Patents

Literature

51 results about "Elemental impurities" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum-silicon based aluminum section and preparation technology thereof

The invention discloses an aluminum-silicon based aluminum section. The aluminum section is composed of, by weight, 5.0-14.0% of silicon, 0.2-0.7% of magnesium, less than 0.03% of boron, less than 0.06% of strontium, 0.1-6.55% of strengthening elements, less than 0.25% impurity elements, and the balance aluminum. The aluminum-silicon based aluminium section has the advantages of high strength, high hardness, good wear resistance, etc. the invention also discloses a preparation technology for the aluminum-silicon based aluminum section, which comprises a first step of adding aluminum-silicon alloy to a graphite crucible and heating the alloy to form melt; a second step of adding the magnesium, the silicon and the strengthening elements; a third step of adding hexachloroethane for refinement; a forth step of adding the strontium for deterioration, casting to a cast iron die to form an ingot casting; and a fifth step of hot extruding, hot rolling for deformation, solid solution treating and aging treating in sequence after annealing the ingot casting, thereby obtaining the aluminum-silicon based aluminum section. The preparation technology is simple.

Owner:SOUTHEAST UNIV

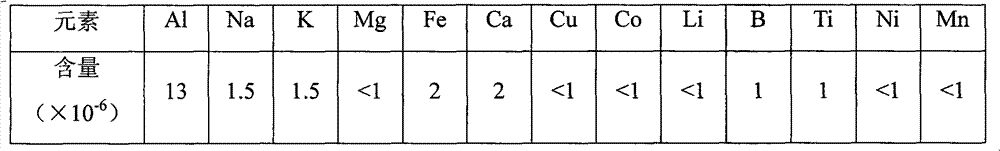

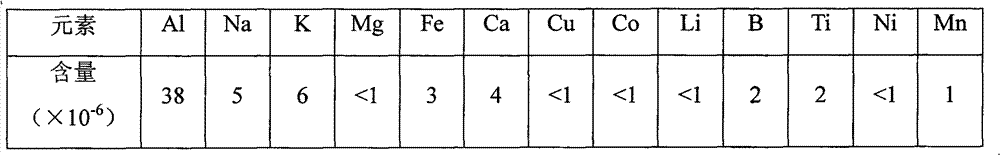

Method for preparing high-purity quartz sands by using natural vein quartz ores

The invention relates to a method for preparing high-purity quartz sands by using natural vein quartz ores, which belongs to the technical field of ore machining and raw materials for a quartz glass crucible for producing a drawn monocrystalline silicon. The method comprises the following steps of: using the natural vein quartz ores as raw materials; carrying out high temperature calcining-water quenching on the natural vein quartz ores so as to remove inclusions in the natural vein quartz ores and impurities in gaps of the vein quartz ores; removing almost trace element impurities through a flotation and mixed acid impregnation technology; and finally, washing the vein quartz ores by using ethanol-deionized water to furthest remove organic impurities introduced in the flotation and acid pickling process and other soluble impurities, so as to obtain the high-purity quartz sands, wherein the raw materials are provided for preparing the quartz glass crucible for producing the drawn monocrystalline silicon.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

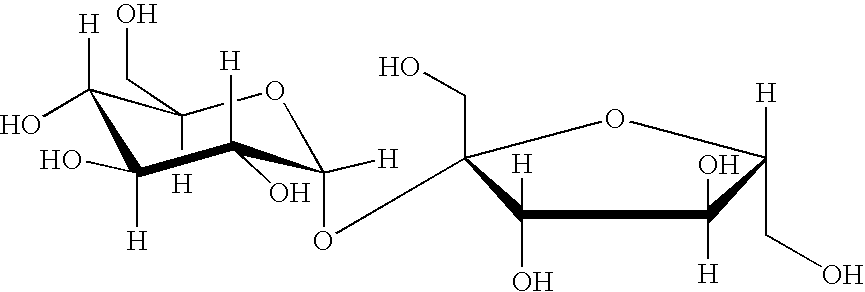

Process for Producing High-Purity Sucrose

InactiveUS20100160624A1Sugar productsPurification using ion-exchange materialsSucrose solutionRefined sugar

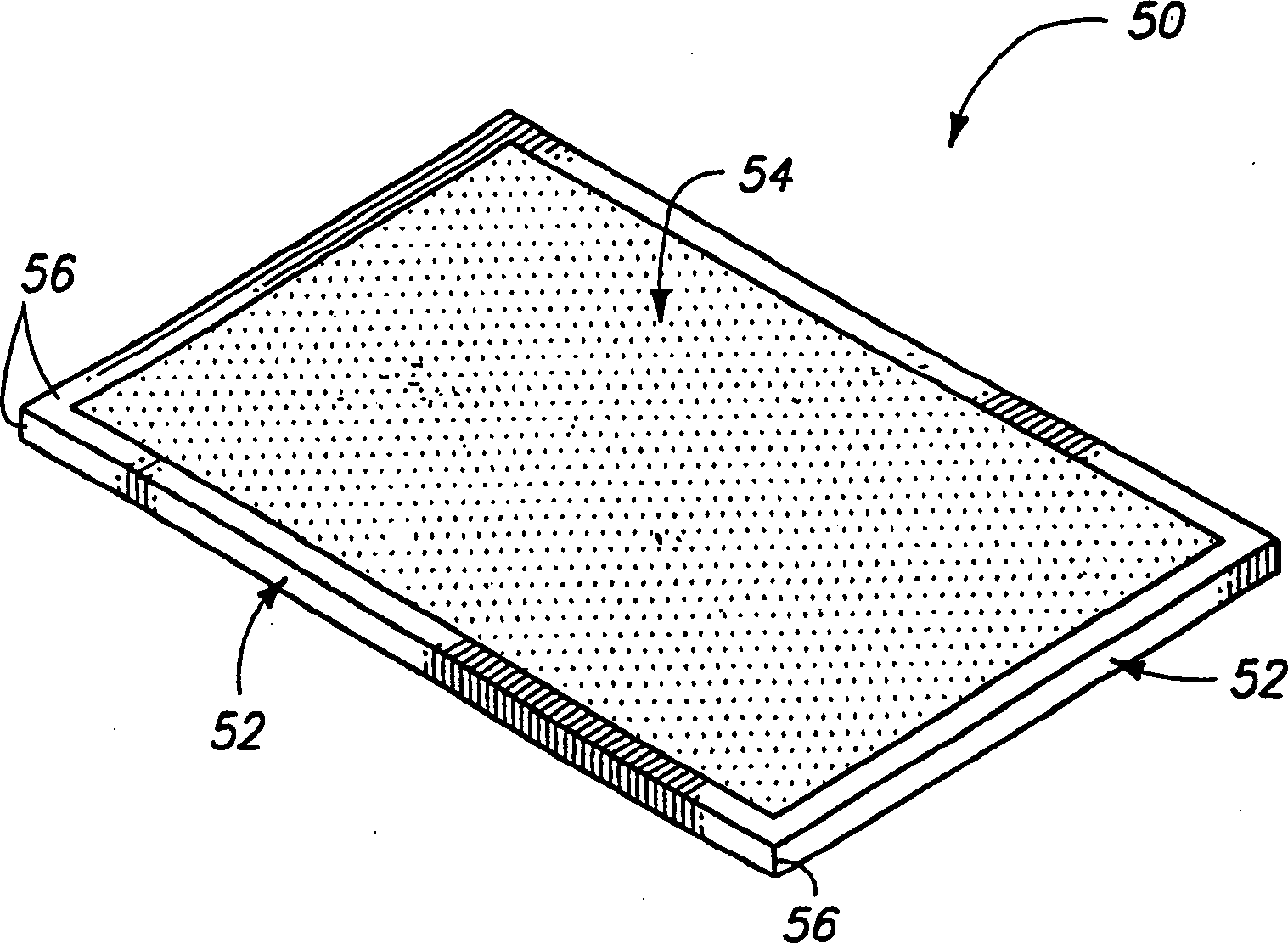

Improved processes for the purification of raw or refined sugar, or sucrose, to produce sucrose and sucrose-related products having substantially no inorganic impurities are described, wherein the processes include the use of both cation and anion exchange resins. In accordance with the process, a sucrose starting material, such as refined sugar or invert syrup, is dissolved in water at a temperature sufficient to dissolve the sucrose product and produce a low visicosity sucrose solution having not more than about 76 wt. % solids. Thereafter, the process includes contacting the low viscosity sucrose solution with one or more ion exchange resin beds, which can be separate or mixed, for a time sufficient to yield a highly-purified sucrose product that is substantially free of inorganic elemental impurities.

Owner:RAGUS HLDG

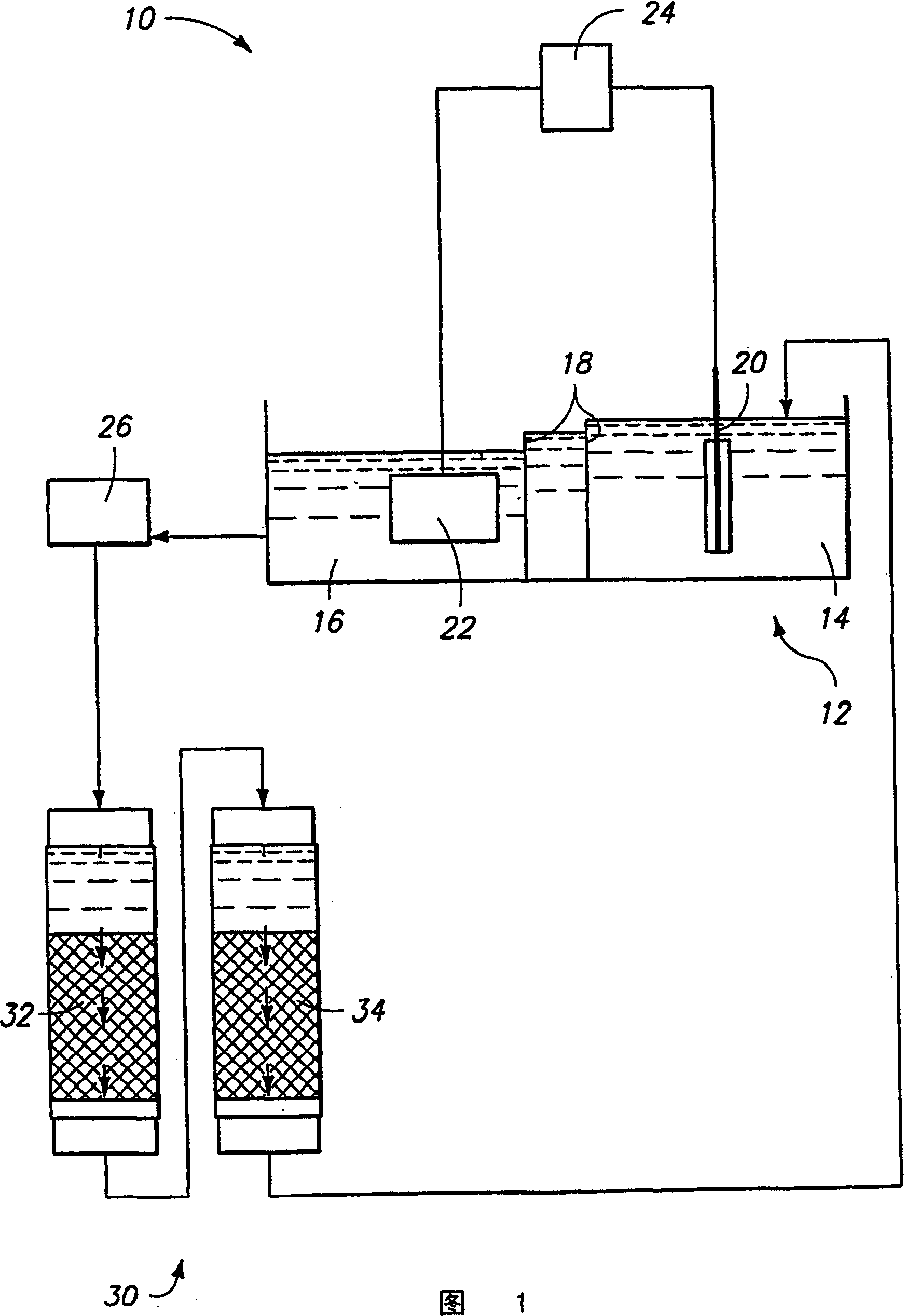

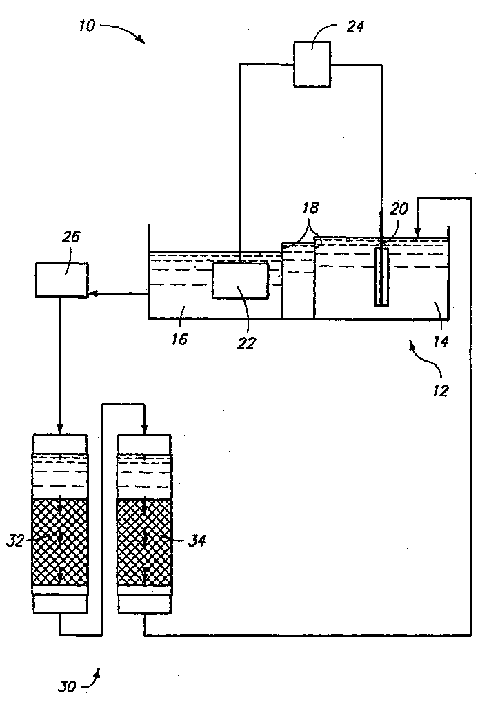

Method and apparatus for processing metals, and the metals so produced

InactiveCN1449457AEliminates the concentration stepPhotography auxillary processesIon-exchange column/bed processesElectrolysisIon exchange

The invention encompasses a method and apparatus for producing high-purita metals (such as, for example, high-purity cobalt), and also encompasses the high-purity metals so produced. The method an comprise a combination of electrolysis and ion exchange followed by melting to produce cobalt of a desired purity. The method can result in the production of high-purity cobalt comprising total metallic impurities of less than 50 ppm. Individual elemental impurities of the produced cobalt can be follows: Na and K less than 0.5 ppm each, Fe less than 10 ppm, Ni less than 5 ppm, Cr less than 1 ppm, Ti less than 3 ppm and O less than 450 ppm.

Owner:HONEYWELL INT INC

Carborundum

The invention relates to carborundum. The content of the impurity of a fifth element of the carborundum is within a specific range, and a carbothermic reduction method, a production method by a purification method and a purpose of being industrially used as a reducer of the carborundum are provided.

Owner:于旭宏

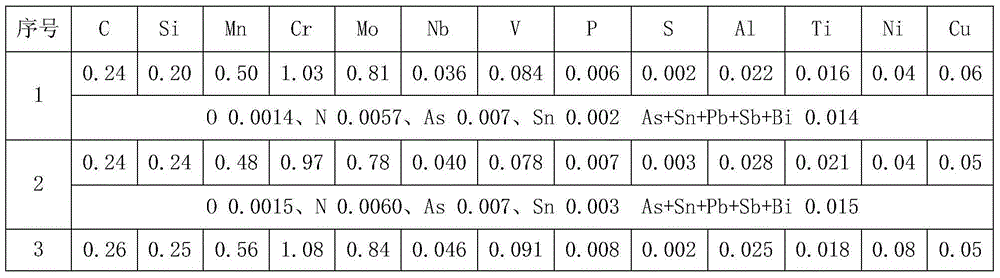

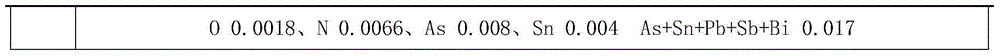

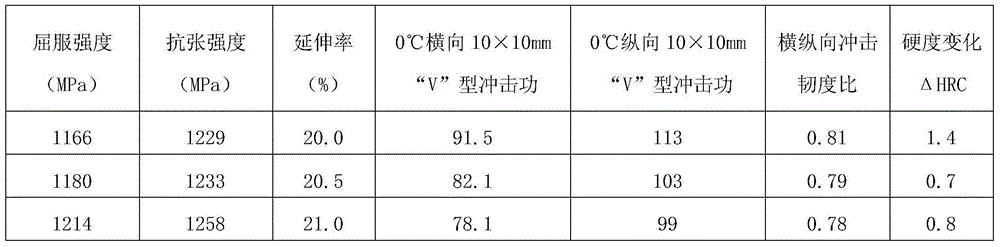

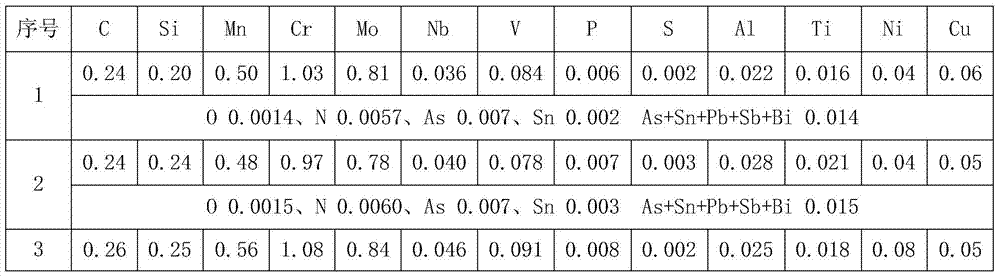

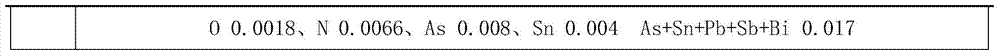

155ksi steel grade high strength-toughness casing steel, casing pipe and preparation method of casing steel and casing pipe

ActiveCN104789875AImprove performanceGood toughness matchFurnace typesProcess efficiency improvementChemical compositionToughness

The invention particularly discloses155ksi steel grade high strength-toughness casing steel, a casing pipe and a preparation method of the casing steel and the casing pipe. The 155ksi steel grade high strength-toughness casing steel comprises the following chemical components by weight percent: 0.23-0.27% of C, 0.20-0.35% of Si, 0.45-0.60% of Mn, 0.95-1.10% of Cr, 0.75-0.85% of Mo, 0.03-0.05% of Nb, 0.07-0.12% of V, 0.015-0.045% of Al, and the balance of Fe and residual element, impurity and five-harmful elements. The high strength casing pipe prepared according to the invention is mainly used for an ultra-deep oil-gas well and a complicated geological oil and gas field; according to the performance requirement of the related casing pipe, the reasonable microalloying component is selected, the stable performance of the high strength-toughness casing steel is guaranteed, the toughness is well matched and the requirements of the ultra-deep oil-gas well and the complicated geological oil and gas field at home and abroad are met.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

Preparation method of high-purity quartz sand

The invention discloses a preparation method of high-purity quartz sand, and belongs to the technical field of mineral refining, and the preparation method comprises the following steps: crushing: crushing quartz sand crude ore into quartz sand particles; ultrasonic scrubbing: performing ultrasonic scrubbing on quartz sand particles; magnetic separation: selecting high gradient magnetic separatorfor three times magnetic separation of quartz sand fine sand; acid leaching: performing microwave heating quartz sand after flotation, then stirring and soaking with a 10% oxalic acid solution; flotation: mixing the quartz sand after acid leaching with water and putting into a flotation machine, adjusting the pH value in three steps, and using different collectors for flotation at the same time; drying and bagging: drying in a vacuum drying oven, and vacuum bagging after cooling. The preparation process is simple, reasonable and efficient in design; iron impurities in the quartz sand can be removed by ultrasonic scrubbing, multiple magnetic separation, microwave heating and acid leaching and flotation; the iron impurities in the prepared high-purity quartz sand are reduced to below 0.35 mg / kg; and the product has stable quality and high efficiency, and is suitable for large-scale popularization and application.

