Compressor, air conditioning system with same and heat-pump water heater system

A compressor, high-pressure compression technology, applied in the direction of compressors, machines/engines, machine operation modes, etc., can solve problems such as affecting compressor fullness, large airflow pulsation, reducing compressor efficiency and compressor energy efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

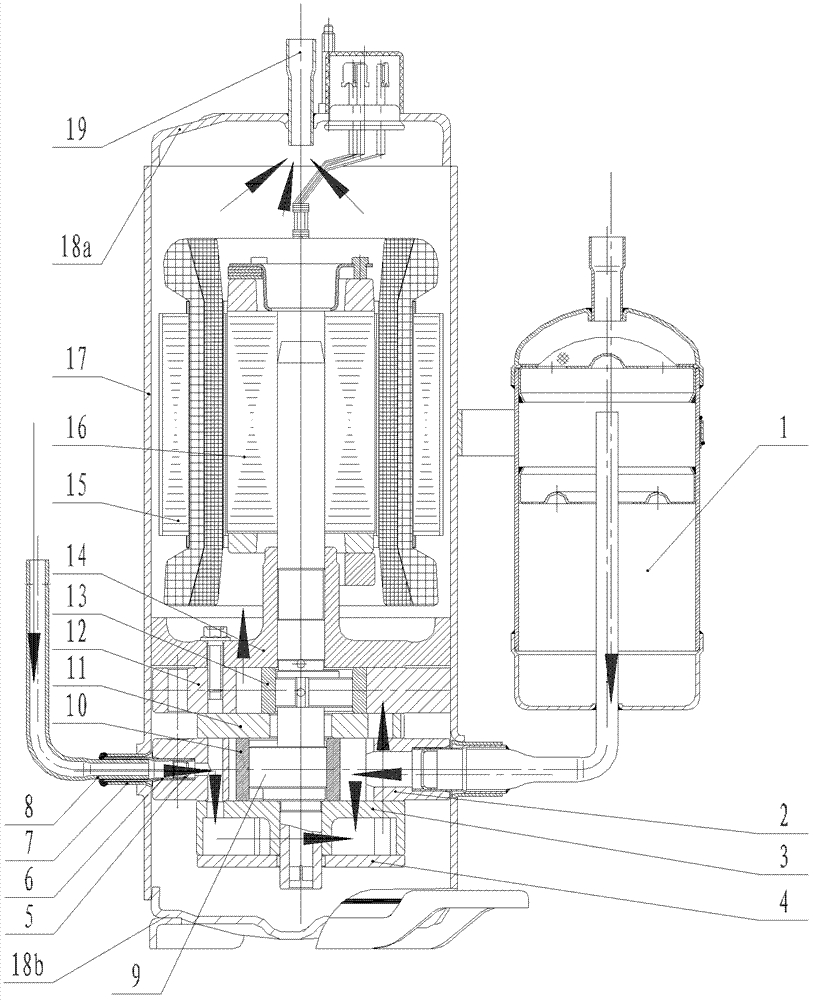

[0047] Figure 1 to Figure 15 The compressor of the first embodiment of the present invention is shown, and the compressor is a two-stage enthalpy-increasing compressor with the medium-pressure chamber at the lower part of the low-pressure chamber.

