Patents

Literature

111 results about "Oxygen impurity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

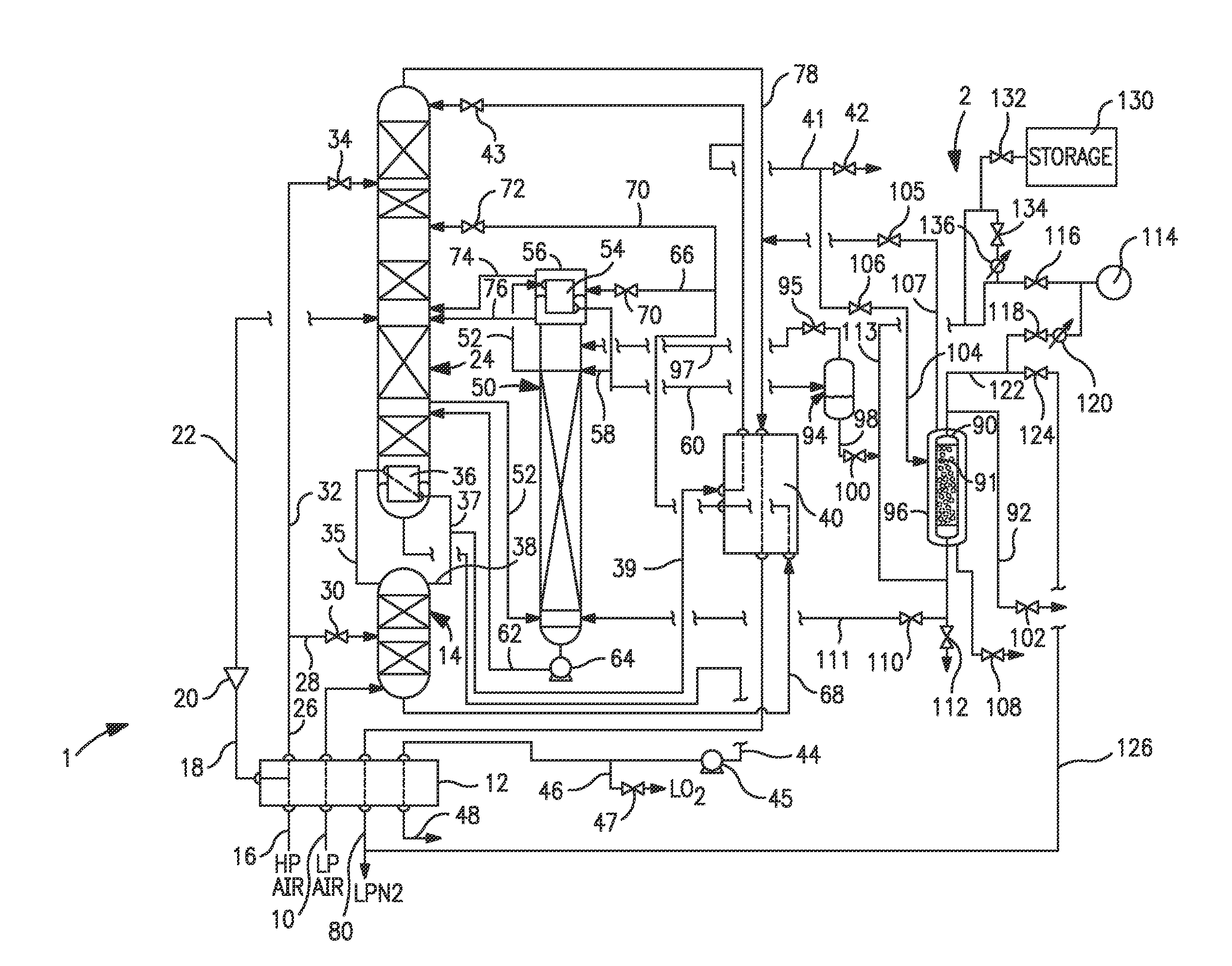

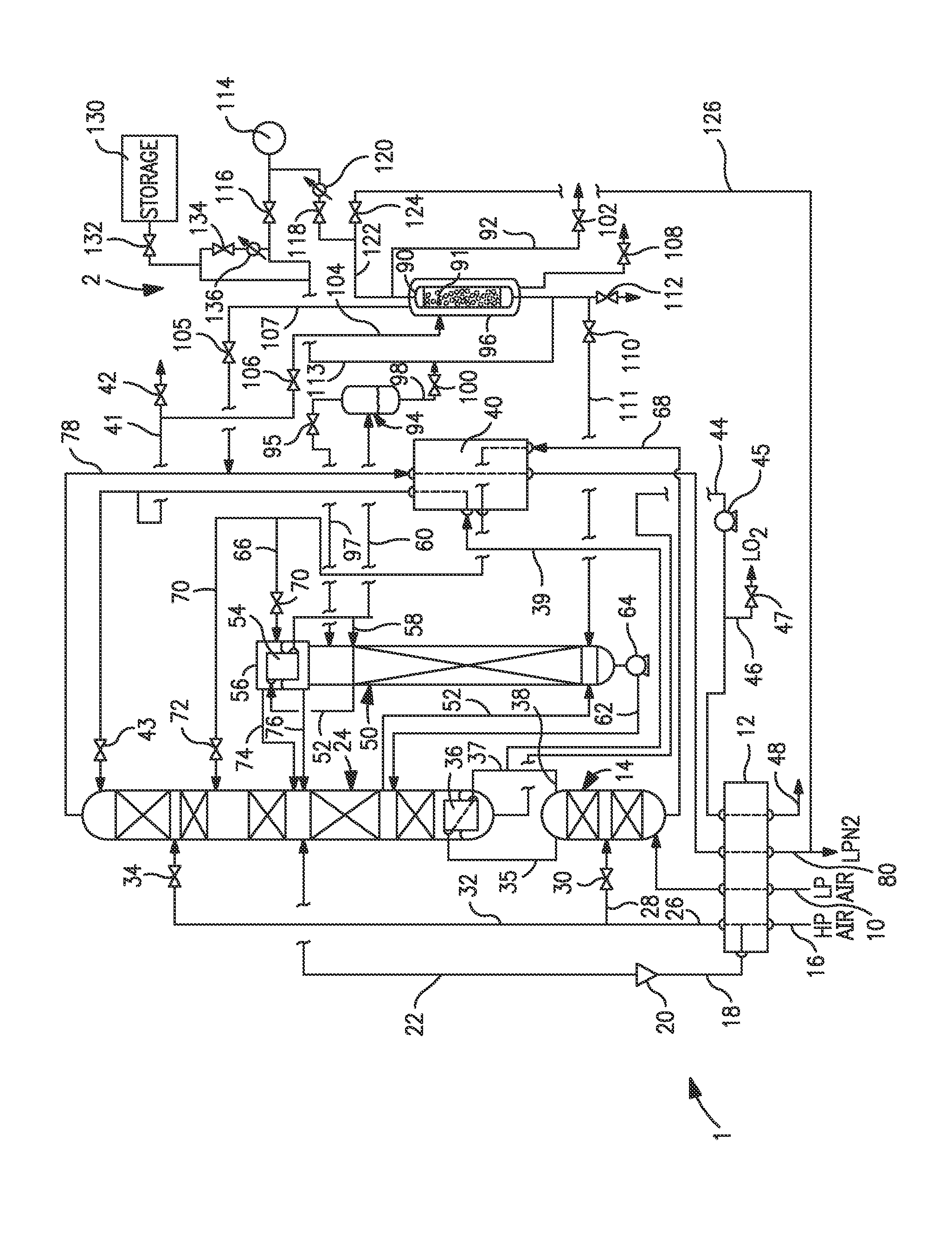

Argon production method and apparatus

ActiveUS20140245782A1Reduce overall coldbox spaceSmall sizeSolidificationGas treatmentLiquid argonSorbent

A method and apparatus for producing a purified liquid argon product in which liquid argon having oxygen impurities is produced in a cryogenic air separation plant by separating argon from oxygen within an argon column. An impure liquid argon stream, composed of part of the liquid argon, is purified in an adsorbent bed by adsorbing the oxygen impurities in an adsorbent to produce a purified liquid argon stream that constitutes the purified liquid argon product. During adsorption, the adsorbent bed is maintained at a reduced temperature with a coolant to prevent vaporization of the liquid argon. The bed is then regenerated by draining residual liquid argon from the adsorbent bed, introducing the residual liquid argon back into the air separation plant and then desorbing the oxygen impurities with a regeneration gas. After regeneration, the adsorbent bed is refilled with purified liquid argon prior to being brought back on-line.

Owner:PRAXAIR TECH INC

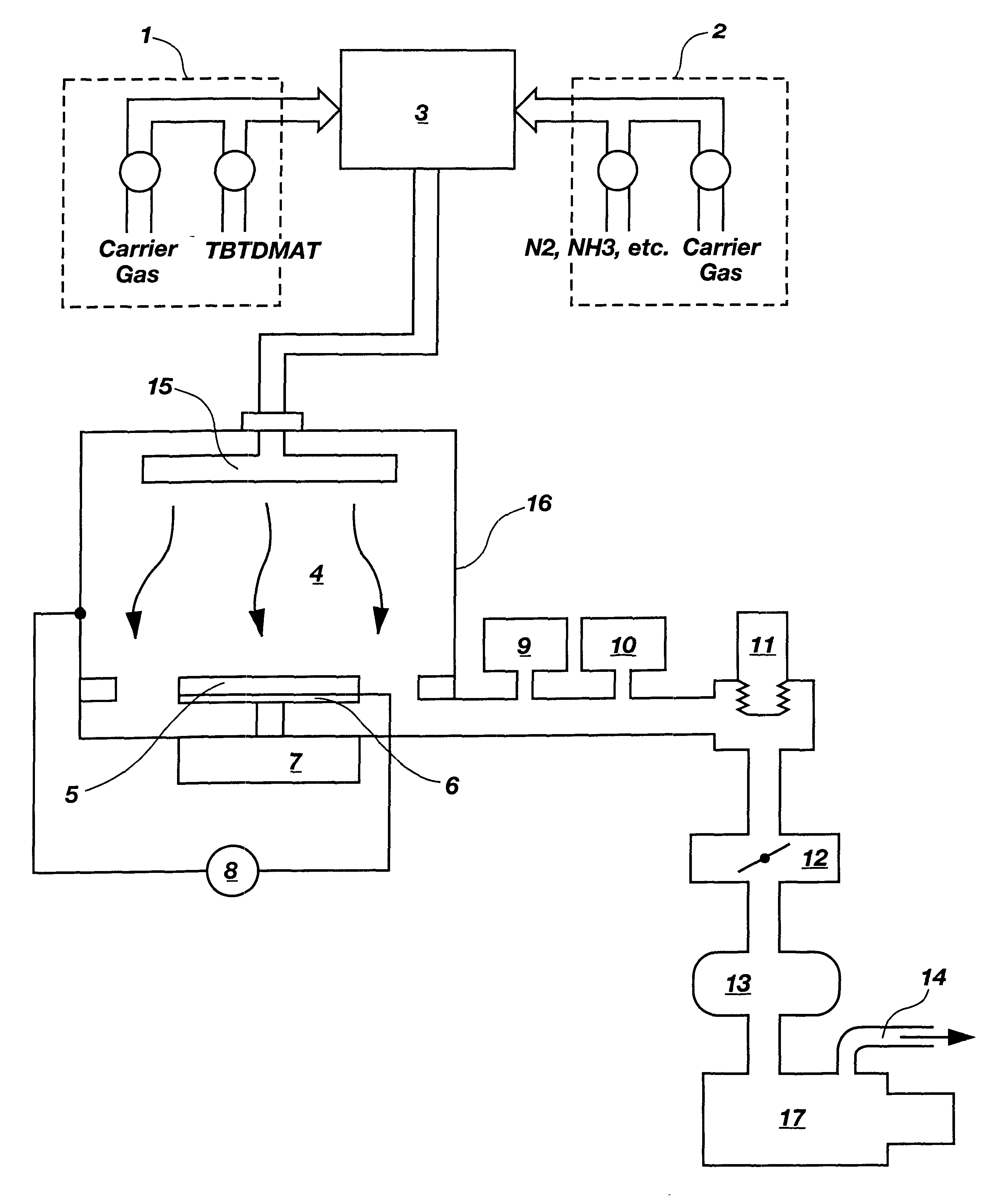

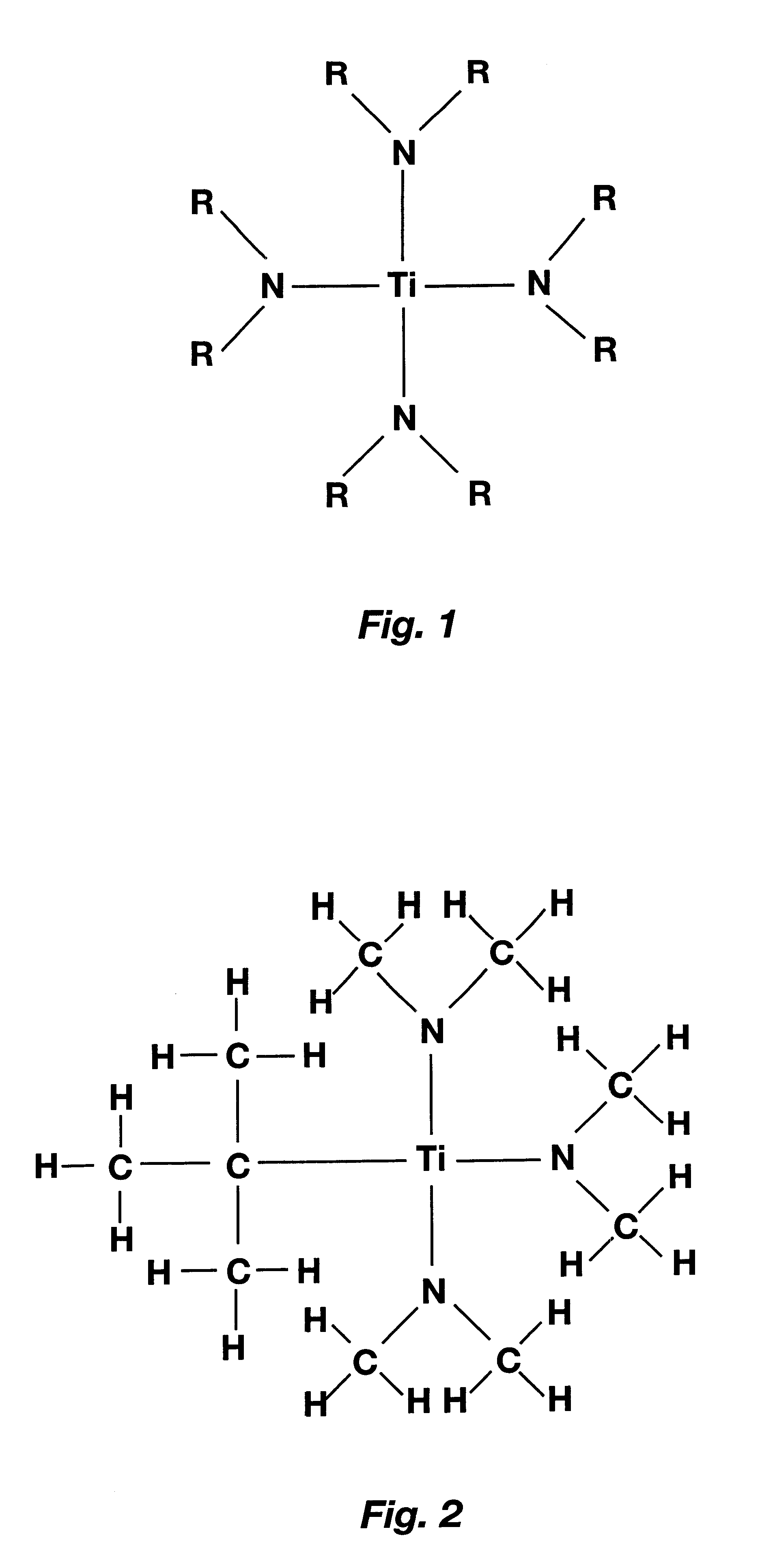

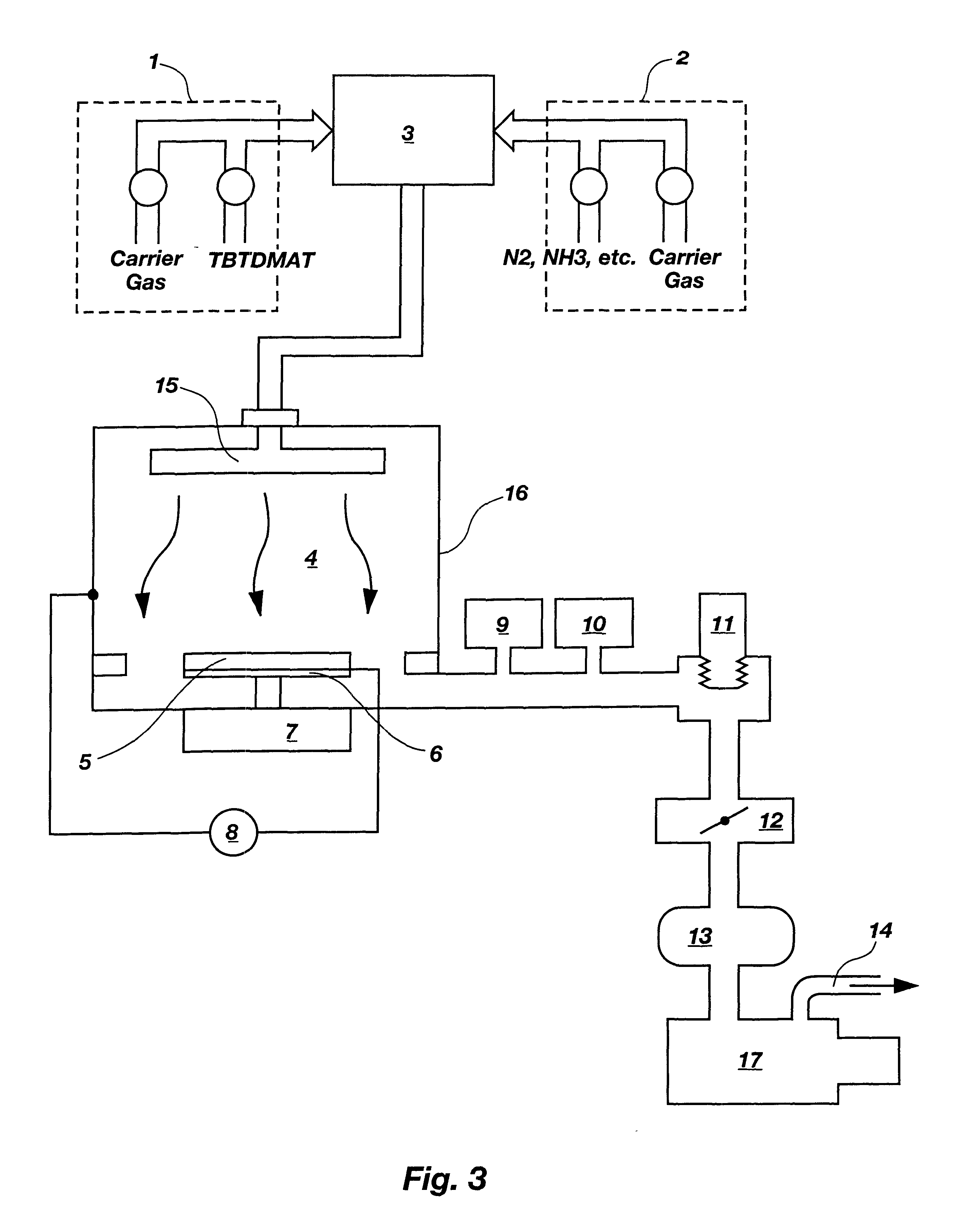

Chemical vapor deposition process for depositing titanium nitride films from an organometallic compound

InactiveUS6338880B1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseHydrazine compound

A process for depositing titanium nitride films containing less than 5% carbon impurities and less than 10% oxygen impurities by weight via chemical vapor deposition is disclosed. Sheet resistance of the deposited films is generally be within a range of about 1 to 10 ohms per square. The deposition process takes place in a deposition chamber that has been evacuated to less than atmospheric pressure and utilizes the organometallic compound tertiary-butyltris-dimethylamido-titanium and a nitrogen source as precursors. The deposition temperature, which is dependent on the nitrogen source, is within a range of 350° C. to 700° C. The low end of the temperature range utilizes nitrogen-containing gases such as diatomic nitrogen, ammonia, hydrazine, amides and amines which have been converted to a plasma. The higher end of the temperature range relies on thermal decomposition of the nitrogen source for the production of reaction-sustaining radicals. In such a case, the use of diatomic nitrogen gas is precluded because of its high dissociation temperature. Other materials may be simultaneously incorporated in the titanium nitride films during either embodiment of the deposition process as heretofore described. For example, a titanium nitride film incorporating aluminum and having the general formula TiAIN may be deposited by introducing aluminum-containing compounds. Additionally, a titanium nitride film incorporating tungsten and having the general formula TiNW may be deposited by introducing tungsten-containing compounds.