Owner:SICHUAN QINGCHUAN HONGYUAN STONE IND

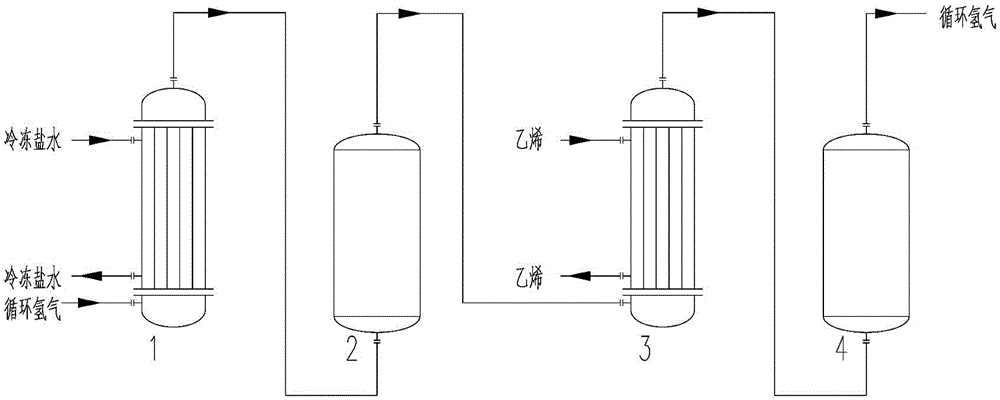

Method and device for circulating hydrogen repurification

ActiveCN105293438AClean up thoroughlyThe removal process is irreversibleHydrogen separation using solid contactPhysical chemistryAdsorption reaction

The invention provides a method and a device for circulating hydrogen repurification and relates to the field of polysilicon production. According to the method and device, the circulating hydrogen is subjected to adsorption and impurity removal to reduce the content impurities of boron and phosphorus in hydrogen from 10 ppba to 0.1 ppba. The specific steps are as below: first introducing circulating hydrogen into a hydrogen cooler for cooling; cooling the hydrogen to 0 to 30 DEG C; introducing hydrogen into a first-stage adsorption reaction column to adsorb and remove impurities mainly containing boron; introducing the circulating hydrogen after the first-stage adsorption into a hydrogen cryogenic device, cooling the hydrogen to -88 to -68 DEG C; and introducing the hydrogen to a second-stage adsorption reaction column to adsorb and remove impurities mainly containing phosphorus element. According to the invention, the circulating hydrogen adsorption reaction is employed for removal of harmful impurities of boron and phosphorus elements, so as to dramatically reduce the content of impurities including boron and phosphorus in hydrogen, and upgrade the quality of circulating hydrogen. The invention makes it possible to improve Siemens method for stable production of electronic grade polysilicon, and breaks the blockade of foreign technology. The process is simple, easy to operate, and has obvious effect of impurity removal.

Owner:YICHANG CSG POLYSILICON CO LTD

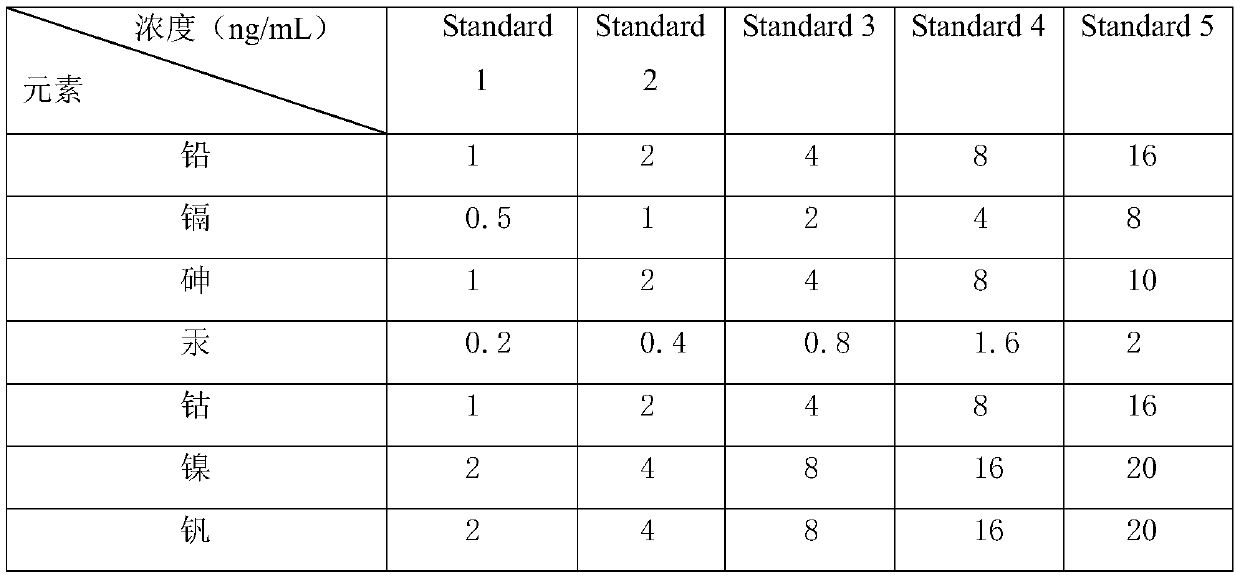

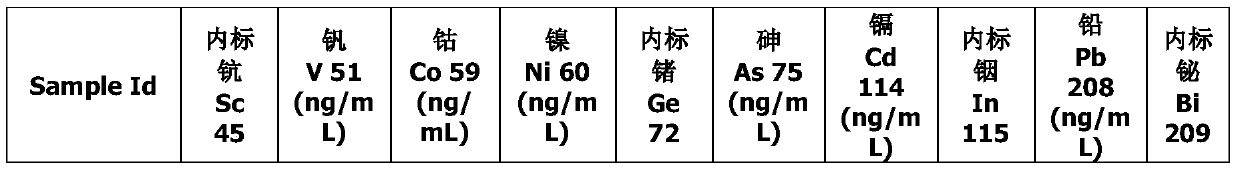

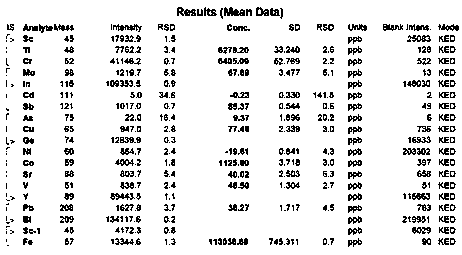

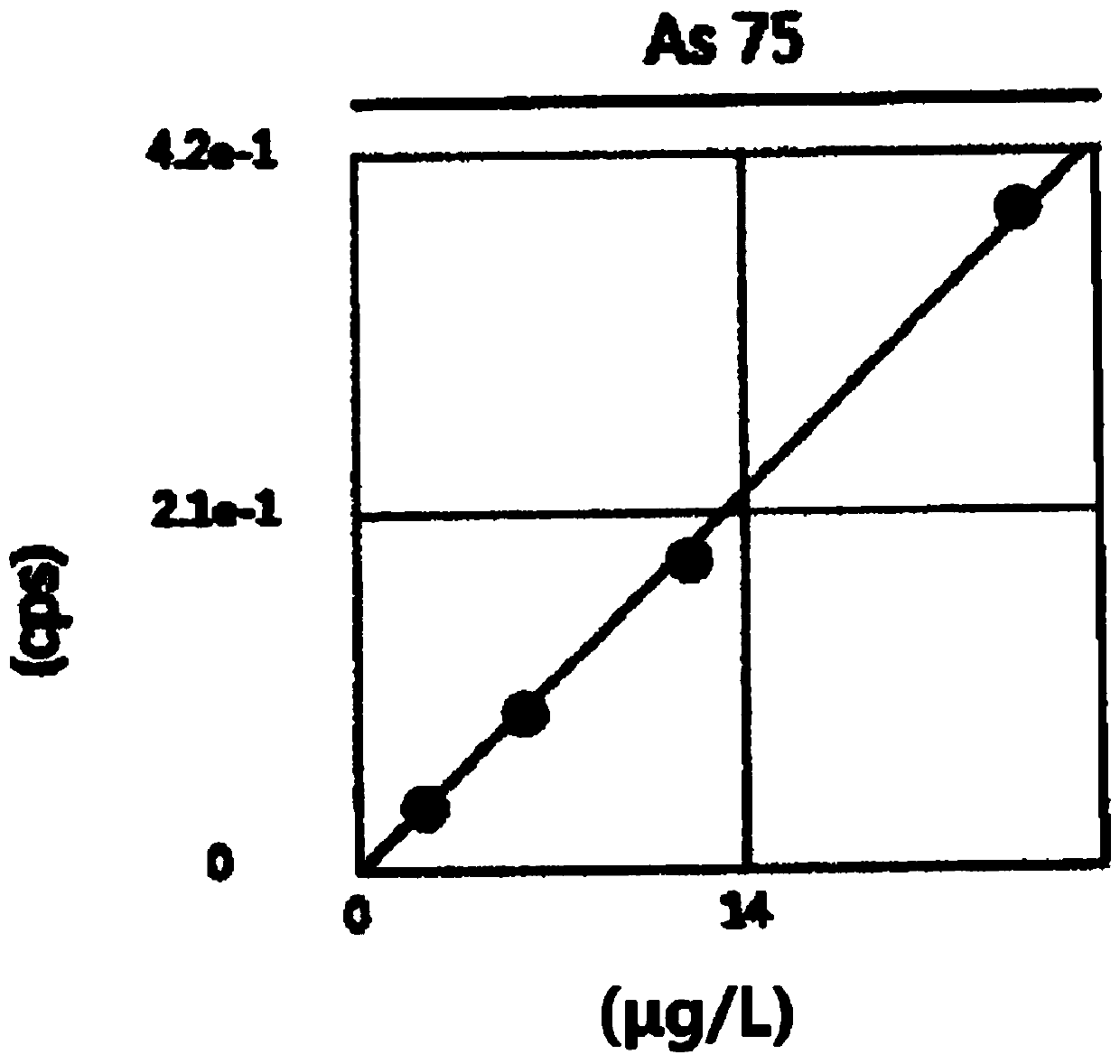

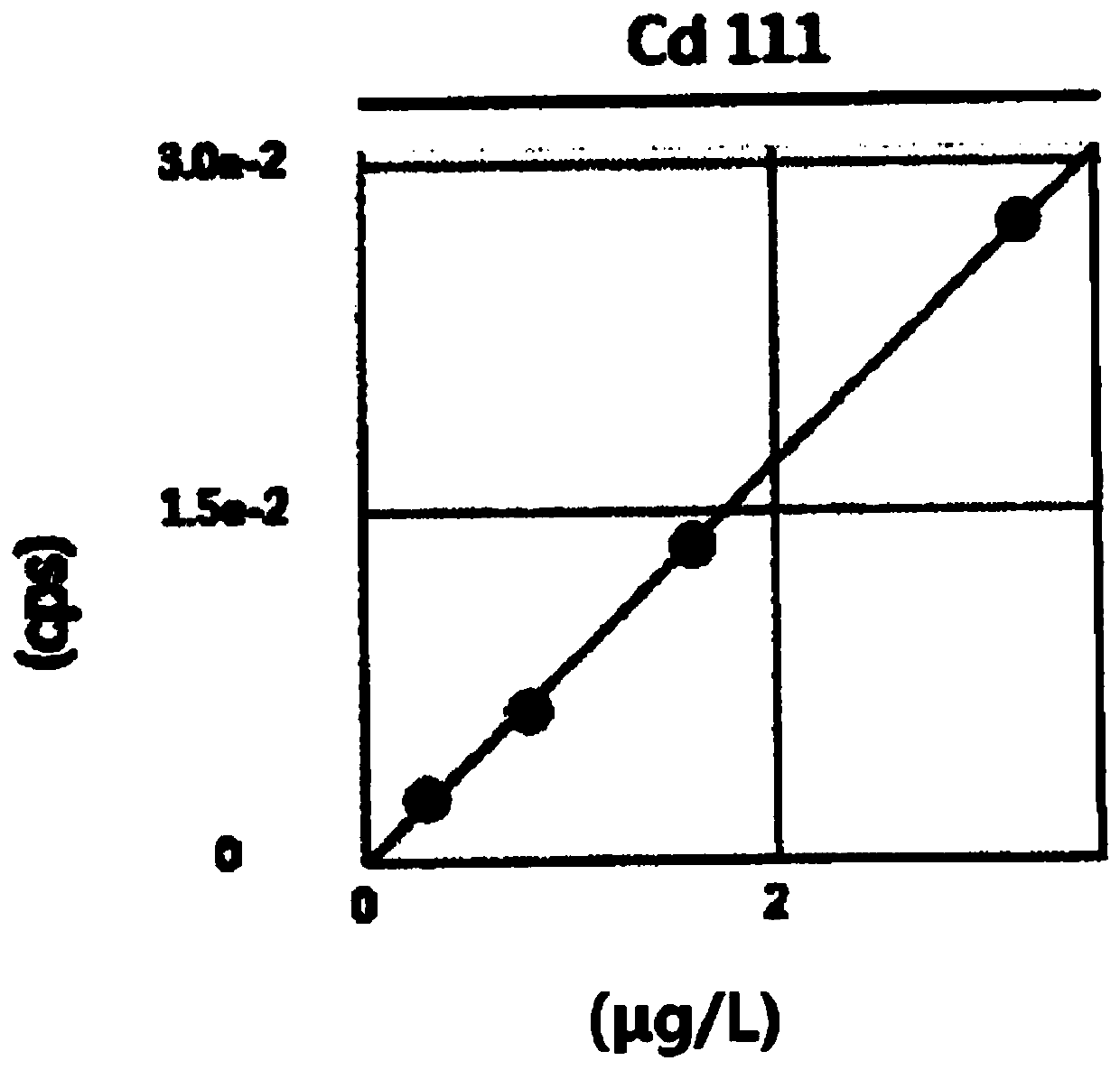

Analysis method for determining hydromorphone hydrochloride bulk drug element impurities

