Water chilling ingot furnace and ingot casting process thereof

A cold casting and water-induced technology, which is applied in the growth of polycrystalline materials, crystal growth, single crystal growth, etc., can solve the problems of reducing the melting speed of silicon materials, the growth rate of crystal growth, the reduction of carrier life, and the increase of carbon impurity content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

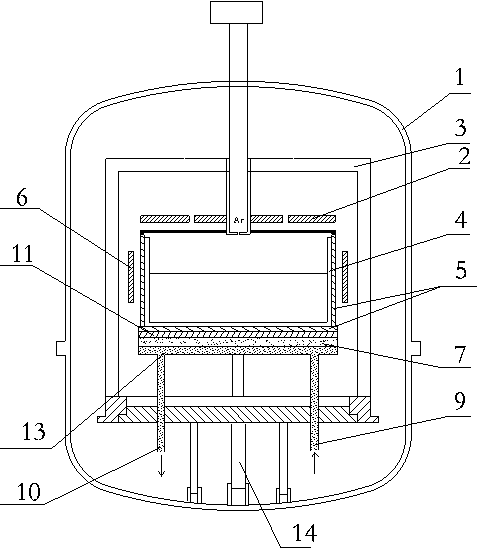

[0021] Such as figure 1 As shown, a water-cooled ingot casting furnace includes a furnace body 1, a heat insulation cage 3 arranged in the furnace body, and a heat exchange platform 11 arranged in the heat insulation cage 3, and a Crucible 4, heaters are distributed on and around the top of the crucible 4, a bottom heater 7 is provided at the lower end of the heat exchange platform 11, and a water cooling plate 13 is provided at the lower end of the heat exchange platform 11, and the water cooling plate 13 is located at At the lower end of the bottom heater 7, a flow cavity is arranged in the water cooling plate 13, and a water inlet 9 and a water outlet 10 are arranged. The water inlet 9 and the water outlet 10 are connected through the flow cavity, and the water inlet 9 and the water outlet 10 are also connected to the furnace body 1 respectively. outer end. This device reduces the temperature at the bottom of the crucible 4 by passing cold water into the water cooling plat...

Embodiment 2

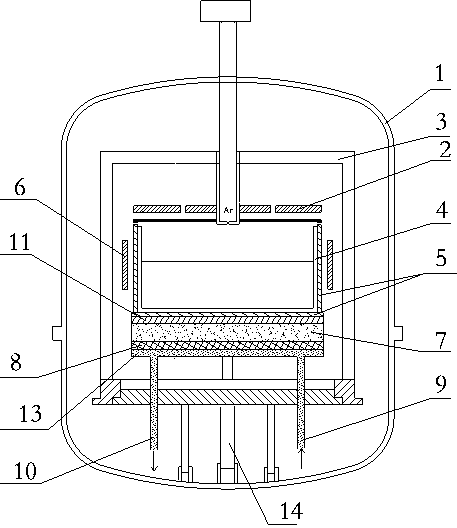

[0036] Such as figure 2 , the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that an adiabatic solidified felt 8 is arranged between the water cooling plate 13 and the bottom heater 7, and the adiabatic solidified felt 8 can effectively block the downward transfer of heat and reduce energy consumption , to ensure the heating effect of the bottom heater 7.

Embodiment 3

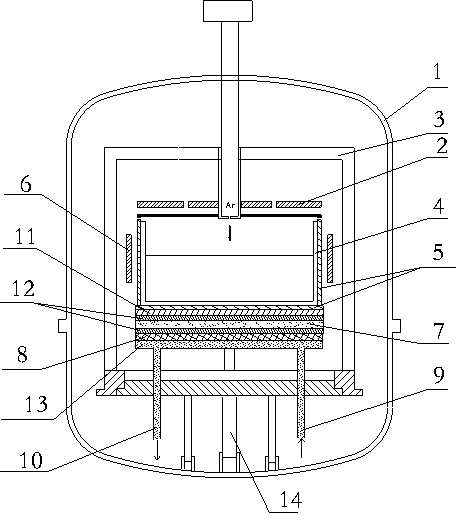

[0038] Such as image 3 , the structure of this embodiment is basically the same as that of Embodiment 2, the difference is that the upper and lower sides of the bottom heater 7 are covered with a layer of cubic boron nitride 12, and the cubic boron nitride 12 is an insulator with good thermal conductivity, which can not only effectively prevent The graphite bottom heater 7 forms a circuit with the graphite exchange platform 3, which can also ensure effective and uniform transfer of heat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com