Purifying method of aluminum nitride powder, aluminum nitride powder prepared by method and application of aluminum nitride powder

A purification method, aluminum nitride technology, applied in the field of materials, can solve the problems of reducing the thermal conductivity of aluminum nitride ceramic products, unfavorable powder production and promotion, and achieve the effect of promoting sintering synthesis and improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Take 18g of the aluminum nitride powder raw material (3.5% by weight of carbon content) prepared by the carbothermal reduction process, put it into a boron nitride crucible, place the crucible in a tubular sintering furnace, vacuumize, and then introduce carbon dioxide gas , the flow rate is 200ml / min, and then the tube furnace is heated, the furnace temperature is raised to 700°C, and the temperature is kept constant for 3 hours to obtain high-purity aluminum nitride powder products.

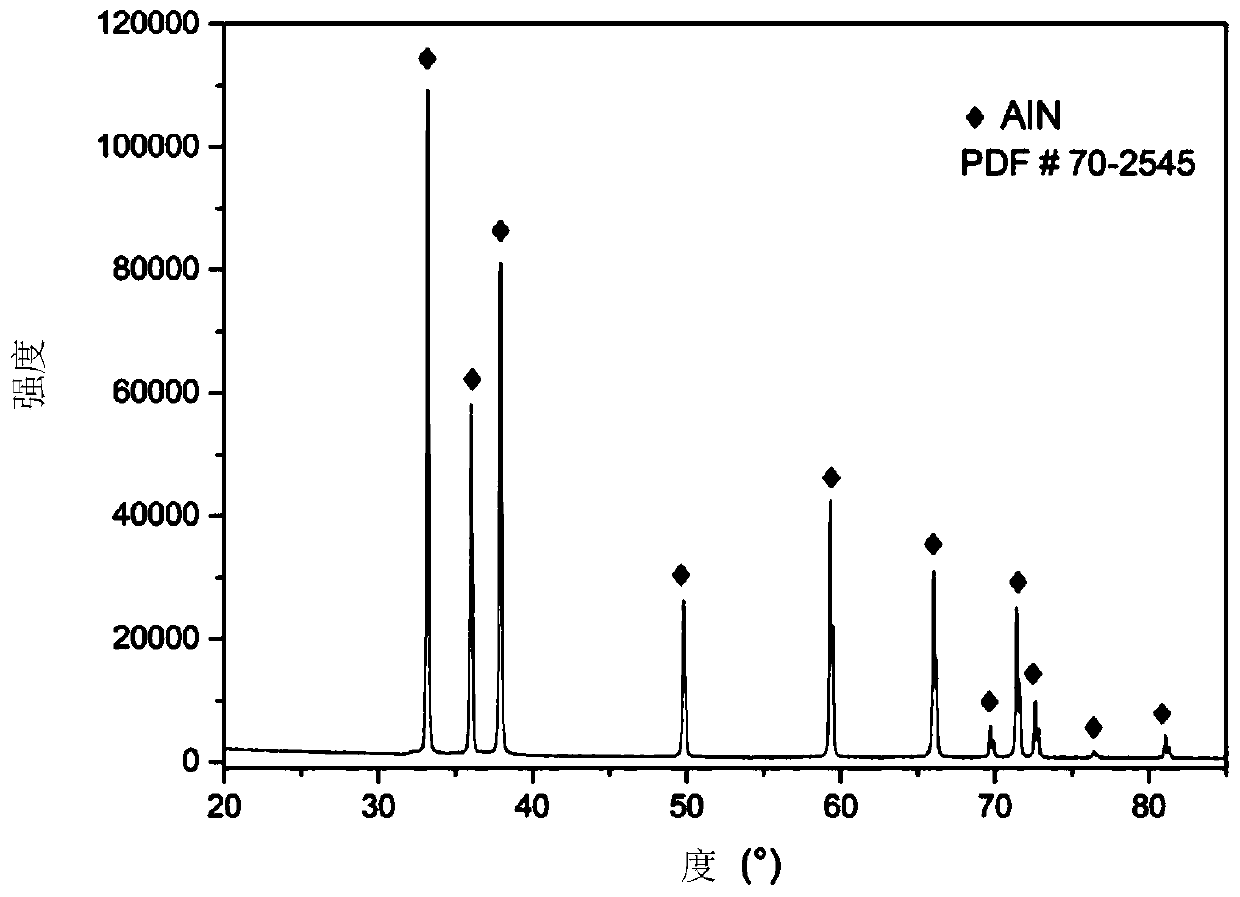

[0034] It is determined that the carbon impurity content of the prepared aluminum nitride powder product is 0.028% by weight as measured by a carbon and sulfur analyzer. The oxygen impurity content was determined to be 0.63% by weight by the inert gas pulse infrared thermal conductivity method, and the results can be seen in Table 1 below. The microstructure of aluminum nitride powder raw materials is as follows: figure 1 As shown, the microstructure of the purified aluminum nitride pow...

Embodiment 2

[0036] Take 33g of the aluminum nitride powder raw material (6.3% by weight of carbon content) prepared by the carbothermal reduction process, put it into a boron nitride crucible, place the crucible in a tubular sintering furnace, vacuumize, and then introduce carbon dioxide gas , the flow rate is 100ml / min, and then the tube furnace is heated, and the furnace temperature is raised to 1000°C, and then kept at constant temperature for 4 hours to obtain high-purity aluminum nitride powder products.

[0037]It is determined that the carbon impurity content of the prepared aluminum nitride powder product is 0.035% by weight as measured by a carbon and sulfur analyzer. The oxygen impurity content was measured by the same method as in Example 1 to be 0.76% by weight.

Embodiment 3

[0039] Take 41g of the aluminum nitride powder raw material (5.8% by weight of carbon content) prepared by the carbothermal reduction process, put it into a boron nitride crucible, and place the crucible in a tubular sintering furnace, vacuumize, and then introduce carbon dioxide gas , the flow rate is 150ml / min, and then the tube furnace is heated, and the furnace temperature is raised to 950°C, and then kept at constant temperature for 3.5 hours to obtain high-purity aluminum nitride powder products.

[0040] It is determined that the carbon impurity content of the prepared aluminum nitride powder product is 0.031% by weight as measured by a carbon and sulfur analyzer. The oxygen impurity content was measured by the same method as in Example 1 to be 0.66% by weight. The results can be seen in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com