Patents

Literature

154results about "Purification using ion-exchange materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Superabsorbent surface-treated carboxyalkylated polysaccharides and process for producing same

Owner:ARCHER DANIELS MIDLAND CO

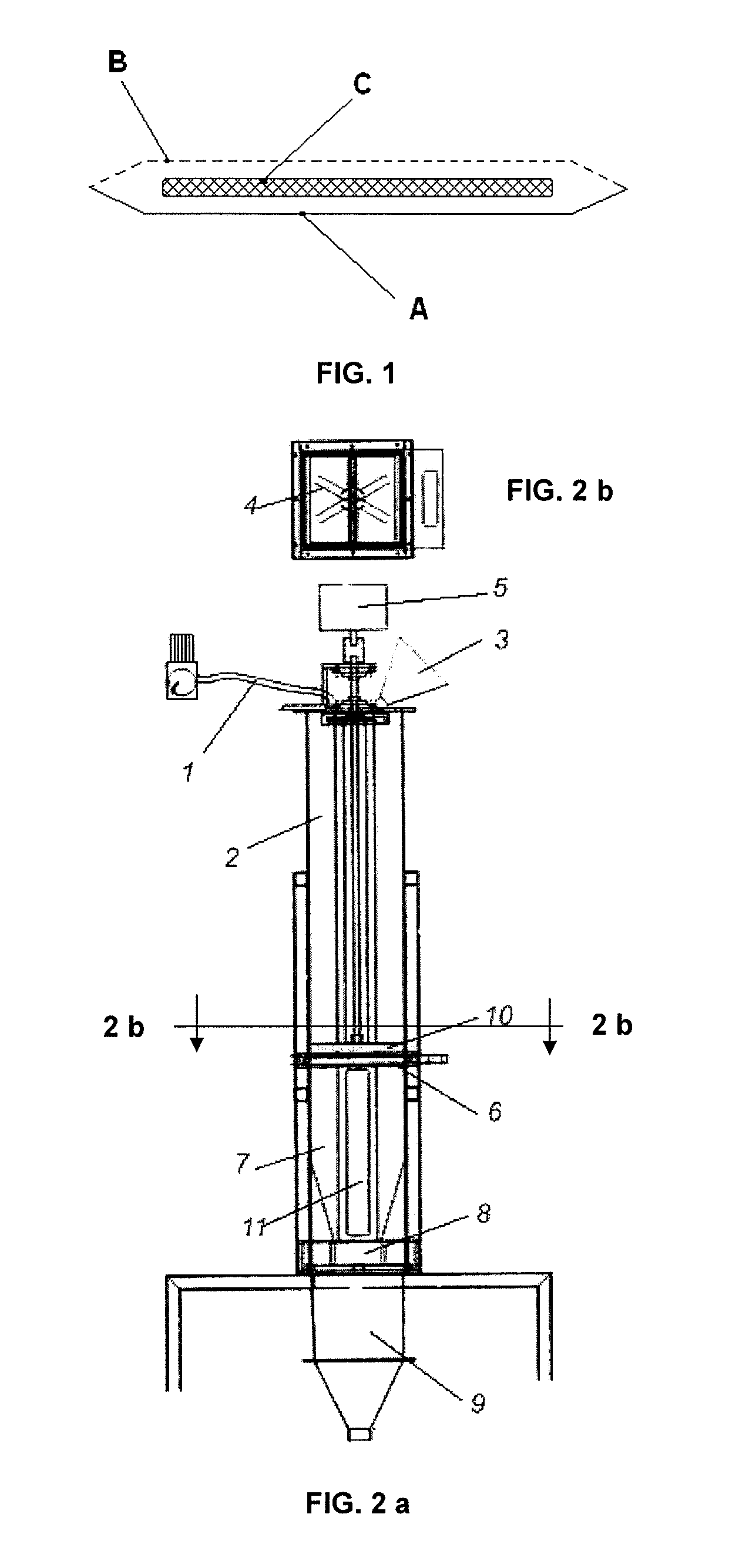

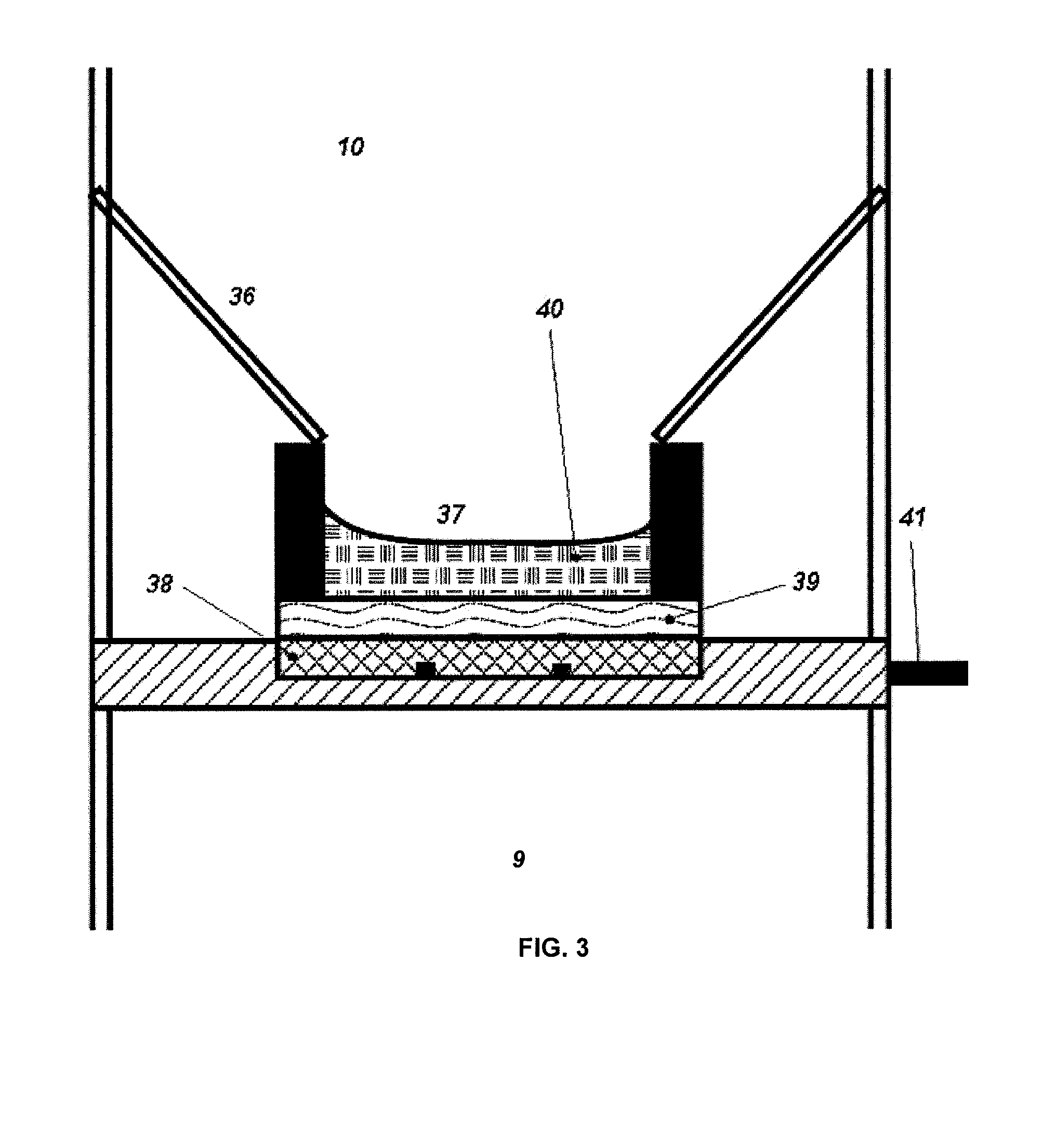

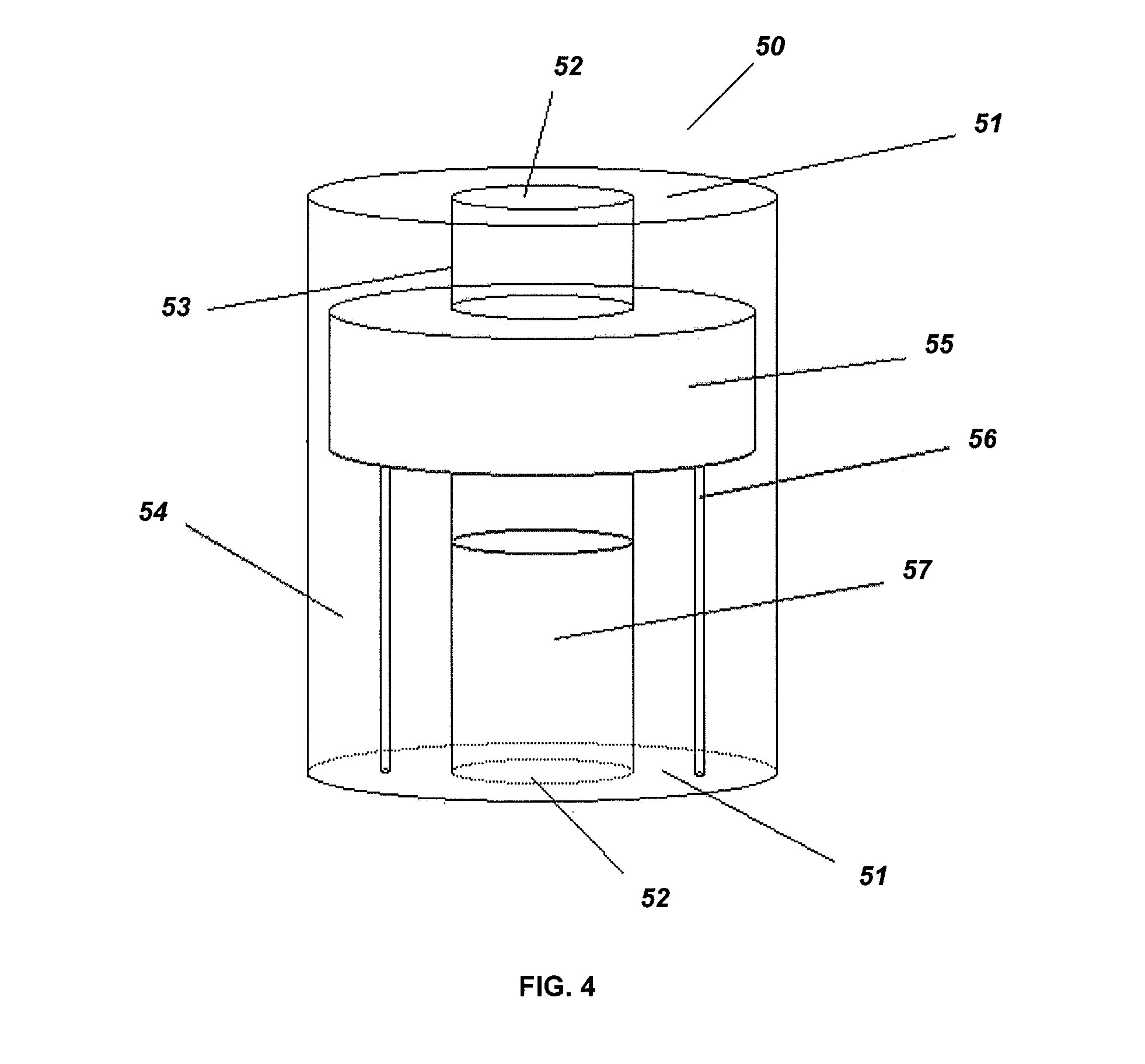

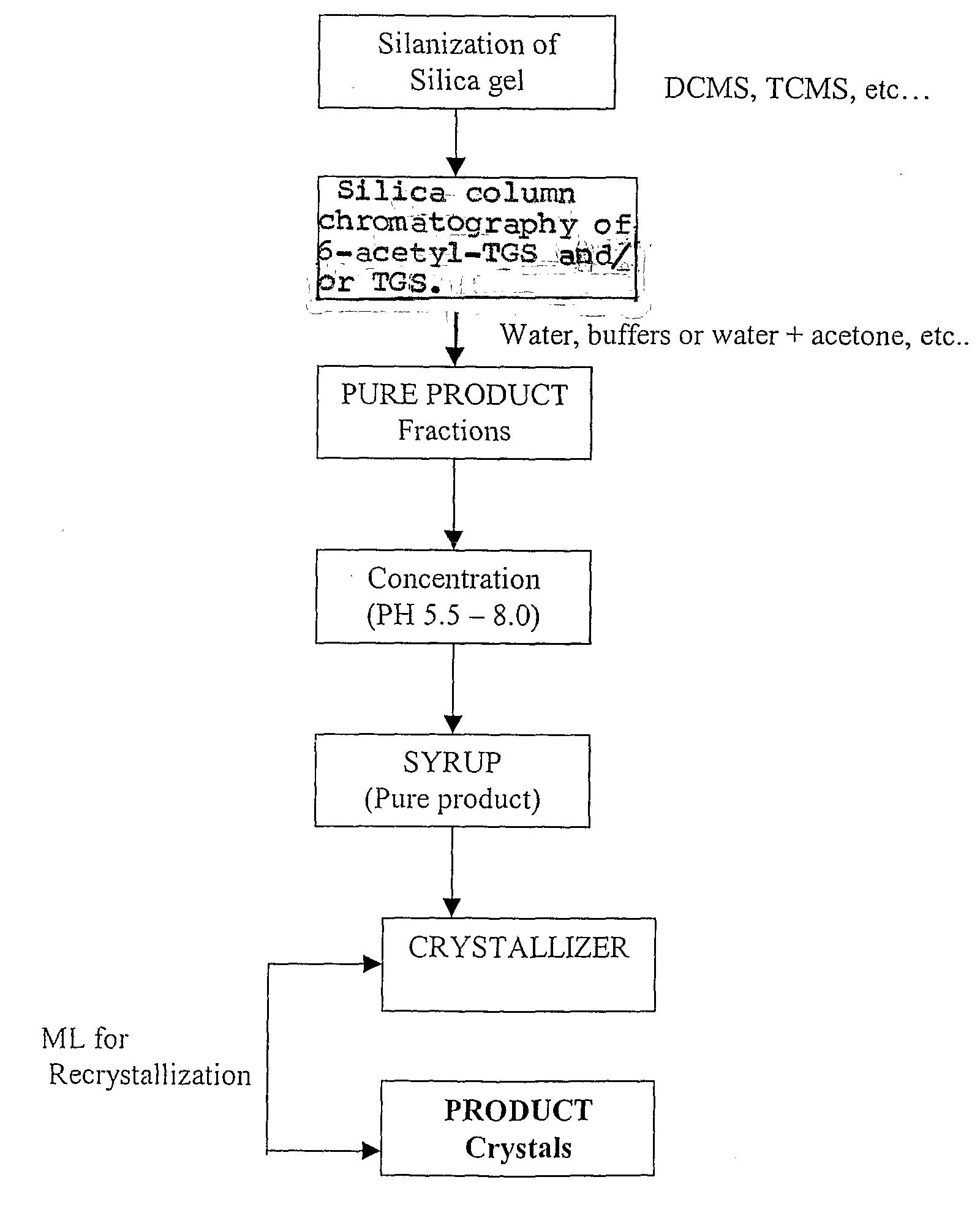

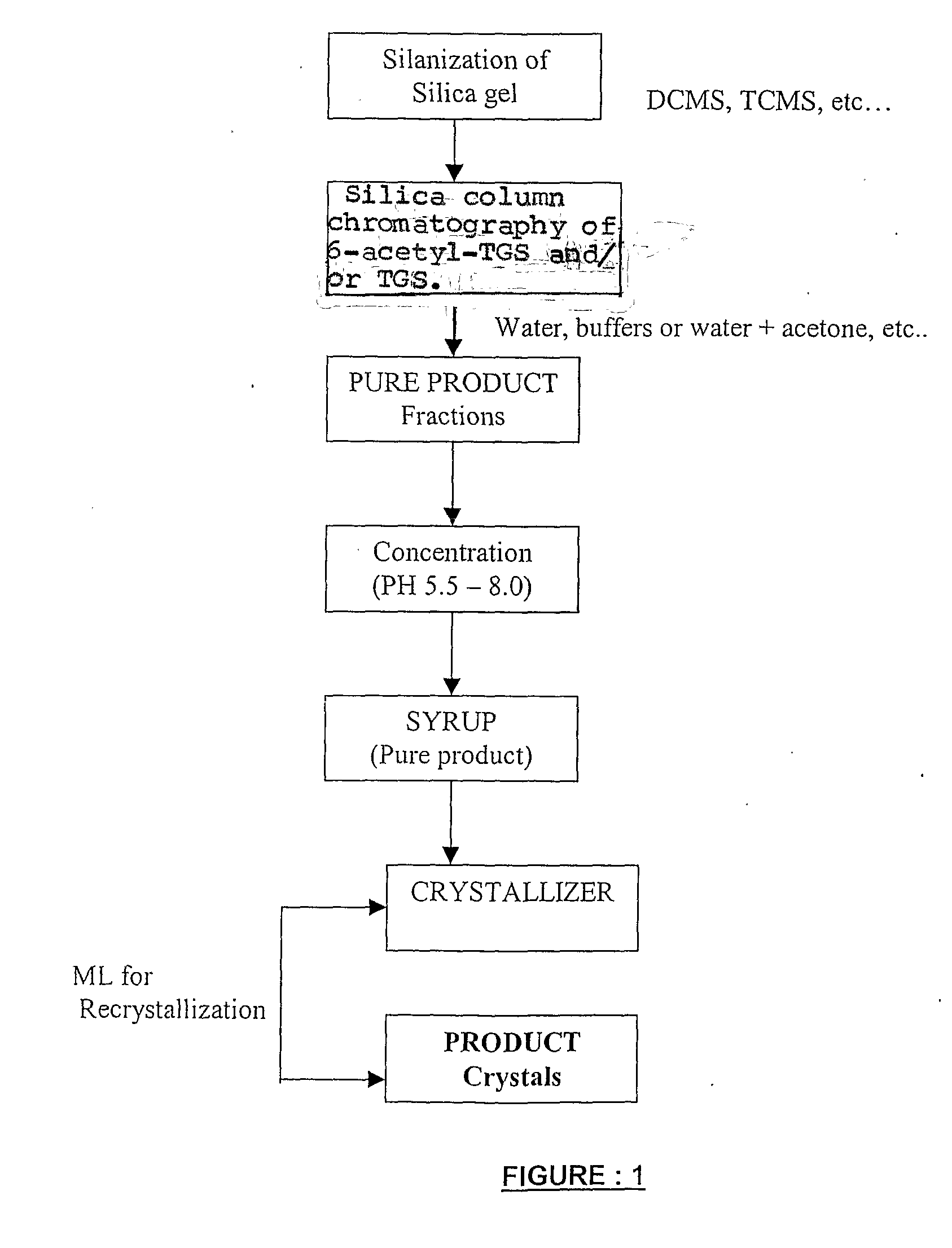

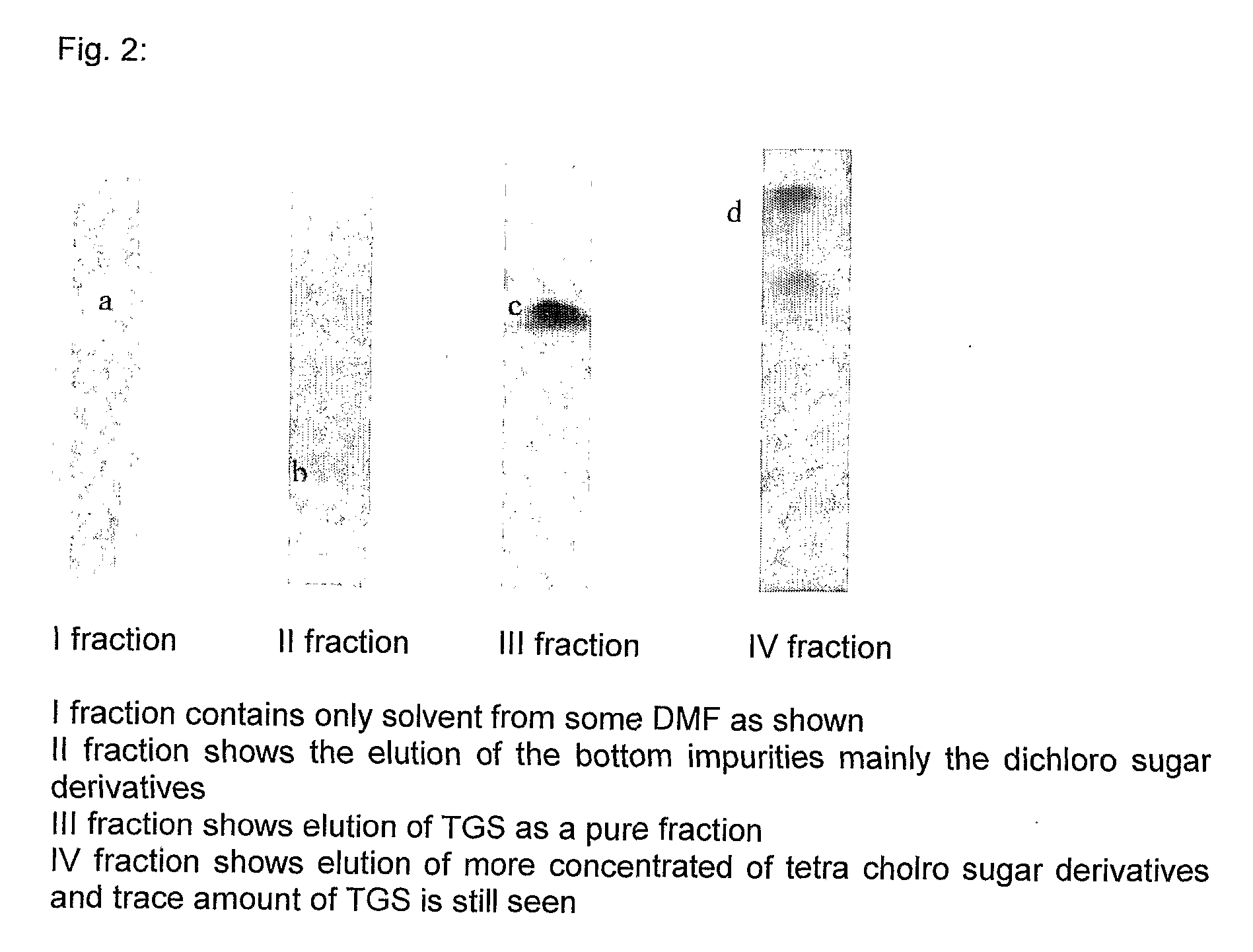

Process for Purification of 6 Acetyl 4,1', 6' Trichlorogalactosucrose and 4,1', 6' Trichlorogalactosucrose by Chromatography on Silanized Silica Gel

InactiveUS20070270583A1Purification using adsorption agentsSugar derivativesStationary phaseOrganic solvent

A reverse phase column chromatographic process of purification of 6-acetyl-4,1′,6′trichlorogalactose and 4,1′,6′trichlorogalactose is described which uses silanized silica as stationary phase and water or predominatly aqeous mixture derived from water and small proportion of organic solvents as a mobile phase.

