Patents

Literature

50results about How to "Reduce the preparation conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

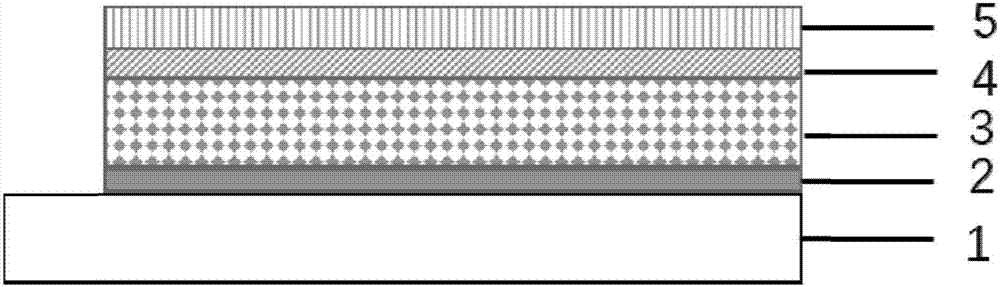

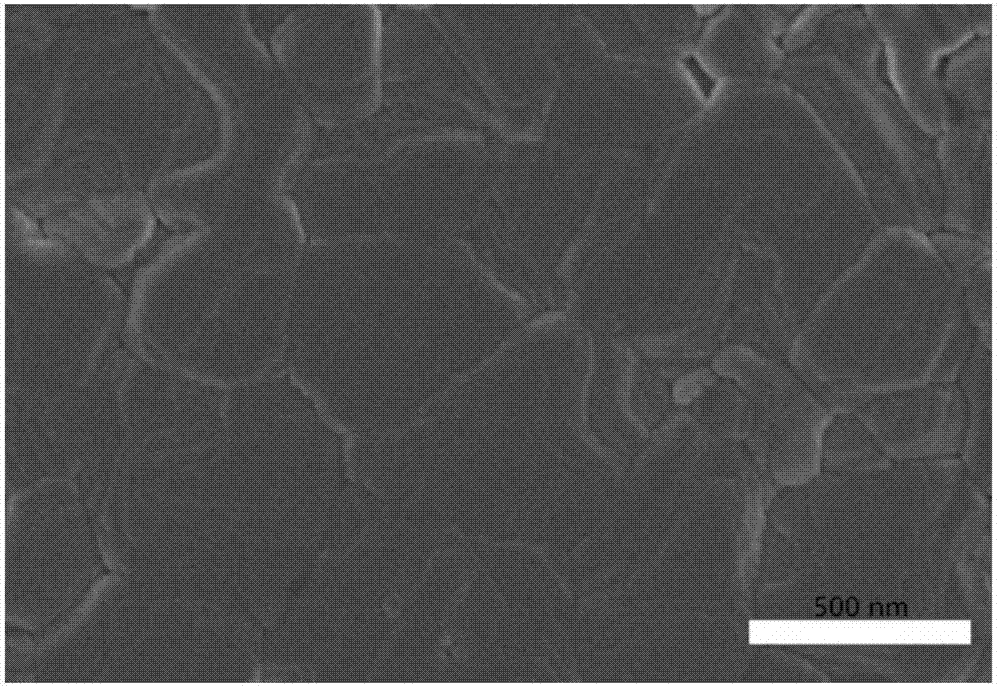

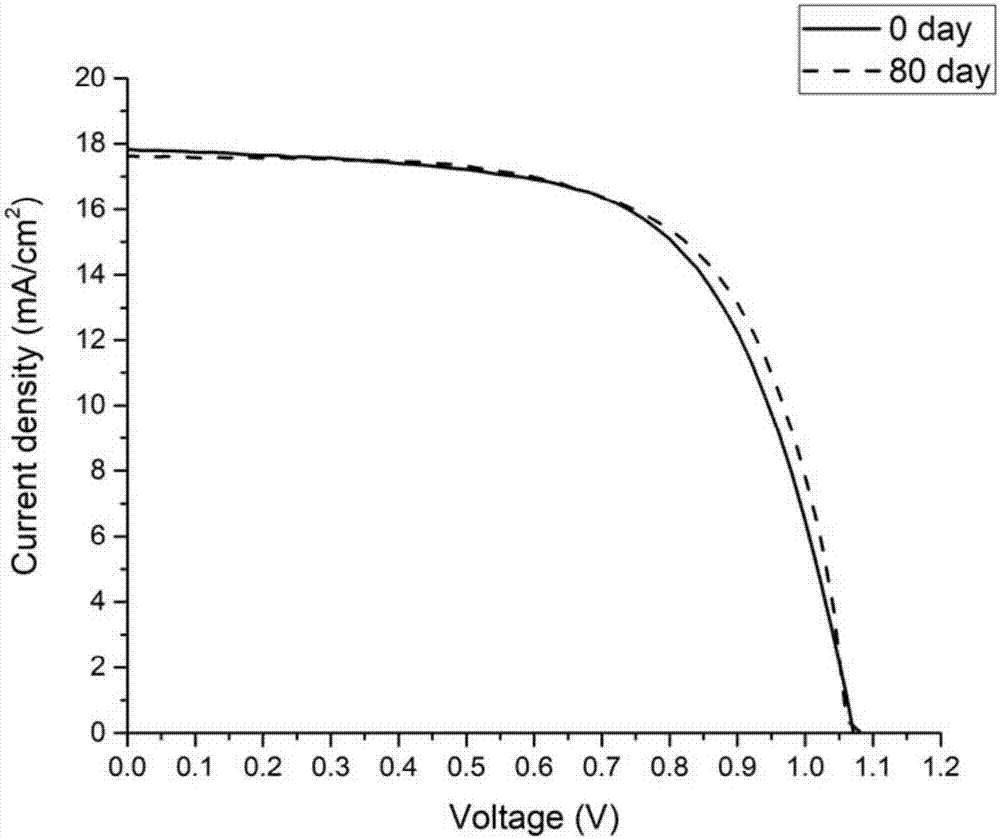

Organic-inorganic hybrid perovskite solar cell and preparation method thereof

InactiveCN107464882AImprove stabilityReduce photoelectric conversion efficiencySolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellEvaporation

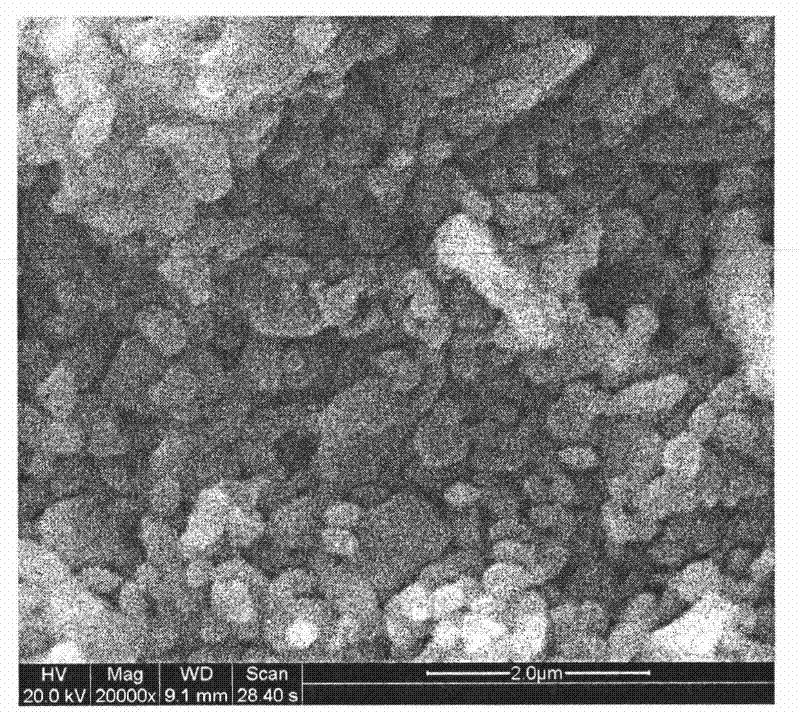

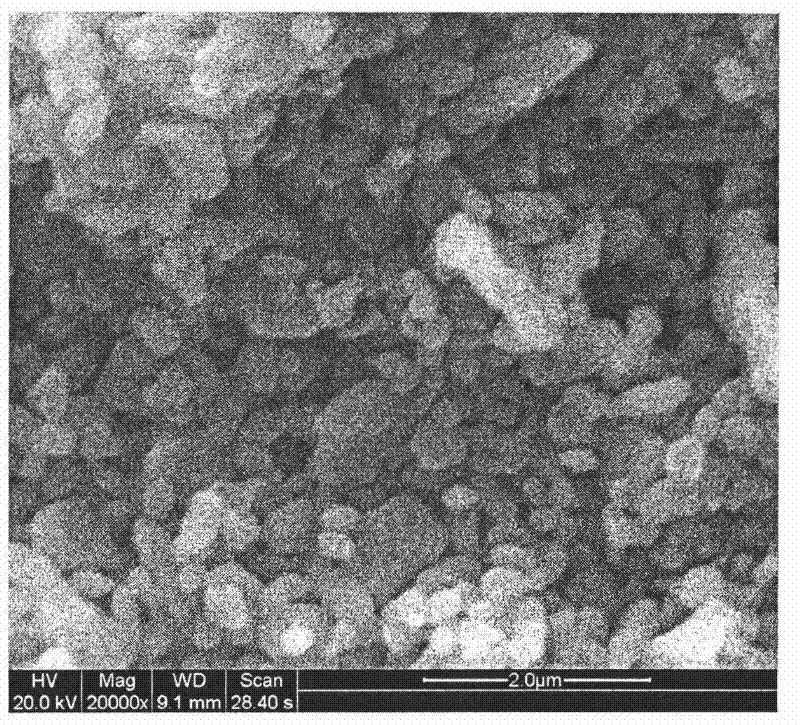

The invention discloses an organic-inorganic hybrid perovskite solar cell and a preparation method thereof. The preparation method comprises the steps of firstly, depositing a semiconductor compact layer on a transparent conductive electrode by a spray pyrolysis method; secondly, spraying a mixed positive ion organic-inorganic hybrid perovskite solution on the semiconductor compact layer by a thermal substrate spraying method to form a hybrid positive ion organic-inorganic hybrid perovskite thin film light absorption layer; thirdly, preparing a hole transmission layer on a surface of the light absorption layer; and finally, evaporating a gold electrode by thermal evaporation to obtain the organic-inorganic hybrid perovskite solar cell. The organic-inorganic hybrid perovskite solar cell is prepared by the thermal substrate spraying method, the preparation process is simplified, a large-area perovskite thin film can be rapidly prepared, and application on a large scale is facilitated; and moreover, the proportion among constituents of the hybrid positive ion organic-inorganic hybrid perovskite solution is optimized, the grain size of the obtained solar cell exceeds 500 nanometers, and the solar cell is relatively good in stability.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

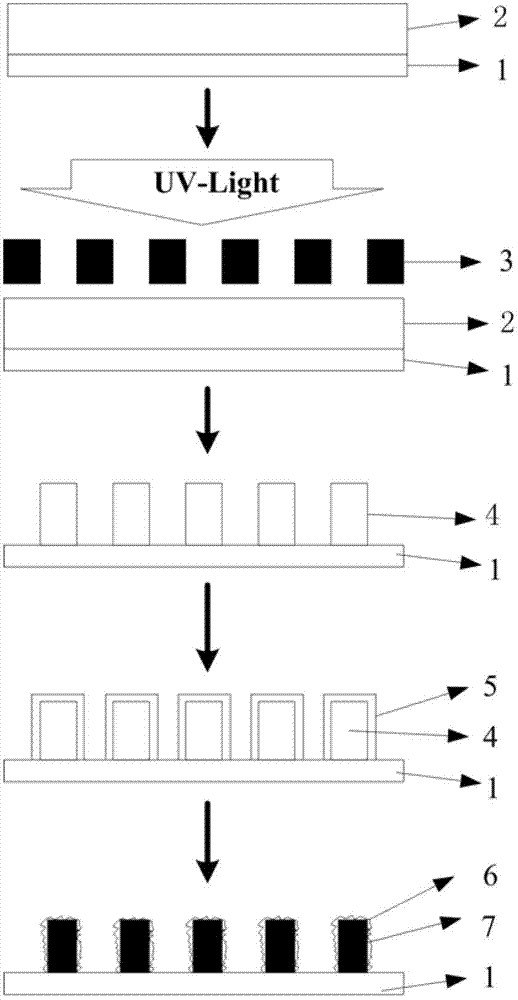

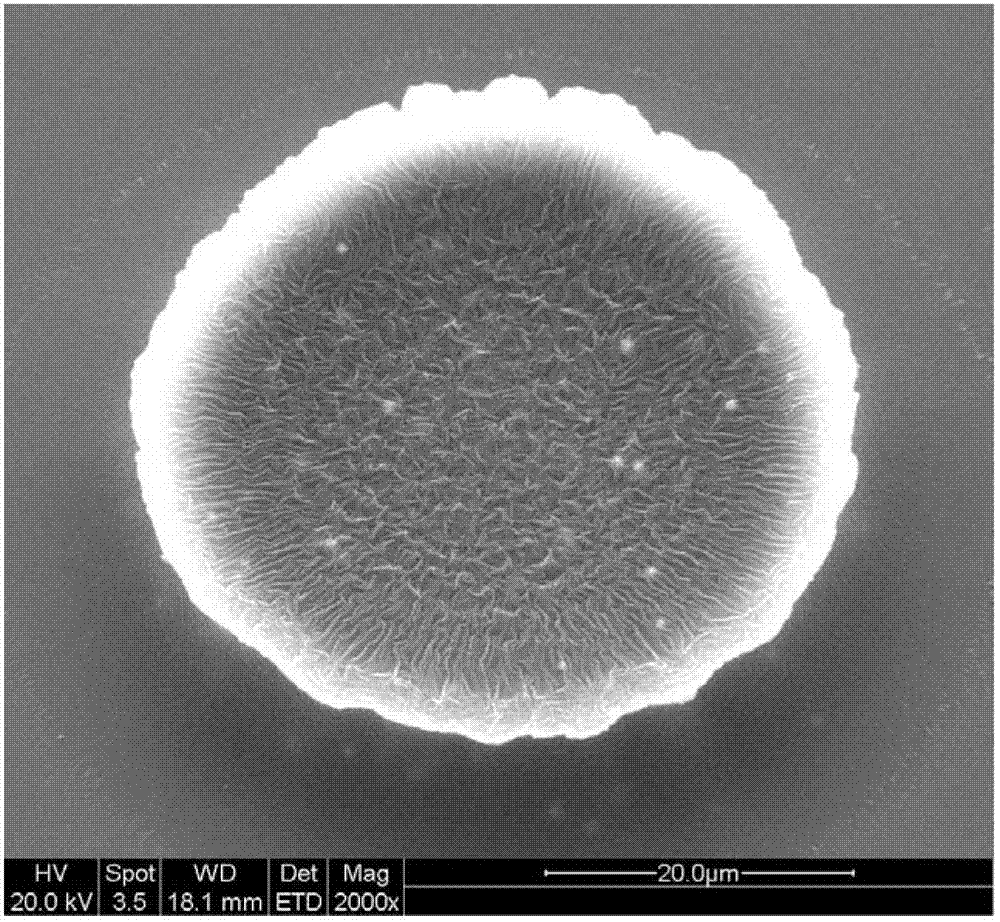

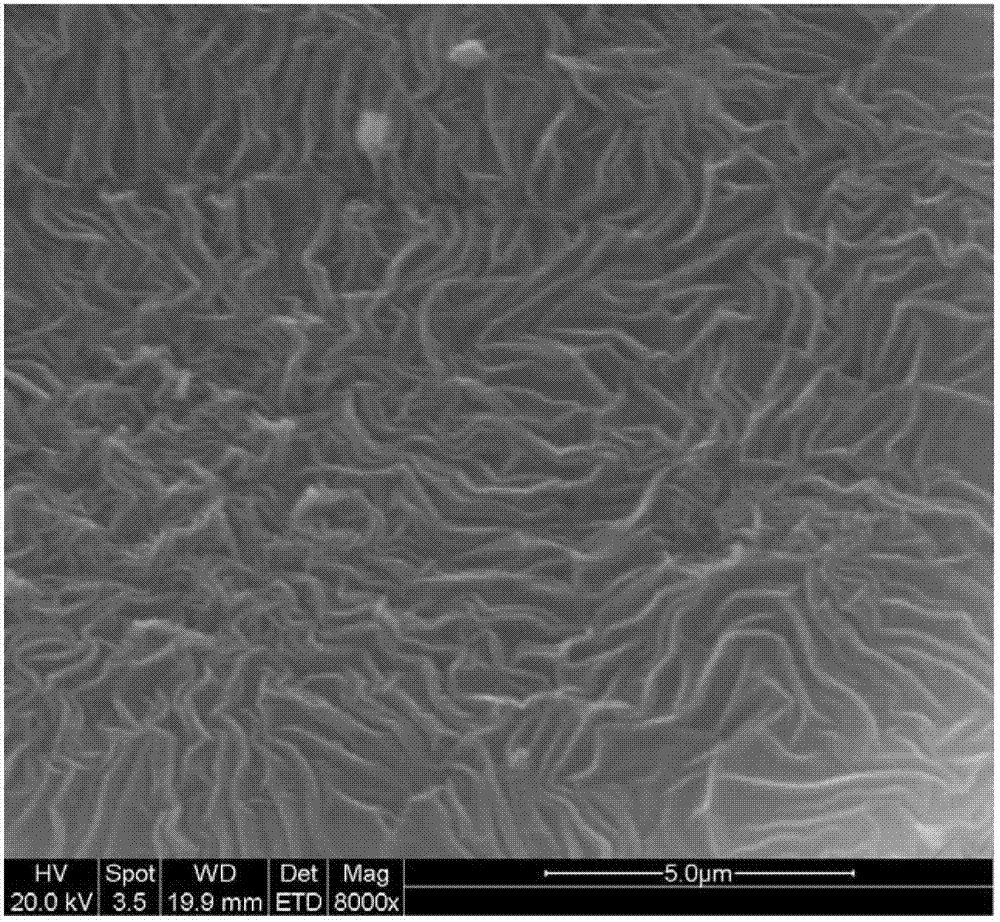

Preparation method for three-dimensional carbon micro-nano electrode array structure integrating carbon nano-drape

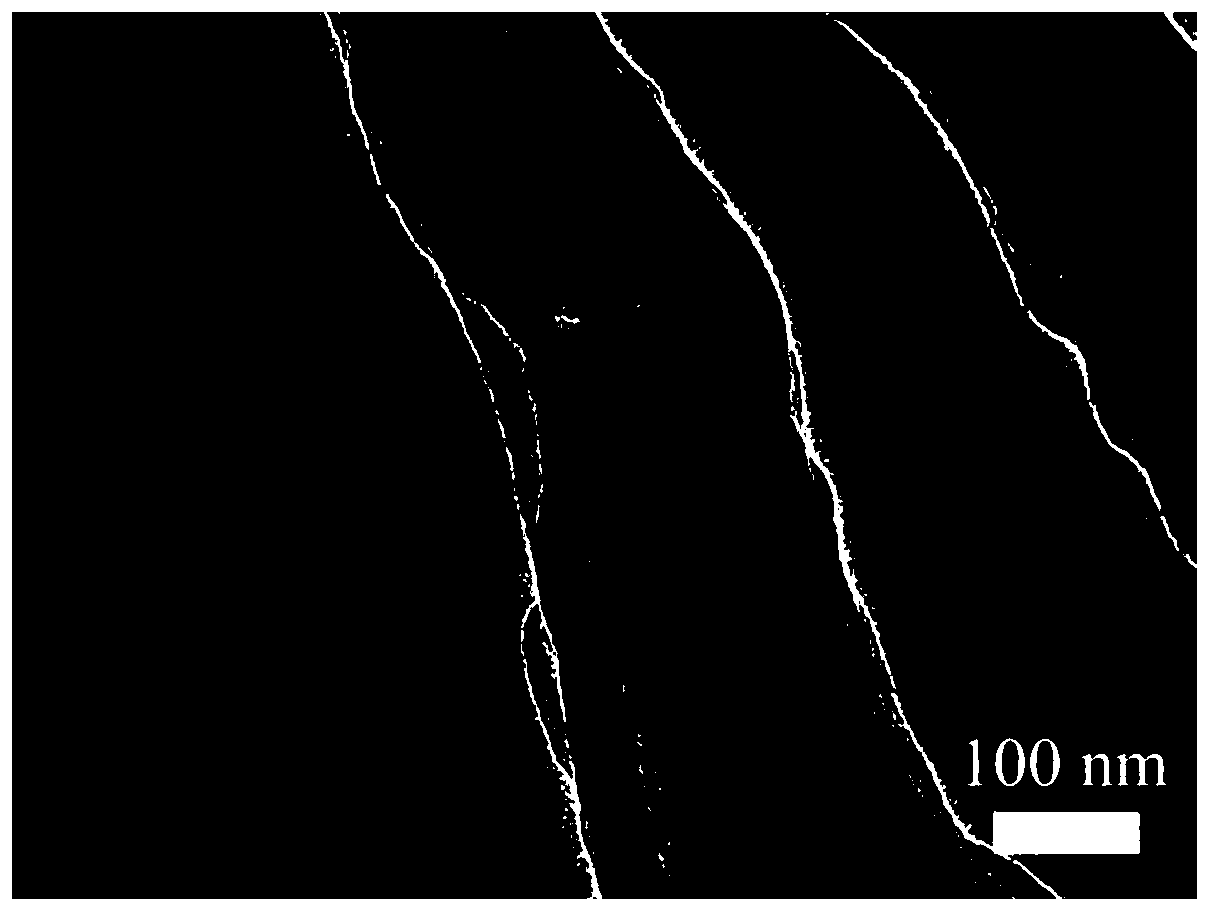

InactiveCN102757013AGood electrical conductivityImprove biological activityDecorative surface effectsChemical vapor deposition coatingCarbon filmMicro nano

The invention provides a preparation method for a three-dimensional carbon micro-nano electrode array structure integrating carbon nano-drape. The preparation method comprises the following steps: 1) photoetching to obtain a photoresist microstrucutre with an electrode pattern; 2) depositing a carbon film: depositing one layer of carbon film on the photoresist microstrucutre; and 3) performing pyrolysis: performing multi-step pyrolysis under the environment of inert gas or other mixed gas, wherein the pyrolysis temperature at each step is different. According to the preparation method, the carbon micro-nano integrated structure by combining the carbon nano-drape and the carbon microstructure and generating nano-drape on the surface of the microstructure. Due to integration of the biologically compatible nano-drape carbon film, the specific surface area of the carbon micro-nano electrode array is greatly increased and the bioactivity and the stability of the enzyme are improved. The method is applied to a micro-electro-mechanical system and has the characteristics of simple and convenient process, firm structure and high biocompatibility. The prepared carbon microstructure can serve as a microelectrode and can be applied to the micro-electro-mechanical fields of biological fuel cells, biological chips, micro-electrochemical sensors and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

