Patents

Literature

45results about How to "Reduce photoelectric conversion efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spiro-OMeTAD/PbS composite hole transport layer based perovskite solar cell and preparation method therefor

ActiveCN106129252AImprove photoelectric conversion efficiencyImprove stabilitySolid-state devicesSemiconductor/solid-state device manufacturingSolar lightEvaporation

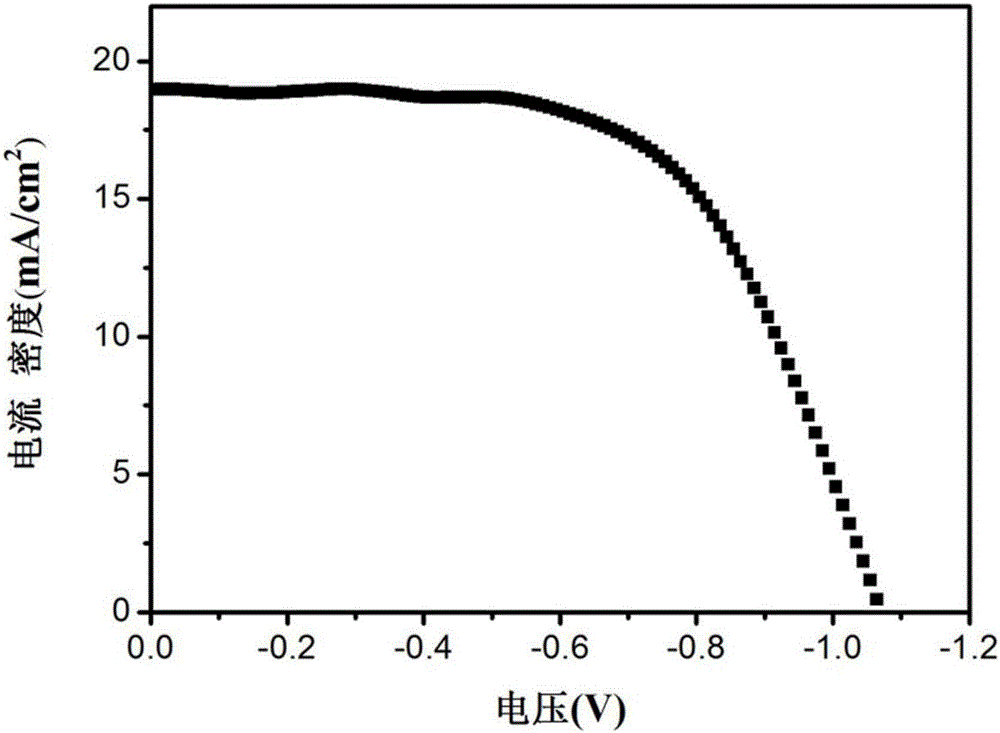

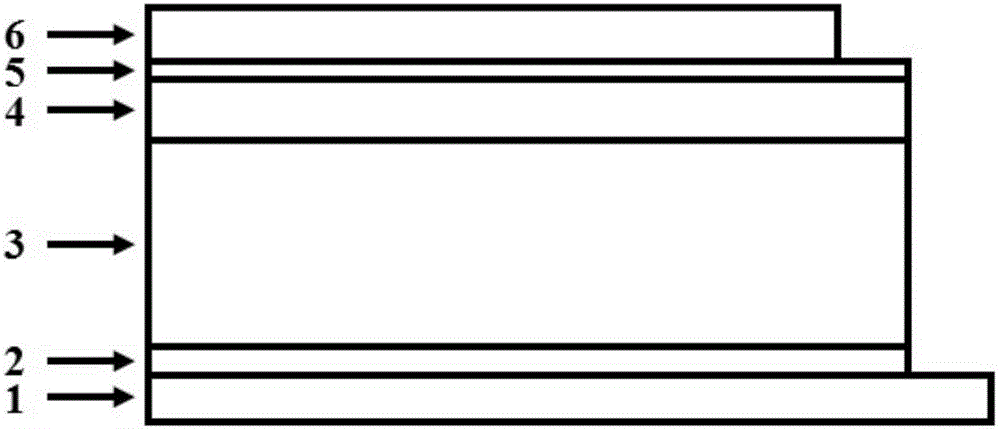

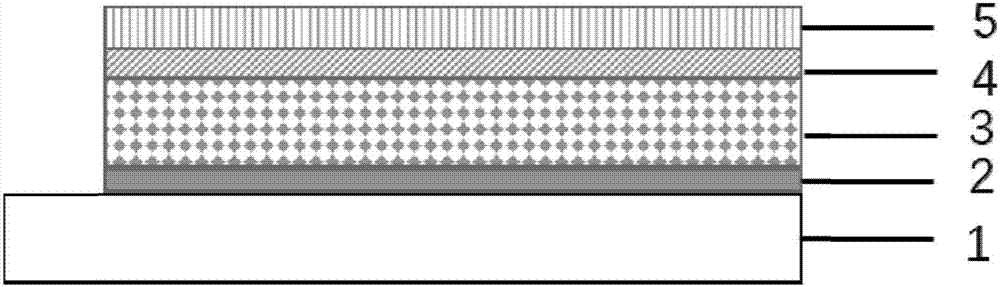

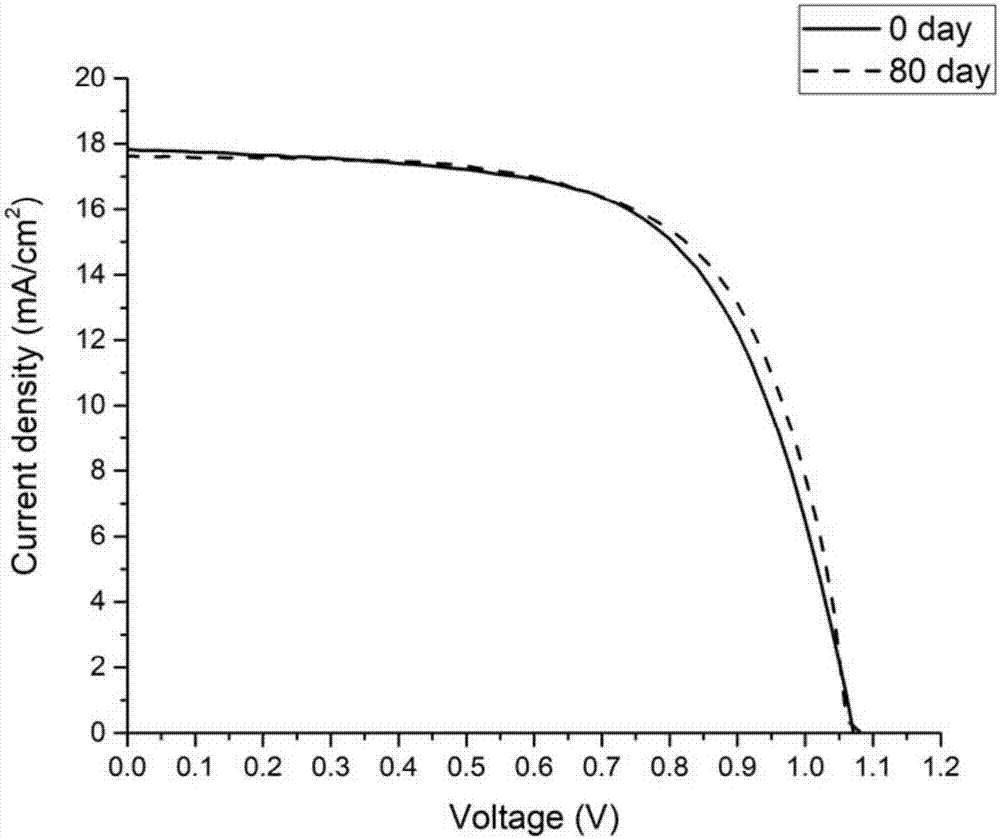

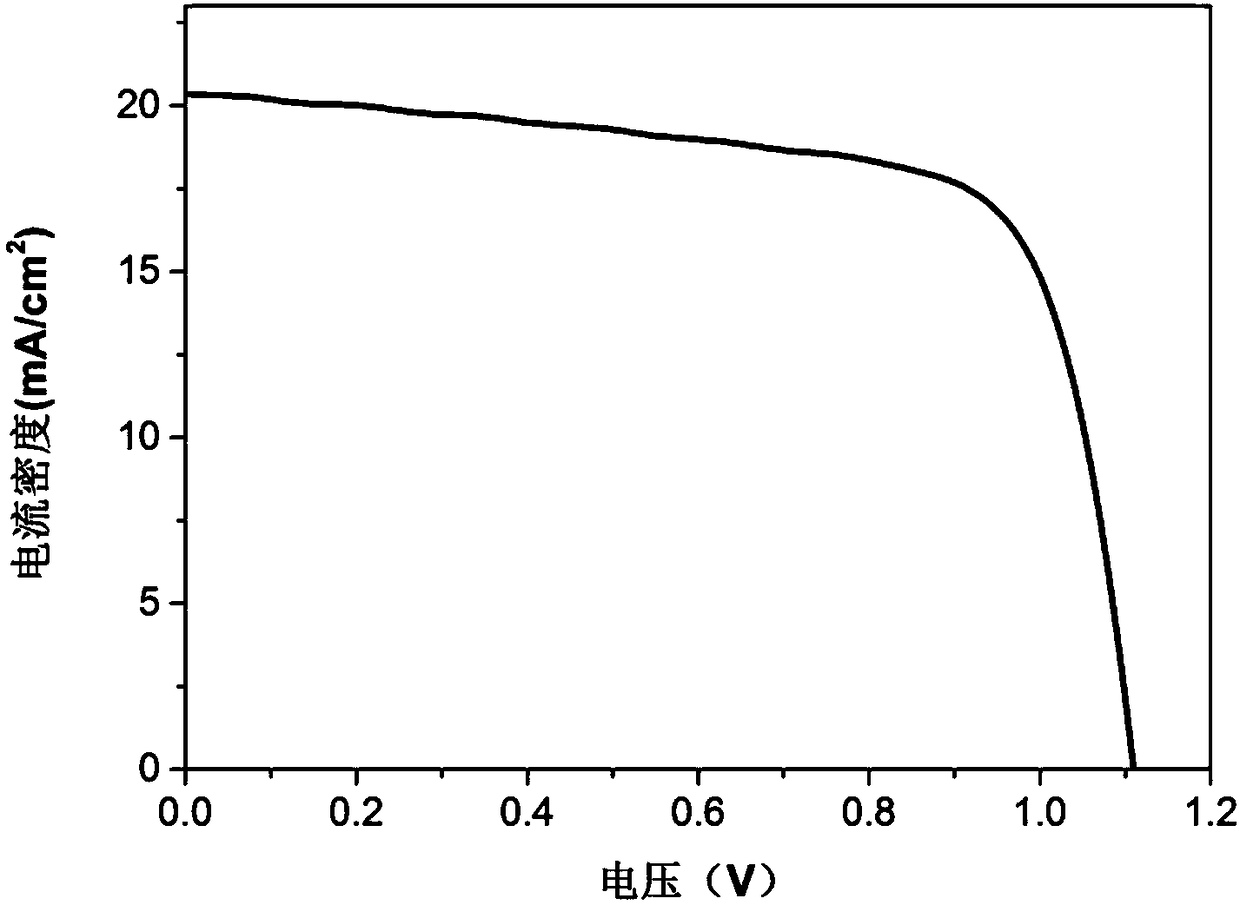

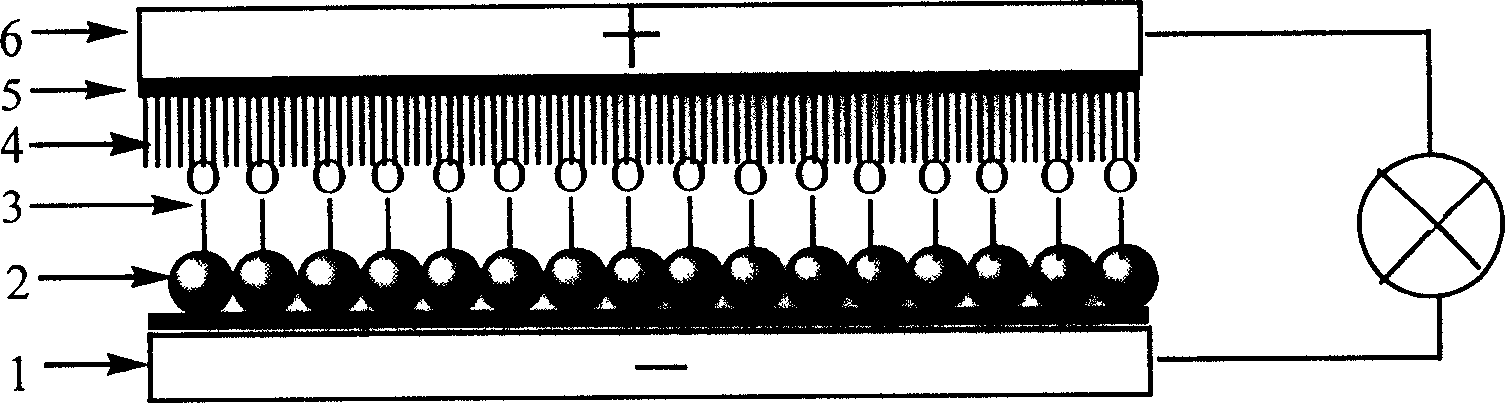

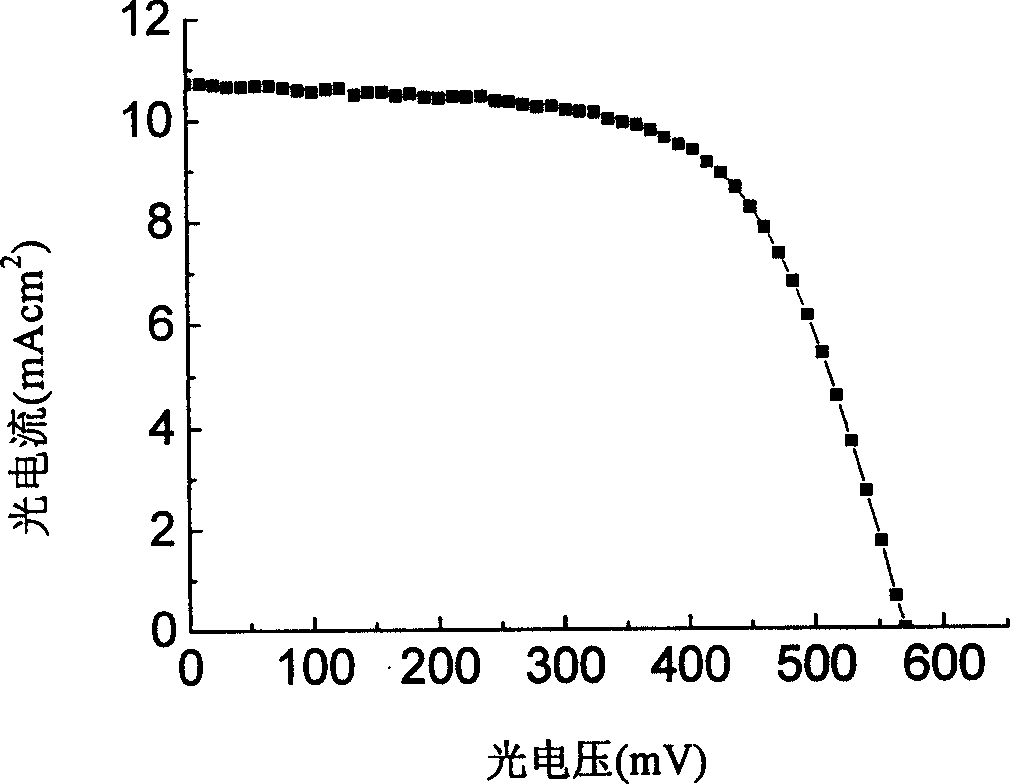

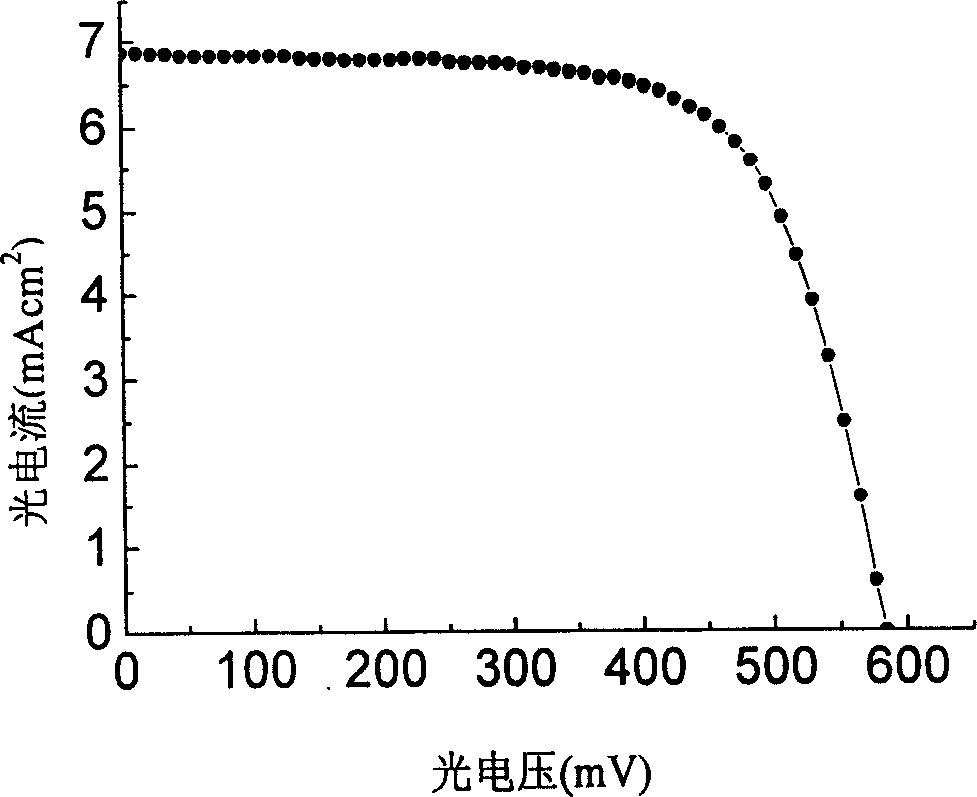

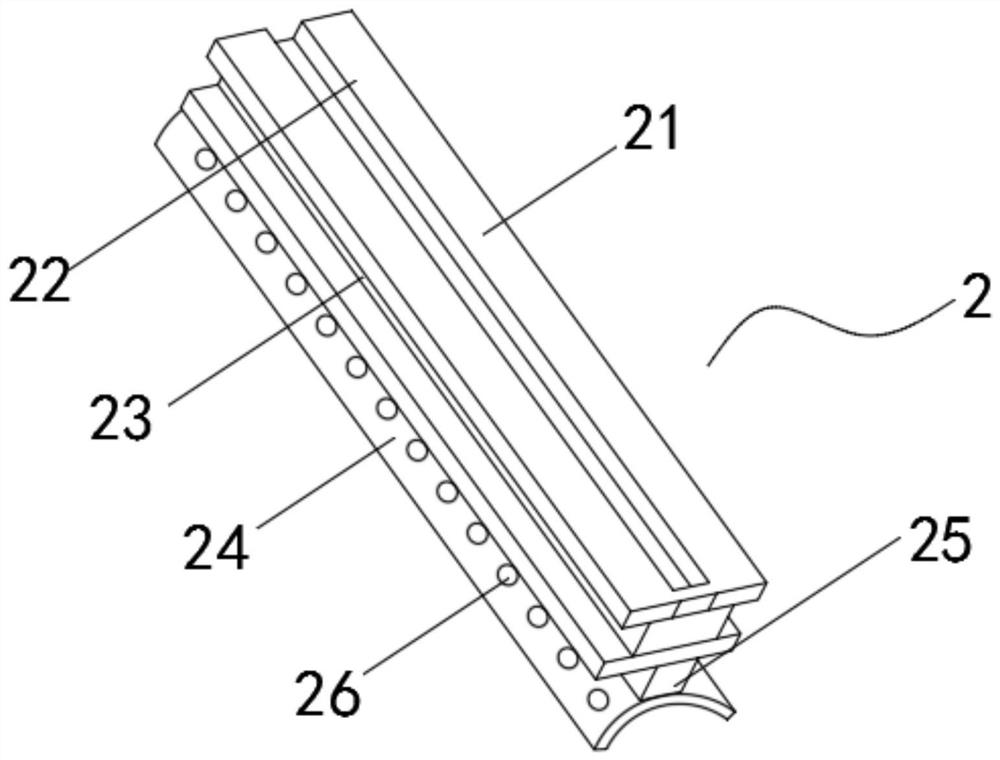

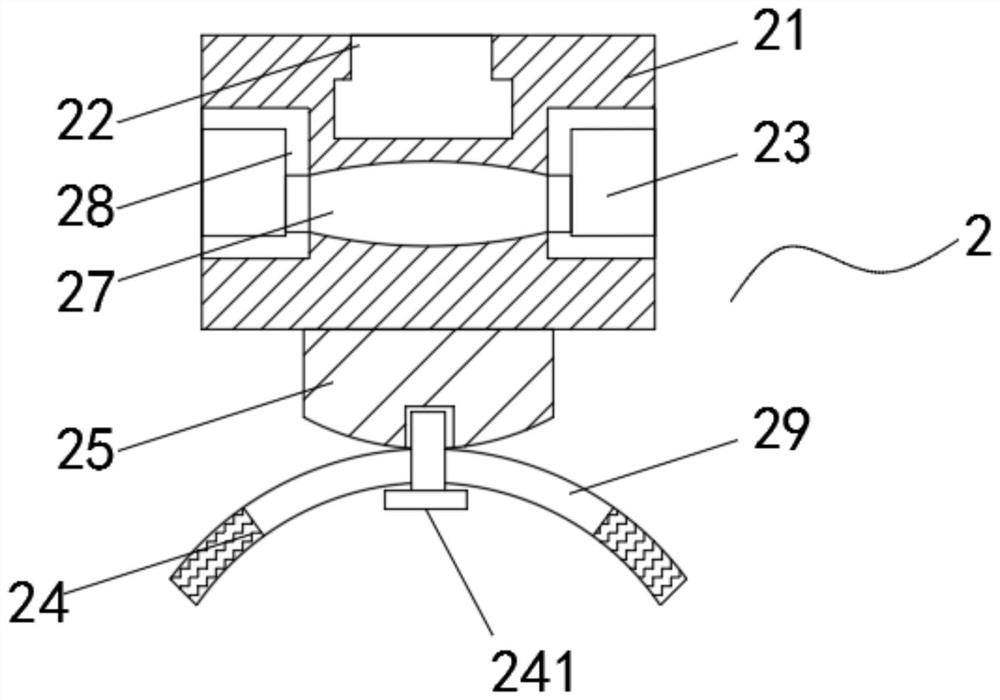

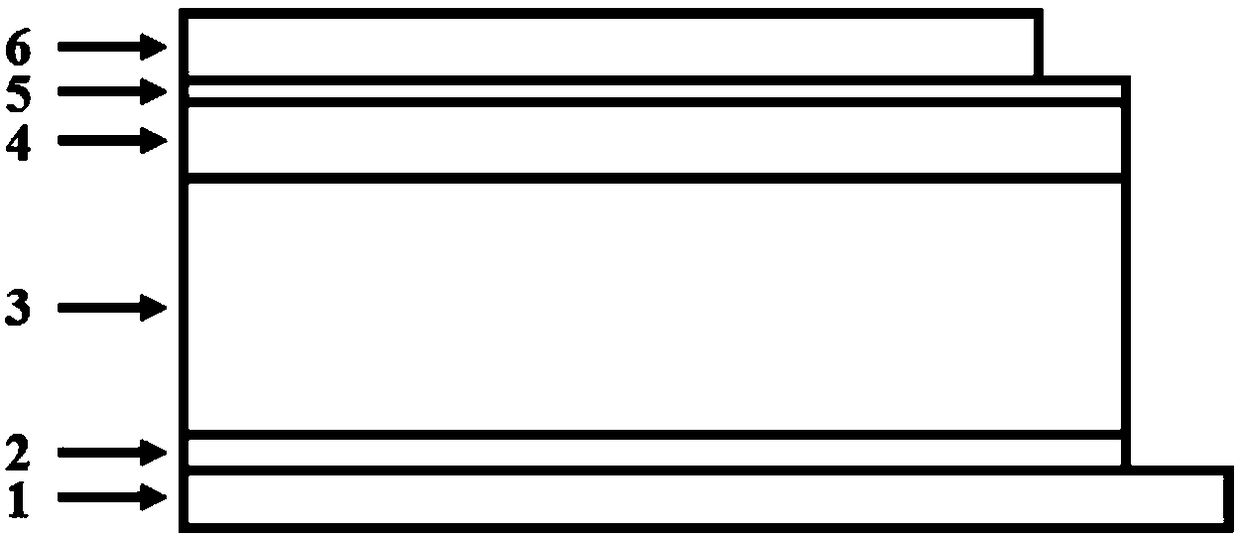

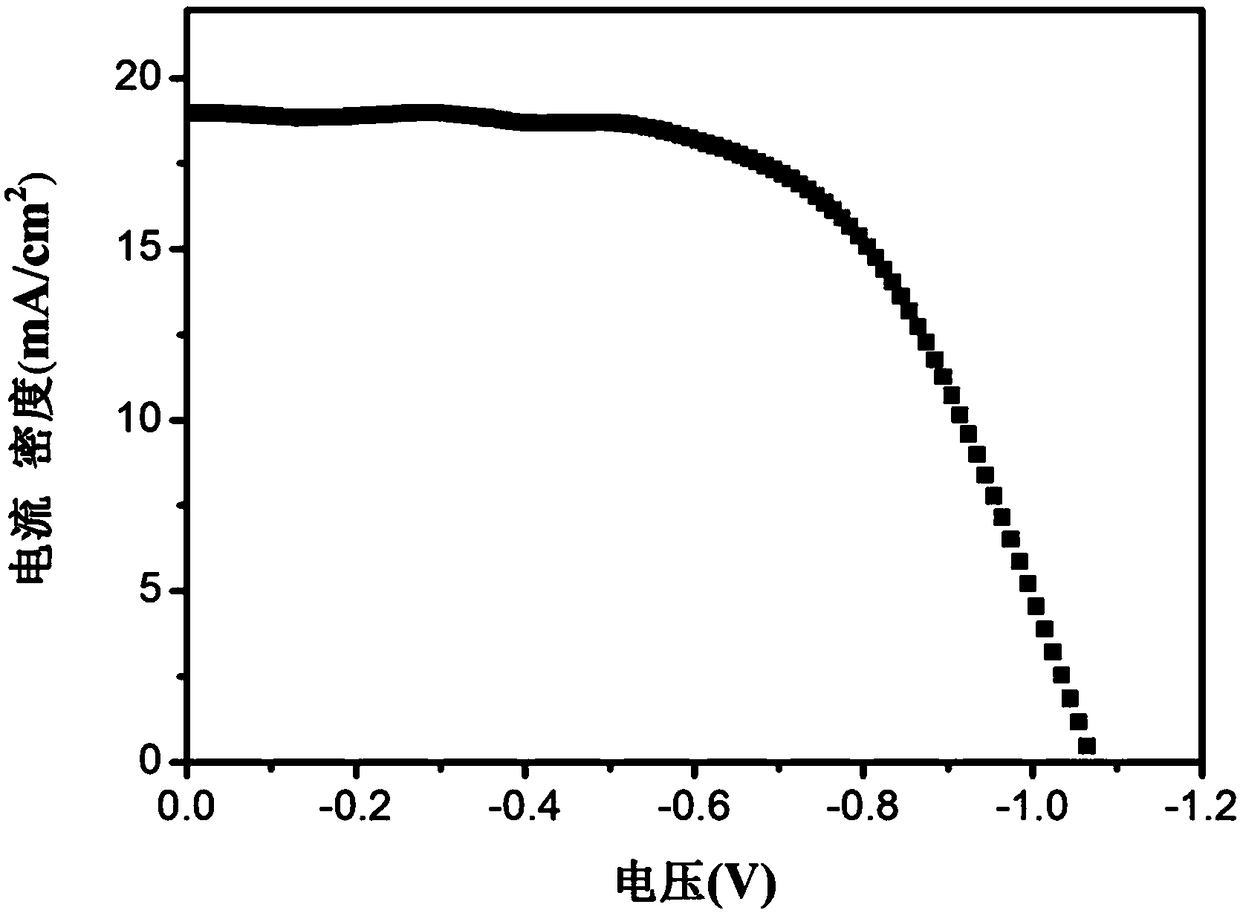

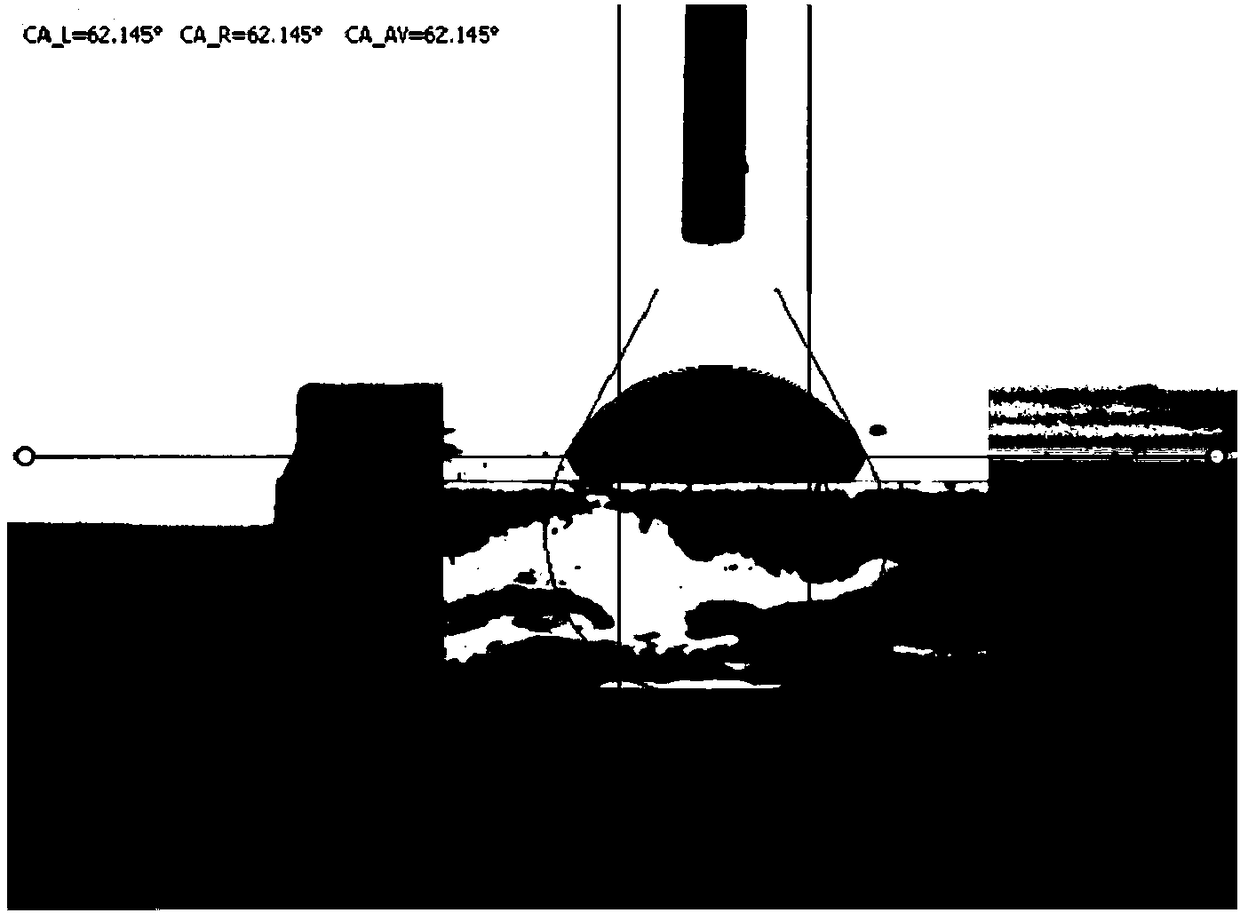

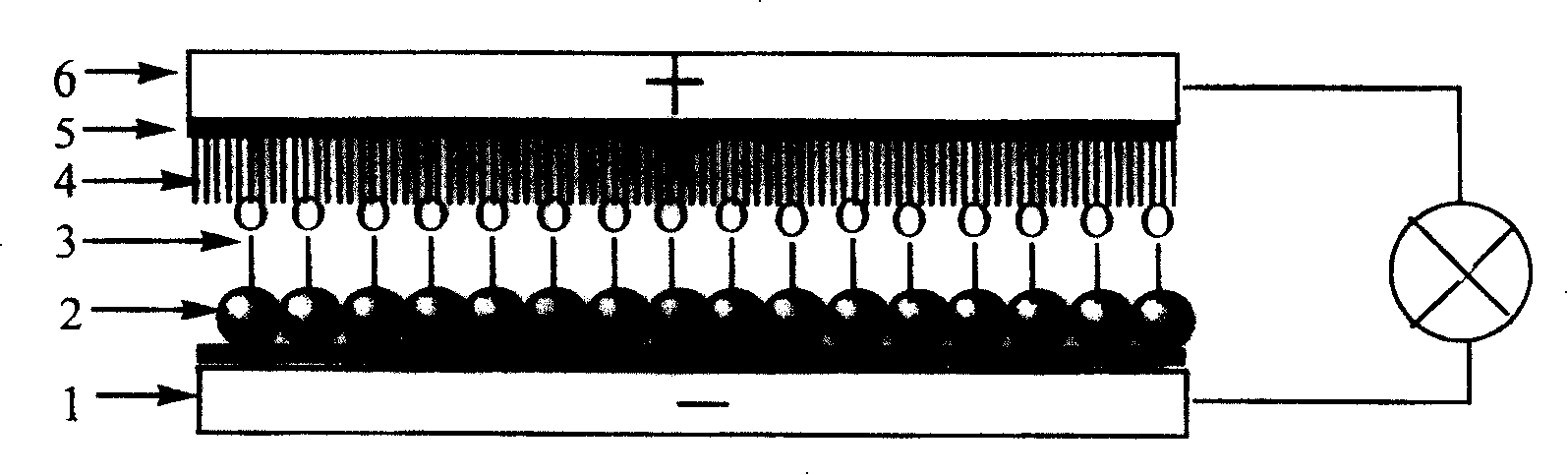

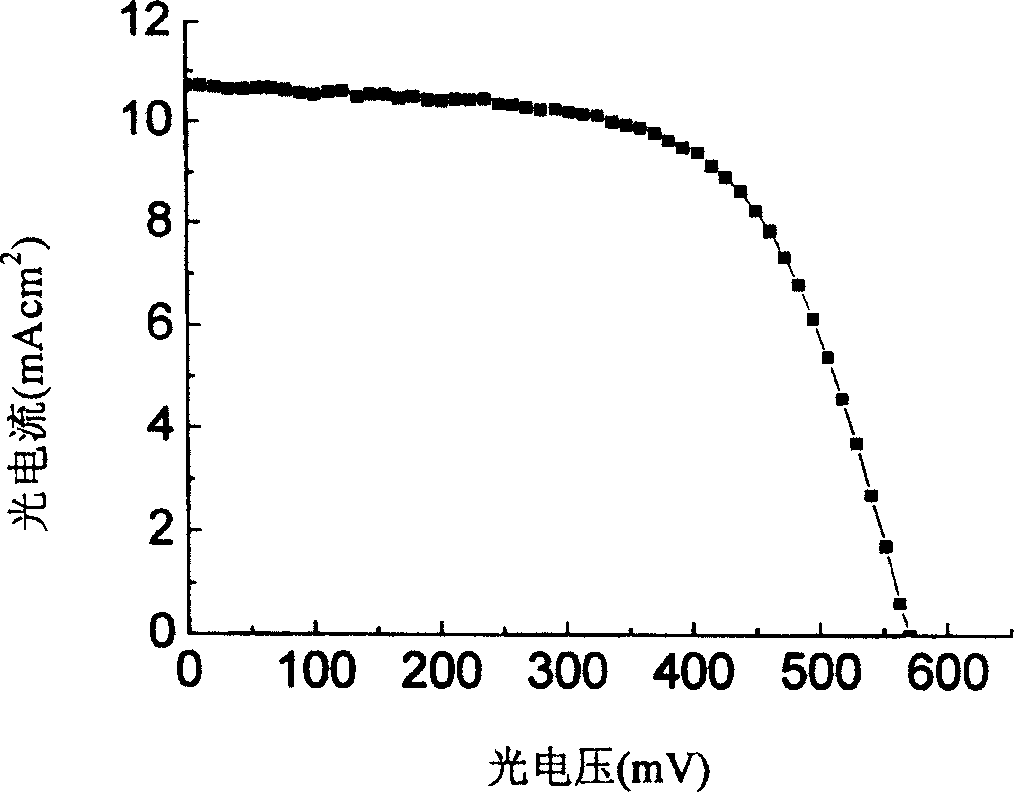

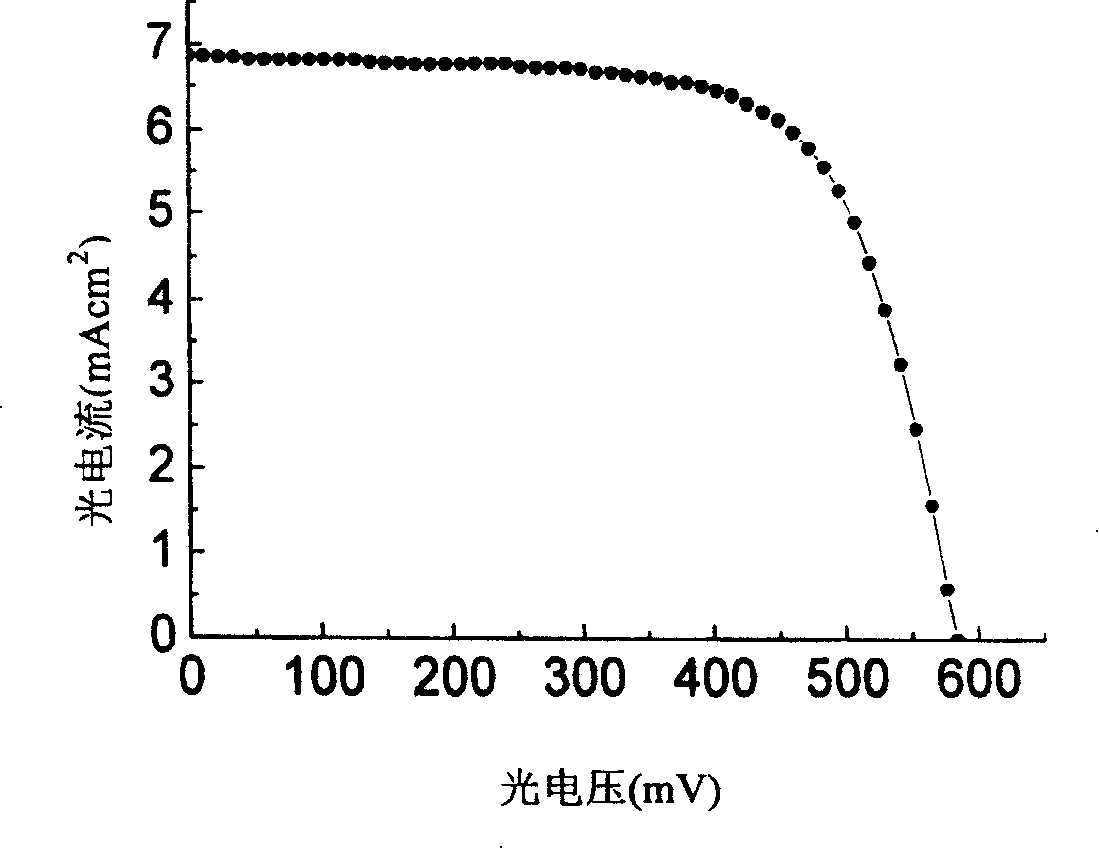

The invention discloses a Spiro-OMeTAD / PbS composite hole transport layer based perovskite solar cell and a preparation method therefor. The perovskite solar cell comprises a transparent conductive substrate, an oxide electron transport layer, a perovskite solar light absorption layer, the Spiro-OMeTAD / PbS composite hole transport layer and a metal electrode. The perovskite thin film solar cell adopts a simple process; a lead sulfide thin film can be prepared by a large-area evaporation method; and the lead sulfide thin film can be inserted between the Spiro-OMeTAD and the metal electrode layer to be used as a buffer layer. The Spiro-OMeTAD / PbS composite hole transport layer based perovskite solar cell achieves a high photoelectric conversion efficiency which is as high as 15.11%; the lead sulfide, which is used as the buffer layer between the hole transport layer and the metal electrode, has higher hole mobility, and higher humidity stability and light and heat stability, so that the recombination of electron-hole pairs can be reduced; meanwhile, the stability of the cell can be improved; compared with other buffer layer materials, the lead sulfide can protect a device and improve the performance of the device as well; and therefore, a positive promotion effect is realized on the industrial development of the solar cell.