Owner:MICRON TECH INC

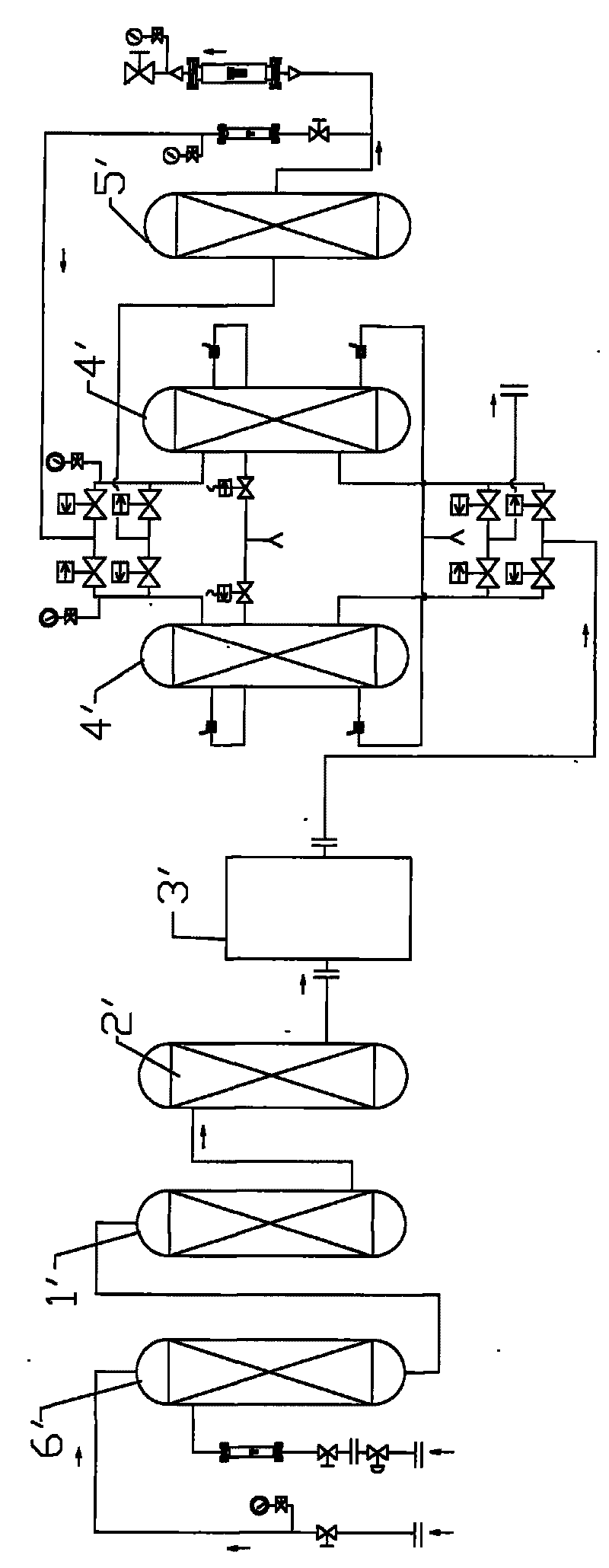

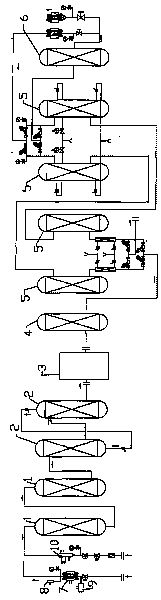

Nitrogen purification method

The invention discloses a nitrogen purification method, wherein nitrogen and hydrogen both mixed with oxygen impurities are fed into a deaerator in which combustion reaction can be formed between the oxygen in the deaerator and the hydrogen to generate water, after the nitrogen mixed with steam is cooling-dewatered by a multistage cooler, freezing-dried by a freezing drier, dewatered by a gas-water separator and drying-dewatered by a multistage dryer, the dew-point temperature of the nitrogen can be lowered to about minus 80 degrees, in this case, the nitrogen hardly contains water, and in the end, the impurities like dust, particles, etc. in the nitrogen are removed by a filter to obtain nitrogen with the purity of 99.999%.

Owner:NANTONG TIANYUAN GAS

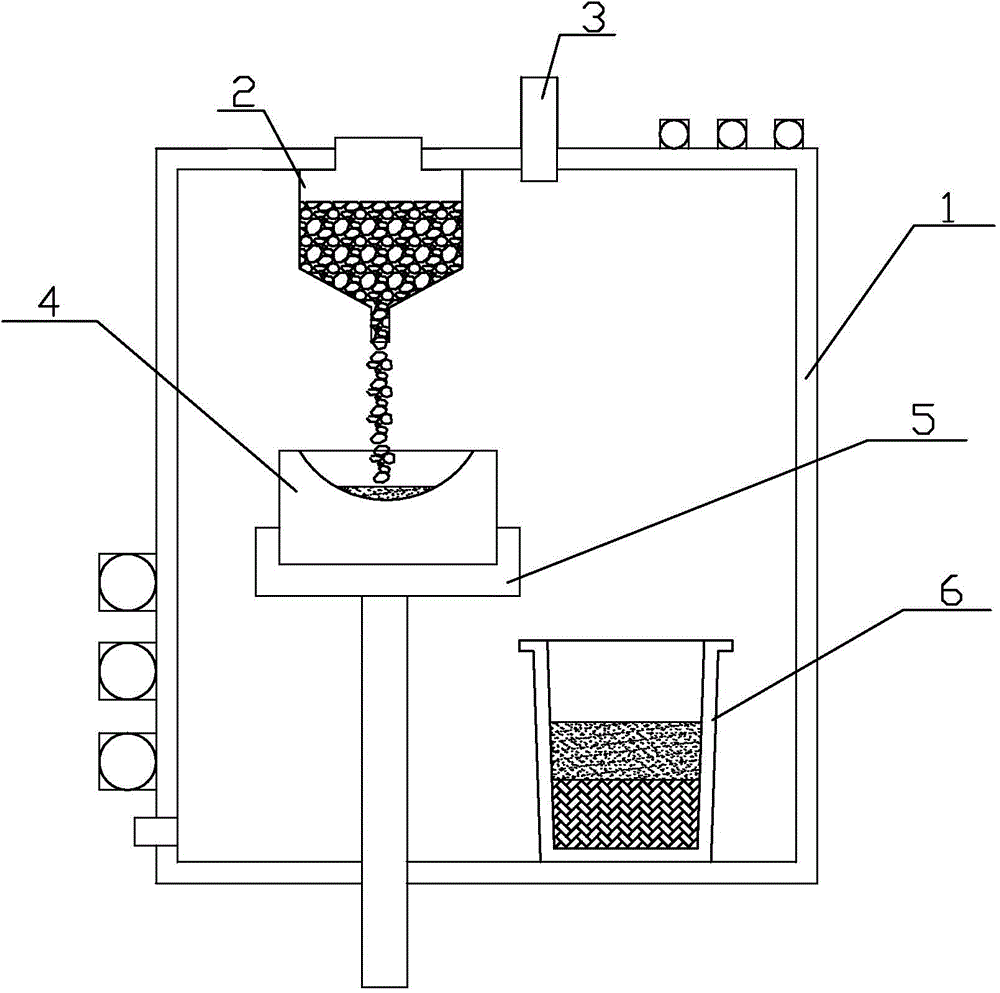

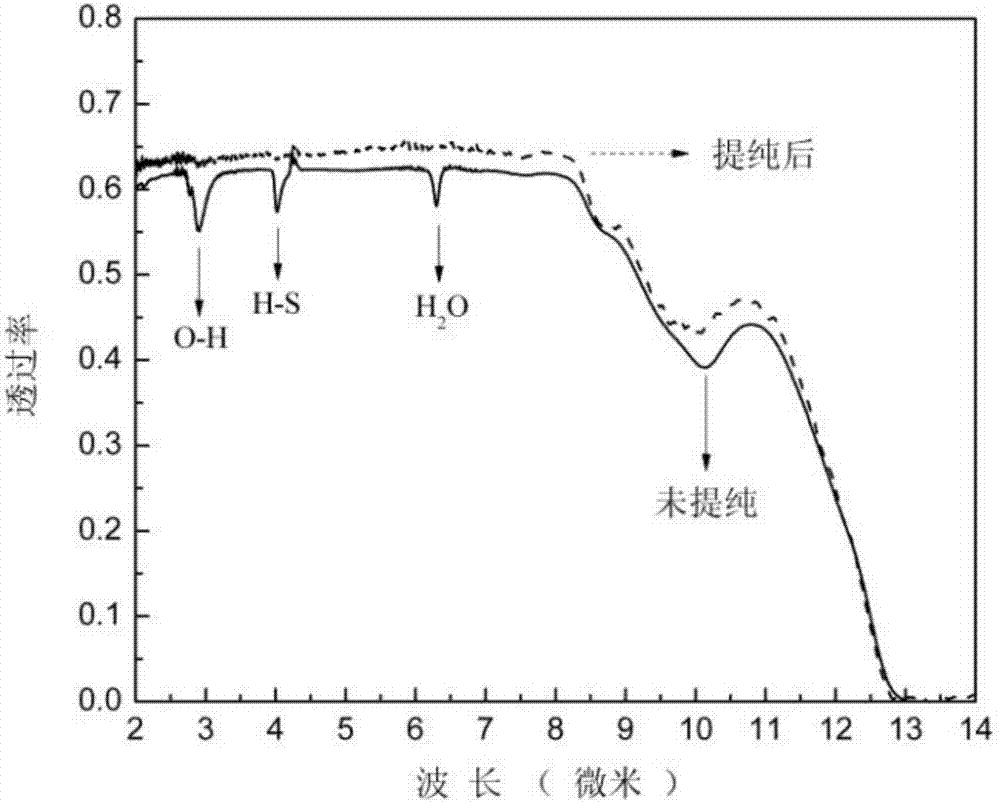

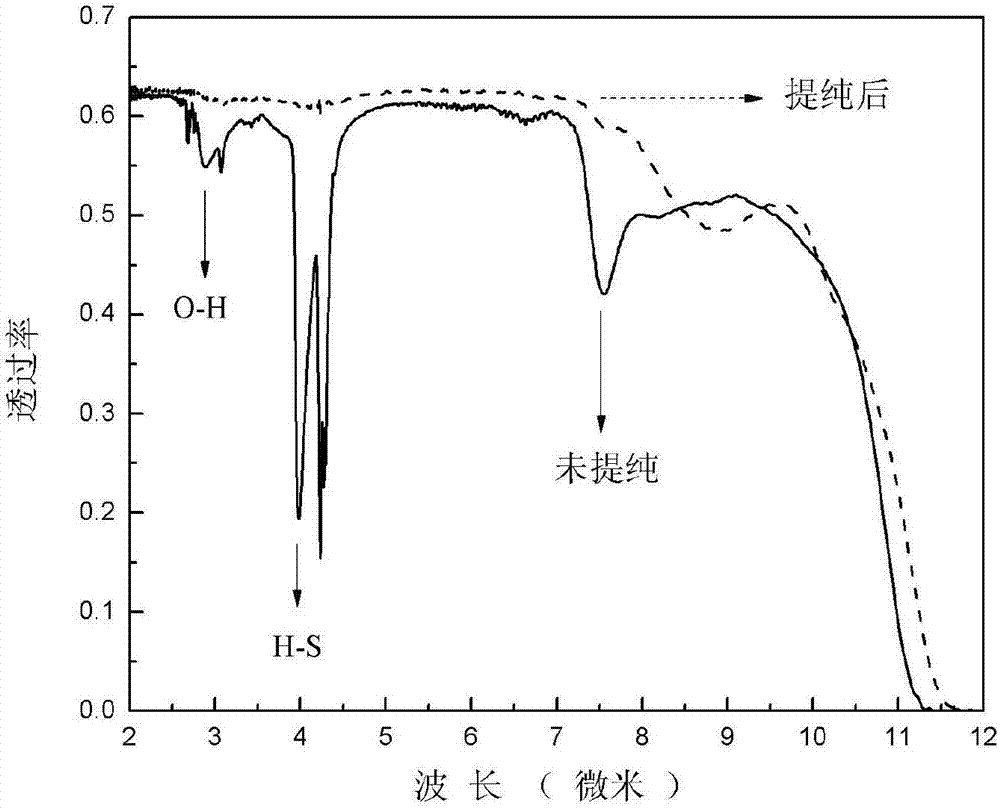

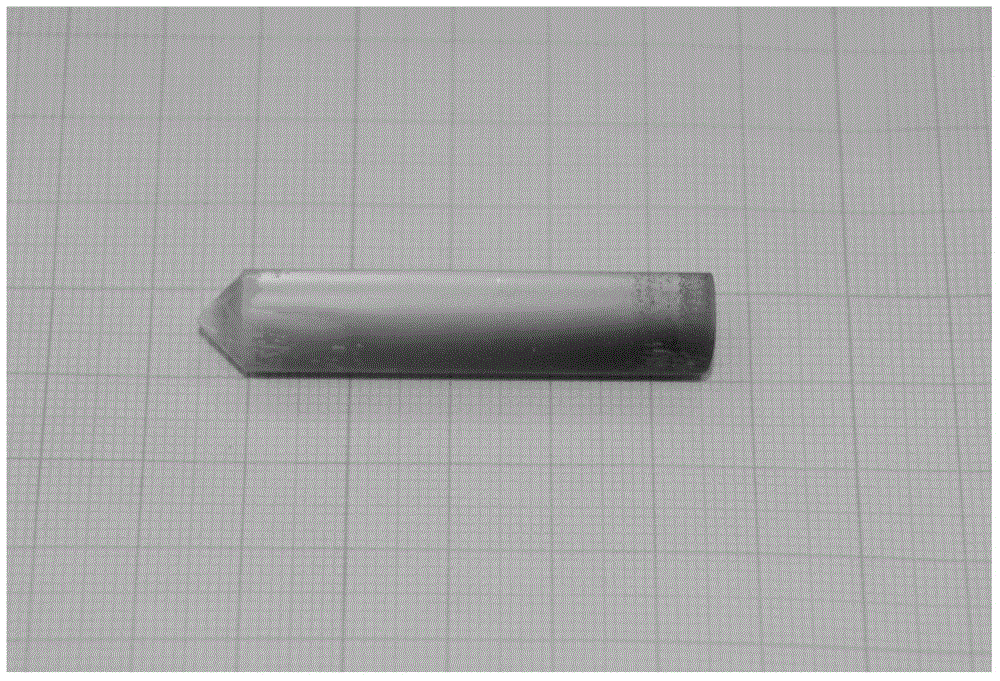

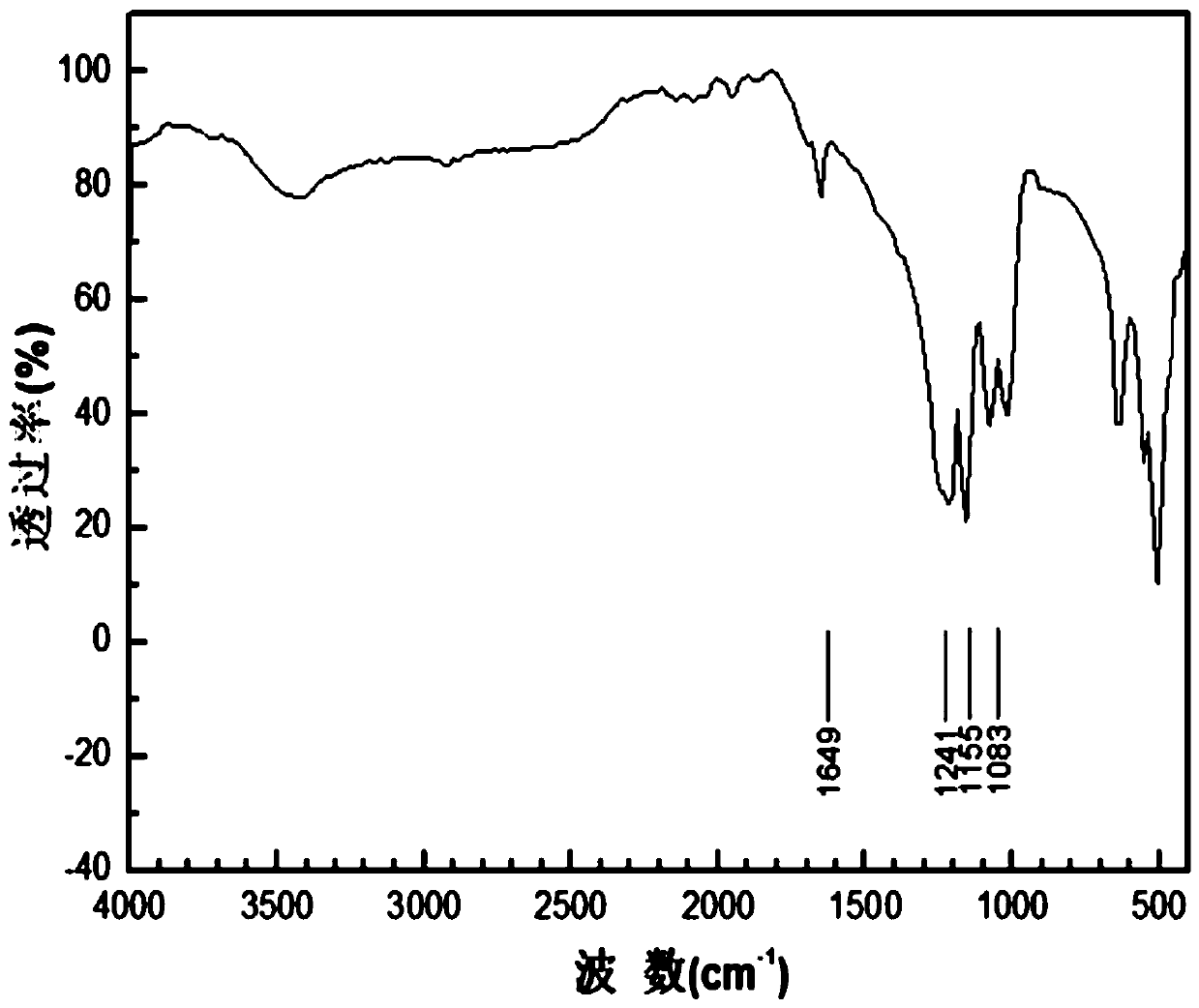

Preparation method of high-purity and low-loss chalcogenide glass

InactiveCN103332851AImprove uniformityHigh purityGlass furnace apparatusChalcogenide glassPhotochemistry

The invention provides a preparation method of high-purity and low-loss chalcogenide glass, belonging to a preparation method of the chalcogenide glass. The preparation method comprises the following steps of: removing hydrocarbon impurity in the glass by taking ultra-dry gallium chloride as a purifying agent, and distilling and purifying the glass in combination with the conventional deoxidant, aluminum, magnesium or zirconium metal; placing glass mixture into a quartz ampoule to be sealed in by means of vacuum supply, founding the glass mixture in a vacuum ampoule, dynamically distilling the glass, and remelting the mixture after distilling; and effectively removing the hydrocarbon impurity in the glass by taking the ultra-dry gallium chloride as the purifying agent, so that the Mie scattering imperfection is hardly formed in the finally-obtained high-purity chalcogenide glass, and the low-loss homogeneous glass can be obtained. According to the high-purity chalcogenide glass synthesized by the preparation method provided by the invention, the minimum loss under the infrared transmission waveband is less than 0.3dB / m, and the corresponding loss of the absorption peak of the residual impurity is less than 8dB / m, so that the preparation method can be used in the field of an infrared glass optical element and an infrared optical fiber. The ultra-dry gallium chloride purifying agent can be easily obtained, and is lower in price; the carbon, hydrogen and oxygen impurities can be removed from the chalcogenide glass at high efficiency; the prepared chalcogenide glass is better in uniformity and less in light scattering.