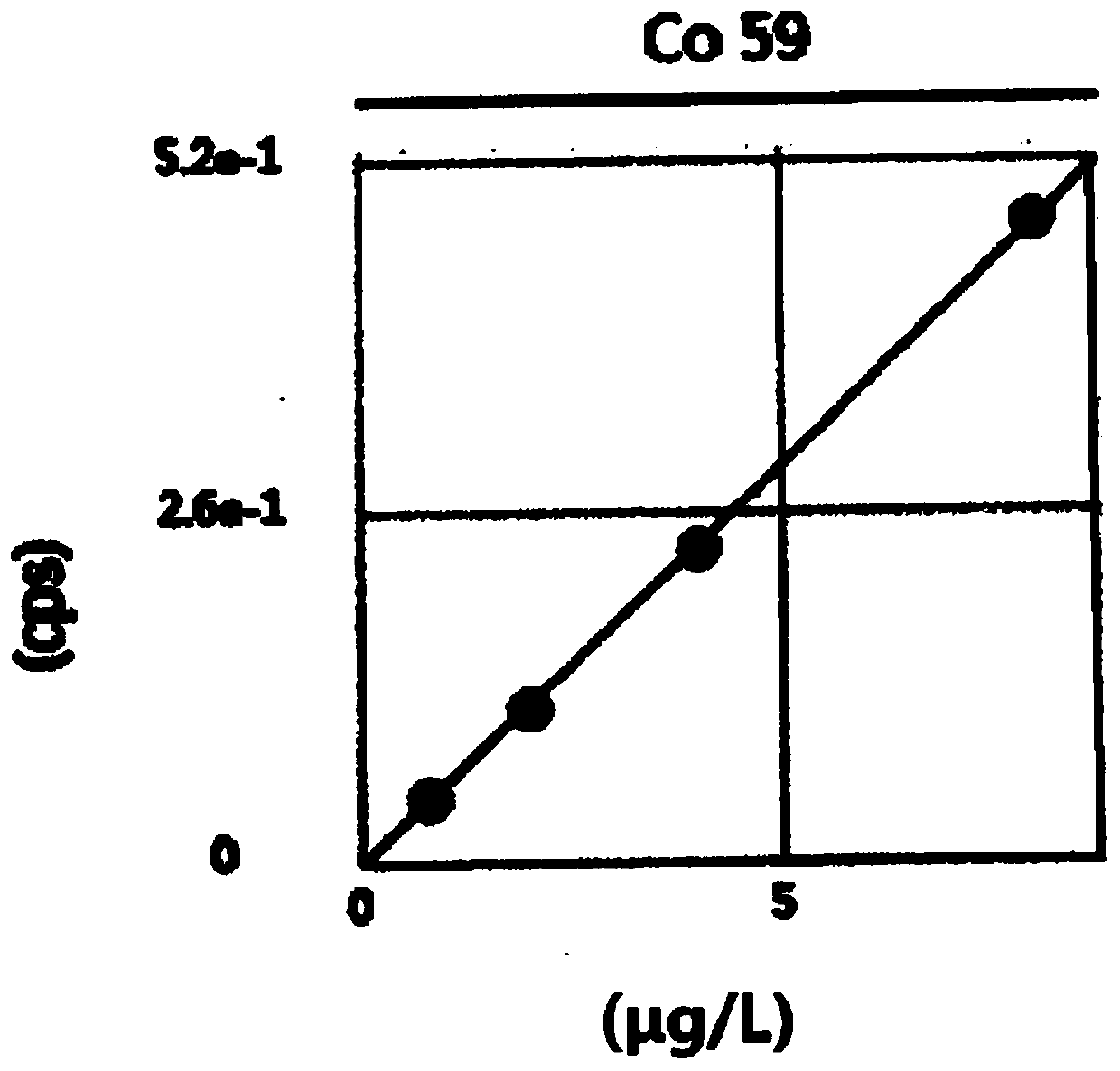

PendingCN110988105ASolve the recovery rate failureReduce distractionsPreparing sample for investigationMaterial analysis by electric/magnetic meansHYDROMORPHONE HYDROCHLORIDEIndium

The invention relates to an analysis method for determining hydromorphone hydrochloride bulk drug element impurities. The method comprises the steps of system applicability, standard curve preparation, internal standard solution preparation, sample preparation and standard recovery sample preparation, and standard curve drawing, detection limit, sample, and standard recovery rate detection. According to the method, the simultaneous determination of seven elements is split into simultaneous determination of six metal elements, namely arsenic, cadmium, lead, cobalt, nickel and vanadium and independent determination of mercury (Hg); the acid removing temperature is reduced from 150 DEG C to 130 DEG C, the problem that the recovery rate of the mercury element does not reach the standard is solved, the recovery rate can be increased to about 90%; and interference of the mercury (Hg) element on other elements due to the strong memory effect can be reduced through independent measurement. Germanium, indium, bismuth and scandium internal standards are selected, so that the influence of signal drift and matrix effect on measurement can be effectively reduced.

Owner:YICHANG HUMANWELL PHARMA

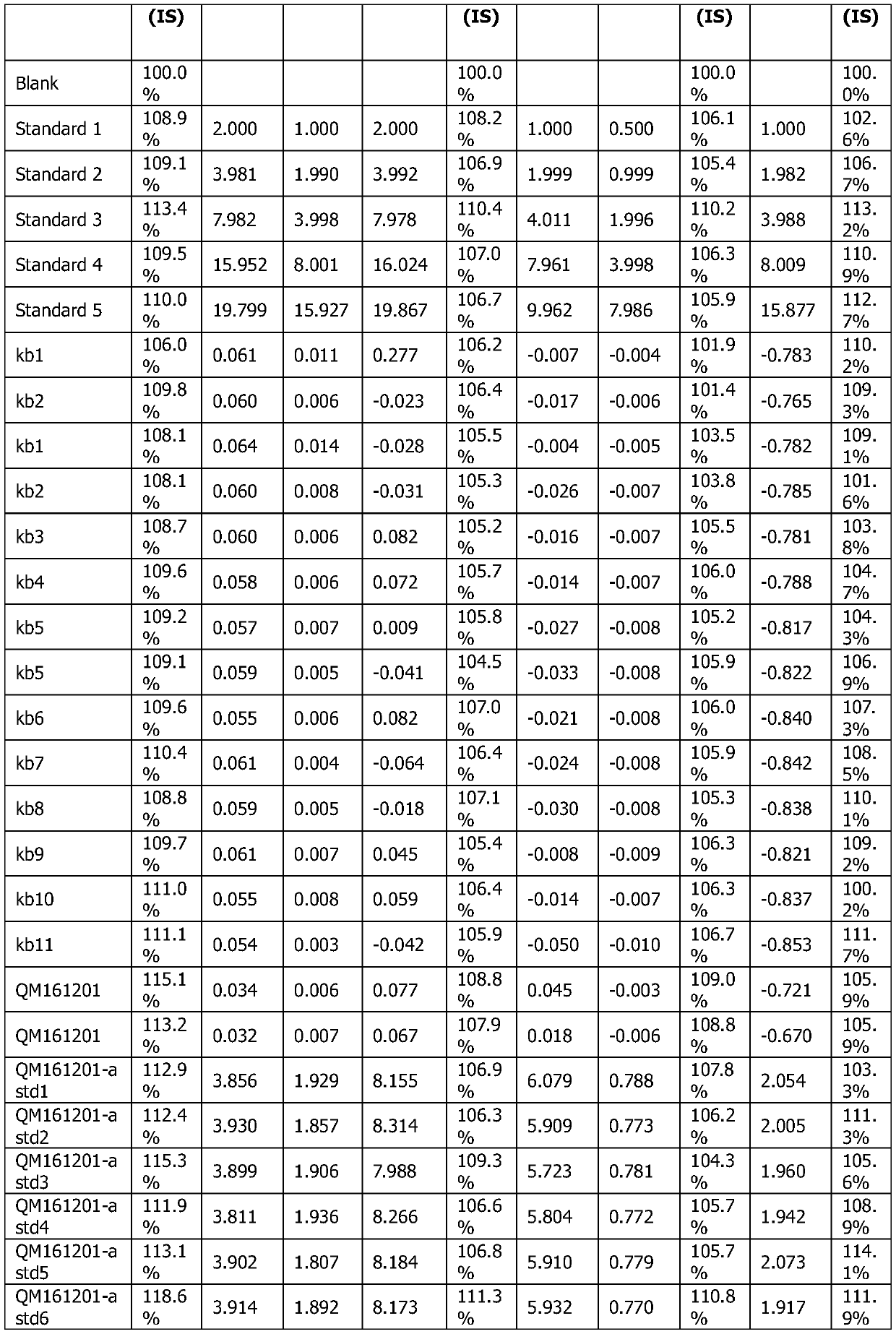

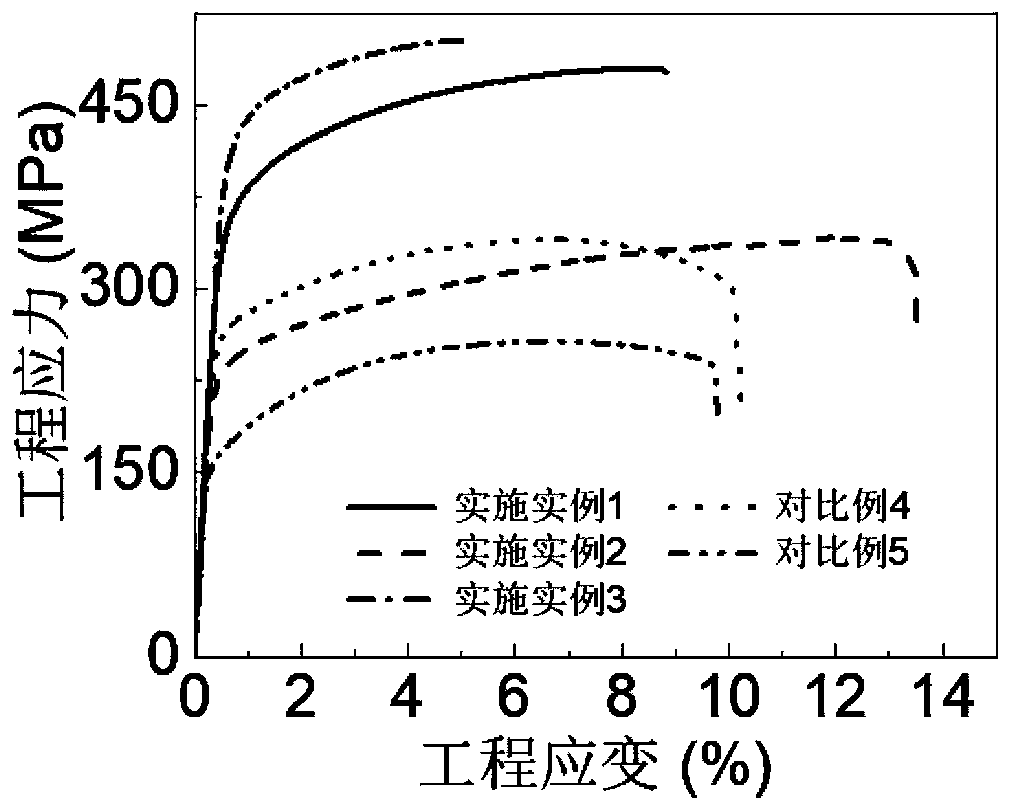

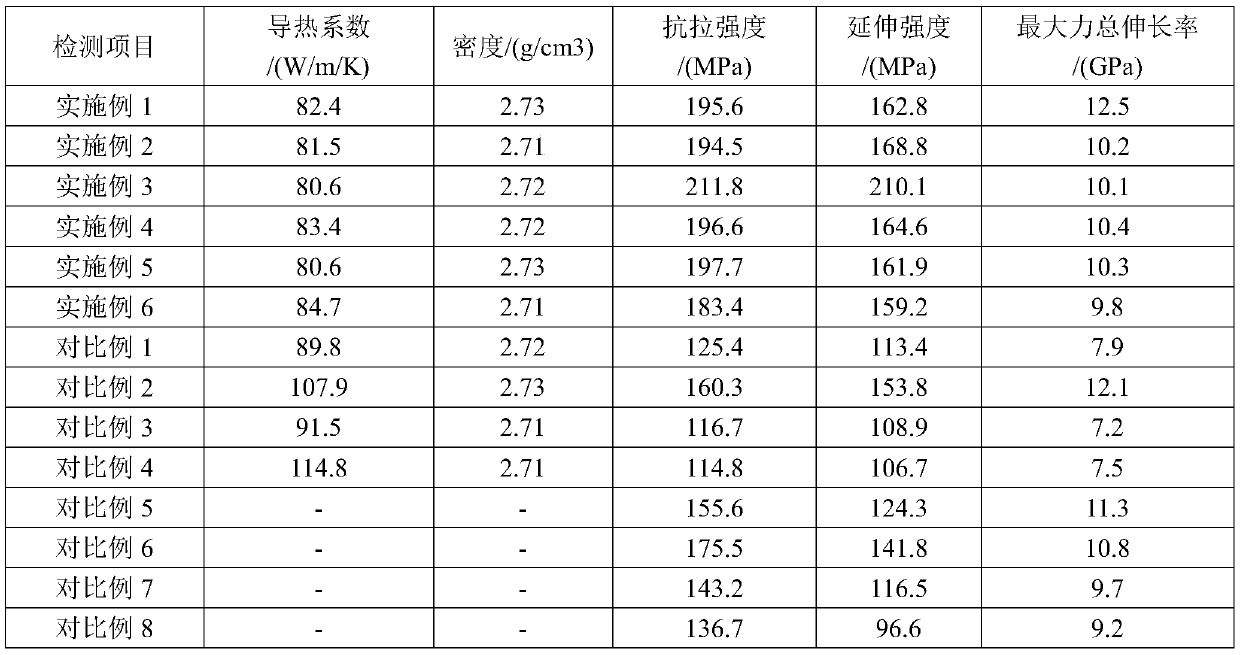

High-strength high-heat-resistance low-scandium sliver added Al-Cu-Mg-series alloy and thermal treatment process thereof

ActiveCN111424200AReduce manufacturing costGood mechanical propertiesThermal deformationThermal treatment

The invention discloses a high-strength high-heat-resistance low-scandium sliver added Al-Cu-Mg-series alloy and a thermal treatment process thereof. Cu and Mg in the alloy are main alloyed elements;Sc, Zr, Si, Ag, Ti, Mn and V are micro-alloyed elements; mass percentage content of Fe in impurities is properly broadened, and the rest of impurities including Ni and Zr need to strictly control; forthe alloy with Mg content greater than 0.3%, thermal deformation is performed before homogenization to avoid hot cracking tendency, and then homogenization is performed again. Ageing treatment comprises combination of natural ageing and artificial ageing; a micro structure and strength are improved by relevance of cluster-precipitation behaviors; and while usage amount of dear scandium and sliverelements is controlled to be smaller than 0.2%, room-temperature tensile strength of the target alloy can be higher than 470 MPa, and tensile strength at a temperature of 300 DEG C and a temperatureof 400 DEG C is separately greater than 160 MPa and 100 MPa.

Owner:XI AN JIAOTONG UNIV

Al-Cu alloy wire for additive manufacturing and preparation method and application of Al-Cu alloy wire

PendingCN112518170AHigh strengthImprove plasticityAdditive manufacturing apparatusWelding/cutting media/materialsManufactured materialAlloy

The invention discloses an Al-Cu alloy wire for additive manufacturing. The Al-Cu alloy wire for additive manufacturing comprises the following chemical components, by mass percentage, 5.5-6.5% of Cu,less than or equal to 0.15% of Fe, less than or equal to 0.06% of Si, 0.26-0.42% of Mn, less than or equal to 0.02% of Mg, less than or equal to 0.10% of Zn, 0.1-0.2% of Ti, 0.10-0.25% of Zr, 0.05-0.15% of V, 0.05-0.25% of Cd, Sn or In, 0.10-0.25% of Sc, less than or equal to 0.0003% of Be, less than or equal to 0.05% of other single elements, less than or equal to 0.15% of total impurities and the balance Al. The invention further provides a preparation method of an alloy of the alloy wire and application of the alloy wire. The problems that a fuse wire additive forming component taking a commercial Al-Cu alloy welding wire as a raw material is prone to micro-crack defects and low in mechanical property are solved.

Owner:CAPITAL AEROSPACE MACHINERY

Method for removing element impurities and pigments in sugammadex sodium refined product

The invention discloses a method for removing element impurities and pigments in a sugammadex sodium refined product. The method comprises steps: dissolving the refined sugammadex sodium product intoan aqueous solution; dropwise adding a certain amount of a poor solvent to separate out a small part of sugammadex sodium and a large part of element impurities and pigments in the solution, separating the precipitate, collecting sugammadex sodium contained in an upper mother liquor, and obtaining a product with the large part of element impurities removed through a direct concentration or solventcrystallization method. The obtained product is light in color, the content of element impurities is remarkably reduced, the requirement of ICH for the limit of the element impurities is met, and themethod is easy, convenient and safe to operate, good in economical efficiency and suitable for industrial production.