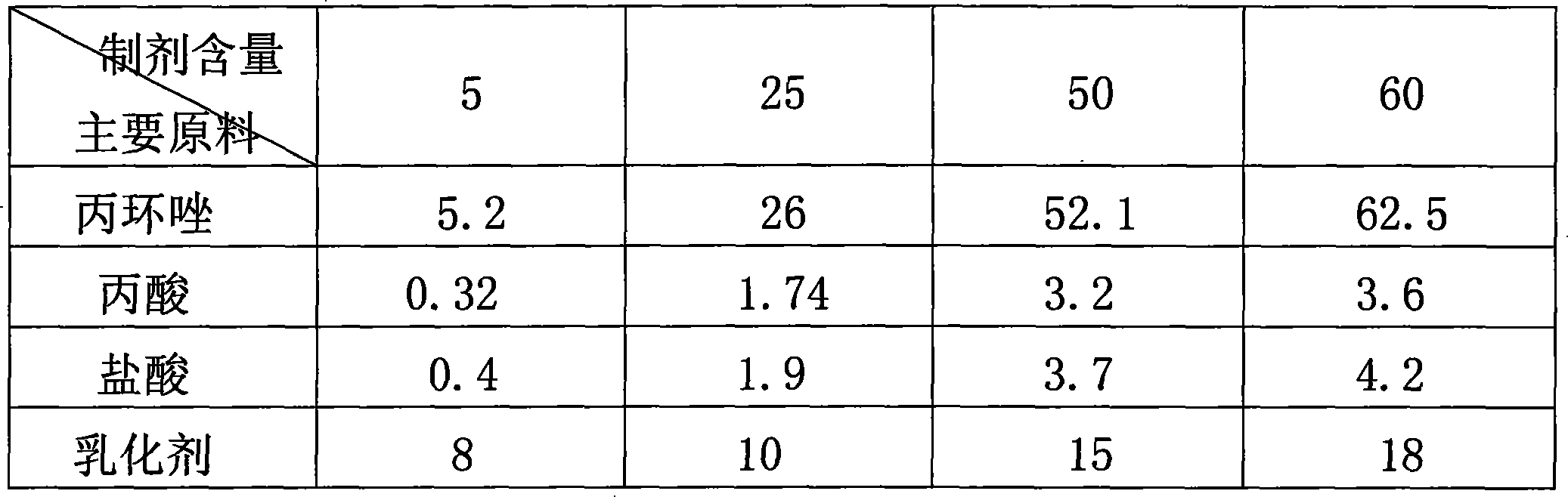

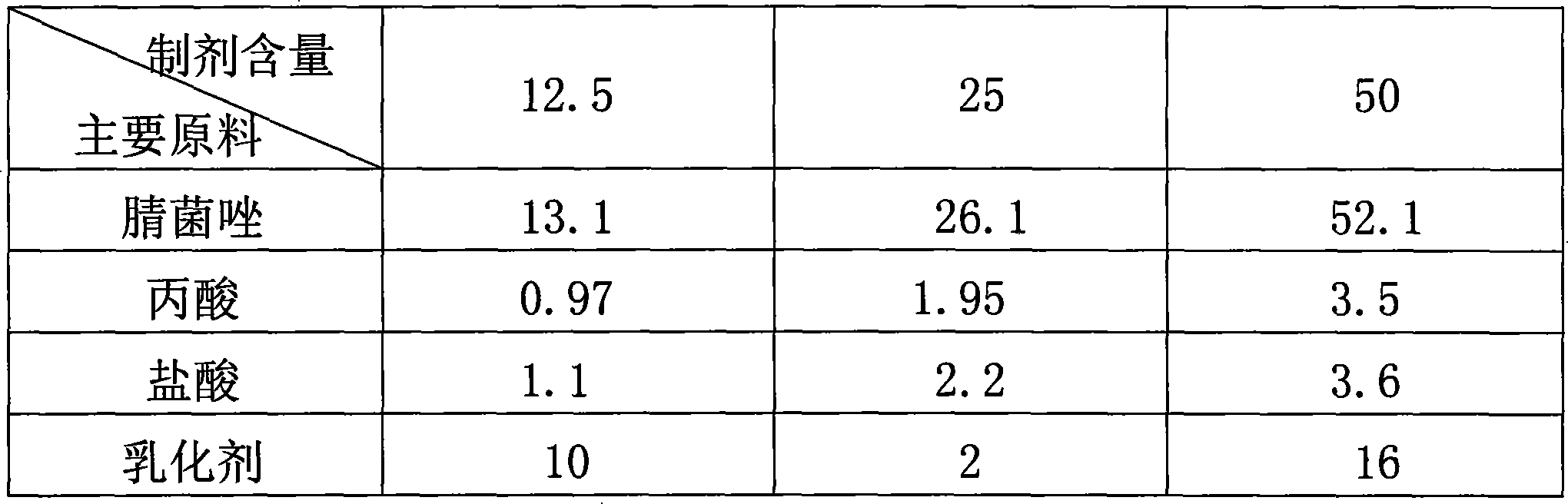

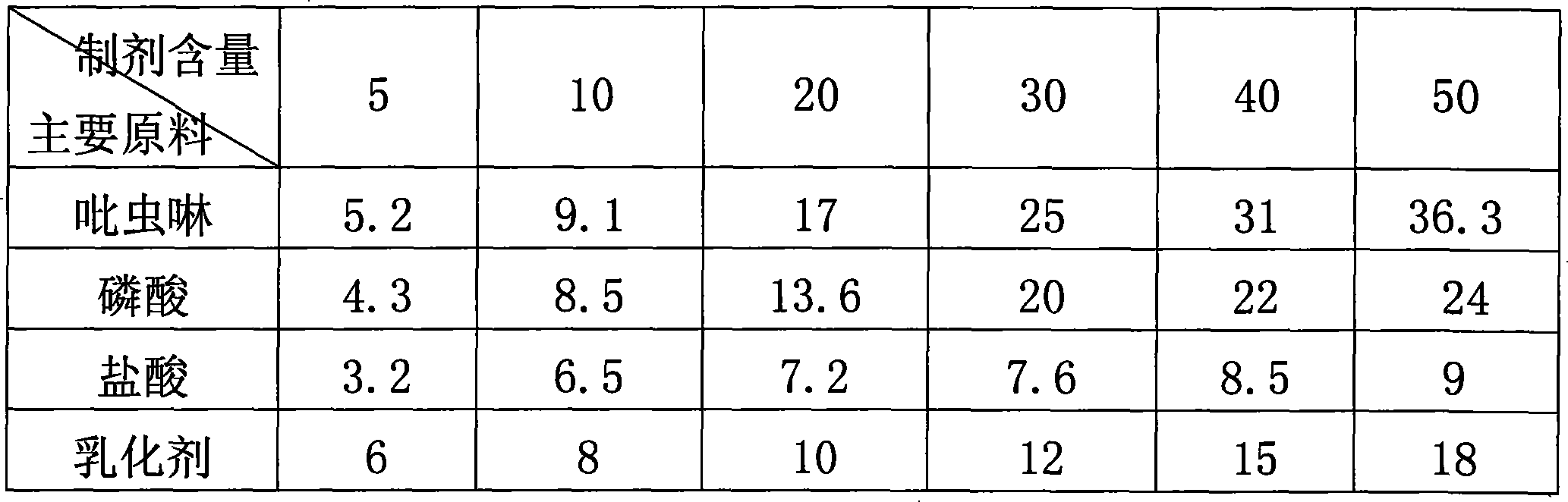

Azacycle containing pesticide microemulsion and its prepn

InactiveCN101019530AThe production method is uniqueReduce typesBiocideAnimal repellantsOrganic acidEmulsion

The azacycle containing pesticide microemulsion and its preparation process relates to many sorts of new water emulsion pesticide preparations. The present invention features that some azacycle containing pesticides may be dissolved temporarily in the mixed solution system of inorganic acid with or without organic acid and the solution may be maintained by using surfactant with or without antifreezing thickener, so as to prepare azacycle containing pesticide microemulsion of 2-60 % concentration and containing no harmful solvent. The present invention opens one new way for preparing water emulsion pesticide preparations.

Owner:周本新

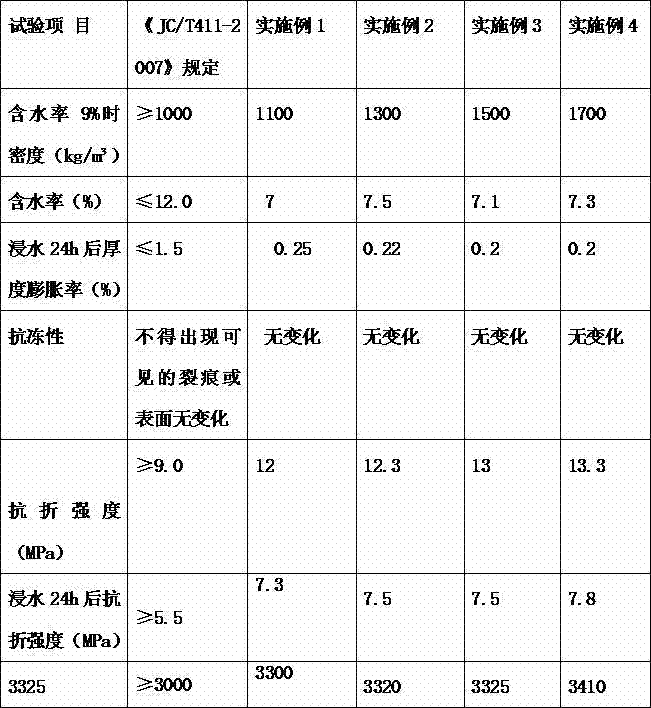

Geopolymer based fibreboard

InactiveCN103803939AHarden fastImprove acid and alkali corrosion resistanceCement productionFiberSlag

The invention discloses a geopolymer based fibreboard which is mainly composed of liquid water glass, aluminosilicate, wood fibers, reinforcement fibers and the like, and also provides a preparation method of the geopolymer based fibreboard. The preparation method comprises the steps of weighing the various raw materials, adding the aluminosilicate, the wood fibers and the reinforcement fibers to a mixer and stirring evenly to obtain a dry powder, adding the liquid water glass to the dry powder which is mixed thoroughly and evenly, and mixing evenly to obtain a slurry, pouring the thoroughly mixed slurry into a fiberboard mold, slicking, and carrying out extrusion forming with pressure of 2.5MPa, maintaining for 6 hours under natural conditions and then demolding, and maintaining under the natural conditions for 7-10 days to obtain the geopolymer based fibreboard. The geopolymer based fibreboard is high in strength, good in water resistant performance, extremely low in water absorbing expansion rate, simple and convenient in maintenance process conditions, good in sound insulation and heat insulation effects, resistant to high temperatures, low in production cost and harmless to the human body; the geopolymer based fibreboard is capable of overcoming the problems of high energy consumption, high maintenance condition requirements and high production cost of the existing material, and also capable of improving the utilization rate of the industrial waste steel slag.

Owner:广西启利新材料科技股份有限公司

Preparation process of lactide

The invention discloses a preparing method of lactide in the macromolecular material preparing domain, which comprises the following steps: a. adopting L-lactic acid as raw material to obtain the low-molecular polymer of lactic acid; b. placing the low-molecular polymer of lactic acid in the reactor to react; controlling the reacting condition under normal pressure; heating to 150-250 deg.c; c. aerating inert gas into reactor at 200-500 deg.c; carrying the reacting product out of reactor; cooling to 80-150 deg.c; collecting; purifying extracted compound to obtain the product.