Owner:XUZHOU NORMAL UNIVERSITY

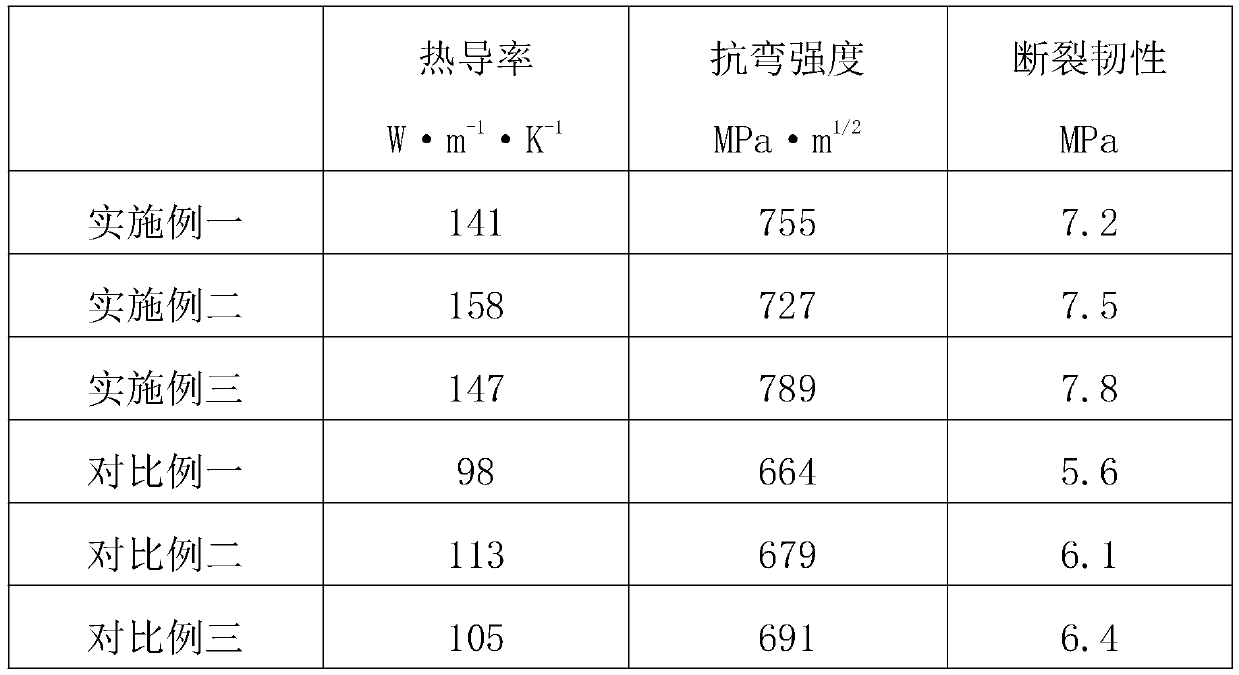

Method for preparing high-thermal-conductivity silicon nitride ceramic by adding fluoride

The invention belongs to the technical field of ceramic material preparation and relates to a method for preparing silicon nitride ceramics with high thermal conductivity by adding fluoride. In the present invention, α-Si3N4 is used as a raw material, and a mixture of silicon magnesium nitride and rare earth fluoride is used as a sintering aid, and the additive amount is 1 to 15 wt%. First, use nano-TiC to pretreat the surface of Si3N4 powder, put the treated raw materials, additives, binders, crystal seeds, defoamers, and solvents into a ball mill and mix them evenly, and then add a dispersant for secondary Secondary ball milling, the mixed slurry after ball milling is dried, granulated, shaped, sintered, and heat treated to prepare silicon nitride ceramics with high thermal conductivity. The present invention prevents the oxygen in the auxiliary agent from entering into the crystal lattice of silicon nitride ceramics by adding rare earth metal fluoride, reduces the adverse effect of lattice oxygen impurity content on the thermal conductivity of ceramics, and the prepared silicon nitride ceramics has relatively high High thermal conductivity has great application potential in the field of electronic packaging materials.

Owner:HEBEI COREFRA SILICON NITRIDE MATERIAL

Apparatus and method for film formation

An apparatus and method for forming a thin film on a substrate by RPCVD which provides for very low levels of carbon and oxygen impurities and includes the steps of introducing a Group VA plasma into a first deposition zone of a growth chamber, introducing a Group IIIA reagent into a second deposition zone of the growth chamber which is separate from the first deposition zone and introducing an amount of an additional reagent selected from the group consisting of ammonia, hydrazine, di-methyl hydrazine and a hydrogen plasma through an additional reagent inlet into the second deposition zone such that the additional reagent and the Group IIIA reagent mix prior to deposition.

Owner:GALLIUM ENTERPRISES

Titanium-aluminium alloy material and preparation technology thereof

The invention provides a titanium-aluminium alloy material and the preparation technology thereof. The titanium-aluminium alloy material is characterized by comprising the following components in percent by weight: 7 to 7.5 percent of Al, 0.1 to 0.25 percent of Cr, 0.5 to 0.8 percent of Mn, 1.2 to 1.4 percent of Nb, 0.15 to 0.3 percent of Mo, 5 to 6 percent of W, 0.75 to 0.9 percent of Bi, 0.05 to 0.08 percent of Dy, 0.05 to 0.15 percent of Gd, 0.3 to 0.45 percent of Er, 3 to 4 percent of Ce, 2 to 2.5 percent of Zr, 3 to 3.5 percent of Sn, and the balance of Ti; the titanium-aluminium alloy material is free from nitrogen-oxygen impurities, has the advantages of good corrosion resistance, high intensity, good low-temperature performance, small heat conduction elasticity and the like, is suitable for manufacturing components of air compressors for airplane motors, and structural parts of rockets, guided missiles and high speed crafts next.

Owner:上海腾辉有色铸造有限公司 +1

Method for growing large-size fluoride crystals through top seed crystal kyropoulos method

InactiveCN103215640AReduce the cost of growthShorten the growth cyclePolycrystalline material growthUsing seed in meltFluoride crystalsCrucible

The invention discloses a method for growing large-size fluoride crystals through a top seed crystal kyropoulos method. The method comprises the following steps: weighing and mixing fluoride crystals and deoxidant powder, and pressing a mixture to form a block; drying the pressed block; putting the block into a crucible, sequentially installing thermal field components and installing seed crystals; vacuumizing, and heating to smelt the material until observing that the block is molten; descending the seed crystals to contact with a melting liquid level so as to slightly melt the seed crystals, pulling seed crystal rods and growing the block on the seed crystals in a condensation manner; after finishing crystal seeding, entering a shouldering period at power reduction, maintaining the crystals rotating and keeping the crystal pulling speed in the period, gradually increasing the diameters of the crystals in an upward pulling process, and entering an isometrical growth period until the crystal growth is finished; and cooling and annealing after the crystal weight reaches the feed weight. The method is low in growth cost and short in growth period; the method is suitable for large-size fluoride crystals, and the fluoride crystals grow in a vacuum condition without oxygen impurities; and the growth process is visible and controllable, so that the crystal quality is improved.