Owner:V B MEDICARE PVT LTD

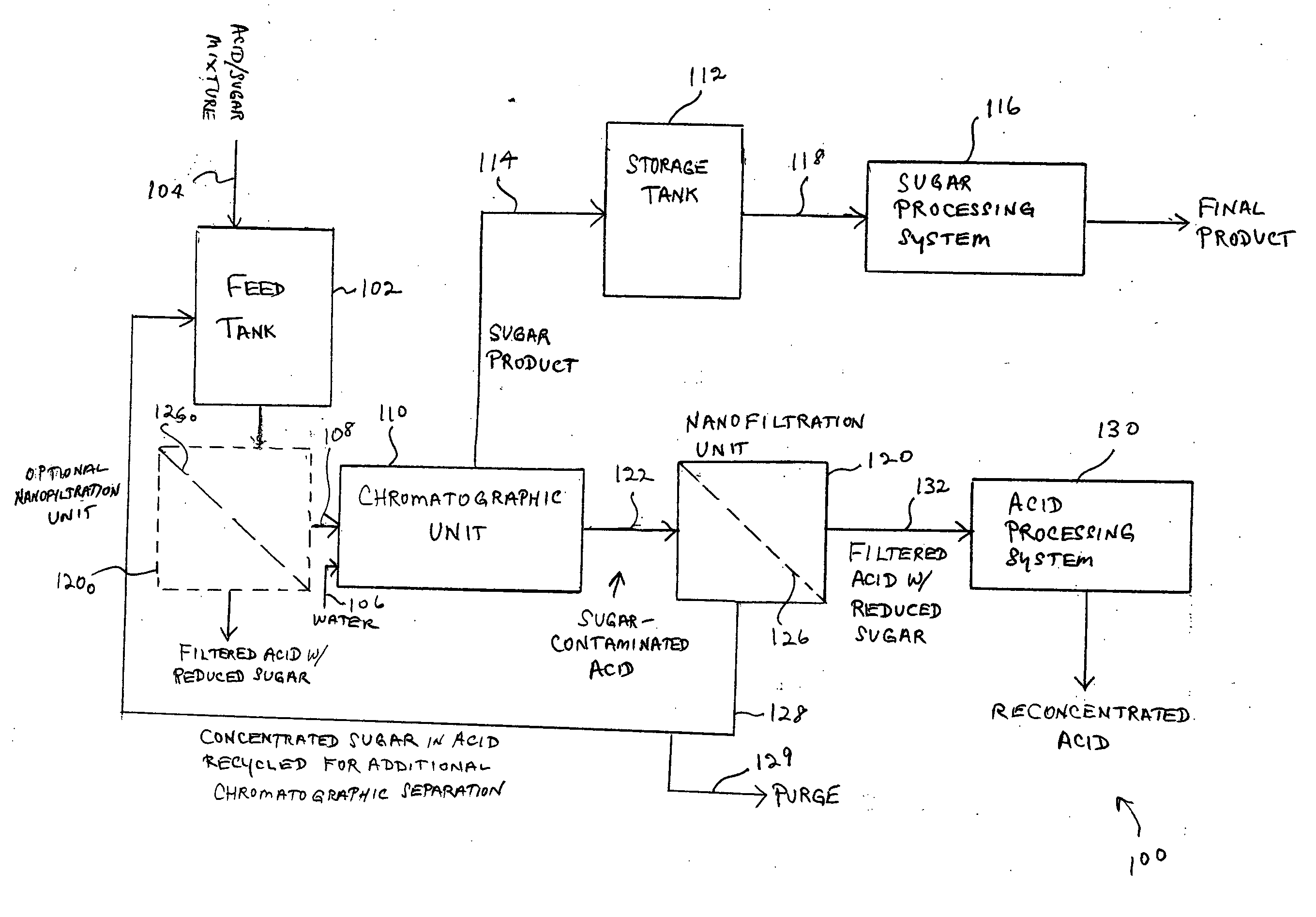

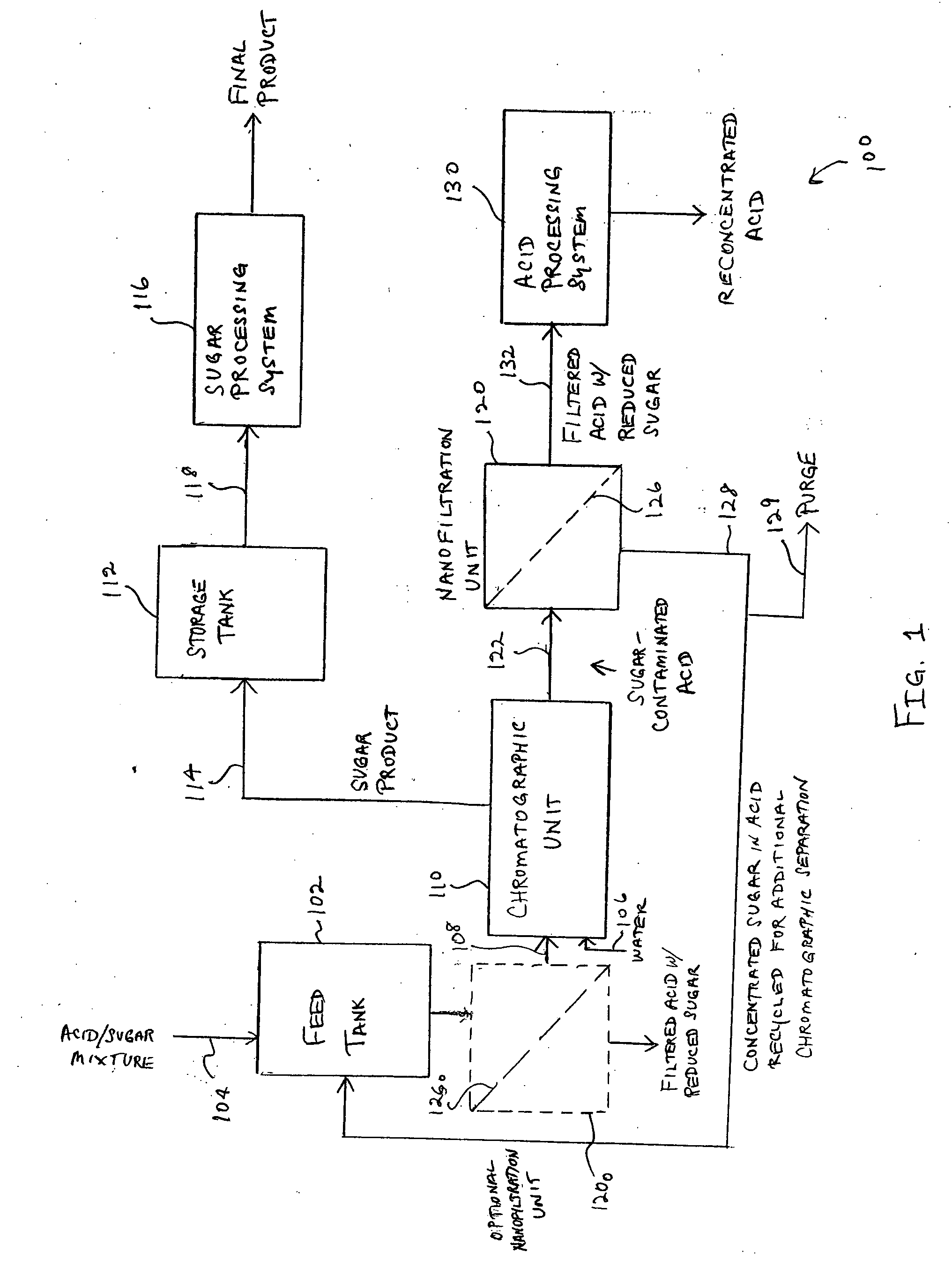

Nanofilter system and method of use

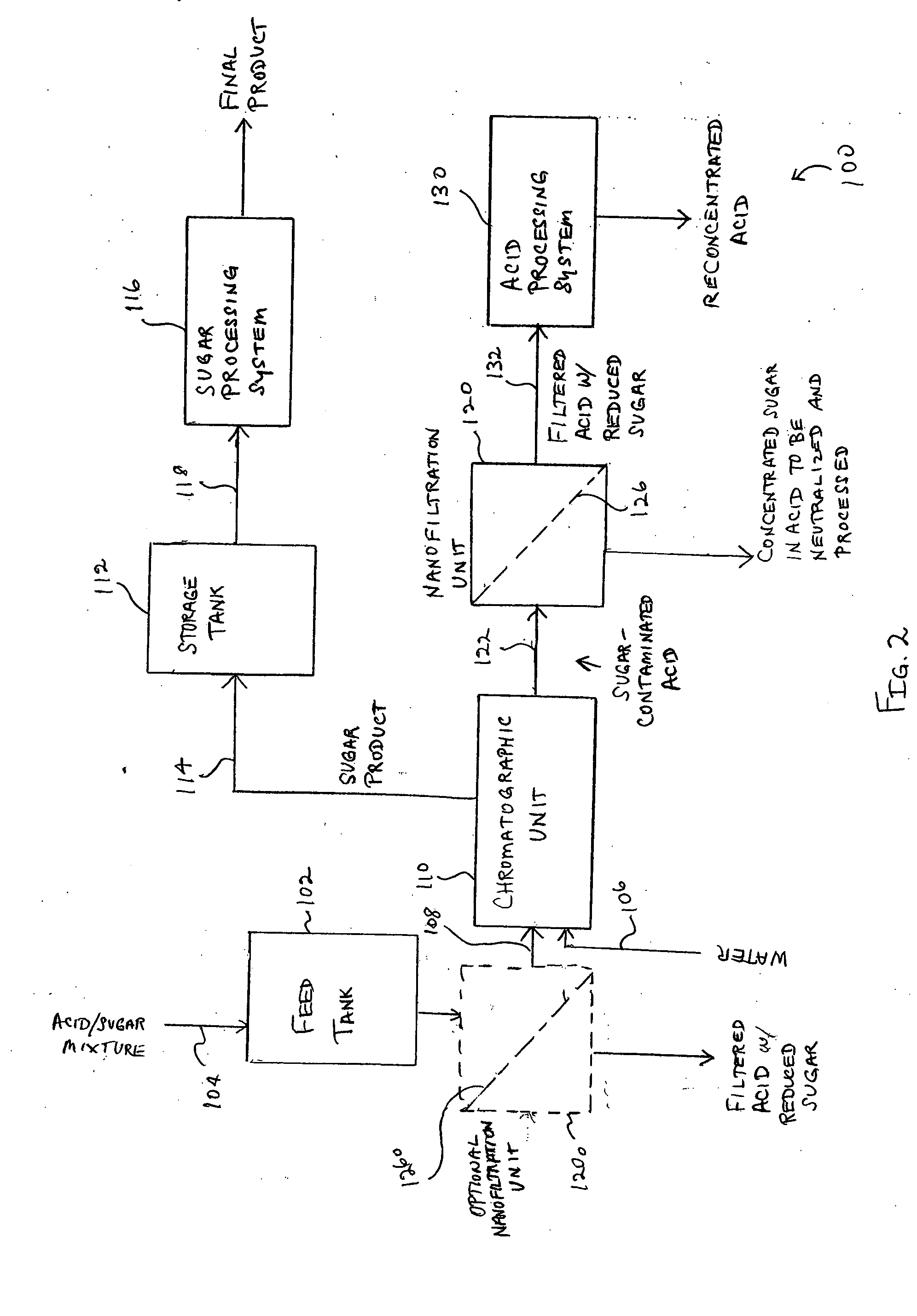

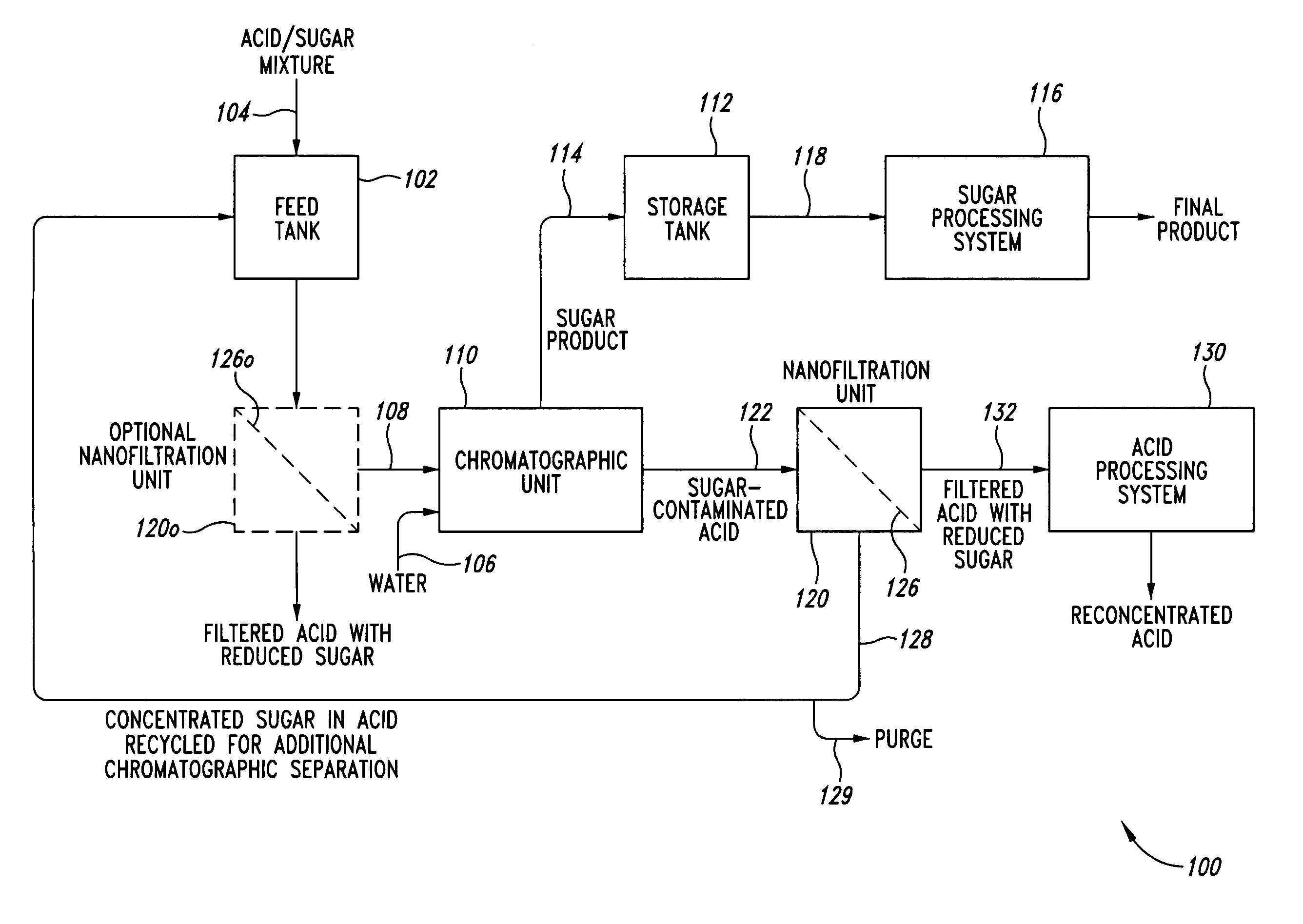

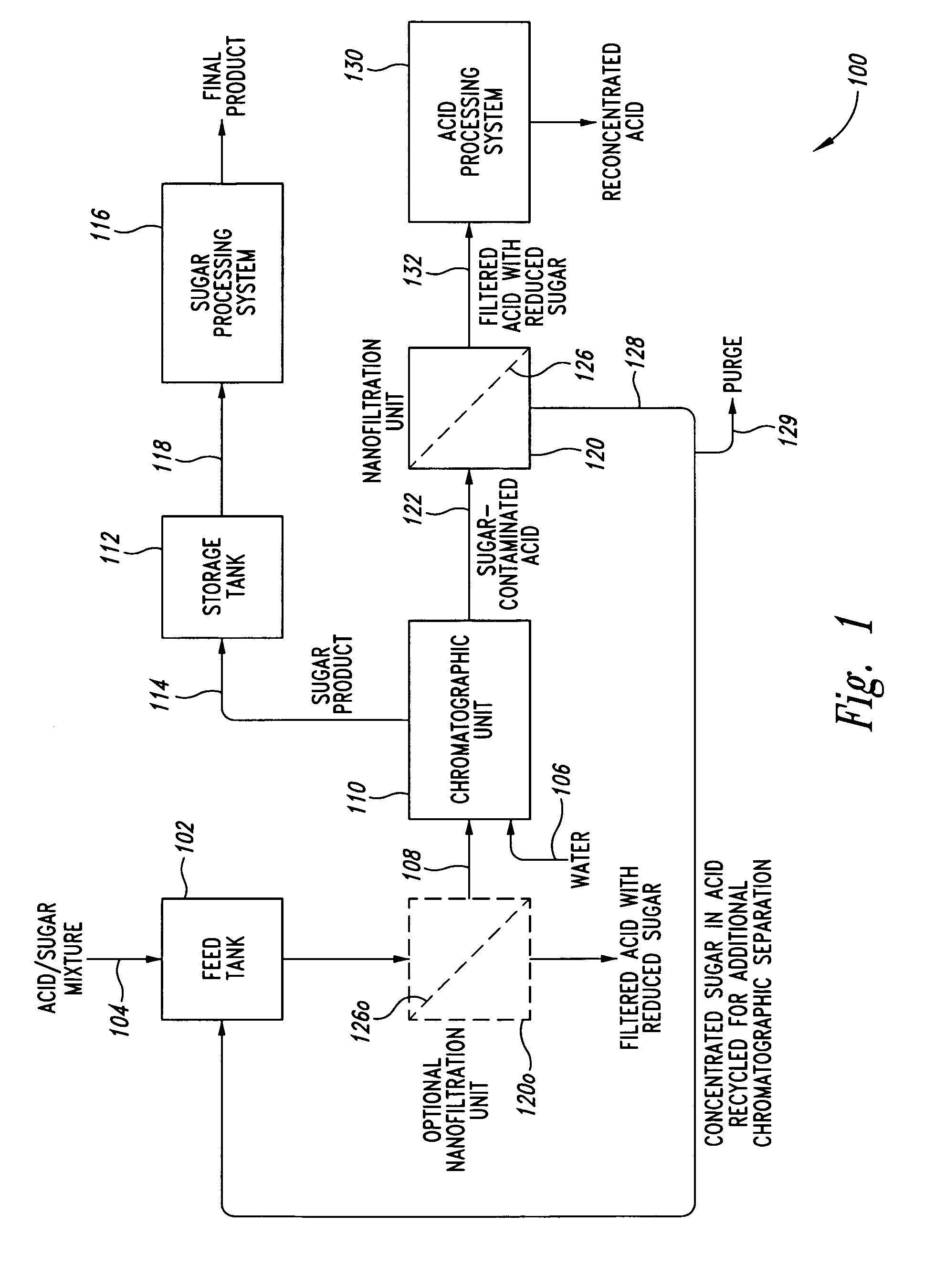

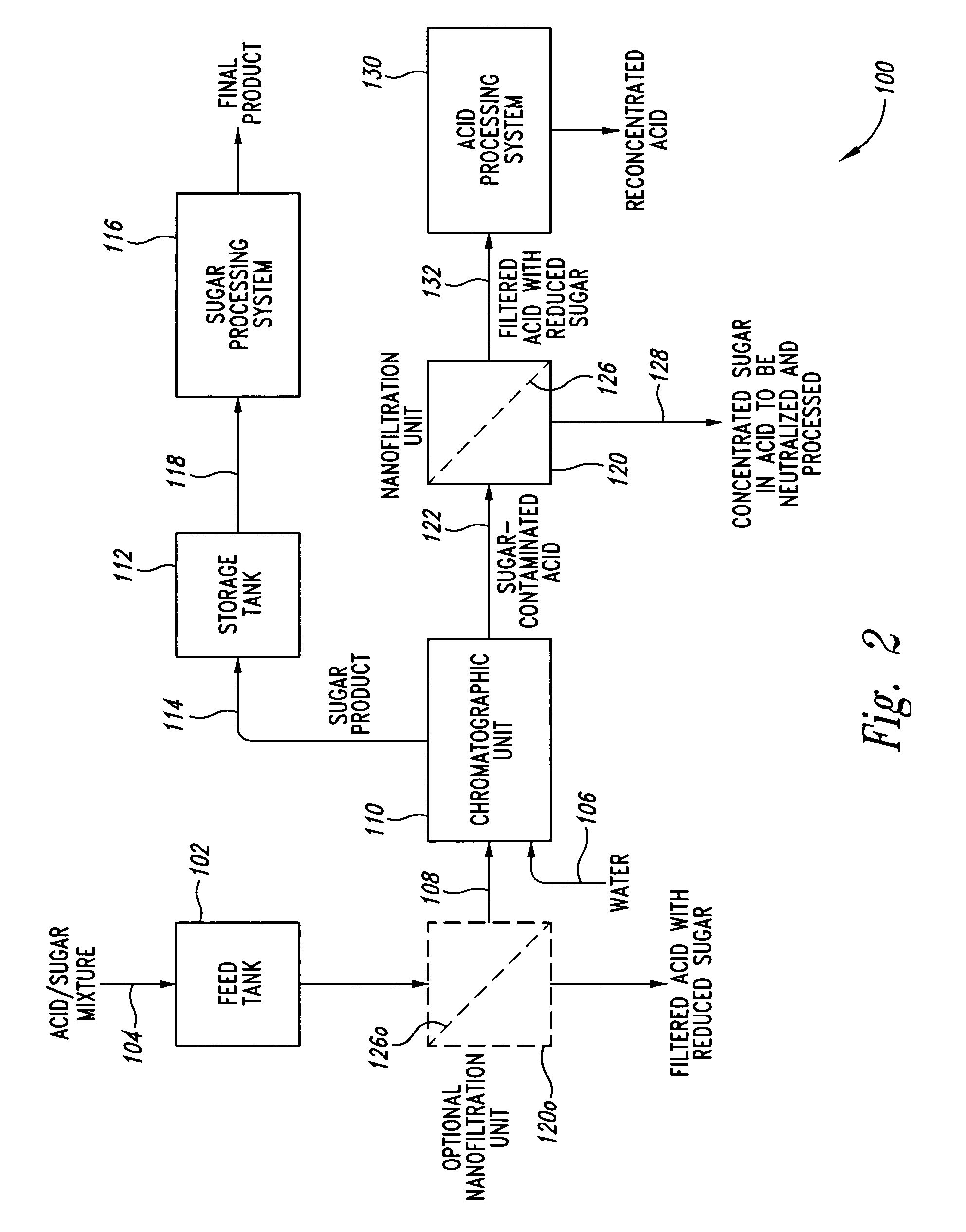

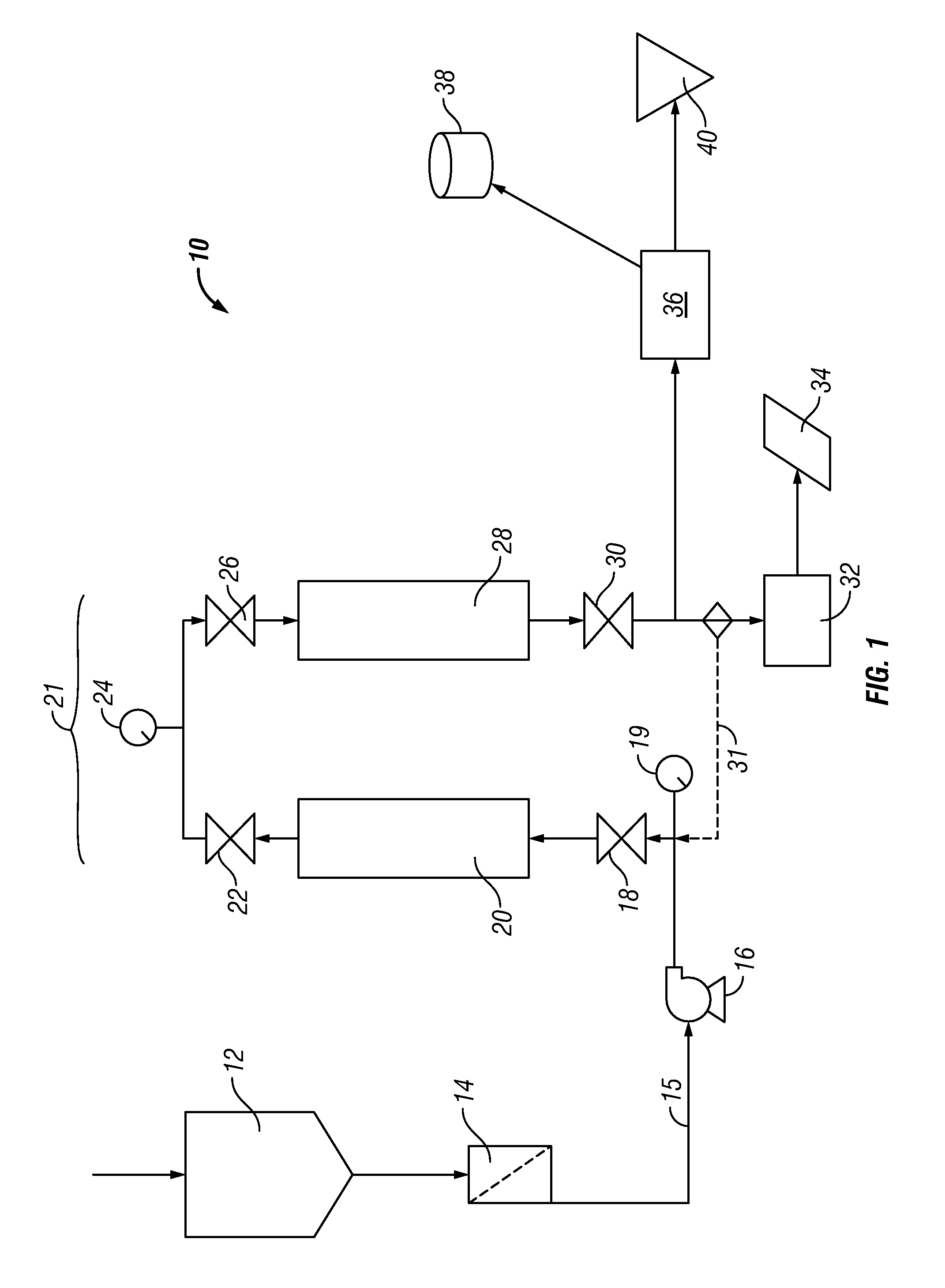

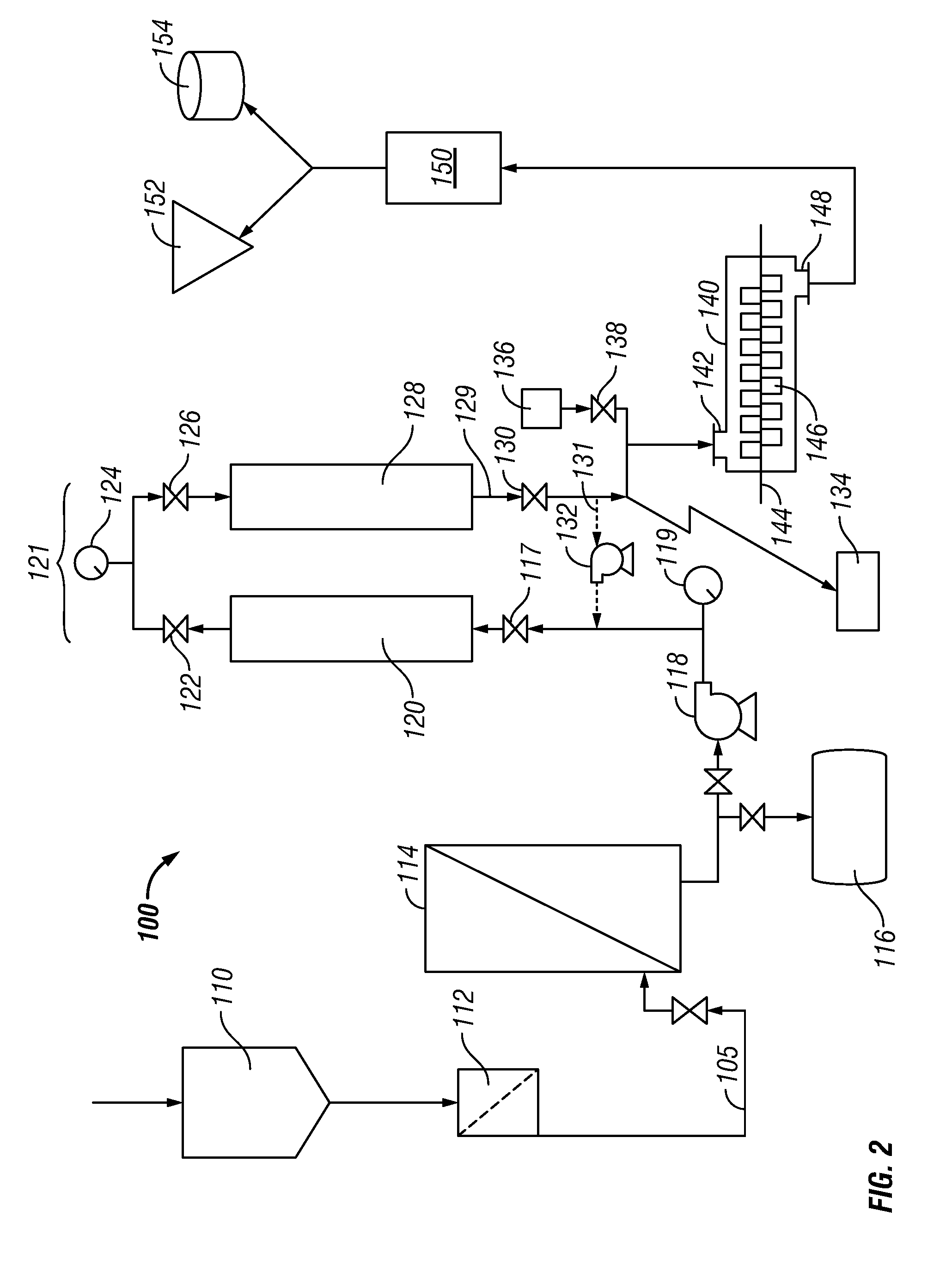

An acid recovery system used in a hydrolysis operation includes a chromatographic unit to provide initial separation of sugar and acid. The sugar product provided by the chromatographic unit is processed to produce higher value products, such as ethanol. The remaining acid is contaminated by sugar. A nanofiltration unit containing a nanofilter membrane processes the sugar contaminated acid. The acid is allowed to permeate across the nanofilter membrane while sugar is rejected. The permeate is provided to a conventional acid recovery system and recycled for use in the hydrolysis process.

Owner:HARRIS GROUP

Nanofilter system and method of use

An acid recovery system used in a hydrolysis operation includes a chromatographic unit to provide initial separation of sugar and acid. The sugar product provided by the chromatographic unit is processed to produce higher value products, such as ethanol. The remaining acid is contaminated by sugar. A nanofiltration unit containing a nanofilter membrane processes the sugar contaminated acid. The acid is allowed to permeate across the nanofilter membrane while sugar is rejected. The permeate is provided to a conventional acid recovery system and recycled for use in the hydrolysis process.

