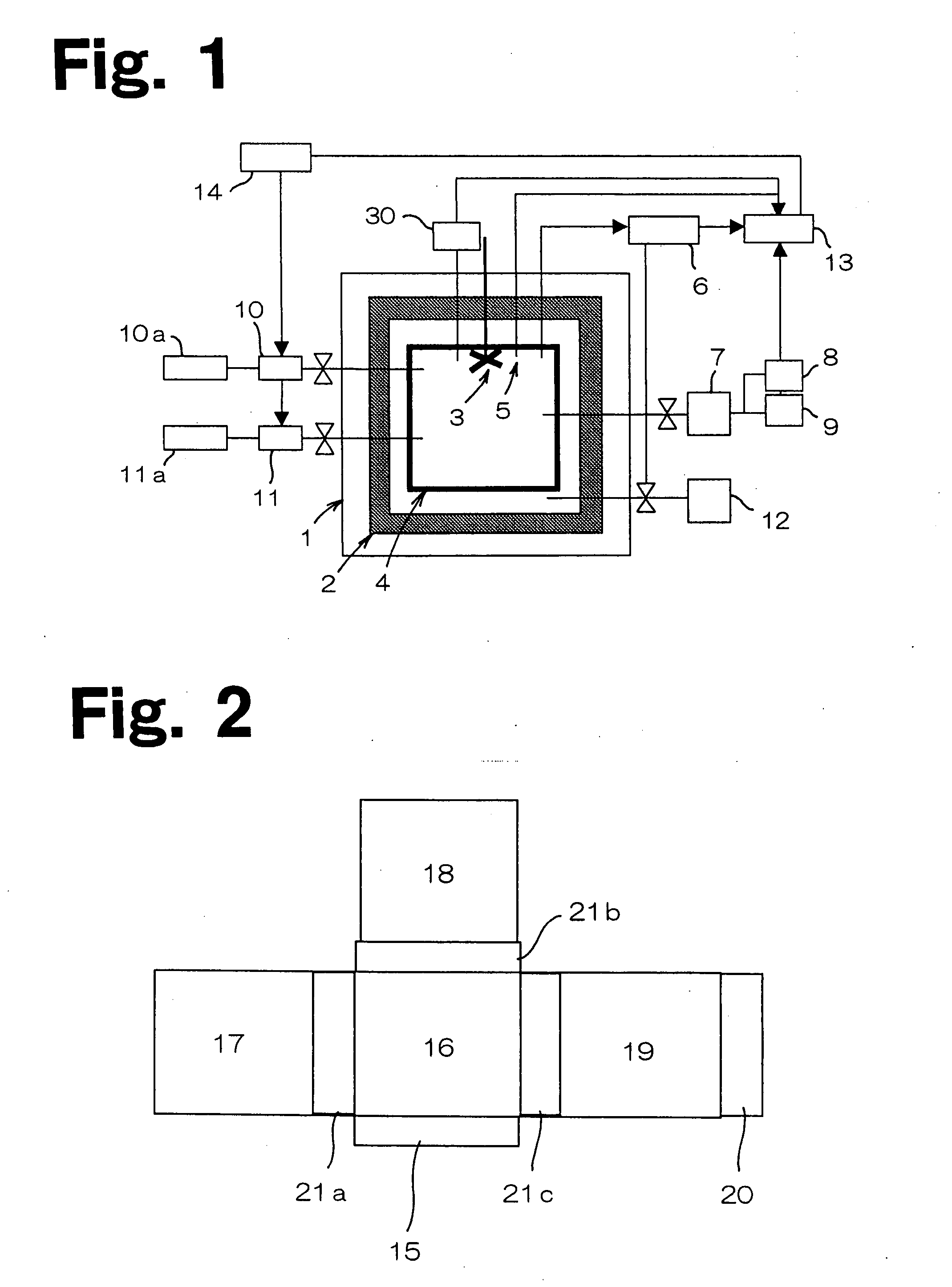

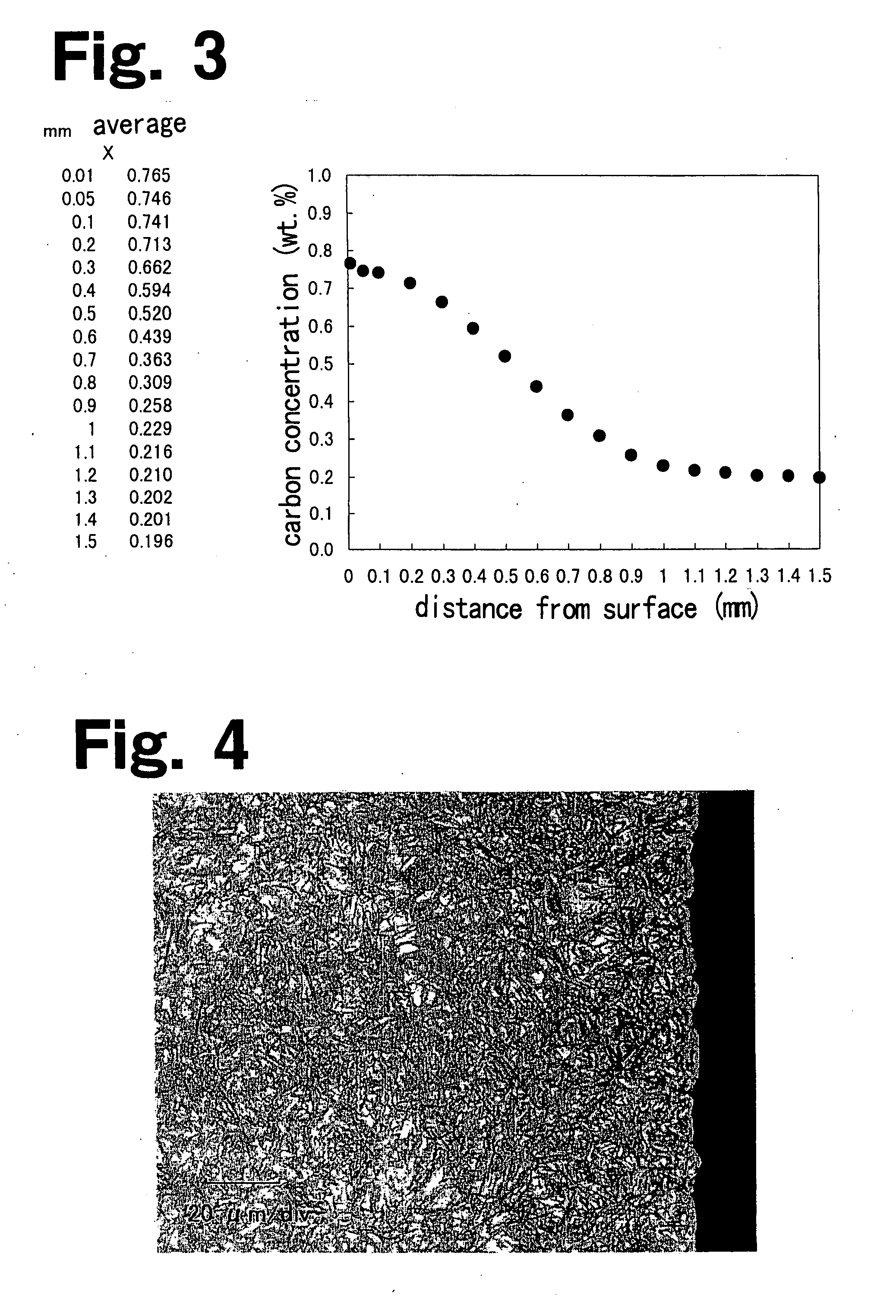

Carburization treatment method and carburization treatment apparatus

InactiveUS7276204B2Easy maintenanceReduce the amount requiredBlast furnace detailsSolid state diffusion coatingInternal pressureHydrocarbon

The invention provides a carburization treatment method in which a carburization treatment is conducted simultaneously with an operation of supplying a hydrocarbon gas and an oxidative gas into a furnace kept under a reduced pressure. Preferably, the internal pressure within the furnace is kept at 0.1 to 101 kPa, the hydrocarbon gas is one, two or more than two kinds of gases selected from the group consisting of C3H8, C3H6, C4H10, C2H2, C2H4, C2H6 and CH4, while the oxidative gas is an air, an O2 gas, or CO2 gas.