Owner:江苏国晶光电科技有限公司

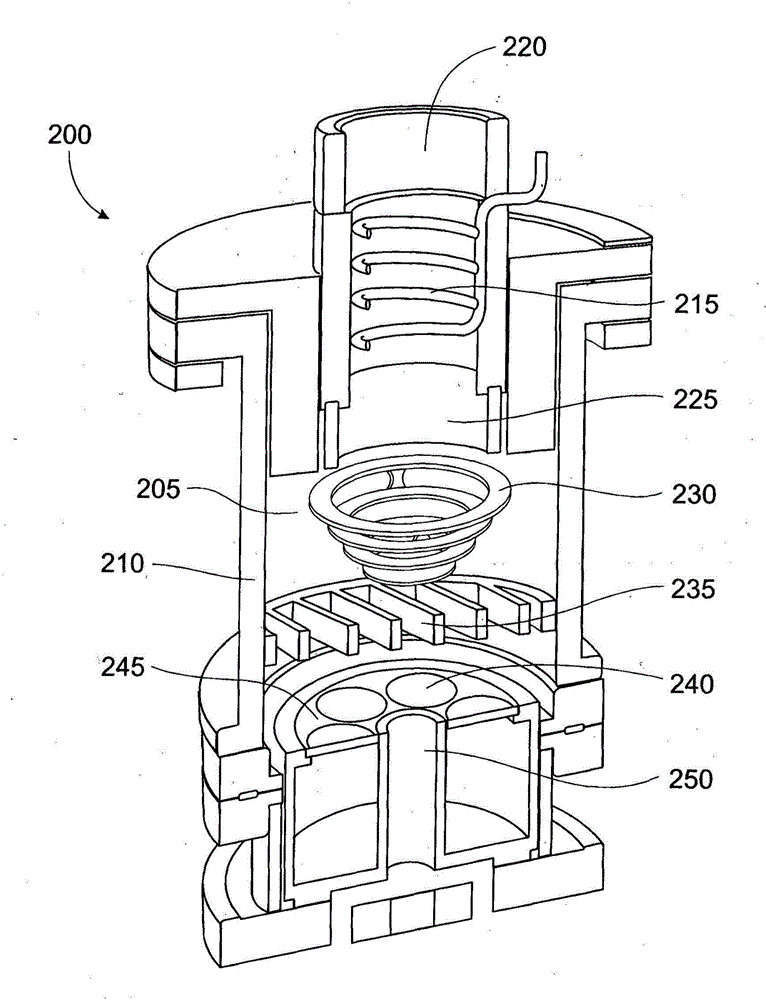

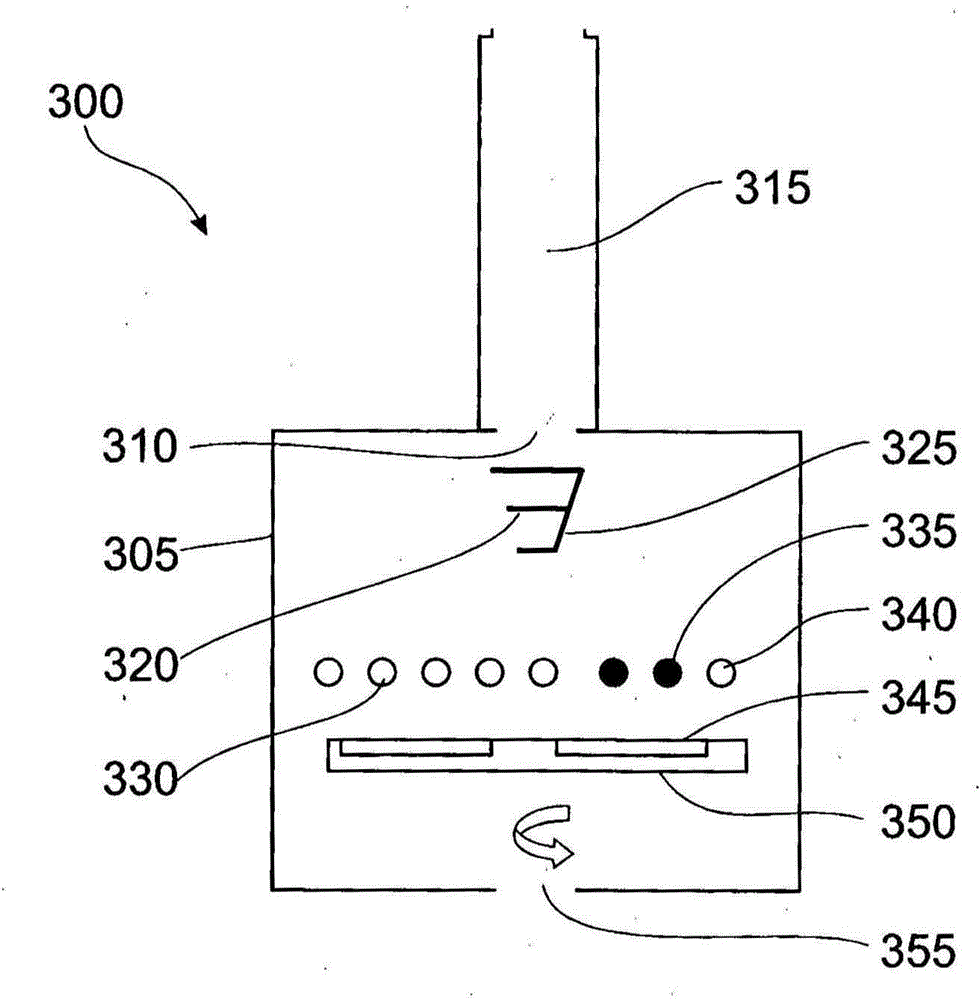

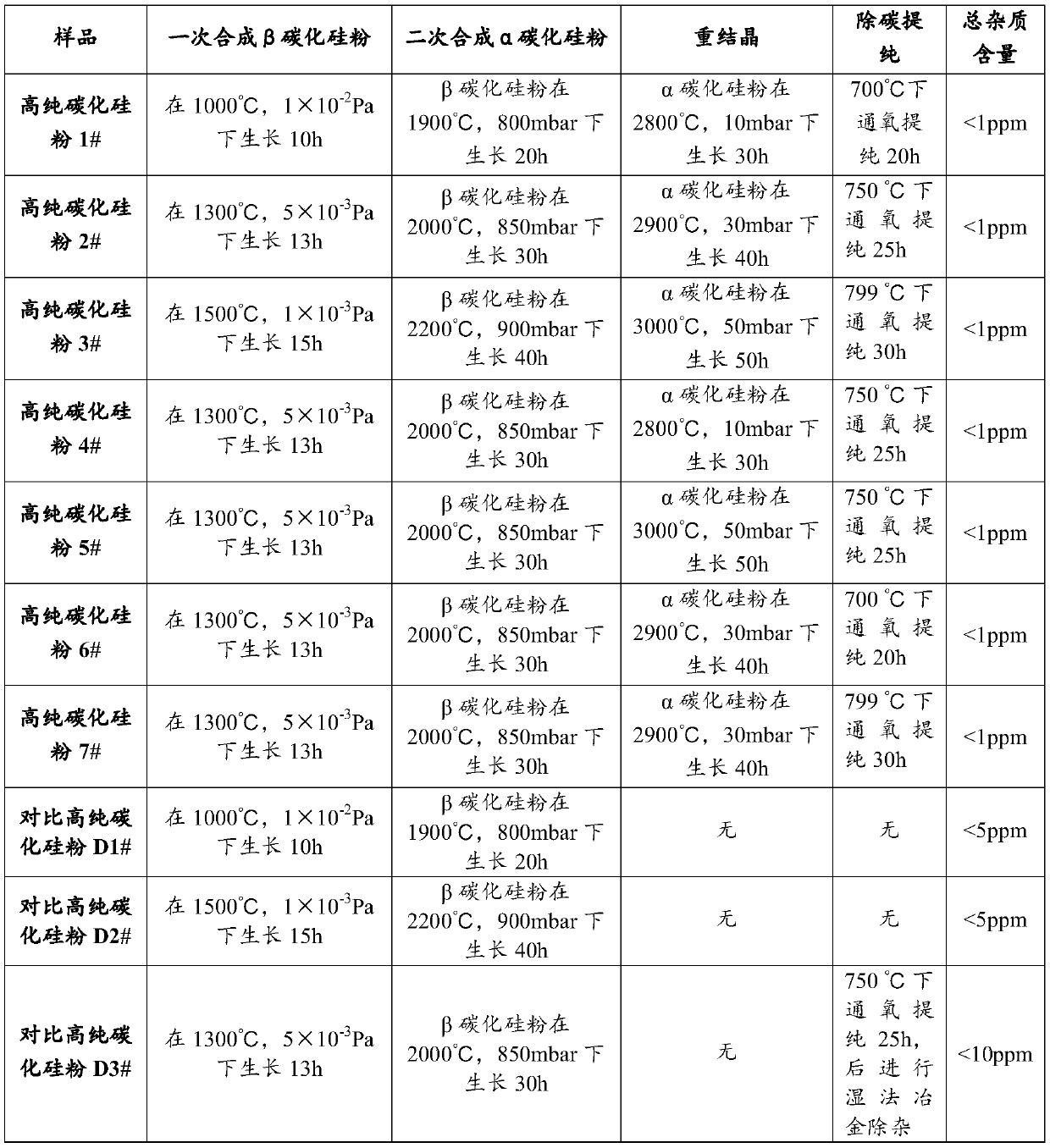

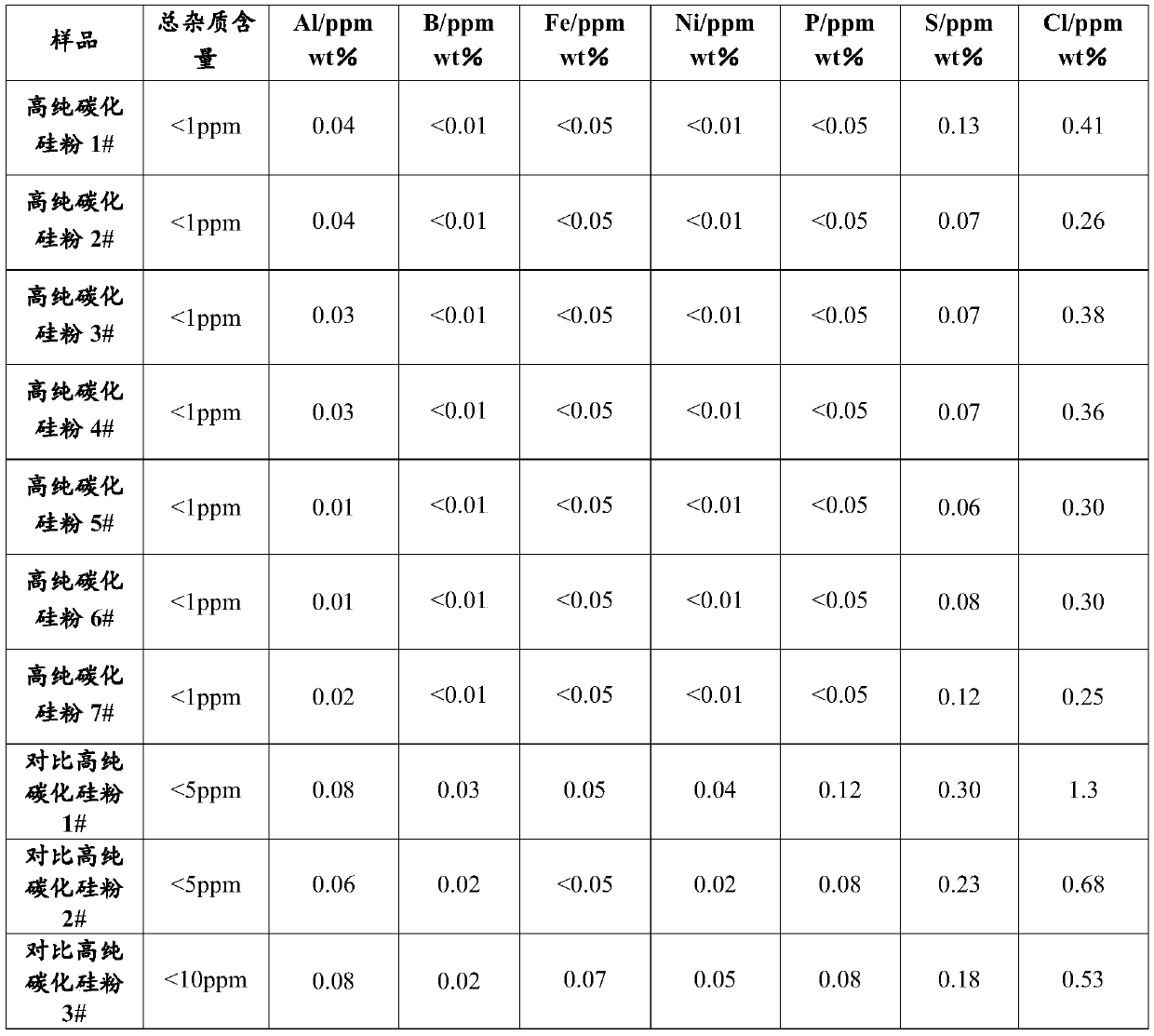

High-purity silicon carbide powder and preparation method therefor

The application discloses high-purity silicon carbide powder and a preparation method therefor and belongs to the field of preparation of semiconductor materials. The preparation method for the high-purity silicon carbide powder comprises the following steps: providing beta silicon carbide powder and / or alpha silicon carbide powder as an initial silicon carbide powder material; recrystallizing theinitial silicon carbide powder material, so as to prepare a silicon carbide polycrystalline block; and subjecting the silicon carbide polycrystalline block to decarburization purification, thereby preparing the high-purity silicon carbide powder, wherein a temperature of recrystallization is not low 2,500 DEG C. According to the high-purity silicon carbide powder and the preparation method therefor, the purity of the prepared high-purity silicon carbide powder is improved by a recrystallization method, impurity removal by a hydrometallurgy or pickling step is not required, and the high-puritysilicon carbide powder is light in pollution, low in toxicity and high in operability; by a decarburization purification step of introducing oxygen gas to pure silicon carbide powder at a temperatureof 600 DEG C to 799 DEG C, the decarburization effect of the carbonized polycrystalline block is good, the prepared high-purity silicon carbide powder is low in degree of oxidation, and the influenceon an oxygen impurity is low when the high-purity silicon carbide powder is applied to growth of silicon carbide monocrystals; and by the preparation method, the high-purity silicon carbide powder with purity not lower than 99.9999% can be prepared, and the particle size of the high-purity silicon carbide powder is controllable.

Owner:SICC CO LTD

Multilayer thin film sealing technology of organic light emitting display

ActiveCN101577317AHigh strengthImprove corrosion resistanceSolid-state devicesSemiconductor/solid-state device manufacturingOrganic filmOptoelectronics

The invention relates to the water-oxygen isolation sealing of an organic light emitting display, in particular to a multilayer thin film sealing technology of the organic light emitting display. The technology is characterized in that two layers of metal oxide films and one layer of high molecular organic film are adopted for sealing the organic light emitting display. The metal oxide film can isolate water and oxygen impurities that are greatly harmful to the organic light emitting display and simultaneously prevent the oxidation of metal layer, thereby improving the corrosion resistance, obviously reducing the degeneration rate of the device, and improving the service life of the organic light emitting display.

Owner:YUNNAN NORTH OLIGHTEK OPTO ELECTRONICS TECH

Red light semiconductor laser structure with aluminum-free waveguide layer

ActiveCN108233179AReduce formationImprove the ability to resist burnoutLaser detailsLaser active region structureLower limitOhmic contact

The invention relates to a red light semiconductor laser structure with an aluminum-free waveguide layer, which sequentially comprises a substrate, a lower limit layer, a lower waveguide layer, a quantum well layer, an upper waveguide layer, an upper limit layer and an ohmic contact layer from the bottom up, wherein the lower waveguide layer, the quantum well layer and the upper waveguide layer are made of a gallium indium phosphide material. The waveguide layer adopts the aluminum-free gallium indium phosphide material, so that there is no aluminum in an active region, and requirements for the growth environment, especially for the concentration of oxygen impurities, are no longer so harsh. Meanwhile, the oxidation resistance is increased because there is no aluminum in the active regionwhen cavity surface cleavage is performed, so that cavity surface defects are effectively reduced. The design not only reduces oxygen impurity defects inside the material, but also reduces the formation of cavity surface defects, thereby being capable of reducing the light absorption, and improving the anti-burning ability of the cavity surface and the life of a semiconductor laser.

Owner:Shandong Huaguang Optoelectronics Co. Ltd.

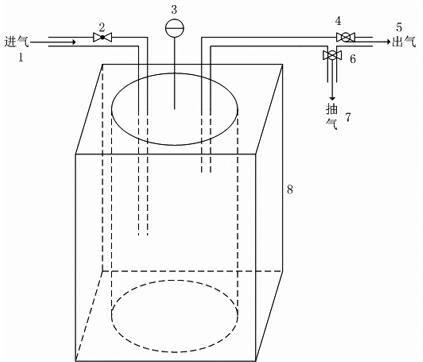

Method and device for highly purifying gas

ActiveCN103301741AAchieve purificationEasy to implementDispersed particle filtrationResonanceContrast medium

The invention discloses a method and a device for highly purifying gas. The method comprises the steps that: alkali metal in a closed container is heated to produce alkali metal atom steam, then gas required to be purified is fed into the container, and alkali metal surface, the alkali metal atom steam and water, oxygen and oxygen impurities contained in the gas required to be purified are subjected to reaction and purification; the gas required to be purified flows out of the container after reaction and purification. The device has excellent property of highly gas purifying, particularly has pertinency, and eliminates the hidden danger that alkali metal in a laser pre-polarization system of a magnetic resonance contrast medium is oxidized. The method can be applied to the manufacture of similar operating systems or devices containing alkali metal, such as highly purifying working gas of atomic steam bubbles in an atomic frequency standard, an atomic filter, an atomic magnetometer and other systems.

Owner:武汉中科极化医疗科技有限公司

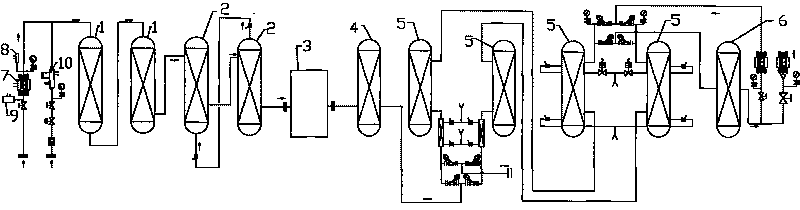

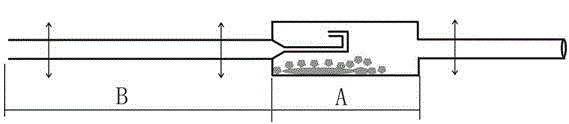

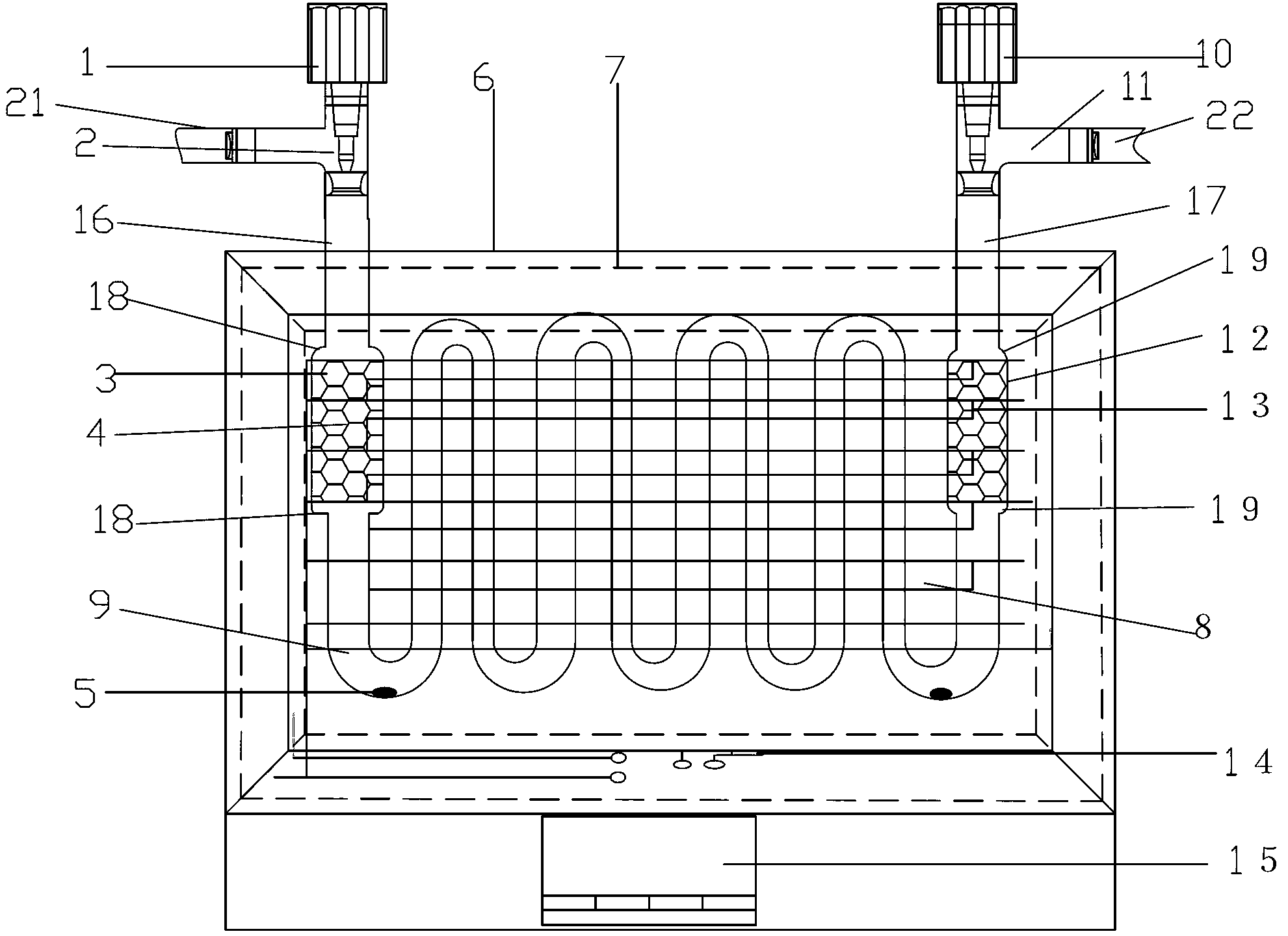

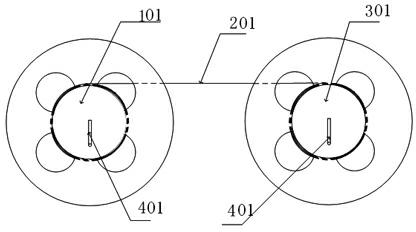

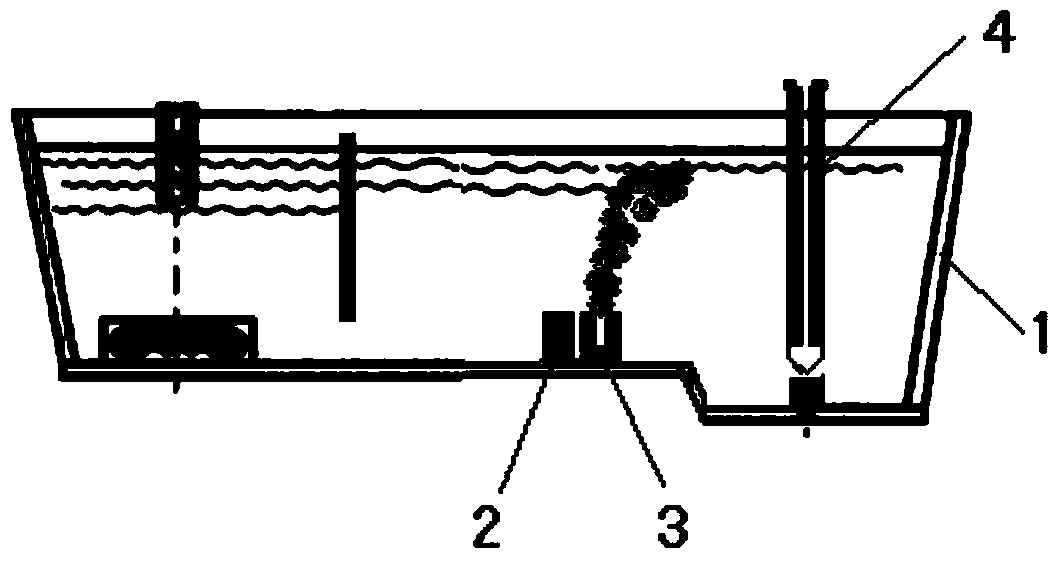

Method for removing oxygen impurities in polysilicon through electron beam continuous melting, and apparatus thereof

InactiveCN104649274ASolve removal puzzlesGuaranteed semi-continuous productionSilicon compoundsIngotSolar battery

The invention belongs to the field of polysilicon purification, and concretely relates to a method for removing oxygen impurities in polysilicon through electron beam continuous melting, and an apparatus thereof. A traditional oxygen removal mode is broken, and electron beam melting is adopted to remove oxygen in order to solve the removal problem of impurity oxygen in the polysilicon. An overturning mechanism and a loading crucible are arranged to guarantee the semi-continuous production of electron beam melting oxygen removal and high output per furnace. The method and the apparatus have the following advantages: 1, electron beam bombardment melting is carried out for 5-15min to make the oxygen content lower than 0.0571ppmw and solar battery's requirements on the oxygen content of polysilicon cast ingots met; 2, the photoelectric conversion efficiency of battery slices is above 0.1% higher than that of polysilicon obtained without an oxygen removal technology; and 3, continuous production is realized, and the production efficiency increases by above 35%.

Owner:青岛隆盛晶硅科技有限公司

Preparation method of high-purity and low-loss chalcogenide glass

InactiveCN103332851BImprove uniformityHigh purityGlass furnace apparatusChalcogenide glassPhotochemistry

The invention provides a preparation method of high-purity and low-loss chalcogenide glass, belonging to a preparation method of the chalcogenide glass. The preparation method comprises the following steps of: removing hydrocarbon impurity in the glass by taking ultra-dry gallium chloride as a purifying agent, and distilling and purifying the glass in combination with the conventional deoxidant, aluminum, magnesium or zirconium metal; placing glass mixture into a quartz ampoule to be sealed in by means of vacuum supply, founding the glass mixture in a vacuum ampoule, dynamically distilling the glass, and remelting the mixture after distilling; and effectively removing the hydrocarbon impurity in the glass by taking the ultra-dry gallium chloride as the purifying agent, so that the Mie scattering imperfection is hardly formed in the finally-obtained high-purity chalcogenide glass, and the low-loss homogeneous glass can be obtained. According to the high-purity chalcogenide glass synthesized by the preparation method provided by the invention, the minimum loss under the infrared transmission waveband is less than 0.3dB / m, and the corresponding loss of the absorption peak of the residual impurity is less than 8dB / m, so that the preparation method can be used in the field of an infrared glass optical element and an infrared optical fiber. The ultra-dry gallium chloride purifying agent can be easily obtained, and is lower in price; the carbon, hydrogen and oxygen impurities can be removed from the chalcogenide glass at high efficiency; the prepared chalcogenide glass is better in uniformity and less in light scattering.

