Preparation method of three-dimensional graphene foam composite nano-cadmium sulfide photoelectrochemical electrode

A photoelectrochemical electrode and graphene foam technology, applied in the field of photoelectrochemistry, can solve problems such as weak electron transport capability, limited cadmium sulfide material, and technology entry bottleneck.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0030] Implementation column 1

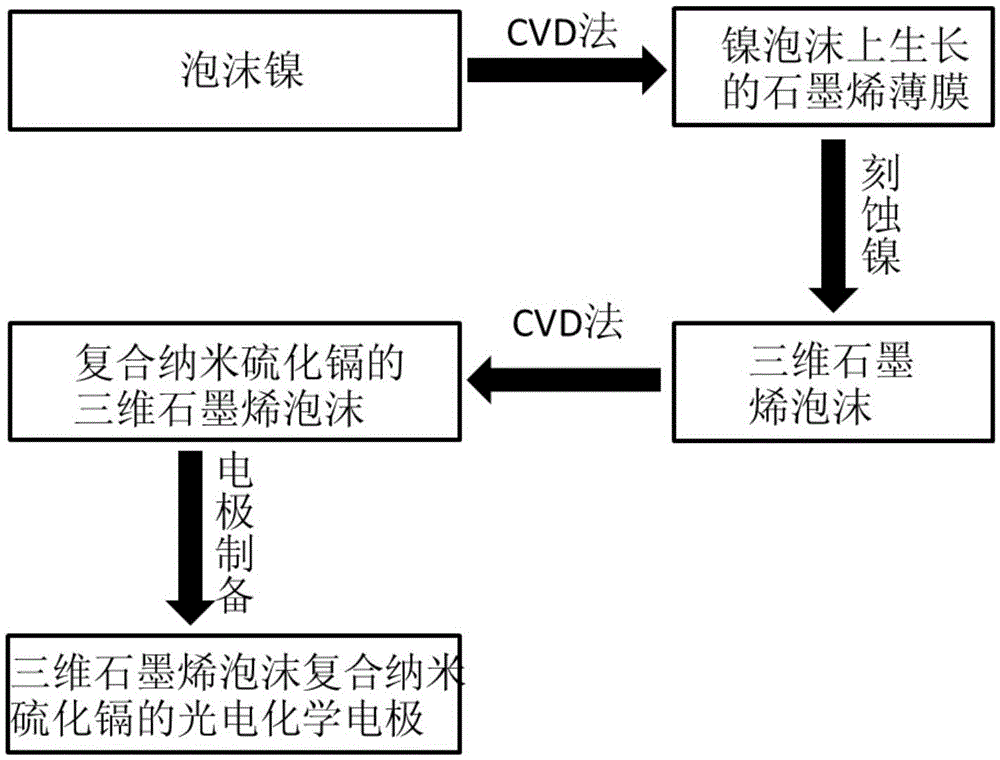

[0031] The preparation method of the photoelectrochemical electrode of a kind of three-dimensional graphene foam composite nanometer cadmium sulfide is as follows figure 1 As shown, the specific steps are as follows:

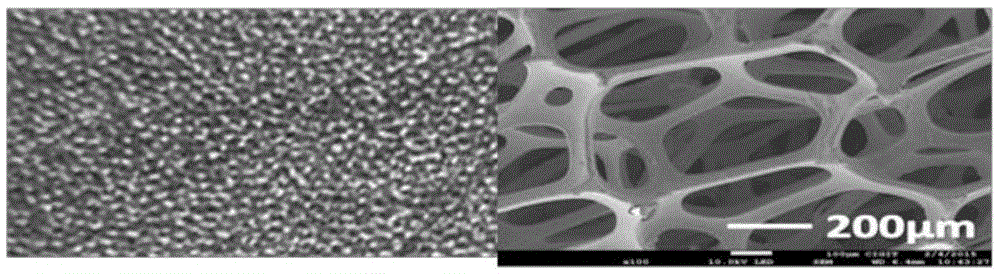

[0032] 1) will be as figure 2 The nickel foam shown is cut into a 1cm*1cm square.

[0033] 2) Place the square nickel foam in acetone, ethanol, and deionized water for ultrasonic cleaning for 10 minutes, and dry it with nitrogen gas for later use.

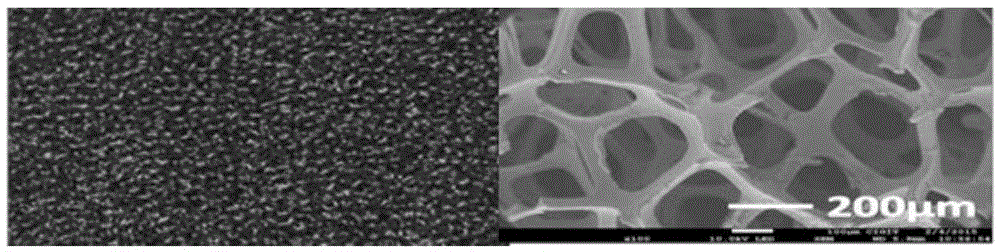

[0034] 3) Place the dried square nickel foam in the vacuum chamber of the CVD system to grow the graphene film to obtain the graphene film. The growth condition of the graphene film is normal pressure growth, the growth temperature is 700°C, a mixed gas of argon, hydrogen and methane is introduced (a special ratio of argon: hydrogen: methane = 200:80:5sccm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com