Gas-supplying enthalpy-increasing type heat pump circulating system with ejector for heat pump device

A technology of supplementing air to increase enthalpy and heat pump device, which is applied in the direction of fluid circulation arrangement, lighting and heating equipment, refrigeration components, etc., to reduce energy consumption, promote development, and solve the effect of heating capacity attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

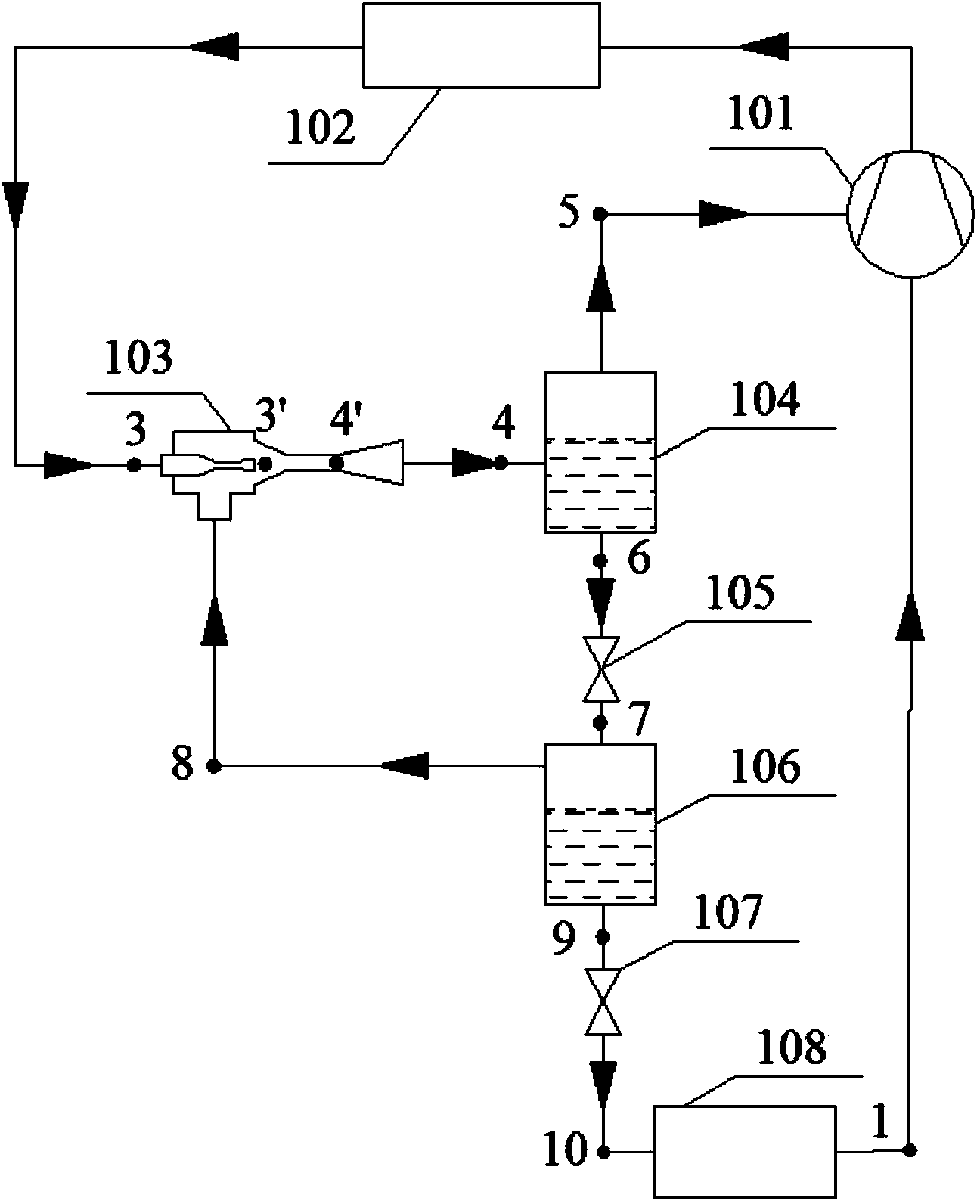

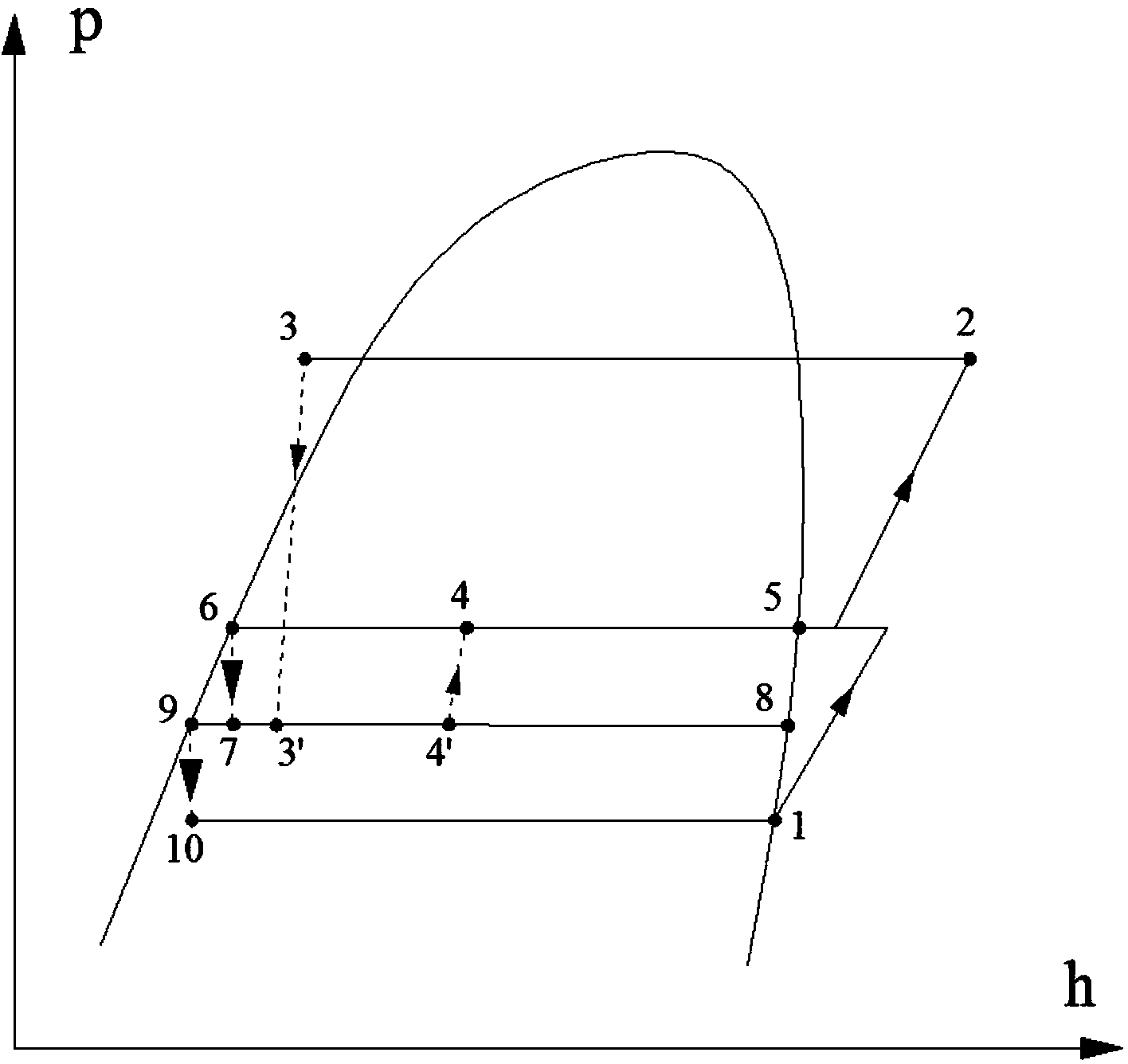

[0016] Such as figure 1 As shown, the present invention is a heat pump circulation system with an ejector for supplementing air and increasing enthalpy, including a compressor 101, the outlet of the compressor 101 is connected to the inlet of the condenser 102, and the outlet of the condenser 102 is connected to the inlet of the condenser 102. The nozzle inlets of the ejector 103 are connected, the injected refrigerant inlet of the ejector 103 is connected with the gas phase outlet of the second-stage flash evaporator 106, and the outlet of the ejector 103 is connected with the inlet of the first-stage flash evaporator 104; The outlet of the first-stage flash evaporator 104 is divided into two routes, one outlet of saturated gaseous refrigerant is connected to the supplementary suction port in the middle of compressor 101, and the oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com