Owner:WUHAN UNIV

Organic-inorganic hybrid perovskite solar cell and preparation method thereof

InactiveCN107464882AImprove stabilityReduce photoelectric conversion efficiencySolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellEvaporation

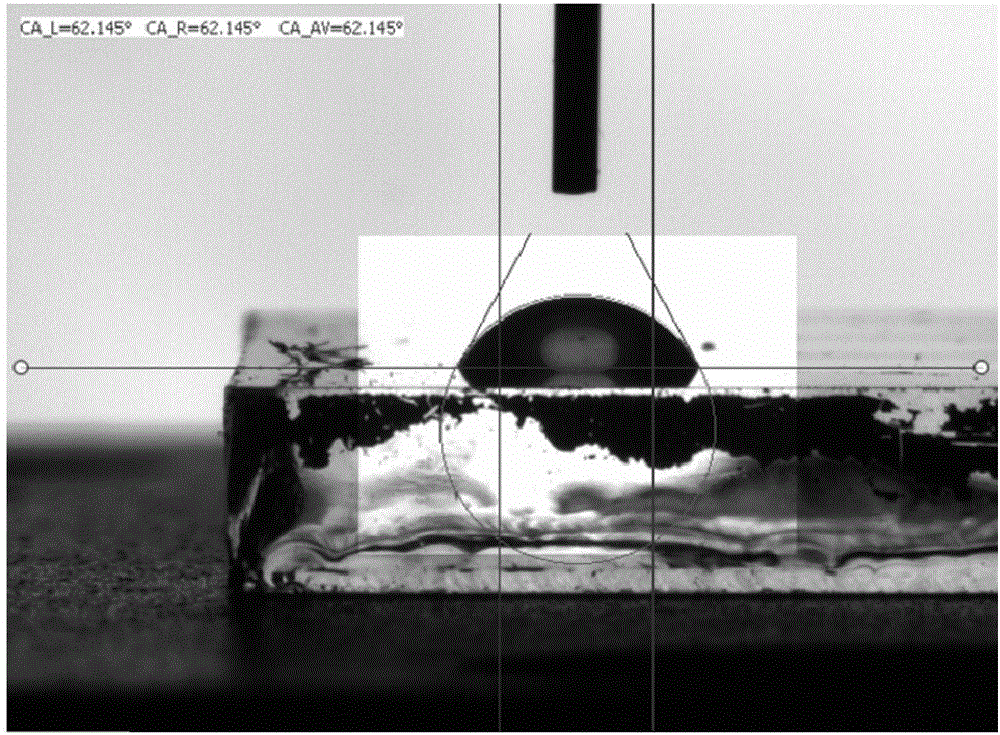

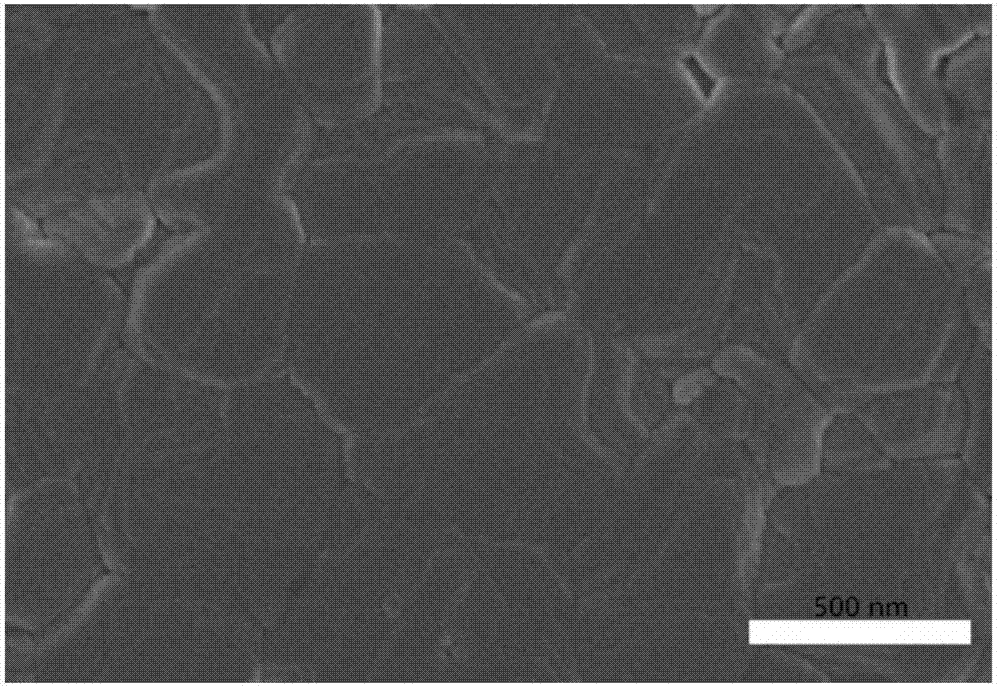

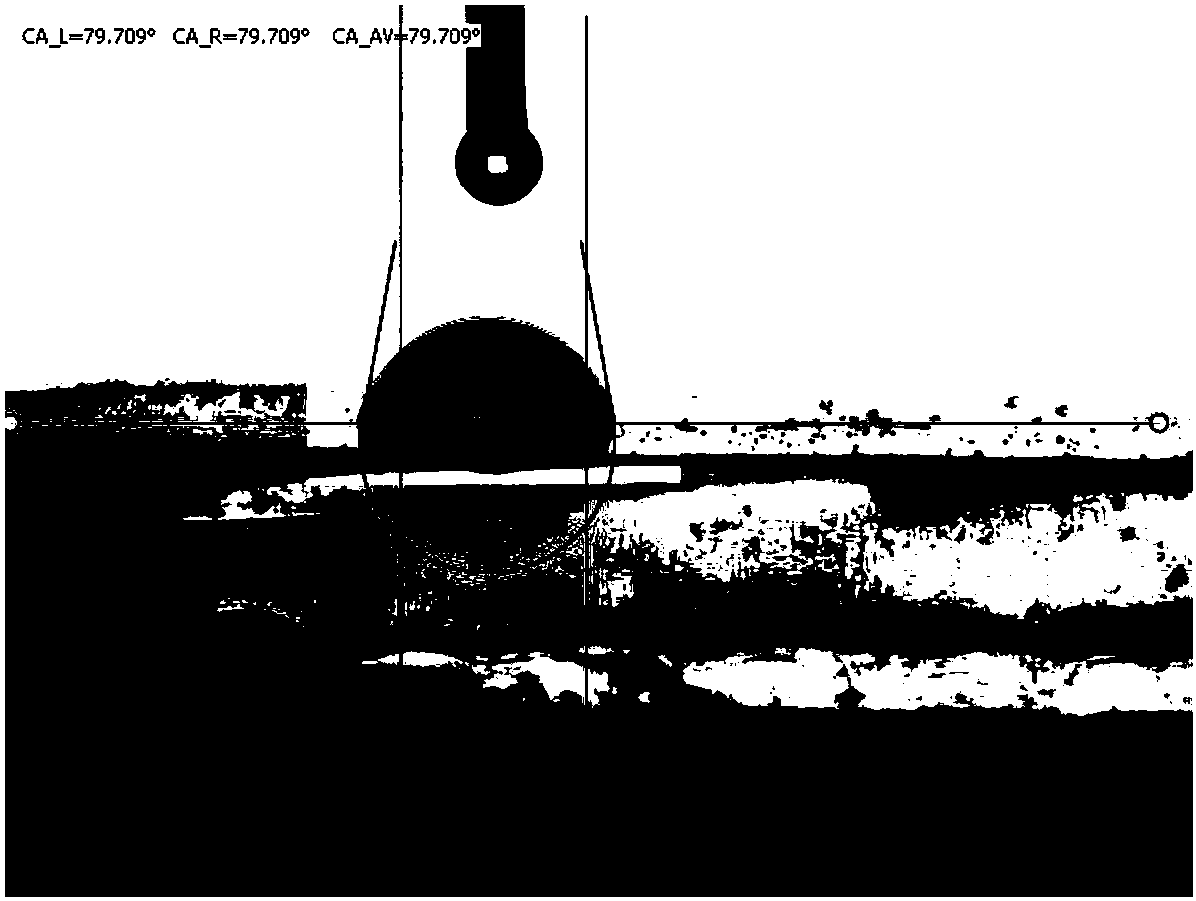

The invention discloses an organic-inorganic hybrid perovskite solar cell and a preparation method thereof. The preparation method comprises the steps of firstly, depositing a semiconductor compact layer on a transparent conductive electrode by a spray pyrolysis method; secondly, spraying a mixed positive ion organic-inorganic hybrid perovskite solution on the semiconductor compact layer by a thermal substrate spraying method to form a hybrid positive ion organic-inorganic hybrid perovskite thin film light absorption layer; thirdly, preparing a hole transmission layer on a surface of the light absorption layer; and finally, evaporating a gold electrode by thermal evaporation to obtain the organic-inorganic hybrid perovskite solar cell. The organic-inorganic hybrid perovskite solar cell is prepared by the thermal substrate spraying method, the preparation process is simplified, a large-area perovskite thin film can be rapidly prepared, and application on a large scale is facilitated; and moreover, the proportion among constituents of the hybrid positive ion organic-inorganic hybrid perovskite solution is optimized, the grain size of the obtained solar cell exceeds 500 nanometers, and the solar cell is relatively good in stability.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Manufacturing method of N-type solar battery

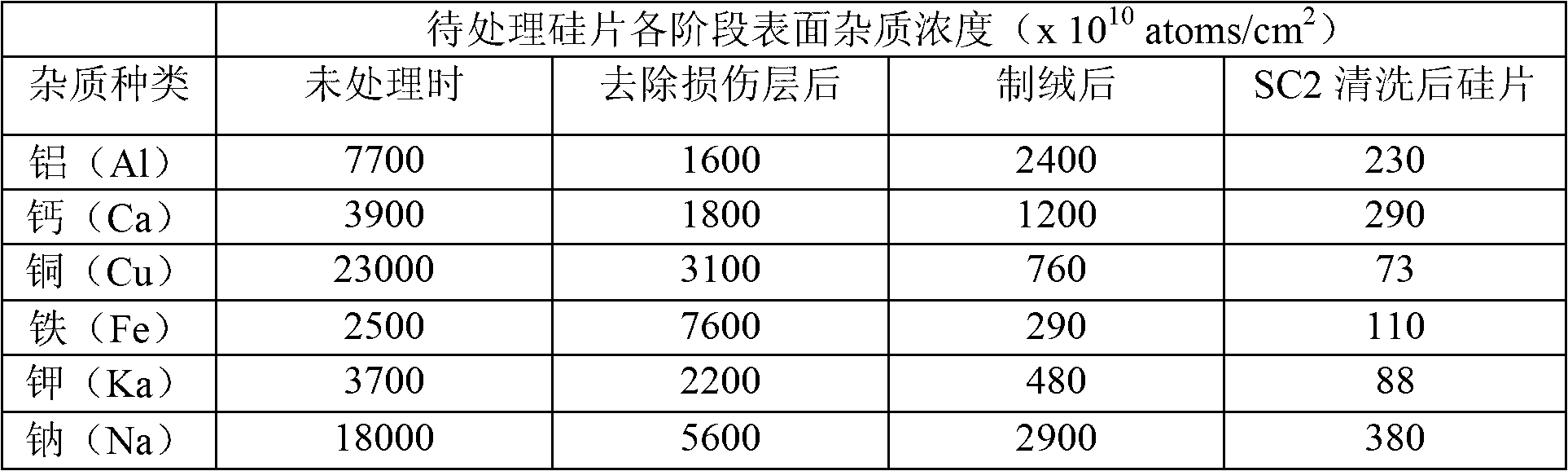

ActiveCN102709401AReduce photoelectric conversion efficiencyDoes not affect the spread effectFinal product manufactureSemiconductor devicesMetal impuritiesSolar battery