Owner:XUZHOU NORMAL UNIVERSITY

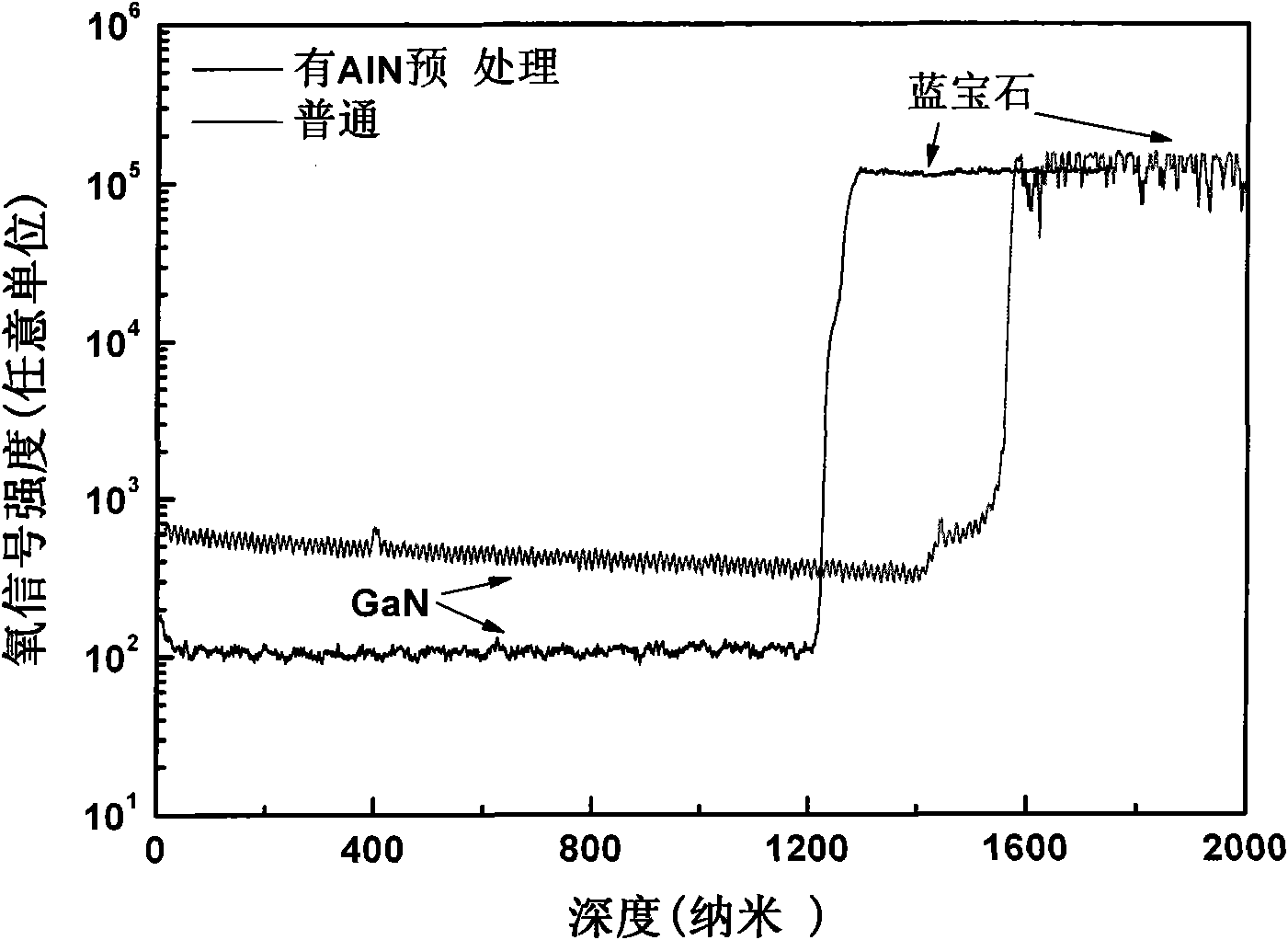

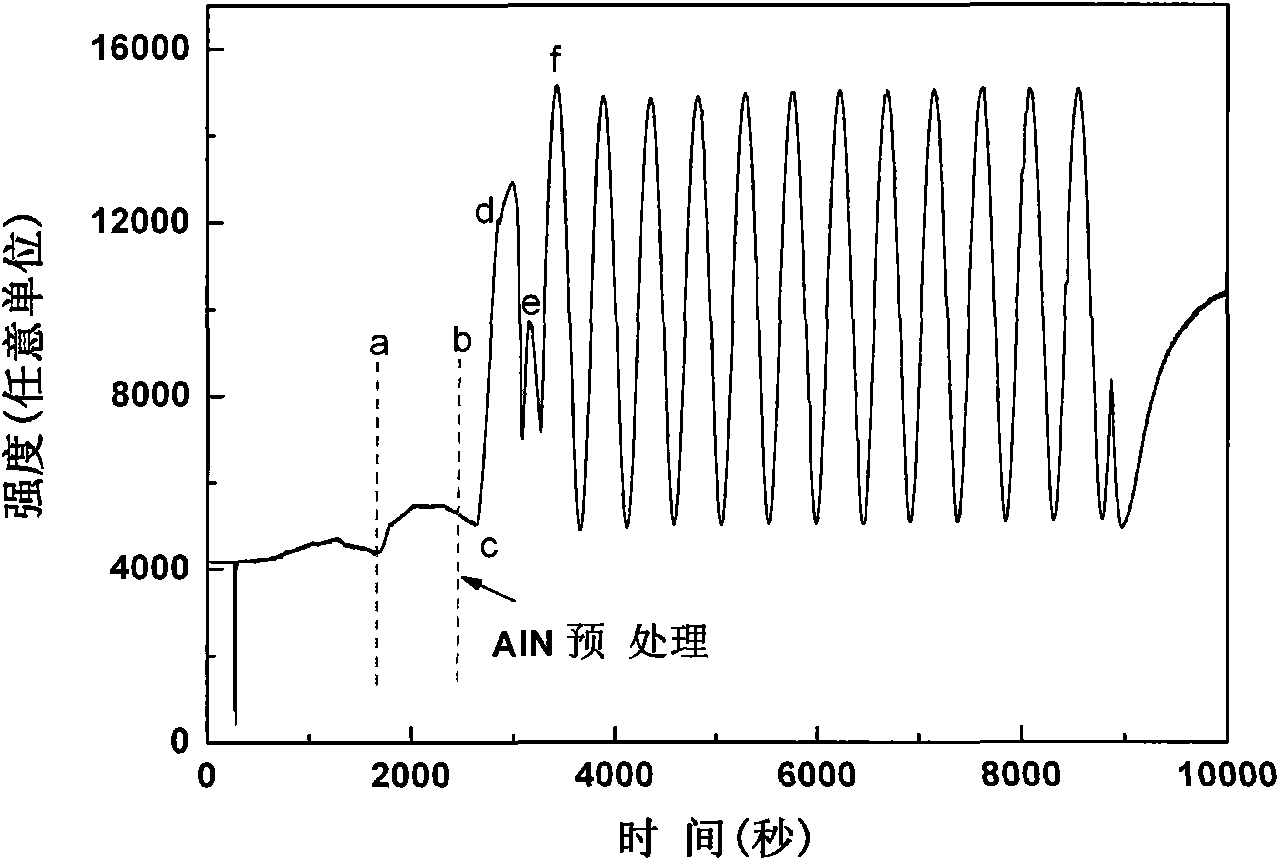

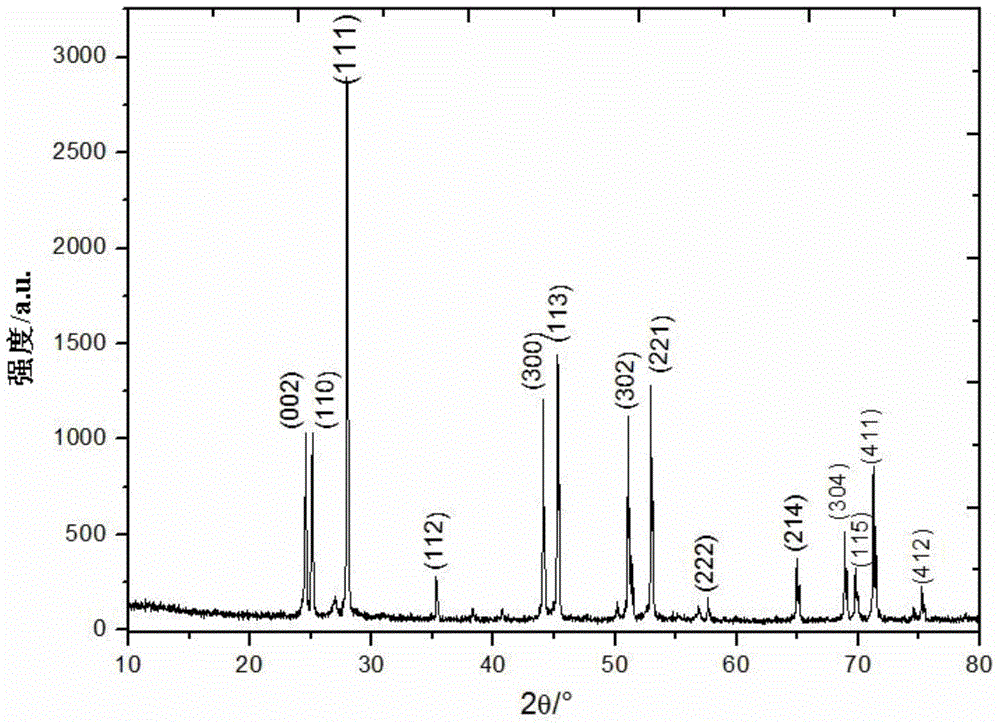

Growing method of high-crystal quality high-resistance GaN epitaxial layer

InactiveCN101871098AReduce concentrationLow oxygen impurity contentFrom chemically reactive gasesChemical vapor deposition coatingHigh resistanceFull width at half maximum

The invention relates to a method for growing a high-crystal quality high-resistance GaN epitaxial layer, which reduces the concentration of oxygen impurities in GaN and reduces background electron concentration which needs to be compensated via pre-depositing low-temperature AlN on a sapphire substrate and carrying out annealing treatment (AlN pretreatment for short), so the high-resistance GaN epitaxial layer can be obtained only by introducing less edge dislocation into the GaN epitaxial layer for compensation. The resistivity of the high-resistance GaN epitaxial layer prepared by the method is greatly larger than 107 ohm. cm at room temperature, the surface roughness (RMS) of 3 mu m x 3 mu m area reaches 0.2-0.3 nm, and the surface is smooth; the full width at half maximum of X-ray diffraction ohm scanning (102) swing curve can be controlled to about 600 arc sec, and the dislocation density is 40-50% lower than that in conventional edge dislocation compensation high-resistance GaN; and the high-resistance GaN growth technology has excellent repeatability, and meets industrial application requirements. The method is simple, and does not cause any pollution on the MOCVD system.

