Solar battery piece diffusion process

A solar cell and diffusion process technology, applied in the field of solar cell diffusion technology, can solve the problems of low-efficiency crystalline silicon solar cells, poor uniformity of surface square resistance, and poor short-wave response of cells, etc. Spectral responsivity and the effect of improving absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

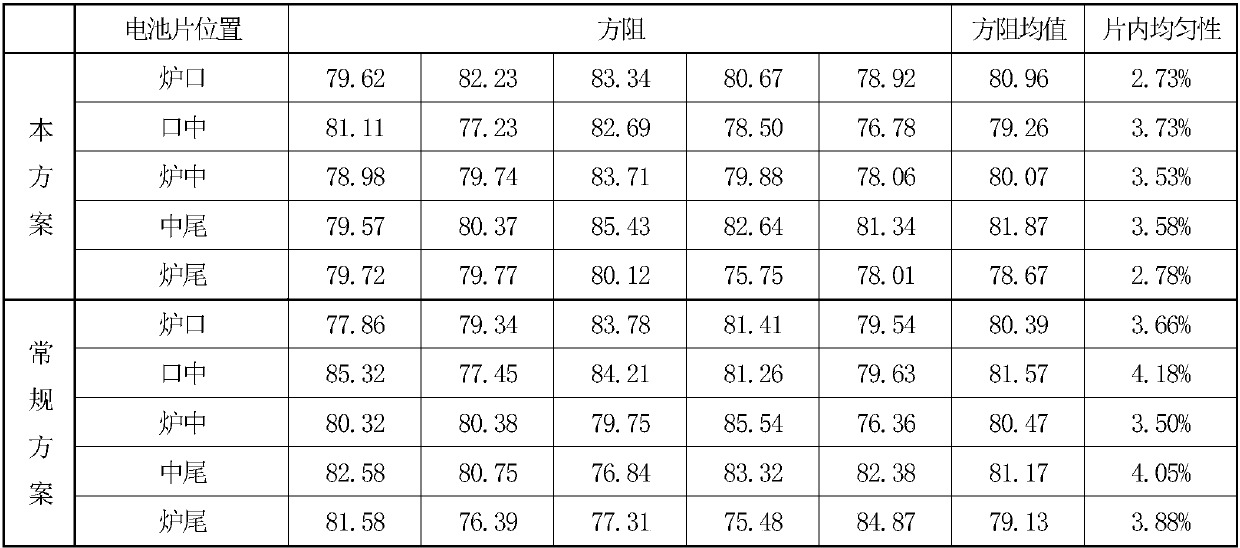

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

[0030] Diffusion is to make a PN junction. P-type silicon wafers are placed in a diffusion furnace, and N-type impurity atoms are diffused from the surface layer of the silicon wafer to the interior of the silicon wafer through the gaps between silicon atoms to form a PN junction, making electrons and air The hole will not return to the original place after flowing, so that an electric current is formed, which makes the silicon wafer have a photovoltaic effect. The large nitrogen mentioned in this application refers to pure nitrogen, while the small nitrogen refers to nitrogen carrying a phosphorus source (phosphorus oxychloride).

[0031] The invention provides a solar cell sheet diffusion process, comprising the following steps:

[0032] A. Put the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com