Owner:HEFEI BOSIKC PHARMTECH CO LTD

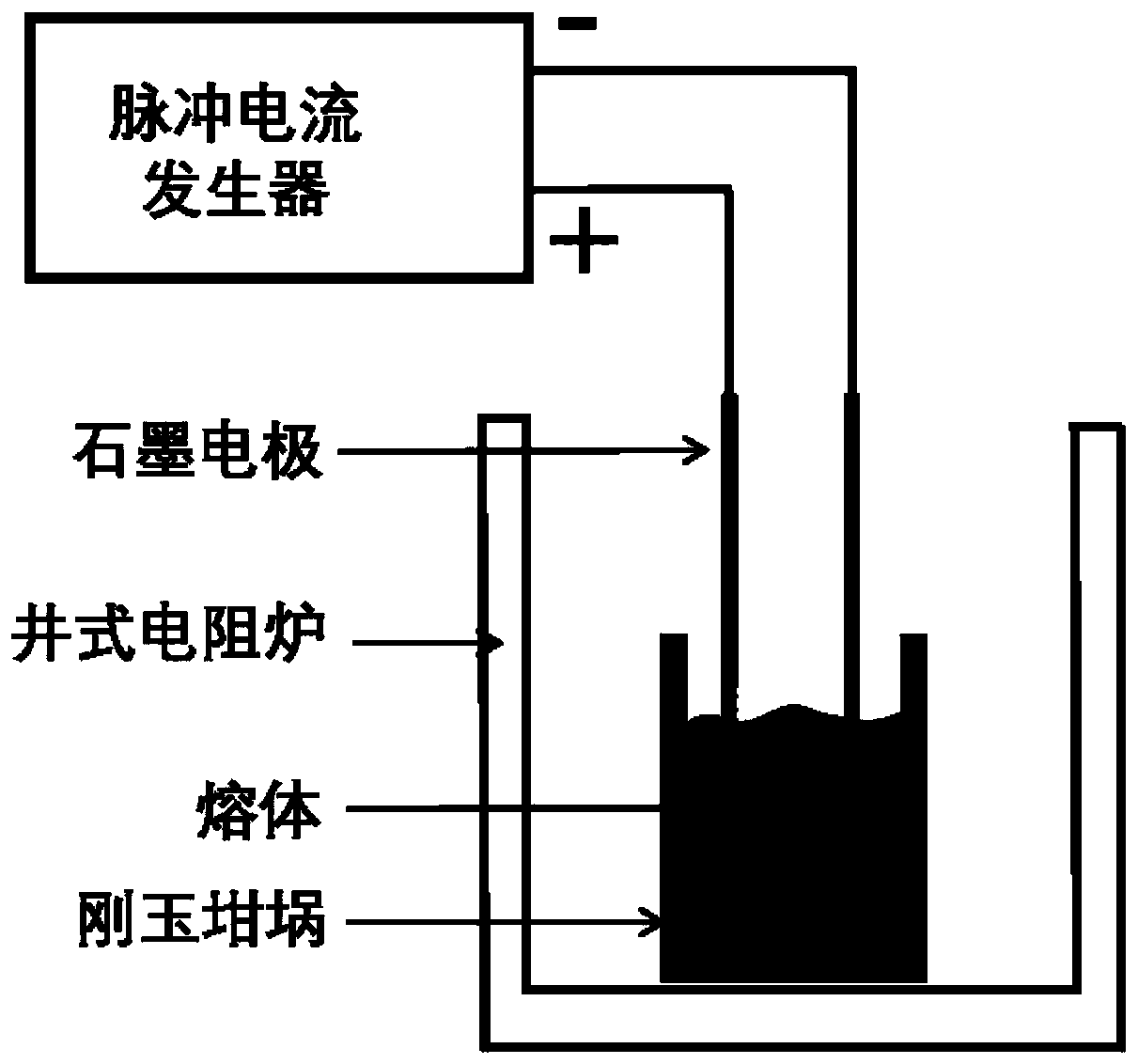

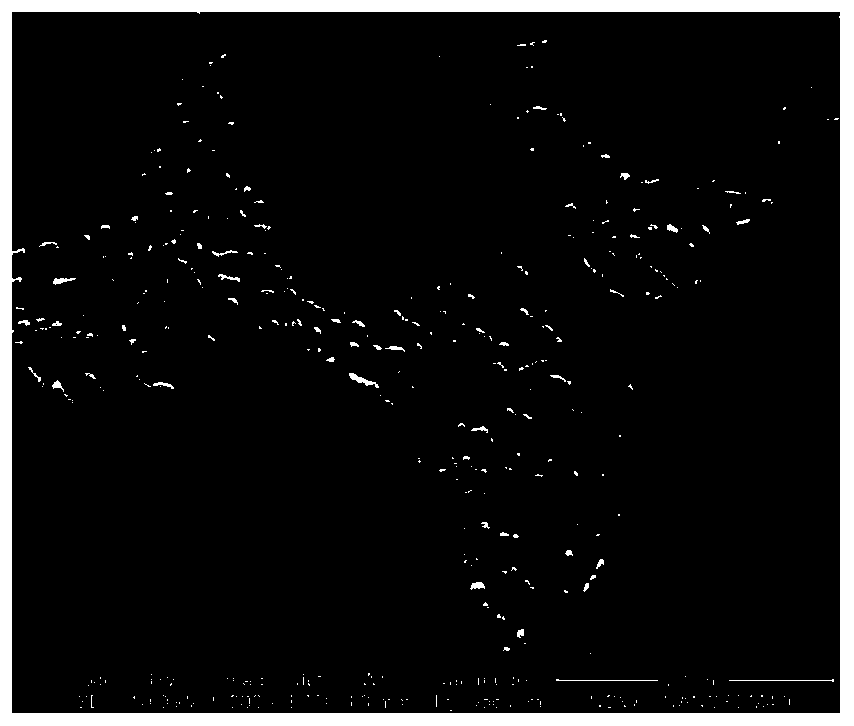

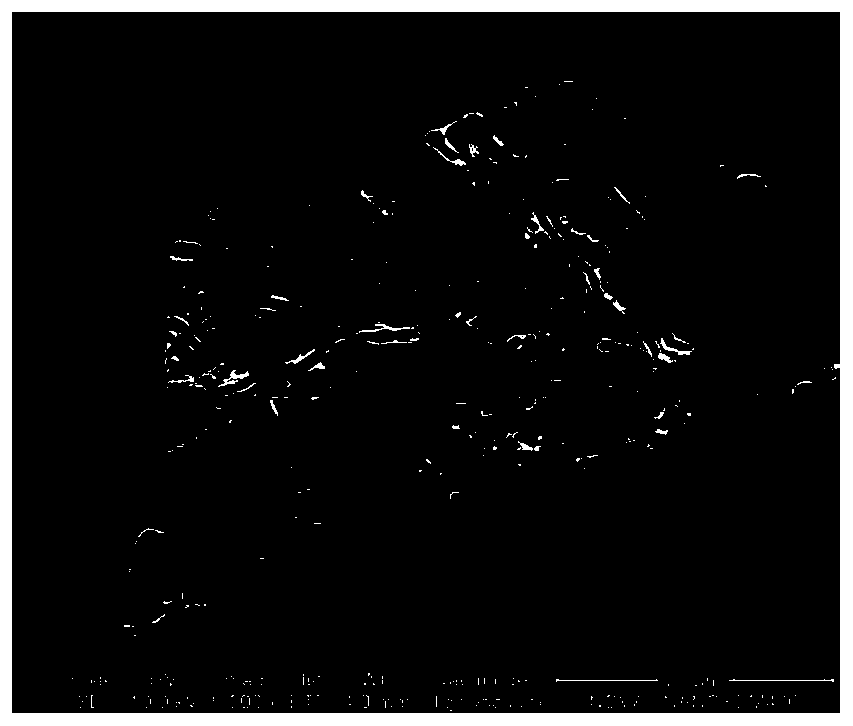

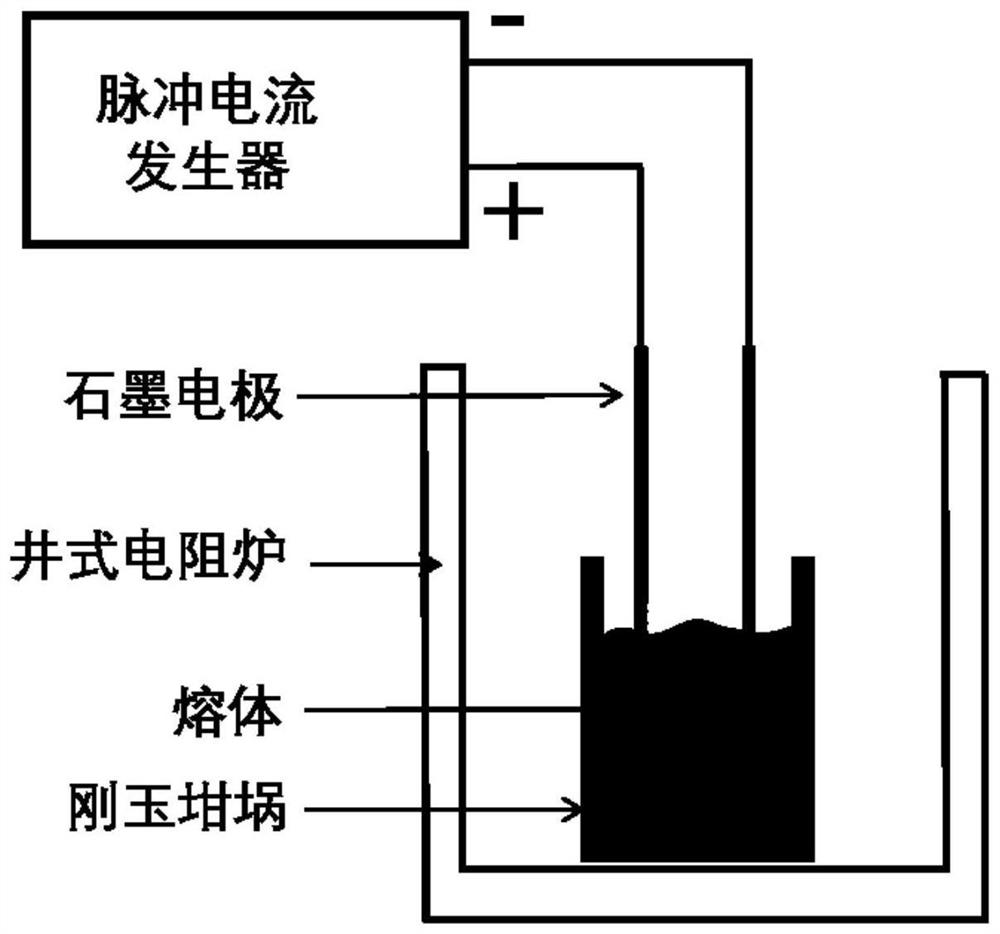

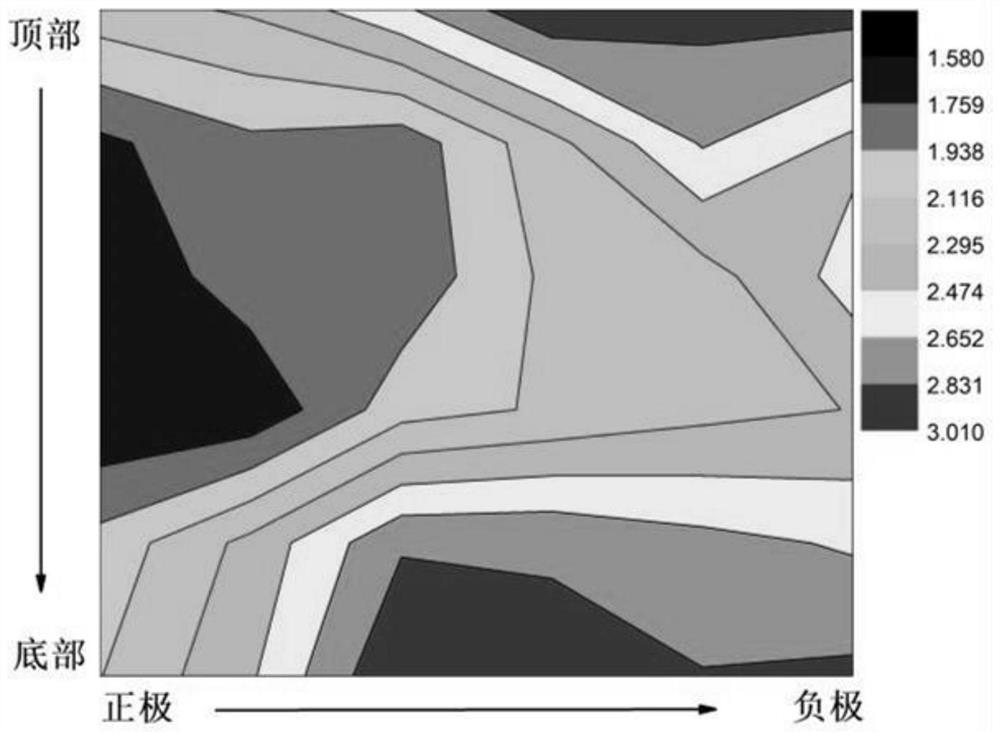

Method for separating iron element impurities from secondary aluminum melt through pulse current

ActiveCN111549237AWill not polluteEnables continuous processingProcess efficiency improvementIron removalMaterials science

The invention discloses a method for separating iron element impurities from secondary aluminum melt through pulse current, and belongs to the technical field of secondary aluminum melt purification.The method comprises the following steps that the secondary aluminum alloy melt with the iron element content exceeding the standard is placed in a crucible, two electrodes and a pulse power supply are connected and inserted into the aluminum melt in parallel, pulse current is continuously applied until corresponding time, and corresponding pulse parameters are selected according to the volume andthe temperature of the melt, wherein the pulse current treatment parameter range comprises the parameters that the frequency is 20 - 50kHz, the voltage is 1 - 100V, the current density is 0.1 - 700A / cm<2>, and the action time is 1 - 10h. According to the method, an Al element and a Fe element in the melt are subjected to electromigration in different directions under the action of the pulse current, so that the Al element and the Fe element are enriched at the positive electrode and the negative electrode respectively, and the purpose of purifying the aluminum melt is achieved; according tothe method for separating the iron element impurities from the secondary aluminum melt through the pulse current, the aluminum melt can be subjected to pulse current treatment under the condition thatno neutralizing element is added to pollute the melt, the iron impurity elements in the aluminum melt are separated, and the melt is purified; and the method is easy to operate, efficient and free ofpollution, the iron removal efficiency is greatly improved, and the requirement of current industrial green development planning is met.

Owner:UNIV OF SCI & TECH BEIJING

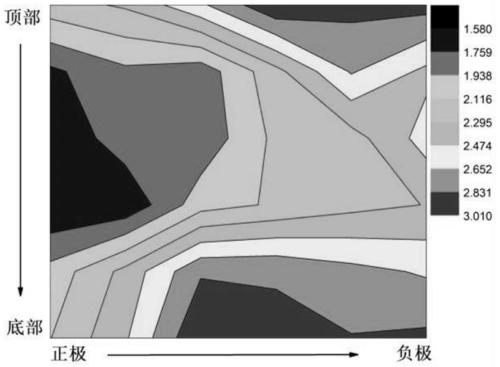

Low-heat-conduction and high-toughness aluminum-manganese-cobalt-series die-cast aluminum alloy and processing technology thereof

ActiveCN110592442AIncrease productivityThe steps of slag removal and refining are simpleTrace elementManganese

The invention relates to a low-heat-conduction and high-toughness aluminum-manganese-cobalt-series die-cast aluminum alloy and a processing technology thereof, and belongs to the technical field of alloys. The components of the cast aluminum alloy comprise Al, Mn, Co, Mg, Cr, Ni, Si, trace elements and impurity elements, the low-heat-conductivity and high-toughness aluminum-manganese-cobalt seriesdie-cast aluminum alloy not only has the advantages of lower thermal conductivity, but also has good strength and meets market requirements. Meanwhile, raw materials of the die-cast aluminum alloy are mixed in steps and batches, sufficient reaction can be carried out between the raw materials, a required compound is formed, the production stability and performance of the die-cast aluminum alloy are increased, the raw materials of the die-cast aluminum alloy are made of intermediate alloys and metal elemental ingots, the raw materials are easy to obtain, and the production cost is reduced.