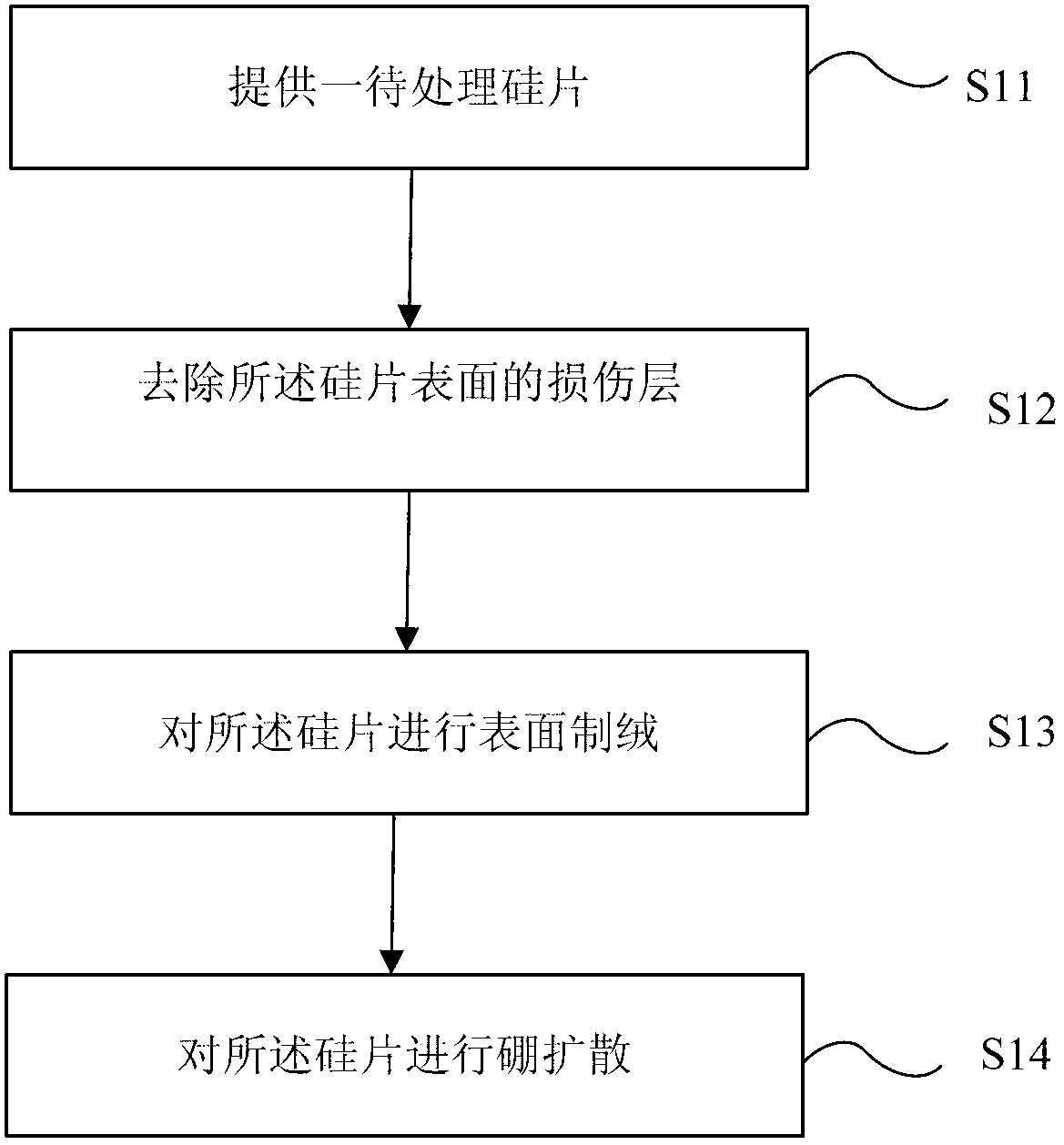

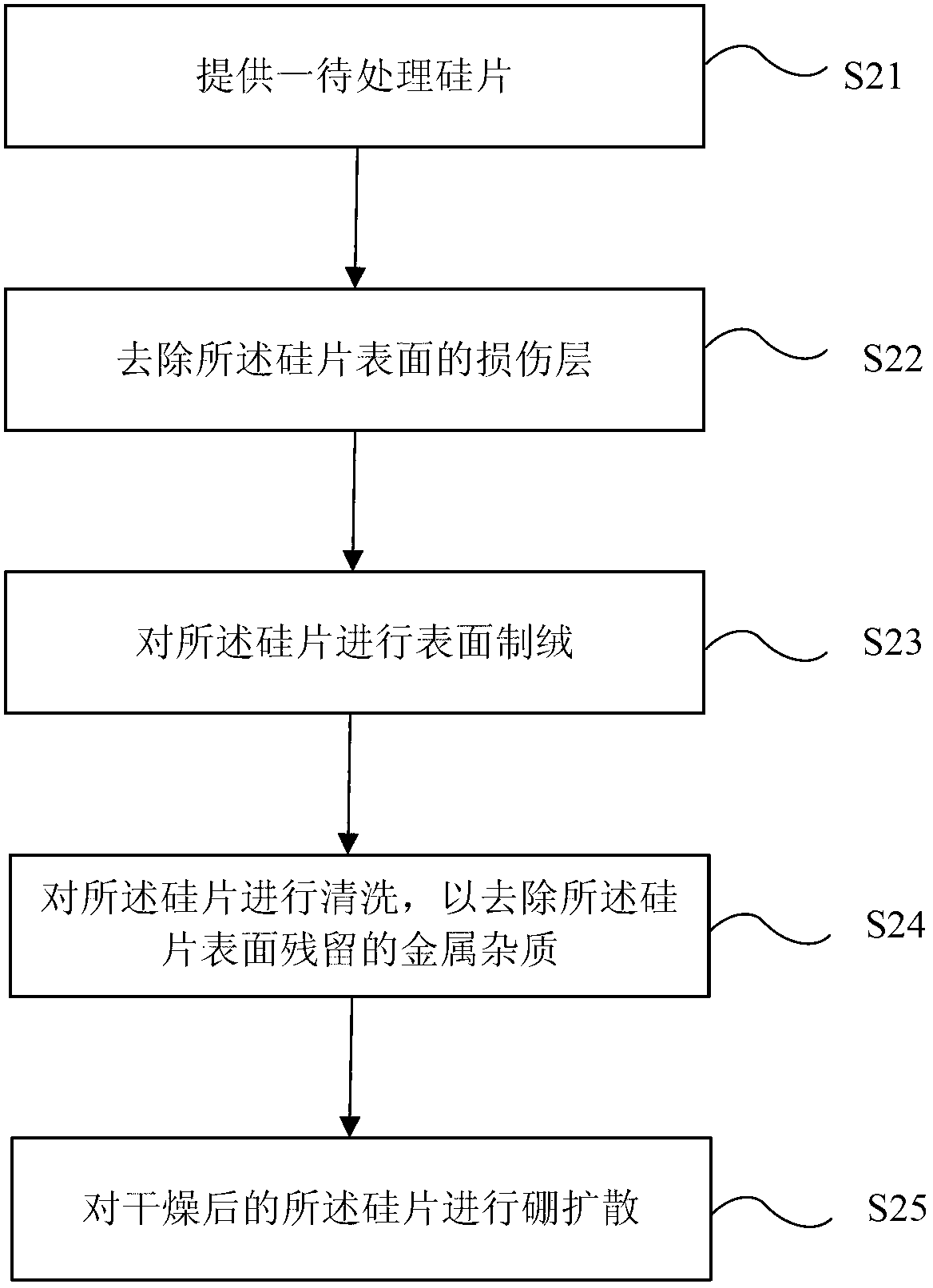

The invention discloses a manufacturing method of an N-type solar battery. The method comprises the following steps of: providing a silicon wafer to be treated; removing a damaged layer on the surface of the silicon wafer; carrying out surface texturing on the silicon wafer; washing the silicon wafer to remove metal impurities remaining on the surface of the silicon wafer; and carrying out boron diffusion on the dried silicon wafer. According to the technical scheme disclosed by the invention, parts of the metal impurities on the surface of the silicon wafer can be removed in a working procedure of removing the damaged layer; after the silicon wafer is textured and before the boron diffusion is carried out, the silicon wafer is washed; a reagent which does not damage surface textured face of the silicon wafer, does not influence the boron diffusion effect of the silicon wafer and is used for transferring the metal impurities on the surface of the silicon wafer into a compound which can be dissolved into water is used for washing the silicon wafer to remove the residual metal impurities on the surface of the silicon wafer, so that the diffusion and blocking quality is guaranteed in the boron diffusion process, and the photoelectric conversion efficiency of the N-type solar battery is further improved.

Owner:YINGLI ENERGY CHINA

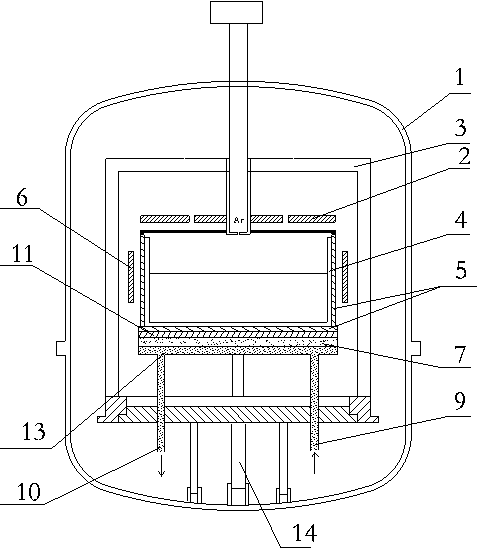

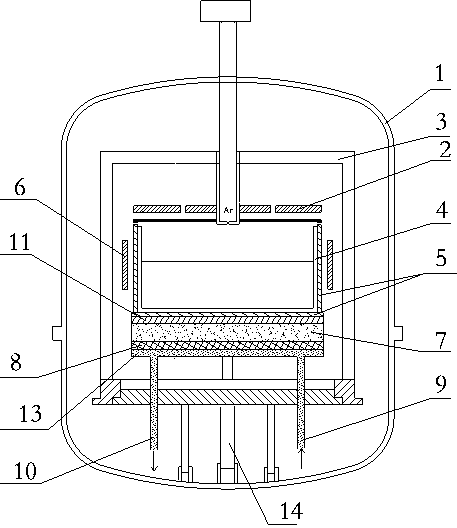

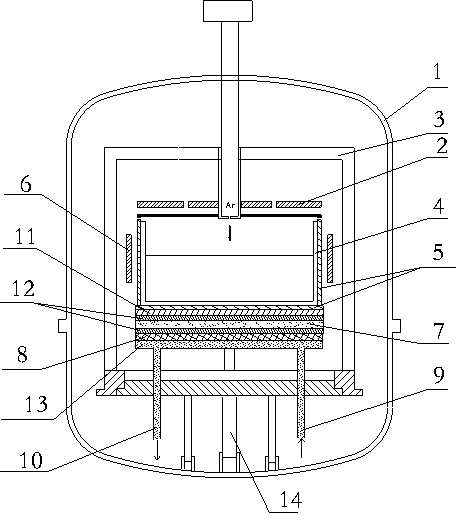

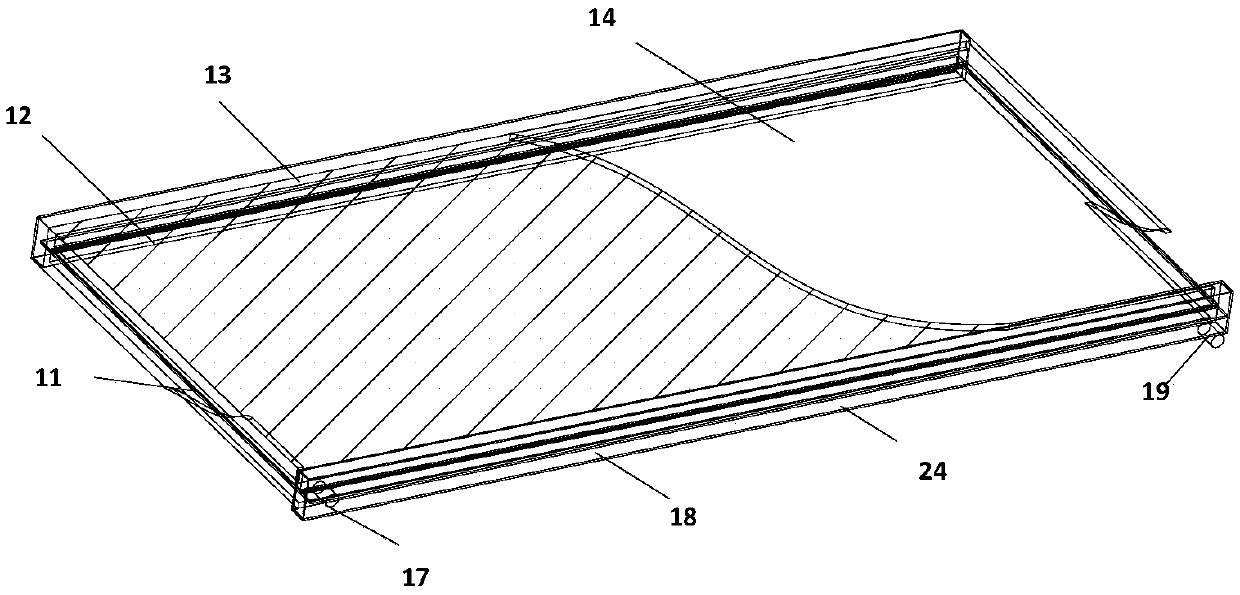

Water chilling ingot furnace and ingot casting process thereof

InactiveCN103451726AFacilitated releaseImprove yieldPolycrystalline material growthSingle crystal growth detailsCrucibleIngot casting

The invention discloses a water chilling ingot furnace and an ingot casting process thereof. A water cooling disc (13) is arranged at the lower end of a heat exchange table (11), located at the lower end of a bottom heater (7), internally provided with a flow cavity and provided with a water inlet (9) and a water outlet (10), wherein the water inlet (9) and the water outlet (10) are communicated through the flow cavity, and are respectively communicated with the outer end of a furnace body (1). The water chilling ingot furnace disclosed by the invention has the beneficial effects that the problem of influence on formation of columnar crystals due to transfer of heat of a crucible in a radial direction caused by lifting an insulating cage to dissipate heat from a side is solved by way of replacing the original mode of lifting the insulating cage to dissipate heat by water cooling; an insulating cage body in a lifting process is prevented from rubbing with the top of the insulating cage to generate carbon dust which is easy to enter the crucible to increase carbon impurity content of a silicon ingot so as to cause lattice deformation.