Owner:江苏华功半导体有限公司

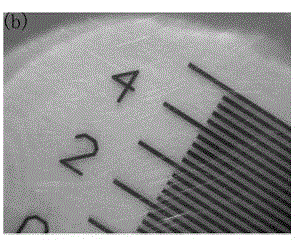

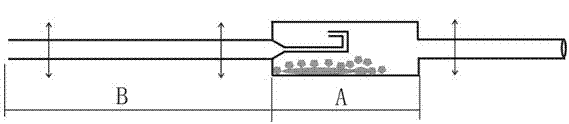

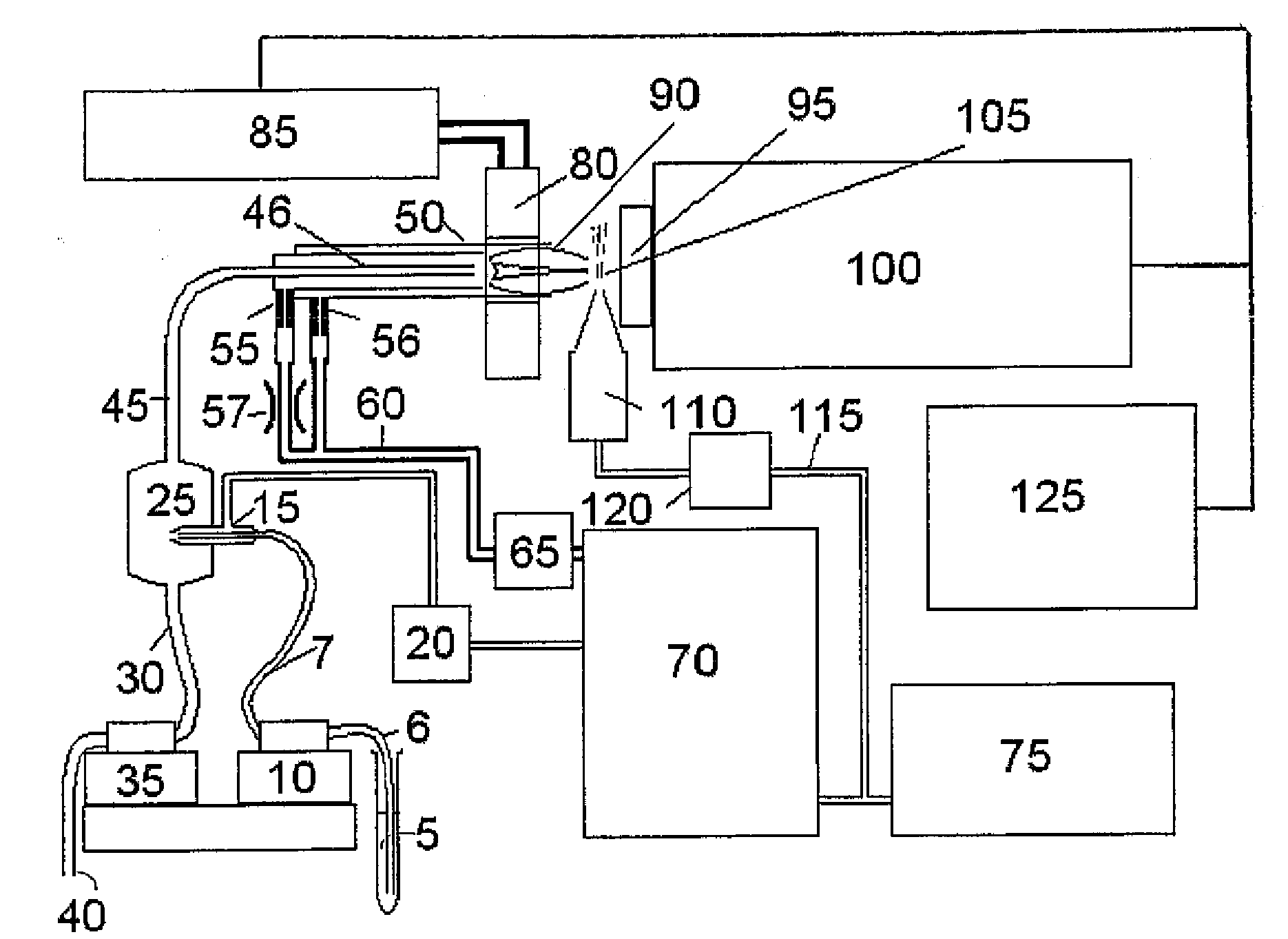

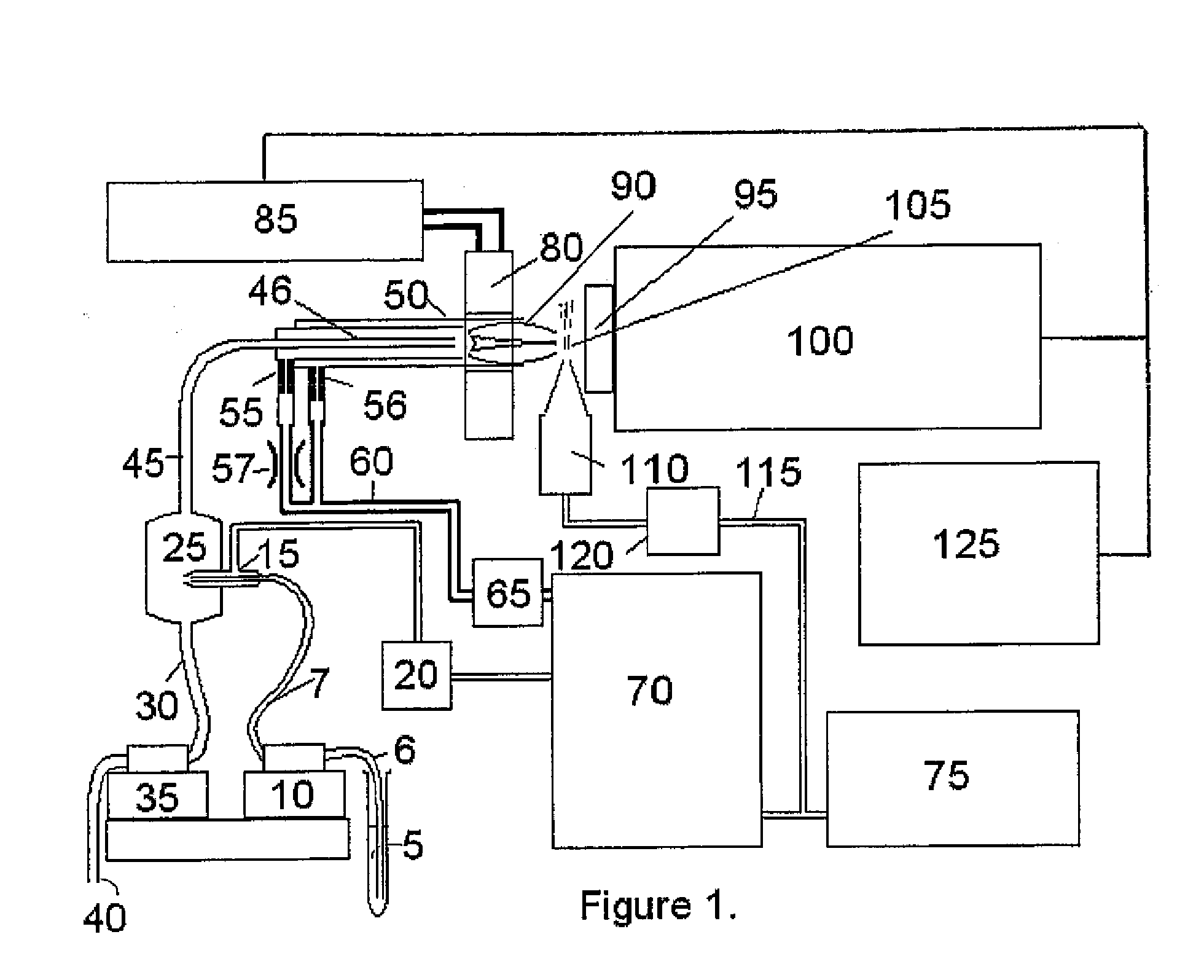

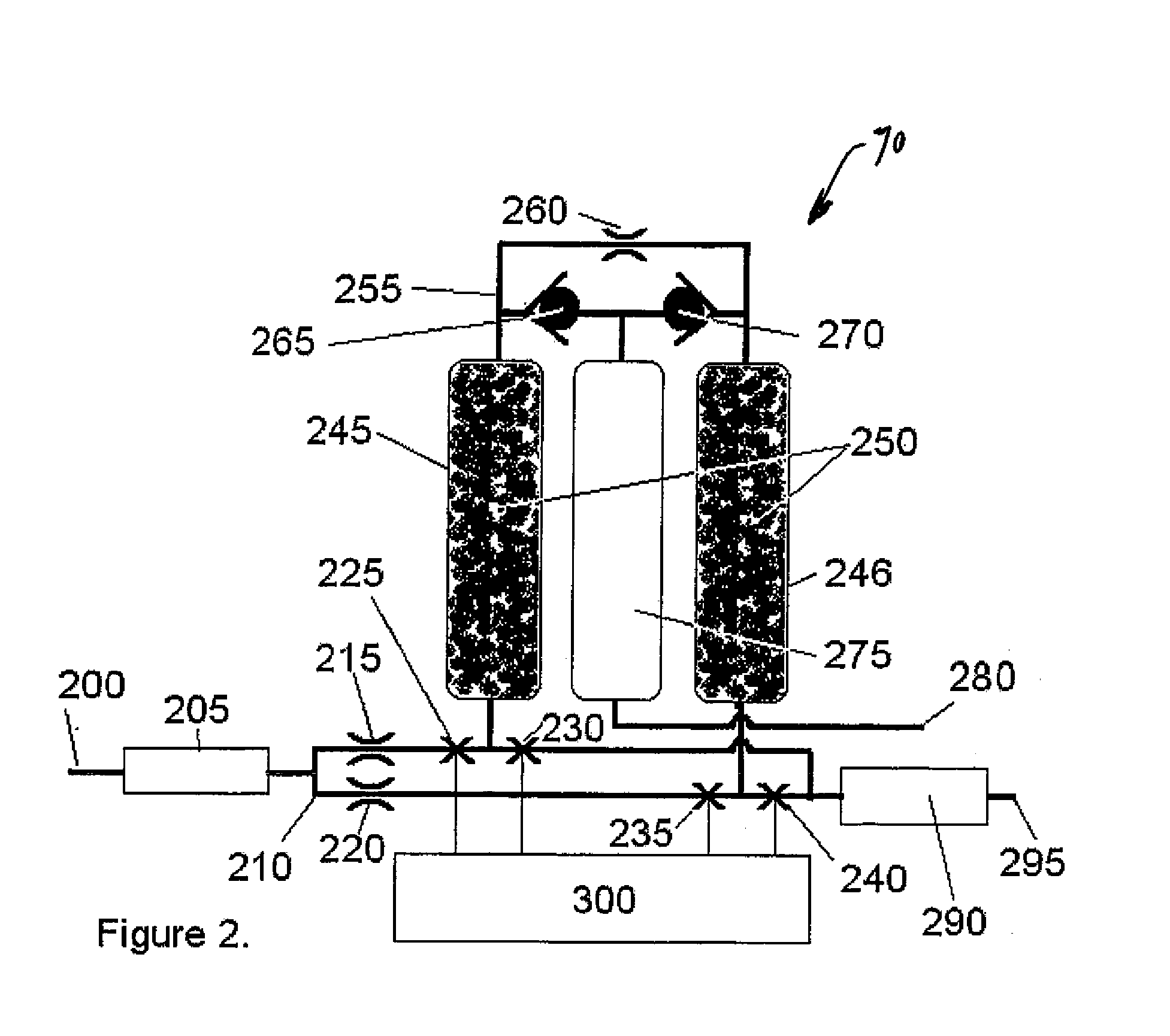

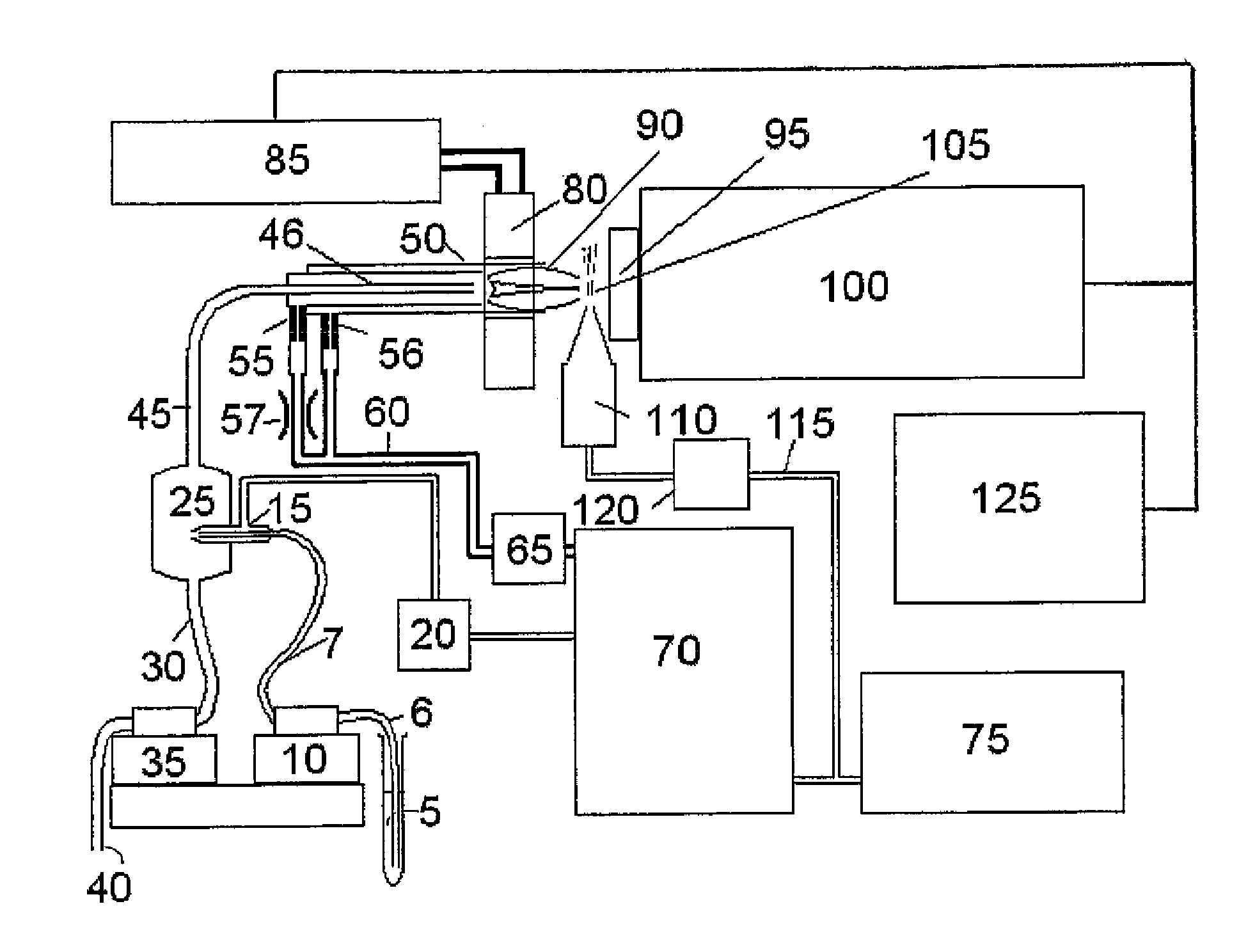

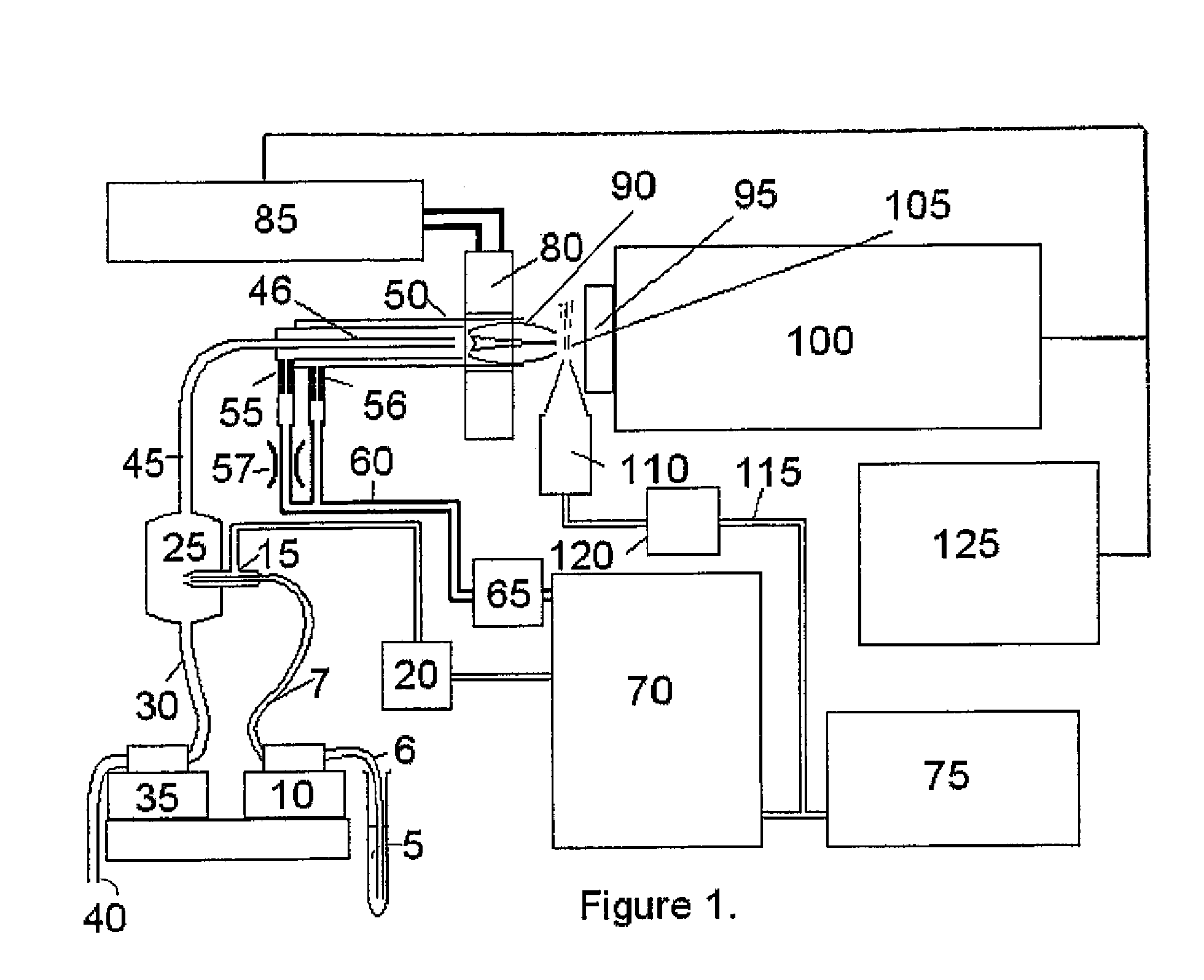

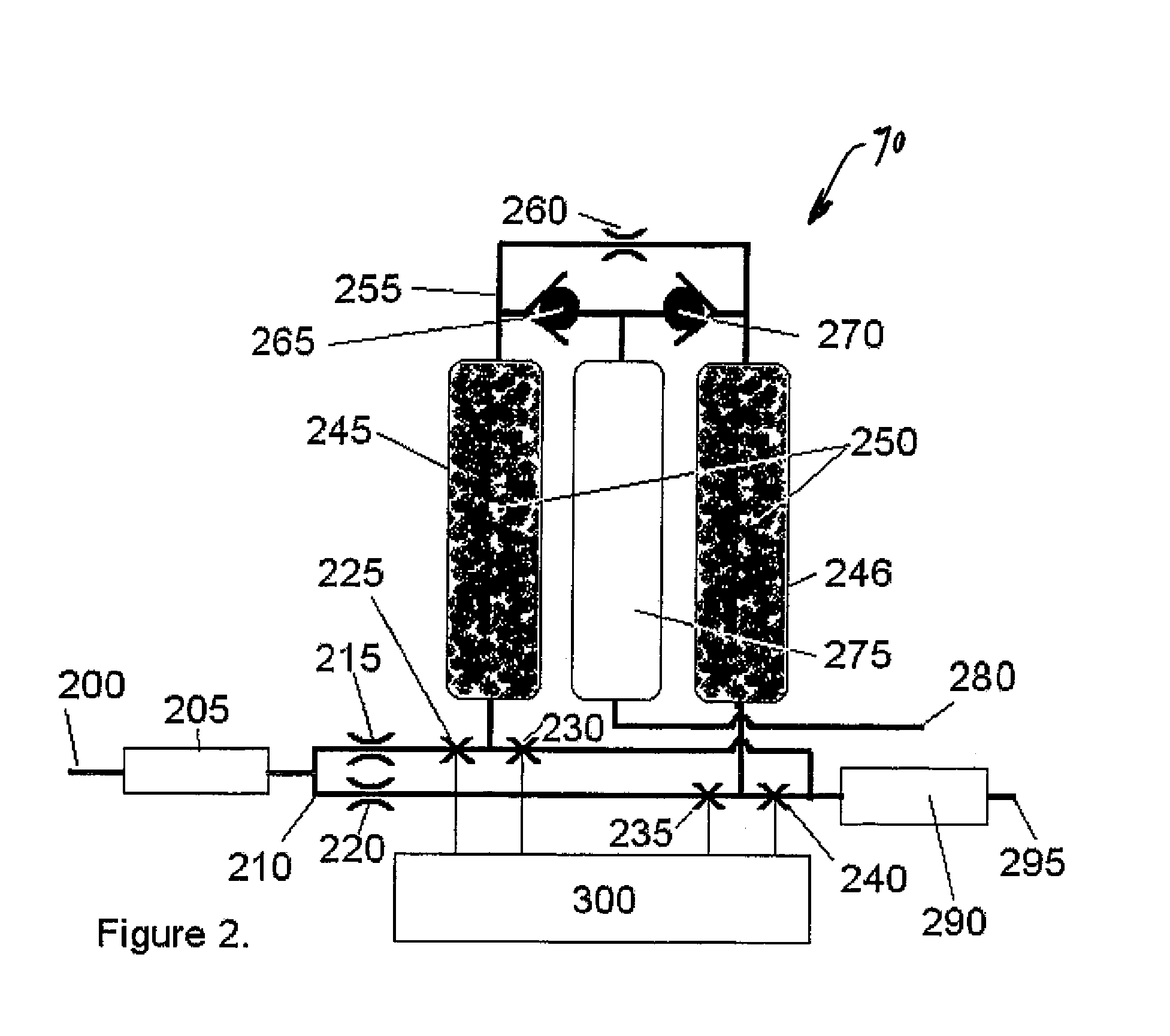

Plasma spectroscopy system with a gas supply

ActiveUS20090059221A1Improve performanceSatisfactory operationRadiation pyrometryParticle separator tubesNitrogen generatorForming gas

A spectroscopy system for spectro-chemical analysis of a sample includes a plasma torch (50) for generating a microwave induced plasma (90) as a spectroscopic source. The plasma forming gas is nitrogen which can contain an oxygen impurity. Thus the system includes a nitrogen generator (70) which is preferably supplied with compressed atmospheric air from a compressor (75) for oxygen to be removed from the air by adsorption. The invention allows the use of an on-site nitrogen gas generator and thus gives cost savings because the need to obtain supplies of bottled high purity gas is eliminated.

Owner:AGILENT TECH AUSTRALIA M

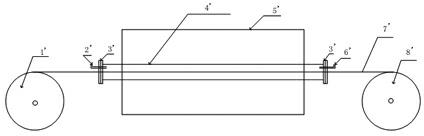

Method for annealing simplified, efficient, low-cost and high-temperature superconductive long band

ActiveCN102682919AIncrease productivityShorten the annealing timeCable/conductor manufactureTemperature controlWinding machine

The invention provides a method for annealing a simplified, efficient, low-cost and high-temperature superconductive long band. The method comprises the following steps of: placing the superconductive long band to be annealed into a manual band winding machine, manually winding the band on an annealing plate, placing the annealing plate into a vacuum box type annealing oven, and annealing under an oxygen atmosphere according to annealing processes. The method has characteristics of low cost, short annealing time, high production efficiency, high temperature controlling precision, and capability of uniformly annealing each part of the superconductive long band. Furthermore, compared with the traditional non-vacuum annealing oven, the purity of the oxygen atmosphere in the annealing oven isgreatly increased through a vacuumizing method, so that adverse effects of N2, NO, NO2, CO, CO2 and other non-oxygen impurity gas in the residual air in an annealing furnace on the performance of thesuperconductive long band under the high temperature in the annealing process are avoided. By the method, the rare earth oxide second generation high-temperature superconductive band subjected to annealing treatment under the oxygen atmosphere has excellent superconductive performance.

Owner:SHANGHAI SUPERCONDUCTOR TECH CO LTD

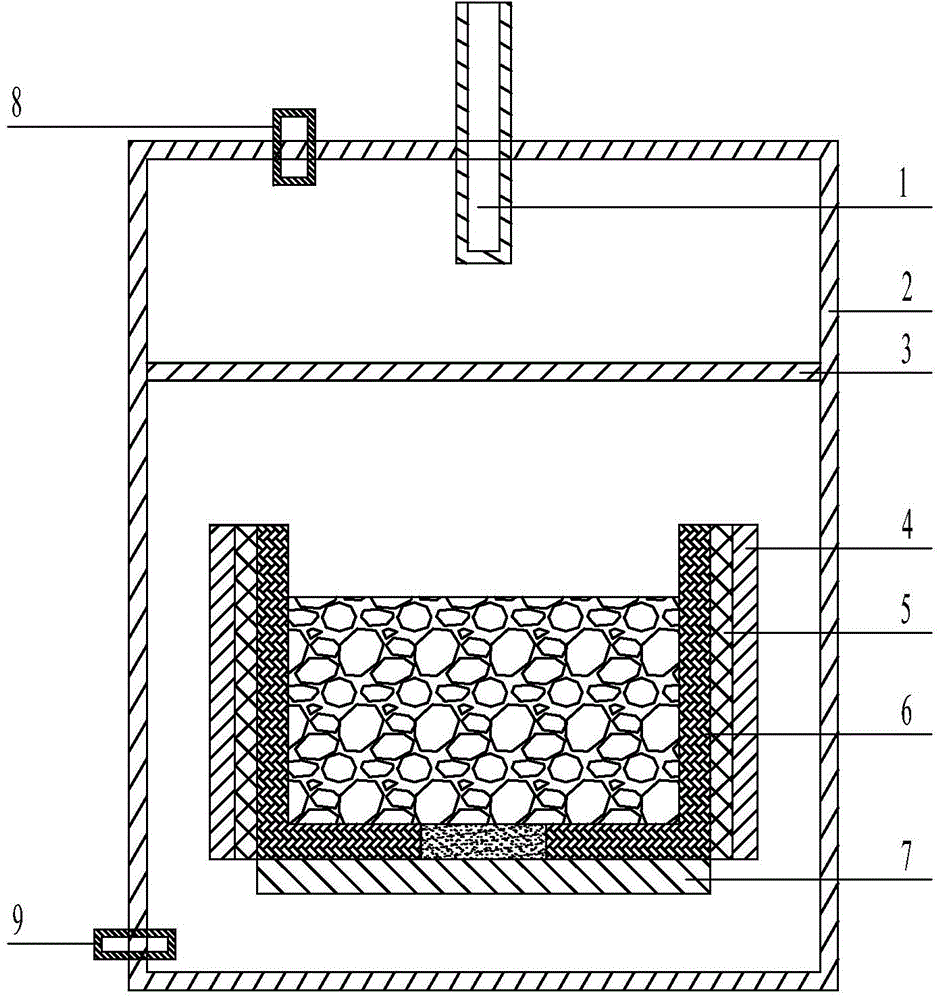

Apparatus for preparing polysilicon through electron beam deoxygenation and preliminary ingot casting coupling, and method thereof

InactiveCN104651930ALow costEfficient removalPolycrystalline material growthSilicon compoundsHigh pressureDeoxygenation

The invention belongs to the field of polysilicon ingot casting, and especially relates to an apparatus for preparing polysilicon through electron beam melting deoxygenation and crystal growing technology coupling, and a method thereof. The apparatus is characterized in that the top of a furnace body is connected and provided with an electron gun, the upper end of the side portion of the furnace body is provided with a gas charging valve, the lower end of the furnace body is provided with a gas discharging valve, a quartz crucible is arranged in the furnace body, the outer wall of the quartz crucible is sequentially encircled with a graphite hater and a graphite carbon felt from inside to outside, the top of the graphite carbon felt is provided with a heat insulation cover, the central position of the bottom of the quartz crucible is provided with a hole, and the bottom of the quartz crucible is provided with a water cooled copper pedestal. The method comprises the following steps: charging, and carrying out vacuum pumping; heating to completely fuse a silicon material; carrying out high pressure and beam preheating, and stopping high pressure and beam; maintaining the silicon material in a liquid state; carrying out electron beam melting deoxygenation; carrying out preliminary ingot casting crystal growth; adjusting a graphite heater to make the growth speed of silicon crystals to 1.2-1.3cm / h; and cooling, and taking the obtained polysilicon. The method realizes two technologies on the same apparatus, electron beam melting is used to remove oxygen impurities in silicon, the total energy consumption reduces by 30%, and the production efficiency increases by 40%.

Owner:青岛隆盛晶硅科技有限公司

Modified molecular sieve for olefin purification and method for removing oxygen impurities from olefins by modified molecular sieve

ActiveCN108126664AWide range of adsorptionEnhanced interactionOther chemical processesCombustible gas purificationMolecular sieveAlcohol

The invention provides a modified molecular sieve for olefin purification and a method for removing oxygen impurities from olefins by the modified molecular sieve. The modified molecular sieve is modified with an organometallic compound. The method comprises the following steps: olefin flow containing water, ether, aldehyde, ketone, alcohol and other oxygen impurities passes through an organometallic compound modified molecular sieve bed layer, and high-purity olefin flow is obtained. The molecular sieve bed layer can be regenerated by purging with inert gas at a high temperature after the molecular sieve bed layer is saturated. Olefins, especially isobutene, purified with the method meets the standard of high purity and can be applied to polymerization-stage reaction and organic synthesisreaction.

Owner:WANHUA CHEM GRP CO LTD

Silicon material cleaning method

ActiveCN109037028AHigh purityImprove cleanlinessSemiconductor/solid-state device manufacturingSocial benefitsAcid washing

The invention discloses a silicon material cleaning method, belongs to the technical field of semiconductor silicon materials, and solves the problems that cleanness of a traditional silicon materialcleaning method is not high, the purity of a cleaned silicon material is not high, and the performance of a product using a silicon material as a raw material is seriously affected. The method mainlyincludes grinding, acid washing, alkali washing, cleaning, wet oxygen impurity removal, washing and drying and other operational processes. The invention has high cleanliness and high purity of the cleaned silicon material, and the high-purity silicon material greatly improves the performance of the product using the silicon material as a raw material. The silicon obtaining rate is high, the silicon material running away in the cleaning process can be recycled, the effects of low carbon, energy saving and environment protection are achieved, considerable economic and social benefits can be created for enterprises, and thus the silicon material cleaning method is of great significance in the technical field of semiconductor silicon material.