Owner:XIAMEN JIAJIADA MACHINERY

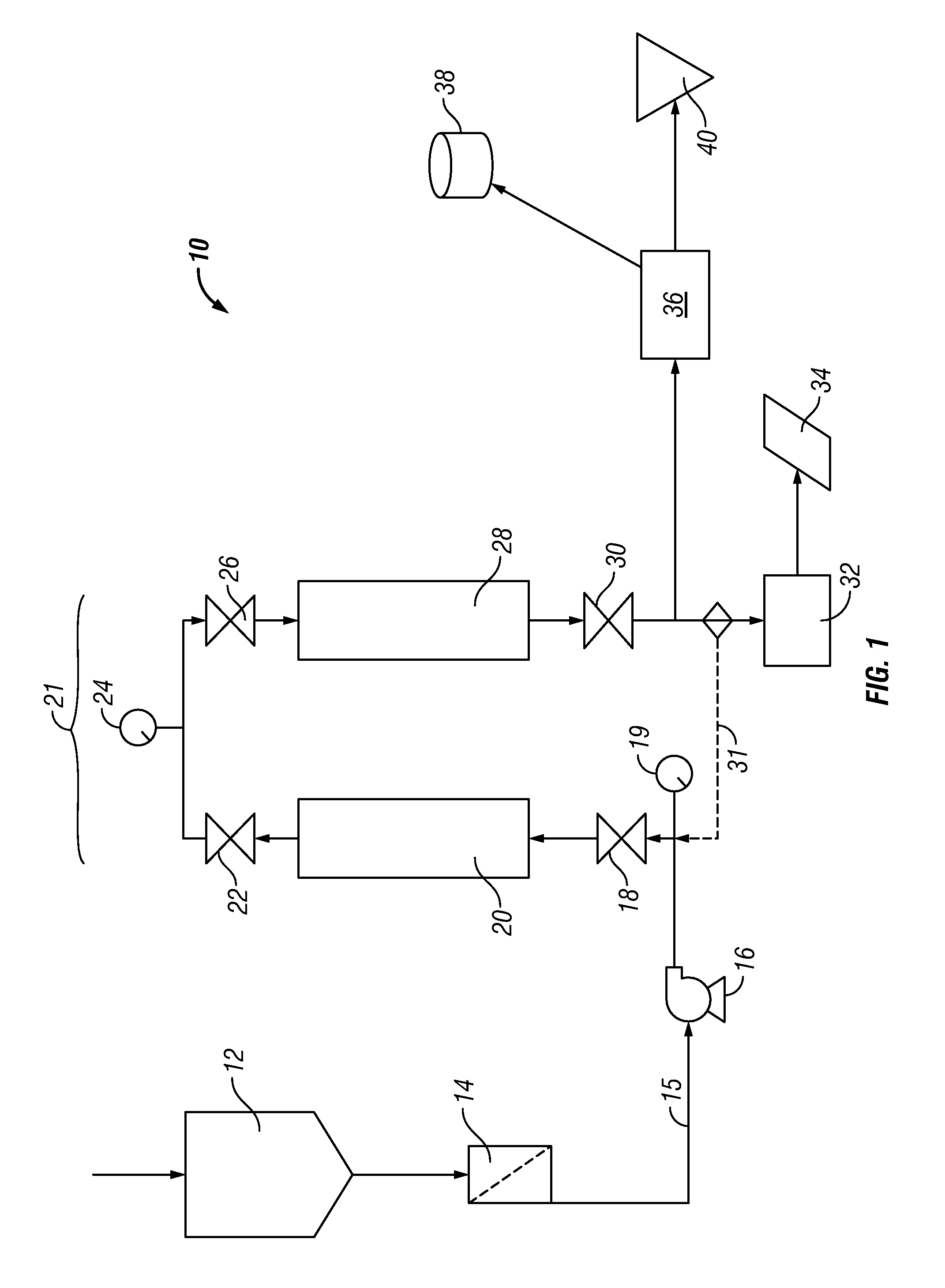

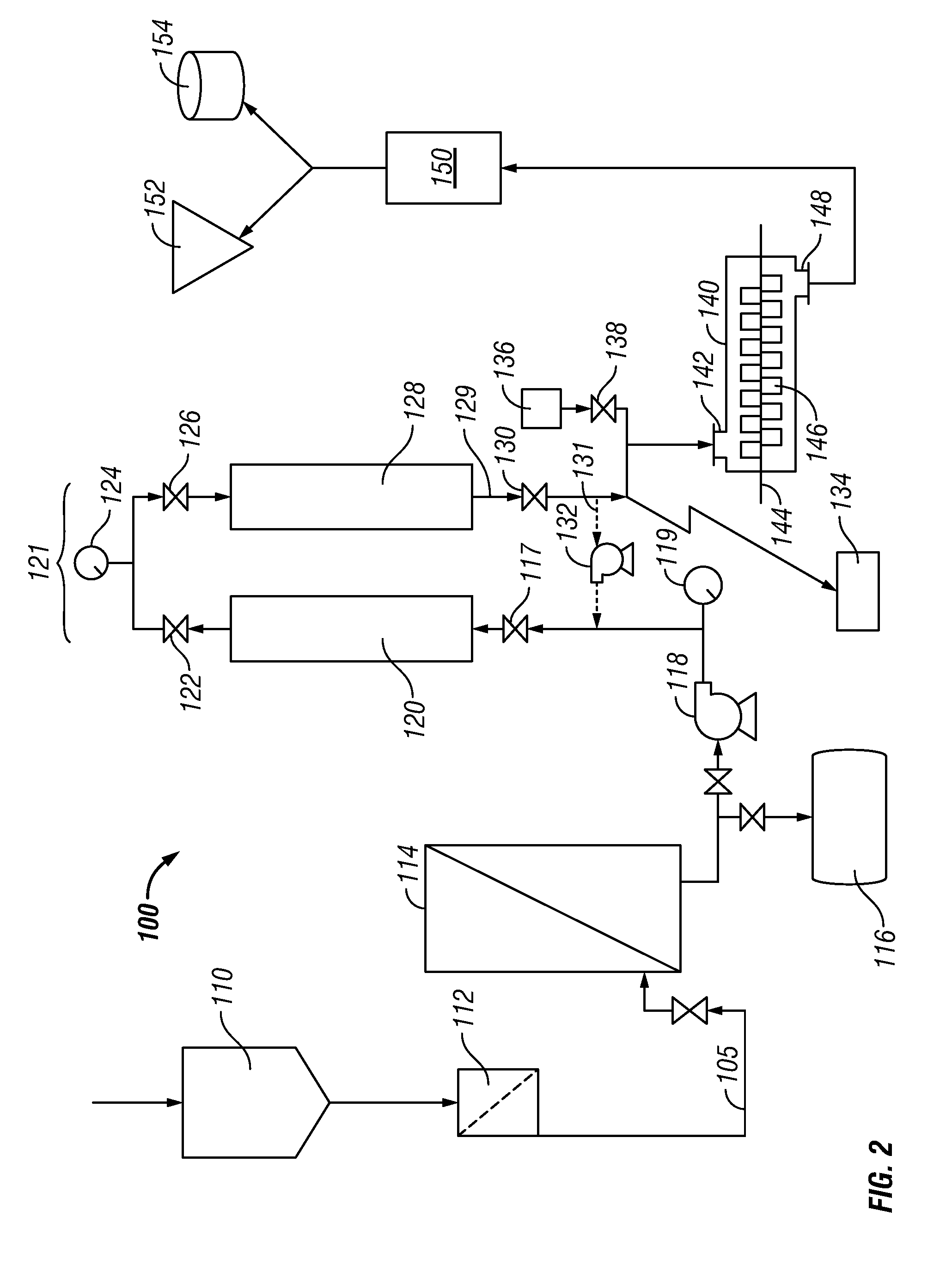

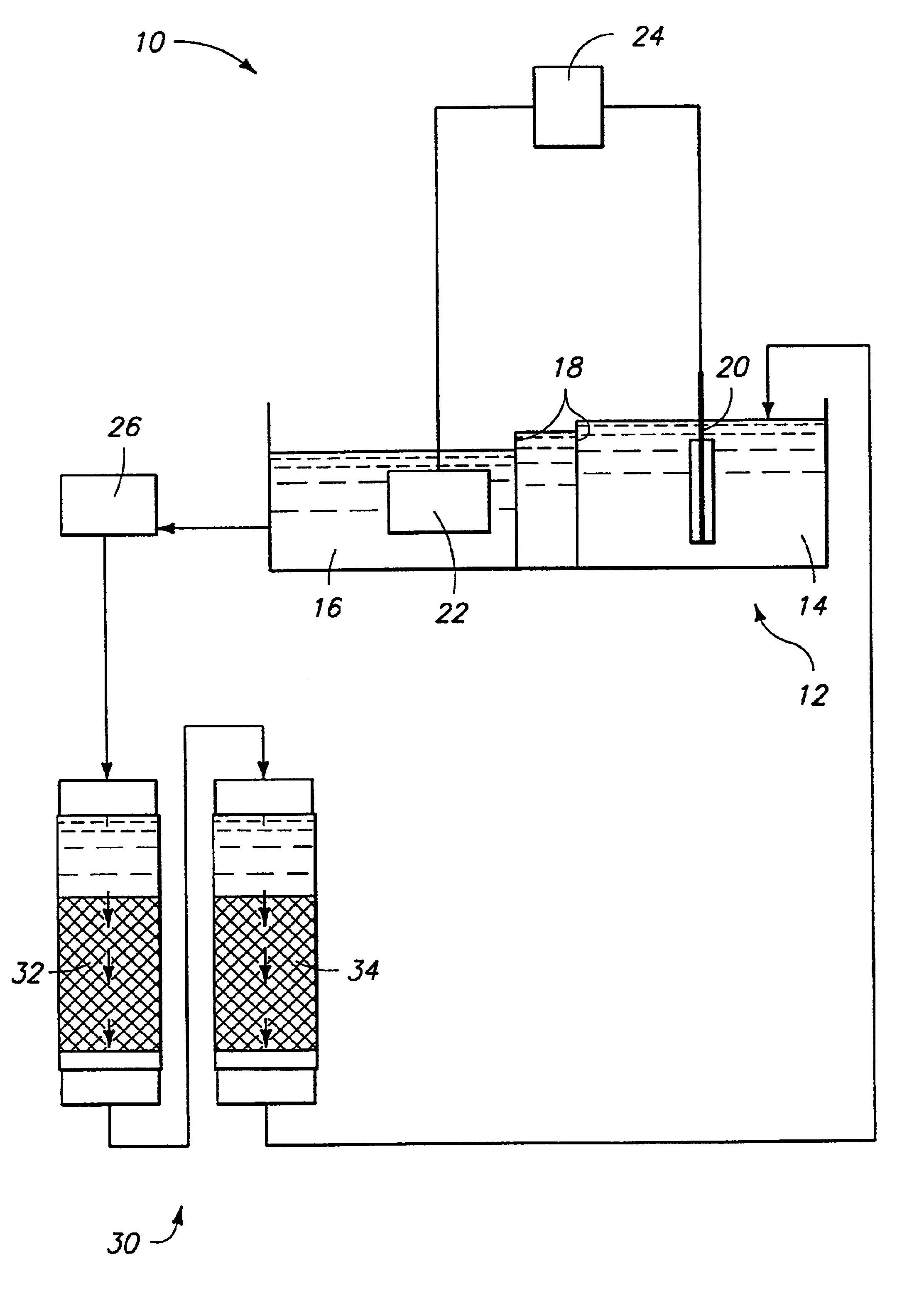

Apparatus for processing metals

InactiveUS6843896B2Minimal impurityPhotography auxillary processesFrom normal temperature solutionsIon exchangeCobalt

The invention encompasses a method and apparatus for producing high-purity metals (such as, for example, high-purity cobalt), and also encompasses the high-purity metals so produced. The method can comprise a combination of electrolysis and ion exchange followed by melting to produce cobalt of a desired purity. The method can result in the production of high-purity cobalt comprising total metallic impurities of less than 50 ppm. Individual elemental impurities of the produced cobalt can be follows: Na and K less than 0.5 ppm each, Fe less than 10 ppm, Ni less than 5 ppm, Cr less than 1 ppm, Ti less than 3 ppm and O less than 450 ppm.

Owner:HONEYWELL INT INC

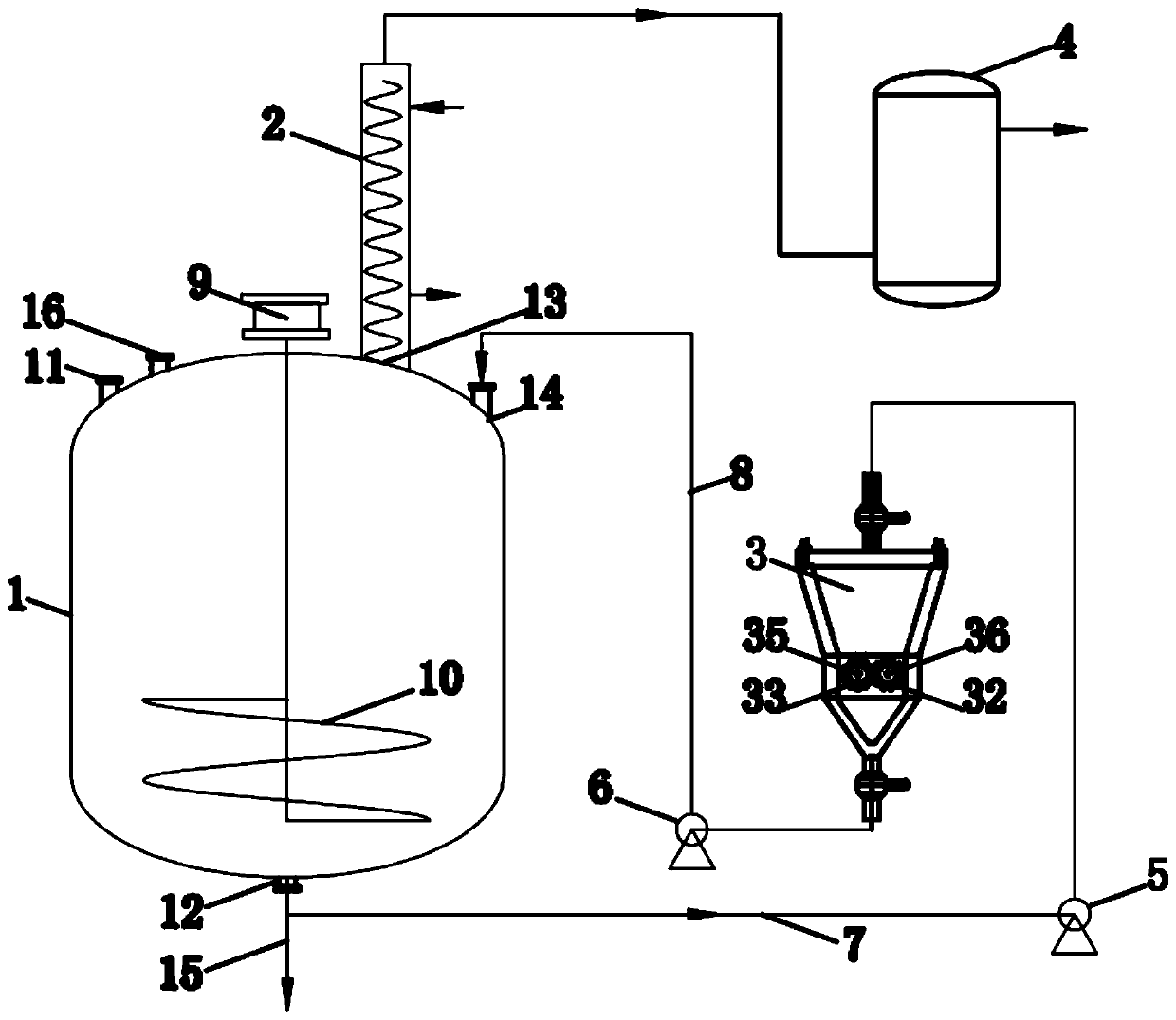

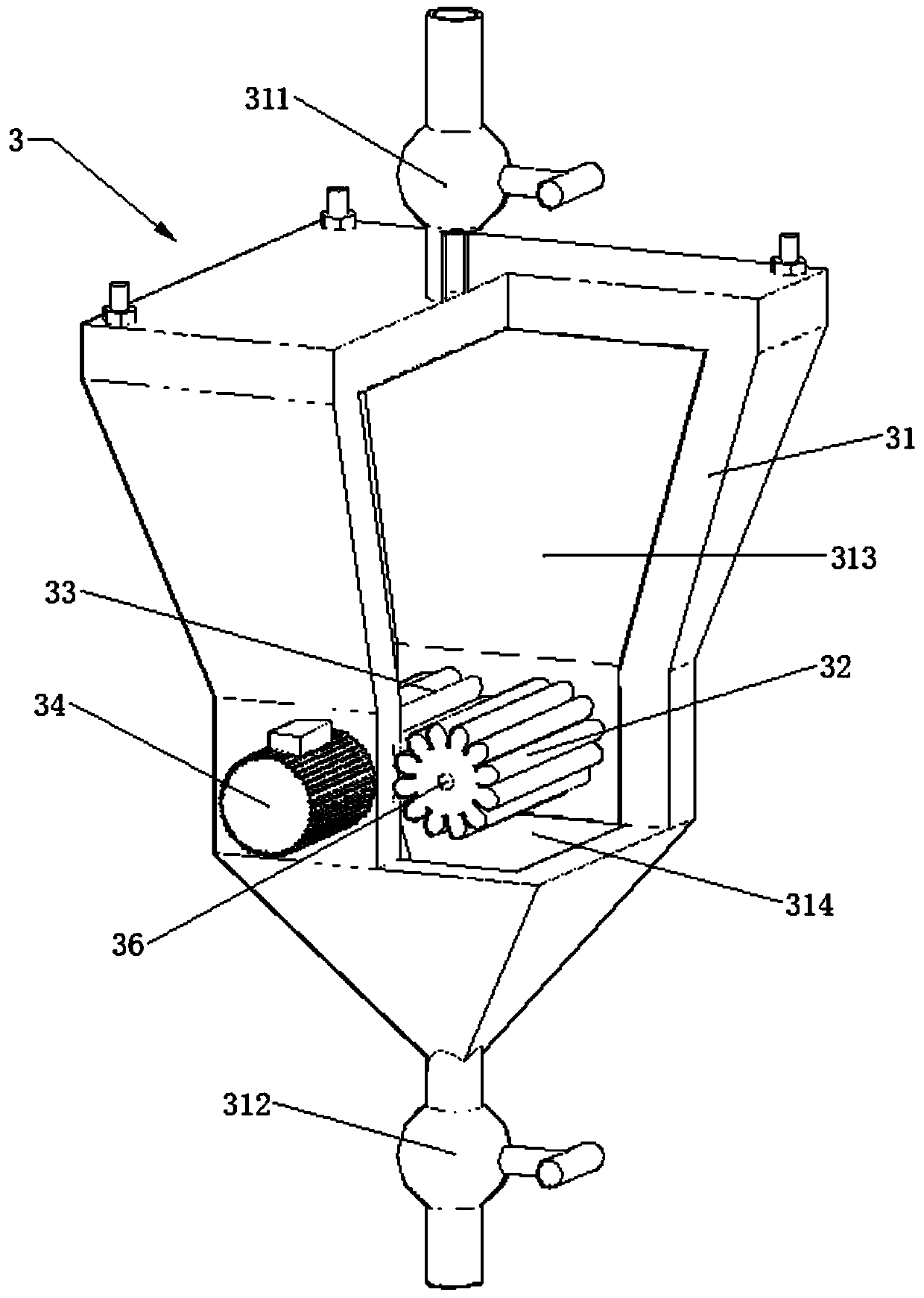

Apparatus and method for preparing high-purity lithium fluoride

PendingCN110193334AAvoid corrosionSolve the separation problemProcess control/regulationChemical/physical/physico-chemical stationary reactorsHydrogen fluorideReflux

The invention discloses an apparatus for preparing high-purity lithium fluoride, wherein the apparatus comprises a reaction kettle, a condensation reflux device, a grinding device and a tail gas absorption device. The invention further provides a method for preparing high-purity lithium fluoride, wherein the method comprises: 1) carrying out a mixing reaction on lithium carbonate solid particles and a hydrofluoric acid liquid in a reaction kettle to form a lithium fluoride-hydrofluoric acid-lithium carbonate mixed slurry, hydrogen fluoride and carbon dioxide gas; 2) conveying the lithium fluoride-hydrofluoric acid-lithium carbonate mixed slurry to a grinding device, and grinding; and 3) conveying the grinded mixed slurry to the reaction kettle, continuously carrying out a reaction, makingthe hydrogen fluoride and the carbon dioxide gas generated by the reaction enter a condensation reflux device, and carrying out condensation reflux on the hydrogen fluoride. According to the present invention, with the apparatus and the method, the reaction process can be completely carried out, the problem of separation of carbon dioxide from hydrogen fluoride in the tail gas of the lithium fluoride synthesis process is solved, no other elemental impurities are introduced during the reaction, and the obtained lithium fluoride has high purity.