Owner:TIANWEI NEW ENERGY HLDG

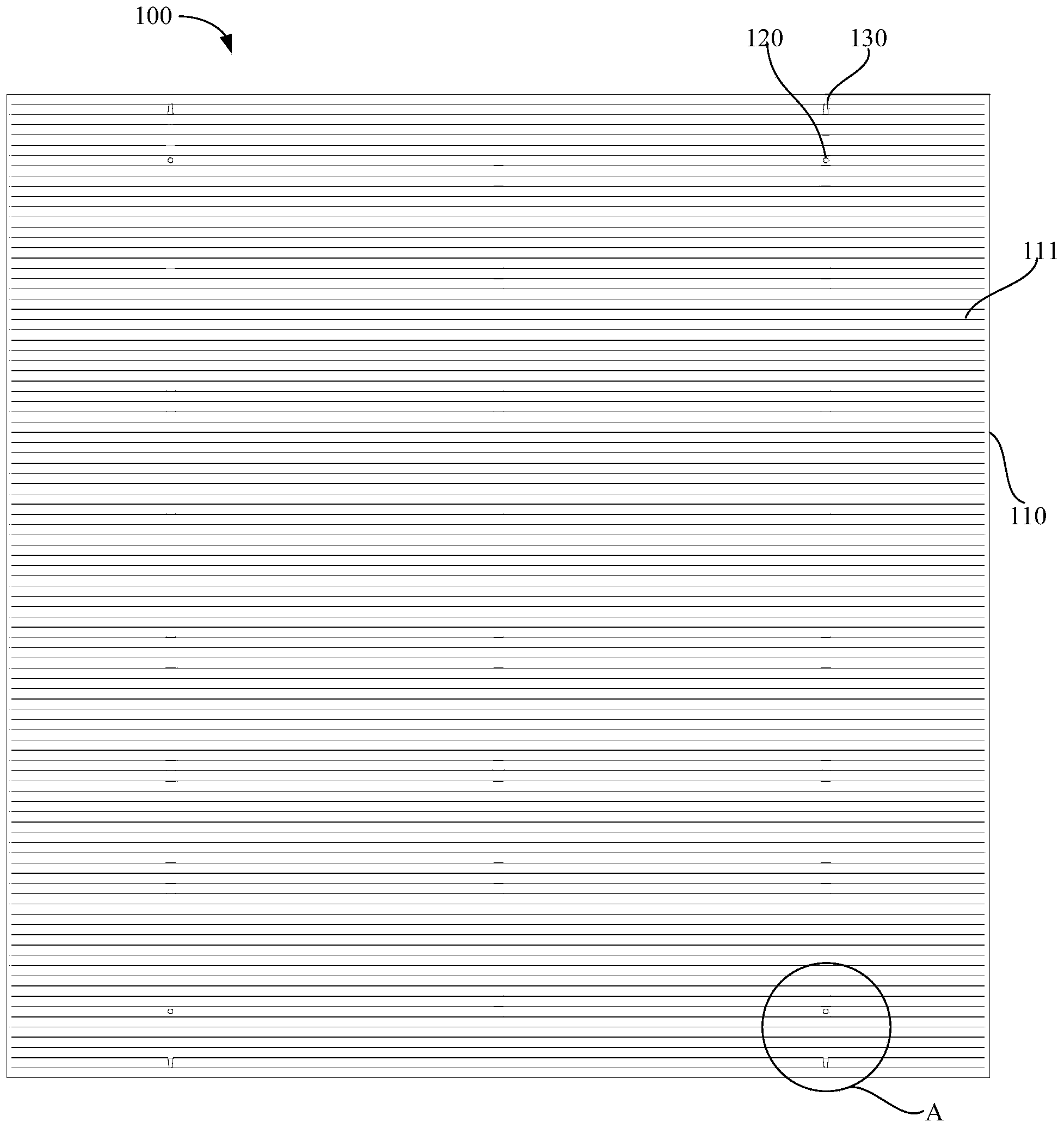

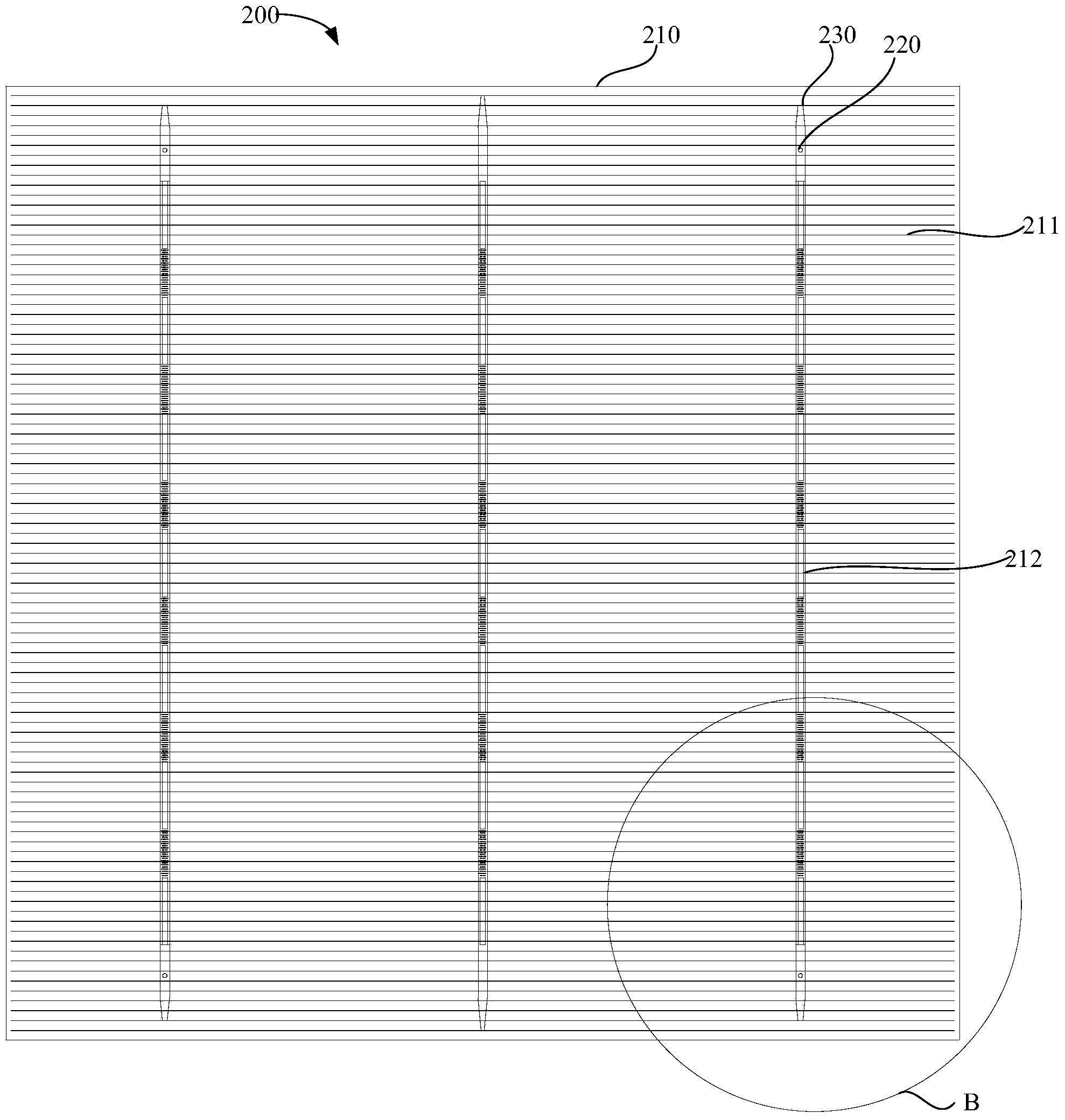

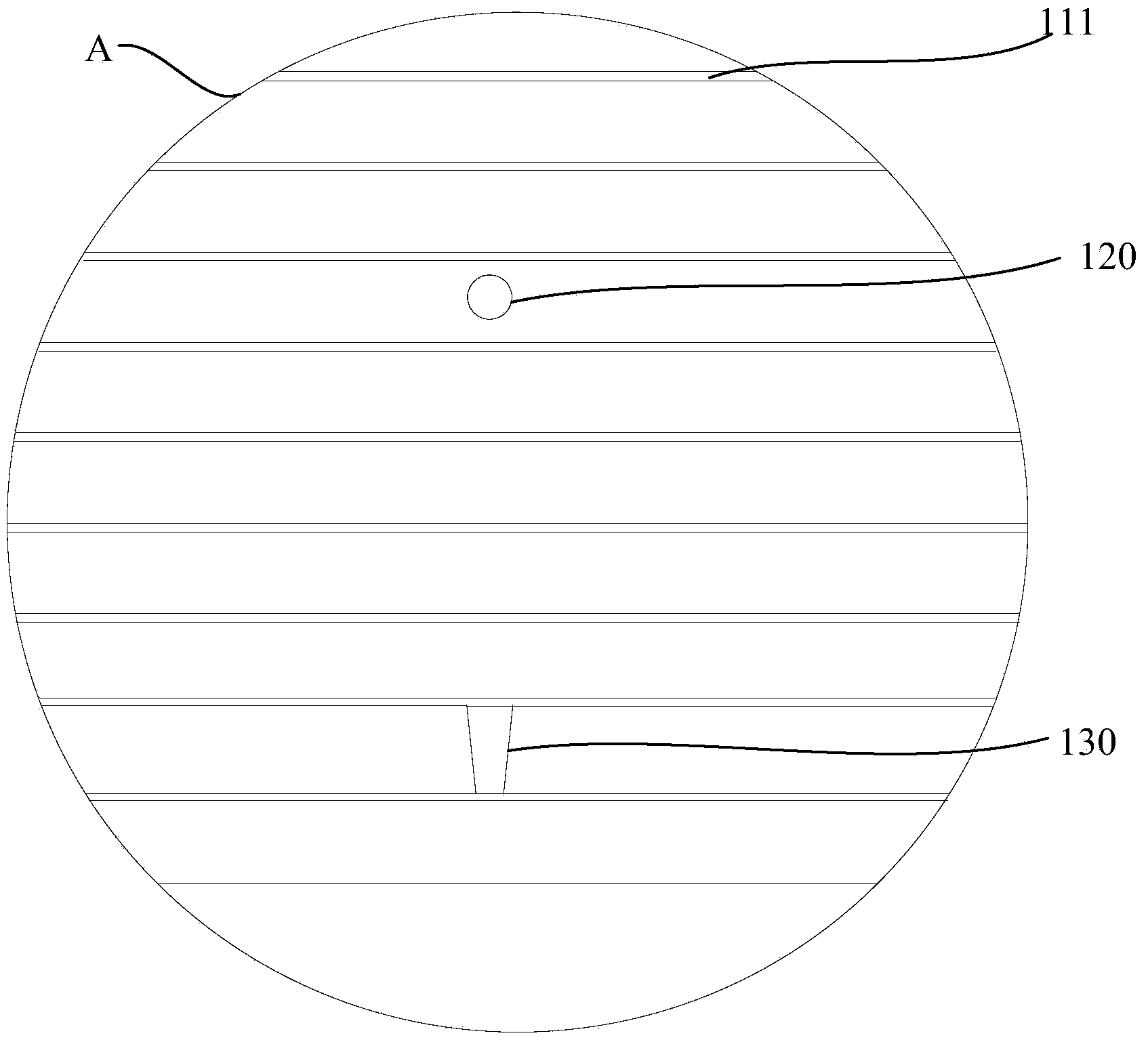

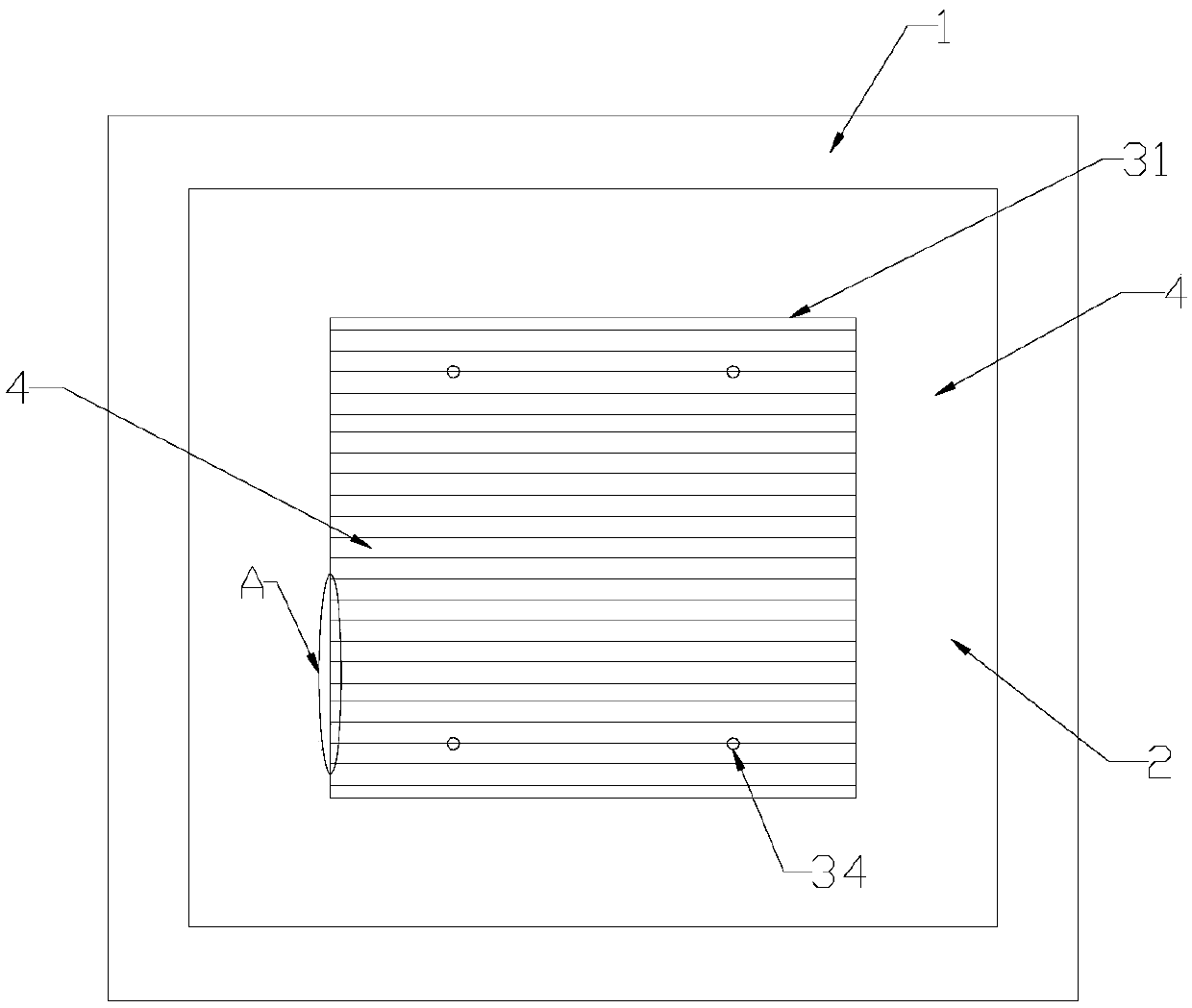

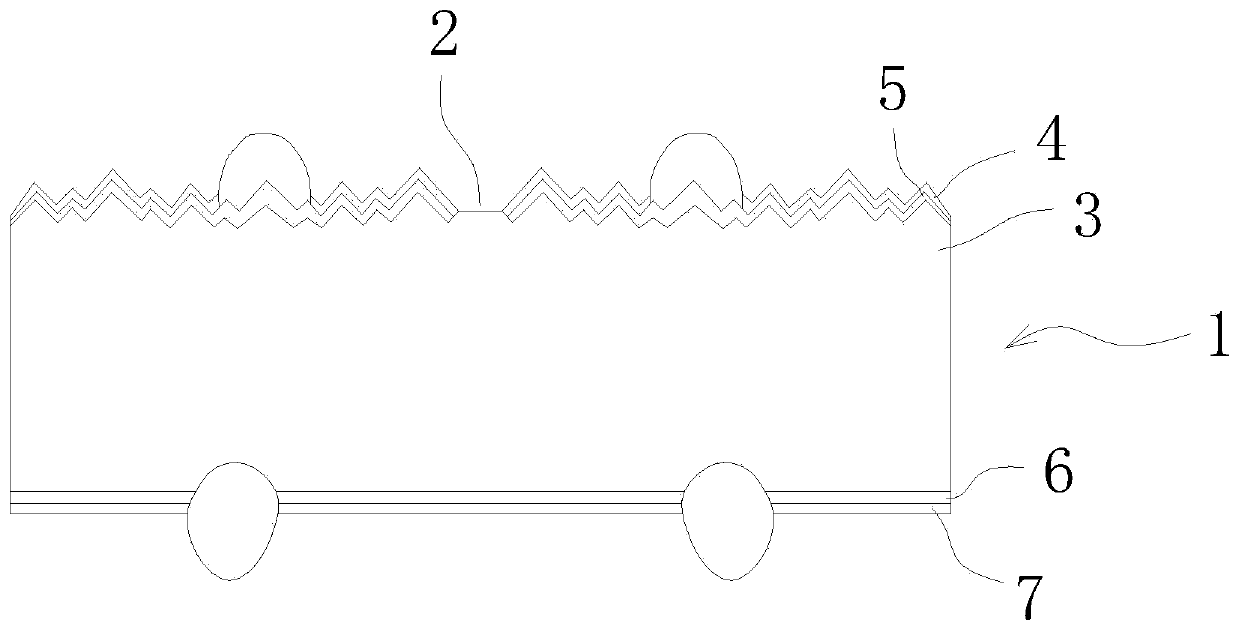

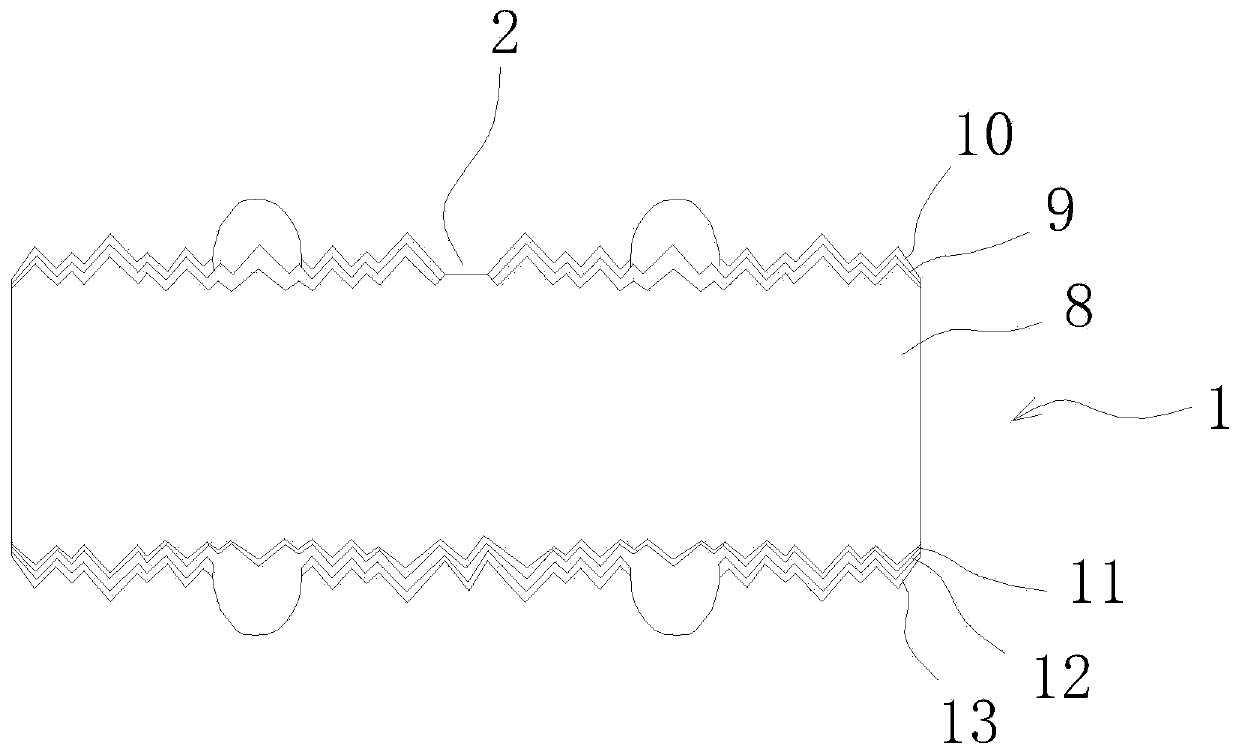

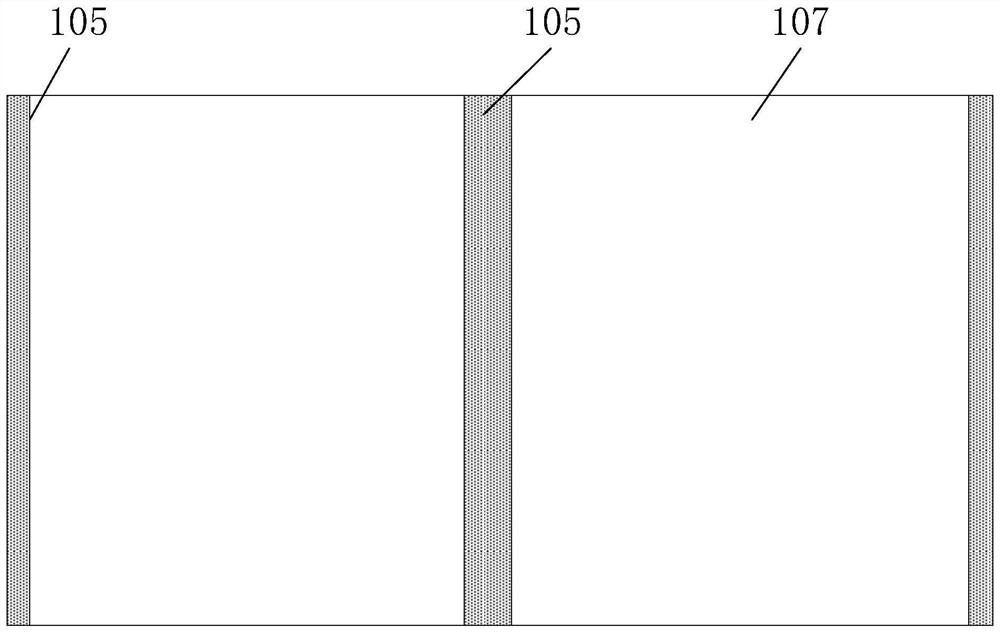

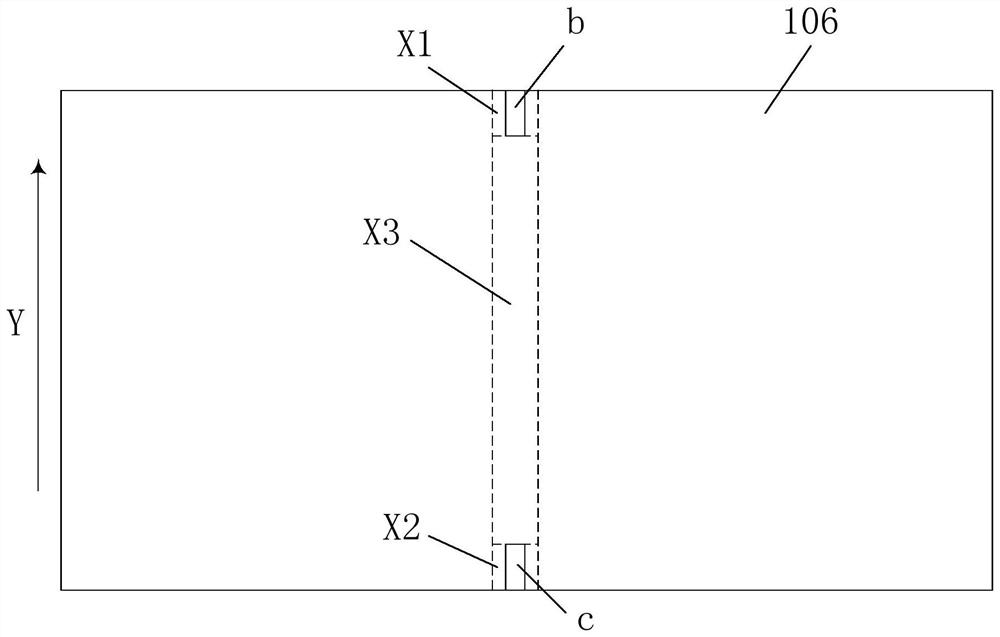

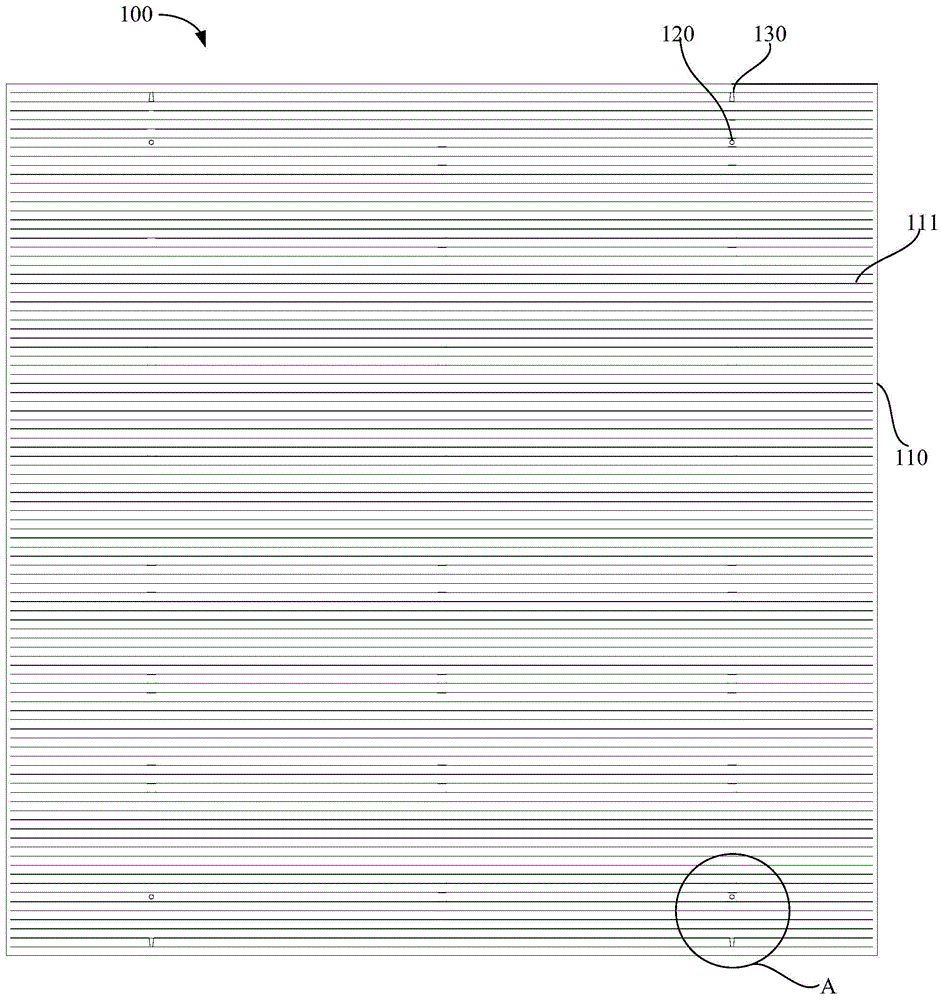

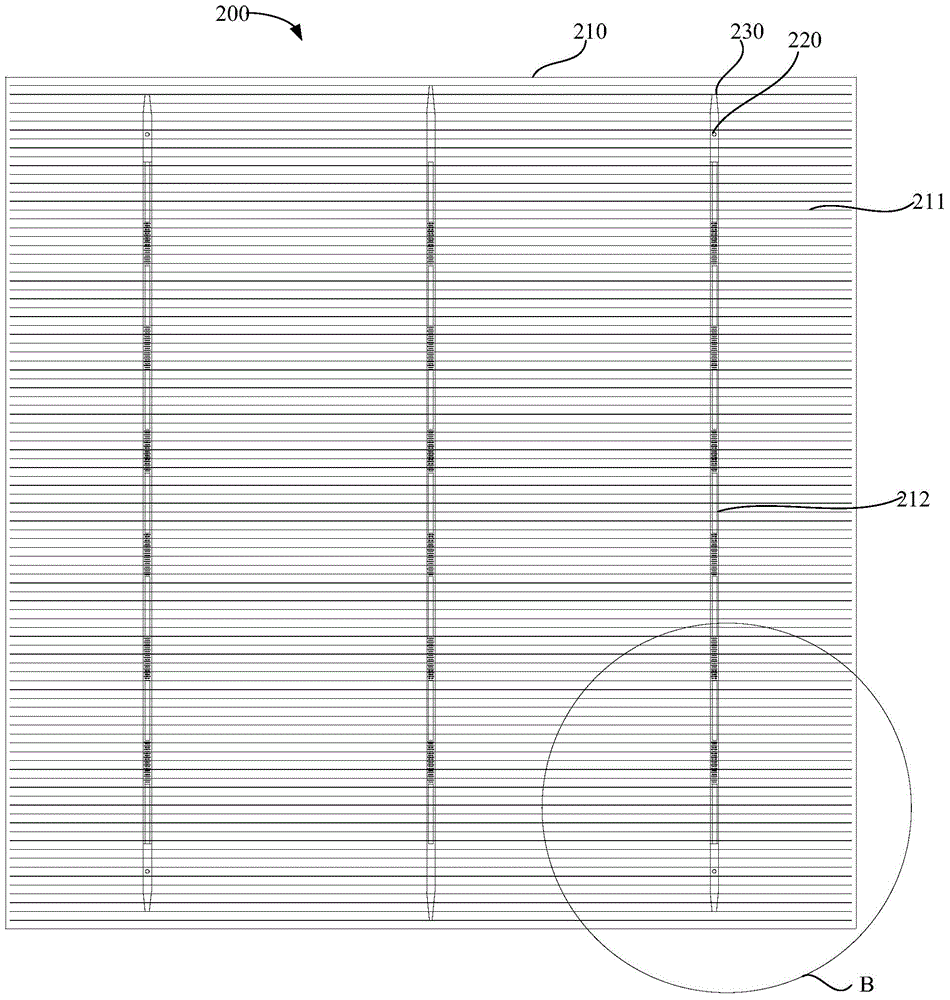

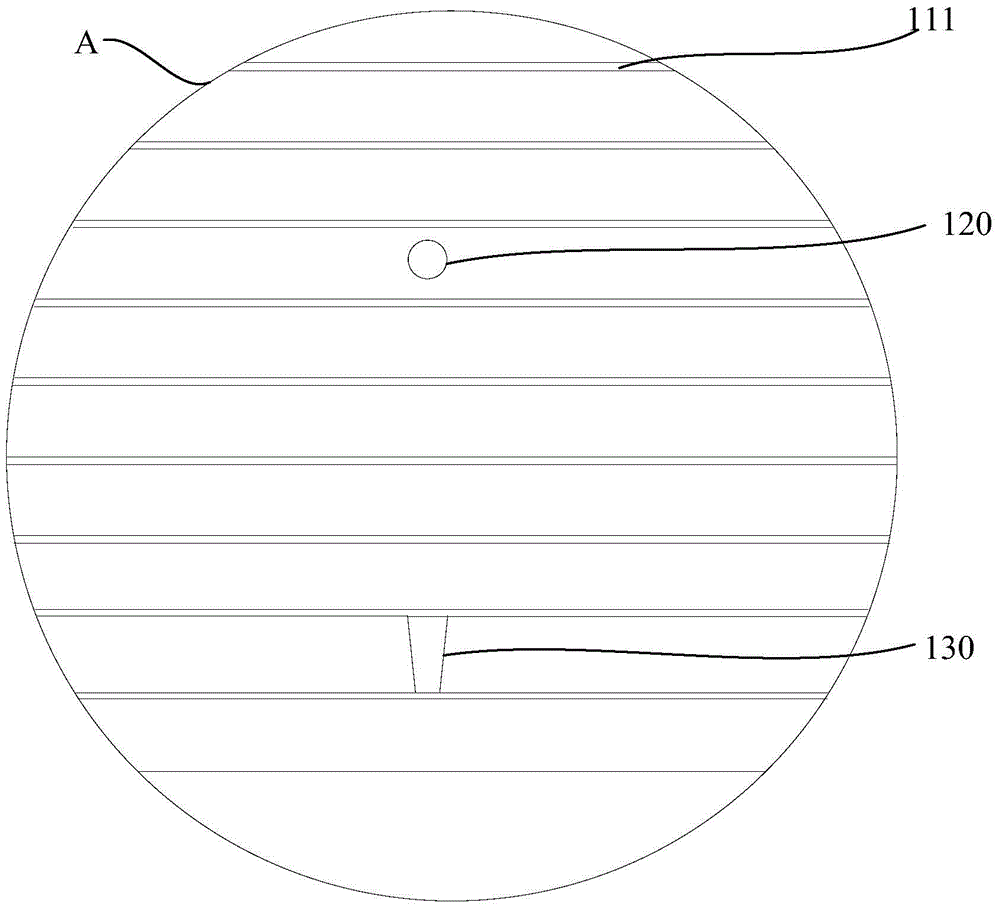

Solar cell electrode printing screen, solar cell electrode and manufacturing method thereof

ActiveCN104332509AReduce photoelectric conversion efficiencyIncrease the shade areaFinal product manufactureScreen printersShortest distanceEngineering

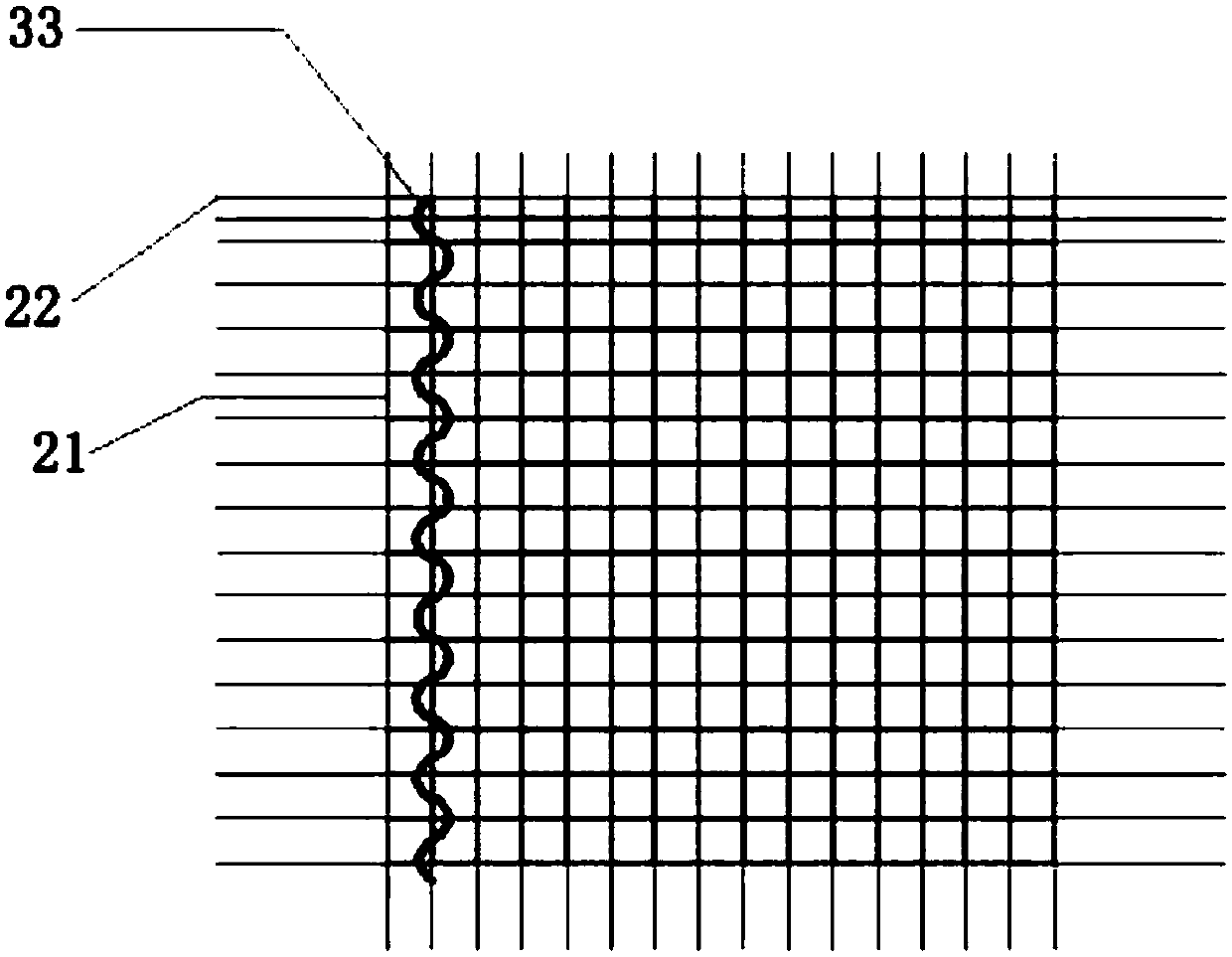

A solar cell electrode printing screen comprises a first screen and a second screen; the first screen comprises a first template; a plurality of first thin grids are formed in the first template; the first template is provided with alignment holes and wedge-shaped holes; the second screen comprises a second template; the second template is provided with a plurality of second thin grids and main grids; the second thin grids and the main grids are intersected; the distance between axes of the adjacent two second thin grids is equal to that between axes of the adjacent two first thin grids; the width of the second thin grids is smaller than or equal to that of the first thin grids; the main grids are provided with alignment portions; one ends of the main grids are provided with sharp corner hollow-outs; the shortest distance between edges of the alignment portions and end surfaces of the top ends of the sharp corner hollow-outs is equal to that between the edges of the alignment holes and the edges of the wedge-shaped holes. According to the solar cell electrode printing screen, substrates after the second screen and the first screen are printed are accurately aligned and dislocation of a thin grid line during printing at the second time and a thin grid line during printing at the first time is avoided. The invention also provides a solar cell electrode and a manufacturing method thereof.

Owner:CSG PVTECH

Inverted gradient bulk heterojunction perovskite solar cell on basis of gallium oxide protective layer and method for preparing inverted gradient bulk heterojunction perovskite solar cell

ActiveCN108281560AImprove photoelectric conversion efficiencyImprove stabilitySolid-state devicesSemiconductor/solid-state device manufacturingLow temperature depositionHeterojunction

The invention relates to an inverted gradient bulk heterojunction perovskite solar cell on the basis of a gallium oxide protective layer and a method for preparing the inverted gradient bulk heterojunction perovskite solar cell. The inverted gradient bulk heterojunction perovskite solar cell which is a perovskite cell comprises a transparent conductive substrate, a hole transport layer, a perovskite light absorption layer, an electron transport layer and metal electrodes. The inverted gradient bulk heterojunction perovskite solar cell and the method have the advantages that a high-quality gallium oxide thin film is prepared by the aid of low-temperature deposition atomic layer bottom sinking processes with simple technologies and is used as a cushion layer between the electron transport layer and the metal electrodes, and accordingly the photovoltaic performance of devices can be effectively improved; the gallium oxide thin film with inorganic and hydrophobic characteristics can be used as the protective layer, accordingly, cell erosion due to external environments can be effectively isolated, and the stability of the devices can be enhanced; non-fullerene materials IDIC are dissolved in a green and environment-friendly solvent ethyl acetate to prepare gradient heterojunction perovskite thin films, accordingly, defects of perovskite can be effectively passivated, the performance of the devices can be enhanced, and thin film preparation toxic environments can be relieved.

Owner:WUHAN UNIV

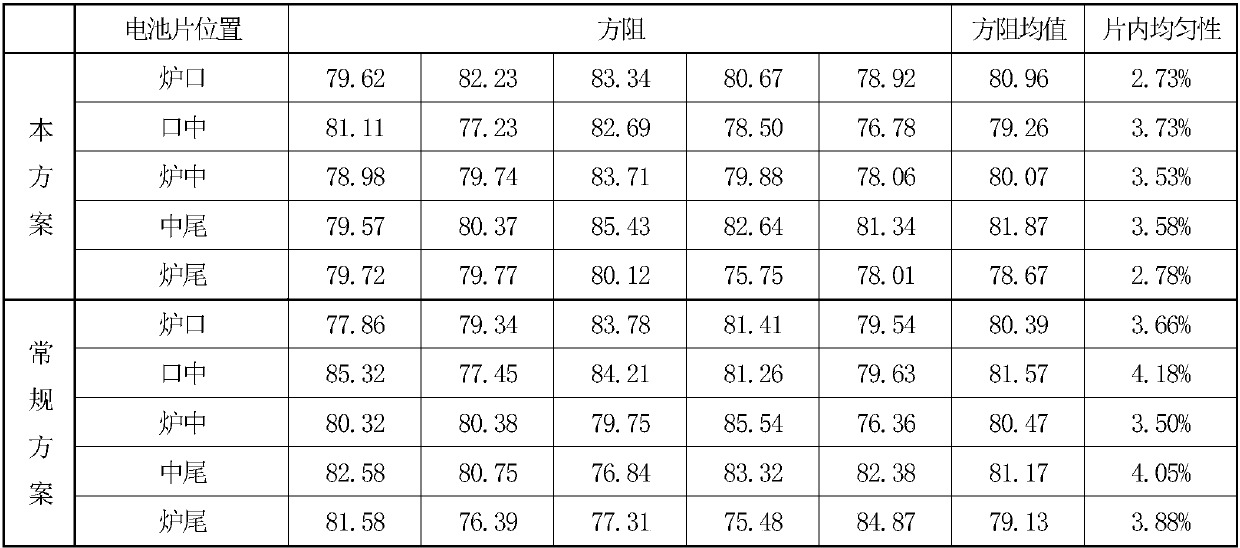

Solar battery piece diffusion process

InactiveCN109616543ALow conversion efficiencyImprove spectral responsivityFinal product manufactureSemiconductor/solid-state device manufacturingNitrogenOxygen

The invention discloses a solar battery piece diffusion process. The solar battery piece diffusion process comprises the following steps of B, heating a furnace chamber of a diffusion furnace to a first temperature, and continuously introducing pure nitrogen; C, maintaining the furnace chamber at the first temperature, and introducing pure nitrogen and oxygen to the furnace chamber to oxidize thebattery piece; D, carrying out low-temperature diffusion at the first temperature, and continuously introducing pure nitrogen, phosphorus source-carrying nitrogen and oxygen into the furnace chamber in the process; E, heating the furnace chamber of the diffusion furnace to a second temperature, simultaneously pumping phosphorus atoms, and continuously introducing pure nitrogen; F, maintaining thefurnace chamber at the second temperature and carrying out high-temperature diffusion, and continuously introducing pure nitrogen, phosphorus source-carrying nitrogen and oxygen into the furnace chamber in the process; G, heating the furnace chamber of the diffusion furnace to a third temperature, and simultaneously pumping the phosphorus atoms, and continuously introducing pure nitrogen; H, continuously pumping the phosphorus atoms at the third temperature, and continuously introducing pure nitrogen and oxygen into the furnace chamber in the process; and I, performing cooling and carrying outoxidation and simultaneously pumping the phosphorus atoms, and continuously introducing pure nitrogen and oxygen into the furnace chamber in the process.

Owner:TONGWEI SOLAR ENERGY (CHENGDU) CO LID

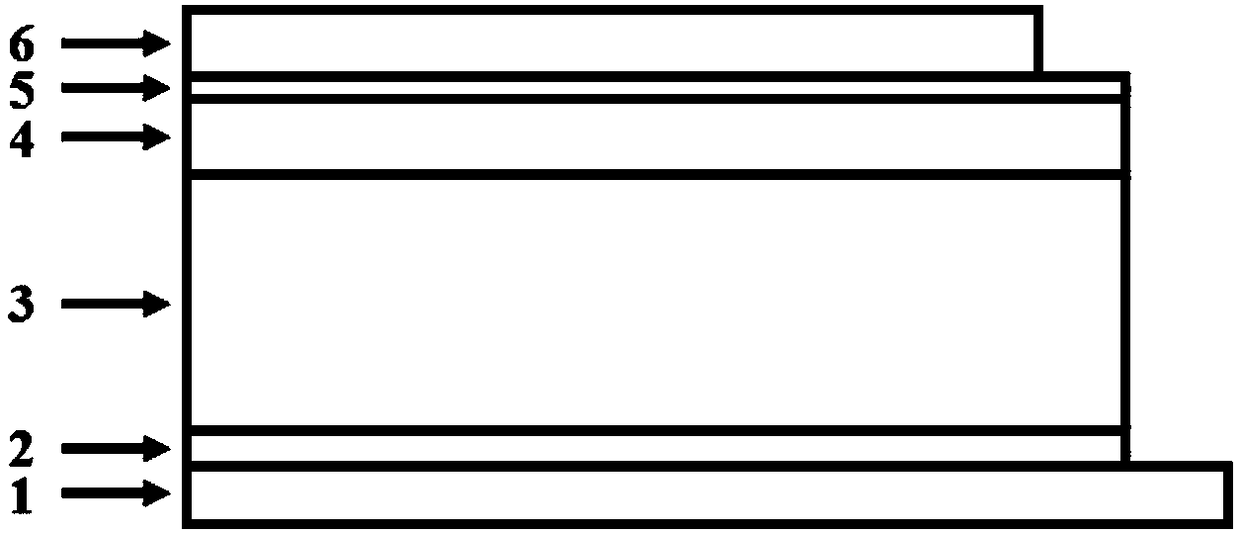

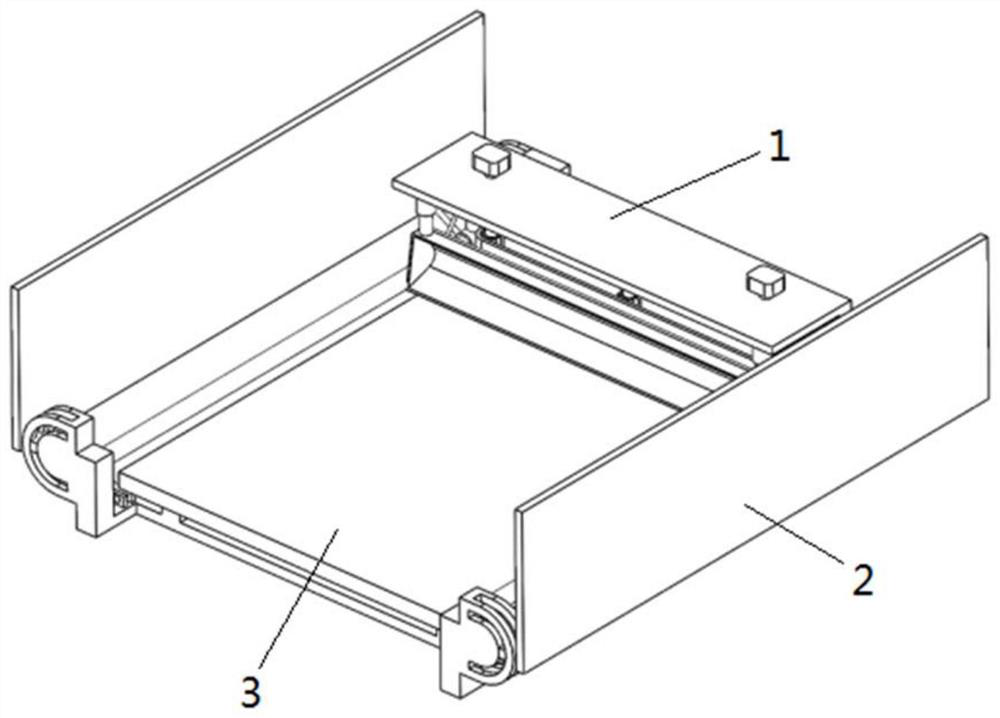

Preparation method for PERC double printing polycrystalline solar cell

InactiveCN109599456ALight attenuation (LID reductionReduced light decay (LID)Final product manufacturePhotovoltaic energy generationEngineeringOxygen

The invention discloses a preparation method for a PERC double printing polycrystalline solar cell. The PERC double printing polycrystalline solar cell is obtained by taking a polycrystalline siliconwafer as a base material and sequentially performing the steps, namely flocking, diffusion, etching, annealing, back passivation, antireflection film plating, back laser grooving, printing, sinteringand light attenuation reduction; in the annealing step, oxygen-free annealing is adopted, in the back passivation step, Al2O3 and SiNX are plated on the back of the silicon wafer, in the antireflection film plating step, SiNX is plated on the front of the silicon wafer, during positive electrode printing, a silk screen printing machine is adopted for printing twice, namely DP1 and DP2, a secondarygrid line is printed during the DP1, a main grid line and the secondary grid line are overprinted during the DP2, and a silk screen printing plate used in the printing DP1 and the printing DP2 is a knotless silk screen printing plate. The preparation method provided by the invention and for the PERC double printing polycrystalline solar cell can reduce LID of the solar cell to be about 1%, powerof a module finished product can be increased, conversion efficiency is high, and grade and electrical properties are obviously improved.