Owner:RUGAO FIBERGLASS FACTORY

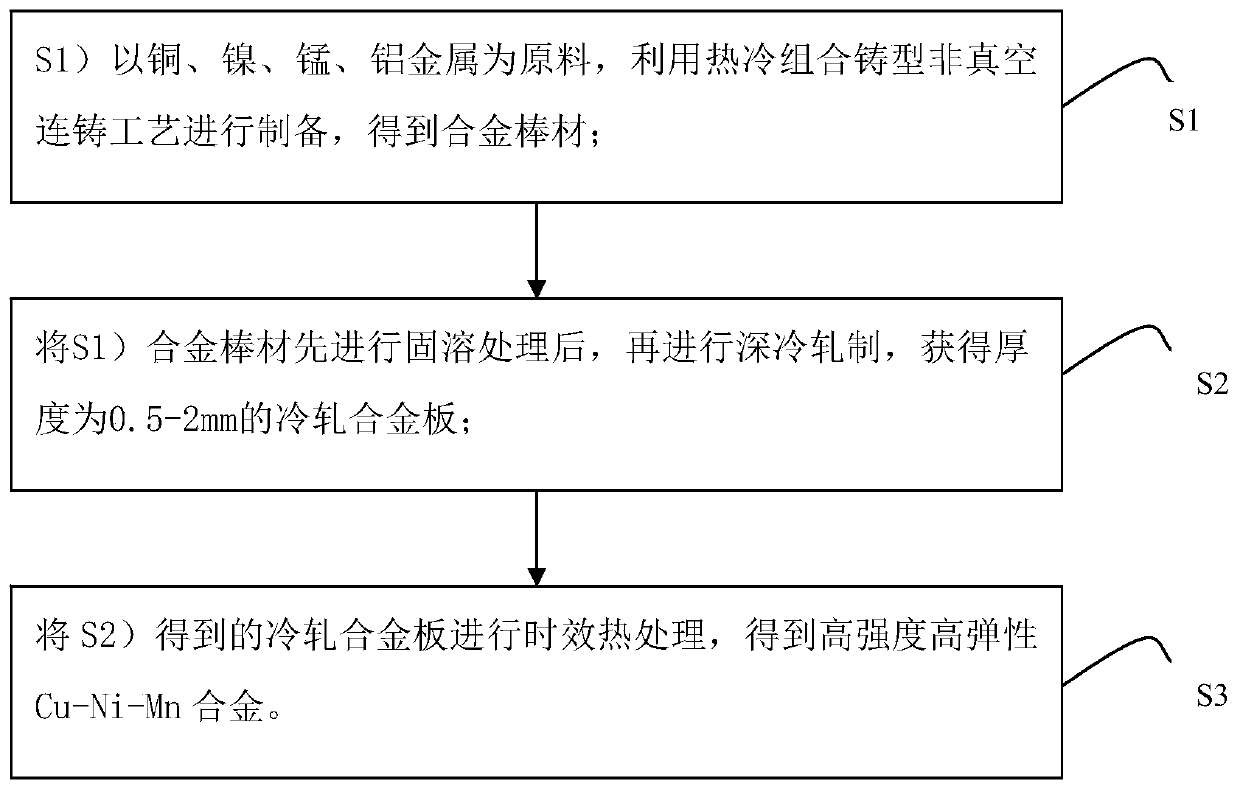

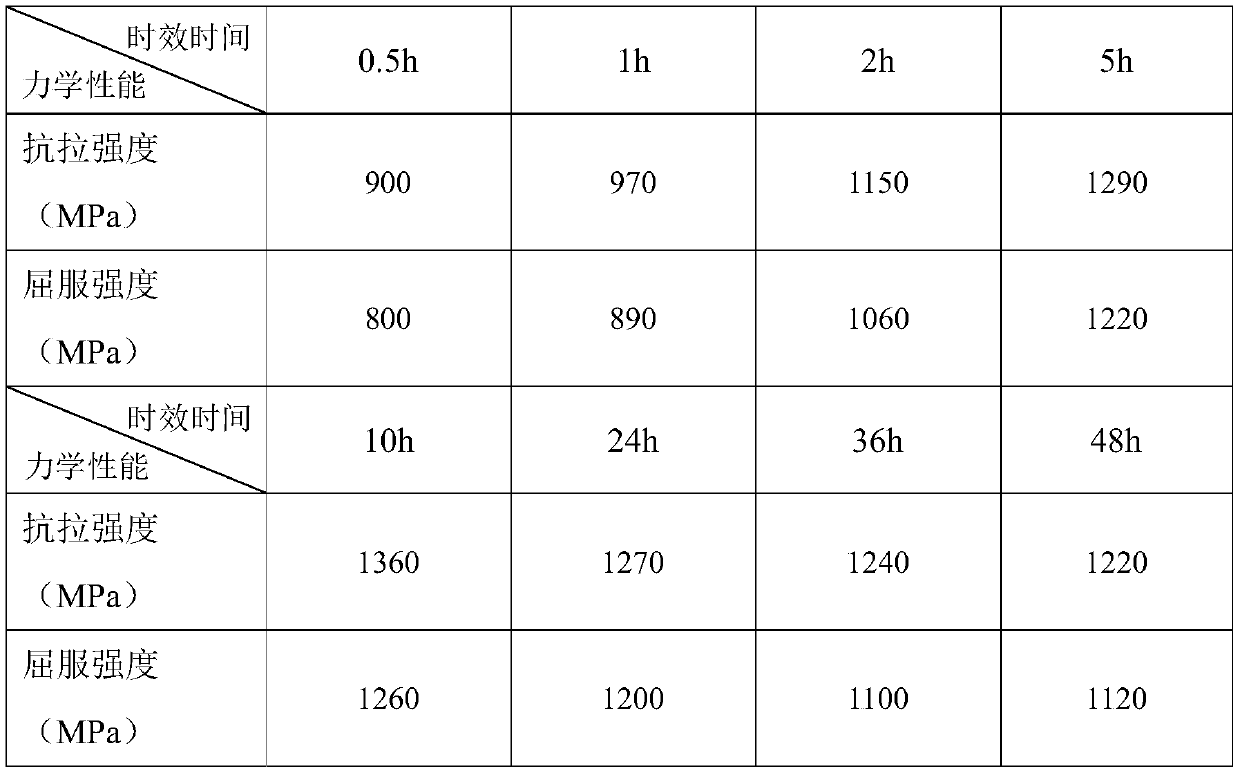

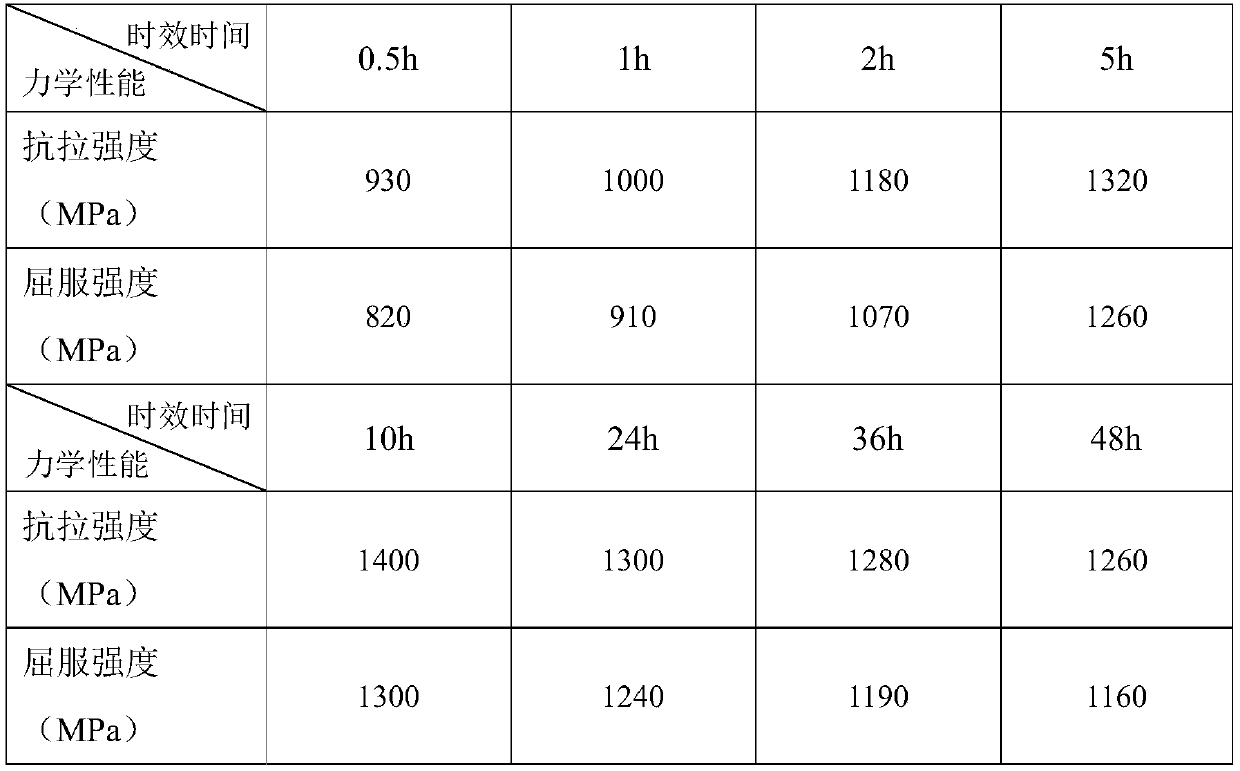

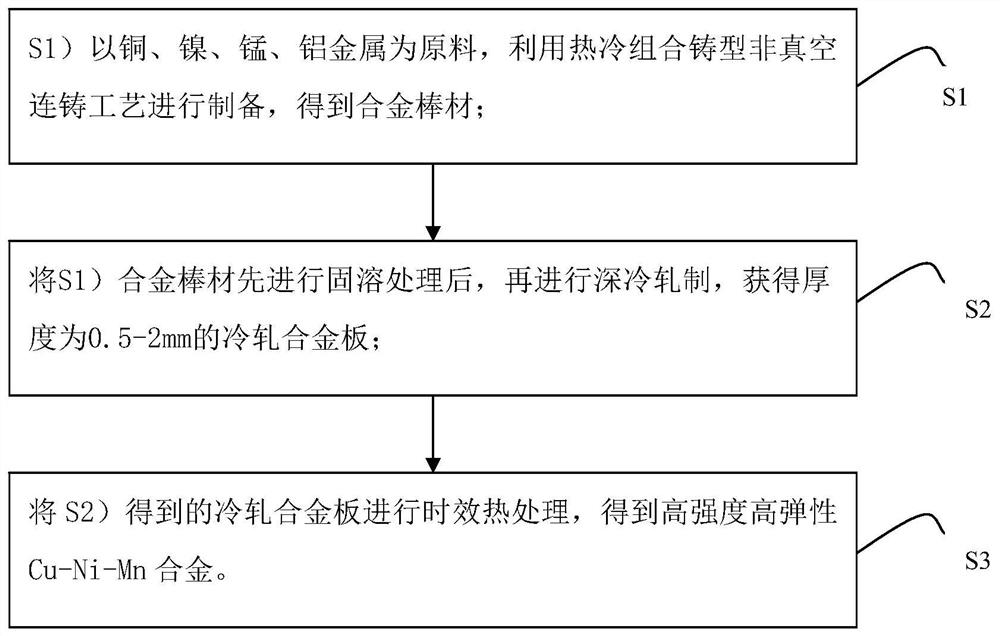

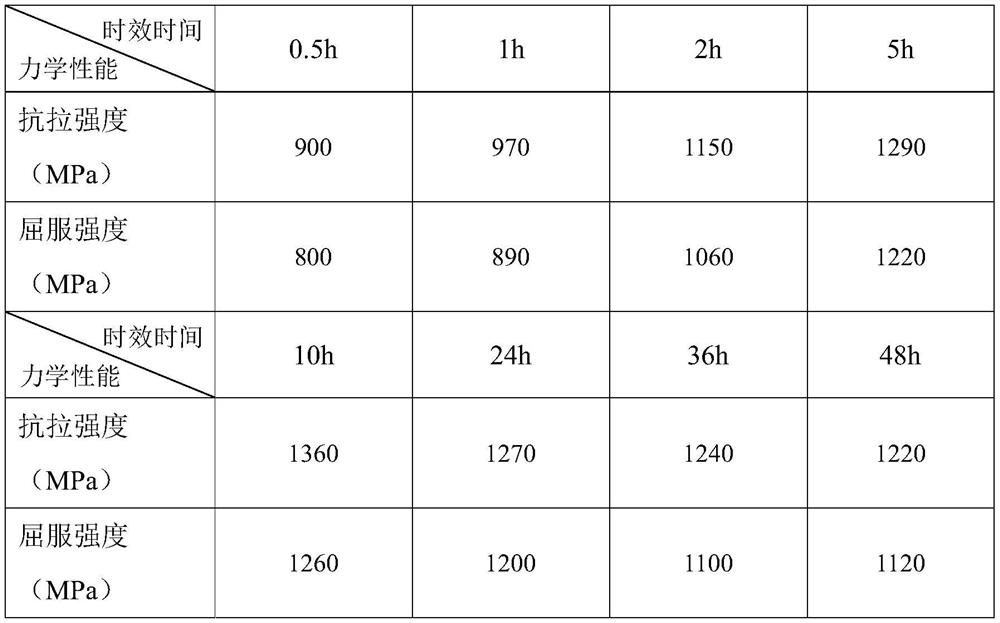

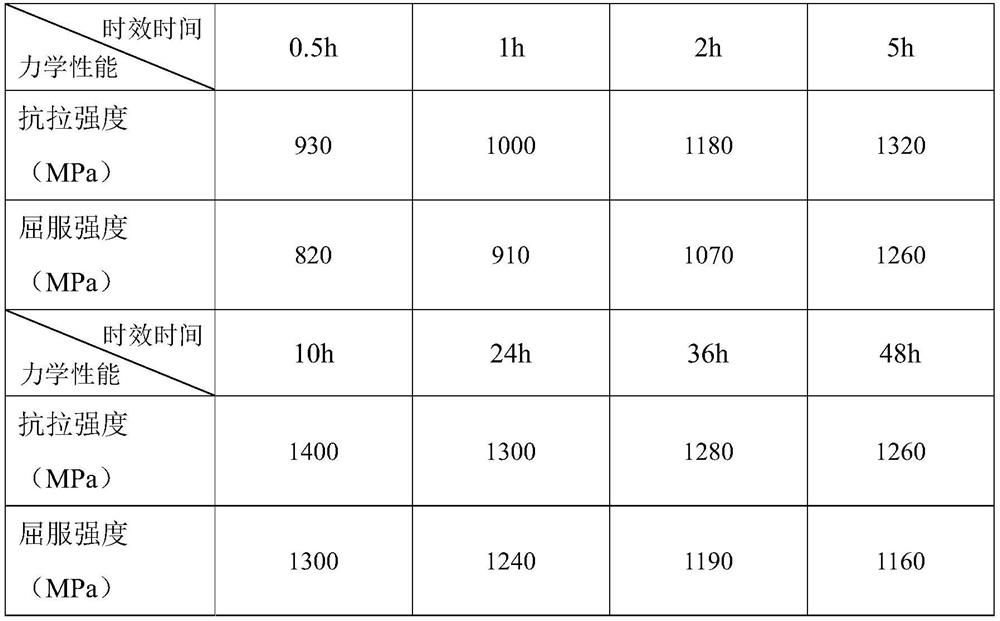

Short flow preparation method of high-strength and high-elasticity Cu-Ni-Mn alloy

The invention belongs to the technical field of copper alloy materials, and particularly relates to a short flow preparation method of a high-strength and high-elasticity Cu-Ni-Mn alloy. The method specifically comprises the following steps that S1), copper, nickel, manganese, aluminum and / or boron with the purity of greater than 99% are used as raw materials, a heating-cooling combined mold non-vacuum continuous casting process is used for preparing, and an alloy bar is obtained; and S2), after the alloy bar obtained in the step S1 is subjected to solid solution treatment, the alloy bar is subjected to deep cold rolling, and a cold-rolled alloy plate with the thickness of 0.5-2 mm is obtained; and S3), aging heat treatment is carried out on the cold-rolled alloy plate obtained in the stepS2, and the high-strength high-elasticity Cu-Ni-Mn alloy is obtained. According to the method, on the basis of high strength, elastic modulus and low cost of the Cu-Ni-Mn alloy, the mechanical property is further improved; and meanwhile, the continuous casting technology is utilized, the technological process is shortened, the preparation condition is reduced, and the method has remarkable technical beneficial effects.

Owner:UNIV OF SCI & TECH BEIJING

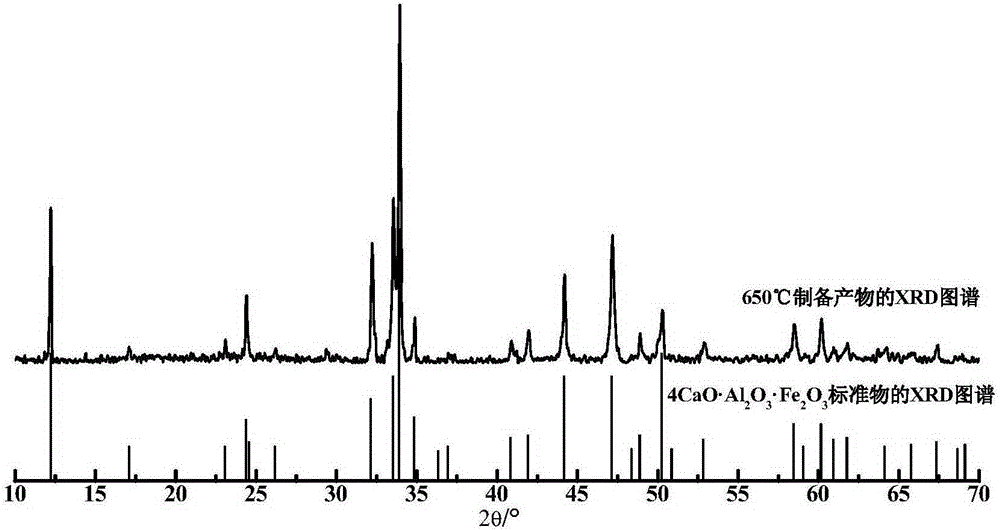

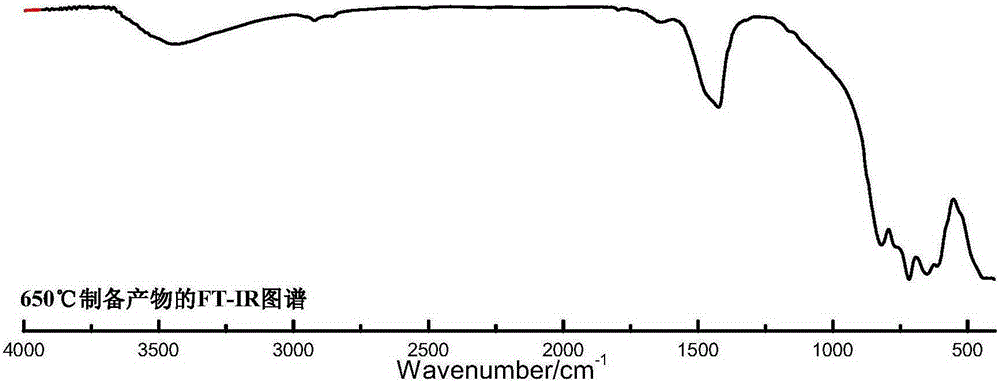

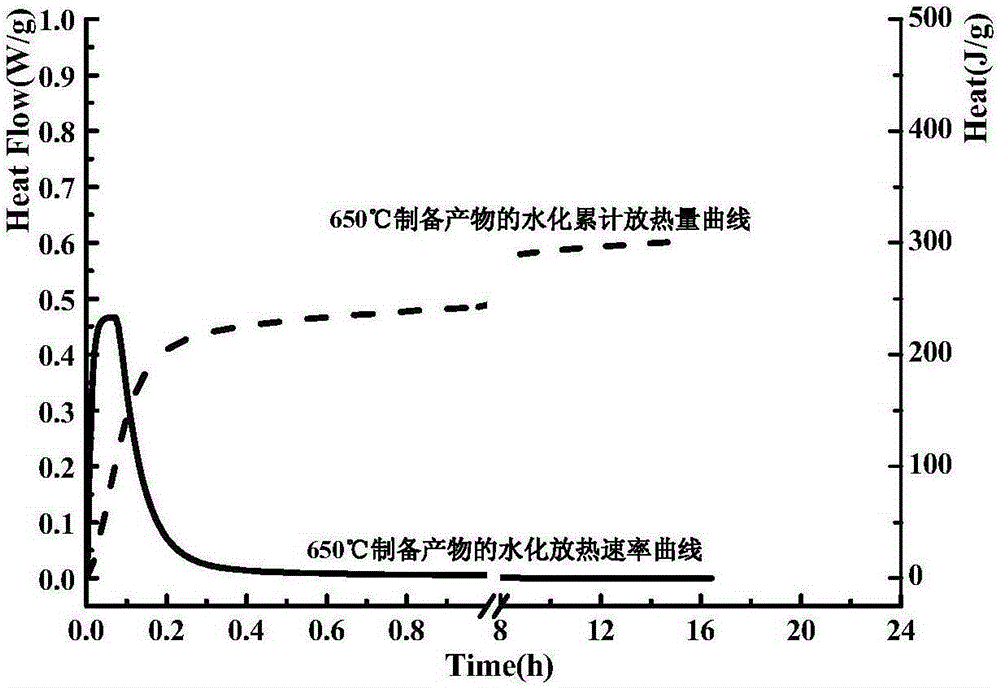

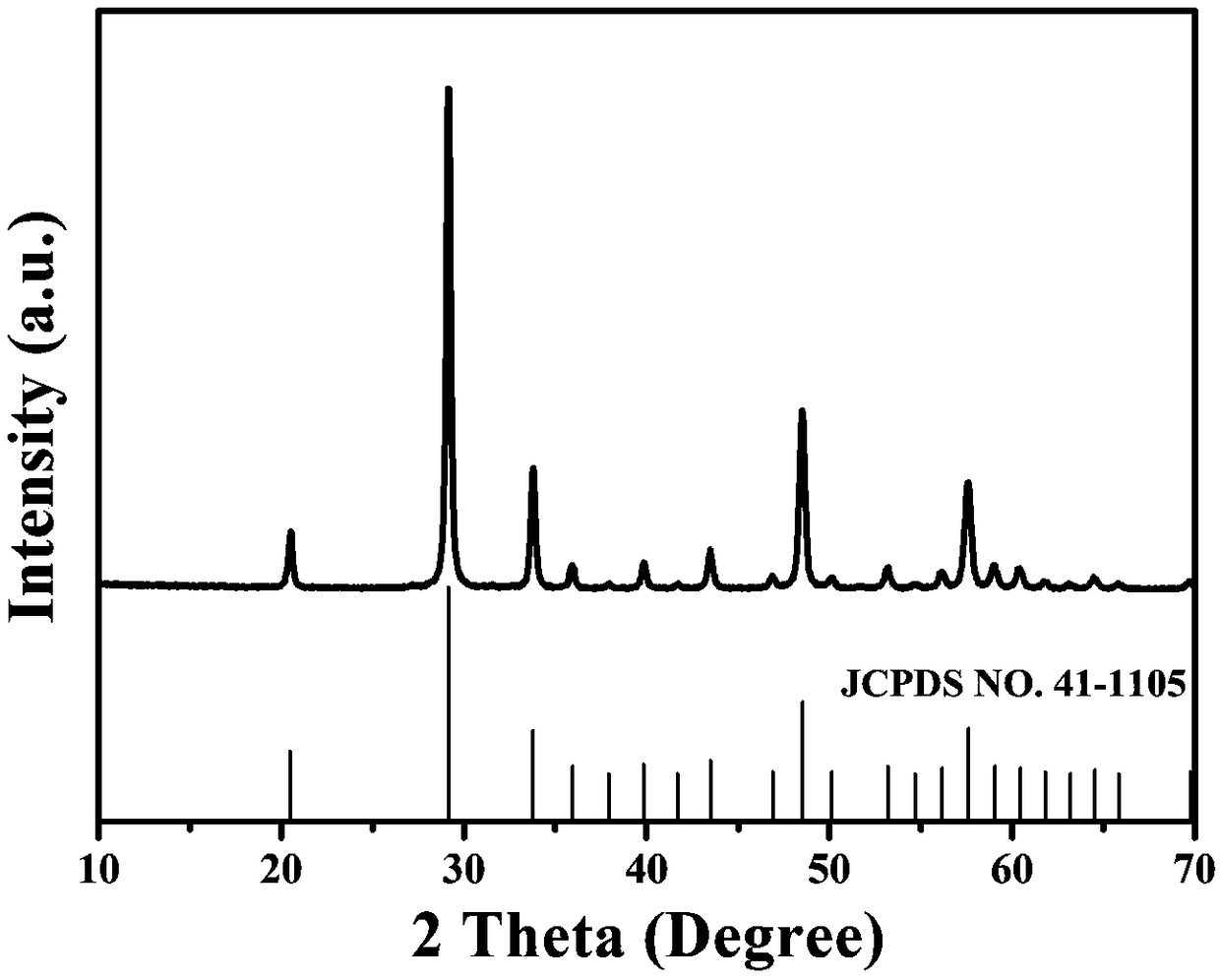

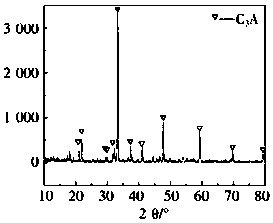

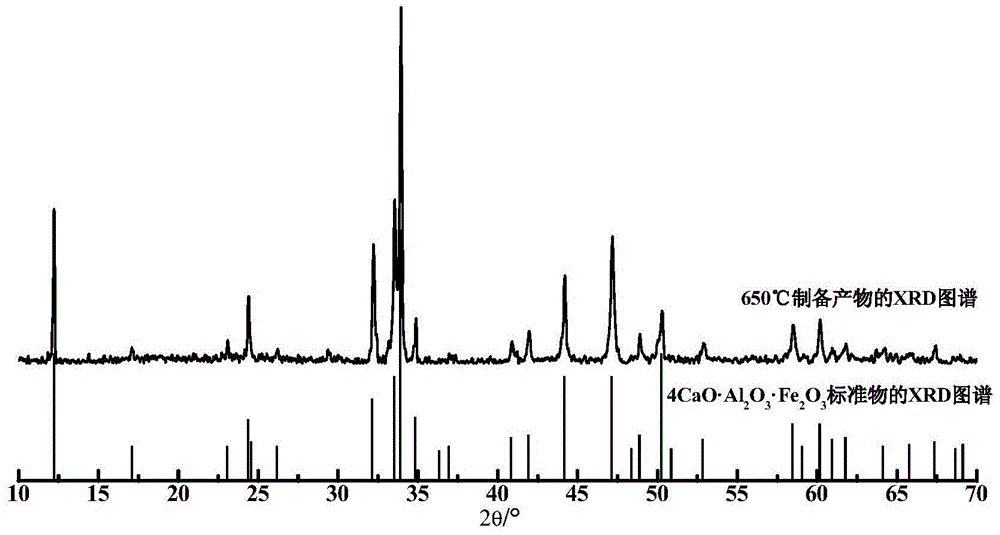

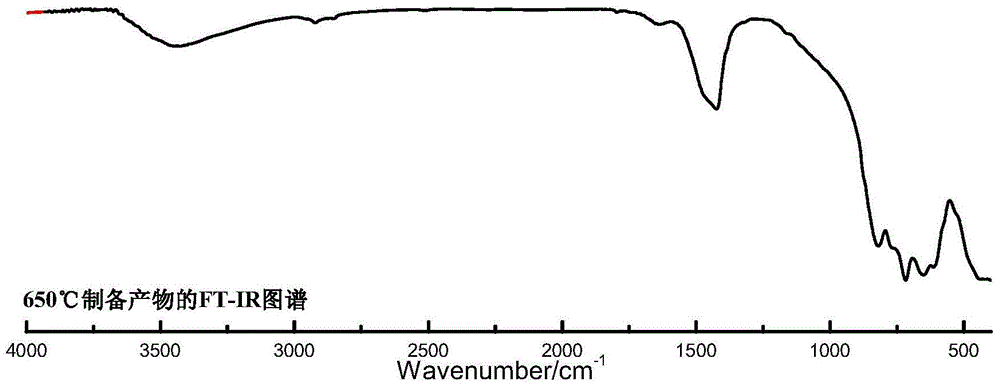

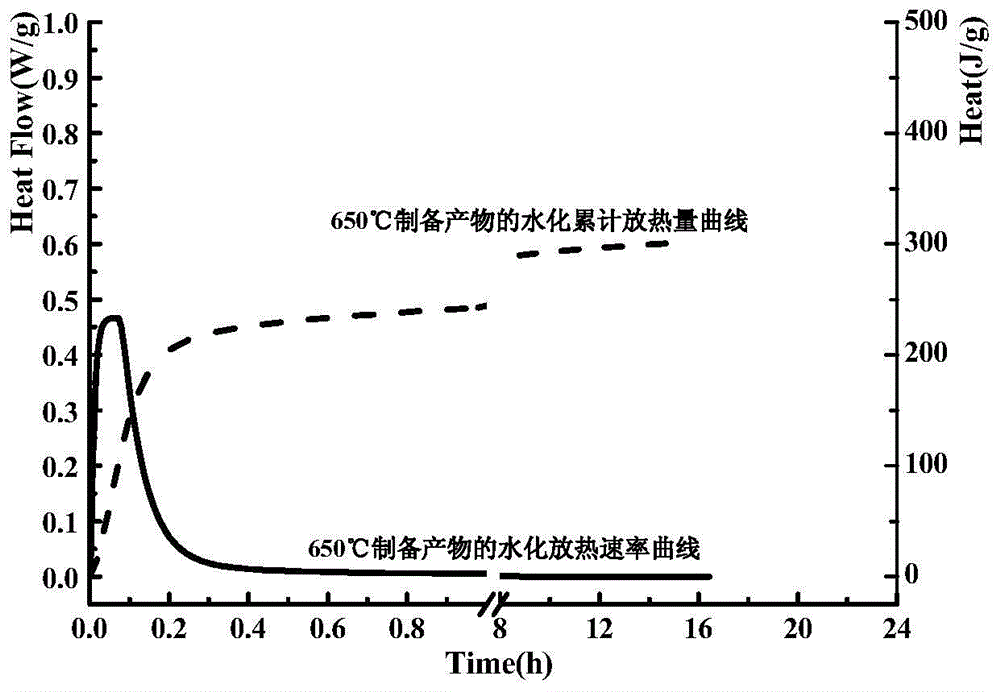

Method for fast preparing polycrystalline tetra calcium aluminoferrite

ActiveCN105271427ALow preparation temperatureLess power consumptionChemical industryIron compoundsAir atmosphereTetra

The invention discloses a method for fast preparing polycrystalline tetra calcium aluminoferrite. The method includes the steps that firstly, raw materials including calcium nitrate terahydrate, aluminum nitrate nonahydrate, iron nitrate nonahydrate and urea are weighed according to the mass ratio of 1:0.7942:0.8554:2.0413-2.1923; secondly, a proper amount of deionized water is added, and dispersion liquid with the concentration ranging from 0.5 mol / L to 0.8 mol / L is prepared and continuously stirred for 1.5 hours to 2 hours till the raw materials are completely dissolved; thirdly, the dispersion liquid is moved into a high temperature stove and heated to 500 DEG C to 510 DEG C in air atmosphere, after the constant temperature is kept for two hours, the dispersion liquid is taken out and grinded into particles with the particle size smaller than or equal to 0.15 mm, and the particles serve as a precursor ready for use; fourthly, the precursor is pressed into a thin piece with the diameter of 35 mm and the thickness smaller than or equal to 5 mm under the pressure of 25 MPa to 30 MPa; finally, the pressed precursor thin piece is heated to 650 DEG C to 950 DEG C at the heating rate of 10 DEG C / min, after the constant temperature is kept for 7 hours, the pressed precursor thin piece is taken out, fast cooled in the air and grinded, and the polycrystalline tetra calcium aluminoferrite with the hydration activity is obtained. The method is small in working procedure number, short in period and high in efficiency, the sintering temperature is 300 DEG C to 600 DEG C lower than the sintering temperature of a traditional method, and the method has the advantages of being fast, efficient and capable of saving energy, and is suitable for industrial large-scale application.

