Method for detecting element impurities in tigecycline for injection

A detection method and tigecycline technology, which are applied in the preparation of test samples, measuring devices, sampling, etc., can solve the problems of complex detection methods for element impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

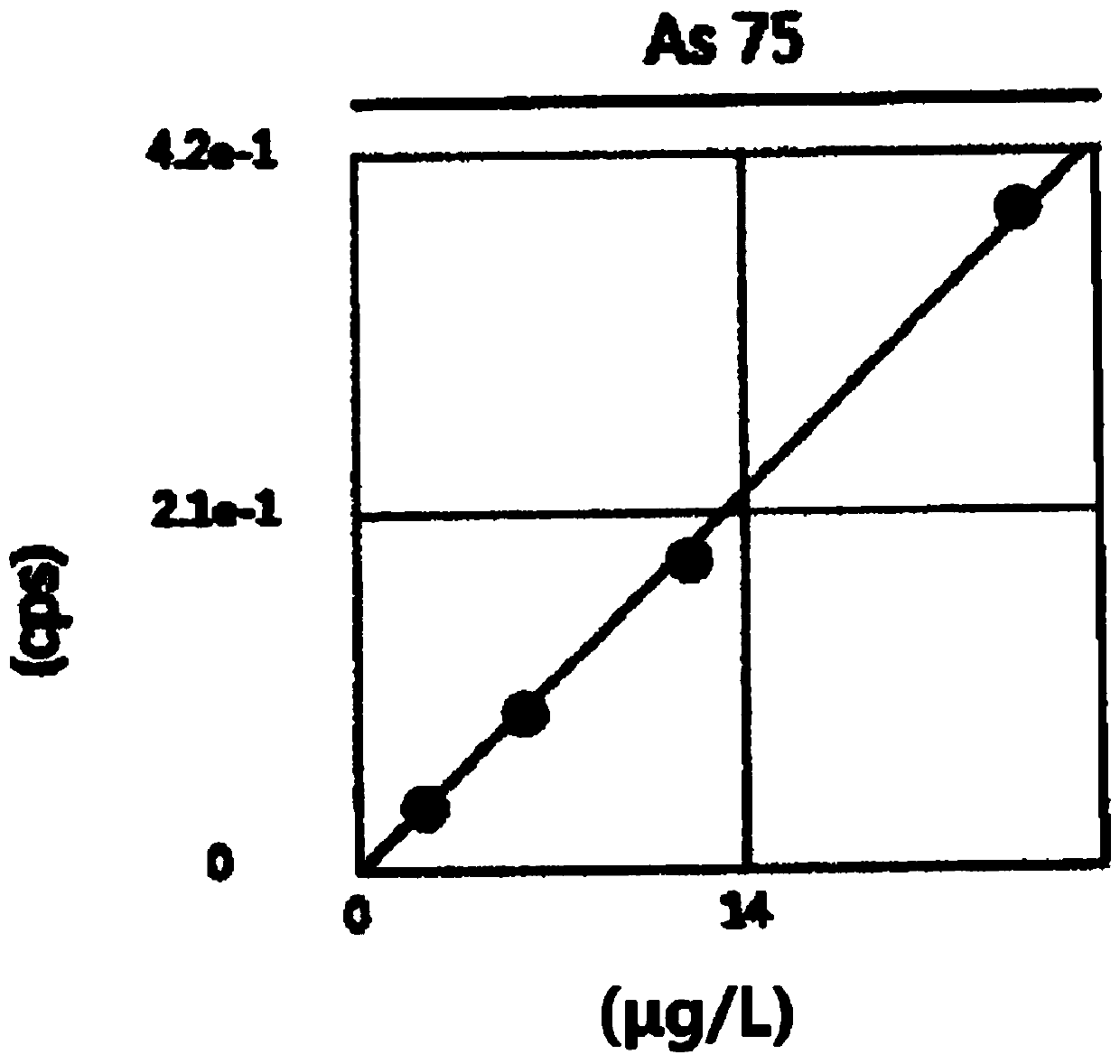

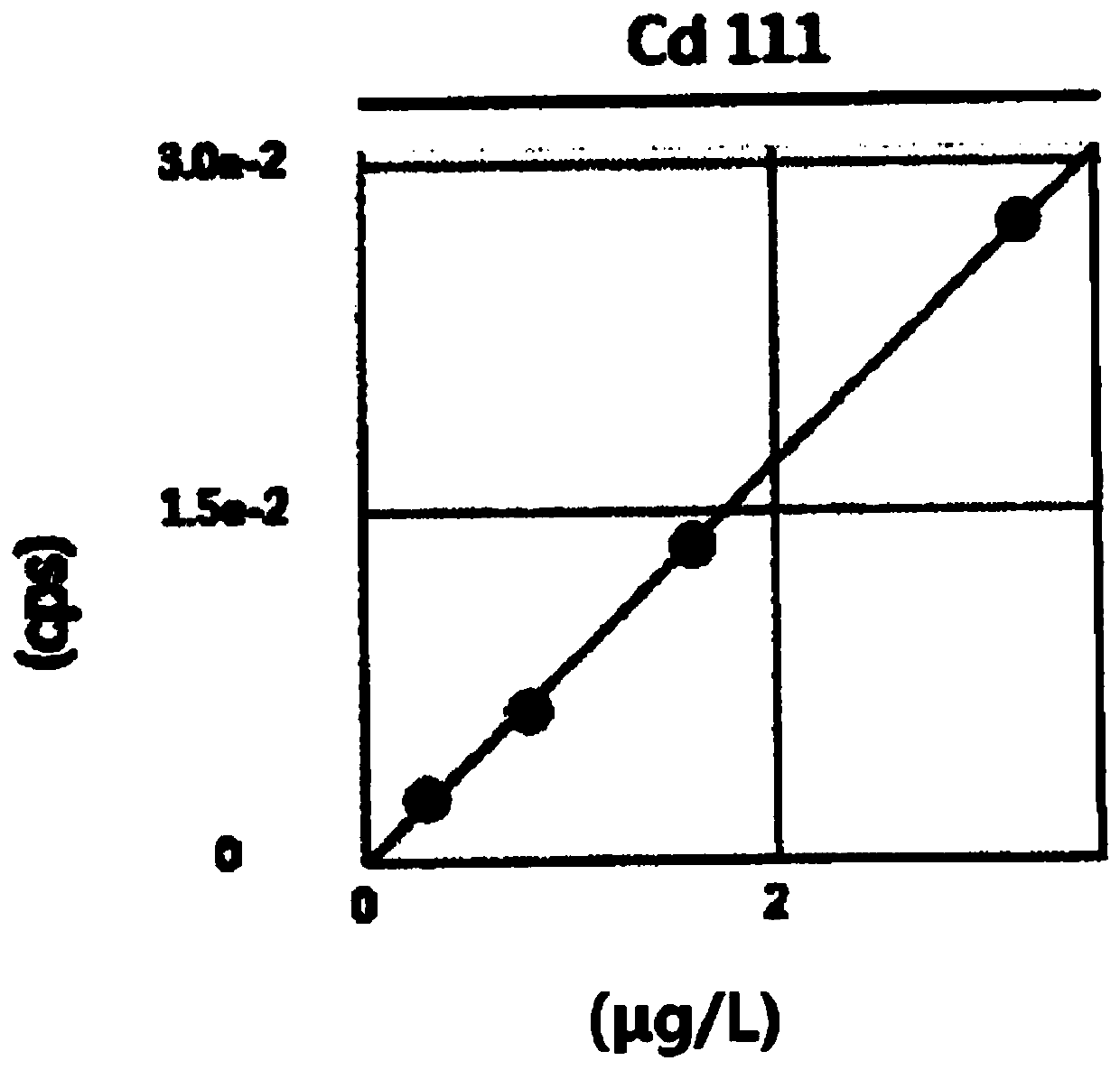

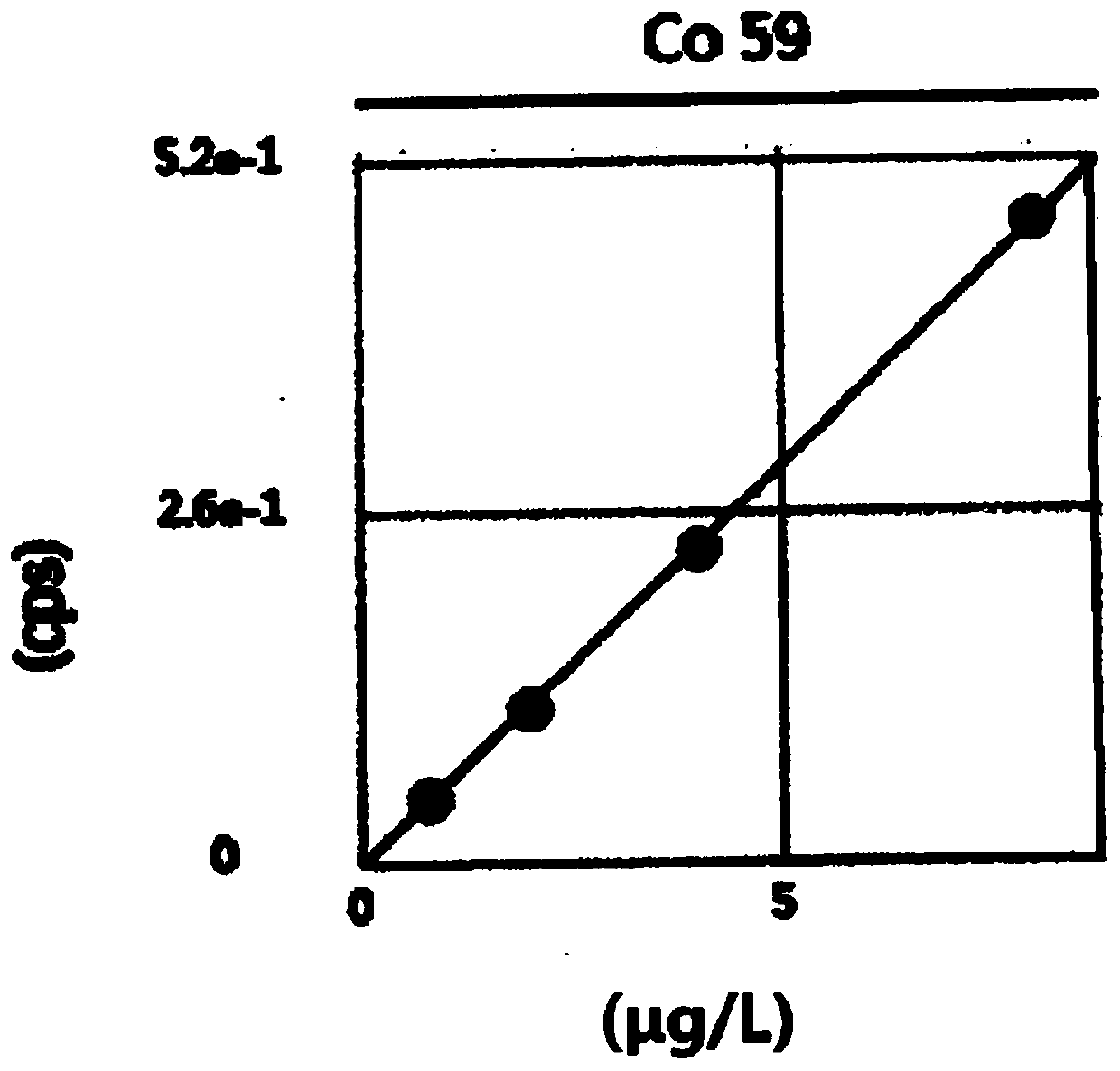

[0051] Prepare linear standard solutions

[0052] Prepare standard solutions of each element with a concentration of 1000 μg / mL; mix 100 μL cadmium standard solution, 250 μL cobalt standard solution, 150 μL mercury standard solution and 250 μL lead standard solution and dilute to 10 mL with diluent to obtain linear stock solution A; Mix 1.0mL linear stock solution