Owner:TONGWEI SOLAR ENERGY CHENGDU CO LID

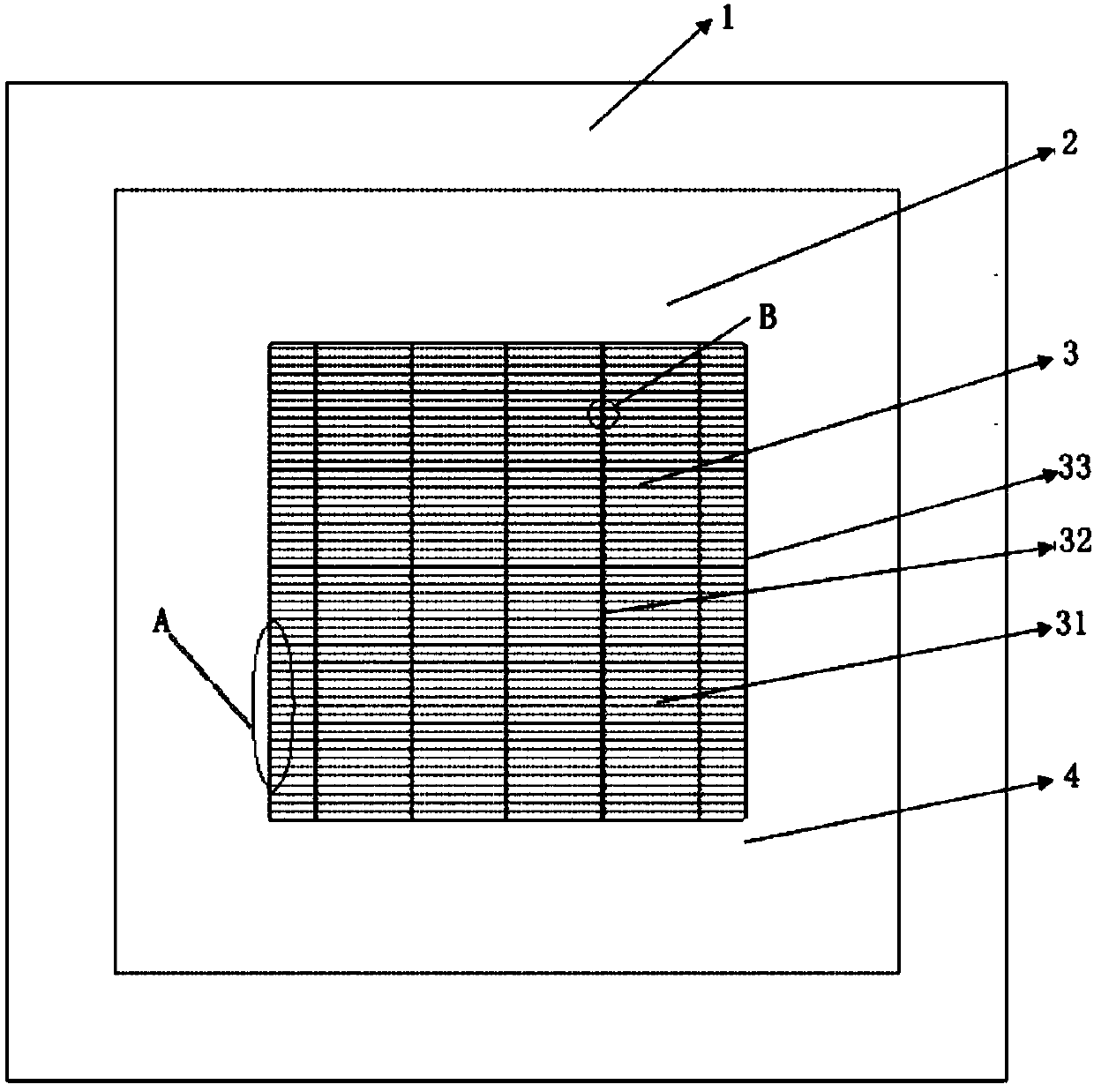

Solar photovoltaic panel intelligent detection processing system based on big data

ActiveCN111726081AExact damageReduce hot spotsPhotovoltaic monitoringMaterial flaws investigationComputer scienceReliability engineering

The invention discloses a solar photovoltaic panel intelligent detection processing system based on big data. The solar photovoltaic panel intelligent detection processing system comprises an environmental parameter acquisition module, a current acquisition module, a voltage acquisition module, a temperature acquisition module, a data distribution module, a conversion analysis module, an attachment judgment module, a data processing module, a guide clearing module and a protection shielding module. According to the invention, the temperature of a photovoltaic panel is analyzed and processed; whether the temperature of the photovoltaic panel is abnormal or not is judged; further, whether sundries are attached to the photovoltaic panel or not can be accurately judged; the damage degree of the attached sundries to the photovoltaic panel is judged; and the data processing module is used for analyzing the damage coefficient of the photovoltaic panel so as to judge whether to control the guide clearing module to clear the sundries causing damage to the photovoltaic panel or not and control the protection shielding module to shield rain or not, so that the photoelectric conversion efficiency reduction speed is greatly reduced, the system is intelligent, and the service life of the photovoltaic panel is prolonged.

Owner:重庆中电自能科技有限公司

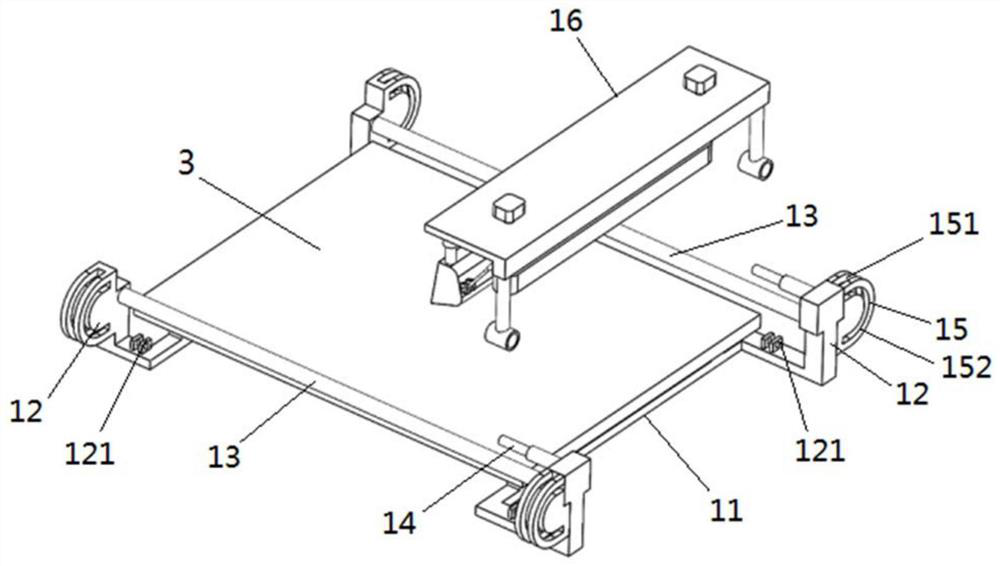

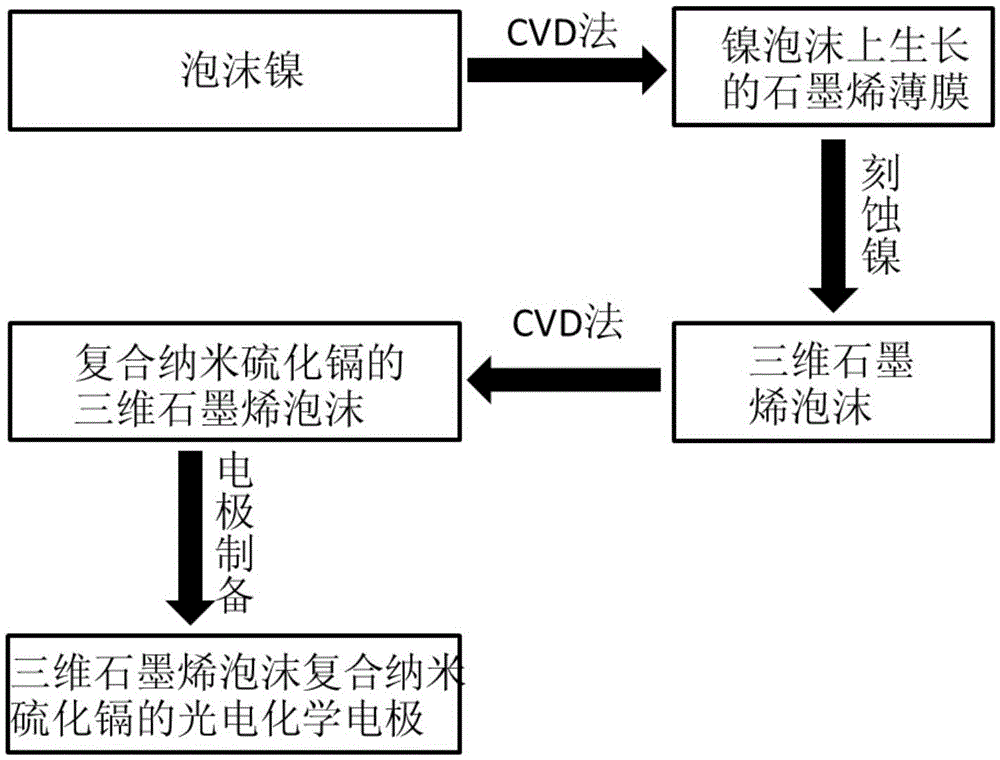

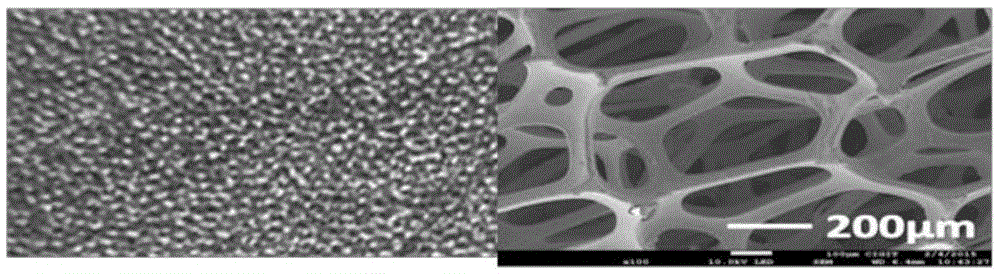

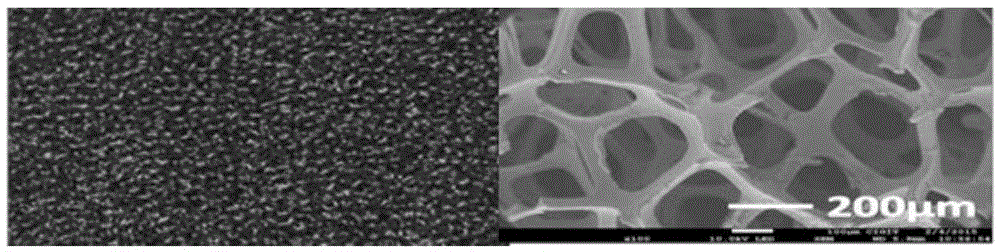

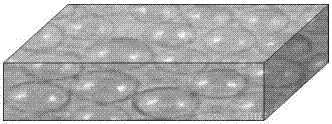

Preparation method of three-dimensional graphene foam composite nano-cadmium sulfide photoelectrochemical electrode

InactiveCN105679848AReduce photoelectric conversion efficiencyLower impedanceSemiconductor devicesGas phasePhotocurrent

The invention discloses a preparation method of a three-dimensional graphene foam composite nano-cadmium sulfide photoelectrochemical electrode. The preparation method is as follows: growing graphene on the nickel foam by chemical vapor deposition, removing the nickel foam by using an etching process to obtain a three-dimensional graphene foam. Then, the nano-cadmium sulfide is composited with the three-dimensional graphene foam by the chemical vapor deposition method. Finally, the three-dimensional graphene foam composite nano-cadmium sulfide was prepared as a photoelectrochemical electrode by the photoelectrochemical electrode process. Three-dimensional graphene has an excellent conductive grid and a large specific surface area, which provides sufficient conductive channels for cadmium sulfide to transport electrons and reduce photocurrent loss. This new low-cost, large-scale production-friendly three-dimensional graphene foam composite nano-cadmium sulfide photoelectrochemical electrode method will have potential application prospects in the field of photoelectrochemical electrodes and sensors.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

Solar cell and laser slicing method

PendingCN111446308AEliminate damageReduce decreaseFinal product manufactureSemiconductor/solid-state device manufacturingFill factorLaser cutting

The invention provides a solar cell and a laser slicing method, and belongs to the technical field of photovoltaics. The solar cell comprises a cell body, wherein at least one non-emitter region is arranged on the front surface of the cell body. The method specifically comprises the following steps: cutting off phosphosilicate glass or borosilicate glass on one surface, having a p-n junction, of acell body by using laser at a subsequent laser slicing position, removing the p-n structure of the film opening region in a wet etching, dry etching or mechanical etching mode to form an emitter-freeregion, manufacturing a cell, and then cutting along the emitter-free region on the front surface by using laser or cutting along the region on the back surface of the cell corresponding to the emitter-free region on the front surface to crack the cell body. According to the invention, the damage of laser cutting to a p-n junction can be eliminated, so that the decrease of the fill factor of thesolar cell due to laser cutting is significantly weakened.

Owner:TRINASOLAR CO LTD +1

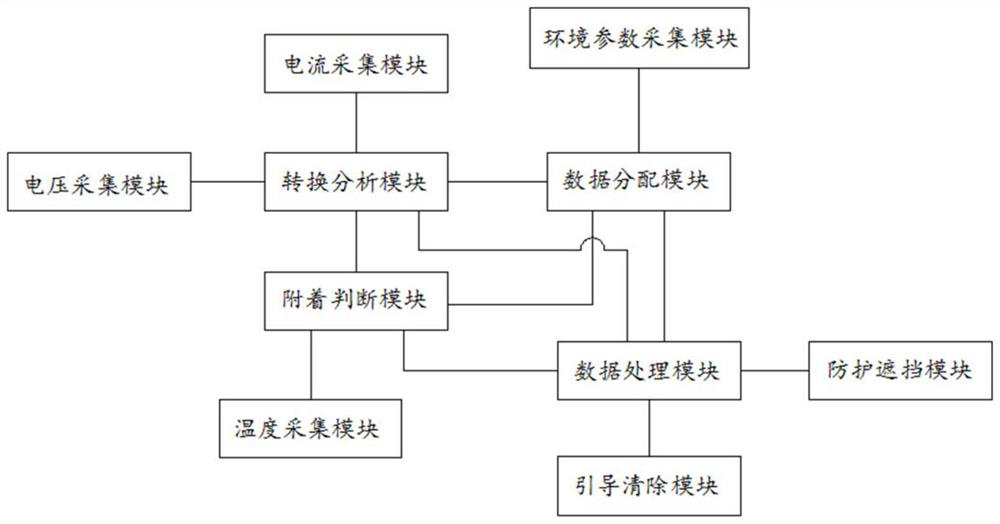

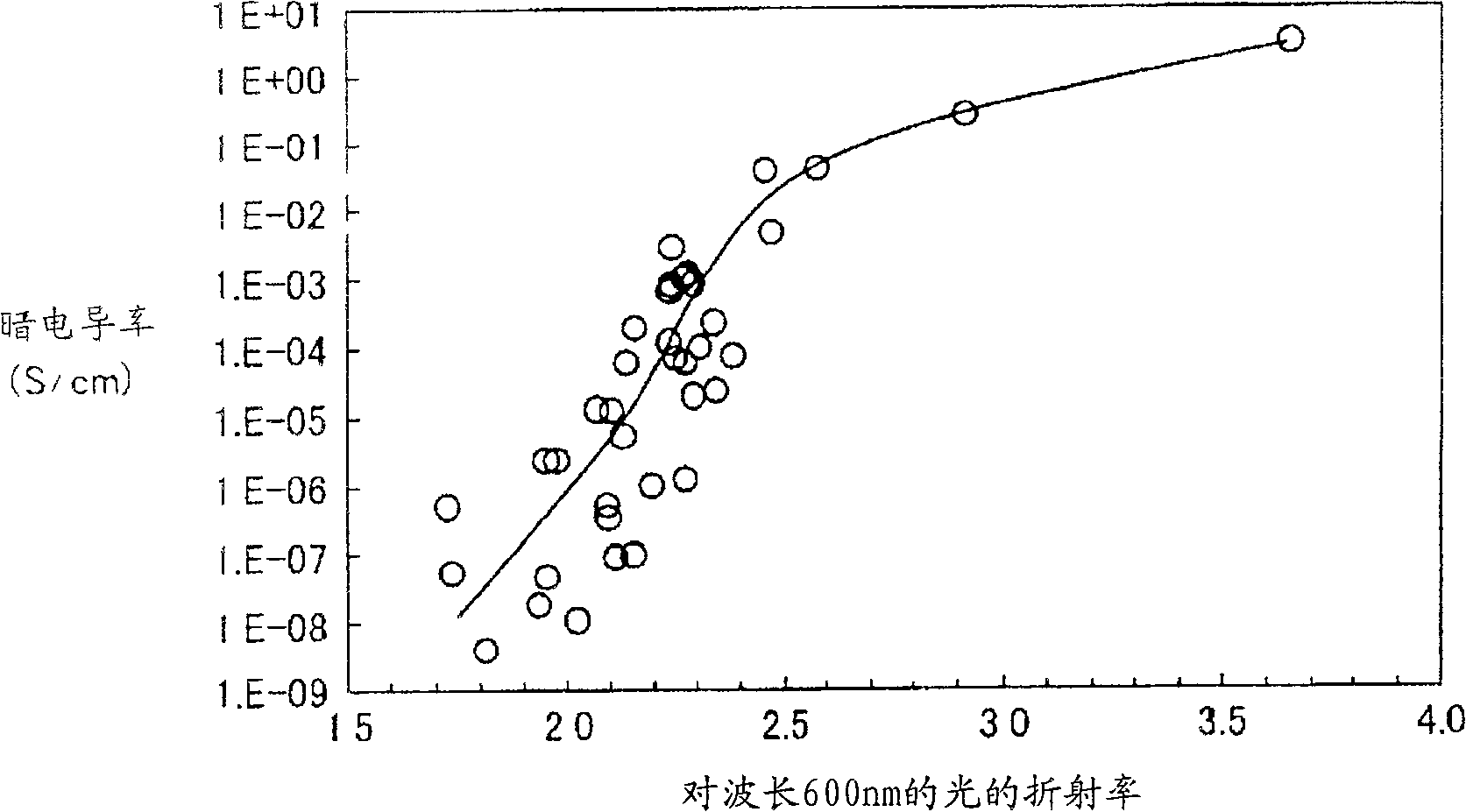

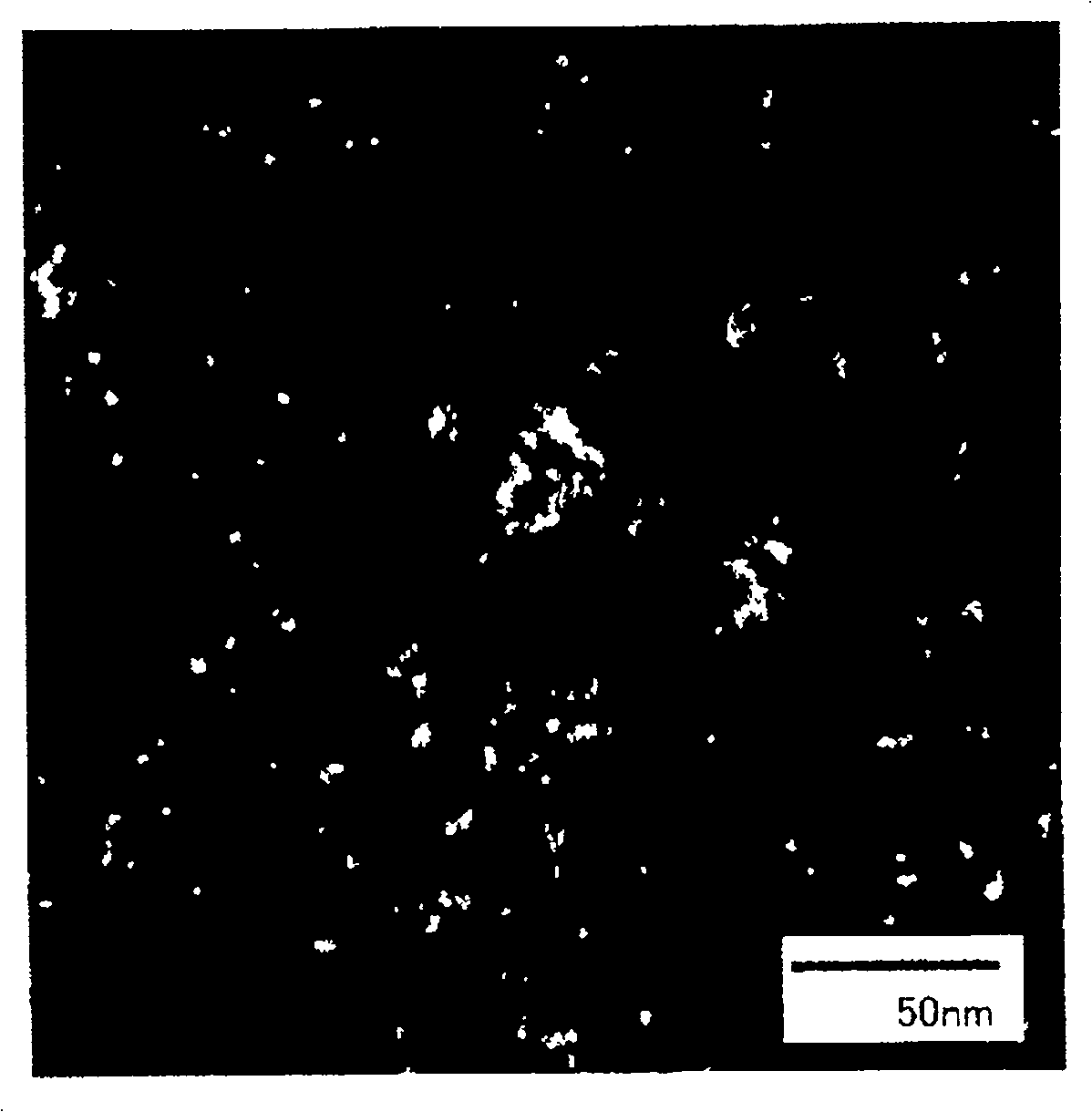

Stacked photoelectric converter

InactiveCN100420039CIncrease the generating currentReduce manufacturing costPhotovoltaic energy generationSemiconductor devicesPhotoelectric conversionOpto electronic

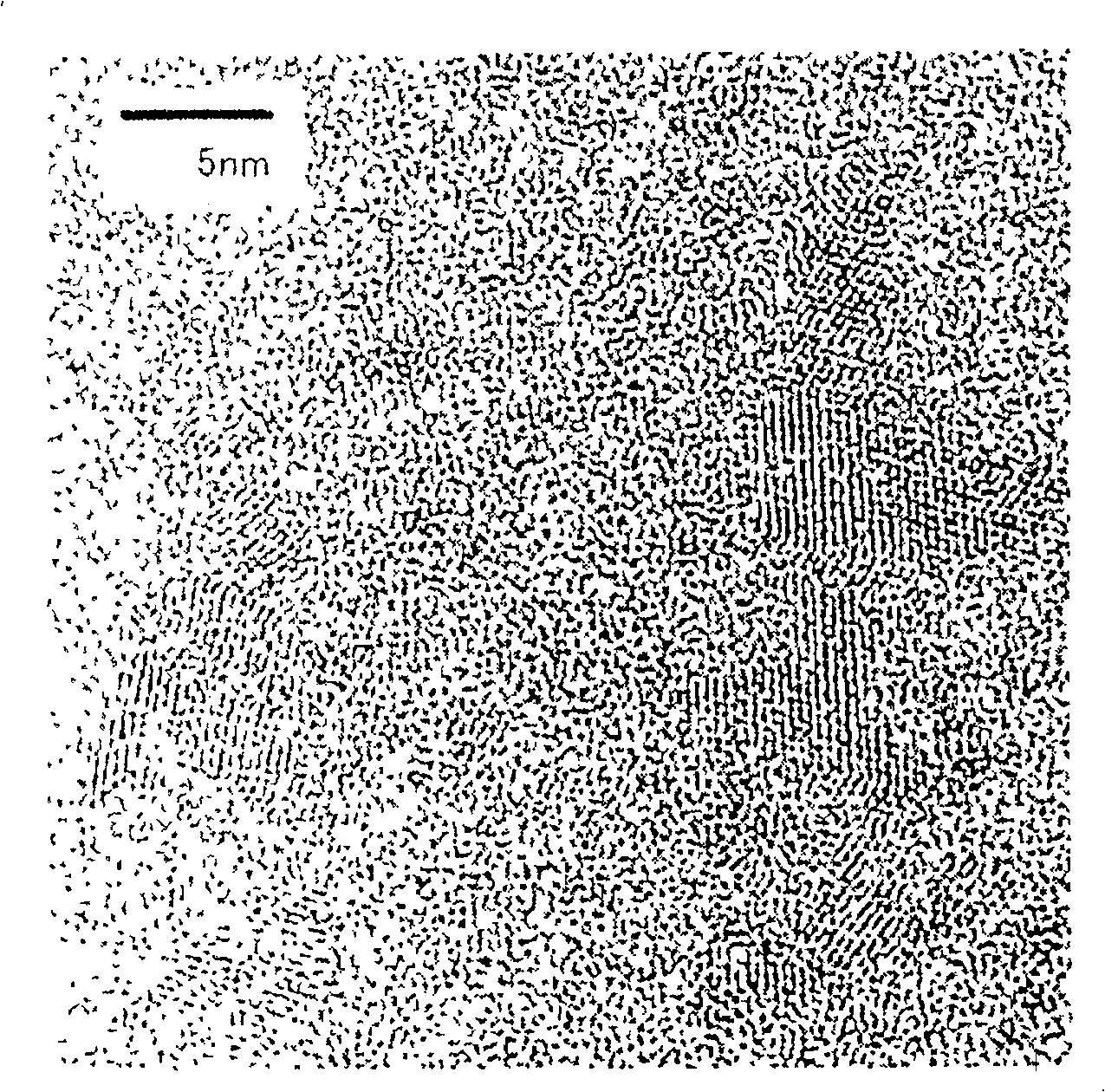

A stacked photoelectric converter comprising a plurality of stacked photoelectric conversion units (3;5) each including one conductivity type layer (31;51), a photoelectric converting layer (32;52) of substantially intrinsic semiconductor, and a reverse conductivity type layer (33;53) that are formed on a substrate (1) sequentially from the light incident side. At least one of the reverse conductivity type layer (33) in the front photoelectric conversion unit (3) arranged relatively on the light incident side and the one conductivity type layer (51) in the rear photoelectric conversion unit (5) arranged contiguously to the front photoelectric conversion unit (3) includes a silicon composite layer (4). The silicon composite layer (4) has a thickness of 20-130 nm and an oxygen concentration of 25-60 atm%.