Owner:WUHAN UNIV

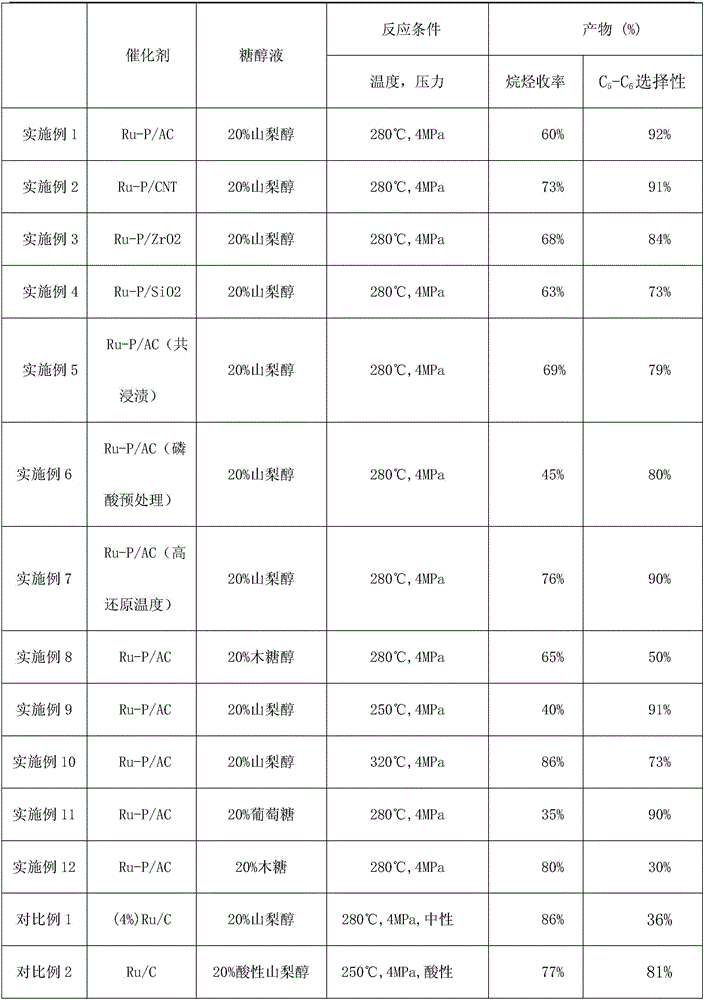

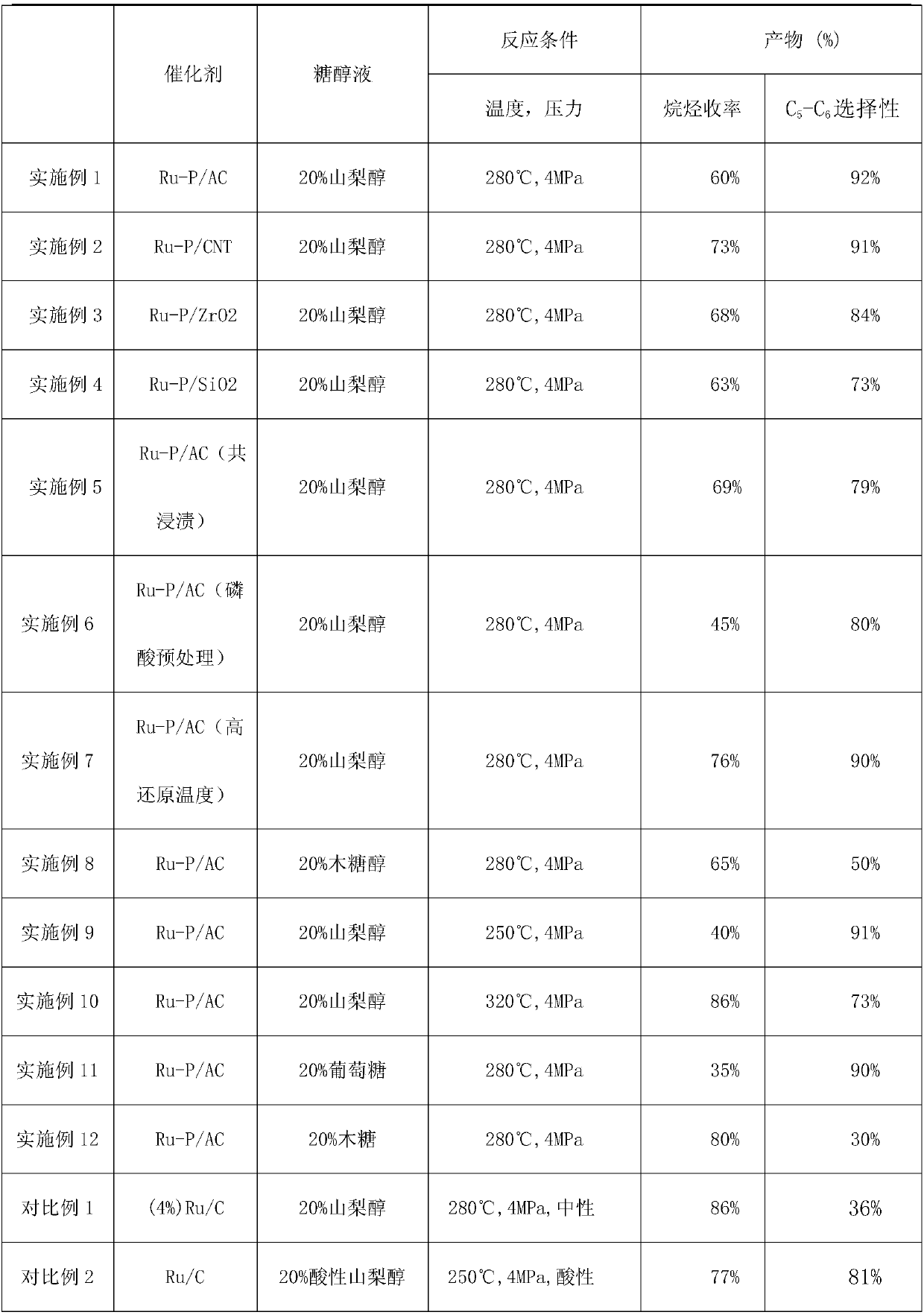

Catalyst for preparing C5 and C6 alkane through catalyzing sugar alcohol raw material in water phase and application thereof

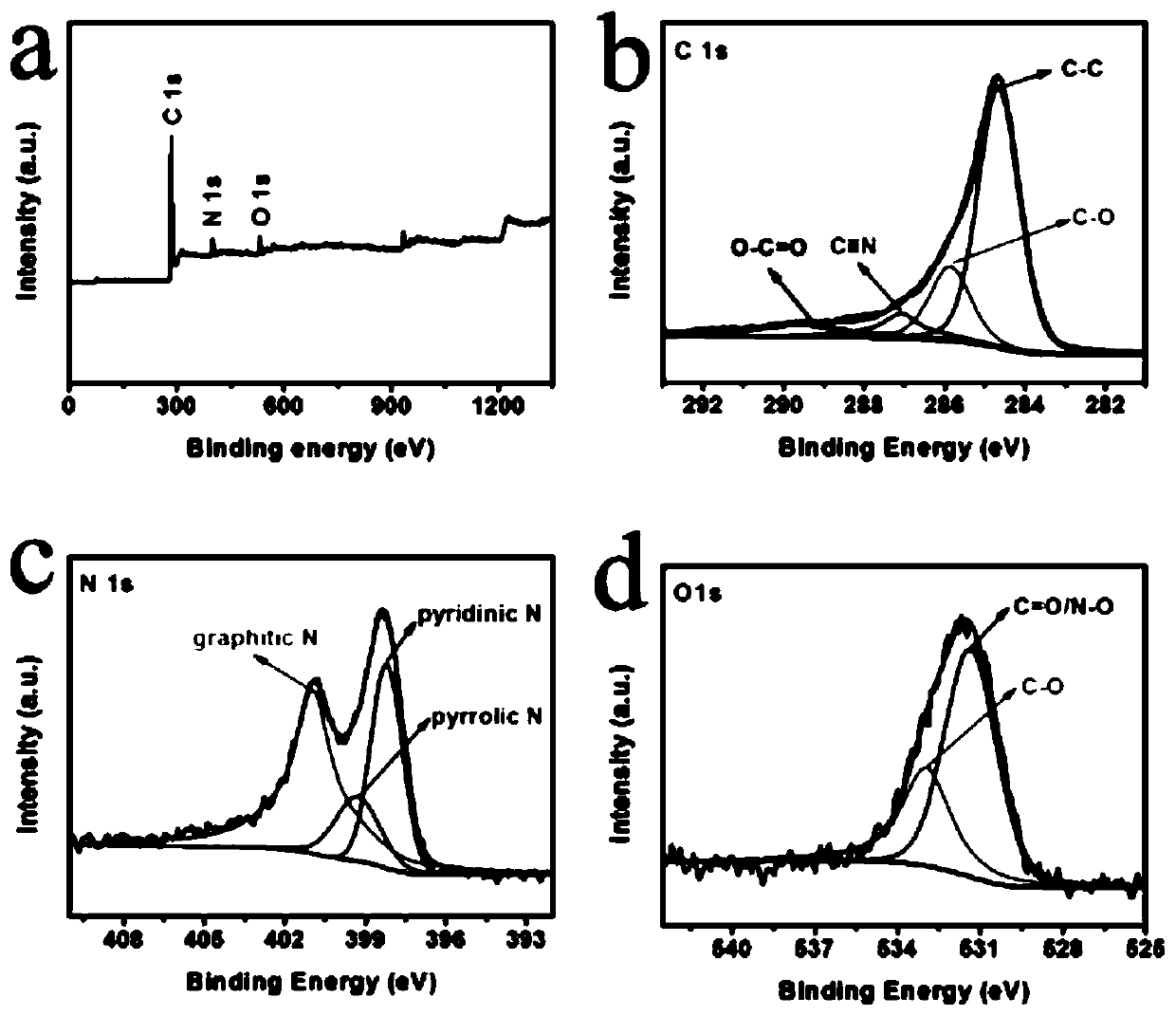

ActiveCN106268888AReduce the preparation conditionsLow preparation temperaturePhysical/chemical process catalystsCatalystsAlkaneCarbon nanotube

The invention discloses a catalyst for preparing C5 and C6 alkane through catalyzing a sugar alcohol raw material in a water phase. The structural formula of the catalyst is a Ru-P / carrier, wherein Ru is a metal component and P is an auxiliary agent; the carrier is one of active carbon, a carbon nanotube, silicon oxide and zirconium oxide; the mol ratio of Ru to P is 0.5 to 5; the loading amount of the metal Ru is 1 weight percent to 5 weight percent; the catalyst has very good catalytic activity and hydrothermal stability; the C5 and C6 alkane is prepared in a continuous reaction kettle at low pressure and low temperature through catalyzing the sugar alcohol raw material in the water phase; the sugar alcohol raw material can be completely converted, and the selectivity of the C5 and C6 alkane is up to 90 percent; the energy consumption is low and a technological process is simple and easy to control; the catalyst has a good industrial application prospect and the problem that an existing biomass-based sugar alcohol water-phase catalysis catalyst is not stable is solved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Method for electrophoresis of dual-color patterns on metal surface

ActiveCN106065490AStructural influenceSimple processPolyureas/polyurethane adhesivesElectrophoretic coatingsOrganic solventElectrophoresis

The invention discloses a method for electrophoresis of dual-color patterns on the metal surface. A masking film of a preset shape is manufactured with hot melt adhesive, and the masking film adheres to the metal surface; a first paint layer is formed in an uncovering area of the masking film through primary electrophoresis; and a second paint layer different from the first paint layer in color is deposited in a covering area of the masking film through secondary electrophoresis after the masking film is removed, and accordingly the patterns of the masking film are transferred to the metal surface. The masking film made of the hot melt adhesive can be removed easily by being dissolved and cleaned with hot water or an organic solvent, strong base or other corrosive matter is not needed, and the film structure cannot be affected; and meanwhile, various dual-color electrophoresis patterns can be formed as needed, the manufacturing process is simple, the appearance life is long, and the application range is enlarged.

Owner:JOMOO KITCHEN & BATHROOM

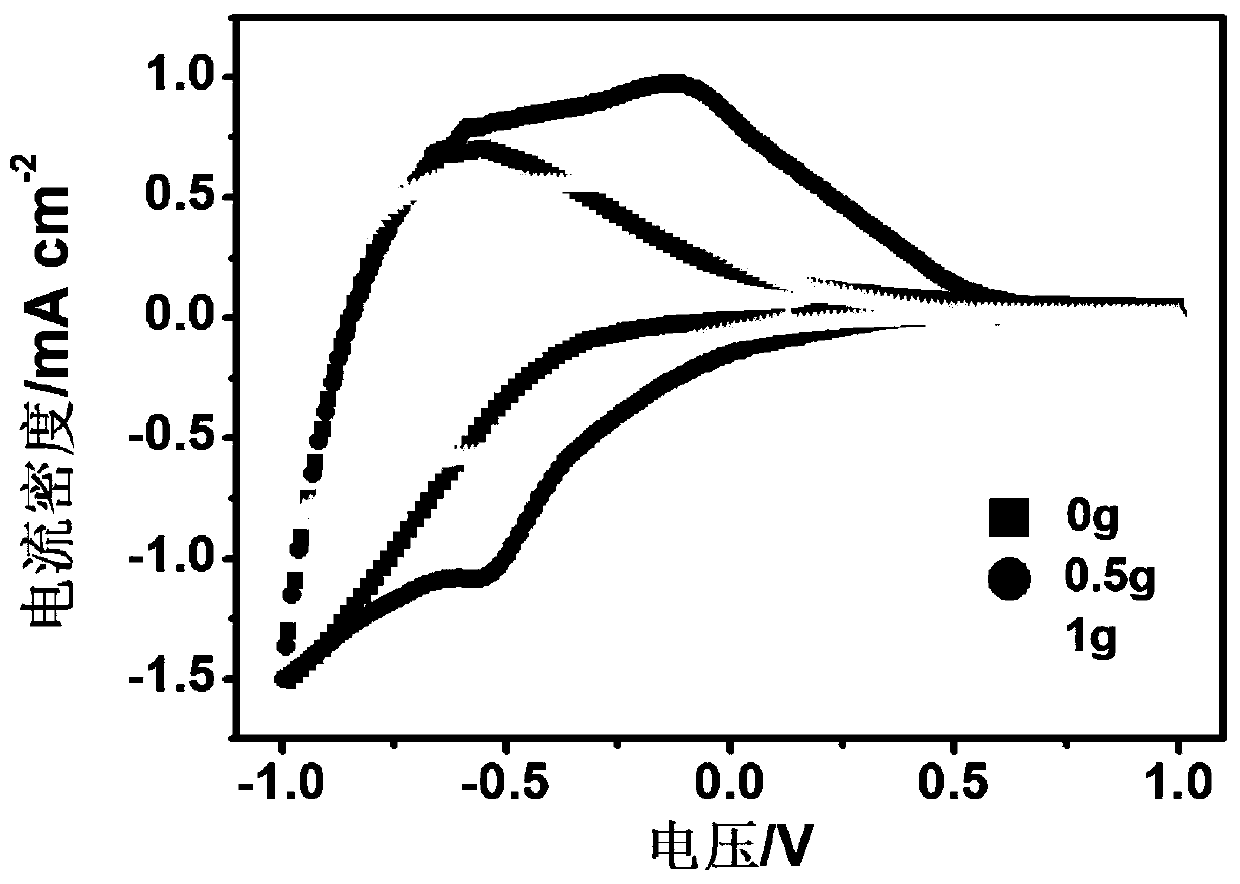

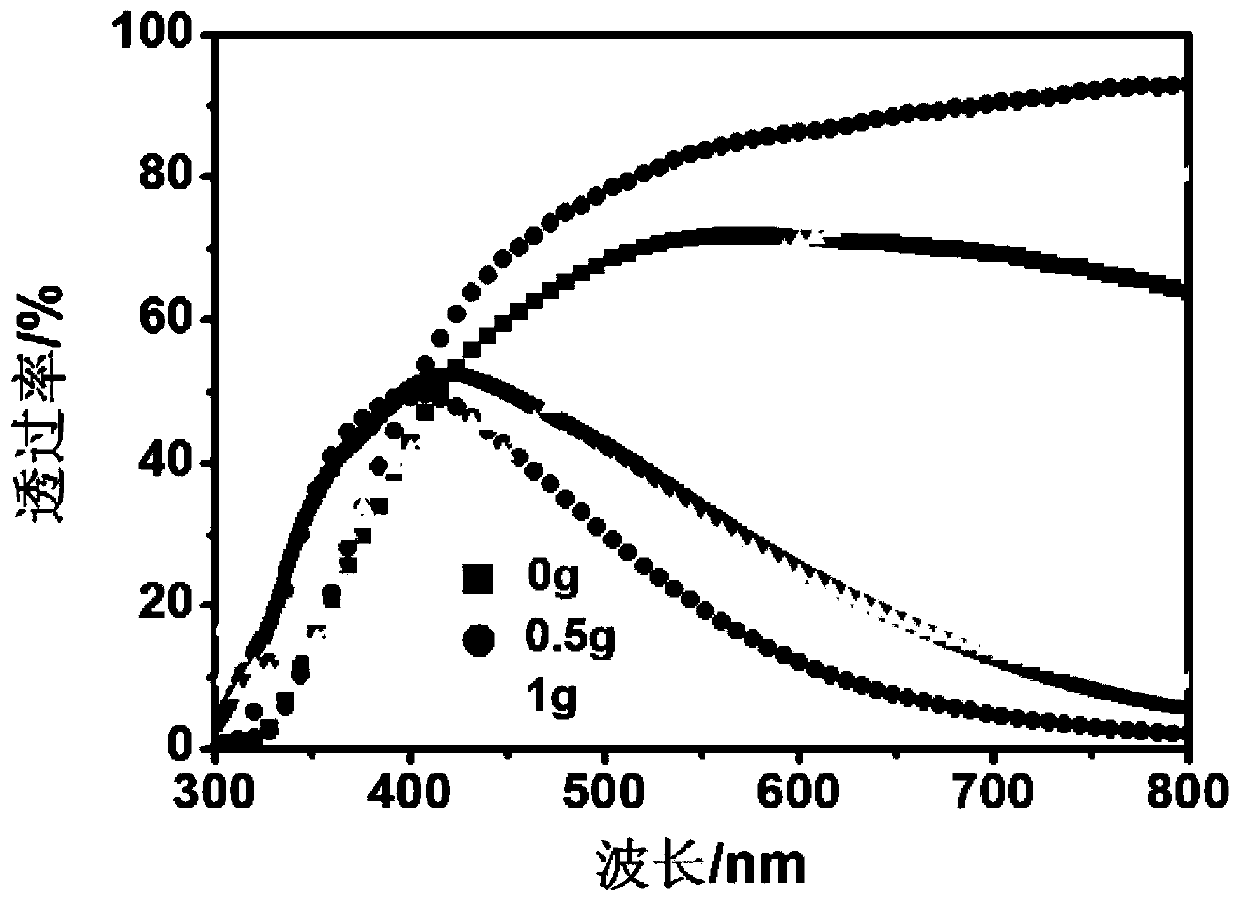

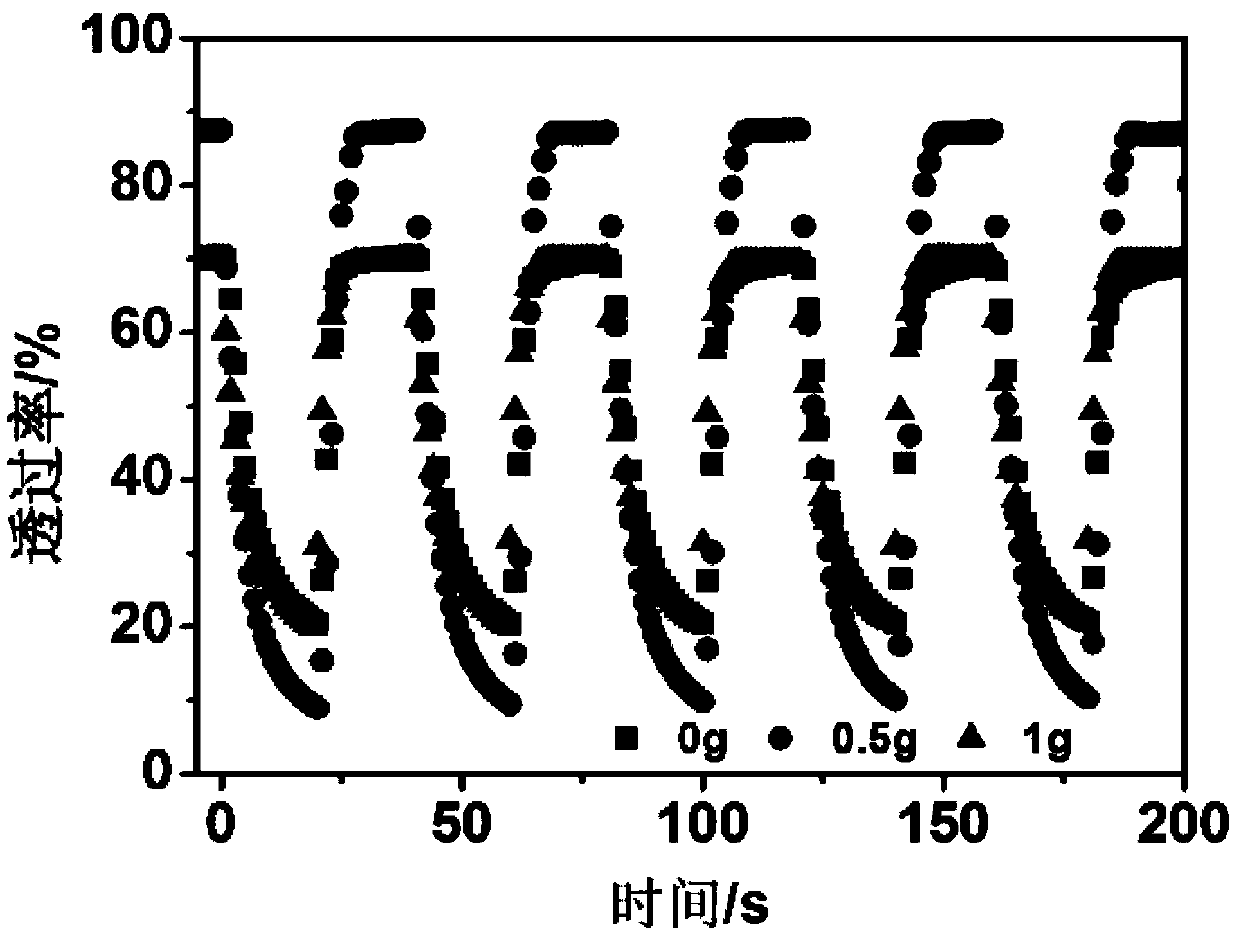

Method for synthesizing tungsten trioxide electrochromic material by one step with assistance of citric acid

InactiveCN107827159AEase of mass productionUniform sizeTungsten oxides/hydroxidesNanotechnologyTungsten trioxideCitric acid

The invention relates to a method for synthesizing a tungsten trioxide electrochromic material by one step with assistance of citric acid. The method comprises the following steps: dissolving a tungsten source and a chelating agent in a molar ratio of (0.4-1.2):1 in water, stirring the mixture uniformly, and adding a morphology control agent to obtain a mixed solution, wherein the molar ratio of the morphology control agent to the tungsten source is (0-0.1):1; adjusting the pH value of the mixed solution to be 0.5-2 by acid to obtain a tungsten trioxide precursor solution; placing a conductiveglass substrate in the tungsten trioxide precursor solution, and growing a tungsten trioxide electrochromic nano-material on the surface of the conductive glass substrate at 85-95 DEG C. The method is easy to operate, and has the characteristics of low cost, low temperature requirement and the like.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

