Apparatus and method for film formation

A thin film and reagent technology, applied in chemical instruments and methods, non-metallic conductors, coatings, etc., can solve the problems of overall product quality impact, unsatisfactory carbon doping level, high equipment cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0194] Process with baffles

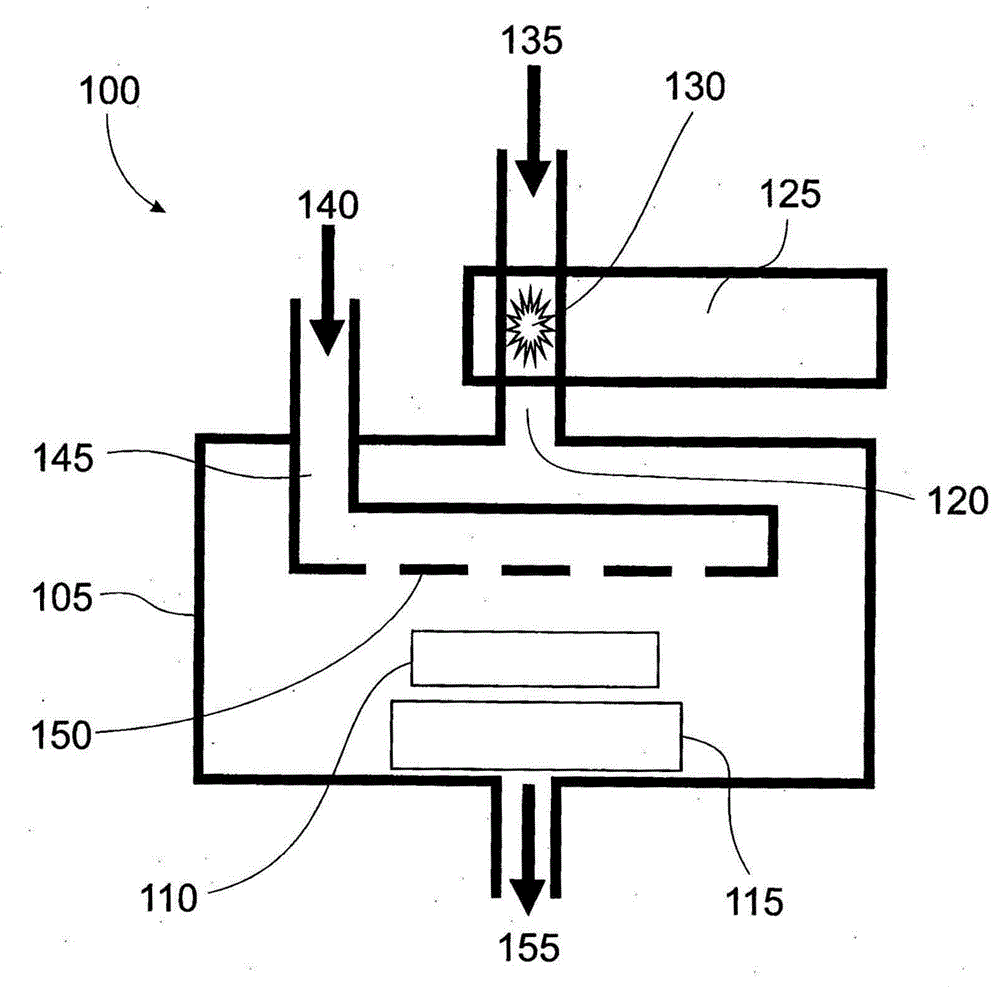

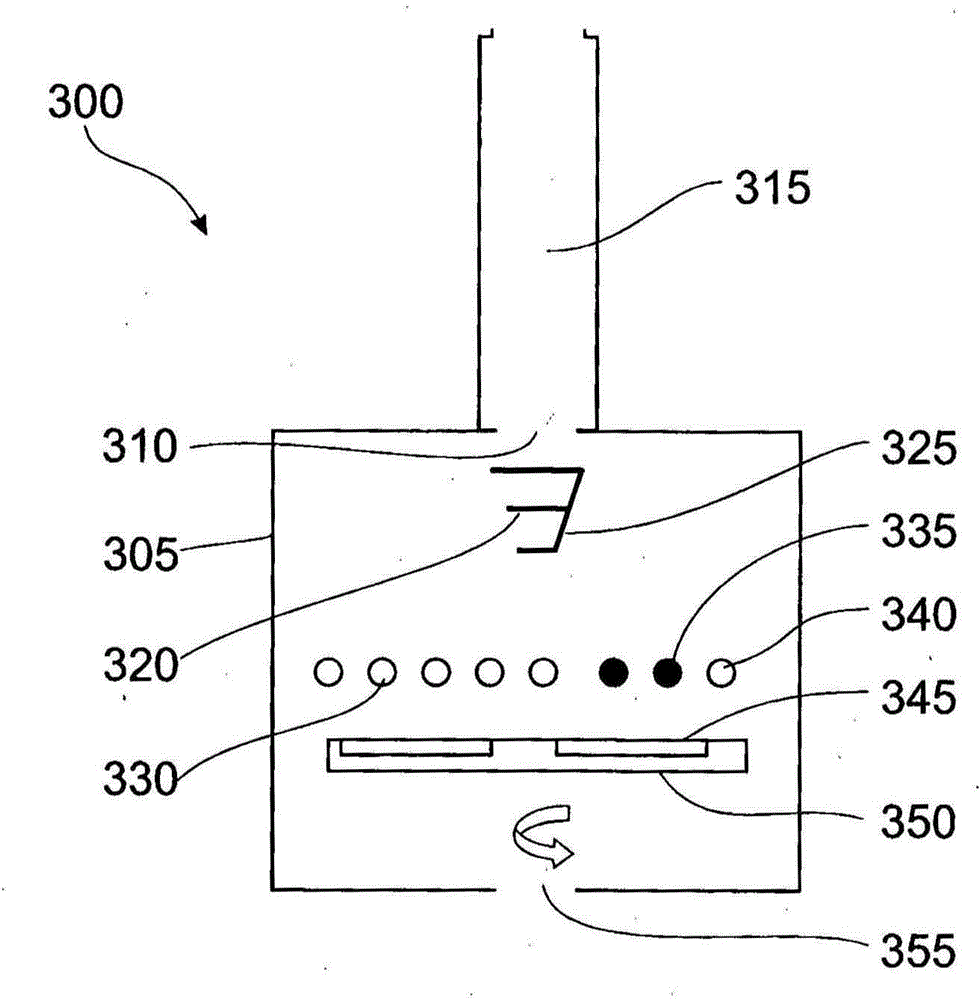

[0195] essentially as Image 6 and Figure 7 The setup employs a stainless steel showerhead baffle located below the plasma inlet. The power of the plasma generator is between 500W-600W, and the growth temperature adopted is 700°C. Films were grown on GaN templates. Nitrogen plasma and trimethylgallium (TMG) as the organometallic reagent were used for initial control, but without any ammonia injection. Membranes thus produced, as when used figure 2 The device produced what was expected, ie had standard levels of oxygen and carbon impurities.

[0196] A second run was then run under substantially similar conditions, but with a 15 seem flow of ammonia injected into the second deposition zone (the deposition zone for the organometallic reagent). The TMG is injected at the same time as the ammonia is injected so that the two are mixed together prior to deposition. The oxygen and carbon content of the films thus produced is significantly redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com