Owner:HARRIS GROUP

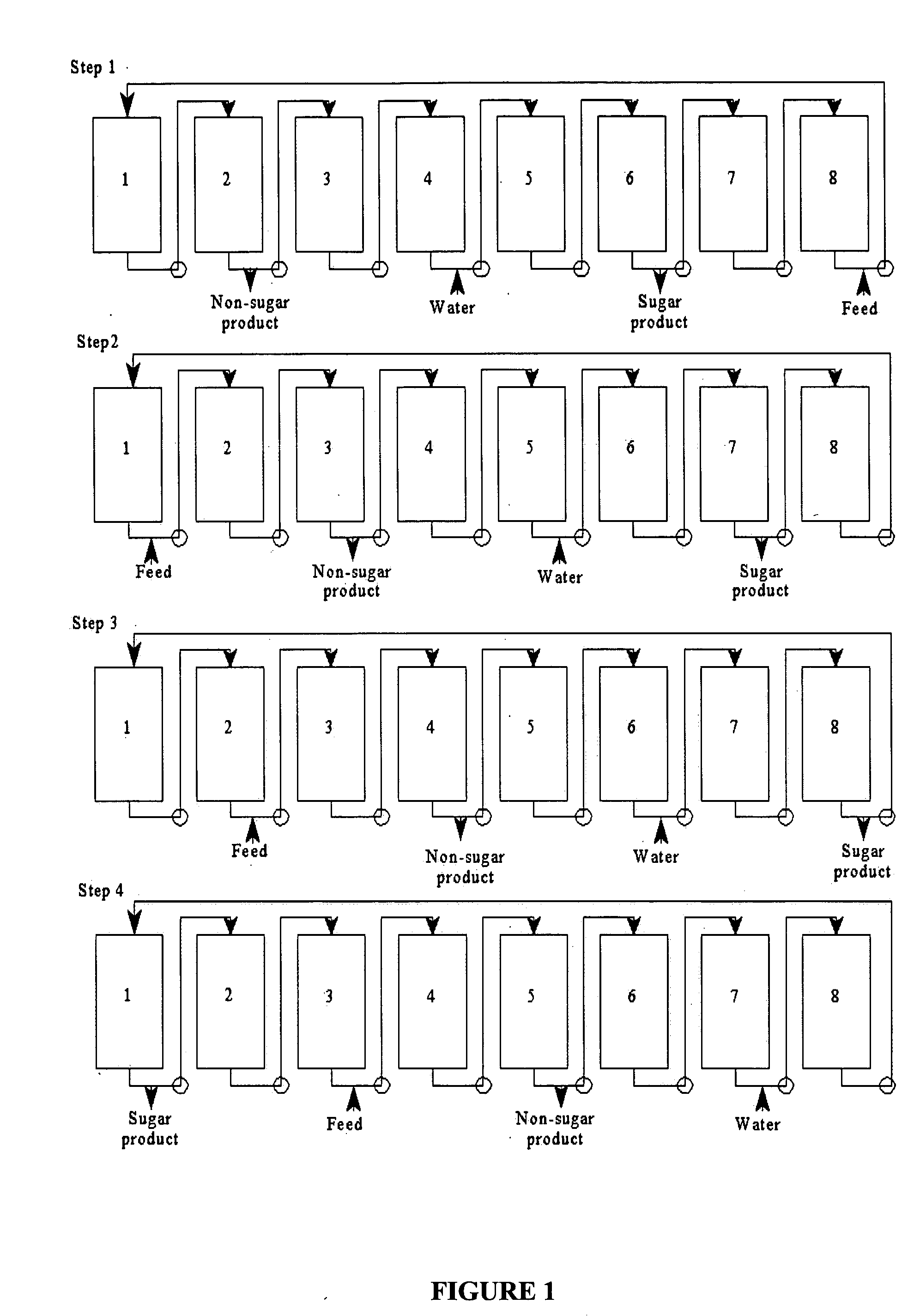

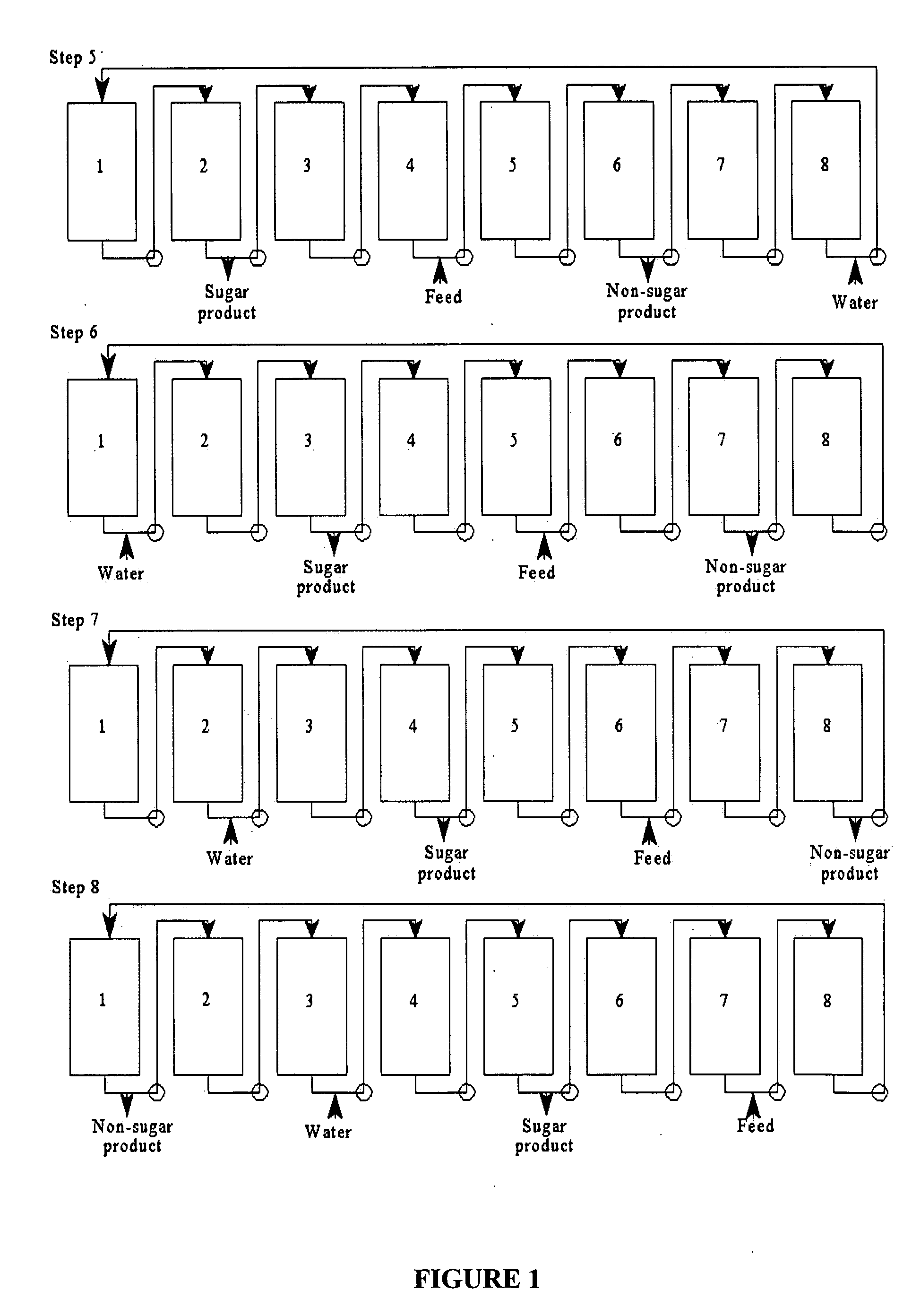

Separation system and process

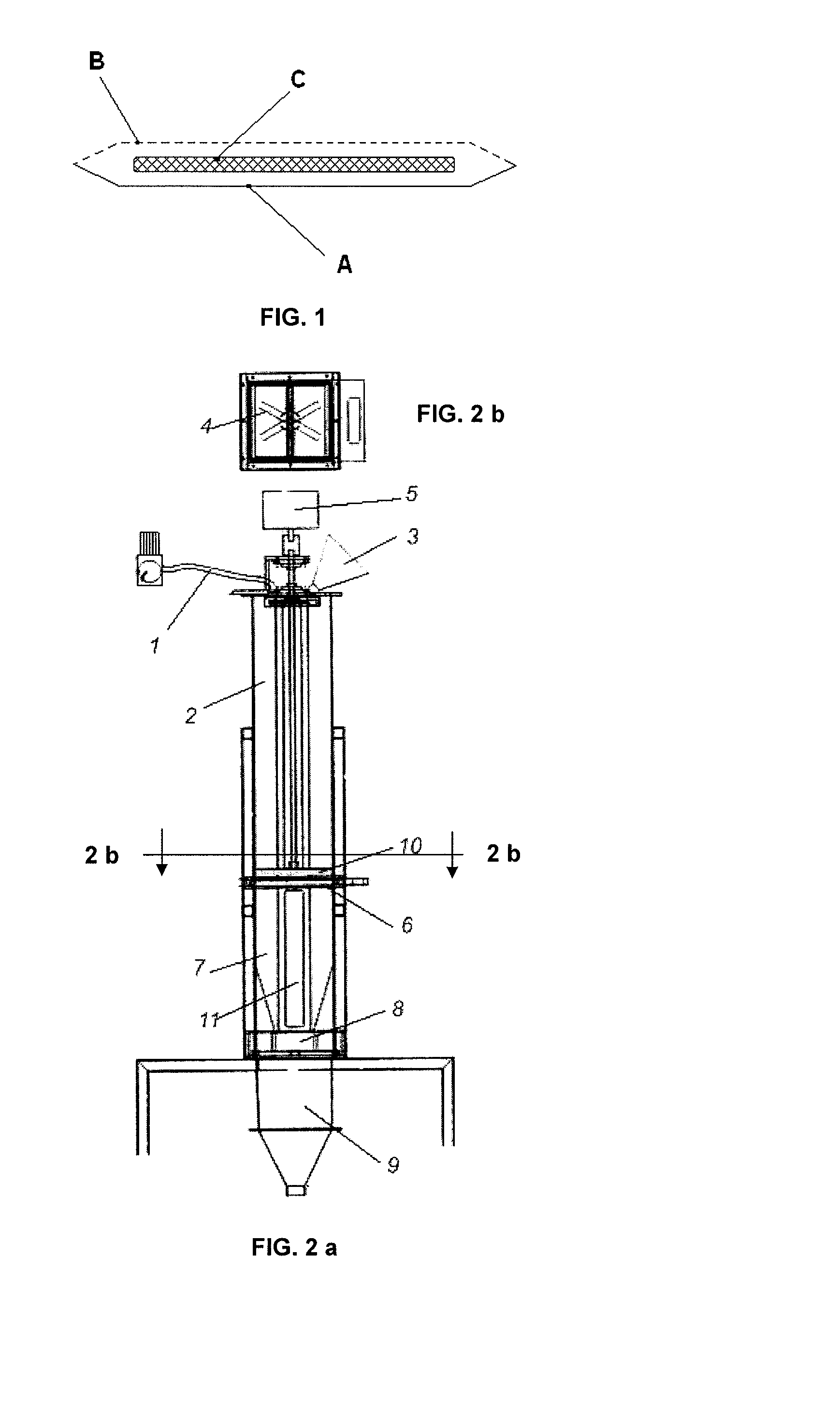

InactiveUS20040251204A1Cation exchanger materialsIon-exchanger regenerationIon-exchange resinSeparation system

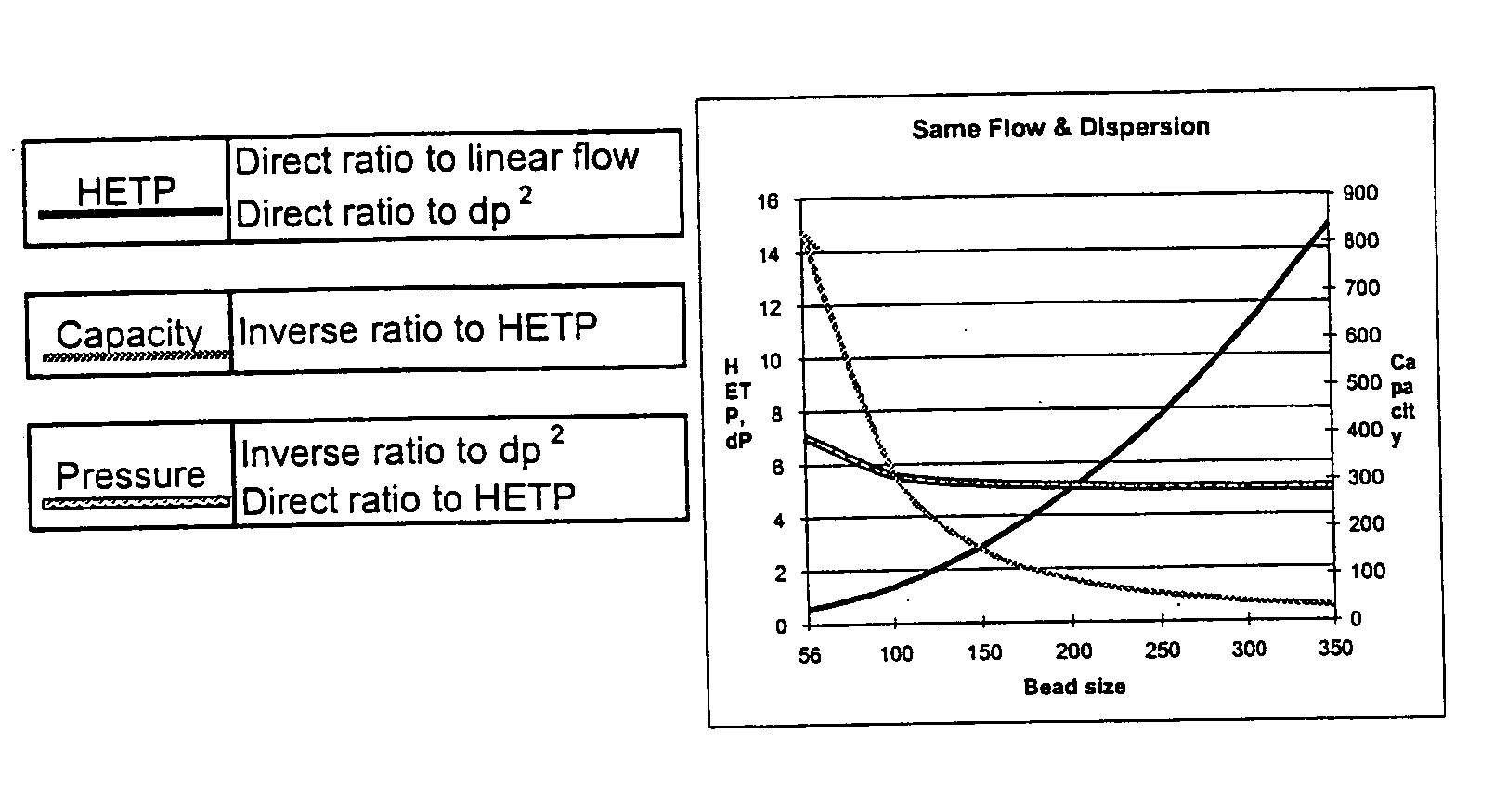

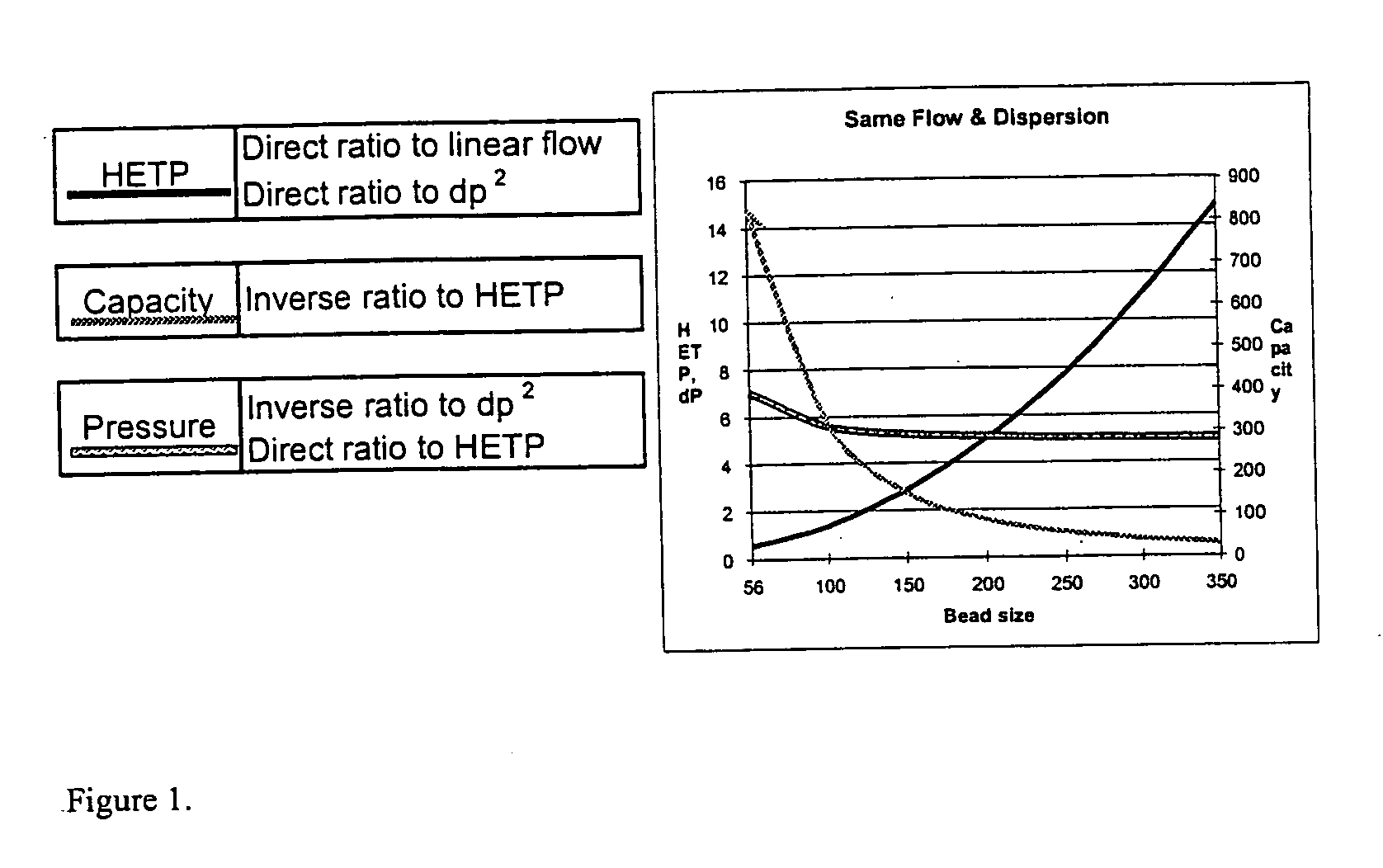

The invention relates to a system and a process for fractionating a solution into two or more fractions. The system of the invention comprises at least two compartments having a diameter of at least about one meter and including a uniform packing of a polymer-based ion exchange resin with a bead size in the range of about 50 to about 250 mum. The mixing volume of the fluid fronts in the system of the invention is not more than 5% of the volume of the compartment.

Owner:FINPHIDE

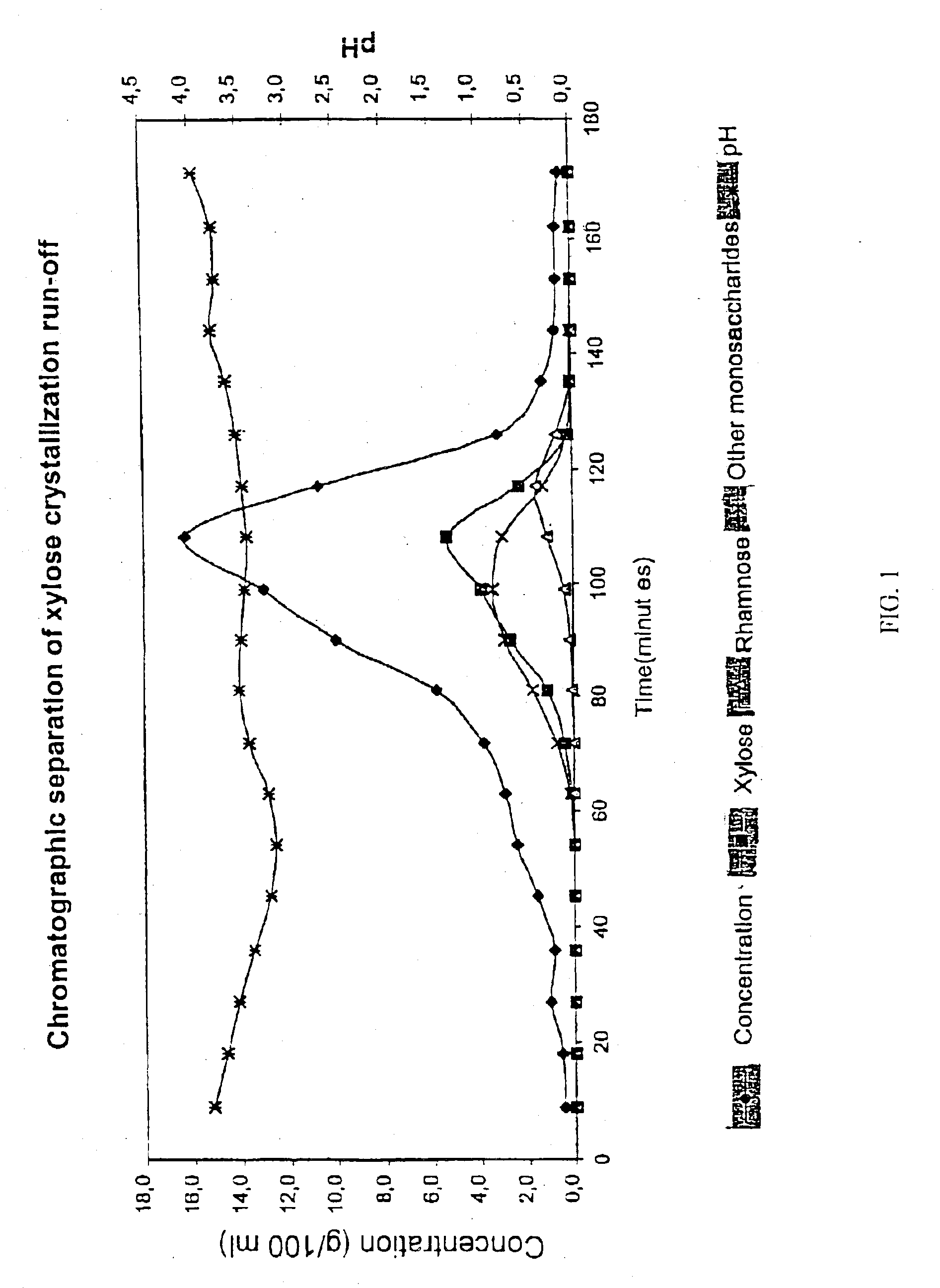

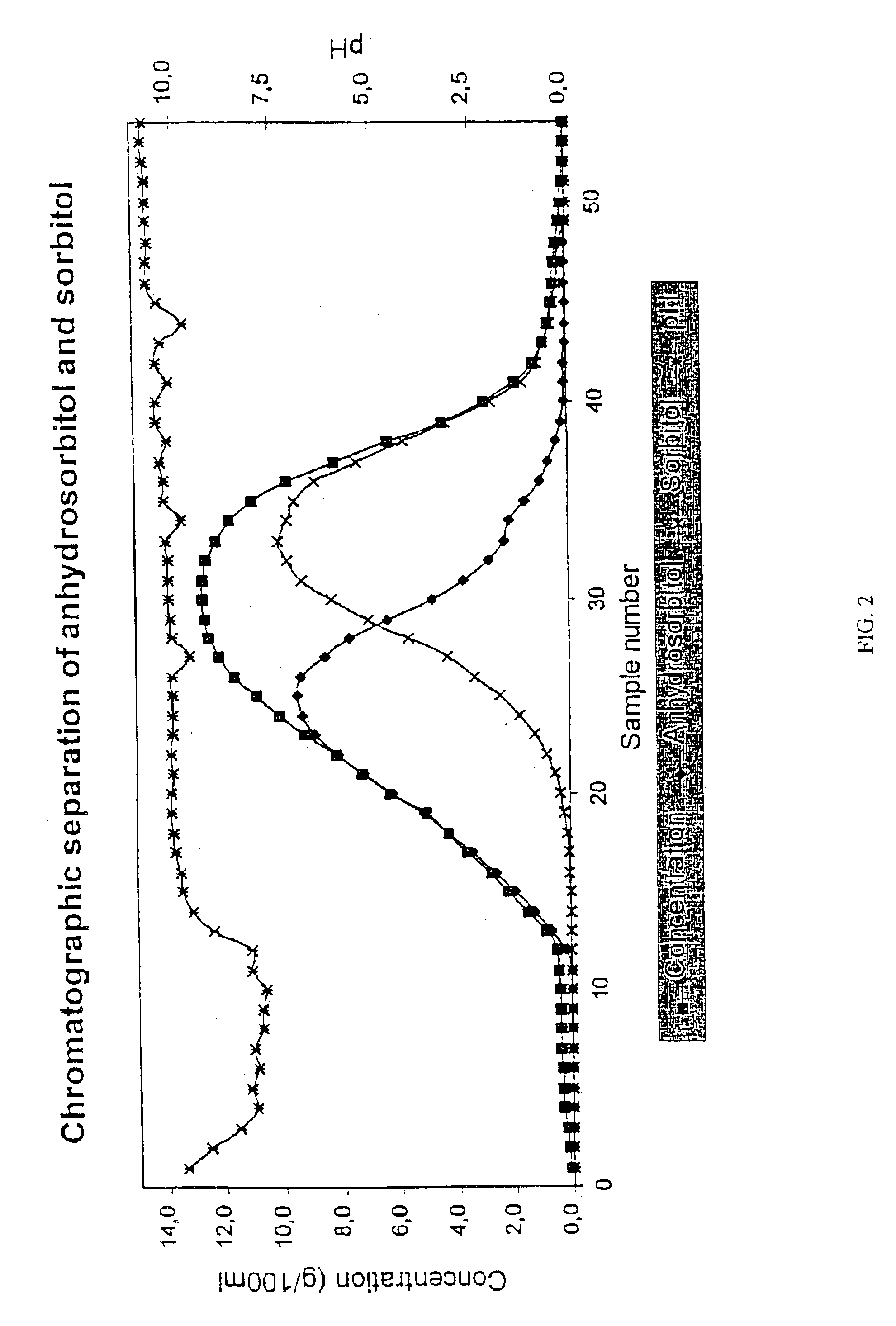

Separation of sugars, sugar alcohols, carbohydrates and mixtures thereof

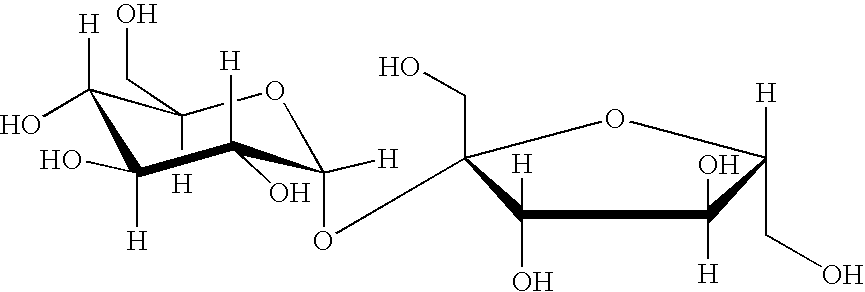

InactiveUS7361273B2Efficient separationCation exchanger materialsIon-exchanger regenerationChromatographic separationAlcohol sugars

The present invention relates to a method of separating sugars and sugar alcohols from each other. More particularly the present invention relates to the use of a weakly basic anion exchange resin in a chromatographic separation process. The advantage of the present invention compared with the prior art is that it is especially suitable for separating reducing sugars in acidic conditions as well as for example in weakly acidic conditions. The method using chromatographic separation comprises at least one step where a weakly basic anion exchange resin is used in a chromatographic column or in a part of a column.

Owner:DUPONT NUTRITION BIOSCIENCES APS

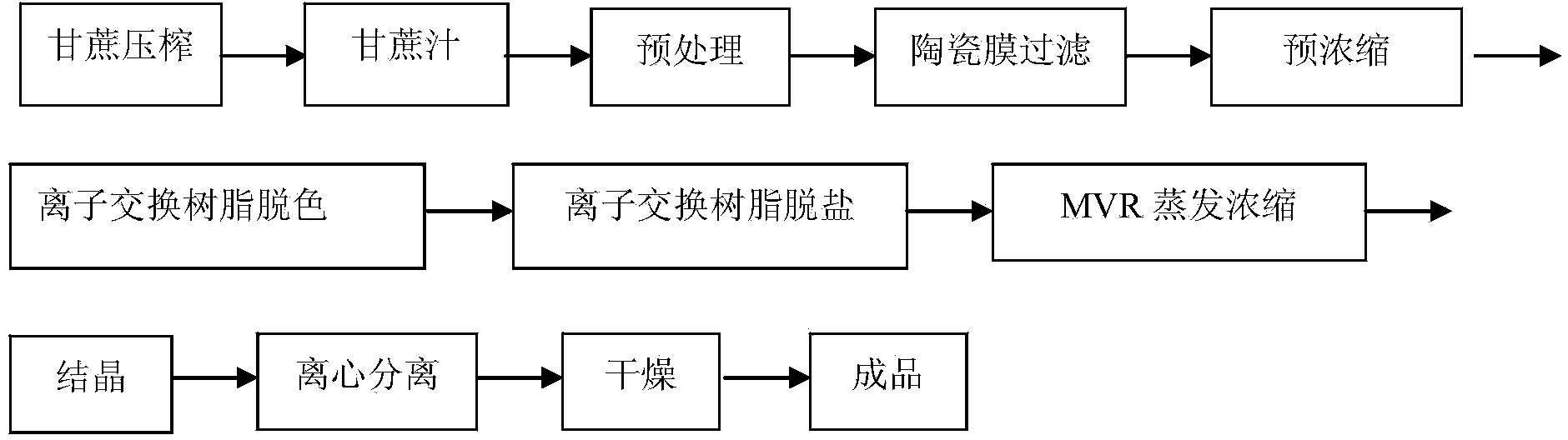

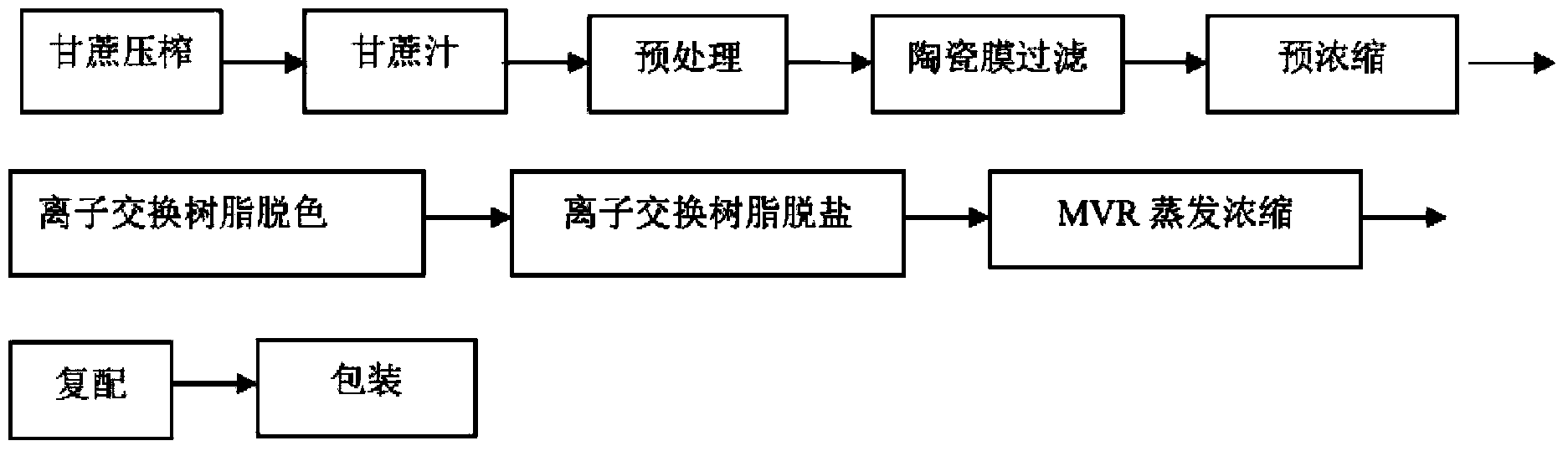

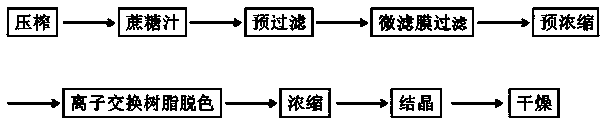

Technology for refining saccharose

ActiveCN103725802ANo color reversionOptimal production process parametersSugar crystallisationPurification using ion-exchange materialsInorganic saltsSucrose

The invention discloses a technology for refining saccharose. The technology comprises specific steps of juicing, pretreating, micro-filtering by a membrane, pre-concentrating, decoloring through ion exchange, desalting, evaporating and concentrating through MVR (mechanical vapor recompression), crystallizing, separating through centrifuging, and drying so as to obtain the saccharose crystal. The technology has the advantages that ceramic microfiltration substitutes for sedimentation by sheet frames and lime, so that the step of ultrafiltration is saved; due to concentration by the membrane, the evaporation capacity of evaporation and concentration equipment is reduced, the energy consumption is lowered, and part of inorganic salt is removed; the technology of decoloring and removing impurities through ion exchange substitutes for the technology of stoving, so that the problem of residual sulphur in the saccharose is solved, and the quality of the product is improved; the manner of ion exchange can effectively remove the salt in cane juice; energy consumption is effectively lowered due to the MVR; by adopting the membrane concentration and separation and ion exchange equipment, the floor space of the equipment is reduced, and investment of capital construction is lowered.