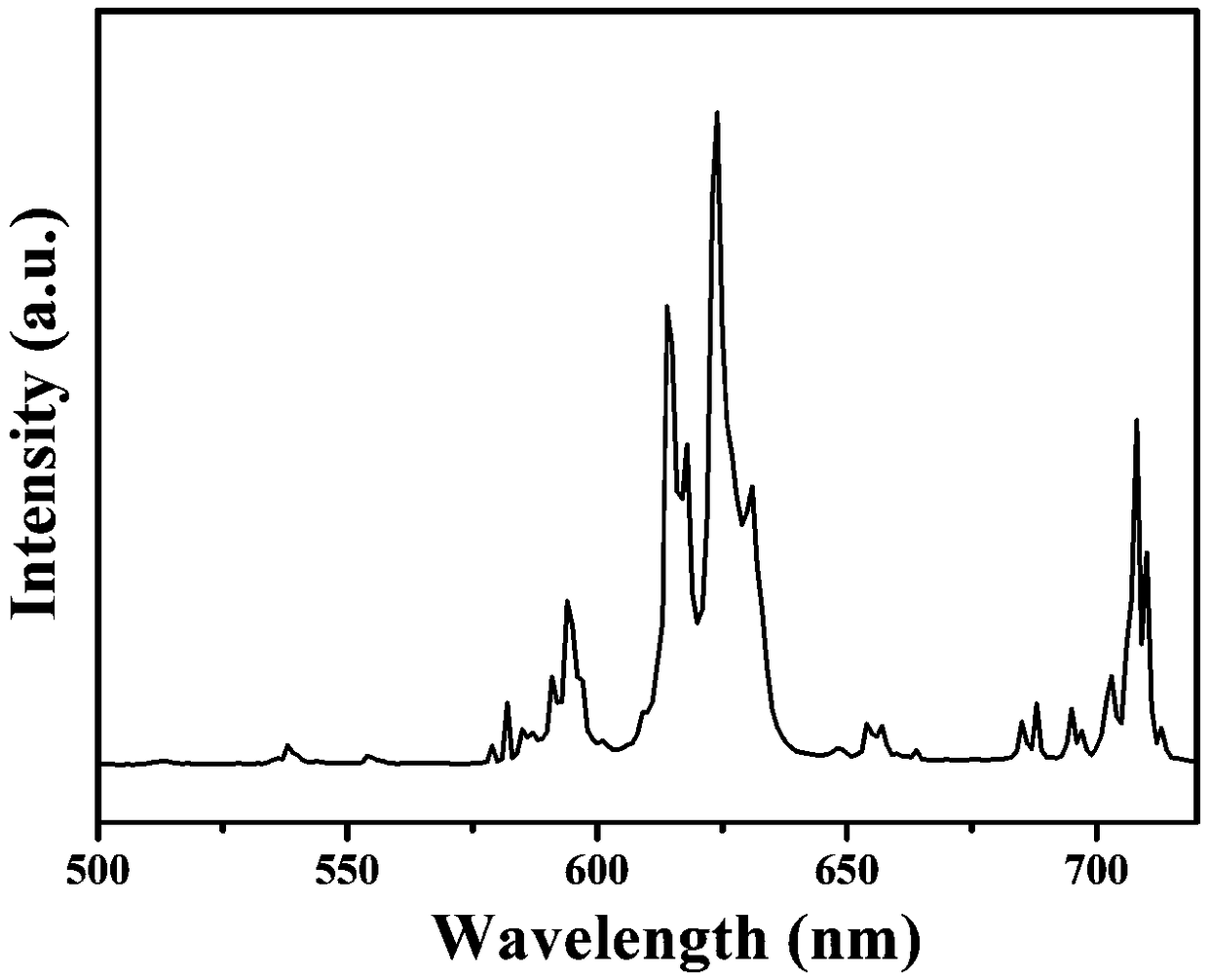

Preparation method of monoclinic phase yttrium oxide

The invention provides a preparation method of monoclinic phase yttrium oxide. The preparation method comprises the following steps: (1) preparing a yttrium-base coordination polymer; (2) calcining the yttrium-base coordination polymer, so as to obtain cubic phase yttrium oxide; (3) pre-pressing cubic phase yttrium oxide at 2MPa-20MPa; and (4) carrying out high-temperature and high-pressure reaction on pre-pressed cubic phase yttrium oxide at 500-1500 DEGC and 1GPa-5GPa, so as to obtain monoclinic phase yttrium oxide. The preparation method has a series of advantages of simple process, relatively low reaction condition, high product purity and yield and the like. According to the preparation method, a rapid and efficient novel method is provided for the synthesis of monoclinic phase yttrium oxide.

Owner:JIANGXI NORMAL UNIV

Method for forming punctate pattern on surface of metal

ActiveCN106011977ASimple processPlay a retro decorative effectNon-macromolecular adhesive additivesMacromolecular adhesive additivesOrganic solventElectrophoresis

The invention discloses a method for forming a punctate decorative pattern on the surface of metal. The method includes the steps that shielding powder is prepared through hot melt adhesive, the shielding powder adheres to the surface of a metal product, a first paint layer is formed in a region unshielded by the shielding powder in a one-time electrophoresis manner, and after the shielding powder is removed, a second paint layer of which the color is different from that of the first paint layer is deposited in the region covered with the shielding powder in a secondary electrophoresis manner, so that the punctate structure of the shielding powder is transferred to the surface of the metal. The hot melt adhesive shielding powder can be dissolved with an organic solvent in a swelling manner to be cleaned and removed or dissolved with hot water to be cleaned and removed or removed through other simple methods without using a strong base or other corrosive substances, and the influence on the paint film structure is avoided; and meanwhile, various punctate patterns can be formed according to the requirements, the manufacturing process is simple, and the application range is broadened.

Owner:长泰科美厨卫科技有限公司

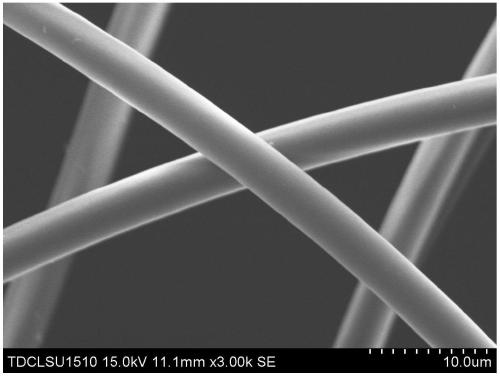

One-dimensional porous carbon nanometer fiber material and preparation method and application thereof

InactiveCN109868528AImprove cycle stabilityHigh reversible capacityElectroconductive/antistatic filament manufactureCell electrodesFiberPorous carbon

The invention relates to a one-dimensional porous carbon nanometer fiber material and a preparation method and application thereof, and belongs to the technical field of lithium-sulfur battery materials. The method comprises the steps that firstly, a carbon source, a template agent and a conductive agent are added into a solvent and mixed to be uniform to obtain a spinning solution ultrasonically,then, a fiber precursor is obtained through electrostatic spinning, and finally, the fiber precursor is dried, pre-oxidized and calcinated to obtain the presser foot spanner cam component. Accordingto the method, by adjusting parameters of electrostatic spinning, the diameter of the finally-prepared carbon nanometer fiber is controlled, and in the later period, the specific area, the hole size and the aperture range of the finally-prepared one-dimensional porous carbon nanometer fiber material are controlled by controlling the pre-oxidization and calcination technological conditions. The one-dimensional porous carbon nanometer fiber material has the long coruscation stability, excellent rate capability and large reversible volume, and the one-dimensional porous carbon nanometer fiber material can be adopted as an anode material of a lithium-sulfur battery. The material preparation technology is simple, operation is easy, the raw materials are low in cost, the needed preparation conditions are low, and commercial application is facilitated.

Owner:QINGDAO NINEX NEW ENERGY TECH CO LTD

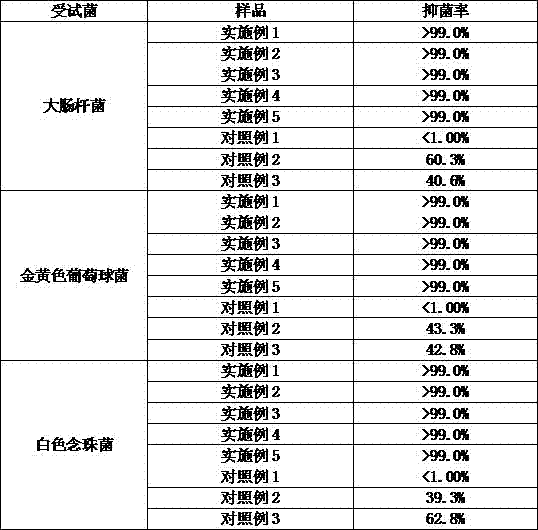

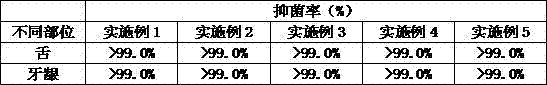

Compound lysozyme sterilizing oral disinfectant and preparation method thereof

PendingCN107280997AAct as a growth inhibitorBroad-spectrum antibacterialAntibacterial agentsCosmetic preparationsDisinfectantGlycerol

The invention discloses a compound lysozyme oral care agent which comprises lysozyme, amidase, sodium dihydrogen phosphate, sodium chloride, citric acid, sodium citrate, glycerol, an organic silicon defoamer, a condiment and water. The invention also discloses a preparation method of the compound lysozyme oral care agent.

Owner:江苏开源康达医疗器械有限公司

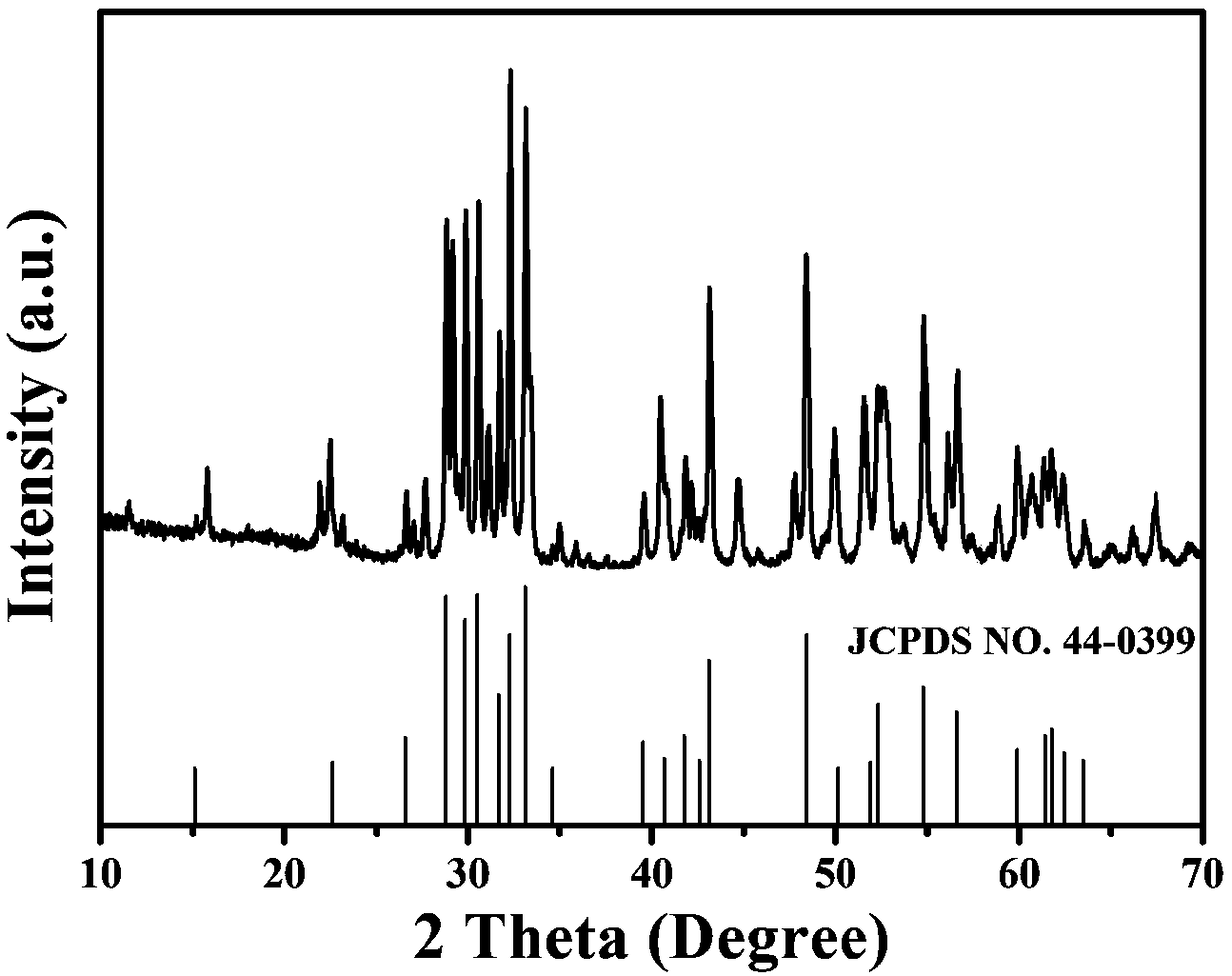

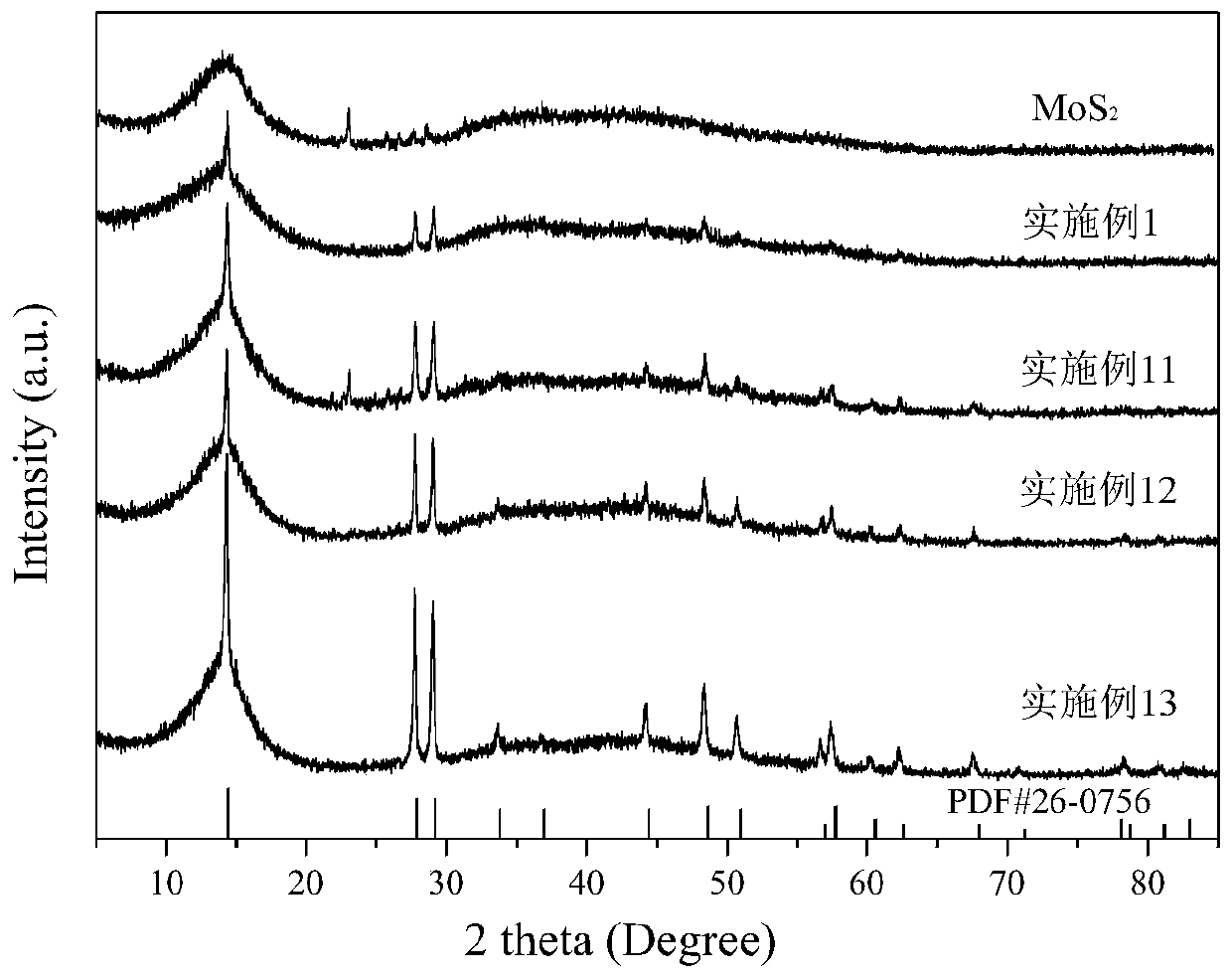

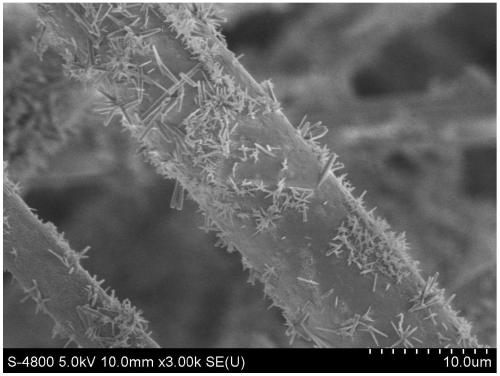

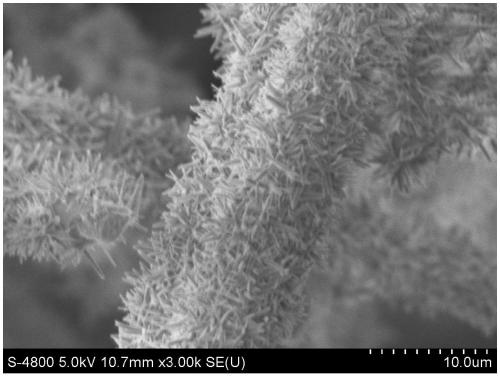

Niobic acid-based sulfide composite material and preparation method thereof

InactiveCN110586133AHigh reactivityReduce the preparation conditionsPhysical/chemical process catalystsWater/sewage treatment by irradiationFiltrationThiourea

The invention relates to a niobic acid-based sulfide composite material and a preparation method thereof. The structural formula of the niobic acid-based sulfide composite material is AxBySz-H4Nb2O7,in the formula, A and B are one or two of different metal elements of Co, Mo, Ni, Cu, Zn and Fe; x is greater than 0 and smaller than 10; y is greater than or equal to 0 and less than 10; z is greaterthan 0 and smaller than 10; and specific values are determined according to specific valence states of compounds. The preparation method comprises the following steps: weighing tin niobate, adding the tin niobate into a polytetrafluoroethylene lining, adding one or two of soluble metal salts and thiourea, dissolving the components with water, and performing a hydrothermal reaction so as to obtainblack precipitate; performing suction filtration washing on the black precipitate, putting the black precipitate into a vacuum drying tank, and performing drying, so as to obtain an AxBySz-H4Nb2O7 composite material. The composite material is low in preparation condition and simple in operation, sulfides are uniformly grown on the surface of niobic acid, rich reaction activity sites can be provided for reactions, and the reaction activity of metal sulfides in catalysis reactions can be sufficiently improved.

Owner:TIANJIN UNIV

Mullite whisker/fiber synergistically reinforced silicon dioxide aerogel multi-scale composite structure, preparation method and application thereof

The invention discloses a mullite whisker / fiber synergistically reinforced SiO2 aerogel multi-scale composite structure, a preparation method and application thereof. According to the method, a mullite whisker / fiber reinforcement and a SiO2 aerogel are combined through physical and chemical methods, and a multi-scale composite structure with certain resilience, mechanical strength and low heat conductivity coefficient can be prepared through micron and submicron scale synergistic reinforcement. According to the invention, the conditions that single-scale fiber reinforcement has defects and theactual application requirements cannot be met due to poor mechanical properties of pure SiO2 aerogel are avoided, and the preparation conditions of the SiO2 aerogel composite material are reduced.

Owner:TIANJIN UNIV

CO2 emulsion and preparation method thereof

ActiveCN103143278AReduce manufacturing costReduce the preparation conditionsMixing methodsWater basedEmulsion

The invention provides CO2 emulsion and a preparation method thereof. The emulsion comprises the following components: CO2, lauryl sodium sulfate, other surfactants and water, wherein based on 100 percent of water quality, the lauryl sodium sulfate has the mass percent concentration of 0.001-1 percent; the other surfactants have the mass percent concentration of 0-10.0 percent, preferably 3.0-7.0 percent; and the volume ratio of CO2 to water based on liquid CO2 is (1-5):1. According to the emulsion, the preparation cost and preparation conditions of the CO2 emulsion can be greatly reduced; and meanwhile, the research proves that the CO2 emulsion can be stabilized for more than several hours.