A, 75μL arsenic standard solution, 50μL vanadium standard solution, 50μL palladium standard solution, 100μL nickel standard solution, 1.0mL calcium standard solution, 2.5mL silicon standard solution, 200μL copper standard solution, lithium standard solution, Antimony standard solution, aluminum standard solution, boron standard solution, barium standard solution, chromium standard solution, iron standard solution, magnesium standard solution, manganese standard solution, molybdenum standard solution and zinc standard solution were mixed and dilute to 25mL with diluent to obtain Linear stock solution B; dilute linea...

Embodiment 2

[0078] The difference from Example 1 is that the diluent consists of HNO 3 : Purified water: gold Au standard solution = 1:99:0.02 (v / v / v).

[0079] Since there are many elements detected in this application, the linear regression equation corresponding to the standard curve of each element is listed in Table 4, and the concentration value is calculated according to the linear regression equation and the detected response value intensity, and the concentration value is converted according to the aforementioned formula. The content of corresponding elements in tigecycline for injection is recorded in Table 4.

[0080] Table 4

[0081]

[0082]

Embodiment 3

[0084] The difference from Example 1 is that the diluent consists of HNO 3 : Purified water: gold Au standard solution = 3:97:0.02 (v / v / v).

[0085] The formula corresponding to the standard curve of each element is shown in Table 5.

[0086] table 5

[0087]

[0088]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com