Owner:JIANGSU JIUWU HITECH

Superabsorbent surface-treated carboxyalkylated polysaccharides and process for producing same

Owner:ARCHER DANIELS MIDLAND CO

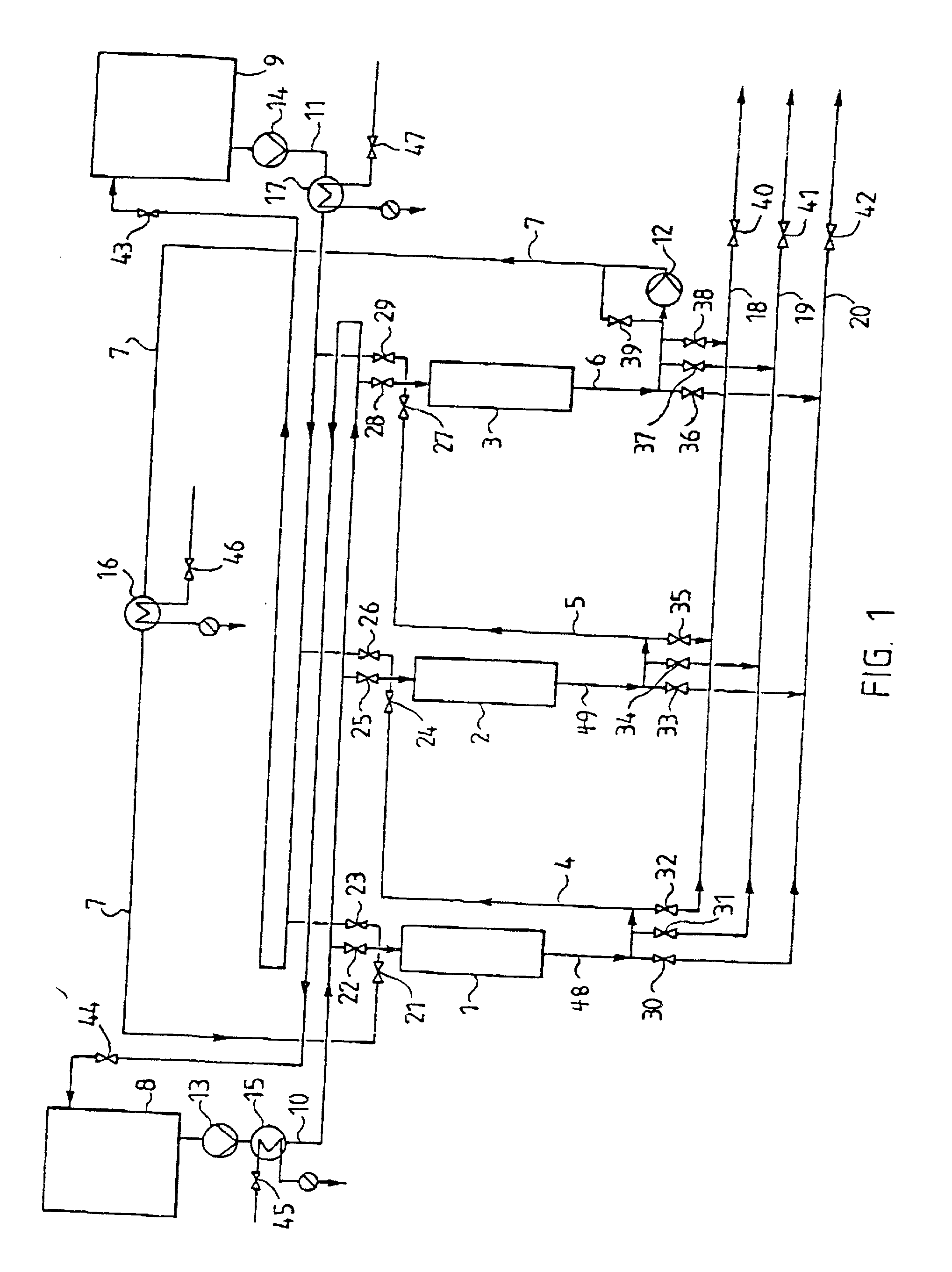

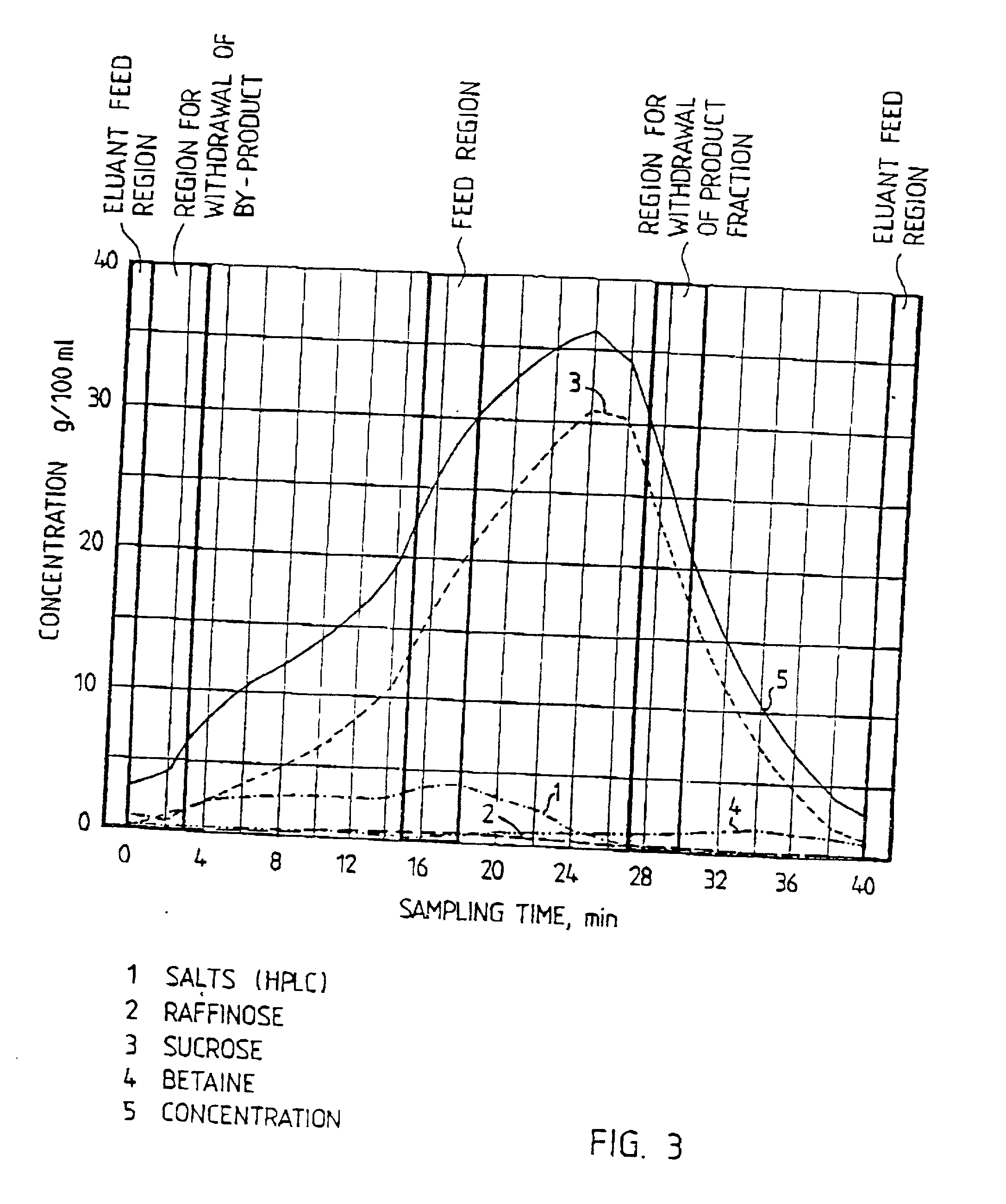

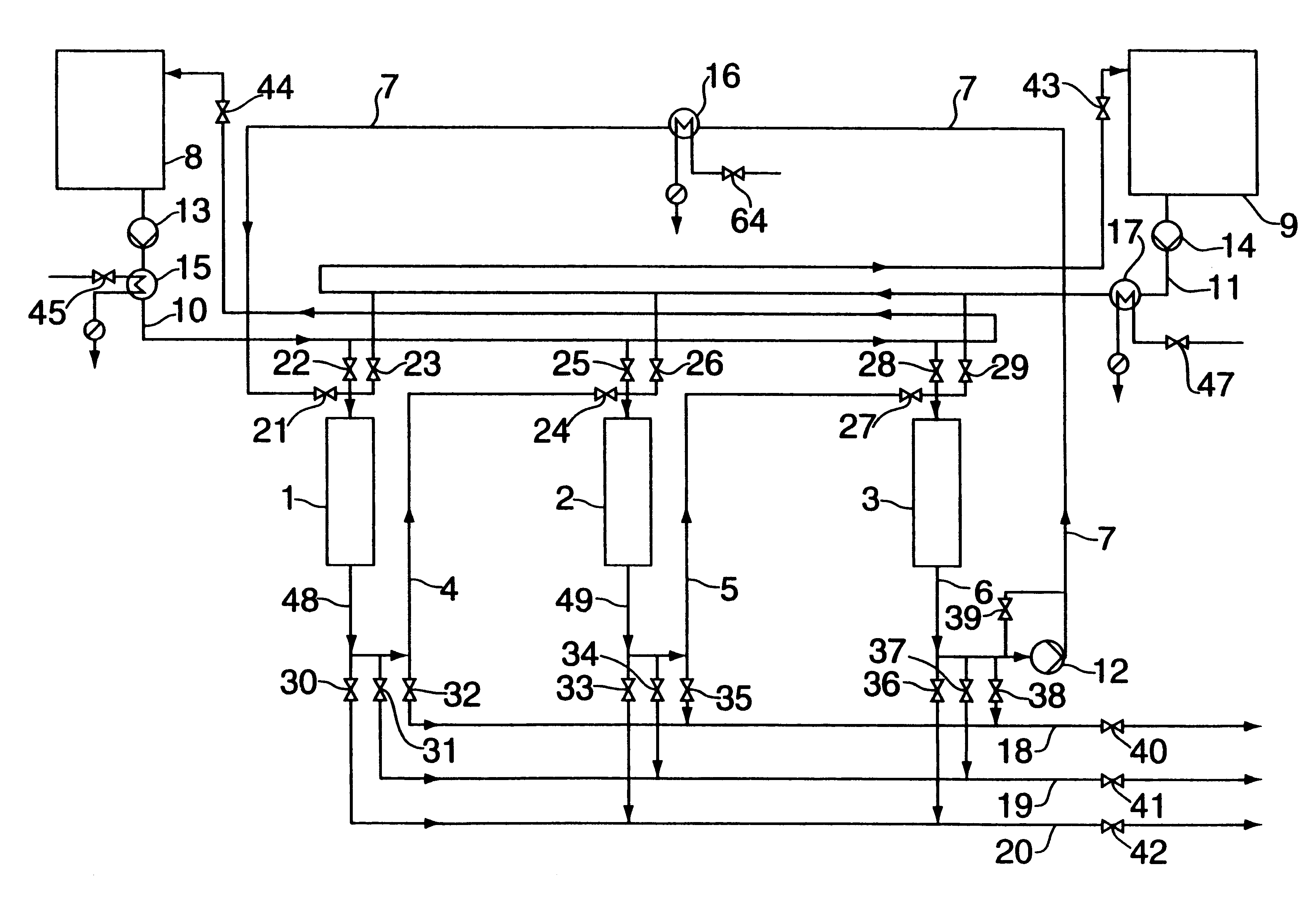

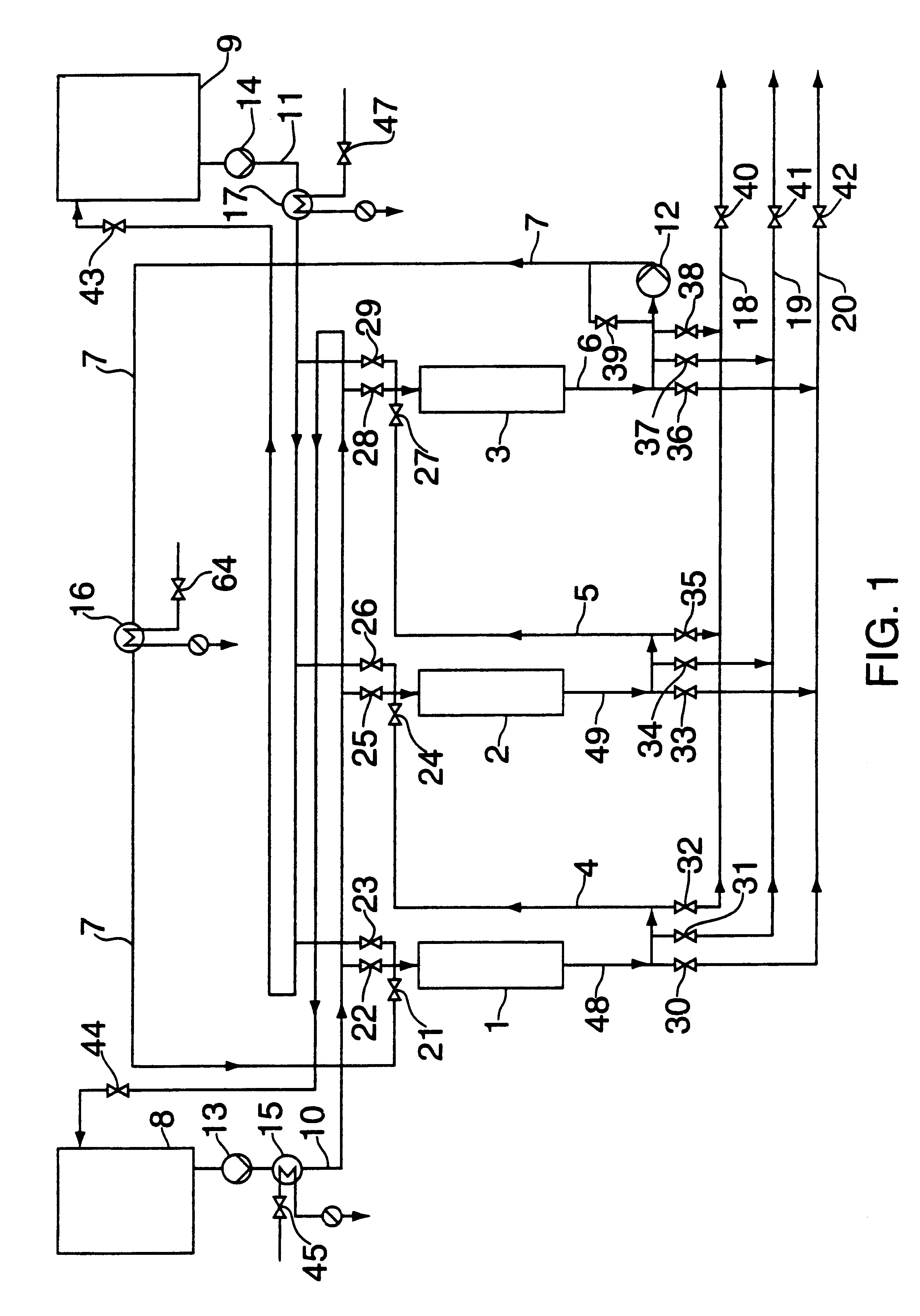

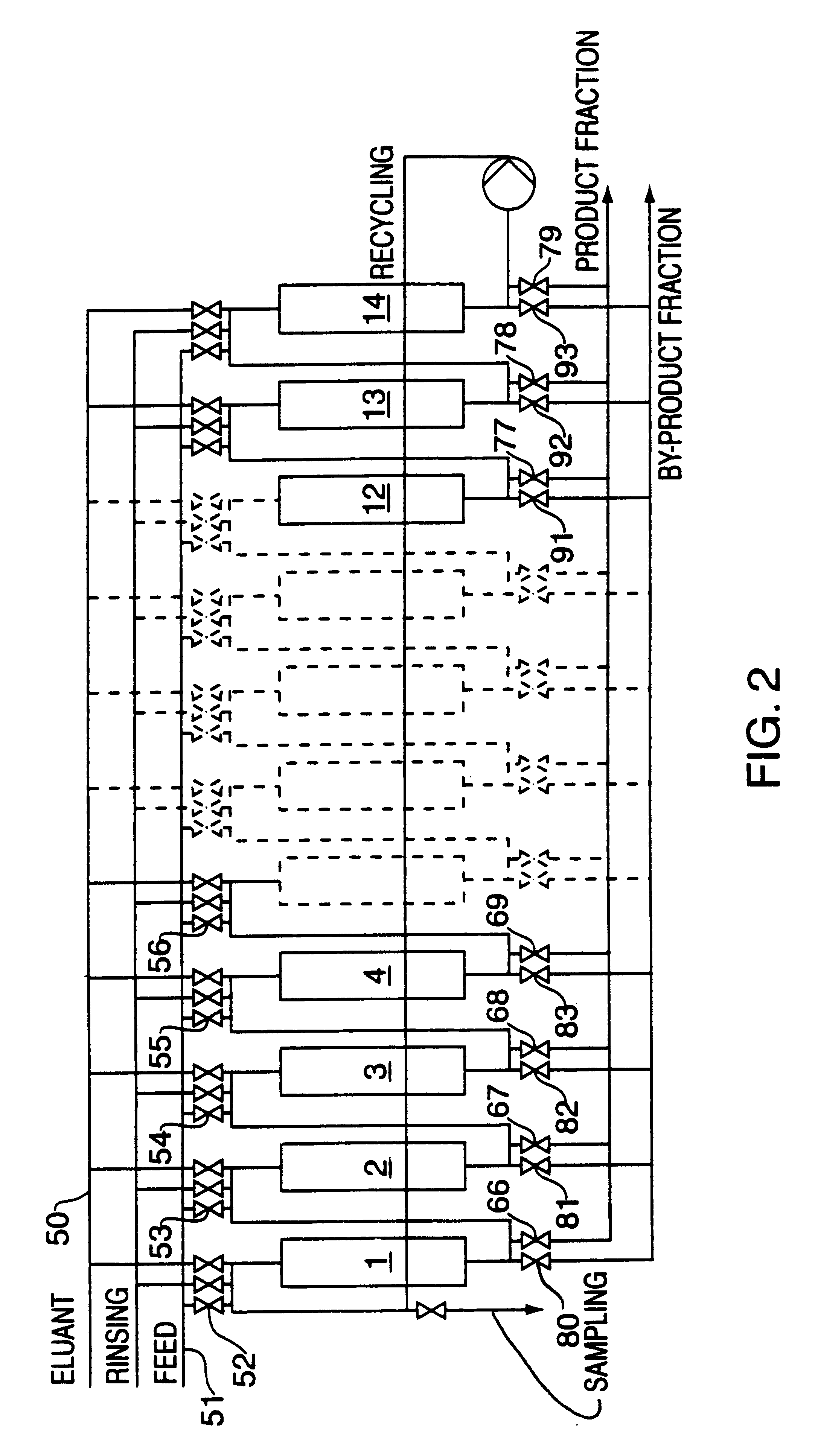

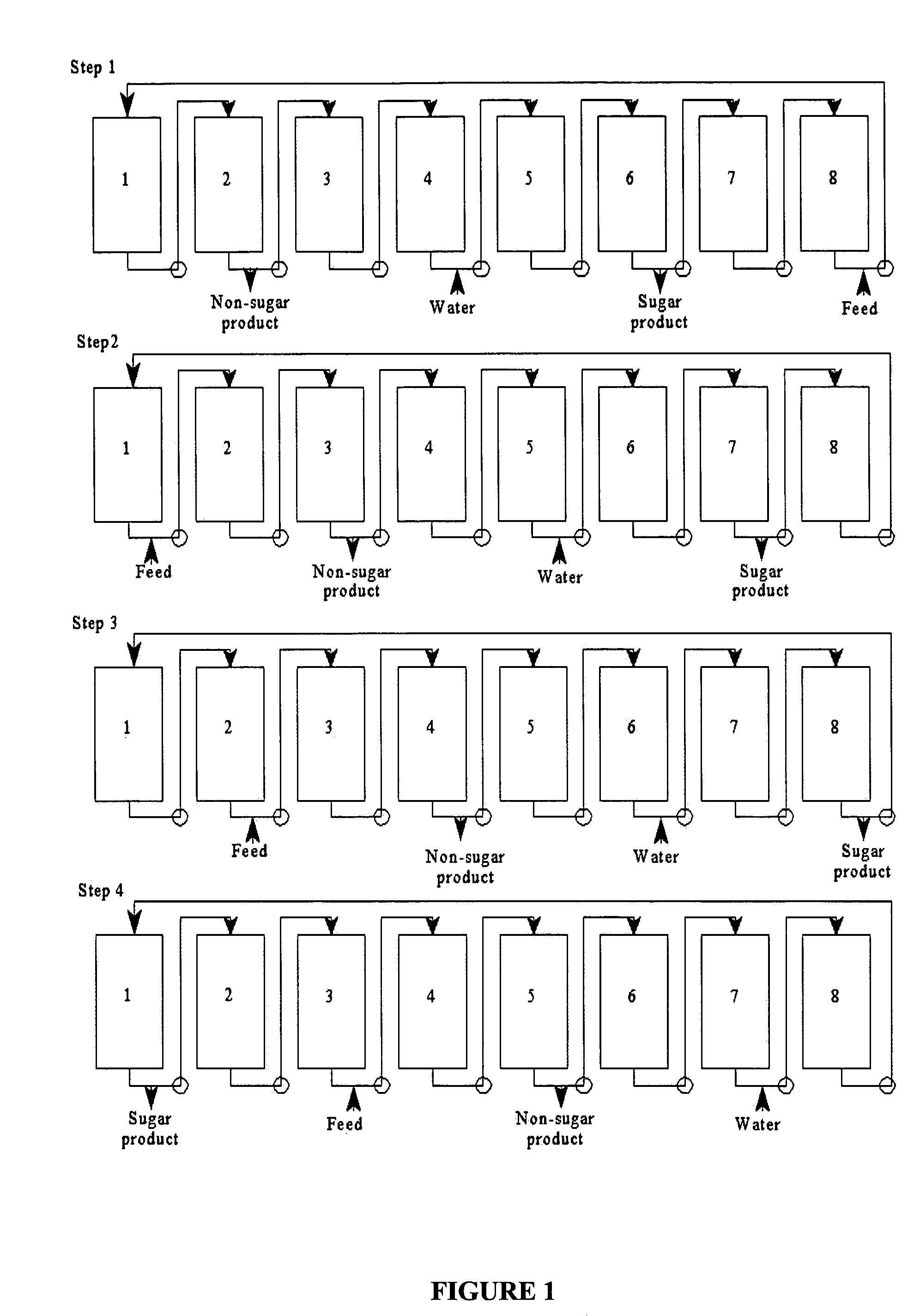

Separation process

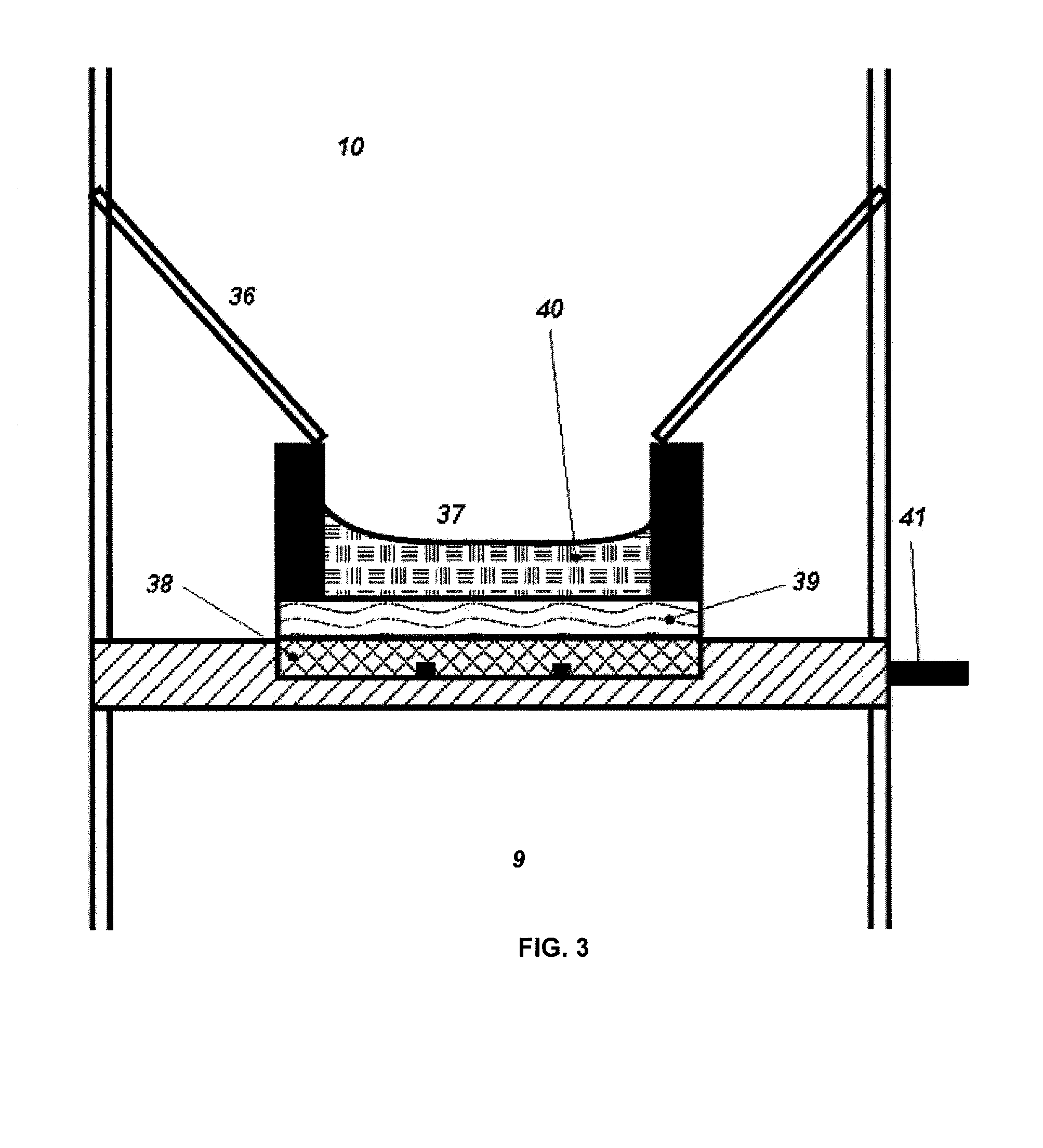

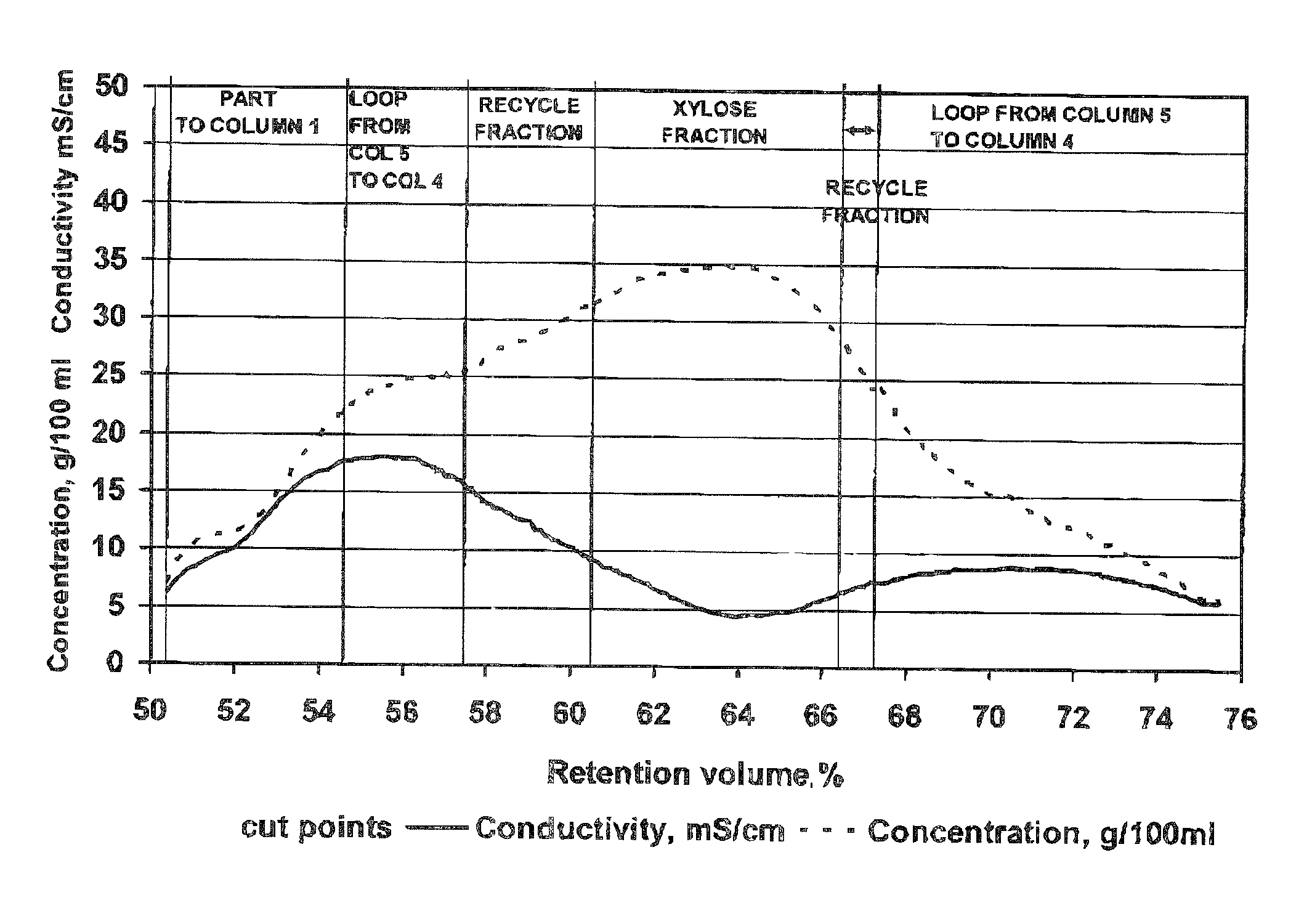

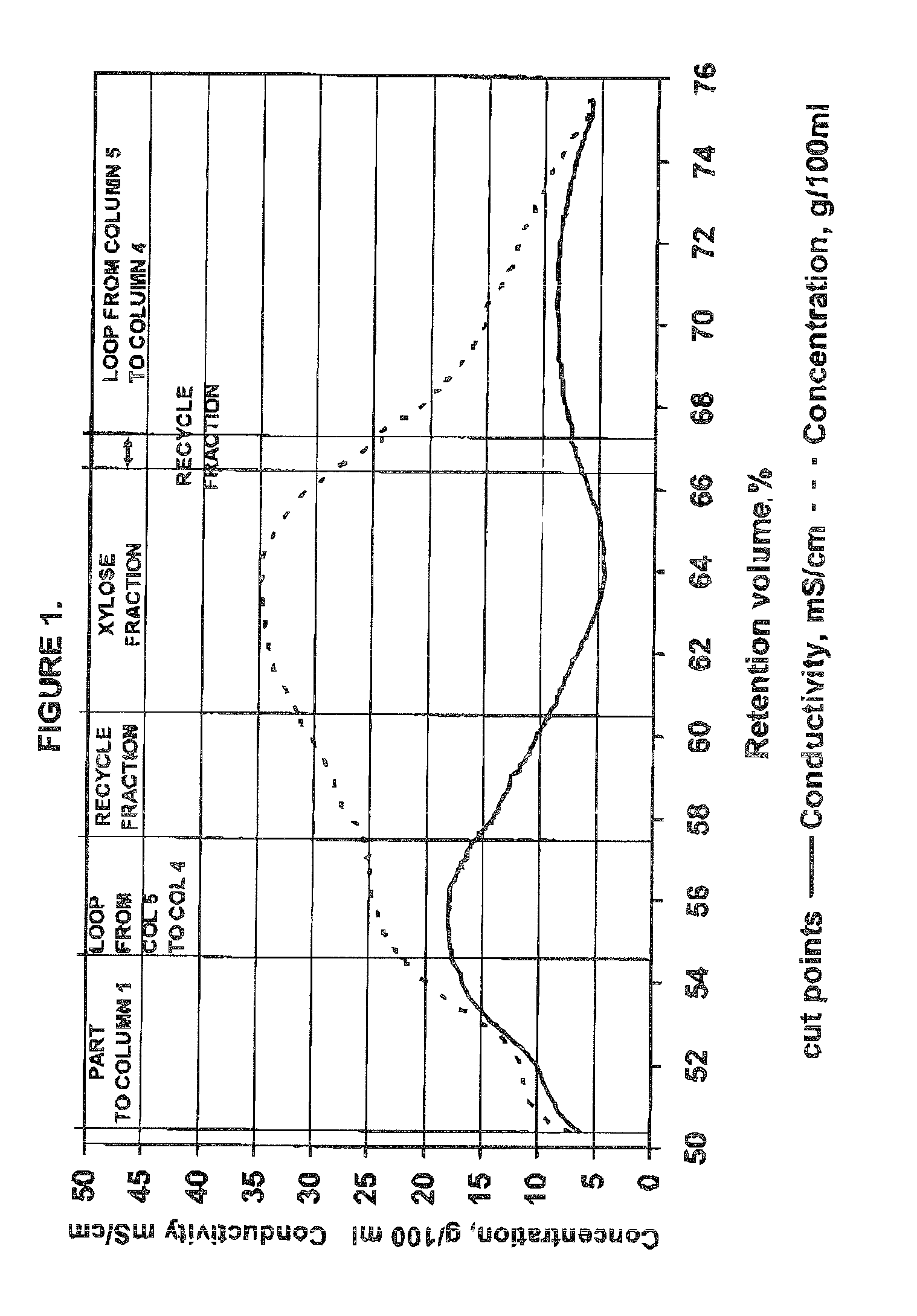

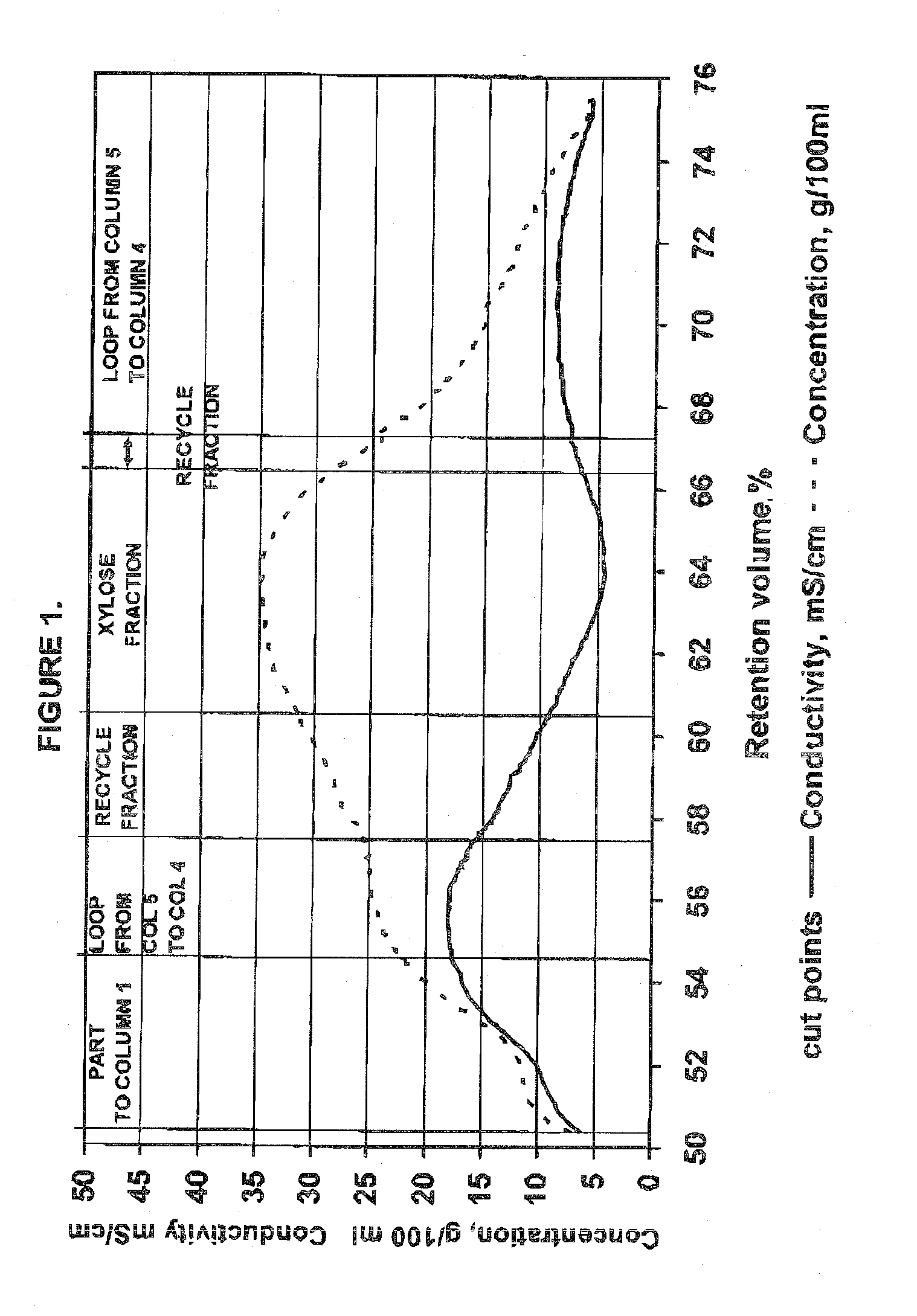

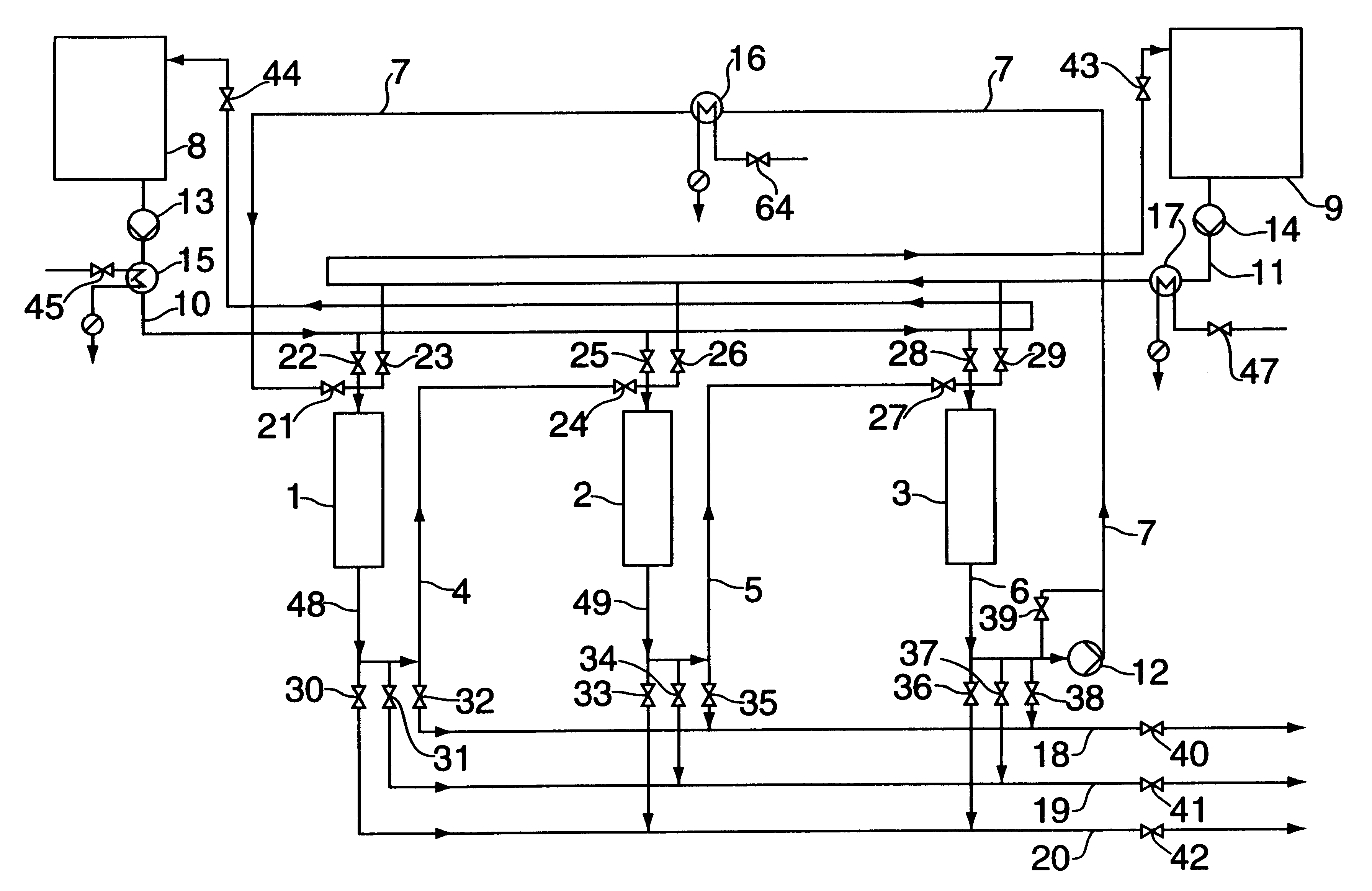

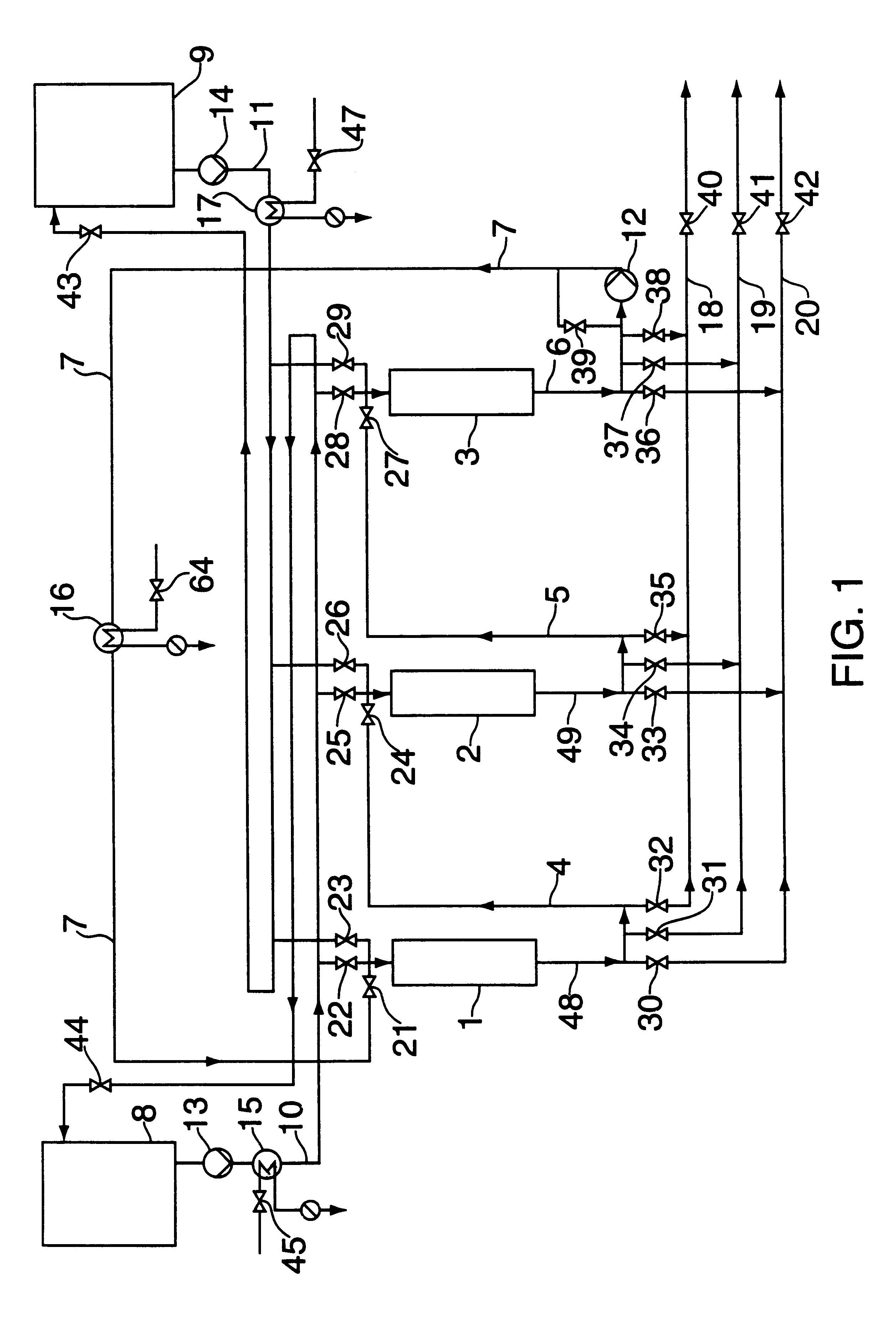

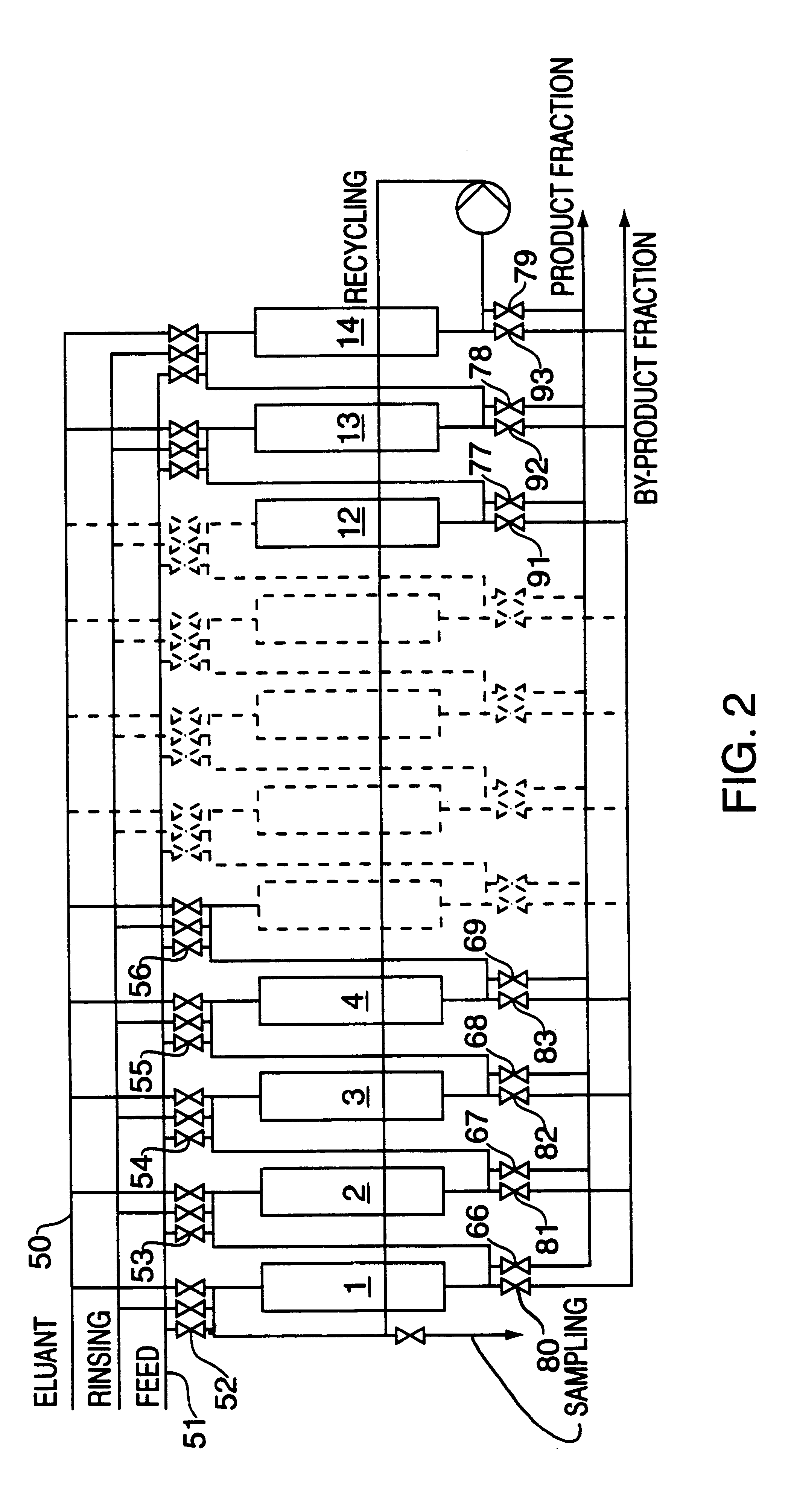

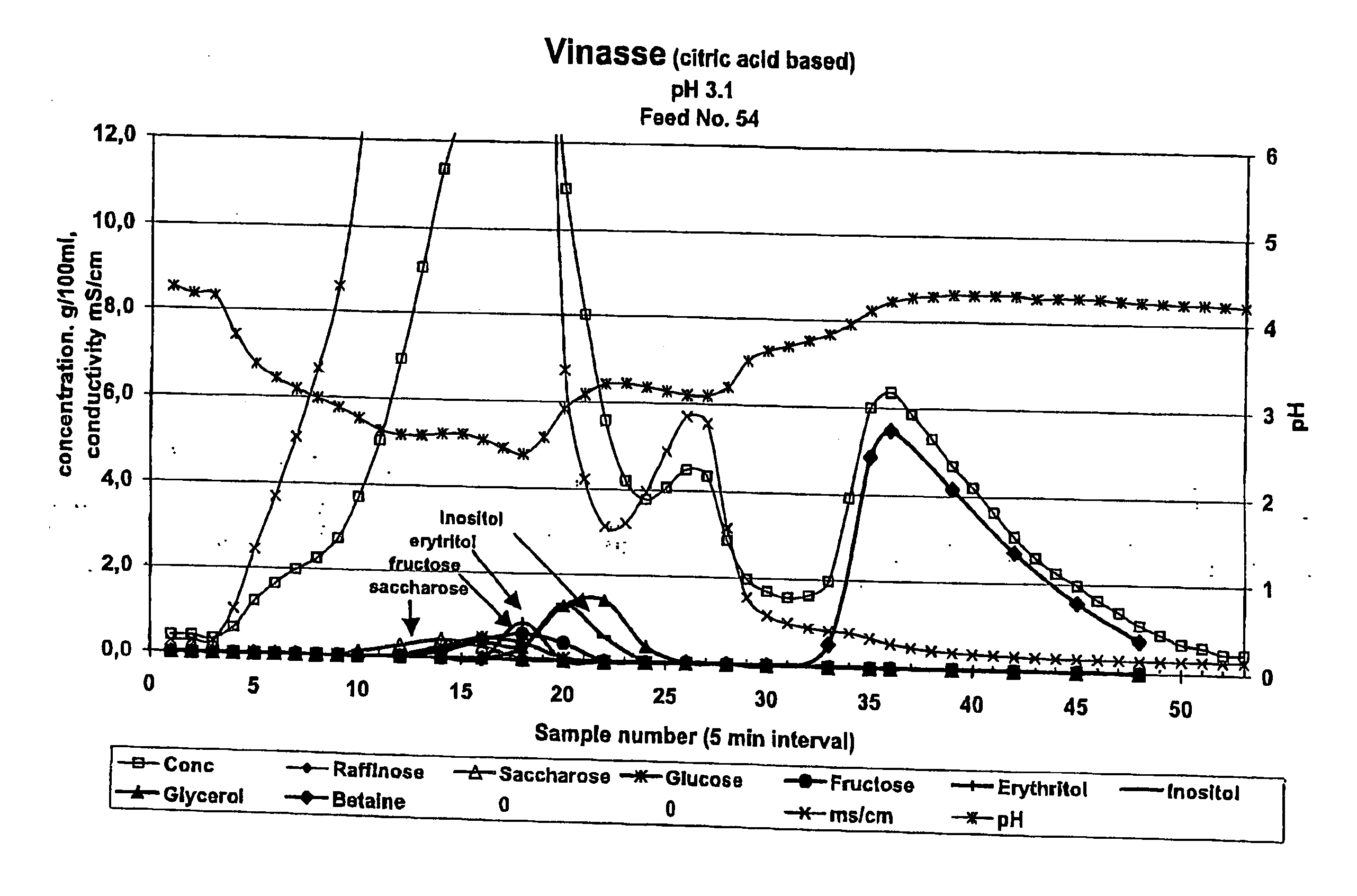

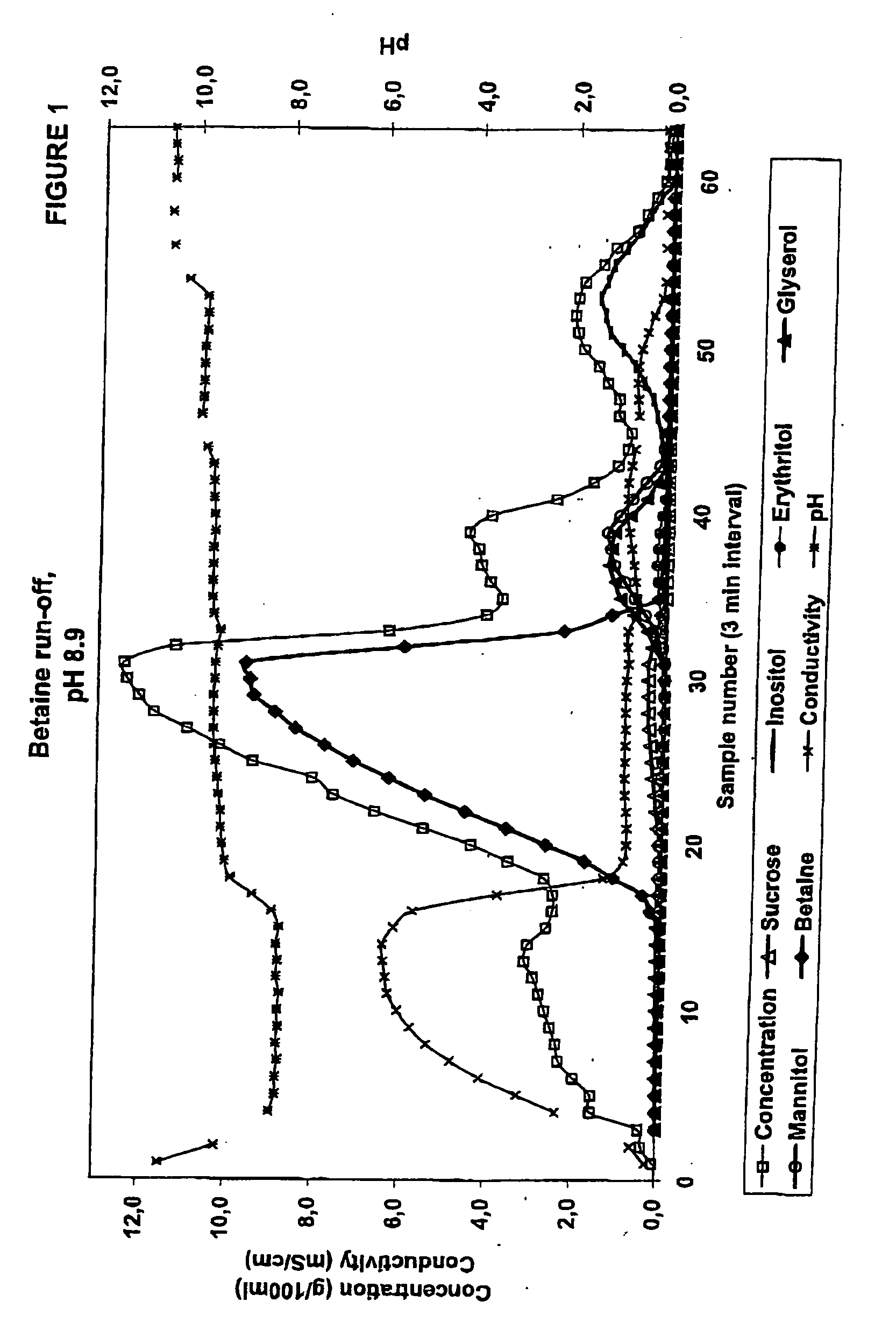

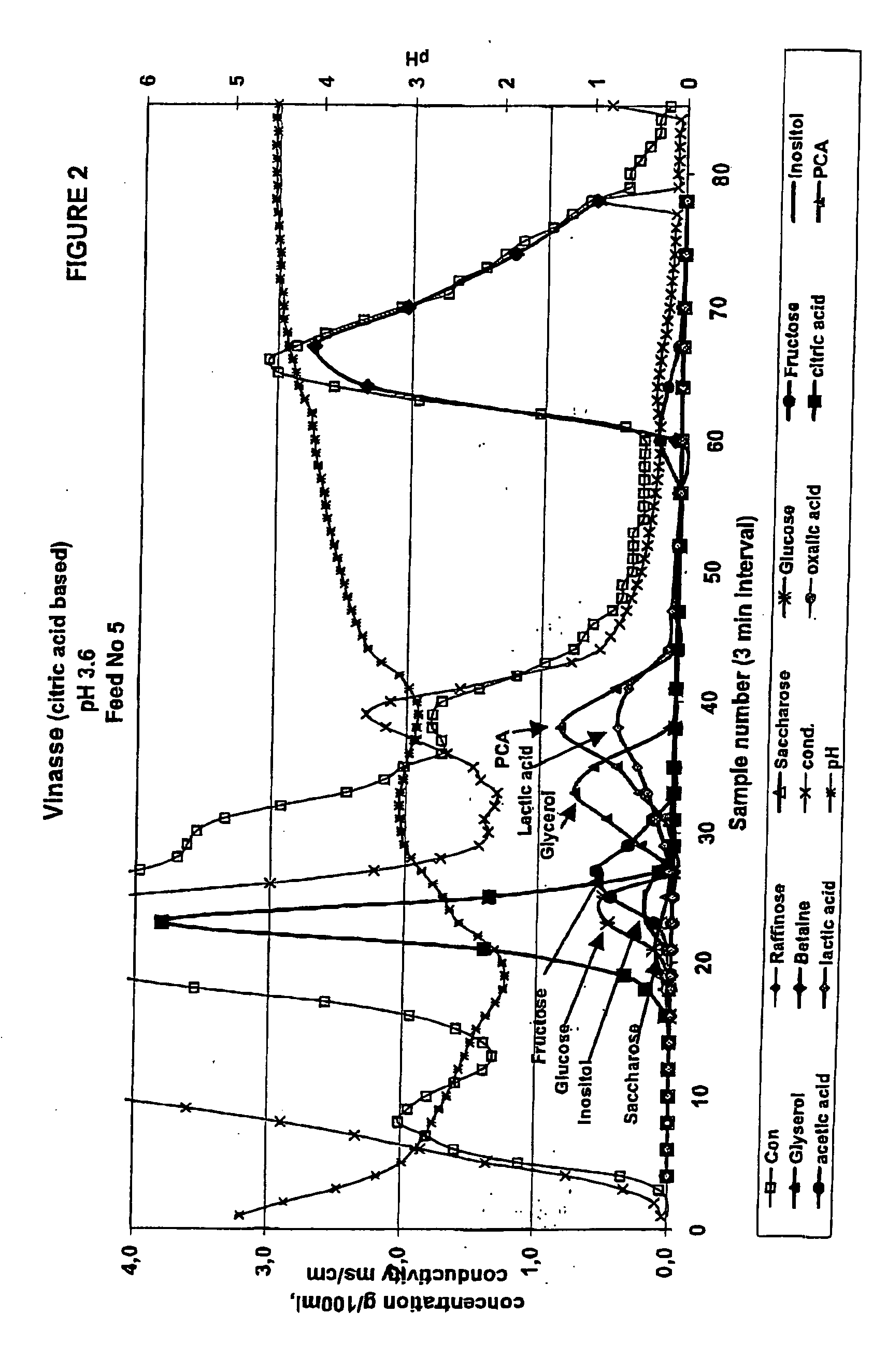

ActiveUS7959811B2Disturb separation efficiency of separationLower the volumeIon-exchange process apparatusSugar derivativesChromatographic separationBetaine

The present invention relates to a chromatographic separation process for fractionating solutions containing sugars, sugar alcohols, sugar acids and / or betaine by utilizing fractions comprising parts of the separation profile as a substituent of the eluent in a novel and inventive manner. The starting solutions are typically multicomponent plant-based extracts and hydrolysates, stillages, and fermentation products and derivatives thereof. The process prow vides improved separation capacity and separation efficiency without affecting the yield or purity of product components, such as sugars, sugar alcohols, sugar acids, and betaine. The process can especially be applied to sequential SMB separation systems.