Owner:PETROCHINA CO LTD

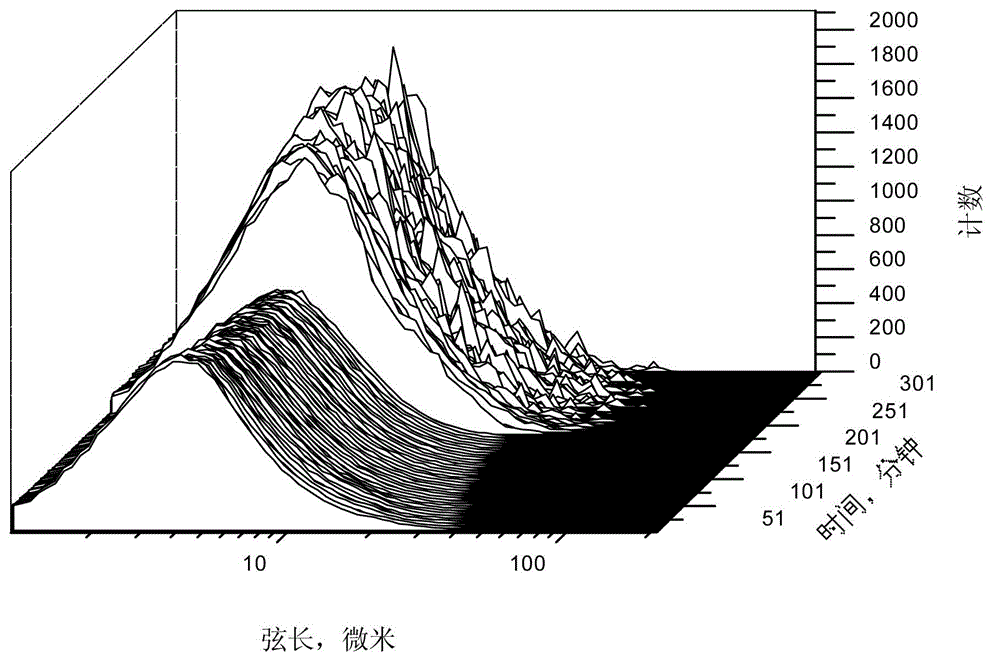

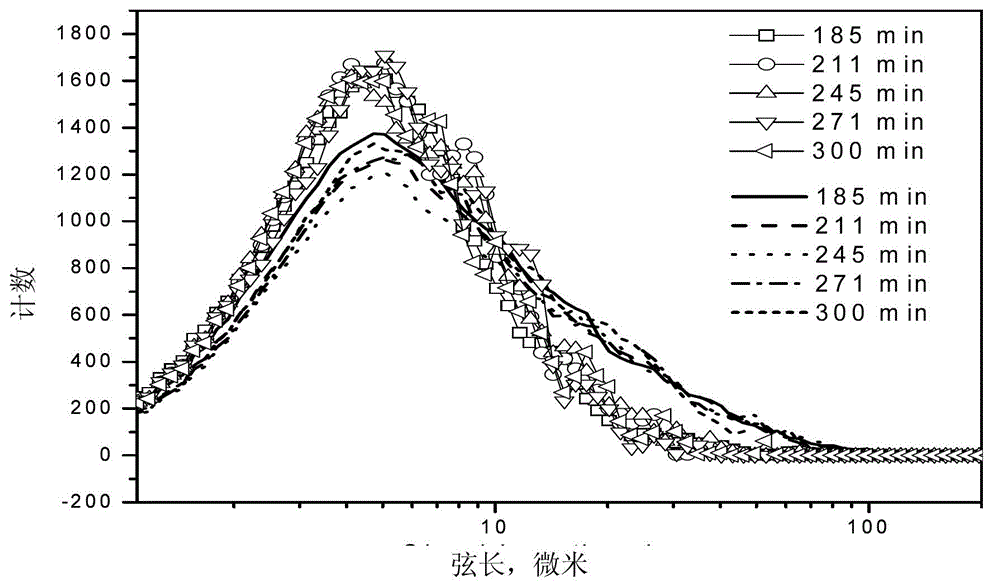

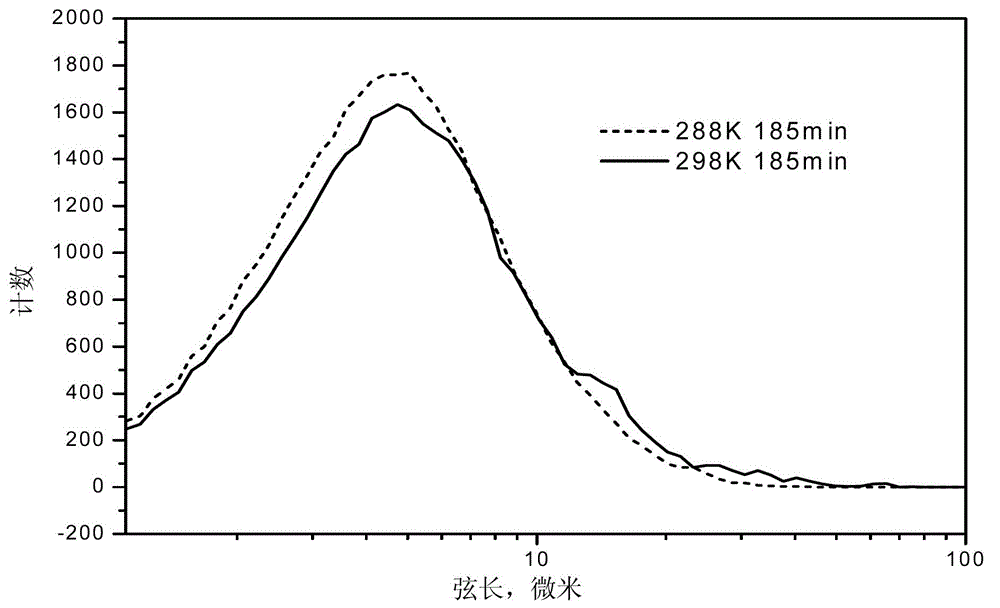

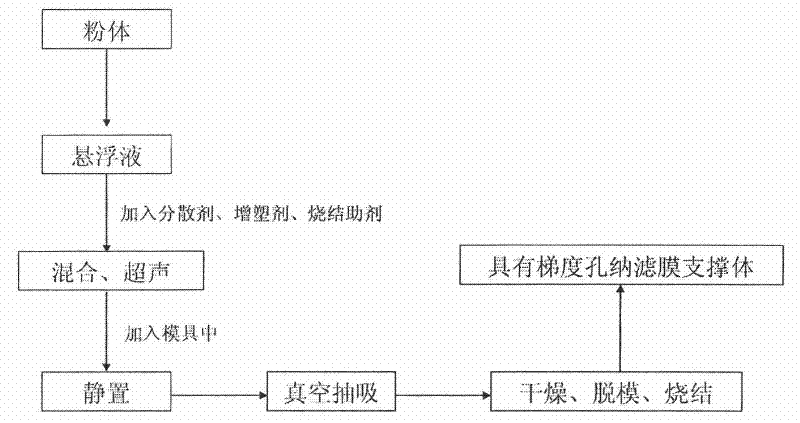

Method for preparing ceramic nanofiltration membrane support body with gradient pores

ActiveCN101670244BImprove surface propertiesImprove permeabilitySemi-permeable membranesHigh surfacePore diameter

Owner:NANJING TECH UNIV

Water-borne epoxy resin, preparation process thereof and epoxy zinc-rich primer

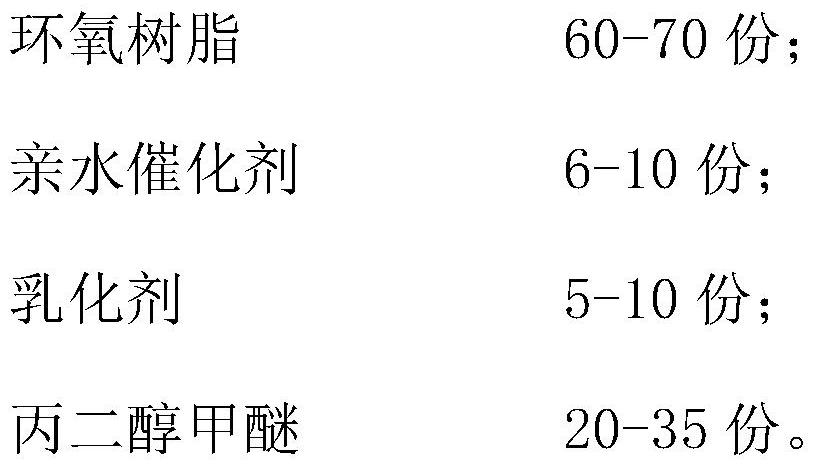

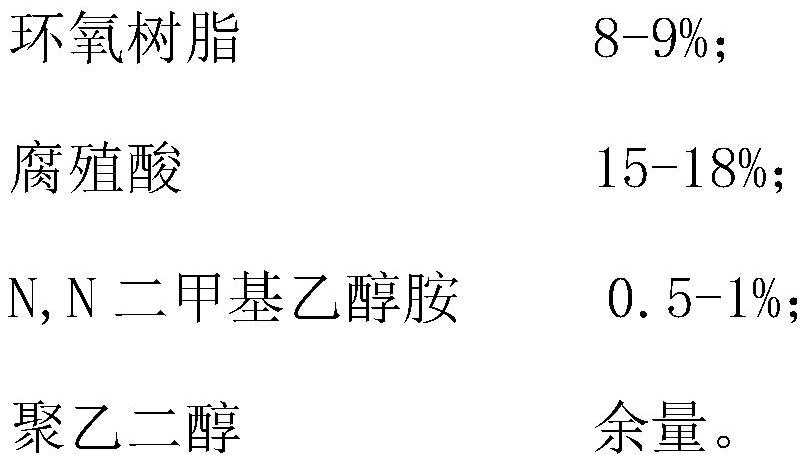

PendingCN113683751AHigh solid contentGood storage stabilityAnti-corrosive paintsEpoxy resin coatingsEpoxyPolymer science

The invention relates to water-borne epoxy resin, a preparation process thereof and an epoxy zinc-rich primer. The water-borne epoxy resin at least comprises the following raw materials in parts by mass: 60-70 parts of epoxy resin; 6-10 parts of a hydrophilic catalyst; 5-10 parts of an emulsifier; and 20-35 parts of propylene glycol methyl ether. The preparation process of the water-borne epoxy resin comprises the step of mixing all the materials and carrying out heat preservation reaction. The waterborne epoxy resin can be used for preparing an epoxy zinc-rich primer. The waterborne epoxy resin has the effects of being high in solid content and wide in application range, and the epoxy zinc-rich primer prepared from the waterborne epoxy resin has the effects of being good in anti-corrosion effect and suitable for being used for rusty bottom plates.

