High-thermal-conductivity silicon nitride ceramic and preparation method thereof

A silicon nitride ceramic, high thermal conductivity technology, applied in the field of ceramic material preparation, can solve the problem of low thermal conductivity of silicon nitride ceramics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

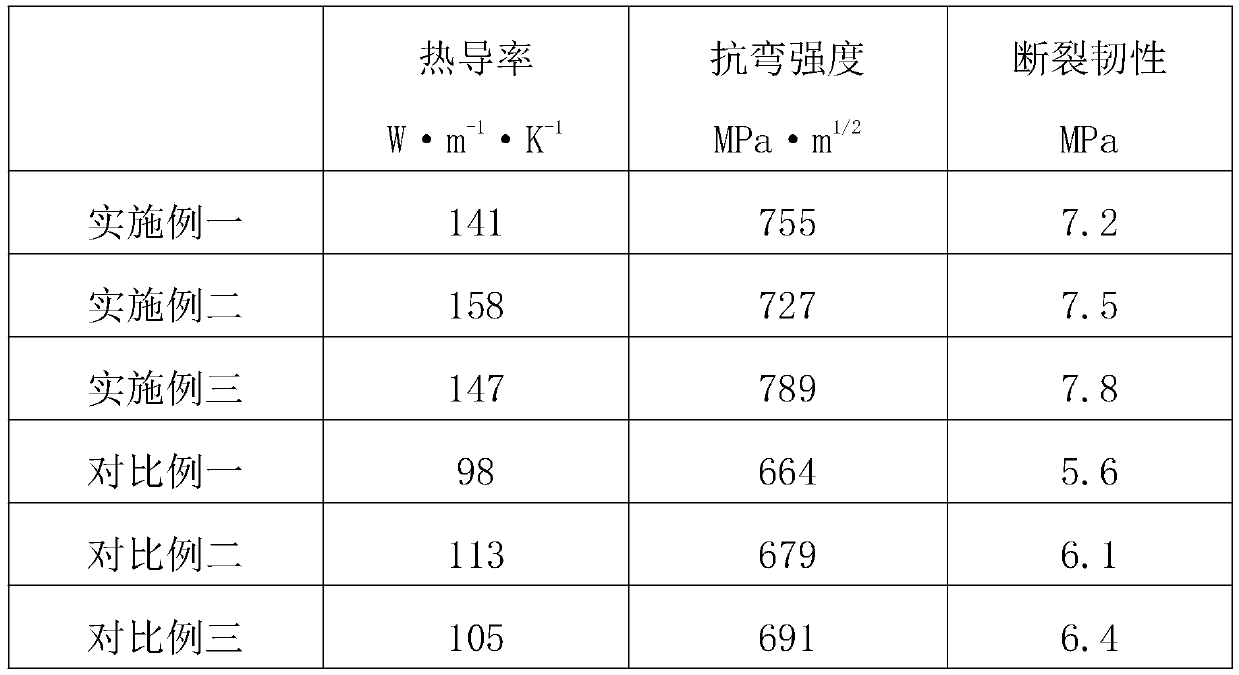

Examples

Embodiment 1

[0021] A high thermal conductivity silicon nitride ceramic, in parts by weight, the silicon nitride ceramic is made of the following raw materials: 60 parts of silicon nitride, 8 parts of silicon carbide, 2 parts of yttrium chloride, and lanthanum chloride 1 part, 0.2 parts of ytterbium fluoride, 0.5 parts of zirconium nitride, and 5 parts of polyisobutenyl succinimide.

[0022] The preparation method of high thermal conductivity silicon nitride ceramic includes the following steps:

[0023] Step 1: Weigh 60 parts of silicon nitride, 8 parts of silicon carbide, 2 parts of yttrium chloride, 1 part of lanthanum chloride, 0.2 parts of ytterbium fluoride, 0.5 parts of zirconium nitride, and polyisobutenyl butadiene by weight. Mix 5 parts of imide to obtain mixed raw materials;

[0024] Step 2: Add the mixed raw materials obtained in Step 1 and 45 parts of isopropanol to the ball mill for the first grinding and crushing. After 15 hours of grinding and crushing, the mixed raw materials ar...

Embodiment 2

[0028] A silicon nitride ceramic with high thermal conductivity, in parts by weight, the silicon nitride ceramic is made of the following raw materials: 75 parts of silicon nitride, 10 parts of silicon carbide, 3 parts of gadolinium chloride, and terbium chloride 1 part, 0.6 parts of ytterbium fluoride, 1 part of zirconium nitride, 8 parts of polyethylene oxide.

[0029] The preparation method of high thermal conductivity silicon nitride ceramic includes the following steps:

[0030] Step 1: Weigh 75 parts of silicon nitride, 10 parts of silicon carbide, 3 parts of gadolinium chloride, 1 part of terbium chloride, 0.6 parts of ytterbium fluoride, 1 part of zirconium nitride, and 8 parts of polyethylene oxide by weight. To mix, get mixed raw materials;

[0031] Step 2: Add the mixed raw materials obtained in Step 1 and 52 parts of isopropanol to the ball mill for the first grinding and crushing. After 16 hours of grinding and crushing, the mixed raw materials are dried and the dried m...

Embodiment 3

[0035] A silicon nitride ceramic with high thermal conductivity, in parts by weight, the silicon nitride ceramic is made of the following raw material components: 90 parts of silicon nitride, 12 parts of silicon carbide, 3 parts of ytterbium chloride, and lutetium chloride 2 parts, 1 part of ytterbium fluoride, 2 parts of zirconium nitride, and 10 parts of polyethylene wax.

[0036] The preparation method of high thermal conductivity silicon nitride ceramic includes the following steps:

[0037] Step 1: Weigh 90 parts of silicon nitride, 12 parts of silicon carbide, 3 parts of ytterbium chloride, 2 parts of lutetium chloride, 1 part of ytterbium fluoride, 2 parts of zirconium nitride, and 10 parts of polyethylene wax by weight To mix, get mixed raw materials;

[0038] Step 2: Add the mixed raw materials obtained in Step 1 and 60 parts of isopropanol to the ball mill for the first grinding and crushing. After 18 hours of grinding and crushing, the mixed raw materials are dried and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com