Owner:DOWA THERMOTECH

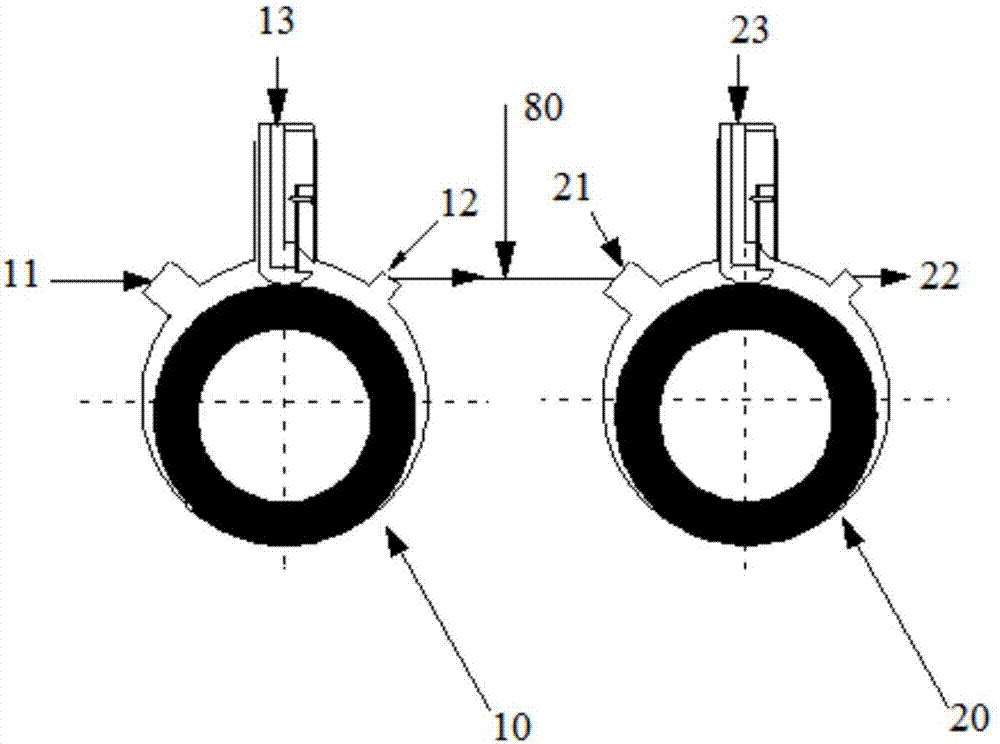

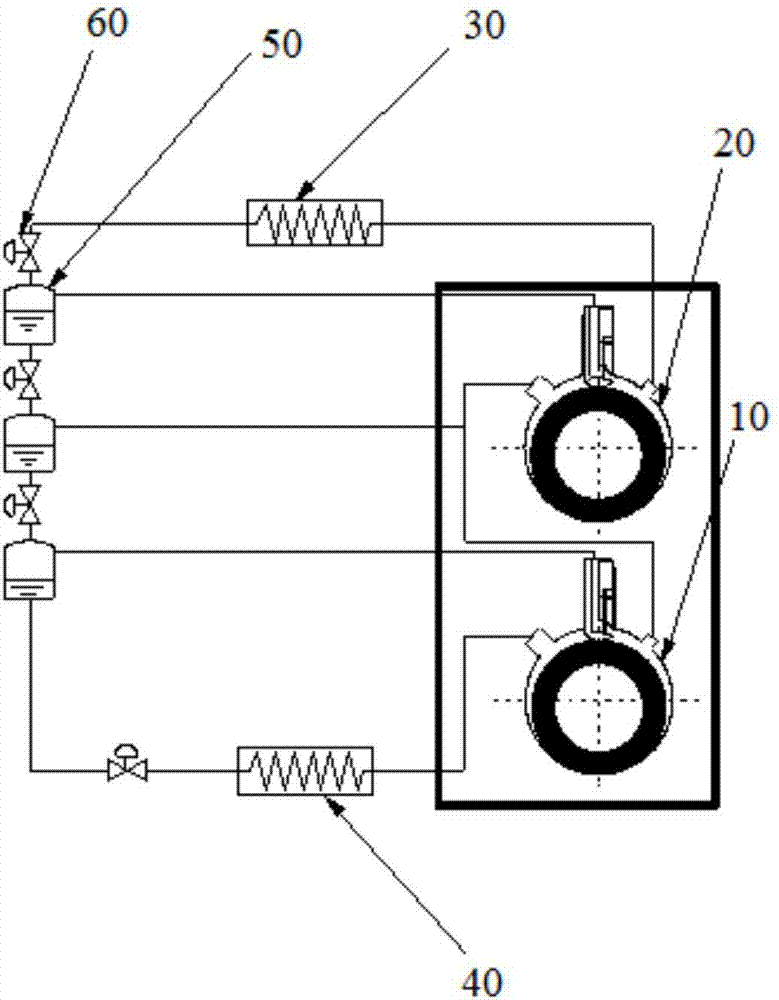

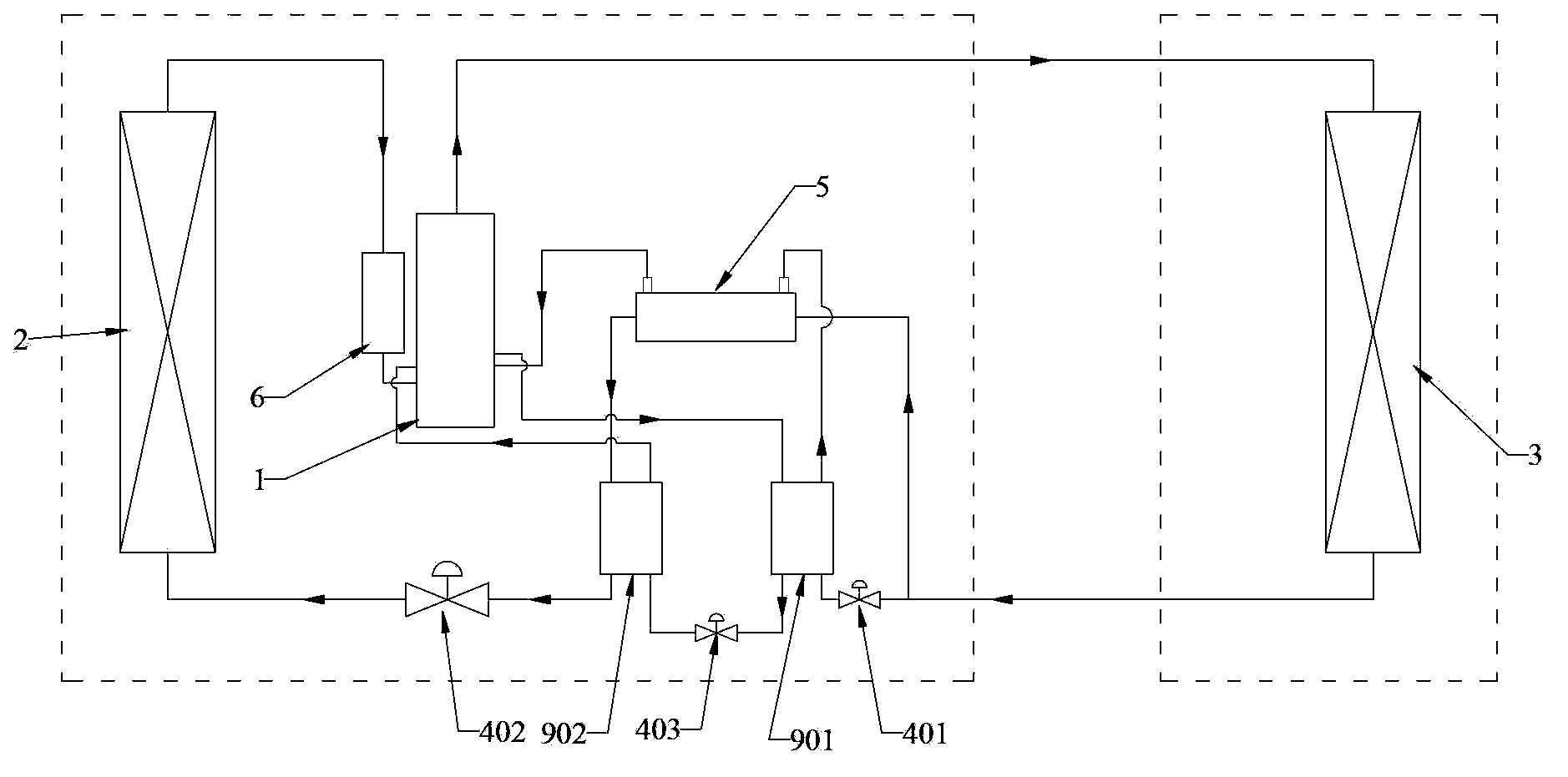

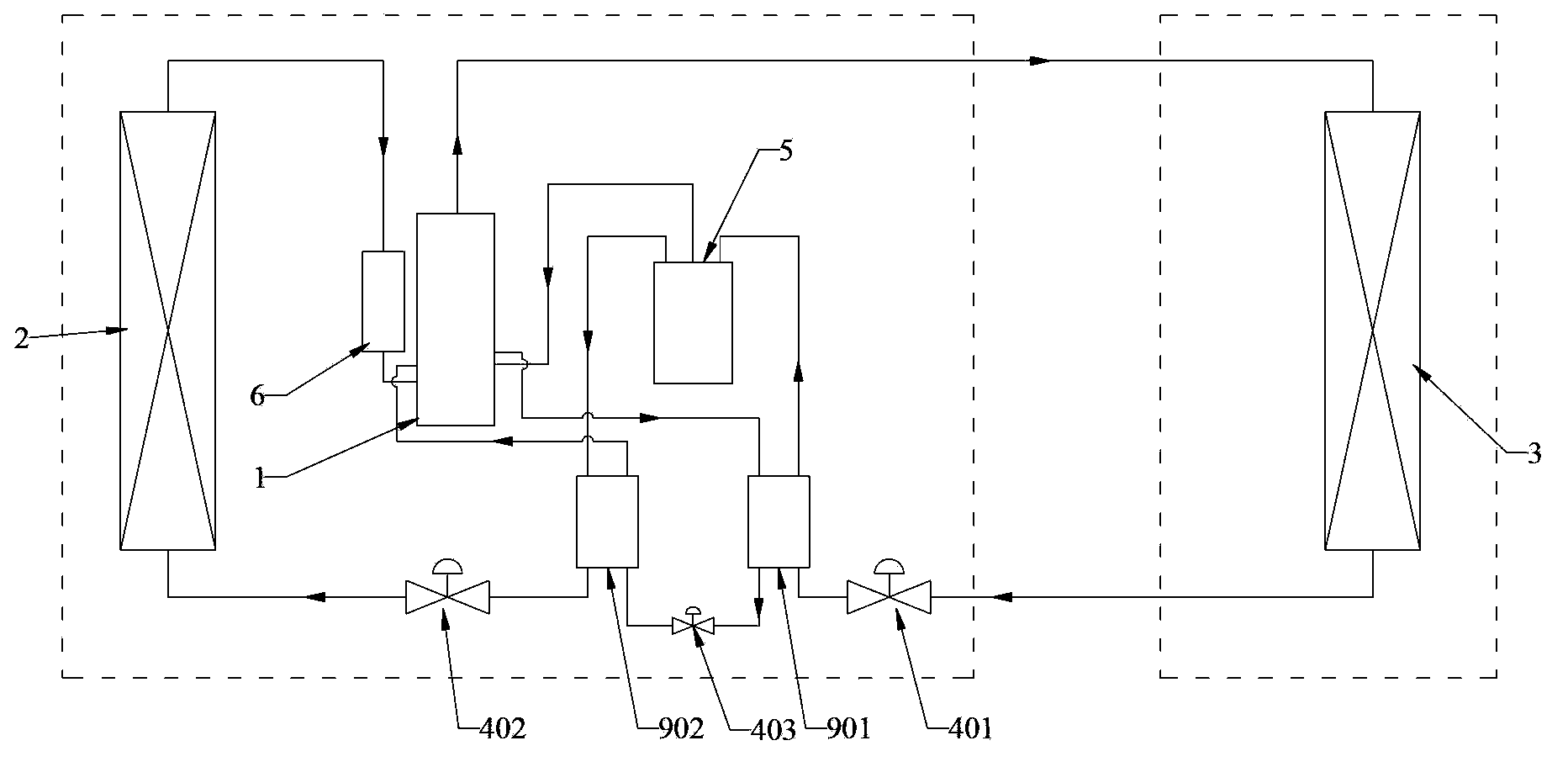

Rotary piston compressor with three-stage air supplementing function and air conditioning system

ActiveCN107366621ASafe and reliable workReduce exhaust temperatureRotary/oscillating piston combinations for elastic fluidsCompression machines with non-reversible cycleThree stageEngineering

The invention provides a rotary piston compressor with a three-stage air supplementing function and an air conditioning system. The rotary piston compressor comprises a first-stage compression unit (10), a second-stage compression unit (20) and air supplementing devices; the first-stage compression unit (10) and the second-stage compression unit (20) each comprises an air cylinder, an end plate, a rotary piston and a sliding plate, each air cylinder is provided with an air inlet and an air outlet, the air supplementing devices are arranged on the second-stage compression unit (20), a pipe between the first-stage compression unit (10) and the second-stage compression unit (20) and the first-stage compression unit (10), and therefore the refrigerant flow is increased, and the refrigerant temperature is decreased. According to the technical scheme, the compressor refrigerant circulation amount is effectively improved, the refrigerant temperature in the compression process is decreased, and the compressor efficiency is improved.