Owner:GUIZHOU INST OF TECH +1

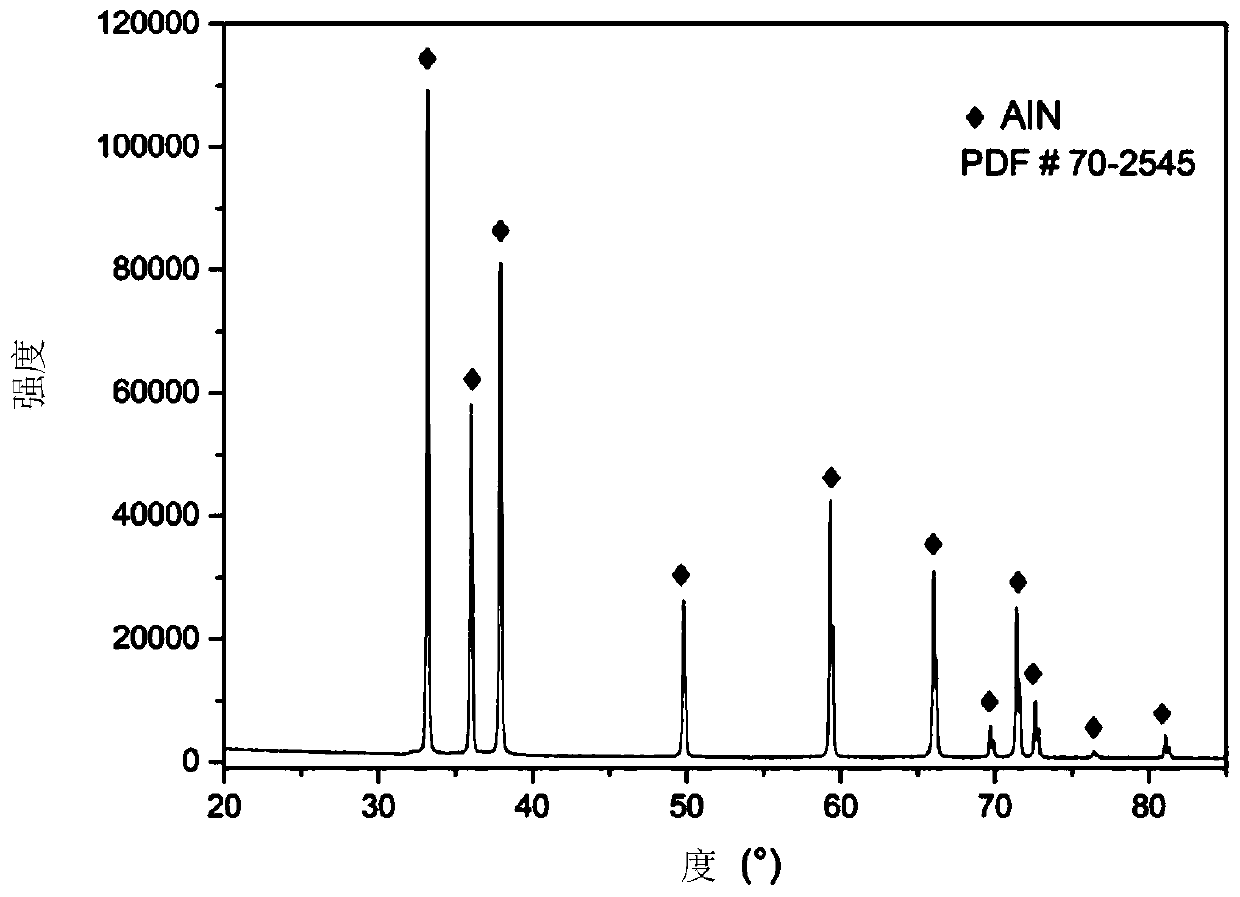

Purifying method of aluminum nitride powder, aluminum nitride powder prepared by method and application of aluminum nitride powder

InactiveCN110697665AHigh purityPromote sintering synthesisNitrogen compoundsCarbon impuritiesAluminium powder

The invention relates to a purifying method of aluminum nitride powder, and the method comprises the following steps: (1) putting an aluminum nitride powder raw material containing carbon impurities into a container, putting the container into a sintering furnace, and vacuumizing to discharge impurity gas in the furnace; and (2) introducing carbon dioxide gas into the sintering furnace, and then performing sintering treatment to obtain the aluminum nitride powder. The invention also relates to the aluminum nitride powder prepared by the method and application of the aluminum nitride powder inpreparation of aluminum nitride ceramics. The method breaks through the limitation of the traditional carbon discharge process; new oxygen element impurities are not introduced, carbon impurities which are not completely reacted in the nitridation reaction are removed, and the high-purity aluminum nitride powder can be obtained; the high-purity aluminum nitride powder can effectively promote sintering synthesis of aluminum nitride ceramic and finally effectively improve the performance such as the heat conductivity of an aluminum nitride ceramic product, and therefore the high-purity aluminumnitride powder has wide application prospects in the field of manufacturing of heat dissipation substrates and circuit substrates, especially large-scale integrated circuit substrates.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

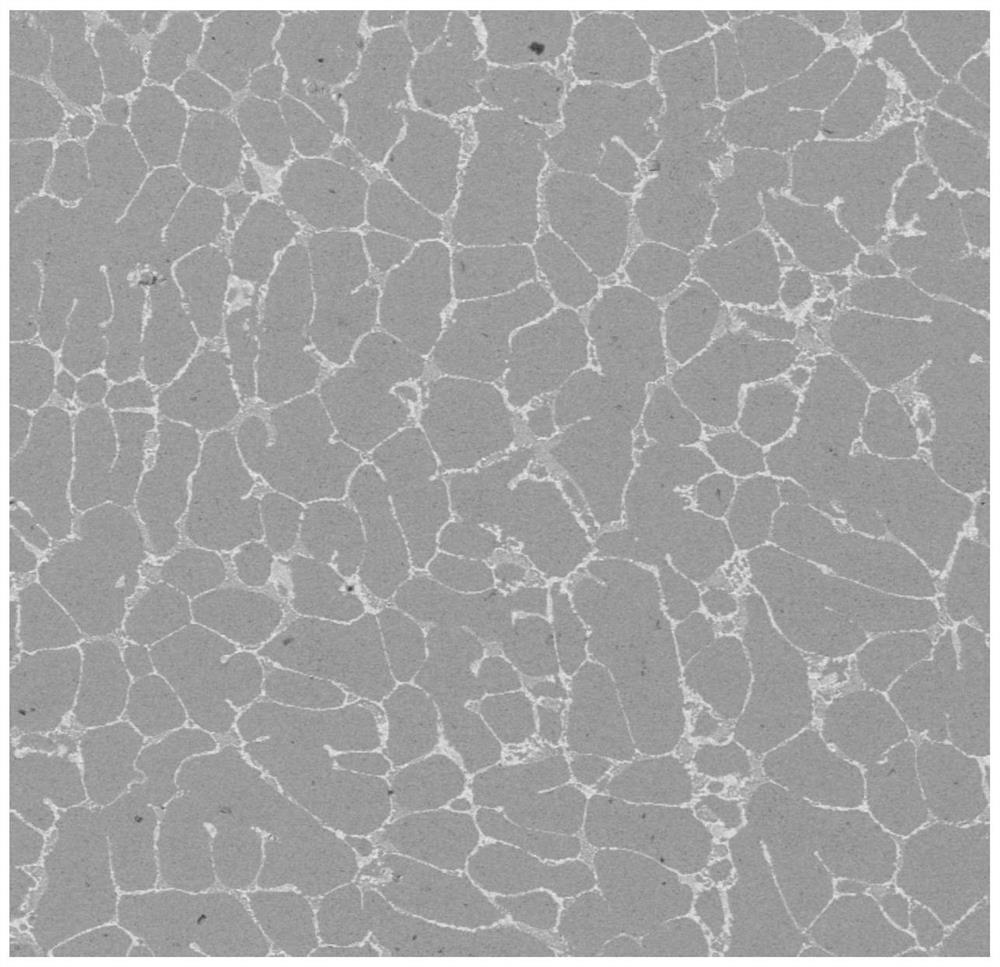

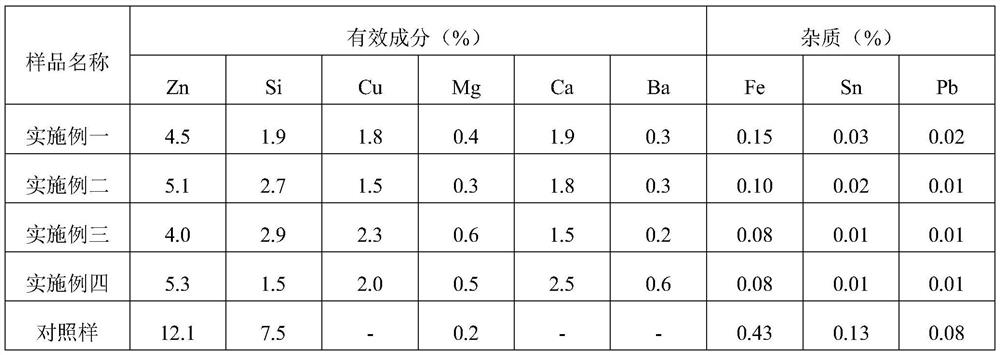

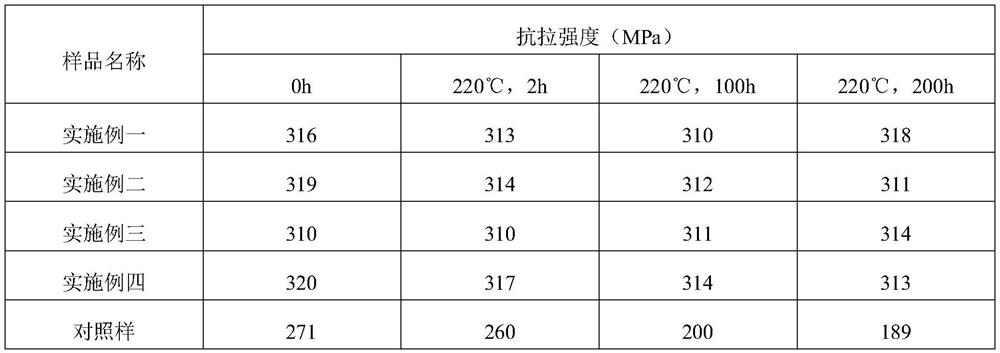

Heat-resistant casting aluminum-zinc alloy and preparation method thereof

The invention provides a heat-resistant cast aluminum-zinc alloy and a preparation method thereof. The alloy comprises the following elements of 4.0%-5.3% of Zn, 1.5%-2.9% of Si, 1.5%-2.3% of Cu, 0.3%-0.6% of Mg, 1.5%-2.5% of Ca, 0.2%-0.6% of Ba, smaller than or equal to 0.2% of impurities and the balance Al, wherein WZn / (WSi+WCa+WBa)<=1.19. The invention further provides a preparation method of the alloy. The preparation method comprises the steps of raw material adding, smelting and pouring. A dense eutectic reticular Al-Zn-Cu-Ca-Mg-Ba precipitated phase is formed, the matrix structure of the alloy is effectively strengthened, the tensile strength of the alloy is obviously improved, the alloy has good heat resistance, and the tensile strength can reach 310-320 MPa; and the tensile strength does not decline after being subjected to heat preservation treatment at 220 DEG C for 200 hours, and the alloy can be used at 220 DEG C for a long time.

Owner:国家高速列车青岛技术创新中心 +1

Method for measuring content of zirconium and impurity elements in uranium-zirconium alloy

PendingCN111307785AAccurate determination of contentThe detection data is accuratePreparing sample for investigationAnalysis by thermal excitationPhysical chemistryZirconium alloy

The invention relates to a method for determining the content of zirconium and impurity elements in uranium-zirconium alloy. The method comprises the following steps: step 1, dissolving a sample; (1)dissolving a sample for measuring zirconium content; (2) dissolving a sample for determining the content of impurity elements; 2, extracting and separating a uranium matrix; (1) extracting and separating a uranium matrix from a zirconium element content sample; (2) extracting and separating a uranium matrix from a sample for determining the content of impurity elements; step 3, sample determination; (1) determining zirconium; and (2) determination of impurity elements. The detection method for determining the contents of the components and the impurity elements in the uranium-zirconium alloy through the plasma emission spectrometry is successfully established, the contents of the to-be-determined element impurities can be accurately determined by utilizing the experimental conditions listed in the content of the invention, accurate detection data is reported, and the method is effectively matched with special production.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

High-strength fatigue-resistant aluminum alloy door frame and preparation technique thereof

InactiveCN108531789ASolve the characteristics of low strength and easy deformationImprove impact resistanceIron powderNitrogen

The invention discloses a high-strength fatigue-resistant aluminum alloy door frame and a preparation technique thereof. The high-strength fatigue-resistant aluminum alloy door frame includes the following elements of, by weight, 6.18-12.87% of silicon powder, 1.28-3.56% of magnesium, 0.89-1.75% of iron powder, 0.56-0.95% of nanometer carbon powder, 0.12-0.31% of boron, 0.03-0.16% of titanium, 0.26-0.48% of chromium, 0.16-0.54% of nitrogen, 0.005-0.12% of minor additive elements, impurities controlled to be smaller than or equal to 0.01% and the balance Al. According to the high-strength fatigue-resistant aluminum alloy door frame and the preparation technique thereof, by optimizing the contents of all the components, mutual compensation is conducted, and the problems that in the using process of an existing aluminum alloy, strength is low, and deformation is likely to occur are solved; and the aluminum alloy door frame made of the materials has great impact resistance and fatigue resistance, the service life of the aluminum alloy door frame is greatly prolonged, and accidents are reduced.

Owner:河南颇文商贸有限公司

155ksi steel grade high-strength toughness casing steel, casing and preparation method thereof

ActiveCN104789875BImprove performanceGood toughness matchFurnace typesProcess efficiency improvementPipeComponents of crude oil

The invention particularly discloses155ksi steel grade high strength-toughness casing steel, a casing pipe and a preparation method of the casing steel and the casing pipe. The 155ksi steel grade high strength-toughness casing steel comprises the following chemical components by weight percent: 0.23-0.27% of C, 0.20-0.35% of Si, 0.45-0.60% of Mn, 0.95-1.10% of Cr, 0.75-0.85% of Mo, 0.03-0.05% of Nb, 0.07-0.12% of V, 0.015-0.045% of Al, and the balance of Fe and residual element, impurity and five-harmful elements. The high strength casing pipe prepared according to the invention is mainly used for an ultra-deep oil-gas well and a complicated geological oil and gas field; according to the performance requirement of the related casing pipe, the reasonable microalloying component is selected, the stable performance of the high strength-toughness casing steel is guaranteed, the toughness is well matched and the requirements of the ultra-deep oil-gas well and the complicated geological oil and gas field at home and abroad are met.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

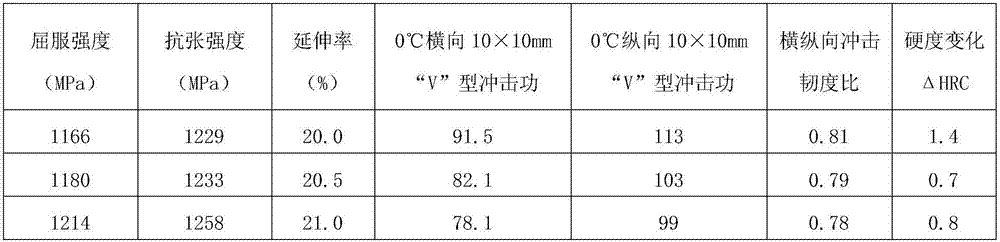

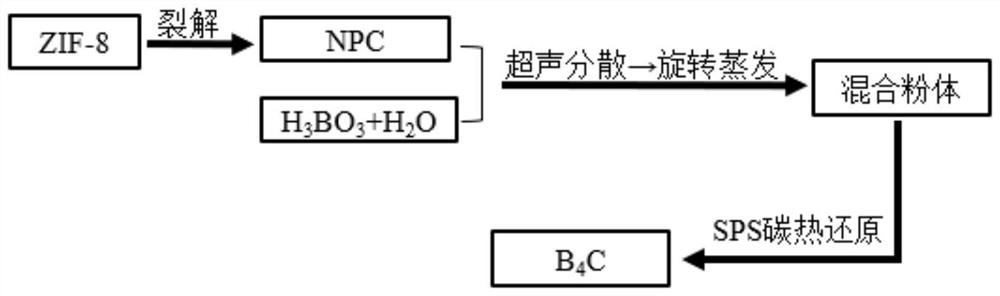

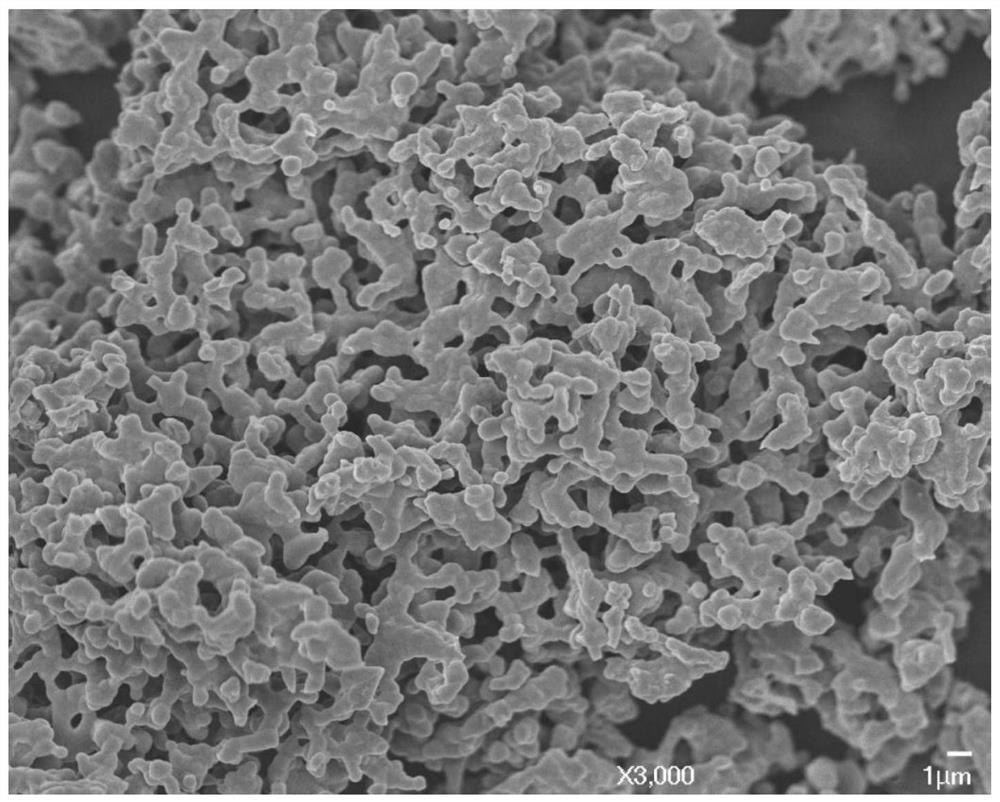

Method for preparing boron carbide powder by adopting organic carbon source

ActiveCN113149014ARegular and uniformIncrease contact areaCarbon compoundsPorous carbonArgon atmosphere

The invention provides a method for preparing boron carbide powder by adopting an organic carbon source. The method comprises the following steps: respectively dissolving zinc nitrate hexahydrate and dimethylimidazole in a solvent methanol; respectively heating the solutions, and continuously performing magnetic stirring; pouring the zinc nitrate hexahydrate solution into the dimethylimidazole solution, and performing mixing and standing; carrying out centrifugal separation to obtain a ZIF-8 white precipitate, washing the white precipitate with methanol, drying the washed ZIF-8 powder, and performing grinding; performing pyrolysis in an argon atmosphere to obtain nano-porous carbon; dissolving boric acid H3BO3 and nano porous carbon in deionized water, carrying out ultrasonic dispersion, then carrying out rotary evaporation, drying in a drying oven, performing grinding, and performing sieving with a 100-mesh sieve; and performing calcining to obtain boron carbide. According to the preparation method disclosed by the invention, the NPC which does not contain Zn element impurities and can retain uniform particle size and an ordered nanopore structure can be obtained by optimizing a pyrolysis process of the ZIF-8 powder, such as pyrolysis temperature and heat preservation time.

