Titanium modified SAPO-34 molecular sieve and preparation method and application thereof

A SAPO-34, molecular sieve technology, applied in the field of molecular sieve, can solve problems such as pollution of the environment, and achieve the effect of low cost and excellent catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

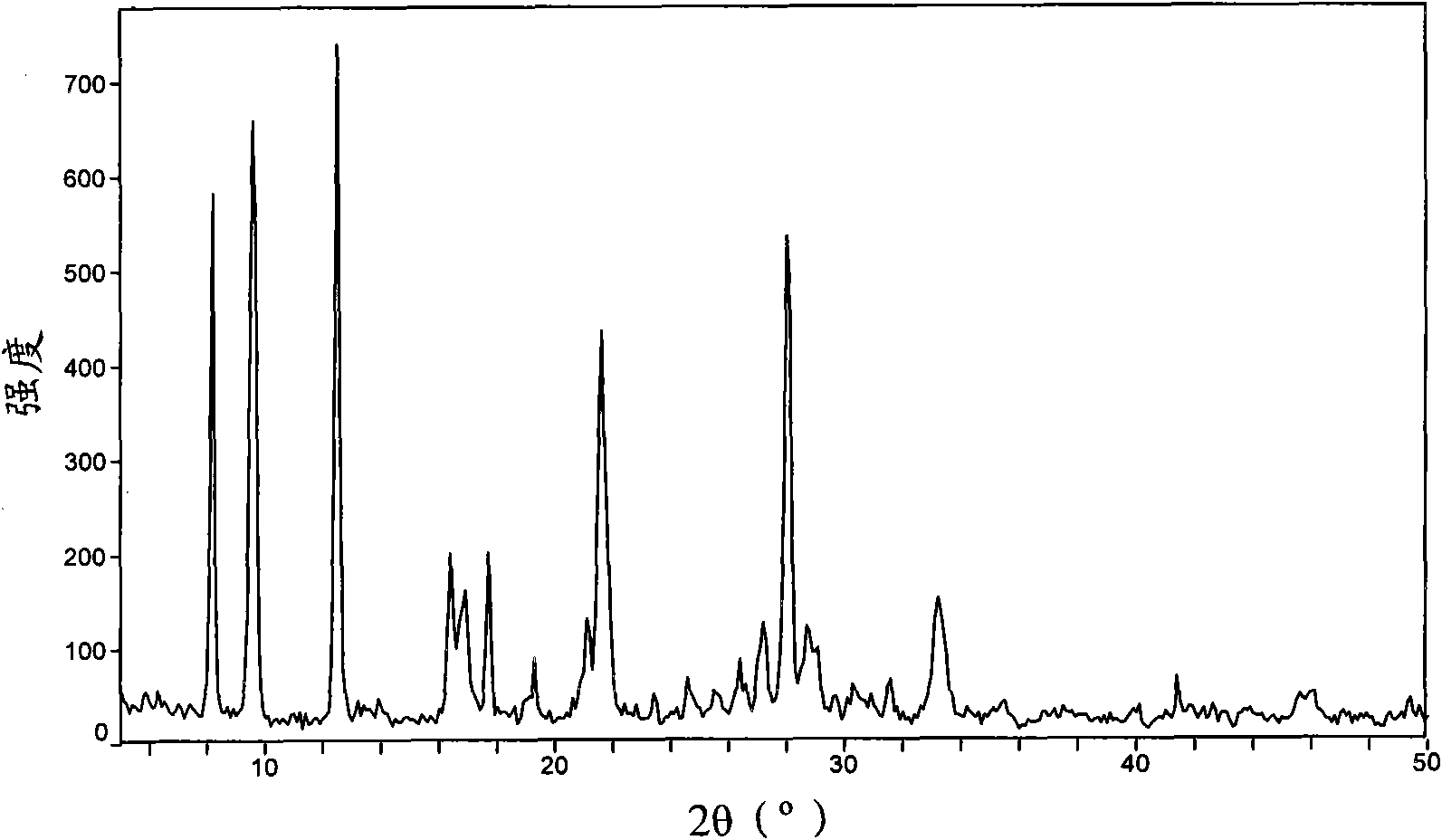

[0052] In the preparation method of the present invention, a colloidal solution containing active aluminum phosphate is formed by mixing the aluminum source and the phosphorus source uniformly; in a stirring state, a silicon source such as silica sol and an organic amine template are added in sequence, and the organic amine template is stirred evenly; The titanate is mixed with an appropriate amount of water, then added to the above mixture, and fully stirred to form a crystallization precursor mixed solution. After static aging for a certain period of time, the above-mentioned crystallization mixed solution is hydrothermally crystallized at 170-230°C for 12-96 hours, and the product is centrifuged and washed with deionized water until the supernatant is neutral (pH value is 7.0). Dry in an oven at about 100°C for 8-12 hours to obtain a solid product Ti-modified SAPO-n molecular sieve, and its anhydrous chemical expression is (0.02-0.3)TiO in terms of the molar ratio of oxides...