Owner:DUPONT NUTRITION BIOSCIENCES APS

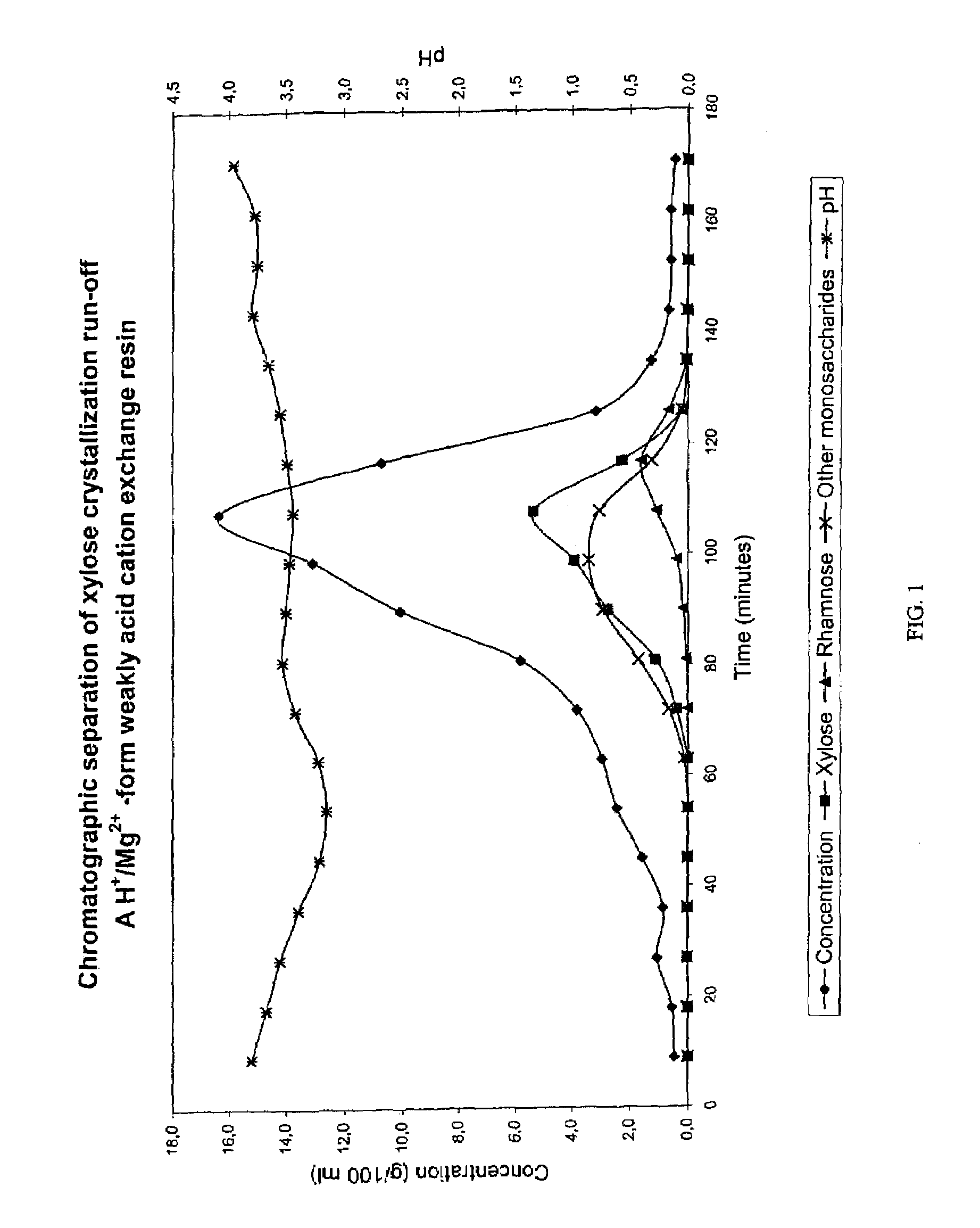

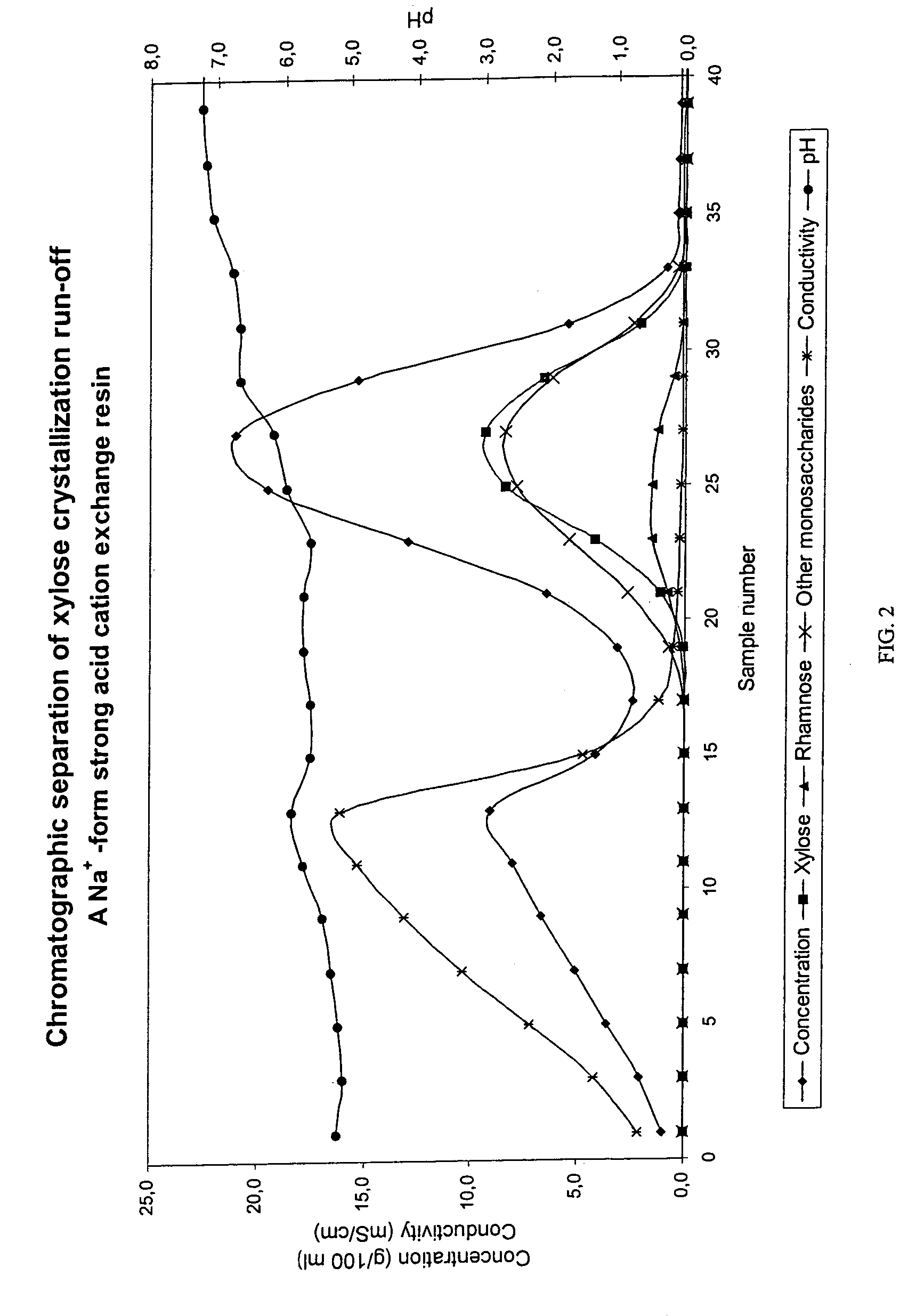

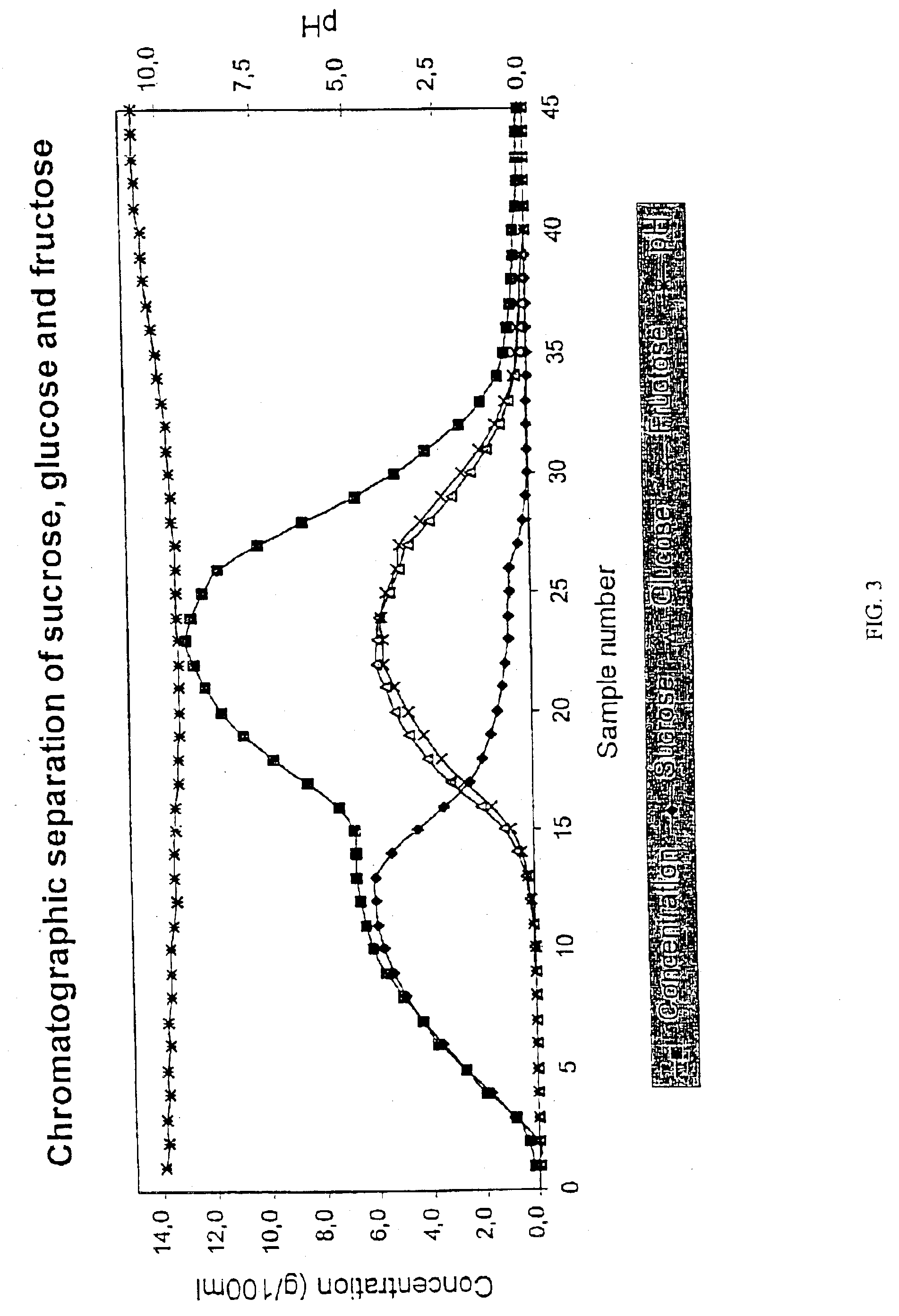

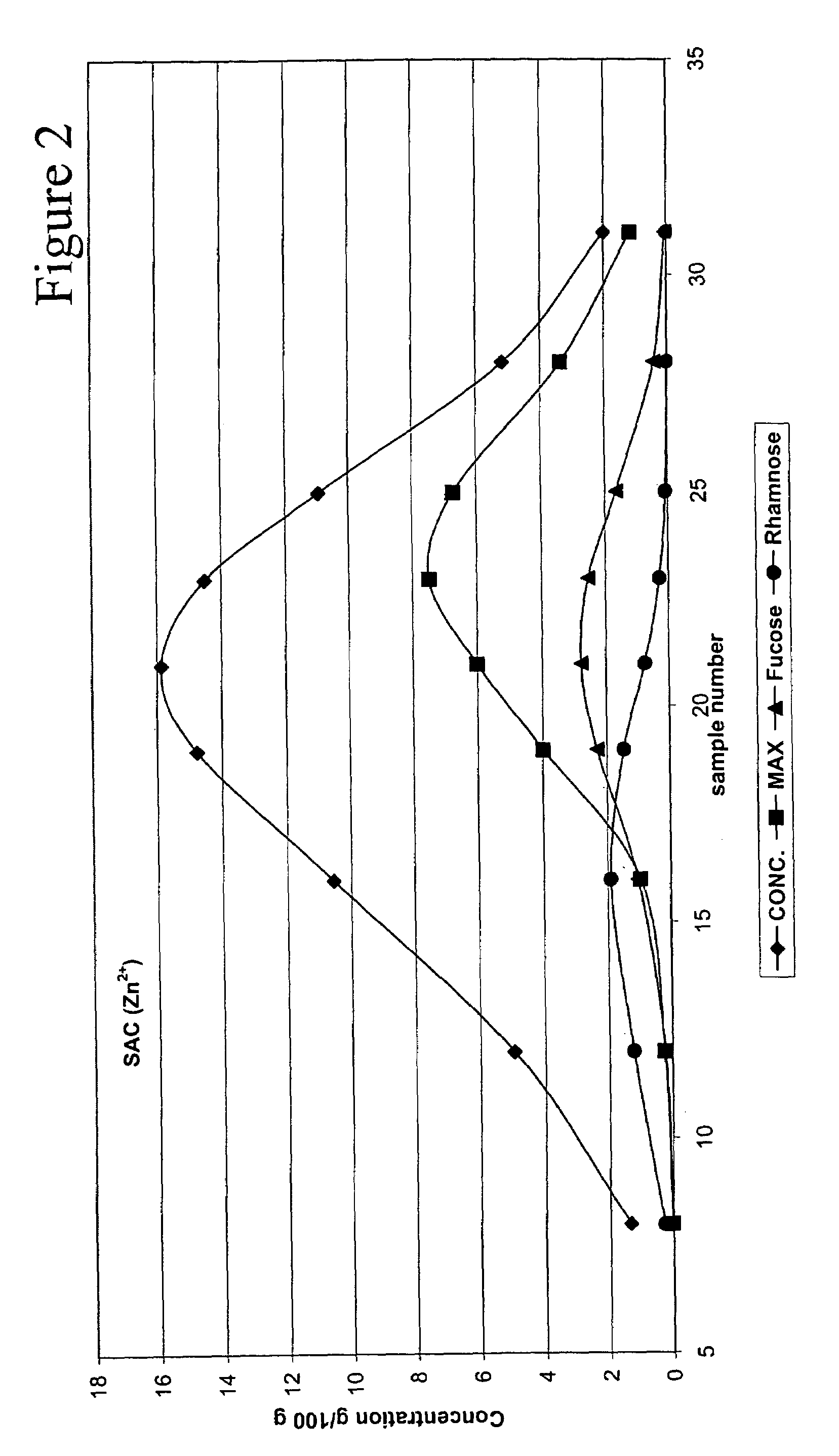

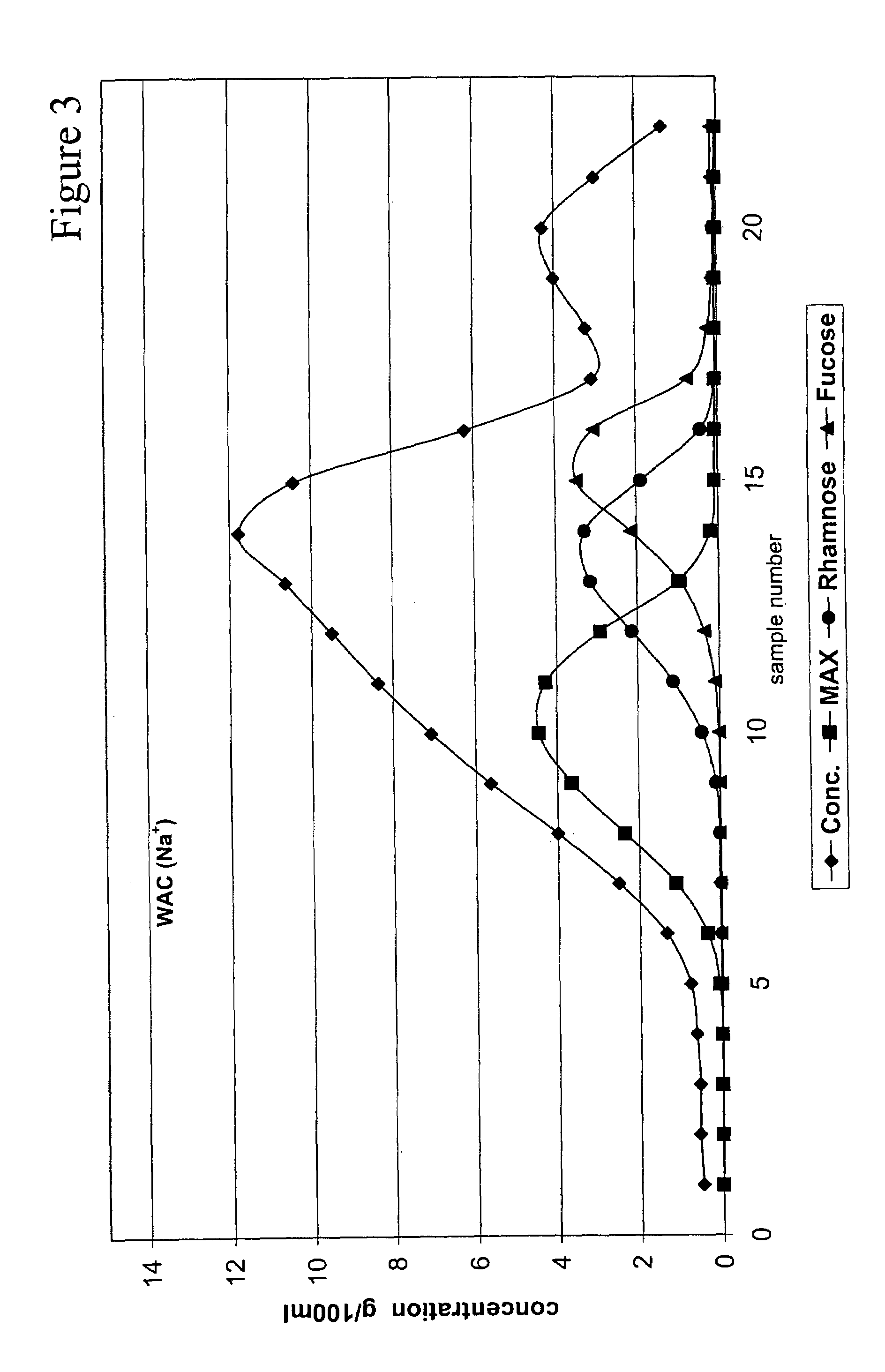

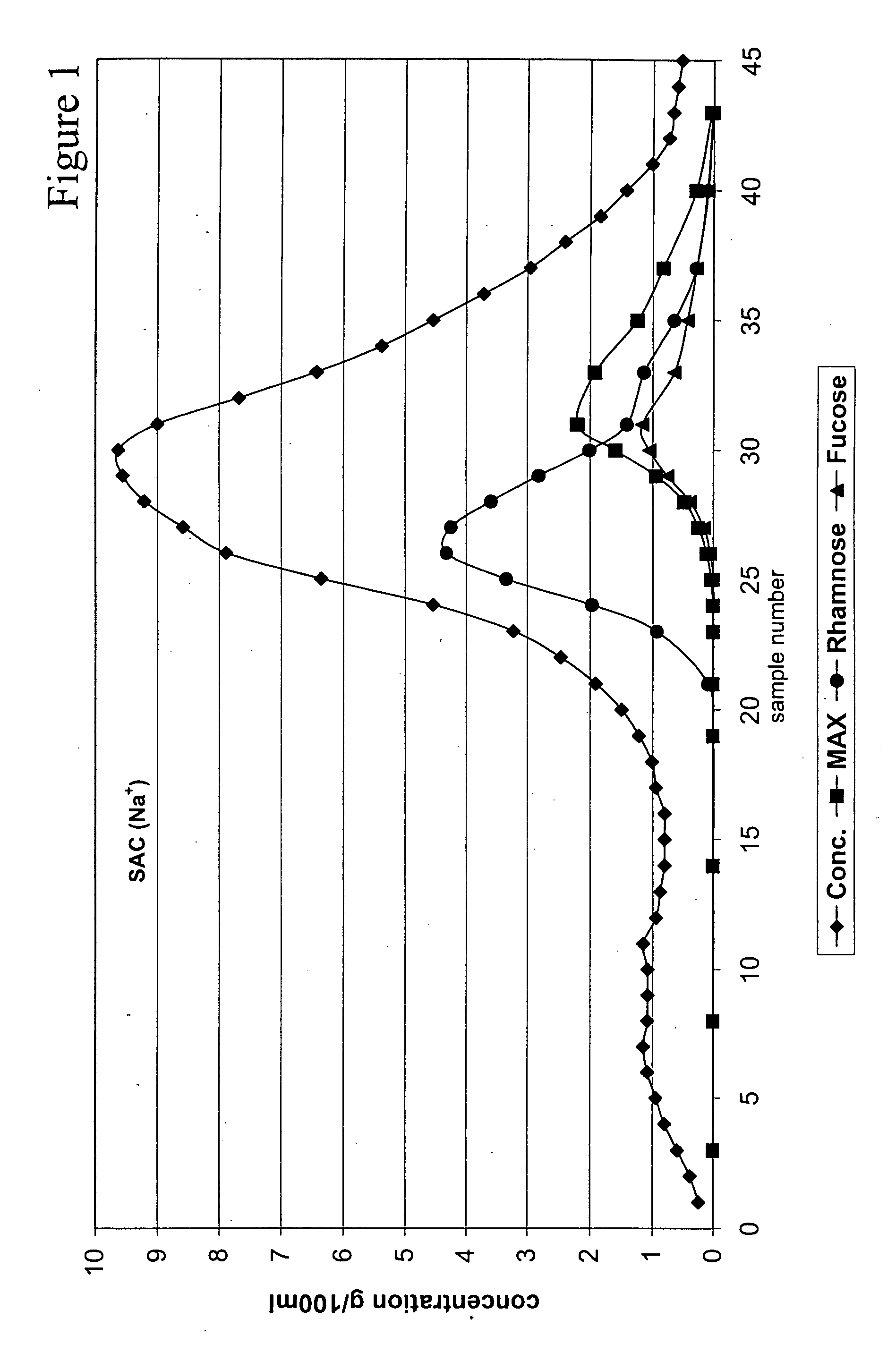

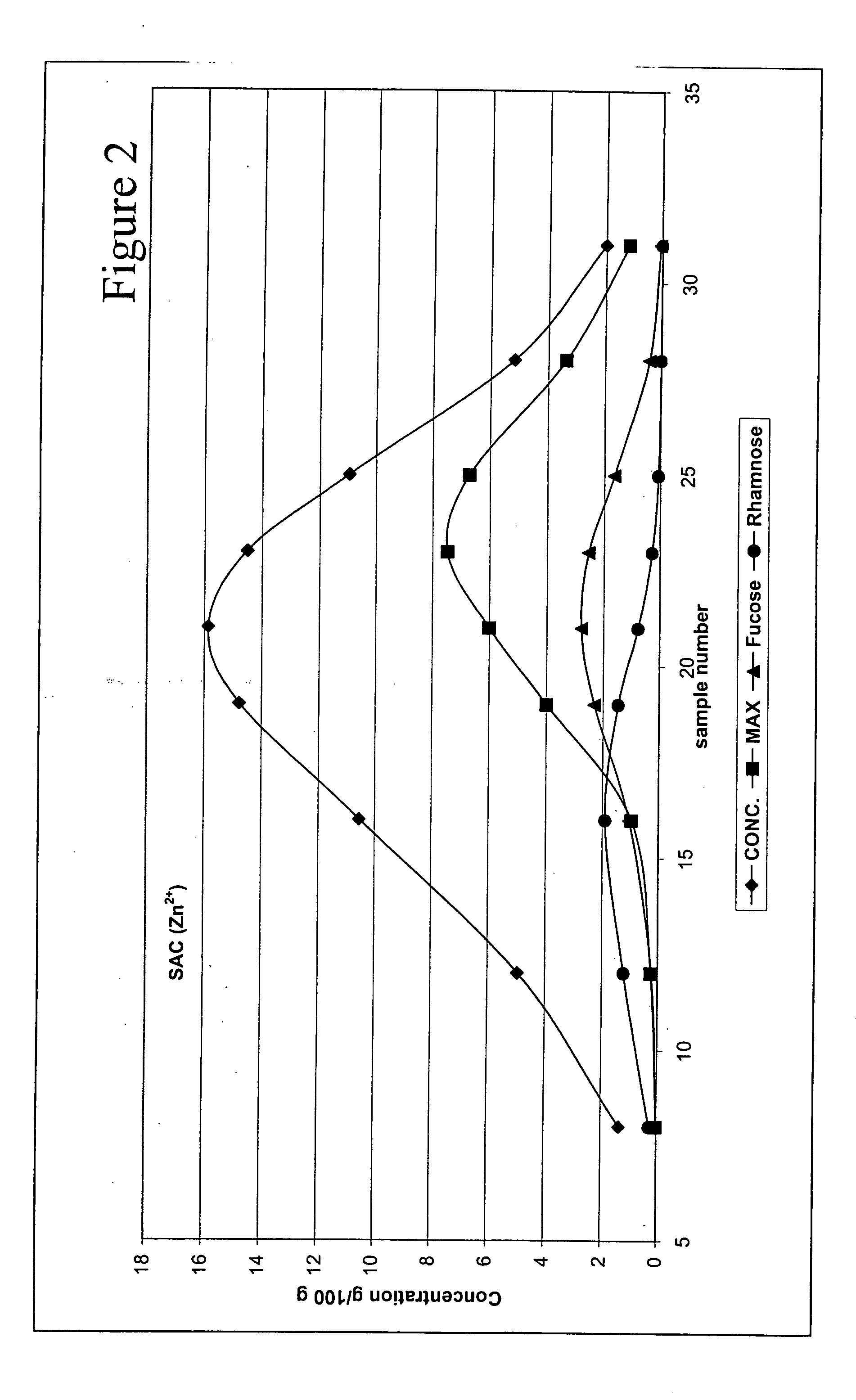

Use of a weakly acid cation exchange resin for chromatographic separation of carbohydrates

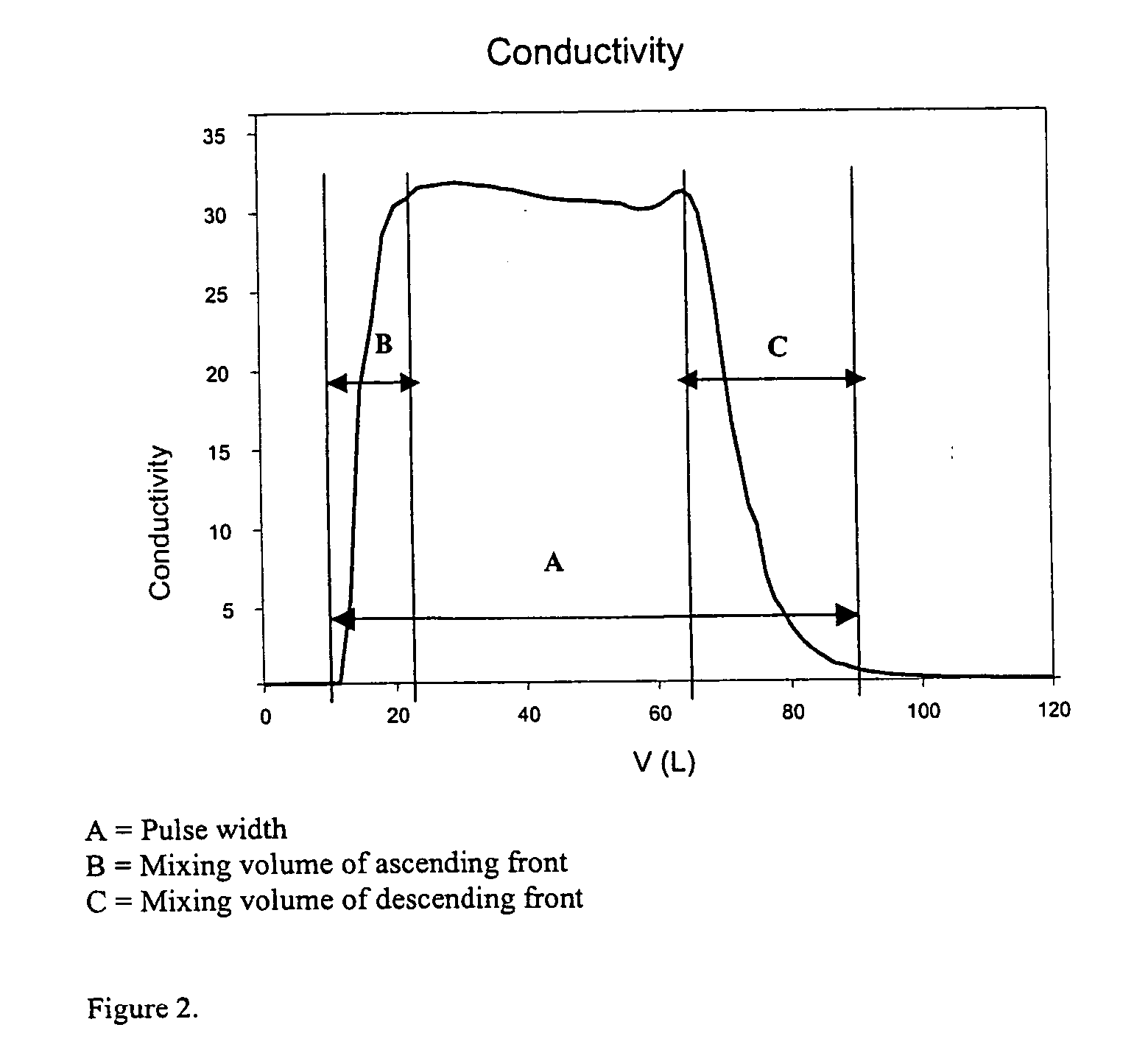

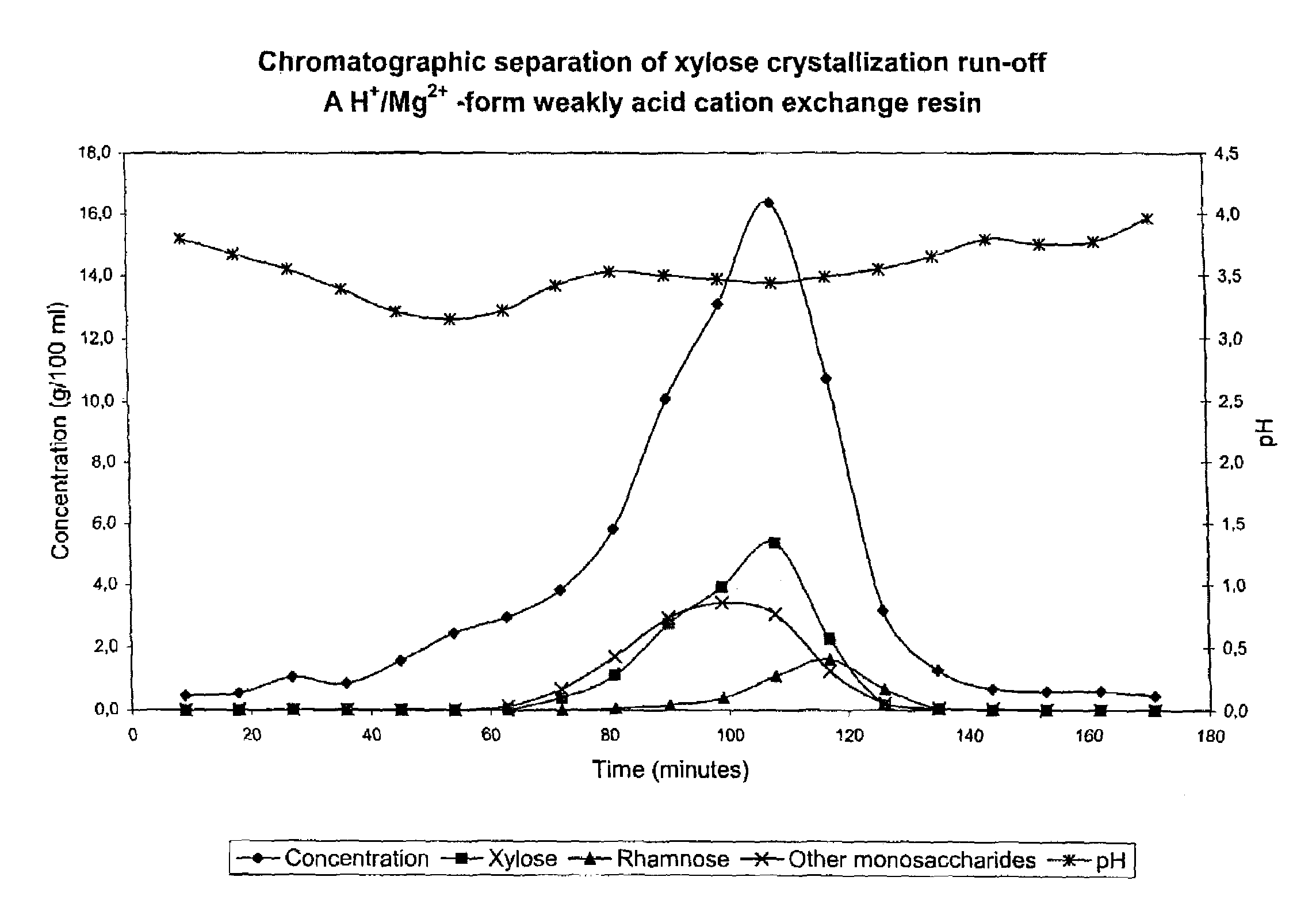

InactiveUS6924371B2High yieldEasy to separateChromatographic cation exchangersCation exchanger materialsChromatographic separationAlcohol sugars

The invention relates to the use of a weakly acid cation exchange resin for chromatographic separation of carbohydrates. In the invention the hydrophilic / hydrophobic interaction of carbohydrates, sugars and sugar alcohols with the weakly acid cation exchange resin is utilized. The weakly acid cation exchange resin is used for separation of hydrophobic saccharides, such as deoxy, methyl and anhydrosugars and anhydrosugaralcohols from more hydrophilic saccharides.

