CO2 emulsion and preparation method thereof

A technology of CO2 and emulsion, applied in mixing methods, chemical instruments and methods, dissolution, etc., can solve problems such as expensive surfactants, poor emulsion stability, and harsh emulsion preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] SDS and Tween 80, whose mass fractions are 0.5wt% and 5wt% respectively, are the compounded surfactants described in the present invention. Liquid CO 2 The volume ratio with water is 2:1; CO 2 The preparation temperature of the emulsion is 288.2K; the preparation pressure is 12MPa, filled with CO 2 , the stirring speed is 1300r / min. CO 2 The emulsion can exist stably for 180min, which shows that the emulsification effect of the compound surfactant of the present invention is very good.

Embodiment 2

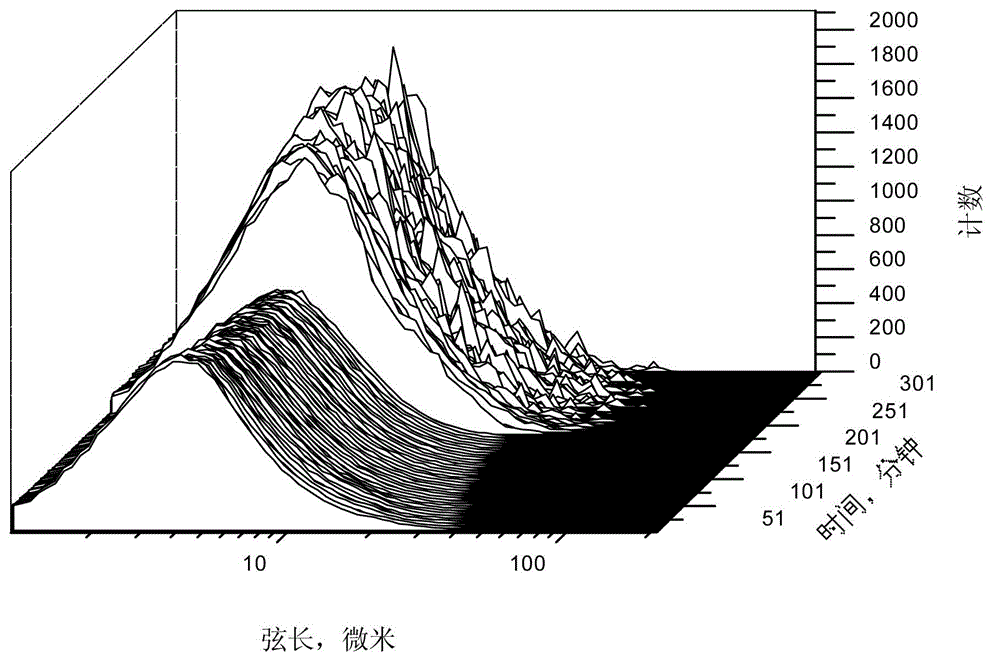

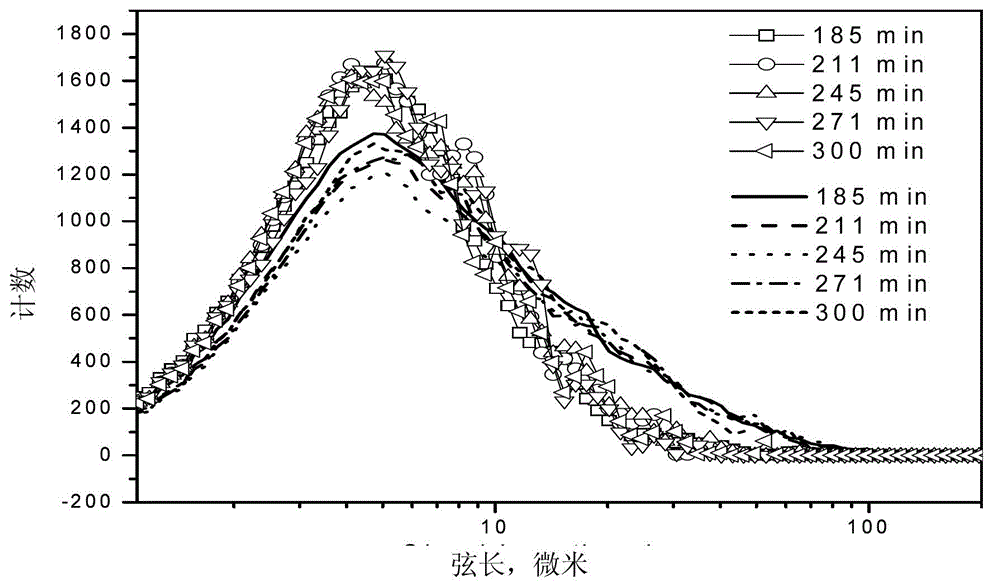

[0077] The mass fractions of SDS and Tween 80 are respectively 0.5wt% and 5wt%, which are the compounded surfactants described in the present invention. Liquid CO 2 The volume ratio with water is 1.5:1, CO 2 The preparation temperature of the emulsion is 288.2K, the preparation pressure is 12MPa, and the stirring speed