Owner:KANEKA CORP

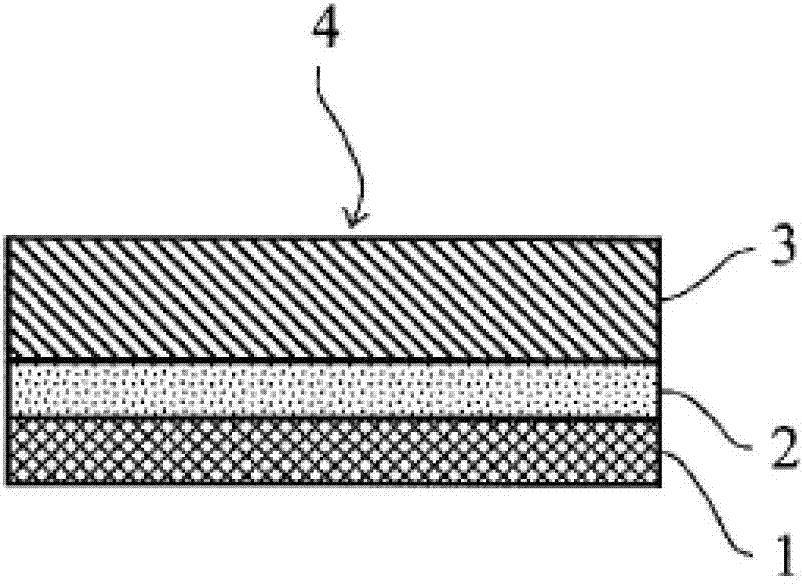

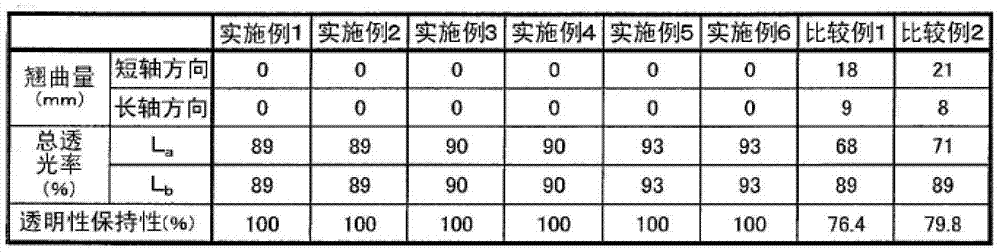

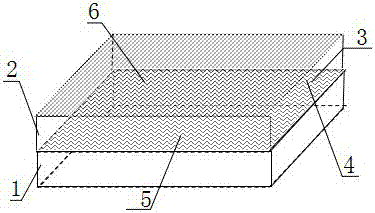

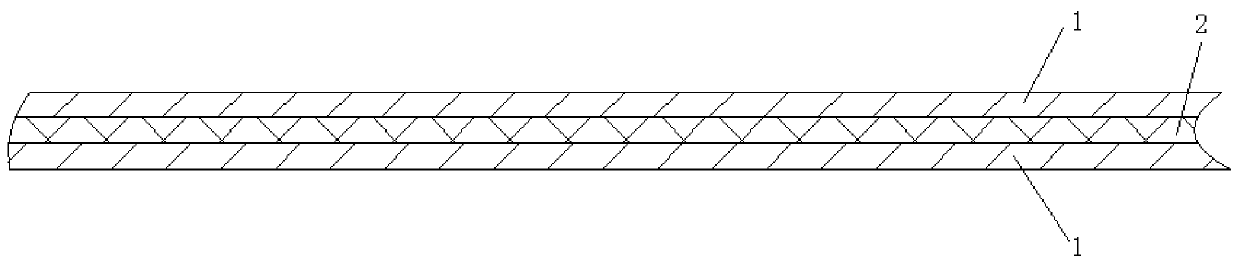

Laminate

InactiveCN103249555ALow utilization efficiencyLow transparencySemiconductor/solid-state device detailsSynthetic resin layered productsTransmittancePhotoelectric conversion

Provided is a laminate of a thermoplastic resin layer and a base, which has excellent transparency and is free from the occurrence of "warping". The laminate is suitable for sealing and surface protection of photoelectric conversion elements. This laminate is obtained by bonding a base and a thermoplastic resin layer that has a thickness larger than 200 [mu]m but 500 [mu]m or less with an adhesive layer being interposed therebetween. The 180 DEG peel strength at 23 DEG C of the thermoplastic resin layer with respect to the adhesive layer is not less than 1.0 N / 25 mm. It is preferable that the total light transmittance of the laminate is not less than 80%.

Owner:NITTO DENKO CORP

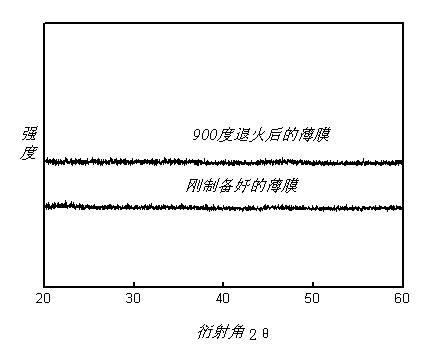

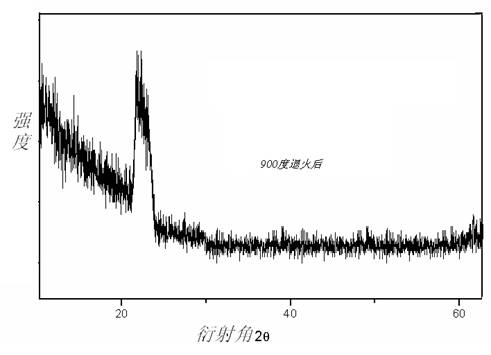

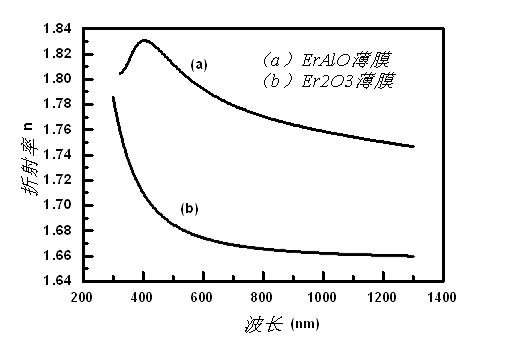

Antireflection material for solar cell and manufacturing method thereof

InactiveCN101997039AImprove thermal stabilityProper refractive indexSemiconductor devicesRadio frequency magnetron sputteringHeat stability

The invention discloses an antireflection material for a solar cell and a manufacturing method thereof. The antireflection material is an erbium oxide-aluminum oxide (Er2O3-Al2O3) composite material, wherein the content of Al2O3 is 20-30 percent. The antireflection material is a stable amorphous composite oxide material. In the invention, the antireflection material is manufactured by adopting radio frequency magnetron sputtering, and a sputtering target is an Er2O3 and Al2O3 mixed ceramic target; and an ErAlO amorphous antireflection oxide film is prepared on a P-type Si (100) substrate. The antireflection material for a solar cell has adjustable refractive index, good antireflection effect and good heat stability and optical characteristics.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

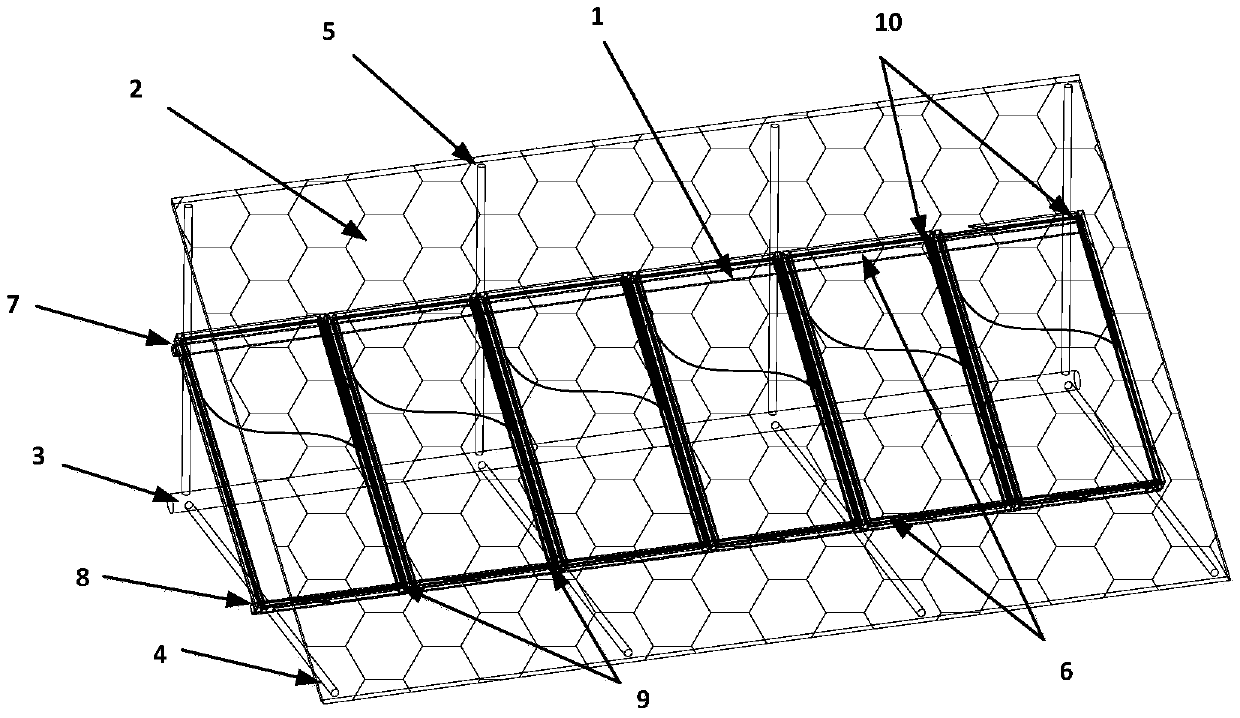

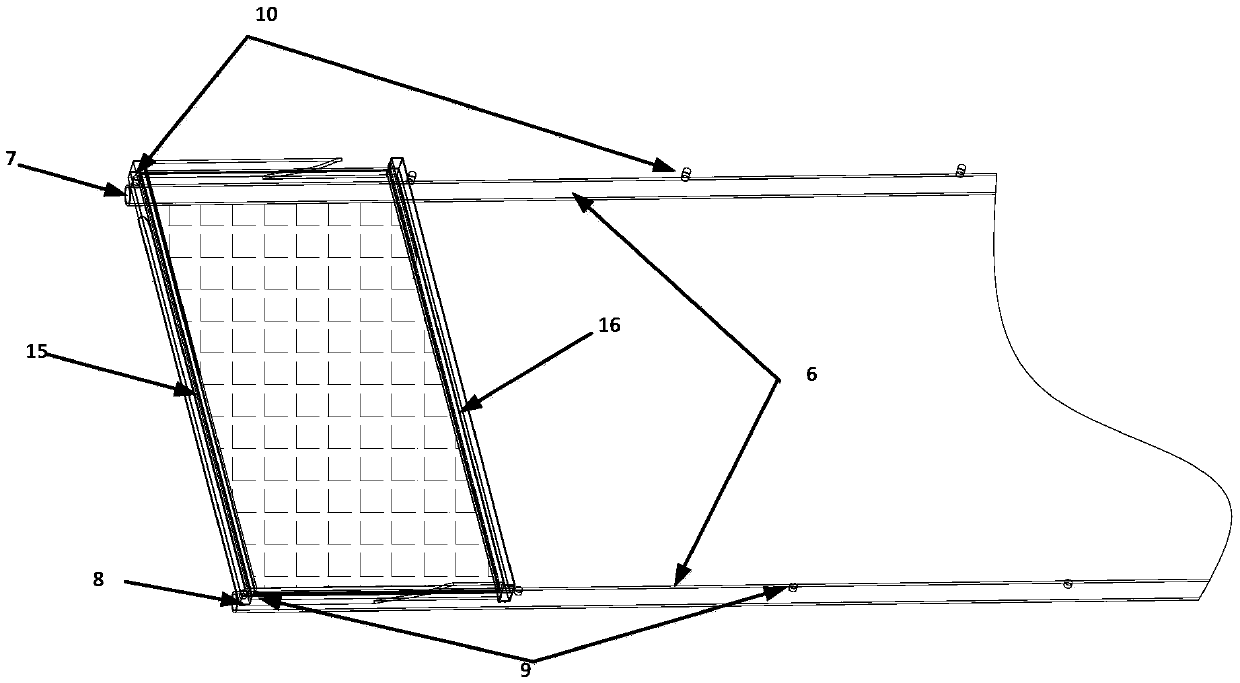

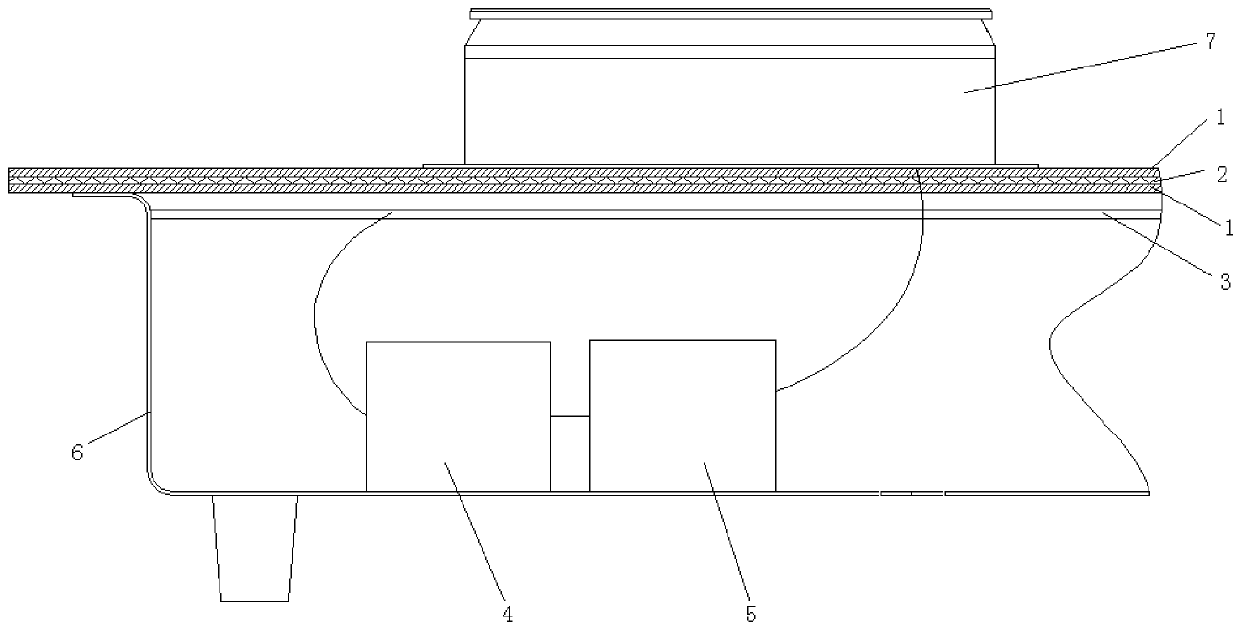

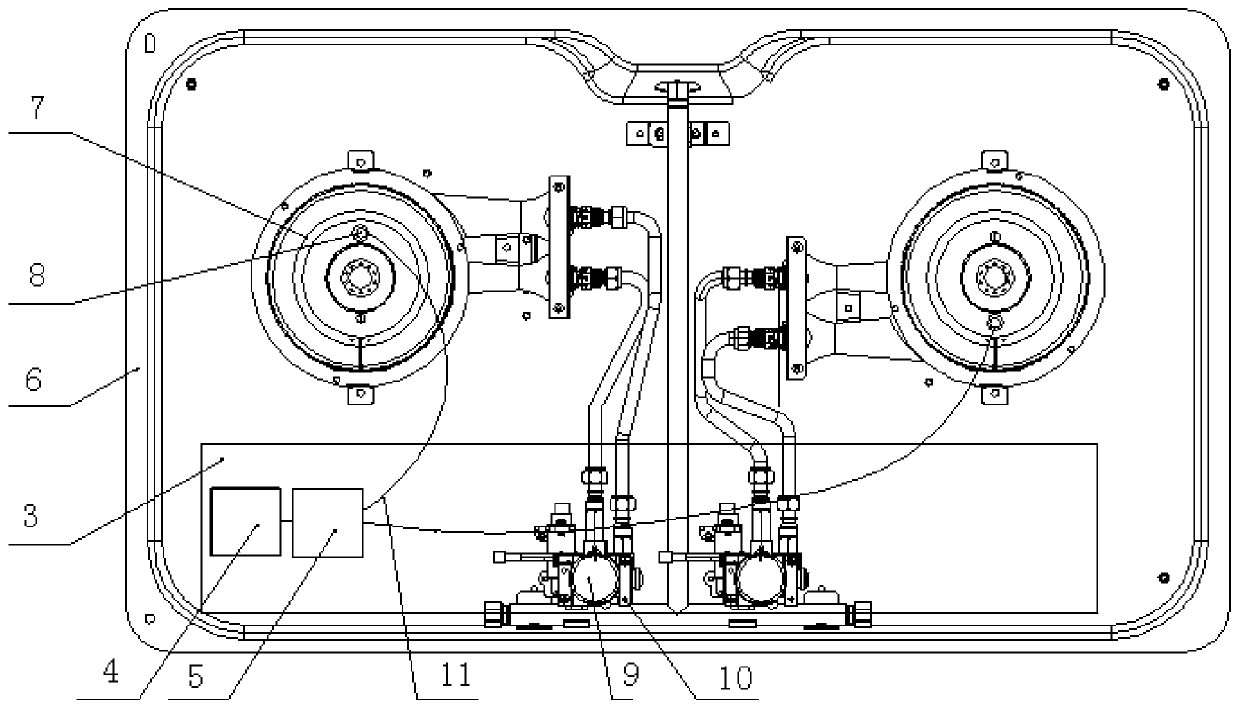

Device based on nanofluid and Fresnel concentrating photovoltaic heat

ActiveCN105591607AImprove photoelectric conversion efficiencyThe overall structure is simple and reliablePhotovoltaicsPhotovoltaic energy generationCouplingEngineering

The present invention discloses a novel device based on nanofluid and Fresnel concentrating photovoltaic heat. The device comprises a solar photovoltaic thermal CPV / T device array, a Fresnel condenser, a system nanofluid cooling working medium outlet, horizontal and vertical fixed shafts, a system nanofluid cooling working medium inlet, a horizontal row fixed array, a vertical row fixed array, a unit photovoltaic thermal device cooling working medium circulation outlet, a unit photovoltaic thermal device cooling working medium circulation inlet, and a nanofluid transportation pipeline. According to the device, the coupling of a solar photovoltaic systems and a solar thermal system is realized, the large area Fresnel condenser is used to concentrate sun radiation to solar photovoltaic thermal CPV / T devices, the frequency dividing absorbing radiation characteristic and efficient heat conduction characteristic of nanofluid are utilized, solar infrared light radiation is adsorbed at an upper layer flow channel, and PV modules are cooled. The light and heat conversion efficiency of solar energy is improved, the PV modules are cooled, high photoelectric conversion efficiency is maintained, and thus the comprehensive utilization of the solar energy is improved.

Owner:HOHAI UNIV CHANGZHOU

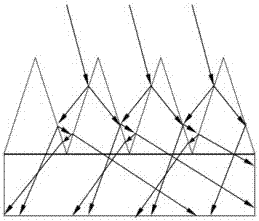

Photovoltaic cell photoelectric conversion efficiency integrated improvement method

ActiveCN107359213AReduce photoelectric conversion efficiencyImprove photoelectric conversion efficiencyPhotovoltaic energy generationSemiconductor devicesProtective glassesEvaporation

The invention relates to a photovoltaic cell photoelectric conversion efficiency integrated improvement method, and aims at solving the problem of low photoelectric conversion efficiency in the prior art. Protective glass is compounded on the surface of a photocell. The upper surface of the protective glass having upper conversion and lower conversion luminescent material is treated into the micro polygonal pyramid array structure surface by using the micro-machining technology. As for surface treatment, certain voltage is applied between a tool electrode and a protective glass electrode immersed in insulating liquid by using discharge or spark erosion of the micro-machining technology, and the electrodes are enabled to be close to each other to discharge to lead to electrocorrosion evaporation of the electrode and the glass, and the surface is treated into the micro polygonal pyramid array structure surface. The array structure surface is the rectangular pyramid micro-pyramid array structure surface or the triangular pyramid micro-pyramid array structure surface. The method has the advantages that photoelectric conversion efficiency improvement of solar spectrum full spectrum energy and long-time maintenance of the conversion efficiency can be realized and finally improvement of the photocell photoelectric conversion efficiency can be realized.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

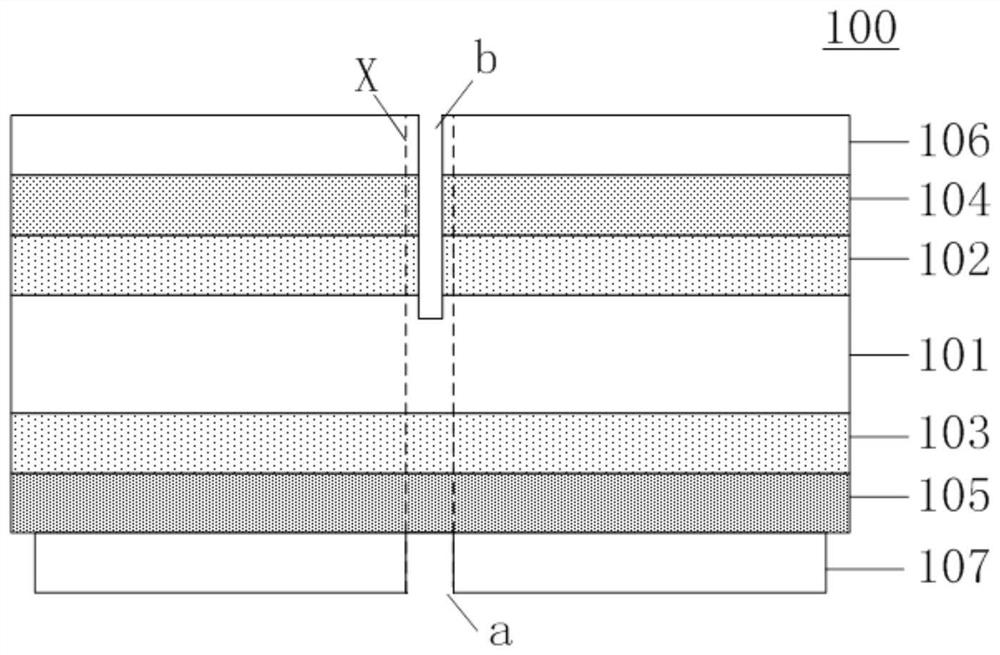

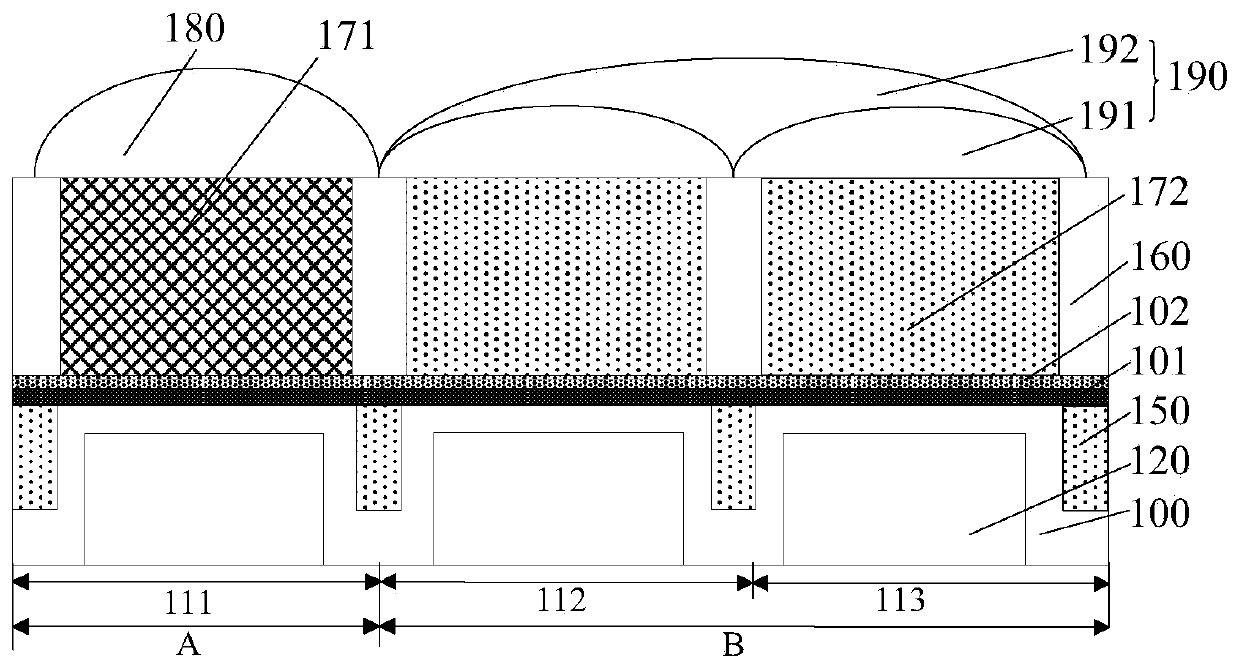

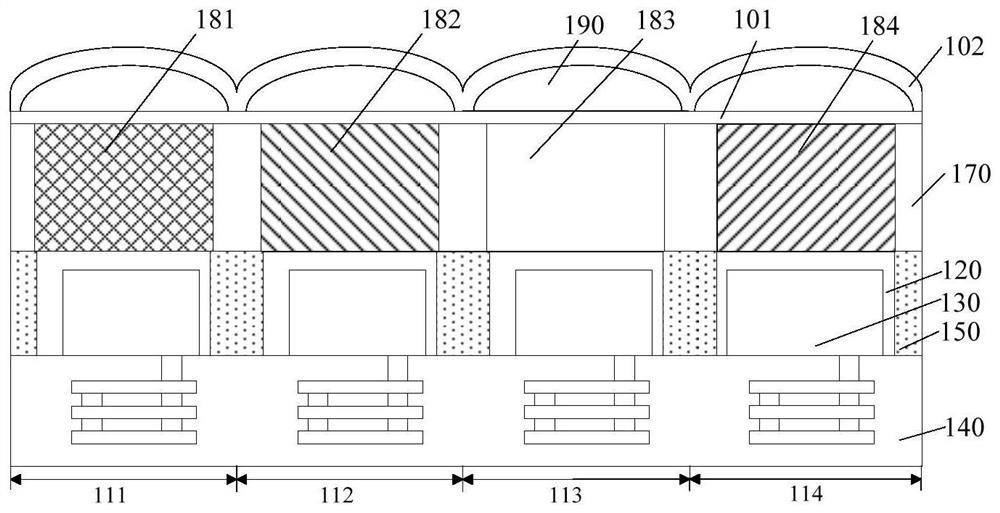

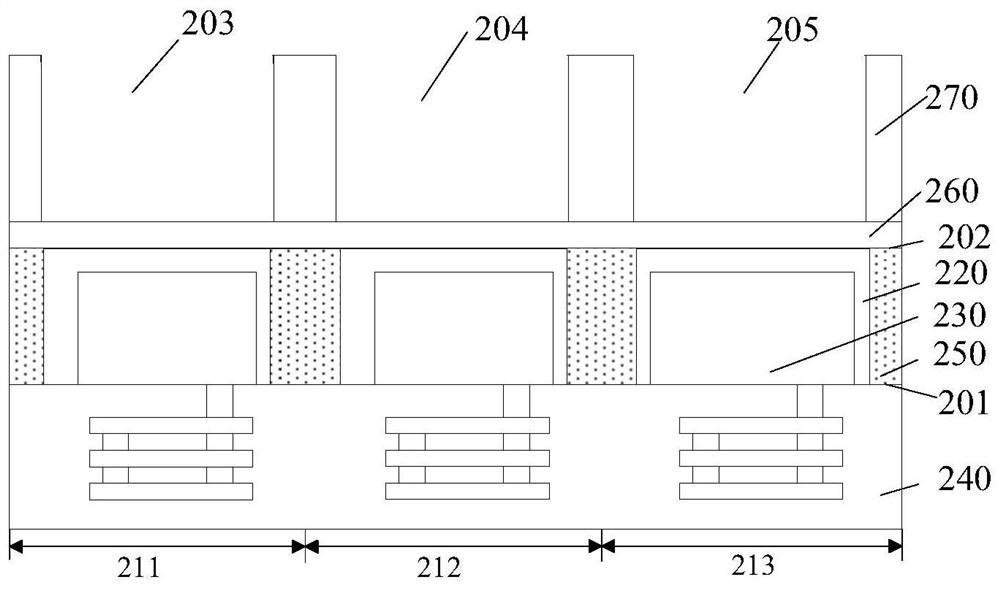

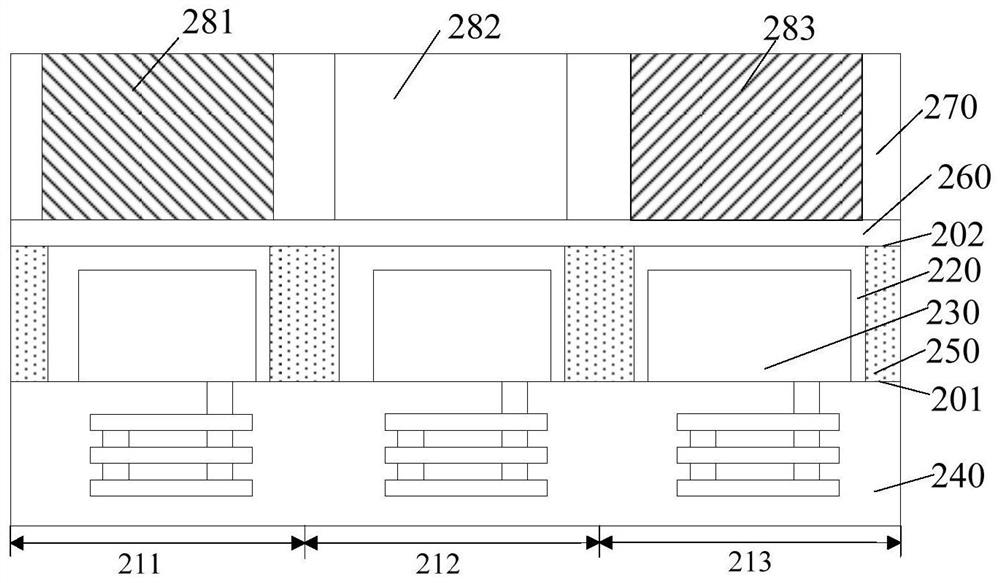

Image sensor, electronic device and manufacturing method thereof

InactiveCN109087926AReduce in quantityPrevent leakageSolid-state devicesRadiation controlled devicesEngineeringElectron

The present disclosure relates to an image sensor, an electronic device, and a manufacturing method thereof. In one embodiment, the present disclosure relates to a substrate of an image sensor, the substrate comprising a first substrate; and a second substrate; the first substrate has a groove, the second substrate is formed in the groove of the first substrate, and the band gap of the second substrate is wider than the first substrate.