Owner:DANISCO SWEETENERS

Separation of sugars

InactiveUS7037378B2Avoid insufficient puritySugar derivativesSugar productsChromatographic separationDeoxy sugar

Owner:DANISCO SWEETENERS

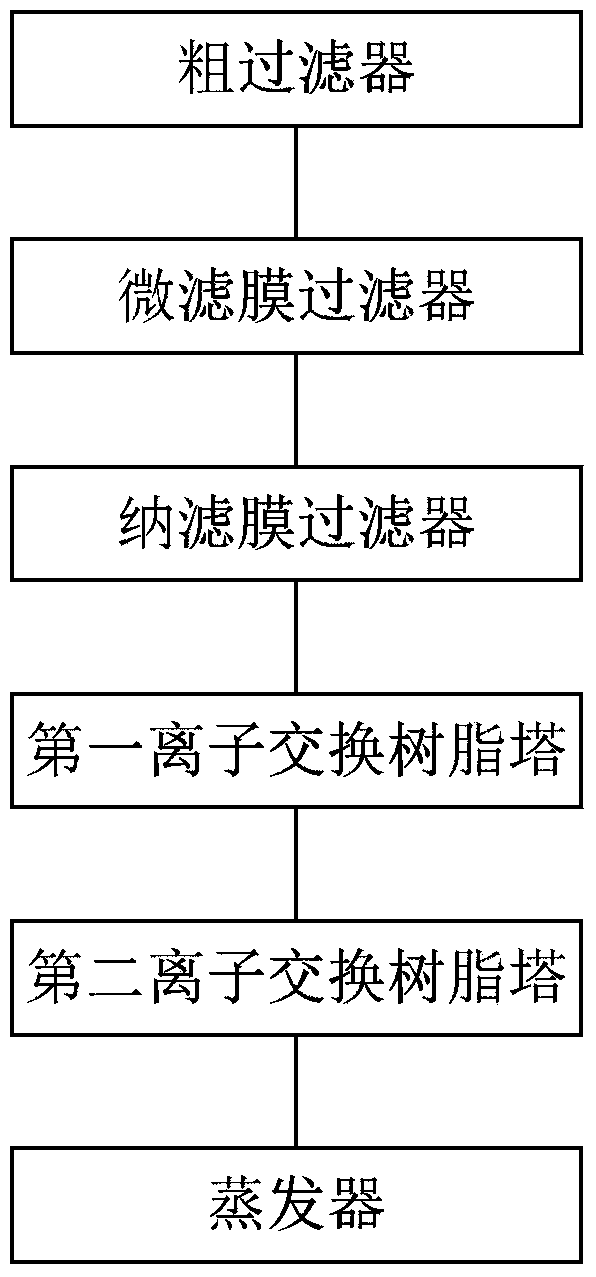

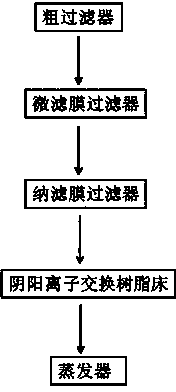

Production technique and device of directly edible edible syrup

ActiveCN103710469ALow chroma valueHigh desalination ratePurification using ion-exchange materialsPurification by physical meansSucroseMicrofiltration membrane

The invention relates to a production technique and device of directly edible syrup. The method comprises the following steps: pressing sugar cane with a juice press to obtain a sugar cane juice; prefiltering the sugar cane juice through a coarse filter, and filtering with a microfiltration membrane to obtain a sucrose juice clear solution; concentrating the sucrose juice clear solution through a nanofiltration membrane to obtain a concentrated solution; sending the concentrated solution into a first ion exchange resin tower to obtain a first permeation solution; sending the first permeation solution into a second ion exchange resin tower to obtain a second permeation solution; and concentrating the second permeation solution in an evaporator to obtain a refined concentrated solution, adding additives and uniformly mixing to obtain the syrup. The product produced by the production technique provided by the invention has the advantages of low chromatic value, high desalting rate and high yield.

Owner:JIANGSU JIUWU HITECH

Separation process

ActiveUS20100213130A1Lower the volumeLower energy requirementsIon-exchange process apparatusSugar derivativesChromatographic separationBetaine

The present invention relates to a chromatographic separation process for fractionating solutions containing sugars, sugar alcohols, sugar acids and / or betaine by utilizing fractions comprising parts of the separation profile as a substituent of the eluent in a novel and inventive manner. The starting solutions are typically multicomponent plant-based extracts and hydrolysates, stillages, and fermentation products and derivatives thereof. The process prow vides improved separation capacity and separation efficiency without affecting the yield or purity of product components, such as sugars, sugar alcohols, sugar acids, and betaine. The process can especially be applied to sequential SMB separation systems.

Owner:DUPONT NUTRITION BIOSCIENCES APS

Crystallization of sugars

The invention relates to removing crystallization inhibitors from a solution comprising one or more reducing sugars by nanofiltration, hydrolysis and / or chromatography. The reducing sugars are typically selected from fructose and xylose.

Owner:DANISCO SWEETENERS

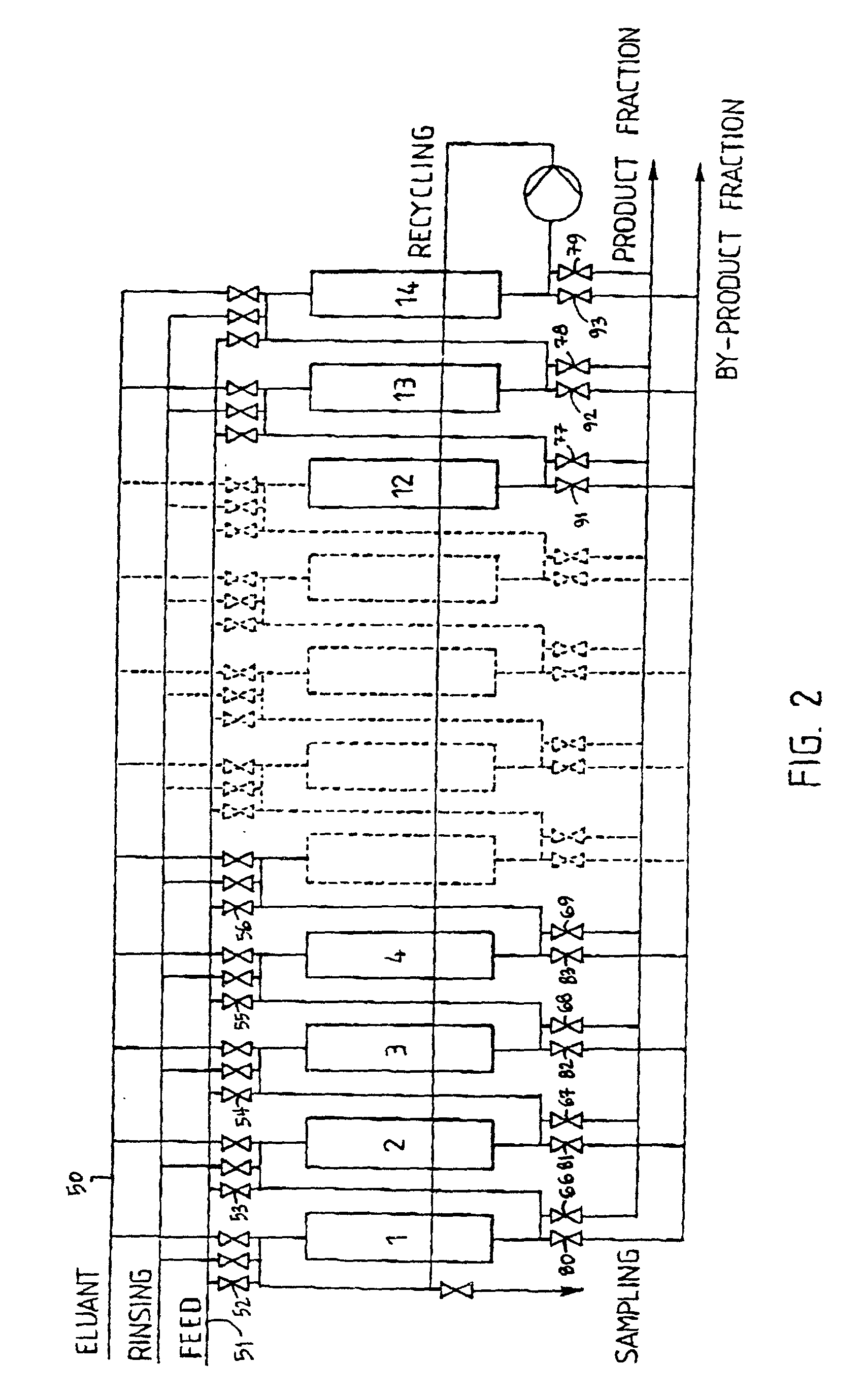

Fractionation method for sucrose-containing solutions

InactiveUS6214125B1High yieldEquivalent purityIon-exchange process apparatusIon-exchanger regenerationSimulated moving bedSaccharophagus degradans

A method for separating sucrose and a second dissolved component from a sucrose-containing solution, preferably a beet-derived sucrose-containing solution, wherein the solution is subjected to a first fractionation by a continuous or sequential chromatographic simulated moving bed process to yield a sucrose-enriched fraction and a fraction enriched with the second dissolved component. The resulting fraction enriched with the second component is subjected to a second chromatographic fractionation that is a simulated moving bed or batch type process, to yield a second sucrose-enriched fraction and a second fraction enriched with the second dissolved component wherein both fractions have an improved yield or purity.

Owner:DANISCO FINLAND OY

Natural Sweetener

ActiveUS20080045464A1Improve gutLowering GIOrganic active ingredientsSugar food ingredientsPhytochemicalWaste product

Owner:POLY GAIN PTE LTD

Method for separating betaine

ActiveUS20070158269A1Ion-exchange process apparatusIon-exchanger regenerationChromatographic separationBetaine

The invention relates to a method for separating betaine from fermentation process solutions, vinasse and other sugar beet based solutions on a weakly acid cation exchange resin in H+-form in the chromatographic separation process. The present invention relates also to use of a weakly acid cation exchange resin in H+-form for the chromatographic separation of betaine.

Owner:DUPONT NUTRITION BIOSCIENCES APS

Process for Producing High-Purity Sucrose

InactiveUS20100160624A1Sugar productsPurification using ion-exchange materialsSucrose solutionRefined sugar

Improved processes for the purification of raw or refined sugar, or sucrose, to produce sucrose and sucrose-related products having substantially no inorganic impurities are described, wherein the processes include the use of both cation and anion exchange resins. In accordance with the process, a sucrose starting material, such as refined sugar or invert syrup, is dissolved in water at a temperature sufficient to dissolve the sucrose product and produce a low visicosity sucrose solution having not more than about 76 wt. % solids. Thereafter, the process includes contacting the low viscosity sucrose solution with one or more ion exchange resin beds, which can be separate or mixed, for a time sufficient to yield a highly-purified sucrose product that is substantially free of inorganic elemental impurities.

Owner:RAGUS HLDG

Fractionation method for sucrose-containing solutions

InactiveUS20010001956A1Equivalent purityHigh yieldSolid sorbent liquid separationPurification using ion-exchange materialsSimulated moving bedSaccharophagus degradans

A method for separating sucrose and a second dissolved component from a sucrose-containing solution, preferably a beet-derived sucrose-containing solution, wherein the solution is subjected to a first fractionation by a continuous or sequential chromatographic simulated moving bed process to yield a sucrose-enriched fraction and a fraction enriched with the second dissolved component. The resulting fraction enriched with the second component is subjected to a second chromatographic fractionation that is a simulated moving bed or batch type process, to yield a second sucrose-enriched fraction and a second fraction enriched with the second dissolved component wherein both fractions have an improved yield or purity.

Owner:DANISCO FINLAND OY

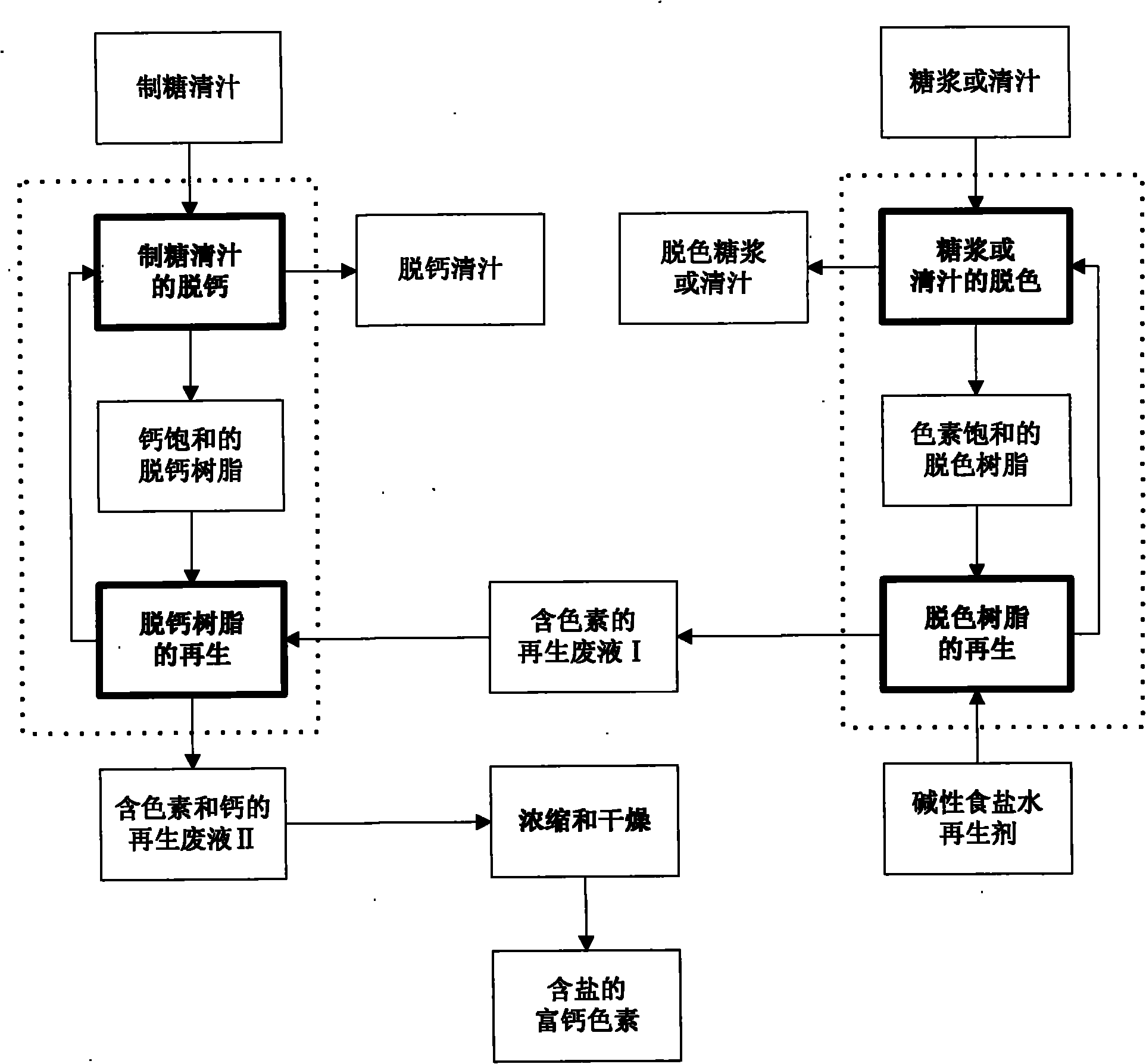

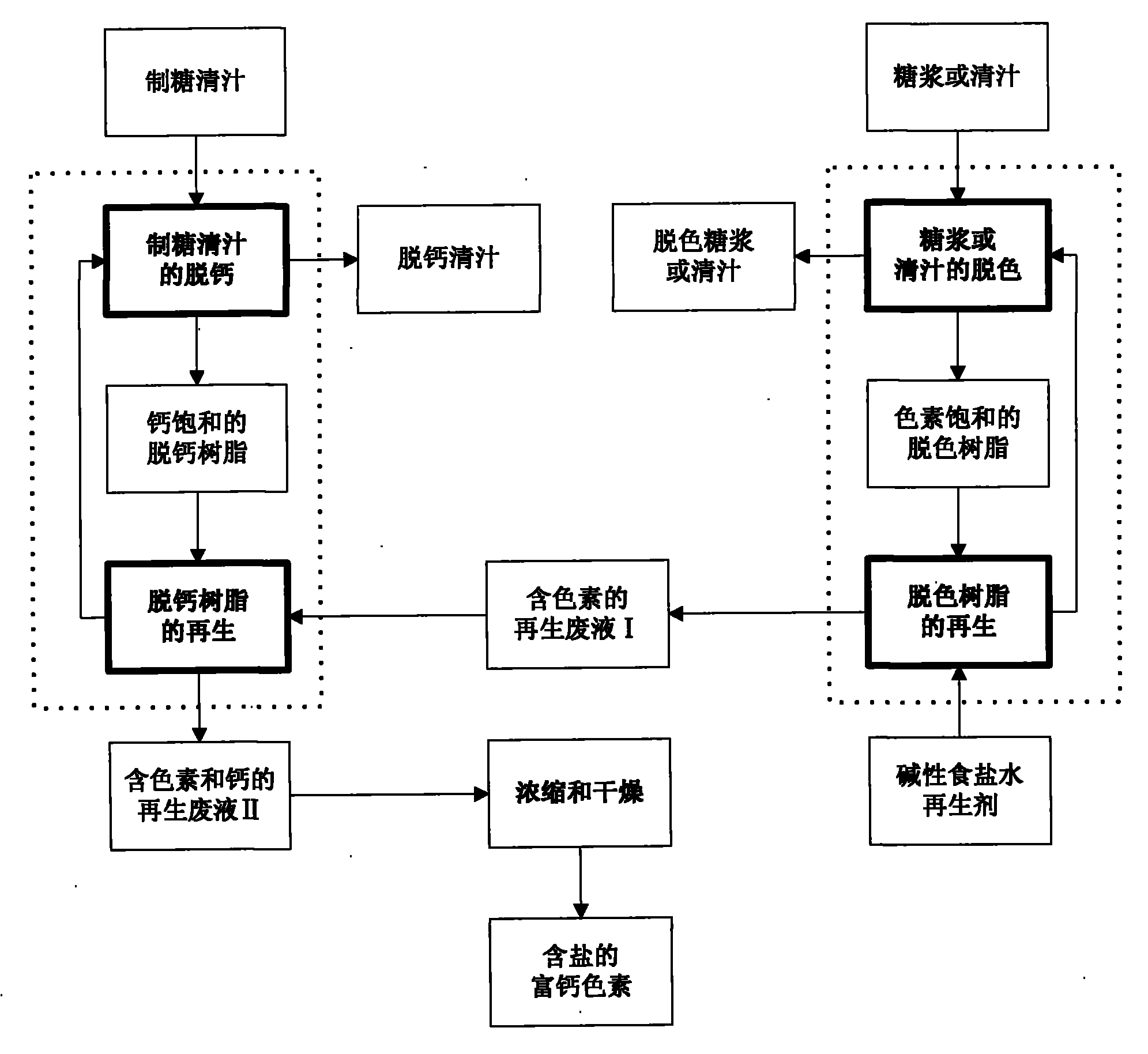

Method for regenerating sugar making decolorized and decalcified resin and method for recycling regeneration waste liquid

ActiveCN102031315AEmission reductionHigh regeneration ratePurification using ion-exchange materialsNatural dyesLiquid wasteEvaporation

The invention discloses a method for regenerating sugar making decolorized and decalcified resin, which comprises the following steps of: (1) decolorizing syrup or clear juice to obtain decolorized resin and decolorized syrup or clear juice; (2) regenerating the decolorized resin to obtain regenerated decolorized resin and decolorized resin regeneration waste liquid I; (3) decalcifying sugar making clear juice to obtain decalcified resin and decalcified clear juice; and (4) regenerating the decalcified resin, namely regenerating the decalcified resin by using the regeneration waste liquid I to obtain regenerated decalcified resin and decalcified resin regeneration waste liquid II. The invention also discloses a method for recycling the regeneration waste liquid II, which is used for preparing a calcium-rich pigment with anti-oxidation activity. The method is suitable for the cleaning or clarifying process of the syrup (juice) in a beet or cane sugar factory, is particularly suitable for decolorizing and decalcifying the sugar making clear juice and the syrup, has the main characteristics of reducing the using amount of a regenerant and the scaling of an evaporator, saving the evaporation energy of an evaporating pot, recycling non-sugar components in the syrup (juice), such as the pigment, calcium and the like, along with safe processing technology, and is environmental-friendly.