Owner:江苏京尚圆电气集团有限公司

High-thermal-conductivity silicon nitride ceramic and preparation method thereof

The invention relates to the technical field of ceramic material preparation, provides high-thermal-conductivity silicon nitride ceramic and a preparation method thereof, and solves the problem of lowthermal conductivity of silicon nitride ceramic in the prior art. The silicon nitride ceramic comprises the following components in parts by weight: 60-90 parts of silicon nitride, 8-12 parts of silicon carbide, 3-5 parts of rare earth chloride, 0.2-1 part of ytterbium fluoride, 0.5-2 parts of zirconium nitride and 5-10 parts of dispersing agent. According to the preparation method, the rare earth chloride is added, so that the sintering activity of the silicon nitride powder is improved under the condition of not additionally introducing oxygen, and densification of the silicon nitride ceramic is realized; the ytterbium fluoride can promote diffusion of Si and N and react with oxygen impurities in silicon nitride crystal lattices, so that the content of dissolved oxygen in the silicon nitride crystal lattices is effectively reduced, and the heat conductivity of silicon nitride is improved; zirconium ions in the zirconium nitride have strong affinity to oxygen and can absorb part of oxygen impurities in crystal lattices. Rare earth chloride, ytterbium fluoride and zirconium nitride are matched with one another, the size of silicon nitride grains can be increased, and oxygen impurities can be discharged.

Owner:FUJIAN HUAQING ELECTRONICS MATERIAL TECH

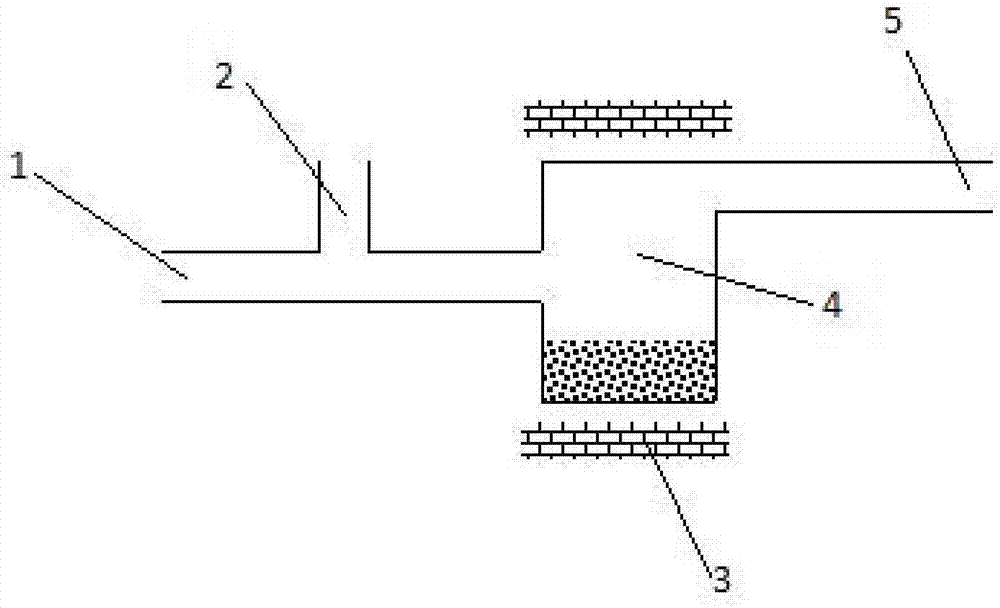

Infrared glass preparation method and water removing device thereof

The invention belongs to the field of infrared optical glass preparation, specifically relates to an infrared glass preparation method and a water removing device thereof and aims at solving the defect that impurities of hydrogen and oxygen in the infrared glass cannot be removed effectively in the prior art. The water removing device comprises an inert gas inlet pipe, a chlorine inlet pipe, a heating furnace, a raw material pipe and a gas outlet pipe, wherein the inert gas inlet pipe, the chlorine inlet pipe and the gas outlet pipe are each communicated with the raw material pipe, and the heating furnace is arranged outside the raw material pipe. Chlorine is utilized to remove water of infrared glass, the chlorine can effectively remove absorption peaks generated at 2.9 and 4.3 micrometer positions by O-H and H-S bonds, and practical foundation of the infrared glass is established. The technological principle is that a strong oxidant, namely of the chlorine, is mainly utilized to snatch the hydrogen impurity in the glass, hydrogen chloride gas is generated to be exhausted out glass melting liquid, and the hydrogen impurity is eliminated.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

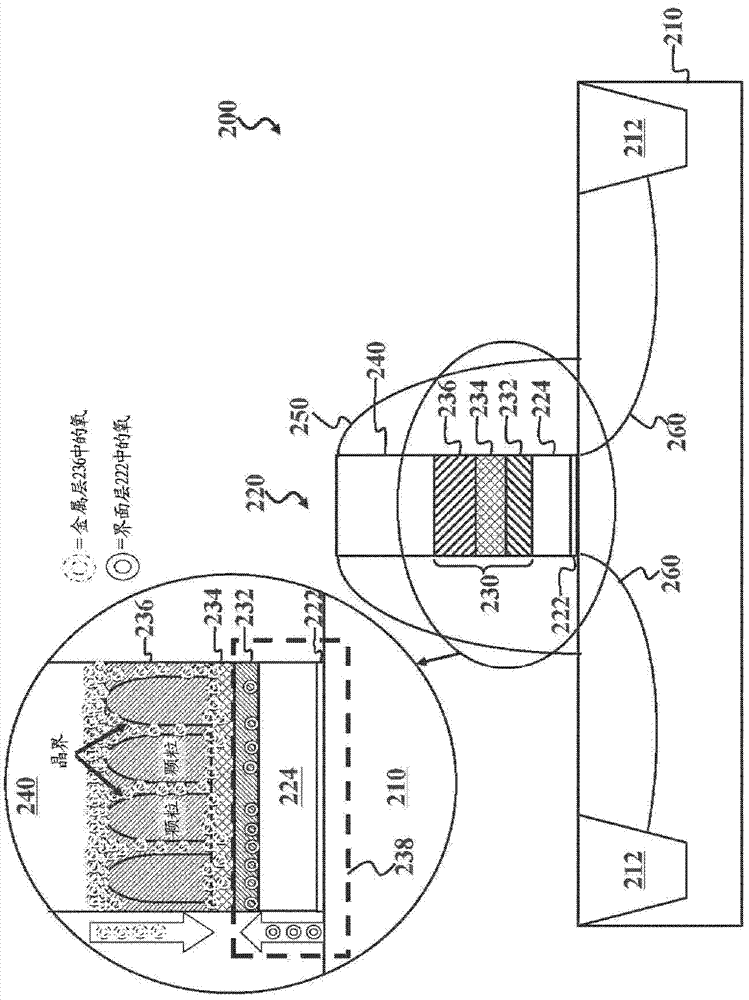

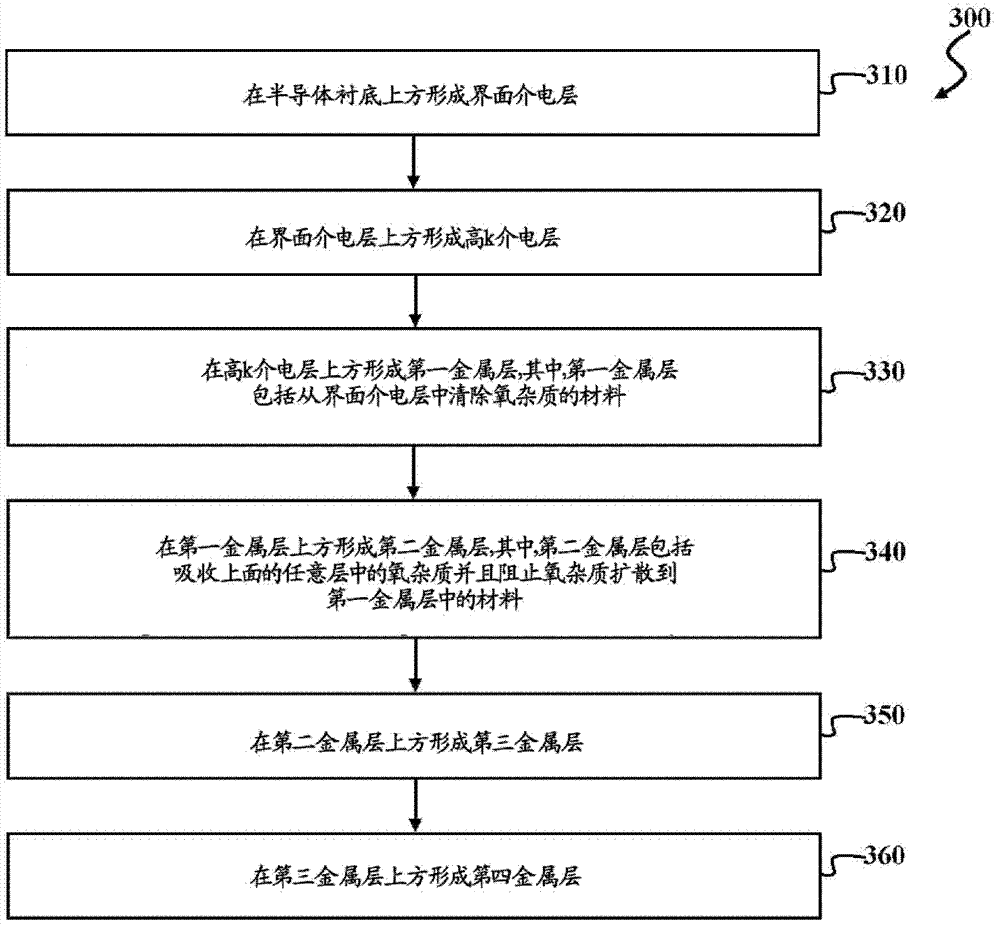

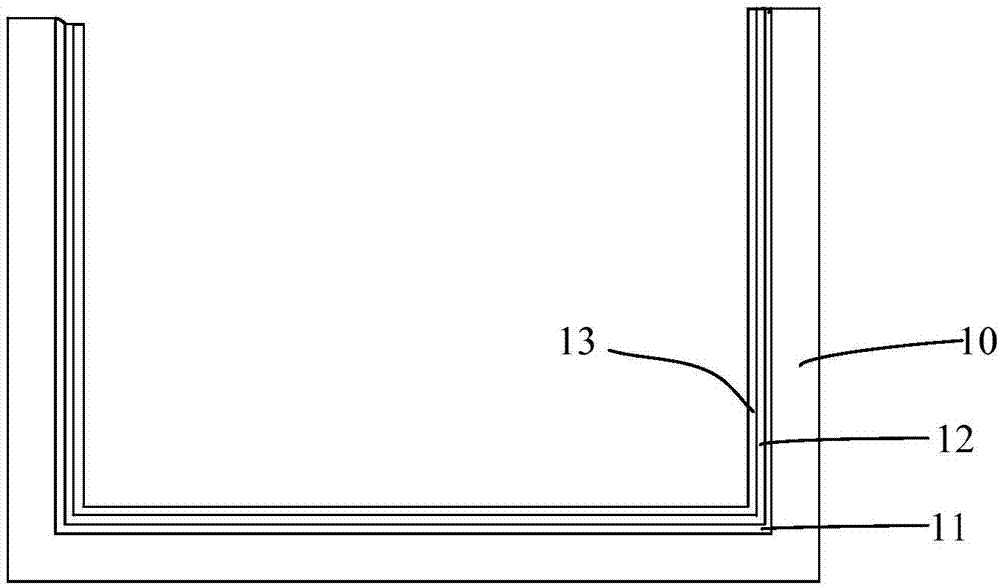

Multi-layer scavenging metal gate stack for ultra-thin interfacial dielctric layer

ActiveCN103022102AStop the spreadTransistorSemiconductor/solid-state device manufacturingGate stackDielectric layer

A multi-layer scavenging metal gate stack, and methods of manufacturing the same, are disclosed. In an example, a gate stack disposed over a semiconductor substrate includes an interfacial dielectric layer disposed over the semiconductor substrate, a high-k dielectric layer disposed over the interfacial dielectric layer, a first conductive layer disposed over the high-k dielectric layer, and a second conductive layer disposed over the first conductive layer. The first conductive layer includes a first metal layer disposed over the high-k dielectric layer, a second metal layer disposed over the first metal layer, and a third metal layer disposed over the second metal layer. The first metal layer includes a material that scavenges oxygen impurities from the interfacial dielectric layer, and the second metal layer includes a material that adsorbs oxygen impurities from the third metal layer and prevents oxygen impurities from diffusing into the first metal layer. The invention provides a multi-layer scavenging metal gate stack for an ultra-thin interfacial dielctric layer.

Owner:TAIWAN SEMICON MFG CO LTD

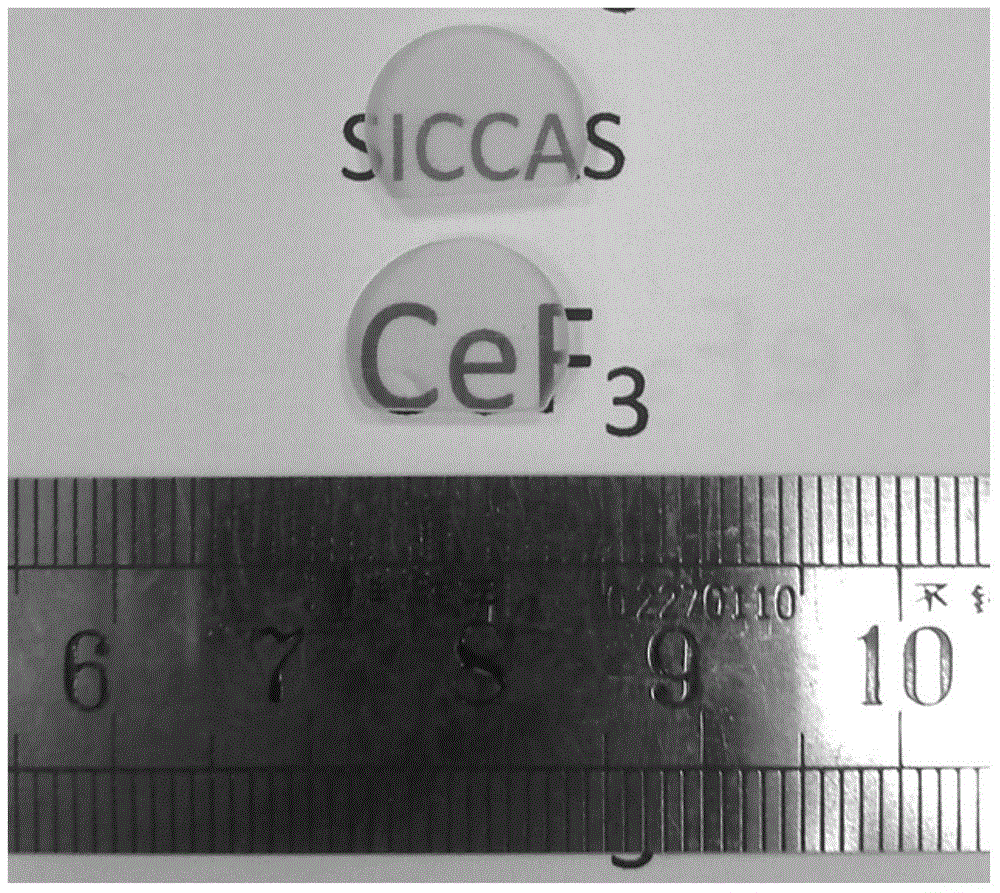

Method for growing cerium fluoride crystal by non-vacuum descent process

InactiveCN104975345AEfficient removalAchieve growthPolycrystalline material growthFrom frozen solutionsBridgman methodMass ratio

The invention discloses a method for growing a cerium fluoride crystal by a non-vacuum descent process. The method comprises the following steps: a) uniformly mixing cerium fluoride powder and polytetrafluoroethylene powder at a mass ratio of 100:(1-5); b) performing vacuum drying of the mixed powder obtained in the step a); and c) putting the dried mixed powder obtained in the step b) into a crucible, and performing crystal growth at a descent rate of 0.5-1.5mm / h in a non-vacuum condition. According to the method disclosed by the invention, the oxygen impurity can be effectively cleared by adding certain amount of polytetrafluoroethylene powder, thus the growth of CeF3 crystal using the Bridgman method in a non-vacuum condition is realized, the growth technology of CeF3 crystal is greatly simplified, and large-scale production of CeF3 crystal is facilitated; and compared with the prior art, the method has remarkable progress and practical value.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Plasma spectroscopy system with a gas supply

ActiveUS7554660B2Improve performanceSatisfactory operationRadiation pyrometryParticle separator tubesNitrogen generatorForming gas

Owner:AGILENT TECH AUSTRALIA M

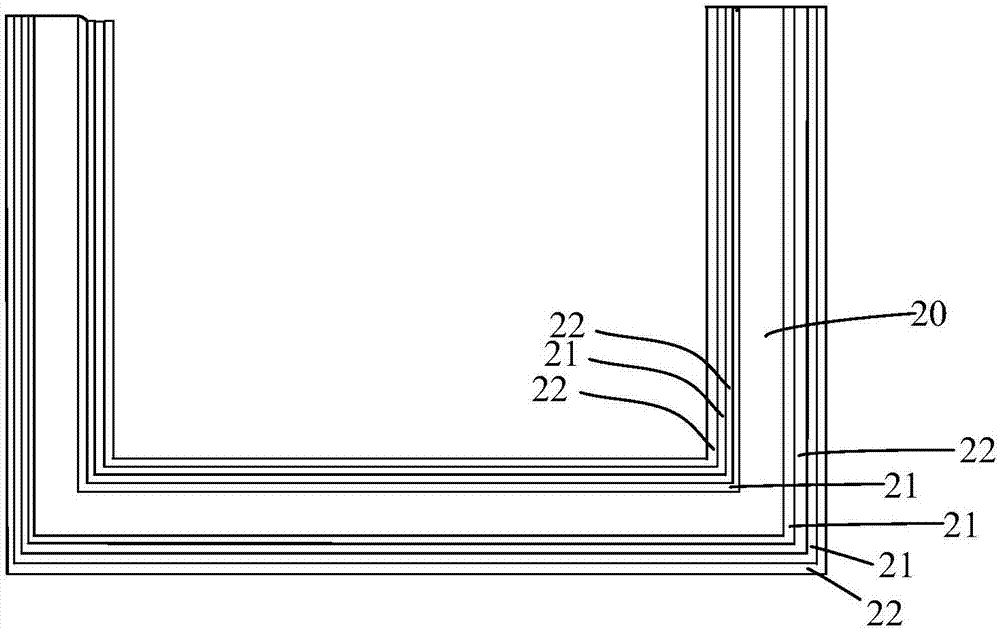

Crucible for polycrystalline silicon ingot, production method of crucible as well as polycrystalline silicon ingot and production method thereof

InactiveCN107460544AProlong clotting timeImprove firmnessPolycrystalline material growthCeramic shaping apparatusCrucibleIngot casting

The invention provides a crucible for a polycrystalline silicon ingot with a coating structure. The crucible comprises a crucible body and the coating structure arranged on the inner surface or the inner and outer surfaces of the crucible body, wherein the crucible body comprises a base and side walls which upward extend from the base; an accommodation space is defined by the base and the side walls; the coating structure comprises impurity absorbing layers and silicon nitride layers; the impurity absorbing layers and the silicon nitride layers are sequentially and alternatively arranged to form an (AB)n arrangement form from the crucible body to the coating structure along the thickness direction; A represents the impurity absorbing layers, B represents the silicon nitride layers, and n is an integer which is greater than or equal to 1; and the A is a polycrystalline silicon powder coating of which the surface is provided with a SiO2 oxide layer, or a mixed coating of a material of which the melting point is greater than or approximates to that of crystalline silicon and surface-unoxidized polycrystalline silicon powder and / or polycrystalline silicon powder of which the surface is provided with the SiO2 oxide layer. The coating structure in the crucible can stop metal impurities and oxygen impurities in the crucible from diffusing into the crucible during ingot casting. The invention also provides a production method of the crucible and application of the crucible in the ingot casting.