Owner:JINGDEZHEN CERAMIC INSTITUTE

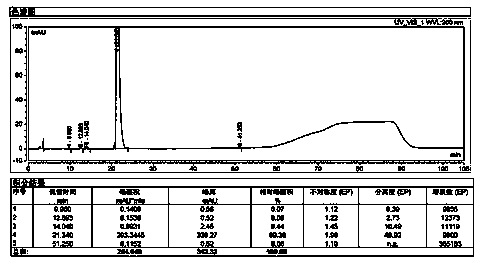

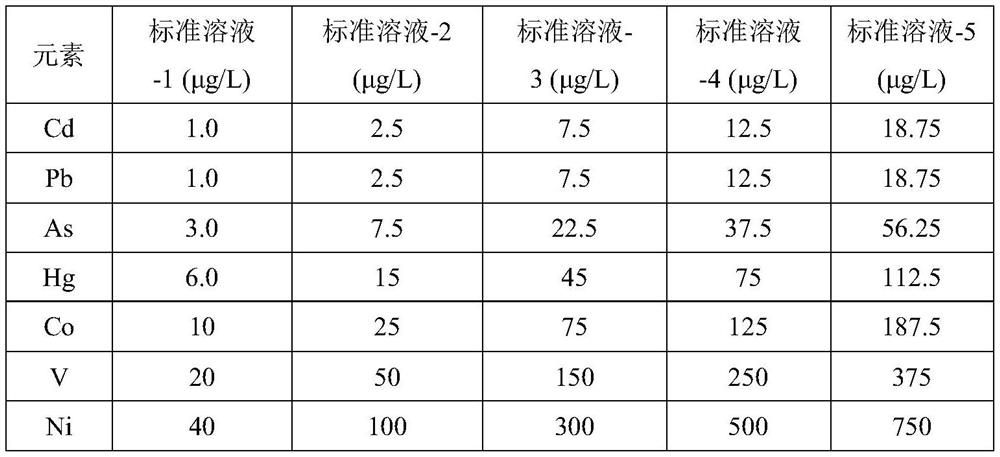

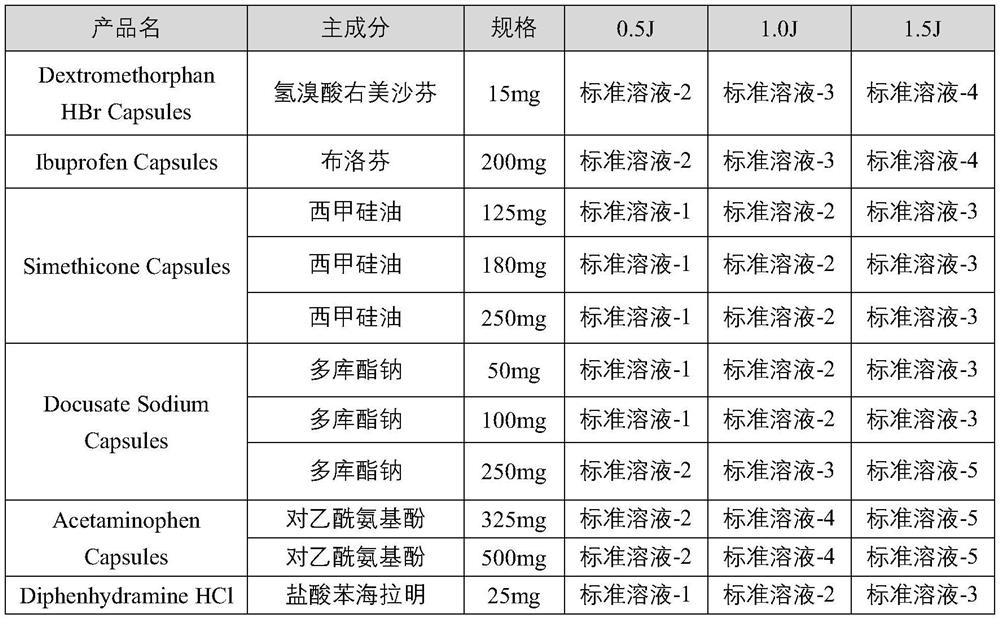

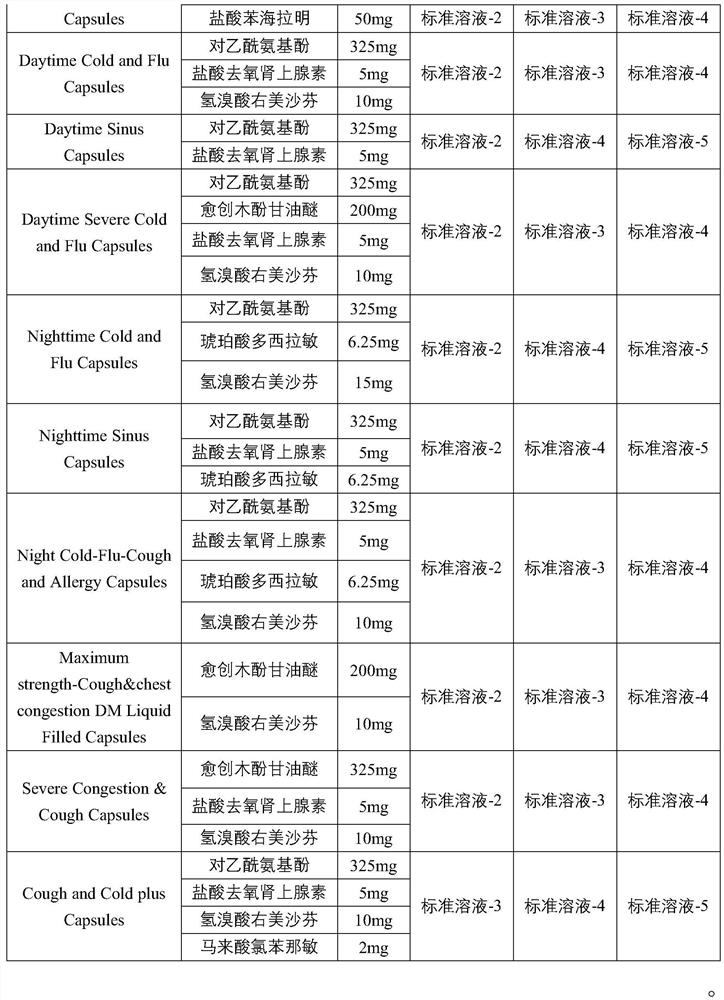

Method for determining element impurities in OTC soft capsule by using inductively coupled plasma mass spectrometry technology

PendingCN113567537AHigh sensitivityImprove accuracyMaterial analysis by electric/magnetic meansSoftgelPhysical chemistry

The invention provides a method for determining element impurities in OTC soft capsules by using an inductively coupled plasma mass spectrometry technology. According to the method, an ICP-MS detection method with high sensitivity and accuracy can be established according to the maximum daily dose of different products and the daily permissible exposure (PDE) of elements; according to the present invention, the ICP-MS can be used to determine Cd, Pb, As, Hg, Co, V, Ni, Ag, Tl, Au, Ir, Mo, Os, Pd, Pt, Rh, Ru, Sb, Sn, Ba, Cr, Cu, Li, Se and other element impurities in the OTC capsule; and the method can meet the determination requirements of a variety of heavy metal elements in the OTC capsule, and has high accuracy, precision and repeatability.