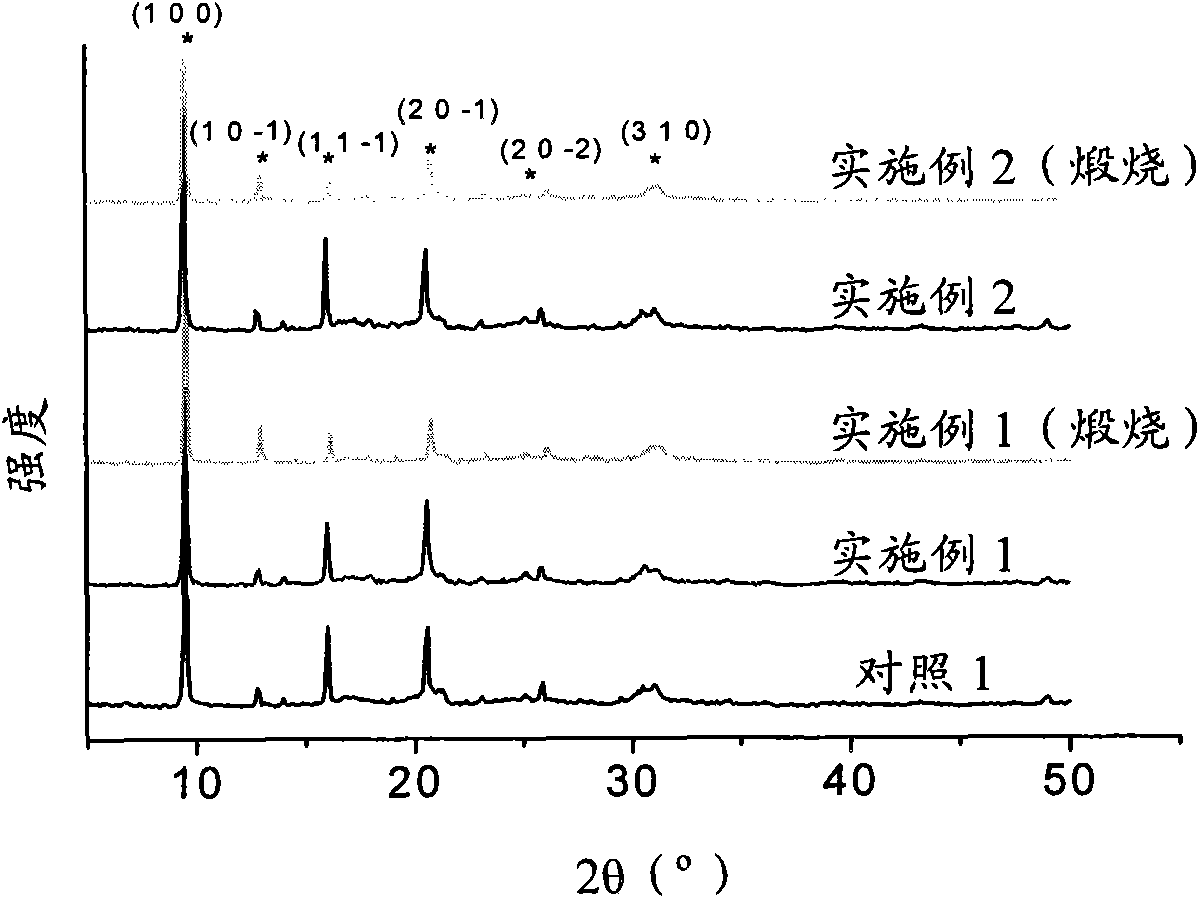

Embodiment 1

[0059] Synthesis of transition metal Ti modified SAPO-34 molecular sieves. 9.03g of pseudo-boehmite (Al 2 o 3: 62wt%) was dispersed in 24g deionized water, stirred and mixed with a magnetic stirrer (Jintan City Ronghua Instrument Manufacturing Co., Ltd. 85-2 type magnetic stirrer) to form a pseudo-boehmite slurry. Take 12.66 g of concentrated phosphoric acid with a concentration of 85% by mass, add 12.20 g of deionized water for dilution, and add the diluted phosphoric acid solution with a concentration of 43% into the pseudo-boehmite slurry to obtain an aluminum phosphate solution. Take 4.7g of 40% silica sol, dilute it with 5g of deionized water and add it to the aluminum phosphate solution. After mixing evenly, add 16.16g of triethylamine to obtain a gel mixture. Then take 0.52g of tetrabutyl titanate, add 2g of deionized water into it, stir well and add to the above gel mixture. The molar ratio composition of the obtained mixture is:

[0060] 3.0Et 3 N:0.6SiO2 2 : Al...

Embodiment 2

[0069] 9.03g of pseudo-boehmite (Al 2 o 3 : 62%) was dissolved in 24g of deionized water, and mixed with high-speed stirring to form a slurry. Take 12.66g concentration of 85% phosphoric acid, add 12.20g H 2 After O is dissolved and diluted, it is added to the slurry of pseudo-boehmite to obtain an aluminum phosphate solution. Dilute 4.7g of 40% silica sol with 5g of deionized water and add to the aluminum phosphate solution, add 16.16g of triethylamine, stir and mix evenly to obtain a gel mixture. Take 1.04g of tetrabutyl titanate, add 2g of deionized water, stir and mix evenly, then add to the above gel mixture. The molar ratio composition of obtained mixture is:

[0070] 3.0Et 3 N:0.6SiO2 2 : Al 2 o 3 :P 2 o 5 : 60H 2 O: 0.056TiO 2

[0071] Stir the above mixture at room temperature for 2 hours, after static aging for at least 2 hours, pour the crystallization mixture into the PPL liner of the stainless steel kettle, hydrothermal crystallization at 200°C and au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com