is 1200r / min. CO 2 The emulsion can exist stably for 300 minutes, and the relationship between the droplet size distribution of the emulsion and time during the process of stopping stirring is as follows: figure 1 shown. It can be seen that the distribution curve of the emulsion droplets does not change much with time, which shows that the emulsion formed by the present invention has better stability.

Embodiment 3

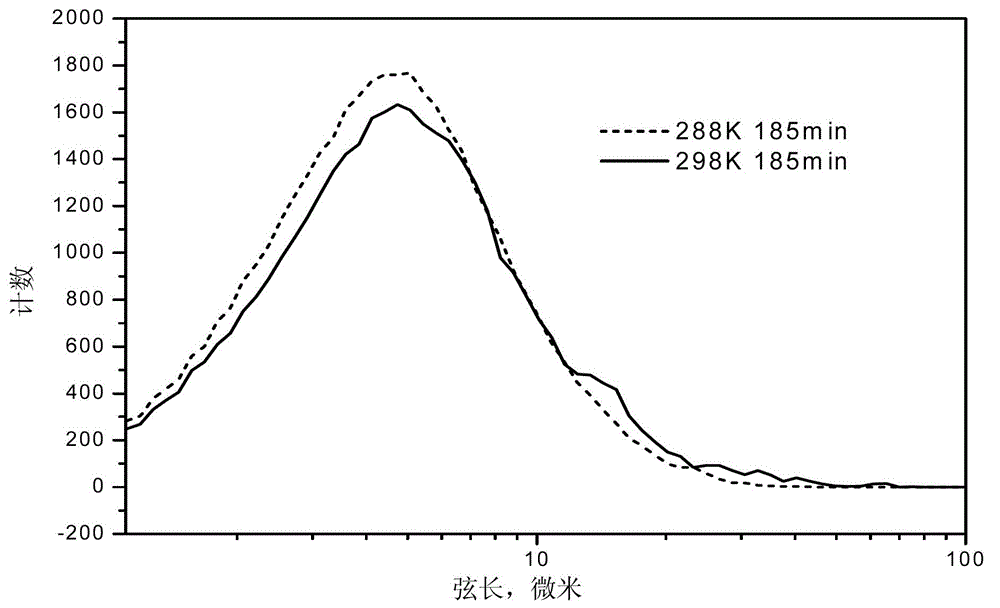

[0079] The mass fractions of SDS and Tween 80 are respectively 0.5wt% and 5wt%, which is the compounded surfactant of the present invention. Liquid CO 2 The volume ratio with water is 3.5:1, CO 2 The preparation temperature of the emulsion is 288.2K, and the preparation pressure is 12MPa. The emulsion droplet size distribution is as figure 2 As shown, wherein, the straight line indicates that the stirring speed is 800r / min, and the dotted line indicates that the stirring speed is 1200r / min. CO 2 The emulsion can exist stably for 210 minutes. It can be seen from the figure that the distribution of the emulsion at high stirring speed is more uniform and stable, and the droplet radius is smaller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com