Owner:HUAIAN IMAGING DEVICE MFGR CORP

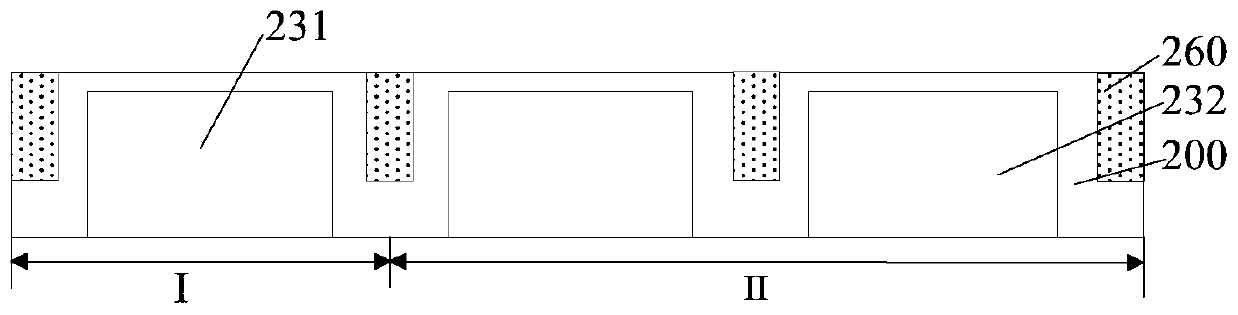

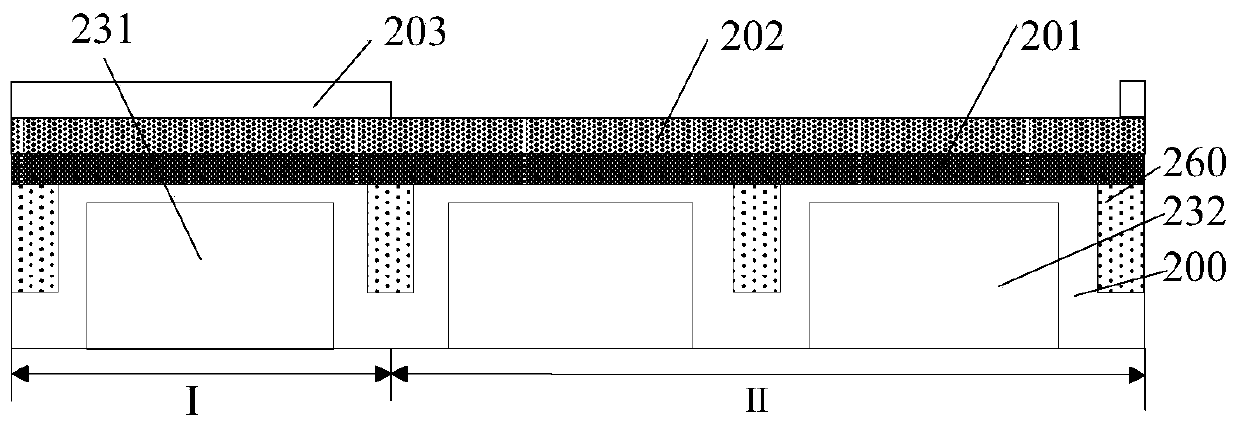

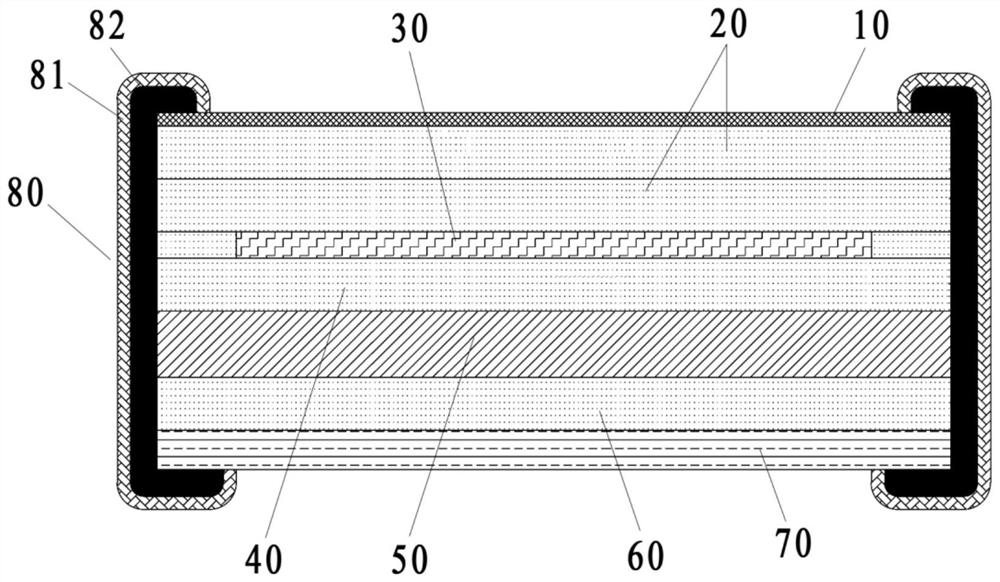

Manufacturing method of heterojunction solar cell and heterojunction solar cell

ActiveCN113380926AAvoid conductionEnsure electrical isolationFinal product manufactureSemiconductor/solid-state device manufacturingHeterojunctionBattery cell

The invention provides a manufacturing method of a heterojunction solar cell and a heterojunction solar cell. The manufacturing method comprises the following steps that: an initial solar cell is formed, the initial solar cell is provided with a cutting area, the formation of the initial solar cell further comprises the following steps of forming a first conductive type semiconductor layer on one side of a semiconductor substrate layer, forming a first transparent conductive layer on one side, back to the semiconductor substrate layer, of the first conductive type semiconductor layer, forming a first cutting groove in the first transparent conductive layer of the cutting area, making the bottom of the first cutting groove expose the first conductive type semiconductor layer; and the initial solar cell is cut along the cutting area, and the width of the first cutting groove is larger than the cutting width of the initial solar cell in the step of cutting the initial solar cell along the cutting area. The method can effectively avoid reduction of photoelectric conversion efficiency caused by cutting.

Owner:ANHUI HUASUN ENERGY CO LTD

Quasi-solid-state dye sensitized nano crystal salar battery and manufacturing method thereof

InactiveCN1624837AReduce photoelectric conversion efficiencyFix the leakLight-sensitive devicesFinal product manufactureSolventSensitization

The invention relates to a dye sensitization nanometer crystal solar cell and its manufacturing method which is used the medium holes oxide gel as the quasi solid electrolyte. In the solar cell, the medium holes oxide quasi solid electrolyte is set to replace the liquid electrolyte at the surface of the wide-gap semiconductor nanometer crystal film absorbed the photosensitizer. The solar cell is utilized the medium holes oxide hole-channel structure to supply transmission channel for the anion. It can effectively solve the solvent leaking problem in the electrolyte at the condition that the photoelectric conversion efficiency of the cell is not sharply reduced.

Owner:FUDAN UNIV

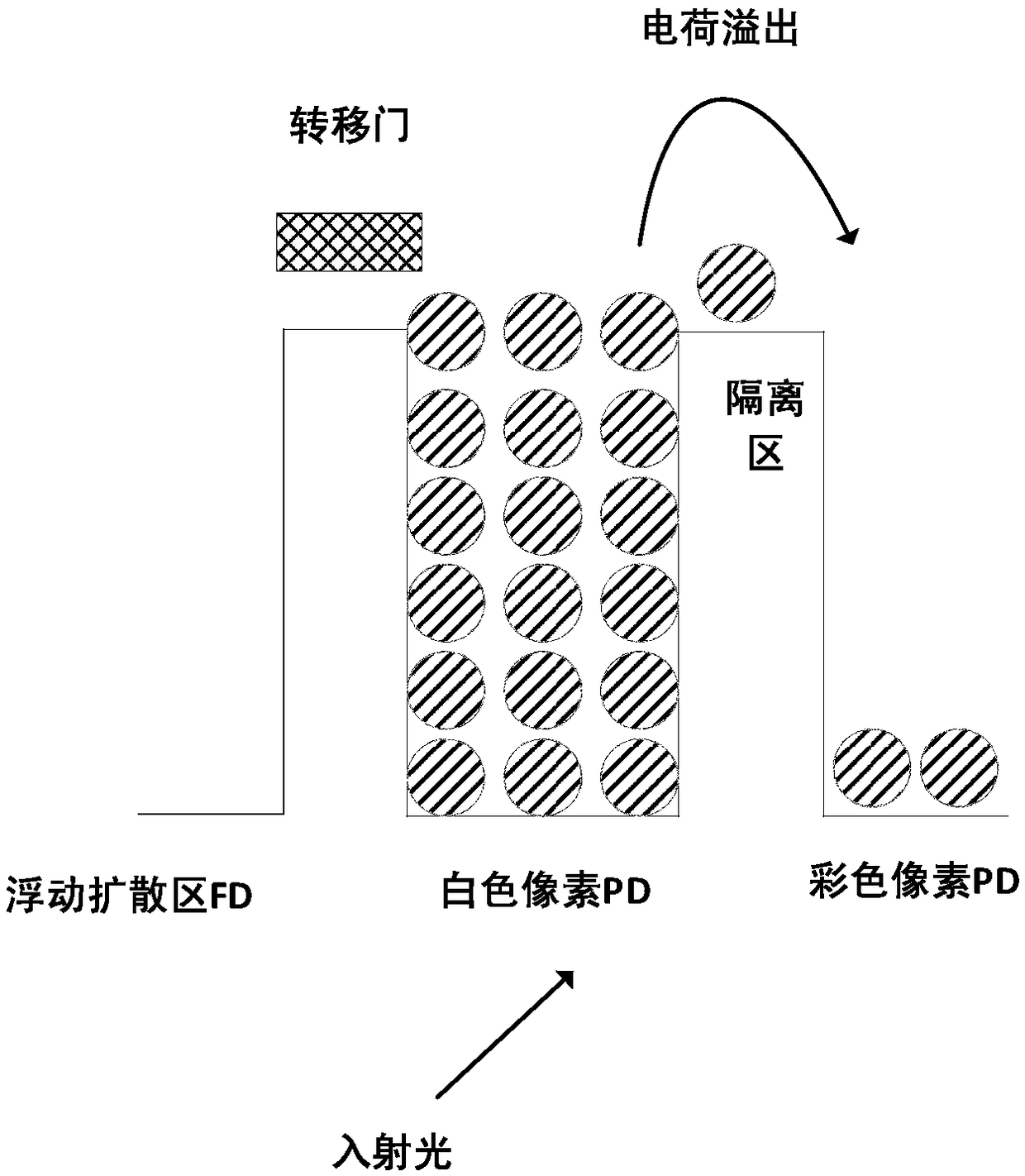

Phase focusing image sensor and forming method thereof

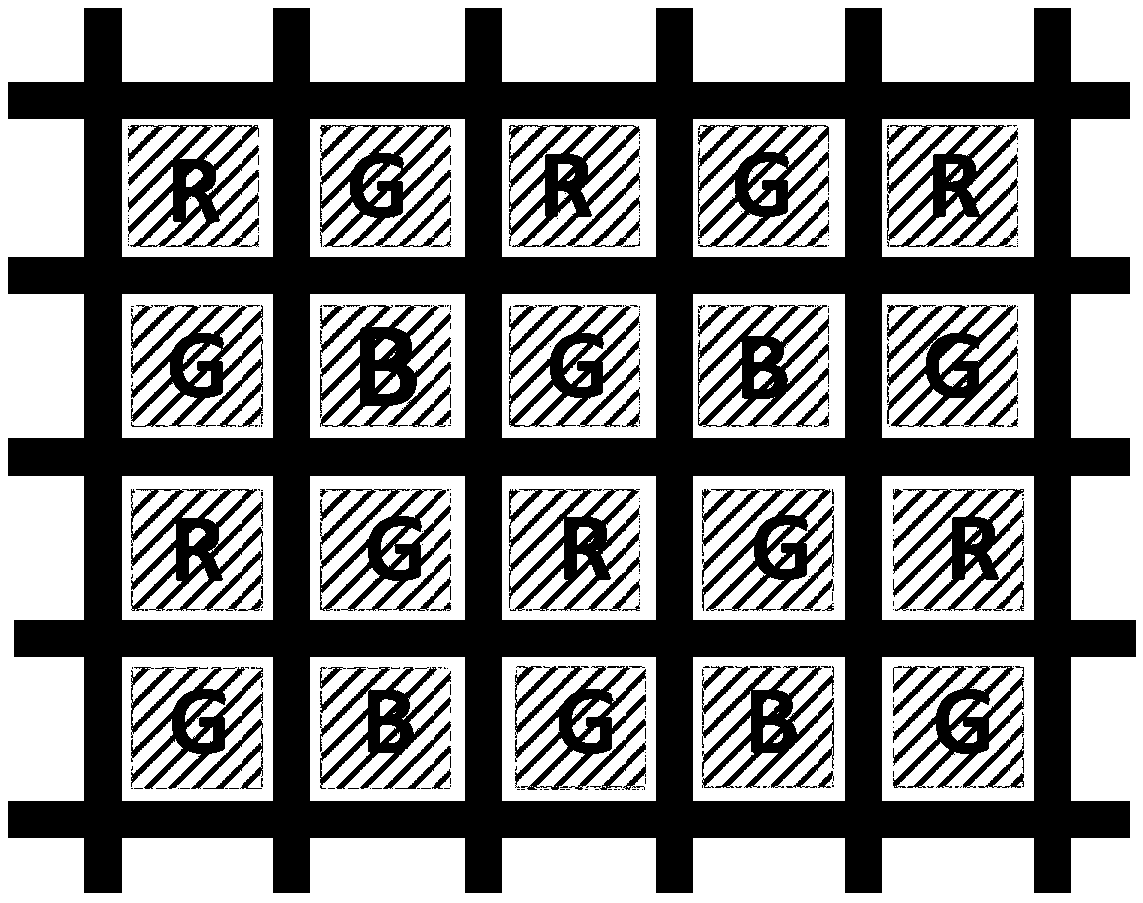

ActiveCN110164897AImprove performanceReduce the amount of incoming lightSolid-state devicesRadiation controlled devicesLight filterMonochrome

The invention relates to a phase focusing image sensor and a forming method thereof, and the image sensor comprises a semiconductor substrate, wherein the semiconductor substrate comprises an image capture region and a phase focusing region. A first photosensitive layer is arranged in the image capture region of the semiconductor substrate, and a second photosensitive layer is arranged in the phase focusing region of the semiconductor substrate. The image sensor also comprises a first anti-reflection structure which is located on the surface of the semiconductor substrate image capture region;a second anti-reflection structure which is located on the surface of the semiconductor substrate phase focusing area, wherein the reflectivity of the second anti-reflection structure is greater thanthat of the first anti-reflection structure; a first light filtering layer which is located on the surface of the first anti-reflection structure, wherein the monochromatic light passes through the first light filtering layer; and a second light filtering layer which is located on the surface of the second anti-reflection structure, wherein the natural light passes through the second light filtering layer. The performance of the phase focusing image sensor is improved.

Owner:淮安西德工业设计有限公司

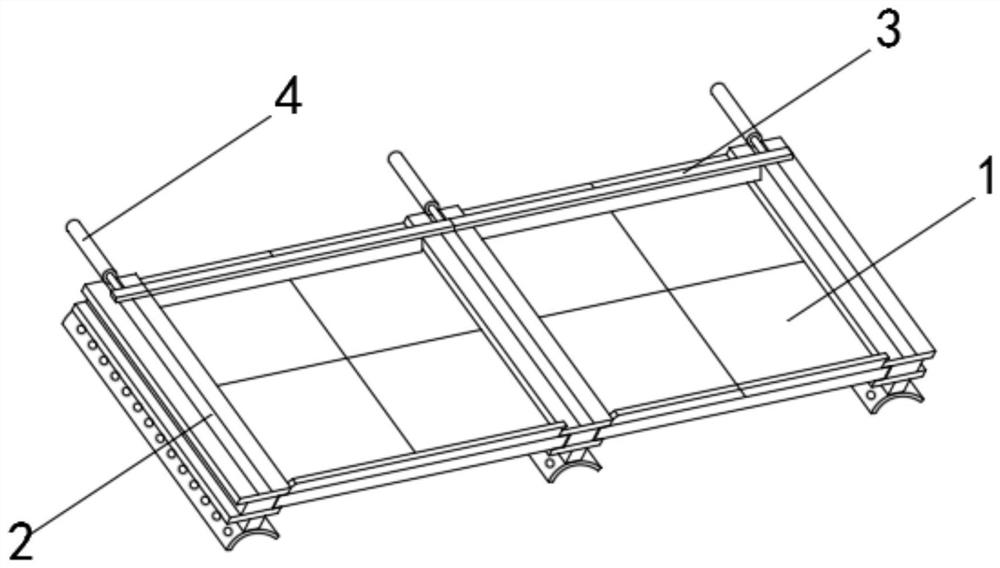

Low-water-permeability flexible photovoltaic module and preparation method thereof

PendingCN113540276AUltra-high water resistanceExtended service lifePhotovoltaic energy generationSemiconductor devicesPhysicsComposite material

The invention provides a low-water-permeability flexible photovoltaic module which comprises a weather-proof layer, at least one first packaging adhesive film layer, a solar cell unit, at least one second packaging adhesive film layer, a flexible insulating layer, at least one third packaging adhesive film layer and a back plate layer which are sequentially stacked. A water-blocking adhesive tape is pasted around the side edges of the weather-proof layer, the first packaging adhesive film layer, the solar cell unit, the second packaging adhesive film layer, the flexible insulating layer, the third packaging adhesive film layer and the back plate layer. The invention further provides a preparation method of the low-water-permeability flexible photovoltaic module. The front surface, the back surface and the side surfaces of the low-water-permeability flexible photovoltaic module can block water vapor, and the low-water-permeability flexible photovoltaic module has ultrahigh water-blocking performance, so that the service life of the flexible photovoltaic module can be effectively prolonged, the attenuation of photoelectric conversion efficiency can be reduced, and the cost per kilowatt hour can be reduced.

Owner:YONZ TECH CO LTD

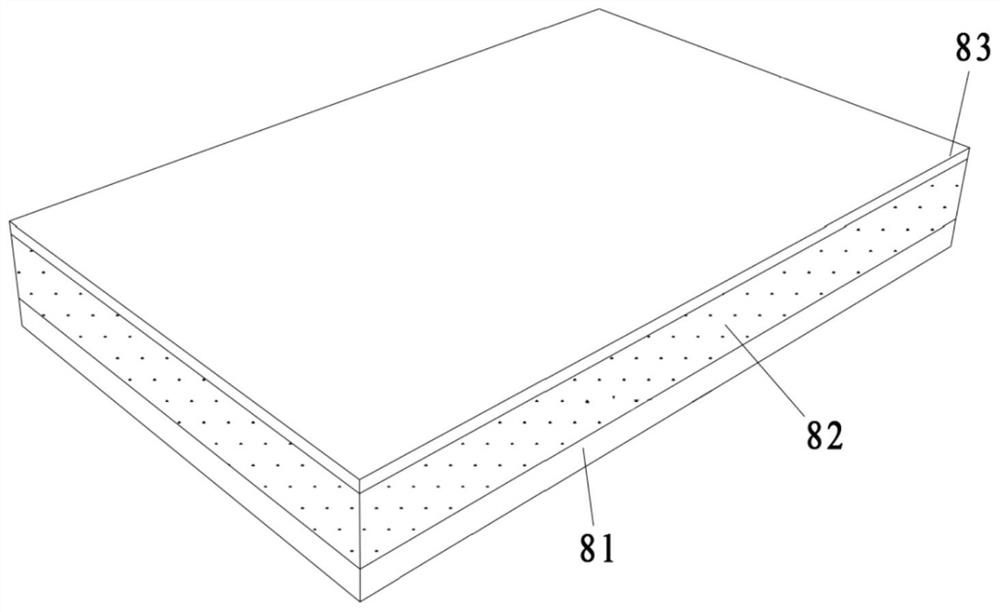

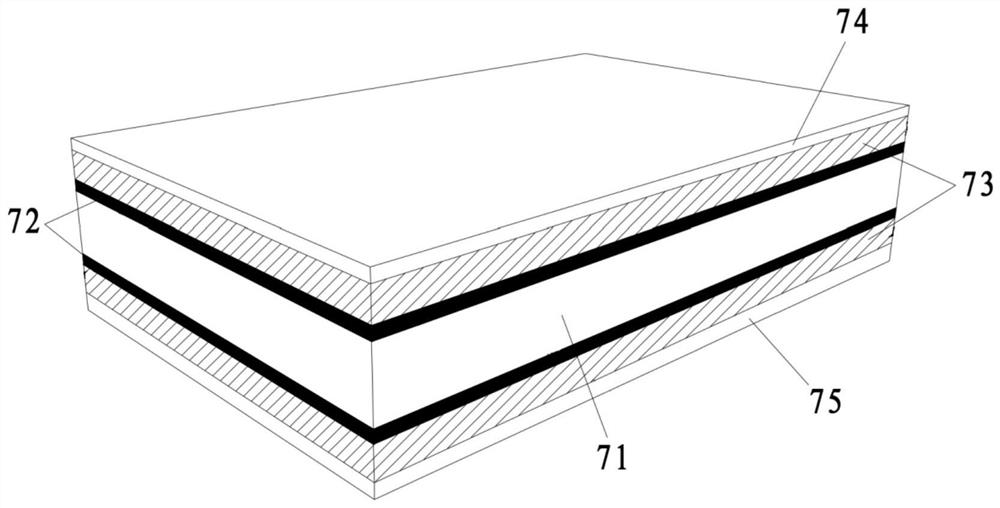

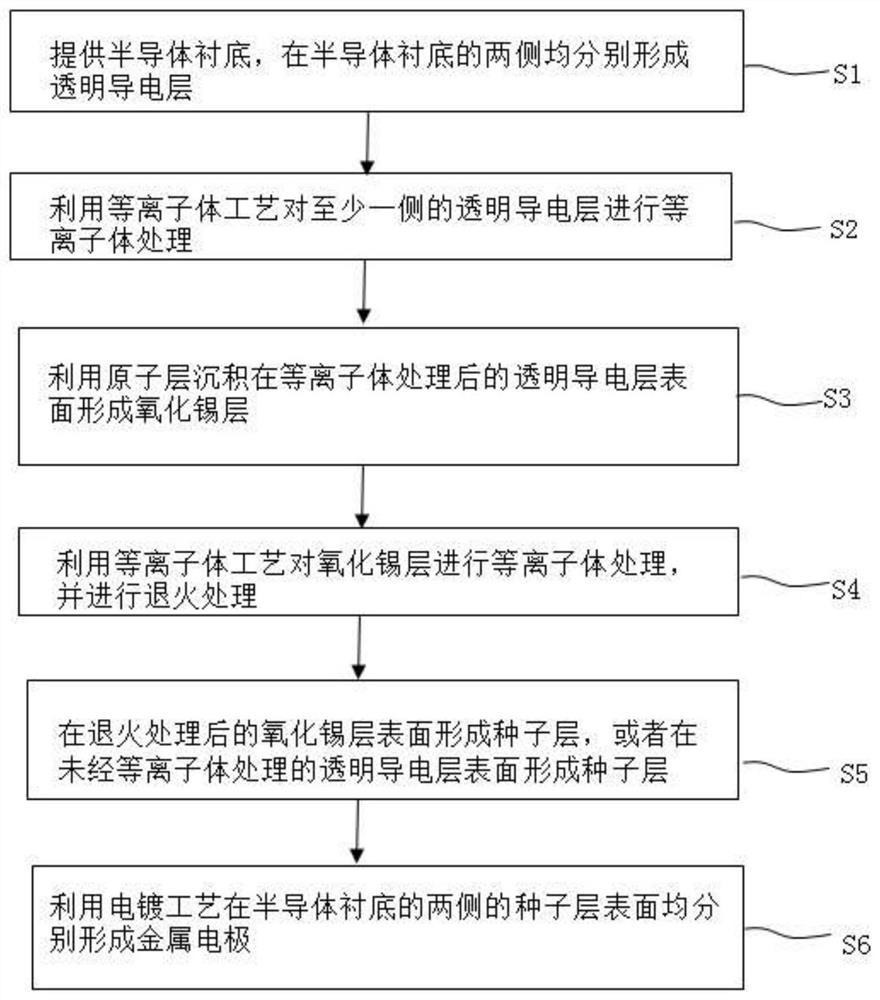

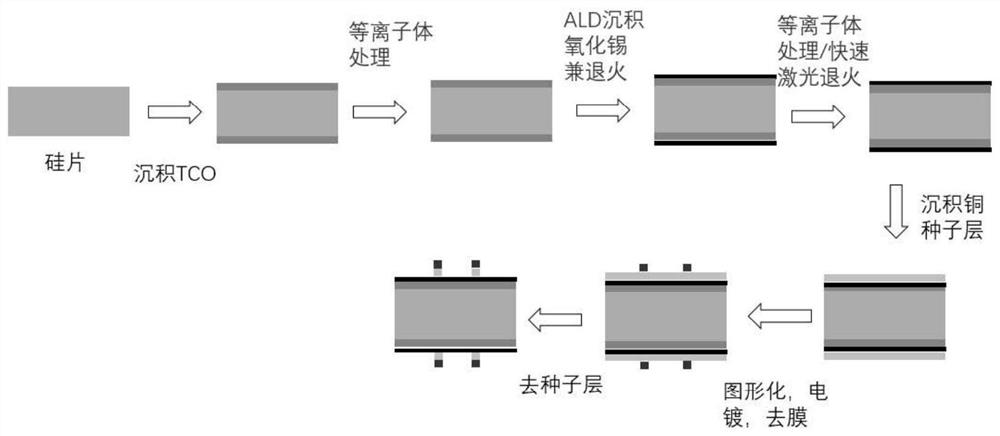

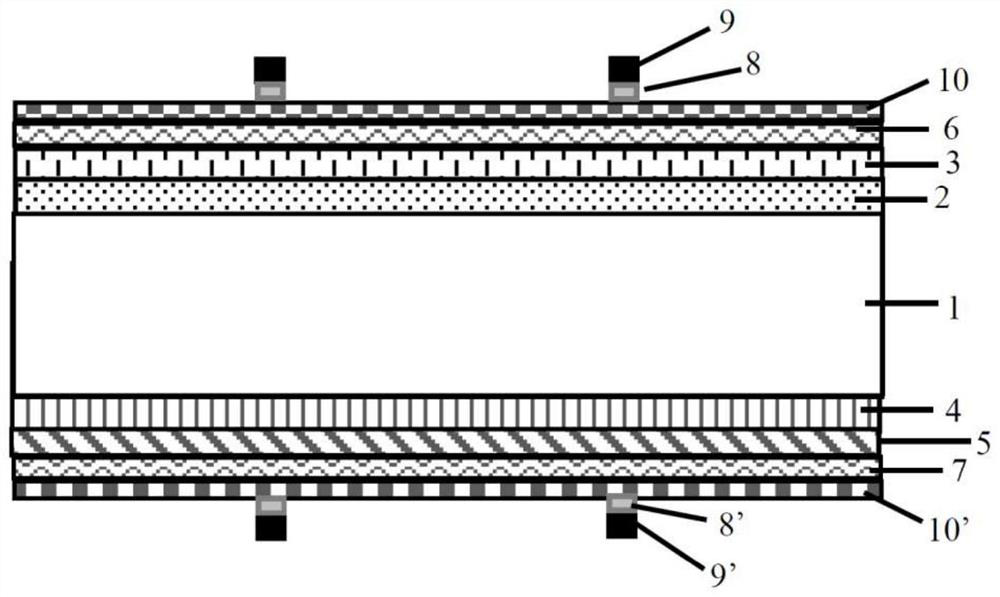

Heterojunction solar cell and preparation method thereof

PendingCN114447152AImprove surface activitySurface cleaningPhotovoltaic energy generationSemiconductor devicesPlasma treatmentBinding force

The invention discloses a heterojunction solar cell and a preparation method thereof, and belongs to the technical field of solar cells. The invention discloses a preparation method of a heterojunction solar cell, and the method comprises the steps: providing a semiconductor substrate, and forming transparent conductive layers at the two sides of the semiconductor substrate respectively; performing plasma treatment on the transparent conductive layer on at least one side by using a plasma process; forming a tin oxide layer on the surface of the transparent conductive layer after plasma processing by using atomic layer deposition; performing plasma treatment on the tin oxide layer by using a plasma process, and performing annealing treatment; forming a seed layer on the surface of the annealed tin oxide layer; and respectively forming metal electrodes on the surfaces of the seed layers on the two sides of the semiconductor substrate by using an electroplating process. According to the invention, the series resistance of the cell can be reduced, the preparation cost of the cell is reduced, the binding force between layers in the cell structure is improved, and the photoelectric conversion efficiency of the cell can be ensured.