Owner:广东华糖实业有限公司

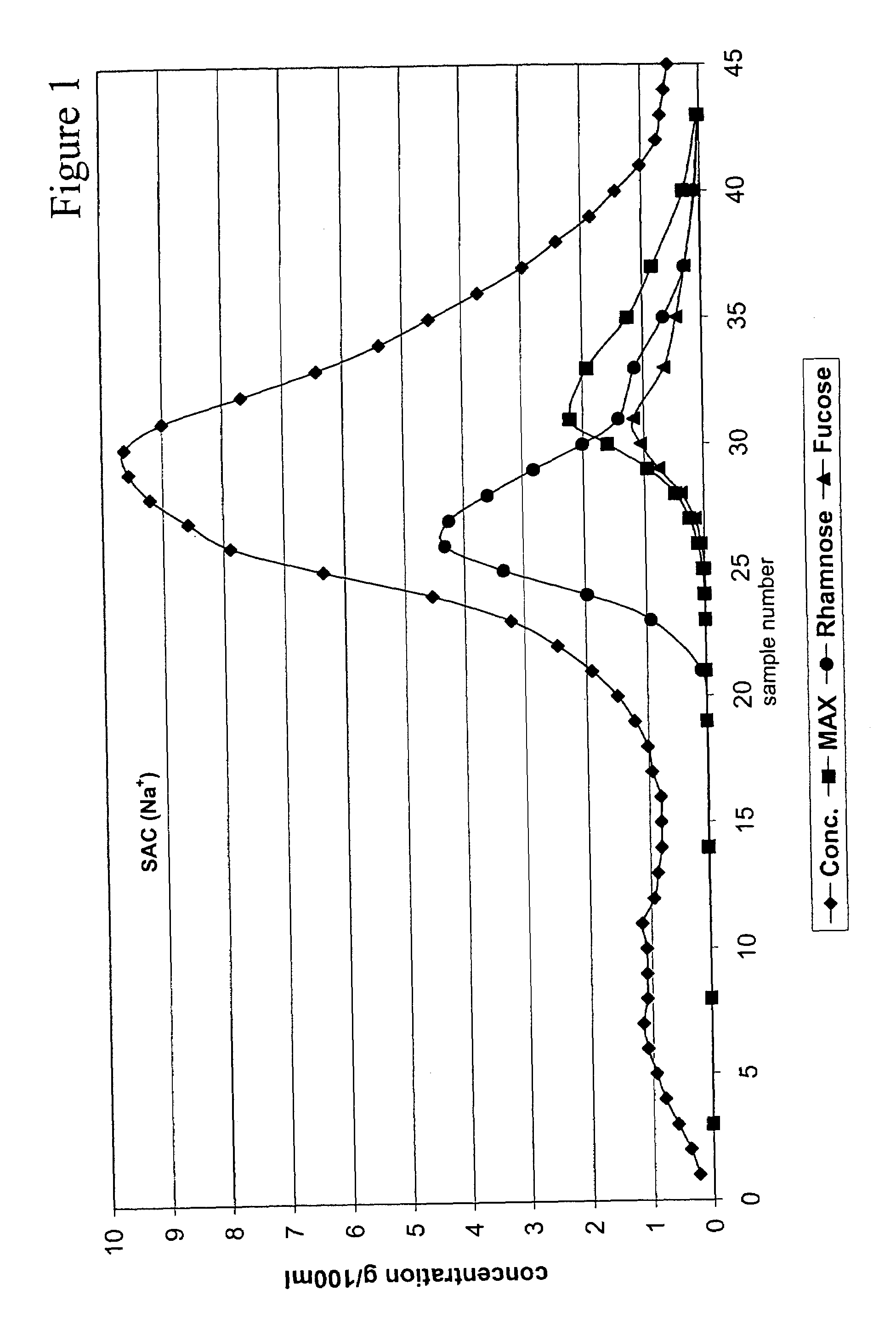

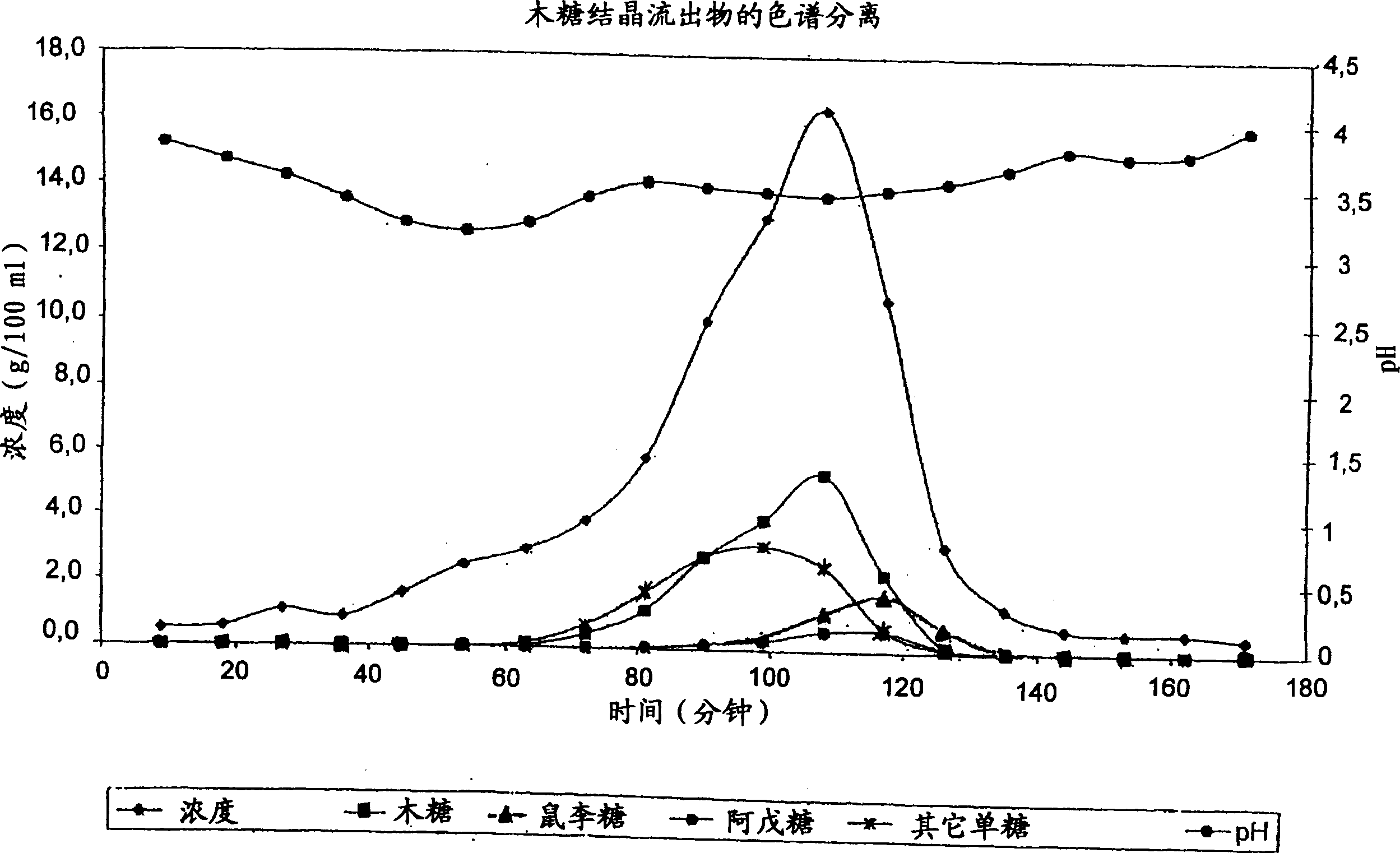

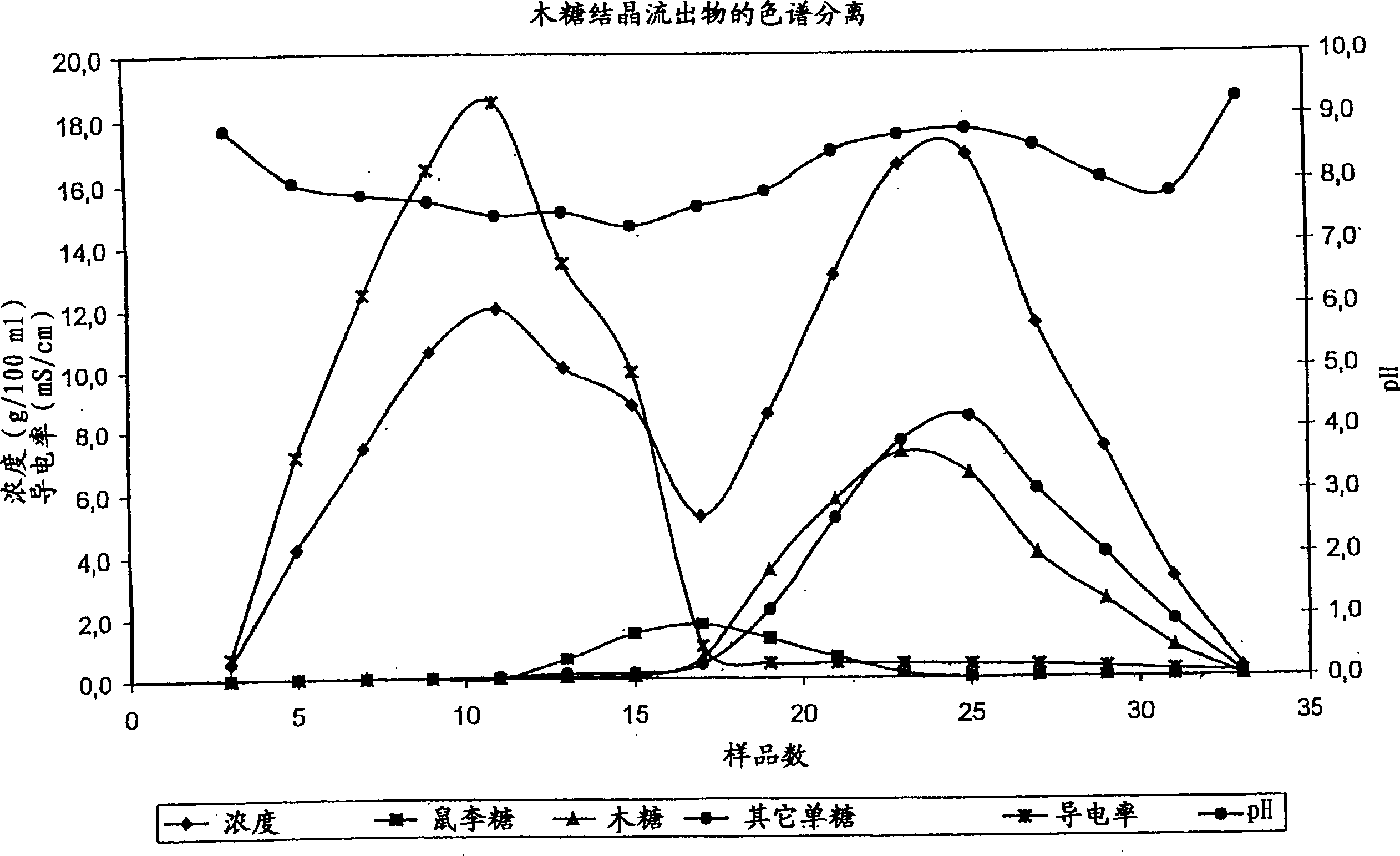

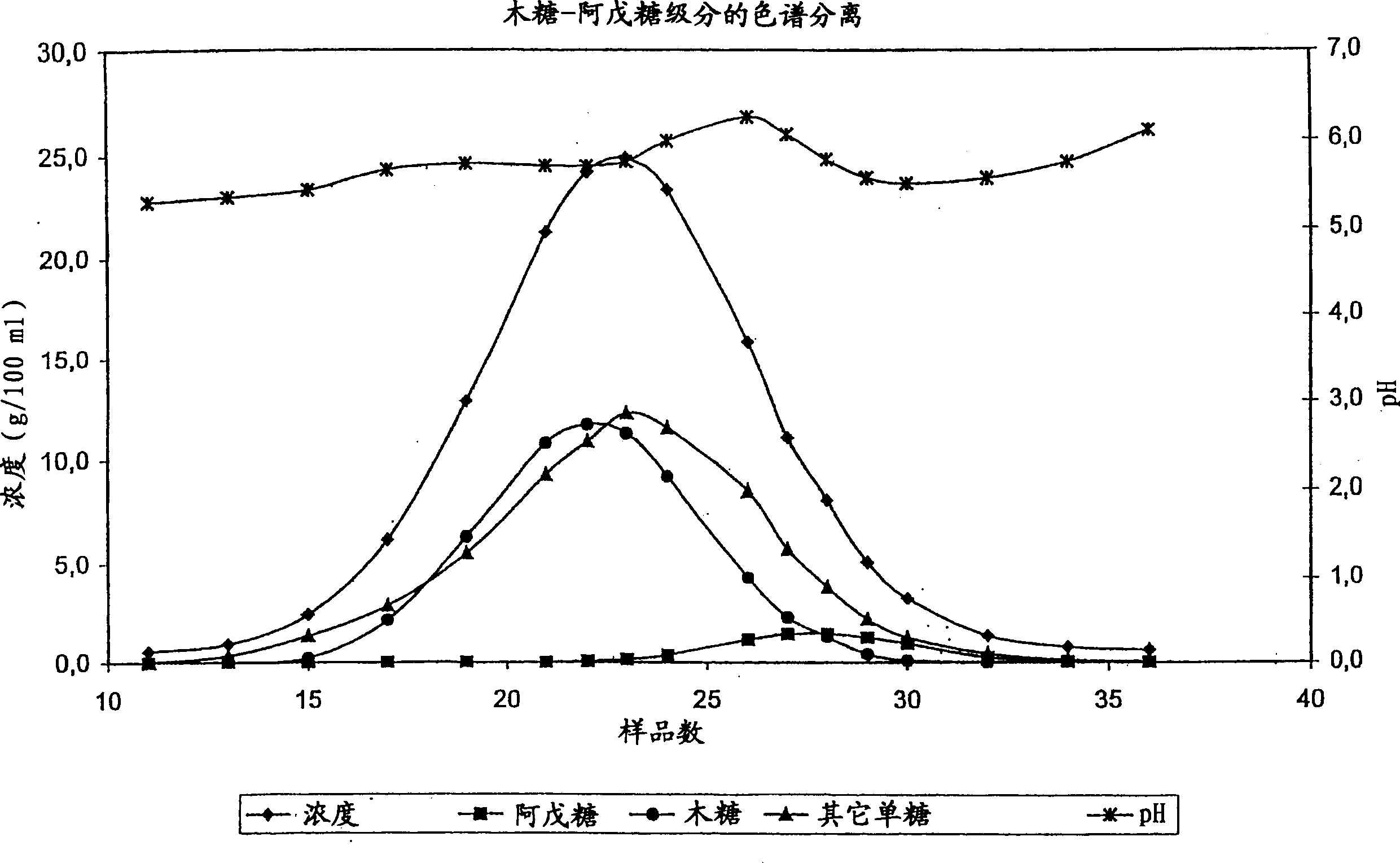

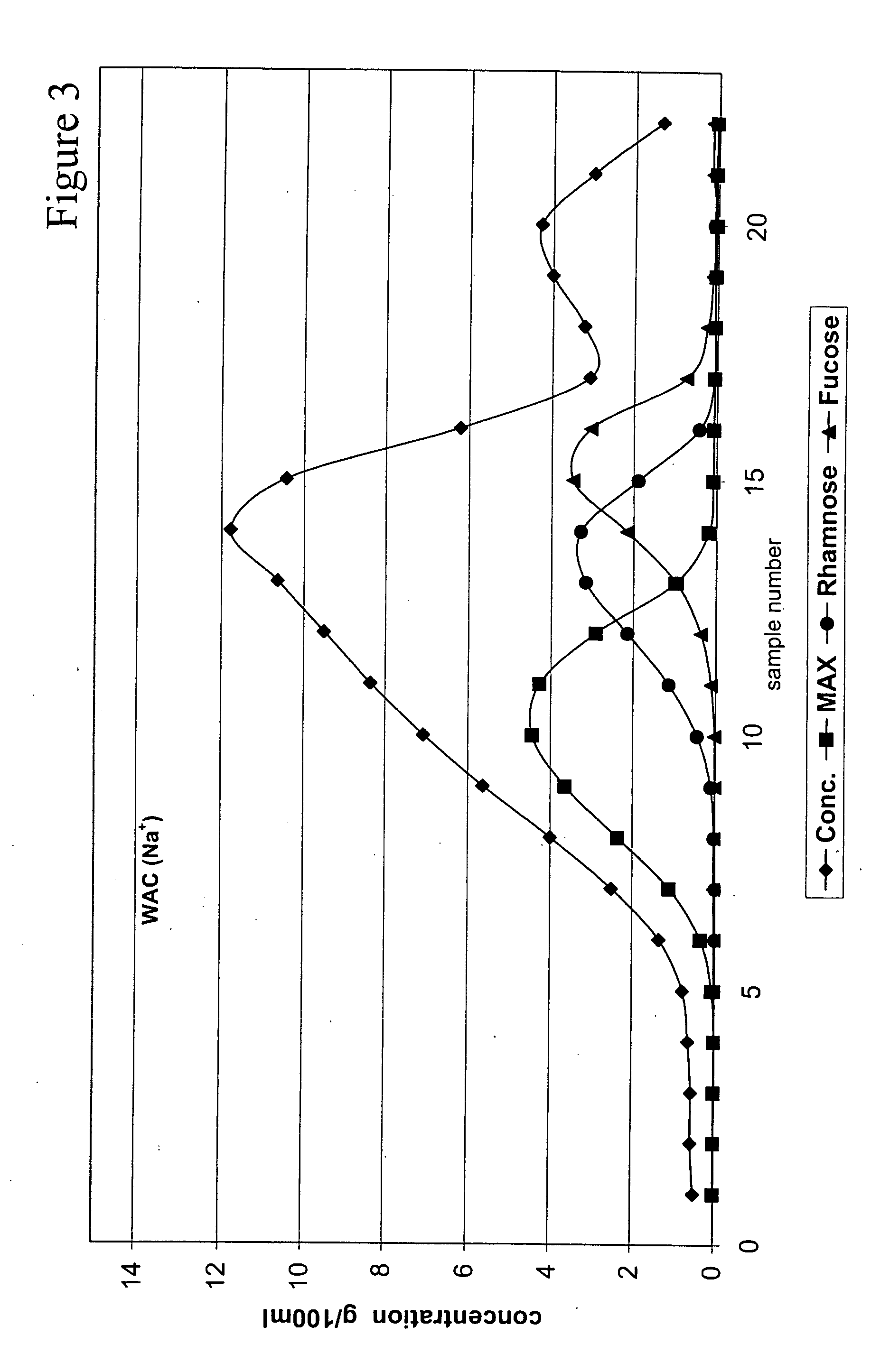

Method for recovering monosaccharide from solution using weakly acid cation exchange resin for chromatographic separation

InactiveCN1466632AChromatographic cation exchangersCation exchanger materialsChromatographic separationPhysical chemistry

The present invention relates to a method for recovering a monosaccharide selected from the group consisting of rhamnose, arabinose, xylose and mixtures thereof from a solution containing the same by a multistep process using chromatographic separation comprising at least one step, where a weakly acid cation exchange resin is used for the chromatographic separation.

Owner:DANISCO SWEETENERS

Fractionation method for sucrose-containing solutions

InactiveUS6482268B2Equivalent purityHigh yieldIon-exchange process apparatusIon-exchanger regenerationSimulated moving bedSaccharophagus degradans

A method for separating sucrose and a second dissolved component from a sucrose-containing solution, preferably a beet-derived sucrose-containing solution, wherein the solution is subjected to a first fractionation by a continuous or sequential chromatographic simulated moving bed process to yield a sucrose-enriched fraction and a fraction enriched with the second dissolved component. The resulting fraction enriched with the second component is subjected to a second chromatographic fractionation that is a simulated moving bed or batch type process, to yield a second sucrose-enriched fraction and a second fraction enriched with the second dissolved component wherein both fractions have an improved yield or purity.

Owner:DANISCO FINLAND OY

Crystallization of sugars

The invention relates to removing crystallization inhibitors from a solution comprising one or more reducing sugars by nanofiltration, hydrolysis and / or chromatography. The reducing sugars are typically selected from fructose and xylose.

Owner:DANISCO SWEETENERS

Production process and device of golden sugar

InactiveCN104004860AHigh desalination rateHigh yieldSugar crystallisationPurification using ion-exchange materialsSucroseIon-exchange resin

The invention provides a production process and a production device of golden sugar. The production process comprises the following steps: pressing sugarcane or beets to obtain cane sugar juice; pre-filtering the cane sugar juice through a coarse filter and feeding the pre-filtered crane sugar juice into a microfiltration membrane for filtering to obtain clear cane sugar juice; pre-concentrating the clear cane sugar juice to obtain a pre-concentrated solution; feeding the pre-concentrated solution into ion exchange resin for desalting to obtain a permeation solution; feeding the permeation solution into an evaporator for concentrating to obtain cane sugar concentrated liquid; heating the cane sugar concentrated liquid to be oversaturated, adding crystal seeds, naturally cooling and crystallizing, and centrifuging the obtained crystals to obtain golden sugar crystals; drying the golden sugar crystals to obtain a finished product of the golden sugar. The production device comprises the coarse filter, a microfiltration membrane filter, a nanofiltration membrane filter, an anion exchange resin bed, a cation exchange resin bed and the evaporator which are connected in sequence. The production method provided by the invention is capable of continuously producing high-quality golden sugar, the chromatic value of the obtained product is 800-3,000, the desalting rate is high, and the yield is high.

Owner:JIANGSU JIUWU HITECH

Separation of sugars

ActiveUS20050061313A1Avoid insufficient purityHigh purityPigmenting treatmentSugar derivativesChromatographic separationDeoxy sugar

The invention relates to the recovery of deoxy sugars, such as fucose from biomass-derived solutions, such as spent liquors obtained from pulping processes. The invention is based on the use of chromatographic fractionation with specific column packing materials and combinations thereof. The deoxy sugar product obtained from the chromatographic fractionation may be further purified by crystallization. The invention also provides a novel crystalline fucose product and a novel process for the crystallization of fucose.

Owner:DANISCO SWEETENERS

Process for producing cation exchangers

InactiveUS20090156798A1Equal and high mechanical and osmotic stabilityImprove Oxidation StabilityChromatographic cation exchangersCation exchanger materialsVinyl etherIon exchange

Strongly acidic cation exchangers with high mechanical, osmotic and oxidation stability can be prepared by sulfonating bead polymers formed from one or more vinylaromatic monomer(s), one or more crosslinker(s) and from 0.2 to 20% by weight of one or more vinyl ethers and / or vinyl esters.

Owner:LANXESS DEUTDCHLAND GMBH

Method for purification of high purity sucrose material

ActiveUS20050056273A1Improve sugar qualityQuality improvementCation exchanger materialsSugar productsSucroseSugar

A method for purifying a sucrose material already in a high purity liquid, crystalline or other form of sucrose, such as raw sugar, utilizing chromatography, or utilizing chromatography in connection with other methods of purification.

Owner:AMALGAMATED RES

Method for purification of high purity sucrose material

ActiveUS7125455B2Improve sugar qualityQuality improvementCation exchanger materialsSugar productsPurification methodsSucrose

A method for purifying a sucrose material already in a high purity liquid, crystalline or other form of sucrose, such as raw sugar, utilizing chromatography, or utilizing chromatography in connection with other methods of purification.

Owner:AMALGAMATED RES

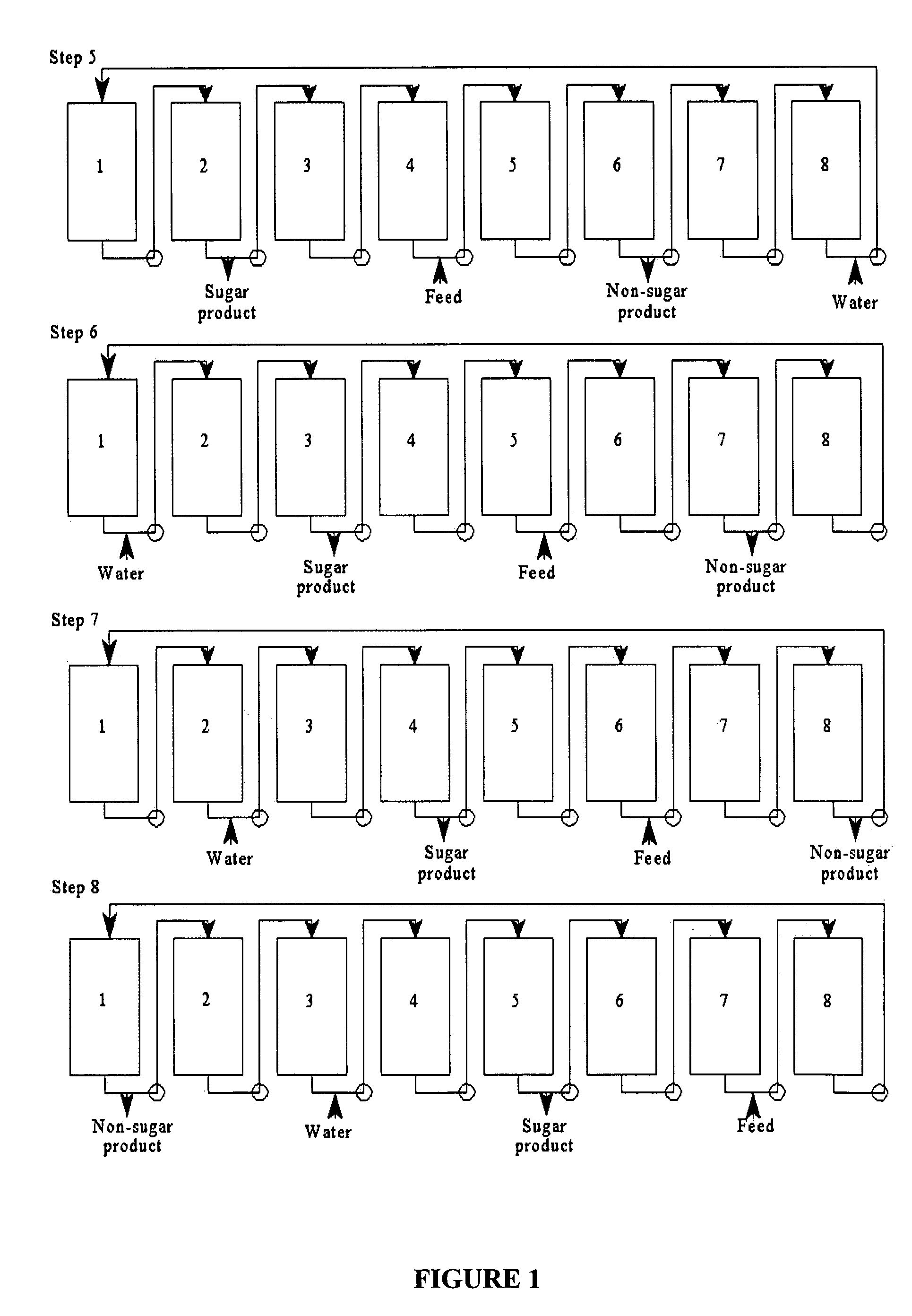

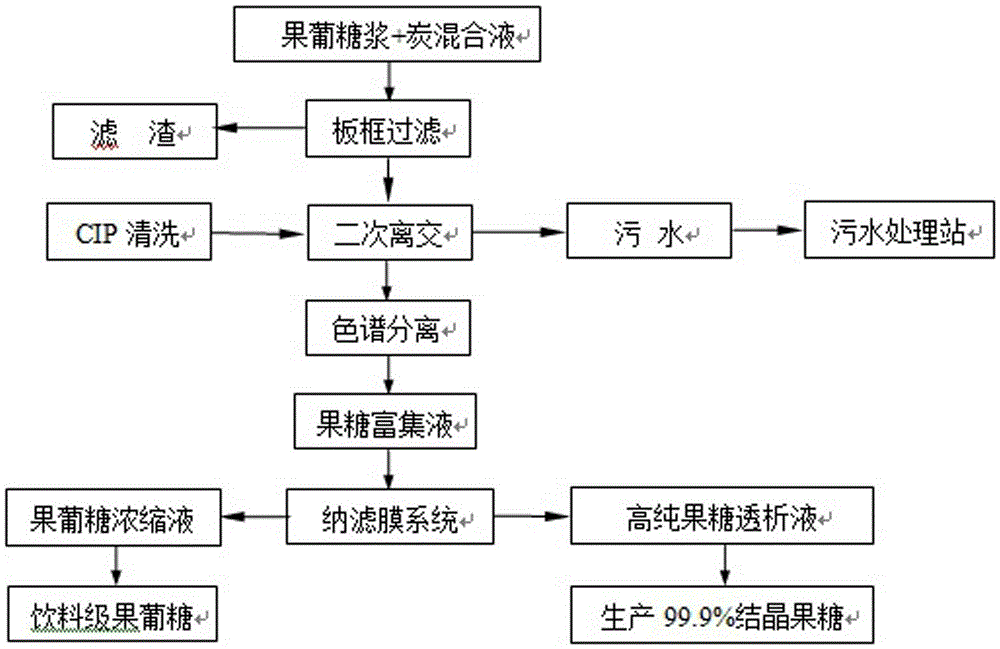

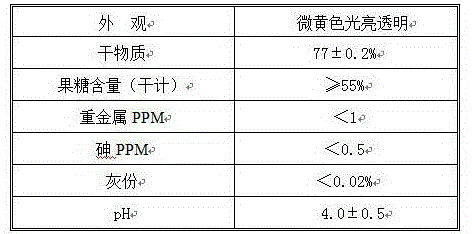

Purification method for HFCS (high fructose corn syrup) in fructose production process

InactiveCN105256079AQuality improvementImprove stabilityPurification using adsorption agentsPurification using ion-exchange materialsIon exchangeActivated carbon

The invention provides a purification method for HFCS (high fructose corn syrup) in a fructose production process. According to the purification method, the HFCS is obtained after cane juice is subjected to neutralization-hydrolysis in a medicinal anhydrous crystalline fructose production process adopting sugarcane as a raw material, the HFCS is decolorized with activated carbon, subjected to ion exchange twice and then separated through chromatography, a fructose rich liquid is obtained, the fructose rich liquid enters a nanofiltration membrane system, a high-purity fructose dialysate and a high fructose corn concentrated solution are filtered out respectively, the high-purity fructose dialysate is used for producing 99.9% crystalline fructose, and the high fructose corn concentrated solution is applied to beverage-grade high fructose corn. According to the purification method, devices and technological parameters of all working procedures are comprehensively optimized and reasonably matched to meet industrial production requirements, equipment input and production cost are greatly reduced, the one-time yield of industrially produced crystalline fructose products is up to 50%, the technical content of fructose production is increased, and the problem about the situation of heavy dependence on import of high-quality medicinal fructose is solved.

Owner:林树仁 +1

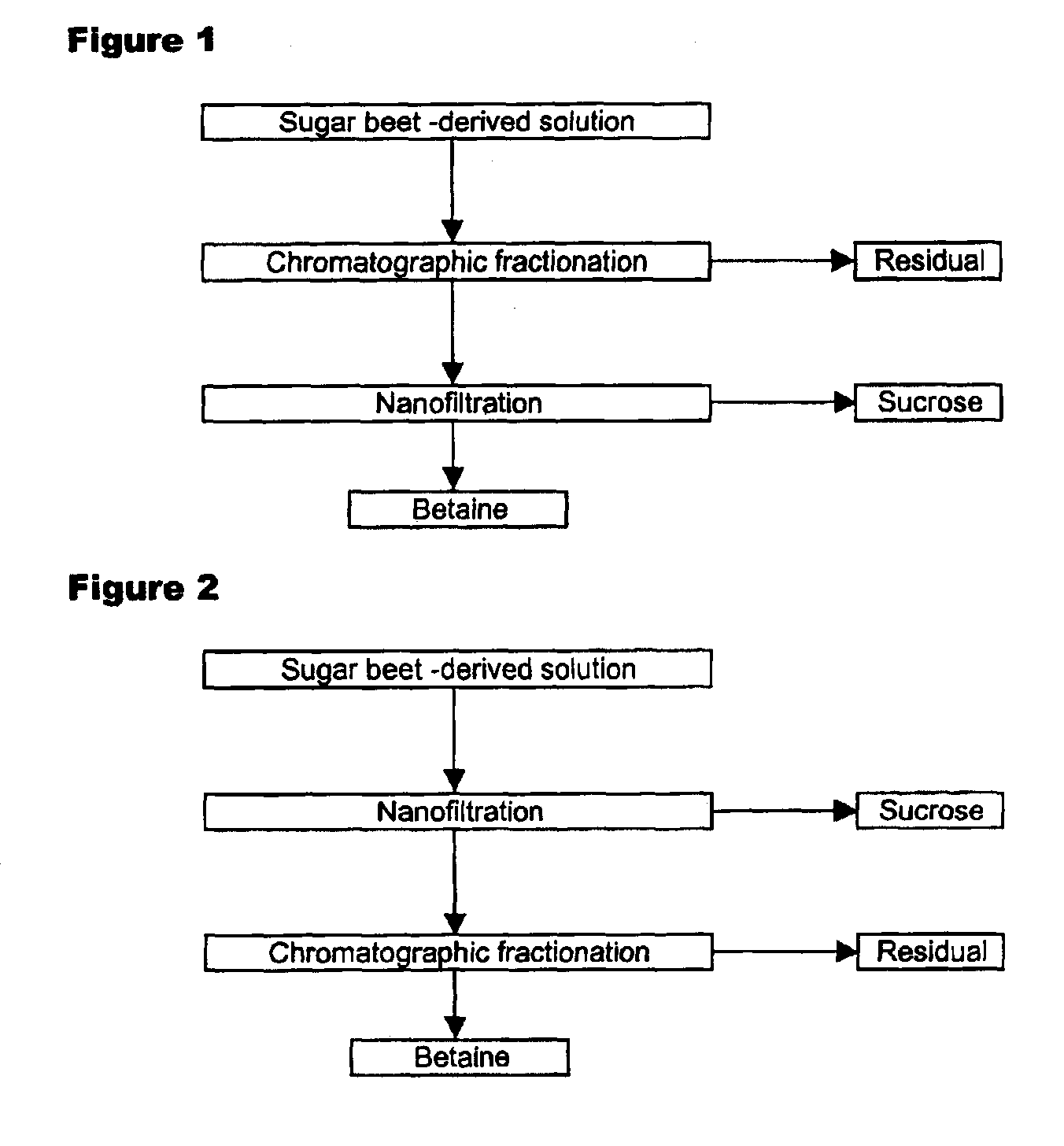

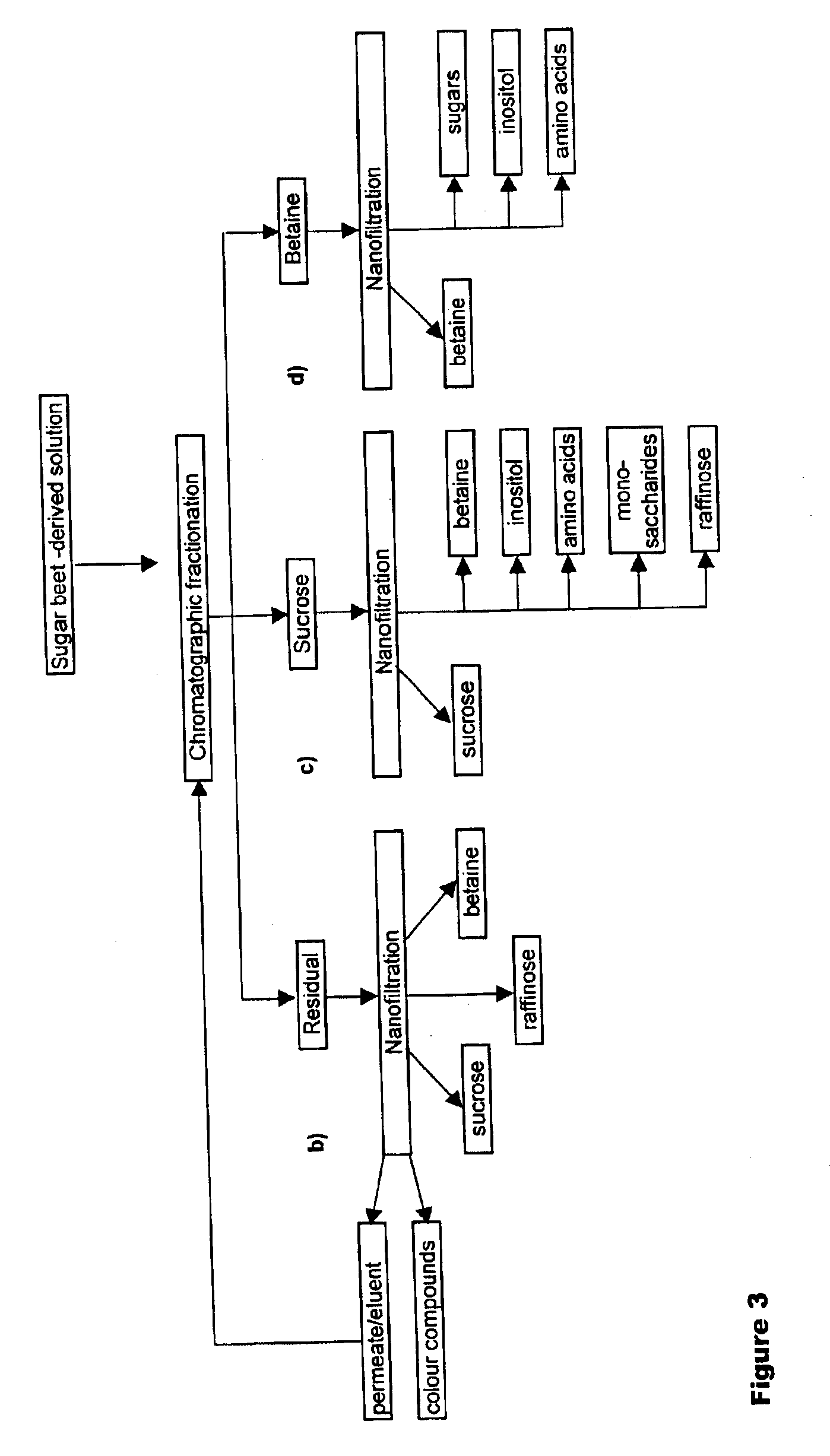

Process for recovering betaine

InactiveUS7009076B2High purityHigh yieldCation exchanger materialsIon-exchanger regenerationBetaineSucrose

The invention relates to a separation process of fractionating a solution comprising betaine and sucrose by subjecting said solution to chromatographic fractionation and nanofiltration and recovering a fraction enriched in betaine and optionally a fraction enriched in sucrose. The solution to be fractionated in accordance with the present invention is typically a sugar beet-derived solution, for instance a molasses solution.

Owner:FINPHIDE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com