Owner:TSINGHUA UNIV

Air conditioner

ActiveCN104101124AImprove cooling effectImprove energy efficiency ratioCompressorCompression machines with non-reversible cycleCavity conditionerRefrigerant

The invention provides an air conditioner. The air conditioner comprises a compressor, and a main cycle and an auxiliary cycle which are connected with the compressor, wherein the compressor comprises a first compression chamber, a second compression chamber and a third compression chamber, the first compression chamber and the second compression chamber are arranged in the main cycle, and the third compression chamber is serially connected in the auxiliary cycle; the main cycle further comprises a condenser, an evaporator and an air compensation device which is connected between the condenser and the evaporator and is used for compensating air to the compressor; the auxiliary cycle further comprises an auxiliary condenser which is used for heating refrigerant entering the air compensation device and an auxiliary evaporator which is used for refrigerating the refrigerant entering the evaporator. The air conditioner has the advantages that since the compressor is provided with three compression chambers, the first compression chamber and the second compression chamber are arranged in the main cycle and the third compression chamber is serially connected in the auxiliary cycle, when the compressor works, the refrigerant in the main cycle and the refrigerant in the auxiliary cycle are simultaneously compressed, one compressor is saved, and the costs, the size and the control complexity are further reduced.

Owner:GREE ELECTRIC APPLIANCES INC

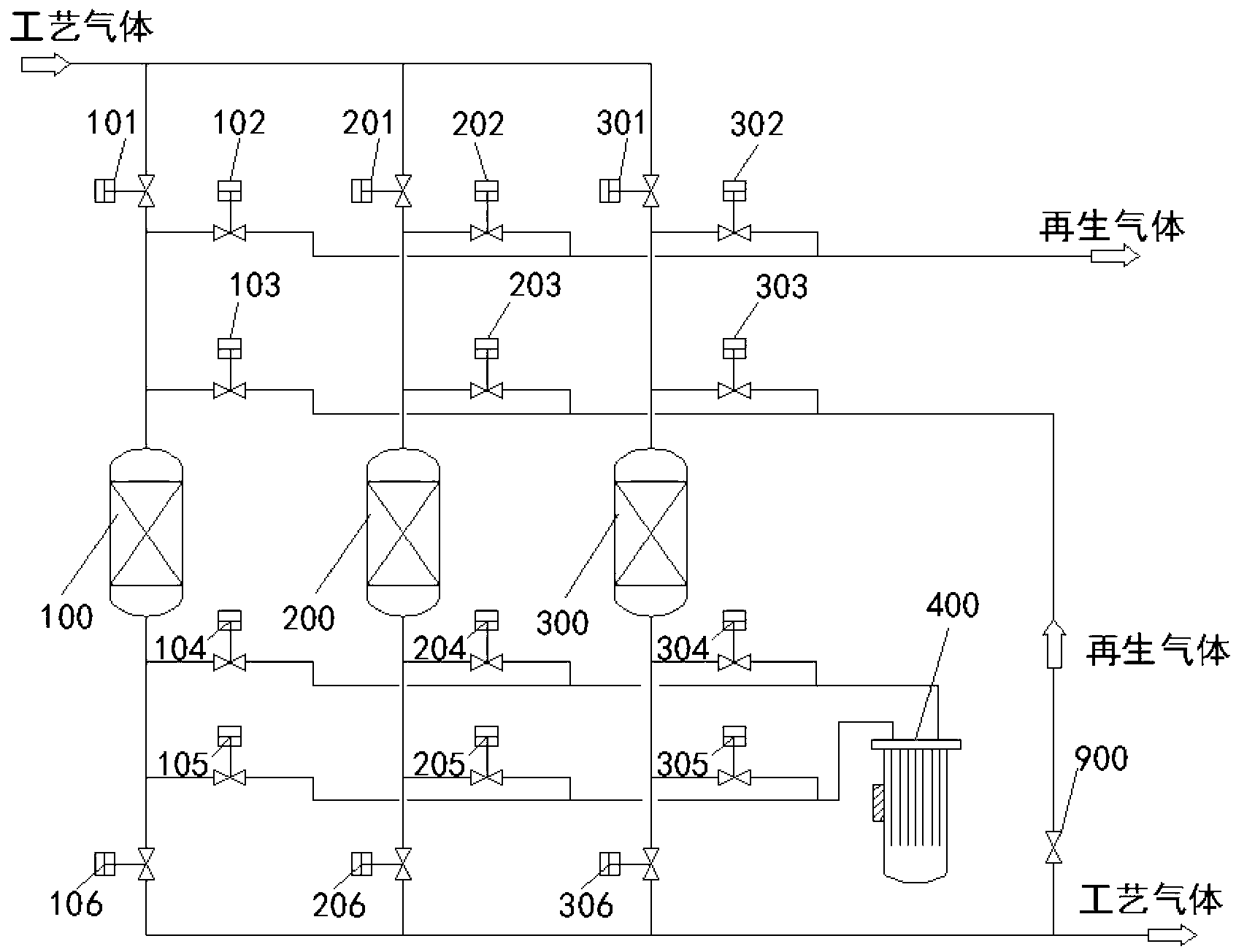

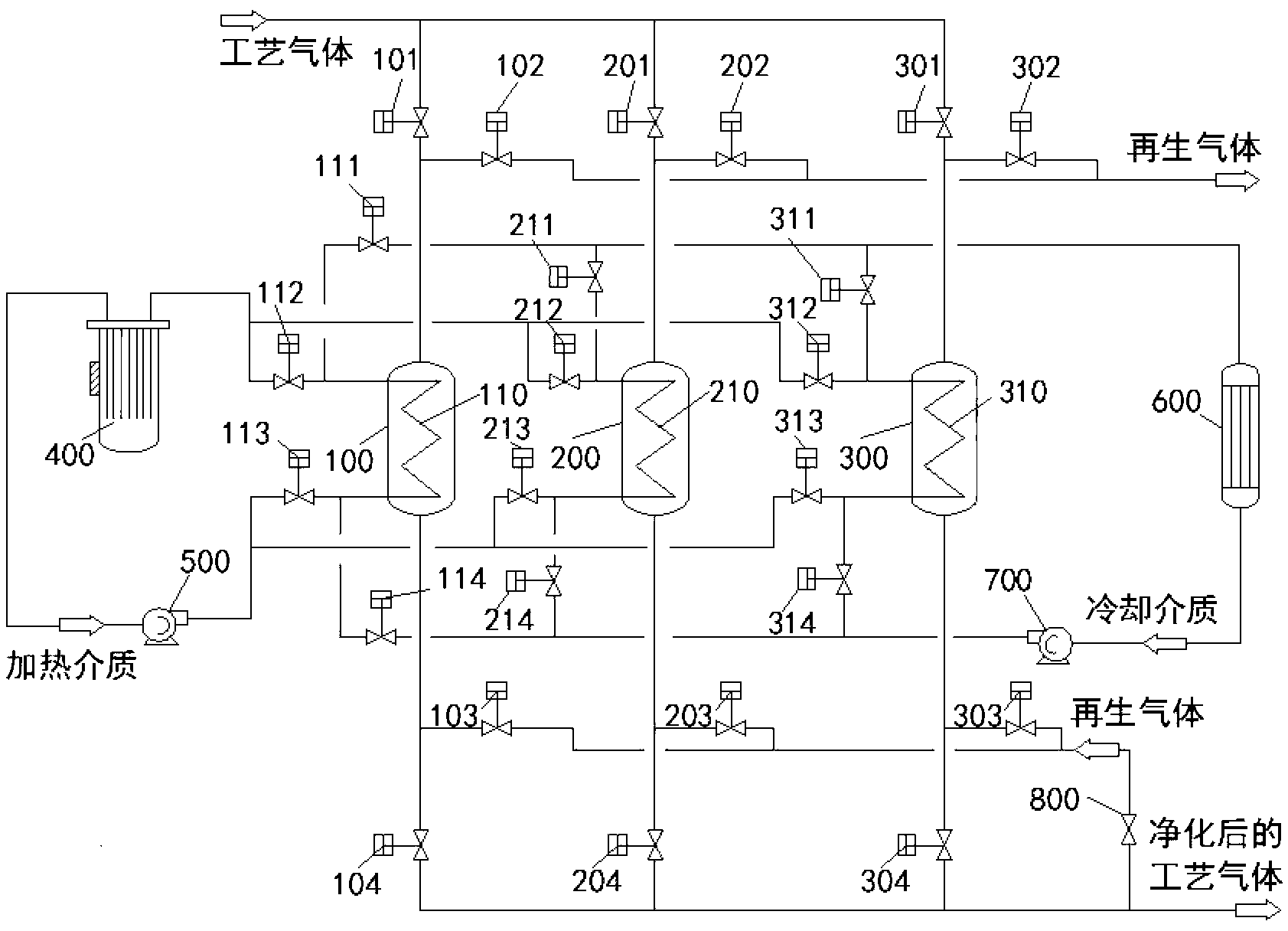

Movable skid-mounted natural/coal bed gas adsorption and purification system with external medium heat exchange function