Owner:HUMANWELL PURACAP PHARM WUHAN CO LTD

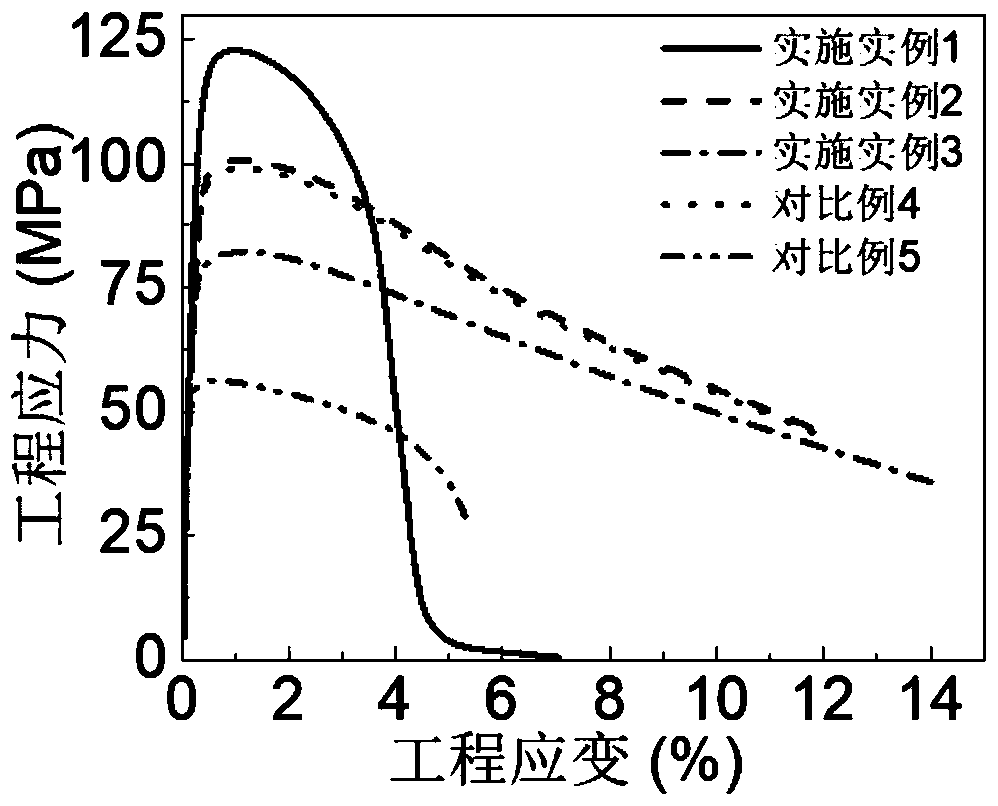

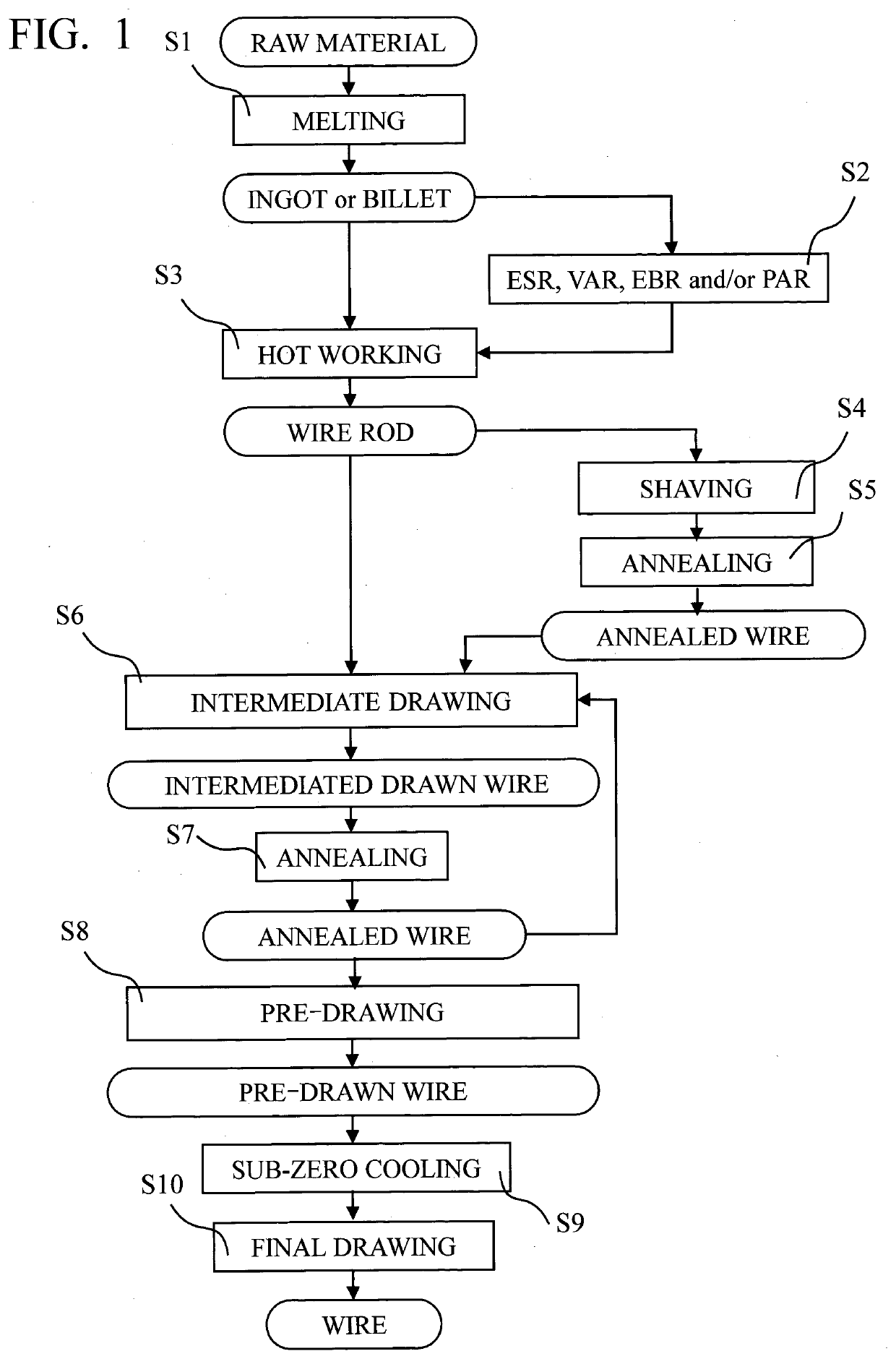

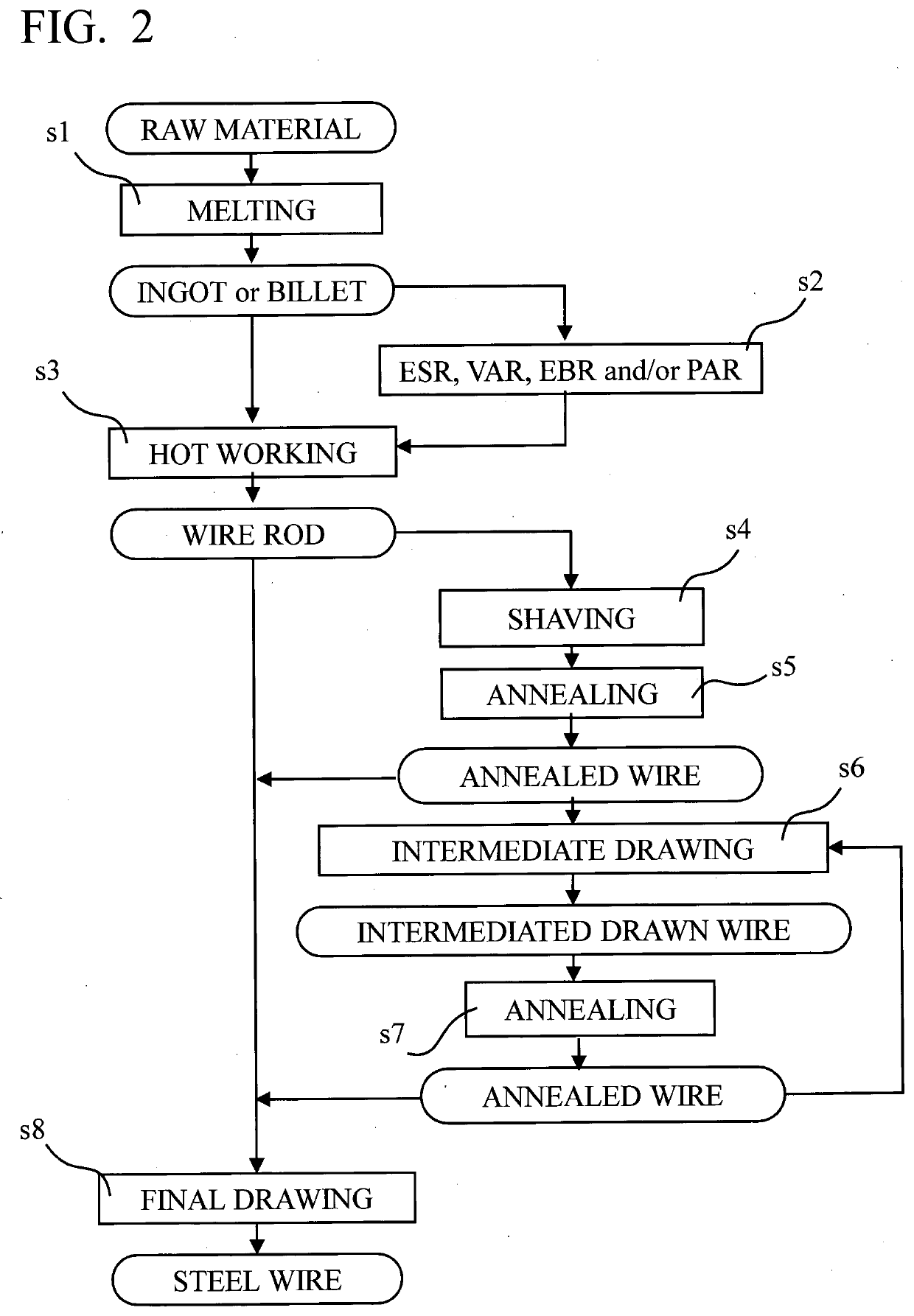

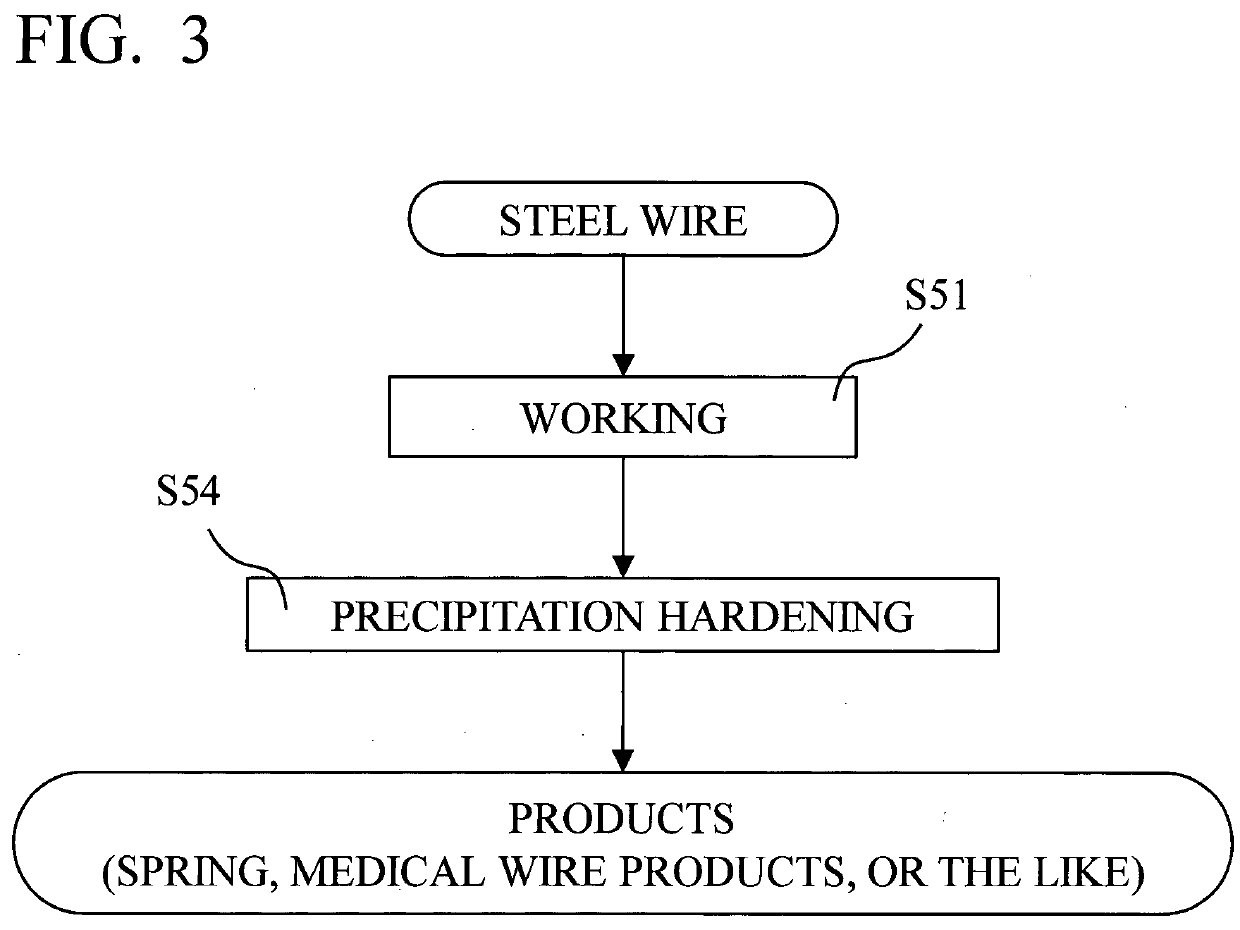

A steel wire, a method for manufacturing the same, and method for manufacturing a spring or medical wire products

PendingUS20210156014A1Improved property profileHigh strengthSpringsFurnace typesEngineeringStainless steel wire

The invention relates to a steel wire suitable for making a spring or medical wire products which remarkably improve the performance of conventional stainless steel wire. The steel comprises (in wt. %): C: 0.02 to 0.15, Si: 0.1 to 0.9, Mn: 0.8 to 1.6, Cr 16 to 20, Ni: 7.5 to 10.5, Mo: ≤3, Al: 0.5 to 2.5, Ti: ≤0.15, N: ≤0.05, optional elements, and impurities, balance Fe, wherein the total amount of Cr and Ni is 25 to 27 wt. %, and wherein the steel has a microstructure including, in volume % (vol. %), martensite: 40 to 90, austenite: 10 to 60, and delta ferrite: ≤5.

Owner:SUZUKI GARPHYTTAN AB

Seedless particles with carbon allotropes

Carbon materials having carbon aggregates including carbon nanoparticles and no seed particles, are disclosed. In various embodiments, the nanoparticles include graphene, optionally with multi-walled spherical fullerenes and / or another carbon allotrope. In various embodiments, the nanoparticles and aggregates have different combinations of: a Raman spectrum with a 2D-mode peak and a G-mode peak, and a 2D / G intensity ratio greater than 0.5, a low concentration of elemental impurities, a high Brunauer-Emmett and Teller (BET) surface area, a large particle size, and / or a high electrical conductivity. Methods are provided to produce the carbon materials.

Owner:利腾股份有限公司

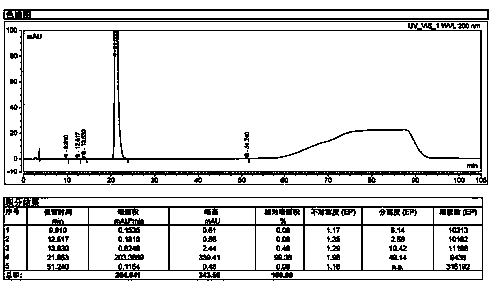

Method for detecting element impurities in tigecycline for injection

InactiveCN111060583AGuaranteed dissolution effectPresence status influencePreparing sample for investigationMaterial analysis by electric/magnetic meansMass analyzerInductively coupled plasma

The invention provides a method for detecting element impurities in tigecycline for injection. The detection method comprises the following steps: preparing a linear standard solution of each elementimpurity; preparing an internal standard solution; preparing a sample to be detected, redissolving tigecycline for injection with purified water to form an aqueous solution, and mixing the aqueous solution with a diluent to form a to-be-detected sample, wherein the diluent is a mixed solution of HNO3, purified water and a gold standard solution in a volume ratio of (1-3): (97-99): 0.02, and the concentration of the gold standard solution is 1000 [mu] g / mL; drawing a standard curve; sample detection: mixing the to-be-detected sample and the internal standard solution, introducing the sample anddetecting by using an inductively coupled plasma mass spectrometer to obtain the response values of each element; and converting to obtain the impurities of each element in tigecycline for injectionaccording to the response value obtained by sample detection and the standard curve. The diluent ensures the dissolution performance of the element impurities so that the content of the impurities ofeach element can be detected by one method.

Owner:瀚晖制药有限公司

Method of Selecting Silicon Having Improved Performance

ActiveUS20080233035A1Improve performanceGroup 4/14 element organic compoundsSilicon halogen compoundsSlagMethod selection

Chemical grade silicon metalloid having improved performance in the direct process for making organohalosilanes is selected by (A) measuring the temperature of each batch of silicon metalloid during both the refing and the casting of the silicon metalloid; (B) measuring the elemental impurity levels in each batch of the silicon metalloid after refining of the silicon metalloid; (C) predicting the properties of the slag phase produced during refining of the silicon metalloid, based on equilibrium calculations, using the elemental impurity levels and the measured temperatures of each batch of silicon metalloid; and (D) selecting a chemical grade silicon metalloid for use in the direct process for making organohalsilanes, based upon the predicted slag properties; such that the slag density, the viscosity, and the melting point of the slag, are within acceptable and predetermined ranges for each individual batch.

Owner:DOW SILICONES CORP

Heat-resistant magnesium alloy as well as preparation method and application thereof

The invention relates to a heat-resistant magnesium alloy as well as a preparation method and application thereof. The heat-resistant magnesium alloy is prepared from the following components of, in percentage by mass, 8.0 wt%-12.0 wt% of Gd, 2.0 wt%-4.5 wt% of doping elements, 1.5 wt%-5.0 wt% of Sm, 0.5 wt%-2.0 wt% of Ag, 0.2 wt%-0.6 wt% of Zr, 0 wt%-0.03 wt% of impurity elements and the balance of Mg, wherein the doping element is selected from at least one of Y and Nd. The heat-resistant magnesium alloy contains the components in a specific proportion, the mechanical property of the magnesium alloy is enhanced in a compounded mode, the effect of synergistically separating out pinning dislocation in the grain boundary and the grain can be achieved through the optimized heat treatment technology, and therefore the heat resistance, the ductility and the creep resistance of the magnesium alloy are improved, and the excellent hardness can be kept at the high temperature.

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

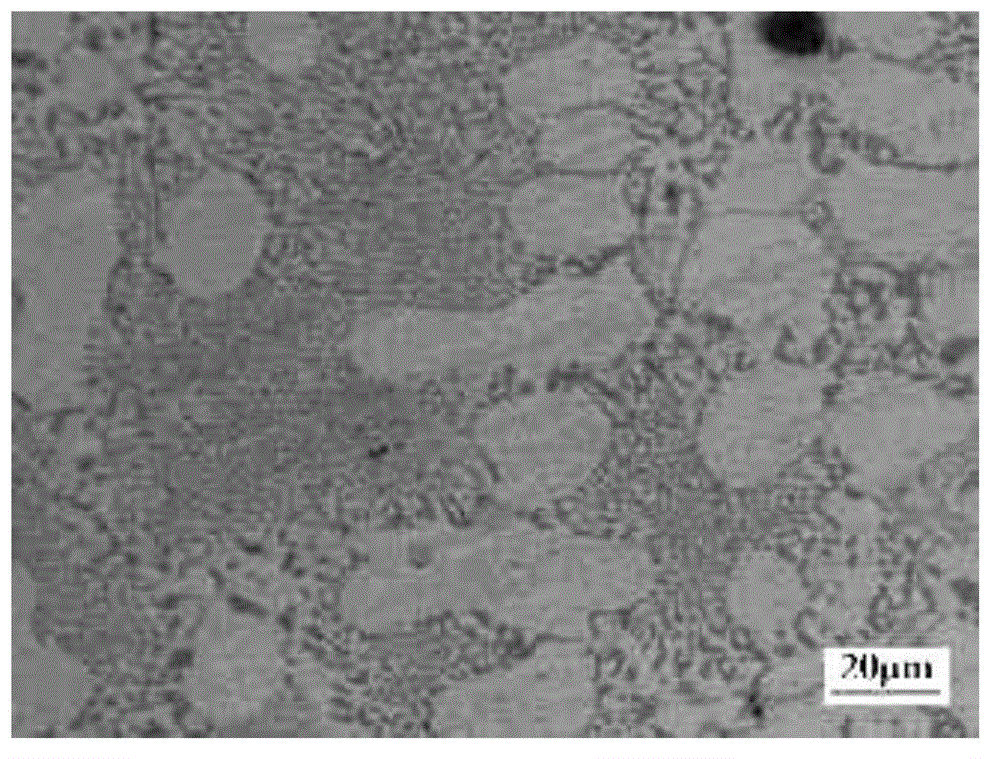

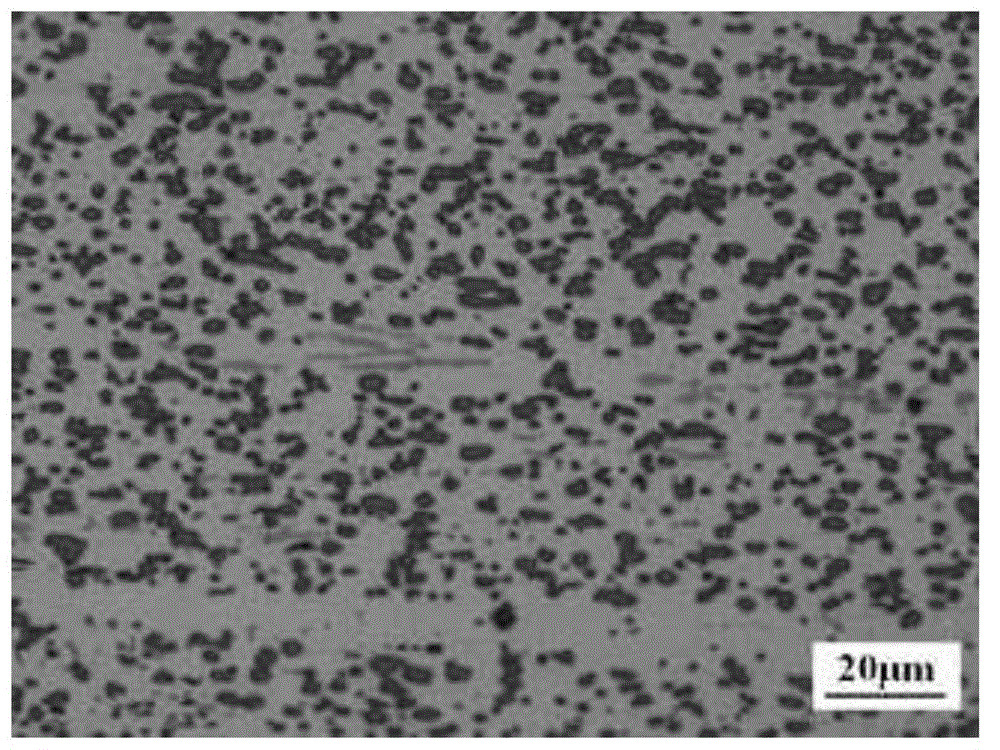

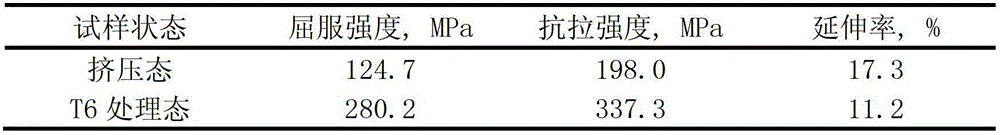

A high-strength and toughness cast aluminum-silicon alloy and its preparation method and application

Provided in the present invention are a high strength and ductility casted aluminum-silicon alloy, a manufacturing method for same, and applications thereof. The aluminum-silicon alloy consists of the following components in terms of mass percent: Si 7-8%, Mg 0.4-0.5%, Fe 0.1-0.2%, Ti 0.1-0.2%, Sr 0.01-0.02%, La 0.03-0.06%, Ce 0.02-0.04%, and the remainder is Al and unavoidable elemental impurities. The manufacturing method comprises the smelting of an aluminum-silicon alloy liquid, refinement and modification, refining for gas removal and impurity removal, casting, and a solution ageing treatment. The present invention, by optimizing the content of elemental Si and Mg, refining and modifying an α-Al crystallite, a β-Fe iron-rich phase, and an eutectic Si phase, allows the α-Al dendritic crystal to be converted into fine equiaxed crystallites, allows the acicular and flaky β-Fe iron-rich phase and the eutectic Si phase to be converted into a fine granular or short rod form, and eliminates the hazards posed by the acicular and flaky β-Fe iron-rich phase and the eutectic Si phase on the strength, plasticity, and fracture toughness of the aluminum-silicon alloy. The casted aluminum-silicon alloy of the present invention is provided with high strength, great plasticity, and excellent fracture toughness and is applicable in casting various force-bearing structural parts, such as vehicular lightweight structural parts.

Owner:GUANGDONG INST OF NEW MATERIALS

A method for separating iron element impurities by pulse current in recycled aluminum melt

ActiveCN111549237BWill not polluteEnables continuous processingProcess efficiency improvementElemental impuritiesPulsed power

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com