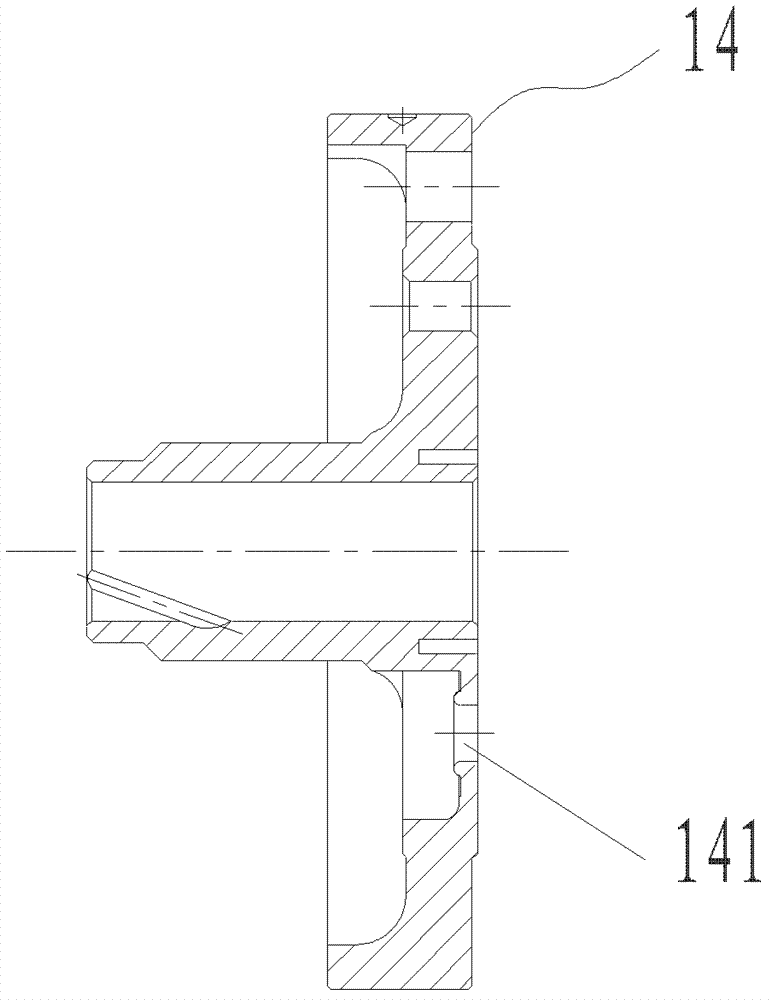

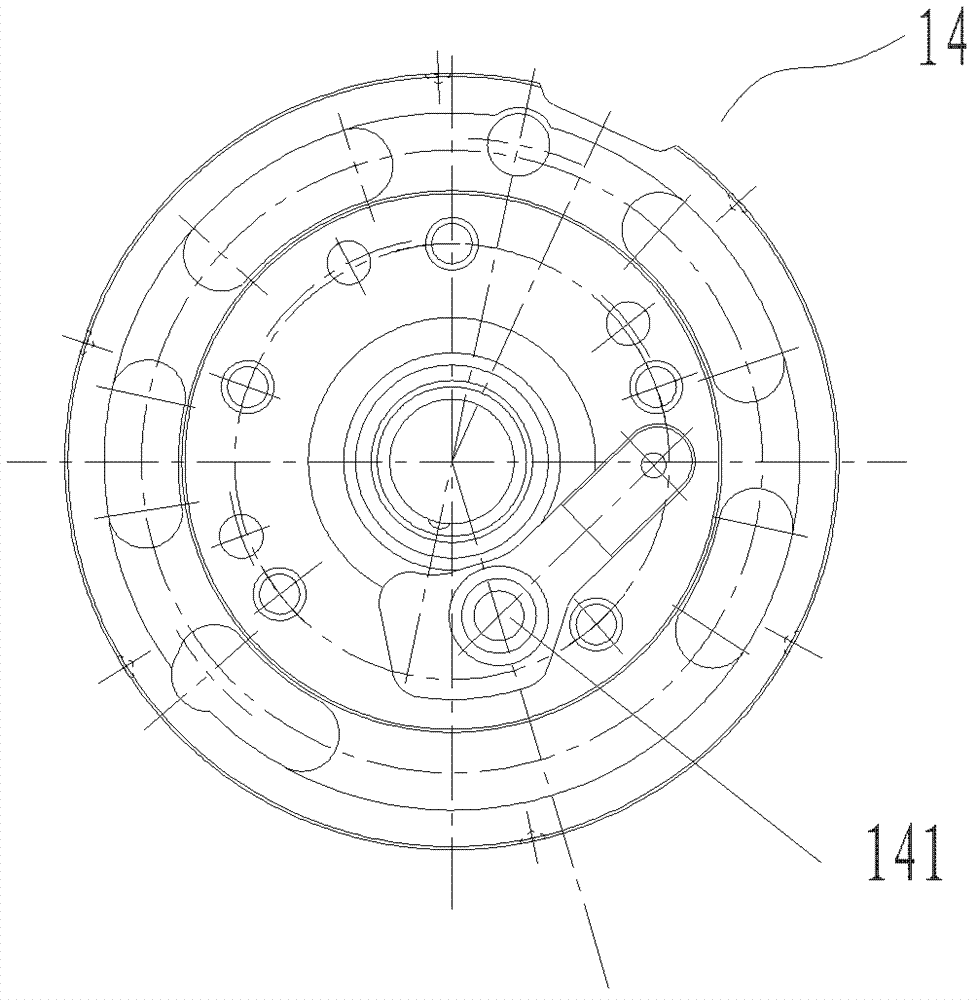

[0048] The compressor of the first embodiment mainly includes a shell assembly, a motor, a low-pressure compression assembly, an enthalpy-increasing assembly, a lower flange 3, a high-pressure compression assembly, a pump body partition 11, an upper flange 14, a liquid separator 1, and the like.

[0049]The case assembly includes an upper case 18a, a middle case 17 and a lower case 18b. The motor is arranged inside the shell assembly and mainly consists of a stator 15 and a rotor 16 . The low-pressure compression assembly mainly includes a low-pressure cylinder 2 and a low-pressure roller 10 arranged in the low-pressure cylinder 2 . A concave cavity is arranged below the lower flange 3, and the lower cover plate 4 is set on the ...

no. 2 example

[0068] Such as Figure 24 As shown, the compressor of the second embodiment is a two-stage enthalpy-increasing compressor with a medium-pressure chamber between the low-pressure compression assembly and the high-pressure compression assembly, which mainly includes a liquid separator 201, a low-pressure cylinder 202, an intermediate cylinder 203, and an enthalpy-increasing compressor. Pipe 204, pump body partition 205, high pressure cylinder 206, upper flange 207 and lower flange 208 and so on. In the compressor of the second embodiment, since the medium-pressure chamber is arranged on the upper part of the low-pressure chamber, the medium-pressure refrigerant of the whole compressor directly flows upward to the high-pressure compression assembly.

[0069] In the second embodiment, the liquid distributor 201 is connected with the low-pressure cylinder 202 through the suction pipe, the low-pressure cylinder 202 is fixed on the lower flange 208 by screws, the middle cylinder 203 ...

no. 3 example

[0076] Such as Figure 25 As shown, the compressor of the third embodiment forms a two-stage enthalpy-increasing compressor with an external structure of a medium-pressure cavity by adding an external airtight intermediate box. The compressor of the third embodiment mainly includes a motor, a low-pressure compression assembly, an intermediate box 304, a high-pressure compression assembly, a shell assembly, a liquid separator 301 and the like.

[0077] The liquid distributor 301 is connected with the low-pressure cylinder 302 through the suction pipe, the low-pressure cylinder 302 is fixed on the lower flange 303 by screws, the middle box 304 is fixed on the shell assembly 309 by welding, and the middle box 304 passes through the first exhaust The pipe communicates with the exhaust port of the low-pressure cylinder on the low-pressure cylinder 302, and communicates with the suction port of the high-pressure cylinder on the high-pressure cylinder 307 through the second exhaust p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com