ActiveCN103007676AFast desorptionRapid coolingGaseous fuelsDispersed particle separationSorbentDesorption

The invention relates to a movable skid-mounted natural / coal bed gas adsorption and purification system with an external medium heat exchange function, which comprises an adsorption tower system and a heat conduction medium heating circulation and cooling circulation system. The adsorption tower system consists of three adsorption towers which are connected in parallel and are switched to be started; one tower is used for adsorption, another tower is used for heating desorption and the third tower is used for cooling; in the heating desorption process, an adsorbent is heated by a high temperature heat conduction medium which is from external circulation so as to be rapidly heated and desorbed, and simultaneously, a small volume of purified process gas is used as regenerated gas to take away impurities generated in the desorption process; and in the cooling process, the adsorbent is cooled by a low temperature heat conduction medium which is from external circulation, so that the temperature of the adsorbent is rapidly reduced and the regeneration process is completed. Regeneration time of the adsorbent can be shortened; consumption of the regenerated gas is reduced; meanwhile, adsorption period is reduced and the heights of the adsorption towers are reduced; and the adsorption and purification system is miniaturized.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI +1

Method of increasing gas production rate of sewage gas fermentation using xylanase

InactiveCN1757742AIncrease gas productionIncrease the amount of gasWaste based fuelFermentationMicroorganismContinuous fermentation

A fermenting method using microbes and enzyme for generating marsh gas with high gas output rate features that the xylanase-type hemi-cellulase is externally added to new marsh gas pool in the ratio of 0.55-0.5 IU / ml (material liquid) and for the normal marsh gas pool, the ratio of xylanase is increased to 5.0 IU / ml. Its advantages are high gas output rate and high content of methane in gas.

Owner:YUNNAN NORMAL UNIV

Novel combined cement clinker roasted and waste heat generation system and technique

InactiveCN101196370AClear functionWith a clear purposeIncreasing energy efficiencyFurnace typesEngineeringHigh pressure

A novel combined cement clinker calcination and power generation system with waste heat and technique are provided. The lower part of a kiln head cover (3) is linked with an air girder grid plate device (19) which is linked with a single barrel cooling machine (2) and is arranged with a plurality of high pressure fans (20) nearby; the upper part of the kiln head cover (3) is linked with a tertiary air duct (17); one end of the middle part is linked with a burner (4) and the other end is linked with a rotary kiln (1); the upper side is linked with a D-D type calciner (10) arranged with a burner (18) nearby; a primary preheater (12) is arranged through a discharge nozzle on the bottom and is linked with a secondary preheater (11) via a connection pipeline; an elevator (16) is arranged near the pipeline; the primary preheater is linked with a novel waste heat boiler (13) via a heat steam pipeline; a high temperature fan (15) and a high-voltage electric dust collector (8) are linked between the primary preheater and a conditioning tower (14) via the pipeline; a boiler induced draft fan (9) is linked with the chimney. The system has high material dispersion, good preheating effect, high clinker output and low heat consumption.

Owner:LUOYANG ZHONGHEXIANG CEMENT +2

Carburization treatment method and carburization treatment apparatus

InactiveUS20080073002A1Easy maintenanceReduce the amount requiredSolid state diffusion coatingInternal pressureHydrocarbon

The invention provides a carburization treatment method in which a carburization treatment is conducted simultaneously with an operation of supplying a hydrocarbon gas and an oxidative gas into a furnace kept under a reduced pressure. Preferably, the internal pressure within the furnace is kept at 0.1 to 101 kPa, the hydrocarbon gas is one, two or more than two kinds of gases selected from the group consisting of C3H8, C3H6, C4H10, C2H2, C2H4, C2H6 and CH4, while the oxidative gas is an air, an O2 gas, or CO2 gas.

Owner:DOWA THERMOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com