Owner:浙江弘利新材料有限公司

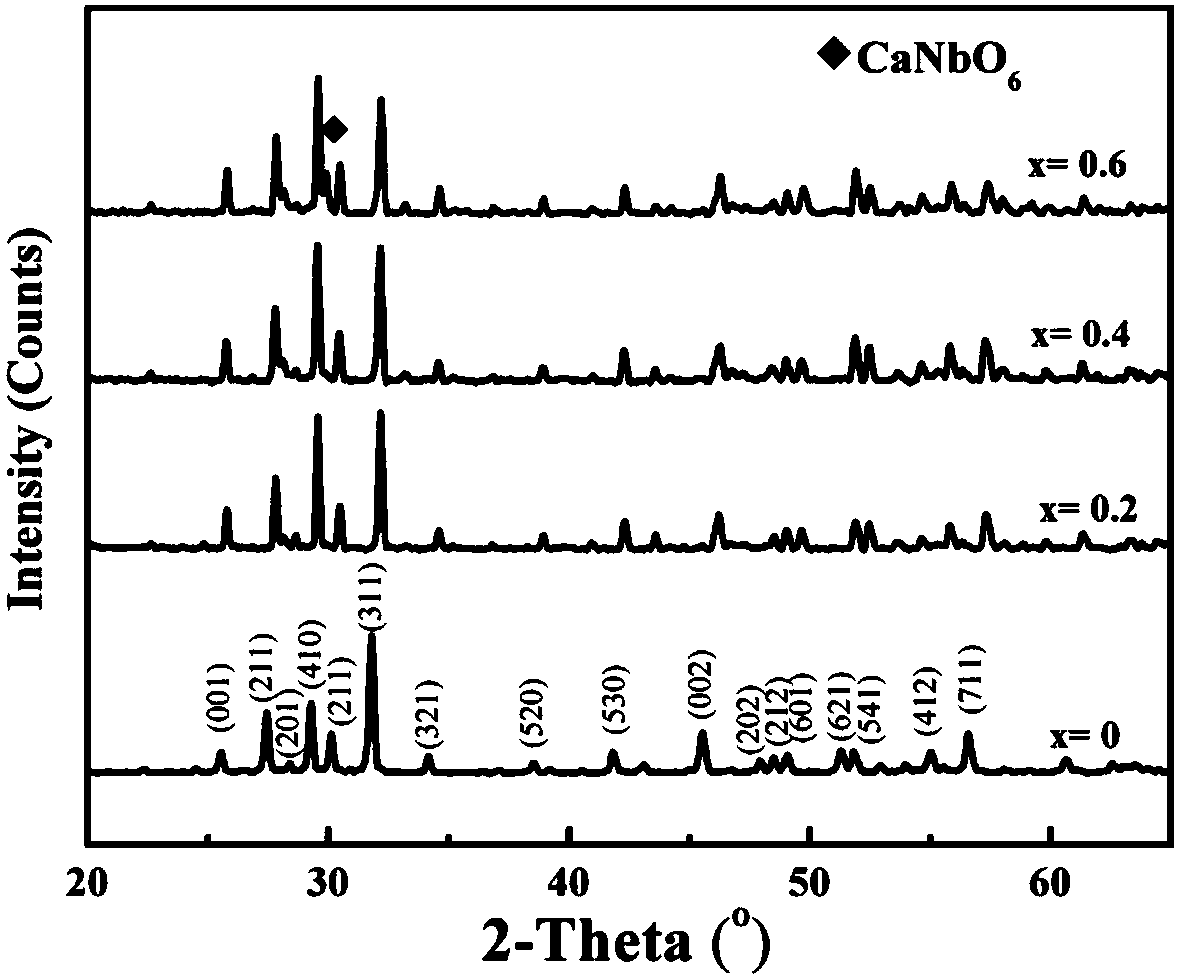

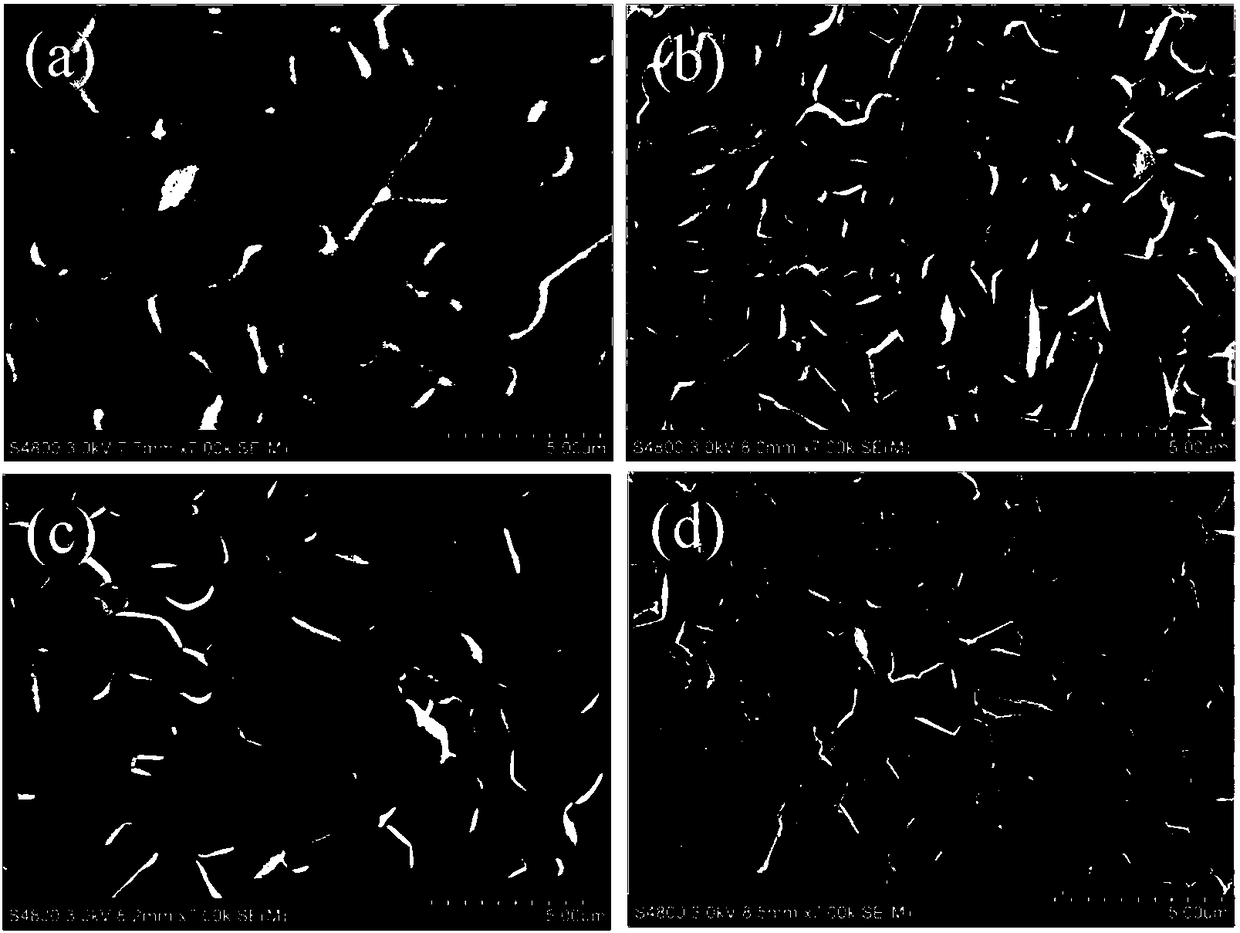

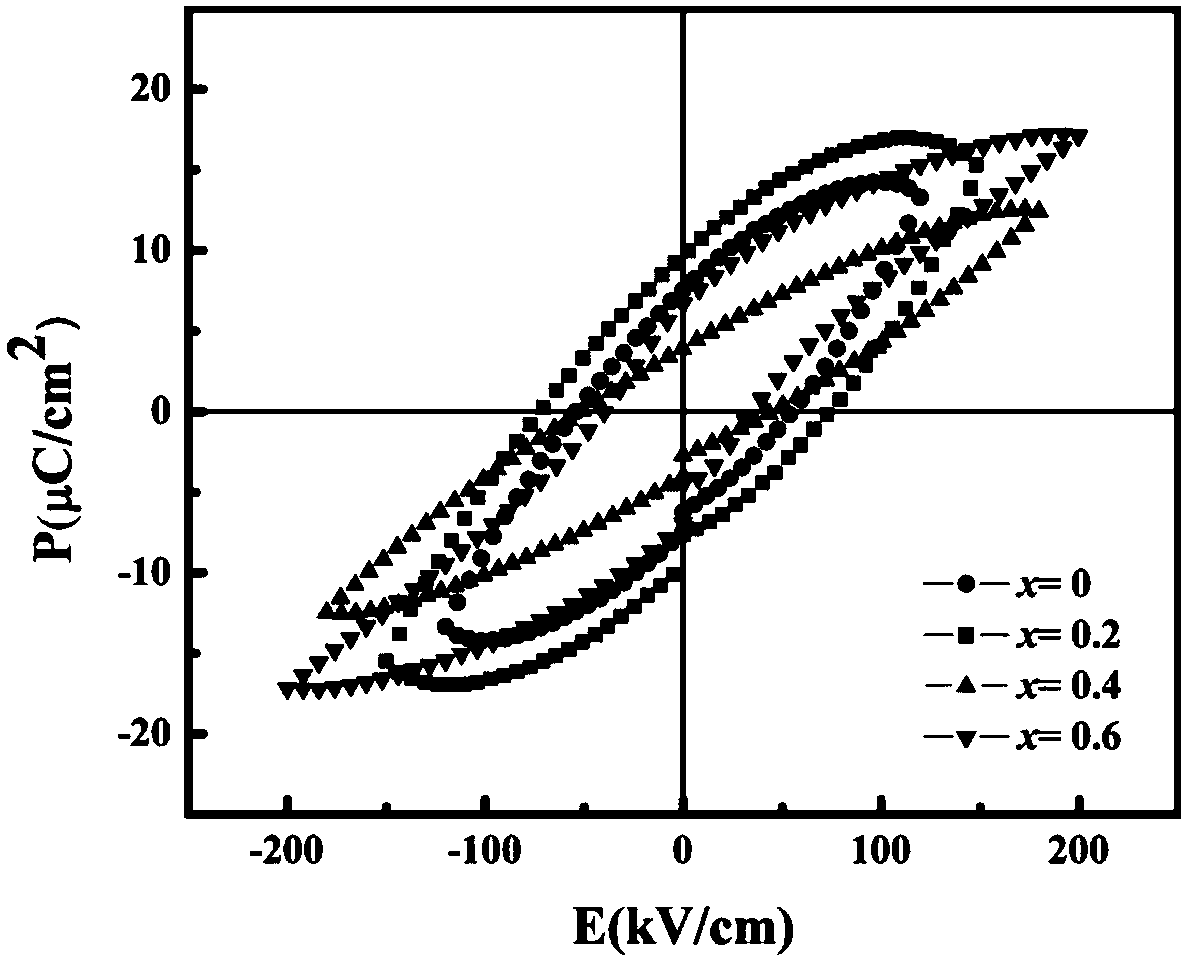

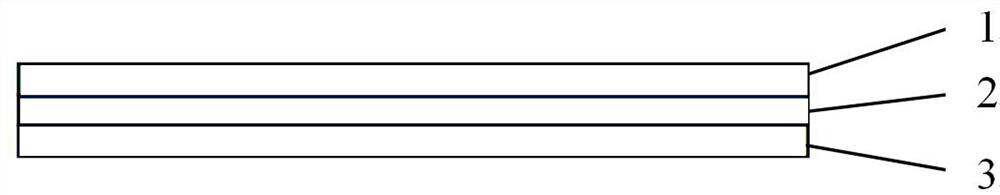

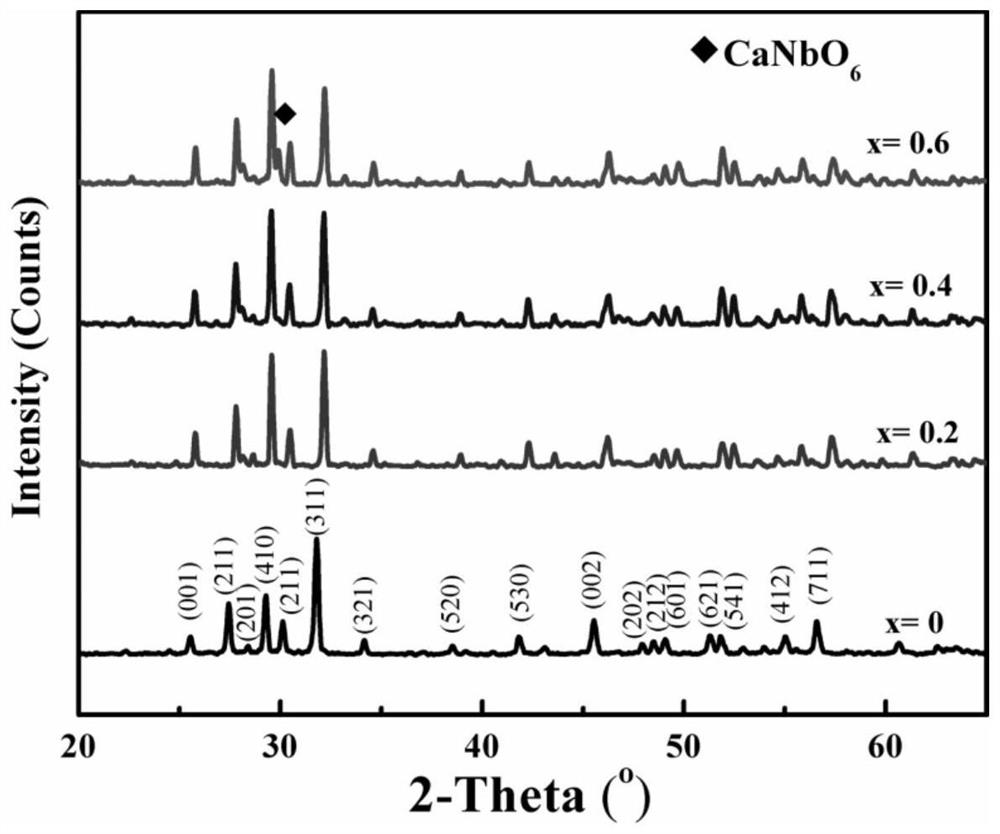

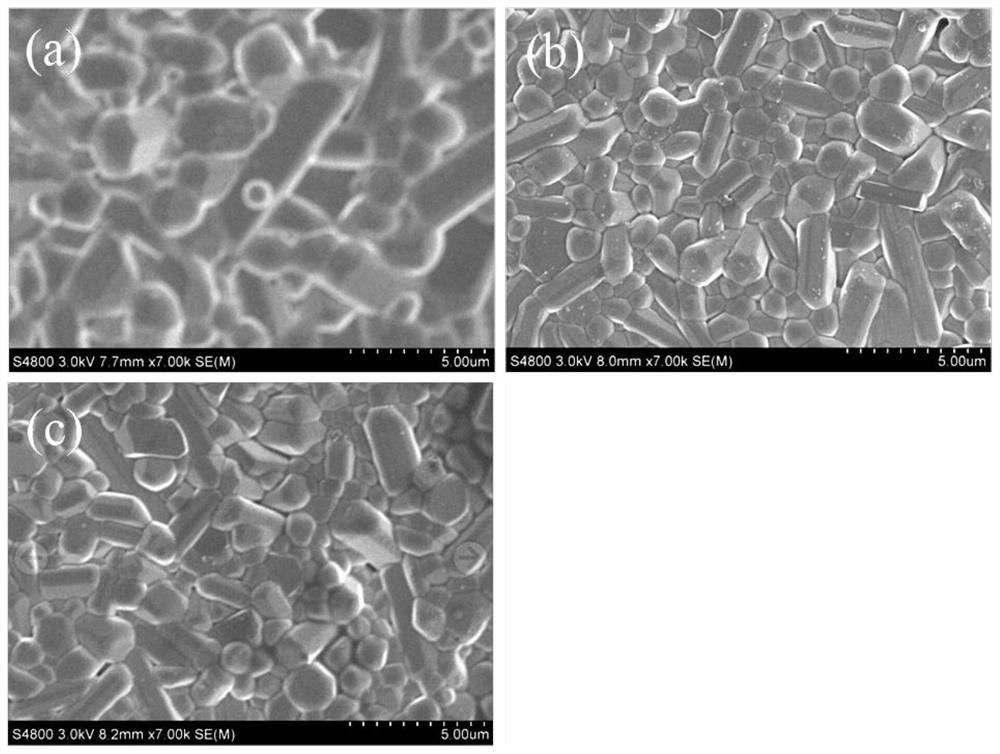

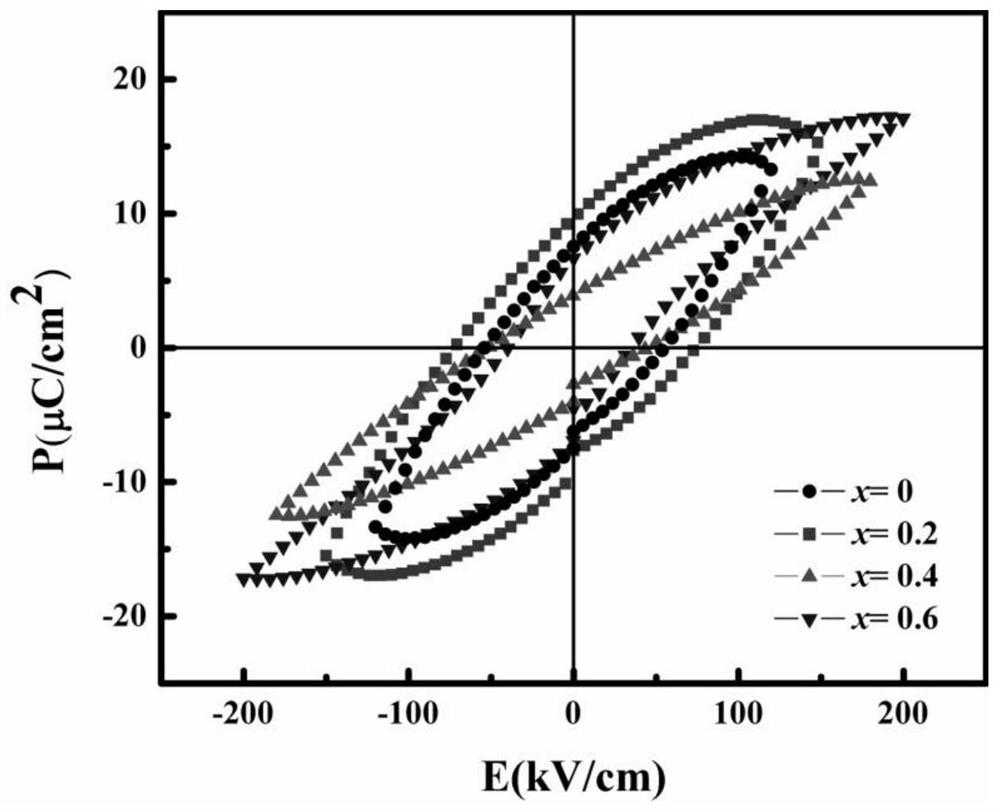

Tungsten bronze monophase multiferroic ceramic material and preparation method thereof

The invention provides a tungsten bronze monophase multiferroic ceramic material and a preparation method thereof. The preparation method includes following steps: 1, preparing pure-phase ceramic powder: well mixing all weighed powder to form ingredients, subjecting the ingredients to ball milling, drying and sieving sequentially to obtain a discharged material which is the pure-phase ceramic powder; 2, subjecting the pure-phase ceramic powder to isostatic cool pressing to obtain a sample, and sintering the sample to obtain a sintered sample; 3, sequentially polishing and cleaning the sinteredsample, uniformly coating the front and the back of the sintered sample with electrode slurry, and sintering the sample coated with the electrode slurry to obtain the tungsten bronze monophase multiferroic ceramic material corresponding to the pure-phase ceramic powder. Ferroelectricity and ferromagnetism of tungsten bronze monophase ceramic can be enhanced. The tungsten bronze ceramic material prepared by the method can improve purity and grain morphology of ceramic, and multiferroic performance of the ceramic is improved greatly.

Owner:SHAANXI UNIV OF SCI & TECH

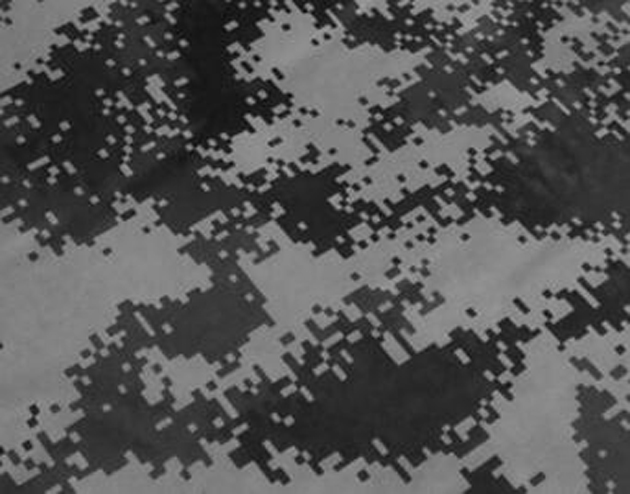

Digital camouflage rubberized fabric and preparation method thereof

PendingCN113524824AImproved camouflageMeet the requirements of protective performanceLamination ancillary operationsProtective equipmentRubber materialVulcanization

The invention relates to the technical field of protective materials, and especially relates to a digital camouflagerubberized fabric and a preparation method thereof, and solves the technical problems in the background art. The digital camouflage rubberized fabric comprises a base cloth, a protective rubber layer and a digital camouflage adhesive film which are sequentially overlapped and fixedly connected. The preparation method of the digital camouflage rubberized fabric sequentially comprises the following steps: performing rubber material mixing; placing a hot-smelted protective rubber layer raw material on a calender, and preparing a protectiverubberized fabric by taking base cloth as a framework material; placing the digital camouflage adhesive film on the other surface, and rolling the prepared protective rubberized fabric for later use; and winding the obtained protective rubberized fabric on a rubber roller of a vulcanizing tank, tearing off the PET protective film on the surface of the digital camouflage rubberized fabric in the winding process, isolating by using talcum powder in the middle, and adopting the vulcanizing tank for electric heating indirect vulcanization to obtain the digital camouflage rubberized fabric. The digital camouflage rubberized fabric not only can meet the requirement of protection performance, but also can meet the requirement of camouflage performance, and the preparation method is simple and easy to operate and can be used for batch production.

Owner:SHANXI XINHUA CHEM

A method for forming a textured pattern on a metal surface

ActiveCN106119931BSimple processImprove controllabilityPolyureas/polyurethane adhesivesElectrophoretic coatingsOrganic solventMetallurgy

The invention discloses a method for forming mesh lines on the metal surface. Hot melt glue silk is adopted for manufacturing a mesh film of a mesh line structure, the mesh film is used as a shielding layer, a first paint layer is formed in the zone not shielded by the mesh film through primary electrophoresis, a second paint layer with the color being different from that of the first paint layer is deposited on the zone covered with the mesh film through secondary electrophoresis after the mesh film is removed, and thus the mesh line structure of the mesh film is transferred to the metal surface. The hot melt glue mesh film can be removed through simple methods such as hot water dissolution and organic solvent swelling dissolution and cleaning instead of strong base or other corrosive substances, and influences on a paint film structure are avoided; and meanwhile, various mesh line patterns can be formed as required, the processing procedure is simple, and the application range is enlarged.

Owner:JOMOO KITCHEN & BATHROOM

Short-process preparation method of high-strength and high-elasticity cu-ni-mn alloy

Owner:UNIV OF SCI & TECH BEIJING

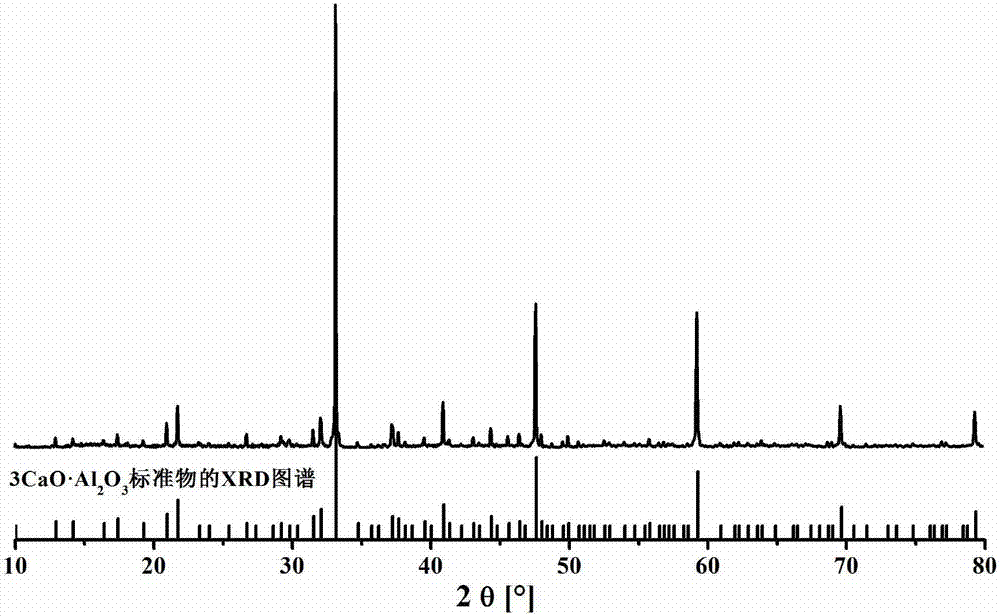

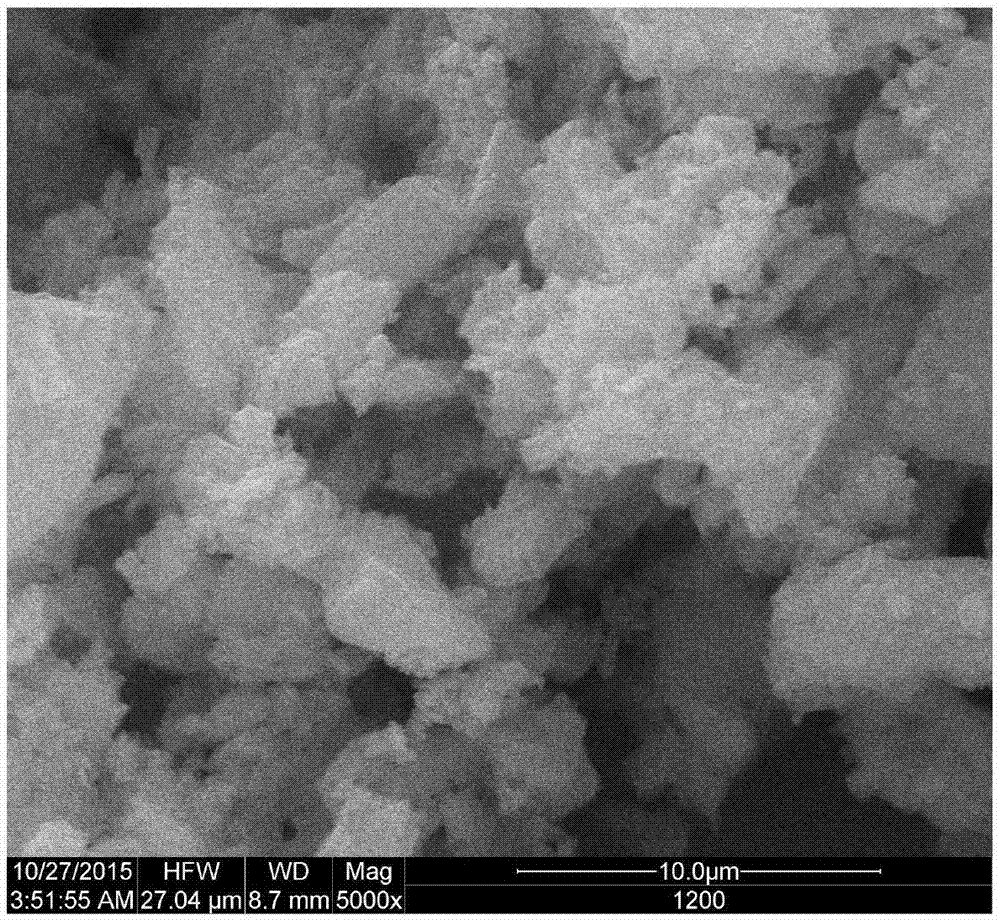

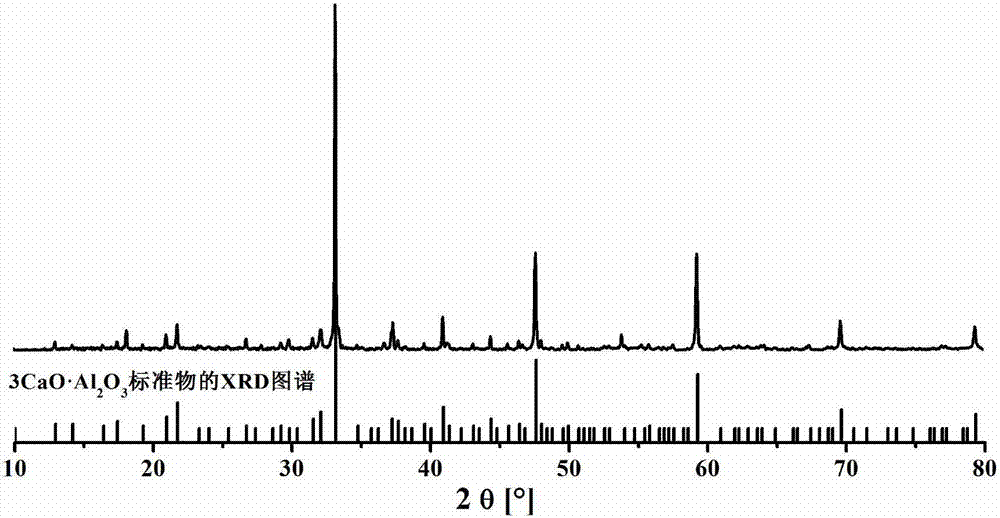

A method for preparing tricalcium aluminate rapidly and with low energy consumption

ActiveCN105836774BLow preparation temperatureLess energy consumptionCalcium aluminatesCalcium nitrate tetrahydrateOxygen

Owner:WUHAN UNIV

A kind of tungsten bronze type single-phase multiferroic ceramic material and preparation method thereof

Owner:SHAANXI UNIV OF SCI & TECH

Catalyst for preparing C5 and C6 alkanes from sugar alcohol raw materials by aqueous phase catalysis and its application

ActiveCN106268888BReduce the preparation conditionsLow preparation temperaturePhysical/chemical process catalystsCatalystsAlkaneCarbon nanotube

The invention discloses a catalyst for preparing C5 and C6 alkane through catalyzing a sugar alcohol raw material in a water phase. The structural formula of the catalyst is a Ru-P / carrier, wherein Ru is a metal component and P is an auxiliary agent; the carrier is one of active carbon, a carbon nanotube, silicon oxide and zirconium oxide; the mol ratio of Ru to P is 0.5 to 5; the loading amount of the metal Ru is 1 weight percent to 5 weight percent; the catalyst has very good catalytic activity and hydrothermal stability; the C5 and C6 alkane is prepared in a continuous reaction kettle at low pressure and low temperature through catalyzing the sugar alcohol raw material in the water phase; the sugar alcohol raw material can be completely converted, and the selectivity of the C5 and C6 alkane is up to 90 percent; the energy consumption is low and a technological process is simple and easy to control; the catalyst has a good industrial application prospect and the problem that an existing biomass-based sugar alcohol water-phase catalysis catalyst is not stable is solved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

