Method for preparing Ti2AlC self-lubricating and heat-resisting structural material

A structural material and self-lubricating technology, which is applied in the field of preparation of self-lubricating heat-resistant structural materials, can solve the problems of high synthesis temperature, narrow synthesis phase zone, and restrictions on material preparation and application, and achieve the goal of improving sintering activity and reducing synthesis temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

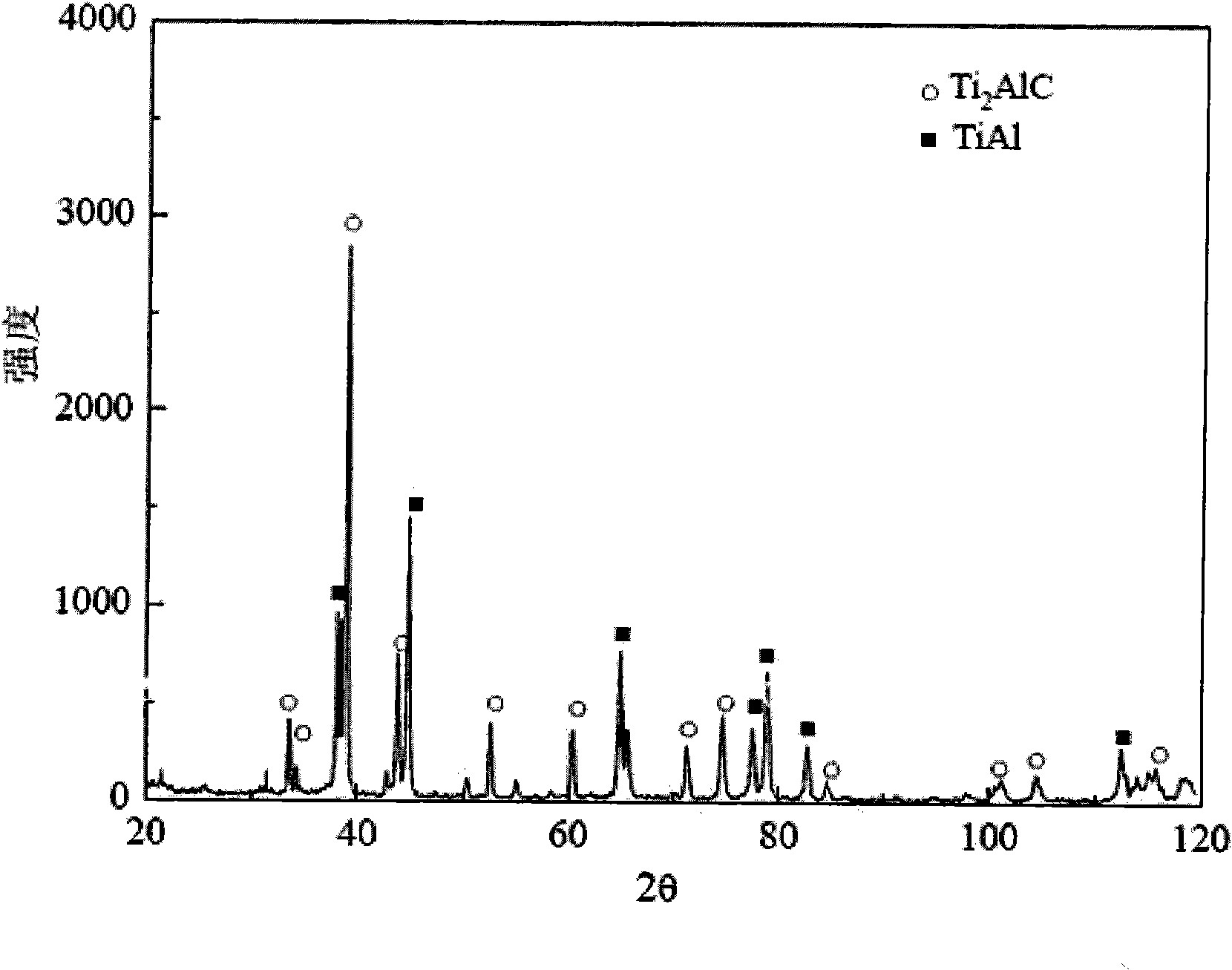

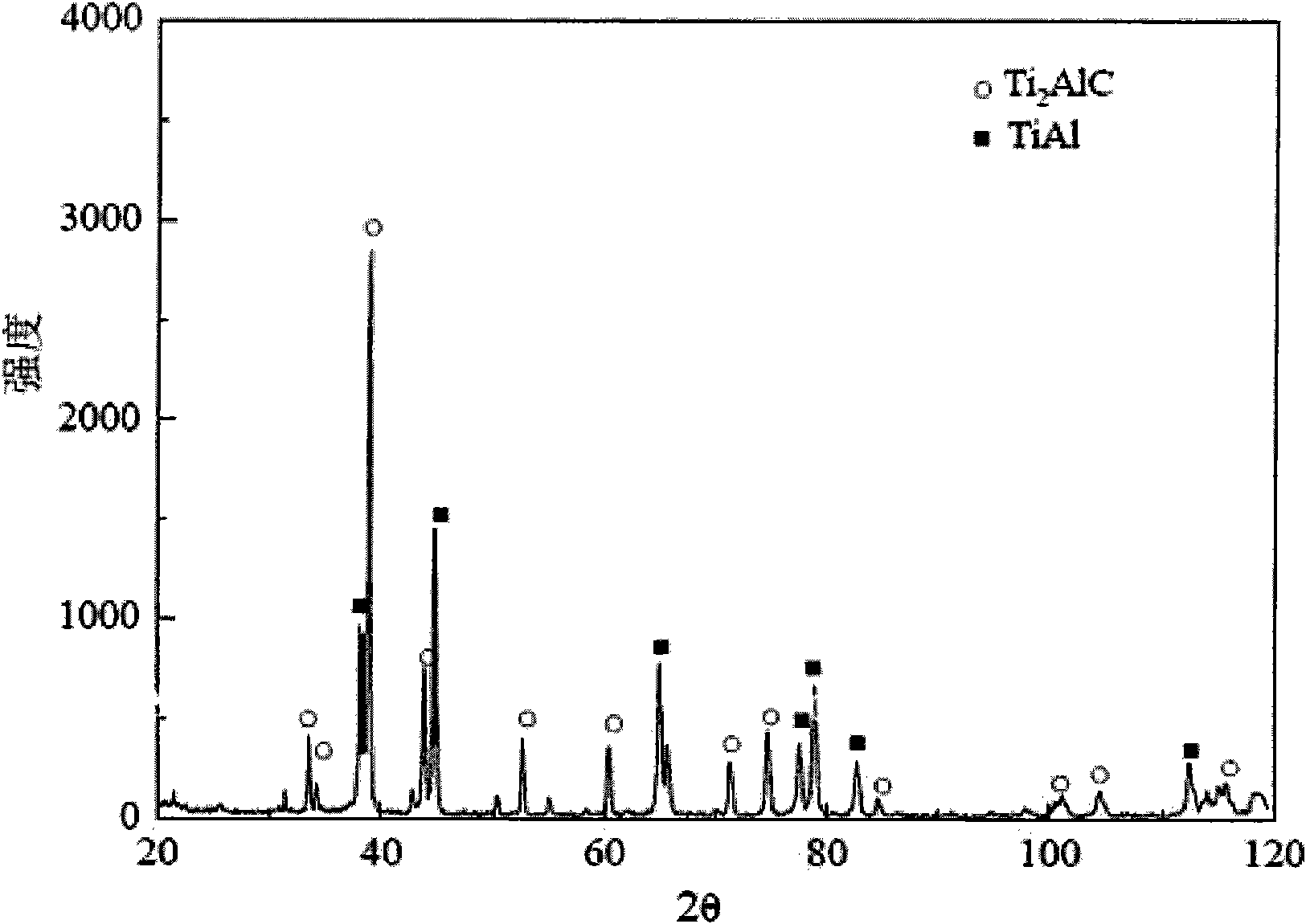

Image

Examples

Embodiment 1

[0011] Example 1: Using Ti powder, Al powder and carbon nanotubes as raw materials, adopting mechanical ball milling and spark plasma sintering technology to prepare Ti 2 AlC self-lubricating heat-resistant structural material, the steps are as follows:

[0012] 1.500 mesh, 99.9% purity of Ti powder and 325 mesh, 99.9% purity of Al powder, according to the atomic ratio Ti: Al is 2: 1.1 ingredients;

[0013] 2. Put the ingredients in step 1 into a vacuum stainless steel ball mill tank, pump the air, then fill it with argon with a purity greater than 99.99%, repeat the pumping and inflation 4 times, and then perform mechanical ball milling, ball milling process conditions: ball material The ratio is 20:1, the ball milling speed is 400rpm, and the ball milling time is 50h; after ball milling, the powder undergoes a lot of plastic deformation and alloying, and the particle size of some ball mill powders reaches 200nm;

[0014] 3. Mix the alloy powder with a large amount of plasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com