Chemical and physical combined explosion fracturing device and manufacturing method thereof

A chemical physics and fracturing device technology, applied in the field of fracturing, can solve the problems of poor safety, narrow application range, limited fracturing effect, etc., and achieve the effect of ingenious design and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

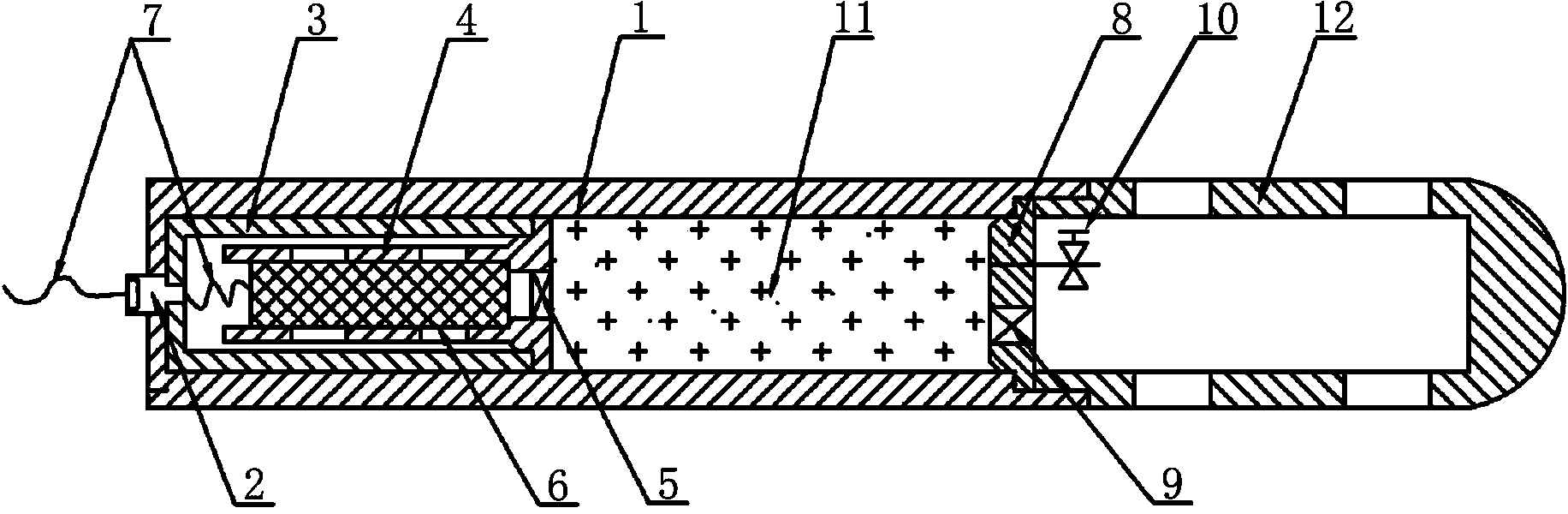

[0020] A chemical-physical composite blasting fracturing device, including a fracturing device shell 1;

[0021] The front opening of the fracturing device shell 1 is sealed with a sealing plug 2; the front part of the inner cavity of the fracturing device shell 1 is interference-fitted with a charge outer cylinder 3; the inner cavity of the charge outer cylinder 3 is provided with a powder screen 4; The rear end of the powder screen 4 extends backwards to the outside of the chamber 3 of the powder chamber, and the outer surface of the rear end of the powder screen 4 is surrounded by a radial extension, the outer surface of the radial extension is in contact with the fracturing device casing 1 is provided with an O-shaped sealing ring between the chamber walls; the rear opening of the gunpowder screen 4 is sealed with a first broken membrane 5; the inner cavity of the gunpowder screen 4 is filled with a gunpowder column 6; There is an ignition wire 7; the front end of the igni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com