Owner:JIANGXI SAI WEI LDK SOLAR HI TECH CO LTD

Purification method of electronic-grade octafluorocyclopentene

ActiveCN110483234AHigh purityMeet the requirements of electronic special gasSemi-permeable membranesOther chemical processesCyclopentenePurification methods

The invention relates to the field of fine chemical engineering, in particular to a purification method of electronic-grade octafluorocyclopentene. The method comprises the steps of rectification purification, low-temperature adsorption purification, pressurized adsorption purification and the like. According to the method, the final product octafluorocyclopentene is obtained from raw material cyclopentene which is easy to obtain by using a gas phase process. A low-temperature rectification technology is adopted, and combined with a low-temperature adsorption technology and a pressurized adsorption technology to purify the octafluorocyclopentene; modified coconut shell charcoal is used as a mesoporous low-temperature adsorbent; further separation purification is performed through membraneseparation, so that the volume concentration of a water impurity in the octafluorocyclopentene product is less than or equal to 5 ppm; the volume concentration of an oxygen impurity is less than or equal to 3.5 ppm, and the volume concentration of nitrogen which is difficult to separate in the traditional process is less than or equal to 1 ppm. The purity of the product is effectively improved, the purity of the octafluorocyclopentene product is 99.999% or above, and the requirements of semiconductor and microelectronic industries on electronic special gas are met.

Owner:ZHEJIANG BRITECH CO LTD

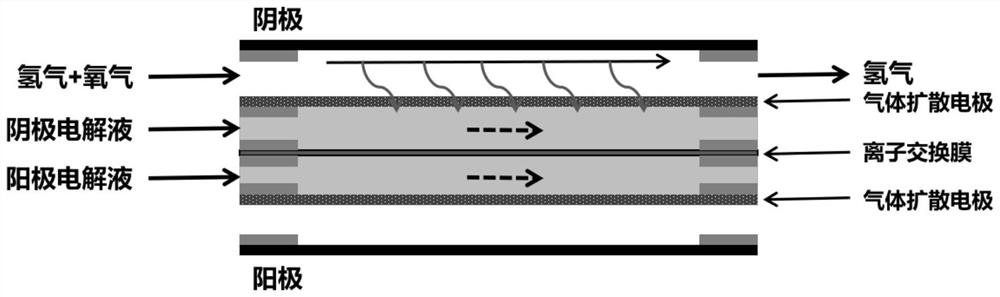

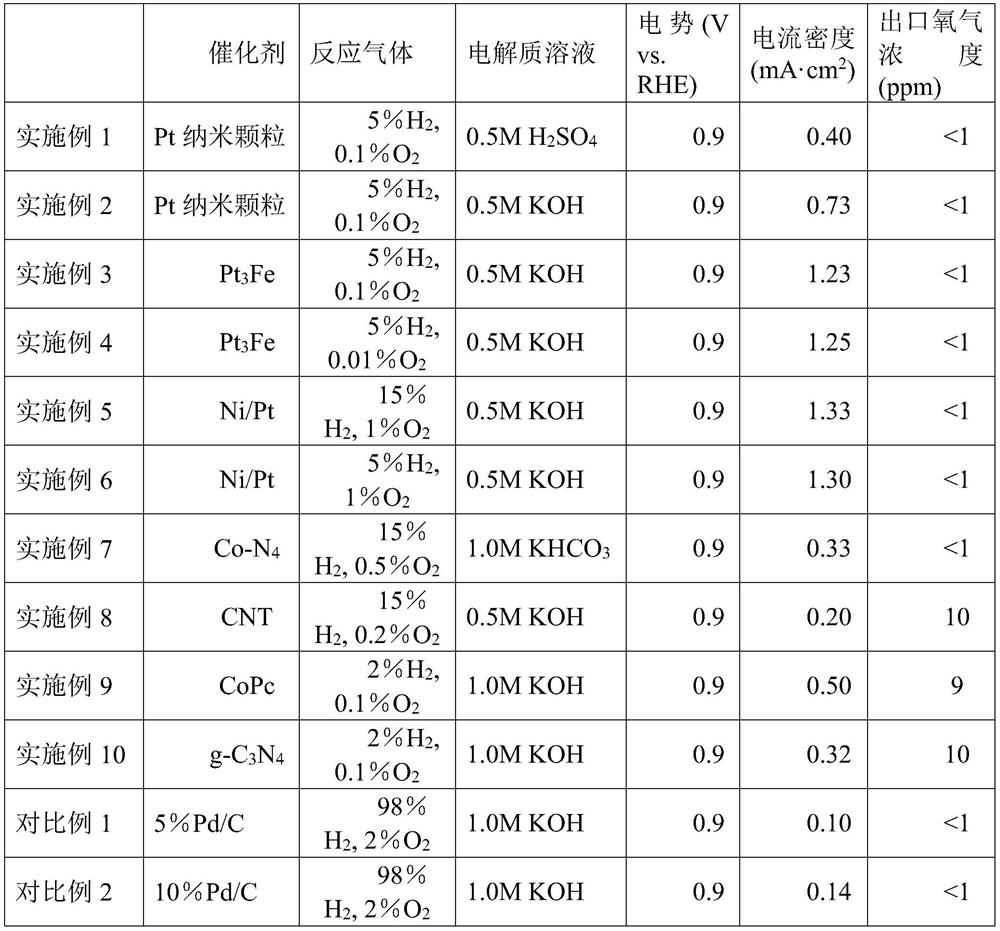

Method for deeply removing oxygen in hydrogen through electrocatalysis at normal temperature and pressure to obtain high-purity hydrogen

ActiveCN113460964AEfficient reductive removalLow costCellsGas treatmentChemical industryPtru catalyst

The invention relates to a method for deeply removing oxygen in hydrogen through electrocatalysis at normal temperature and pressure to obtain high-purity hydrogen; a gas diffusion electrode electrolytic tank is adopted, a catalyst is sprayed on a gas diffusion layer substrate (including electrically conductive carbon paper, the catalyst and the like) to prepare a gas diffusion electrode, and a cathode and an anode are isolated by an ion exchange membrane. Reaction gas contains oxygen impurities with a certain concentration, electrochemical performance testing is carried out by adopting a three-electrode or two-electrode system constant voltage method, and the oxygen impurities in impurity-containing hydrogen are continuously and deeply removed. By adopting the method provided by the invention, the residual concentration of oxygen can be reduced to 1 ppm or less and the purity of hydrogen can reach 99.9999% or more by regulating and controlling a proper voltage range. Compared with a traditional technology, the method can efficiently reduce and remove oxygen in hydrogen at normal temperature and normal pressure, has the obvious advantages of greenness, safety, low cost, high efficiency and the like, better meets the requirements of green chemical industry, and has a wide practical application prospect.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for capturing and absorbing suspending impurities in tundish

The invention relates to the field of continuous casting of slabs, in particular to a method for capturing and absorbing suspending impurities in a tundish. The method is characterized in that a dike building plate containing CaCO3 is arranged at the bottom of the tundish, a nucleation center and bubble power are self-generated in the process of pouring by utilizing heat burst characteristics of the CaCO3 material, and oxides in the continuously-cast tundish are captured and removed to enter furnace slag. The method specifically includes that 1), the dike building plate is built on one side of a tundish dike at the bottom of the tundish; 2), in the process of pouring, CaCO3 particles burst and decompose layer by layer, generated CO2 and CaO particles enter molten steel, slag washing is performed on the molten steel flowing through above, a protection atmosphere is formed, the CaO particles are combined with aluminum impurities, and the objective of purifying the molten steel is achieved. Compared with the prior art, the method has the advantages that tiny bubbles formed by CO2 generated during bursting of CaCO3 float upwards and expand, and capturing of aluminum-oxygen impurities is realized.

Owner:ANGANG STEEL CO LTD

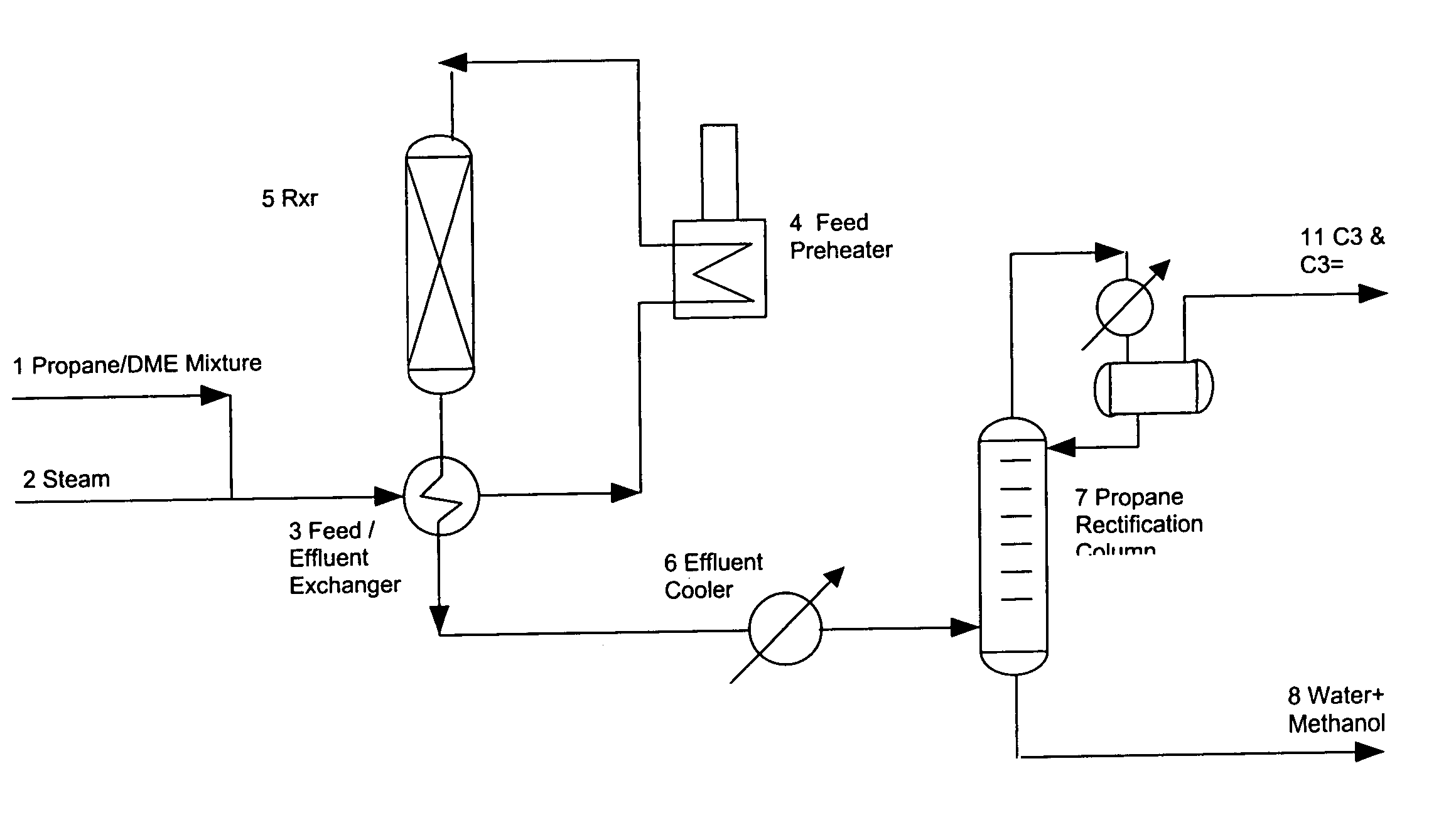

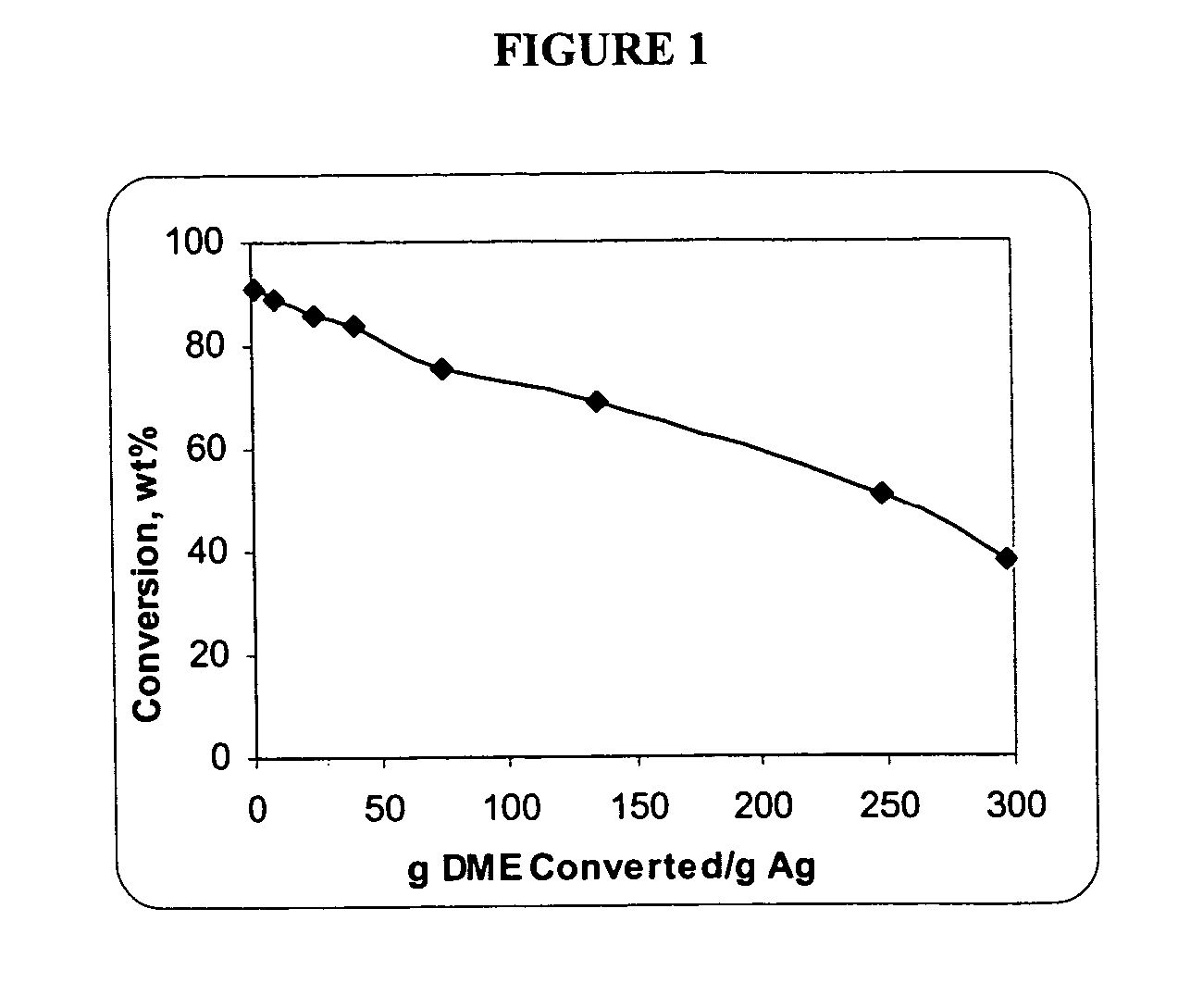

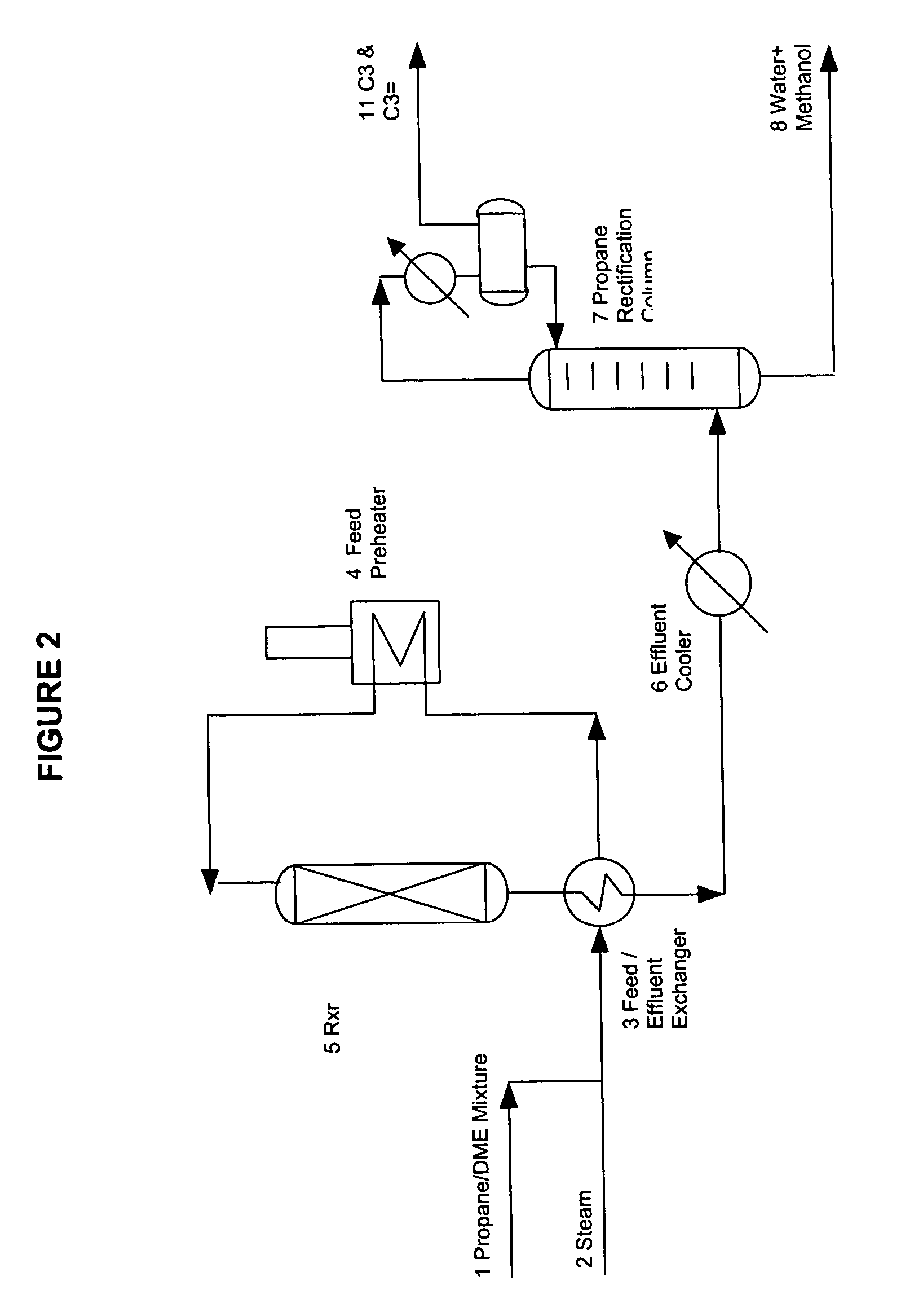

Process for removing oxygenates from an olefinic stream

The present invention provides a process for removing oxygenate impurities, e.g., dimethyl ether, from an olefinic product stream by converting the oxygenate impurity to a compound whose boiling point differs by at least about 5° C. from the oxygenate impurity. Typically, the compound is more readily removable from the product stream than the oxygenate impurity.

Owner:EXXONMOBIL CHEM PAT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com