Method for synthesizing tungsten trioxide electrochromic material by one step with assistance of citric acid

A technology of tungsten trioxide and electrochromism, which is applied in the direction of color-changing fluorescent materials, chemical instruments and methods, tungsten oxide/tungsten hydroxide, etc., can solve the problems of reducing electrochromic performance, increasing preparation cost and complexity, and achieving Excellent electrochromic performance, low cost, and controllable preparation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

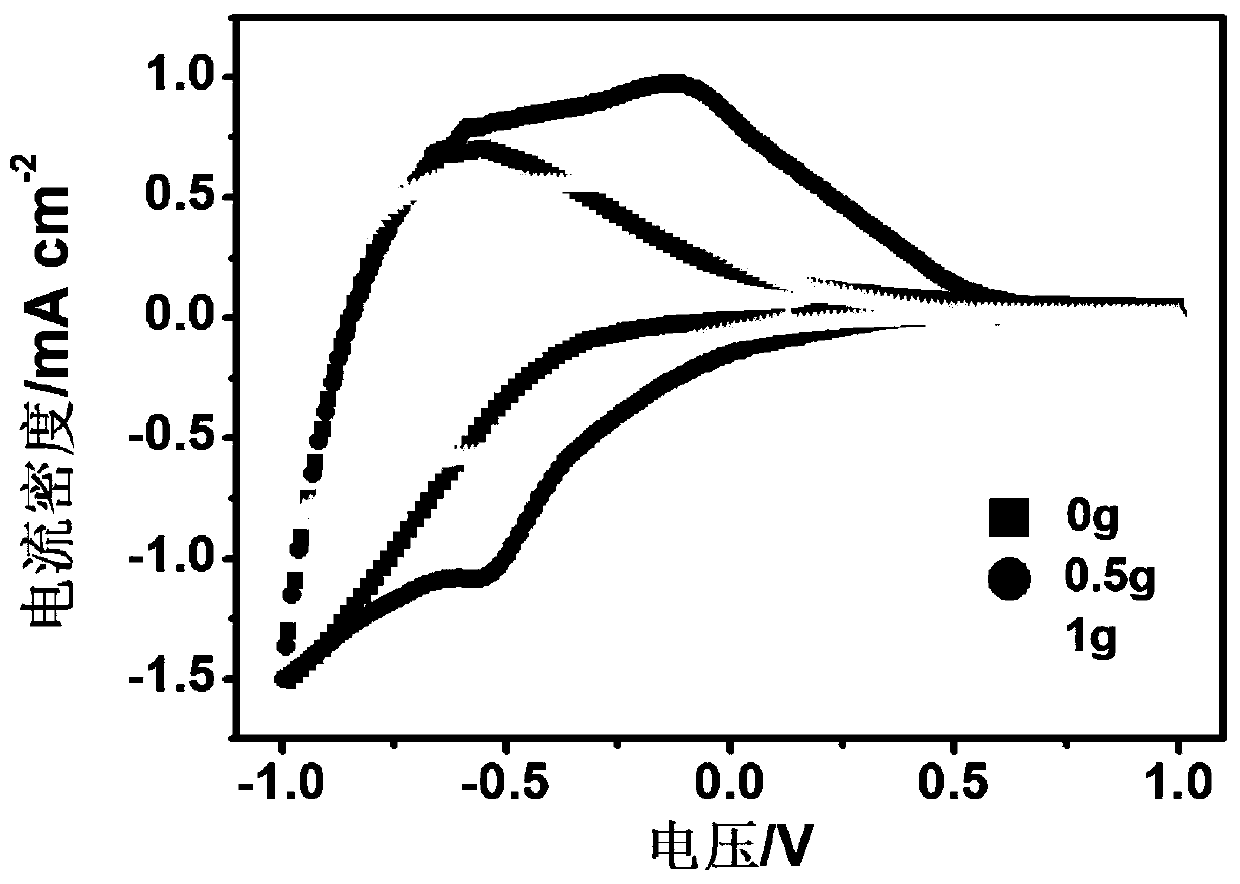

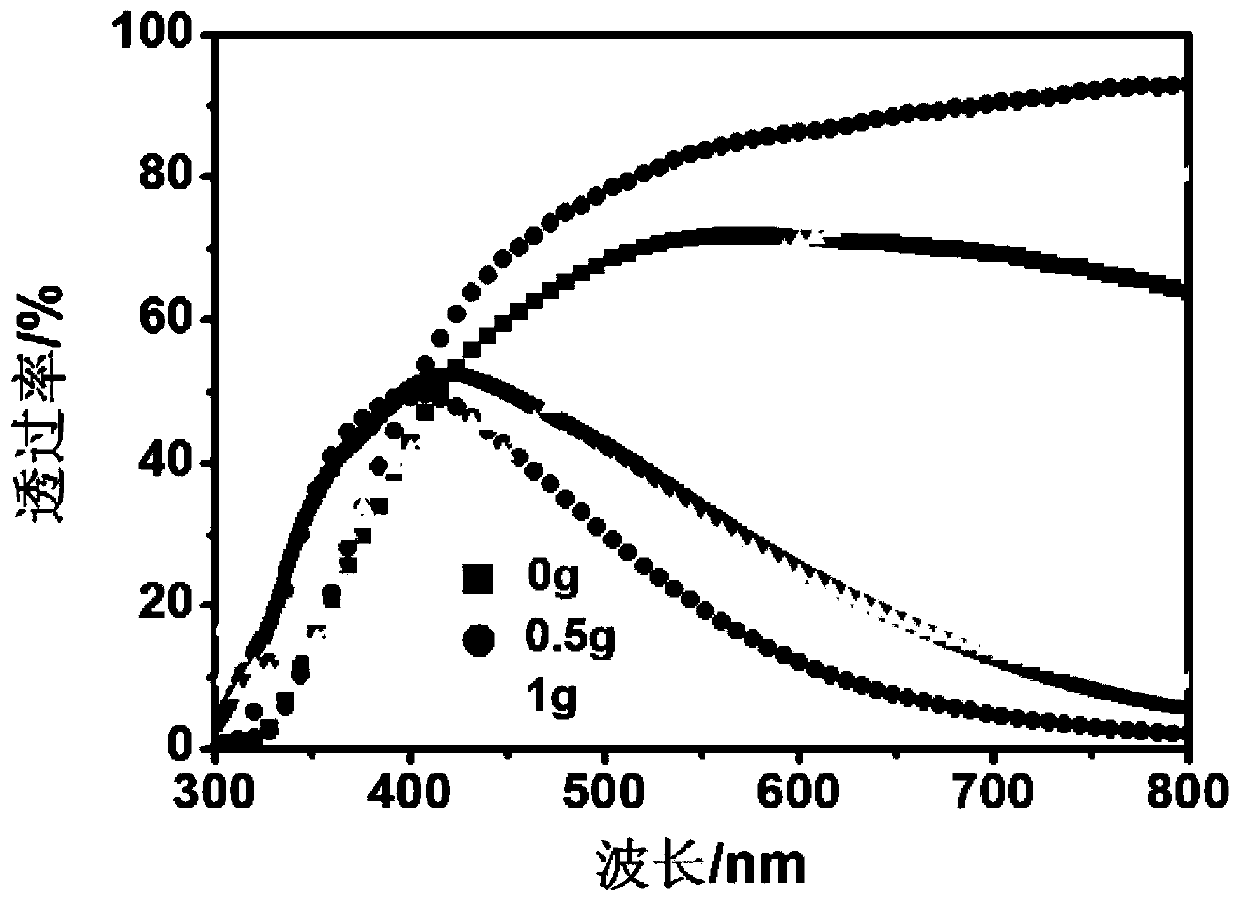

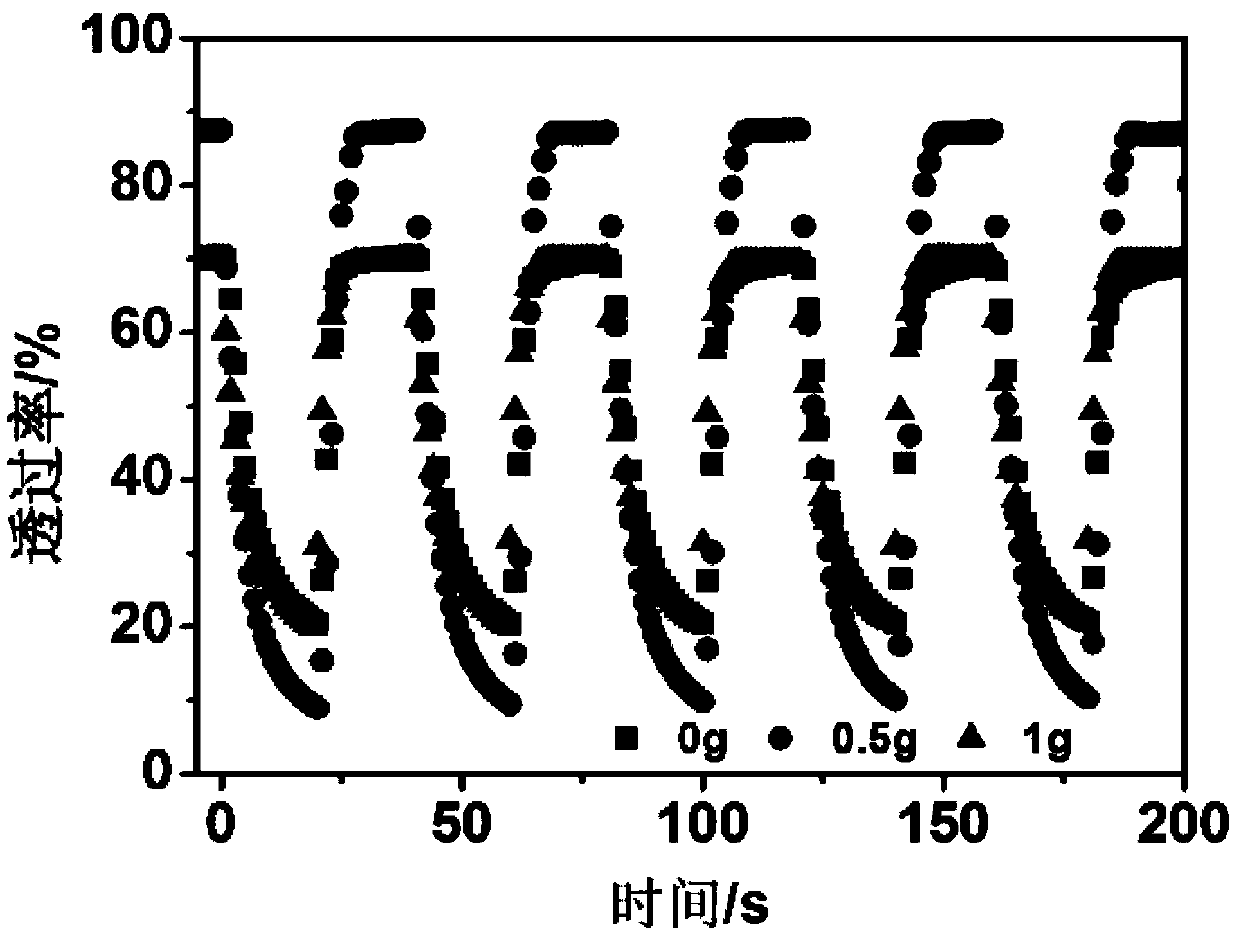

[0041] 0.8246g sodium tungstate dihydrate (Na 2 WO 4 2H 2 O) and 1.0507g citric acid monohydrate (C 6 h 8 o 7 ·H 2 O) Dissolve in 100mL deionized water, stir magnetically at room temperature until completely dissolved, and form Na 2 WO 4 2H 2 O and C 6 h 8 o 7 ·H 2 O molar ratio is the solution of 1:2; Then the hydrochloric acid of 5mol / L is dripped in the above-mentioned solution dropwise, adjusts the solution pH value to 0.5, after stirring at room temperature, obtains the tungsten trioxide precursor solution;