Owner:SUZHOU MAXWELL TECH CO LTD

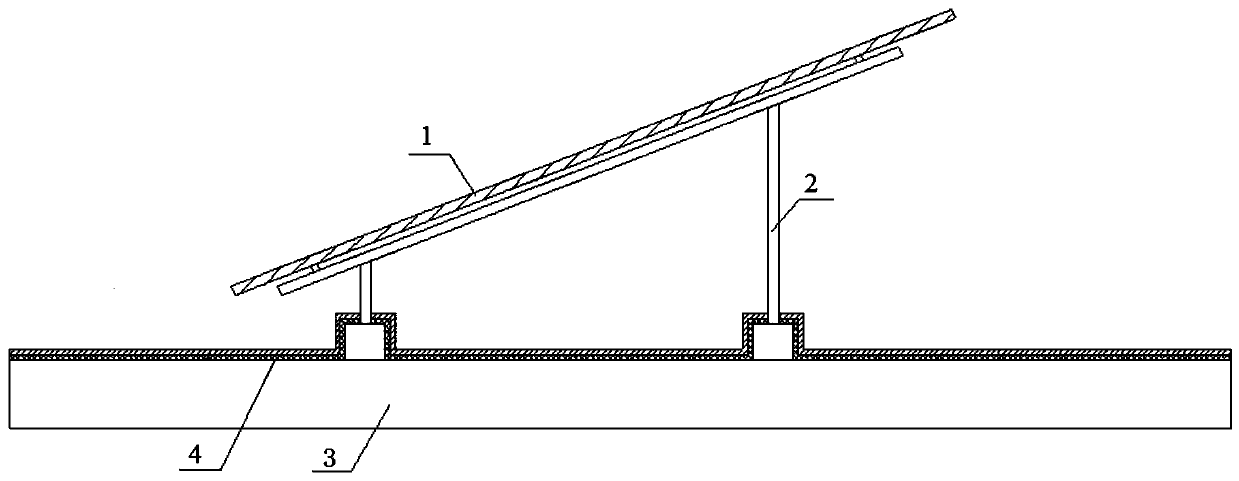

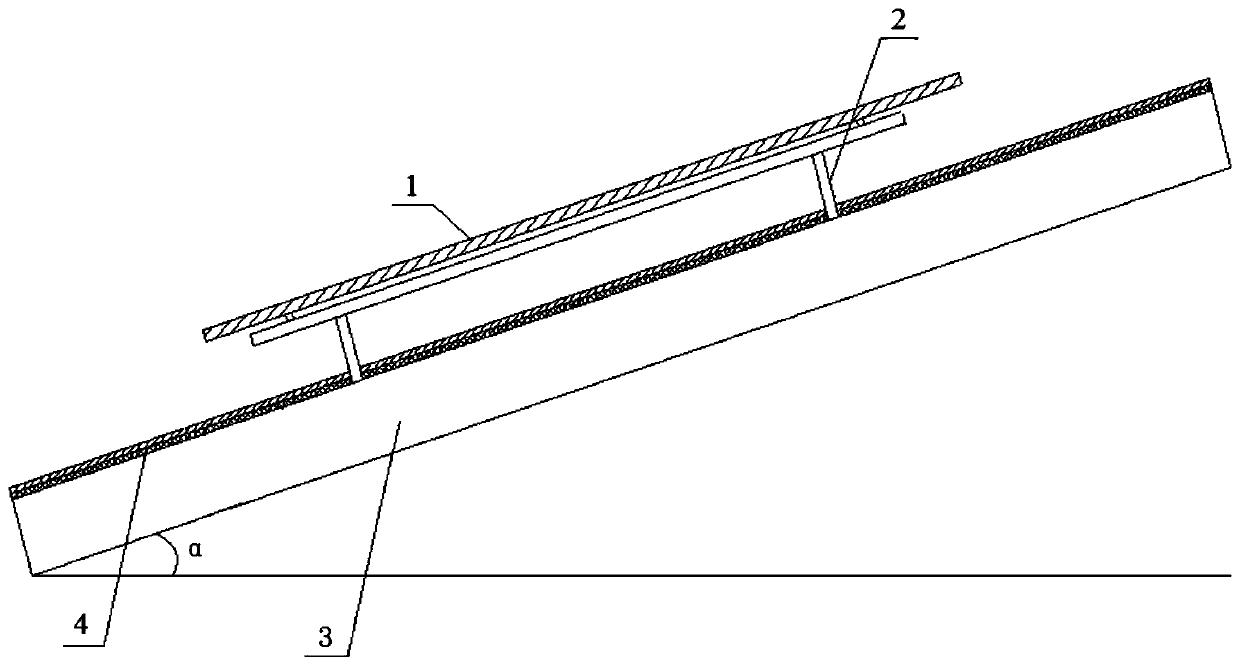

Application of reflective film for increasing photoelectric conversion efficiency of roof distributed photovoltaic power generation system

InactiveCN110277959AImprove reflective effectIncrease light intensityPhotovoltaicsPhotovoltaic energy generationEngineeringGenerating capacity

The invention discloses an application of a reflective film for increasing the photoelectric conversion efficiency of a roof distributed photovoltaic power generation system, and relates to an application of the reflective film. The invention solves problems that the existing photovoltaic power generation is low in photoelectric conversion efficiency, the service life of a photovoltaic inverter is short, and the generating capacity is influenced. According to the invention, the reflective film is arranged on a roof foundation layer or the surface of an inverter cabinet. The reflective film provided by the invention can reduce the roof surface temperature by 5-25 DEG C, thereby reducing the temperature of the photovoltaic power generation panel, increasing the roof photoelectric conversion efficiency, and increasing the roof distributed photovoltaic photoelectric conversion efficiency by 1-6%. The temperature in the inverter cabinet can be reduced by more than 5 DEG C. The service life of electronic equipment in the cabinet is prolonged by more than 2 years, the photovoltaic power generation amount is increased by 0.3%-1.5%, and the equipment faults are reduced. Therefore, the maintenance cost is saved. The reflective film is suitable for the distributed photovoltaic power generation system.

Owner:哈尔滨拓百世环保涂料有限公司

Solar cell electrode printing screen, solar cell electrode and manufacturing method thereof

ActiveCN104332509BReduce photoelectric conversion efficiencyIncrease the shade areaFinal product manufactureScreen printersElectrical batteryEngineering

A solar cell electrode printing screen comprises a first screen and a second screen; the first screen comprises a first template; a plurality of first thin grids are formed in the first template; the first template is provided with alignment holes and wedge-shaped holes; the second screen comprises a second template; the second template is provided with a plurality of second thin grids and main grids; the second thin grids and the main grids are intersected; the distance between axes of the adjacent two second thin grids is equal to that between axes of the adjacent two first thin grids; the width of the second thin grids is smaller than or equal to that of the first thin grids; the main grids are provided with alignment portions; one ends of the main grids are provided with sharp corner hollow-outs; the shortest distance between edges of the alignment portions and end surfaces of the top ends of the sharp corner hollow-outs is equal to that between the edges of the alignment holes and the edges of the wedge-shaped holes. According to the solar cell electrode printing screen, substrates after the second screen and the first screen are printed are accurately aligned and dislocation of a thin grid line during printing at the second time and a thin grid line during printing at the first time is avoided. The invention also provides a solar cell electrode and a manufacturing method thereof.

Owner:CSG PVTECH

Panel and gas stove

PendingCN110207192AReduce the temperatureReduce light transmittanceDomestic stoves or rangesLighting and heating apparatusLight irradiationLight energy

The invention provides a panel and a gas stove. The panel is suitable for being arranged on the light irradiation side of a photoelectric conversion device; the panel comprises at least one layer of light transmission structure and a thermochromic discoloring layer, and the thermochromic discoloring layer is stacked with the light transmission structure, and the color of the thermochromic discoloring layer is darker with the increase of temperature. In the case of low panel temperature, light can penetrate through the light transmission structure and the thermochromic discoloring layer to irradiate to the photoelectric conversion device, and the photoelectric conversion device converts light energy into electric energy; with the increase of panel temperature, the color of the thermochromicdiscoloring layer is darker, and the transmittance of the panel is decreased; the panel can absorb heat at the same time, therefore, the heat can be prevented from being transferred to the photoelectric conversion device, and the photoelectric conversion device can be protected against overheating so that the normal power generation of the photoelectric conversion device can be ensured; and the lower transmittance of the panel and the lower photoelectric conversion efficiency of the photoelectric conversion device can further protect the photoelectric conversion device against overheating.

Owner:GREE ELECTRIC APPLIANCES INC

A photovoltaic solar system

ActiveCN111928497BEven by forceAvoid damagePhotovoltaic supportsSolar heating energyPhotovoltaic solar energySnowpack

The invention discloses a photovoltaic solar energy system, comprising a solar panel main body, connecting components are arranged on both sides of the solar panel main body, a cleaning mechanism is arranged between the two connecting components, and the cleaning mechanism is located on the solar panel main body On the outer side of the upper end, the upper end of the connection assembly is provided with an air pump, and the lower side of the upper outer surface of the solar panel main body is provided with an extrusion assembly, and both ends of the extrusion assembly are connected to the two connection assemblies through bolts Connection, and can connect and fix two adjacent solar panel main bodies through this component structure, and at the same time, through its lower fixing plate structure, it can be snapped and fixed on the surface of roof tiles, so that the whole component is evenly stressed, and at the same time, by adding a cleaning mechanism , not only can clean the dirt on the surface of the main body of the solar panel, but also can clean the snow through this mechanism in case of snow accumulation in the high cold, so as to ensure the normal operation of the equipment.

Owner:ZIQUAN ELECTRIC POWER DESIGN DESIGN

Perovskite solar cells based on spiro-ometad/PBS composite hole transport layer and its preparation method

ActiveCN106129252BSimple processReduce manufacturing costSolid-state devicesSemiconductor/solid-state device manufacturingEvaporationHole transport layer

The invention discloses a perovskite solar cell based on a Spiro‑OMeTAD / PbS composite hole transport layer and a preparation method thereof. The perovskite solar cell consists of a transparent conductive substrate, an oxide electron transport layer, a perovskite light absorbing layer, a Spiro‑OMeTAD / PbS composite hole transport layer, and a metal electrode. The perovskite thin-film solar cell adopts an evaporation method with a simple process and can be used for large-scale production to prepare a lead sulfide thin film, which is inserted between Spiro-OMeTAD and the metal electrode layer as a buffer layer. This perovskite solar cell based on the Spiro‑OMeTAD / PbS composite hole transport layer achieved a high photoelectric conversion efficiency of 15.11%. As a buffer layer between the hole transport layer and the metal electrode, lead sulfide has higher hole mobility, better humidity stability and photothermal stability, which can reduce the recombination of electron-hole pairs and improve battery stability. sex. Compared with other buffer layer materials, lead sulfide can improve device performance while protecting the device, and has a positive role in promoting the industrialization of solar cells.

Owner:WUHAN UNIV

Quasi-solid-state dye sensitized nano crystal salar battery and manufacturing method thereof

InactiveCN100383981CReduce photoelectric conversion efficiencyFix the leakLight-sensitive devicesFinal product manufactureSolid state electrolyteEngineering

The invention relates to a dye sensitization nanometer crystal solar cell and its manufacturing method which is used the medium holes oxide gel as the quasi solid electrolyte. In the solar cell, the medium holes oxide quasi solid electrolyte is set to replace the liquid electrolyte at the surface of the wide-gap semiconductor nanometer crystal film absorbed the photosensitizer. The solar cell is utilized the medium holes oxide hole-channel structure to supply transmission channel for the anion. It can effectively solve the solvent leaking problem in the electrolyte at the condition that the photoelectric conversion efficiency of the cell is not sharply reduced.

Owner:FUDAN UNIV

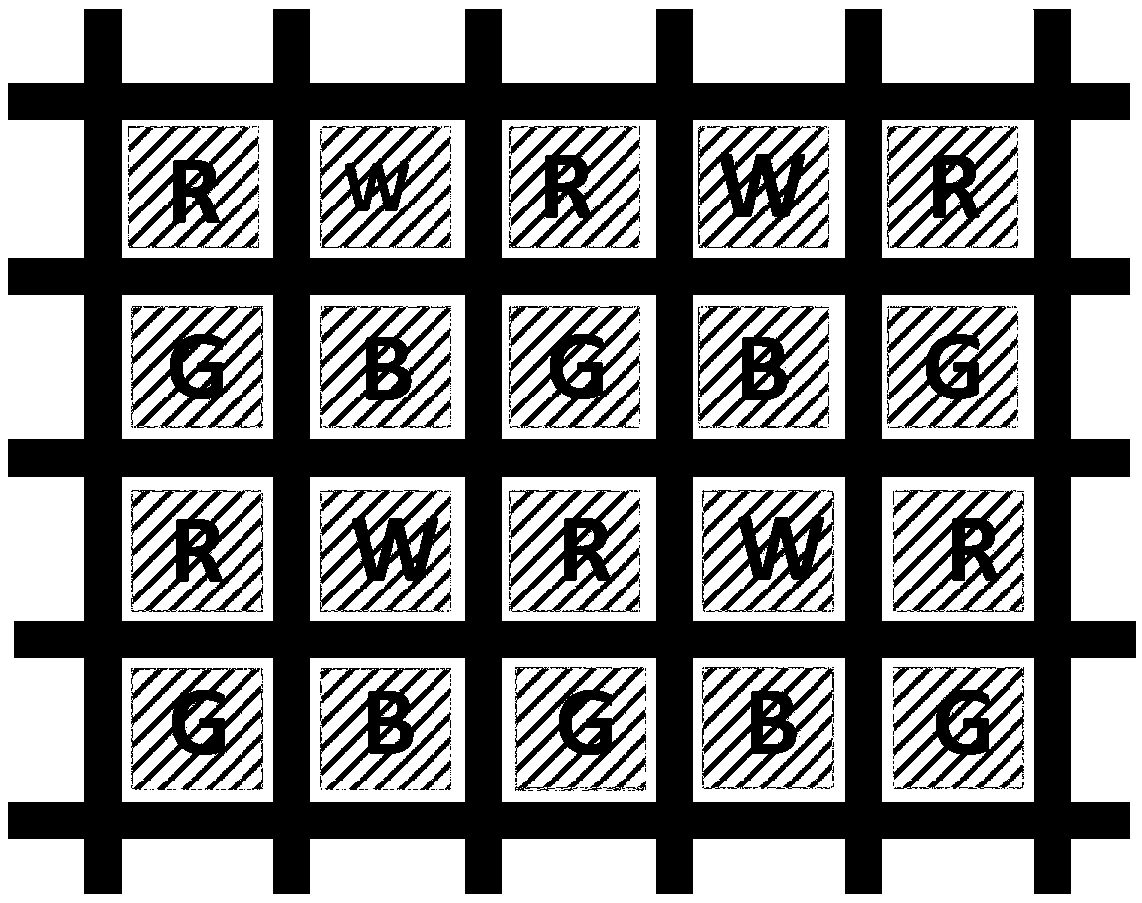

Image sensor and method of forming the same

ActiveCN109065564BImprove performanceReduce reflectionSolid-state devicesRadiation controlled devicesAnti-reflective coatingMaterials science

An image sensor and a forming method thereof are provided. The image sensor includes a substrate including a first pixel region and a second pixel region; a substrate surface in the first pixel regionprovided with a first filter lay for passing monochromatic light; a second filter layer for transmitting natural light on the surface of the substrate in the second pixel region; a first anti-reflective structure located in a first pixel region, the first anti-reflective structure comprising one or both of a first anti-reflective coating and a second anti-reflective coating, the first anti-reflective coating being located between the first filter layer and the substrate, the second anti-reflective coating being located on the first filter layer; a second anti-reflective structure located in the second pixel region, the second anti-reflective structure having a thickness smaller than the first anti-reflective structure, the second anti-reflective structure comprising one or both of a thirdanti-reflective coating and a fourth anti-reflective coating, the third anti-reflective coating being located between the second filter layer and the substrate, and the fourth anti-reflective coatingbeing located on the second filter layer. The performance of the image sensor is improved.

Owner:淮安西德工业设计有限公司

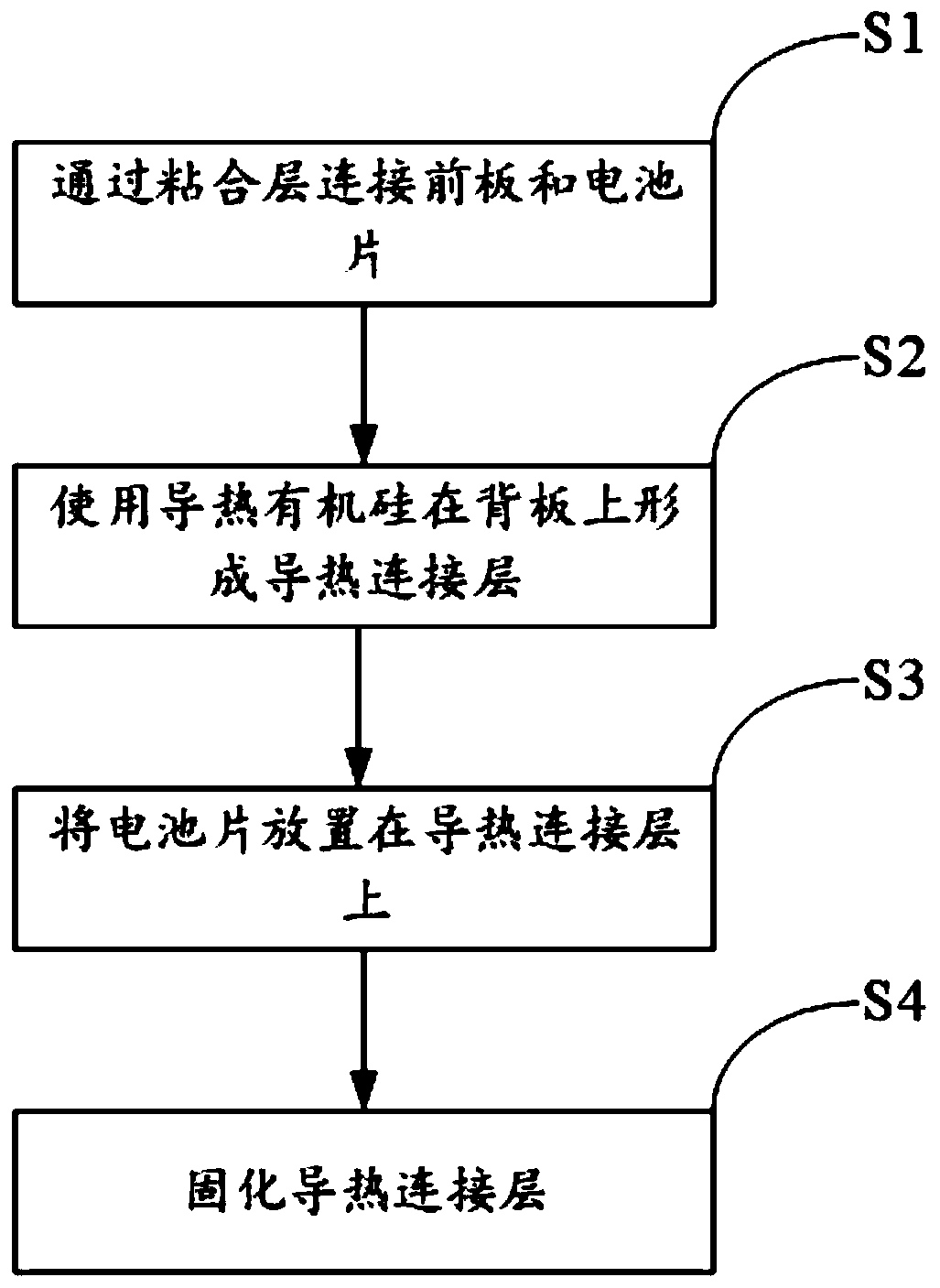

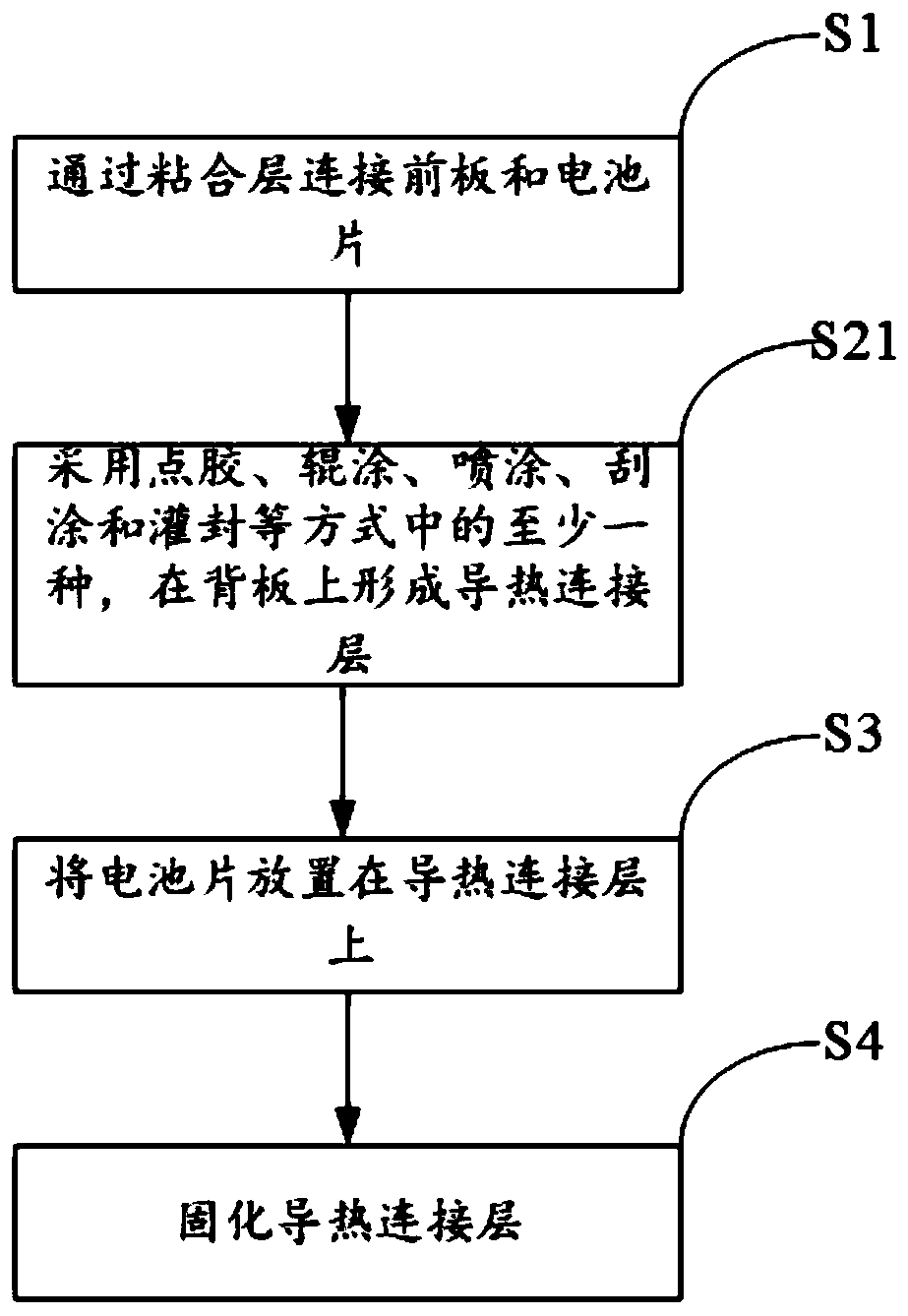

Heat-conducting organosilicon, photovoltaic module and packaging method of the photovoltaic module

PendingCN111334046AImprove thermal conductivityReduce photoelectric conversion efficiencyPhotovoltaic energy generationSemiconductor devicesPtru catalystPhysical chemistry

The invention relates to the technical field of photovoltaic modules, in particular to heat-conducting organosilicon, a photovoltaic module and a packaging method of the photovoltaic module. The heat-conducting organosilicon comprises a component A and a component B in a set weight ratio, wherein the component A comprises 5-20 parts by weight of hydrogen-containing silicone oil, 0.1-2 parts by weight of a catalyst and 0.1-2 parts by weight of an inhibitor; the component B comprises 40 to 60 parts by weight of vinyl polysiloxane, 1 to 20 parts by weight of a reinforcing filler and 5 to 50 partsby weight of a heat conduction filler. The heat-conducting organosilicon material provided by the invention is relatively good in heat-conducting property.

Owner:鸿翌科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com