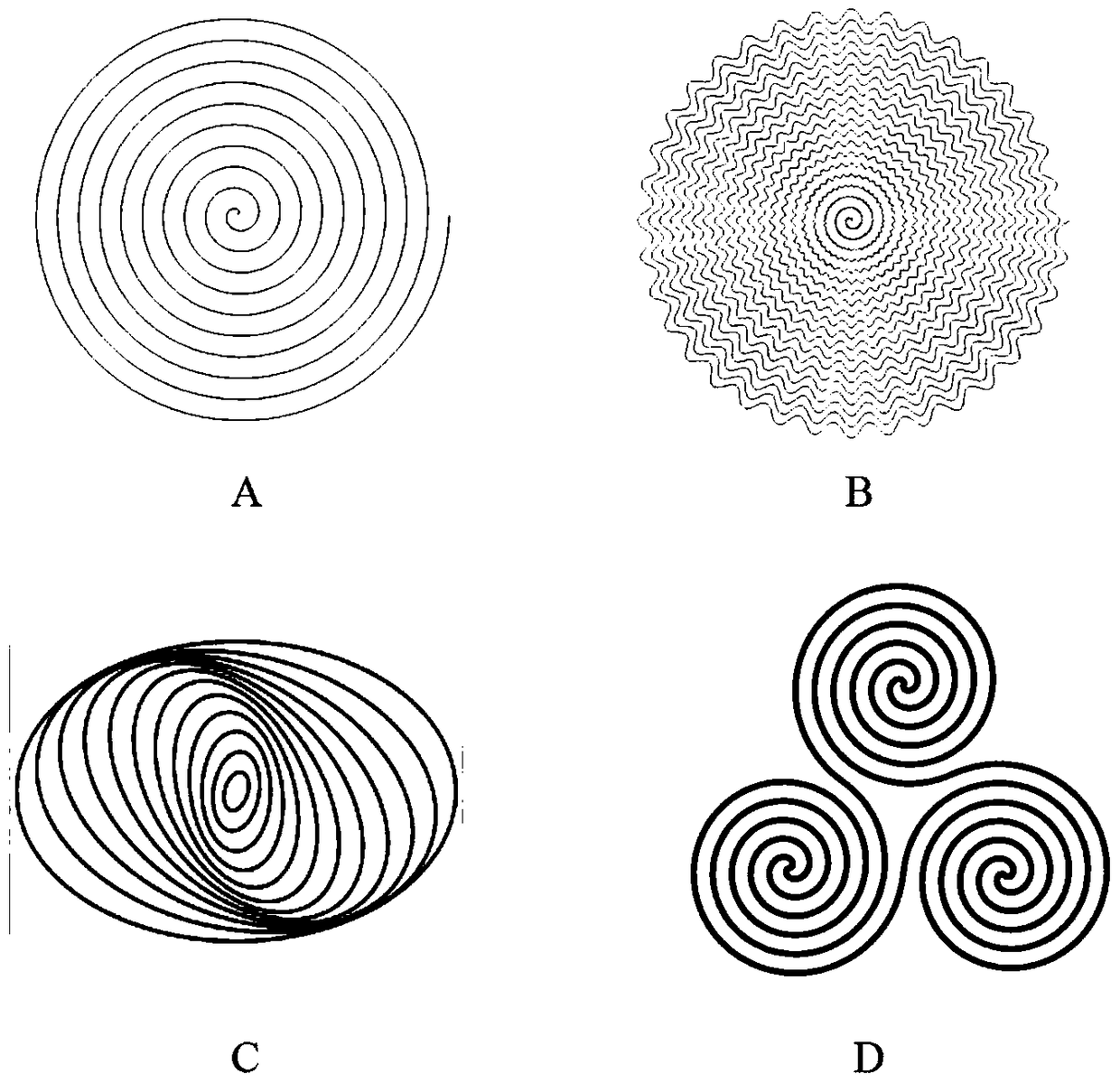

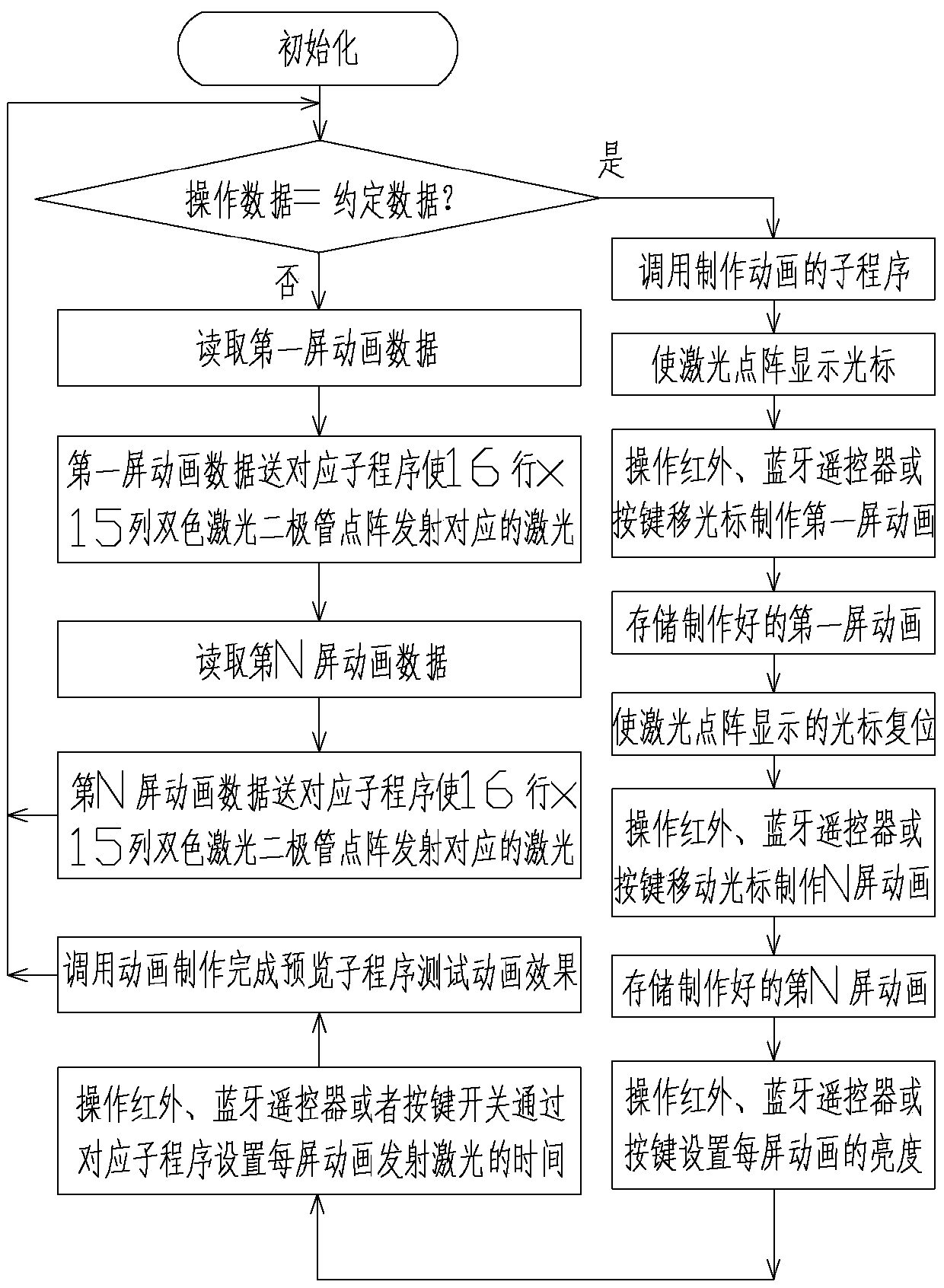

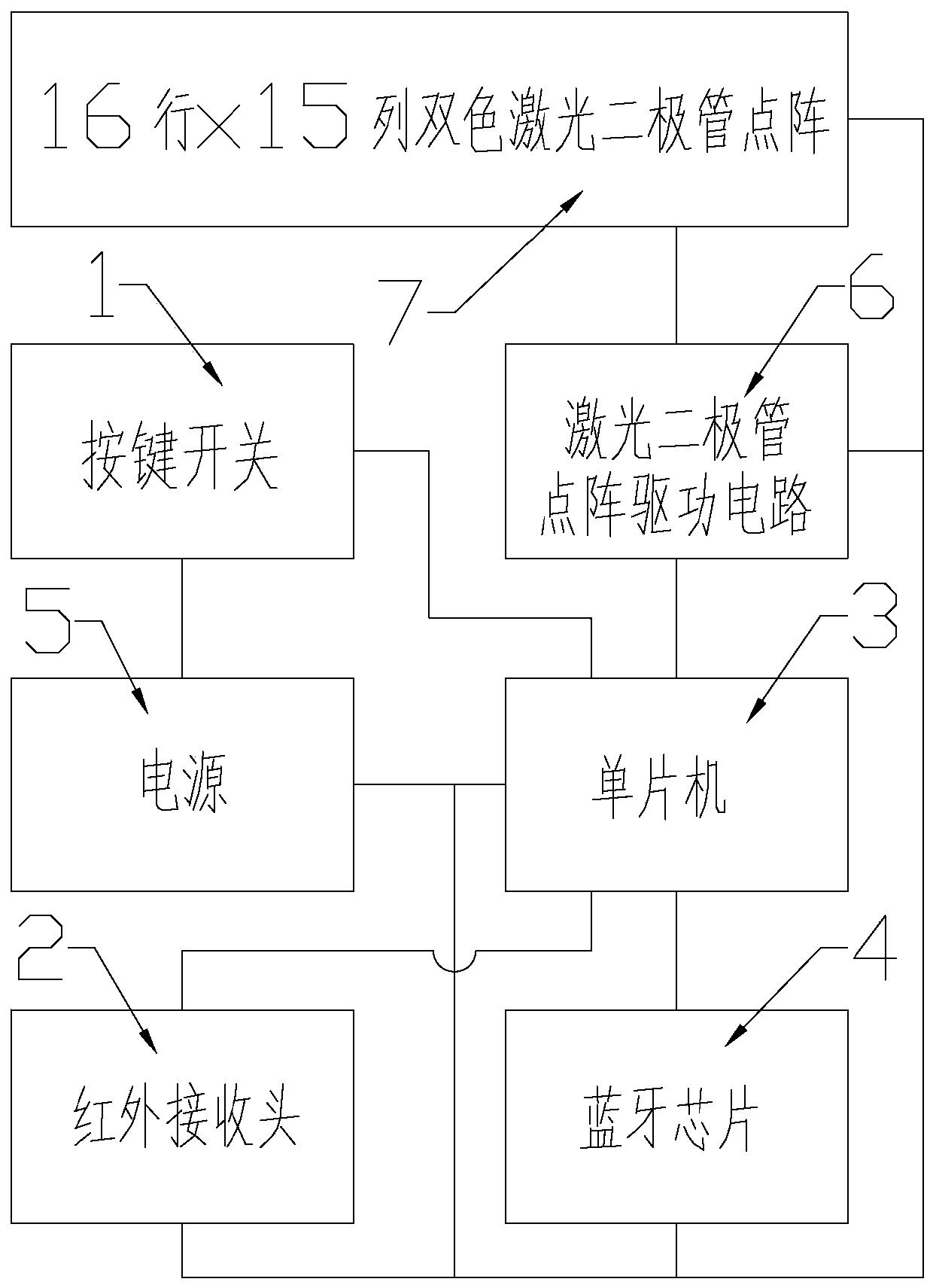

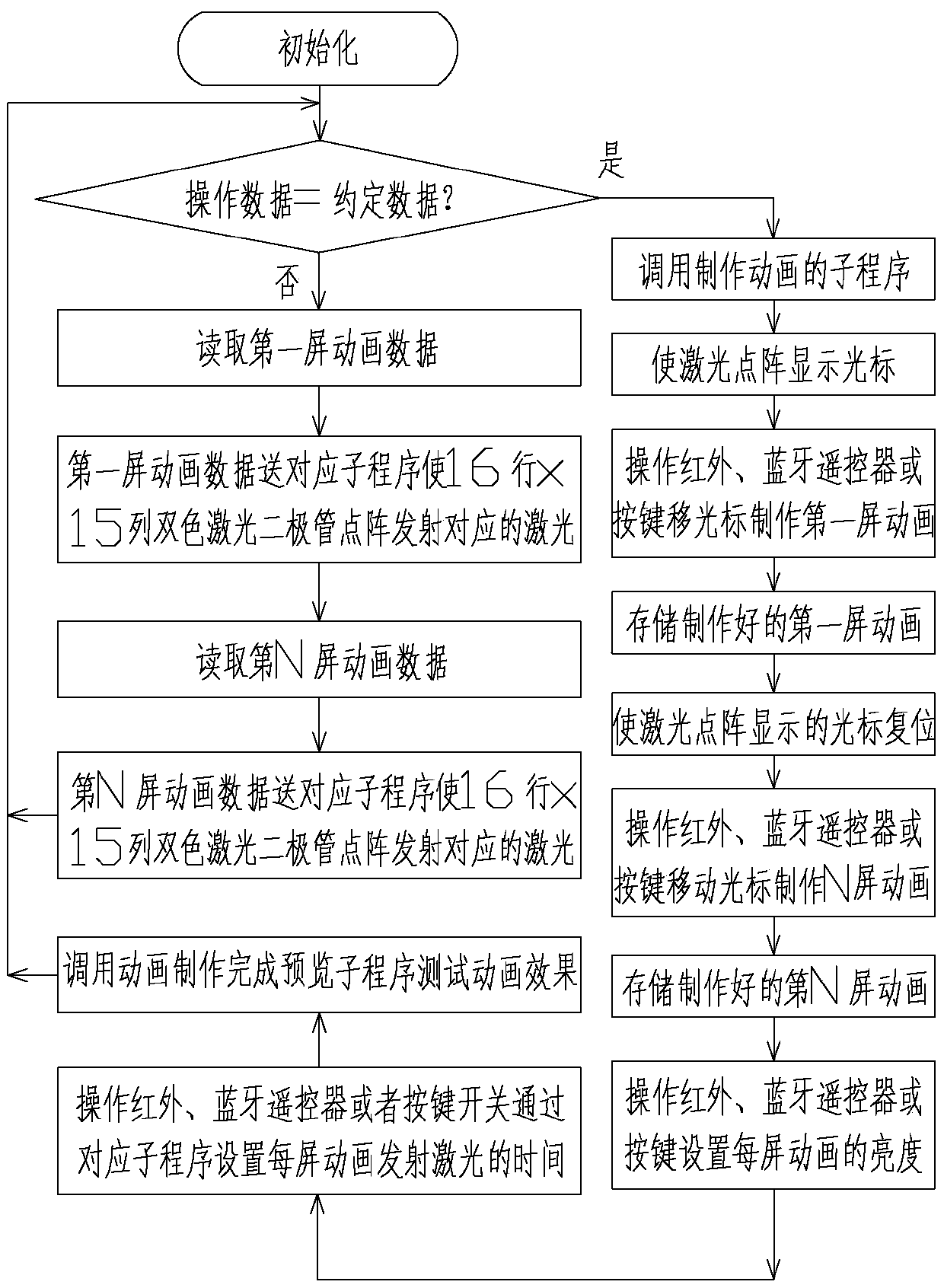

A laser show method

The invention relates to laser animations, in particular to a laser show method using a laser diode lattice. According to the method, a bicolor laser diode lattice arranged on one side of a circuit board, a power source arranged on the other side of the circuit board, a single-chip microcomputer, an infrared receiver, a Bluetooth chip, key switches and a bicolor laser diode lattice drive circuit are utilized, the circuit board is connected with the other components, and the prior laser show method is simplified under software support; in other words, an infrared or Bluetooth remote control can be operated to remotely compose and control a laser show, through the integrated laser diode lattice integrated to the circuit board, also the key switches can be manually controlled to compose and control the laser show, a fantastic, magical and wonderful laser show can be performed in space or on a screen efficiently and simply through coded laser beams transmitted by the bicolor laser diode lattice, and the laser show is interesting.

Owner:管存忠

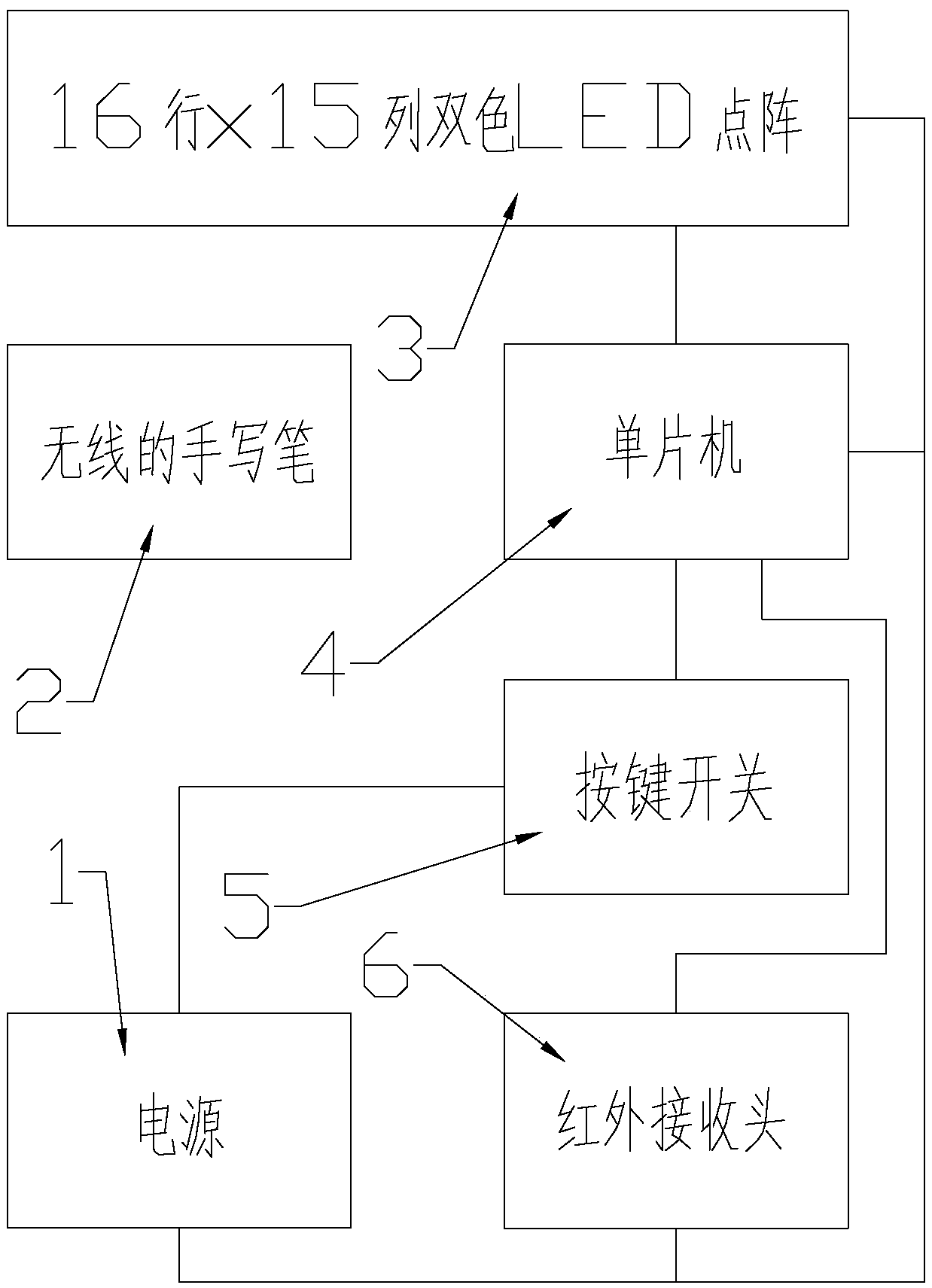

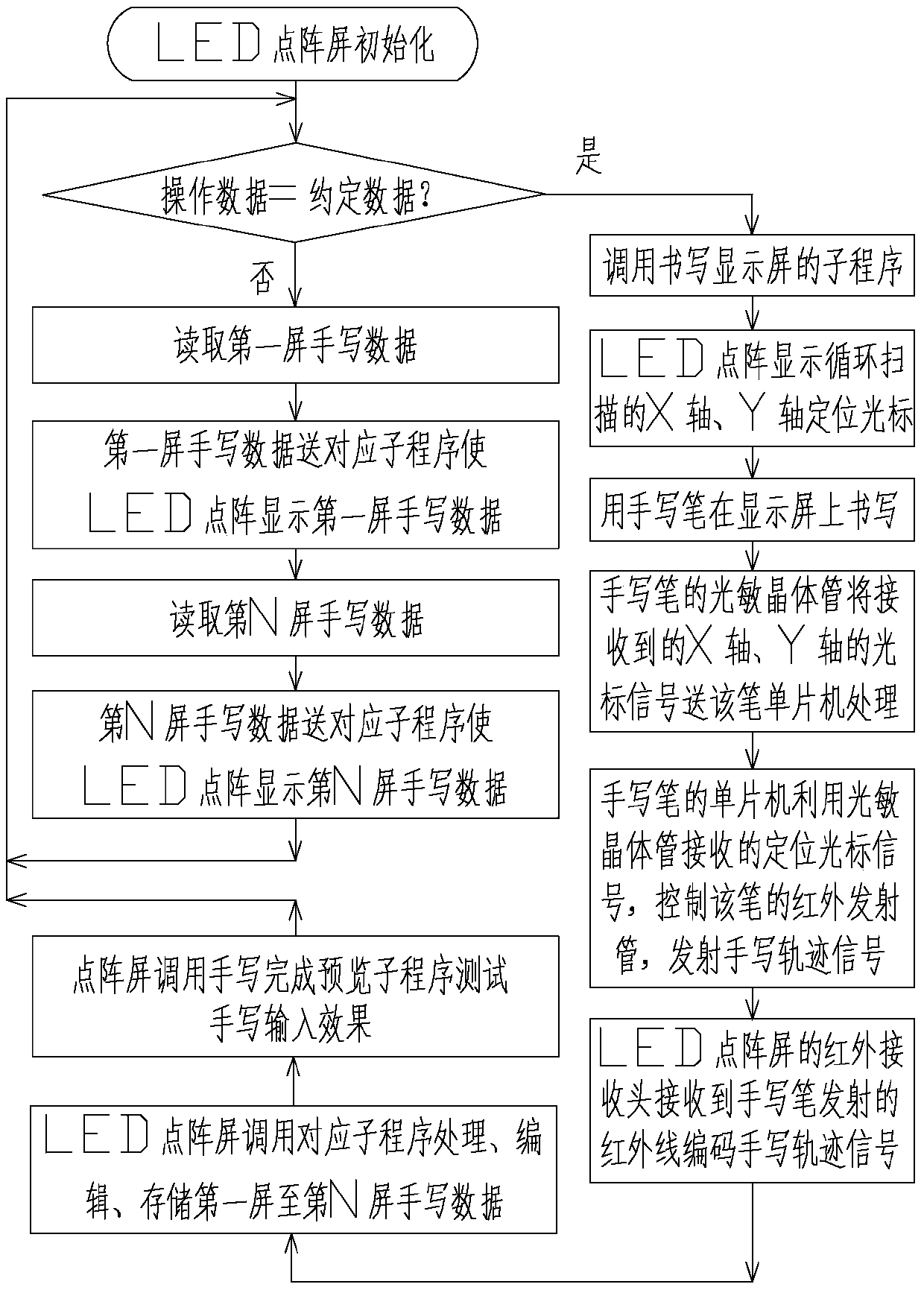

A wireless handwriting input method for led dot matrix display

ActiveCN104156122BSimple designLow costInput/output processes for data processingHandwritingDot-matrix display

The invention relates to an LED dot-matrix display screen, in particular to a wireless handwriting input method for the LED dot-matrix display screen. According to the method, a wireless handwriting pen, a power supply of the LED dot-matrix display screen, a bicolor patch LED dot matrix with the row-column specification of 16*15, a single-chip microcomputer, a key switch and an infrared receiving head are structurally adopted; the single-chip microcomputer is respectively connected with the bicolor patch LED dot matrix with the row-column specification of 16*15, the key switch, the infrared receiving head and the power supply; the power supply is further respectively connected with the bicolor patch LED dot matrix with the row-column specification of 16*15, the key switch and the infrared receiving head; the handwriting pen is in wireless connection with the LED dot-matrix display screen. Wireless handwriting input of the LED dot-matrix display screen can be achieved, the wireless handwriting input for the LED dot-matrix display screen is convenient and flexible, and the application range can be expanded.

Owner:管存忠

Method of preparing high-purity tricalcium aluminate quickly

InactiveCN110171838AImprove the shortcoming of long cycleHigh purityCalcium aluminatesChemical industryCalcium nitrate tetrahydrateAluminium hydroxide

The invention relates to a method of preparing high-purity tricalcium aluminate quickly and is mainly applied to the field of building materials. The method comprises the following steps: by taking analytically pure calcium nitrate tetrahydrate and aluminum hydroxide as raw materials, adding a proper amount of deionized water to prepare a homogeneous solution; then fixing the homogeneous solutionto a magnetic stirrer to be stirred for 10-20 min under the conditions that the temperature is 60-80 DEG C and the rotating speed is 170-200 r / min, adjusting the PH value with ammonia water in the process, wherein the PH value is in a range of 10.5-11.5; placing a sol which is formed in a blowing drying box to be dried for 6-8 h at 60-80 DEG C, ageing and drying the mixture and grinding the mixture till the grain size is 0.075 mm, and pressing the mixture to 4 mm sheets under the pressure of 20 MPa; putting the sheets in a crucible, heating the crucible by an electric furnace, carrying out programmed temperature heating, insulating the mixture for 4 h at 1100 DEG C, and taking out a sample and quenching the sample to prepare high-purity C3A. The method is easily available in use material,simple to operate, few in synthetic process, short in preparation period, low in calcining temperature and low in energy consumption, and has the advantages of being energy-saving and efficient and the like.

Owner:UNIV OF JINAN

A kind of method for rapidly preparing polycrystalline tetracalcium ferric aluminate

ActiveCN105271427BLow preparation temperatureLess power consumptionChemical industryIron compoundsAir atmosphereAluminate

The invention discloses a method for fast preparing polycrystalline tetra calcium aluminoferrite. The method includes the steps that firstly, raw materials including calcium nitrate terahydrate, aluminum nitrate nonahydrate, iron nitrate nonahydrate and urea are weighed according to the mass ratio of 1:0.7942:0.8554:2.0413-2.1923; secondly, a proper amount of deionized water is added, and dispersion liquid with the concentration ranging from 0.5 mol / L to 0.8 mol / L is prepared and continuously stirred for 1.5 hours to 2 hours till the raw materials are completely dissolved; thirdly, the dispersion liquid is moved into a high temperature stove and heated to 500 DEG C to 510 DEG C in air atmosphere, after the constant temperature is kept for two hours, the dispersion liquid is taken out and grinded into particles with the particle size smaller than or equal to 0.15 mm, and the particles serve as a precursor ready for use; fourthly, the precursor is pressed into a thin piece with the diameter of 35 mm and the thickness smaller than or equal to 5 mm under the pressure of 25 MPa to 30 MPa; finally, the pressed precursor thin piece is heated to 650 DEG C to 950 DEG C at the heating rate of 10 DEG C / min, after the constant temperature is kept for 7 hours, the pressed precursor thin piece is taken out, fast cooled in the air and grinded, and the polycrystalline tetra calcium aluminoferrite with the hydration activity is obtained. The method is small in working procedure number, short in period and high in efficiency, the sintering temperature is 300 DEG C to 600 DEG C lower than the sintering temperature of a traditional method, and the method has the advantages of being fast, efficient and capable of saving energy, and is suitable for industrial large-scale application.

Owner:WUHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com