[0042] Fluorine-doped tin oxide (FTO) transparent conductive glass substrates were ultrasonically cleaned in acetone, ethanol, and deionized water for 15 minutes and dried, and placed obliquely in the lining of a hydrothermal kettle with the transparent conductive layer facing down. Transfer the tungsten trioxide precursor solution to the lining of the hydrothermal kettle, and then tighten the hydrothermal kettle; place the hydrothermal kettle in an oven,...

Embodiment 2

[0045] 1.3194g sodium tungstate dihydrate (Na 2 WO 4 2H 2 O) and 1.0507g citric acid monohydrate (C 6 h 8 o 7 ·H 2 O) Dissolve in 100mL deionized water, stir magnetically at room temperature until completely dissolved, and form Na 2 WO 4 2H 2 O and C 6 h 8 o 7 ·H 2 O molar ratio is the solution of 1:1.25; Then the hydrochloric acid of 5mol / L is dripped in the above-mentioned solution dropwise, adjusts the solution pH value to 1, after stirring at room temperature, obtains the tungsten trioxide precursor solution;

[0046] Fluorine-doped tin oxide (FTO) transparent conductive glass substrates were ultrasonically cleaned in acetone, ethanol, and deionized water for 15 minutes and dried, and placed obliquely in the lining of a hydrothermal kettle with the transparent conductive layer facing down. Transfer the tungsten trioxide precursor solution to the inner lining of the hydrothermal kettle, and then tighten the hydrothermal kettle; place the hydrothermal kettle in a...

Embodiment 3

[0049] 2.0616g sodium tungstate dihydrate (Na 2 WO 4 2H 2 O) and 1.3134g citric acid monohydrate (C 6 h 8 o 7 ·H 2 O) Dissolve in 100mL deionized water, stir magnetically at room temperature until completely dissolved, and form Na 2 WO 4 2H 2 O and C 6 h 8 o 7 ·H 2 O molar ratio is the solution of 1:1; Then the hydrochloric acid of 5mol / L is dripped in the above-mentioned solution dropwise, adjusts the solution pH value to 0.5, after stirring at room temperature, obtains the tungsten trioxide precursor solution;

[0050] Fluorine-doped tin oxide (FTO) transparent conductive glass substrates were ultrasonically cleaned in acetone, ethanol, and deionized water for 15 minutes and dried, and placed obliquely in the lining of a hydrothermal kettle with the transparent conductive layer facing down. Transfer the tungsten trioxide precursor solution to the inner lining of the hydrothermal kettle, and then tighten the hydrothermal kettle; place the hydrothermal kettle in an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| coloring efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com